10 minute read

HIP TO BE SQUARE: FIBCS & BAGGING EQUIPMENT

Jay Venter

STATEC BINDER: specialist in high-performance packaging and palletizing systems

With more than 40 years of experience in packaging and palletizing technology, STATEC BINDER offers not only highquality equipment but also efficient and high-speed total solutions for the customer's entire packaging process. STATEC BINDER stands for absolute reliability, distinguished by precision and constant innovation. The customer and his individual requirements are in the foreground at the globally active company. Each machine is individually adapted to the customer's product in order to achieve the best possible solution and capacity.

Whether petrochemicals, food or pet food — the company is active in a wide range of industries for free-flowing or powdery bulk materials. With over 1,700 machines successfully installed worldwide, STATEC BINDER looks back on numerous positive references. The company counts small firms as well as large corporations, represented on all five continents, among its existing customer base. Thanks to proven technology as well as continuous developments and optimizations, STATEC BINDER serves as an internationally recognized partner to many.

For many customers, it is a very complex process to weigh, pack, seal and deliver their actual goods on a pallet — and that too with a high number of bags per hour. The wide product portfolio allows the company to meet the needs of its customers in a variety of industries, while also offering an excellent customer service programme.

On the one hand, there is the PRINCIPAC — one of the world’s fastest bagging machines with up to 2,000 bags per hour — and on the other hand, the CERTOPAC, which is ideally designed for bagging free-flowing materials up to 1,500 bags per hour. The ACROPAC model was developed by STATEC BINDER for small and medium-sized operations with lower

production capacities and is suitable for bagging up to 600 bags per hour.

STATEC BINDER’s high-performance pallet izer PRINCIPAL-H with a capacity of 2,400 bags per hour completes an all-around high-quality and efficient palletizing process with a nice and stable layer pattern. With the robotic palletizer PRINCIPAL-R, which is a high-tech version, bags up to 1,400 bags or boxes per hour can be achieved.

The various longlasting machines differ

YOUR SPECIALIST FOR BAGGING & PALLETIZING

OPENMOUTH & FFSbagging machines

HIGH-LEVEL PORTAL & ROBOT palletizing systems

more than 40

years

of experience more than 1700

installed machines in over 80

countries

Global

customer service

STATEC BINDER GmbH Industriestrasse 32, 8200 Gleisdorf, Austria Tel.: +43 3112 38580-0 E-Mail: oce@statec-binder.com from the competition not only in terms of capacity but also in the high quality and service related to the purchase of the equipment. Expertise in consulting and service are important factors for the company when it comes to long-term partnerships.

Therefore, STATEC BINDER customers are not left alone even after purchase: Customer training and service appointments ensure that the entire packaging and palletizing process runs smoothly. The 1-6-11 service programme was also developed for this purpose, which ensures that the customer receives intensive support from the customer service team after purchase. STATEC BINDER specialists are always available to provide assistance and answers to questions, from dealing with orders of spare parts and their delivery, ongoing inspections and maintenance of machines and individual customer training programmes, to tailor-made service agreements — the fullest satisfaction of the customers has the highest priority. The company focuses on a high level of communication, fast availability and proximity to the customer within its partnerships and ensures that the machine is state of the art. Customer service is characterized by highly trained employees and remote service with real-time support.

Customers all over the world put their trust in STATEC BINDER every day. Expert consulting services, a high level of service competence and support for any concern provide reasons for this.

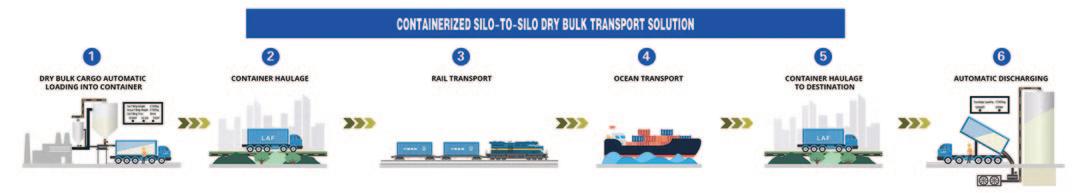

Qingdao LAF Technology Co., Ltd. is a manufacturer of economic dry bulk liners, manufactured using cutting edge production techniques. The company offers full-service and technical support covering every aspect in the course of dry bulk commodity shipment.

Container liners are economical solutions for free-flowing bulk cargo. The transportation distance of bulk cargo is usually very long and needs to be transported from one continent to another, so it makes full use of the advantages of containers. The liner will be installed close to the inner wall of the container, it makes full use of the space of the container, which is equivalent to forming another nested ‘container’ within the container.

Liners can be used very easily and flexibly in containers ranging from 20 feet to 40 feet. The dry bulk liners can be customized according to the requirements of the end user, as well as according to the loading and unloading equipment. The adapted liner bag can greatly improve the efficiency of loading and unloading. Before designing the container liner, Qingdao LAF Technology ensures that it understands the loading and unloading methods that will best meet the needs of its customer.

WHAT ARE THE BENEFITS OF CONTAINER LINER BAGS? v The major advantage of using container liners is that they are very easy to install and require up to one Image Copyright: Qingdao LAF. Technologies Co., Ltd.

v

v

v

v or two people to complete the installation process without investing too much time or effort. In addition, it only takes about one hour to fill the goods at place of departure or unload the goods at the destination. Compared with the traditional bags, it completely realizes the door-to-door transportation method: eliminating the links of traditional labour-intensive filling, moving to the warehouse, packing into the container, and unloading the container to the storage warehouse — in this way, it improves efficiency and saves logistics costs. In addition to the reduction of logistics links, using container liners in this way can secure the integrity of the goods and reduce cargo losses. Because of its excellent sealing and easy disassembly function, compared with bare loading in containers, the cargo residue will be much reduced after unloading from liner bag. As a package, it can protect the goods

v

v inside. Some dry bulk food commodities have strict sanitary conditions. In this case, the dry bulk container liner bag is used firstly because the liner bag itself can be a food-grade hygiene standard, the second is that it can effectively avoid the invasion of external environmental pollutants during transportation. In addition, it can play a role in moistureproof. For some goods that are easy to pollute containers, such as carbon black, the use of dry bulk container liners can prevent pollution of the container walls and crosscontamination with previously loaded goods, thereby reducing cleaning costs and improving the turnover rate of containers.

Is it possible for an FFS machine to pack cements & fine powders into plastic bags?

EXPLORING THE FFS MARKET Building, infrastructure and construction industries around the world rely on cement for its versatility and wide range of applications. It’s used in everything from small residential projects to massive industrial builds and experts predict that this year, global cement production will exceed four billion metric tonnes.

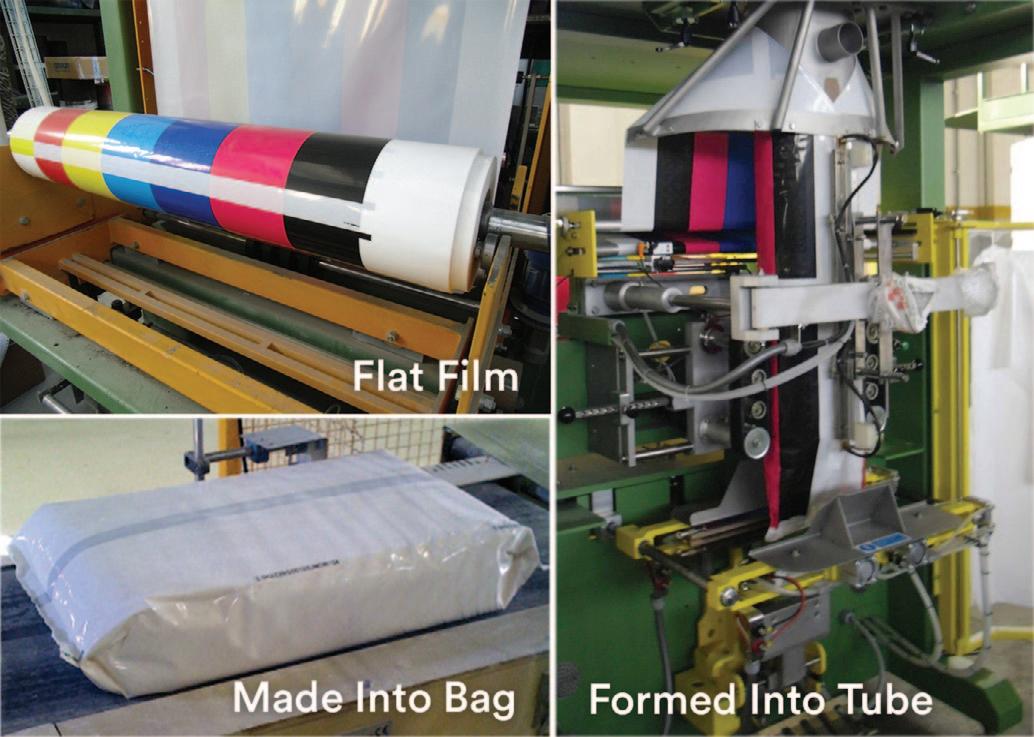

Customers that sell cement products and are looking for a new packaging solution might be considering purchasing a Form Fill Seal (FFS) packaging machine. Before doing so, it is important to know about this machine’s capabilities.

HOW SHOULD CEMENT BE PACKAGED? Paper bags and fabric sacks are popular materials for packaging cement, thanks to

their low cost and ease of use. However, they might not protect the product adequately or be a feasible packaging option when scaling up production volumes. With FFS machines becoming more widely adopted and packaging materials like polyethylene (PE) widely available, customers might wonder if this option is right for them. The following information details what factors should be taken into consideration.

Cement requires careful packaging to preserve its quality. It is vital to protect it from water, dampness or moisture to avoid triggering a chemical reaction that will harden it. It should also be packaged securely to keep it from rupturing and spilling.

By selecting the wrong packaging, it is possible that the end result would be a poorly performing or useless product . It’s important to remember that a moisture content of just 5% can render a bag of cement useless for construction — and if its packaging allows it to leak, it could lead to workers inhaling it unknowingly.

PACKING CEMENT USING FFS MACHINERY PE has become a popular packaging material as it’s cheap, accessible and can keep air and moisture away from the products it packages. Using it with an FFS machine could help package cement

products quicker and more efficiently.

Before making the switch, it is important to recognize that FFS machines have certain limitations. Cement is a fine and light powder and will need special treatment during packaging. FFS machines tend to trap air inside the packaging when dealing with lightweight and aerated powders like cement. This can cause it to burst or make each package bigger and more challenging to store and transport.

To circumvent this, some FFS machine manufacturers perforate the packaging material so air can escape. This solution might work in the short term but in time will allow atmospheric moisture to enter the packaging and ruin the cement.

A creative solution is required here. It is essential to work with an FFS machinery manufacturer that won’t just give a standard solution and will be willing to adjust the machine to the customer’s needs. An FFS system can integrate a combination of air blasting, deaeration or evacuation technology to keep cement hermetically sealed.

CHOOSING WEBSTER GRIFFIN As a specialist in FFS packaging machines, Webster Griffin can develop a solution for its customers’ businesses that saves time and money while keeping the integrity of the product intact.

Since 1975, Webster Griffin has provided businesses in locations ranging from Siberia to Saudi Arabia with packaging solutions. Whether customers need a palletizing unit to add to an existing arsenal or an integrated packing plant solution, Webster Griffin can help.

JEM INTERNATIONAL INC.

6873 Martindale, Shawnee KS 66218 USA Phone: 913‐441‐‐4788 www.JemBaggingScales.com

For all your Bagging Line Equipment Needs JEM International offers a complete line of gross and net weigh , openmouth bag filling machinery We also manufacture bag closing, bag positioning and bag transferequipment. We design and provide complete automatic systems from bag placement through palletizing and wrap

JEM International’s Product Line Includes ⚫ Surge Hoppers ⚫ Bagging Scales ⚫ Bag Hanger/FFS Machine ⚫ Conveyors ⚫ Sewing Pedestals ⚫ Heat Sealers ⚫ Manual & Robotic Palletizing Systems

The France-based company RBL-REI, a worldwide expert in the design, manufacturing and construction of bulk handling systems, is still proving its skills, particularly in terms of turnkey projects, capabilities and innovation for such challenging works. RBL-REI recently took the order to design two automatic big bag bagging lines for one of its port customers in France.

The first harbour company at La Rochelle in France has entrusted RBL-REI with the design and construction of two automatic big bag bagging lines. The contract includes all the complexities involved in this type of turnkey project, including: civil works, electricity/ automation works, dedusting systems, ATEX design, firefighting systems, commercial weighing systems, and so forth.

Each line has a capacity of 100tph (tonnes per hour), and has the capabilities to load different sizes of big bag — 500kg, 600kg, 800kg and 1,000kg. The system was originally, designed for fertilizer products, and the customer asked RBL-REI to also load cereals, biomass, etc. For this, RBL-REI has integrated ATEX equipment, dedusting systems, a good cleaning system and nonretention of product to prevent crosscontamination between the different products. In addition, all equipment has

full redundancy, allowing loading at a minimum capacity of 100tph. With this kind of installation, the customer has an installation that is flexible in complete correlation with its markets. DCi