As an integral element of the supply chain of European fastener distributors, Fastbolt has developed a wide range of digital connectivity tools to support the purchasing processes of its customers. With our own team of software developers we are able to provide customized EDI- and API-based connectivity and offer access to FBonline - our market leading e-commerce solution allowing customers efficient and intuitive digitized processes, information and documentation in purchasing. Fastbolt’s digital solutions help to reduce processing costs for fastener distributors and make daily sourcing of standard fasteners effortless.

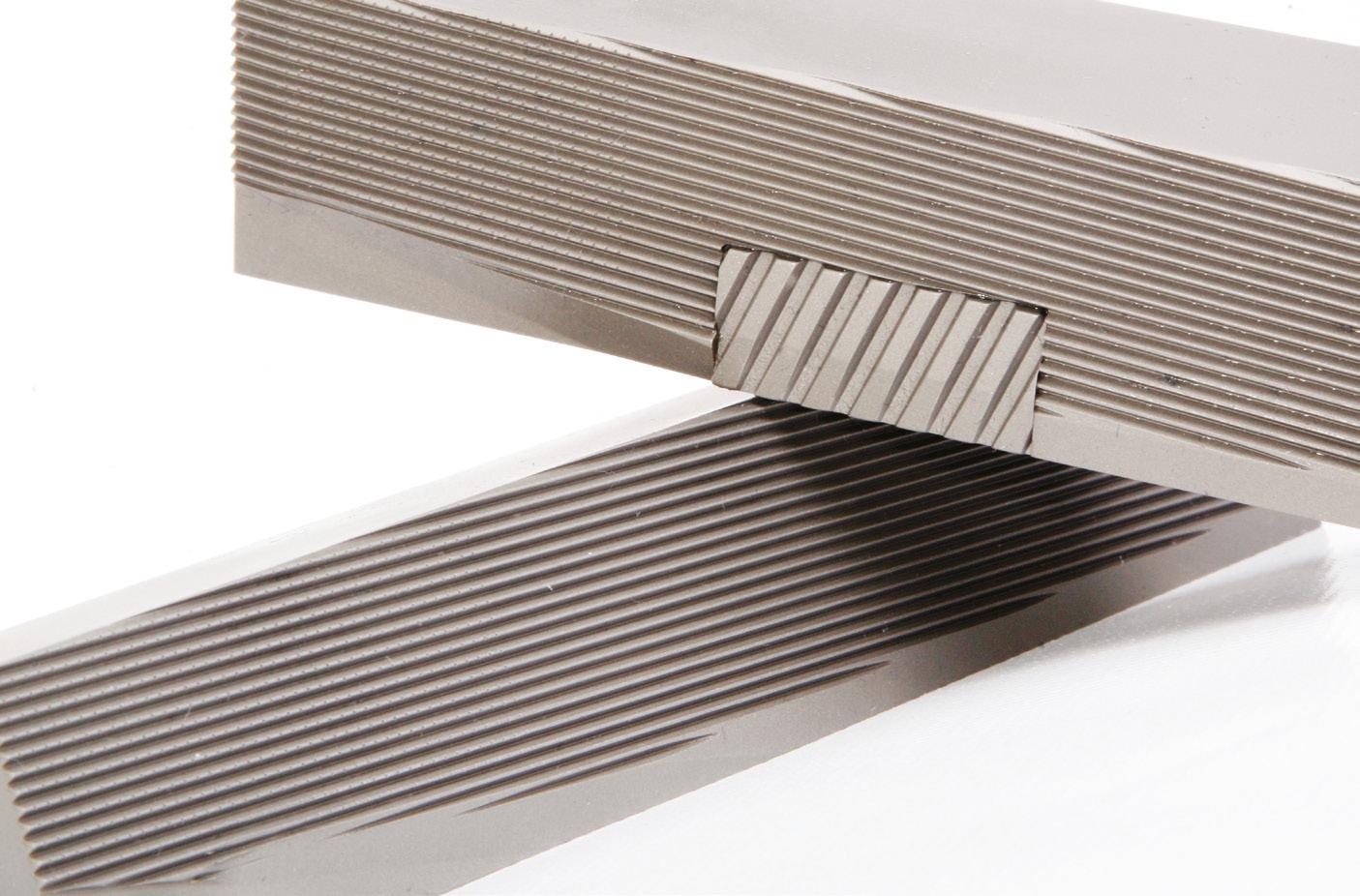

Ideal for making reliable electrical connections between copper or aluminium busbars, PCBs, or cable terminals.

• Innovative design

• Simple installation

• Consistent electrical connections

• Reduced total installed cost

Will Lowry, content director, Fastener + Fixing Magazine

There are certain topics within the fastener sector that, as a magazine, we can always guarantee will elicit a response from an interviewee or company, for instance anti-dumping, freight prices and delivery, as well as raw material prices. As our special Fastener Distribution feature in this edition underlines, CBAM can certainly be added to this list.

The fastener sector has seemingly faced geopolitical issues almost every year since Covid-19, and it seems that for 2024 the challenge fastener distributors are facing is how they handle the Carbon Border Adjustment Mechanism (CBAM) regulation, which is requiring a lot of time and effort to not only understand the regulation, but ensure the right data and information is being collected.

Nearly every article within the Fastener Distribution feature discusses CBAM, with each business outlining how they are tackling the topic, as well as some of the issues they are facing. The phrase ‘misery loves company’ might be a little strong, but the feature is certainly worth a read for those businesses that would like to see how other companies are approaching the topic.

in automation, digitisation, sustainability and storage capacity – emphasising that even in the current slow market, businesses are still planning for growth.

from national associations, including Fachverband des Schrauben-Großhandels (FDS) of Germany, Unione Distributori Italiani Bulloneria (UDIB) of Italy, PRISMEFIX –Association des Distributeurs Français Specialistes en Elements de Fixations of France, Asociación de Distribuidores Españoles de Fijaciones (ADEFI) of Spain, the British and Irish Association of Fastener Distributors – BIAFD, as well as the Dutch association NEVIB.

Another leading business within the fastener distribution sector is Fastbolt Group, with the company the focus of our Cover Story. Managing Director Ekkehard Beermann explains how the business is preparing to be one of the first in the world to pilot an automated compact storage system in order to further strengthen the supply chain for distributors in Europe.

The feature also does highlight some positive developments within the sector as well, including warehouse extensions, automated warehouses, and new warehouses located outside Europe, as well as new product lines, new services, plus investments

www.fastenerandfixing.com

Published by

Managing Director

Jamie Mitchell jamie.mitchell@verulammedia.com

Content Director

Will Lowry will.lowry@verulammedia.com

Deputy Editor Claire Aldridge claire.aldridge@verulammedia.com

The Fastener Distribution feature also includes an article from the European Fastener Distributor Association (EFDA) that concentrates on CBAM and how the association is looking to support members during the transition phase, as well as insights

Assistant Editor Rebecca England rebecca.england@verulammedia.com

Sales Director Mac Rahman mac.rahman@verulammedia.com

Business Development Manager –Italy

Emiliano Pagliaroli emiliano.pagliaroli@verulammedia.com

Business Development Manager –DACH & Europe

Chantal Ridings chantal.ridings@verulammedia.com

Production & Design Manager Lee Duskwick lee.duskwick@verulammedia.com

As always there are a host of other insights, articles and new developments throughout the magazine, so please do make sure you give every section a read to keep yourself better informed about what is happening within the fastener and fixing sector.

Fastener + Fixing Magazine is a dedicated, trade–only publication which is circulated freely throughout the European trade. Disclaimer

The Publisher cannot be held responsible or, in any way, liable for errors or omissions, during input or printing of any material supplied or contained herein although the utmost care is taken to ensure that information contained is accurate and up to date. The Publisher also cannot be held liable for any claims made by advertisers or in contributions from individuals or companies submitted for inclusion within this publication. The opinions expressed are not necessarily those of the Editor or Verulam Media.

Copyright Entire contents copyright © Verulam Media Ltd 2024. No part of this publication may be reproduced, stored in a retrieval system, or transmitted in any form or by any means without the prior permission of the publisher.

Annual subscription (6 issues) to non–trade and outside EU is €200.00 Verulam Media Limited, Office 3, 17 Holywell Hill, St Albans AL1 IDT Tel: +44 (0) 1727 743 882 Find us online:

+

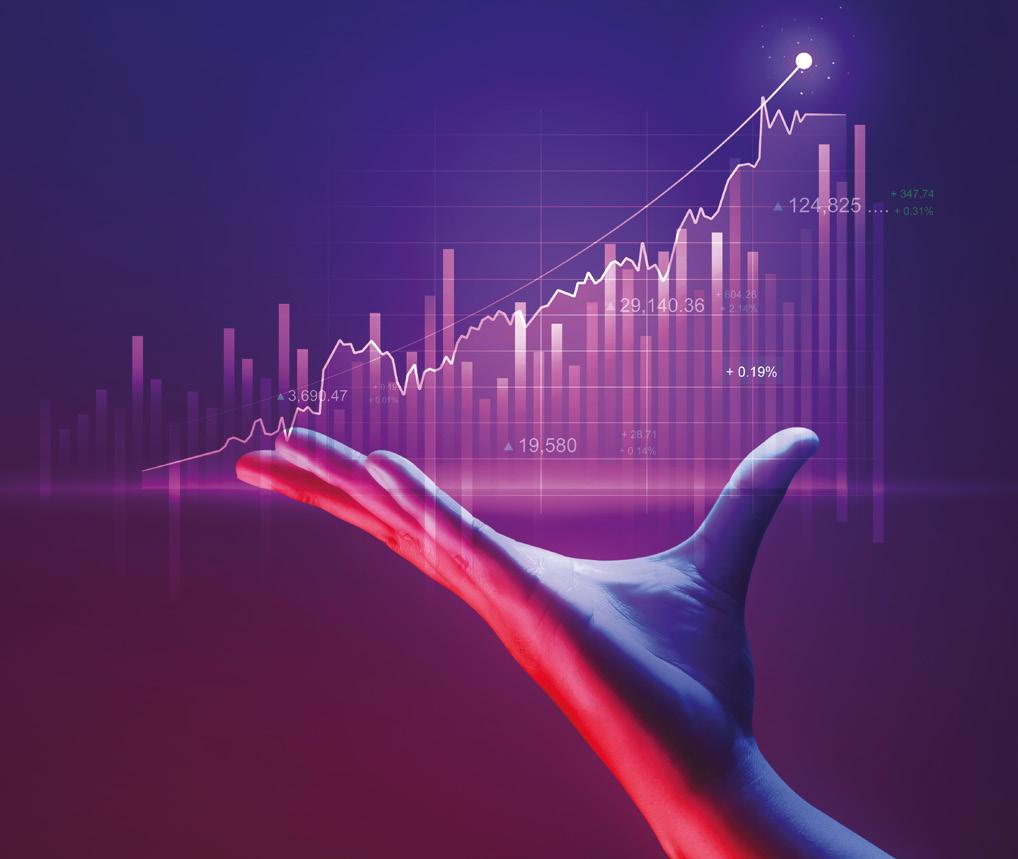

Over the first four months of 2024 Hilti Group recorded sales growth of 2.9% in local currencies compared to the same period of the previous year. Translated into Swiss francs, sales declined by 1.8% to CHF 2.103 billion (€2.161 billion) resulting from an ongoing significant negative currency effect.

Jahangir Doongaji, CEO at Hilti, explains: “Construction activity in Europe has slowed down significantly, while in other parts of the world, such as Asia and Latin America, we still see some market growth. We are confident that our robust global footprint will enable us to outperform the market.” Although the Swiss franc has weakened against the euro and the US dollar in recent weeks, the negative currency effect on sales remains significant and amounts to -4.7% for the first four months of the current year.

The sales development in the business regions varies strongly. Europe recorded a slight growth of 0.5% in local currencies, with southern Europe being the only region to escape this downward trend. The Americas increased sales by 2.6%, primarily driven by double-digit growth in Latin America. The Asia/Pacific region took advantage of an improved market environment to increase sales by 6.7%. The eastern Europe/Middle East/Africa region also remained on the growth track (+16%).

For 2024, the company anticipates sales growth in the low to mid single digit range in local currencies.

H.B Fuller Company, one of the biggest pureplay adhesives companies in the world, has announced that it has acquired ND Industries Inc, a provider of speciality adhesives and fastener locking and sealing solutions – serving customers in the automotive, electronics, aerospace, as well as other industries.

The acquisition is expected to accelerate the realisation of H.B Fuller’s top growth priorities, consistent with the company’s strategy to proactively drive capital allocation to the highest margin and highest growth market segments within the functional coatings, adhesives, sealants and elastomer (CASE) industry. As part of the acquisition, products under ND Industries’ Vibra-Tite® brand will be added to H.B Fuller’s existing epoxy, cyanoacrylate, UV curable and anaerobic product range.

“ND Industries has been a very profitable, family-owned business for several decades and has impressively built one of the most extensive product portfolios in the pre-applied fastener industry,” says Celeste Mastin, president and CEO at H.B Fuller. “Its products are a natural fit with our existing market segments and bring new technology to our portfolio – combining the benefits of an adhesive and a mechanical fastener within extremely demanding applications –resulting in a powerful advantage for our customers.”

ND Industries specialises in formulating and manufacturing a wide variety of materials applied on fasteners and assemblies to aid in critical functions such as locking, sealing, masking, lubricating, as well as noise and vibration dampening. The company also has a network of processing centres providing in-house engineered coating application services to help increase the safety and reliability of fastener assemblies, as well as a line of small pack technologies for maintenance, repair and operations (MRO). The combination of innovative adhesives, custom equipment, and pre-applied processing centres, expands H.B Fuller’s already extensive adhesive application expertise.

“With more than 55 years of excellence and a strong customer base, ND Industries has been at the forefront of technological advancements for decades,” adds Richard Wallace, chairman of ND Industries Inc. “Both companies have worked closely over the past several months to ensure a smooth transition and share many of the same values, including close customer collaboration and innovating with speed.”

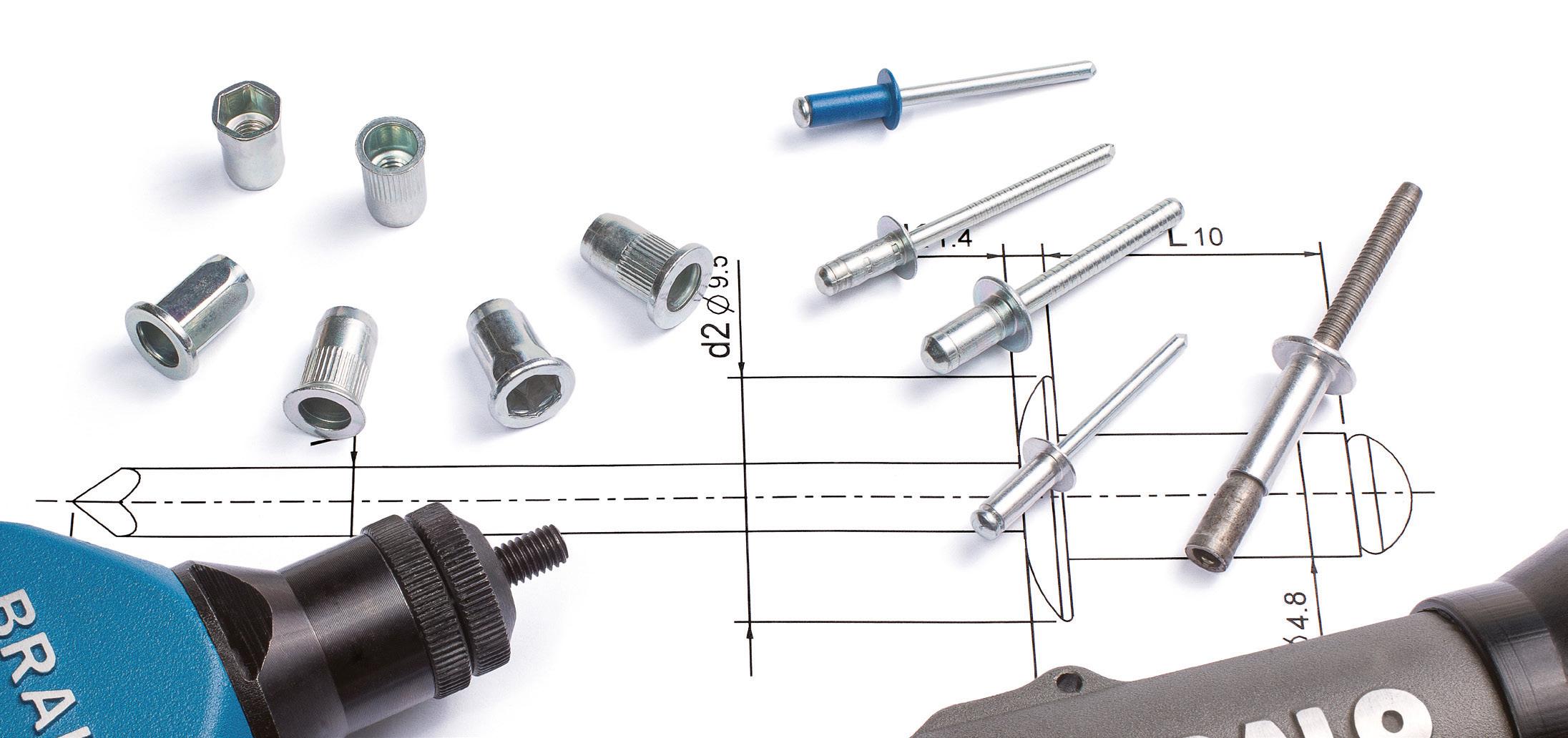

Goebel Germany is celebrating the opening of its new showroom ‘Riveting World’ with its World Riveting Congress (WRC2024) for buyers, distributors and manufacturers of blind rivet fasteners.

Being held on 26th – 28 th September, the WRC2024 will give attendees the chance to test the latest blind rivet developments, such as new riveting machines, robot arms, as well as automatic feeding systems. There will also be a tour of Goebel’s manufacturing plant, where the company manufactures blind rivets, such as the G-Grip®

Also taking place will be a line-up of technical lectures from experts including the Fraunhofer Institute, Deloitte, Smart Cert and many more. WRC2024 will conclude with an opening party at one of the most famous clubs in Düsseldorf, as well as a golf tournament. Space and availability to attend is limited and potential attendees are asked to contact marketing@goebel-group.com for an invitation.

Peter-Thomas Büsing recently took over the role of CEO Europe at KAMAX, a global technological leader for high strength fasteners and complex cold form parts in the automotive industry.

In his role Peter-Thomas Büsing is in charge of all European plants, the subsidiary GALOL, and the sales, supply chain, technology and tools departments – making him responsible for around 2,500 employees, more than half of KAMAX’s workforce.

At KAMAX he will now drive forward the development of processes and the organisational structure. “My goal is to consolidate KAMAX’s position in Europe as a strategic partner for our customers that can be relied upon even in times of upheaval and complex challenges. Technologically, we will continue

to build on our strengths to offer innovative and individual solutions in the future,” states Peter-Thomas Büsing.

Previously, the 55 year old was president of the EMEA region and, since October 2022, a member of the executive committee of Grammer AG. In this role, he had overall operational responsibility for Europe, Middle East, and Africa, which has 18 organisational units.

Peter-Thomas succeeds Dr Reinhard Rupprecht, who has been appointed CEO of the KAMAX Group, with Peter-Thomas reporting directly to Dr Rupprecht.

In order to further reduce its carbon footprint, Bulten AB has signed an agreement with Dutch wire rod manufacturer, FNsteel B.V, giving it access to the most circular steel on the market for fastener production, as well as enabling the company to offer its customers a greener product option.

The greener wire rod is based on 60% – 80% recycled scrap from ‘end of life’ products and is made using fossil-free electricity. This can be compared to the most common scrap-based wire rod used in fastener production today, which is usually based on steel scrap from industrial manufacturing processes.

With access to the unique wire rod, Bulten is able to take a critical step towards a product offering based on material with less than 300kg carbon dioxide per tonne of steel – a milestone on the way to carbon neutrality.

Bulten’s agreement with FNsteel runs for three years and will have a major impact for Bulten when it comes to achieving its Scope 3 emissions target, which is to reduce emissions from suppliers by 25% per tonne of products sold by 2030. The wire rod will mainly be used to produce fasteners for the automotive industry at Bulten’s European plants. These currently account for the majority of the company’s global production volumes.

“This exciting collaboration allows end user customers to access a truly bespoke green product, which is ‘best in class’ from a carbon footprint perspective when compared to any alternative in the market,” says Matthijs van der Schoot, managing director at FNsteel.

Novastone Capital Advisors GmbH, a Swiss company renowned for managing the world’s largest Entrepreneurship Through Acquisition (ETA) programme, has successfully acquired 100% of Mecavit Srl, through an Italian special purpose vehicle.

With a 40 year history and based in Castel Guelfo di Bologna, Mecavit has established itself as a trusted name in the fastener manufacturing industry, known for its high-quality products. The company’s growth and reputation have been carefully nurtured by its partners over the years. The sellers will reinvest in the project, ensuring its continuity and future success.

Nicoletta Nutrito, an engineer and local resident with extensive experience in both national and international industries, will lead the company. Her vision is to maintain the company’s high standards of quality while fostering innovation and growth. “Our goal is to prioritise quality, technical expertise, and reliability, while expanding our offerings to new markets,” explains Nicoletta Nutrito.

Former partners Giuseppe Verdoliva and Giorgio Grillini will continue to support the company alongside Mrs Nutrito. “We are pleased to pass the management to a professional from our region who not only possesses the necessary skills but also shares our values and is committed to ensuring growth and continuity,” adds Bruno Carafa, director, speaking on behalf of the other partners.

Profast Group – a supplier of fasteners, fixings, window and door hardware to the construction and manufacturing industries in Ireland and the UK – has been successfully acquired by three dedicated colleagues.

Led by Stephen Clarke, alongside Craig Milne and Jonathan Aiken, the team has taken ownership of Profast Group for an undisclosed sum, with Belfast-based business advisory firm BDO Northern Ireland serving as the lead advisor during the acquisition. The strategic acquisition, which includes Profast Ltd in Ireland, Profast (NI) Ltd, and Fortus Hardware Ltd, sets a robust foundation for future growth and expansion.

As part of the successful management buyout, Stephen Clarke has been appointed chief executive officer, Craig Milne as chief operating officer and Jonathan Aiken as chief commercial officer. The company has been acquired from Brendan Flynn, who has driven its growth since 1995, with the support of his wife Helen and Managing Director Philip Gregg. The new leadership team is committed to increasing Profast Group’s footprint across

Ireland and the UK market, leveraging its extensive experience from large-scale public and private sector projects, such as Belfast’s new iconic Transport Hub and the Belfast Grand Central Hotel.

Currently employing more than 55 full time staff members, Profast Group has also contributed significantly to high profile developments, including Windsor Park in Belfast, Aviva Stadium in Dublin, the Titanic Museum, Belfast Film Studios, H&W, new educational institutions, residential projects and, in recent years, global data centres and renewable energy initiatives.

Reflecting on this transition Stephen Clarke commented: “The business remains in very capable hands. I am honoured to assume the role of CEO and lead Profast Group into its next phase of growth. No one understands the business and its potential better than

AICHELIN Group and Sistem Teknik have signed an agreement to establish a joint venture in Austria, to produce and distribute industrial vacuum heat treatment technologies and services in Europe.

With this joint agreement, AICHELIN Group is adding a promising segment to its existing product portfolio. Christian Grosspointner, CEO of AICHELIN Group, explains: “As one of the global market leaders in the production of industrial furnaces for industrial heat treatment, we want to become an even stronger partner in the supply of vacuum furnaces for industry. The joint venture combines the best of two worlds, with the products developed by Sistem Teknik and our global aftersales and service network, we create maximum customer focus – a perfect combination to better meet the increasing demand for vacuum solutions in the future.”

Mehmet Özdeşlik, CEO of Sistem Teknik Sanayi Firinlari A.S, adds: “The motivation of our joint venture is to offer the best possible technology that fits our time, which inevitably demands environmental efficiency and sustainability. We have noticed that there is a strong market for megatrends such as carbon footprint, electromobility and Lean production. With our vacuum furnaces, we aim to provide solutions that ensure low carbon emissions and maximum process quality. I am very confident that this collaboration will not only bring innovation, but also benefit our industry.”

Jonny, Craig, and I, and most importantly our amazing team. I am incredibly excited about the future, and I am very proud of our entire team. The Profast Group has come an incredibly long way since it was established almost 50 years ago.”

Bossard Group has expanded its market position within innovative fastening technologies, acquiring Belgian company Dejond Fastening – a manufacturer of blind rivet nuts and specialist in the distribution of high-quality fastening systems.

Dejond Fastening N.V, headquartered in Antwerp, employs 68 people and expects net sales of around €15 million for the current financial year. With its own brand Tubtara®, the company is a pioneer in innovative solutions for sheet metal, profiles, composites and plastic fastening solutions for a wide range of industries.

Dejond’s solutions enable engineers to optimise both their product design and manufacturing processes, which fits well with Bossard’s ‘Proven Productivity’ philosophy. With this acquisition, Bossard will further strengthen its market presence in the Benelux region.

“Bossard has been working with Dejond for over 30 years. We have consistently been impressed by the company’s reliability and innovations ever since. By combining technical expertise with our global market reach, technical sales expertise, and trusted access to a wide range of industrial customers, we see great potential to offer even more value to our existing and new customers,” reports Daniel Bossard, CEO of Bossard Group.

“Becoming part of the Bossard Group guarantees continuity for our existing customers and it opens up completely new possibilities to expand the global market presence of Tubtara®. It will give us new opportunities to widen our product offering and invest in new technologies and sales capabilities,” concludes Jan Maeyens, director R&D and manufacturing at Dejond.

The metal business, including the Metal Service Center, is not part of the acquisition and will continue to operate independently under the name Dejond N.V.

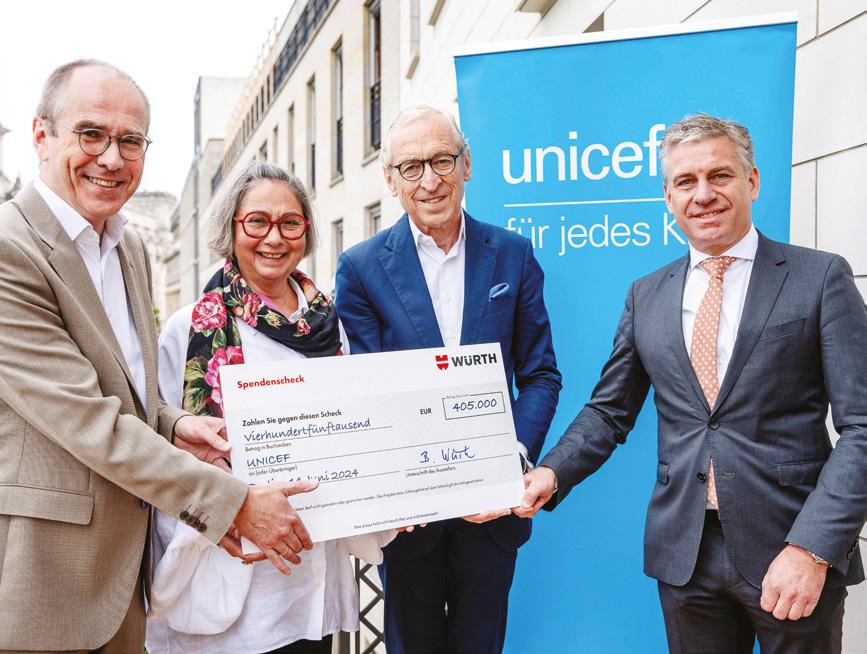

As part of a worldwide campaign week, Würth Group has supported the UN Children’s Fund UNICEF by making a donation of €405,000 to an aid programme providing children in Sudan with access to safe learning spaces and safeguarding their future.

In Berlin, Germany, on 14 th June 2024, Würth Group presented a donation cheque to UNICEF for the seventh time from the Group’s annual RW WORKOUT Week – a worldwide sales campaign running for over 34 years, in which staff team up in ‘ride-alongs’ where inside employees accompany sales representatives on their daily customer visits.

“Millions of children around the world cannot go to school. With this donation for safe learning spaces in Sudan, we want to restore access to education for children in the midst of the deep education crisis, so that they can not only go to school, but also be kids despite the difficult situation,” reports Bettina Würth, chairwoman of the advisory board of Würth Group and member of the UNICEF Committee for Germany.

The donation will be used for the UNICEF aid programme and aims to provide safe learning spaces for children in the midst of the brutal conflict in Sudan. Even before the outbreak of the ongoing armed conflict in Sudan, around 8.5 million children needed humanitarian aid. Today, the country faces one of the largest displacement and education crises in the world. Around 14 million children need humanitarian aid and 19 million children are no longer able to attend school due to the closure of 18,000 schools in conflict areas.

The donation will serve to set-up safe learning spaces, providing children and adolescents with access to protection, social contacts and education. UNICEF equips the learning spaces with learning materials

and toys and sees to the psychological and psychosocial support of children. If the safety situation does not permit for children to attend school in person, they can learn at home using an eLearning program on solar powered tablets. The UNICEF facilities also support family members by providing them with access to water and healthcare.

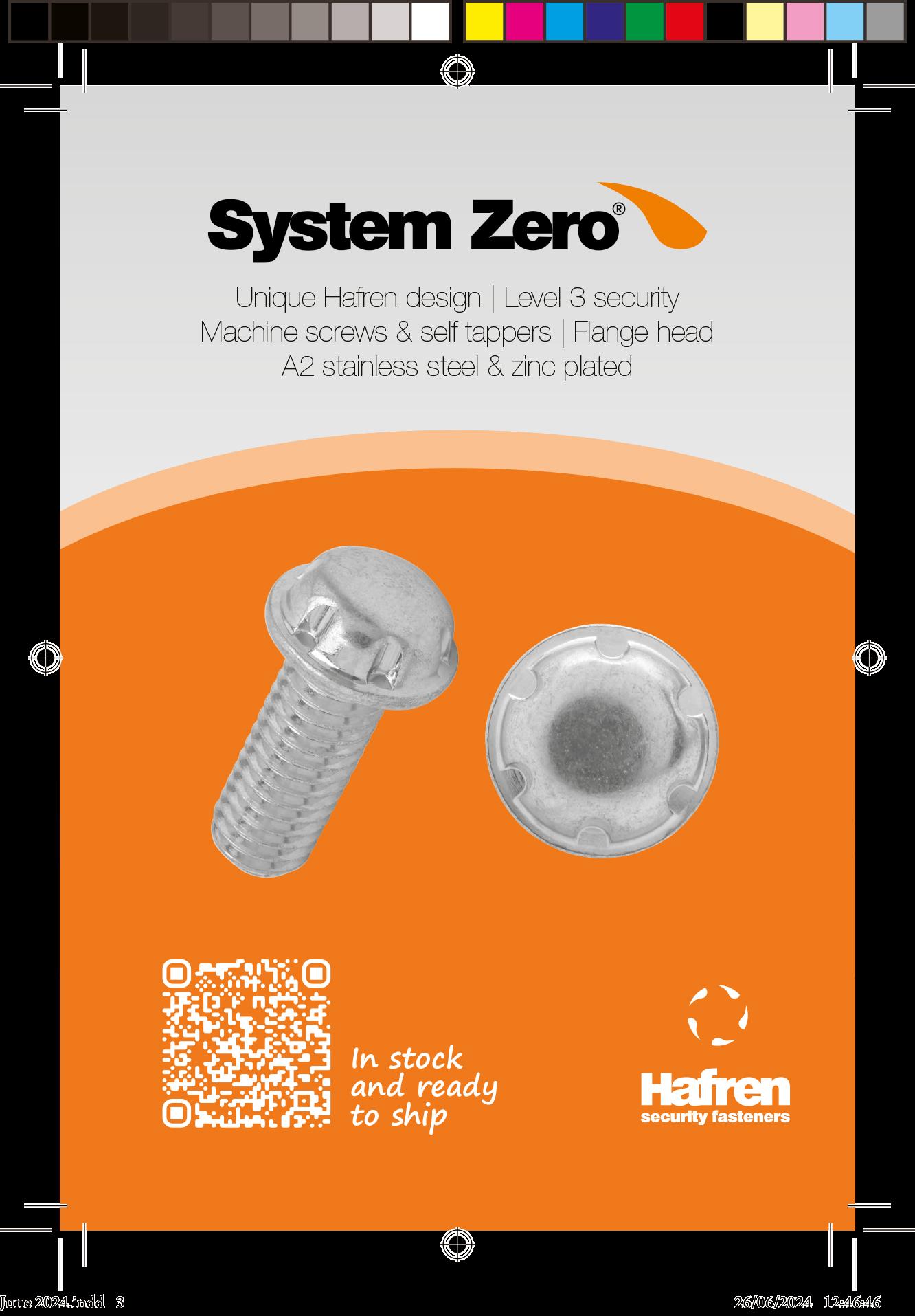

Hafren Fasteners has marked its 29 th anniversary, celebrating nearly three decades of innovation, growth and dedication to providing top tier security fastening solutions, as well as being committed to safeguarding the assets and interests of customers through unparalleled quality and service.

From humble beginnings in 1995, Hafren Fasteners Ltd has evolved into a trusted name in the industry, renowned for an extensive range of tamper resistant fasteners designed to meet the diverse needs of a global customer base. Its journey has been one of continuous improvement and adaptation, driven by a clear mission to deliver security and peace of mind through reliable and innovative fastening solutions.

Over the years, Hafren has expanded its product lines and services, staying ahead of the curve with cutting edge technology and a deep understanding of the evolving security challenges faced by various industries. Its dedication to excellence is reflected in the numerous partnerships and long-standing relationships the company has built with customers across the world.

“As we celebrate this significant milestone, we extend our heartfelt gratitude to our dedicated team, whose unwavering commitment and expertise have been the cornerstone of our success. We also thank our valued customers and partners for their trust and support, which have been instrumental in our growth and achievements,” comments the company. “Looking ahead, Hafren Fasteners remains committed to pushing the boundaries of security fastening technology and is excited to continue our journey, innovating and expanding our offerings, to better serve our customers and address the ever-changing landscape of security threats.”

Vossloh has been awarded a contract to supply rail fastening systems in connection with the construction of two high-speed lines in China.

One of the two lines connects the megacity of Xining with the metropolis of Chengdu, which has developed into the most important economic metropolis in western China alongside Chongqing. The second line runs between Lanzhou, the capital of Gansu province, and the city of Hezuo in the south-east of the province.

Vossloh Fastening Systems China Co Ltd, Vossloh AG’s subsidiary based in Kunshan, China, will be responsible for the execution of the order, with deliveries scheduled from 2025. “Our high-quality, innovative strength and systems expertise are long appreciated in China. Our technical expertise in the construction of high-speed lines is leading worldwide. I am pleased about the trust placed in Vossloh by our customers in China, which is once again underlined by the award of this important order,” states Oliver Schuster, CEO at Vossloh AG.

BOLTING: ANCHOR BOLTS, ASSEMBLED BOLTING, BSW HEXAGON BOLTS, BSW HEXAGON SETSCREWS, CUP SQUARE BOLTS, CUP SQUARE HEX BOLTS WITH NUTS, FINE PITCH HEXAGON BOLTS, FINE PITCH HEXAGON SETSCREWS, GUTTER BOLTS AND NUTS, HEXAGON BOLTS, HEXAGON SETSCREWS, SERRATED FLANGE BOLTS, UNSERRATED FLANGEBOLTS, ROOFING BOLTS AND NUTS, SQ SQ HOLDING DOWN BOLTS AND NUTS, UNC HEXAGON BOLTS, UNC HEXAGON SETSCREWS, UNF HEXAGON BOLTS, UNF HEXAGON SETSCREWS. NUTS: 4-PRONGED TEE NUTS, BSF FULL NUTS, BSW FULL NUTS, DOME NUTS, FINE PITCH FULL NUTS, FINE PITCH NYLON INSERT NUTS T TYPE, FULL NUTS, LOCK NUTS, NYLON INSERT FLANGE NUTS, NYLON INSERT NUTS P TYPE, NYLON INSERT NUTS T TYPE, SERRATED FLANGE NUTS, SQUARE NUTS, SQUARE PRESSED NUTS, SQUARE ROOFING NUTS, SQUARE WELD NUTS, STOVER LOCKING NUTS, UNC FULL NUTS, UNC LOCK NUTS, UNC NYLON INSERT NUTS, UNF FULL NUTS, UNF LOCK NUTS, UNF NYLON INSERT NUTS, UNSERRATED FLANGE NUTS, WELD NUTS, WING NUTS. WASHERS: EU WASHERS, EXTERNAL SERRATED WASHERS, EXTERNAL TOOTHLOCK WASHERS, FORM A WASHERS, FORM B WASHERS, FORM C WASHERS, FORM G WASHERS, INTERNAL SERRATED WASHERS, INTERNAL TOOTHLOCK WASHERS, MUDGUARD WASHERS, SINGLE-COIL RECTANGULAR SPRING WASHERS, SINGLE-COIL SQUARE SPRING WASHERS, SQUARE PLATE WASHERS, T3 HP WASHERS, T3 LP WASHERS, T4 HP WASHERS, WASHERS, CRINKLE WASHERS, FLAT WASHERS, SCREW CUP WASHERS. STUDDING: STUDDING CONNECTORS, STUDDING, ALL THREAD STUDS, BSW STUDDING, UNC STUDDING. MACHINE SCREWS: POZI COUNTERSUNK MACHINE SCREWS, POZI PAN MACHINE SCREWS, SLOTTED CHEESE MACHINE SCREWS, SLOTTED COUNTERSUNK MACHINE SCREWS, SLOTTED PAN MACHINE SCREWS. SELF-TAPPING SCREWS: SLOTTED PAN SELF-TAPPERS AB POINT, POZI PAN SELF-TAPPERS AB POINT, POZI PAN SELF-TAPPERS B POINT, POZI COUNTERSUNK SELF-TAPPERS AB POINT, POZI COUNTERSUNK SELF-TAPPERS B POINT, POZI FLANGE SELF-TAPPERS AB POINT, ROUND HAMMER DRIVE, INDENTED HEAD HEX SELF-TAPPERS AB POINT, POZI RAISED COUNTERSUNK SELFTAPPERS AB POINT, POZI FLANGE SELF-TAPPERS AB POINT, HEX SEMS AB COMPLETE WITH WASHER, ROUND HAMMER DRIVE TYPE U, POZI PAN SELFTAPPERS BT POINT TYPE 25, POZI COUNTERSUNK SUPERTITE SCREWS, HEX WASHER HEAD SUPERTITE SCREWS, POZI PAN SUPERTITE SCREWS. WOODSCREWS: GENERAL PURPOSE WOODSCREWS, CHIPPY SCREWS, SINGLE THREAD WOODSCREWS, TWIN-THREAD WOODSCREWS, COACH SCREWS, EXTERIOR WOODSCREWS, DECKING SCREWS, TIMBERDRIVE EXTERIOR WOODSCREWS, MIRROR SCREWS, CARCASS SCREWS, ANTIVANDAL SCREWS, DRYWALL SCREWS, SELF-DRILLING DRYWALL SCREWS. MATERIALS: CARBON STEEL, A2-304 STAINLESS STEEL, A4-316 STAINLESS STEEL, BRASS, PHOSPHOR BRONZE, COPPER, ALUMINIUM, METAL, NYLON, PLASTIC, RED FIBRE. FINISHES: SELF-COLOUR, BRIGHT ZINC PLATED, GALVANISED, ZINC AND YELLOWPLATED, BLACK JAPANNED, MAGSHO GREEN 7494C, GREEN ORGANIC COATING MAGNI 599, BLACK OXIDE, BLACK PHOSPHATE, ELECTRO BRASSED. GRADES: A2-50, A2-70, A2-70, A4-70, A2-304, A4-80, A4-316, SAE GRADE 5 , GRADE 4.6, GRADE 4.8, GRADE 8.8, GRADE 10.9 GRADE 12.9, GRADE R, GRADE NE2, GRADE 1, GRADE 2, GRADE A, CLASS 17H, CLASS 10, CLASS 12, CLASS 4, CLASS 6, CLASS 8, AISI 301. BOLTING: ANCHOR BOLTS, ASSEMBLED BOLTING, BSW HEXAGON BOLTS, BSW HEXAGON SETSCREWS, CUP SQUARE BOLTS, CUP SQUARE HEX BOLTS WITH NUTS, FINE PITCH HEXAGON BOLTS, FINE PITCH HEXAGON SETSCREWS, GUTTER BOLTS AND NUTS, HEXAGON BOLTS, HEXAGON SETSCREWS, SERRATED FLANGE BOLTS, UNSERRATED FLANGEBOLTS, ROOFING BOLTS AND NUTS, SQ SQ HOLDING DOWN BOLTS AND NUTS, UNC HEXAGON BOLTS, UNC HEXAGON SETSCREWS, UNF HEXAGON BOLTS, UNF HEXAGON SETSCREWS. NUTS: 4-PRONGED TEE NUTS, BSF FULL NUTS, BSW FULL NUTS, DOME NUTS, FINE PITCH FULL NUTS, FINE PITCH NYLON INSERT NUTS T TYPE, FULL NUTS, LOCK NUTS, NYLON INSERT FLANGE NUTS, NYLON INSERT NUTS P TYPE, NYLON INSERT NUTS T TYPE, SERRATED FLANGE NUTS, SQUARE NUTS, SQUARE PRESSED NUTS, SQUARE ROOFING NUTS, SQUARE WELD NUTS, STOVER LOCKING NUTS, UNC FULL NUTS, UNC LOCK NUTS, UNC NYLON INSERT NUTS, UNF FULL NUTS, UNF LOCK NUTS, UNF NYLON INSERT NUTS, UNSERRATED FLANGE NUTS, WELD NUTS, WING NUTS. WASHERS: EU WASHERS, EXTERNAL SERRATED WASHERS, EXTERNAL TOOTHLOCK WASHERS, FORM A WASHERS, FORM B WASHERS, FORM C WASHERS, FORM G WASHERS, INTERNAL SERRATED WASHERS, INTERNAL TOOTHLOCK WASHERS, MUDGUARD WASHERS, SINGLE-COIL RECTANGULAR SPRING WASHERS, SINGLE-COIL SQUARE SPRING WASHERS, SQUARE PLATE WASHERS, T3 HP WASHERS, T3 LP WASHERS, T4 HP WASHERS, WASHERS, CRINKLE WASHERS, FLAT WASHERS, SCREW CUP WASHERS. STUDDING: STUDDING CONNECTORS, STUDDING, ALL THREAD STUDS, BSW STUDDING, UNC STUDDING. MACHINE SCREWS: POZI COUNTERSUNK MACHINE SCREWS, POZI PAN MACHINE SCREWS, SLOTTED CHEESE MACHINE SCREWS, SLOTTED COUNTERSUNK MACHINE SCREWS, SLOTTED PAN MACHINE SCREWS. SELF-TAPPING SCREWS: SLOTTED PAN SELF-TAPPERS AB POINT, POZI PAN SELF-TAPPERS AB POINT, POZI PAN SELF-TAPPERS B POINT, POZI COUNTERSUNK SELF-TAPPERS AB POINT, POZI COUNTERSUNK SELF-TAPPERS B POINT, POZI FLANGE SELF-TAPPERS AB POINT, ROUND HAMMER DRIVE, INDENTED HEAD HEX SELF-TAPPERS AB POINT, POZI RAISED COUNTERSUNK SELFTAPPERS AB POINT, POZI FLANGE SELF-TAPPERS AB POINT, HEX SEMS AB COMPLETE WITH WASHER, ROUND HAMMER DRIVE TYPE U, POZI PAN SELFTAPPERS BT POINT TYPE 25, POZI COUNTERSUNK SUPERTITE SCREWS, HEX WASHER HEAD SUPERTITE SCREWS, POZI PAN SUPERTITE SCREWS. WOODSCREWS: GENERAL PURPOSE WOODSCREWS, CHIPPY SCREWS, SINGLE THREAD WOODSCREWS, TWIN-THREAD WOODSCREWS, COACH SCREWS, EXTERIOR WOODSCREWS, DECKING SCREWS, TIMBERDRIVE EXTERIOR WOODSCREWS, MIRROR SCREWS, CARCASS SCREWS, ANTIVANDAL SCREWS, DRYWALL SCREWS, SELF-DRILLING DRYWALL SCREWS. MATERIALS: CARBON STEEL, A2-304 STAINLESS STEEL, A4-316 STAINLESS STEEL, BRASS, PHOSPHOR BRONZE, COPPER, ALUMINIUM, METAL, NYLON, PLASTIC, RED FIBRE. FINISHES: SELF-COLOUR, BRIGHT ZINC PLATED, GALVANISED, ZINC AND YELLOWPLATED, BLACK JAPANNED, MAGSHO GREEN 7494C, GREEN ORGANIC COATING MAGNI 599, BLACK OXIDE, BLACK PHOSPHATE, ELECTRO BRASSED. GRADES: A2-50, A2-70, A2-70, A4-70, A2-304, A4-80, A4-316, SAE GRADE 5 , GRADE 4.6, GRADE 4.8, GRADE 8.8, GRADE 10.9 GRADE 12.9, GRADE R, GRADE NE2, GRADE 1, GRADE 2, GRADE A, CLASS 17H, CLASS 10, CLASS 12, CLASS 4, CLASS 6, CLASS 8, AISI 301. BOLTING: ANCHOR BOLTS, ASSEMBLED BOLTING, BSW HEXAGON BOLTS, BSW HEXAGON SETSCREWS, CUP SQUARE BOLTS, CUP SQUARE HEX BOLTS WITH NUTS, FINE PITCH HEXAGON BOLTS, FINE PITCH HEXAGON SETSCREWS, GUTTER BOLTS AND NUTS, HEXAGON BOLTS, HEXAGON SETSCREWS, SERRATED FLANGE BOLTS, UNSERRATED FLANGEBOLTS, ROOFING BOLTS AND NUTS, SQ SQ HOLDING DOWN BOLTS AND NUTS, UNC HEXAGON BOLTS, UNC HEXAGON SETSCREWS, UNF HEXAGON BOLTS, UNF HEXAGON SETSCREWS. NUTS: 4-PRONGED TEE NUTS, BSF FULL NUTS, BSW FULL NUTS, DOME NUTS, FINE PITCH FULL NUTS, FINE PITCH NYLON INSERT NUTS T TYPE, FULL NUTS, LOCK NUTS, NYLON INSERT FLANGE NUTS, NYLON INSERT NUTS P TYPE, NYLON INSERT NUTS T TYPE, SERRATED FLANGE NUTS, SQUARE NUTS, SQUARE PRESSED NUTS, SQUARE ROOFING NUTS, SQUARE WELD NUTS, STOVER LOCKING NUTS, UNC FULL NUTS, UNC LOCK NUTS, UNC NYLON INSERT NUTS, UNF FULL NUTS, UNF LOCK NUTS, UNF NYLON INSERT NUTS, UNSERRATED FLANGE NUTS, WELD NUTS, WING NUTS. WASHERS: EU WASHERS, EXTERNAL SERRATED WASHERS, EXTERNAL TOOTHLOCK WASHERS, FORM A WASHERS, FORM B WASHERS, FORM C WASHERS, FORM G WASHERS, INTERNAL SERRATED WASHERS, INTERNAL TOOTHLOCK WASHERS, MUDGUARD WASHERS, SINGLE-COIL RECTANGULAR SPRING WASHERS, SINGLE-COIL SQUARE SPRING WASHERS, SQUARE PLATE WASHERS, T3 HP WASHERS, T3 LP WASHERS, T4 HP WASHERS, WASHERS, CRINKLE WASHERS, FLAT WASHERS, SCREW CUP WASHERS. STUDDING: STUDDING CONNECTORS, STUDDING, ALL THREAD STUDS, BSW STUDDING, UNC STUDDING. MACHINE SCREWS: POZI COUNTERSUNK MACHINE SCREWS, POZI PAN MACHINE SCREWS, SLOTTED CHEESE MACHINE SCREWS, SLOTTED COUNTERSUNK MACHINE SCREWS, SLOTTED PAN MACHINE SCREWS. SELF-TAPPING SCREWS: SLOTTED PAN SELF-TAPPERS AB POINT, POZI PAN SELF-TAPPERS AB POINT, POZI PAN SELF-TAPPERS B POINT, POZI COUNTERSUNK SELF-TAPPERS AB POINT, POZI COUNTERSUNK SELF-TAPPERS B POINT, POZI FLANGE SELF-TAPPERS AB POINT, ROUND HAMMER DRIVE, INDENTED HEAD HEX SELF-TAPPERS AB POINT, POZI RAISED COUNTERSUNK SELFTAPPERS AB POINT, POZI FLANGE SELF-TAPPERS AB POINT, HEX SEMS AB COMPLETE WITH WASHER, ROUND HAMMER DRIVE TYPE U, POZI PAN SELFTAPPERS BT POINT TYPE 25, POZI COUNTERSUNK SUPERTITE SCREWS, HEX WASHER HEAD SUPERTITE SCREWS, POZI PAN SUPERTITE SCREWS. WOODSCREWS: GENERAL PURPOSE WOODSCREWS, CHIPPY SCREWS, SINGLE THREAD WOODSCREWS, TWIN-THREAD WOODSCREWS, COACH SCREWS, EXTERIOR WOODSCREWS, DECKING SCREWS, TIMBERDRIVE EXTERIOR WOODSCREWS, MIRROR SCREWS, CARCASS SCREWS, ANTIVANDAL SCREWS, DRYWALL SCREWS, SELF-DRILLING DRYWALL SCREWS. MATERIALS: CARBON STEEL, A2-304 STAINLESS STEEL, A4-316 STAINLESS STEEL, BRASS, PHOSPHOR BRONZE, COPPER, ALUMINIUM, METAL, NYLON, PLASTIC, RED FIBRE. FINISHES: SELF-COLOUR, BRIGHT ZINC PLATED,

BIGGER AND BETTER RANGE THAN EVER BEFORE

Lesjöfors Group’s manufacturing plant in Changzhou, China, has passed the certification process for ISO 13485 – the medical industry’s optimal medical device standard.

The medical industry is constantly evolving and growing, partly due to an aging population. Innovations in drug delivery devices and diagnosis are not only improving a generation’s quality of life, but also enabling individuals to self-monitor and self-medicate.

Crucially sitting at the heart of many of these devices, and performing a vital function within the device application, are springs and pressings.

Mikael Andersson, vice-president at Lesjöfors Asia, explains: “Lesjöfors is one of the largest global suppliers of springs and pressings to the medical sector and this recent certification in China takes us one step closer to achieving our strategic growth goals. Our ambition is to not only become the largest supplier but also to be seen as the preferred supplier of springs and pressings to the global medical industry. We recognise that market growth for medical devices is stronger in Asia than in Europe and the USA. Achieving the ISO 13485 medical certification is a comprehensive quality certification of our quality and manufacturing processes, enabling our China operation to be increasingly confident within the marketplace.”

The medical sector is known for developing projects worldwide, sourcing from a bank of global suppliers. Lesjöfors’ global footprint, with spring and pressing manufacture operations across Asia, America and Europe, offers a ‘one stop shop’ supply partner to meet the demands of the international medical marketplace.

Mikael continues: “We appreciate companies have different sourcing strategies. We want to simplify procurement. Lesjöfors’ global sales and manufacturing platform enables our customers to avoid supply chain risks, as we’re geographically positioned to offer efficiencies. Our network of operations delivers a ‘local’ supply chain, reducing lead time risks within the purchasing cycle.”

With a record attendance of just over 100 delegates, The British and Irish Association of Fastener Distributors’ (BIAFD) Spring meeting enabled fastener professionals to network with one another and learn about important challenges currently facing the sector.

The Carbon Border Adjustment Mechanism (CBAM) regulation took centre stage as Jamie Mcleod of Crowe UK gave an overview of the initiative and explained the differences between EU and UK CBAM. Jamie’s session was followed by Andreas Bertaggia of the European Fastener Distributor Association (EFDA) who detailed the work EFDA is doing to support its members. BIAFD Chairman Ian Doherty then shared the association’s position on UK CBAM.

“I’m pleased that BIAFD members were in support of our position. Having an aligned position is vitally important so I’d like to thank Crowe UK for its advice, EFDA for its input, and BIAFD members for their support,” commented Ian Doherty.

The final session of the day was delivered by David Kivlin of the Health and Safety Executive (HSE). David explained the role of inspectors and how the HSE’s investigation process works. This was followed by an update from a member who had experienced an HSE investigation and what they had learnt from the incident. BIAFD’s next meeting will take place on Thursday 10th October 2024.

Auto Fasteners Ltd, a global supplier of fasteners and metal engineered components to the automotive sector, has expanded its presence by taking up 15,000 square feet (1,393.5m2 ) of space at a new industrial scheme.

UK-based Auto Fasteners, which already has five units in Southam, Warwickshire, has signed a 10 year lease on a trio of units at Sucham Park to support its continued expansion. It will provide warehouse, assembly, quality inspection and office space for the business, which supplies parts to Volvo Group, Scania, Daimler Group, Ford, Stellantis, VW Group, Aston Martin and Jaguar Land Rover to name but a few.

The business, which has 14 staff, formed by Scott Simpson in 2007 and moved to Southam in 2011, is a major exporter with 90% of its business exporting around the world, supplying OEMs with engineered fasteners and metal components of the highest quality.

“We’re growing with our long-term customers and gaining new customers too, which has contributed to year-on-year turnover growth and a need for more space to support our expansion. It gives us the option to keep expanding and explore new opportunities. We have business in North America, Brazil, India, Japan and all over Europe. We are currently going through the process of opening a facility in North America, but our headquarters will always remain here in Southam, Warwickshire,” highlights Scott Simpson, founder and managing director of Auto Fasteners.

Standard and non-standard items

Norm- und Standardteile

DIN, ISO, EN and others / und andere

Special parts and special materials

Sonderteile / Sonderwerkstoffe

chavesbao.com

A manufacturer of high-tech adhesives and other multifunctional materials, DELO recorded sales revenue of €229 million in the last fiscal year ending 31 st March 2024.

This is an increase of 12% compared to the previous year, with South Korea and Mexico among the most dynamic markets. Overall, around half of sales were generated in Asia and the other half is divided between Europe and North America.

Deligo has moved to a new headquarters, featuring a spacious 40,000 square foot (3,716m 2) warehouse, providing the necessary infrastructure for enhanced efficiency and a more dynamic operation.

In addition to the increased space, the new location is designed for speed and efficiency. State of the art processes and facilities will enable Deligo to process orders more quickly, leading to reduced turnaround times and smoother transactions.

UK-based manufacturer Tension Control Bolts Ltd has been recognised by His Majesty The King with a King’s Award for enterprise in the international trade category.

Currently exporting some 20 million bolts to over 30 countries around the world annually, Tension Control Bolts’ exports have increased by more than 700% in the last six years. The company’s biggest export markets include the Netherlands, Germany, Australia, France and Portugal.

CMZ has formalised the purchase of a 22,000m 2 plot in the Aboro district, Berriz-Vizcaya, Spain, to build a new assembly plant. This area will be the setting for the manufacture of the new lathe model the company plans to bring to the market.

This new investment joins those made by the manufacturer in the last few years – with the intention of increasing capacity to 1,000 machines a year. The medium term objective is to consolidate production of 800 lathes a year.

Bufab AB has signed an agreement to divest its manufacturing companies Bufab Lann AB and Hallborn Metall AB to Arbona Industri AB for a purchase price of SEK 230 million (€20 million) on a cash and debt free basis.

Lann and Hallborn are two companies that manufacture components through turning and milling. The divestment is in-line with Bufab’s previously communicated plan to evaluate strategic alternatives for the two companies, in light of the updated strategy presented by Bufab in December 2023.

Bon Precision Engineering, a manufacturer of precision engineered components, has taken delivery of a Star SB-20R CNC sliding head machine to increase capacity and accommodate a growing order book.

The SB-20R CNC machine, purchased at the 2024 MACH Show, represents a significant advancement in Bon Precision Engineering’s manufacturing capabilities, adding to the machinery already in place at its UK-based production unit.

by Jason Sandefur, editor/publisher, GlobalFastenerNews.com

US President Joe Biden has announced new tariffs on goods from China that will see tariffs of between 25% – 100% being imposed on the value of the imported item, applicable to US$18 billion (€16.7 billion) worth of goods.

The tariffs extend to semiconductors, electric vehicles, batteries, critical minerals, solar cells, ship-to-shore cranes, medical products, as well as steel and aluminum. The tariffs for steel and aluminum were tripled to 25%, making it likely that imported fastener costs will increase. Section 301 tariffs were imposed in 2018 under the Trump administration on US$300 billion in Chinese products.

The tariffs include 25% duties on bolts, screws and other fasteners (HTS subheadings 7318.11.00 to 7318.29.00) manufactured in China and 15% on all Chinese iron and steel nuts (HTS subheading 7318.16.00).

The Office of the US Trade Representative (USTR) list includes:

7318.11.00 – Iron or steel, coach screws.

7318.12.00 – Iron or steel, woodscrews (other than coach screws).

7318.13.00 – Iron or steel, screw hooks and screw rings.

7318.14.10 – Iron or steel, self-tapping screws, w/shanks or threads less than 6mm in diameter.

7318.14.50 – Iron or steel, self-tapping screws, w/shanks or threads 6mm or more in diameter.

LISI Group has strengthened its partnership with Watch-Out by acquiring a minority stake in its holding company. LISI Group and Watch-Out have partnered for nearly 20 years in the field of high precision machining and are developing a disruptive AI solution for fully autonomous machining.

LISI Group explains: “We have decided to support Watch-Out in the deployment of this turn-key autonomous precision machining solution now ready for scale-up.” The Watch-Out solution combines all conventional machining cycles in a perpetual loop with a specific Artificial Intelligence – Machining 4.0. It is a virtually self-sufficient production machine that constantly self-corrects according to data generated and captured in ‘real time’ on parts and tools.

More than just an improvement on previous generation machine tools, the Watch-Out solution “represents a dramatic change in industrial paradigm aimed at eliminating the element of randomness in the treatment of chronic failures in the production chain”, explains Emmanuel Neildez, CEO at LISI Aerospace.

LISI Aerospace is part of France-based LISI Group, which manufactures fasteners and assembly components for the aerospace, automotive and medical industries.

7318.15.20 – Iron or steel, screws and bolts and their nuts or washers, imported in the same shipment.

7318.15.40 – Iron or steel, machine screws (o/than cap screws), 9.5mm or more in length and 3.2mm in diameter.

7318.15.50 – Iron or steel, threaded studs.

7318.15.60 – Iron or steel, screws and bolts, nesoi, having shanks or threads less than 6mm in diameter.

7318.15.80 – Iron or steel, screws and bolts, nesoi, having shanks or threads 6mm or more in diameter.

7318.19.00 – Iron or steel, threaded articles similar to screws, bolts, nuts, coach screws and screw hooks, nesoi.

7318.21.00 – Iron or steel, spring washers and other lock washers.

7318.22.00 – Iron or steel, washers (other than spring washers and other lock washers).

7318.23.00 – Iron or steel, rivets.

7318.24.00 – Iron or steel, cotters and cotter pins.

7318.29.00 – Iron or steel, non threaded articles similar to rivets, cotters, cotter pins, washers and spring washers.

The Mid-West Fastener Association will hold its 42 nd annual trade show and 71 st annual golf outing during FSTNR Week 2024, which will take place from 18 th – 23 rd August at the Marriott Lincolnshire Resort, 18 miles north of Chicago O’Hare International Airport.

There will be plant tours in the Chicago area and a welcome reception from 5:30pm to 7:30pm on Monday 19th August. The tabletop trade show will be from 1pm to 6pm on Tuesday 20th August followed by the traditional Fastener Bash until 7pm.

MWFA’s 71 st annual golf outing will be on Wednesday 21 st August. An educational session on fastener failures is scheduled for Tuesday morning and Fastener Training Week for Monday through to Friday.

The global industrial vending machine market is expected to grow from US$1.6 billion in 2024 to US$2.5 billion (€2.3 billion) by 2029, at a CAGR of 10.1%, according to a Markets & Markets report.

The report analyzed the projected value of industrial vending machines by type (vertical lift, coil, carousescale, locker or drawer) and found that the carousel vending machine is expected to experience the most growth in value due to its ability to have compartments of various sizes and the fact that it can provide access to products by item, employee or designation. Additionally, the carousel machine has fewer moving parts, reducing overall maintenance cost.

The report also revealed that the aerospace segment is expected to be one of the major adopters of industrial vending machine technology, as a way to reduce foreign object debris (FOD). These machines will keep track of items and manage critical assets, such as radios, scanners and airport ramp operations.

Europe is showing significant growth in adopting industrial vending machines. There is also a growing emphasis on sustainability within the UK manufacturing sector. Vending machines can minimize waste and ensuring optimal utilization of resources.

The UK government has initiatives promoting Industry 4.0 adoption in manufacturing. This includes potential funding or tax breaks for companies with industrial vending machines that contribute to a more connected and automated factory environment.

Industrial vending machines are finding applications beyond traditional manufacturing sectors, such as automotive or aerospace – they are also being used in healthcare and construction sites.

The Industrial Fasteners Institute (IFI) has published the 12 th edition of the IFI Book of Fastener Standards, which serves as the industry’s resource and is a compilation of the most commonly used fastener standards for inch fasteners and non-ISO metric fasteners.

In addition to the book’s 96 standards, 30 of which are updated, the latest edition now includes IFI 171, which covers thread dimensions for the assembly of bolts, studs and nuts in the steel construction industry.

The 12 th edition is US$675 and can be ordered online (indfast.org/book). It represents 83 years of continuous development in fastener standards since the first edition was published in 1941 and has been distributed to manufacturing and construction interests throughout the world.

“IFI’s Book of Fastener Standards is known throughout the world as a ‘go to’ resource and is really unique because it combines the most requested fastener standards from ASTM, ASME, SAE and IFI in one convenient

resource,” highlights Salim Brahimi, IFI’s director of engineering and technology. “It also represents tremendous cost savings, because purchasing those standards separately would cost more than US$3,000. It would also require someone to source and organize the standards for engineering or quality personnel so the book saves you time.”

In addition to the Book of Fastener Standards, IFI also offers the IFI Technology Connection, which is an online tool that utilizes the latest data found in the standards to generate tables and specification sheets for requested parts that can be used by sales, engineering and quality professionals. IFI also hosts numerous education and training events throughout the year that are available to the public through the IFI website.

Aerospace distributor Aeromed Group has named Todd Sider, who has over 30 years of experience in the aerospace and commercial markets, as executive director for strategic sourcing.

Todd has worked for several companies within the fastener sector, including Century Fasteners Corp, Heads & Threads International, Federal Bolt & Nut Supply and Reynolds Fasteners.

Declan Grant, president at Aeromed Group, noted Sider’s experience in strategic sourcing and supply chain management will be “instrumental in driving our procurement initiatives a developing and growing with our strategic partners”. North Carolina-based Aeromed is an alliance of aerospace distribution companies.

by Fastener World Inc www.fastener-world.com

According to statistics obtained through the European Commission, China is the top exporter of carbon intensive products with more than 25,000 entries, and Taiwan ranked fifth with between 5,000 and 6,000 entries.

The US ranked second with about 10,000 entries, the UK third with around 7,000 to 8,000 entries, and Turkey fourth with around 6,000 to 7,000 entries. India ranked sixth ranging between 5,000 and 6,000 entries.

From the data, it is clear that China’s carbon intensive export entries are more than double those of the US and the UK and are nearly five times those of Taiwan and India. This is partially reflected in the fact that the value of China’s exports to the EU is the highest.

Taiwan, which ranks eighth in the world in terms of export value, also has a high value of exports to the EU. In addition, fasteners are the top downstream steel product category exported from Taiwan and are mostly produced by several SMEs.

Sheh Kai Precision is reducing greenhouse gas emissions and energy consumption by improving manufacturing processes, increasing resource utilisation efficiency, and using cleaner manufacturing technologies.

Currently Sheh Kai uses energy efficient air compressors to improve the insulation performance of building structures, and plans to use more energy efficient equipment and machines. The company has also said it has completed carbon inventory and will apply for certification to verify the inventory data.

“Stock level is still high at European customers’ locations, but the customers are slowly coming back to purchase from Taiwan. Sheh Kai is using the void to upgrade our ERP system and equipment, focusing on carbon reduction and carbon inventory of the manufacturing process, to make full preparations for the future implementation of full CBAM and economic recovery,” comments Sheh Kai Precision Co Ltd.

In addition, the Taiwanese government has attached great importance to the Carbon Border Adjustment Mechanism (CBAM) regulation. Around 5,000 out of the 13,000 reports submitted by local EU importers came from Taiwan. However, it is worrisome that the completion rate of the first submission is less than 10%, as many EU local importers are unfamiliar with their reporting obligations. If they do not complete the submission by mid-July 2024, they will face fines up to €50 per tonne of carbon emission.

The European Commission has said it will simplify the system to make it easier for them to operate. However, it is still necessary for manufacturers who are most familiar with their own carbon emissions to work with EU importers to complete the submission smoothly.

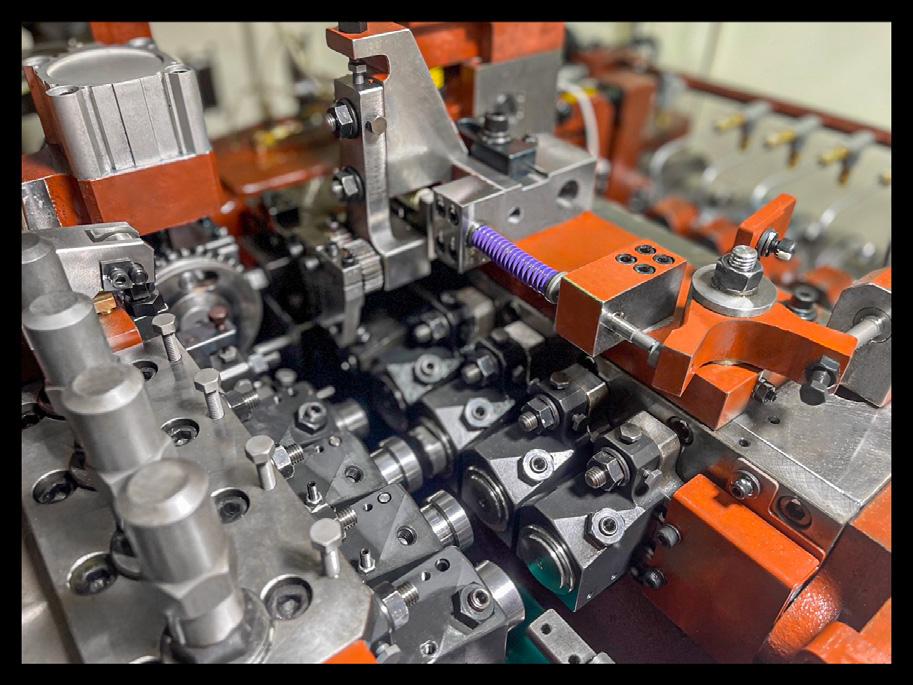

With an average monthly capacity of 3 million pieces, Kanon Precision Co Ltd, a specialist in the customisation of CNC precision lathe machined parts, has recently made several investments including new machinery to enter new markets –in particular Europe and America.

Recognising that it is an inevitable trend for factories to go international and communicate directly with customers face-toface, Kanon began its transformation in the second half of 2022. In addition to installing several CNC sliding/fixed head processing machines to meet different needs, its plant has recently added six computerised composite machines and two optical sorting machines to improve the process and control the quality. The company has also invested in Japanese Nomura’s full complex machining equipment, which is capable of completing sophisticated processing such as drilling and tapping holes on small sized turning products with precision tolerances.

“The introduction of the composite machines allows us to complete the drilling and milling process with a single machine, avoiding the displacement error caused by multiple clamping of workpieces between different machines, and realising the results of high precision and efficiency,” comments the company.

In 2025, Kanon will also participate at Fastener Fair Global in Germany, with the hope to promote its product technology and cooperate with more customers in developing new products.

Shandong Tengda Fasten Tech Co Ltd, a Chinese stainless steel fastener manufacturer, successfully conducted its initial public offering (IPO) on the Shenzhen Stock Exchange (SZSE), signifying a milestone in China’s fastener industry for 2024 by becoming the first listed fastener enterprise of the year.

In the listing hall of SZSE, Chairman Chen Peijun, along with various leaders and distinguished guests, jointly witnessed the historic moment of the company ringing the bell, ushering in new opportunities for the development of China’s stainless steel fastener industry.

Since its inception, Tengda Technology has been dedicated to the research, production and sales of stainless steel fastener products, including bolts, nuts, screws, washers, etc. The IPO raised approximately Rmb849 million (€108.7 million), which is planned to be used for the expansion and technical transformation of stainless steel fasteners; the expansion of fastener product lines and the construction of supporting production lines; the construction of production and intelligent storage bases for stainless steel fasteners; as well as the replenishment of working capital.

“Looking ahead, Tengda Technology will always maintain a humble and respectful attitude towards the industry, steadfastly advancing towards the goal of becoming a world renowned stainless steel fastener manufacturer, sales integrator, and provider of specialised fastener technology solutions,” commented Chairman Chen.

In the vast expanse of the southernmost ice fields on Earth, China is actively constructing its fifth Antarctic research station, the Ross Sea New Station. Over 70,000 sets of high strength bolts made in China played a crucial role in this process. These bolts not only had to withstand extreme cold, but also face the challenges of strong winds, ice and snow.

These Antarctic bolts are not ordinary fasteners, they are specially designed and manufactured fasteners. Yang Zhaojun, the general manager of a fastener enterprise in Anhui, said that these steel bars are actually special weather resistant steel, which contains more than a dozen special elements compared to ordinary steel. These special elements enhance the steel’s cold resistance and toughness, enabling it to maintain stable performance in extremely low temperature environments.

Moreover, the manufacturing process of these bolts is highly rigorous. The warm forging process ensures the steel does not crack during processing. Subsequently, these formed bolts undergo heat treatment and chemical treatment to enhance their weather resistance and delayed cracking resistance. Among every 3,000 sets of bolts, eight sets are randomly selected for impact performance testing in simulated extreme cold conditions to ensure their reliability.

Behind a seemingly ordinary bolt lies the dedication and intelligence of research teams and workers. It is these carefully crafted Antarctic bolts that have become the key cornerstone –ensuring the sturdiness and durability of the steel structure of the Ross Sea New Station and making outstanding contributions to China’s Antarctic scientific exploration.

The third session of the First Membership Conference of the Yongnian Chamber of Commerce for Import and Export took place at the Yongnian Fastener Expo Centre, China, at the beginning of the year – bringing together experts from the hardware and fastener industries from all over the country, to collectively explore and embark on a new chapter in the development of Yongnian’s foreign trade.

In attendance at the event was Zhang Ning, the chief of Yongnian District, who delivered a significant address. He emphasised the crucial role of the Chamber in driving regional economic development and expressed high expectations for future development. He affirmed the government’s commitment to further supporting the Chamber’s initiatives, providing more policy and resource support for Member enterprises, and jointly propelling the economic prosperity of Yongnian District.

Yang Zhuqiang, president of the Yongnian Chamber of Commerce for Import and Export, presented a comprehensive summary of the work in 2023 and outlined the work plan for 2024. She meticulously reviewed the outstanding achievements of the Chamber over the past year and acknowledged the remarkable results achieved through the collaborative efforts of Chamber Members under the guidance of the Yongnian District Committee, District Government and District Commerce Bureau.

Looking ahead, the Chamber will continue to strengthen organisational development, expand its scale, enhance cohesion, and better serve its Member enterprises – contributing to the global influence of ‘Yongnian manufacturing.’

Sérgio

editor, Revista do Parafuso, www.revistadoparafuso.com.br

With motorcycle production returning to 2014 levels in Brazil, and the automotive sector remaining stagnant, is there a fundamental change in consumer behaviour and is owning a car declining in consumers’ ‘hierarchy of desires’?

Around 2013, when the Uber service was still not widespread in Brazil, an article in the Folha de S.Paulo newspaper recommended: “If you use your passenger car for less than 26km/day, sell it and use a regular taxi, a very expensive service in these times!”

By the end of 2014, the last major year before a series of economic crises, the Brazilian passenger car, truck and bus industry produced 3.15 million units (2.978 million passenger vehicles), against the 2.324 million units (2.041 million passenger vehicles) in 2023 – with trucks and buses representing around 5.5% of the total. Meanwhile, in 2023, 1.573 million motorcycles were manufactured, almost the same as in 2014, with 1.517 million units produced – with

HEICO Group, a German specialist in bolt securing elements, pre-tensioning systems and cold forged parts, has named Fixoved as a new distributor in the Brazilian market.

Founded more than 120 years ago, HEICO Group has a wide range of lines, including the HEICO-LOCK ® wedge locking system, HEICOTEC ® tensioning system and HEICO-FORM cold forged parts.

In April 2023 executives from HEICO met with representatives of Fixoved to confirm the new partnership. Since 1986, Fixoved Fixação e Vedação Ltda has acted as a sales agent for industrial metallic components, such as fasteners and items to use on sealing systems, establishing itself as a C-parts supplier.

Located in São Bernardo do Campo City, Brazil, Fixoved provides services and inventory management to manufacturing lines, with a portfolio made up of over 15,000 items.

the growth attributable to the multiplication of delivery services using motorcycles.

This means that over the last decade, the number of vehicles produced in Brazil has stagnated with only minimal, if any, growth. Furthermore, if mobility by electrified vehicles goes ahead, the demand for fasteners will decrease even further, which raises more questions for fastener manufacturers.

Add to this the high costs of owning a car – taxes, insurance, parking, as well as penalty fines for speeding, etc – is it any wonder the younger generation are refraining from buying a car, at least in Brazil. Are we witnessing a change in consumer behaviour, where owning a car may be fast declining on the ‘hierarchy of desires’?.

Júlio Milko, owner of Metalac SPS – a Precision Castparts Corp subsidiary since 2003, passed away on 5 th April 2024. Born in Hungary, Milko was living in Sorocaba City, Brazil.

Júlio was known within the Brazilian fastener market and was part of the group, during the first half of the 1960s, that was involved in the consolidation of the Sinpa union – the local fastener manufacturers’ association, in addition to other activities outside the sector – especially in the social sector.

More than 65,000 visitors attended FEIMEC –a machinery and tools fair that took place from 7th – 11th May in the São Paulo Expo events pavilion –located in São Paulo City, SP, Brazil.

An acronym for ‘fair and mechanics’ (feira e mecânica), FEIMEC covered 80,000m² of exhibition space, with more than 1,100 international brands, made up of from 37 different industrially robust nations, including Germany, China, India, and others.

FEIMEC included leading agents active in every aspect of the industrial sector, including machinery, tooling, as well as the most recent technological advances in metal mechanical production –including productive processes such as abrasion, forging (cold and hot), cutting, drilling, folding, gluing, machining and welding.

The next edition of FEIMEC will take place from 5 th – 9th May 2026.

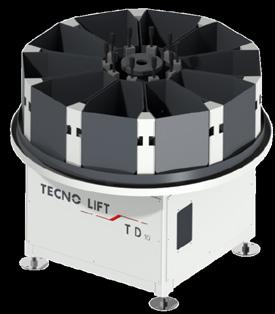

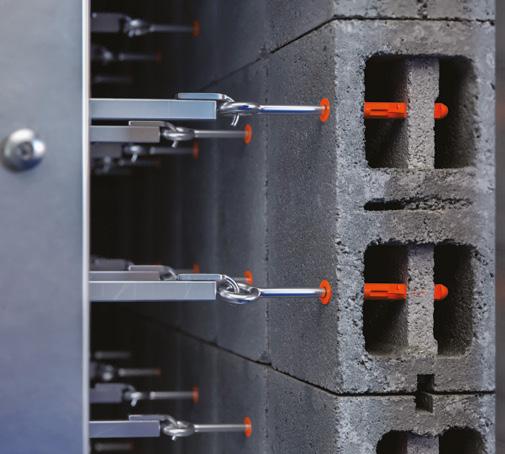

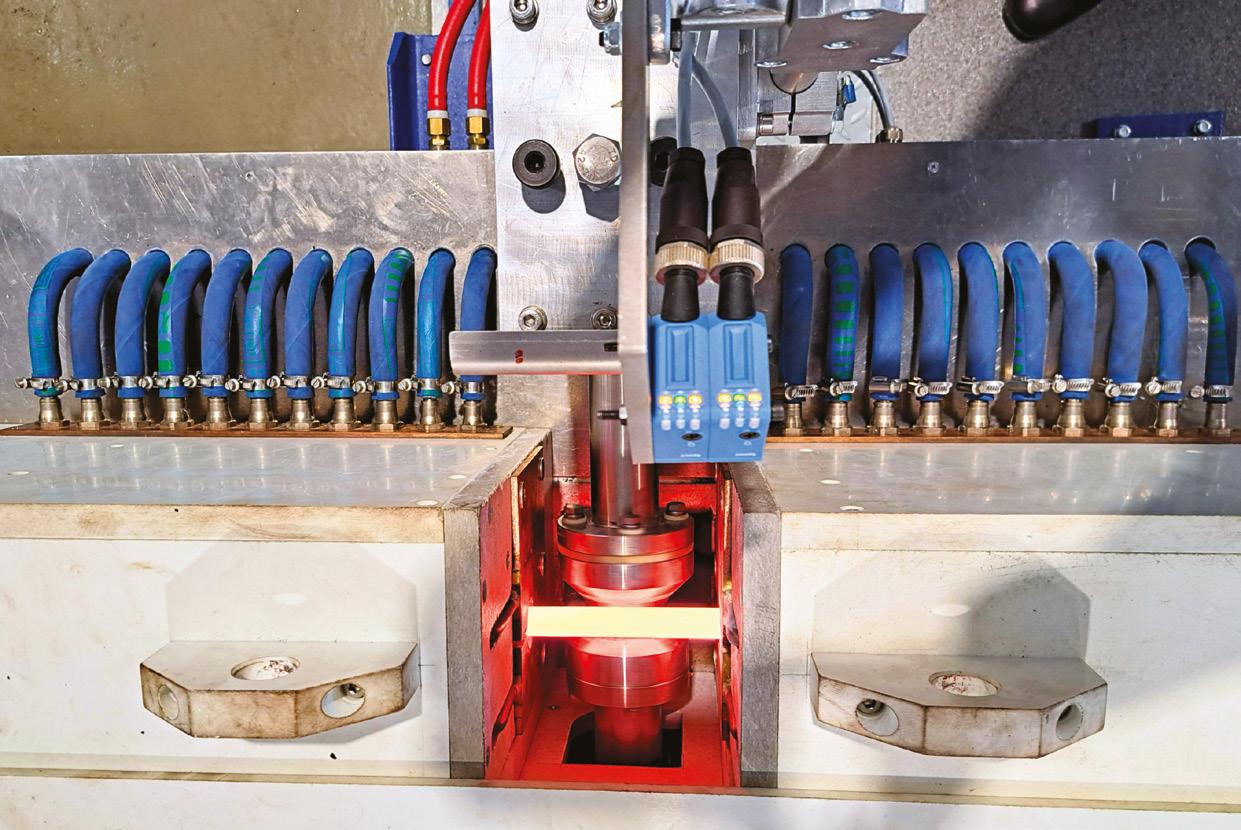

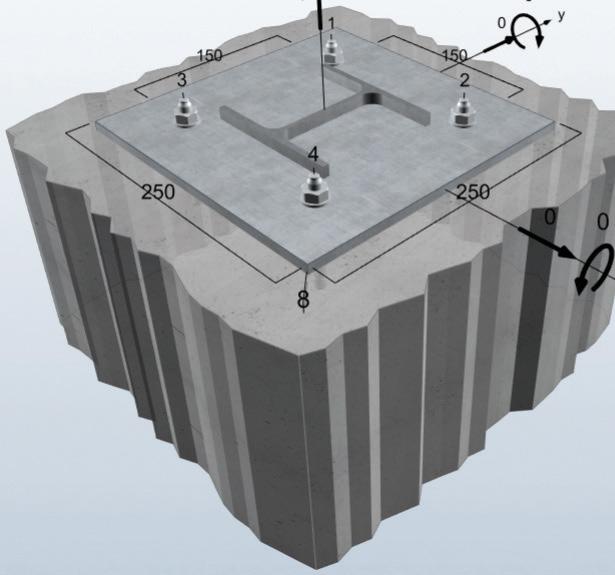

With the ongoing challenges within the global fastener industry, and wider global markets, it has never been more important for businesses to adapt quickly and efficiently to meet the needs of customers. That’s why global fastener distributor Fastbolt is preparing to be one of the first companies worldwide to pilot an automated compact storage system to further increase its efficiency.

Ekkehard Beermann, managing director at Fastbolt Group, explains: “We see various trends in these times of constant change and one challenge we have been experiencing for some years now is recruiting qualified labour for all sectors of our company. Although we focus on promoting young talents by offering various education and training models for commercial, logistics and IT job profiles, external recruiting is not easy. In our market position, as an importing wholesaler, efficiency in handling goods receipts and order preparation is likely to be one of the keys to success in the future and without automation we will not be able to increase our output in the years to come –partly also because skilled logistics staff are extremely hard to find on the employment market. With that in mind we decided to work with proven external logistics experts on a consultancy project on how we could benefit from a much higher level of technology and automation at our central warehouse

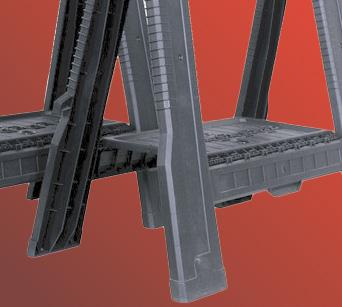

The first stage of this long-term consultancy project included an extension of Fastbolt’s warehouse and the installation of an innovative automatic bin storage system – the Jungheinrich PowerCube.

Being only the second company in the world installing this new automated compact storage system, Fastbolt is very excited to be part of the technical evolution of intralogistics.”

The Jungheinrich PowerCube will add 20,000 bin locations to Fastbolt’s current 20,000 manual pallet locations, increasing the efficiency of handling smaller quantities and a wider range of stock items – whilst also increasing overall storage capacity by at least 30% as smaller volumes will be transferred from pallets to bins.

“Being only the second company in the world installing this new automated compact storage system, Fastbolt is very excited to be a pilot customer and therefore part of the technical evolution of intralogistics,” states Ekkehard. “This first step into automation will certainly not be our last and we now have a clear idea on what areas of our intralogistics need further technological support to be more efficient in the future.”

The Jungheinrich PowerCube will create a more ergonomic workplace for Fastbolt’s staff and increase work safety, but at the same time will free up pallet locations creating room for stock range extensions, something Ekkehard believes to be key in light of the current market challenges impacting the fastener industry.

“With all the exceptional but very significant market developments and changes in the past three to four years – such as the Covid-19 pandemic, the introduction of anti-dumping duties against China for carbon steel fasteners, the Russian attack on Ukraine, with all its consequences to European economies, as well as the extremely volatile market for sea freight – the main challenge for the past two years has been adapting the business to these drastic changes, which is certainly very demanding.”

Another regulatory change has been the recent introduction of CBAM regulations – something that, as a business trading mostly standard fasteners that have traditionally been sourced in many different supply markets outside the EU, will have a massive impact for Fastbolt Group. “It came as a surprise for the entire industry that fasteners were added to CBAM at the last minute, with only very little preparation time,” explains Ekkehard. “While I fully support the general principles behind CBAM of trying to reduce carbon emissions worldwide, rather than only in Europe, I still see the inclusion of fasteners as being very problematic for our industry and creating massive risks for the European economy as a whole.”

He continues: “Looking at the regulation itself it becomes obvious that it had been designed for upstream products and certainly not for complex downstream products such as fasteners – with multi-stage production processes and traded through fragmented supply chains. The small to medium sized, but extremely relevant, manufacturers of fasteners all over Asia are having severe problems obtaining and providing the CBAM relevant emission data, which puts us importers under extreme pressure as we need to know and report specific emission data in order to import the product. Therefore in our view, fasteners should be taken out of the CBAM product scope, as the system is far too complex for our product and its supply chain. In any case it would have been much more realistic to exclusively focus on the CBAM based compensation of emissions caused by the production of the steel raw material in comparatively only very few different steel mills. It is these emissions anyway that count for the vast majority of total emissions caused by the production of a fastener. Relevant compensation would still be achieved while the unnecessary collection of minor but very detailed, as well as hard to collect and verify, emission values caused within thousands of different fastener manufacturing places outside the EU could be set aside. The effort of collecting, reporting and monitoring this particular data by far outweighs its relevance.”

Ekkehard continues: “At Fastbolt we are working with a high-level of effort to handle CBAM and its consequences to our business. However, we also know that we will not be able to place orders anymore to suppliers that are not able to provide the required data. Looking at the current stage of CBAM it becomes a certainty that it will therefore have a massive negative impact on the fastener supply for the European economy. As it is not too late yet, we still hope that fasteners can be taken out of CBAM, or at least necessary amendments to the regulation can still be made by the EU during the current transition period so that damages to our industry can be avoided.”

To continue trading in an extremely competitive and challenging market environment, Fastbolt Group has a commitment to quality to ensure

consistency on all levels of activity. The company maintains an increasing amount of high-quality stock in its warehouses in Germany, the UK, and Portugal, as well as having strong relationships with competent supply partners all over Asia, looked after and supported by its own Asian sourcing team.

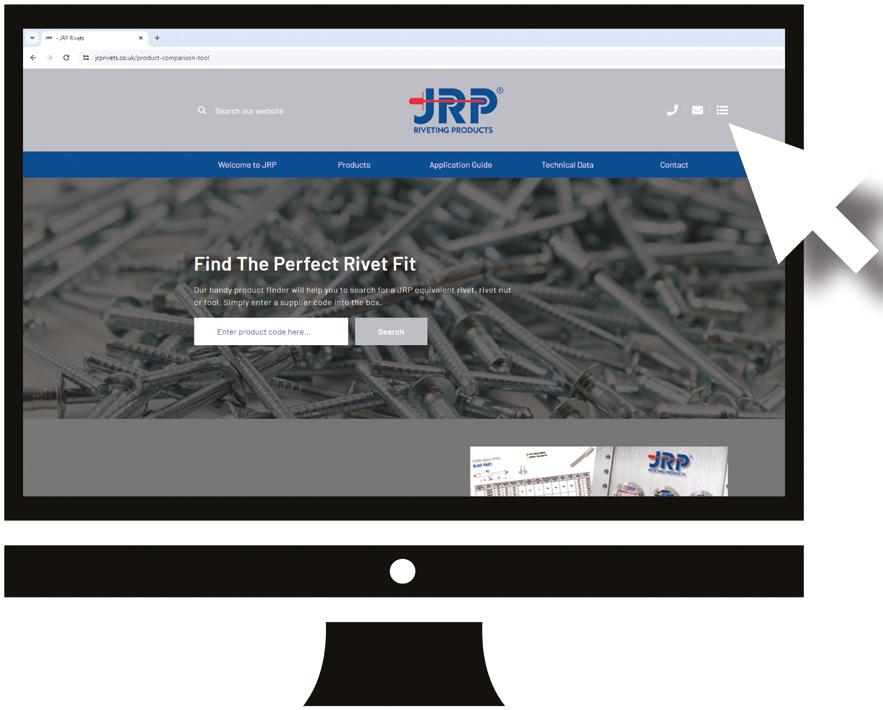

Exclusively supplying distributors, Fastbolt also offers customers efficient digital supply solutions from EDI via API up to FBonline, its in-house developed eCommerce solution that was introduced almost 20 years ago and has been developed consistently over the years. “Our services offered to distributors go far beyond just providing a comprehensive and competitive range of products,” proudly states Ekkehard. “We strive to be the best choice supplier for distributors – offering the best overall package. The need to be extremely efficient, error-free, reliable and innovative is huge. There is constantly more data involved and a higher level of system integration required in order to maximise the advantages and to comply with an increasing level of regulatory demand.”

He adds: “We have continued to invest in systems, more advanced inspection equipment and machinery, as well as spend more and take additional time to ensure we are a highly qualified supplier to distributors and continue to be in the years to come. In an increasingly complex global trading environment of more demanding regulations and documentation requirements, Fastbolt has the infrastructure, competence and processes to strengthen the supply chain for distributors in Europe.”

www.fastbolt.com

The Jungheinrich PowerCube will add 20,000 bin locations to Fastbolt’s current 20,000 manual pallet locations

exclusive insights from distributors and associations

The European Fastener Distributor Association (EFDA) is increasingly developing into a focal point for European fastener distribution, with its members being able to meet and exchange ideas more often than ever before in recent years.

New topics such as the Carbon Border Adjustment Mechanism (CBAM) regulation are increasing the need for information and dialogue, and through webinars

EFDA has been able to provide added value to many companies – with the good and pragmatic exchange between member organisations, and the companies, paying off for the entire European fastener distribution industry. In addition, EFDA has created the CBAM Working Group, set-up in December last year, which has also been able to produce very useful documents and assistance for members.

“Our members benefit from regular information from EFDA on trade policy measures from the European Commission, such as anti-dumping, or CBAM and other legal requirements,” points out Andreas Bertaggia, EFDA president. “This gives them not only expertise and security, but we can often provide the companies with a realistic scenario of what they need to prepare for in the coming weeks and months. The opinion of experts from the EFDA Task Force is certainly a better guide than rumours on the world markets.”

Andreas continues: “CBAM represents a major challenge for our industry. It is a very ambitious EU project, whose goal of tackling climate change we share, but which is not yet fully developed. Nine months into the transition period, it is obvious that CBAM was not developed for downstream products such as fasteners, but for the import of raw materials. In addition, importers of fasteners under CN Code 7318 are at a significant disadvantage compared to importers of comparable products and especially compared to fastener manufacturers in the EU. This will lead to a clear financial disadvantage, especially from 2026, when importers will have to purchase certificates for emissions. This discrimination must end. The best solution would be to remove fasteners from the scope of CBAM. The EU legislator’s decision to include fasteners in CBAM at the last moment was not well thought out.”

From the outset, EFDA has informed its members and companies about CBAM and the resulting obligations for importers, and its impact on the fastener trade, through webinars, guidelines and a regular information service. The EFDA Working Group has also created a template that suppliers outside the EU can use to provide its members with the required data for their quarterly reports.

“The EFDA template is significantly leaner and less complex than the Commission’s template. Nevertheless, the response rate is still far from what would be required to successfully implement CBAM,” explains Andreas. “According to a survey of our members, only 12% of suppliers provide reasonably complete data – including concrete emission values. Without the use of default values even after 1 st July 2024, our member companies will not be able to submit their quarterly reports. We have made our position clear to the European Commission.”

In order to support European fastener distributors in the implementation of CBAM, EFDA is also active outside the EU –supporting its partner associations in Asia and America so that suppliers there can fulfil the requirements of CBAM and provide EU importers with the necessary data.

“We will do everything we can to support our members, and their member companies, in continuing their business successfully and we will lobby the EU to ensure that gross errors in CBAM are eliminated,” states Andreas. “The issues of sustainability and the increasing regulation of the supply chain, such as CBAM, are becoming an ever-greater challenge for both small and large companies in the fastener distribution industry. At EFDA we look to address these issues, inform our members at an early stage, get involved in legislative processes and support companies in implementing the requirements. Whether it’s the customer’s desire for a carbon footprint or the European Union’s obligations through CBAM, our member companies are rising to the challenge.“

www.efda-fastenerdistributors.org

Italian wholesaler King SpA – a ‘one stop shop’ for high-quality, reliable and durable stainless steel fasteners – is currently in the midst of a digital transformation, with the company investing to improve its business processes and provide a better service to customers.

For more than 50 years King has been at the forefront of the standard stainless steel fasteners and bolts market, steadily growing in Italy, and abroad, thanks to the quality of its products and the speed at which it responds to requests.

“Working to fully meet the expectations of each individual customer is definitely challenging,” states the management of King SpA. “However, achieving the goal is almost more satisfying than finalising the business itself, which becomes the natural consequence once the customer has the solution they need.”

Guided by this realisation, King has looked to bring to life a management system designed in-house and fine-tuned specifically to ensure 100% satisfaction of each and every customer. “The program is calibrated to well defined and strict corporate standards but tailored to the personal expectations and needs of each individual customer,” underlines the management. “In addition, our bolts, nuts, screws, and other stainless steel supplies, are designed with high-quality materials and meet strict manufacturing standards.”

To add to this, and with a view to maximise customer satisfaction, King has also initiated a total quality programme to ensure the excellence of the products it offers, including chemical and dimensional aspects. “This ensures that each product undergoes a dimensional analysis that certifies its adequate compliance with the reference standards in terms of lengths, diameters, impressions, and threads, with each product analysed with an X-ray spectrometer that allows the detection of the main chemical elements that compose them,” points out the management. “This means that every product marketed by King is guaranteed to be 100% stainless steel and DIN compliant.”

In an ever changing market, where technology occupies a primary place in customer satisfaction, and where offering a quality product in a short time has become a prerequisite, King has also developed an online

For more than 50 years King has been at the forefront of the standard stainless steel fasteners and bolts market…”

system for accessing a shortlist of customised services. This includes an online shop for purchasing products and requesting quotations – with the aim of getting closer to its customers and creating a new system that could be the frontier of online sales; a tracking system for purchased products; a recall system for all documentation when reconstructing the procurement history; as well as a system for viewing the statistical trend of orders.

The Italian wholesaler is also making significant investments in order to increase its product range, as well as improve its automation in the search for the best logistical performance. “We have introduced new MRP and CRM systems that are allowing us to grow significantly, which has also led to us hiring many new professionals,” mentions the management. “We are able to further meet the needs of our customers thanks to our digital transformation and investments, especially within our sales department, which has allowed us to grow significantly. As a business we will continue to work hard, adapt to changes whilst adopting new technologies, as well as constantly invest to improve our performance, products and service.”

www.king-inox.com

In recent years, data, eCommerce and automation have played an increasingly larger role in the global fastener distribution market. Assistant Editor Becca England visited Apex Stainless Fasteners to find out how the UK-based company has been actively investing in all of these areas, to continue to offer its customers the highest level of service, while setting the company up for future success.

With the future in mind, Apex has implemented numerous changes – resulting in more investment in the last year than in the previous two decades of the company’s history. The first of these changes took place in 2023 with the company opting to change its ERP system to gain more efficiency in its operations. This change has enabled the business to operate more efficiently by using an eWMS system and several EDI integrations.

With a focus on continuing to improve its operational effectiveness, a walkway system has also been implemented in Apex’s warehouse to enable multiple orders to be picked simultaneously, making it easier for the company to handle peaks in demand.