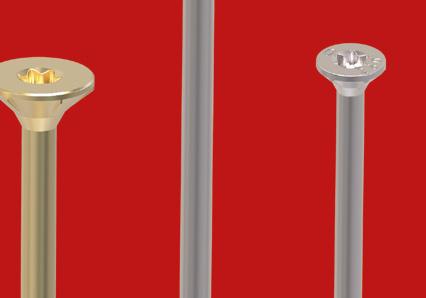

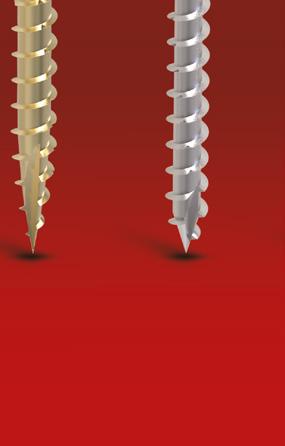

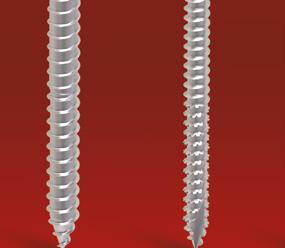

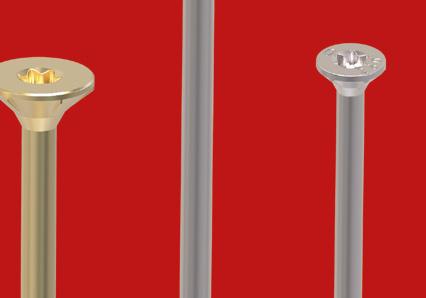

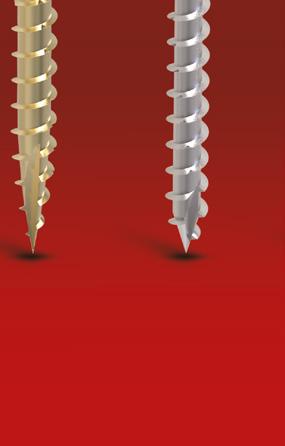

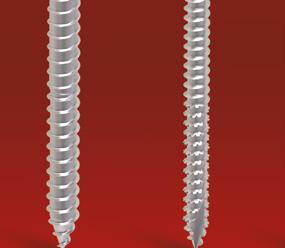

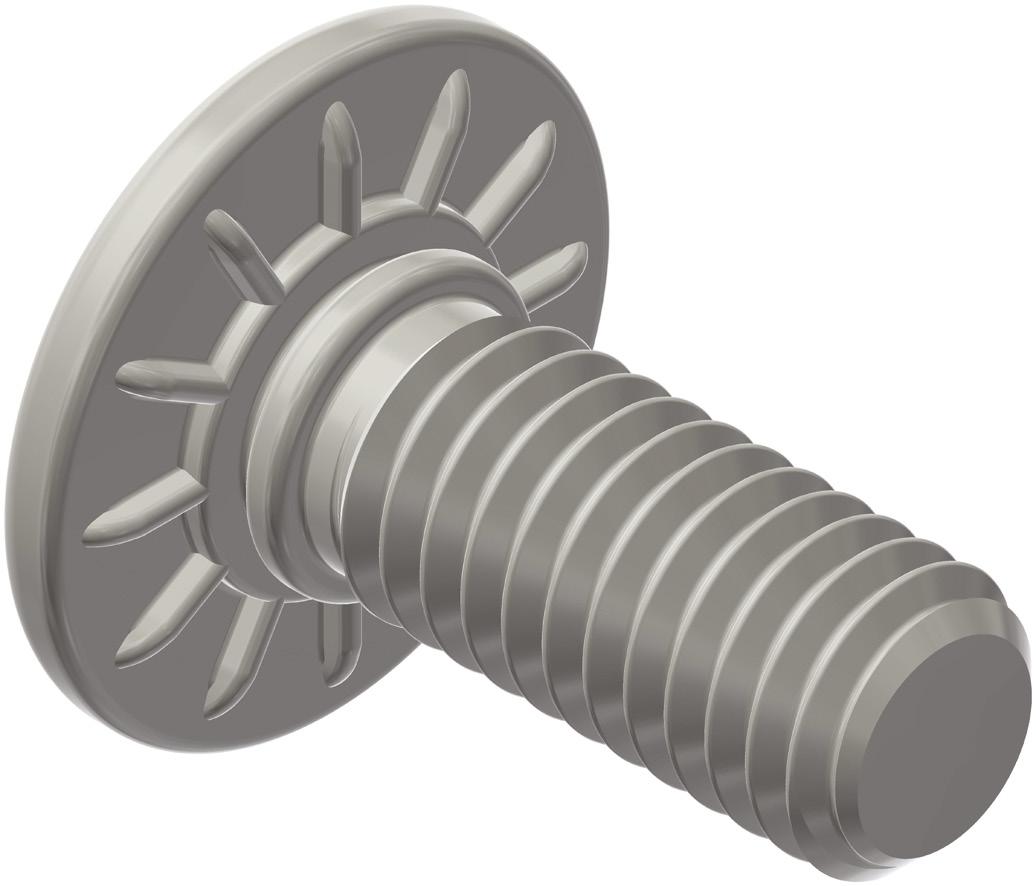

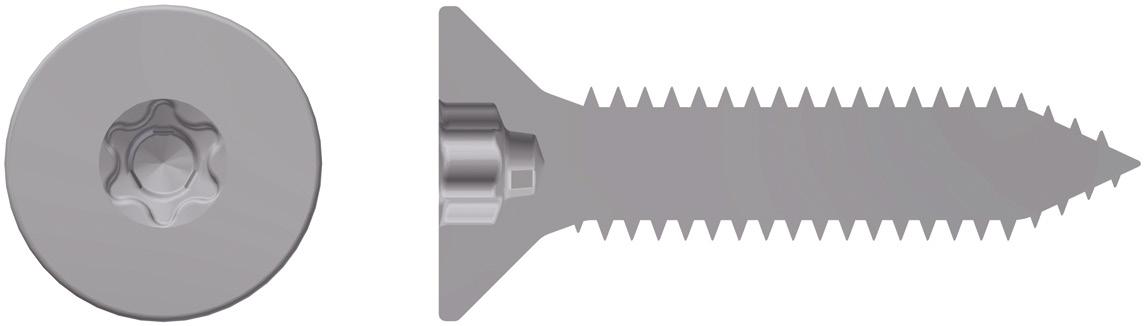

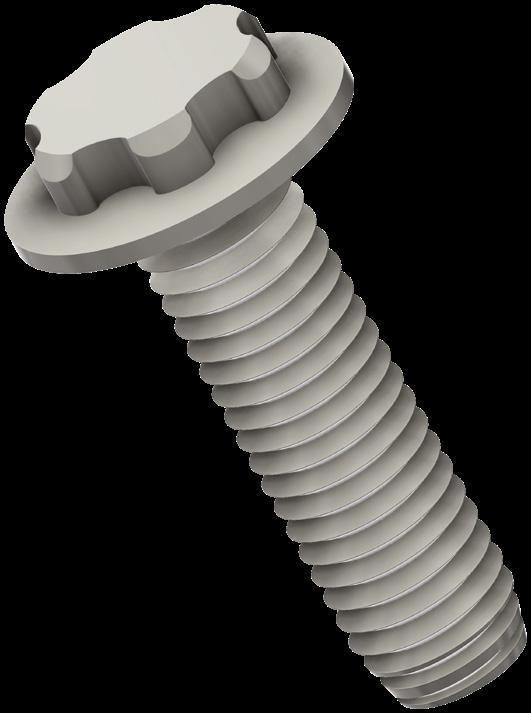

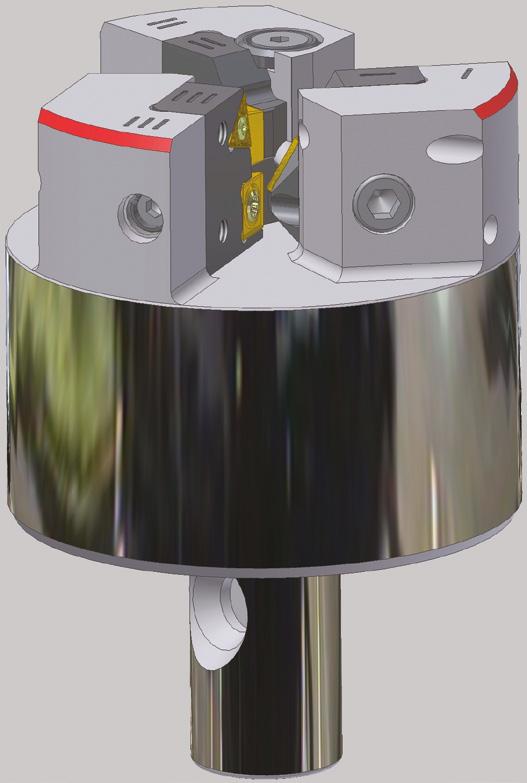

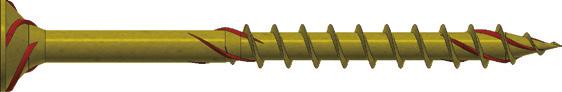

A durable and ecologically friendly woodscrew! The same bit for different diameters of woodscrews!

We believe in sustainability! The Hapax woodscrew with 4Top coating was designed with environmental consciousness in mind. The coating not only protects the screws but also ensures a longer lifetime, reducing the need for replacements and contributing to a greener, more sustainable approach to construction.

For pgb-Europe it is our daily aim to provide our customers with quality products and service to match. We have been an established supplier and manufacturer for fasteners and fixings for more than 60 years. It has been in our genes for 3 generations.

To save time and quickly find the correct screw bit, the recess for screw diameters 3.5, 4.0, 4.5 and 5.0 is unified to a Tx20 stick-fit recess. A free bit is included in each box!

Order now!

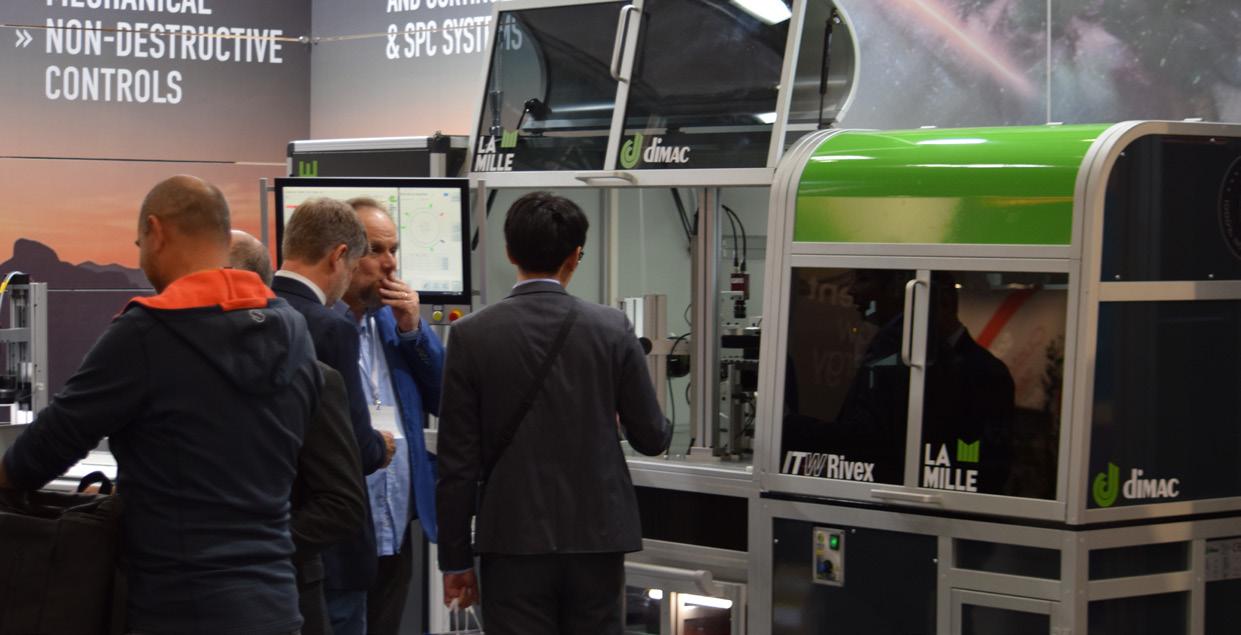

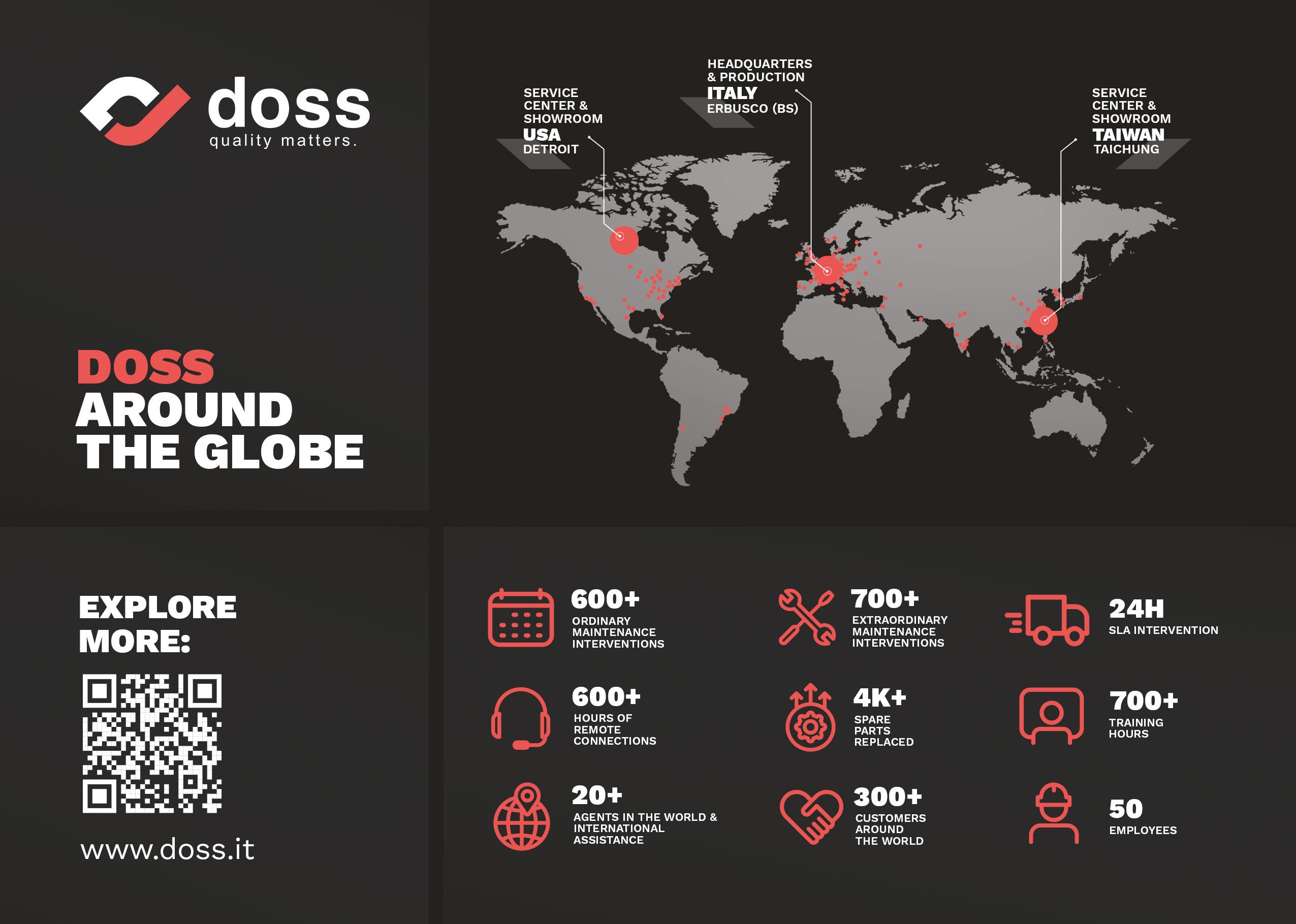

After attending the wire® Düsseldorf show in April I was reminded of the importance of a global reach and delivering quality leads and business opportunities.

Iam old enough to remember when the fastener machinery aspect of wire® Düsseldorf filled two halls, a far cry from the two thirds of only one hall it filled at this year’s show, with the remainder of the hall spring related technology. However, even with a smaller number of fastener related exhibitors, those that did exhibit reported a positive show – especially when it came to the international reach and the quality of the visitors.

It really does underline that there is simply no replacement for platforms that can deliver high-quality, genuine leads and business. As a magazine, with 25 years within the industry, it is the commitment to delivering valuable content to our readership and a ROI for our advertisers that continues to drive us forward.

A prime example of our ability to deliver this unique global insight is highlighted throughout the magazine, but especially in our Insight section – where we have news from the US, Japan, Germany, Italy, Ireland and the UK. Our Cover Story in this edition also focuses on ALFIRSTE, a Chinese manufacturer that specialises in the production of screws and anchors, with a reputation for its high-quality products and excellent service – with the company investing in new factories in Thailand, in order to continue to meet the needs of its customers when it comes to carbon steel products.

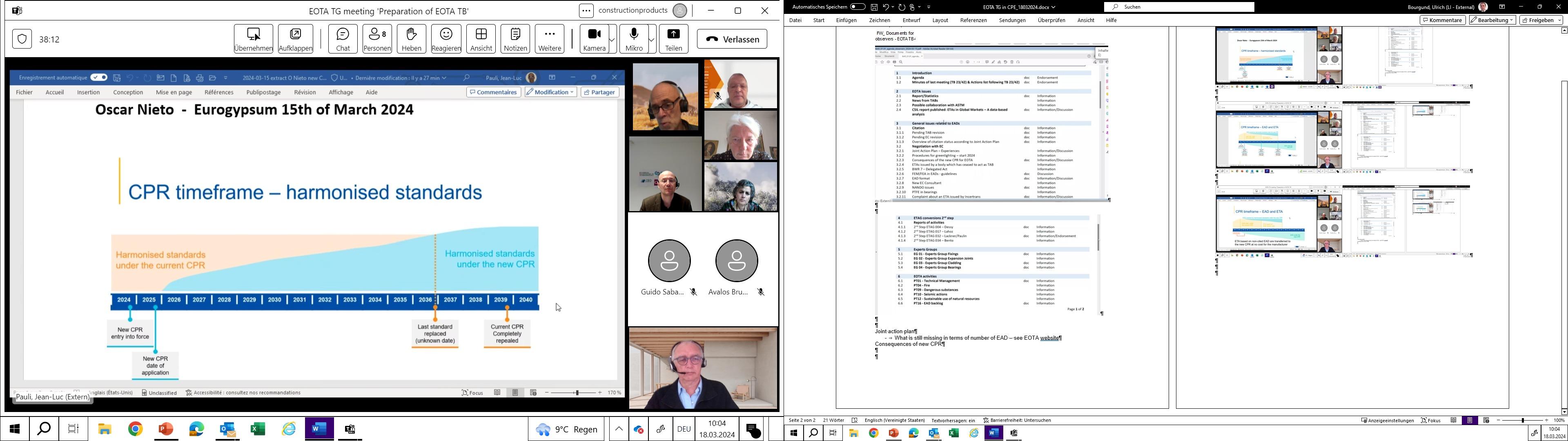

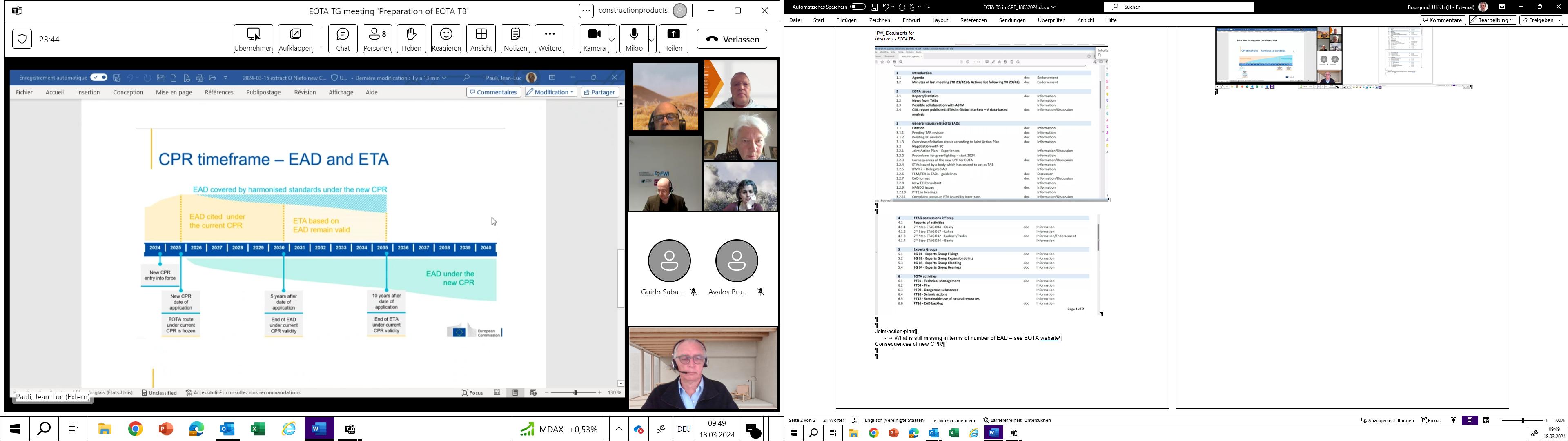

At the start of the Construction Fixings section, we have a thought-provoking article from Construction Fixings Europe that focuses on the planned concept and timeline for the transition from the existing Construction Products Regulation to the new

www.fastenerandfixing.com

Published by

Managing Director

Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director

Will Lowry will.lowry@verulammedia.com

Deputy Editor Claire Aldridge claire.aldridge@verulammedia.com

Assistant Editor

Rebecca England rebecca.england@verulammedia.com

Sales Director Mac Rahman mac.rahman@verulammedia.com

Business Development Manager –Italy

Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager –DACH & Europe

Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

version and the impact this could have on innovation within the construction sector.

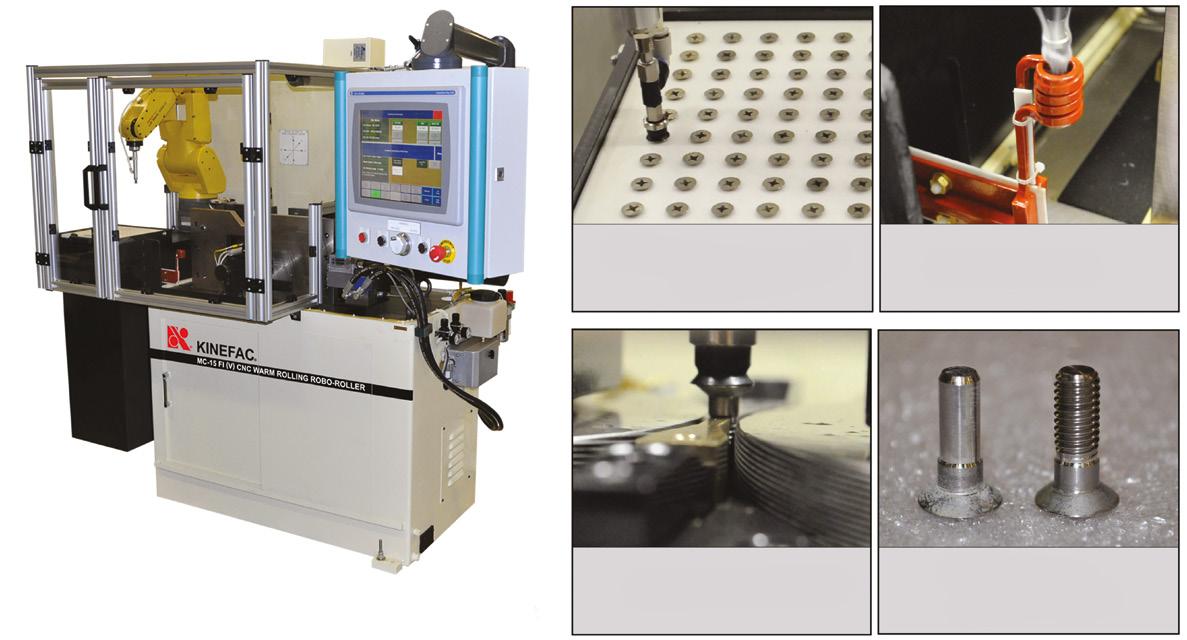

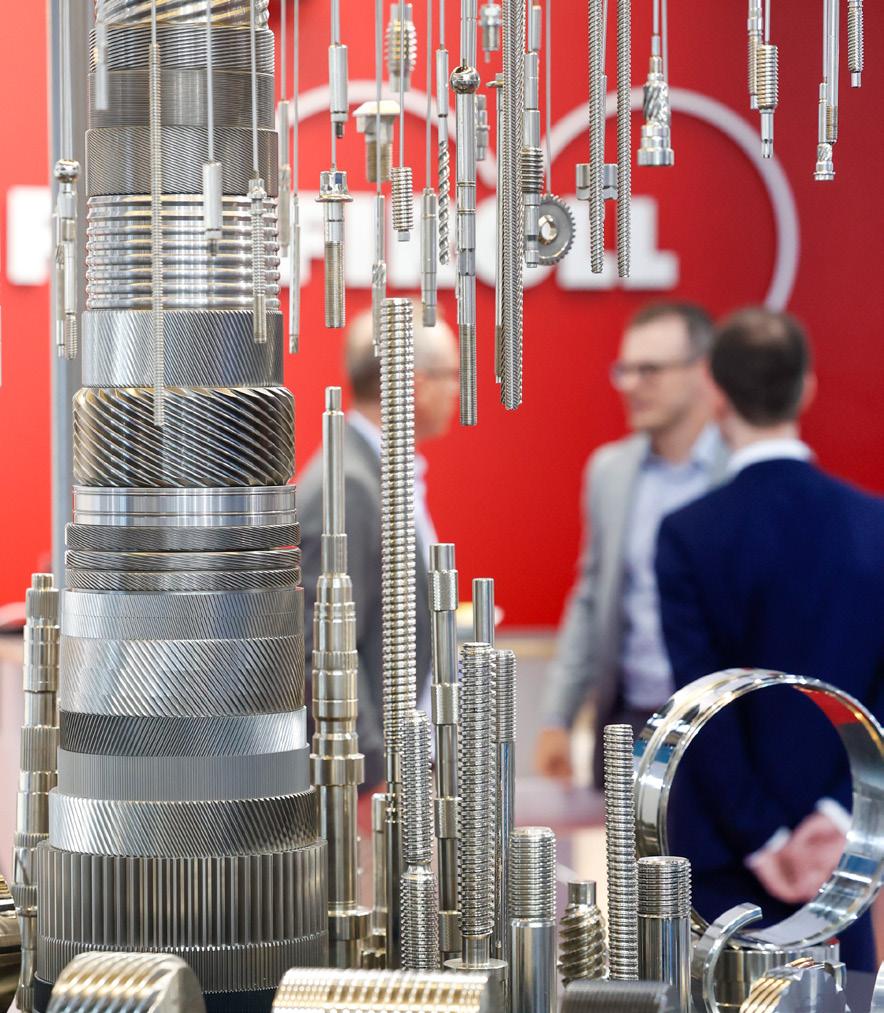

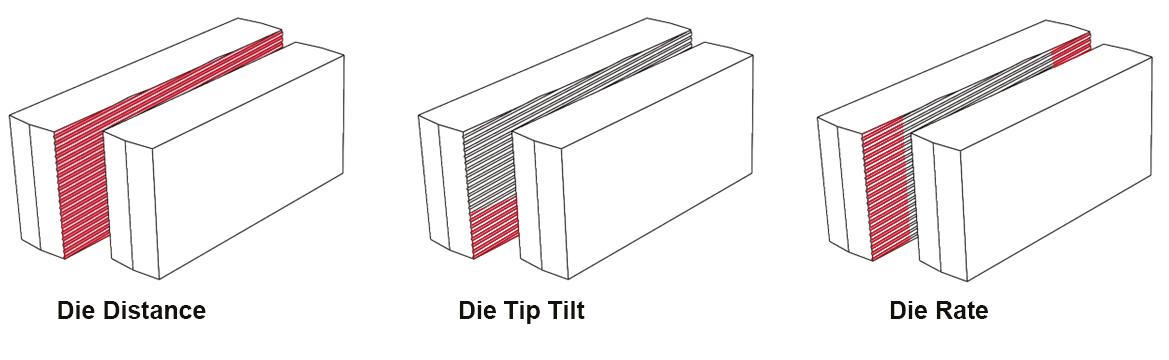

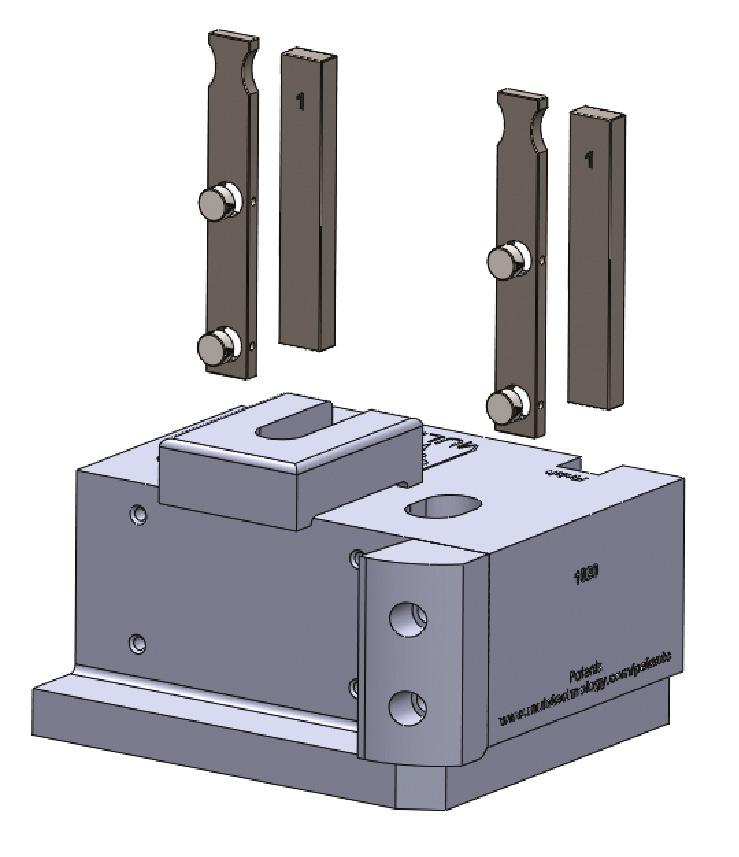

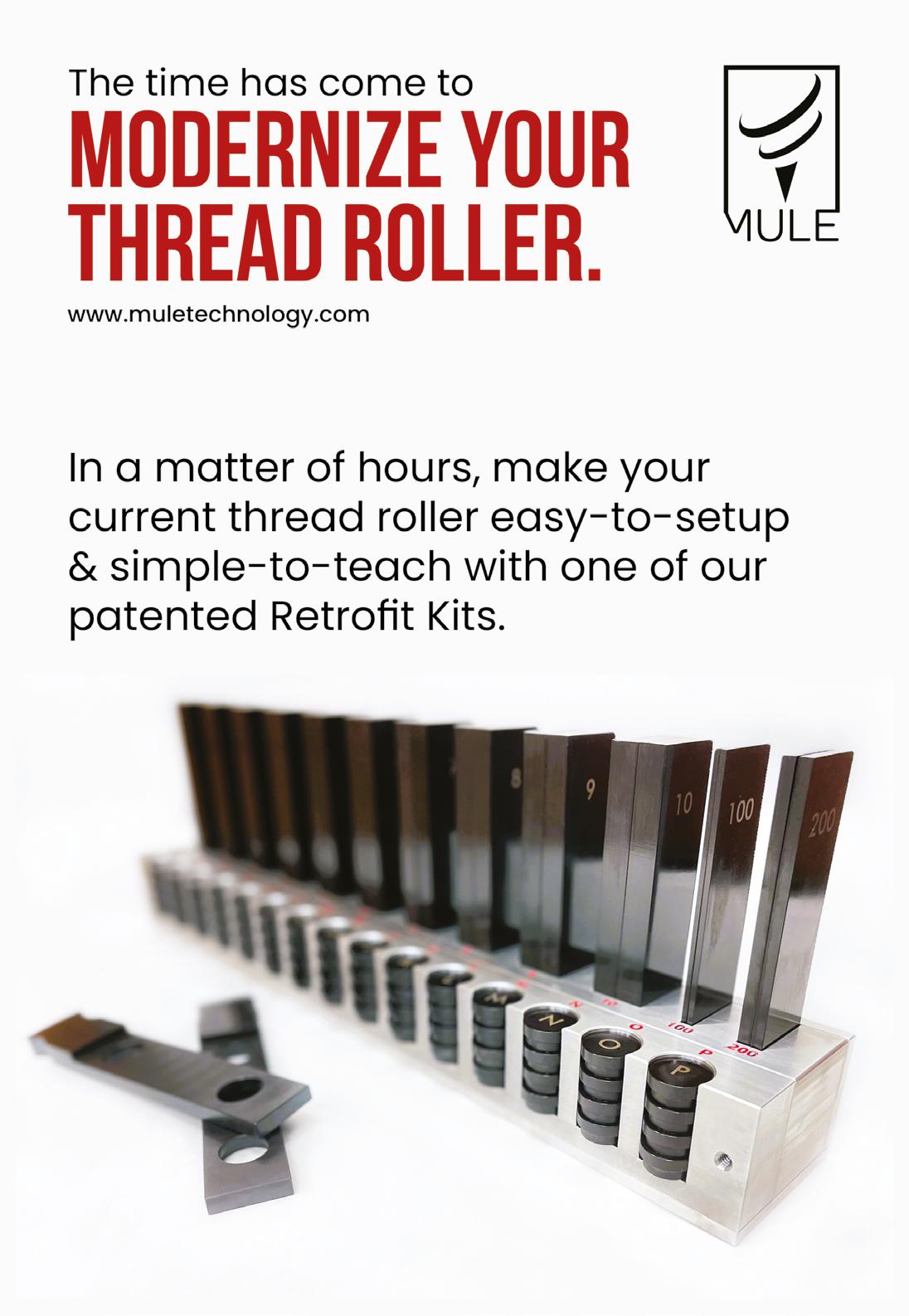

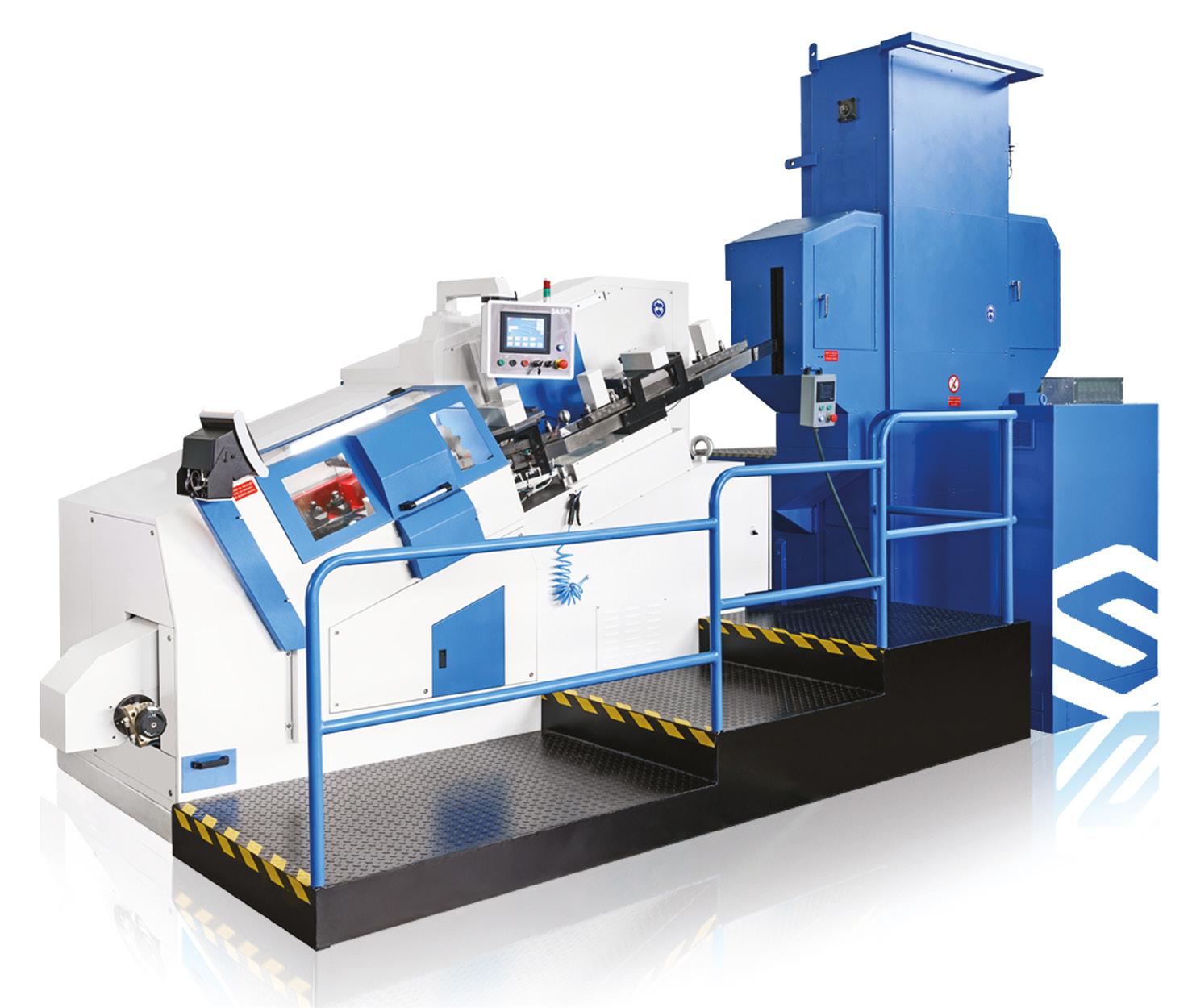

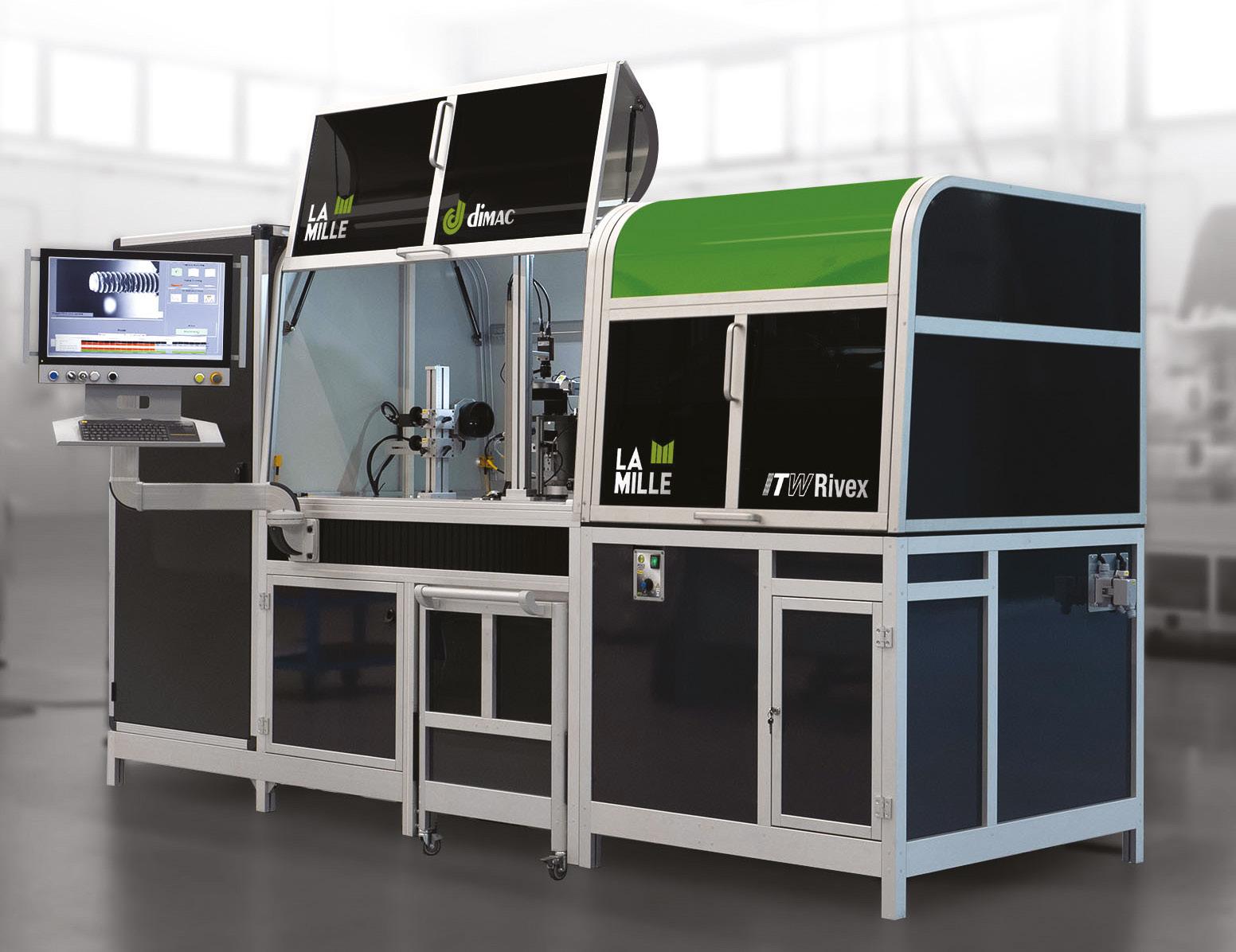

Within our Manufacturing Technology section, we have an excellent feature on threading, machining and secondary operations, which highlights some of the latest machines and developments within this area. This includes how SASPI is able to constantly reengineer and update its thread rolling machines thanks to a combination of decades of know-how and its significant R&D potential; SMART Machinery talks about its innovative technological solutions and how they can be applied to thread rolling machines; Mule Technology explains how it is revolutionising thread rolling set-ups; and UTA Auto Industrial underlines how its advanced assembly machines can help optimise production processes.

Also within Manufacturing Technology, NOF METAL COATINGS GROUP reports on how it is already in the process of planning for the potential ban by the European Chemical Agency on PFAS, based on REACH, with the company using it as an opportunity to align its technical requirements on a global scale.

To add to this there is also a special Business Intelligence feature within Management + Systems that highlights some of the latest software solutions available, which can provide insight and analysis in order for companies to make more informed business decisions. Within Application Technology there is also a marine feature that looks at the challenges and solutions when it comes to fastening in marine environments.

Fastener + Fixing Magazine is a dedicated, trade–only publication which is circulated freely throughout the European trade.

Disclaimer

The Publisher cannot be held responsible or, in any way, liable for errors or omissions, during input or printing of any material supplied or contained herein although the utmost care is taken to ensure that information contained is accurate and up to date. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or Verulam Media.

Copyright Entire contents copyright © Verulam Media Ltd 2024. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

Annual subscription (6 issues) to non–trade and outside EU is €200.00

Verulam Media Limited, Office 3, 17 Holywell Hill, St Albans AL1 IDT Tel: +44 (0) 1727 743 882

Find us online:

for

Part of the Mack Brooks Group

In the first quarter of 2024, Bossard Group recorded a decline in sales of 15.5% to CHF 257.4 million (prior year: CHF 304.5 million) in a continuously challenging market environment and as a result of the strong Swiss franc.

The decrease in local currency was 11.2%. In a quarter-on-quarter comparison, the record high comparative basis of the previous year is noticeable. As expected, demand in Europe continued to decrease, as it has since the second quarter of 2023. Sales declined by 12.2% to CHF 150 million (in local currency: -9.3%). Despite the challenging market environment, the first quarter saw continuing investments in future growth, additional efficiency and productivity improvements, including the successful rollout of the new ERP system in France.

Sales in America declined by 22.9% to CHF 65.8 million (in local currency: -18.4%). Since the record sales in the first quarter of the prior year, a normalisation of demand has been observed. With a decline in sales by 13.9% (in local currency: -5.2%) to CHF 41.6 million, weaker demand persisted in Asia as well. The appreciation of the Swiss franc was particularly noticeable in this market region. The continued two digit growth rates in India marked a gratifying exception, as Bossard benefited from nearshoring trends, a dynamic start-up landscape, and the above average growth in the focus industries of electromobility and electronics.

Based on current market observations, Bossard expects the economy to remain restrained in the first half of 2024. However, even this market environment also offers growth opportunities. Thus, the acquisition of new customers as well as the project pipeline make Bossard optimistic for the future. In addition, the continued trend towards nearshoring and the digitalisation of processes, with a focus on efficiency and productivity enhancements, further strengthens the demand for Smart Factory services in the current environment. The Group continues to stand by the communicated medium-term financial goals and the consistent implementation of Strategy 200.

Bulten Group has reported that net sales amounted to SEK 1.533 billion (€131.36 million) for the first quarter of 2024, an increase of 10.5% on the same period the previous year (2023: SEK 1.387 billion). Adjusted operating earnings totalled SEK 116 million, equating to an adjusted operating margin of 7.5%.

Bulten highlights that to achieve the strategic ambitions on the markets where it operates, and further increase innovative power, the organisation was restructured at the beginning of the quarter.

The new interdisciplinary regional structure is divided into three regions – Europe, Asia and North America – which were given responsibility for sales, manufacturing and financial results. There were also adaptations to the company’s engineering resources, in order to enhance product development and innovation.

“The year began with good sales and a sequentially improved operating margin. It is clear that efforts following the capacity challenges in Europe and the launch of a new regional organisational structure, combined with closer cost control, are starting to have an impact on financial results,” comments Christina Hallin, interim president and CEO.

“I am pleased to see the operating margin has improved on the three previous quarters, and it is satisfying too that our customer mix in automotive, along with sales in new customer groups, is contributing to stable growth. It is also worth noting that we have now had two consecutive quarters with sales in excess of SEK 1.5 billion. Again this quarter, our main priority has been to reduce the production backlog in Europe, which is adding extra costs. We have not yet caught up but have made good progress, and this can also be seen in the improved operating margin,” adds Christina.

LISI Group has achieved sales of €449.3 million in Q1 2024, up 12.5% compared to 2023. LISI AEROSPACE finished up 26.4% compared to the same period of last year, with LISI AUTOMOTIVE and LISI MEDICAL finishing down 1.2% and 6.9% respectively.

LISI AEROSPACE sales totalled €252.5 million at the end of the first quarter. Sales for Q1 in the ‘Fasteners’ business in Europe increased by 26.9% and in the US was up 22.7%, making it the strongest performer in the first quarter of 2024.

The ‘Structural Components’ business benefitted by the strong demand across the aerospace sector as a whole, with robust global air traffic levels resulting in strong aerospace market activity across all industry segments.

LISI AUTOMOTIVE’s annual revenue amounted to €157.3 million by the end of the first quarter 2024, down 1.2% on the same period the previous year. First quarter revenue was down by 0.6%, when adjusted for currency effects and excluding scope effects, which should be seen in the context of the 5.4% downturn in production for the division’s client base.

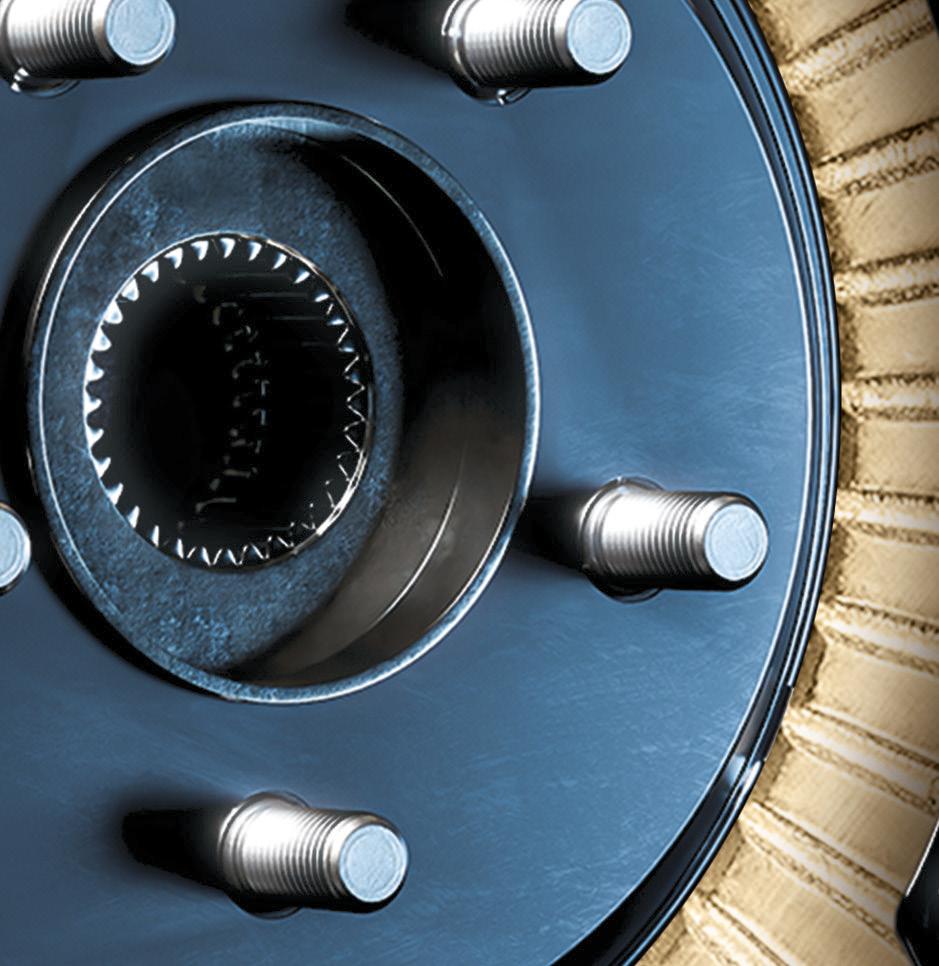

The structural change in the market is both technological and geographical with Chinese manufacturers, with whom LISI AUTOMOTIVE is forging relationships, taking market share. New product orders remain buoyant and largely follow the rapid developments in electric vehicle technology (powertrain and related systems) and new generation braking systems.

Finally, LISI MEDICAL’s sales revenue reached €39.7 million at the end of the first quarter 2024, down 6.9% on the same period in 2023 when it was at 27.7%. In addition to this negative base effect comparison, there was a one off adjustment to inventory levels. Manufacturing was also hit by a lack of raw materials. Sales revenue fell by 6.7%, when adjusted for exchange rate variations and excluding scope effects.

Despite a challenging market environment, NORMA Group still managed to achieve a robust margin in the financial year 2023. Thanks to increased levels of efficiency in production and logistics, the company achieved profitability at the prior year level despite a slight decline in sales.

Group sales in the 2023 financial year amounted to €1.22 billion (2022: €1.24 billion). The company achieved organic growth of 0.7% over the previous year. There was, however, a 2.4% burden on sales growth from negative currency effects in connection with the US dollar and the Chinese renminbi yuan. Overall, Group sales were down slightly, declining 1.6% compared to the previous year. Growth momentum came from business with joining technology for vehicles (Mobility & New Energy) in Europe.

What was at times weaker demand in key customer industries in America had a negative impact. In the first half of the year, business with water management products in the US was weaker due to extreme weather conditions. Strikes that took place and the subsequent production stoppages at major American automotive manufacturers had a negative impact on the automotive joining technology business.

“Despite the difficult market conditions, we achieved robust profitability that was in-line with our forecast. With our ‘Step Up’ improvement programme, we have succeeded in making ourselves more efficient and achieved an important interim goal. We will continue to systematically implement the programme and are now putting a stronger focus on additional growth opportunities. The recently completed acquisition of the Italian irrigation specialist Teco represents an important step forward in the expansion of our water management solutions business in Europe,” comments Guido Grandi, CEO at NORMA Group.

In the financial year 2023, adjusted earnings before interest and taxes (adjusted EBIT) totalled €97.5 million (2022: €99 million). The adjusted EBIT margin was 8% (2022: 8%). Earnings and margin were impacted by factors such as higher personnel costs. In addition to inflation related wage increases, there were additional expenses for extra shifts and temporary workers especially in the first half of the year to reduce production backlogs at European plants. Reduced material costs had a positive effect. Overall, more efficient management

of production and logistics capacities were key to achieving robust profitability. Especially in the fourth quarter, the adjusted EBIT margin of 8% was well above the level of the prior year (Q4 2022: 6.4%).

In the Americas region sales in 2023 declined organically by 4.5% year-on-year while currency effects reduced sales growth by an additional 2.4%. Overall, sales in the region reached €534.5 million (2022: €574.2 million), down 6.9% compared with the previous year. In the first half of the year, the US water business was weaker than in the same period of the previous year due to a weather related one off effect, but recovered again over the course of the year. Business with joining technology for industry applications declined. Sales of joining technology for passenger cars and commercial vehicles were also lower, partly as a result of strikes at US vehicle manufacturers that lasted several weeks.

In the EMEA region, sales in 2023 grew organically by 5.7%. Negative currency effects reduced growth marginally by 0.5%. Overall, sales in the region grew by 5.2% compared to the previous year to €514.7 million (2022: €489.2 million). The Mobility & New Energy business with joining solutions for cars with all types of drive systems increased significantly by 6.8%. In Industry Applications, sales rose by 0.6% thanks to improved product availability.

In the Asia-Pacific region, there was organic sales growth of 4% in 2023. Demand for joining technology from Chinese automotive manufacturers in particular increased compared with the previous year, leading to higher business volumes in the region. The sales increase was, however, offset by negative currency effects (-7.4%), meaning that sales in the region fell by 3.3% overall to €173.6 million (2022: €179.6 million).

Scell-it (UK) has expanded its presence in the UK by acquiring both Rivco Ltd and Kamtech Fasteners (ARK brand), strengthening its position as one of the leading distributors nationally of construction fixings, rivets, rivnuts and setting tools. This will further enhance the wide Scell-it (UK) Group brand range with names such as ARK, Huck®, FAR, RIVIT and Lobster.

Kidderminster-based Rivco was established in 1994 and is a longstanding player in the UK market, bringing an existing turnover of circa GB£3 million (€3.4 million) and a workforce of ten sales and warehouse staff. This acquisition complements the direction and vision of the Group’s growth strategy.

Kamtech Fasteners, based in West Bromwich, was established in 2015 and has a customer base that perfectly aligns with that of Scell-it (UK). This acquisition brings a further GB£1.5 million of turnover and four sales and warehouse staff to the newly formed Group. Steven Auld, the original majority shareholder of both acquired businesses, will continue with the Group in his new role as joint managing director, supporting the Group’s staff and customers.

Gary Moseley, joint managing director and one of the founding shareholders of Scell-it (UK), says: “We are thrilled to announce our acquisition of Rivco and Kamtech Fasteners, both businesses have

excellent reputations in the UK and align perfectly with the existing Group. From initial discussions it was clear that this acquisition would fit in perfectly with our existing culture and help strengthen our position in the marketplace.”

“These acquisitions reinforce Scell-it (UK) Group’s dedication to providing unparalleled supply at competitive prices to meet the precise needs of our customers. We will continue to look for opportunities to grow and Steven and I are excited to embark on this journey with both teams, leveraging our combined expertise to ensure a seamless integration for all involved.”

European partners, Scell-it SAS, based at the Group’s headquarters in France, echoes this growth vision. With established operations in Poland and Italy, it actively seeks further European acquisitions, propelling the total Group revenue beyond the current €50 million mark.

Nord-Lock Group, a global leader in bolting and engineering solutions, has announced Daniel Westberg as its new Chief Executive Officer. Daniel will assume his responsibilities as CEO on 1st August 2024.

Daniel comments: “I am honoured and excited to take on the role of CEO at Nord-Lock Group, a company with a rich legacy. The Group is on an exciting journey, and I look forward to unlocking new horizons and developing the Group and its four technology brands towards even greater success.”

For more than 20 years, Daniel has held various executive level roles within SKF Group and its different subsidiaries, both in Sweden and abroad, most recently Daniel served as president and CEO at Ewellix.

“The appointment of Daniel as CEO marks an exciting chapter for Nord-Lock Group and Latour. Daniel has proven to drive results and has consistently propelled the businesses he has led forward. With his international industrial background, strong commercial and technical understanding, Daniel brings a fresh perspective and strategic vision to the organisation,” says Johan Menckel, chairman of the board for Nord-Lock Group.

Daniel holds a master of science in mechanical engineering, and his strong technical acumen, along with a passion for innovation, has been instrumental throughout his career. Having lived and worked in Canada, Germany, and France, Daniel has an extensive global background. These diverse cultural encounters have brought enriched perspectives and provided valuable insights that Daniel now brings into his role as CEO at Nord-Lock Group.

First quarter revenues for Stanley Black & Decker reached US$3.9 billion (€3.6 billion), down 2% versus the previous year – as growth in DEWALT and Engineered Fastening was more than offset by lower infrastructure volume and muted consumer and DIY demand.

Donald Allan Jr, Stanley Black & Decker’s president and CEO, comments: “Our first quarter performance was the result of consistent, solid execution and continued progress against key operational objectives. We continue to see significant value creation opportunities tied to our strategic business transformation, and we remain focused on disciplined execution of our strategy. Looking forward, we expect mixed demand trends to persist across our businesses in 2024, and we are driving supply chain cost improvements designed to expand margins, deliver earnings growth and generate strong cash flow. At the same time, the long-term growth and market share gains we are focused on achieving, will be driven by introducing exciting new products within our most powerful brands – designed to deliver enhanced productivity for end users. We are funding growth investments intended to further accelerate innovation and differentiated market activation to capture these compelling long-term opportunities.”

He continues: “Stanley Black & Decker continues to become a more streamlined business, built on the strength of our people and culture, with an intensified focus on our core market leadership positions in Tools & Outdoor and Industrial. I am confident that by executing our strategy, we are positioning the company to deliver higher levels of organic revenue growth, profitability and cash flow to drive strong long-term shareholder returns.”

Patrick D. Hallinan, executive vice-president and CFO at Stanley Black & Decker, adds: “The actions we are taking to advance our strategic transformation are progressing successfully, and despite the tepid market backdrop so far in 2024, our profitability remains on an upward trajectory. We will continue our disciplined approach to cost management as we drive toward our target of 35% adjusted gross margins – while funding additional organic revenue growth investments. The organisation is focused on delivering margin expansion, cash generation and balance sheet strength, while working together to position the company for long-term growth and value creation.”

Owlett-Jaton has achieved certification to ISO 45001:2018, the Occupational Health and Safety Management System from the British Standards Institution (BSI), for its head office in Stone, Staffordshire.

ISO 45001 provides a framework to allow an organisation to proactively and continuously build and improve safety performance and culture to reduce risk. It demonstrates an organisation’s commitment to a safe, healthy and sustainable workplace. With a constant review and improvement process, established health and safety initiatives look to mitigate risks and improve operational performance.

“As a wholesaler, we understand our responsibility to protect the wellbeing of our employees and wider stakeholders. Our teams have worked hard to achieve accredited status. Attaining this global benchmark for occupational health and safety is a major achievement for all at Owlett-Jaton. Health and safety is always the first point on our agenda, and this accreditation recognises the team’s hard work

and dedication. We plan on continuing to improve how we operate,” commented Gareth Phillips, facilities and accreditations manager at Owlett-Jaton.

This is Owlett-Jaton’s third BSI certification, having already achieved certification to ISO 9001, the international standard for quality, and ISO 14001, the international standard for environmental management.

“We value our people and their health and safety is a priority. By ensuring our business meets the standards set out by ISO 45001 we can reduce risk and provide a safe working environment for all. The ISO 45001 accreditation is something we are very proud of as a business. We always strive to provide the highest standards of quality while maintaining the highest standards of safety and environmental responsibility,” adds Ian Doherty, CEO at Owlett-Jaton.

The Lesjöfors Group is increasing its global logistics network with the opening of a purpose-built distribution and sales centre in Haaksbergen, the Netherlands, to enable faster deliveries across Europe.

Lesjöfors Stock Spring Europe will service Lesjöfors’ extensive standard stock range across continental Europe, expanding the Group’s express delivery service already available in the Nordics. This latest investment is part of a strategic programme that has seen the Lesjöfors Group grow from a €250 million turnover company to €400 million in the last three years.

“Expanding our sales and distribution network into Europe is very exciting as we are now able to respond to customers’ demands for same day deliveries across our standard range of springs, gas springs, pressings, wire forms and adjacent products. Strengthening our market position in our rapidly expanding standard range, we’re

looking to this new logistics hub to secure our ambitions to be the number one supplier of quality standard items in the industry,” comments Ola Tengroth, CEO at the Lesjöfors Group.

Henrik Furhoff, head of business area standard at Lesjöfors Group, adds: “Our objective is to significantly accelerate the growth of our standard items across Europe and this investment is a crucial enabler for that. Our goal is to deliver the widest range of standard stock items, the best customer service and the fastest delivery. This new development continues the Lesjöfors Group’s ongoing expansion, enhancing our customers’ accessibility and convenience in our standard range.”

CELO, a global manufacturer of screws and fixings, has acquired Sistema Masa, a well reputed Spanish company renowned for its technical excellence and its innovative approach to the design, manufacture and installation of ventilated façade systems.

Sistema Masa was established in 1994 and has been designing and installing cutting edge systems for both national and international markets. With over 15,000 projects, Sistema’s international footprint extends to more than 50 countries, establishing it as a trusted partner for projects of all scales and complexities.

Both CELO and Sistema Masa were aligned in providing high-quality and time saving solutions that reduce overall costs. In fact, the new acquired portfolio includes six CE-certified façade mounting systems, as well as a premium products range that delivers remarkable efficiency gains in installation time, outpacing competitors in the industry.

To cope with an increasing demand for complex requirements in terms of sustainability, safety, protection, efficiency, and aesthetics, CELO Façades Technology will become CELO’s unit to support planners, architects, builders and façade contractors in developing building envelopes with market expertise, high-quality product systems, with a full customer service approach. Also, all systems related to structures for ventilated façades will use the commercial brand ‘Masa Ventilated Façade Systems’ as a guarantee of quality and heritage.

The acquisition of Sistema Masa not only contributes to increasing CELO’s business activities and offerings toward new business areas but also supports its commitment to promoting sustainable construction practices that meet the increasing demand for energy efficient buildings.

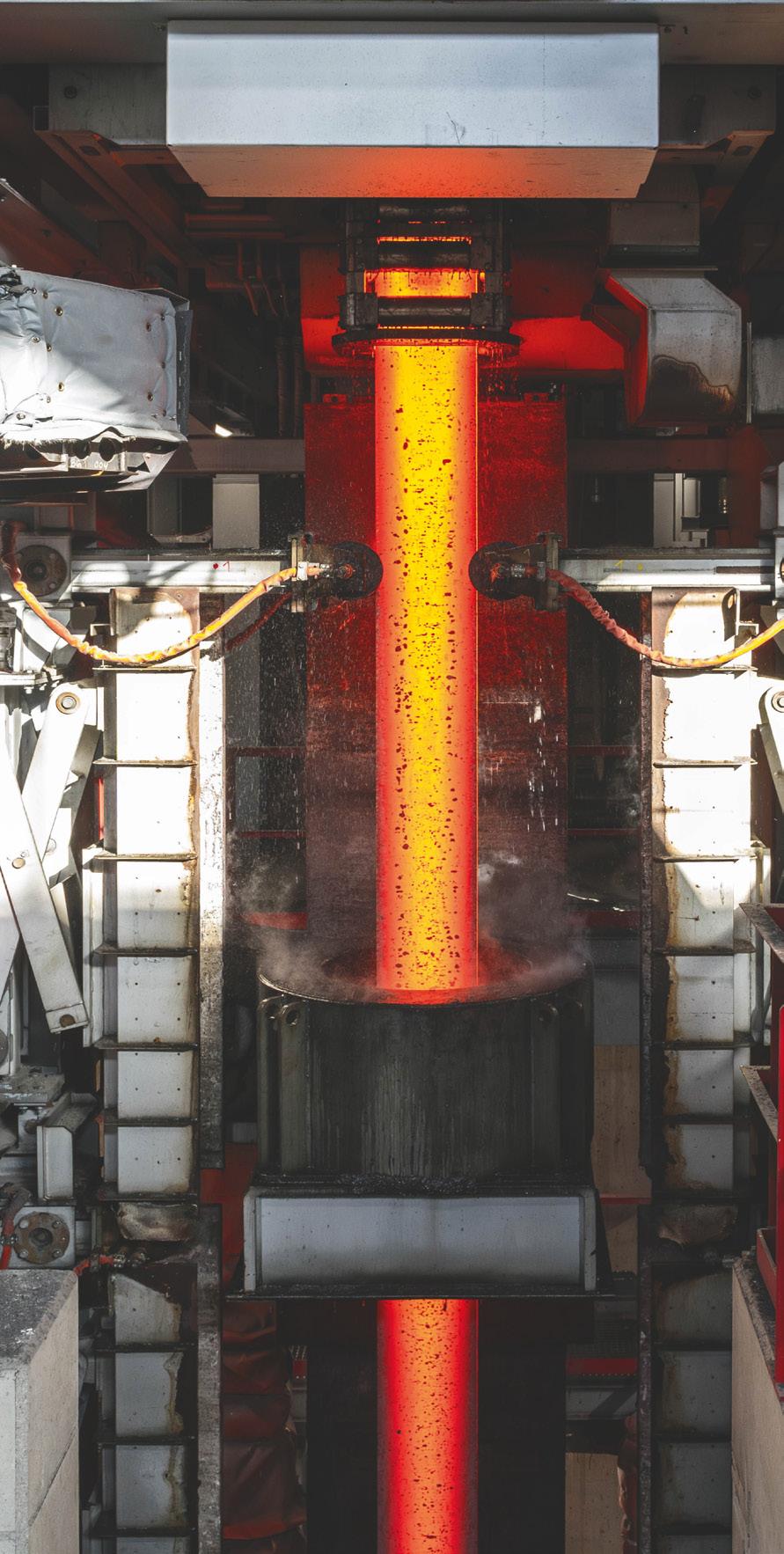

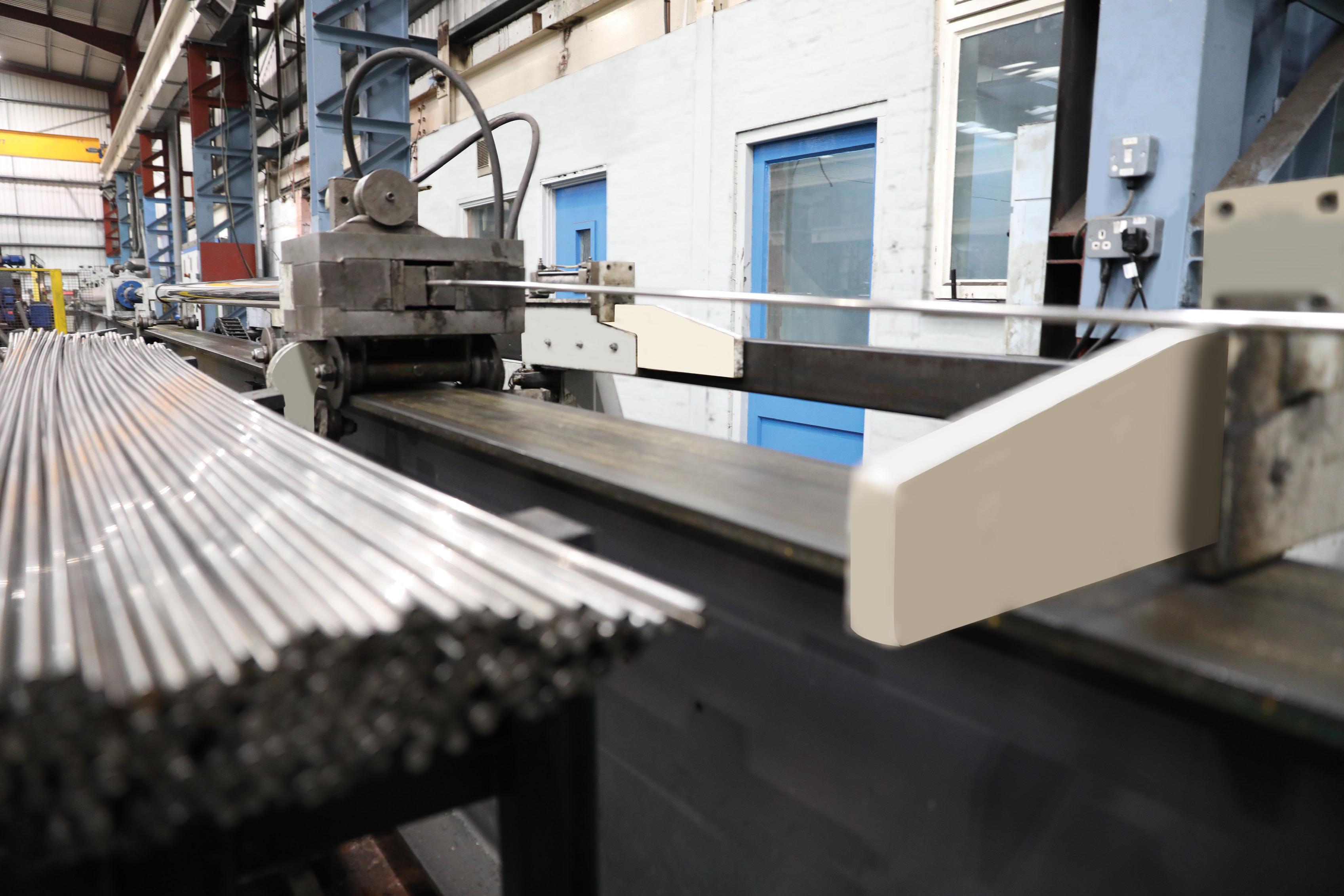

voestalpine has melted the first high-quality ‘green’ wire rod from hydrogen reduced pure iron and scrap at its site in Donawitz, Austria.

The hydrogen reduced pure iron was produced in the Hyfor pilot plant, while the landmark melting was carried out in the Group’s own Technikum Metallurgie research facility – a unique, small but complete, steel plant. The CO 2 reduced steel was further processed in the wire rod mill to produce roller bearing steel, which is characterised by its particular hardness and wear resistance. The production of high-quality, CO 2 reduced steel grades is one of the biggest technological challenges in the transition to ‘green’ steel production.

greentec steel is an ambitious and feasible phased plan with which voestalpine can make a valuable contribution to achieving the climate goals. “We have already made a successful start on our path to ‘green’ steel production and are advancing quickly with the construction of two arc furnaces powered by ‘green’ electricity in Linz and Donawitz. Parallel to this, we are researching various breakthrough technologies with partners from industry and science. The first ever melting of hydrogen reduced pure iron and its further processing into high-quality wire rod is a historic milestone,” comments Herbert Eibensteiner, CEO at voestalpine AG.

Hyfor is a joint research project of Primetals Technologies, voestalpine, Montanuniversität Leoben and K1-MET, with the goal of researching the use of hydrogen to reduce fine iron ore. In the future, the resulting hot sponge iron could be melted down in an electric arc furnace or used to produce hot briquetted iron (HBI).

“The Technikum Metallurgie provides us with an ideal test environment to quickly adapt our steels to the needs of our customers and to changed market requirements. I am very pleased that we are now also doing pioneering work in ‘green’ steel production and would like to thank all the researchers and employees for their commitment,” states Franz Kainersdorfer, head of the metal engineering division and member of the management board at voestalpine.

At the Technikum Metallurgie, voestalpine is conducting research into the production of new high performance steels, for subsequent processing into special rails, high-quality wire rod, as well as heavy-duty oil field pipes. The product development involves a CO 2 reduced route – the input material is melted using electricity from renewable energy sources.

In a first step from 2027, voestalpine will reduce its CO 2 emissions by up to 30% by partially replacing its current coal-based blast furnace technology with electric arc furnace technology – powered by ‘green’ electricity. This represents almost 5% of Austria’s entire annual CO 2 emissions, making greentec steel the largest climate protection programme in Austria.

The Group is aiming for carbon neutral steel production by 2050 and is researching intensively on several new processes, as well as investing in pilot projects that explore new pathways in steel production.

4PS by Hilti, a software supplier for the construction industry, is continuing its international growth course with the launch of 4PS Construction Software AB in Sweden. A team of dedicated experts will support the Swedish construction industry in digitising, optimising and automating business processes from Gothenburg.

Founded in the Netherlands in 2000, and part of the Hilti Group since 2023, 4PS is a leading player in the Dutch market and has since expanded its operations to the UK, Belgium and Germany. With more than 70,000 daily software users, 4PS has built a strong reputation for its in-depth expertise in the industry. This launch in Sweden confirms 4PS’ ambition to become an international market leader as a digitalisation partner for the construction industry.

“The start of 4PS in Sweden is a great opportunity for us to support the construction industry in Sweden with our innovative software solutions. We are very pleased that, strengthened by the Hilti Group, we can focus on realising our international growth ambitions. This launch in Sweden brings 4PS and Hilti closer to the goal of becoming the leading digitalisation partner in Europe,” comments Johan Bakker, director sales and marketing at 4PS.

“Our Cloud software solutions enable construction companies to make their business processes more efficient and sustainable. With 4PS, the Swedish construction industry can rely on software solutions from a supplier with a long-term orientation and a strong commitment to innovation,” adds Paula Middelkoop, director of product and development at 4PS.

A team of experts from 4PS International will accompany the start-up in Sweden and build a local team to support the Swedish construction industry in further digitalisation from Gothenburg.

Hafren Security Fasteners is commemorating 25 years of exceptional dedication and invaluable service from its esteemed colleague, Mike Williams – a significant milestone for a valuable member of TeamOrange.

Since joining Hafren on 3 rd May 1999, Mike has been a committed pillar of the organisation, embodying the company’s core values and mission of ‘stamping out the impact of theft globally’. Mike’s journey with Hafren Security Fasteners has been nothing short of remarkable. His unparalleled attention to detail and unwavering commitment to accuracy have made him an indispensable asset to warehouse operations.

“As the mastermind behind our warehouse organisation, Mike has meticulously ensured that every aspect of our environment thrives under his care, setting the gold standard for efficiency and excellence,” comments Hafren.

Beyond his professional achievements, Mike is also a passionate cycling enthusiast and a courageous cancer survivor, embodying resilience and determination in every facet of his life. His ability to overcome challenges with grace and perseverance serves as an inspiration to us all.

“On this momentous occasion, TeamOrange extends our heartfelt gratitude to Mike for his unwavering dedication, loyalty and support over the past 25 years. As we reflect on his remarkable journey with us, we are filled with immense pride and gratitude for the invaluable contributions he has made to the success of Hafren. Looking ahead, we are confident that Mike’s expertise, leadership and unwavering commitment to excellence will continue to shape the future of our organisation for many years to come. As we raise our glasses in salute, here’s to more years of ‘stamping out the impact of theft globally’ alongside our esteemed colleague.”

Harrison & Clough has appointed Malcolm Becker as national development manager, bringing with him over 30 years of experience to strengthen customer relationships and build product ranges to be supplied across the UK.

Beginning his career with Harrison & Clough as a warehouse operative 28 years ago, Malcolm quickly progressed through the business into a sales position as a product demonstrator and then up to head of product management. Malcolm has gained considerable experience across a variety of roles that involve having hands-on logistic, supply chain and key product expertise. After a brief stint away from Harrison & Clough, Malcolm seized the opportunity to return to his new role.

He now plans to apply his holistic knowledge of the fastener market, work closely with business development teams, expand product lines, and enhance merchant knowledge of its products with a particular focus on Metalmate®

“By leveraging my three decades of experience within the fastener and fixing industry, I plan to pass on my product expertise

to our merchants, better familiarise them with the specifics of our products and help them to boost customer satisfaction and ultimately drive sales. Whilst I plan on strengthening relationships with existing accounts and expanding on those opportunities, I will also jump on new market research to identify the most efficient routes to market,” says Malcolm.

Malcolm strives to solidify new and expanding ranges of fasteners and fixings by applying his product expertise to best match items to suit client needs. Mark Dorrington, business development director at Harrison & Clough, adds: “Malcolm’s long-term understanding of Harrison & Clough sets him to be a sales driving force. I am excited about the growth of our sales team and the wealth of expertise Malcolm will contribute to our collective knowledge.”

Sonderteile / Sonderwerkstoffe

by Jason Sandefur, editor/publisher, GlobalFastenerNews.com

by Jason Sandefur, editor/publisher, GlobalFastenerNews.com

Passengers aboard an Alaska Airlines plane that made an emergency landing after a Boeing fuselage panel blew off this year, have started to receive letters from the US Federal Bureau of Investigation identifying them as possible victims of a crime, Reuters reports.

The move indicates that the US Justice Department’s criminal investigation into Boeing is ramping up. “As a victim specialist with the Seattle division, I’m contacting you because we have identified you as a possible victim of a crime,” reads the letter from the FBI’s Seattle office. The letter says the incident is under criminal FBI investigation but adds that such inquiries can be lengthy and that “for several reasons, we cannot tell you about its progress at this time”.

The catastrophic failure occurred 5th January 2024 when a door plug blew off a new Alaska Airlines Boeing 737 Max 9 at 16,000 feet, imperilling 171 passengers and 6 crew members. The National Transportation Safety Board determined that the door plug was missing four bolts meant to secure it in place. However, a month after the NTSB determined that the bolts were missing, the agency is no closer to questioning any of the 25 door crew employees involved.

“To date, we still do not know who performed the work to open, reinstall, and close the door plug on the accident aircraft,” NTSB Chair Jennifer Homendy stated. “Boeing has informed us that it is unable to find the records documenting this work. A verbal request was made by our investigators for security camera footage to help obtain this information; however, they were informed the footage was overwritten.”

The seasonally adjusted Fastener Distributor Index bounced back to growth in February 2024 with a reading of 50.5 amid stabilizing demand. Following solid month-over-month improvement in January, the FDI saw further modest sequential improvement in February.

When looking at the underlying drivers, the FDI paints a slightly more mixed picture as three of the four components (sales, employment and customer inventories) were stable to lower from the previous month. Only the supplier deliveries index improved, which drove the overall month-over-month improvement in the headline FDI.

Looking at the sales index, 31% of respondents indicated sales came in above seasonal expectations, which was down versus the 44% in January, but essentially matched the 30% average over the past year.

The Industrial Fasteners Institute has elected Dan Curtis of MacLean-Fogg Company to lead the board as chair, along with Larry Spelman of J.H. Botts LLC as vice-chair and Gene Simpson of Semblex Corporation as ex-officio chair.

Founded in 1931, the Industrial Fasteners Institute (IFI) represents North American manufacturers of mechanical fasteners and formed parts –who are key suppliers to customers, government and the public –with IFI looking to advance the competitiveness, products and innovative technology of member companies.

New division chairs included Division I: Industrial Products – Chair Attsie Hashimoto, Unytite Inc; Division II: Aerospace Products – Chair Doug Carlton, Click-Bond Inc; Division III: Automotive Products – Chair John Medcalf , Agrati Inc; and Associate Suppliers Division: Chair Herb Gottelt, Metal Resource Solutions.

indfast.org

The Fastener Training Institute (FTI) has announced Birmingham Fastener will sponsor its two remaining Fastener Training Weeks in 2024 – the next being in Chicago, Illinois, from 19th – 23rd August and the final one in Cleveland, Ohio, from 18th – 22 nd November.

FTI is the leading non-profit provider of fastener product and technical training and expertly instructed courses. FTI’s flagship training, Fastener Training Week, is a week-long program dedicated to enhancing fastener knowledge across the industry, recognizing those who complete the course and pass a final exam as a Certified Fastener Specialist™. The week includes hands-on exercises, case studies, networking opportunities, learning labs, as well as plant tours to witness all stages of the manufacturing process.

Jo Morris, marketing director at FTI, commented: “Birmingham Fastener’s mission to provide customers with quality products aligns with our commitment to train the industry that uses them. We are thrilled to have its support.”

Birmingham Fastener, based in Birmingham, Alabama, is a leading manufacturer and distributor of fasteners. “With 16 locations from New York, to California, to Mexico, our company is fortunate to have the very best team and best customers in the industry. Our heavy foundation in manufacturing, and broad offering in distribution, have allowed us to become a renowned partner for companies in the Americas. We are forever indebted and will always be supportive of the fastener industry, as it is who we are at Birmingham Fastener,” says Rodney Holmes, vicepresident of sales for Birmingham Fastener. “Fastener Training Institute is dedicated to keeping our industry safe with robust training and Fastener Training Week is the pinnacle program, which develops the ‘best of the best’ fastener professionals. We are privileged to provide support.”

Fastenal Company reported fastener sales improved in February 2024, falling 3.5% to US$198.2 million (31.6% of overall sales) compared to a 6% decline in January. A year earlier, February fastener sales increased 8%.

Total February sales gained 7.7% to US$627.1 million (€582.5 million). Daily sales improved 2.6% to US$29.9 million. Sales in the US grew 2.4% to US$524.9 million, while sales in Canada and Mexico increased 4.8% to US$83.4 million.

Sales to heavy manufacturing customers rose 3.1%, with sales to non-residential construction customers falling 3.4% during February. Fastenal’s full time workforce increased 3.9% during the month to 20,999 employees. Distribution/transportation personnel grew 6.6% to 3,226, while manufacturing personnel declined 0.3% to 704 workers.

Boeing CEO Dave Calhoun said it could take until the end of 2024 to iron out sector wide supply chain problems that have hampered global jetliner production – with his projection echoing comments by Guillaume Faury, chief executive at Airbus, who told France Inter that production would regain pre-pandemic levels at the end of 2024 or even in 2025.

Referring to Boeing and its main European rival Airbus, Calhoun told the Qatar Economic Forum that “priority one for the two airplane manufacturers is stability. We have to resolve the supply chain issues and the surprise associated with it; and we have to resolve it once and for all.”

Calhoun added: “That is not a short-term job. It sounds like it might be, but I think it could take all of this year and probably all of next year.” In April Calhoun had reported progress in tackling the supply chain and repeated November guidance that “significant supply chain improvement” was unlikely “until well into 2024”.

Despite the overall pattern of disruption, Calhoun said that he did not think recent manufacturing problems with the bestselling 737 narrow body jet would defer those production schedules for more than “maybe a month or a month and a half”.

On future developments, Calhoun said the industry was unlikely to introduce all new jet designs before the mid-2030s. “I think in our industry, because of some of the constraints both in propulsion and the design of the wing, it’s going to be at least until the mid-2030s before we – in this case I’m just going to assume my competitor – will call out that airplane. That is not a short-term job.”

Under the leadership of President Jimmy Chang and General Manager Henry Chang, Special Rivets Corp has celebrated its 40th anniversary with a new plant in Thailand – called Apex International (Thailand) Co Ltd – representing a new chapter in the Group’s rivet production line layout and global business map.

With an average monthly production of 500 million blind rivets and 100,000 riveting tools, Special Rivets Corp (SRC) is one of the most representative and influential companies in the Taiwan fastener industry. Because of this knowledge, SRC recognised Thailand as a major production centre for the south-east Asian automotive industry. In order to serve more international fastener demand, SRC selected the East Coast Industrial Park in Chonburi to build a new 45,000m 2 factory.

The inauguration of phase one was held at the end of October 2023, with more than 160 important guests from Taiwan, China, and Thailand, as well as local officials, attending the ceremony. The new factory houses two new heat treatment furnaces, fully automatic plating equipment, as well as 1,500m 2 of office space to offer employees a more comfortable and efficient working environment.

“Our development goal is not only to make the Group bigger, but also stronger,” explains President Jimmy Chang. “Since our establishment, SRC has been aiming at exporting to the world and actively cooperating with major global suppliers to create a ‘win win’ situation. On the other hand, under the wave of globalisation, we’ve been developing many emerging markets, where customers are looking for trustworthy brands. SRC with its 40 years of reputation, combined with the price competitiveness generated from scale manufacturing, has made us the preferred choice in these markets.”

Automotive fastener company Spec Products, with its plant located in Sinji Industrial Park in Tainan City, is aiming to be the first screw factory in Taiwan to enter into Smart manufacturing – with the company also recently debuting on the Emerging Stock Board (ESB) of the Taipei Exchange (TPEx).

Expected to be in partial mass production by the end of this year, the second phase will aim to increase Spec Products’ self manufacturing rate from 15% to 30% within 2 – 3 years.

The company has also recently acquired a new 13,408m 2 piece of land, which is now under construction in Sinji Industrial Park to drive the operation and development in the next 5 – 10 years. The Sinji plant has a land area of 5,950m 2 and a floor area of 6,942m 2 and will also introduce Smart manufacturing – where raw wire rods go in and come out as finished fastener products. This plant will also use ‘Smart’ transportation vehicles.

The cost of the land in Sinji Industrial Park was approximately NT$240 million (€6.9 million) and the cost of building the Sinji plant is approximately NT$200 million. The plant is expected to be fully

operational next year or the year after, but the company is already testing machines and has already recruited staff.

“As a business we mainly produce screws of special specifications, at small volume, which are suited for Smart manufacturing. On top of that, the Sinji plant is located near leading semiconductor factories, which makes it harder for us to recruit manpower, so if we do not turn to Smart manufacturing, it will be extremely difficult to expand production. We will also introduce Artificial Intelligence to manage production. In addition, fastener production and profits mainly depend on dies, but our operators of the first generation are 60 years old. We hope to use AI to assist in developing and designing dies and retain our technical know-how,” comments Mr Hung-Chen Chang, president at Spec Products Corp.

In order to facilitate communication within the Taiwan fastener industry, and to discuss the current market situation, as well as its challenges, Taiwan CSC – the largest wire supplier to Taiwanese fastener manufacturers –held a ‘Production and Sales Meeting for Q2 2024’ on 5th March in Gangshan, Kaohsiung, Taiwan.

TIFI Chairman Tu-Chin Tsai put it bluntly in his opening speech that the current overall market situation can be said to be very poor.

Many fastener companies around the world are experiencing a squeeze on profits due to regional conflicts – such as the war between Israel and Hamas, as well as the war between Russia and Ukraine – and the higher costs caused by the USA’s 25% tariff on certain steel and aluminium products from China.

Many orders for small screws initially made out to Taiwan have been taken over by Chinese or Vietnamese companies, making a difficult situation for Taiwanese manufacturers. Under these market conditions, Chairman Tsai hopes that when Taiwan CSC announces its prices for next quarter, it will take into account the fact that it is already very difficult for the industry to receive orders and refrain from raising prices if it can.

In addition, in terms of the global industry’s most discussed trends of ESG, energy saving, and carbon reduction, Chairman Tsai also reminded the industry to keep up with the ‘net zero’ carbon reduction trend, and to pay closer attention to ISO 14064, ISO 14067, as well as other carbon management standards. He also urged companies to implement the relevant ‘net zero’ carbon emission declarations in accordance with the law and regulations.

He also asked Taiwan CSC to provide strong support to help the industry save energy and reduce carbon emissions, and to produce more wire products that meet the low carbon trend for the fastener industry. Chairman Tsai believes that although compliance with carbon reduction regulations may indirectly increase manufacturers’ costs, Taiwan’s serious and hardworking industry can do a good job. Moreover, when more countries start to propose ‘net zero’ carbon reduction measures, it may also create more opportunities for the Taiwan fastener industry to receive more orders and establish new collaborations.

Mr Ming Yuan Chen, vice-president of Taiwan CSC commercial division, said that he has observed the orders of some companies are

indeed not good. However, he also mentioned that after two years of de-inventorying in the global manufacturing industry, reports published by many scholars and experts on the GDP forecasts of most countries have shown an upward sign and the optimistic forecasts of many countries (including Taiwan) are above 3%.

Despite the downward trend in the market until Q4 last year, the demand this year should be better than last year as Q2 is traditionally a high season for the industry (statistics also show that the Q2 result has been always the highest of the year for the past decade) and the Q2 industry survey conducted internally by Taiwan CSC also indicates that demand will be 8% higher than Q1 2024. Therefore, even though there is still turbulence in the market, there is no need to be pessimistic as the overall trend is still forecast to ‘recover gradually’. As long as everyone has confidence, works hard, and enhances the company’s strengths of all aspects, there’ll be lots of opportunities this year.

It is understood that Taiwan CSC does not have any annual renovation plan at present. Its current capacity can fully meet the subsequent demand of the industry and the lead times are also expected to be advanced. In addition, in response to the trend of energy saving and carbon reduction, Taiwan CSC has provided the carbon emission data of Q4 last year to manufacturers for subsequent CBAM reporting, and will provide the data of the previous quarter to the industry on a regular basis in the first month of each quarter thereafter. If the industry has any needs or questions about carbon reduction, Taiwan CSC also has a team of industry experts and senior colleagues who can provide relevant information on the industry.

The International Trade Administration (ITA) of Taiwan’s Ministry of Economic Affairs has released an analysis of Taiwan’s exports from January to December 2023, which shows that Taiwan’s fastener exports amounted to approximately US$4.6 billion (€4.27 billion) for that period, down 25% year-on-year from 2022 (US$6.14 billion).

The margin of the export decline deteriorated from the 2022 figures mainly due to the impact of geopolitical conflicts, inflation, and slowing economic growth, which led to conservative orders from customers and thus affected export performance.

However, according to another International Economic and Trade Situation Analysis Report for January to December 2023 – published by ITA, S&P Global forecasts the growth of global exports and imports will turn positive in 2024 at 5.4% and 6.7% respectively, with major

Asian countries such as China, South Korea, Japan and Taiwan showing a more significant growing trend of over 5%.

In terms of metal prices, due to the gradual realisation of the benefits of production reductions by steel mills in the USA, Europe and China – coupled with the increasing steel prices in Europe and the USA – the Asian steel market is warming up, and iron and steel prices are expected to stop declining and rebound from the fourth quarter of 2023 onwards.

January 2024 was the biggest month in fastener imports since October 2013, with over 22,600 tonnes of fasteners (with a value of US$101 million) being imported – 14.7% more than the previous record of 19,700 tonnes that were imported back in October 2013 (at a value of US$103 million).

Comparing the Q1 of 2023 to Q1 of 2024, there was a 6.8% increase in fasteners imported, with 61,512 tonnes imported at a value of US$269.65 million in Q1 of 2024. Only 48,868 tonnes of fasteners were imported, at a value of US$252.38 million in Q1 of 2023.

The fasteners imported to Brazil were from some of the biggest global players, with around 48% coming from Asian countries – including China (29%), Japan (7.2%), South Korea (2.8%) and Taiwan (2.8%).

Brazilian motorcycle production is a sophisticated market and a strong consumer of fasteners – with more than 1.5 million motorcycles produced in 2023. This is not the only sector that has experienced expansion.

When we focus on the export of fasteners, in Q1 of 2023 Brazil exported US$41.48 million of fasteners (around 7,224 tonnes), with Q1 of 2024 only reaching US$36.28 million (5,391 tonnes), a decrease of 12.5%.

The trade fair season within Brazil has truly started, with several key shows taking place in April, including South America’s biggest construction show FEICON –one of the most important trade shows in Brazil when it comes to the fastener market.

FEICON took place between 2 nd – 5 th April at the São Paulo Expo, in São Paulo City. In fact, the show was so popular that there were not enough taxis or Uber services to serve the huge demand from so many visitors.

The 28th edition of the show had more than 100,000 visitors and around 600 exhibitors –including the most important local fastener manufacturers in the shape of INOX-PAR , Jomarca Industrial de Parafusos Ltda, New Fix Indústrie e Comércio Ltda, as well as other companies with mixed distributor activities that involve screws, bolts, and similar, as side products for the general construction sectors, such as Amatools Ferramentos, Walsywa Trade Metallurgical Products and the Waves Plus (a CBS Parafusos Group member).

Brazilian business RWD International, already an exclusive representative for the Chum Yuan brand in Brazil, has been appointed as a sales agent for Jern Yao Enterprise Co Ltd.

With a mission to increase Jern Yao machine sales and services within the region, RWD International and Chum Yuan Co Ltd were appointed as business partners of Jern Yao in Brazil by Paul Lin, commercial manager at Jern Yao, in November 2023.

Already present at many Brazilian fastener manufacturers’ facilities, Jern Yao Enterprises, a traditional brand for more than 30 years, has been proactive in its production of multi-stage machines that are dedicated to cold forming processes – with its lines divided into three series: Bolt formers, with 2 – 5 stages for forming screws; nut formers, with 5 – 6 stages for making nuts; and finally part formers, with 5 – 7 stages for pressing special parts.

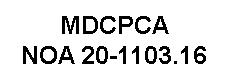

You are dealing with an complex fastener sourcing situation? Instead of managing several (small) suppliers, concentrate on one!

4fastening creates simplicity through customized logistics solutions, a global network of suppliers in addition to the in-house production at KAMAX - Quality ensured as certified remote location according to IATF16949 as well as certified according to ISO9001, ISO14001 and TISAX.

You name it, we get it! Tailored services for non-standard parts. Smart small and large scale logistics, lean sourcing process, as well as fast and personalized interaction. Our ser vices enable you to concentrate resources on your core business.“

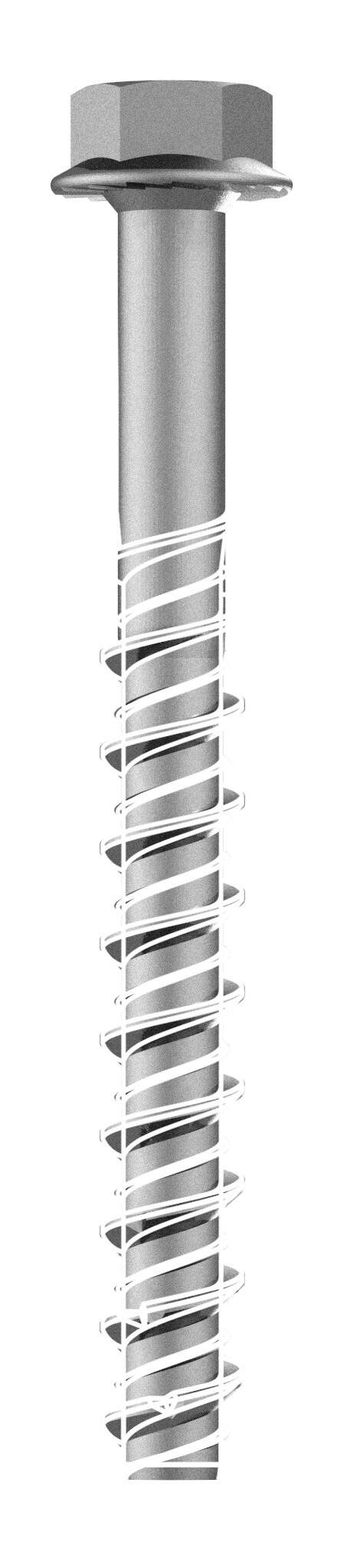

ALFIRSTE, a Chinese manufacturer that specialises in the production of screws and anchors – that has a reputation for high-quality products and excellent service, has invested in new factories in Thailand, in order to continue to meet the needs of its customers when it comes to carbon steel products.

Established in 2006, Yuyao ALFIRSTE Hardware Co Ltd has developed from a small local workshop into an international business with three factories that cover an area of 15,000m 2 – with a monthly production capacity of 1,500 tonnes. Across its factory the company uses only the latest production machinery, including heading machines, thread rolling machines, drilling machines, point cutting machines, straightening machines, multi-station machines, as well as other equipment.

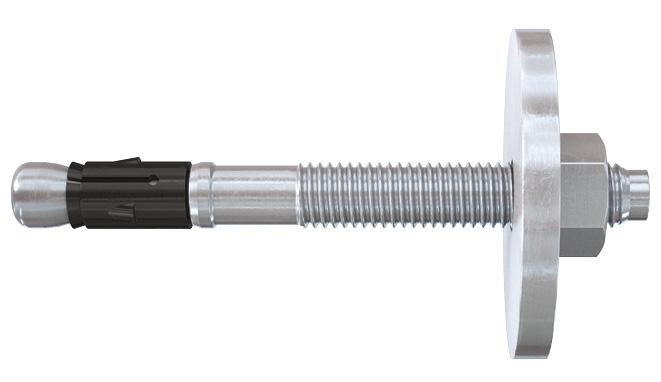

This wide production capability has enabled the company to become renowned for the production of screws and anchors, especially timber screws (construction screws), chipboard screws, roofing screws, drywall screws, coach screws, self-drilling/self-tapping screws, sleeve anchors, metal frame anchors, as well as threaded rods. “Initially, we only produced standard parts,” mentions Michael Wu, sales manager at ALFIRSTE. “However, through the addition of leading experts, and the ongoing improvement of the laboratory, we have continued to grow our product portfolio and now have the ability to develop products in-house.”

In recent years the company has used this technical know-how to also develop the production of stainless steel products and bi-metal screws. “We see these two product ranges as a key factor in the future growth of the business,” underlines Michael. “At the same time, we have not given up optimising the production of our carbon steel products to make sure they continue to be competitive within the global market.”

Due to the EU anti-dumping tariffs that were introduced on certain carbon steel products from China in 2022, ALFIRSTE made the decision to set-up new factories within Thailand – in order to meet the ongoing demand from customers for such products. “We believe that setting up a factory in Thailand, specifically for the production of carbon steel products, can help customers avoid the high tariffs associated with products from China,” explains Michael. “When this factory is added to our factories in China, as well as our excellent service, high-quality products, and fast delivery times, it means we can provide customers with more choice. At the same time, it can allow us to gain a further foothold overseas and lay a solid foundation for exploring more markets and establishing more factories in the future.”

The main markets for ALFIRSTE’s products are Europe, the United States, and Russia, with the company reporting that the global market is also picking up. “We believe that there is a rigid demand for fasteners and there will not be much change in the trend in a short period of time,” reports Michael. “As long as we make our own products carefully, and improve the cost-effectiveness of our products, all problems will be solved and new opportunities will be created.”

Alongside the development its production capabilities, ALFIRSTE has also been committed to developing the quality of its products –helping to ensure customers receive only the highest quality solutions. “As a company we continuously look to optimise our production processes to guarantee we are consistently producing quality products that are customers can trust,” states Michael. “From the storage of materials to the delivery of finished products, each batch of materials and goods is tested by our laboratory. Every production process is also checked by our quality inspectors to certify only qualified products can enter the next production process.”

Many of ALFIRSTE’s products have successfully obtained CE, ETA and ICC certifications – with the company still developing new products. “With the economic recovery of the European Union and the United States, we will seize the opportunity to meet the greatest needs of customers with products that best meet market demand,” underlines Michael.

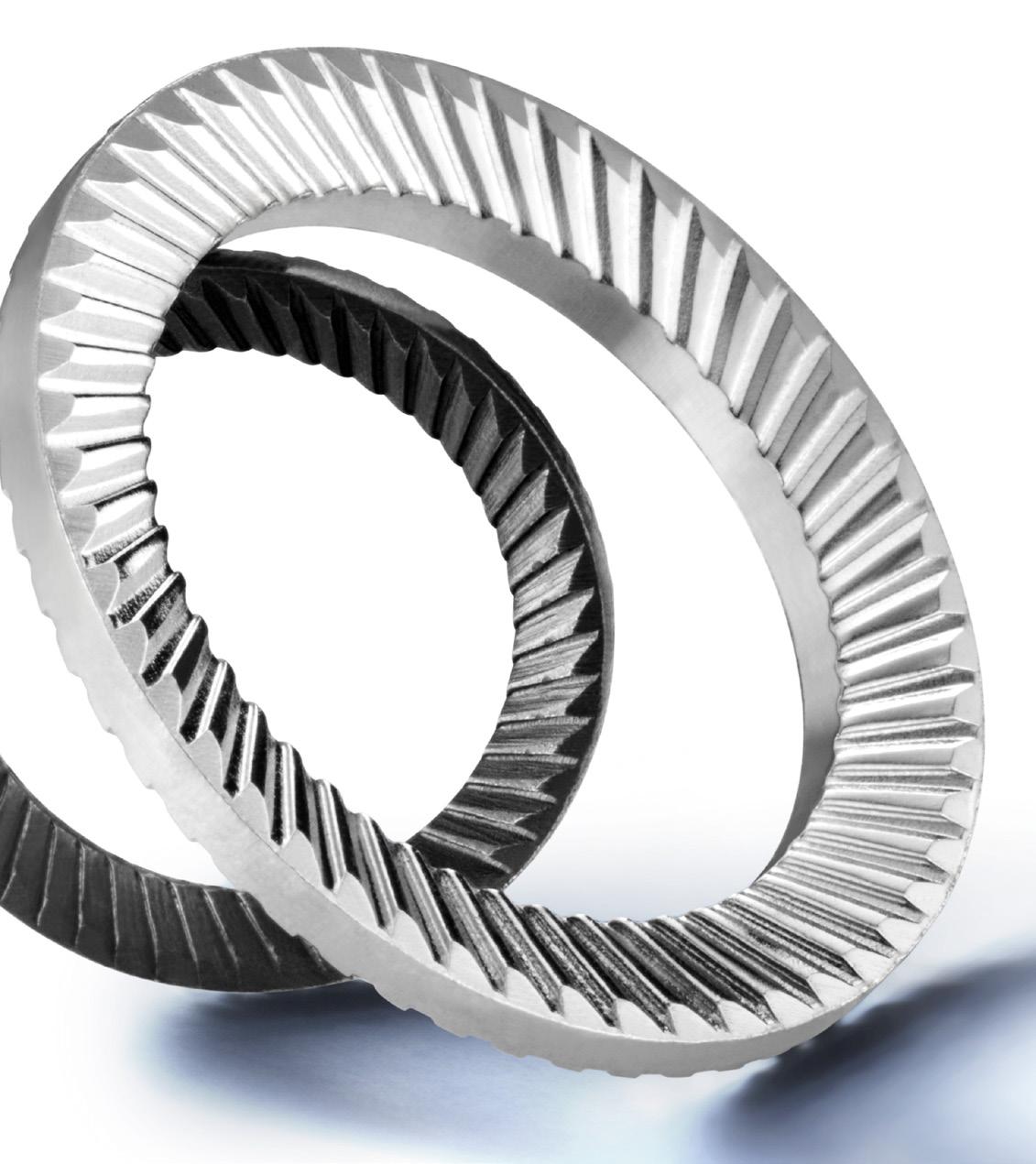

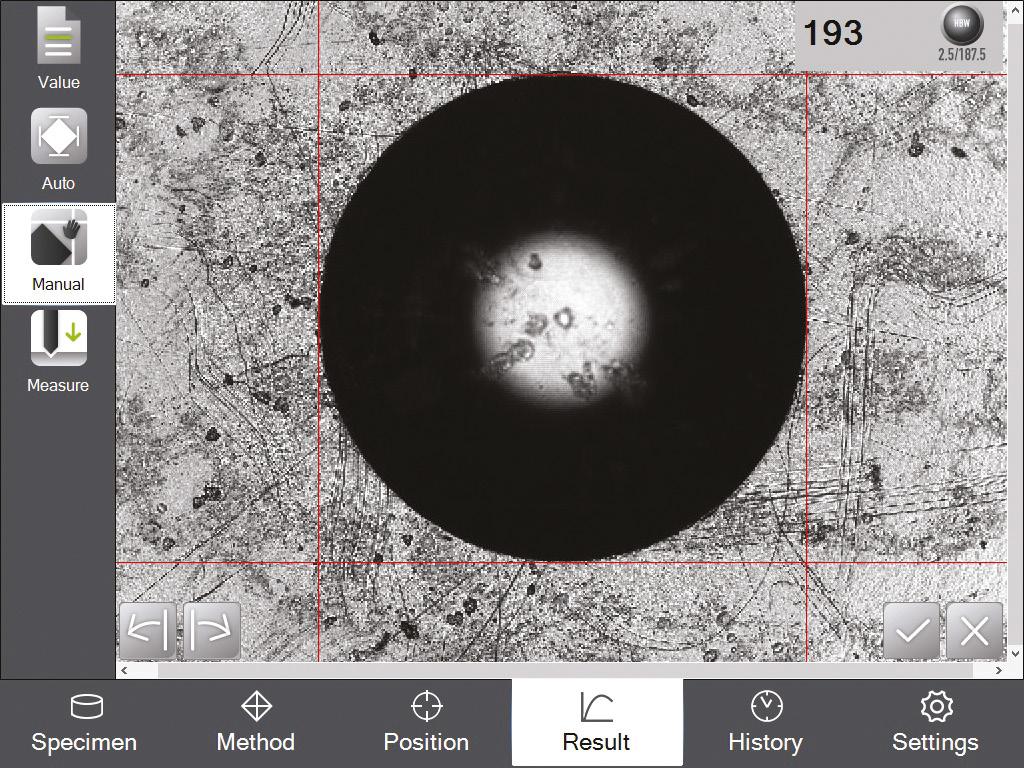

ALFIRSTE is able to deliver this quality thanks to its first-class quality department and fully equipped laboratory, which includes a salt spray test machine, a high and low temperature humidity box, image measuring instruments, a universal testing machine, a drilling testing machine, a Rockwell hardness machine, a metallographic specimen Mosaic machine, a Vickers hardness machine, a metallographic specimen polishing machine, a Fischer scope X-RAY, a torque testing machine, a concentricity metre, a bending measuring machine, a metallographic microscope, a SPECTRO spectrometer, a temperature and humidity metre, as well as standard callipers, groove depth gauges, torque wrenches, electronic scales and angle rulers.

“Our dedication to quality across every aspect of our business has enabled us to create strong relationships with customers, with our products

We believe that setting up a factory in Thailand, specifically for the production of carbon steel products, can help customers…”

being sold to around 20 countries,” points out Michael. “As a business we are always looking to create close partnerships with our customers, which is why we invest a lot of money in participating at exhibitions every year. We are also very proactive in inviting potential customers to our factory so they can see first-hand our capabilities. It is only by visiting our factory and seeing our production workshop, packaging workshop, and laboratory, that customers can really understand our commitment to quality. Every customer who visits our factories is full of praise for us and can see we are a trustworthy and reliable partner.”

During the development of its production processes, expansion of its product portfolio, and continuous focus on quality, ALFIRSTE has always ensured innovation is at the core of its business, which has been fundamental in the company’s success and growth. “Innovation is undoubtedly a core competitiveness for us,” states Michael. “The expansion of the business cannot be separated from the role of innovation, which in turn depends on investment in the company. The two complement each other, which is why, in order to continue to innovate, you need to continue to invest money.”

Michael continues: “Technological innovation also promotes industrial innovation and in the future fastener manufacturing will develop towards a trend of being more refined, higher quality and more humane. China’s fastener manufacturing industry is moving towards automation, digitalisation and intelligence. ‘Made in China’ is no longer limited to the mid to low end markets. Superior and stable quality and good cost performance will become the core advantages for Chinese companies to capture the mid to high-end markets in Europe and the United States. Continuously improving the competitiveness of enterprises and entering the high-end market is the direction of our efforts, which is why we are committed to innovation and investment.”

An area ALFIRSTE is currently investing, and therefore looking to innovate, is its sustainable development. “Since the establishment

of the business, we have looked to serve our customers, employees, and partners, in the correct way. It is the basis for the healthy and sustainable development of the business,” mentions Michael. “The topic of sustainability has become a key factor within every sector and as a company we want to make sure we are meeting the needs of our customers. That is why we are already taking the initiative to adopt cleaner production processes, which includes reducing raw material usage and waste generation, as well as using solar power. We are also actively cooperating with the EU and participating in the CBAM regulation. Additionally, we are also looking at ‘greener’ procurement and how we can work more effectively from an environmental perspective.”

Michael concludes: “Thanks to our sophisticated production equipment; innovative methods of production and material combinations; as well as in-depth product range; we are optimistic about our future place within the fastener industry. We are deeply aware that we must adhere to management principles and business ethics, such as integrity and respect, whilst focusing on quality, compliance with laws, cultural tolerance, supplier management, etc. These are the basis for the healthy and sustainable development of ALFIRSTE and it is only by doing this that we can realise our mission, and vision, and inherit and demonstrate our spirit.”

www.alfirste.cn

In March, the German Fastener Association (Deutscher Schraubenverband e.V.) held its 6th Alumni event of the Certified Fastener Qualification programme (DSV) at the Technical University of Dresden – with 140 certified fastener engineers (DSV) and certified fastener technicians (DSV), from various courses, attending.

Attendees were welcomed by Hans Führlbeck, general manager of the DSV, as well as Pasquale Gatto and Dr Andrea Eberhard, who are responsible for the DSV Fastener Academy. In addition to interesting presentations on the latest trends and current developments in the wide field of fasteners, all graduates received a special lapel pin showing they had successfully passed the exam courses for the ‘Certified Fastener Engineer’ (DSV) or ‘Technician Studies’ (DSV). Thanks to the lapel pin, every certified fastener engineer (DSV) and certified fastener technician (DSV) is now visible and recognisable to their business partners and colleagues in their day-to-day business.

In the evening, the participants had the now legendary networking get together in the cult tavern ‘Bärenzwinger’, a typical student pub in the old town of Dresden.

The 2024 advanced training courses available from the DSV Fastener Academy are listed online and available to everybody: www.schraubenverband.de/ubersichtfortbildungsangebote

In association with the 6 th Alumni, DSV also held the 15 th Workshop Industrial Fastener Assembly in cooperation with the Technical University of Dresden,

represented by Professor Dr Schmale, at the German Hygiene Museum in Dresden on 13 th March.

The well accepted workshop was attended by around 240 participants from all over Europe, including fastener manufacturers and retailers, OEMs, tier suppliers, as well as interested parties from the whole process chain. During the workshop, exciting presentations were held by fastener experts and engineers about industrial fastener assembly and related themes under the headline: ‘Sustainable, efficient, digital’. Many companies also used the workshop as

an opportunity to present themselves and their latest developments in the exhibition area in the lobby of the Hygiene Museum. DSV reports that the opportunity for professional discussion, all around fastener assembly, was well received by all participants.

The event, which has developed into the European meeting place for the fastener assembly industry, will take place again in Dresden in March 2027.

The annual DSV General Assembly will take place 13 th – 15 th June. Further to that, EIFI will have its annual General Assembly in Florence, Italy, on 23 rd – 26th May.

*120 pcs per minute.

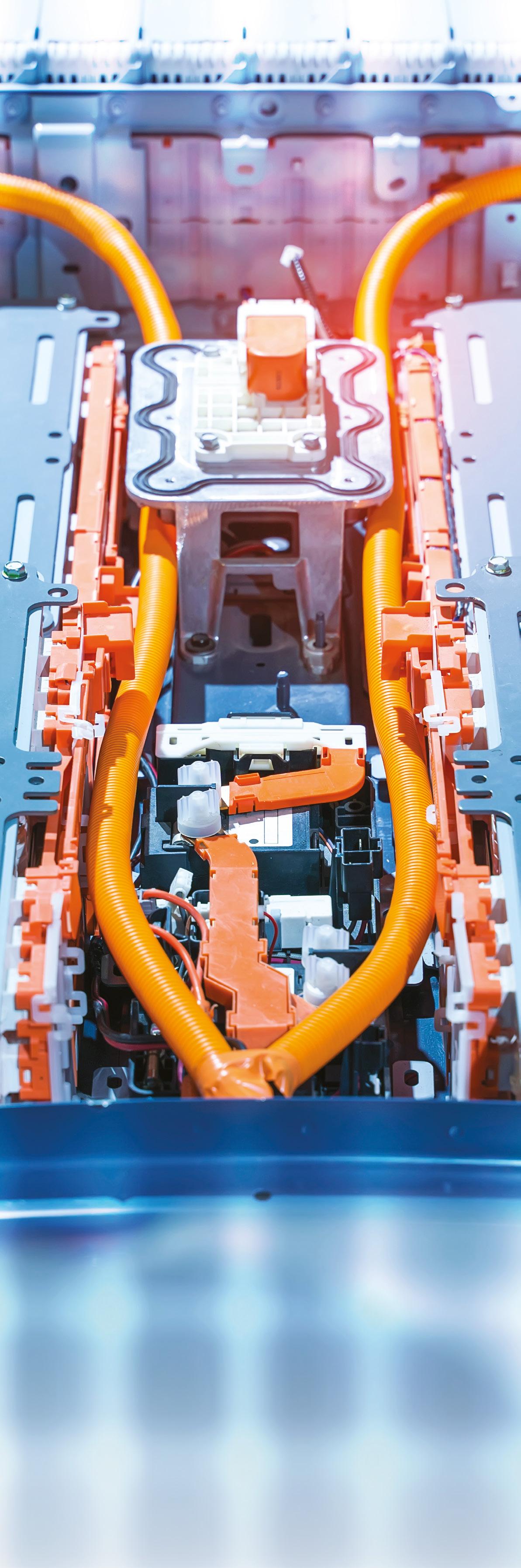

Take stainless steel, process it with a special cold forging machine. Spend 0,5 second per step and repeat 4 times. Add a pinch of innovation, just enough. The special formula for dedicated electric vehicle applications.

Product: Long Bolts

Applications: Battery Pack | Power tubes rods | E-bike | Bike spokes | Stator Bolts

PennEngineering® is a company that has both innovation and new technologies at its core. Here, we speak to Gerard Quaid, vice-president of sales and marketing Europe, about how the company is continuing to push the boundaries and deliver the best possible fastening solutions.

How does PennEngineering® work with customers to provide optimal fastening solutions and services?

“What makes PennEngineering® so different from our competitors is that we aim to offer complete fastening solutions. Even with over 2,000 part numbers in our catalogue, we provide thousands of specifically tailored custom designed PEM® fasteners to meet the unique requirements of our customers’ applications.

We work closely with our customers to understand their applications and what they are trying to achieve with their end product. This enables us to ensure that a customer is presented with the most cost-effective, high performance fastener during the design and installation stage, which we fully support via our range of Haeger® and in-die installation equipment.

It’s all about the relationships we build and our customers having complete trust in us. We consider our customers more as partners because we share knowledge and collaborate. As part of this we encourage our customers to make use of our testing facilities and laboratories.

Over the past five years, our customers’ requirements have become increasingly challenging, particularly with the transition from internal combustion engines (ICE) to electric vehicles (EV). This transition has tested us and pushed PennEngineering® into new product development, as well as new industries, which is something I feel we have really excelled at.

If you look at some of the standards that our customers have to work with, from cleanliness to IP-rated fasteners, we are able to design a new fastening solution, produce it quickly, install it in the customer’s material of choice, test it in-house and then present all performance criteria back to the customer. Our customers rely on this service for each product generation as the requirements get stricter.”

What are the key markets for

What are the current challenges within these markets and where do you see opportunities?

“PennEngineering® originally started out serving the electronics market and has since moved across to a number of industries, such as

automotive, automotive electronics, consumer electronics, datacom and telecom, defence, EV, power management and charging, industrial and commercial, medical, as well as sheet metal and metal enclosures.

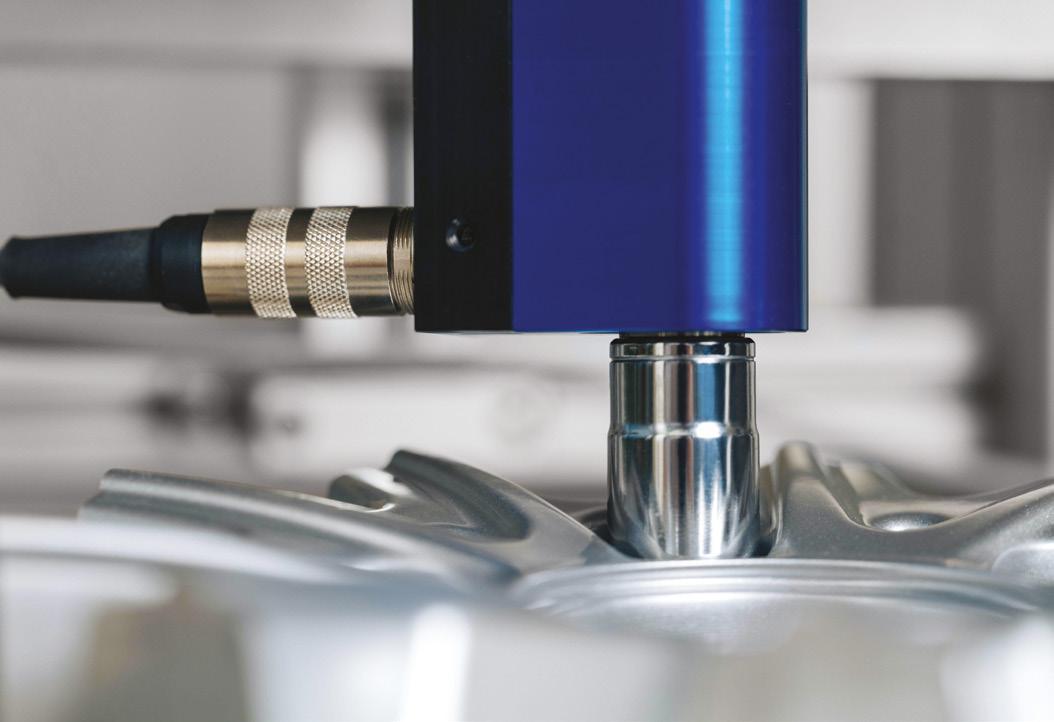

An area with opportunities at the moment is the rapid increase in busbar manufacturing for electric vehicles, power management and charging stations, which is pushing OEMs and tiers to look for new cost-effective solutions to reduce electrical resistance. Therefore PennEngineering® has launched PEM eConnect™ Contact Bushing, which can be used to make reliable electrical connections between copper or aluminium busbars, PCBs or cable terminals. This new range not only answers the need to be more cost-effective but also answers the specific needs of our customer base.

One of the most significant challenges currently facing the market is speed. Customers want products quickly and don’t want to be burdened by supply chain issues. This is where PennEngineering® is different. We make our products where they’re being sold and used – whether that’s in Asia, the USA, or Europe – so our customers can get their products quickly.

We have 25 locations worldwide, with over 4,000 employees and eight product development centres. Our European headquarters is in Galway, Ireland, where we produce over one billion fasteners a year with our cold forging, cold heading, screw machining, heat treatment and electric plating facilities.

In addition, in 2023, we set-up a Haeger® Europe facility in Galway, where we assemble the full range of Haeger® installation equipment as well as design and manufacture the tooling for fastener installation. This enables us to ensure installation confidence and optimal production performance, which is key in today’s market.

We are proud that PennEngineering® delivers the complete process to customers – right the way from the design to the end product. When we say ‘Made in Europe, for Europe’ we mean it. We have full control over our products and can bypass common supply chain issues that our customers are commonly facing.”

The unique high surface area knurl design pierces the corrosion layer on busbars creating a consistent electrical current connection without needing to plate the busbar itself. Ideal for making reliable electrical connections between copper or aluminium busbars, PCBs, or cable terminals.

• Innovative design

• Simple installation

• Consistent electrical connections

• Reduced total installed cost

What investments has the company made in recent years? Why did you decide to make these investments?

“PennEngineering® is constantly investing, but one of the most important investments has, and will continue to be, our employees. 10% of our workforce is in further education at any one time – with many completing engineering qualifications at a master’s degree level.

As well as this, one of the biggest investments we have made is the transition to digitalisation at our manufacturing plant in Galway. Whether that’s through new equipment or digitising old equipment, we now have full visibility over every piece of essential equipment on the shop floor. That means we now have visual control of multiple operational productivities via dashboards and integration between different business elements, which has been a key turning point for us –changing the way we operate every day.

Because of these investments, we were honoured with the Medium Lean Business of the Year Award 2023 from Lean Business Ireland for continuously innovating and thinking outside the box in the fastener industry.

We also recently announced the opening of a UK office in Burnley to renew our commitment to this important market. The site features a comprehensive stock of fasteners that will streamline logistics and provide customers with prompt access to the entire portfolio of PEM ® fasteners. We also have a new UK sales team to ensure we are readily available and accessible to meet the unique needs of our customers.”

Sustainability continues to grow in importance within markets. What steps has PennEngineering® taken on this topic and how do you see this area developing?

“PennEngineering® believes in doing what’s right for our employees, our communities, and the environment, so we are constantly looking at ways to stay ‘one step ahead’. With our manufacturing facility in Galway, we manufacture our products near our European client locations, as well as source our materials close to our manufacturing locations, to reduce the carbon footprint of material shipping. We have also made changes within the facility, such as updating the rectifiers on plating lines and upgrading equipment so it’s more energy efficient.

We also have a waste disposal programme that involves composting and recycling, as well as our water usage and how we can reduce it – whilst still efficiently operating our heat treatment furnaces and plating lines.

We have full control over our products and can bypass common supply chain issues that our customers are commonly facing.”

Reducing usage involves changing our process, including draining, filtering, etc. The Galway site has also recently attained ISO 45001 and ISO 14001 in 2024 and is run according to Lean Manufacturing procedures. All these efforts add up to PennEngineering® being a responsible and thoughtful manufacturer. Traceability and transparency is extremely important to us. We have a responsibility to work together with our facilities, customers and suppliers to encourage sustainable behaviour.

As part of our global environmental sustainability plan, we are committed to reducing our greenhouse gas emissions by 50% by 2030, with the goal of achieving carbon neutrality by 2040 and being a ‘net zero’ company by 2045. We have also implemented a sustainability team of around 30 people worldwide who review and provide suggestions that are aligned with business demand. Our sustainability report will also be released in 2025.

There is also a considerable drive from the EV market right now, in particular, to ‘track’ a product’s carbon footprint. Obviously, with the CBAM legislation, our customers are demanding more information, and rightly so. PennEngineering® takes away the headache of CBAM paperwork and submissions. We have carried out comprehensive studies and reviews of our manufacturing processes and, as a result, can supply documentation relating to the carbon footprint of our products. PennEngineering® customers do not need to worry about compliance in that area or risks to their supply chains.

PennEngineering® stays close to our customers and delivers innovative fastening solutions that enable our customers to develop new products. We want to help drive change and our commitment to sustainability and protecting our environment is reflected in the many efforts we practice every day.”

www.pemnet.com

Mark Revak has been working at Harrison & Clough – a leading UK distributor of quality fasteners and fixings, as well as related accessories and tools – for nearly 37 years. Here we talk to him about his career within the fastener industry and the steps Harrison & Clough has taken to ensure it continues to meet the needs of its customers.

Tell us about your career and the roles you have held at Harrison & Clough since joining the business.

“I joined Harrison & Clough (H&C) in October 1987 and initially started on the late shift picking in the warehouse. I then had multiple other warehouse roles, such as FLT, loading, checking, as well as a floor planning and process development. The latter roles reflected my eye for improvement in efficiencies and they were all a real learning curve in terms of product, systems and processes.

The journey through the warehouse environment was very beneficial, as I was able to understand all the roles and gather first-hand knowledge of how things truly worked. I then moved from the warehouse into the commercial team, initially in sales processing, and then went onto account management – forming the original key accounts sales team. As with the warehouse systems, the processes within the commercial side were very manual and I was a part of the team that brought automation to processes and pricing.

For instance, back in the early 1990s we had to write out every order in its entirety, which could mean writing every detail for a 200 line order. I therefore suggested that instead of all the details, why didn’t we just write the start of the part code, as that was the unique identifier. This proved to be a big success and helped us streamline the entire process, so that we could take even more calls.