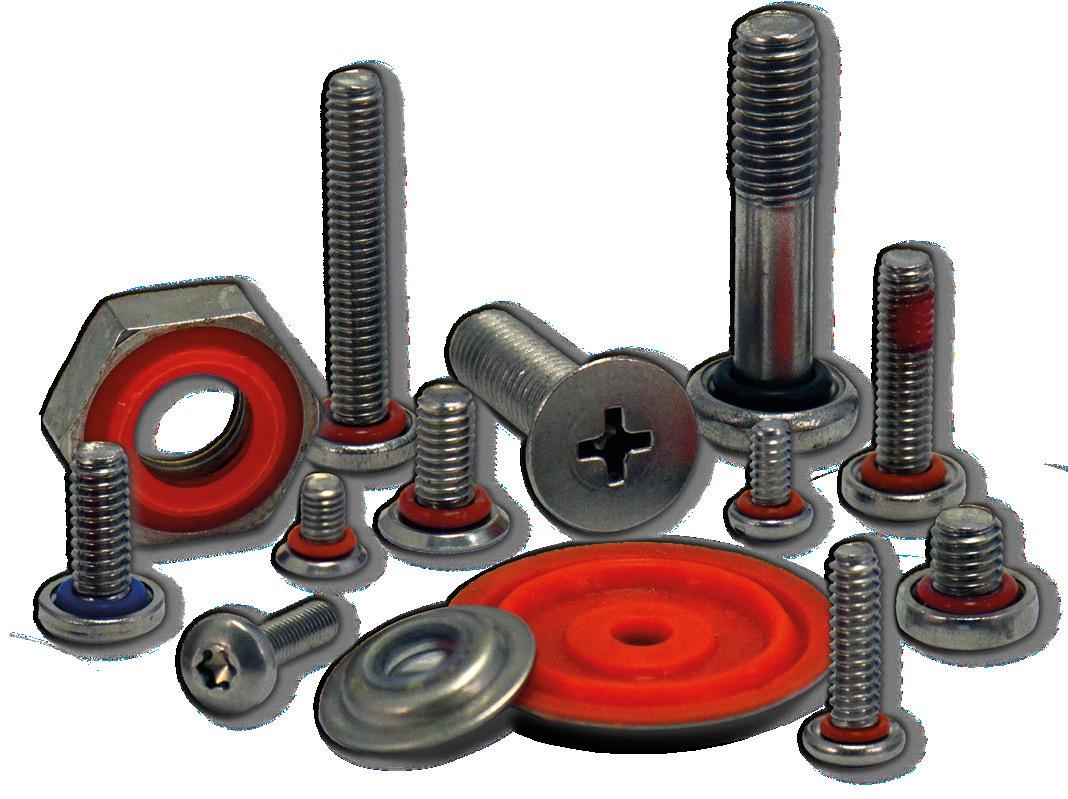

When speed and accuracy are vital, only PEM® and Haeger® deliver maximum efficiency for the most critical fastener applications. Our first-time-right solution eliminates downtime, boosts productivity, and empowers fabricators to work smarter.

LEARN MORE

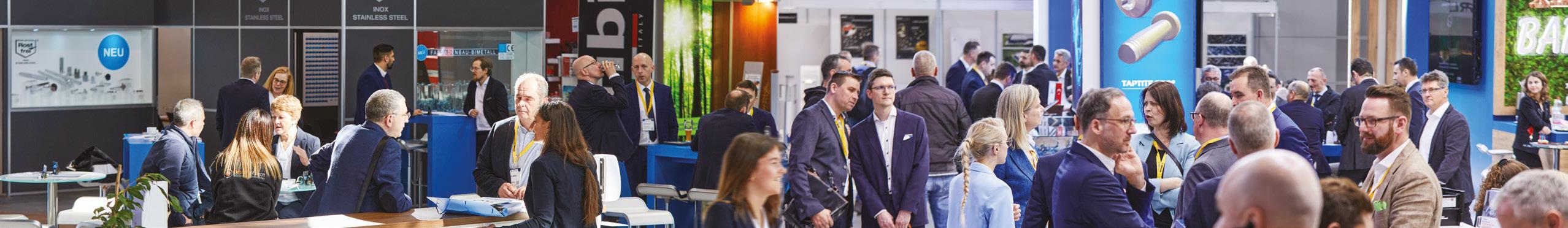

This is the 150th issue of Fastener + Fixing Magazine and we are very proud to have reached such a milestone and provided breaking news and analysis on the fastener sector for over 25 years. We have established ourselves as the ‘go to’ news source within the industry and we promise to go on providing the intelligence and insight that helps inform our global readership.

Some more big news at Fastener + Fixing Magazine is that Claire Aldridge has been promoted to editor, so it will be the last time you see my (older than I would like to admit) photo on this page. Claire has been with the magazine for 12 years and has been a key part of the success and growth of the Fastener + Fixing brand, ensuring we supply the insight that we are renowned for within the industry.

I will still very much be part of the magazine and my role as content director will be to look at the strategy of the publication, and different media channels, as well as where we can provide even further analysis when it comes to the fastener and fixing industry – ensuring we focus on the topics and issues our readership want to read.

With all that in mind, I will leave it to Claire to give you a breakdown of what to expect in this special 150 th issue.

Claire Aldridge, editor

www.fastenerandfixing.com

Published by

Managing Director

Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director

Will Lowry will.lowry@verulammedia.com

Editor Claire Aldridge claire.aldridge@verulammedia.com

Will Lowry, content director

Fastener + Fixing Magazine has continuously grown over the last 150 issues, thanks to a simple commitment – to keep the fastener industry better informed. In a special timeline feature, we underline some of the highlights in our journey, as well as the exclusive articles we have published to help further support our readers.

T hat commitment is even more evident in this issue, with an article in our News section on the European Commission’s decision to launch a new anti-dumping investigation, as well as an article from Alexander Kolodzik, secretary general of the European Fastener Distributor Association, who outlines how the association is continuing to help its members meet the challenges of the Carbon Border Adjustment Mechanism (CBAM) regulation.

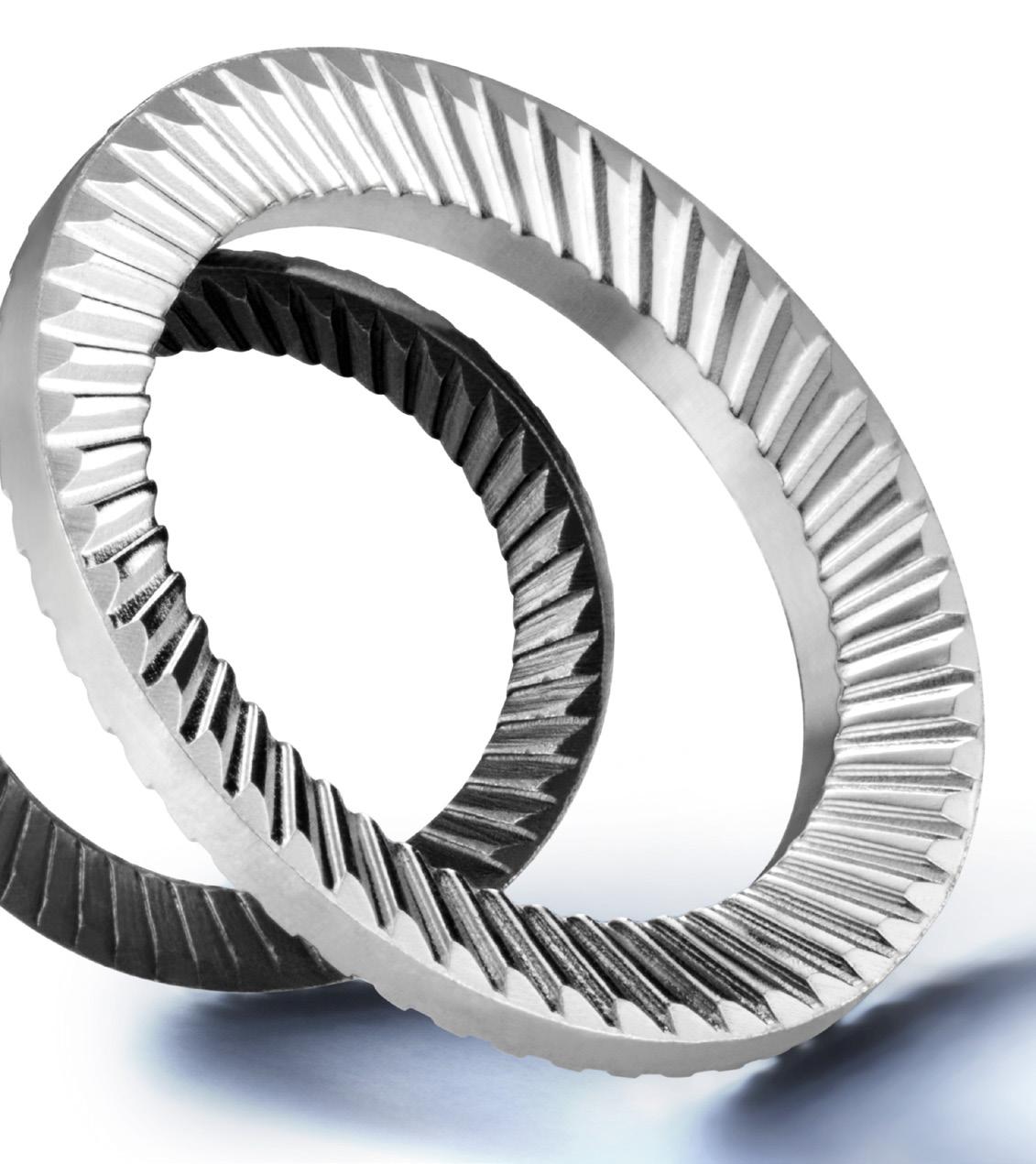

Our Cover Story is an exclusive interview with Nord-Lock Group’s new CEO Daniel Westberg, who discusses the Group’s recent reorganisation period, as well as how Nord-Lock is actively trying to accelerate growth through investments, internal initiatives and acquisitions.

We also have a special ‘Made in eastern Europe’ feature that gives an in-depth look at the latest developments from eastern European fastener manufacturers, with an underlining theme of investments and a focus on sustainability.

Finally, we have a special ‘sealants + adhesives’ feature in Construction Fixings, a ‘renewable energy’ feature in Application Technology, an ‘inspection + packing’ feature in Manufacturing Technology, as well as a ‘tapes + adhesives’ feature in Products – it really is a busy issue.

Assistant Editor

Rebecca England rebecca.england@verulammedia.com

Sales Director Mac Rahman mac.rahman@verulammedia.com

Business Development Manager –Italy

Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager –DACH & Europe

Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

Fastener + Fixing Magazine is a dedicated, trade–only publication which is circulated freely throughout the European trade.

Disclaimer

The Publisher cannot be held responsible or, in any way, liable for errors or omissions, during input or printing of any material supplied or contained herein although the utmost care is taken to ensure that information contained is accurate and up to date. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or Verulam Media.

Copyright Entire contents copyright © Verulam Media Ltd 2024. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

Annual subscription (6 issues) to non–trade and outside EU is €200.00 Verulam Media Limited, Office 3, 17 Holywell Hill, St Albans AL1 IDT Tel: +44 (0) 1727 743 882 Find us online:

The European Commission has given notice of the initiation of an anti-dumping proceeding, concerning imports of screws without heads, originating in the People’s Republic of China.

Published on 17 th October 2024, the product subject to this investigation is screws and bolts, with or without their nuts and washers, without heads, of iron or steel other than stainless steel, regardless of tensile strength – excluding coach screws and other woodscrews, screw hooks and screw rings, self-tapping screws, as well as screws and bolts for fixing railway track construction material.

The notice reports: “The European Commission has received a complaint pursuant to Article 5 of Regulation (EU) 2016/1036 of the European Parliament and of the Council of 8 th June 2016 on protection against dumped imports from countries not members of the European Union, alleging that imports of screws without heads, originating in the People’s Republic of China, are being dumped and are thereby causing injury to the Union industry.”

“The product allegedly being dumped is the product under investigation, originating in the People’s Republic of China, currently classified under CN codes 7318 15 42 and 7318 15 48. The CN code is given for information only

and without prejudice to a subsequent change in the tariff classification.”

“The investigation of dumping and injury will cover the period from 1 st July 2023 to 30th June 2024 (‘the investigation period’).

The examination of trends relevant for the assessment of injury will cover the period from 1 st January 2021 to the end of the investigation period (‘the period considered’).”

The full notice can be viewed online.

LISI Group achieved sales of €1.323 billion for the first nine months of 2024, up 8.6% compared to 2023, with LISI AEROSPACE up 20.7% on the same period and LISI AUTOMOTIVE and LISI MEDICAL finishing down 4.6% and 0.6% respectively.

LISI AEROSPACE sales totalled €742.2 million in the first nine months of 2024. The ‘Fasteners’ segment continued to benefit from the ramp up in single aisle aircraft production rates, and from strong demand for maintenance services linked to the sustained traffic in the commercial aircraft fleet. Third quarter sales rose by 26.8% in Europe and 22% in the United States, despite an unfavourable currency effect.

The resilience of the global commercial aeronautics market is reflected in high order levels, particularly at Airbus. Nevertheless, production rate increase ambitions have been postponed due to tensions throughout the aeronautical supply chain. The strike at Boeing since early September has halted assembly of the B737 MAX –around 38 aircraft per month. Although this stoppage has not yet had a significant impact on LISI AEROSPACE in the third quarter, it will weigh on general demand.

LISI AUTOMOTIVE division sales came to €447.2 million in the first nine months of 2024, down 4.6% on the same period in

2023. This takes into account the accelerated decline in sales in the third quarter, down 9.1% compared with the same period last year, particularly noticeable among OEMs.

LISI MEDICAL division sales came to €134.3 million in the first nine months of 2024. They were virtually stable, down 0.6% compared with the same period in 2023.

LISI AEROSPACE has appointed Equity Energies to deliver bespoke energy management and decarbonisation solutions to further advance its net zero progress in the UK.

Through its consultancy offer, and proprietary technology, Equity Energies will develop and deliver a tailored energy management strategy and net zero pathway, helping the business meet the growing demand for emissions reductions while accelerating its decarbonisation through energy efficiency and waste reduction.

www.achill-fasteners.com

Bulten Group has reported net sales amounted to SEK 1.33 billion (€1.3 billion) for the third quarter of 2024, a decrease of 3.3% on the same period the previous year. Adjusted operating earnings totalled SEK 91 million (€7.8 million), equating to an adjusted operating margin of 6.8%.

Christina Hallin, interim president and CEO, highlights: “The reported operating earnings for the third quarter are an improvement on the corresponding quarter of 2023 and on the previous quarter this year. This is a clear sign that our efforts over the past year to stabilise and streamline production, combined with a focus on reducing our costs, are paying off. The operating margin has improved during Q3, which is generally a weaker quarter as there are fewer days of production. The margin has been positively impacted by non recurring items, including insurance compensation relating to machinery in Poland. Our long-term ambition to have an operating margin of 8% remains, although this will be difficult to achieve for 2024 as a whole.”

She continues: “There has been a slight decline in demand for fasteners from vehicle manufacturers in all markets during the quarter. The falling demand is largely due to a decrease in vehicle sales, but also

to the fact that some of our larger customers are shifting platforms, thus affecting their Q3 2024 net sales production volumes in the short term.”

“In addition, there are other disruptions in OEM supply chains, which impact on our sales volumes. Although the market is not growing at the same rate as before, we now have an operation that is more stable and flexible, which is able to handle large fluctuations. The fall in demand gives us the opportunity to review our customer base and focus on customers and segments where we see better margins. It also enables us to review our customer contracts and phase out any unprofitable ones, something we have been doing during the quarter. We have also begun to reduce working hours in a couple of factories and we are working on a number of minor structural issues, including a review of some of our joint ventures. We cannot rule out additional structural changes moving forward, if they are necessary to further improve profitability levels,” concludes Christina.

Bufab Group has reported that in the third quarter its net sales declined by 9.2% to SEK 1.8 billion (2023: SEK 2.07 billion), with organic growth down 2.6%.

Demand in the quarter remained cautious, with continued large variations between different industries and regions. Similar to previous quarters, the strongest developments were noted in energy and defence. Organic growth amounted to -2.6%, indicating an improvement to the previous quarter (-6.6%). The region Asia-Pacific showed a new trend with organic growth of a strong 13.2%, driven by particularly strong growth in China.

Erik Lundén, president and CEO at Bufab, comments: “We have continued our efforts to strengthen the gross margin, which increased by 1.6% in the quarter to an all time high of 30.6%. The gradual strengthening over the past few quarters is a result of the long-term work that began in 2023 to improve our customer and product mix, develop our value creation for customers, as well as achieve purchasing savings.”

“The adjusted operating margin was in-line with last year, amounting to 12.7% (2023: 12.6%), which is a stable level given the challenging market conditions. Our dedicated work with cost control throughout the organisation have yielded the expected results, primarily due to staff reductions, but also reduced overhead costs. At the same time, we continue to invest in driving growth and improving profitability in the long-term and have continued to invest in our customer offering during the quarter.”

He continues: “Uncertainty regarding the general economic outlook remains, but we see indications of improved demand from general industry, likely not until the first half of 2025. At the same time, a weaker economy creates favourable conditions for a strong player such as Bufab to take new market shares. This, together with our focused work on strengthening our gross margin and on cost savings, will put us in a strong position once the market rebounds.”

With over 20 years of experience from management, sales, strategy, business development, and international business, in several global manufacturing companies, Martin Dahlgren has become the new managing director of BUMAX Sweden AB.

Martin joins BUMAX from a position as head of linear motion Asia Pacific at motion technology group Schaeffler and has a broad range of experience in developing and leading OEM brands across the EMEA and APAC regions, through various managerial positions with companies including Ewellix, SKF Group, Thule Group and Volvo Cars. Martin also holds a degree from Chalmers University of Technology, with further studies at London Business School and China Europe International Business School.

He comments: “I am thrilled to join the global leader in fastener technology. BUMAX is such an innovative company, whose high strength stainless steel fasteners help many companies to unlock new design capabilities, improve the performance and durability of its products, while supporting industry sustainability goals.”

Berardi Group, a portfolio company of H.I.G Capital, has completed the acquisition of Italian-based Fixi Srl – a distributor of fastening systems offering a wide range of products such as rivets, threaded inserts, self-clinching fasteners, welding studs and related professional equipment.

With depots in Veneto, Emilia Romagna, Marche, and Abruzzo, Fixi serves over 2,000 industrial customers in Italy and across Europe. The transaction represents a significant step in Berardi’s growth strategy, aiming to enrich the range of products and services offered to its customers through strategic acquisitions of distributors specialised in high potential product categories.

The acquisition will strengthen Berardi’s position as a national leader in the fastening systems category, a segment in strong growth for its customers. It will also improve the geographic coverage and service in Italy and throughout Europe, to the benefit of its customers.

“The partnership with Fixi is a step of enormous importance in the growth path that we have outlined for our Group, which will enable us to

have a greater geographical presence and to provide our customers with a product portfolio and a range of services suited to their every need,” underlines Giovanni Berardi, chairman of Berardi, and Mauro Pasini, CEO at Berardi Group.

Maurizio and Alessandro Mora, majority shareholders and CEOs of Fixi, added: “We are excited about our new partnership with Berardi, the undisputed leader in the distribution of industrial components in Italy. Our history and shared culture of excellence, innovation and maximum attention to our customers and employees enables us to fully leverage our specialist skills in fastening systems and seize new growth opportunities that will enable us to accelerate the development of the business.”

NORMA Group achieved a sound level of profitability in the third quarter of 2024 despite a difficult market environment. Group sales in the third quarter were down 7.9% over the prior year to €273.6 million (2023: €297.1 million)

NORMA reports that business with joining technology for vehicles – Mobility & New Energy, suffered under a weak global automotive industry with low production figures for cars and trucks. Sales in the Water Management sector, on the other hand, remained stable at a high-level. The Industry Applications business unit was especially impacted by the persistently weak economy in large parts of Europe and in China.

In the Americas region, sales in the third quarter fell by 1.2% year-on-year to €131.3 million due to negative currency effects in

connection with the US dollar (Q3 2023: €132.9 million). Adjusted for currency effects, sales development was slightly positive (up 0.1%).

In the EMEA region sales amounted to €108 million in the third quarter of 2024, down 9.4% on the prior year figure (Q3 2023: €119.3 million).

In the Asia-Pacific region, third quarter sales were down 23.9% to €34.2 million (Q3 2023: €45 million). Currency effects had a slightly positive impact here. Business with customers in the Chinese automotive industry (Mobility & New Energy) declined significantly.

Hilti Group reported sales growth of 1.9% in local currencies over the first eight months of the 2024 business year. Consistently negative currency effects impacted sales and resulted in a decrease of 1.1% in Swiss francs compared to the same period last year. The operating result grew by 4.9% to CHF 489 million (€520 million).

Business development over the first eight months of 2024 was largely influenced by a challenging market in central and northern Europe (up 0.2% in Europe in local currencies). In the Americas, Hilti Group recorded a slight increase of 1.2%. In Asia-Pacific the company was able to grow by 5.5%, while the EMEA region continued to grow strongly, at 11%.

“We expect the market environment to continue to vary strongly, from negative in our home market of central Europe to positive in Asia-Pacific and the Middle East. With our business model, we can successfully navigate these uncertain times,” explains Jahangir Doongaji, CEO at Hilti Group.

Hilti recognised as carbon management leader

Hilti Group has achieved a Gold rating in the EcoVadis assessment for the fourth consecutive year, placing the company in the top 2% of over 130,000 companies evaluated across all industries worldwide and in the top 1% in the industry segment.

EcoVadis has once again declared Hilti to be a ‘leader in carbon management’ and a ‘company with a best-in-class greenhouse gas management system and strong ambitions for decarbonisation’. This outstanding rating is also based on Hilti’s commitment to the Science Based Targets initiative (SBTi), which aims for a significant carbon footprint reduction by 2032 and net zero emissions by 2050.

“We are honoured to see our efforts in sustainability once again recognised,” says Jahangir Doongaji. “We will continue to diligently work on our initiatives to be our customers’ best partner for sustainability.”

On 1 st January 2025, Marc Schaad, the longstanding CTO, will take over operational management of Kistler Group from Rolf Sonderegger, who has led the group as CEO for 22 years.

Marc Schaad is a mechanical engineer and graduate of the Swiss Federal Institute of Technology Zurich (ETH). In his current role, he has played a crucial part in Kistler Group’s ongoing development. He has been responsible for research and development, has headed a business unit and, at the beginning of 2024, he added strategic product management to his remit. Thanks to his wide-ranging experience in these key areas, Marc Schaad is excellently qualified to continue Kistler Group’s successful development.

Marc Schaad comments: “Kistler’s DNA and values remain unchanged: A family run company with a long-term strategic vision that focuses on cutting edge technology to meet the challenges of today’s and tomorrow’s customers. I look forward to continuing this success story with a highly motivated Kistler team.”

Under the leadership of Rolf Sonderegger, Kistler Group has evolved from a component manufacturer into a global provider of complete measurement technology solutions for highly dynamic applications. The company was founded at Winterthur, Switzerland, in 1959 by Hans Conrad Sonderegger (Rolf Sonderegger’s father) and Walter P Kistler. In 2002, Rolf Sonderegger assumed overall responsibility as CEO and delegate of the board of directors, acquiring Walter P. Kistler’s shares at the same time. Driven by a targeted growth strategy and strategic acquisitions, the company has achieved sustainable growth of over 500% and created more than 1,500 jobs.

Joint administrators from BDO have completed a sale of two divisions of The Electrolytic Plating Company Limited (EPC) to Wolverhampton Electro Plating Limited, part of the Anochrome Group of Companies.

Kerry Bailey and Lee Causer of BDO were appointed as joint administrators of EPC – an electrolytic plating, high performance surface coatings and metal finishing business –on 5 th September 2024. A sale of two divisions, and certain assets of the business, was completed immediately following their appointment to Wolverhampton Electro Plating Limited.

The remaining business has ceased to trade and certain employees have been made redundant. Kerry Bailey, one of the joint administrators, said: “The Electrolytic Plating Company Limited has traded for over a century, but it has had to navigate a number of financial challenges, particularly since the Covid-19 crisis. We are delighted that the sale of the two divisions and certain assets will see the business continue, securing the continued employment for the divisional employees. Regrettably, the administration has also resulted in a number of redundancies and the administrators are supporting affected staff members with their statutory redundancy claims. We are now taking steps to maximise the remaining assets of EPC for the benefit of creditors, in-line with our duties.”

“As the years have gone by, we have worked together to surmount half a dozen crises, overcome various setbacks and celebrate some extraordinary successes. Growth has been the keynote in 19 out of the last 22 financial years – years that have been magnificent and thrilling, but always challenging. However, there is a time for everything, so I will be stepping down as CEO at the end of 2024,” outlines Rolf Sonderegger.

Rolf Sonderegger will remain the majority owner of Kistler Group and he will take over as chairman of the board of directors from Valentin Vogt in spring 2027 after a two year sabbatical.

To significantly expand its presence in Germany and eastern Europe, Bossard Group has signed an agreement to acquire Ferdinand Gross Group.

Headquartered in Leinfelden-Echterdingen, Ferdinand Gross is one of the leading distributors of fastening technology in Germany and is celebrating its 160 th anniversary this year. The Group employs around 260 people and also operates in locations in Hungary and Poland.

With the contemplated acquisition of the Ferdinand Gross Group, which expects net sales of around €80 million for the current financial year, Bossard will be able to better serve its customers in Germany and eastern Europe even more comprehensively.

“I eagerly look forward to the upcoming collaboration with our new colleagues. The planned acquisition of the Ferdinand Gross Group not only brings together two companies with a long tradition, but also two strong partners who share common values and business philosophies – in the spirit of ‘Proven Productivity’,” comments Daniel Bossard, CEO of Bossard Group.

We offer a range of socket head cap screws, socket countersunk head screws, socket button head screws, socket sets, socket shoulder screws, taper pressure plugs and socket wrenches. Available in a range of sizes from M1.6 - M30.

Socket Screws Available in

Finish: Self-Colour, Bright Zinc Plated, Galvanised, A2 and A4 Stainless Steel

Grade: 10.9 and 12.9 Steel

Metric and Imperial

Head Type: Button, Button Flange, Cap, Countersunk and Low Head Cap Standard: DIN 912, 7991, ISO 7379, 7380-1, 7380-2, 10642 and ANSI B18.3

Socket Sets Available in

Finish: Self-Colour, Bright Zinc Plated, A2 and A4 Stainless Steel Class: 45H Steel

Point Type: Flat, Cone, Dog, Plain Cup and Knurled Cup Standard: DIN 913, 914, 915 and 916

Products are available for free-next delivery, with low minimum order levels, across the majority of the UK mainland.

On 1 st October 2024, Reinhold Würth, chairman of the supervisory board of the Würth Group, celebrated his 75th work anniversary during a ceremony at Carmen Würth Forum in the German town of Künzelsau.

From a hardware wholesaler with two employees to a global market leader with more than 88,000 employees, family and friends, numerous guests from the worlds of politics, business and the arts, as well as the company management, congratulated Professor Reinhold Würth on this impressive milestone.

“I stand before you, immensely grateful, and in all modesty and humility, knowing that I would never have achieved the success we are seeing today without the hard work and the loyalty of these 88,000 people from all these different cultures, different backgrounds, with different nationalities and different religions,” outlined Professor Würth at the ceremony.

German Chancellor Olaf Scholz also offered his congratulations: “It is thanks to entrepreneurs like Reinhold Würth that Germany has such a strong economy. His entrepreneurial courage and his tireless commitment to the company and its employees are impressive and deserve my respect and admiration. The company’s success is exemplary of one of the most important pillars of Germany as a business location.”

Nord-Lock south-east Asia and Taiwan, part of the Nord-Lock Group – the world’s leading provider of advanced bolting and engineering solutions, has announced the inauguration of its regional office in Q Sentral, located at the heart of the capital’s transportation hub, Kuala Lumpur Sentral.

Nord-Lock Group’s move to relocate its regional office from Singapore to Kuala Lumpur underscores the market leader’s commitment to expand its presence and it will serve as a hub for its operations in the Asia-Pacific region, to better serve its customers and partners.

Norbert Hentschel, head of Asia-Pacific at Nord-Lock Group, explains: “Nord-Lock Group’s investment in this new regional office underscores our long-term vision for growth in Malaysia. Over the years, Malaysia has emerged as a key market for us, offering a skilled workforce, strategic location, as well as a conducive business environment. This relocation strengthens our presence in the region and marks the start of an exciting chapter in Nord-Lock Group’s journey to establish closer relationships with our distributors, strengthen our global presence and deliver excellence to our customers regionally.”

Robert Lejon, deputy head of mission of the embassy of Sweden to Malaysia, who was at the inauguration event, agreed with Norbert Hentschel. “Through safe bolted connections, Nord-Lock Group provides a critical component that holds modern society together, and through its decision to expand and invest, it is also bringing Sweden and Malaysia closer together. This will open more doors for growth in business and cooperation between our nations, providing more job opportunities in both our countries respectively. We are excited about the opportunities this move will bring and look forward to mutual success.”

The Malaysian office will be helmed by Kang Tzee Chang, general manager, Nord-Lock south-east Asia and Taiwan. Kang Tzee Chang comments: “Our new office in Kuala Lumpur represents a significant milestone for Nord-Lock as we continue to expand our footprint in south-east Asia. We are committed to investing in Malaysia, fostering local talent, and contributing to the country’s economic development. This

move is a testament to our belief in the immense potential of the Malaysian market.”

Nord-Lock takes a long-term view of its presence in Malaysia with plans to continue investing in its operations, as well as establishing a regional distribution centre by the end of the year. Kang continues: “Our Malaysian office is staffed by a dynamic and professional workforce with in-depth expertise – our plan is to further expand this established and experienced team.”

Standard and non-standard items

Norm- und Standardteile

DIN, ISO, EN and others / und andere

Special parts and special materials

Sonderteile / Sonderwerkstoffe

The perfect union occurs when everything fits

To expand its European spring supply solutions, Lesjöfors Group has acquired Ressorts Lacroix –a French-based manufacturer of springs and wire parts for customers within the hydraulic, automotive, aerospace and medical sector.

The completion of the purchase of Ressorts Lacroix builds on a strategic growth plan for Europe. Yohan Dutheil, CEO of Ressorts Lacroix, highlights: “Our potential is now limitless and with Lesjöfors as a global parent company, we are able to access new markets and give a greater reach.”

Qingdao Fervi International Trading Co Ltd is the latest addition to the FERVI Group, marking a significant milestone in its global expansion strategy.

Based in Qingdao, one of China’s most vital port cities, this new subsidiary is strategically positioned to enhance logistics and streamline the Group’s ‘go to market’ efforts, reinforcing its commitment to international growth.

The fischer group of companies has acquired a majority stake in its trading partner SEEFELDER GmbH – a specialist retailer for fittings, tools and assembly technology.

With the majority shareholding, fischer is further expanding its product range and services for retailers and will work together with SEEFELDER to develop new product ranges, product innovations and service concepts.

As of 23 rd October 2024, Mungo Befestigungstechnik AG has been acquired by a group of investors with extensive international industrial expertise.

The acquisition also brings changes in Mungo’s executive leadership, with Mr Claude Mion announced as Chief Executive Officer, with a vision to unlock synergies that will reestablish Mungo as one of the most influential global players in the fastening industry.

SFS Group has acquired EPRO d.o.o, a longtime distribution partner for high-end applications to the building envelope in Slovenia, further strengthening the Group’s presence in the Adriatic region.

EPRO is a family run company specialising in the distribution of fasteners, fixings, fall protection systems and accessories for flat roofs, roofing and façade elements. The company generated sales of approximately €4 million in 2023 with about ten employees.

Fastener supplier Rapierstar is supporting a Scottish window and door manufacturer and installer to realise its growth ambitions by keeping its product quality and factory productivity on track.

Precision Windows has always used Rapierstar fasteners to manufacture its PVC-U product range, because the team recognises the value of quality components and profiles in achieving a competitive advantage, including the Veka FS70 fully sculptured and M70 bevelled systems.

As part of the UN Global Compact Leaders Summit, which took place from 24th – 25th September in New York, USA, representatives from Norm Holding presented a waste energy recovery project as part of the SDG Innovation Accelerator for Young Professionals.

The UN Global Compact Leaders Summit aims to bring together opinion leaders and business pioneers in the field of sustainability on the global stage, with the Norm team gathering significant praise for the project proposal on waste energy recovery.

The Norm Holding team included Senior Sustainability Specialist İzel Özgür Tekeli, Method Engineer Elif Yegen, Strategy and Business Development Specialist Berk Akşit, under the leadership of Sustainability and Management Systems Director Muhsin Doğan.

“We place great importance on supporting the transformation and development of society and the business world, especially our customers. While driving this transformation with high value added, high-quality, safe and innovative products, we also support the development of the sectors and regions in which we operate through the responsible investment approach we have adopted,” underlines Mustafa Sabri Doğrusoy, sustainability committee chairman at Norm Holding.

He added: “Sustainability is critical in every department and area of our company, serving as a core focus across all our business processes.

The project presented at the Leaders Summit, developed through the collaboration of our colleagues from sustainability, strategy, and methodology departments, holds special significance as it reminds us once again that sustainability is a responsibility shared by all departments and, indeed, by all of us.”

by Jason Sandefur, editor/publisher, GlobalFastenerNews.com

The global industrial fastener market, valued at US$91.34 billion (€83.9 billion) in 2023, is projected to grow at a CAGR of 3.5% through 2030, according to Maximize Market Research.

The industrial fastener market is witnessing significant trends, including the miniaturisation of fasteners – to meet demand for compact and multifunctional products in industries such as consumer electronics, healthcare and automotive.

Additionally, there is a growing focus on innovative fastening technologies that enhance functional permanence and operational efficiency. The trend towards sustainability is also influencing the market, with a shift towards using environmentally friendly materials and processes in fastener production.

Opportunities are emerging from the increasing demand for lightweight and durable materials, particularly in the automotive and aerospace industries. The push towards electric vehicles and advancements in renewable energy infrastructure also present new avenues for growth.

The adoption of smart manufacturing technologies, and the development of customised fastener solutions for specific applications, are additional opportunities that market players can leverage. The Asia-Pacific region accounts for over 45% of total output. The region’s manufacturing sector is growing rapidly, driven by significant foreign investments and favourable economic conditions.

The seasonally adjusted Fastener Distributor Index (FDI) improved to 53.8 in August (July 47.5), “mainly on a recovery from last month’s abysmal sales reading, much slower supplier deliveries and slightly higher pricing,” wrote R.W. Baird Analyst David Manthey with Quinn Fredrickson.

Sales, supplier deliveries and customer inventories drove the improvement, while employment remained flat. Nearly four in 10 respondents (35%) indicated sales came above seasonal expectations compared to just 22% last month and the 34% average over the past year. An equal amount of respondents said sales were in-line with expectations.

The fastener industry is working with manufacturing customers to seek new ways to reduce vehicle weight – by reducing the number, type and weight of fasteners, Design News reports. In terms of number of parts in a vehicle, fasteners can be up to 50% of the vehicle’s Bill Of Material (BOM).

Reducing the number of fasteners through innovative fastener technology helps manufacturers meet new Corporate Average Fuel Economy (CAFE) standards, requiring an industry wide fleet average of 50.4 mpg for passenger cars and light trucks, by 2026.

There are several ways fastener manufacturers are helping automotive OEMs innovate to improve performance, according to Design News, including:

Optimising production with advanced raw materials to enable manufacturers to produce high performance, cost-effective lighter weight products – with better fuel efficiency and enhanced performance.

Working in an integrated fashion that combines design, analysis and optimisation techniques for lightweighting products, at the request of OEMs.

Redesigning fasteners, moving to lightweight materials, such as going from steel to aluminium, to reduce weight in areas like non-structural rivet applications.

As part of CAFE efforts, the fastener industry is continuing to do its part to introduce methods reducing weight in vehicles by consolidating parts; redesigning and reengineering fasteners; using alternative materials; and generally thinking of new ways to reduce weight and increase performance.

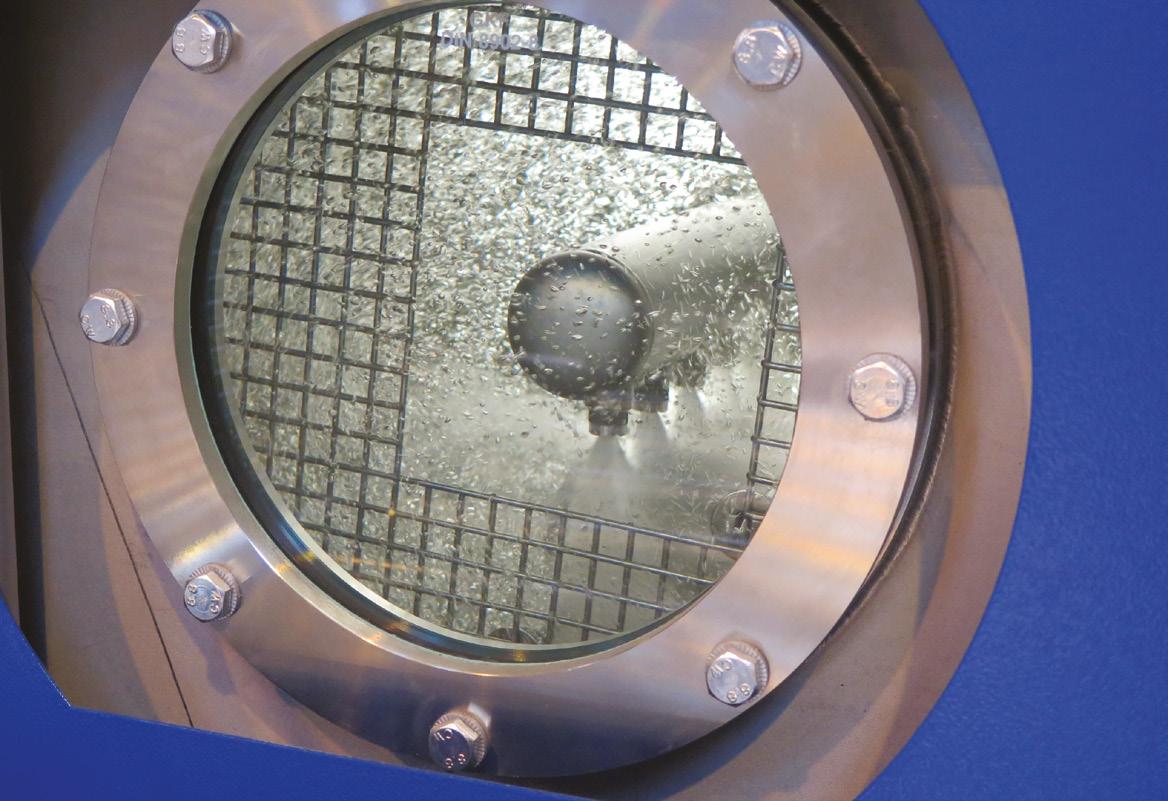

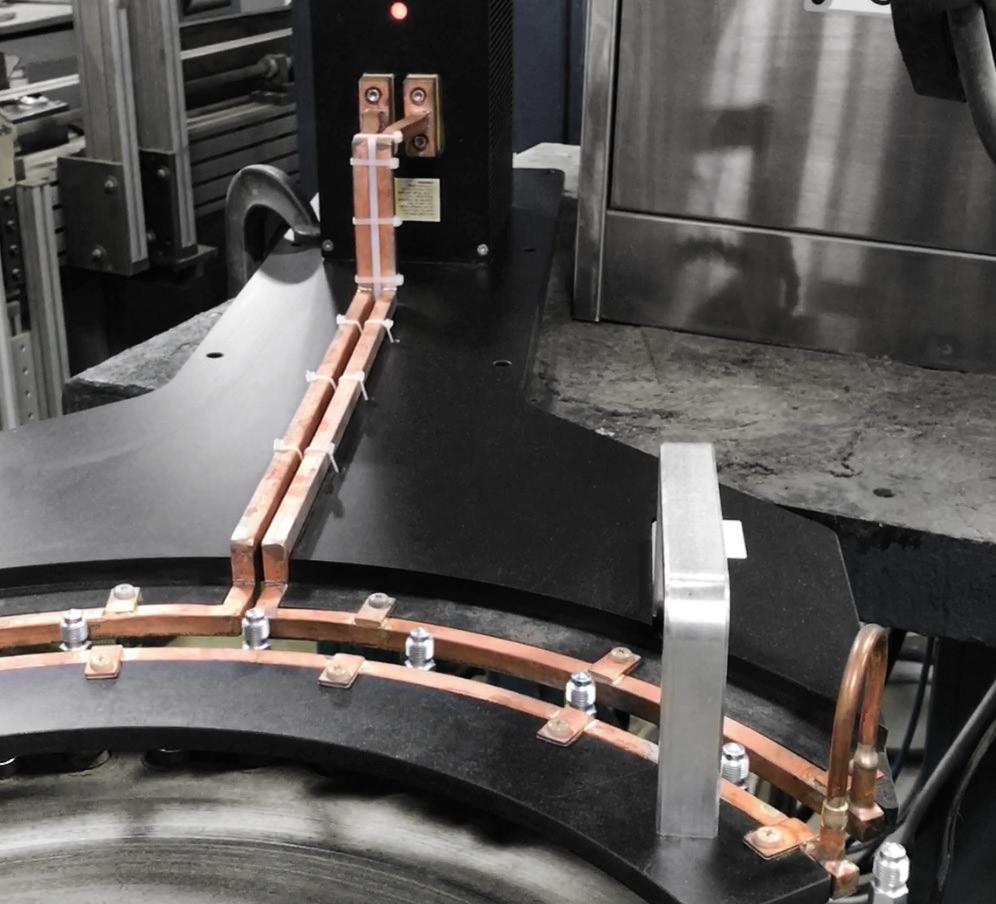

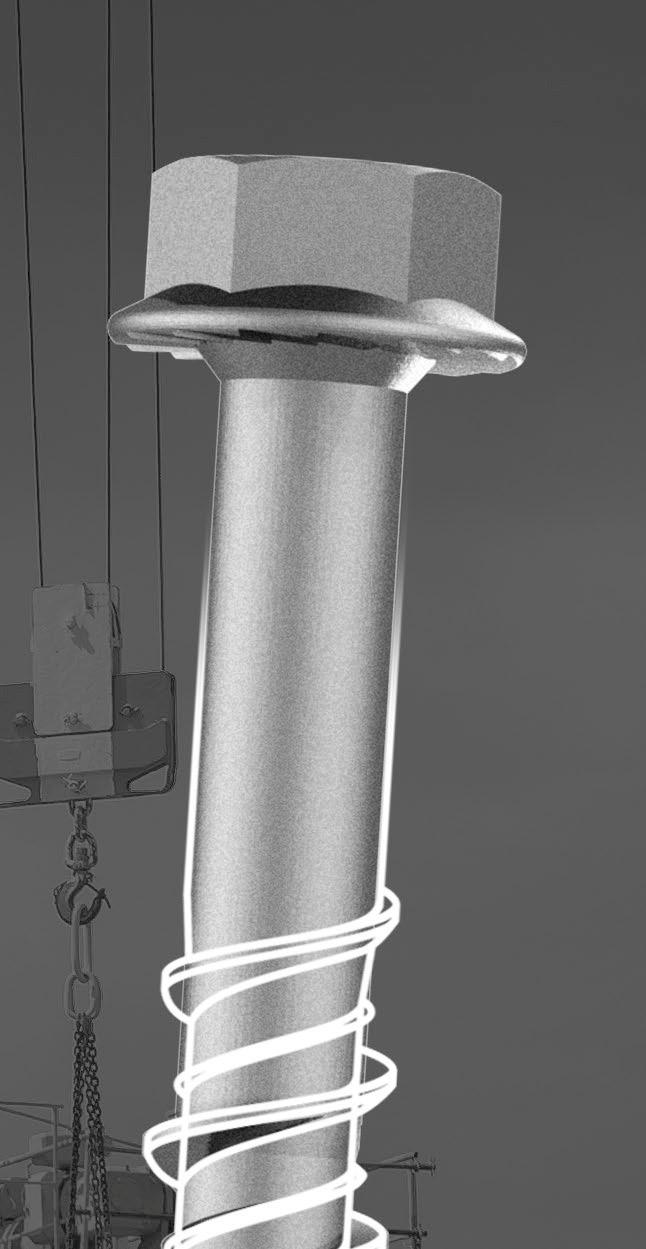

Weidmuller USA recently introduced BOLTcontrol, a monitoring that detects broken bolts or studs in the wind blade root that connects to the hub, alerting operators immediately of any issues.

With BOLTcontrol, broken bolts are held securely in place with detection plates, which prevent consequential damage that would result if pieces fell into the hub and ricocheted as it rotated. By continuously monitoring the rotor blade bolts, BOLTcontrol minimises downtime, reduces repair costs and ensures the safe uninterrupted operation of the turbine.

“The bolted connections between the hub and the rotor blade are constantly subjected to dynamic loads in a wind turbine,” explains Pete Tecos, director of new energy solutions at Weidmuller USA. “Stud and bolt failures have become more common and BOLTcontrol not only alerts operators to blade root fastener failures, but also prevents the fractured components from falling into the hub, thereby avoiding costly damages to the pitch systems and other critical components.”

Primary benefits of BOLTcontrol includes prevention of damage – holds broken bolt securely in place to avoid damage to hub and components; ensures continued operation – improves safety at the turbine site and a reduction of climbs for needed repairs; safe and economical – reduces downtimes and control operation and maintenance costs by continuously monitoring the blade bolts; as well as being quick and easy to retrofit – adaptable and can be customised to different turbine types.

“Using ‘real time’ data at the site, decision making can significantly improve with BOLTcontrol. This helps operators prioritise inspections based on conditions of the blade root connection and be one step ahead of maintenance and service needs.” highlights Pete

R.J Leahy Company Inc, a 96 year old fastener distributor in San Francisco, has closed permanently after filing for Chapter 7 bankruptcy.

The storied company supplied metal fasteners that “held together WWII-era ships, Disneyland art commissions, and historical renovations of restaurants, residences and San Francisco City Hall,” according to the San Francisco Business Times.

Founded in 1928 by Ray Leahy Sr, the company prospered in the growing maritime and military industries by offering non-ferrous fasteners, as well as copper and brass metal products. As those industries faded in the Bay Area, R.J. Leahy supplied fasteners and metal products to contractors, architects, artisans, and metalsmiths, looking for vintage fasteners.

By studying the financial reports from 2021 to 2023 in Commonwealth Magazine Issue 798 (May 2024), Fastener World Magazine has created a table for the top Taiwanese fastener companies in 2024. Units of revenue, profit after tax, and total assets, are in NT$ 100 million.

During its production and sales meeting for Q4 2024, on 3rd September 2024, Taiwan China Steel Corporation (CSC), the largest integrated steel maker in Taiwan, reported on the status of the global economy and Taiwanese fastener industry to more than a hundred business owners and professionals working in the fastener, wire rod, surface treatment and machinery industries.

As part of the briefing, the National Development Council of Taiwan announced that Taiwan’s leading indicators and concurrent indicators continued to rise, showing that the domestic economy maintains a growth trend. As of July, Taiwan’s purchasing managers’ index had exceeded the boom-bust line for three consecutive months and remained in an expansion state. Export orders had achieved positive growth for five consecutive months.

The cumulative export orders value from January to July this year increased by 2.7% compared with the same period last year. The IMF, Taiwan Institute of Economic Research, and other institutions also predicted that Taiwan’s GDP growth rate in 2024 will exceed 3% and be up to as high as 3.9%.

In the first seven months of 2024, Taiwan CSC imported 277,000 tonnes of wire rods from around the world, an increase of 34% from

206,000 tonnes over the same period last year. Among them, 33% of wire rod imports were from Indonesia, 21% from South Korea, 12% from India, 11% from China, 8% from Japan, and 7% from Vietnam. The materials of imported wire rods were mainly low carbon steel (accounting for 50%) and alloy steel (42%).

According to statistics from the Taiwan Industrial Fasteners Institute, the export weight of fastener products in the first seven months of 2024 was 740,100 tonnes, a year-on-year decrease of 2.77%. The average export unit price was US$3.5, an annual decrease of 8.05%. Although Taiwan’s fastener export weight to Germany dropped by 13.31%, the export weight to the USA, Japan and Canada increased by 1.83%, 0.4% and 22.17% respectively. As of the second quarter of 2024, Taiwan’s fastener export weight to the world achieved a

of 1.6%.

Chinese new energy vehicle manufacturer, BYD Company Ltd, expects to sell 50,000 electric vehicles in Mexico this year and aims to achieve a sales target of 100,000 by 2025, with plans to open its first factory in Mexico.

It is reported that the initial production capacity of this new factory will reach an annual output of 150,000 electric vehicles, with potential expansion to an annual output of 300,000 in the future, demonstrating BYD’s confidence in the development prospects of the Mexican market.

Jorge Vallejo, general manager of BYD Mexico, stated that the company expects to announce the location of this factory by the end of this year.

On 10 th October 2024 the Yongnian International Sourcing Fair of Fasteners was successfully held, establishing a deep communication bridge for the fastener industry in Yongnian to access the international market, as well as inject new vitality into the integrated development of regional industrial clusters and high-quality growth in foreign trade.

With the theme of ‘Connecting Global Fastening Force to Build Yongnian Purchasing Festival’, the event attracted industry professionals from around the world. Through a series of carefully planned activities, such as business matchmaking meetings, product exhibitions, and technical exchanges, the event provided a precise matching platform for global fastener enterprises, enabling efficient communication and cooperation between suppliers and buyers.

The event not only broadened the international market horizons of Yongnian’s fastener enterprises, but also provided global buyers with direct access to the latest technologies and high-quality products in China’s fastener industry, further enhancing the international competitiveness of Chinese fasteners.

The successful hosting of the event significantly increased the international reputation and brand influence of Yongnian’s fastener products. Driven by the fair, the synergistic effects within Yongnian’s fastener industrial cluster became more pronounced, actively guiding enterprises towards high-end, intelligent and green development. At the same time, the event also encouraged enterprises to adopt international standards, improve product quality and service levels, as well as promote the transformation of the entire industry towards a higher quality foreign trade development model.

China’s Zhejiang Geely Holding Group Co Ltd has signed a cooperation agreement with Vietnamese enterprise Tasco, planning to construct a joint venture automotive assembly plant in Thai Binh Province, Vietnam.

The total investment for this joint venture project is expected to be approximately US$168 million, (€156 million) with Geely contributing 36% of the capital.

I nitial annual production capacity of the joint venture is expected to be 75,000 vehicles, primarily assembling models under the Lynk & Co and Geely brands, with potential expansion to other brands in the future. The new plant is expected to commence construction in the first half of 2025, with the first batch of vehicles anticipated for delivery in early 2026. Meanwhile, Tasco’s subsidiary, Tasco Auto, will become the official dealer for the Geely brand.

In the first half of 2024, Geely’s cumulative export sales reached 197,428 vehicles, marking an increase of over 67% compared to the previous year. Based on this strong market performance, Geely has revised its annual sales target for 2024 to 2 million vehicles. The collaboration with Tasco will undoubtedly further propel Geely’s strategic layout and development in the international market.

By Fasteners India

Super Screws Pvt Ltd, one of the leading Indian bolt manufacturers, has announced the signing of a Memorandum of Understanding (MoU) with Mitsuchi Corporation, an Japanese-based provider of custom fasteners for automotive components in Japan.

The MoU aims to establish a joint venture for setting up a new plant in India focused on the manufacturing and sale of special cold forged parts. The joint venture highlights Super Screws’ intent to fulfil the rising needs of local Japanese companies and the burgeoning Indian market.

SK Kapoor, chairman at Super Screws, comments: “Super Screws has always been in pursuit of new and advanced technologies. This new partnership strengthens the engineering competence of the company and accelerates the localisation and manufacturing of cold forged parts for the Indian market and global exports.”

Reiterating similar sentiments, Samrat Kapoor, director at Super Screws, highlighted key offerings from both the parties. He mentioned Super Screws’ expertise in value focused engineering, manufacturing processes, and customer connections, as well as Mitsuchi’s technical know-how, global experience, and future technology access and how they create a formidable platform for success and growth in India.

Sundram Fasteners has reported its standalone net profit for the first quarter of 2024 increased by 17% year-on-year to INR 131.64 crore (€14 million) compared to the INR 112.78 crore during the same period of the last fiscal year. Profit before tax reached the highest for the company, reaching INR 177 crore for the period, an increase of 17.4% on the previous year.

Earnings before interest, depreciation, and taxes (EBITDA) for the quarter were INR 223 crore, and the margin was at 17%. Gross margins showed an enhancement due to growth in exports, comparatively sound commodity prices and a favourable product mix. Operations revenue even grew to a record INR 1,310.33 crore, up 7.7% from the previous year. Domestic sales were up by INR 855.75 crore, which was a slight increase from the previous year. Exports surged by 21.5% to INR 422.65 crore.

Preethi Krishna, the eldest daughter of Suresh Krishna, chairman at Sundram Fasteners, is planning to sell a part of her stake in the holding company. Preethi’s stake will be acquired by her father Suresh Krishna, mother Usha Krishna, and sisters Arathi Krishna and Arundathi Krishna, further consolidating their control in the holding company.

To finance this transaction, the four family members propose to offer INR 400 crore (€44 million) of Sundram Fasteners shares to institutional investors, including those from the Middle East.

After the proposed transaction, Preethi will be left with a 14% – 15% stake in the holding company, from the present 20%, whereas her family members would continue to hold 20% each in the company. Currently, the holding company owns 48% of the stock in Sundram Fasteners and has a market capitalisation of INR 28,000 crore. The sale involves a block deal of 1.5% of Sundram Fasteners shares to foreign investors.

Sérgio Milatias, editor, Revista do Parafuso, www.revistadoparafuso.com.br

Böllhoff Brazil – headquartered in Jundiaí town, São Paulo State,since 1964 – recently celebrated its 60th anniversary, with the celebrations dedicated to local employees and executives.

Guests to the celebration also included global directors CFO Thomas Pixa and co-CEO Wilhelm Böllhoff, who spoke Portuguese to the attendees. A manufacturer of a wide range of mechanical fastening elements, with strong ties to customers in the automotive sector, as a leading fastener provider, Böllhoff Brazil’s 60th celebration was a good ‘rehearsal’ for the larger Böllhoff Group who will achieve the impressive 150 year milestone in 2027, with a big celebration planned.

Fontana Gruppo recently celebrated 10 years in Brazil, with several key guests attending the ceremony, including Fabrizio Fontana and Salvatore De Giorgi – board member and COO of Fontana Gruppo respectively – who travelled from Italy to take part in the celebration.

The ceremony opened with brief speeches from Fabrizio and Salvatore, followed by Fernanda Bueno (interim development secretary of Atibaia). Presentations by Nei Teodoro (general director at LATAM general) and Hailton Alcantara (commercial director) concluded the formal part of the event. The event wrapped up on a high note with a tour of the factory, a cocktail party and a special gift for all the guests – a commemorative book celebrating the Group’s 70th anniversary.

As one of the leading global players in the fastener manufacturing industry, with over 70 years of experience, the Fontana Gruppo consolidated its presence in Brazil back in 2014. It further solidified its presence by acquiring eleven Acument industrial units located in the USA, Mexico and Brazil. Since then, all operations, including the two facilities of Acument Brasil, have been fully integrated under the Italian group’s control.

Founded in 1943 in São Paulo, originally under the name Mapri, the company has built a reputation for adhering to the highest quality standards in the supply of fastening systems, particularly for the Brazilian automotive sector (cars, trucks, buses, agricultural and road machinery, as well as motorcycles).

Under Fontana’s leadership, the company further strengthened its position by expanding its industrial park – with the introduction of robust multi-stage presses and thread rolling machines, along with numerous other investments, such as in laboratories, inspection systems, heat treatments and various other aspects of ‘Made in Brazil’ production.

Since it was acquired by Primat Curtis Group in 2022, Prosdac – the Brazilian anti-corrosive coatings service company – has looked to continue to develop and take the next step in its growth through strategic investments.

Located in Jundiaí Town, São Paulo State, Prosdac has been receiving robust investment from Primat Curtis since the acquisition, including the purchase of a neighbouring warehouse – increasing its total area to 10,000m². Other investments included the introduction of a new painting line with an overhead conveyor, two new finishing lines with a new state of the art oven, and a big investment in its people, such as the introduction of the English language into daily operations, especially after the new Brazilian Operations Director Danny Thompson joined the business.

“I have been in automotive Tier 1 companies my entire career, almost 23 years now,” underlines Danny.

“I have worked in many divisions inside industries, such as interior, exterior, stamping, injection moulding, blow moulding, paint and paint systems, as well as full on assembly, which includes headliners, consoles, door panels, glove box and digital instrument panels. This gives me excellent experience that I can use for Prosdac.”

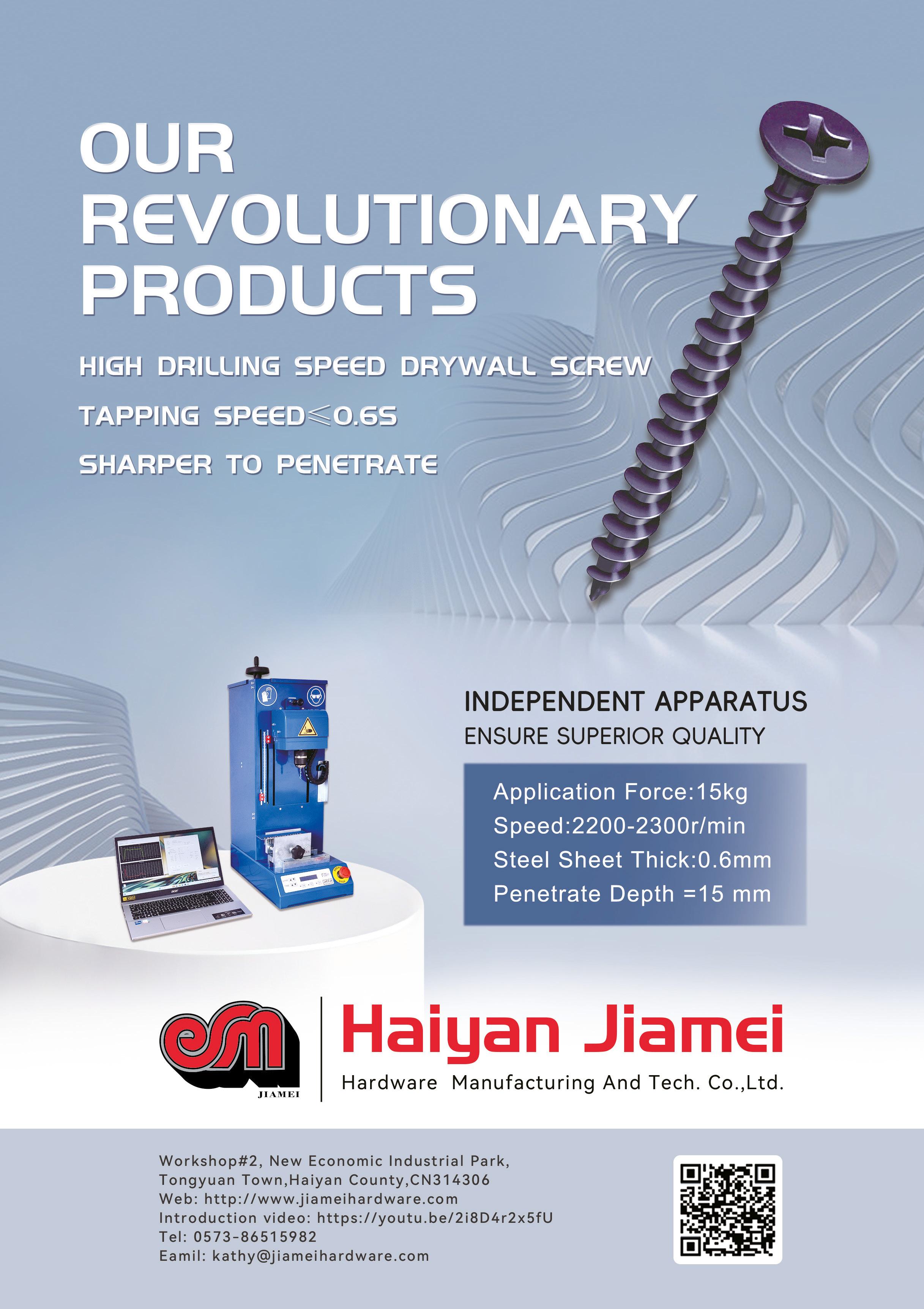

You joined Nord-Lock Group three months ago, what insights and perspectives do you bring with you? Tell us a little more about your career history.

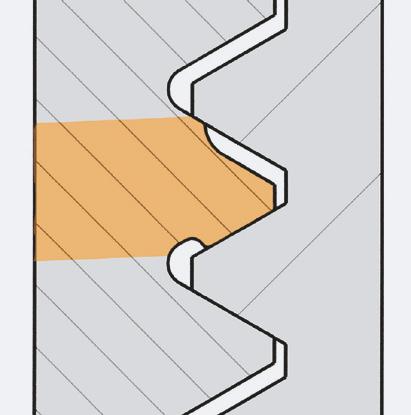

“I spent the first 20 years of my career within the SKF Group, where I held various positions in departments such as sales, manufacturing, business development and acquisitions. Looking at the customer ecosystems, there are many similarities between SKF and Nord-Lock Group and what I’ve learned during my time at SKF is valuable. This includes insights related to manufacturing, where I can leverage my experience in high volume bearing production and apply it to the high volume manufacturing of Nord-Lock washers.

For the past eight years, I served as CEO at Ewellix, a global automation company with around 1,300 employees. Ewellix supplies components and subsystems and manages high mix, low volume production, which is similar to how the Nord-Lock Group technology brands Superbolt®, Boltight® and Expander® operate. However, learning never stops, and I continue to experience new and exciting things every day here at Nord-Lock Group.”

What are your initial impressions of Nord-Lock Group and the fastener market in general?

“There’s plenty to be excited about when it comes to the fastener market and Nord-Lock Group’s position. The fastener market is a large and offers numerous high potential opportunities to grow our business.

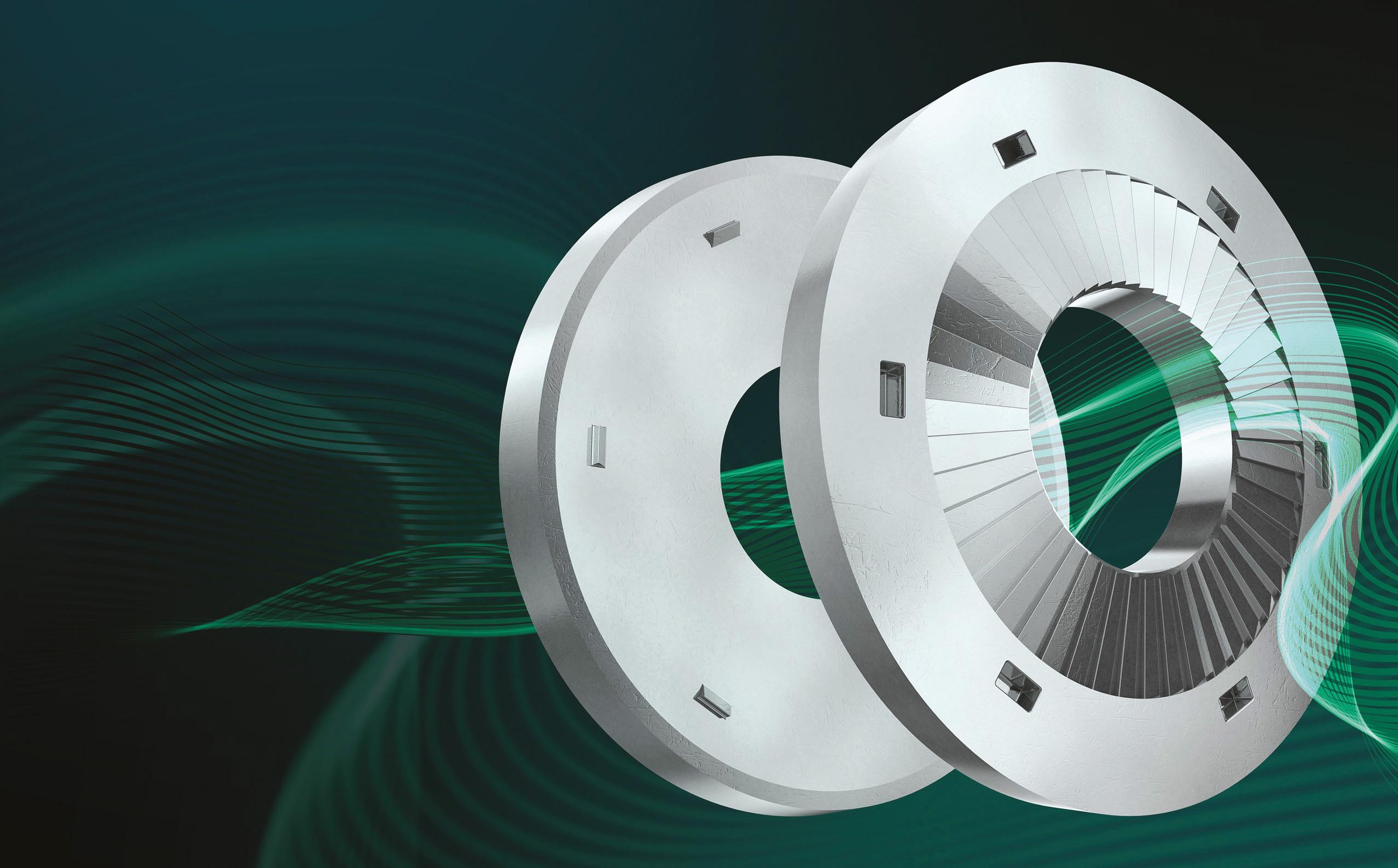

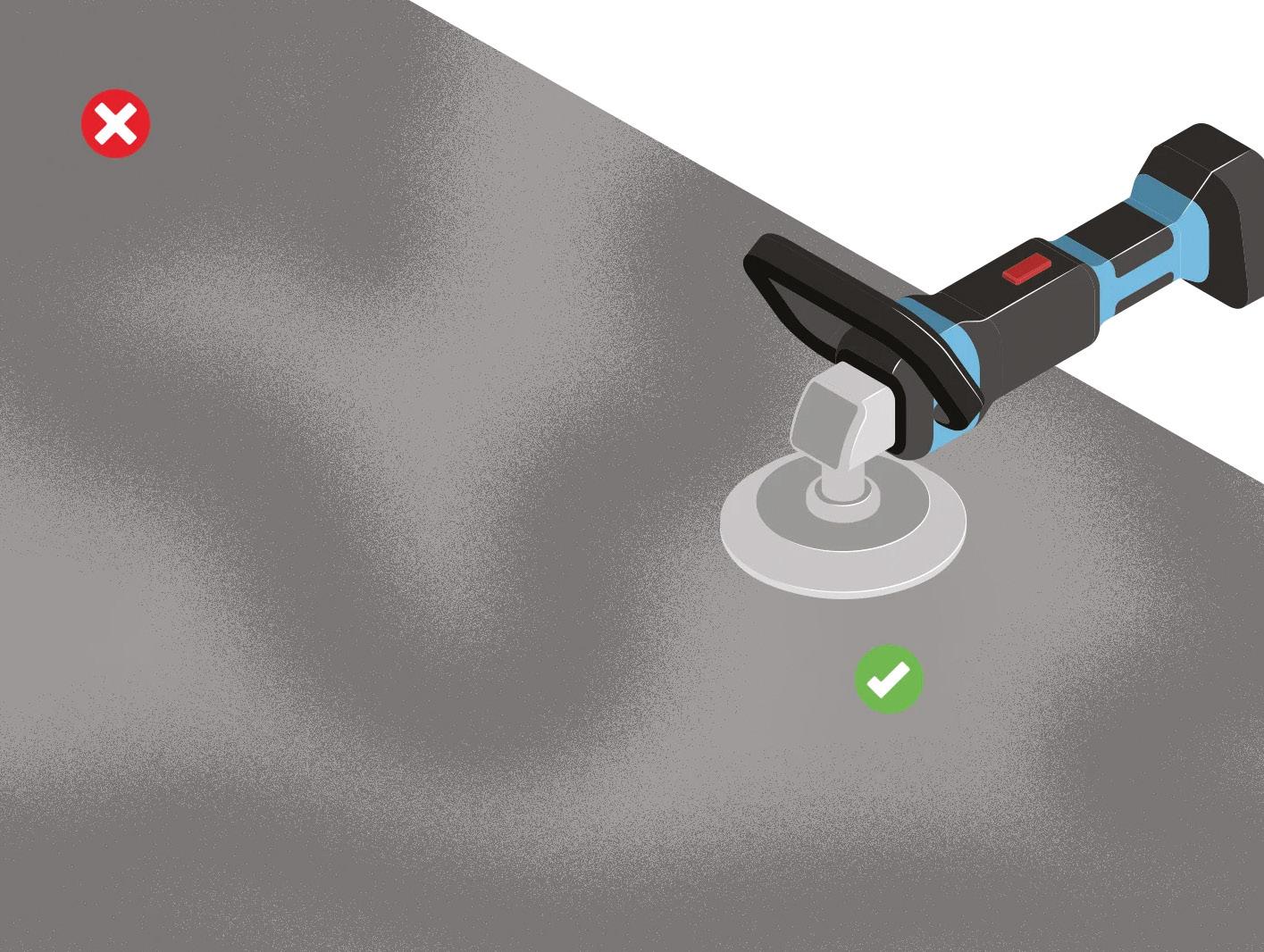

On 1st August 2024, after a period of reorganisation, Daniel Westberg became Chief Executive Officer at Nord-Lock Group. We caught up with Daniel to discuss what this means for customers and how, as the global leader in bolting and engineering solutions, Nord-Lock is committed to delivering what its customers’ need, when they need it.

As the leader in the fastening industry, NordLock Group is well positioned to pursue opportunities, particularly through our business unit Nord-Lock, which offers an outstanding product portfolio of wedge-locking washers – creating exceptional customer value across a wide range of applications.

The tensioning side of Nord-Lock Group is quite engineering intensive and when coupled with an extensive global distribution network, it translates into impressive capabilities for supplying both standardised and customised solutions that serve the needs of our customers.

Nord-Lock’s network of partnerships and distributors is another aspect that excites me about Nord-Lock Group’s position in the fastening industry. As a crucial component of the company’s success, I am committed to continuing to cultivate and expand these mutually beneficial partnerships.

What Nord-Lock Group has managed to achieve in terms of product quality, on-time deliveries, and short lead times, is something that I’ve been really impressed with. It’s nothing less than world class and creates significant value for our customers. This value is both direct, for example, by enabling customers to carry less inventory, and indirect, by avoiding costs related to replanning and dealing with quality issues. We are also known for our exceptional experience and expertise, which our customers can rely on no matter where they are located in the world. Add to this the internal process control, and years of performance in every mechanical and industrial application imaginable, and there is certainly a great deal of substance behind the unique lifetime warranty that Nord-Lock Group offers.”

Last year Nord-Lock Group went through a period of reorganisation to become more customer driven – why was this decision made and what are the benefits to customers?

“An organisational set-up with three business units, each having end-to-end responsibility for delivering what their customers need, makes a lot of sense. This is because getting Nord-Lock washers to our customers through a distributor is quite different from engineering a tensioning solution for large industrial applications –together with an OEM. With our decentralised, customer first set-up, we can excel in all of our business processes while ensuring that our customers’ needs permeate the entire

organisation at all levels. Reassuringly, I’ve already been part of quite a few customer meetings, and based on the positive feedback we receive, our organisational customer first approach is certainly working.”

How has 2024 progressed for Nord-Lock Group and how do you see the next twelve months developing?

“Nord-Lock Group is growing and we are actively trying to accelerate that growth. Fortunately, we have several ways to achieve this, such as leveraging internal initiatives, making investments, or acquiring businesses that fit into our business model.

However, we are not immune to the effects of the year’s long trend of weaker industrial demand. I do want to stress, though, that we are well aware of, and prepared for, potential business climates ahead and the challenges they can bring. In any case, I am fully confident that with our customer first philosophy, and competent team of co-workers, we will have what it takes to navigate uncertain times and still deliver what our customers need, when they need it.

We can do this thanks to Nord-Lock Group’s dedicated sales teams, in about 25 countries, each with an extensive partner network. By combining the benefits of being close to our customers with an extensive global reach, we can support and collaborate with customers in every region of the world.

I believe that at this moment, we are at a low point in terms of demand. After the turbulent years brought by the Covid-19 pandemic, inventories are back to normal levels. I also expect industrial demand to start growing again during 2025 as interest rates drop in Europe and North America, as well as with the increase in stimulus we see in

Nord-Lock Group is growing and we are actively trying to accelerate that growth.”

China. So, from our side, we’re ready to meet such growing demand for our products with maintained short lead times and virtually 100% on time deliveries. All of this brings me to a positive future outlook and I believe that 2025 will be another positive year for Nord-Lock Group.”

Sustainability continues to grow in importance within markets. What steps has Nord-Lock Group taken on this topic and how do you see this area developing? Have you seen demands from customers in regards to sustainability?

“As the dangers of our changing climate become increasingly noticeable, Nord-Lock Group takes this very seriously. As one

of the larger companies in the industry, we acknowledge our position to achieve real positive impact, which we strive to do in several ways. Firstly, we have a responsibility to engage our co-workers so that their knowledge, curiosity and entrepreneurship can contribute to our company’s sustainability transformation, as well as that of our entire industry.

Secondly, we commit ourselves to a comprehensive sustainability programme that addresses not only environmental sustainability issues, but also business ethics and social sustainability. With our Code of Conduct for business partners, we ensure that these partners are aligned with our values. We have also committed to the Science Based Targets initiative to reduce emissions in-line with the Paris Agreement, which will entail investments and changes to our own operations, as well as awareness and mitigation of emissions related to our suppliers and other partners in the value chain.

In regards to customer demands changing, the short answer is yes. Compared to only two years ago, our partners and customers now want more information about exactly how we work with sustainability. Many of our bigger accounts also define specific thresholds for sustainability performance in their tendering processes, and if we don’t manage to meet their standards, we’re no longer a viable option for them. We must show that we not only take environmental issues, human rights and a sustainable supply chain seriously, but also that we have focused initiatives in place committing us to net zero carbon emissions by 2040.

Moving forward, we will see more customers wanting to know the environmental impact of specific products. Given the challenges of raw material shortages and climate change, the use of circulated or carbon free steel will grow. So, life cycle analysis to determine our products’ environmental footprint will be a bigger focus of ours, both because our customers demand it and in order to make a positive contribution to the sustainability of our industry. We believe all of these developments are overwhelmingly positive and well needed.”

www.nord-lock.com

By Alexander Kolodzik, secretary general, European Fastener Distributor Association

It has now been a year since the European fastener industry found itself in the CBAM transition period and the sector is struggling with the challenges of the EU Carbon Border Adjustment Mechanism –with the reporting requirements for EU importers of fasteners increasing once again for Q3 of 2024.

The further complication for Q3 onwards is that EU importers can no longer use the European Commission’s default values for direct and indirect emissions for their quarterly report in the CBAM transition register. Instead, they must report the actual values of the emissions generated during the production of the imported fasteners. This poses major challenges not only for European fastener distributors, but for all participants

The further complication for Q3 onwards is that EU importers can no longer use the European Commission’s default values for direct and indirect emissions for their quarterly report in the CBAM transition register.”

in the supply chains – from any intermediaries to the manufacturers of the fasteners, as well as the suppliers of the raw materials used to produce the fasteners. According to CBAM, all parties are required to provide EU importers with data on emission values and other data so that EU importers can fulfil their legal reporting obligations according to CBAM. However, this is a huge endeavour that requires tremendous efforts from all parties involved.

The European Fastener Distributor Association (EFDA) is making every effort to ensure European fastener distributors, and their business partners around the world, can meet these challenges as effectively as possible. It is clear that the EU CBAM regulation has been prepared too hastily and poorly, which is why the mechanism is completely inadequate and, in particular, unsuitable for downstream products such as fasteners, which have complex supply chains and thousands of parties involved around the world. It is also obvious that EU importers under CBAM are at a severe disadvantage compared to EU manufacturers of fasteners under the European Trading System (ETS), especially from 2026 when EU importers must buy CBAM certificates per tonne of emissions embedded in the imported goods. For this reason, EFDA is advocating for fasteners to be excluded from the scope of CBAM. However, that is not the issue at hand in this article.

Currently CBAM still applies to EU fastener importers and as an association we are doing everything we can to support our members. That is why EFDA, with its members from the national member associations and companies, has set-up an EFDA CBAM Working Group –with a group of experts from distributor companies in various European countries. This team is doing an excellent job, which enables us to keep our industry informed about many aspects of CBAM and provide them with some useful documents and tools.

From the outset, we have kept our members informed about CBAM in webinars that we conducted together with the steel expert Andreas Schneider from StahlmarktConsult. We have also provided them with shorter and more detailed briefing documents that they can use to inform their suppliers that they, too, are affected by CBAM and how. This also applies to the many intermediaries who have to provide EU importers with CBAM data from the manufacturers they used to purchase the goods, an extremely difficult task.

Suppliers need to understand CBAM in order to obtain the data to be reported. This is a huge challenge for all parties involved, but especially for small and medium-sized companies around the world. The communication template created by the European Commission is far too extensive and complex for suppliers to use to report the required data to their customers in Europe. EFDA therefore created its own template very early on, which requests the necessary data in a clear and user-friendly way. Despite all our efforts, the number of suppliers that returned the template with specific emission values was only 12% a few months ago.

Since specific emissions data must be reported from the third quarter of 2024, the EFDA CBAM Working Group, together with the consultancy Carboneer, has added an EFDA Calculator to the EFDA Template. The EFDA Calculator makes it easier for fastener manufacturers to calculate the data to be supplied for direct and indirect emissions. A new ‘EFDA guide for non-EU suppliers of fasteners subject to CBAM’ also provides

information on the main hurdles of CBAM and highlights the most important aspects when completing the EFDA template. The EFDA guide has been prepared by Carbooner and the expertise of the members of the EFDA CBAM Working Group. We have also created a tutorial that guides users step by step through the EFDA template. Initial reports from our members confirm that the quantity and quality of the data reported by suppliers has increased since then.

Nevertheless, it remains extremely difficult to obtain the required information from all suppliers. EFDA and its member associations and companies will therefore continue to work to ensure that the enormous burden that CBAM places on our industry is lifted.

www.efda-fastenerdistributors.org

EU importers under CBAM are at a severe disadvantage compared to EU manufacturers of fasteners under the European Trading System (ETS), especially from 2026 when EU importers must buy CBAM certificates per tonne of emissions embedded in the imported goods…”

Are you facing challenges developing your application? We offer a tailored solution with lightweight design, more clamping force and smaller fasteners.

KAMAX experts challenge your drawing, analyze your problem and review your application. Our dedicated Application Engineering team is always at your side.

What you need is what we have: bolt design, lab validation, simulation of assembly conditions, supply of test parts as well as high-quality production and shipping of your fastener solution – anywhere in the world.

As a business driven by the need to optimise customer satisfaction, Owlett-Jaton is continually looking to invest when it sees an opportunity to improve the service it offers to its customers and make cost savings. The installation of its vertical storing storage systems are a prime example, as they support the UK wholesaler’s mission to offer customers an extensive ‘one stop shop’ for fasteners and fixings.

Investing over GB£500,000, Owlett-Jaton has installed nine Modula vertical lift storage machines at its Staffordshire warehouse. These machines have enabled Owlett-Jaton to expand its product range; improve picking speed and accuracy; create a safer working environment; and become more cost efficient at the same time.

Each machine has over 60 trays with a weight capacity of 750kg per tray and each tray can be adapted to hold up to 50 different products. The choice of products depends on pack type, size, weight and pick frequency, with Owlett-Jaton now able to store and pick over 6,500 products in an area that previously only allowed for 450 products. This additional capacity enabled the launch of a 1,000+ strong range of rivets under the JRP brand and the consolidation of over 5,000 products from a second warehouse, bringing all picking activity under one roof and consolidating company stockholding.

Part of Owlett-Jaton’s customer offering is the ability to place orders up to 17:30 – with customers receiving delivery the next working day. With over 7,000 lines per day being picked, this creates a period of intense activity between the order cut-off and the timing of the last trailer leaving for the carrier hub at 22:00. The vertical storage systems allow for much higher picking rates to be achieved, with a good operator being able to pick over 200 lines per hour, compared to around 40 lines per hour in conventional picking.

This additional speed is invaluable in keeping to the tight deadlines created in meeting the next day promise to customers. The vertical storage systems operate by bringing the product to the picker and have an inbuilt laser pointer system to identify which products are to be picked, thus reducing the potential for errors, particularly important at such high picking rates.

The health, safety and wellbeing of its staff is of paramount importance to Owlett-Jaton, and by installing the Modula machines a number of health and safety benefits were also realised. The first was that picking from the machines is done at waist height, with the product being brought to the operator. This eliminates the need for much of the

bending and stretching, which was needed previously. Given the heavy weight of many fastener products, this reduces the risk of strains and other injuries in the workplace.

A second major benefit was realised as the vertical storage systems have enabled the creation of a large pedestrian only, vehicle-free zone in the warehouse, reducing the risk of staff being hit and hurt by one of the forklift trucks or order picking machines. The machine picking also provides another different job in the warehouse and facilitates the rotation of staff between roles, lessening the risk of repetitive strain injuries.

Financially the Modula machines have also proven to be a sound investment. The higher picking rates achieved have enabled a reduction in headcount, which, even after all maintenance costs were factored in, enabled the machines to pay for themselves in under three years.

Replenishment of the Modula machines is done during the night shift via system generated replenishments at a time when there is no scheduled picking of customer orders. The team replenish the machines with approximately five days’ worth of stock. The mix of products in the machines is kept under constant review – with the aim to optimise the right balance between exploiting the picking rates that can be achieved, and the amount of stock that needs to be held to ensure stock is always available to pick. The sheer volume of some of the faster moving lines keeps them in pallet-based picking locations, as keeping them stocked in the Modula machines would prove a challenge.

Owlett-Jaton’s entire warehouse has changed many times over the last 75 years. Modern warehouses with narrow aisle multi-level pallet racking are increasingly becoming the norm, but the addition of modern picking automation is groundbreaking in the UK fastener and fixing wholesale industry – with Owlett-Jaton planning additional vertical storage systems in the future.

www.owlett-jaton.com

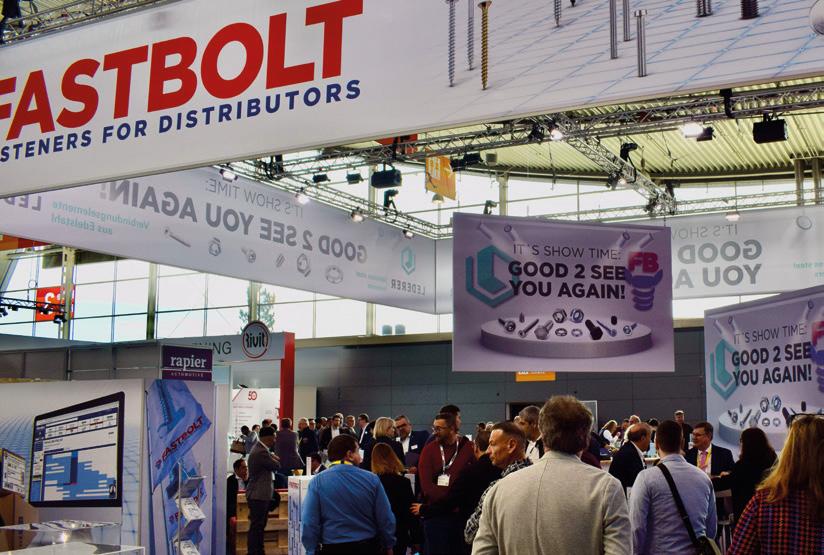

Lederer has confirmed current Managing Director Peter Henke will retire at the end of 2024, with Sebastian Ovenhausen, current managing director at NORMTEC Montage- und Befestigungstechnik GmbH –acquired by Lederer in 2021 – taking the role from January 2025.

Peter Henke has been a key part of Lederer for 32 years – playing a fundamental role in the company’s growth and success.

“Peter really has been a major player in our business and has always been ambitious and loyal to Lederer – handling the company as if it was his own,” explains Volker Lederer, also managing director at Lederer GmbH. “Over the years we have created an optimal relationship and worked together very constructively, and in a trustful way, which has led to Lederer being successful. I am very happy and honoured that he worked for us for such a long time and brought us to the position we are in today – especially in the end user railway sector, which in many ways was his ‘baby’ and is now a strong market for us. He has certainly helped us push forward and grow as a company and I wish him a happy retirement.”

With Peter retiring, Lederer has decided to appoint Sebastian Ovenhausen, current managing director of NORMTEC, as the new managing director. Acquired by Lederer four years ago, NORMTEC is also a distributor for stainless fasteners – partnered with effective and cost efficient logistic processes, whilst also guaranteeing high availability and precise delivery times.

“Sebastian has demonstrated his capabilities and leadership at NORMTEC and he will play a key role in the generational change of the management team at Lederer,” underlines Volker. “As a business we are looking to bring in the next generation of employees – putting them into more and more responsible positions within the management team, so we can guarantee our long-term success and continue to move the company forward.”

As a business we are looking to bring in the next generation of employees –putting them into more and more responsible positions within the management team, so we can guarantee the long-term success of Lederer…”

Volker adds: “Almost everything for NORMTEC customers will stay the same, in most cases even keeping the same contact person. It will only be those customers who buy from both companies where we will create one contact point.”

By integrating NORMTEC fully into Lederer it will also generate

With Sebastian becoming managing director of Lederer, it has also been decided that it is the right time to fully integrate NORMTEC into the Lederer brand. “NORMTEC is very similar to Lederer, but on a smaller scale, and with Sebastian becoming managing director sales, it was decided it would be more efficient to integrate NORMTEC fully into Lederer and provide both companies with new opportunities to grow going forward,” highlights Volker. “For example, the range of NORMTEC is relatively small, but we can add the Lederer range to the offering, meaning NORMTEC customers can get access to even more products.”

opportunities for Lederer. “With its end user business NORMTEC does some very special things, which could prove beneficial to Lederer and help us move further into new markets over the coming years,” mentions Volker. “The end user market is already proving a successful sector for us and we have established a reputation as a reliable supplier of stainless steel fasteners, especially within the railway market. Our position within the railway sector is very strong and the rail sector in the coming years will continue to grow, not only in Europe but around the world. As already mentioned, Peter Henke had a lot to do with our success in this area and we are keen to continue to grow the market.”

A prime example of Lederer’s success in the end user rail sector is its partnership with a global rail customer – who recently announced plans to establish a new branch on the east coast of the USA, with Lederer given the opportunity to tender for the business, for which it was successful. “As part of this tender process it was necessary for us to establish a branch in the USA and to be able to serve the customer directly,” explains Volker. “That is why we have set-up a branch close to the client. Whilst we already have customers in the US, this is the first time we have our own physical location, making it a big step for us.”

Volker continues: “Our first objective for Lederer USA is to serve the rail customer in question and ensure we are providing a first-class service. Once this is successful, we can think about possibly expanding our business within the US, but this a second or even third step for us currently. The main focus will be our key rail customer and guaranteeing a complete service.”

With the new management structure and generational shift; the addition of the US operation; as well as ongoing growth targets; Lederer is looking to reaffirm its organisation and structure in order to go on providing the products and service its customers have come to rely on. “At Lederer we realise the importance of continuously moving forward and growing as a business, which is why we have focused on our management team, the markets we supply, as well as the products and

services we deliver to customers,” concludes Volker. “We also make sure we are flexible as a business, so we can react quickly to the challenges of the market, such as freight costs, exchange rates, etc, whilst continuing to provide our customers with the products and services that have enabled us to become one of the leading companies within the stainless steel fastener sector.”

www.lederer-world.com

As part of the tender process it was necessary for Lederer to establish a branch in the USA, so it can serve its customer directly.”

Supplying over 175 customers in more than 25 countries, Indian manufacturer Gala Precision Engineering states it is embarking on a transformative journey of expansion, with an ongoing commitment to quality, as well as embracing sustainability, which promises to offer exceptional value to its global clientele.

As part of this journey, Gala Precision has launched its Initial Public Offering (IPO), a strategic move designed to fuel innovation, expand production capacity and enhance its global footprint. The capital raised is being invested in two key areas – expanding its existing Indian facility in Wada and establishing a new, state of the art manufacturing plant in Chennai.

The Chennai plant represents a significant milestone for the company. Strategically located to serve key markets more efficiently, this expansion brings Gala Precision closer to its customers in southern India and enhances connectivity to global markets such as Europe and the USA. This proximity reduces lead times and improves logistics, making it easier for customers to receive products faster and engage in collaborative projects.

Being closer to its customers also enables Gala Precision to better understand its customers’ specific needs and challenges, as well as deliver customised products that meet exacting specifications. This customer centric approach fosters long-term relationships – built on trust and mutual success.

At the heart of Gala Precision’s operations lies an unwavering commitment to quality. Gala Precision Engineering manufactures high-tensile fasteners and technical springs with unmatched precision and quality, adhering to stringent testing standards to ensure every product meets and exceeds customer expectations. Gala Precision is proud to be ISO and IATF certified, reflecting its dedication to maintaining the highest quality management systems in manufacturing.