PLUS GREEN TOWNS: Raising sustainability levels of HDB towns INDUSTRIAL ESTATES: The red dot’s race to a green future MARITIME AND PORT DEVELOPMENT: Setting sail towards net-zero THE MAGAZINE OF THE INSTITUTION OF ENGINEERS, SINGAPORE www.ies.org.sg SINGAPORE THE ENGINEER Singapore engineers leading the way to a greener built environment SPECIAL EDITION ON SUSTAINABLE ENGINEERING Celebrating UNESCO’s World Engineering Day for Sustainable Development 2024 February 2024 | MCI (P) 002/03/2024

CHARTERED ENGINEER (SINGAPORE) *** Get your skills and competency Certified! *** *** Apply Now! Visit us at www.charteredengineers.sg *** (Terms and Conditions Apply: Washington Accord Degree, 4 years working experience and be an IES member) ❑ AEROSPACE ❑ ENERGY ❑ ENVIRONMENTAL & WATER ❑ CHEMICAL & PROCESS ❑ SYSTEMS ❑ DIGITAL (New!) ❑ PORT & MARINE ❑ RAILWAY & TRANSPORTATION ❑ INFRASTRUCTURE ❑ ENGINEERING PROJECT MANAGEMENT

MESSAGE

12 Message From The President of The Institution of Engineers, Singapore

14 Message From The President of The World Federation of Engineering Organizations COVER STORY

22 Singapore engineers leading the way to a greener built environment

GREEN TOWNS

26 Raising sustainability levels of HDB towns

URBAN DESIGN

30 Singapore’s built environment traps heat in surprising places INDUSTRIAL

ESTATES

32 The red dot’s race to a green future

MEP ENGINEERING

34 CFD for the Built Environment – a critical & necessary step in Singapore’s Net Zero Journey

President Mr Dalson Chung

Chief Editor

T Bhaskaran t_b_n8@yahoo.com

Publications Manager Desmond Teo desmond@iesnet.org.sg

Publications Executive

Nuraini Ahmad nuraini@iesnet.org.sg

Editorial Panel

Dr Chandra Segaran

Dr Ang Keng Been

Dr Aaron Sham

A/Prof Yuzhu Pearl Li

Mr Jaime Vega Bautista Jr

Dr Victor Sim

Mr Soon Ren Jun

Dr Alexander Wiegand

Media Representatives For The Special

Trevor Teh IES@mnc-link.com

Multimedia

06 THE SINGAPORE ENGINEER February 2024

CONTENTS FEATURES www.ies.org.sg 22 26 32 Design & layout by 2EZ Asia Pte Ltd Cover designed by Irin Kuah Cover image by Shaw Towers Realty Private Limited Published by The Institution of Engineers, Singapore 70 Bukit Tinggi Road, Singapore 289758 Tel: 6469 5000 I Fax: 6467 1108 Printed in Singapore

Edition

Ltd

Communications (2000) Pte

sales@multimediacomms.sg

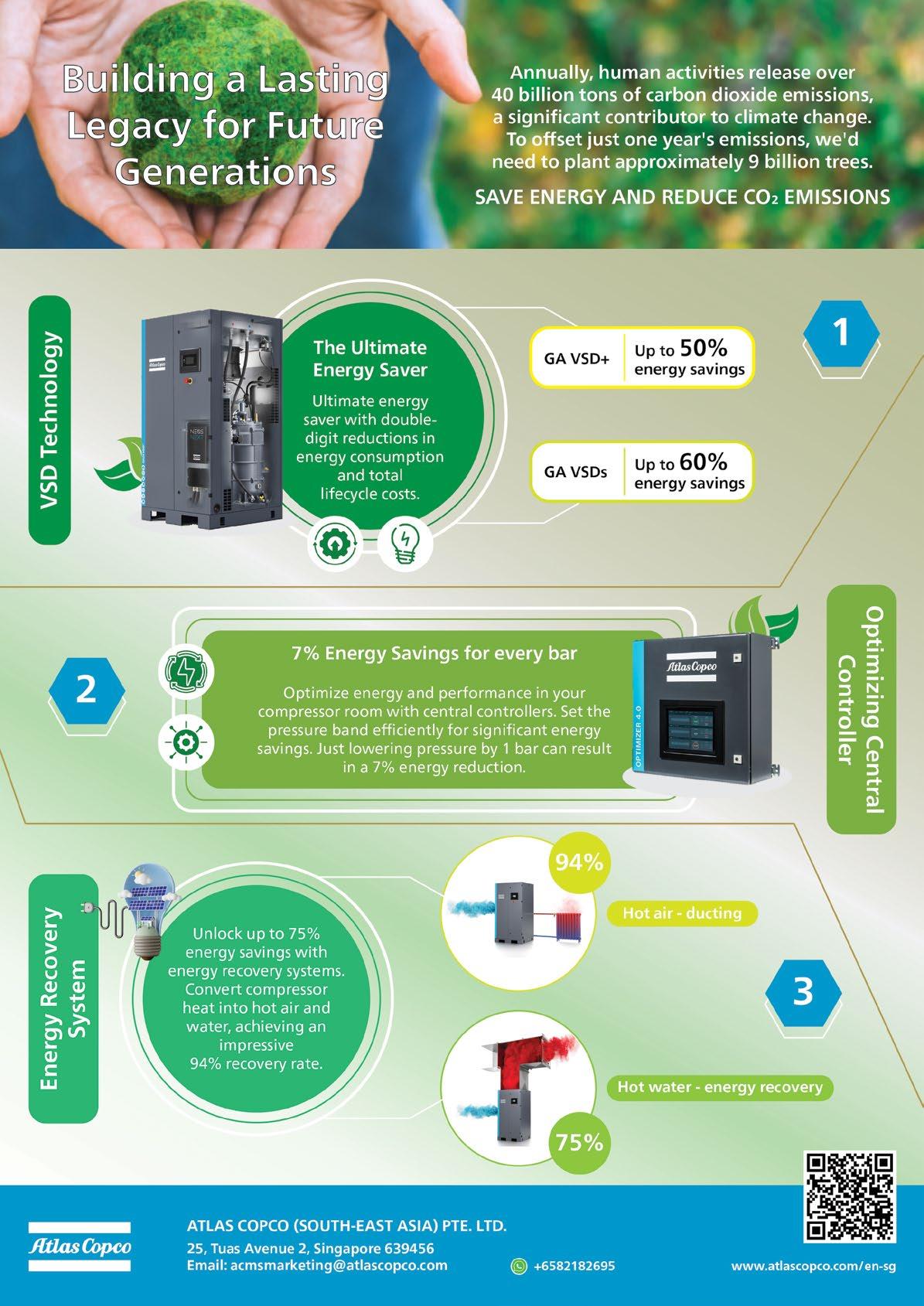

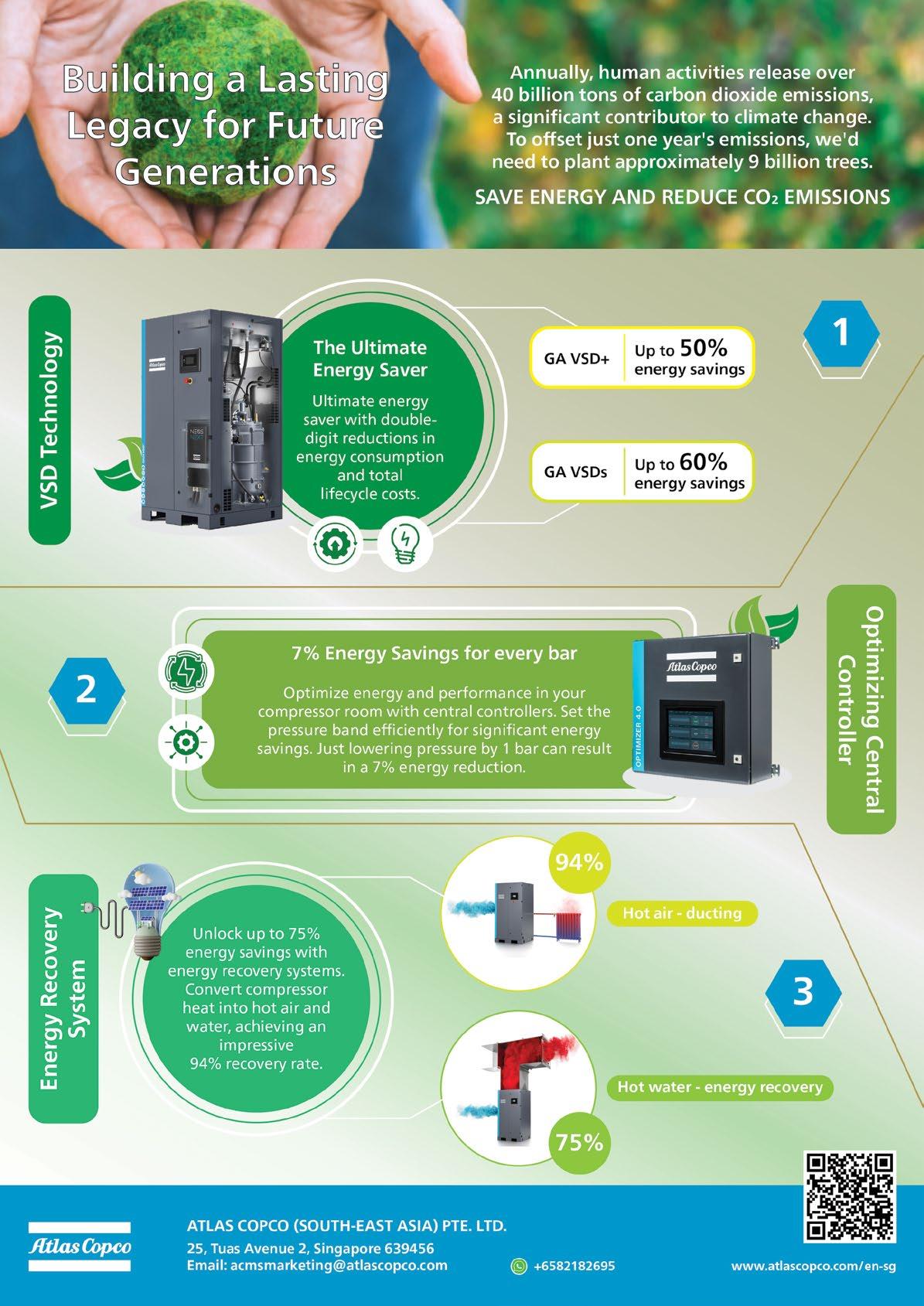

CLEAN AIR AT A LOWER COST

Get the most from your Air filters (AHU). Changing them according to differential pressure drop will reduce energy consumption and CO2 annually by up to 25 000+ Tonnes*.

CLEAN AIR SOLUTIONS

*Calculation based on Eurovent kWh data and volumes in EMEA WWW.CAMFIL.COM

Hi-Flo: General Ventilation Filter

www.ies.org.sg

MEP ENGINEERING

36 Shining a light on how buildings can hit the green mark

38 Strategic approaches to address the Mandatory Energy Improvement directive

40 Innovative water treatment systems for cooling towers

AUTOMATION

42 Azbil’s global sustainability charge through automation

ENERGY ENGINEERING

44 Solutions for a broad range of industries and geographies

45 Accelerating energy transition in Southeast Asia

46 Plant digital twins for sustainable energy generation

ENERGY & UTILITIES ENGINEERING

48 A sustainable approach to pipeline integrity management

CONSTRUCTION MATERIALS

50 A multi-faceted approach to sustainable development in Singapore

52 The unexpected tale of carbon dioxide in the built environment

53 Lightweight green aggregate for sustainability in the building and construction industry

08 THE SINGAPORE ENGINEER February 2024

45 50 53 36

www.ies.org.sg

WASTE MANAGEMENT

54 Make the difference, one bag after another: A Mapei Sustainability Project

56 Towards achieving net-zero emissions

MARITIME AND PORT DEVELOPMENT

58 Setting sail towards net-zero

PORT TECHNOLOGY AND SUSTAINABLE DEVELOPMENTS

60 A sustainable smart port

EDUCATION & RESEARCH

64 Temasek Polytechnic’s progressive strides towards a sustainable future

66 The role of higher education in a sustainable future

68 Supporting the nation’s sustainable development plans

REGULAR SECTIONS

16 NEWS & EVENTS

The Singapore Engineer is published monthly by The Institution of Engineers, Singapore (IES). The publication is distributed free-of-charge to IES members and affiliates. Views expressed in this publication do not necessarily reflect those of the Editor or IES. All rights reserved. No part of this magazine shall be reproduced, mechanically or electronically, without the prior consent of IES. Whilst every care is taken to ensure accuracy of the content at press time, IES will not be liable for any discrepancies. Unsolicited contributions are welcome but their inclusion in the magazine is at the discretion of the Editor.

10 THE SINGAPORE ENGINEER February 2024

60 64 54

Message from Mr Dalson Chung, President, The Institution of Engineers, Singapore (IES)

Dear Friends,

As the global engineering community celebrates the annual World Engineering Day (WED) for Sustainable Development on 4 March 2024, the Institution of Engineers, Singapore (IES) will once again join in to celebrate the contributions of our engineers for a better and sustainable world.

Through this special edition of ‘The Singapore Engineer’, we wish to spotlight the ubiquitous, extraordinary work of engineers that not only safeguards our environment but also fosters economic growth and social inclusion. The ingenuity of engineers continuously pushes technological advancements in artificial intelligence (AI), photovoltaics, water technology and more, into new frontiers, promoting better food and water security, renewable energy, better waste and resource management, job creation, economic resilience and more.

Engineering is also a key enabler of efforts to mitigate the worsening climate change. IES, as the national society of engineers in Singapore, launched the IES Green Plan 2030 in January 2023 to initiate and amplify engineering actions to support and realise Singapore’s ambitious but vital climate targets under the Singapore Green Plan 2030.

We have made notable progress since then. One of the milestones is the presentation of the inaugural IES Sustainability Awards during our Annual Dinner on 9 November

2023, to recognise outstanding engineering accomplishments incorporating sustainability practices and designs for sustainability.

Another exciting accomplishment in 2023 is the installation of two electric vehicle (EV) chargers at the IES Building carpark. This might be a small but a firm step by IES to support efforts by Singapore’s government to encourage EV adoption and facilitate the transition towards cleaner transport.

Since the start of 2024, IES has continued to press on with our efforts to accelerate Singapore’s sustainable development agenda through our ongoing collaborations with over 30 government agencies, industry partners and academia, to develop and implement sustainable engineering practices across different sectors.

WED 2024 provides another impetus to elevate our efforts. We will hold the inaugural Charles Rudd Distinguished Global Lectures on 4 March to celebrate WED. On the back of many successful editions of local lectures, it is timely for IES to bring this lecture series to international fora, as IES’ contribution towards the global sustainability movement.

This international lecture features global experts who will discuss topics of significant interest and attract participants from diverse backgrounds across borders to engage in meaningful dialogues.

IES will also continue to lead by example to green the built environment. Our two IES buildings are in the process of adopting transformative measures to achieve net-zero emissions.

This will involve investments in advanced energy-efficient technologies, renewable energy sources and innovative building materials.

In addition, IES will continue to nurture interest amongst our youths to engineer a sustainable future for Singapore through the National Engineers Day (NED) in the third quarter of 2024.

Let us continue to keep the gears turning to create a thriving, sustainable future.

Dalson Chung President The Institution of Engineers, Singapore (IES)

12 MESSAGE THE SINGAPORE ENGINEER February 2024

Mr Dalson Chung

Message from Engr. Mustafa B. Shehu, President, World Federation of Engineering Organizations (WFEO)

Dear Colleagues,

It gives me great pleasure to give a message to the engineering community in Singapore, during the celebration of the 2024 World Engineering Day (WED) which marks the 5th in the series of WED celebrations, having started in 2020.

The Institution of Engineers, Singapore (IES) is one of the National Member organisations in WFEO, that I have high respect for, since the time I attended the World Engineers Summit and WFEO General Assembly hosted by IES in 2013, in my capacity as the President of the Nigerian Society of Engineers (NSE).

That has been so because, since then, I have observed with keen interest the Institution’s high-level participation in all WFEO activities, as well as in promoting engineering and engineers not only in their jurisdiction but in other jurisdictions, through collaborations and knowledge exchange.

You have also answered the call from WFEO to ensure that WEDs are celebrated widely within your country by engineering institutions, academia and industries.

These, I believe, are part of the cumulative efforts that resulted in the election victory of my good friend, Seng Chuan Tan as the President-elect of WFEO at the last General Assembly, held on 14th October 2023 in Prague, the Czech Republic.

I therefore use this opportunity to congratulate Seng Chuan Tan and the entire membership of the IES for this victory which will provide wider opportunity for IES to serve the global engineering community.

The theme of this year’s WED, ‘Engineering Solutions for a Sustainable World’, could not have come at a better time than now, when the world is faced with unprecedented challenges from climate change to disasters such as floods and earthquakes, to unsolicited conflicts and wars. All these result in loss of lives, destruction of infrastructure and properties, and displacement of people from their homes, towns and settlements. Their solutions are rooted in engineering.

As engineers, the solutions we

should bring to these challenges have to be people-centred, environmentally considerate, economically sustainable as well as ethical. However, getting solutions to satisfy these criteria entails engineers getting multi-disciplinary training and (or) working collaboratively with other engineers and professionals, towards getting a solution.

In today’s world therefore, we need, as a matter of necessity, to be continuously learning not only the various disciplines of engineering but also other disciplines like law, economics, sustainability, business administration and the like.

In conclusion, while congratulating you on this momentous occasion of celebrating the 2024 World Engineering Day, I urge all of you to keep in touch with the WFEO through constantly visiting the website for information on developments taking place, for your professional development.

You should also feel free to comment on our activities through the leadership of IES that attends our Executive Council meetings and (or) General Assemblies. That feedback loop is important for us, to serve you better.

Looking forward to seeing you in one of the WFEO or IES programmes / activities.

Mustafa B. Shehu President, WFEO

14 MESSAGE THE SINGAPORE ENGINEER February 2024

C M Y CM MY CY CMY K

Engr. Mustafa B. Shehu

Purtop® System

COP28 Agreement signals ‘beginning of the end’ of the fossil fuel era

The United Nations Climate Change Conference (COP28) closed on 13 December 2023, with an agreement that signals the ‘beginning of the end’ of the fossil fuel era, by laying the ground for a swift, just and equitable transition, underpinned by deep emissions cuts and scaled-up finance.

In a demonstration of global solidarity, negotiators from nearly 200 Parties came together in Dubai with a decision on the world’s first ‘global stocktake’ to ratchet up climate action before the end of the decade –with the overarching aim to keep the global temperature limit of 1.5 °C within reach.

“Whilst we didn’t turn the page on the fossil fuel era in Dubai, this outcome is the beginning of the end. Now all governments and businesses need to turn these pledges into real-economy outcomes, without delay,” said UN Climate Change Executive Secretary Simon Stiell in his closing speech.

The global stocktake is considered the central outcome of COP28 – as it contains every element that was under negotiation and can now be used by countries to develop stronger climate action plans due by 2025.

The stocktake recognises the science that indicates global green-

house gas emissions need to be cut 43% by 2030, compared to 2019 levels, to limit global warming to 1.5 °C. But it notes Parties are off track when it comes to meeting their Paris Agreement goals.

The stocktake calls on Parties to take actions towards achieving, at a global scale, a tripling of renewable energy capacity and doubling energy efficiency improvements by 2030. The list also includes accelerating efforts towards the phasedown of unabated coal power, phasing out inefficient fossil fuel subsidies, and other measures that drive the transition away from fossil fuels in energy systems, in a just, orderly and equitable manner, with developed countries continuing to take the lead.

In the short-term, Parties are encouraged to come forward with ambitious, economy-wide emission reduction targets, covering all greenhouse gases, sectors and categories, and aligned with the 1.5 °C limit in their next round of climate action plans (known as nationally determined contributions) by 2025.

Strengthening resilience to the effects of climate change

The two-week-long conference got underway with the World Climate Action Summit, which brought to-

gether 154 Heads of States and Government. Parties reached a historic agreement on the operationalisation of the loss and damage fund and funding arrangements – the first time a substantive decision was adopted on the first day of the conference.

Commitments to the fund started coming in moments after the decision was gavelled, totalling more than USD 700 million to-date.

There was more progress on the loss and damage agenda with an agreement also reached that the UN Office for Disaster Risk Reduction and the UN Office for Project Services will host the secretariat of the Santiago Network for Loss and Damage. This platform will catalyse technical assistance to developing countries that are particularly vulnerable to the adverse effects of climate change.

Parties agreed on targets for the Global Goal on Adaptation (GGA) and its framework, which identify where the world needs to get to in order to be resilient to the impacts of a changing climate and to assess countries’ efforts.

The GGA framework reflects a global consensus on adaptation targets and the need for finance, technology and capacity-building support to achieve them.

16 NEWS & EVENTS THE SINGAPORE ENGINEER February 2024

Negotiators from nearly 200 Parties came together in Dubai with a decision on the world’s first ‘global stocktake’ to ratchet up climate action before the end of the decade. Image: UN Climate Change / Kiara Worth.

Increasing climate finance

Climate finance took centre stage at the conference, with Stiell repeatedly calling it the “great enabler of climate action.”

Event participation and inclusivity

World leaders at COP28 were joined by civil society, business, Indigenous Peoples, youth, philanthropy, and international organisations, in a spirit of shared determination to close the gaps to 2030. Some 85,000 participants attended COP28 to share ideas and solutions, and build partnerships and coalitions.

Strengthening collaboration

In parallel with the formal negoti-

ations, the Global Climate Action space at COP28 provided a platform for governments, businesses and civil society to collaborate and showcase climate solutions.

The conference also saw several announcements to boost the resilience of food and public health systems, and to reduce emissions related to agriculture and methane.

“We must get on with the job of putting the Paris Agreement fully to work. In early 2025, countries must deliver new nationally determined contributions. Every single commitment – on finance, adaptation, and mitigation – must bring us in line with a 1.5-degree world,” said Mr Stiell.

“My final message is to ordinary people everywhere raising their voices for change. Every one of you is making a real difference. In the crucial coming years, your voices and determination will be more important than ever. I urge you never to relent. We are still in this race. We will be with you every single step of the way,” he added.

“The world needed to find a new way. By following our North Star, we have found that path. We have worked very hard to secure a better future for our people and our planet. We should be proud of our historic achievement,” said COP28 President, Dr Sultan Al Jaber, during his closing speech.

17 NEWS & EVENTS THE SINGAPORE ENGINEER February 2024

Showcasing a robust ecosystem for accelerating collective climate action

The Singapore Pavilion at the 28th Conference of the Parties of the United Nations Framework Convention on Climate Change (COP28) demonstrated and reaffirmed Singapore’s climate solutions, uniting players across sectors, domains and geographical regions.

Themed ‘Accelerating Collective Climate Action’, the programmes at the pavilion showcased Singapore’s commitment to global climate goals, emphasised the citystate’s vision to achieve net zero by 2050 and highlighted innovative and collaborative solutions, backed by a strong ecosystem of partners across the private and people sectors, international organisations and governments.

The pavilion attracted in-person visitorship of more than 6,000, along with nearly 60,000 unique online visitors, across its 12 days of programming. The diverse range of programmes – involving around 100 partner entities and including panel discussions, workshops, fireside chats as well as ‘pitch days’ – covered multifaceted climate issues and provided attendees with opportunities for knowledge exchange and partnership development.

Numerous noteworthy announcements, launches and Memoranda of Understanding (MoU) signings took place at the pavilion, as well as key announcements demonstrating the concrete action Singapore is taking to support and accelerate the green transition in the region and beyond.

These include the FAST-P (Financing Asia’s Transition Partnership), Singapore-Asia Taxonomy and the Transition Credits Coalition (TRACTION). In addition, Singapore signed its first Implementation Agreement with Papua New Guinea on carbon credits cooperation under Article 6 of the Paris Agreement.

During the pavilion’s closing ceremony, Minister for Sustainability

and the Environment Ms Grace Fu said, “I am heartened by the ‘bias to action’ that we have witnessed here at the pavilion. Many new climate initiatives and partnerships have been unveiled on this stage, by the Singapore government as well as our partners. Like Singapore itself, our pavilion has been ‘small, but mighty’. It is not about size, but impact. It is not about quantity, but quality. And it is not about making a once-off splash, but a sustained commitment with follow-through actions.”

Among the visitors to the Singa-

pore Pavilion were foreign dignitaries, organisational and business leaders and key change-makers in the global climate ecosystem, reflecting Singapore’s position as a trusted regional and international partner that facilitates climate collaborations and the development of solutions.

The pavilion provided a space for the private, public and people sectors, from various countries and backgrounds, to gather and work towards advancing climate action and building a better and more sustainable future for all.

18 NEWS & EVENTS THE SINGAPORE ENGINEER February 2024

The Singapore Pavilion at COP28 demonstrated and reaffirmed Singapore’s climate solutions. Images: COP28 Singapore Pavilion.

Surbana Jurong (SJ) has signed a Memorandum of Understanding (MoU) with Invest Sarawak, an entity under the State Government of Sarawak’s Ministry of International Trade, Industry and Investment (MINTRED Sarawak) to develop cooperation and partnership opportunities to pursue industrial transformation, energy transition and industrial decarbonisation, CCUS (carbon capture, utilisation and storage), and industrial park development and management, in Sarawak.

The key aims of the cooperation include identifying challenges and opportunities present in Sarawak’s industrial landscape, such as green economy opportunities, and enhancing and developing skillsets to equip the people of Sarawak for new opportunities, as well as implementing energy transition and industrial decarbonisation projects integrated with greenfield and brownfield industrial activities.

The partners will identify carbon capture opportunities especially in the power generation sector, such

as potential carbon utilisation and sequestration projects.

One of the key features of the partnership is the joint establishment of an industrial park venture to implement best-in-class standards in the planning, development and future management of greenfield industrial parks that prioritises decarbonisation and sustainable power sources.

This is the second partnership between SJ and MINTRED Sarawak, following its first partnership agreement signed in 2021.

19 NEWS & EVENTS THE SINGAPORE ENGINEER February 2024 ADVANCE YOUR AUTODESK SKILLS: Premier Learning Resources from ASCENT From AutoCAD to Inventor to Revit, get professional training materials to master your CAD software. • Printed Books • Digital eBooks • eLearning Bundles • Learning Content Development SAVE 25% ON TRAINING MATERIALS Use promo code IES-25 at ASCENTestore.com ASCENTed.com | info@ASCENTed.com

Surbana Jurong and Invest Sarawak sign MoU to deepen sustainability initiatives

Clean energy transition picks up momentum

Global electricity demand is expected to grow at a faster rate over the next three years as the clean energy transition gathers speed, with all the additional demand forecast to be covered by technologies that produce low-emissions electricity, according to a new report from the IEA (International Energy Agency).

Electricity 2024 is the latest edition of the IEA’s annual analysis of electricity market developments and policies, providing forecasts for demand, supply and carbon dioxide (CO2) emissions from the sector through 2026.

The report finds that while global growth in electricity demand eased slightly to 2.2% in 2023 due to falling electricity consumption in advanced economies, it is projected to accelerate to an average of 3.4% from 2024 through 2026. About 85% of the increase in the world’s electricity demand through 2026 is expected to come from outside advanced economies – most notably China, India and countries in Southeast Asia.

However, record-setting electricity generation from low-emissions sources – comprising renewables, such as solar, wind and hydro, as well as nuclear power – should reduce the role of fossil fuels in providing power for homes and businesses. Low-emissions sources are expected to account for almost half of the world’s electricity generation by 2026, up from a share of just under 40% in 2023.

Renewables are set to make up more than one-third of total electricity generation by early 2025, overtaking coal. By 2025, nuclear power generation is also forecast to reach an all-time high globally as output from France climbs, several plants in Japan come back online, and new reactors begin commercial operations in many markets, including in China, India, Korea and Europe. When the share of fossil fuels in global generation falls beneath 60%, this will mark the first time it has gone below this threshold in IEA records, dating back

more than five decades.

“The power sector currently produces more CO2 emissions than any other in the world economy, so it’s encouraging that the rapid growth of renewables and a steady expansion of nuclear power are together on course to match all the increase in global electricity demand over the next three years,” said IEA Executive Director Dr Fatih Birol.

“This is largely thanks to the huge momentum behind renewables, with ever cheaper solar leading the way, and support from the important comeback of nuclear power, whose generation is set to reach a historic high by 2025. While more progress is needed, and fast, these are very promising trends,” he added.

The report finds that the increase in electricity generation from renewables and nuclear appears to be pushing the power sector’s emissions into structural decline. Global emissions from electricity generation are expected to decrease by 2.4% in 2024, followed by smaller declines in 2025 and 2026.

The decoupling of global electricity demand and emissions would be significant, given the energy sector’s increasing electrification, with more consumers using technologies such as electric vehicles and heat pumps. Electricity accounted for 20% of final energy consumption in 2023, up from 18% in 2015, though meeting the world’s climate goals would require electrification to advance significantly faster in the coming years. Although demand for electricity in Europe and the United States declined in 2023, many emerging and developing economies recorded robust growth that is set to continue through 2026 in response to increasing populations and industrialisation.

During the outlook period, China is expected to account for the largest share of the global increase in electricity demand in terms of volume, even as its economic growth slows and becomes less reliant on heavy industry. Meanwhile, India is set to see electricity demand rise the fast-

est among major economies, with demand added over the next three years forecast to be roughly equivalent to the current electricity consumption of the United Kingdom.

As a region, Africa remains an outlier in electricity demand trends, according to the report’s analysis. While electricity use per capita in India and Southeast Asia has risen rapidly, it has been effectively stagnant in Africa for more than three decades.

“Electricity use is a key indicator of economic development in any country, and it’s a grim sign that it has flatlined in Africa on a per capita basis for over three decades. Access to reliable, affordable and sustainable energy for all citizens is essential for African countries to achieve their economic and climate goals. The international community needs to work together with African governments to enable the urgent progress that is needed,” said Dr Birol.

Net zero implementation and decarbonisation in Asia

In a memo written by investors for investors, 16 investors managing over USD 6 trillion in assets under management shared rare candid insights on the realities and challenges of addressing the climate crisis in their investment portfolios.

This follows a series of closed-door dialogues that the Asia Investor Group on Climate Change (AIGCC) organised in 2023 amongst institutional investors. Each dialogue included perspectives from both asset owners and asset managers, either regionally headquartered in Asia or internationally headquartered with large investments in Asia.

20 NEWS & EVENTS THE SINGAPORE ENGINEER February 2024

Singapore engineers leading the way to a greener built environment

The Building and Construction Authority (BCA) provides an update on the efforts and achievements.

As global citizens, everyone, including the Built Environment sector, has a role to play to mitigate the effect of climate change. In Singapore, we have raised our national climate target to achieve net zero emissions by 2050.

With buildings accounting for about 20% of Singapore’s carbon emissions, green buildings are key in our transition to a low-carbon and climate resilient future. The Building and Construction Authority (BCA) launched the Singapore Green

Building Masterplan (SGBMP) 2021, which is part of the Singapore Green Plan 2030. It charts out our collective commitment to pursue more ambitious sustainability standards in our Built Environment.

The SGBMP aims to deliver the three key targets of ‘80-80-80 in 2030’. While we are working with industry stakeholders to green 80% of our buildings and make Super Low Energy (SLE) buildings more mainstream by 2030, we are also pushing technological boundaries to achieve

80% energy efficiency over the 2005 baseline in 2030. This includes driving more passive design strategies through naturally ventilated design and alternative cooling strategies such as hybrid cooling.

HIGHER STANDARDS

Green Mark buildings with higher ratings are the new normal. The launch of the BCA Green Mark scheme in 2005 formed the backbone of Singapore’s first Green Building Masterplan. Over 2,500 unique

COVER STORY THE SINGAPORE ENGINEER February 2024 22

Progress of the SGBMP

buildings have since been issued Green Mark (GM) certifications.

Following the introduction of the SLE programme in 2018, an increasing number of buildings are achieving higher GM certification standards. About 65% of the 120 GM SLE, Zero Energy and Positive Energy buildings were certified in the last three years.

Moreover, green buildings, especially GM SLE buildings, are a smart investment, with good payoffs derived from energy savings over the building lifecycle. For instance, a newly-built office, with 350,000 m2 GFA and with SLE rating, will save 4.0 GWh of energy per year. The corresponding carbon abatement is equivalent to having around 970 hectares of forest or removing 360 non-electric cars from the road annually.

A CRUCIAL ROLE FOR ENGINEERS

As we continue to push the boundaries of environmental sustainability, engineers play an instrumental role in our efforts to decarbonise the built environment. By developing and implementing energy-efficient systems and technologies, they help to transform the built en-

vironment into one that is liveable and sustainable. With Green Mark SLE buildings fast becoming mainstream, the entire built environment value chain must step up or risk getting left behind.

CASE STUDIES

Shaw Tower Redevelopment

The Shaw Tower Redevelopment project was certified GM Platinum SLE in 2022. The building incorporates an energy-efficient, dual temperature, water-cooled chilled water plant and hybrid air-conditioning system with active chilled beams, in addition to an energy-efficient air distribution system with EC fans for all Air Handling Units (AHUs). Shaw Tower Redevelopment has also obtained the Intelligence, Health & Wellbeing, and Maintainability Badges under the GM 2021 scheme.

The Shaw Tower Redevelopment is one of the recent projects undertaken by Ms Irene Yong, Technical Director of Beca Carter Hollings & Ferner (S.E. Asia) Pte Ltd.

Ms Yong has numerous achievements to her credit, in incorporating sustainability in the built environ-

ment. As a Green Mark Advanced Accredited Professional (GMAAP), she has completed more than 80 GM projects to-date, including projects within the Nanyang Technological University (NTU Singapore) campus, DUO and Marina One.

A Green Mark Advanced Accredited Professional (GMAAP) is the top-tier accreditation for technical professionals in the built environment industry with more than five years of experience in Green Mark projects. A GMAAP possesses deep technical expertise and is able to carry out detailed design, prediction and enhancement of building performance for Green Mark certification.

Ms Yong has helped clients to conceptualise targets to achieve top-tier sustainability awards including the GM Platinum STAR Champion Award, GM Platinum Award for Districts and GM Platinum Award for New Parks.

She has also been involved in several R&D projects as Principal Investigator and Industry Collaborator on green building technologies and ESD-related research work, in collaboration with NTU Singapore and University of California, Berkeley,

COVER STORY THE SINGAPORE ENGINEER February 2024 23

Shaw Tower Redevelopment. Image: Shaw Towers Realty Private Limited.

USA. In recognition of her exemplary leadership and contributions, she was conferred the Professional Leadership in Sustainability Award at the SGBC-BCA Leadership in Sustainability Awards, in 2022.

Dulwich College (Singapore)The Greenhouse

The school uses extensive on-site Building Integrated Photovoltaics (BIPV) on the building façade and roof, as well as off-site photovoltaics within the campus, and Passive Displacement Cooling. Smart technologies are utilised to improve the building performance, building management process and user experience.

A Smart IDD / Digital Twin platform is developed to monitor energy efficiency metrics, remote control of equipment and real-time zonal demand control using IoT (IAQ and Occupancy) sensors. The digital twin platform also incorporates smart FM capabilities including building analytics for system optimisation and predictive performance, as well as integration across different sub-systems for incident management, which improves the maintenance process during operation.

This project is the first new building and first international school to attain GM Platinum Zero Energy and the Intelligence, Health & Wellbeing, and Maintainability Badges under the GM 2021 scheme.

Paya Lebar Green

The building incorporates multiple green building technologies such as an energy-efficient, dual temperature, water-cooled chilled water plant and hybrid air-conditioning system with active chilled beams, as well as energy-efficient air distribution system with Electronically Commutated (EC) fans for all AHUs.

The building also comprises technologies like smart LED systems with demand control, real-time performance and monitoring of the building’s energy and indoor air quality, and smart facilities management capabilities including building analytics for predictive maintenance to achieve sustainability goals. The

building attained GM Platinum Super Low Energy and is also the first in Singapore to obtain all five sustainability badges under the GM 2021 scheme.

Both Dulwich College and Paya Lebar Green are higher-tier GM projects certified in 2023. They are among the 25 GM projects completed by Er. Yong Siew Onn, Director of DP Sustainable Design Pte Ltd.

Er. Yong is a GMAAP who has made significant contributions in Environmentally Sustainable Design (ESD), including contributions to alternative cooling. He received the Green Engineer Award at the SGBC-BCA Leadership in Sustainability Awards 2019 for his extensive involvement and achievements in advancing a green and sustainable built environment.

Er. Yong and his ESD team are responsible for ensuring that green building design elements go handin-hand with the overall concept design of a building. He works closely with design architects and

engineers to enhance the sustainable design process and ensure that passive design and energy-efficient M&E solutions are integrated into the building’s environmental design, while still reflecting the aesthetics and functional needs of a building.

THE NEXT PHASE

Engineers will continue to play an important role in shaping the next phase of green buildings. With their technical expertise, they can help to advise developers and building owners to strive for the highest GM SLE, Zero Energy or Positive Energy standards for new projects and for their existing building portfolios.

With the continued urgency to tackle climate change, stakeholders in the Built Environment value chain, including developers, architects, consultants and contractors, need to work towards greening our buildings – both new and from the existing stock.

COVER STORY THE SINGAPORE ENGINEER February 2024 24

Dulwich College (Singapore) – The Greenhouse. Image: Dulwich College (Singapore) Pte Ltd.

Paya Lebar Green. Image: DBS Trustee Limited (as trustee of Certis & Lendlease Property Trust).

JustDimension Just Dimension Pte Ltd 118 Tuas South Ave 2 Singapore 637164 sales@justdm.com.sg

PTFE LINED PIPES & FITTINGS MANUFACTURER

RICHTER PFA LINED VALVES STOCKIST

RICHTER PFA LINED PUMPS SUPPLY

STEULER-KCH FRP PIPING SYSTEM

PTFE HOSE ASSEMBLY

PTFE BELLOWS STOCKIST

PFA SHEET LINING FOR VESSELS

Raising sustainability levels of HDB towns

The Green Towns Programme includes the implementation of several features.

As the master developer of public housing in Singapore, the Housing & Development Board (HDB) plays a key role in supporting the nation’s commitment to sustainable devel opment. In 2020, HDB announced the Green Towns Programme, a 10year plan that aims to bring sustain able living to all existing HDB towns, with large-scale implementation of green features to improve resi dents’ quality of life.

Through the Green Towns Pro gramme, HDB aims to reduce ener gy consumption by 15% from 2020’s levels, by 2030. The programme focuses on reducing energy consumption, recycling rainwater, cooling HDB towns, promoting green commute and reducing waste. It brings together initiatives that have already been implemented or trialled successfully in some HDB towns/estates, as well as new initiatives that have the potential for scaling up.

announced a new solar target of 540 MWp by 2030. The new target could potentially generate 648 GWh of clean energy annually, contributing towards the national solar targets of 1.5 gigawatt-peak (GWp) by 2025, and 2 GWp by 2030, as set out under the Singapore Green Plan.

REDUCING ENERGY CONSUMPTION

Solar Panels

Launched in 2014, the SolarNova Programme is a Whole-of-Government effort led by the Economic Development Board (EDB) and HDB, to accelerate the deployment of solar photovoltaic (PV) systems in Singapore. Under the SolarNova programme, HDB aggregates public sector demand for the installation of solar panels across HDB blocks and government sites.

In HDB towns, solar energy that is harnessed is first used to power common services (e.g. lifts, lights and water pumps), with the excess solar energy then channelled back to Singapore’s electrical grid. On average, HDB blocks are able to achieve net-zero energy consumption for the common areas.

Having surpassed the earlier solar target of 220 megawatt-peak (MWp) by 2020, HDB had, in 2019,

In February 2024, HDB awarded the eighth and largest SolarNova tender, covering the installation of solar panels across 1,075 HDB blocks and 104 government sites. Including the eighth SolarNova tender, HDB has committed a total solar capacity of 455 MWp. This is almost 85% of the solar target and is equivalent to powering 114,000 4-room flats.

HDB aims to install solar panels on as many blocks as possible. To-date, solar panels have been installed on about 3,900 HDB blocks. Solar panels for the remaining HDB blocks, where feasible, will be progressively installed, in batches, over the next three years. Actual installation of the solar panels will be determined based on the feasibility assessment of the site conditions for each block.

Smart LED Lighting

To reduce energy consumption in the common areas of HDB estates, HDB will work with the Town Coun-

cils to replace existing lighting for the common areas with Smart LED Lighting, from 2024. The common areas include common corridors, stairwells, void decks, carparks, linkways and playgrounds.

The system is equipped with sensors and smart analytics to automatically adjust the luminosity of LED lights in response to detected motion. It also collects and analyses data on lighting performance, enabling the prediction of potential faults and proactive maintenance to be carried out. Smart LED Lighting can potentially help to reduce energy consumption by up to 60%, as compared to conventional LED lighting.

Elevator Energy Regeneration System

To further reduce energy consumption in HDB estates, HDB will work with the Town Councils to retrofit 4,000 lifts, islandwide, with the Elevator Energy Regeneration System (EERS), from 2024.

The EERS recovers energy generated during lift motions and braking operations, to power other services within the lift such as lighting, ventilation and functioning of the lift display panel. With the EERS, lift energy consumption can be reduced by an average of 20%.

26

THE SINGAPORE ENGINEER February 2024

GREEN TOWNS

HDB aims to install solar panels on as many blocks as possible. Image: HDB.

GREEN TOWNS

COOLING HDB TOWNS

Cool Coatings

A key consideration in creating a more liveable and sustainable living environment is to improve thermal comfort for residents, thereby mitigating the Urban Heat Island effects due to climate change. In 2021, HDB and Tampines Town Council announced a pilot study on the effectiveness of cool coatings in reducing ambient temperature by up to 2 °C. The pilot will see 130 HDB blocks in Tampines applied with cool coatings.

As compared to conventional paints, cool coatings contain pigments that reflect the heat of the sun. Surfaces treated with cool coat-

ings will absorb less heat during the day and, as a result, will emit less heat at night, thereby cooling the environment. This pilot project will also enable HDB to conduct a comprehensive study on:

• The effect of cool coatings on various block heights, layouts and orientations.

• The effect of surrounding greenery on the performance of cool paints.

• The market readiness for widescale implementation of cool coatings.

Since painting works began in October 2022, the first 42 blocks have been painted. The pilot, including its findings, is expected to conclude by end-2024.

Greenery Intensification

Over the years, HDB has provided a myriad of green spaces in every housing development, so that residents can enjoy greenery at their doorsteps. Besides offering visual and spatial relief for residents in a high-rise living environment, the greenery also helps to cool and enhance the liveability of the estates.

To further green HDB blocks, HDB will introduce greenery to the top decks of more Multi-Storey Carparks (MSCPs), by repurposing them for extensive greenery, by using the Prefabricated Extensive Green (PEG) Roof Tray system or through allotment or community gardening, where feasible.

27

THE SINGAPORE ENGINEER February 2024

GREEN TOWNS

The PEG roof system is a green roof solution developed by HDB. Portable and easily adopted by var ious building types, the PEG Roof System is a convenient and cost-ef fective system that suits Singapore’s tropical climate and uses suitable local plants. It comprises innovative modular and lightweight green roof trays that are easily installed on site, simply by connecting one to anoth er, using locking plugs. No hacking or heavy construction works are re quired.

Thus far, HDB has completed the installation of PEG trays at nine MSCPs. One of the MSCPs, at Ju rong, has been converted to HDB’s first allotment garden where resi dents can plant herbs, vegetables or any other ornamental plants in the plot, while the remaining eight MSCPs have been covered with ex tensive greenery, of which six come with community gardens.

In 2024, HDB will commence in stallation of PEG trays at four more MSCPs.

RECYCLING RAINWATER

UrbanWater Harvesting

As part of efforts to conserve water, HDB developed the UrbanWater Harvesting System (UWHS) to har vest rainwater for non-potable uses like washing of common areas.

The UWHS collects rainwater and stores it in an underground harvesting tank. The harvested rainwater is treated before being recycled for washing of common areas and irrigation. In this way, the use of potable water (drinking water) for washing of common areas and irrigation can be reduced by more than 50%. The UWHS also slows down the discharge of storm water to the drainage system, thus helping to mitigate flood risk.

commute. Cycling also enhances the first-mile and last-mile connectivity from residential estates to public transport nodes as well as helps reduce CO2 emissions.

Since 2020, HDB has installed more than 18,000 dual bicycle racks and up to 30,000 such racks will be installed islandwide by 2025.

Electric Vehicle Chargers

In 2022, HDB announced that the UWHS will be rolled out to existing estates through a pilot project in Yishun and Jurong. Approximately 12 UWHS systems will be installed at Yishun and Jurong, from 2024, potentially reaping water savings of about 14,000 m3 per year, or the average yearly consumption of pota-

HDB is supporting the Land Transport Authority (LTA) in the nationwide deployment of Electric Vehicle (EV) chargers in HDB carparks, by ensuring that the infrastructure (in terms of electrical capacity) is ready for EV charger deployment.

Since 2022, more than 1,600 EV chargers have been installed at 504 carparks. By 2025, EV chargers will

be installed at nearly 2,000 HDB carparks, which will help to reduce the carbon footprint in Singapore.

REDUCING WASTE

E-waste Recycling Bins

The deployment of e-waste recycling bins is mainly in shopping malls and Community Clubs. The locations of these bins may not be convenient for residents to recycle their bulky e-waste. Hence, HDB has worked with the National Environment Agency (NEA) to pilot the deployment of e-waste recycling bins at three different HDB precincts – Hong Kah North, Punggol Clover, and Fengshan Mulberry – to increase convenience for residents to recycle their e-waste.

28

THE SINGAPORE ENGINEER February 2024

Dual bicycle racks are being installed islandwide. Image: HDB.

HDB will introduce greenery to the top decks of more Multi-Storey Carparks. Image: HDB.

If We Can’t Help You Save Money, We Don’t Deserve Your Business. DEN-JET INDUSTRY PTE LTD 48 Pandan Loop Singapore 128264 Tel: (65) 6264 7080 Fax: (65) 6264 7083 Email: mo@denjet.com Website: www.denjet.com After Before Grade 50 Concrete Block (Surface Preparation) Waler (Formwork accessories) After Before Pipe Brace Before After Jack Pipe Before & After Wet Sand-blasting on Corroded steel plates Surface PrepBefore & After Scaffold beam (Pipe) After Before Removing concrete Rust removal on metal deck Before & After Removal of waterproof coating Paint removal in operation Removal of cement on aluminium formwork Sheet Pile rust removal Before & After Removal of concrete (Before) After blast ( nish) Removal of rust (Before) Aluminium walk plank REMOVAL CONCRETE RUST PAINT CONCRETE SURFACE PREPARATION CONCRETE DEMOLITION AND CUTTING Model: CE40 **Available in Electrical, Diesel, Petrol, Hydraulic, Pneumatic driven unit. Pressure ranging from 200Bar - 2750Bar (3KPSI - 36KPSI) with flow-rate of 9 L/Min - 300 L/Min** * Conversion kits are available to convert machine to higher pressure or flow * Call Us For a Free Demo TEL: 6264 7080

Singapore’s built environment traps heat in surprising places

Arup's digital heat analytics tool reveals ‘hot spots’.

A new study by Arup, a global sustainable development consultancy, has revealed Singapore’s heat island ‘hot spots’, highlighting the areas of the city’s urban centre where temperatures are highest compared to their rural surroundings. These are also known as Urban Heat Island (UHI) hot spots.

Arup’s Urban Heat Snapshot has identified a large cluster within the Singapore Central Business District (CBD) – including not only high-rise areas but also historical low-rise streets – as the most extreme ‘hot spots’ in Singapore, experiencing temperatures 6 °C higher than their rural surroundings. Using AI and satellite images, the research compared Singapore to the urban centres of six other cities - Cairo, London, Los Angeles, Madrid, Mumbai, and New York – on the hottest day

they experienced last year.

The study mapped the whole of Singapore, with a particular focus on a 150 km2 snapshot of Singapore’s urban centre, using Arup’s digital heat analytics tool UHeat. The tool has the ability to take a rapid snapshot of an area and model solutions to reduce the impact of its hot spots. The tool brings together advanced academic models, real-world scenarios and technology.

Singapore’s hottest and coolest locations

While the cluster of hot spots included obvious locations with hard, impermeable surfaces or tall, closely packed buildings like Raffles Place, Shenton Way and Lau Pa Sat, other surprising locations included historical low-rise streets like Telok Ayer and Amoy Street. Despite

these streets having low-rise development, green spaces and close proximity to Marina Bay, crucial elements are intensifying heat.

The once coastal roads are now surrounded by high-rise urban developments that block the cooling effect from the nearby coast. The adjoining shophouses on the streets also have dark terracotta roofs that reach very high temperatures due to solar radiation. This heat is transferred to the air around the buildings, which is more impactful for low-rise areas close to pedestrian height.

Other neighbourhoods experiencing a temperature difference of above 5 °C compared to their rural surroundings, included industrial zones like Kampong Ubi, areas with high population density in Rochor and Marine Parade, and areas within Orchard as well as Sembawang.

Arup’s report recommends essential urban design solutions to cool cities including increasing tree canopy cover, creating more permeable surfaces, and using every space possible like white or reflective roofs to passively cool the buildings themselves and reduce the need for air conditioning.

Scan the QR code to download Arup’s Urban Heat Snapshot to find out more.

For more information, please contact Tony Chan, Planning Business Leader Southeast Asia, Arup at tony-yw.chan@arup.com

URBAN DESIGN 30 THE SINGAPORE ENGINEER February 2024

Using UHeat, a digital heat analytics tool, Arup analysed the entire city, in detail.

The red dot’s race to a green future

Mr Poon Ek Whye, Project Manager at JTC and former JTC Undergraduate Scholar, shares a young person’s vision.

Singapore stepped on the accelerator of climate change goals when we declared net-zero emissions by 2050. It is a bold commitment that will take the effort of many stakeholders. With industry and buildings collectively contributing 45% to primary carbon emissions and 30% to secondary emissions, industrial estates play a huge role.

Since the 2005 launch of the Green Building Master Plan, industrial estates have made significant progress on environmental sustainability. In fact, Green Mark certifications are the norm among industrial buildings today, even though industrial buildings present unique energy efficiency challenges rarely seen in residential or commercial typologies.

Think cold rooms or server rooms that run 24/7, or cleanrooms with very high air change rates and air filtration, all of which are energy-intensive to operate. Achieving the highest certifications in industrial buildings therefore requires a strategic combination of technology and design solutions, such as highly efficient district cooling plants complemented by buildings designed to minimise heat transfer and optimise natural ventilation.

For industrial estates to be future-ready and to punch above their own weight, three interrelated paradigm shifts are crucial.

The first shift is to adopt a wholelife carbon accounting mindset. This means looking beyond just operational carbon emissions, to also the upstream embodied carbon emissions rising from the manufacture, transportation and installation of building materials, and the downstream emissions such as those from commute, waste treatment and disposal.

The adoption of mass engineered timber by JTC for the development of Tower 4 in Punggol Digital District brought about drastic savings in em-

bodied carbon. For buildings with higher floor loading requirements, such as factories, scrap-produced steel could help avoid an estimated 63% of embodied carbon emissions from concrete reinforcements. We are also constructing building facades with reused materials from carefully and gently deconstructed older buildings.

Waste accountability ties in closely with the second paradigm shift – the move towards residue-to-resource circular economies. In the city of Kalundborg in Denmark, the local power station forms the ‘heart’ of an organically developed circular economy. Process steam generated by the station contributes to 15% of the city’s oil refinery’s needs and 100% of a pharmaceutical company’s needs. Gypsum residue is also delivered to a plasterboard company.

In other places, a matchmaker that maps out resource flows and identifies potential synergies may be a necessary catalyst.

Perhaps Singapore’s industrial estates could develop an online estate-wide platform with a Materials Marketplace that serves as a ‘clearing house’ for trading residue products – from scrap metal to construction and demolition waste, to even used office stationery – between companies.

Finally, there is a need to harness

the Internet of Things (IoT) to optimise sustainability performance. Sensors could be integrated with a building management system, to enable the adjustment of air-conditioning, fresh air and lighting, in a responsive manner, based on occupant demands and weather conditions.

Yet even with the trifecta in place, there is still a need to close the gap to net-zero further. While the baseload power requirements of the industrial estate continues to draw from the national grid, peak demands could be bridged by a combination of solar energy, stored in battery-like storage systems to eliminate intermittency even on a cloudy day, as well as on-site ammonia or hydrogen fuel cells.

We can realise more carbon abatement potential if breakthroughs can be achieved not just technologically, but also in the way we master plan our industrial estates and its ecosystem, with life-cycle thinking in mind. As corporate sustainability rapidly shifts from choice to critical necessity, the hope is that green premiums will become more widely accepted with the aid of sustainability grants, and the eventual affordability of green technologies.

(The article is adapted from a story first produced in JTC’s publication, Dream Factories)

INDUSTRIAL ESTATES 32 THE SINGAPORE ENGINEER February 2024

Tower 4 at Punggol Digital District is a Green Mark Platinum Super Low Energy Building (SLEB) constructed with mass-engineered timber (MET), a highly renewable material. The use of MET neutralises 1,248 tonnes of embodied carbon and enables significant savings of around 50% to 60% in manpower and construction time.

CFD for the Built Environment – a critical & necessary step in Singapore’s Net Zero Journey

by Vivek Parawati and Amit Deshpande, SCx Solutions

by Vivek Parawati and Amit Deshpande, SCx Solutions

The Built Environment is at the junction of energy needs, policy and a changing climate. CFD can provide an accurate, meaningful insight into the dynamic relationship between the three.

Extensive urbanisation since the mid-1970s has led to Singapore rapidly heating up. According to the Meteorological Service Singapore, the island is warming up twice as fast as the rest of the world, at 0.25 °C per decade.

Last year (2023) was the fourth warmest year on record for Singapore, tied with 1997 and 2015. At the Changi climate station, the last nine months of the year saw above average temperatures, with record-breaking temperatures in May and October.

Singapore’s equatorial climate necessitates air-conditioning in almost 99% of condominiums.

A standard 2 kW AC unit, switched on for 8 hours a day for 20 days a month, to cool a 20 m2 room, produces 1.4 tonnes of carbon emissions annually. Four such AC units, in a home, will generate about 5.6 tonnes of carbon emissions annually.

Singapore faces the dual problem of increasing energy consumption and increasing carbon emissions.

It also impacts the island nation’s energy security.

Application of Computational Fluid Dynamics

Computational Fluid Dynamics (CFD) is a powerful tool available to today’s designers in the AEC sector, to help them make the right energy-efficient choices, ahead of time, throughout the lifetime of the asset.

Complex systems involving fluid flow phenomena are commonly found along the energy value chain. CFD is a tool that can be used to predict fluid flow phenomena using numerical algorithms.

Various combinations of HVAC systems, microclimatic conditions

(wind direction, wind load etc), shading, occupancy levels etc, can be simulated, providing AEC professionals with usable results.

Today’s commercial CFD solutions, can model thermal comfort and internal air quality for different occupancy levels while considering planned HVAC capacity and different ventilation schemes.

CFD is a powerful tool available to today’s designers in the AEC sector, helping them to make the right energy-efficient choices ahead of time.

This will help Singapore achieve the goals of reduced emissions to 60 million tonnes of carbon dioxide equivalent by 2030, Net Zero emissions by 2050 and Improved Energy Security.

34 MEP ENGINEERING THE SINGAPORE ENGINEER February 2024

Singapore Climate 2023: Average temperature for each year. Meteorological Service Singapore.

Mr Amit Deshpande

Mr Vivek Parawati

Computational Fluid Dynamics (CFD) solutions can help designers, architects and engineers create energy-efficient buildings.

Shining a light on how buildings can hit the green mark

by Vijay Venkatsubramanian, Leader - Specification and lighting applications South East Asia, Signify

An important contribution can be made by lighting systems.

Come 1 June 2024, all building projects in Singapore will be assessed using the second edition of the Green Mark 2021 (GM 2021) scheme developed by the Building and Construction Authority (BCA).

BCA’s intent for the tightened scheme is clear – to accelerate the elevation of sustainability standards for Singapore’s built environment, by enhancing overall environmental performance and driving decarbonisation.

As the built environment enters the last phase of preparation for this significant change, it is of paramount importance to examine if you have maximised the potential of lighting – a key enabler in achieving the refreshed certification standards – and are doing well in the revised scoring framework.

To fully comprehend and embrace the transformative capabilities of lighting, in fulfilling the GM 2021 criteria, Signify, the world leader in lighting, breaks the key considerations for you in four critical areas –Energy Efficiency, Intelligence, Health and Well-being, and Maintainability.

ENERGY EFFICIENCY

In the second edition of GM 2021, energy efficiency (EE), via demand reduction in watts/square metre (W/m2) and consumption reduction in kilowatts hours (KWhrs), has become the singular determinant of a building’s rating.

According to research conducted by Signify, lighting, on average, constitutes between 20% and 40% of a municipality’s electricity consumption. Cities use about 78% of the world’s energy and account for more than 60% of its greenhouse gas emissions. These statistics un-

derscore the importance of harnessing lighting technologies to enhance energy efficiency for buildings.

Supported by rapid technological advancements, incorporation of improvements in lighting has become the quickest path to a greener and smarter built environment. LED lighting can cut 50% of a city’s lighting energy consumption, while connected LED lighting can reduce it by 70%, according to Signify’s research.

In fact, if all cities flip the switch to LED lighting, the world could save around 1.4 billion tonnes of CO2 by 2030. For Singapore, the annual savings would amount to 1 million tonnes of CO2 emissions and SGD 700 million in energy costs.

But how does good lighting actually help a building to score well in GM 2021? Let us find out.

Demand reduction

Achieving the targeted Lighting Power Density (LPD) in GM 2021 is a challenging endeavour, whether it is for developing a new building or retrofitting an existing one.

It is hard to achieve these LPDs while maintaining the required uniformity and glare limit. The solution lies in incorporating high-efficiency LED luminaires, such as Signify’s ultra-efficient luminaires that are capable of delivering LPDs of less than 3.5 W/m2 with more than 180 lumens per watt (lm/W), with sophisticated optics and control systems.

Mr Vijay Venkatsubramanian

Mr Vijay Venkatsubramanian

Consumption reduction

To significantly reduce consumption, dimming or switching off lights, through intelligent sensors that detect occupancy and daylight penetration, is key. This can be accomplished through a retrofit-ready wireless control system to enable multi-site management and monitoring of lighting infrastructure suitable for large spaces.

Employing such a system makes it possible to monitor temperature, air quality, noise level and relative humidity, to optimise the environment for end-users. Another feature of the system is guiding employees to uncrowded areas of a building, allowing them to reserve spaces based on acceptable occupancy levels while maintaining physical distance. There are standalone control systems designed for small- and medium-sized offices or retail set-ups.

SUSTAINABILITY BADGES

Apart from the mandatory energy efficiency, the new standard also recognises sustainable parameters via badges for Intelligence, Health and Well-being, and Maintainability, as well as for Whole Life Carbon performance and for Resilience.

Buildings can obtain a sustainability badge in each of the above categories, by achieving a score of 10 points in that particular category.

Intelligence

A way in which you could raise your score, in the category of Intelligence, is through the deployment of smart lighting control systems.

It is advisable to use LED luminaires and control systems as they help buildings achieve over 70%

36 MEP

THE SINGAPORE ENGINEER February 2024

ENGINEERING

Green Mark Award LPD in Watts (W) /m2 Super Low Energy Building 5.0 Platinum 5.5 GoldPLUS 6.0

savings in Building Operating Expenses (OPEX). They provide facility managers with peace of mind, as such luminaires have a lifetime of more than 50,000 hours, equivalent to about 14 years in an office, with little maintenance expense.

Tapping on the power of data, smart lighting (intelligent wireless lighting), ‘light on demand’ solutions, as well as sensors (to determine occupancy levels, energy use breakdown, and space utilisation), can enable you to gain 1 point under each section or a total of 4 points to your score.

Employing lighting technology such as Signify’s Interact IoT platform enables businesses to use embedded sensors, IoT devices and software, to make more effective decisions and actions, delivering new operational efficiencies, customer benefits and services.

Health and Well-being

Lighting is a proven tool for better health and well-being. The power of light can transform indoor spaces, where we spend 90% of our time, into happier and healthier places.

The internal clock in our brain, which synchronises physiological functions with dynamic lighting levels, can be disturbed when we are inside a building because of non-exposure to direct daylight.

Signify’s ‘NatureConnect’ lighting, which uses BioUp technology, simulates the daily patterns of sunlight, using light recipes that boost our energy and productivity levels, while helping indoor spaces feel in sync with nature.

Having good natural daylight indoors generates a high Melanopic Daylight Efficiency Ratio (MDER) and stimulates certain photoreceptors in the eye that influence our internal body clock. Circadian rhythms are 24-hour cycles that are part of the body’s internal clock, with an important role of giving us good sleep quality, cognitive performance and immune systems.

Additionally, solutions such as the BioUp technology, used in good quality lighting, fine-tune specific wavelengths in the LED light spec-

trum, enhancing the biological impact of light without changing its visual colour or intensity. It supports your circadian rhythm, improving daytime engagement and promoting good sleep quality at night.

Lighting is linked to the stimulation of the hormone, cortisol, which helps to deal with stress and avoid the sleep-inducing effects of melatonin. In doing so, we can stay more alert during work hours and sleep better at night. By balancing the correct type of light, through replicating natural variations in colour temperature at the correct time of day, our energy levels and overall well-being will be boosted.

By opting for high-quality artificial lighting such as Signify’s NatureConnect with colour rendering index and responsive light control, as well as circadian light for all lighting, including task lighting, you will be on your way to scoring 2.5 out of 10 points in this category.

Maintainability

It is extremely important to opt for high-quality lighting products. Pay attention to these factors – lifespan and failure rate, absence of light flickering and minimum colour shift –as together they contribute to 2 out of 10 points. Go for lighting technology with a long lifespan, using sustainable materials that limit wastage, facilitate recycling and automatically contribute to a circular economy.

ILLUMINATING A GREEN FUTURE

While scoring well in the GM 2021 framework is of practical concern, it is also important to not just do the minimum but strive to continuously attain higher standards to make a building as green, healthy and sustainable, as possible.

Let lighting, a vital part of any building or structure, be the primary and quickest strategy for you to make a mark in the transition to a net-zero future.

37

THE SINGAPORE ENGINEER February 2024

MEP ENGINEERING

Signify’s NatureConnect lighting system uses BioUp technology which mimics the natural patterns of daylight indoors.

Signify’s Ultra Efficient LEDtubes with 20 years of lifespan.

Strategic approaches to address the Mandatory Energy Improvement directive

Retrofitting ACMV systems with EC fans.

To bring Singapore closer to its goal of greening 80% of its buildings by 2030, BCA will be introducing the Mandatory Energy Improvement (MEI) regime by the end of this year. The directive aims to support existing buildings with a Gross Floor Area of 5,000 m2 and above, that have poor energy performance, to reduce their energy consumption.

To reduce a building’s energy consumption, the first step is to analyse the building’s energy consumption profile. For most buildings in tropical Singapore, the ACMV systems tend to consume the most energy. Examples include air handling units (AHUs), fan coil units (FCUs), cooling towers and more.

According to a BCA study, up to 70% of the energy consumed in a typical office building can be due to the the cooling (60%) and ventilation systems (10%). And within the ACMV systems, fans account for 35% of the energy consumption, according to a National Climate Change Secretariat (NCCS) study.

By reducing overall ACMV energy consumption through retrofitting fans, the overall energy consumption of the building can be reduced.

Why EC technology?

The conventional fan solution typically refers to belt-driven Alternating Current (AC) fans. But these are known to be inefficient and require frequent maintenance with high operating costs. In contrast, Electronically Commutated (EC) fans utilise integrated electronics to enable precise control of speed, leading to improved energy efficiency.

The latest generation 3 EC motors have efficiency levels above IE5 efficiency requirements and feature advanced electronics that boast a configurable control interface, allowing a 0 to 10 volt DC (VDC) control signal for smoothly adjustable speed.

With MODBUS-RTU compatibility, seamless integration into building management systems can be facilitated, enabling data-driven facilities management (FM) which allows the FM team to make smarter decisions that can further reduce energy consumption.

Other key features encompass integrated resonance detection, protective measures like locked rotor and thermal overload protection, and environment-resistant cable glands – all contributing to enhanced operational reliability.

Last but not least, a vibration sensor can be installed in EC centrifugal

fans, enabling resonance detection. This ensures the prevention of operations within critical ranges. This sensor not only monitors the fan’s health, but also enables preventive maintenance, optimises performance and ultimately prolongs the fan’s lifespan.

Reducing the energy consumption of existing buildings can be challenging, especially since there is no ‘one size fits all’ plan. However, through collaborations with various stakeholders such as consultants, contractors and suppliers, it is possible to take an existing building’s efficiency to greener heights.

38 MEP

THE SINGAPORE ENGINEER February 2024

ENGINEERING

In a typical office building, fans account for 35% of the energy consumption by ACMV systems.

EC fans utilise integrated electronics to enable precise control of speed, leading to improved energy efficiency.

Innovative water treatment systems for cooling towers

Article by Mohan Chavan, Founder & CEO, Ecomax Solutions Pvt Ltd, Pune, India

Saving water and energy.

In today’s water stressed society, over 1 billion people lack access to fresh drinking water. With climate change challenges, the availability of fresh water is becoming scarcer and scarcer. Looking at the ever increasing population across the globe and the rapid urbanisation and industrialisation, saving water is very crucial.

Centrally air-conditioned buildings, data centres and industries that use water-cooled chillers, consume huge amounts of water for the cooling towers. Further, owing to the water quality challenges in cooling towers, chemical dosing is done in order to reduce scaling, biofouling and corrosion, resulting in tons of water being wasted as blowdown. The harmful chemicals cause environmental hazards.

Innovative technologies based on electrolysis have proven to be very promising, for treating the cooling tower circulation water without using any chemicals, and yet reducing blowdown water consumption substantially, thereby resulting in saving precious fresh water. Using such technologies not only helps to save water but also results in a substantial reduction in energy consumption, thereby helping to reduce the carbon footprint significantly.

What sets Ecomax Solutions apart is their comprehensive approach to sustainability. Their solutions span across diverse industries – from hospitality and pharmaceuticals to manufacturing and utilities – with each benefitting from the commitment to reducing the carbon footprint. The innovative products not only enhance energy efficiency but also significantly cut down on operational and maintenance costs.

A leading delivery and logistics

company, with their headquarters in USA, has implemented an Electrolysis based Water Treatment System for a 4800 TR Cooling Tower for their office and data centre building in India, as part of their sustainability drive. For them, cooling, being a major energy consumer, presented an opportunity to enhance water efficiency, energy efficiency and sustainability, while reducing operational costs.

The adoption of this innovative technology in existing and new cooling circuits exemplifies how innovative and sustainable solutions can

significantly enhance the efficiency and cost-effectiveness of existing and new projects for any company. This is one way of managing the trifecta of energy, water and cost savings.

Ecomax Solutions enables its clients to achieve the benefits of sustainability and cost reduction, as their contribution to Singapore’s Green Plan 2030 and global sustainability. Ecomax Solutions commits to creating a sustainable and resilient future, and setting a benchmark in the industry, that will inspire others to follow in their footsteps.

40 MEP ENGINEERING THE SINGAPORE ENGINEER February 2024

Installation of the electrolytic water treatment system.

Parameters With Chemical Treatment With ECOMax-CT Benefits pH 8.5 8.2 pH is maintained in the range Total Dissolved Solids, TDS (ppm) 2607 1905 Reduced TDS Total Hardness, TH (ppm) 90 38 Reduced TH Blowdown, m3/ day 55 15 >70% Reduction in Blowdown Water Consumption Chemical Cost, USD 3,000 Per Month 0 ZERO Chemical Consumption Performance of the electrolytic water treatment system

Azbil’s global sustainability charge through automation

An expanded role to achieve carbon neutrality.

As a global leader in the field of automation technology, the azbil Group (azbil) has been shaping its legacy over 118 years and defining a sustainable future for tomorrow. Guided by its group philosophy of human-centred automation, azbil is dedicated to perfecting its measurement and control technology to create new value through automation and contribute to the sustainability of industry and society.

azbil’s commitment to sustainability includes its proactive efforts to reduce CO2 emissions at customer sites. By 2030, azbil targets an annual effective reduction of 3.40 million metric tons of CO2 at customers’ sites, under one of its essential goals of the azbil Group for the SDGs – Environment and Energy.

Leveraging its three business segments – Building Automation, Advanced Automation, and Life Automation – azbil provides its unique value to customers in offices, production sites and in daily life. These segments strive to enhance the quality of indoor spaces and productivity while efficiently controlling the energy and resource consumption in buildings, factories and lifeline utilities.

Embracing changes in the business environment, marked by globalisation, social responsibility,

technological innovation and societal shifts, automation is increasingly demanded for its expanded role in achieving carbon neutrality.

Prioritising the three growth fields

– new automation, environment and energy, and life-cycle solutions – at the core, azbil leverages its unique technologies, products and services, to accelerate transformation, driving global development and business field initiatives.

• New automation: Solving new challenges with new and innovative products and services.

• Environment and energy: Applying proven strengths in energy efficiency and renewable energy.

• Life-cycle solutions: Supporting customers’ assets over the long term.

The azbil Group targets JPY 400 billion in sales by 2030, with a substantial JPY 100 billion from global markets. This fuels strategic expansion in key markets through partnerships worldwide, working towards the carbon-neutral future.

Outside Japan, Azbil Corporation established its Strategic Planning & Development Office for Southeast Asia in Singapore, spearheading business promotion, strategic plans and business management in the region. The office further functions as an additional research and development base, linking collaborative technology development across Japan, the Americas and Asia.

For more information, visit: www. azbil.com.

42 AUTOMATION THE SINGAPORE ENGINEER February 2024

Takayuki Yokota is responsible for business management, finance and sustainability.

Azbil’s sustainability initiatives.

Solutions for a broad range of industries and geographies

A commitment to sustainability.

As the world continues its sustainability journey, Honeywell is committed to providing unique insights to gauge how climate change is tangibly affecting corporate actions to reduce the environmental impact of their operations.

Environmental sustainability remains a top priority, both in the solutions Honeywell provides its own customers and in its own operations. Honeywell is ready now to equip customers with innovative tools to fight the effects of climate change and become more sustainable. By continuing to spend approximately 60% of its research and development funding on ESG-oriented solutions, the company is introducing cutting-edge offerings for a vast number of global markets and industries and helping to solve some of the world’s most complex challenges.

Honeywell has ‘ready now solutions’ to support environmental, safety, security and productivity objectives. Five key areas where companies are investing now, for sustainability, are:

• Tackling Emissions: Methane is about 27 to 30 times more potent than carbon dioxide and there were a lot of discussions at COP28 about reducing methane emissions faster. Both voluntary and mandatory reduction efforts are being implemented (e.g. IRA Waste Emission Charge, Global Methane Initiative and Global Methane Pledge). Honeywell has outcome-based offerings enabled by enterprise emissions management software-as-a-service, fixed and portable connected gas detectors (Signal Scout), Rebellion gas visualisation cameras and Flare Gas Recovery Systems, as well as

the Emissions 360 services program.