www.ies.org.sg

www.ies.org.sg

WORKPLACE SAFETY & HEALTH: Workplace fatal and major injury rates for 2023 at record low

COLLABORATIVE CONTRACTING: L aunch of NEC4 contract for construction and engineering projects in Singapore

MATHEMATICS IN ENGINEERING: Elevating students’ appreciation through real-world applications

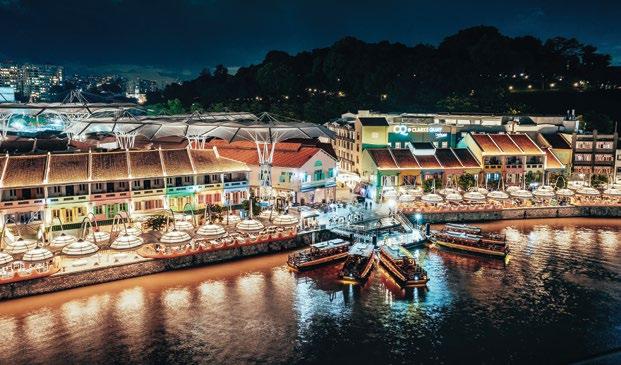

11 Ushering in a new era of CQ @ Clarke Quay

The riverside lifestyle hotspot relaunches as a vibrant day-and-night destination.

17 Workplace fatal and major injury rates for 2023 at record low

The achievement reflects the collective efforts of the government, various organisations and workers.

22 Launch of NEC4 contract for construction and engineering projects in Singapore

The benefits include effective time and cost control, risk management and project management.

24 Elevating students’ appreciation through real-world applications

Connecting the theoretical to practical usefulness.

President Er. Chan Ewe Jin

Chief Editor T Bhaskaran t_b_n8@yahoo.com

Publications Manager Desmond Teo desmond@iesnet.org.sg

Publications Executive Nuraini Ahmad nuraini@iesnet.org.sg

Editorial Panel

Dr Victor Sim

Dr Chandra Segaran

Dr Ang Keng Been

Dr Aaron Sham

Mr Jaime Vega Bautista Jr

Mr Soon Ren Jun

Dr Alexander Wiegand

Media Representative Trevor Teh IES@mnc-link.com

Design & layout by 2EZ Asia Pte Ltd

Cover designed by Irin Kuah

Cover images by CapitaLand

by

Institution of Engineers, Singapore

Bukit Tinggi Road, Singapore 289758

6469 5000 I Fax: 6467 1108 Printed in Singapore

28 Study proves viability of urban electric construction Conditions can be created to support a smooth transition to electric construction sites and emission-free contracting.

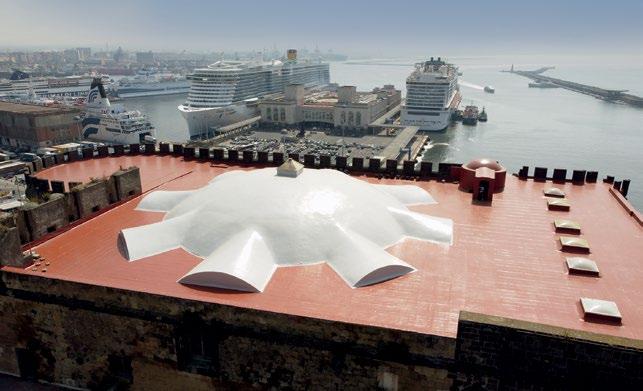

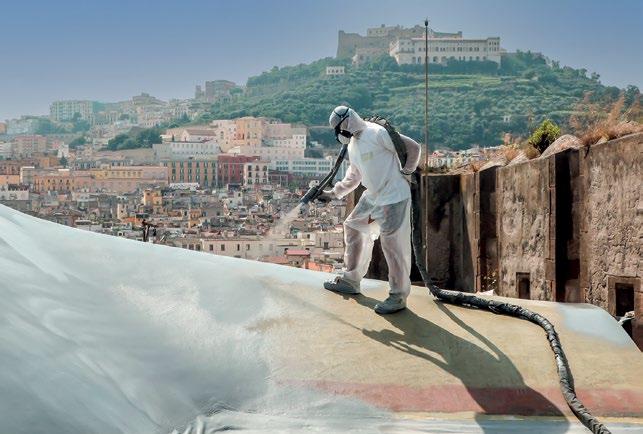

30 Counteracting water infiltrations

The latest generation of waterproofing membranes was used in the redevelopment of the historic Castel Nuovo in Naples, Italy.

33 Supporting the construction of Eunoia Junior College Effective management of tasks through digitalisation.

34 Danjiang Bridge reaches record-breaking proportions Upon completion, it is expected to be the world’s longest, asymmetric, cable-stayed bridge.

free-of-charge to IES members and affiliates. Views expressed

necessarily reflect those of the Editor or IES. All rights reserved. No part of this magazine shall be reproduced, mechanically or electronically, without the prior consent of IES. Whilst every care is taken to ensure accuracy of the content at press time, IES will not be liable for any discrepancies. Unsolicited contributions are welcome but their inclusion in the magazine is at the discretion of the Editor.

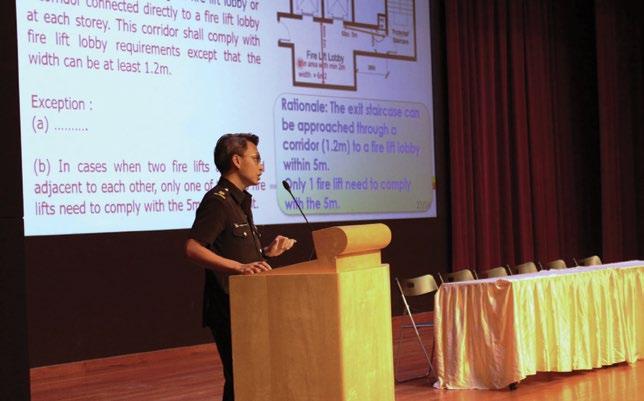

Organised by the IES M&E Engineering Technical Committee, and supported by the Singapore Civil Defence Force (SCDF) and the Fire Safety Managers’ Association Singapore (FSMAS), the annual ‘Key Amendments to Fire Code’ event was held on 15 May 2024, at HDB Hub Auditorium.

Over 400 participants gathered for the seminar, created for professionals looking to stay on top of the latest fire safety standards.

The seminar provided a comprehensive overview of significant changes to the fire code, addressing the industry’s need for current information and understanding of new standards.

It provided an avenue for discussing common consultation queries, where participants could gain clarity on challenging aspects of the fire code, to ensure a uniform application of the regulations across projects.

Additionally, the seminar shed light on common audit findings, highlighting areas where compliance often fell short, and offered guidance for improvement.

A special session on the fire safety of electrical transformers in underground structures offered targeted insights into managing these highrisk areas effectively.

A notable inclusion in the line-up was a presentation on the implementation of fire-smoke dampers, including compliance with the SS 333 standard to issuance of the Certificate of Conformity (COC).

The seminar served as an essential conduit for professionals to enhance their understanding, improve submission quality and ensure adherence to the latest fire safety standards.

Fire safety and building design experts, including consultants, fire safety officers, and engineers gathered to hear MAJ Muhammad Izwan Bin Ibrahim, Senior Consultant

at SCDF, break down updates to the Fire Code within the Code of Practice for Fire Precautions in Buildings, and everything from submission processes for SCDF approval to the responsibilities of Qualified Persons (QPs), as well as interpret clauses of the Fire Code.

SCDF Consultant CPT Joyce Ng provided the audience with common audit findings, focusing on

typical non-compliances in commercial and industrial projects, and highlighting key areas for QPs to improve the quality of their submissions.

Er. Simon Lee, Director, Bescon Consulting Engineers Pte and IES M&E Engineering TC Chairman, highlighted the fire risks for electrical transformers in underground structures and the mitigation measures to

be taken to ensure fire safety.

Er. Yee Poh Kin, Principal, New Universal Solution and VP, Institution of Fire Engineers, Singapore, shared valuable insights on the critical role of fire-smoke dampers in buildings.

IES specially thanks the speakers, moderator and the audience, for their participation in the seminar and panel discussion.

PUB, Singapore’s National Water Agency, snagged two awards at the Global Water Awards 2024, held in London, recently. The Global Water Awards are announced annually by Global Water Intelligence (GWI), to recognise the most important achievements in various water sectors.

Singapore’s Changi Water Reclamation Plant (WRP) was conferred the ‘Wastewater Project of the Year’ award, while the Jurong Island Desalination Plant (JIDP) clinched the distinction award in the ‘Desalination Plant of the Year’ category.

Mr Ong Tze Ch’in, PUB’s Chief Executive, said, “We are grateful for this recognition by the global water industry, as it affirms PUB’s continuing journey of innovation and excellence. With climate change, we will need to continue improving our water infrastructure and operational efficiency.”

Used water treatment and desalination are key elements of Singapore’s integrated water management. Singapore has effectively closed the water loop through the treatment of used water for the production of NEWater, and through desalinating seawater. NEWater and desalinated water, Singapore’s 3rd and 4th National Taps, introduced in 2002 and 2005, respectively, are weather-resilient sources that strengthen Singapore’s water security amidst the challenges of climate change.

Changi WRP, one of the largest and most advanced water reclamation facilities in the world, was conferred the ‘Wastewater Project of the Year’ award, in recognition of its innovative practices in reducing its physical footprint.

This is PUB’s second win in this category, following the Ulu Pandan Integrated Validation Plant’s success in 2018.

Commissioned in 2008, as part of the Deep Tunnel Sewerage System (DTSS) Phase 1 project, the plant boasts a compact design and innovative features, as it was constructed partially underground. The used water treatment facilities at Changi WRP are stacked to optimise space, allowing it to occupy a third of what conventional WRPs would require.

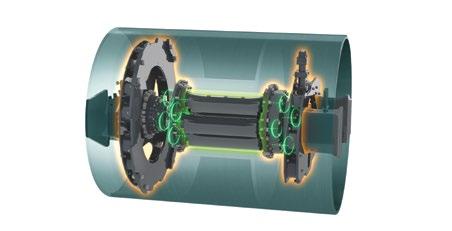

Changi WRP’s Phase 2 expansion project, which is scheduled for completion by end-2024, will increase the plant’s used water treatment capacity from 176 million gallons

per day (mgd) to 246 mgd – the equivalent of more than 440 Olympic-sized swimming pools. The increase in capacity will be achieved through the construction of a fifth treatment train, a separate wet weather facility (WWF) and the installation of advanced membrane bioreactor (MBR) equipment.

Upon completion, Changi WRP will be Singapore’s largest MBR facility. MBR is a 3-in-1 solution that combines conventional bioreactors, secondary sedimentation tanks and microfiltration/ultrafiltration, in a single stage.

This allows downstream NEWater processes to be simplified with just reverse osmosis (RO) membranes and ultraviolet disinfection, negating the need for microfiltration. The filtrate obtained from MBR is also of higher quality, improving the overall lifespan of RO membranes and producing less biosolids. This will help PUB achieve a more efficient and reliable used water treatment process, while also optimising the subsequent NEWater treatment process.

Jurong Island Desalination Plant Singapore’s latest and fifth desalination plant, the Jurong Island Desalination Plant (JIDP), which opened in 2022, picked up the distinction award in the ‘Desalination Plant of the Year’ category, losing out to Saudi Arabia’s 3A Jubail Independent Water Plant, for the top award.

JIDP’s co-location with the Tembusu Multi-Utilities Complex (TMUC) allows it to tap on potential synergies and the sharing of resources with the power plant in TMUC. JIDP draws electricity directly from the adjacent power plant at TMUC, improving process efficiency and reducing the energy consumption, by 5%, as compared to conventional desalination plants, translating to annual energy savings sufficient to power nearly 1,000 HDB households.

Modular systems were created in different areas of the desalination process and prefabricated off-site to simplify and speed up the completion of JIDP. The operations at the plant are highly automated, to significantly reduce operator workload, allowing for more streamlined operations that can be controlled from the main control room. JIDP also incorporates advanced water treatment equipment and membrane technologies such as dissolved air flotation, ultra-filtration, and reverse osmosis, enabling the plant to further optimise the desalination process.

Global Water Intelligence

Global Water Intelligence researches and publishes business data and information about water markets worldwide.

Water Company of the Year

WINNER – SUEZ

DISTINCTION – Gradiant

Desalination Company of the Year

WINNER – Acciona

DISTINCTION – Saline Water Conversion Company (SWCC)

Water Technology Company of the Year

WINNER – Grundfos

DISTINCTION – Siemens

Breakthrough Technology Company of the Year

WINNER – Aqua Membranes

DISTINCTION – Purecontrol

Public Water Company of the Year

WINNER – Saudi Water Partnership Company, Saudi Arabia

DISTINCTION – New York City Department of Environmental Protection, USA

Desalination Plant of the Year

WINNER – Jubail 3A IWP, Saudi Arabia

DISTINCTION – Jurong Island Desalination Plant, Singapore

Water Project of the Year

WINNER – Poblacion WTP, Philippines

DISTINCTION – San Fernando Groundwater Treatment Program, USA

Wastewater Project of the Year

WINNER – Changi WRP

Expansion, Singapore

DISTINCTION – Umm Al Hayman WWTP, Kuwait

Smart Water Project of the Year

WINNER – Dubai Hydro Insight, UAE

DISTINCTION – Lahaina emergency sewer assessments, USA

Water Reuse Project of the Year

WINNER – ADSWS Recycling Transformation, UAE

DISTINCTION – Santa Monica Sustainable Water Infrastructure Project, USA

Industrial Project of the Year

WINNER – Slaughterhouse wastewater treatment, Saudi Arabia

DISTINCTION – NMDC ZLD plant, India

Water Stewardship Programme of the Year

WINNER – Intel water conservation and restoration

DISTINCTION – Danone Aguascalientes programme, Mexico

Net Zero Carbon Champion

WINNER – Xylem DISTINCTION – Scottish Water

A JTC development, LaunchPad @ one-north, an innovator’s playground for new solutions, is set to host Singapore’s first-ever co-living train hotel, featuring the adaptive reuse of a decommissioned SMRT train carriage into a boutique co-living hotel. This new hospitality concept is the creation of local startup, Tiny Pod, and will be piloted with the support of JTC.

The co-living train hotel will incorporate a total of eight rooms, each equipped with an attached bathroom. Additionally, LCD panels mounted inside the driver’s compartment will depict real-life footage of the train’s earlier journey through the tunnel, creating an immersive experience for guests.

The train hotel will be located at the car park next to Block 69 Ayer Rajah Crescent. A public recreational green space will be developed beside the co-living train hotel. Integrated with food and beverage vending machines and bicycle racks, this new amenity node will also incorporate repurposed train chairs as outdoor public benches. Renovation works commenced in March 2024, with the co-living train hotel anticipated to be operational in September 2024.

Recognising the value of being in an ecosystem of like-minded startups within LaunchPad @ one-north, Tiny Pod has leveraged this opportunity to partner with local start-up, Igloo Home, for the hotel’s smart lock system to enhance the co-living train.

Tiny Pod’s co-living train hotel project is an extension to its pop-up shipping container hotel at LaunchPad @ one-north, which was launched in 2020. Since then, Tiny Pod’s shipping containers have expanded to urban and public spaces at Gardens by the Bay and Haw Par Villa.

“In today’s market, where consumers prioritise eco-conscious choices, pop-up hotels are swiftly emerging as a lucrative niche. Our

endeavour taps into this trend and exemplifies a fusion of profitability and sustainability. By transforming underutilised spaces into unique accommodation experiences, we unlock new revenue streams and minimise our environmental footprint,” said Mr Seah Liang Chiang, Founder & CEO, Tiny Pod Pte Ltd.

“This endeavour aligns seamlessly with evolving consumer preferences, where conscientious travellers seek authentic and eco-friendly alternatives. With the support of our partners, JTC, LTA, MTI and STB, and the growing momentum of eco-conscious tourism, this project demonstrates our commitment to catalyse positive change within the industry, while delivering memorable experiences for our guests,” he added.

Ms Yap Eai-Sy, JTC’s Director for New Estates Business Development and Marketing Division said, “At LaunchPad, we have curated an ecosystem of players for startups like

Tiny Pod to collaborate, co-create as well as validate new concepts and business models. Building on the success of its shipping container hotel testbed, Tiny Pod’s co-living train is a natural progression for sustainable hospitality solutions through adaptive reuse. It is also an innovative option to cater to the demand for short-term accommodation in one-north.”

The Land Transport Authority (LTA) will step up efforts to facilitate Walk, Cycle, Ride journeys.

First, LTA will expand its Friendly Streets initiative to more towns. Second, LTA will improve first-andlast-mile connectivity with more commuter infrastructure. These two initiatives, which are also in support of Age Well SG, will receive additional funding of around SGD 1 billion, over the next decade.

LTA will additionally fund two new road repurposing projects to prioritise road space for pedestrians and cyclists. These enhancements aim to create safer, more inclusive public spaces, and encourage active and sustainable modes of transport.

Located at areas with high pedestrian flow and close to key amenities, Friendly Streets was announced in the Ministry of Transport’s Committee of Supply debate in 2023. This initiative started with five pilot locations and aims to make walking and cycling commutes within the neighbourhoods safer, more inclusive and comfortable. The locations are Ang Mo Kio, Bukit Batok West, Tampines, Toa Payoh and West Coast.

LTA has started works at Ang Mo Kio, Bukit Batok West and Tampines, and works for the remaining pilot locations will commence in the coming months.

Encouraged by the strong community support for the five pilots, LTA will expand the Friendly Streets initiative to all HDB towns by 2030, as well as to private estates with high-activity areas and key amenities nearby. The next phase of the Friendly Streets initiative will cover 10 more towns, in the following locations – Bedok, Buangkok, Bukit Panjang, Choa Chu Kang, Holland/Buona Vista, Jurong East, Pek Kio, Punggol, Sembawang and Tiong Bahru/Havelock.

LTA will start engaging the community and relevant stakeholders in these

towns, later this year, to determine the specific locations and Friendly Streets features to be implemented.

LTA will enhance commuter infrastructure which is aimed at improving barrier-free access and making walking to key public transport nodes more convenient and comfortable. These enhancements provide residents, especially seniors, with improved access to amenities and public transport nodes, and encourage them to lead more active lifestyles and stay socially connected.

Planned commuter infrastructure enhancements over the next decade include:

• Upgrading and implementing senior-friendly features at more bus stops, such as additional seats with arm and back rests, as well as ensuring wheelchair accessibility.

• Building more covered linkways to connect MRT stations to more Friendly Streets and some key amenities nearby, that are largely within an 800 m radius, for more comfortable and convenient walking experiences.

• Retrofitting more pedestrian overhead bridges with lifts, to provide barrier-free access, especially those near public transport nodes and healthcare institutions.

LTA has been retrofitting lifts at pedestrian overhead bridges, since 2013. Currently there are 87 existing pedestrian overhead bridges with lifts. This effort is prioritised for locations that are expected to benefit a high number of seniors and commuters with mobility challenges, such as for pedestrian overhead bridges near public transport nodes and healthcare institutions.

New road repurposing projects Road repurposing will continue to

enhance the Walk, Cycle, Ride experience and facilitate smoother connections between surrounding amenities. Last year, LTA announced plans to pedestrianise an 80 m-long stretch of road along Choa Chu Kang Terrace and an 18 m-long stretch at Yung Sheng Road. Works are ongoing at these locations and are slated for completion by end-2024.

This year, LTA will embark on two more road repurposing projects – at Zion Road and Sims Place.

LTA will repurpose up to two of the five to six road lanes along Zion Road (around 700 m, between River Valley Road and Ganges Avenue). The repurposed space will feature a widened footpath and a new cycling path to connect Zion Road to the Alexandra Park Connector. It will also enable LTA to expand the existing bus shelter opposite Great World City as well as provide sheltered connectivity for commuters to Zion Riverside Food Centre.

At Sims Place, LTA plans to repurpose a 300 m road stretch fronting Sims Vista Market and Food Centre, from four road lanes to two lanes. There will be space for a widened footpath and a new cycling path. LTA will also provide sheltered connectivity across Sims Place to the market and food centre.

These two projects are expected to commence later this year with completion slated for 2026.

The 2024 edition of INTERMAT, the show for sustainable construction and technologies, was held from 24 to 27 April 2024, at Paris Nord Villepinte, Paris, France.

With its redesigned offering and format, INTERMAT 2024 attracted 127,500 visitors, 21% of whom came from 130 countries outside France. A total of 1,065 exhibitors, including 68% from outside France, welcomed a high-quality visitor audience, keen to witness the industry’s drive towards environmental and technological progress.

The show acted as a business-conducive catalyst, with the presence of a large proportion of decision-makers. A third of the visitors came with investment plans to accelerate the low carbon and digital transition of construction projects.

INTERMAT 2024 was also the point of convergence for professionals who came in search of innovation to address climate-related and societal challenges faced by the construction industry.

The exhibition was opened by the chairmen of the five main construction trade associations in France, who signed the manifesto ‘4 keys to support the decarbonisation of construction equipment’.

Adopting the right energy for each use, saving energy, raising stakeholder awareness of CSR, and improving the safety and appeal of jobs in construction, were at the heart of some highly productive debates staged in the new Industry Forum and Academy spaces.

Talks, round tables and special features gave an opportunity to visitors and, in particular, to the 1,400 young people in attendance, to gain an insight into the major issues in the sector and help accelerate the green and digital transitions.

International innovation on show

This edition was marked by the representation of major international construction companies. The main countries represented by the exhibitors included Belgium, the Netherlands, Italy, Germany, the UK, Finland, North African countries and Türkiye. The ReBuild Ukraine talk addressed all the themes essential for the reinforcement of the Ukrainian nation through reconstruction.

At the 2024 show, the INTERMAT Innovation Awards provided further evidence of the powerful innovation dynamic in the design and manufacture of equipment and machinery to support energy transition, digitalisation and safety.

The New Technologies and Energies hub and the Start-up Village showcased technology and equipment incorporating new, alternative or renewable energy sources (biofuel, electric, hydrogen), virtual and digital engineering, energy storage solutions and autonomous vehicles.

The multiple machinery demo zones, both outdoors and on stands, gave visitors a chance to discover the momentum of the latest developments by manufacturers, for better safety, productivity and energy efficiency.

The exhibition zone and educational forum focussing on the low carbon transition of the concrete sector attracted the attention of nearly one in two visitors. The INTERMAT Innovation Awards rewarded the sector’s efforts to reduce the carbon impact of materials, processes, technology and equipment.

The 2024 edition was a tradeshow redesigned in terms of format and offering, and revolving around four pillars – Innovation, Energies, New equations, and Commitments. Over and above the valuable business opportunities, the show reasserted its ambition of bringing together and sharing with the entire ecosystem, the wealth of innovation in support of decarbonisation.

Exhibitors were able to meet many visitors and help them bring their purchasing plans to fruition. The 2024 show succeeded in its goal of collectively providing novel responses to the questions from professionals.

The next edition of INTERMAT will be held in April 2027.

The riverside lifestyle hotspot relaunches as a vibrant day-and-night destination.

Nestled along the Singapore River at the fringe of Singapore’s Central Business District, CQ @ Clarke Quay is a unique conserved landmark, seamlessly blending heritage with modernity.

The rejuvenated CQ @ Clarke Quay was officially unveiled recently, marking the culmination of an asset enhancement initiative (AEI) that has transformed the development into an iconic, riverfront dayand-night destination.

Generating a net lettable area of approximately 290,000 ft2, the development comprises sheltered internal streets (Read Street & Clarke Street); a riverfront promenade with outdoor refreshment areas; three blocks of shophouses (Blocks A, D and E), two blocks of warehouses (Blocks B and C); and a multi-storey carpark block with 406 carpark lots and 23 motorcycle lots.

CQ @ Clarke Quay has three distinctive zones – The Warehouses (Block B), The Riverfront (Blocks A and D) and The Circuit (Blocks C and E).

The Warehouses (Block B) offers an exciting blend of retail, lifestyle and

F&B concepts, in conserved godowns.

The Riverfront (Blocks A and D) features riverside dining in an alfresco or heritage shophouse setting.

The Circuit (Blocks C and E) showcases high-energy concepts, entertainment and F&B establishments.

Owned by CapitaLand Integrated Commercial Trust (CICT) and managed by CapitaLand Investment Limited (CLI), CQ @ Clarke Quay is now a vibrant hub of excitement and entertainment, with an expanded range of day activities and nightlife attractions for locals and tourists.

With the completion of the AEI, which commenced in August 2022, CQ @ Clarke Quay has about 60 dining, retail and lifestyle concepts, achieving a strong occupancy of 93% to-date. CQ @ Clarke Quay has refreshed its tenant mix by introducing more than 50% new concepts, comprising international and homegrown brands. This dynamic transformation is in tandem with the ongoing urban renewal of the Singapore River precinct to incorporate more leisure amenities as well as residential and hospitality developments.

The ceremony to unveil CQ @ Clarke Quay was graced by the Guest-ofHonour, Ms Low Yen Ling, Minister of State for Ministry of Culture, Community and Youth, and Ministry of Trade & Industry.

Representatives from CapitaLand, industry partners, tenants, media and members of the public, were present at the event.

Guests were treated to a spectacular showcase of entertainment and cultural experiences, curated to delight visitors. This included a drone show that traced the rich tapestry of CQ @ Clarke Quay’s history, from its origins as a bustling riverport trading district to the vibrant riverfront lifestyle destination it has become today.

Mr Tony Tan, CEO of the manager of CICT, said, “Guided by our value creation strategy, we regularly review our asset plans to optimise and future-proof our properties through AEIs. The repositioning of CQ @ Clarke Quay as a vibrant day-andnight destination with more diversified offerings will further strengthen the resilience of our portfolio. We expect CQ @ Clarke Quay to see strong demand from tourists and locals as the Singapore River

precinct evolves.”

“With the upgraded sustainability features at the property, CQ @ Clarke Quay’s green rating has been elevated to Green Mark GoldPLUS With this, all 21 properties in our Singapore portfolio have achieved a minimum rating of Green Mark Gold by the Building and Construction Authority,” he added.

Mr Chris Chong, CEO, Retail & Workspace (Singapore & Malaysia), CLI said, “Through strategic enhancements and active placemak-

ing efforts, we have transformed CQ @ Clarke Quay into a dynamic and immersive environment for visitors to enjoy, solidifying its position as a day-and-night destination for leisure, dining and entertainment. Beyond preserving the rich heritage of Clarke Quay, we have injected fresh energy into the precinct, integrating new retail and lifestyle experiences, including the introduction of pet-friendly amenities that cater to the diverse preferences of our visitors.”

New concepts at CQ @ Clarke Quay include FairPrice Finest Clarke Quay which offers a wide range of products curated in collaboration with Singapore-based partners. The Grocer Food Hall, a food experience zone, offers ‘You Pick, We Cook’ services as well as curated cocktails infused with local flavours that are exclusive to CQ @ Clarke Quay.

Another new concept is Swee Lee Clarke Quay, which devoted approximately 60% of the repurposed warehouse unit to curate an experiential and community space. The musical instrument store houses a bar and café, an artist lounge, vinyl listening stations, a creator corner with music editing set-ups and a large hall that doubles as a dining space and performance venue. This is Swee Lee’s largest outlet in Singapore.

Opening in 3Q 2024, wellness enthusiasts can embark on a holistic fitness journey with LAVA, offering three exciting new concepts – Reformer Pilates, Kickboxing, and Electro Muscle Stimulation training.

Visitors looking for day to night activities can check out Home Singapore. By day, Home Dawn welcomes visitors with delicious brunch specialties. At sundown, Home Dusk transitions into an electrifying live music lounge. Alongside these are newly added dining establishments such as IL Clay Supper Club, a Neapolitan-style pizzeria and bar concept by renowned Naples-born chef Ciro Sorrentino, and Jules, a French bistro by Chef Laurent Brouard.

There are also a variety of latenight entertainment offerings. The line-up includes new Mexican taqueria Señor Taco, offering mescal and handcrafted agave cocktails, Mexican cuisine and Latin live band; arcade bar Level Up as well as homegrown icon Zouk and K.STAR Karaoke which features 22 futuristic-themed rooms. Along the riverfront are live music bars with international cuisine, like Chupitos, Cuba Libre Café & Bar, Little Saigon, Octapas by El Mesa, Simply Retro and Warehouse.

Beyond the diverse array of dayand-night options, CQ @ Clarke Quay has also unveiled a comprehensive suite of pet-friendly amenities, catering to the needs of valued visitors and their furry companions. These amenities include wellplaced pet hydration bays, waste bins and designated pet parking zones, providing convenience to visitors. Furthermore, pet owners can enjoy dining at a selection of eight pet-friendly establishments along the picturesque riverside, each labelled with pet-friendly logos for easy identification.

CQ @ Clarke Quay will also be unveiling the Fort Canine Swimming Club in 3Q 2024, which provides grooming services, an active daycare programme and curated ame-

nities tailored for the ultimate canine experience.

CQ @ Clarke Quay has the largest number of different types of heritage warehouses and shophouses in the city centre in Singapore.

A key focus of the AEI was to preserve the rich heritage and cultural legacy of CQ @ Clarke Quay, while enhancing it with modern and exciting offerings. Seven warehouses have been restored by preserving their godown typology while adorning them in new colours.

As a conserved heritage site, concerted efforts were made to profile CQ @ Clarke Quay’s rich history.

The new arrival canopy, made of lightweight ethylene tetrafluoroethylene (ETFE), integrates with the Angel structures. The new CQ @ Clarke Quay logo, which is prominently featured, is visible along River Valley Road and across, at Fort Canning Hill.

Along the Singapore River, the new Read Bridge landing has a new accessibility ramp with lookout points and upgraded steps that double up as seats, paying tribute to the Read Bridge’s historical role as a communal space for storytelling.

The steps of the ramps are clad, in the Read Bridge’s signature Bronze Age finish, with upcycled wood

pieces, taken from the last two Twa Kows (historical cargo vessels) that were previously located at CQ @ Clarke Quay.

The historical preservation and modern functionality results in a one-of-a-kind space, offering an exciting blend of retail, lifestyle and F&B concepts, in a collection of seven, side-by-side, conserved godowns. Heritage jack roofs were also reinstated and glass skylights were incorporated to draw natural light in. The bright and naturally-lit interiors are spacious and come with high ceilings. The revitalised space provides a setting of heritage

charm with contemporary amenities.

Fronting the restored The Warehouses’ facade is the ‘Fire Fish’ mural, a modern myth, uniquely created by homegrown artists Yip Yew Chong and tobyato, which is inspired by Clarke Quay’s heritage as a Teochew enclave.

The mural features the firewood trade in the area, distinctive red and white Teochew bumboats that once lined the Singapore River, and iconic storytellers entertaining the coolies on Read Bridge. The walkway was also widened to improve accessibility. Visitors can now also access the units at Block B from Tan Tye Place.

A heritage building with distinctive tiled roof and decorative features, known as the Riverhouse (Lian Yi Xuan in Chinese), is a feature landmark at CQ @ Clarke Quay. The removal of the dining platform resembling a lilypad and eight bluebell-shaped canopies created a new scenic resting stop for visitors along the riverfront promenade.

The connection with the river is re-established with the removal of some of the lilypads and replaced by historically-referenced new balustrades in the signature Bronze Age finish. Riverside dining is enhanced as the bluebell-shaped canopies have been refreshed with new Polytetrafluoroethylene (PTFE) membranes and high-volume-lowspeed (HVLS) fans, to improve thermal comfort. The timber deck of the lilypads were also refurbished. Lighting within these riverside structures is designed to enhance the ambience for diners.

Existing Angel canopies have been upgraded with ETFE membranes to reduce solar heat gain and optimise daylight conditions. Adding to the sustainability features are new omni-directional fans which lower the environmental temperature, through evaporative mist cooling, reducing energy consumption.

New barriers at the outdoor refreshment areas were introduced, with design patterns coherent to each zone’s identity.

Heritage panels and bronze plate tiles, strategically positioned throughout the area, recount the enthralling history of the Singapore River and Clarke Quay precinct, serving as educational elements for visitors as they explore the area’s rich history.

The Peddlers Walk has been refreshed with a new lobby portal and directional signage to improve wayfinding. In addition, the bronze heritage plaques and terracotta colour flooring are a nod to the area’s past

as back-to-back shophouses. Other features include a heritage airwell and jagged walls. Timber stools and seats, incorporating the original wood pieces from the Twa Kows, serve as resting spots.

A new lighting concept was introduced to add vibrancy to the development. To celebrate the rich heri-

tage along the riverfront promenade and internal streets, key architectural elements of the building façade were highlighted. The original cool lighting of the Angel structures and bluebell-shaped canopies were changed to warm lighting to complement the heritage buildings. In addition, the latest LED lighting that is energy-efficient and reduces maintenance requirements has been adopted.

Another key enhancement at the revamped CQ @ Clarke Quay is its focus on sustainability. Approximately 34% of the AEI cost was allocated towards improving operational efficiency and integrating sustainable building features.

One notable improvement is the reduction of daytime ambient temperature, which enhances the thermal comfort of the property’s inner streets.

To achieve this, existing Angel canopies have been upgraded with advanced ETFE membranes that optimise daylight conditions and reduce solar heat gain, by 70%, along all internal streets.

Further, the iconic bluebell-shaped canopies along the river promenade were fitted with enhanced Polytetrafluoroethylene (PTFE) membranes to improve thermal comfort.

New omni-directional fans were installed to further enhance air circulation, while reducing fan energy consumption by approximately 50%. Equipped with nozzles to release evaporative cooling mists, these new fans lower ambient temperature by approximately 2 °C, thereby reducing the urban heat island effect.

Further, upgrading of the chillers has contributed to a 30% improvement in energy efficiency, achieving the industry’s best practice of less than 0.6 kW/RT.

These green features have collectively enabled CQ @ Clarke Quay to achieve 1.03 million kilowatt-hours (kWh) per year of energy savings, equivalent to the annual energy requirements for powering about 240 four-room HDB flats.

Also, the existing steel and concrete structures in the canopies have been retained. In extending the operational lifespan of these components, approximately 1,000 tonnes of embodied carbon have been potentially avoided.

With the enhanced sustainability features and improvements in energy efficiency, CQ @ Clarke Quay’s Green Mark certification by the Building and Construction Authority was elevated to Green Mark GoldPLUS

CapitaLand Integrated Commercial Trust (CICT) is the first and largest real estate investment trust (REIT) listed on Singapore Exchange Securities Trading Limited (SGX-ST) with a market capitalisation of SGD 13.3 billion as at 31 March 2024. It debuted on SGX-ST as CapitaLand Mall Trust in July 2002 and was renamed CICT in November 2020 following the merger with CapitaLand Commercial Trust.

CICT owns and invests in quality income-producing assets primarily used for commercial (including retail and/or office) purpose, located predominantly in Singapore. As the largest proxy for Singapore commercial real estate, CICT’s portfolio comprises 21 properties in Singapore (including its 45.0% interest in CapitaSpring), two in Frankfurt, Germany, and three in Sydney, Australia, with a total property value of SGD 24.5 billion.

CICT is managed by CapitaLand Integrated Commercial Trust Management Limited, a wholly owned subsidiary of CapitaLand Investment Limited, a leading global real asset manager with a strong Asia foothold.

Headquartered and listed in Singapore, CapitaLand Investment Limited (CLI) is a leading global real asset manager with a strong Asia foothold.

As at 31 March 2024, CLI had SGD 134 billion of assets under management as well as nearly SGD 100 billion of funds under management (FUM) held via six listed real estate investment trusts and business trusts, and more than 30 private vehicles across Asia Pacific, Europe and USA. Its diversified real estate asset classes cover retail, office, lodging, business parks, industrial, logistics, self-storage and data centres.

CLI aims to scale its FUM and fee-related earnings through fund management, lodging management and commercial management, and maintain effective capital management. As the investment management arm of CapitaLand Group,

CLI has access to the development capabilities of and pipeline investment opportunities from CapitaLand’s development arm.

As a responsible company, CLI places sustainability at the core of what it does and has committed to achieve Net Zero carbon emissions for Scope 1 and 2 by 2050. CLI contributes to the environmental and social well-being of the communities where it operates, as it delivers long-term economic value to its stakeholders.

Project CQ @ Clarke Quay

Location 3 River Valley Road

Owner

CapitaLand Integrated Commercial Trust

Project Manager

CapitaLand Development Pte Ltd

PROJECT CREDITS

Design Architect

META Architecture

Project Architect

Formwerkz Architects LLP

Civil & Structural Engineer

RSP Architects Planners & Engineers (Pte) Ltd

Mechanical & Electrical Engineer

J Roger Preston (S) Pte Ltd

Quantity Surveyor

Asia Infrastructure Solutions

Singapore Pte Ltd

Environmental Sustainability

Design & Green Mark

Consultant

Atelier Ten (Asia) Pte Ltd

Landscape Designer

ICN Design International Pte Ltd

Lighting Designer

Nipek Pte Ltd

Conservation Consultant

MAEK Consulting Pte Ltd

Fire Safety Engineer

IGnesis Engineering Pte Ltd

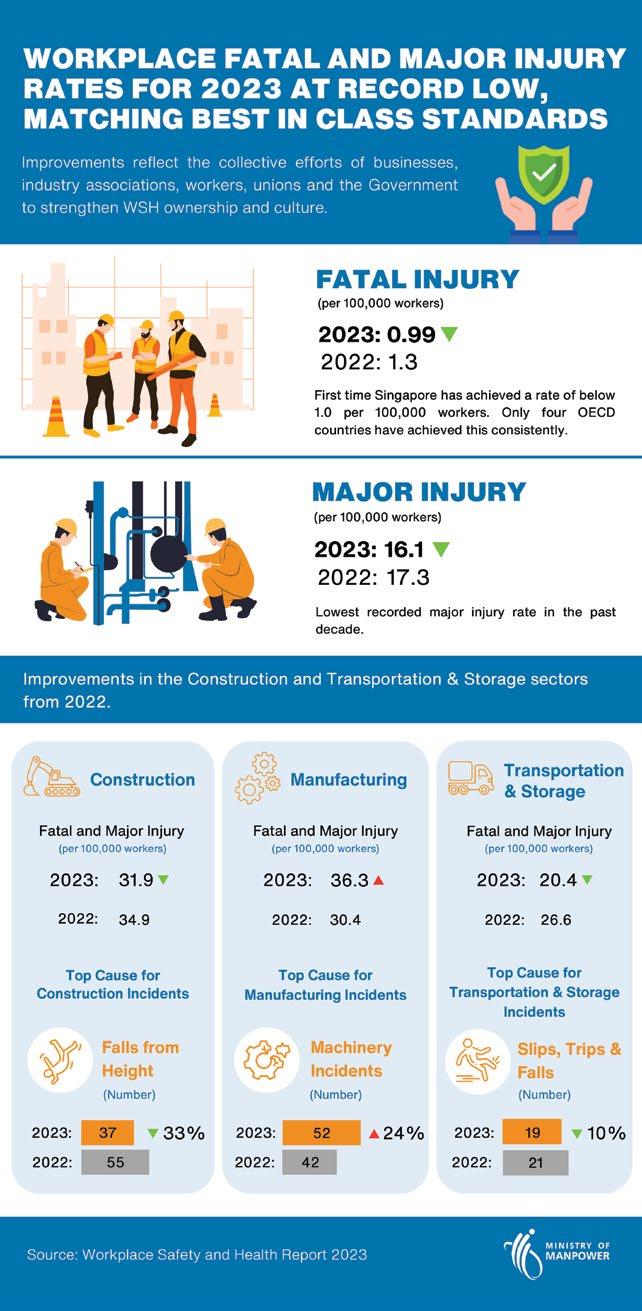

The achievement reflects the collective efforts of the government, various organisations and workers.

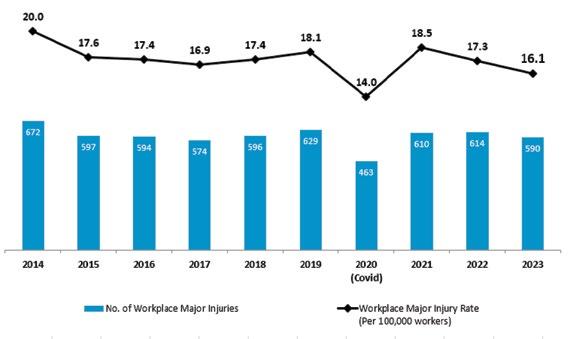

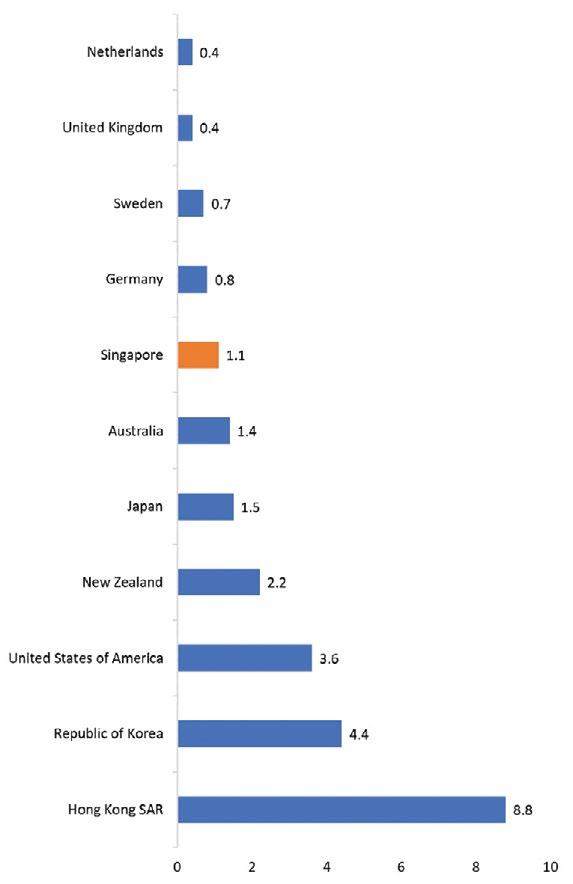

Singapore’s workplace fatal injury rate declined to 0.99 per 100,000 workers in 2023, from 1.3 in 2022. Excluding 2020, when the COVID-19 pandemic disrupted work, this is the first time the workplace fatal injury rate has fallen below 1 per 100,000 workers, which is the country’s Workplace Safety and Health (WSH) 2028 target. The workplace major injury rate also decreased to 16.1 per 100,000 workers in 2023, from 17.3 the previous year, and is the lowest recorded in the past decade.

Singapore’s 2023 WSH performance is a significant improvement from 2022, when a Heightened Safety Period was imposed. It reflects the collective efforts of businesses, industry associations, unions, workers

and rates (per 100,000 workers) in the past decade.

and government agencies, through the Multi-Agency Workplace Safety and Health Taskforce (MAST), to strengthen WSH ownership and culture. Only four OECD countries have achieved a workplace fatal injury rate of below 1 per 100,000 workers, consistently – the United Kingdom, Netherlands, Sweden and Germany.

Improvements in workplace fatal and major injury rates were

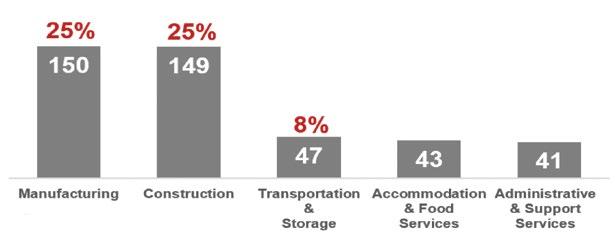

also seen across high-risk sectors. Construction, Manufacturing, and Transportation & Storage remained the top three contributing sectors to fatal and major injuries, although there were improvements in the Construction and Transportation & Storage sectors.

Incidents in Manufacturing rose, due to more Machinery and Struck by Falling Objects incidents. MAST has introduced targeted measures to uplift standards in the Manufacturing sector, such as the Demerit Point System. Legal duties on manufacturers and suppliers of machineries will be expanded to cover more types of machinery, to ensure they are safe when used. This new requirement will be introduced later this year.

The goal now is to sustain the WSH achievements. All stakeholders – employers, industry associations, unions, workers as well as the government – need to press on with the collective efforts to prevent workplace incidents, and ensure that Singapore remains a safe workplace for all. MAST will continue to pursue SAFE measures to drive home the safety culture in every workplace and in every employer and worker.

SUMMARY OF FINDINGS

FATALITIES

Top causes of workplace fatalities

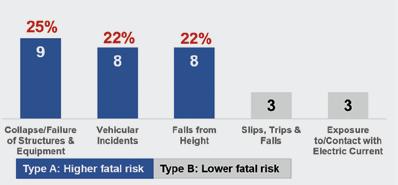

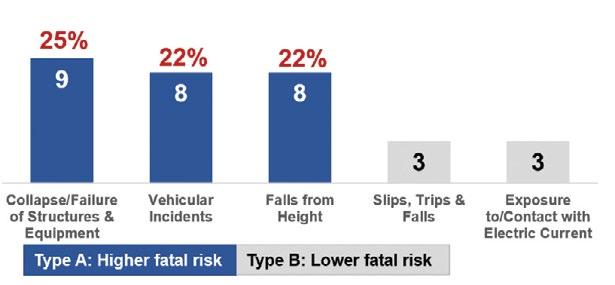

The top causes of fatalities were Collapse/Failure of Structures & Equipment, Vehicular Incidents, and Falls from Height.

There were 36 fatalities in 2023, of which 81% arose from Type A incidents, i.e. those with a higher fatality risk such as Collapse/ Failure of Structures & Equipment, Falls from Height, and Vehicular Incidents.

Reduction in major injury numbers and rates

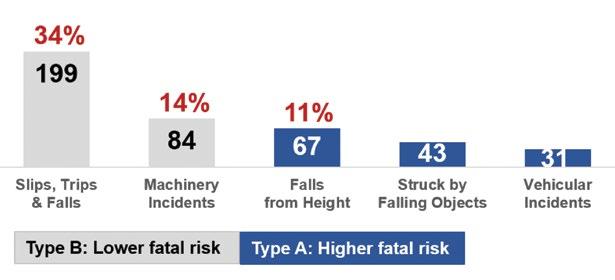

Slips, Trips & Falls continued to be the leading cause of non-fatal injuries.

The major injury rate decreased to a decade low of 16.1 per 100,000 workers in 2023, from 17.3 in 2022.

Reported minor injury rate was also stable at 606 per 100,000 workers, as compared to 596 in 2022.

Major injuries caused by Type A incidents accounted for 35% of all major injuries in 2023. Type A incidents are stronger precursors to workplace fatalities. Common root causes of these injuries included inadequate fall prevention measures, unsafe worker behaviours, inadequate WSH management systems, and failure to adhere to safety measures and procedures.

Major injuries caused by Type B incidents (i.e. those with a lower risk of fatality such as Slips, Trips & Falls, and Machinery Incidents) accounted for 65% of major injuries. Common root causes included the lack of safety measures such as failure to install non-slip flooring/ anti-slip mats on wet areas, poor housekeeping that results in obstructions or tripping hazards, failure to enforce wearing of suitable footwear, lack of or inadequate machine guarding, non-compliance with safety measures such as bypass of safety interlocks, or unsafe behaviour by workers when operating machines.

Slips, Trips & Falls (STFs) remained the top cause of non-fatal injuries, accounting for 34% of all major and 28% of all minor injuries. In 2023, there were 199 STF-related major injuries, comparable to the 200 in 2022. Machinery Incidents were the second most common cause for major injuries, accounting for 14% of all major injuries in 2023. There were 84 machinery-related major injuries in 2023, an increase from 77 in 2022. Machinery Incidents were also the second most common cause for minor injuries. There were 3,030 machinery-related minor injuries in 2023 (14% of total minor injuries), comparable to the 3,029 in 2022.

A mixed performance

There were continued improvements in Construction and Transportation & Storage, but performance in Manufacturing worsened.

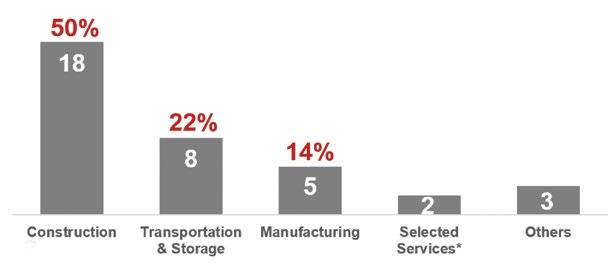

Construction (18), Transportation

& Storage (8) and Manufacturing (5) accounted for about 86% of all workplace fatalities in 2023.

Construction’s workplace fatal and major injury rate per 100,000 workers reduced from 34.9 in 2022 to 31.9 in 2023. Similarly, in the Transportation & Storage sector, the workplace fatal and major injury rate per 100,000 workers reduced from 26.6 in 2022 to 20.4 in 2023.

However, in the Manufacturing sector, the fatal and major injury rate per 100,000 workers increased from 30.4 in 2022 to 36.3 in 2023.

Metalworking and Food & Beverages are the two main contributing industries. Metalworking’s fatal and major injury number increased from 40 in 2022 to 61 in 2023, while that of Food & Beverages reduced from 48 to 38.

Similar to previous years, the fatal and major injuries in Manufacturing were generally Type B incidents led by Machinery Incidents, followed by Slips, Trips & Falls. The common root causes remained – companies’ lack of control measures and workers’ non-compliance to safety measures.

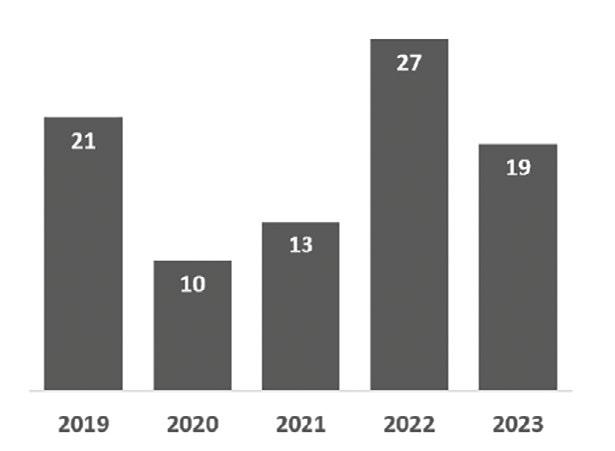

A decrease recorded

Dangerous Occurrences (DOs) decreased, with Collapse/Failure of Structures & Equipment continuing to be the main cause.

DOs refer to prescribed incidents with the potential to cause serious damage, injury or death, such as crane collapse and explosion.

The number of DOs decreased from 27 in 2022 to 19 in 2023. Amongst the DO cases, 13 involved Collapse/Failure of Structures & Equipment and six involved Fires & Explosion.

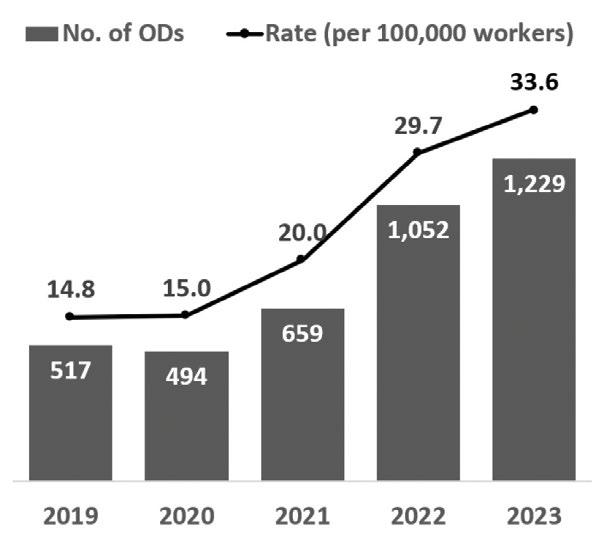

Incidence rate rises

The annualised Occupational Diseases (ODs) incidence rate per 100,000 workers increased from 29.7 in 2022 to 33.6 in 2023. This increase was driven by the rise in reported Noise-Induced Deafness (NID) cases due to the ongoing Enhanced Workplace Health Surveillance (WHS+) efforts, which heightened awareness of reporting amongst doctors and employers, and expanded the surveillance footprint.

In 2021, MOM (Ministry of Manpower) rolled out the Enhanced Workplace Health Surveillance (WHS+), under the national 10-year WSH 2028 strategy, to minimise hazards that lead to occupational diseases, including NID.

Sixty-five percent of the Occupational Diseases were contributed by noise-induced deafness (NID), followed by work-related musculoskeletal disorders (29%) and occupational skin disease (4%). The top two industries contributing to Occupational Diseases were Manufacturing and Construction, and the top sector contributing to noise-induced deafness was Manufacturing.

Under WHS+, companies with workers found to have higher exposures to toxic substances or noise are required to adopt upstream risk controls and put in place programmes (e.g. Management of Hazardous Substances Programmes and Hearing Conservation Programmes) that effectively reduce health risks. Companies also need to undergo third party audits to ensure their workplace health programmes are effective, and submit an audit report to MOM. MOM will

continue to increase the number of workplaces under WHS+, as well as collaborate with the WSH Council to increase awareness and implementation of workplace health programmes.

More than 70% of the global workforce, are likely to be exposed to climate change-related health hazards, and existing occupational safety and health (OSH) protections are struggling to keep up with the resulting risks, according to a new report by the International Labour Organisation (ILO).

The report, titled ‘Ensuring safety and health at work in a changing climate’, says that climate change is already having a serious impact on the safety and health of workers in all regions of the world.

The ILO estimates that more than 2.4 billion workers (out of a global workforce of 3.4 billion) are likely to be exposed to excessive heat at some point during their work, according to the most recent figures available (2020). The proportion has increased from 65.5% to 70.9% of the global workforce, since 2000.

In addition, the report estimates that 18,970 lives and 2.09 million disability-adjusted life years are lost annually due to the 22.87 million occupational injuries which are attributable to excessive heat. This is not to mention the 26.2 million people worldwide living with chronic kidney disease linked to workplace heat stress (2020 figures).

However, the impact of climate change on workers goes well beyond exposure to excessive heat, the report says, creating a ‘cocktail of hazards’ which result in a range of dangerous health conditions.

The report also explores current country responses, including revising or creating new legislation, regulations and guidance, and improving climate mitigation strategies in working environments.

The benefits include effective time and cost control, risk management and project management.

The Building and Construction Authority (BCA) announced the launch of NEC4 contract for construction and engineering projects in Singapore, at the BuildSG Leadership Engagement and Development (LEAD) Summit 2024, held at the Sands Expo & Convention Centre, Marina Bay Sands.

BCA, together with NEC, have developed a set of additional contract clauses (Y clauses) to align NEC4 contract with Singapore’s laws – as with The Building and Construction Industry Security of Payment Act 2004; The Contracts (Rights of Third Parties) Act 2001; The Insolvency, Restructuring and Dissolution Act 2018; The Prevention of Corruption Act 1960; and The Penal Code 1871.

NEC is a division under Thomas Telford Ltd, UK, the commercial arm of the Institution of Civil Engineers (ICE), the owner and developer of the NEC suite of contracts.

The NEC4 contract is the latest edition of a suite of collaborative contracts for construction and facilities management projects. The Y clauses are developed to align NEC4 with Singapore’s laws, when used for the appointment of a contractor for engineering and construction work. More information on NEC4 can be obtained from https://www. neccontract.com/

This launch marks another milestone in promoting collaborative contracting in Singapore’s built environment sector, by facilitating the use of the NEC4 contract in construction and engineering projects in Singapore, which is in line with the Built Environment Industry Transformation Map (BE ITM).

To widen the adoption of collaborative contracting in Singapore, BCA has been driving efforts which

include identifying pilot projects to use the Public Sector Standard Conditions of Contract (PSSCOC) Option Module and, more recently, the NEC4 contract.

The Option Module comprises a set of collaborative clauses to be used together with the PSSCOC which is a common contract form used for all public sector construction projects in Singapore.

Public sector developers such as the Housing & Development Board (HDB), JTC Corporation (JTC), and Land Transport Authority (LTA) will be piloting the use of the NEC4 contract in their upcoming projects. BCA will work with industry partners to facilitate the adoption of the NEC4 contract in their projects as suitable opportunities arise.

Commenting on the significance of the launch, BCA CEO, Mr Kelvin Wong, said, “Collaborative contracting seeks to overcome the issues in conventional construction contracts; it builds trust, strengthens communication, and facilitates a more balanced share of risks among contracting parties. It also nudges parties to consider and implement solutions to address the issues identified, to avoid additional costs and project delays.”

“Having seen the positive impact of NEC4 contract in overseas projects, we encourage our industry partners to adopt the use of NEC4 contract in their projects. It is a step forward in our collective commitment to drive excellence and collaboration in project delivery, in line with our refreshed Built Environment Industry Transformation Map goals,” he added.

The NEC4 contract originated from the United Kingdom and has been adopted in jurisdictions like the United Kingdom and Hong Kong,

with demonstrated success in project delivery.

Mr Sathia Jagateesan, Partner at law firm, Allen & Gledhill LLP, said “Collaborative contracting allows project parties to have better time and cost control, better management of risks and efficient project management. Compared to conventional lump-sum contracts, collaborative contracts, such as NEC4 contract, provide a target cost option which allows project parties to share cost savings or overruns when they occur. This could encourage project parties to resolve issues early and explore more productive solutions together.”

Mr Peter Higgins, Chair of the NEC4 Contract Board welcomed the release of the Y clauses saying, “These Y clauses provide contracting parties in Singapore with the necessary provisions to fully implement NEC4 contract for engineering and construction projects and achieve the benefits of the contract form’s collaborative approach.”

With the launch of the NEC4 contract in Singapore, the built environment sector now has more options to consider when adopting collaborative contracting in their projects for better project delivery. Private and public sector developers can start their collaborative contracting journey early, by adopting the PSSCOC Option Module or the NEC4 contract. Some consultancy firms and contractors have proactively undergone training to deepen their knowledge on the NEC4 contract and other collaborative contracting provisions.

In anticipation of the training demand, several organisations have introduced courses and seminars to raise competencies in collaborative contracting, including BCA Academy;

Singapore Academy of Law; Institutes of Higher Learning (e.g. Singapore University of Social Sciences); and industry associations such as Singapore Contractors Association Ltd (SCAL), Association of Consulting Engineers Singapore (ACES) and Society of Project Managers (SPM).

Moving ahead, BCA Academy will also provide training to facilitate the adoption of the NEC4 contract in the pilot projects.

The Building and Construction Authority (BCA) champions the development and transformation of the built environment sector, in order to improve Singapore’s living environment. BCA oversees areas such as safety, quality, inclusiveness, sustainability and productivity, all of which, together with stakeholders and partners, help to achieve the mission to transform the Built Environment sector and shape a liveable and smart built environment for Singapore.

NEC is a division of Thomas Telford Ltd which is a wholly owned subsidiary of the Institution of Civil Engineers (ICE), the owner and developer of the NEC.

Each standard contract within the NEC family has the following characteristics:

• Stimulates good management of the relationship between the two parties to the contract and, hence, of the work included in the contract.

• Can be used in a wide variety of commercial situations, for a wide variety of types of work and in any location.

• Is a clear and simple document – using language and a structure which are straightforward and easily understood.

The NEC4 contract is designed to facilitate and encourage good management of risks, through mutual trust and cooperation of project parties. The target cost payment option allows project parties to share the cost of risks and savings made, and this can encourage them to re-

solve issues and explore more productive solutions together.

This contract is not new and has been adopted in various jurisdictions. The Hong Kong government carried out its first NEC pilot in 2009 and has been extending its use for various public sector construction projects. Preliminary analysis shows that the NEC4 contract can help improve performance, in terms of cost and time management, including for large and complicated projects, enabling their delivery on time and within budget.

Based on a review, in 2021, by the Hong Kong government, NEC projects are found to achieve 10% savings in time and 2% savings in costs, compared to those procured under the standard General Conditions of Contract (GCC) forms.

Aligned with collaborative contracting, the NEC4 contract offers the following potential benefits to project parties:

• Time and cost control: The contract includes provisions for effective time and cost management, helping developers to better control project schedules and budgets.

• Better risk management: The early warning system stipulated in the contract allows issues to be identified early, so that project parties can avoid or mitigate the risks, by dealing with them early.

• Efficient project management: The contract emphasises efficient project management through effective communication, clear response timelines, and encourages project parties to settle claims quickly. This can lead to streamlined processes and reduced delays for all project parties, resulting in earlier project delivery.

The NEC4 contract is a form of construction contract used internationally. BCA worked with NEC to develop a set of Y clauses to align the contract with Singapore’s laws. The Y clauses comprise amendments for complying with local laws such as the Security of Payment Act (SOPA).

Firms adopting the NEC4 contract

may wish to incorporate the set of Y clauses as part of their contracts. The Y clauses were scheduled to be made publicly available on 1 May 2024, on the NEC website (https://www.neccontract.com/Singapore-Y-Clauses). More information on collaborative contracting may be obtained directly from BCA.

The Contract Network is a USbased legal technology company that has built what is said to be the world’s first AI-powered collaborative contracting platform. The company provides a neutral platform to radically accelerate their negotiations and to collaboratively manage their contract compliance.

Launched in 2023, the platform parses out contracts into their individual clauses, turning agreements into ‘data from the first draft’, and uses generative AI to provide context and market insights for each change and redline. Stakeholders can collaborate on contracts in real-time and with full visibility into every change that is made, with AI-powered translation from legal jargon to plain language.

Contracting processes today are largely managed either exclusively in Office products or using CLM tools that serve the needs of one, but not all parties. The Contract Network is said to be the first platform built for the purpose of bridging these disparate applications and bringing all parties, including their advisors and counsel, together on a single platform to promote speed and efficiency.

The Contract Network works in concert with existing Contract Lifecycle Management (CLM) platforms and also connects to the various software silos that currently exist in a typical contract negotiation.

Connecting the theoretical to practical usefulness.

The teaching of mathematics has traditionally involved imparting theoretical knowledge through direct lectures and constant practice of tutorial questions. However, this method often does not establish meaningful connections for students, between the subject’s specific topics and their applications in the real world. Consequently, students often find themselves questioning the relevance and purpose of learning mathematics.

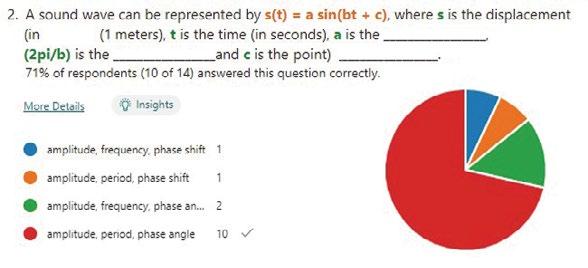

This study aims to bridge the gap between abstract mathematical concepts and their relevance to engineering, using case studies – one of the pedagogies adopted at Singapore Polytechnic. I conducted a pilot study on 50 students from three engineering disciplines. I designed a case study that enables students to apply the concepts they have learned in trigonometric graphs and functions to the field of sound engineering.

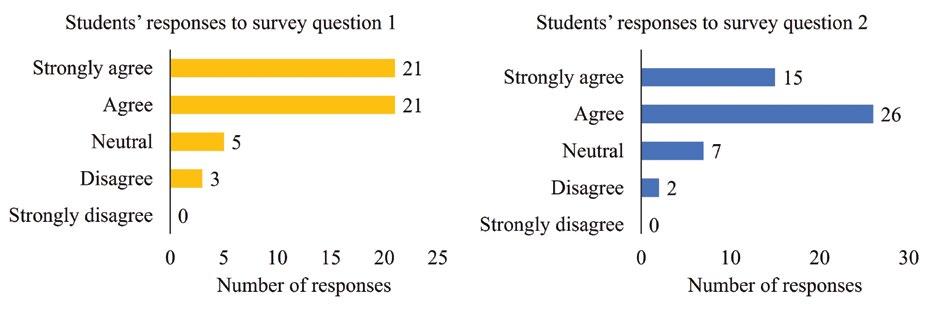

The implementation of this case study did not require extra time during lessons, as it replaced the original learning activity. It was highly encouraging to receive positive feedback from the students, as evident from the survey results. 82% of students responded with “agree” and “strongly agree” that the case study has helped them better understand the topic and how it extends to applications in the real world.

I suggest that case studies be integrated into the Basic Mathematics module, providing students with opportunities to relate the theoretical aspect of mathematics and its applications in engineering.

LITERATURE REVIEW

Mathematics contributes to the core of engineering, providing

the fundamental tools for problem-solving, modelling and innovation. It articulates precision, allowing engineers to transform abstract ideas into tangible solutions. Yet, a perceptible gap persists – students often struggle to see the practical relevance of mathematics in their daily lives and in their future careers within the field of engineering.

Case studies can facilitate learning by highlighting the connections between academic subjects and their real-world applications (Davis, 2009, Harris, 2015). Case studies are commonly delivered in a narrative format, followed by questions and tasks designed to engage students in group discussions.

Consequently, case studies have the potential to foster cognitive learning at higher levels of Bloom’s taxonomy (a framework for categorising educational goals) – transcending the recall of facts to encompass the application, analysis, and evaluation of knowledge (Bonney, 2015).

Engineering students taking the Basic Mathematics (BM) module at Singapore Polytechnic find it challenging when applying mathematical knowledge they have acquired to practical contexts in their specialised fields. The theoretical dimension of mathematics is typically conveyed through traditional methods, involving the repetitive practice of tutorial questions and memorisation of specific problem-solving steps.

Nonetheless, when it comes to applying foundational mathematics to real-world engineering challenges, it is crucial to teach students in the context of their specialisations (Ooi, 2007). This means incorporating references to practical engi-

neering problems that underlie the subject matter.

Accordingly, I introduced the use of case studies in the Basic Mathematics (BM) module for first-year engineering students at Singapore Polytechnic.

This study aims to help students relate the theoretical knowledge they have learnt in BM to applications in engineering. The research question is whether incorporating real-life engineering applications to BM will enhance students’ learning and appreciation of the subject matter.

The use of case studies is one of the approaches adopted by Singapore Polytechnic to engage students in problem-based learning and enhance their analytical skills. This paper discusses the integration of case studies into the BM module, providing students with the opportunity to bridge the gap between the theoretical knowledge they have acquired and its application in engineering contexts.

I chose the topic of trigonometric functions and graphs for the pilot study, as this topic is characterised by conceptual intricacies – students often find it challenging to establish connections to engineering applications. I carried out the study with first-year students from three courses – Diploma in Mechanical Engineering (DME), Diploma in Aeronautical Engineering (DARE) and Common Engineering Programme (CEP).

One class from each of the three diploma courses took part in the study. The total number of students in the study was 50.

The choice of classes enabled me to investigate the potential advantages of this study for students across various disciplines and assess the representativeness of the students’ survey responses within these disciplines, as can be seen from the ‘RESULTS AND DISCUSSIONS’ section.

I structured the class activities into three segments, consisting of (a) pre-class – taking place a week before the class was conducted, (b) in-class and (c) post-class. Table 1 shows a summary of the activities during the three segments.

The case study pertains to signal processing, particularly within the domain of sound engineering. It encompasses the application of trigonometric functions and graphs in noise-cancellation headphones, a topic that is both applicable and relatable to students.

Pre-class segment

During the pre-class segment, I provided students with a Microsoft Teams link directing them to a YouTube video (Khan Academy, 2014). This video presented concepts related to the formation of sound waves. It expounded on the representation of these waves through sinusoidal functions (sine and cosine) and elucidated the influence of amplitude and frequency on the respective attributes of sound, namely loudness and pitch.

In-class segment (quiz)

During the in-class segment, I first conducted a diagnostic assessment, by presenting four quiz questions through Microsoft Forms, to evaluate students’ comprehension of the materials presented in the pre-class videos. Figure 1 illustrates an example of one of these quiz questions. I could view the results of the quiz in real time. If the result for a particular question was poor, I could go through the concepts with the students again, before conducting the learning activity.

In-class segment (case study) I grouped students in pairs to carry out this learning activity. The case

Pre-Class In-Class Post-Class

Task • Pre-class videos via Brightspace

• YouTube video on sound waves

Learning activity in pairs 3 tutorial questions from lecture notes

Quiz - 4 multiple-choice questions via Microsoft Forms -

Survey - - 3 survey questions via Microsoft Forms after learning activity

study connects the amplitude and frequency (features of the trigonometric graph), to the loudness and pitch (quality) of sound, respectively. In adopting a student-centric approach, I allocated five minutes for students to independently engage with this segment. I reminded them to identify the important points in the case study. Subsequently, I addressed any queries they may have had and reiterated the main learning points.

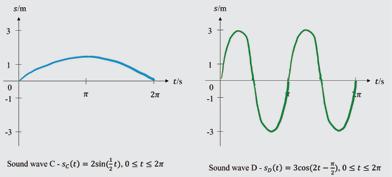

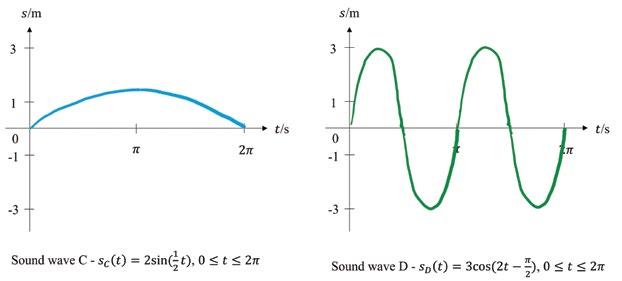

I gave students 20 minutes to carry out the learning activity in their groups, fostering an environment of active learning. There was a total of four questions. I asked students to sketch two sound waves, C and D, in the form of trigonometric graphs (with different amplitude and frequency), and predict how the loudness and pitch will vary, respectively, in the first two questions. The two sound waves are illustrated in Figure 2.

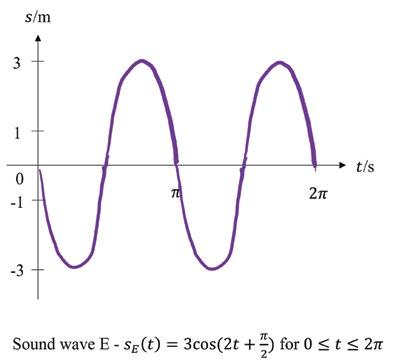

Students checked their answers using EduTech tools, including Desmos Graphing Tool and GeoGebra applet. I then instructed the students to draw another sound wave, E (Figure 3), in the third question. The sound wave is the anti-wave of sound wave D. Lastly, I prompted students on what would happen when sound waves D and E were superimposed together and where such operations can be applied in real-life scenarios.

Two sound waves, C and D, can be represented by the following equations, where s is the displacement of an air molecule (in metres) and t is the time in seconds:

Sound wave C

s� (t) = 2sin (1/2t), 0≤ t ≤2π

Sound wave D

s� (t) = 3cos (2t - π/2), 0≤ t ≤2π

Question 1: Draw the graphs of sound waves C and D.

Question 2: Can you comment on how the loudness and pitch of sound D differ from that of C?

Question 3: Go to https://www. desmos.com/calculator, enter the equations for sound waves C and D and check your answer for Question 1. Go to https://www.geogebra. org/m/Vet82Qy3 and adjust the shapes of sound waves C and D to what you have as your answer in Part 1. Note that the equations are different in GeoGebra, but make

sure the shapes are similar. Check if your answers for Question 2 are correct.

Question 4: Sketch the graph of sound wave E, sE (t) = 3cos (2t + π/2) for 0 ≤ t ≤ 2π.

Question 5: What do you think will happen to the sound if we add sound wave E and sound wave D together?

Post-class segment

I concluded the class by directing students to participate in a survey related to the learning activity. Table 3 in the ‘RESULTS AND DISCUSSIONS’ section gives the list of survey questions. I also asked students to write down their feedback on the learning activity. I allocated three tutorial questions on trigonometric functions and graphs for students to practise under the postclass segment – these questions reinforce their learning on the topic.

RESULTS AND DISCUSSIONS

Learning activity

Most groups of students were able to complete the learning activity with little guidance. The last question, on whether the superimposition of sound waves D and E will lead to sound cancellation, aims to stretch students’ thinking. Students had to come up with examples of how sound cancellation can be applied in engineering.

Some of their answers include noise cancellation headphones and signal processing. This illustrates

that students understood how trigonometric graphs are related to the quality of sound and can apply the concepts to answer questions associated with higher levels of Bloom’s taxonomy.

I carried out a survey after the class to assess the efficacy of the learning activity in benefitting students’ learning. Students answered the survey questions, based on a Likert scale of 1 to 5, illustrated in Table 2. The survey questions are shown in Table 3 and the responses are illustrated in Figure 4 and Table 4.

It is extremely encouraging to see positive feedback, as indicated by the students’ post-class survey results – a notable 82% of them expressed agreement and strong agreement to questions related to the learning activity and would like to participate in more of such learning activities. I am heartened to know that the pilot study has helped students better appreciate the application of trigonometric functions and graphs in engineering.

I examined the use of case studies in the BM module taken by first year engineering students at Singapore Polytechnic. I designed a case study that allowed students to apply concepts that they have learnt, on the topic of trigonometric functions and graphs, to audio (sound) signal processing. Students have gained a nuanced understanding of the underlying rationale behind studying trigonometric functions and graphs, emphasising their relevance to engineering.

I received positive feedback from students’ post-class survey results – 82% of them responded with “agree” and “strongly agree” that the case study has helped them better understand the topic and how it extends to applications in the real world. This pilot study exemplifies how case studies can be used as an approach to let students appreciate the relevance of mathematics in real-life applications and in their future studies or careers.

Likert scale

1 I can state some examples on how trigonometric functions and graphs are applied in engineering.

2 How useful is it to you that learning activities, like the one we did today, helps you to better understand a topic and how it is applied to a real-life application?

3 Do you have any feedback regarding the learning activity?

Table 3: Survey questions posted to students after the class.

“I hope tutorials to be like this more often.”

“I now understand how trigonometric functions can be used in real-life application.”

Table 4: Students’ responses to Survey Questions 3.

REFERENCES

Davis B G (2009): ‘Tools for teaching’, John Wiley & Sons.

Harris D, Black L, Hernandez-Martinez P, Pepin B, Williams J and The Transmaths Team (2015): ‘Mathematics and its value for engineering students: what are the implications for teaching?’, International Journal of Mathematical Education in Science and Technology, 46(3), 321–336.

Bonney K M (2015): ‘Case study teaching method improves student performance and perceptions of learning gains’, Journal of Microbiology & Biology Education, 16(1), 21–28.

Ooi A (2007): ‘An analysis of the teaching of mathematics in undergraduate engineering courses’, Proceedings of the 2007 AaeE Conference, Melbourne, Australia.

Khan Academy (2014, January 2): ‘Sound Properties (Amplitude, Period, Frequency, Wavelength)’, https://Www. Youtube.Com/Watch?V=-_xZZt99MzY. Desmos (no date): ‘Graphing Calculator’, https://Www.Desmos.Com/Calculator. GeoGebra (no date): ‘Sound waves modelled as sine functions’, https:// www.geogebra.org/m/Vet82Qy3.

[This article is based on a paper presented at the World Engineers Summit (WES) 2023, held in Singapore, from 8 to 10 November 2023. WES 2023 was organised by the Institution of Engineers, Singapore (IES).]

Conditions can be created to support a smooth transition to electric construction sites and emission-free contracting.

A multi-partner study, ‘Electric Worksite’, which mapped the infrastructure needs for electric machines through testing at real-life worksites in Gothenburg, Sweden, has confirmed that electric machines equal diesel machines in performance and offer added advantages.

The added advantages include zero exhaust emissions and a better working environment.

Societies today are transforming towards more sustainable city planning. Fossil-fuel-free construction plays a major part in accelerating that shift and making progress towards national and global climate, environment, and air quality goals. The electrification of the construction sector will greatly contribute to a reduction in greenhouse gas

emissions, noise pollution and other harmful emissions, ensuring it plays a central role in sustainable community building.

In parallel with rising demand for emission-free construction contracting and a growing market for electric machines, the need for collaboration between all players across the value chain is also increasing to ensure the infrastructure is up to par for the change. This puts new demands on the energy supply and electrical system, among other areas.

The goal of the Electric Worksite project was for several players across the supply chain to come together, to gain an important understanding of the opportunities

and needs, when putting to work electric equipment in urban applications. The project, which recently presented its final results, has had a clear focus on the system perspective, testing electric machines, energy storage and charging infrastructure, in different urban sites, to clarify the varied needs across interconnected technical and organisational systems.

The tests were carried out in real-life construction sites with electric-powered wheeled and crawler excavators, wheel loaders and load carriers, weighing between 3.5 t to 30 t. Some of the machines were battery-powered and others cable-connected. The study concluded that all tests have been successful, with the following main lessons:

• Electric construction machines can perform the same work to the same standard as fossil-fuel-driven Variants, in urban construction projects.

• Workers in and around electric machines experience several positive effects in the handling of machines and the working environment.

• Like most construction projects, in general, the success of electrification is based on foresight, planning and flexibility.

• New requirements for power supply are solved, based on machine type and available electricity – such as electrical cabinets, mobile charging stations, cable-connected machines and potentially also energy storage units.

• End-customers need to be made aware of new opportunities and challenges with electric machines, as well as of existing business conditions and contracting requirements for contractors and subcontractors.

Volvo CE is one of the collaborators, that has played a key role in the research project, by project-managing the tests and providing electric machines in various sizes and models, as well as technical solutions for charging, mobile energy storage and cable management.

“Electric machines are already available on the market and performing well, but the challenge can often be how to establish a reliable supporting infrastructure. This project confirmed that when all actors in the value chain around a construction site collaborate, both from the public and the private sector, we solve the infrastructure around it. In all tests, regardless of application and location, the electric machines performed as well as, if not better than, equivalent models with combustion engines, but without harmful emissions and disturbing noise”, said Bobbie Frank, Research Leader at Volvo CE.

Municipalities and government bodies play an important role in enabling and driving the transition, for example, by setting requirements for emission-free vehicles and ma-

chinery in the procurement of construction work, and by establishing clear city development goals for all societal players to work towards.

The City of Gothenburg was keen to be involved in this project, seeing that there are many benefits in accelerating electrification within construction.

“As the City of Gothenburg is a major procurer of construction and civil engineering contracts, we want to be involved in leading the transition towards an emission-free industry. We also see many other benefits for both the surrounding environment and the working environment, such as reduced noise and improved air quality”, said Peter Lindgren, Business Developer for Electrified Transports at the Environmental Management Department, City of Gothenburg.

For the construction contractor NCC, the Electric Worksite has meant evaluating opportunities and challenges with electrification, together with other actors in the value chain.

“Once again, we can conclude that the most important take-away is that we need to get involved early in the project to plan for electrification – because the opportunities to influence emissions are greatest in the planning stage. To scale up the use of electric construction ma-

chines and vehicles, increased competence is also needed throughout the value chain. We also need electric machines to be demanded in the contracting, by customers, and that they set requirements that drive the development forward,” says Pernilla Löfås, Sustainability Manager, NCC Infrastructure.

Partners

Volvo Construction Equipment

NCC Sweden

Gothenburg City

Chalmers University of Technology

Lindholmen Science Park

Gothenburg Energy