THE MAGAZINE OF THE INSTITUTION OF ENGINEERS, SINGAPORE www.ies.org.sg PLUS SINGAPORE THE ENGINEER July 2023 | MCI (P) 033/03/2023 CapitaLand unveils Geneo life sciences and innovation cluster STANDARDS DEVELOPMENT: Learning more about the land transporta on sector in Japan RAILWAY & TRANSPORTATION ENGINEERING: Is the transporta on industry ready for digital twins? STRUCTURAL ENGINEERING: Award-winning demonstra on of new materials and new applica ons

CHARTERED ENGINEER (SINGAPORE) *** Get your skills and competency Certified! *** *** Apply Now! Visit us at www.charteredengineers.sg *** (Terms and Conditions Apply: Washington Accord Degree, 4 years working experience and be an IES member) AEROSPACE ENERGY ENVIRONMENTAL & WATER CHEMICAL & PROCESS SYSTEMS DIGITAL (New!) PORT & MARINE RAILWAY & TRANSPORTATION INFRASTRUCTURE ENGINEERING PROJECT MANAGEMENT

Planitop Smooth & Repair R4 Zero is a structural R4-class, rapid-setting, shrinkage compensated, thixotropic, fibre-reinforced, cementitious mortar, applied in a single layer from 3 to 40 mm thick, for repairing and smoothing concrete.

ADVANTAGES:

- 2 products in 1

- Rapid-set

- Easy to apply

- EC1 Plus marking

- May be applied in thin layers

- Smooth-textured finish

- Structural repairs

- Excellent fatigue strength

- Very low emission of VOC

Residual greenhouse gas emissions offset through the acquisition of certified environmental credits.

Mapei Far East Pte Ltd

28 Tuas West Road, Singapore 638383

Tel: +65 6862 3488 |

Fax: +65 6862 1012/13

Website:www.mapei.com.sg | Email:mapei@mapei.com.sg

SCANINFOfor Ofor

Building a SUSTAINABLE future together

CONTENTS

FEATURES

COVER STORY

14 CapitaLand unveils Geneo life sciences and innova on cluster

Sustainability is a key considera on in the design and construc on.

SUSTAINABILITY

20 New addi ves could turn concrete into an effec ve carbon sink

MIT engineers discover new carbona on pathways for crea ng more environmentally friendly concrete.

STANDARDS DEVELOPMENT

21 Learning more about the land transporta on sector in Japan

The Transporta on Standards Commi ee undertakes a six-day study trip to Japan.

RAILWAY & TRANSPORTATION ENGINEERING

22 Is the transporta on industry ready for digital twins? The benefits of this disrup ve technology are already being proven.

President Mr Dalson Chung

Chief Editor

T Bhaskaran

t_b_n8@yahoo.com

Publica ons Manager Desmond Teo desmond@iesnet.org.sg

Publica ons Execu ve Nuraini Ahmad nuraini@iesnet.org.sg

Editorial Panel

Dr Chandra Segaran

Dr Ang Keng Been

Mr Jaime Vega Bau sta Jr

Dr Victor Sim

Mr Soon Ren Jun Dr Alexander Wiegand Media Representa ve Mul media Communica ons (2000) Pte Ltd sales@mul mediacomms.sg

Design & layout by 2EZ Asia Pte Ltd

Cover designed by Irin Kuah

Cover images by CapitaLand Published by

6467

02 THE SINGAPORE ENGINEER July 2023 14 21 22

Singapore

The Ins tu on of Engineers, Singapore 70 Bukit Tinggi Road, Singapore 289758 Tel: 6469 5000 I Fax:

1108 Printed in

www.ies.org.sg

STRUCTURAL ENGINEERING

26 Award-winning demonstra on of new materials and new applica ons

The innova ve design of a network arch bridge in Germany is described.

WASTE RECYCLING

28 Waste genera on and recycling rates increase Singapore’s overall recycling rate improved in 2022, compared to the previous year.

PROJECT APPLICATION

30 Refurbishing the Centro Piacen niano one century on Paving solu ons in this project in Bergamo, Italy, considered the stresses and loads they would be subjected to.

34 Climbing systems for the tallest residen al tower in Canada

They help to increase the speed of construc on and improve safety.

The Singapore Engineer is published monthly by The Ins tu on of Engineers, Singapore (IES). The publica on is distributed free-of-charge to IES members and affiliates. Views expressed in this publica on do not necessarily reflect those of the Editor or IES. All rights reserved. No part of this magazine shall be reproduced, mechanically or electronically, without the prior consent of IES. Whilst every care is taken to ensure accuracy of the content at press me, IES will not be liable for any discrepancies. Unsolicited contribu ons are welcome but their inclusion in the magazine is at the discre on of the Editor.

03 THE SINGAPORE ENGINEER July 2023 26 30 34

04 NEWS & EVENTS 12 IES UPDATE 36 PRODUCTS & SOLUTIONS REGULAR SECTIONS

Contract awarded for purchase of 44 New Trains for the Cross Island Line

The Land Transport Authority (LTA) has awarded a contract for the supply of 44 six-car trains for the Cross Island Line (CRL) to the consor um of CRRC Qingdao Sifang Co Ltd and Singapore CRRC Sifang Railway Vehicles Service Pte Ltd (CRRC Sifang).

The contract, valued at SGD 589 million, includes the op on to procure up to 11 addi onal trains as well as the op on for provision of Long-Term Service Support (LTSS). The new fleet of fully automated CRL trains will be wholly designed and manufactured by CRRC Sifang in Qingdao, China.

The CRL is Singapore’s eighth MRT line. It will serve exis ng and future developments in the eastern, north-eastern and western corridors, linking major hubs such as Jurong Lake District, Punggol Digital District and the Changi region.

The CRL will have almost half of its sta ons as interchanges with other rail lines, making it easier and more convenient for commuters to travel across the rail network.

The trains are expected to be delivered progressively from 2027, in me for commencement of CRL Phase 1 opera ons in 2030.

Similar to the trains for the Thomson-East Coast Line, each car on the new trains will have five doors on each side. To improve accessibility within the train, the gangways between CRL train cars will be wider, at 1.6 m, compared to the 1.4 m on the other train lines.

The new trains will be powered by a 1500 V DC Overhead Conductor Rail (OCR) system which will increase energy efficiency compared to a typical 750V DC third rail system. To enhance opera ons and maintenance, the CRL trains will include condi on monitoring and diagnos c systems for early detec on of poten al equipment faults. Some trains will also be equipped with an Automated Track

Inspec on system to monitor the condi on of the running rail and OCR in real me.

CRRC Sifang has previously supplied trains for Singapore’s North-South and East-West Lines (NSEWL) and Thomson-East Coast Line, through a consor um formed with Kawasaki Railcar Manufacturing. CRRC Sifang also has an established track record interna onally, having supplied trains to Beijing, Shenzhen, Hong Kong, Chicago and Sao Paulo. Meanwhile, the first 16 of the 106 new trains for the NSEWL were scheduled to enter passenger service progressively from 4 June 2023.

These new trains, purchased from Alstom SA (formerly known as Bombardier Transporta on) will replace the NSEWL’s earliest genera ons of six-car trains, with the oldest having served for over 30 years. As the tes ng is completed, approximately two trains will be put into passenger service every month and trains from the original fleets will be decommissioned accordingly.

Sixty-six new trains were purchased in 2018, with another 40 purchased in 2020.

Commuters from all walks of life can look forward to more pleasant

and convenient journeys, as the new train cabins have more open spaces to accommodate strollers and wheelchair users. Large, panoramic windows will provide commuters with an improved viewing experience while travelling above ground. The new trains are also designed with ergonomic perch seats which can accommodate more commuters on the trains. Other features include an LCD display system above every door to show the route and sta on informa on.

To enhance train reliability and enable efficient maintenance, the new trains are equipped with a self-test system which automa cally checks that the trains are fit for opera on before services commence each day. These trains will subsequently be equipped with condi on-monitoring features to pre-emp vely iden fy emerging faults and enable early rec fica on.

LTA has also purchased six new trains to serve the North East Line (NEL) and 23 new trains to serve the Circle Line (CCL), from Alstom. The new NEL and CCL trains are intended to cater for addi onal capacity when the North East Line Extension (NELe) and the Circle Line 6 (CCL6) begin opera ons.

04 NEWS & EVENTS THE SINGAPORE ENGINEER July 2023

Ar st’s impression of a CRL Train.

Turner & Townsend unveils latest edi on of its Interna onal Construc on Market Survey

Global professional services consultancy, Turner & Townsend, has launched the 14th edi on of its Interna onal Construc on Market Survey (ICMS), which reports posi ve levels of construc on ac vity across the majority of Asian markets.

The report analyses input costs, such as labour and materials, and charts the average construc on cost per square metre (m ) for commercial, residen al and industrial projects, in 89 markets around the world.

Established markets see strong pipelines

Established markets for real estate development, such as Singapore, Hong Kong, Japan and South Korea, are seeing demand and strong pipelines across mul ple sectors. These markets, however, con nue to face ongoing challenges posed by skills shortages and rising labour costs.

The state of Singapore’s construc on industry

Singapore experienced the highest rate of cost escala on in Asia in 2022, at 12%. It is expected to remain high at 8% in 2023, as the market con nues to be faced with skills capacity challenges and high labour and material costs.

However, the city-state is seeing a strong pipeline of construc on projects driven by public housing, infrastructure (such as the Cross Island and Jurong Region MRT lines) and commercial developments, along with an emerging biomedical sector.

Construc

on costs in Tokyo and

Osaka are some of the highest in the world, ranking fi h and sixth, respec vely, in the top 10 most expensive places to build in. Average costs are USD 4,497 per m in Osaka and USD 4,567 per m in Tokyo. Singapore is ranked fourth in Asia and 31st, globally, with an average cost of USD 3,307 per m

All three ci es are seeing high levels of construc on cost infla on, with rates in Tokyo and Osaka at 9% in 2022, so ening to a forecast of 7.5% in 2023. Fuelling a strong backlog of construc on projects in an already hot Japanese construcon market is the upcoming 2025 World Expo in Osaka. As a result, construc on cost infla on in Japan is likely to remain high.

Hong Kong remains one of the most expensive markets to build in, globally, despite dropping from the 7th to 11th posi on this year, with an average cost of USD 4,292 per m . The city has been overtaken in the top 10 spots which are dominated by US ci es, reflec ng the strength of the US dollar, and the double-digit construc on cost infla on in many of the US ci es.

Emerging markets in Asia

Emerging markets including India, Indonesia, Malaysia, Vietnam and the Philippines are warming up, driven by strong pipelines of major mul -year transport projects, data centre and manufacturing growth, and increasing ac vity by commercial developers.

Driving growth across Asia

Across the region, growth sectors for real estate construc on include data centres and health and life sciences, in line with the local boom in development and delivery of medical technologies. Singapore, Hong Kong, and Shanghai, in par cular, have announced plans to localise the development, produc on and delivery of vaccines and medical technologies, through increased numbers of manufacturing facili es and research laboratories.

Push towards sustainability

The region is also feeling an increased pressure from the global push towards net zero. Global corporate occupiers have shi ed sustainability up their priority lists

and are applying more stringent requirements to their interna onal por olios, helping to establish supply chain exper se in environmental best prac ce and drive innovaon in the built environment.

Cheryl Lum, Director and Head of Data and Research at Turner & Townsend Asia, said, “The Asian construc on industry has stayed resilient throughout the pandemic. There are strong pipelines across all Asian countries with construcon growth and major investment directed to emerging markets in par cular. More established markets such as Hong Kong, Japan, Singapore and South Korea con nue to see high construc on demand despite Asia being home to some of the most expensive ci es in the world to build in.”

“Asia’s diverse and ambi ous market economies place it in a strong posi on to command sustained construc on growth and a ract investment, par cularly in industrial, science & technology, healthcare, transport and real estate developments,” she added.

“In an economic climate of rising construc on costs and infla onary pressures, it is impera ve for the construc on industry to work collabora vely to raise efficiency and increase produc vity through digitalisa on, innova ve technologies and upskilling of the value chain. Common to all markets is the need for strong supply chain engagement from clients to understand capacity and capability, benchmark costs and closely manage project performance,” Ms Lum con nued.

Turner & Townsend

Turner & Townsend is a global professional services company with over 10,000 people in 50 countries. The company is majority-owned by CBRE Group Inc, the world’s largest commercial real estate services and investment firm.

06 NEWS & EVENTS THE SINGAPORE ENGINEER July 2023

Grundfos acquires Metasphere to pioneer solu ons for water and climate challenges

Grundfos, a global leader in advanced pump solu ons and water technologies, has completed the acquisi on of XPV Water Partners por olio company Metasphere, a leading provider of telemetry and analy cs solu ons for water networks.

By adding the capabili es of Metasphere to its por olio, Grundfos is set to provide its global municipal customers even stronger offerings. The partnership will help make water networks worldwide more robust in the face of climate change, thereby solving a pressing global challenge.

Water system failures cost ci es a total of USD 194 billion annually – a number which will rise with climate change and resul ng extreme weather events. Sewer networks are heavily impacted, but with Internet-of-Things-enabled hardware and weather data, coupled with strong analy cs, the challenges can be significantly reduced.

The UK is at the global forefront of comba ng sewer overflow. Despite this and improvements in recent years, raw sewage flowed into rivers and seas in England for more than 1.75 million hours in 2022. This includes sewer overflows caused by blockages and intrusion, causing damage to property and the environment.

Water companies across the world ba le sewer overflows. Against this backdrop, the acquisi on of Metasphere is an important milestone in Grundfos’ strategy to add to the company’s core competencies within pumps and hydraulics to address challenges requiring a holis c network perspec ve.

Key among Metasphere’s offerings is its ART Sewer integrated solu on which provides hardware and analy cs so ware for the predic on and preven on of sewer network overflows. With its proven easy-to-install deployment

and immense insights, ART Sewer already supports leading water u li es to combat the effects of environmental change.

H P Nanda, CEO of Water U lity at Grundfos, said, “It is clear that smart sewer technology will play a cri cal role in improving the ability of sewer systems worldwide to handle extreme weather events and overflows. We are excited about introducing Metasphere and their innova ve solu ons to our global audience of partners, as part of our strategic journey towards a sustainable future where our water is safe.”

Tim O’Brien, CEO of Metasphere, said, “Joining forces with one of the biggest names in the water u lity industry is an important milestone on the journey towards our vision of zero spillage. With Grundfos, we will also be able to explore innova ve ways to u lise different assets in a sewer network to avoid overflow across its global network.”

Khalil Maalouf, Investment Partner at XPV Water Partners, said, “We are proud to have worked alongside the Metasphere team to scale a robust, leading company that is contribu ng to a water secure future. We look forward to watching

Metasphere’s global expansion as part of the Grundfos family.”

Grundfos

As a leading global pump and water solu ons company, Grundfos provides energy- and water-efficient solu ons and systems for a wide range of applica ons for water u lies, industries and buildings.

Metasphere

Metasphere helps customers predict and prevent leaks and spills for a cleaner, greener world. A wastewater management specialist business, Metasphere provides smart network management solu ons to the global u lity industry, liaising with all sectors of the industry, from major u lity companies to environmental and regulatory bodies.

XPV

Water Partners

XPV Water Partners is a team of experienced operators and investors who are commi ed to making a difference in the water sector. The firm manages investment capital from some of the world’s top ins tu onal investors, and partners with emerging water-related companies to help them rapidly expand and achieve their strategic goals.

07 NEWS & EVENTS THE SINGAPORE ENGINEER July 2023

Grundfos has announced the acquisi on of Metasphere.

Accident reports rise but fatality rate falls

Despite reports increasing over the past year, the fatality rates of the leading types of accidents have declined – an encouraging sign that collec ve ac on across the powered access industry to tackle key underlying causes of accidents is star ng to take effect, according to the latest report from the Internaonal Powered Access Federa on (IPAF), based on analysis of incidents logged through its Accident Reporting Portal.

Launched via a webinar, held recently, the IPAF Global Safety Report 2023 analyses the latest data collected via the IPAF portal, covering the period 2013-23, focusing par cularly on year-on-year trends, to iden fy how well the industry is doing in tackling the key causes of accidents involving powered access.

While the use of mobile elevating work pla orms (MEWPs), mast-climbing work pla orms (MCWPs) and construc on hoists are sta s cally among the safest ways to work at height, this year’s report shows that, in 2022, there were 759 reports of safety incidents from 34 countries, up 15% and 21%, respec vely. There were 831 people involved, and 102 deaths reported, a decline of around 19% on 2021, when there were 126 fatali es.

In terms of incidents resul ng in deaths or major injury, falls from the pla orm remained the most common underlying cause, with overturns second. Hit by machine, vehicle or object was third, entrapment fourth, electrocu on or electric shock fi h and unsafe situa on sixth. Mechanical failure was joint seventh with falls from height (no machine involved) – a notable reduc on following a spike in reported incidents across 2021.

In 2022, the main sectors from which reports were received, were rental ac vity, construc on, and facili es management. There were 45 fatali es and 39 major injuries in construc on – a decrease from the number of fatali es reported in 2021, when there were 55 deaths. In facili es management there were

15 fatali es, down on 2021, and rental ac vity saw three fatali es in 2022, the same as in 2021, and 19 major injuries.

The top MEWP categories involved were 3a-type machines with 217 incidents (26%), followed by 3b types on 197 (24%), and 1b vehicles on 152 (18%). Compared to 2021, 3a MEWPs saw 60 more reports, replacing 3b machines for the most reports.

Brian Parker, IPAF’s Head of Safety & Technical, said, “When we look at the data from 2022 and the key trends and annual changes, there are some encouraging signs. For one, repor ng has increased, both in terms of the number of reports received in total and countries repor ng – up from 692 reports from 28 countries in 2021 to 831 (and coun ng) from 34 countries worldwide in 2022.”

“There are now more countries where IPAF members are mandated to report all incidents into the portal, and the three countries, where it is a requirement of membership, have seen increased repor ng over the past three years. Repor ng companies can also benefit from new dashboards to benchmark safety performance,” he added.

“The other key sta s c is that, while reports have increased, the number of deaths has fallen. In 2021 there were 126 deaths reported, the same as in 2020. However, in 2022, that number was 102 – this means the effec ve fatality rate among reported incidents has reduced by around one fi h (19%). This is cause for cau ous op mism,” Mr Parker con nued.

“It is not yet possible to directly measure the impact of industry safety campaigns and the introduc on of new safety and technical guidance or updates to training. But it is nonetheless encouraging to think campaigns, such as IPAF’s Don’t Fall for It! or High Voltage!, along with key technical guidance documents, may have helped to save lives or reduce the risk of accidents leading to life-changing injury, since being published,” he added.

Peter Douglas, CEO & Managing Director of IPAF, said, “IPAF connues to empower all operators and supervisors to report incidents quickly, easily and, if so wished, anonymously via its ePAL app. We hope this unlocks widespread repor ng of accidents, as well as minor and near-miss incidents that o en go under-reported.”

10 NEWS & EVENTS THE SINGAPORE ENGINEER July 2023

The IPAF Global Safety Report 2023 was released recently.

New Construc on Quality banding to help homebuyers

The Building and Construc on Authority (BCA) has developed a new banding system for the Construcon Quality Assessment System (CONQUAS), to help homebuyers be er discern the performance of developers and builders, based on their track record of private residen al projects for the past six years.

According to Mr Neo Choon Keong, Deputy CEO of Industry Development at BCA, “The new CONQUAS banding system builds on the exis ng CONQUAS framework to offer a more accurate assessment of developers’ and builders’ quality performance, based on their track records. We encourage homebuyers to leverage the Quality Housing Portal and CONQUAS banding system to conduct thorough research before making property purchase decisions.”

The new CONQUAS banding system rates developers, builders and private residen al projects on a scale of Band 1 (very low incidence of major defects) to Band 6 (higher incidence of major defects). Bands 1 and 2 are reserved for firms that have consistently delivered projects with li le to no major defects, highligh ng their strong performance.

Based on past data, projects in Band 1 were found to have an average of 0.6 dwelling units with major defects per 1000 dwelling units. Major defects are defects that significantly affect func onality and liveability, e.g. sha ered glass, water leakage etc.

The CONQUAS banding for developers, builders and private residen al projects are published in BCA’s Quality Housing Portal (QHP). Developers and builders both play an important role in contribu ng to the overall quality of a project. To be er discern the quality of upcoming projects, homeowners can check the CONQUAS banding of the project’s developer and builder. Homebuyers will also soon be able to spot the CONQUAS banding logo with a link to the QHP, which developers have been encouraged to display in show-flats and marke ng collaterals.

The QHP currently contains the CONQUAS banding of 110 developers and 76 builders, covering 350 private residen al projects completed in past six years as well as projects undergoing assessments.

Currently, 20 developers and 15 builders have been accorded Band 1,

including City Developments Limited and Woh Hup (Private) Limited, both of which have achieved the BCA Quality Excellence Award for 10 consecu ve years, since the incep on of the award in 2013. They have consistently developed Band 1 private housing projects together.

Mr Chia Ngiang Hong, Group General Manager of City Developments Limited (CDL) shared, “This recogni on affirms our commitment to crea ng well-built, sustainable proper es with though ul design. CDL priori ses quality outcomes from the outset, informing builders and consultants about each project’s quality objec ves, performance goals and targets, before construc on begins.”

Mr Selvamani Murugappan, Director of QA/QC of Woh Hup, said, “We believe the new CONQUAS banding system aligns with the necessary changes we need to see in the Built Environment sector. The CONQUAS banding system will allow homebuyers to easily differen ate top quality builders and homes from the rest. It will also provide the pla orm for us to showcase our quality standards as we strive towards upholding our status as a ‘Band 1’ builder.”

Recent research conducted by scien sts at SINTEF Energy Research, Norway and Del University of Technology (TU Del ), The Netherlands, demonstrates that implemen ng carbon capture and storage (CCS) in industrial facili es can result in significant CO reduc ons at minimal cost. These findings have been published as a paper ‘Is CCS really so expensive? An analysis of cascading costs and

CO emission reduc on of industrial CCS implementa on on the construc on of a bridge’, in the journal, Environmental Science and Technology.

The paper, authored by Sai Gokul Subrave (SINTEF), Elda Rodríguez Angel (TU Del ), Andrea Ramírez (TU Del ) and Simon Roussanaly (SINTEF), examines how CCS implementaon in steel and cement producon would have impacted the

cost of the Lake Pontchartrain Causeway bridge in Louisiana, USA.

This work was performed in collabora on with the Norwegian CCS Research Centre (NCCS).

The bridge is currently the longest beam bridge over con nuous water in the world. It is made from approximately 225,000 m of concrete and 24,209 tonnes of steel.

11 NEWS & EVENTS THE SINGAPORE ENGINEER July 2023

CCS can result in significant CO reduc ons at a marginal cost

SEMINAR ON BUILDING FAÇADE INSPECTION 2023 FOCUSES ON SOLUTIONS AND CHALLENGES

Organised by ‘The Singapore Engineer’ and IES, in support of BuildSG, and with the sponsorship of Mitsubishi Electric, the ‘SEMINAR ON BUILDING FAÇADE INSPECTION 2023’ was held on 27 June 2023, at Holiday Inn Singapore Atrium.

The event a racted more than 100 delegates, from within the building façade sector of the built environment industry.

A line-up of nine experts shared their knowledge, over two sessions. A panel discussion and Q&A rounded off each of the two sessions.

HIGHLIGHTS OF PRESENTATIONS

‘Ensuring Façade Safety via Implementa on of Periodic Façade Inspec on’ by Er. Chin Leong Siong, Principal Engineer, Façade Engineering and Technology Department, Building and Construc on Authority (BCA)

Common pi alls in the prepara on of Periodic Façade Inspec on (PFI) reports include missing or incomplete reports, missing or incomplete façade informa on, inability of the visual inspec on to meet PFI guidelines, inability of the closerange inspec on to meet PFI guidelines, no indica on of the condi on of defects, inclusion in the report of too many aesthe c defects, low resolu on or unclear photos in the report, and unclear conclusions.

The characteris cs of good repor ng and inspec on prac ces include the use of proper plans, clear indica on of the various types of facades, highligh ng of key components of the façade support systems, showing original photos and zooming in on the defects, use of Infrared Thermography (IRT) to complement visual inspec on, and the use of appropriate tools for close-range inspec on.

‘AI-powered façade inspec on’ by Mr Harris Sun, CEO and Dr Dhanada

Mishra, Managing Director, RaSpect AI, Hong Kong

RaSpect AI’s façade inspec on workflow consists of four simple steps – autonomous data capture, AI data localisa on, AI safety assessment, and result visualisa on on the cloud. Implementa on of these steps significantly shortens the inspec on me, from months to weeks, due to the use of AI and robo cs.

The Mandatory Building Inspecon Scheme (MBIS) is a government-mandated programme, introduced in 2012, that requires owners of buildings in Hong Kong to have their buildings inspected every 10 years, in order to ensure that the buildings are safe and well-maintained. The MBIS includes a specific requirement for facade inspec on.

‘Experience and challenges in carrying out Periodic Facade Inspecon in CBD Singapore’ by Er. Ivan Phuah, Co-Founder, WCT Consult LLP Pte Ltd

AI-based drone inspec on (visual inspec on) was performed over 100% of the façade of a 24-year old, 140 m high office building. The images were then analysed using AI algorithms to detect defects that required repair.

These defects were then manually inspected, using a gondola and rope access, as part of the 10% closerange façade inspec on criterion.

The close-range inspec on determined the unsafe defects that required urgent repairs and the recommenda on was accordingly made to the building owner.

The challenges in the use of AIbased drone inspec on of facades in CBD Singapore, include proximity to GPS signals from other high-rise towers, pedestrian and popula on density, co-ordina on with mulple stakeholders, façade materials and structure, and drone waypoint planning.

‘Possibili es offered by Advanced Technologies for Building Facade Inspec on’ by Er. David Ng, Co-Founder, One Smart Engineering Pte Ltd

For carrying out a 100% visual inspec on of building facades, drone and Ar ficial Intelligence (AI) technologies are deployed, to carry out the PFI in a more efficient and prac cal way, to improve producvity and enhance the safety of the Competent Person (CP) and the Façade Inspector (FI).

Drone photos can be analysed, using AI, to accurately iden fy defects such as cracks, spalling concrete, distor ons etc. This can save a lot of me and avoid human errors. For the 10% close-range inspec on, a boom li or gondola could be deployed along with a rope accessor who is a RFI.

12 THE SINGAPORE ENGINEER July 2023

IES UPDATE

A endees at the seminar.

The limita ons include regulatory constraints, obstruc on by trees, loss of GPS signals and inability to execute autonomous drone flights, the complex shapes of buildings and the large number of façade faces, as well as the accuracy and reliability of the data analy cs.

However, the benefits of using drone and AI for PFI outweigh the limita ons.

‘Periodic Façade Inspec ons: Praccal Considera ons’ by Mathieu Meur, Director, DP Facade

The Periodic Façade Inspec on (PFI) framework was launched several years ago. Since then, façade inspecons for hundreds of buildings have been completed.

Prac cal considera ons when conduc ng such inspec ons, include the PFI workflow; the choice of inspec on methodologies; types of façade systems; availability of drawings; the existence of signages, ligh ng or special features; access availability including restric ons for drones; manpower availability (training requirement and costs); differences in the quality of findings between service providers (FIs versus drone service operators); insurance requirements; inspec on tools; the repor ng process; and the steps that follow.

‘Considera ons in the Successful Applica on of Digital Tools for Façade Inspec ons’ by KabiSubramaniam, Associate Principal, Arup Singapore

In recent years, commercial drones have been increasingly used in the Built Environment industry, for façade inspec ons. The use of drones can significantly reduce me and cost, and improve safety.

However, this requires trained personnel and exper se in the applica on of digital tools, such as Arup Inspect 3D, for façade inspecons. Arup Inspect 3D is a flexible and scalable digital pla orm that captures and stores structured asset data, so that Arup’s domain experts can derive key insights and deliver value-based outcomes for clients.

The benefits include improved on-site safety as well as be er data capture, repor ng and analy cs. For

clients, it means reduced financial risk and increased asset life.

‘Remote site monitoring using UAVs: Livestreaming and automated scan to BIM’ by Jus n Chan, Ave cs Global Pte Ltd Ave cs offers unmanned aerial vehicle (UAV), or drone, services for external facade inspec ons and confined space inspec ons, as well as the FlightVault report genera on system and 3D modelling for BIM. FlightVault is a drone data management pla orm that makes use of AI to perform data analy cs on drone photos for ac onable insights.

Livestreaming of footage from external façade inspec ons by UAVs facilitates remote project management and viewing. High detail streaming is possible, depending on the opera ng environment. The footage can also be streamed to mul ple loca ons.

Clients can view the live feed from

mul ple loca ons. Pairing with a remote communica on procedure allows near-instant commands to be relayed to the team on the ground.

‘Unveiling the Future: Advanced Microwave Holographic Imaging Technology for Holis c Façade Inspec on’ by Eric Lim, Opera on Director, WaveScan Technologies Pte Ltd

A spin-off from A*STAR, Singapore-based WaveScan specialises in R&D and product development, in the area of electromagne cs-based 3D imaging scanner systems and advanced AI algorithms.

The company has developed a non-destruc ve inspec on solu on for engineering façades that opmises the use of robo c pla orms. The solu on can be used for the inspec on of facades such as led walls, plastered walls, architectural (such as marble) walls and other types of walls.

13 THE SINGAPORE ENGINEER July 2023 IES UPDATE

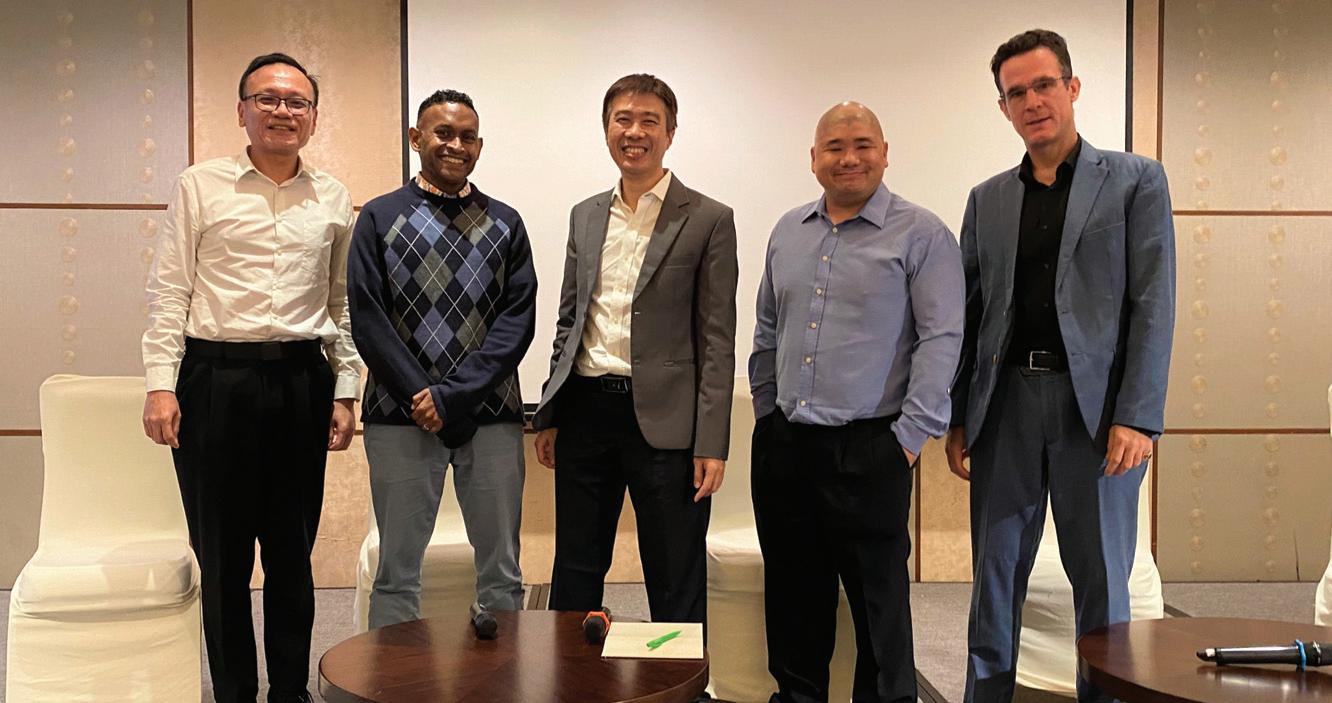

Presenters in the morning session, at the Panel Discussion and Q&A: From le , Dr Dhanada Mishra, Managing Director and Mr Harris Sun, CEO, RaSpect AI, Hong Kong; Mr T Bhaskaran, Editor, ‘The Singapore Engineer’ (Moderator); Er. Chin Leong Siong, Principal Engineer, Façade Engineering and Technology Department, Building and Construc on Authority (BCA); Er. Ivan Phuah, Co-Founder, WCT Consult LLP Pte Ltd; and Er. David Ng, Co-Founder, One Smart Engineering Pte Ltd.

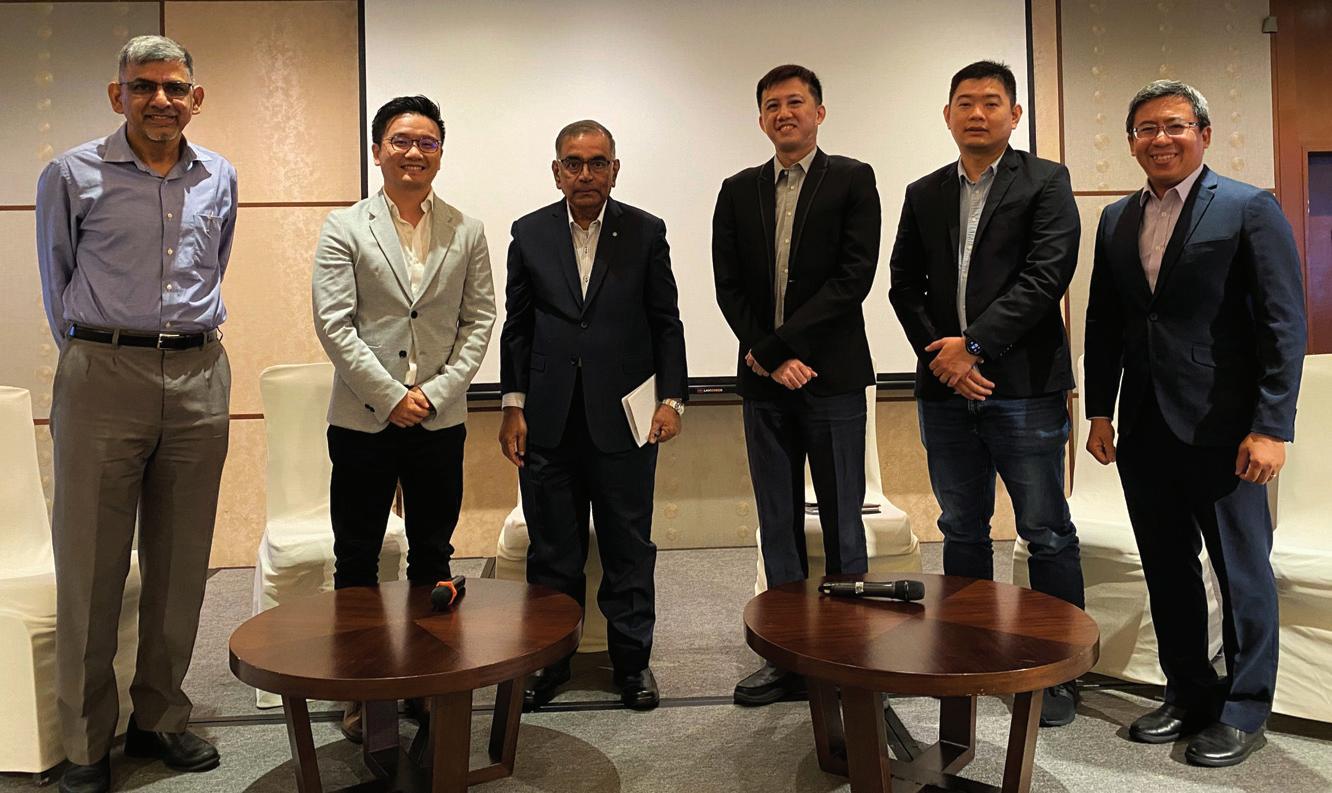

Presenters in the a ernoon session, at the Panel Discussion and Q&A: From le , Mr Eric Lim, Opera on Director, WaveScan Technologies Pte Ltd; Mr Kabi Subramaniam, Associate Principal, Arup Singapore; Er. Jonathan Kok, Technical Director of PH Consul ng Pte Ltd (Moderator); Mr Jus n Chan, Ave cs Global Pte Ltd; and Mr Mathieu Meur, Director, DP Façade.

CapitaLand unveils Geneo life sciences and innova on cluster

Sustainability is a key considera on in the design and construc on.

CapitaLand Group (CapitaLand) recently launched the Geneo life sciences and innova on cluster in the 55-hectare Singapore Science Park (SSP). The launch event was a ended by Mr Gan Kim Yong, Minister for Trade and Industry, as well as representa ves from SSP tenants and community and industry partners.

The development comprises three proper es with five sustainable buildings at various stages of comple on, which will offer about 180,600 m of gross floor area (GFA) with work-live-play elements when fully completed in 2025. The proper es are 1 Science Park Drive (comprising three buildings), 5 Science Park Drive and 7 Science Park Drive.

Totalling about SGD 1.37 billion in investments, Geneo marks the latest phase in CapitaLand’s mul-

stage, precinct rejuvena on of SSP, the country’s first research & development (R&D) and technology park which is commemora ng its 40th anniversary this year. When

the development is fully operaonal, SSP’s popula on is expected to increase by approximately 75% to about 21,000, from the current 12,000.

COVER STORY 14 THE SINGAPORE ENGINEER July 2023

Geneo comprises three proper es with five sustainable buildings at various stages of comple on, which will offer about 180,600 m of gross floor area with work-live-play elements when fully completed in 2025.

At the launch of Geneo are, from le , Mr Jonathan Yap, CEO of CapitaLand Development; Mr Gan Kim Yong, Minister for Trade and Industry; Mr Wong Kan Seng, Chairman, CLA Real Estate Holdings; and Mr William Tay, CEO of the manager of CapitaLand Ascendas REIT.

Mr Jonathan Yap, CEO of CapitaLand Development (CLD), the master developer and park operator of SSP, said, “Over the last four decades, SSP has established itself as one of Asia’s most pres gious addresses for R&D and technology. It is home to more than 350 mul na onal corpora ons, homegrown companies, start-ups and laboratories. Of these, about 30% or 100 companies are from the life sciences sector, with representaon across the value chain, ranging from venture capital investors, incubators and business accelerators to companies undertaking discovery/R&D, preclinical/clinical research and commercialisa on ac vi es. They have been drawn to SSP’s collabora ve, campus-style environment with convenient access to public transport and suppor ng ameni es, as well as proximity to academia, research ins tutes and teaching hospitals.”

“Against this backdrop, we have created Geneo to build on and expand SSP’s vibrant industry ecosystem with purpose-built infrastructure that is conducive for life sciences and innova on companies to thrive, complemented by first-rate work-live-play ameni es that help companies to a ract and retain talent. Catering to the needs of sustainability-minded tenants, all the buildings in the Geneo cluster have obtained notable green creden als. With Singapore con nuing to be the region’s R&D hub for a diverse range of technologies, we are pleased to leverage CapitaLand’s real estate exper se to support the growth of these industries at SSP,” he added.

Mr William Tay, CEO of the manager of CapitaLand Ascendas REIT (CLAR), said, “We are proud to take part in the development of the Geneo life sciences and innova on cluster in SSP as a joint venture partner for 1 Science Park Drive, with a 34% stake in the property. 1 Science Park Drive accounts for about 64% of Geneo’s total GFA of 180,600 m . Given its prime loca on, seamless underground connec on to the Kent Ridge MRT sta on and state-of-the-art design and property specifica ons, we

expect strong demand from tenants in new economy sectors such as biomedical sciences, digitalisa on and technology.”

Celebra ng 40 years of innova on and community building at SSP

At the launch event, Mr Gan Kim Yong was invited to put the finishing touches to the pain ng of a bench adorned with mo fs commemora ng Geneo’s launch. This was part of the CLD-organised ‘Art Jam Science Park’ programme, a SSP 40th anniversary placemaking ini a ve aimed at driving inclusive community engagement through bringing 40 art benches into SSP’s communal spaces.

Featuring colourful designs, created mostly by ar sts with disabili es, the benches have been adopted by 18 companies located in SSP and partners of the park.

Key highlights of the Geneo life sciences and innova on cluster

Geneo marks CapitaLand’s first concerted effort to curate the offerings across mul ple buildings to form a unified cluster, since it embarked on rejuvena ng SSP about a decade ago. Inspired by the word ‘ingenuity’ and containing the word ‘gene’, the name Geneo underscores the cluster’s focus on suppor ng life sciences companies in bringing their innova on to frui on. Geneo can

also be read as ‘Gen Neo’ which expresses the cluster’s ambi on to foster the next genera on of innovators through the reinven on of real estate offerings and experiences.

CapitaLand envisions the development, with its three proper es, to be the stage that brings researchers, scien sts and knowledge workers together to make a posi ve impact.

• 1 Science Park Drive comprises three Grade-A buildings linked by an event plaza, offering about 112,600 m of workspace as well as 3,600 m of retail and food & beverage ameni es. It occupies a prime loca on at the main entrance of SSP and is seamlessly linked to the Kent Ridge MRT staon by an underground connecon. Targe ng for comple on by 2025, the project is owned by a 66:34 joint venture between CLD and CLAR.

• 5 Science Park Drive, owned by CLD, is a future-ready business park building, completed in 2019 and featuring collabora ve workspaces and lifestyle ameni es, with a total GFA of about 25,600 m .

• 7 Science Park Drive, owned by CLD, is a mixed-used development targeted for comple on in 2024. It houses about 28,800 m of workspace and 10,000 m of serviced residence with a hotel licence.

COVER STORY 15 THE SINGAPORE ENGINEER July 2023

Gree ng visitors at the arrival area is a cascading water fountain bedecked with lush foliage along the edges of its planters.

Specialised

life sciences real estate catering to robust demand

Catering to the robust demand for quality life sciences real estate in Asia Pacific, about 80,000 m of Geneo’s workspace are purpose-built to accommodate biomedical R&D ac vi es, with specifica ons like exhaust risers to the roof to meet ven la on requirements, mul ple floor traps for dry or wet laboratory configura ons and high floor loading to accommodate laboratory and research equipment. To support emerging life sciences start-ups, the development will host CapitaLand’s first coworking laboratory space in Singapore featuring flexible shared laboratory space equipped with common laboratory equipment and facili es.

Green creden als mee ng the needs of sustainability-minded tenants

7 Science Park Drive has achieved the BCA Green Mark Pla num Super Low Energy cer fica on from the Building and Construc on Authority (BCA).

It is the first CapitaLand greenfield project and first SSP property to be accorded this cer fica on which is the latest feather in the cap for SSP 1, the first exis ng business park to receive recer fica on for BCA Green Mark Pla num for Districts. SSP 1 is one of only two exis ng districts to have achieved this pres gious award. The other two proper es in Geneo have obtained the BCA Green Mark Pla num cer fica on.

Geneo is provisionally designed to achieve energy savings of about 13 million kilowa -hours (kWh) per year, equivalent to powering the annual electricity consump on of over 3,343 four-room HDB flats. The energy savings exclude energy offsets from renewable energy.

Key sustainability features include SSP’s first distributed district cooling network, in partnership with SP Group, as well as 1,400 roo op photovoltaic solar panels that generate an es mated 1.1 million kWh of renewable energy each year – equivalent to powering the annual electricity consump on of 236 four-room HDB flats.

In addi on, Geneo adopts though ul design strategies that maximise building users’ comfort while minimising energy use. For instance, the closely knit, u-shaped arrangement of the various buildings and the design of their accordion shaped façade help to block out sunlight, thus reducing the amount of heat trapped within the buildings. With a total landscaped area of more than 21,000 m , equivalent to about 33% of its site area of about 64,000 m , the development’s abundant greenery also helps to reduce the urban heat island effect while enhancing SSP’s biodiversity.

Furthermore, water-efficient fi ngs are adopted throughout Geneo and rainwater is harvested for non-potable uses. An auto-irriga on system is also employed to op mise water usage for landscaping. With these provisions, the development’s es mated annual potable water savings are sufficient to provide the water supply for 190 four-room HDB flats for a year.

COVER STORY 16 THE SINGAPORE ENGINEER July 2023

The development features a total landscaped area of more than 21,000 m , equivalent to about 33% of its site area of about 64,000 m

Holis c work-live-play elements to enliven SSP

Geneo is set to further enliven SSP with the provision of about 3,600 m of retail and food & beverage ameni es. The development will also introduce SSP’s first lodging facility, Citadines Science Park Singapore, a serviced residence, with hotel licence, operated by The Asco Limited, a lodging business unit wholly owned by CapitaLand Investment. Located at 7 Science Park Drive, Citadines Science Park Singapore is slated to welcome guests from 1Q 2024. It will offer 250 studio, studio lo and studio premier apartments as well as facili es such as a cafe, an indoor gymnasium, mee ng rooms, a residents’ lounge, a restaurant, a shared working space and a swimming pool.

Even as the park popula on and ameni es con nue to grow, CapitaLand is commi ed to preserving SSP’s trademark lush urban campus ambience. Geneo will offer abundant communal spaces, including a naturally ven lated event plaza with verdant landscaping. Covered by a drama c louvred glass canopy and mber structures, the event plaza serves as a relaxing place to hang out and doubles up as a se ng for large-scale community events.

To encourage ac ve lifestyles, Geneo provides a diverse range of fitness and recrea onal facili es, including a basketball court, a yoga deck, a running track that circles the perimeter of the development and a 25 m lap pool in Citadines Science Park Singapore. For workouts with a twist, the ‘MyEquilibria’ fitness corner in 5 Science Park Drive features a 7 m tall sculpture that doubles up as an outdoor fitness system.

In support of the sustainable transport vision in the Singapore Green Plan 2030, Geneo will offer 466 bicycle lots and 14 electric vehicle charging lots, as well as a dedicated 490 m cycling path that is linked to nearby park connectors.

COVER STORY 17 THE SINGAPORE ENGINEER July 2023

Geneo is set to further enliven Science Park with the provision of about 3,600 m of retail and food & beverage ameni es.

Geneo will introduce Science Park’s first lodging facility, Citadines Science Park Singapore, a serviced residence with hotel licence, located at 7 Science Park Drive and opening in 1Q 2024.

‘MyEquilibria’ fitness corner in 5 Science Park Drive.

Sustainable and innova ve construc on

In line with CapitaLand’s commitment to sustainability, Geneo adopts several low carbon technologies and sustainable innova ons during the construc on process. To lower Geneo’s embodied carbon footprint, mass engineered mber (MET) harvested from sustainably managed forests is used to construct the canopies and columns at its event plaza. Compared to tradional construc on materials, MET produces rela vely lower net carbon emissions, with an es mated embodied carbon savings of 88% over steel and 63% over concrete. When completed, Geneo’s 3,000 m all-weather event plaza measuring 27 m in height will be Singapore’s tallest MET canopy structure.

In addi on, cer fi ed Singapore Green Building Product (SGBP) materials such as green concrete, architectural fi nishes and M&E equipment are used in the construc on of Geneo. These help to improve indoor air quality and reduce energy consump on, making it healthier and more cost-effec ve for building occupants. On top of being the fi rst CapitaLand project to adopt carbon dioxide mineralised concrete, Geneo is the fi rst project in Singapore to use this green concrete for superstructure works including

ver cal elements, resul ng in an es mated 28% reduc on in embodied carbon. Carbon dioxide mineralised concrete is a type of low-carbon sustainable concrete that uses carbon capture and u lisa on technology to chemically convert carbon dioxide into a mineral embedded in concrete, producing harder concrete.

Instead of diesel generators, a battery energy storage system is used at the development’s construc on site to provide power to construcon machinery, lowering carbon emissions by about 78% while maintaining a produc ve worksite.

Nurturing SSP’s innova on ecosystem with showcase and networking opportuni es

As SSP enters its fi h decade, the park community can look forward to more showcase and networking opportuni es organised by CLD with its partners including Smart Urban Co-innova on Lab, Southeast Asia’s first industry-led laboratory for smart ci es solu ons development located in The Galen building at SSP, and Catapult, Southeast Asia’s first shared execu ve learning centre located in Rochester Commons.

An example is ‘Flavours of Tomorrow: Tas ng Tomorrow's Nosh’, an ini a ve by CLD and NUS Enterprise, the entrepreneurial arm of

the Na onal University of Singapore, that supports development of Singapore’s agrifood-tech industry. The ini a ve offers SSP tenant community a chance to sample a range of novel ingredients and flavours as well as gain insights to the product development process, while serving as a pla orm for the par cipa ng agrifood-tech startups and companies to discuss their latest innova ons and connect with fellow industry players.

CLD will also make ‘Innova on Made Real’, which debuted last year, a staple event on SSP’s annual calendar. Featuring dialogue sessions as well as special exhibits and workshops by partners of SSP, Innova on Made Real is aimed at providing members of the SSP innova on ecosystem with a pla orm to showcase their endeavours to poten al partners in SSP and beyond.

CapitaLand Group

CapitaLand Group (CapitaLand) is one of Asia’s largest diversified real estate groups. Headquartered in Singapore, CapitaLand’s por olio focuses on real estate investment management and real estate development, and spans across more than 260 ci es in over 40 countries.

COVER STORY 18 THE SINGAPORE ENGINEER July 2023

All images by CapitaLand

Geneo has also incorporated several low carbon mobility op ons.

COVER STORY 19 THE SINGAPORE ENGINEER July 2023

When completed, the 3,000 m , all-weather event plaza, measuring 27 m in height, will be Singapore’s tallest MET canopy structure.

Covered by a drama c louvred glass canopy and mber structures, the event plaza serves as a venue for relaxa on and doubles up as a se ng for large-scale community events.

New addi ves could turn concrete into an effec ve carbon sink

MIT engineers discover new carbona on pathways for crea ng more environmentally friendly concrete.

Despite the many advantages of concrete as a modern construc on material, including its high strength, low cost and ease of manufacture, its produc on currently accounts for approximately 8% of global carbon dioxide emissions.

Recent discoveries by a team at MIT reveal that introducing new materials into exis ng concrete manufacturing processes could significantly reduce this carbon footprint, without altering concrete’s bulk mechanical proper es.

The findings were published recently in the journal PNAS Nexus, in a paper by MIT professors of civil and environmental engineering Admir Masic and Franz-Josef Ulm, MIT postdoc Damian Stefaniuk and doctoral student Marcin Hajduczek, and James Weaver from Harvard University’s Wyss Ins tute.

A er water, concrete is the world’s second most consumed material and represents the cornerstone of modern infrastructure. During its manufacturing, however, large quanes of carbon dioxide are released, both as a chemical by-product of cement produc on and in the energy required to fuel these reac ons.

Approximately half of the emissions associated with concrete producon come from the burning of fossil fuels such as oil and natural gas which are used to heat up a mix of limestone and clay that ul mately becomes the familiar grey powder known as Ordinary Portland Cement (OPC). While the energy required for this hea ng process could eventually be subs tuted with electricity generated from renewable solar or wind sources, the other half of the emissions is inherent in the material itself.

As the mineral mix is heated to temperatures above 1,400° C

(2,552° F), it undergoes a chemical transforma on from calcium carbonate and clay to a mixture of clinker (consis ng primarily of calcium silicates) and carbon dioxide –with the la er escaping into the air.

When OPC is mixed with water, sand and gravel material, during the produc on of concrete, it becomes highly alkaline, crea ng a seemingly ideal environment for the sequestra on and long-term storage of carbon dioxide in the form of carbonate materials (a process known as carbona on). Despite this poten al of concrete to naturally absorb carbon dioxide from the atmosphere, when these reac ons normally occur, mainly within cured concrete, they can both weaken the material and lower the internal alkalinity, which accelerates the corrosion of the reinforcing rebar. These processes ul mately destroy the load-bearing capacity of the building and nega vely impact its long-term mechanical performance.

As such, these slow, late-stage carbona on reac ons, which can occur over mescales of decades, have long been recognised as undesirable pathways that accelerate concrete deteriora on.

“The problem with these post-curing carbona on reac ons is that you disrupt the structure and chemistry of the cemen ng matrix that is very effec ve in preven ng steel corrosion, which leads to degrada on,” said Professor Masic.

In contrast, the new carbon dioxide sequestra on pathways discovered by the authors rely on the very early forma on of carbonates during concrete mixing and pouring, before the material sets, which might largely eliminate the detrimental effects of carbon dioxide uptake a er the material cures.

The key to the new process is the addi on of one simple, inexpensive ingredient, that is, sodium bicarbonate, otherwise known as baking soda. In lab tests using sodium bicarbonate subs tu on, the team demonstrated that up to 15% of the total amount of carbon dioxide associated with cement produc on could be mineralised during these early stages – enough to poten ally make a significant dent in the material’s global carbon footprint.

“It is all very exci ng because our research advances the concept of mulfunc onal concrete by incorpora ng the added benefits of carbon dioxide mineralisa on during produc on and cas ng,” Professor Masic added.

Furthermore, the resul ng concrete sets much more quickly via the forma on of a previously undescribed composite phase, without impac ng its mechanical performance. This process thus allows the construc on industry to be more produc ve. Form works can be removed earlier, reducing the me required to complete a bridge or building.

According to Professor Masic, the composite, a mix of calcium carbonate and calcium silicon hydrate, is an en rely new material and through its forma on, the mechanical performance of the early-stage concrete can be doubled. He points out, however, that this research is s ll an ongoing effort.

The current discoveries by the MIT team highlight the fact that the pre-curing capacity of concrete to sequester carbon dioxide has been largely underes mated and underu lised.

The research was supported by the Concrete Sustainability Hub at MIT, which has sponsorship from the Concrete Advancement Founda on and Portland Cement Associa on.

20 SUSTAINABILITY THE SINGAPORE ENGINEER July 2023

Learning more about the land transporta on sector in Japan

by IES-SDO

On 23 April 2023, the Transporta on Standards Commi ee (TPSC) of the Singapore Standards Council (SSC) embarked on a study trip to Japan to explore advancements in the land transporta on sector. Led by Dr Richard Kwok, Chair of TPSC, and supported by Mr Cheong Tak Leong, Director of Standards (Services) at Enterprise Singapore, the delega on included members from the TPSC, Ins tutes of Higher Learning (IHL), and transporta on-related companies. The trip was organised by Ins tu on of Engineers, Singapore – Standards Development Organisaon (IES-SDO).

Over the course of six days, the delega on visited various organisa ons to gather valuable insights and seek guidance on the development of standards and conformance criteria to support railway, automo ve, and intelligent transport systems. Knowledge was shared on how standards facilitate opera onal and maintenance challenges faced by Japanese rail companies, as well as on the role of standards in suppor ng transportaon-related regula ons in Japan.

Among the highlights of the trip were visits to two major railway operators, JR East and Tokyo Metro. It was observed that these operators and their subcontractors work collabora vely to achieve high effecveness through standardisa on. Notably, standardisa on efforts encompassed various aspects such as wayfinding signages, emergency procedures, and management of common assets across different train operators.

In addi on to railway operators, the delega on met with Mitsubishi Electric, an organisa on specialising in building equipment and services. Discussions revolved around the

latest technologies, procedures, and processes for maintaining electrical and mechanical systems in li s, escalators, and building management systems. The importance of developing solu ons to reduce manpower due to increasing labour costs was emphasised, leading to insights on connec ng elevators and escalators to AI-enabled informa on centres for asset management and opera on.

In the automo ve and intelligent transport systems sector, the delegates visited the Japan Automobile Research Ins tute (JARI). JARI’s state-of-the-art tes ng facili es allowed for tests in various environmental and extreme climate condi ons. A notable concern highlighted during the visit was the decreasing number of professionals in Japan's electric vehicle (EV) industry. This prompted the delega on to consider the need for workforce training to support the EV industry in Singapore.

Japan’s standards bodies, par cularly the Japan Standards Associaon (JSA), shared their challenges of an ageing popula on and a lack of experts par cipa ng in stan-

dardisa on ac vi es. To address this, they have developed and maintained a database of human resources involved in standardisaon to aid in analy cs, planning for engagement/recruitment strategies, and deployment. Addi onally, training courses have been developed to groom younger standards partners and refresh the age structure of standards experts.

A similar ini a ve is being undertaken in Singapore, where Enterprise Singapore con nues to strengthen its Young Professional Programme to engage young professionals under the age of 40 in Singapore's standardisa on ac vi es.

Overall, the study trip provided the delegates with valuable insights into the methodologies of standards incorpora on in Japan, exposure to new technologies, and an understanding of the challenges faced and solu ons being implemented. It also served as an excellent pla orm for collaboraon, enabling en es to pool their strengths, exchange ideas and work collec vely towards advancing a be er rail system.

21 STANDARDS DEVELOPMENT THE SINGAPORE ENGINEER July 2023

The delega on from the Transporta on Standards Commi ee together with officials from Japan’s standards bodies.

The Transporta on Standards Commi ee undertakes a six-day study trip to Japan.

RAILWAY & TRANSPORTATION ENGINEERING

Is the transporta on industry ready for digital twins?

by Steve Cockerell, Industry Marke ng Director, Rail and Transit, Bentley Systems

The benefits of this disrup ve technology are already being proven.

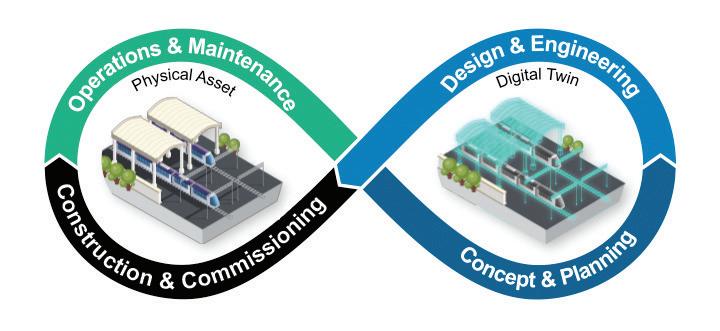

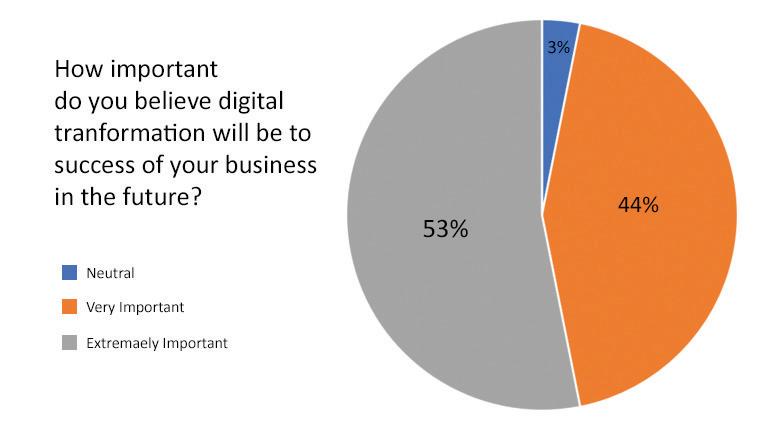

At the start of 2022, I had wri en that the future of transporta on infrastructure is happening now and how, with rapid popula on growth, urbanisa on and the urgent need for significant reduc ons in carbon emissions, digital twins would be key to building back be er. However, is the rail and transit industry – one that is o en accused of being slow to embrace change – ready for the type of digital transforma on needed to fully realise the poten al of digital twins? Have digital twins already taken centre stage in what is a complex industry, or is the sector s ll in the early stages of their adop on and deployment?

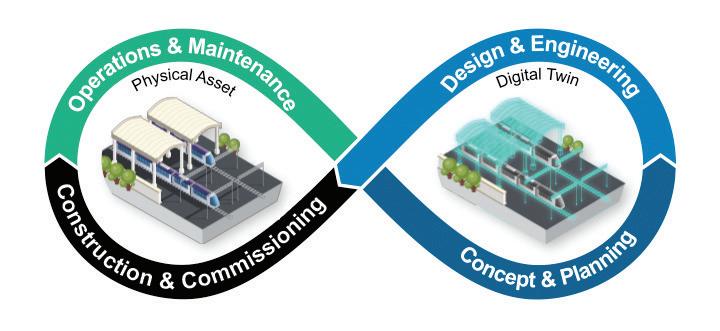

What is a digital twin?

To explore the poten al that digital twins provide, it is important to understand what a digital twin is. For many, the defini on of a digital twin might just be a 3D BIM model of a physical asset. In our world, that might be a length of track, a

bridge, tunnel or sta on. However, without a connec on between the digital version and its physical counterpart in the real world, all they really have is a digital snapshot of an asset at a given point in me.

In this scenario, not only do users run the risk of one version being out of sync with the other, resul ng in rework, delay, and/or increased cost, they also lose the ability to see the data behind the design, construc on schedule or operaonal asset, as well as leverage that insight to enable be er decision-making and improved business outcomes.

At Bentley, we define a digital twin as a realis c and dynamic digital representa on of a physical asset, process or system, in the built or natural environment. A digital twin connects the physical and digital worlds so that the digital dynamically reflects changes in the physical. A digital twin, therefore, represents its physical counterparts’

real- me or near real- me status, working condi on or posi on.

Throughout the asset lifecycle – from concept and planning, through design and engineering, construc on and commissioning, and across opera ons and maintenance – that link, that connec vity, really makes the difference. In this way, digital twins provide improved visualisa on, analy cs and simula on capabili es. At any me, anywhere, users of a digital twin can view, monitor and gather the insight that they need to make the decisions that improve efficiency, reliability, and sustainability.

Digital twins in rail today

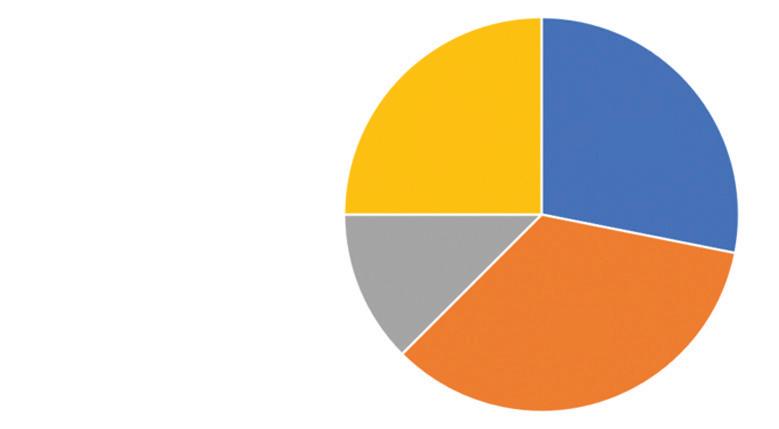

Working with New Civil Engineer, the official magazine of the United Kingdom’s Ins tu on of Civil Engineers, Bentley recently conducted a survey to look at where the industry is today, as well as examine the poten al of, and barriers to, the adop on of infrastructure digital twins.

22

THE SINGAPORE ENGINEER July 2023

A digital twin connects the physical and digital worlds so that the digital dynamically reflects changes in the physical. Image: Bentley Systems.

The industry professionals responding to our ques ons represented every phase of the lifecycle of transporta on assets as well as many of the different specialist disciplines involved. Around 30% were owner-operators or government agencies, while 60% are working within their supply chains as engineers, architects and/or contractors. The remainder of the input came from academic organisa ons or technology developers.

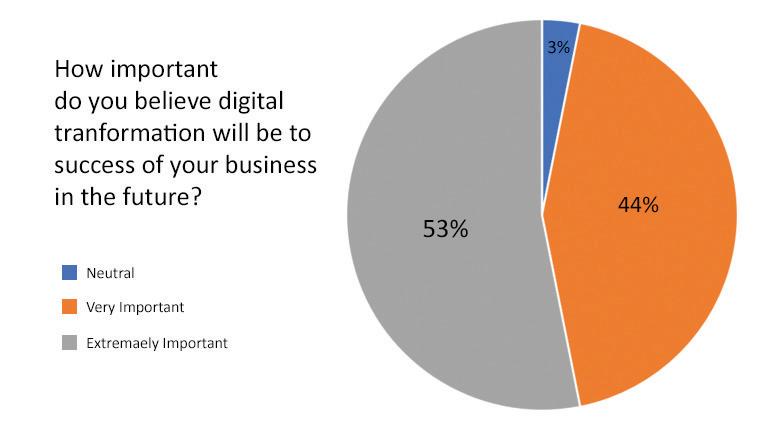

Reassuringly, everyone confirmed the urgent need to digitally transform the way we work. With the backdrop of ghter budgets and shorter deadlines, Bentley knows that organisa ons are looking for new and innova ve ways to drive improved produc vity and efficiency, as well as the quality of assets being delivered and maintained throughout their opera on.

When you consider the nega ve effects of climate change, including the increased frequency and severity of severe weather events that directly impact the safe and efficient opera on of our railways, I think it is clear that as an industry, the need for real change is no longer a future problem.

I have wri en previously about how the global pandemic was a wake-up call for all of us. The experience of the last two to three years has shown what we can do when forced to change. It is also an indica on of the opportunity that change provides when it is part of a strategy versus when it is a reac on to challenges that we encounter in our everyday working lives.

Aligned with this idea, it was encouraging to see that digital twins are expected to be part of organisa ons’ business processes within the next five years. Furthermore, around a quarter of the organisa ons surveyed said that digital twins will be a vital component of their future success. The majority, nearly three quarters, also confirmed that they were either exploring the poten al that digital twins offered their business or are already in the process of adop ng a digital twins approach.

Project delivery versus asset performance

While this insight is great news, what are these organisa ons doing with their digital twins? Where, within the rail and transit asset lifecycle, does the survey suggest that digital twins are having the most impact? Nearly three quarters of those surveyed indicated that their use was limited to design and engineering. This key phase of the asset lifecycle, along with digital construc on, ranked as the top two use cases for digital twins within the organisa ons represented.

Exis ng paper-based workflows and/or the lack of direct links to the current or as-built condi on of assets were iden fied as the primary reasons for limited adop on today. This current focus on project delivery was reinforced by an overwhelming majority that felt that 3D design, plus 4D modelling to

simulate and op mise construc on schedules, were the most important elements of any infrastructure digital twin solu on.

Whether through improved collabora on and coordina on of teams and with stakeholders, or to enable improved insight and be er decision-making, around three quarters of those surveyed felt that digital twins will be the key to op mising design and engineering outcomes. These outcomes include helping to increase produc vity, explore more design alterna ves, deliver higher quality and more sustainable assets, as well as improve the level of service to their clients and stakeholders.

Barriers to adop on and deployment

Clearly, the poten al benefits for digital twins in rail extend beyond project delivery. But while asset

23 RAILWAY & TRANSPORTATION ENGINEERING THE SINGAPORE ENGINEER July 2023

Importance of digital transforma on from rail digital twin survey. Image: Bentley Systems.

Organisa on digital twin strategy from rail digital twin survey. Image: Bentley Systems.

RAILWAY & TRANSPORTATION ENGINEERING

commissioning and condi on assessment, plus asset performance management and op misa on, were recognised as key use cases within the survey results, it also showed that there are fewer digital twins in use within opera ons and maintenance.

Perhaps, the reason for this is in what our survey found were the biggest challenges organisa ons face today when implemen ng digital twins. Very few indicated that availability of digital twin technology was their main barrier to adop on. Most suggest that the biggest obstacles to adop on and deployment were a lack of owner or client buy-in and senior management support, and the perceived cost of se ng up and maintaining a digital twin.

As demonstrated through our Going Digital Awards entries this year, the evidence, that the benefits of digital twins outweigh their cost par cularly when calculated across an asset’s whole life, gets clearer all the me. Indeed, all of the finalists in our Rail and Transit category this year cite digital twins as an important element of their team’s ability

to demonstrate excellence across the lifecycle of assets.

In the Philippines, Oriental Consultants Global is working on phase 1 of the Metro Manila Subway Project, developing a common digital engineering system and a single source of truth using Bentley’s integrated technology and digital twin applica ons. The result is real- me data sharing that has helped op mise collabora on to save 5,000 resource hours within the project’s first six months, as well as already achieving an ROI of over USD 600,000.

In Jakarta, Indonesia, PT Wijaya Karya (Persero) Tbk is using Bentley’s open civil design and reality modelling applica ons as well as digital twin technology, in their work to deliver Indonesia’s first integrated high-speed rail line between Jakarta and Bandung. Its integrated solu on has helped streamline workflows that has improved efficiency and design quality, while shortening the construc on schedule by six months and saving USD 185 million in construc on costs.

In the United Kingdom, Arcadis has used Bentley technology to create a digital twin of Carstairs railway sta on, located close to the key rail junc on dividing northbound trains between Glasgow and Edinburgh, in southern Scotland. Arcadis’ use of the Bentley iTwin pla orm has enabled improved communica on among team members, with the ability to detect and resolve clashes early in the design, to help op mise the design while reducing modelling me by 35%.

The future of digital twins in rail

It is arguably the rail and transit owner-operators who stand to benefit from the greater upside of digital twins, with their ability to improve asset performance and reliability, refine maintenance strategies and explore different op ons for required upgrades. While benefits beyond financial can be difficult to quan fy, it is the owners, rather than the consultants and contractors in their supply chains, who should s ll take the lead in defining the value digital twins should deliver.

24

THE SINGAPORE ENGINEER July 2023

In the Philippines, Oriental Consultants Global is developing a common digital engineering system and a single source of truth using Bentley’s digital twin applica ons. Image: Oriental Consultants Global.

It will not always be a straigh orward process to harness data and technology through digital twins to improve how we work and what we deliver across every phase of the asset lifecycle. However, if they are to become part of our industries’ new normal, every organisa on needs to invest in, and have a clear strategy for, change. As with previous examples of disrup ve technology in our business and beyond, those that do not invest in making and managing this change are more likely to fail.

At Bentley, we believe that digital twins are the next big digital disrup on in our industry. That disturbance is happening right now – among owner-operators, engineering consultants, contractors and the organisa ons that maintain our railways around the world. Digital twins and the different processes that they enable must be embraced to deliver the improved business outcomes demanded in our changing world. While digital twins in rail might not have taken centre stage yet, they are wai ng in the wings, and with our users taking the lead, they will transform the way we plan, design, build, and operate our rail and transit networks in future years.

First narrow-gauge trains with hydrogen propulsion for Italy

Italian railway operators, Azienda Regionale Sarda Traspor (ARST) and Ferrovie della Calabria (FdC), have awarded Stadler two framework agreements for the design, producon, delivery and maintenance of 10 hydrogen trains for ARST in Sardinia and 15 similar vehicles for FdC in Calabria.

This will make Stadler the first train manufacturer in the world to supply narrow-gauge trains with hydrogen propulsion.

A er delivering the FLIRT H for American passenger transport, Stadler is now supplying hydrogen trains to Europe for the first me.

As ini al call-off orders from the framework agreements, ARST and FdC signed two contracts

with Stadler in Rome recently, for the delivery of the first 12 hydrogen trains – six for each of the Italian companies.

The vehicles will be developed and built at Stadler’s headquarters in Bussnang (Switzerland).

The vehicles will be equipped with ecological fuel-cells and hydrogen propulsion and be dedicated to regional and suburban services for the narrow-gauge (950 mm) network in the two Italian regions. Both projects are being financed with EU funds from the Na onal Recovery and Resilience Plan (PNRR).

The two framework agreements and ini al call-off orders will enable Stadler to further strengthen its leading role in the decar-

bonisa on of rail transport. The vehicles consist of two passenger cars, whose lightweight aluminium construc on helps to increase the train’s energy efficiency, and a power pack to house the fuel cells and hydrogen tanks as well as other technical equipment.

With an overall length of around 50 m, the new trains will have 89 seats per vehicle, for a total of 155 passengers transported, and are fully accessible for people with reduced mobility. Furthermore, the new vehicles offer specific areas for wheelchairs, pushchairs and bicycles, posi oned near the access and exit doors, as well as PRM toilets compliant with TSI standards.

25

THE SINGAPORE ENGINEER July 2023

RAILWAY & TRANSPORTATION ENGINEERING

PT Wijaya Karya (Persero) Tbk is using digital twin technology to deliver Indonesia’s first integrated high-speed rail line between Jakarta and Bandung. Image: PT Wijaya Karya (Persero) Tbk.

Arcadis has used Bentley technology to create a digital twin of Carstairs railway sta on. Image: Arcadis.

Award-winning demonstra on of new materials and new applica ons

Stadtbahnbrücke, a network arch bridge in Stu gart, Germany, was the winner of the Award for research informed innova on of novel high-performance materials, at Structural Awards 2022. The project has also won several other awards.

The light rail arch bridge, ‘Stadtbahnbrücke’, consists of a central main span and two approach spans at 24 m. The main span is connected by an 80 m network arch and two protruding truss frames which con nue the swing of the slender arches, not only as sloped concrete supports but also as a visual element that leads all the way to the ground. The span between the foo ngs is 107 m. The free-standing arches are made from tapered steel box girders.

A prestressed concrete slab is suspended from the arches by means of two series of inclined carbon fibre reinforced polycarbonate (CFPC) hanger cables.

The integral design and the use of a high-performance material for the hangers in the case of the light

rail bridge allows for a low material input and high transparency.

The development of the bonded carbon-fibre composite members was the result of material science research and a rigorous tes ng regime, involving over a million stress-test cycles, to demonstrate the suitability of this hybrid material for use in these circumstances.

The bridge was built for Stu garter Straßenbahnen AG and spans the busy A8 highway, east of the Stu gart-Degerloch (B27) juncon. It is an important part of the extension of the U6 light rail line to the city’s trade fair grounds and the airport. The bridge does not require any supports to span the highway, which features six lanes as well as four merging lanes and is approxi-

mately 80 m wide at this spot. The sloped, crossing suspension cables, consis ng of carbon-fibre composite tension elements, provide a suppor ng structure that is efficient and visually appealing. It is said to be the first commercial applica on of carbon-fibre composite cables for a network arch bridge.

The three most important design objec ves were minimal disrup on of traffic, an appealing design of the exposed structure, as well as a robust and long-las ng design of all components and details.

The main sec on of the bridge was manufactured on a temporary suppor ng frame beside the motorway. Then, during a brief closure of the highway, it was pushed to its final des na on.

STRUCTURAL ENGINEERING 26 THE SINGAPORE ENGINEER July 2023

Stadtbahnbrücke is a light rail arch bridge. Image: sbp-Andreas Schnubel.

STRUCTURAL ENGINEERING

PROJECT DATA

Project Stadtbahnbrücke

Loca on Stu gart, Germany

Type of structure

Integral network arch bridge with carbon-fibre composite suspenders

Span between abutments 107 m (axle 20 to axle 50)

Arch span 80 m

Arch rise

8.5 m

Total length of superstructure 130 m

Width of superstructure

8.5 m - 11.7 m

Bridge area 1,424 m²

Date of comple on

December 2021

PROJECT CREDITS

Owner

Stu garter Straßenbahnen AG (SSB)

Structural Designer schlaich bergermann partner (sbp)

Architect schlaich bergermann partner (sbp)

Collaborators

EMPA

MPA

CarboLink

Syrjakow

Contractor

Adam Hörnig Baugesellscha

mbH & Co KG + MCE AG

Awards

Deutscher Ingenieurbaupreis

2022

Structural Awards 2022 (Winner)

German Bridge Construc on Award 2023 (Winner)

27

THE SINGAPORE ENGINEER July 2023

A prestressed concrete slab is suspended from the arches by means of two series of inclined carbon fibre reinforced polycarbonate (CFPC) hanger cables. Image (on top): sbp-Andreas Schnubel. Image (below): Patrick Grossien.

The free-standing arches are made from tapered steel box girders. Image: sbp-Andreas Schnubel.

Waste genera on and recycling rates increase

Singapore’s overall recycling rate improved from 55% in 2021 to 57% in 2022.

According to the Na onal Environment Agency’s (NEA) latest waste and recycling sta s cs for 2022, about 7.39 million tonnes of solid waste were generated [1], of which 4.19 million tonnes were recycled. Waste generated by the non-domesc [2] and domes c [3] sectors both increased, compared to 2021 – from 5.12 million tonnes and 1.82 million tonnes, respec vely, in 2021, to 5.53 million tonnes and 1.86 million tonnes, respec vely, in 2022.

Of the waste generated in 2022, around 3.20 million tonnes were disposed of. Overall, the recycling rate [4] increased from 55% in 2021 to 57% in 2022. The non-domesc recycling rate increased by 2% from 70% in 2021 to 72% in 2022, while the domes c recycling rate decreased by 1% from 13% in 2021 to 12% in 2022.

Increase in waste generated

As economic ac vity picked up in 2022, more waste was generated. Waste generated in 2022 was 6.4% higher than in 2021. Two major industrial waste streams were the main contributors to the increase in overall waste genera on, namely construcon and demoli on (C&D) waste, and ferrous metal waste. These waste streams saw increases as a result of the pick-up in construc on and demoli on ac vi es in 2022.