WWW.FOODSAFETYAFRICA.NET YEAR 1 | ISSUE NO. 1 JUNE/JULY 2021 AfDB - FUNDING AFRICA’S FOOD SAFETY CAPABILITY EXECUTIVE INTERVIEW: EXECUTIVE INTERVIEW: OPINION: OPINION: WWW.FOODSAFETYAFRICA.NET YEAR 2 | ISSUE NO. 3 OCTOBER 2022 FOOD SAFETY AFRICA STEVEN CARLYON AFSNS 2022 REVIEW LABAN KABIRU KENYA DAIRY BOARD KENCHIC LTD TENYEARS OF IMPACT 2012 2022 10

Dairy AFRICA MANUFACTURING SUMMIT & EXPO AN FW AFRICA EVENT September 20-22, 2023 THE SUSTAINABILITY & INNOVATIONS TRADE SHOW & SUMMIT FOR AFRICA’S DAIRY INDUSTRY CONFIRMED SPEAKERS JOACHIM WESTERVELD Executive Chairman, Bio Food Products, Kenya HYBRID SUMMIT: LIVE FROM NAIROBI, KENYA & VIRTUALLY FROM AFRICA & THE WORLD DAVID CHITOWE Founder & CEO, Mzuzu Dairy, Malawi NKOSANA MTIMKULU Founder, South Western Dairy, South Africa info@fwafrica.net +254 725 343 932 www.dairybevafrica.com Sign up to Sponsor, Attend & Speak

Without food safety, Africa’s food security dream will continue to be just that: a dream

We cannot confidently say that Africa can achieve the Sustainable Development

Goal 2 which aims to achieve zero hunger by 2030 without ensuring that all food for its inhabitants, which at the time is expected to have ballooned to 1.69 billion people, is safe.

As a continent, we have a long way to go, as we already can’t feed the approximately 1.2 billion people that already reside in the continent. According to recent reports by the Food and Agriculture Organization (FAO) and the African Union (AU), an estimated 346 million people in Africa are affected by the current food crisis. The paradox is that food estimated to be worth US$4 billion goes to waste in Sub-Saharan Africa while millions of people go hungry.

While many are making concerted efforts to address the food waste problem as a way of achieving food security, efforts need to also be directed towards food safety initiatives to wholistically address the food security problem. Africa currently has the world’s highest per-capita rate of foodborne illnesses. Foodborne hazards are responsible for 137,000 deaths and 91 million acute illnesses in Africa every year, mostly affecting children under age 5, according to World Health Organization data cited in a February 21, 2019, WBUR article. Without food safety being part and parcel of food security initiatives, we will continue losing millions of our people to food safety incidents and thus fall short of SDG 3 which is aimed at good health and wellbeing.

The just concluded Africa Food Safety Summit brought together key stakeholders in the food industry to discuss way in which to improve

safety of our foods. A mixture of highlevel keynote speeches and expert panel discussions delivered a wealth of information on food safety to participants attending both physically and virtually. At the end of the 3-day summit, we all came to one agreement: “If its not safe, its not food”.

Incase you missed this important event around food safety, this edition of the food safety magazine gives a detailed review of the events that took place. In these pages, you will find keynote speeches from Damian Ihedioha, PhD., Agribusiness Development Division Manager at AfDB on the bank’s role in driving food safety across the continent as well as the speech of Margaret

Kibogy,

Discussions with key players in the food industry from Steven Carlyon, President of Simplifine Foods to Jim Tozer, the Managing Director of East Africa’s largest poultry processing company Kenchic as well as a review of some of the panel discussions are also included in this edition.

We wish you a good read.

Paul Ongeto, Lead Editor, FW Africa.

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 1

the Managing Director of Kenya Dairy Board on steps Kenya is taking to ensure milk within its borders is safe.

EDITORIAL

www.afmass.com EASTERN AFRICA'S MOST INFLUENTIAL FOOD PRODUCTS & NEW TECHNOLOGIES TRADE SHOW Sarit Expo Centre, Nairobi, Kenya FOOD Afmass EXPO The Future of Food in Af rica MARCH 30 - APRIL 1, 2023

FOUR PAVILLIONS THAT COVER THE FOOD INDUSTRY FROM A-Z FOOD EXPO INGREDIENTS AFRICA DISCOVER NETWORK BE INSPIRED MARKET FOOD AFMASS DRINKS PACK AFRICA EXPO Process & EXPO BOOKINGS OPEN!!

ON THE COVER

Damian Ihedioha: PhD - Division Manager, Agribusiness Division, African Development Bank Group

In this

issue

1 Editorial 10 News Updates:

• Zimbabwe boosts antimicrobial resistance surveillance capacity

• FoodLogiQ ties up with ESHA Research creating a formidable force in traceability

• South Africa launches National Biosecurity Hub to combat diseases

• Naturo improves Haelen milk processing technique allowing dairy-sensitive people to indulge

• FAO, SADC debut Regional Agricultural Information Management System

• BSI to help Ghana Standards Authority improve its technical capacity

• Edible oil manufacturers dispute KEBS suspension of products

• Kenya, Zambia in bid to resolve more than decade-long non-tariff trade barriers

• Study reveals high Brucella contamination in Tunisia’s raw dairy products

• Kenya lifts 10-year GMO cultivation and importation ban

• Consumers in Kenya to gain access to variety of fortified foods

• Egerton University researchers reveal contamination in most Nakuru meat

• Lack of oversight impedes food fraud regulation in Africa - report

• Study reveals high Brucella contamination in Tunisia’s raw dairy products

19 Supplier News & Innovations:

• Syngenta releases digital tool to detect harmful nematodes through satellite images

• Neogen debuts quantitative Cashew ELISA test with great sensitivity, finalizes 3M merger

• PathogenDx presents new virus detection technology to curb plant-borne pathogens

• Agilent partners with Mettler Toledo to provide seamless weighing results

• ABB makes break-through, develops first-ever antimicrobial detectable cable ties

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 4

48 54

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 5 OCTOBER 2022 | Year 2 Issue 3. No. 5 54 48 58 62 66 70 70 66

Kenya Dairy Board keen on ensuring the safety of milk across the country’s supply chain

Venturing into the food industry: Tips from leading industry professionals in Kenya

Simplifine Foods President Steven

build

safe, reliable and efficient food supply chain

Getting

58 62 AFRICA FOOD SAFETY & NUTRITION SUMMIT REVIEW

25

OPINION

OPINION

EXECUTIVE INTERVIEW: Steven Carlyon

Carlyon on how to

a

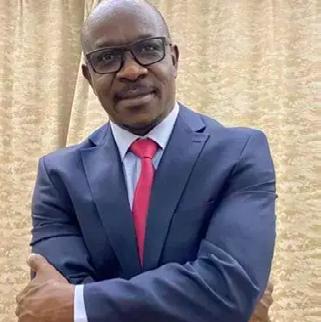

DAMIAN IHEDIOHA: PhD - Division Manager, Agribusiness Division, AfDB Damian Ihedioha, speaks on the AfDB’s role in driving the food safety agenda in Africa EXECUTIVE INTERVIEW: Laban Kabiru

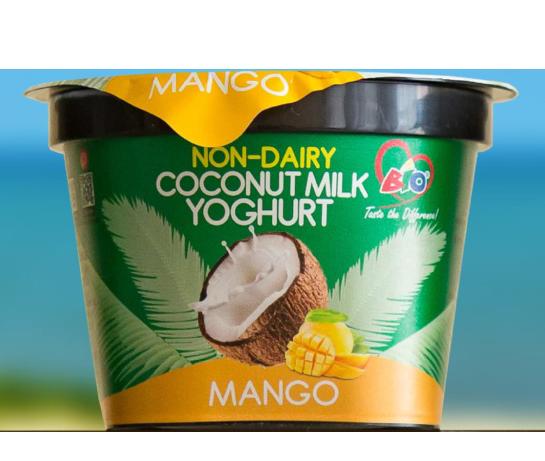

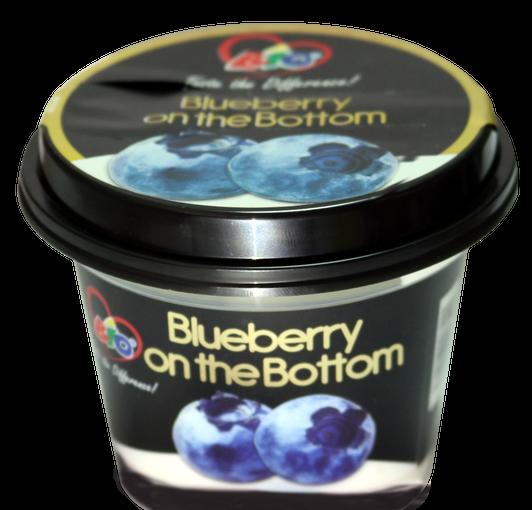

Quality from the word go: An interview with Laban Kabiru, Manufacturing and Logistics Director at Bio Food Products Ltd OPINION Kenchic’s Managing Director speaking on Emerging food safety & quality concerns in the food & animal feed industry in Africa at the Africa Food Safety Summit 2022

2022

FOOD SUSTAINABILITY SUMMIT FRICA BETTER PLANET. BETTER COMMUNITIES. MORE PROSPERITY March 28, 2023 Emara Ole Sereni Hotel, Nairobi, Kenya DEFINING THE FUTURE OF SUSTAINABLE AGRICULTURAL PRODUCTION, FOOD MANUFACTURING AND RETAIL IN AFRICA. info@fwafrica.net +254 725 343 932 www.foodbusinessafrica.com/future Sign up to Sponsor, Attend & Speak Sign up to Attend the first pan-African high-level summit on mainstreaming sustainability in Africa's food and agriculture value chains. Join private sector food industry leaders, Government ministries and agencies, non-profit and academic/research institutes as they share their goals, strategies and policies to create a better planet, enable vibrant local communities and improve prosperity in the communities they operate in. Confirmed Sponsor:

CONFIRMED SPEAKERS

ASHISH PANDE Country Head, Olam Agri, Nigeria

ESSAM EL-MADDAH HR & General Secretary Director, Danone Egypt & North East Africa

JUSTIN ARCHER COO East Africa & Group Head of Sustainability, Sucafina SA

CLAUDIA CASTELLANOS Managing Director, Black Mamba

JOACHIM WESTERWELD Executive Chairman, Bio Food Products

MILLICENT A. ADOBOE Co-Founder, Achiever Foods Ghana

CAESAR ASIYO Chief Development Officer, Victory Farms

SAINT-FRANCIS TOHLANG Corporate Affairs Director, Nestle East & Southern Africa

NICO ROOZEN Honorary President, Solidaridad Network

ROZY RANA Managing Director, Dormans Coffee

GAURAV VJ CEO, 260 Brands

BRETT THOMPSON Co-Founder & CEO, Mzansi Meat

ASHISH PANDE Country Head, Olam Agri, Nigeria

ESSAM EL-MADDAH HR & General Secretary Director, Danone Egypt & North East Africa

JUSTIN ARCHER COO East Africa & Group Head of Sustainability, Sucafina SA

CLAUDIA CASTELLANOS Managing Director, Black Mamba

JOACHIM WESTERWELD Executive Chairman, Bio Food Products

MILLICENT A. ADOBOE Co-Founder, Achiever Foods Ghana

CAESAR ASIYO Chief Development Officer, Victory Farms

SAINT-FRANCIS TOHLANG Corporate Affairs Director, Nestle East & Southern Africa

NICO ROOZEN Honorary President, Solidaridad Network

ROZY RANA Managing Director, Dormans Coffee

GAURAV VJ CEO, 260 Brands

BRETT THOMPSON Co-Founder & CEO, Mzansi Meat

FOUNDER & PUBLISHER Francis Juma

EDITORIAL Catherine Odhiambo ADVERTISING & SUBSCRIPTION

Jonah Sambai | Virginia Nyoro

DESIGN & LAYOUT

Clare Ngode

PUBLISHED BY: FW Africa

P.O. Box 1874-00621, Nairobi Kenya Tel: +254 20 8155022, +254725 343932

Email: info@fwafrica.net Company Website: www.fwafrica.net

Food Safety Africa is published

4 times a year by FW Africa. Reproduction of the whole or any part of the contents without written permission from the editor is prohibited.

All information is published in good faith. While care is taken to prevent inaccuracies, the publishers accept no liability for any errors or omissions or for the consequences of any action taken on the basis of information published.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 8

Year 2 | Issue 3 | No.5 EDITORIAL FOOD SAFETY

WWW.FOODSAFETYAFRICA.NET WWW.FOODSAFETYAFRICA.NET CEO BUSINESS AFRICA WWW.CEOBUSINESSAFRICA.COM FOOD SAFETY AFRICA WWW.HEALTHCAREAFRICA.INFO WWW.FOODBUSINESSAFRICA.COM OUR PUBLICATIONS WE PUBLISH AFRICA'S LEADING MAGAZINES, INCLUDING: WWW.FOODBUSINESSAFRICA.COM/MBA WWW.PACKAGINGAFRICAMAG.COM Packag ng AFRICA SUSTAINABLE Food Business HealthCare AFRICA

AFRICA

2022 2022 2022

International Food Safety Congress (IFSC)

03 - 04 Nov 2022

Istanbul, Turkey www.foodsafetycongress.org

Smarter Food Safety - Busan 10 - 11 Nov 2022 South Korea www.am.foodhygiene.or.kr

6th International Conference On Food Chemistry, Nutrition and Safety 10-11 Nov 2022 Vancouver, Canada www.foochemistry. conferenceseries.com

International Conference on Food Microbiology and Food Safety (ICFMFS)

12 - 13 Nov 2022

Jakarta, Indonesia www.theires.org/Conference2022/ Indonesia/5/ICFMFS

OFPA Annual Fall Food Safety Symposium & Annual General Meeting

15 - 16 Nov 2022

Mississauga, Canada www.ofpa.on.ca/upcoming-events

Food Safety Conference 16 Nov 2022 London, UK www.foodsafetytrendsconference. com

The Proactive Food Safety Conference

16 Nov 2022 Amsterdam, Netherlands www.foodsafetytrendsconference. com

World Congress on Food Safety and Nutrition Science

21 - 22 Nov 2022 Rome, Italy www.conferenceseries.com

Arab Food Safety Summit 22 - 24 Nov 2022 Tunis, Tunisia www.arabfoodsafetysummit.com

Food Safety Conference 24 Nov 2022

Salford, UK www.salford.ac.uk/spd/conferences/ food-safety-conference

SC Food Safety Task Force Annual Conference

05 - 06 Dec 2022

West Columbia, USA www.eventbrite.com/e/southcarolina-food-safety-conferencetickets-432076130337

Annual India Food Safety Summit & Awards

15 - 16 Dec 2022 New Delhi, India www.indiafoodsafetysummit.com

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 9 EVENTS CALENDAR

Zimbabwe boosts antimicrobial resistance surveillance capacity

of Zimbabwe increase awareness and comprehension of the features of antimicrobial use in the agriculture sector and their impact on the environment and humans using the One Health concept.

WHO also recently educated 60 training of trainers (ToTs) from various ministries on the WHONET software, a crucial data tool created for the management and analysis of microbiology laboratory data.

ZIMBABWE – At least 14 laboratories in Zimbabwe have been equipped to provide antimicrobial resistance (AMR) surveillance data thanks to financing from the Fleming Fund, a UK aid programme that helps countries fight AMR.

Five of these are devoted to veterinary research, seven to human health, one to food, and one to the environment.

The Foodand Agriculture Organization (FAO) and World Health Organization (WHO) have helped the Government

The technology is essential for increasing collaborations and data sharing at the national (District Health Information System 2), regional, and international levels as well as for improving the utilization of surveillance data for local requirements.

Morocco earns organic standard “Bio-Maroc” certification

MOROCCO – Morocco has earned the certificate of admission for the Moroccan organic standard “Bio-Maroc”, as evidence of its compliance with the IFOAM –Organics International (OI) criteria.

The accreditation was granted following a “comprehensive” evaluation of Morocco’s “Bio-Maroc” national organic standards in conformity to the

MERGERS

Common Objectives and Requirements of Organic Standards (COROS), claims the Moroccan Ministry of Agriculture.

The COROS contains requirements that have been found common across many private and government organic standards.

Standards can be compared to this reference in an equivalence exercise,

which will highlight their strengths and weaknesses as compared to the international reference.

According to the statement from the ministry, Morocco gains credibility abroad as a result of acquiring this certificate because it conforms with IFOAM-IO requirements.

FoodLogiQ ties up with ESHA Research creating a formidable force in traceability

U.S – FoodLogiQ, the top SaaS provider of solutions for supply chain transparency, food safety, and traceability, has announced a strategic merger with ESHA Research, a world leader in nutrition analysis and regulatory-compliant labeling software and services.

The combination of FoodLogiQ and ESHA will give the food industry an unmatched ability to extend product development and nutritional analysis into supplier compliance, improved traceability, and automated recall management.

This is due to the increased emphasis on digitizing the supply chain to improve food safety and transparency.

“FoodLogiQ broadens the ESHA

platform and expands the universe of potential product extensions and add-on acquisitions that will be attractive to the combined company.

“We will continue to invest meaningfully in product innovation, sales and marketing, and customer support,

while closely evaluating complementary add-ons to strengthen the company,” said Riverside Senior Partner Brian Sauer.

The Riverside Company, a global private investor with a concentration on the smaller end of the middle market, contributed funding for the purchase.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 10

LABORATORY, CALIBRATION & TESTING

NEWS UPDATE

LABORATORY, CALIBRATION & TESTING

UNBS commissions second food safety laboratory in Mbale City

second food safety laboratory in Mbale City to provide Conformity Assessment and Quality Assurance of products manufactured in Eastern Uganda.

This comes following the commissioning of the first laboratory in Gulu City in July 2022, to serve Northern Uganda, as part of the Bureau’s Strategic Plan to decentralize quality infrastructure and other standardization services to other parts of the Country.

Earlier in March, TMEA boosted UNBS’ regional offices in Mbarara, Gulu, and Mbale with equipment worth US$1,885,280.

UGANDA – The Uganda National Bureau of Standards (UNBS) has opened its

DISEASES, OUTBREAKS & RECALLS

Trade Mark East Africa (TMEA) and the Danish Government have thus far furnished the UNBS Regional Testing Laboratories with equipment worth US$4,455,283.

To improve the quality and safety of their products, Mr. David Livingstone Ebiru, the Executive Director of UNBS, asked all businesses engaged in production, processing, and value addition to make use of the decentralized quality infrastructure by obtaining certification services (Q-Mark) from UNBS before releasing them onto the market.

In the near future, the regulator plans to establish a laboratory in the Western Region.

South Africa launches National Biosecurity Hub to combat diseases

SOUTH AFRICA – To aid in the prevention and control of agricultural and animal diseases in South Africa, the Department of Science and Innovation (DSI) has established the National Biosecurity Hub at the University of Pretoria’s (UP’s) Future Africa campus.

Professor Sanil Maharaj, Dean of the Faculty of Engineering, Built Environment, and Information Technology stated at the hub’s opening that the hub would draw from top research from international institutions and contribute to improving market access, economic growth, and job creation in the nation.

This will be through improved national

sanitary and phytosanitary (SPS) capacity and increased awareness of current and emerging biosecurity threats.

He continued by saying that the hub will make sure that South Africa was better equipped to handle disease outbreaks because it would be able to make choices more quickly and effectively.

The National Biosecurity Hub’s mission is to greatly expand the capabilities now available to the South African SPS regulatory bodies and to be relevant across all agriculture and forestry industries.

To meet SPS requirements of international trade and improve biosecurity, it will offer research and information services to the public and private sectors.

AUSTRALIA – The Australian company Naturo has improved its Haelen milk process, which created a 60-day shelf life – to now have double the digestibility.

Since the Haelen process destroys more bacteria than conventional pasteurization, it is easier for people who have dairy sensitivity to ingest.

Naturo handles the whey proteins in milk differently since it doesn’t employ the high heat associated with conventional milk processing like pasteurization, ultrahigh-temperature (UHT), and Extended

shelf-life (ESL).

This method breaks down the proteins further than the standard, allowing for easier and faster digestion and enhanced nutrient absorption.

“This latest digestibility finding is a market breakthrough for our Haelen Technology partnerships and licensing agreements worldwide as well as opening the door to new products and market opportunities,” says Jeff Hastings, Founder and CEO of Haelen.

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 11

Naturo improves Haelen milk processing technique allowing dairy-sensitive people to indulge

THE NATIONAL BIOSECURITY HUB’S MISSION IS TO GREATLY EXPAND THE CAPABILITIES NOW AVAILABLE TO THE SOUTH AFRICAN SPS REGULATORY BODIES.

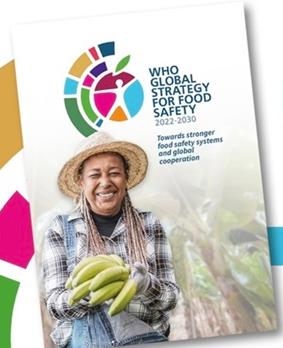

WHO launches Global Strategy for Food Safety 2022–2030

GLOBAL – The World Health Organization (WHO) has released the WHO Global Strategy for Food Safety 2022–2030, which was approved by Member States during the 75th World Health Assembly Session through Resolution WHA75 (22).

The launch represents a significant accomplishment in WHO’s efforts to advance health, ensure global security, and protect the vulnerable.

The goal of the Global Food Safety Strategy is to support Member States in their efforts to prioritize, plan, implement, monitor, and regularly evaluate actions aimed at reducing the burden of foodborne diseases (FBD) by fostering international cooperation and continuously improving food safety systems.

It addresses new and developing issues, takes advantage of modern technology, and proposes creative methods for enhancing food safety systems.

The policy also establishes specific

FAO, SADC debut Regional Agricultural Information Management System

goals and intends to reduce the incidence of foodborne diarrheal illnesses, which mostly affects children under the age of five and other vulnerable populations, by 40%. It further aims to have 100% operational coordination systems to handle foodborne incidents and improved laboratory capacity for foodborne illness surveillance.

AFRICA – The Southern African Development Community (SADC) and the Food and Agriculture Organization of the United Nations (FAO) have together unveiled the first SADC Agricultural Information Management System (AIMS), a platform to generate agricultural data for the region’s evidence-based decisionmaking.

For policy makers, the lack of trustworthy and consistent data in the agricultural sector in Southern Africa has always been a hindrance.

This has led to significant delays in the planning and execution of regional responses that are well-coordinated and designed to address threats like transboundary pests and diseases like the Fall Armyworm and Foot and Mouth Disease, which have a negative impact on productivity and trade in the region.

To address this, the European Unionfunded STOSAR project, “Support Towards Operationalization of the SADC Regional Agricultural Policy”, developed the AIMS platform (EU).

“The SADC AIMS is an integrated and multilingual system providing policy makers with access to reliable and timely data on which to base policies, resource allocations, and emergency interventions.

“This web-based application will provide SADC Member States with standardized instruments necessary to produce and disseminate comparable

The SADC AIMS platform is a webbased application with 12 modules for collecting, storing, and analyzing agricultural information.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 12

NEW TECHNOLOGIES

statistical information to inform SADC policies,” said Patrice Talla, FAO Subregional Coordinator for Southern Africa.

THIS APPLICATION WILL PROVIDE SADC MEMBER STATES WITH STANDARDIZED INSTRUMENTS NECESSARY TO PRODUCE AND DISSEMINATE COMPARABLE STATISTICAL INFORMATION TO INFORM SADC POLICIES.

Talla, FAO Subregional Coordinator for

Africa NEWS UPDATE

Patrice

Southern

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 13 SAFETY FOOD SUMMIT & NUTRITION Eastern Africa Edition AFRICA SAFETY FOOD SUMMIT & NUTRITION Western Africa Edition AFRICA SAFETY FOOD SUMMIT & NUTRITION Southern Africa Edition Nairobi, Kenya May 10-12, 2023 Lagos, Nigeria July 5-7, 2023 Date and Location to be determined DISCOVER THE FUTURE OF FOOD SAFETY, NUTRITION & FOOD SECURITY IN AFRICA REASONS TO ATTEND THE SUMMIT Be inspired by an unprecedented lineup of food safety and nutrition experts and opinion shapers from across Africa and the World. Meet and network with some of the most influential key decision makers from the private and public sectors, NGOs and more across various disciplines and countries from Africa and beyond of career-changing exchanges and innovative ideas. Get answers to the most-pressing food safety, nutrition and food security challenges at the regional high-impact conferences and exhibitions info@fwafrica.net +254 725 343 932 www.summit.foodsafetyafrica.net Sign up to Sponsor, Attend & Speak AFRICA SAFETY FOOD SUMMIT & NUTRITION

Study reveals high Brucella contamination in Tunisia’s raw dairy products

Brucellosis is a significant public health threat for urban and rural populations of endemic countries, particularly the Middle East and North Africa region, as the trade of unpasteurized milk and raw dairy products is widespread, says the study.

Samples were purchased from 75 retail marketing points for dairy products from March to November 2019.

B. melitensis highlights that zoonotic high-pathogen agent control remains a challenge for food safety and consumer

TUNISIA – A study has revealed a high rate of Brucella contamination in dairy products in Tunisia, shortly after another study conducted in Kenya discovered a cocktail of micro-organisms in milk.

The study investigated the occurrence of Brucella in 200 raw milk, ricotta, and artisan fresh cheese samples, collected from four districts in Tunisia.

According to the study published in the journal Foods, forty samples of cow’s raw milk, 102 of artisanal fresh cheese, and 58 of ricotta were collected.

Out of the 200 samples, Brucella was spotted in 150 (75%) with Brucella abortus being found in 47 (31.3%) samples, and Brucella melitensis in eight (5.3%). Almost half of the tested products had both species, while 21 (14%) were neither Brucella abortus nor melitensis.

The detection of both B. abortus and

OUT OF THE 200 SAMPLES, BRUCELLA WAS SPOTTED IN 150 (75%) WITH BRUCELLA ABORTUS BEING FOUND IN 47 (31.3%) SAMPLES, AND BRUCELLA MELITENSIS IN EIGHT (5.3%).

health protection, and could represent a serious emerging foodborne disease in Tunisia.

U.S – The U.S Food and Drug Administration (FDA) has recommended an amendment to the requirements for using ‘healthy’ labels on food packaging, to be consistent with present nutrition science, the Nutrition Facts label, and the Dietary Guidelines for Americans.

The proposed rule intends to more accurately take into account how nutrients

& RESEARCH

from different food groups interact and contribute to the formation of healthy dietary patterns and improvements in health.

Under the prospective new rule, food products advertised as ’healthy‘ would need to contain a ‘meaningful‘ amount of food from one of the food groups or subgroups suggested by Dietary Guidelines. Among these food groups

and subgroups are fruits, vegetables, and dairy.

Furthermore, items would have to adhere to strict guidelines for certain nutrients like sodium, saturated fat, and added sugars.

The new proposal is a component of the FDA’s ongoing efforts to enhance dietary habits and nutrition in the U.S.

Study demonstrates potential of x-ray technology in agricultural sector

INDIA – A study led by a team of researchers from the International Crops Research Institute for the Semi-Arid Tropics (ICRISAT) and the Fraunhofer Development Center for X-ray Technology (EZRT), has demonstrated the potential of X-ray radiography for a rapid and non-destructive determination of key market-related traits from X-ray scans of peanuts while still inside the hull.

Consequently, the evaluation process for peanut pods is now quicker and easier to complete. A single specialist can now complete the task, which took three to five expert professionals 30 minutes, in just two minutes.

Thus, it is possible to accurately and quickly assess peanut pods for crucial market-related traits like kernel weight or shelling percentage using an X-ray scan of intact, unshelled peanut pods, say the researchers.

“ICRISAT crop researchers pointed to the important gaps frequently restraining the Indian farmers from reaping the benefits of their hard labor, and researchers from rapid breeding of improved crops. The collaboration helped us to adapt our technology so that the gaps can be closed,” Dr. Stefan Gerth, Head of Department, EZRT said.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 14

SCIENCE

SCIENCE & RESEARCH

NEWS UPDATE

FDA proposes amendment to requirements for using ‘healthy’ labels on food packaging

Kenya,

non-tariff trade barriers

harmonizing the standards to include other nations will ensure that Kenya’s dairy products are available in other markets through the African Continental Free Trade Area (AfCFTA).

Zambia, one of the top markets for Kenyan milk, banned the export of Kenyan milk over safety concerns after processors in the Southern African country claimed that milk imports exceeded the country’s total bacteria count.

AFRICA – A study titled “Food fraud amid COVID-19 in Sub-Saharan Africa: A challenge of the present” has intimated that lack of oversight and a wide range of informal markets have made it challenging to regulate food fraud in Sub-Saharan Africa (SSA).

KENYA – Kenya and Zambia are at the brink of signing a memorandum of understanding to end the long-simmering trade dispute that saw Zambia ban the export of Kenyan milk more than a decade ago.

Although Kenya has enough standards for a variety of industries, according to KEBS Director General Bernard Njiraini,

REGULATORY & POLICY

Zambia’s standard allows a total bacteria count (TBC) of 200,000 while Kenya’s follows the international benchmark of one million TBC per millilitre.

“Now we are moving to another level of having harmonized standards across Africa so that people from Zambia can access our milk because sometimes we have disparities in terms of their thresholds in the counts and what we have,” said Njiraini.

UK to revise 20-year-long Bread and Flour Regulations

UK – The Department for Environment, Food and Rural Affairs (Defra) has launched a 12-week public consultation on revising the 1998 Bread and Flour Regulations and called on consumers, millers and bakers, retailers, and regulators from all four nations of the UK to contribute.

Defra launched the consultation on September 1 together with the Department for Health and Social Care (DHSC), Food Standards Scotland (FSS), and the Food Standards Agency (FSA) in Wales and Northern Ireland (NI).

The purpose of the consultation is to gather feedback on suggestions for modifying the nutrients currently added to non-wholemeal wheat flour and the addition of folic acid to improve public health outcomes for the people of Scotland and the rest of the UK.

“This consultation marks an important stage in the process of ensuring that the regulations covering bread and flour in Scotland, and the rest of the UK, are fit for purpose and, critically, support public

health,” said Geoff Ogle, Chief Executive Officer at FSS.

The FSA has announced that the public consultation will end on November 23, 2022, and that a summary of the replies will be published in the months that follow.

The study led by Dr. Helen Onyeaka, Lecturer at the University of Birmingham, states that the disruption caused by the COVID-19 pandemic will continue to impact the possibility of many food fraud risks.

“In a COVID-19 pandemic era where the issue of food security has taken center stage, toxic rice and grains, gamalinpoisoned fish (as a result of killing fish by poisoning water with gamalin), formaldehyde-treated fish, formalintreated meat, and fake Coca-Cola have been on the menu for millions of victims of food fraud in SSA,” the study reads.

The article continues by stating that the emergence of COVID-19 caused the focus given to food fraud in SSA to lessen as the priority became improving health systems.

As stated by the study, so many policies and standards exist across countries in SSA, however, implementation has been failing.

“With the pandemic still largely at hand, it is imperative to mandate and tighten checks at entry points, borders, hotels, formal and informal food vendors, shops, and abattoirs. Also, healthseeking habits should be embedded in the consumers through adequate sensitization, in both rural and urban areas,” reads the article.

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 15

TRADE, EXPORTS & IMPORTS

Zambia in bid to resolve more than decadelong

Lack of oversight impedes food fraud regulation in Africa - report

THIS CONSULTATION MARKS AN IMPORTANT STAGE IN THE PROCESS OF ENSURING THAT THE REGULATIONS COVERING BREAD AND FLOUR IN SCOTLAND, AND THE REST OF THE UK, ARE FIT FOR PURPOSE.

Geoff Ogle, Chief Executive Officer at FSS

KENYA – Barely a year after the United Kingdom-based World Animal Protection revealed the contamination of meat stocked in outlets across the country, Egerton University researchers have also unearthed a similar finding in Nakuru county.

The study which evaluated the microbiological safety of meat and readyto-eat (RTE) meat products in urban and peri-urban parts of the county, indicates that the presence of Staphylococcus aureus, Escherichia coli (E. coli), Salmonella spp and Shigella bacteria is worrying and efforts have to be put in place to cut on their levels.

FORTIFICATION

Consumers in Kenya to gain access to variety of fortified foods

In 87 samples of beef, goat, and other meat products, Staphylococcus aureus was the most prevalent negative bacterium with a prevalence of 100%, followed by Shigella spp. in 81 samples (93 percent).

All 15 samples of water that were randomly obtained from the butcheries and eateries tested positive for E. coli, salmonella spp., and Shigella bacteria, according to the report written by principal investigators Dr. Hillary Odeckh Indago, Prof. Joseph Wafula Matofari, and Dr. John Masani Nduko.

“These results indicate a public health risk for consumers of RTE meat products in Nakuru County,” the report stated.

“The presence of these bacteria points a direct finger to bad handling and poor hygiene practices because they indicate that the products have been in contact with faecal matter.”

KENYA – Non-profit international development organization TechnoServe has launched a program known as the Technical Assistance Accelerator Programme (TAAP), aimed at increasing the diversity of fortified foods available to consumers.

During the launch of the programme which was also graced by the private sector and Government agencies, Dominic Schofield, the Director of the TechnoServe Global Program, explained how the program will further guarantee that Kenyan consumers will continue to have access to wholesome food.

According to him, the TAAP is vital to ensure that consumers have access to

nutrition at a time when supply chain disruptions and high food prices are affecting consumption patterns.

“For example, the Russia-Ukraine conflict has disrupted supply chains and upended the global trade of agricultural goods, mounting increases in the price of food staples has also forced households to alter their diets, likely impacting their consumption of essential nutrients,” said Schofield.

He noted that food fortification has been widely identified as a cost-effective strategy for addressing micronutrient malnutrition at scale.

“The prospect of lower calorie intakes increases the importance of fortifying staple foods such as maize flour, rice, and edible oil,” he added.

TAAP follows the Strengthening African Processors on Fortified Foods (SAPFF) program, which was established in 2017 and aimed to raise compliance levels with food fortification among two staples of Kenya: wheat and maize flour.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 16

Egerton University researchers reveal contamination in most Nakuru meat

THE PROSPECT OF LOWER CALORIE INTAKES INCREASES THE IMPORTANCE OF FORTIFYING STAPLE FOODS SUCH AS MAIZE FLOUR, RICE, AND EDIBLE OIL.

NEWS UPDATE

Dominic Schofield, the Director of the TechnoServe Global Program

Kenya lifts 10-year GMO cultivation and importation ban

and disease…” read the statement in part. Across Africa, GM crops are commercially grown in South Africa, Nigeria, and Sudan.

More than a dozen other nations are currently undertaking trials on about eight GM crops, including banana, cassava, and maize, in preparation for their introduction into the food supply.

KENYA — The Kenyan government has lifted its ban on Genetically Modified Crops in the country after 10 years of suspension, permitting farmers to cultivate and import food crops and animal feeds that have been genetically enhanced through biotechnology.

In a meeting Chaired by President William Ruto in State House Nairobi, the cabinet decided per the recommendation of the Task Force to Review Matters Relating to Genetically Modified Foods and Food Safety, and in fidelity with the guidelines of the National Biosafety Authority on all applicable international

treaties including the Cartagena Protocol on Biosafety (CPB).

Kenya has been reluctant to approve the import or planting of genetically modified food crops since November 2012, amid an ongoing debate about the safety of GM crops, which have been lauded for their advantages including resistance to drought, pests, and higher yields.

“As part of the medium to long term responses to the ongoing drought, and as a progressive step towards significantly redefining agriculture in Kenya by adopting crops that are resistant to pests

KENYA – East African counterparts and other activists have raised an eyebrow in response to Kenya’s recent move to repeal the 10-year prohibition on genetically modified (GM) foods, remaining skeptical of the goods’ safety.

The lobbies claim that the decision was made without consulting the public and

that it “basically restricts Kenyans’ ability to pick what they want to consume.”

They urged the prohibition to be promptly lifted and the establishment of an inclusive participatory process to consider long-term and viable solutions to problems affecting food security.

“Food security is not just about the amount of food but the quality and safety of food. Our cultural and indigenous foods have proved to be safer, with diverse nutrients and with less harmful chemical inputs,” said a joint statement signed by a dozen groups, including Greenpeace Africa.

Given Kenya’s porous borders and the lack of a formal regional policy on GM technology, its neighbors are racing to tighten regulations.

Hussein Bashe, Tanzania’s Minister of Agriculture, stated that Dodoma was adamantly opposed to the use of biotechnology in food production and

would enact stricter regulations to stop GM foods or cash crops produced in “neighboring nations” from entering the nation.

African Organic Network (AfroNET), a Dar es Salaam-based organization, claimed Kenya proceeded without adequately assessing the long-term effects of GM technology on the general health of its populace.

“They have taken a wrong approach to such a contentious issue. It is not simply about ensuring food security in times of drought, as they seem to think,” said Constantine Akitanda, AfroNET Spokesperson.

Kenya is the second country after South Africa to back out of an African Union resolution to adopt organic agriculture instead of genetically modified organisms (GMOs) methods to minimize the effects of climate change.

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 17 BIOTECHNOLOGY

Amidst mixed reactions from activists, East African counterparts

THE KENYAN GOVERNMENT HAS LIFTED ITS BAN ON GENETICALLY MODIFIED CROPS IN THE COUNTRY AFTER 10 YEARS OF SUSPENSION, PERMITTING FARMERS TO CULTIVATE AND IMPORT GMO FOOD & ANIMAL FEED

ISRAEL – To lower the exorbitant cost of living in the nation, the Israeli government has authorized a plan to follow European food safety standards, abolishing the great majority of Israeli requirements.

The changes will affect the production and import of items such as canned vegetables, pasta, rice, candies, spices, soup powder, condiments, and milk products, among others.

DISEASES, OUTBREAKS & RECALLS

Edible oil manufacturers dispute KEBS suspension of products

specification in iron levels.

The standard sets out the requirement for iron as 2.5 mg/Kg at the maximum. However, the findings of the KEBS test on the particular batches revealed that a particular batch of cooking oil and fats that the companies placed on the market ranged between 4.6mg/kg and 198.99mg/ kg.

KENYA – Following the suspension of several brands of edible oil in the Kenyan market, sector players are now calling for joint testing of the claimed non-compliant batches.

The Kenya Bureau of Standards (KEBS) recently suspended the sale of 10 brands after subjecting the oil and fats to tests at their laboratory against the requirements of the Standards Act, and the respective product standard KS EAS 769: KS 2019 fortified edible oils & fats –

PARTNERSHIP

Israel’s cost of living is among the highest among Organisation for Economic Co-operation and Development (OECD) member nations. However, this has often been attributed to import restrictions that prevent foreign companies from operating there, as well as a lack of competition among local importers and manufacturers, which allows them to hike prices.

An Interministerial Committee headed by Yoel Bris, a former Legal Adviser to the Finance Ministry, decided to adopt the European criteria.

The adoption of European food standards in place of Israeli ones will go into effect on January 1. On that date, 97 of the present 127 food requirements will be instantly repealed for imports into Israel.

However, for domestic manufacturers, the 97 safety criteria will be phased out over the course of four years, with 60 being abolished on January 1, 21 being withdrawn a year later, one being eliminated the next year, and 15 being eliminated in August.

GHANA – The Ghana Standards Authority (GSA) has partnered with the British Standards Institute (BSI) to ease the adoption of international standards and participation in the development of global standards.

BSI is the national standards body of the United Kingdom. It produces technical standards on a wide range of products and services and also supplies certification and standards-related services to businesses.

Mr. Graham Holloway, a BSI Consultant met with senior officials as part of a series of engagements to go through the specifics of an upcoming “Standards Partnership Pilot Programme” anticipated to run for 8 months.

The programme, among other things, is expected to improve the technical capacity of the GSA, promote awareness and use of international standards across the continent and enhance trade facilitation to reduce time and costs.

Of the banned products, Bidco was ordered to recall Bahari Fry batch number 107921 and Olive Gold batch number 105948, with Pwani Oil removing its four oil brands –Fresh Fri batch number FF1L17487D, Fresh Fri with Garlic batch number FF500175260, fry mate batch number 8941D, and Salit batch number SS1L17472D.

Menengai withdrew its Top Fri oil of batch number OL4A3 MF9.25.05.22, while Kapa Oil Refineries was told to recall Postman of batch number 0210322B, Rina oils of batch number 0340522B, and Tilly cooking fat of batch number 152222A.

The Standards Partnership programme is an initiative started in Ghana and Rwanda by Vicky Ford, UK Foreign, Commonwealth & Development Office Minister.

The programme, unveiled during the Africa Debate 2022 in July, will strengthen supply chains, and reduce barriers to trade by helping both countries meet global standards and regulations.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 18

BSI to help Ghana Standards Authority improve its technical capacity

Israeli government adopts European food safety standards to lower cost of living

NEWS UPDATE

THE PROGRAMME IS EXPECTED TO IMPROVE THE TECHNICAL CAPACITY OF THE GSA AND PROMOTE USE OF INTERNATIONAL STANDARDS ACROSS THE CONTINENT.

U.S – Neogen Corporation has introduced a new quantitative assay for detecting cashew allergens in products, just a few months after it debuted one for peanut allergens.

The second assay in Neogen’s new Veratox VIP line of enhanced quantitative ELISA products, Veratox VIP for Cashew allergen test demonstrates robust performance across sample types while maintaining the simple testing methodology of the Veratox product line.

“As plant-based foods and alternative proteins become more in demand in the marketplace, it is important that we offer highly sensitive tests that are able to detect even the lowest levels of food allergens in order to protect consumers around the world.

“Cashew is being used more frequently and in more unique ways than before, and it is important that Neogen offers an easyto-use and highly sensitive solution for its detection,” said John Adent, President and CEO, Neogen.

This novel quantitative assay exhibits great sensitivity to cashew protein concentrations as low as 0.2 ppm.

In addition to heat-processed and UHT matrices, the product is suitable for evaluating samples from a wide range of product types and processing settings.

The testing process used by Veratox VIP for Cashew is the same as that used by Neogen’s other Veratox products, which includes a 30-minute time-to-result and ready-to-use, non-hazardous reagents.

In May this year, the company launched Veratox VIP for peanut assay which rapidly quantifies low levels of peanut protein residues in food products, ingredients, and clean-in-place rinses.

Meanwhile the company recently wound up the earlier announced merger with 3M’s Food Safety business to create an innovative leader in the food safety sector.

The transaction which was first announced on December 14, 2021, will provide the companies with a comprehensive product range and a strategic focus on the category’s longterm growth opportunities.

The combination of Neogen and 3M’s Food Safety business creates a leading innovator with an enhanced geographic footprint, innovative product offerings, digitization capabilities, and financial flexibility to capitalize on robust growth trends in sustainability, food safety, and supply chain integrity.

3M’s former Food Safety business is a leading provider of food safety testing solutions. It offers a broad range of food safety testing solutions that support multiple industries within food and

releases

images

SWITZERLAND – International leader in agricultural innovation, Syngenta Crop Protection has made a milestone in the management of nematodes in soybean crops, thanks to its latest digital solution that examines satellite images to detect plant-parasitic nematode infestations.

“Harmful nematodes that devastate crops are a major threat to farmers and food security, and Syngenta is using cutting-edge digital solutions to help combat these pests,” said Jeff Rowe, President of Global Crop Protection.

The new digital tool analyzes satellitecaptured photos of fields using a special, proprietary algorithm that enables it to spot places where plant-parasitic nematodes are heavily populated in crops and calculate the potential damages these tiny parasites could cause.

With the use of the technology, farmers can quickly modify their field management techniques, preventing production losses while also maximizing input utilization and enhancing the sustainability of their farms.

beverage, helping producers to prevent and protect consumers from foodborne illnesses.

The launch comes just as Syngenta is also debuting its new technology known as VICTRATO which utilizes TYMIRIUM technology to provide long-lasting protection against all plant-parasitic nematodes and key fungal diseases across major crops, including soybeans, corn, cereals, cotton, and rice.

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 19 SUPPLIER NEWS & INNOVATIONS

Neogen debuts quantitative Cashew ELISA test with great sensitivity, finalizes 3M merger

Syngenta

digital tool to detect harmful nematodes through satellite

CASHEW IS BEING USED MORE FREQUENTLY AND IN MORE UNIQUE WAYS THAN BEFORE, AND IT IS IMPORTANT THAT NEOGEN OFFERS AN EASY-TO-USE AND HIGHLY SENSITIVE SOLUTION FOR ITS DETECTION.

John Adent, President and CEO, Neogen

waste

UK/U.S – Oli-Tec has developed a smart label technology it claims will help industry and consumers manage waste better, a process which began in 2015.

“We designed Oli-Tec label technology with converters, retailers, and consumers in mind. We wanted to make technology that could be easily integrated into complex processes in the supply chain and in the store so that each label could play a role in reducing waste.

“We also aimed to develop a simple visual indicator to help consumers see when food is going off. They can then decide whether to use it, freeze it or cook it,” explained Nick Richardson, CEO of Oli-Tec.

Oli-Tec’s smart label technology is temperature and time-sensitive. The label is basically designed to “mirror the cycle of decay” of the labeled product. The 100% recyclable polypropylene label can be affixed to any product with a shelf life of five to 15 days.

Its time window changes from yellow to red when product quality deteriorates over time. Being time sensitive, the diffusion line accelerates when the product is at high temperatures and slows down at low temperatures.

The thermometer icon is displayed in blue, but only when the product is stored at the correct temperature.

For consumers, the benefits are clear: the label provides a lifecycle monitor for fresh, prepackaged, or frozen foods so they know when perishables are “at their best.”

Salvus develops

Interferometric-based

biosensor to improve food safety in poultry industry

U.S – Salvus LLC has come up with an Interferometry-based detection technology that could help the poultry industry rapidly identify the presence of diseases, viruses, and chemicals in both production and processing environments, improving food safety.

Interferometric-based biosensors use a laser light source, a waveguide, and an optical detector to detect the presence of key chemicals and pathogens pen-side or in a food production environment.

“We are excited about the possibilities this technology has in poultry production, animal health, food safety, and other applications. We are looking forward to the next steps and engaging with commercial partners to deliver the product to the market,” Andre Tatar, Product Manager, Salvus LLC, said.

Derived from the Latin word for safe, Salvus detection technology utilizes a lightweight, handheld, and easy-to-use device that offers many benefits. It can be used across multiple industries to detect many types of contaminants such as pathogens, chemicals, and proteins while processing and sharing findings within minutes.

The device is also extremely sensitive detecting chemicals down to parts per trillion (PPT) and proteins in picograms per milliliter, according to the company.

The underlying technology leading to the Salvus detection device came out of sponsored research conducted originally at the Georgia Tech Research Institute while exploring ways to improve detection throughout the food and agriculture industry.

The technology is currently going through its commercial validation phase and is expected to be ready for commercial use in 2023.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 20 SUPPLIER NEWS & INNOVATIONS

Oli-Tec develops smart label to reduce food

WE ARE EXCITED ABOUT THE POSSIBILITIES THIS TECHNOLOGY HAS IN POULTRY PRODUCTION, ANIMAL HEALTH, FOOD SAFETY, AND OTHER APPLICATIONS.

Andre Tatar, Product Manager, Salvus LLC

U.S – PathogenDx, manufacturer of DNA-based pathogen testing kits, has introduced a new patented virus detection technology — Phytox — to help curb the spread of new and existing plant-borne pathogens, which are currently on the rise.

The company claims that the new Asymmetric RT-PCR microarray technology for the cannabis, food and agriculture industries can detect nine viruses or more in a single test and offers simultaneous, accurate viral testing in around three hours.

Additionally, Phytox supposedly offers testing labs up to 100 times greater sensitivity when detecting specific viruses while saving them 70% in expenses when compared to other viral testing methods now available on the market.

Co-Founder and CEO of PathogenDx Milan Patel noted that in order to protect public health and prevent producers from losing yields to pathogens that can cause huge economic damages, Phytox should become the new industry standard.

“Our patented technology shatters nearly all of the testing technology standards today for accuracy and efficiency in plant virus and pathogen detection. It is easy to administer and extraordinarily cost-effective, presenting a win-win scenario for both businesses and public health alike,” he said.

U.S – Agilent Technologies has partnered with METTLER TOLEDO to come up with an integrated solution to address error-prone sample preparation, one of the biggest concerns in any laboratory.

The solution offers a fully automated and digitalized liquid chromatography (LC) or Gas Chromatography (GC) workflow designed to eliminate common errors in the weighing process.

It enables the automatic and seamless transfer of weighing results and the associated metadata from METTLER TOLEDO LabX Balance software to Agilent OpenLab software.

The sample preparation is a critical part of many laboratory workflows, says Agilent. It is a time-consuming bottleneck and a frequent source of errors and inaccuracies that often leads to costly quality investigations or rework.

The complete solution automatically transfers weighing results to the latest release of Sample Scheduler for Agilent OpenLab CDS.

SWITZERLAND – Pioneering technology leader ABB has developed a two-piece cable tie that is both antimicrobial and detectable for use in contaminationsensitive environments such as food and beverage processing.

In food processing, where reducing the growth of unhealthy microorganisms is critical, the presence of heat, moisture, and organic material common in these environments can encourage the growth of bacteria, fungi, and mold.

Cable ties generally provide a conducive environment for these microorganisms to thrive due to their design which is full of notches and grooves.

The company says the Ty-Rap TyGenic cable ties help guard against a wide range of microorganisms such as bacteria, viruses, protozoans, and fungi like mould and mildew.

Sample Scheduler retrieves the sample and weight data from the METTLER TOLEDO LabX software and allows users to seamlessly route sample and weighing information to any instrument in the laboratory.

The two companies hope that by addressing one of the biggest, most basic laboratory challenges—transferring weighing results accurately to other lab systems—their solution will accelerate the digital transformation of laboratories.

Ty-Rap TyGenic cable ties combine antimicrobial properties with detectable particles and a deep blue color for easy three-way identification via x-ray, metal, and visual detection systems, enhancing its efficacy.

“No one wants to worry about fragments in their product and risk costly contamination. Our Ty-Rap TyGenic cable ties combine antimicrobial technology with detectability and fastening performance to help customers create cleaner, safer environments,” said Matthias Heilmann, President, ABB Installation Products Division.

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 21

PathogenDx presents new virus detection technology to curb plant-borne pathogens

Agilent partners with Mettler Toledo to provide seamless weighing results

ABB makes breakthrough, develops first-ever antimicrobial detectable cable ties

THE SOLUTION OFFERS A FULLY AUTOMATED AND DIGITALIZED LC OR GC WORKFLOW DESIGNED TO ELIMINATE COMMON ERRORS IN THE WEIGHING PROCESS.

Dr. Abigail Stevenson appointed Mars’ Chief Science Officer

Quality Service International names Thomas Janssen as new Managing Director

GERMANY – Quality Service

International GmbH (QSI), a leader in the field of quality control as a food, honey, and trade laboratory has brought on board Thomas Janssen as its new Managing Director.

Janssen, who has an academic background in economics, is notable for his extensive expertise in the laboratory and life science fields.

“I am pleased and motivated to be part of QSI and also part of the Tentamus Group. It will be our common goal to grow together more, to form a unit, and to create internal structures for successful cooperation – both for our team and our customers, who will benefit from it,” he said.

International Association for Food Protection announces new President

UK – Mars, Incorporated, the world’s leading manufacturer of confectionery, has appointed Dr. Abigail Stevenson as Chief Science Officer (CSO) who will champion Mars’ involvement in global, cutting-edge scientific discovery.

Dr. Stevenson will lead the Mars Science Leadership Team in her new position and drive partnerships with peers, academic institutions, and nongovernmental organizations while also contributing to the development of Mars’ pipeline of top science and technology talent.

“As the world around us continues to evolve, I am excited to be driving discoveries that have the potential to impact not only the future of our business but also to improve the lives of people and pets around the world,” said Dr. Stevenson.

She will also be in charge of the Mars Global Food Safety Center (GFSC), a trailblazing research and training center at the center of an international network of partners and collaborators addressing the most significant food safety challenges facing the planet today.

In the course of his professional experience, Mr. Janssen has had the opportunity to assist numerous laboratories in starting up and growing into globally competitive businesses.

His most recent position was as Managing Director of a major, globally recognized, publicly traded provider of technology-based solutions.

Part of the Tentamus Group of laboratories since 2013, QSI is an accredited laboratory that provides a comprehensive range of analyses for foodstuffs which is focused, among other products, on honey, coffee, and tea.

U.S – The International Association for Food Protection (IAFP) has once again handed its Presidential gavel to a new face as it culminated this year’s conference at the annual awards banquet.

The outgoing President Dr. Ruth Petran handed over the gavel to the incoming President, Michelle Danyluk of the University of Florida.

Dr. Danyluk is an Associate Professor and Extension Specialist of Food Safety and Microbiology in the Department of Food Science and Human Nutrition at the University of Florida (UF).

An IAFP Member since 2002, the Professor has organized, convened, and presented several IAFP symposia. She actively participates in Professional Development Groups (PDGs) and has served on several committees, including the Program Committee, the Nominating Committee, the Food Protection Trends Management Committee, and various Awards Selection Committees, records the Association.

The incoming IAFP President holds a B.S. in Biological Sciences with a specialization in Microbiology from the University of Alberta in Edmonton, Canada. She earned her master’s in Food Science and Technology from the University of Georgia in Athens, and her Ph.D. in Food Science from the University of California – Davis, where she also completed a postdoc for an additional ten months.

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 22

APPOINTMENTS UPDATE

Amanda Bosse takes helm as CEO of Certified Group

U.S – Amanda Bosse has joined testing and regulatory consulting services provider Certified Group as its new CEO, succeeding John Bellinger, who will remain with the company as its Chairman.

Bosse brings over 20 years of global experience in pharmaceutical and science-led service businesses. She has experience in growing complex service businesses in regulated environments, building and enabling high-performing teams, and a proven track record in leadership roles across strategy, commercial operations, and business, Certified Group said.

“It is an honor to lead this exceptional company and advance its role as a premier laboratory testing platform in North America. I look forward to working closely with John

EFSA appoints new Chief Scientist

SADCAS inaugural CEO Maureen Mutasa retires

AFRICA – Maureen Mutasa has stepped down from her position as Chief Executive Officer (CEO) of the Southern African Development Community Accreditation Service (SADCAS), culminating her 14 years of service.

Present in 14 countries throughout Southern Africa, SADCAS guarantees the technical proficiency of service providers supplying calibration, testing, medical laboratory, and inspection and certification services.

In June 2008, Mrs. Mutasa was chosen to lead the organization as its first CEO. Since then, she has worked to elevate SADCAS to a position of prominence on a global scale.

With a wide range of managerial, agricultural research, and food sector experience spanning over 40 years, she retires as one of the finest experts on accreditation, standards, and quality assurance on the Continent.

EUROPE – The European Food Safety Authority (EFSA) has appointed Carlos Gonçalo das Neves as its new Chief Scientist, effective 1 November 2022.

Das Neves, a Portuguese and Norwegian national, holds a Ph.D. in Veterinary Science, his areas of research and teaching being animal health, biodiversity, emerging threats, and One Health.

“I am incredibly thankful for the opportunity to join EFSA and its amazing network of scientists who make sure our food is safe, healthy, and sustainable.

She has also served as Chair of the

and this talented team as we further strengthen and expand our product offering, capabilities, and reach,” said Amanda Bosse, CEO, Certified Group.

Previously, Bosse was President of Drug Product Services at Thermo Fisher Scientific, a provider of life sciences and diagnostics.

“I look forward to focusing on Certified’s key customers, and supporting the company strategy as the company Chairman,” John said.

“As a strong One Health advocate, I hope that in my new role as EFSA’s Chief Scientist I can help to connect us all even better in this common mission for Europe and our planet,” he said.

He currently serves as the Director of Research and Internationalisation at the Norwegian Veterinary Institute (NVI) where he has worked for almost ten years. He is also a Professor at the Faculty of Health Sciences at The Arctic University of Norway (UiT).

Das Neves previously served as Head of Virology and Head of Food Safety & Emerging Threats at the NVI.

ISO Policy Committee of Developing Countries (ISO DEVCO), Vice Chair of the African Accreditation Cooperation (AFRAC) and Chair of the SADC Accreditation Cooperation (SADCA), and Chair of SADC Cooperation in Standardization.

She is currently the Chair of the AFRAC Mutual Recognition Arrangement a position which she will carry to the end of her term in September 2023.

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 23

ON SHOW AT THE EVENT

Why the

Kenya

Nutrition, Health & Wellness Exhibitions

The Kenya Nutrition, Health & Wellness Exhibitions are a range of weekend consumer expos and seminars that are targeted at creating and improving the consumer awareness on healthy living and general well being. The expos are held over the weekend to ensure the attendance of the entire family.

The goals of the Kenya Nutrition, Health & Wellness Exhibitions are:

• Provide a forum for food and beverage processors, distributors and importers to interact directly with consumers, with a goal of informing the consumers of the unique features and benefits of their products in relation to healthy eating and living;

• Provide a forum for providers of health, personal and home hygiene products to interact directly with consumers

• Bring together medical, nutritional, healthcare and wellness experts and practitioners face to face with consumers to discuss disease management, lifestyle choices, diet management, wellness goals and practices with a view to imparting the right knowledge to the consumers;

• Provide a platform for a number of industry associations and corporates to interact with

& Expo Diagnostics Medilab Africa Expo Health & Care Animal Africa Expo Africa & Care Hospitals Expo Devices Medical Africa & Expo Logistics Supply Chain Africa Health Expo Africa & Health Nutrition Wellness Expo Pharma Africa Expo Africa Health Financing & Insurance Expo Africa HealthTech Sarit Expo Centre, Nairobi, Kenya THE BIGGEST HEALTHCARE & PHARMA EXPO IN EASTERN AFRICA www.expo.healthcareafrica.info +254 725 343932 info@fwafrica.net

consumers

community, with

view to

JUNE

and the

a

WHAT’S

15-17, 2023

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 25 DISCOVER THE FUTURE OF FOOD SAFETY, NUTRITION & FOOD SECURITY IN AFRICA REPORT 2022 www.summit.foodsafetyafrica.net AFRICA SAFETY FOOD SUMMIT & NUTRITION y Afmass SUMMIT outh CO-LOCATED WITH

ABOUT THE SUMMIT 01

At the exquisite Emara Ole Sereni Hotel, situated in the country’s capital Nairobi, a plethora of guests both from within and outside Kenya gathered to grace the momentous premiering of the in-person edition of the Africa Food Safety Summit collocated with the AFMASS Youth Summit.

Launched in 2021, the Africa Food Safety Summit is Africa’s premier and largest international food safety, quality management, and conformity conference and exhibition. Held from the 20-22nd of July, this year’s Summit was hosted in partnership with the African Development Bank (AfDB), a multilateral development finance institution, and backed by Kerry, an Irish multinational specializing in taste and nutrition solutions.

The 300 attendees comprised investors, managers, and professionals in the private, public, academic, and NGO/ development organizations gained from a mix of high-level keynote speeches, presentations, panel discussions, one-on-one networking, and Expo Hall discovery sessions. They were also able to relish Ole Sereni’s diverse global cuisine while busking in the area’s panoramic landscape courtesy of the Nairobi National Park.

The Summit also tapped into the digital space, bringing onboard about 700 attendees from all over Africa and the world.

As he flagged off the event, Dr. Damian Ihedioha, Division Manager, Agribusiness Development Division, AfDB, in his keynote speech said, “Our desire to participate in this Summit was predicated on the key fact that we want you to know that we are what we eat. Feeding Africa is beyond the production of food. It involves making sure that the foods guarantee good health and boost the incomes of producers and processors.”

In her presentation, Margaret Rugut Kibogy, the Managing Director, of Kenya Dairy Board and also one of the Chief Guests, called upon all food and agriculture industry stakeholders to join hands to implement food safety strategies that will ensure the production of quality, nutritious, and most importantly safe food from farm to fork.

Held on the 2nd day of the Summit, the AFMASS Youth Summit brought together students in tertiary institutions, young professionals, and start-up entrepreneurs in the food and agriculture value chain. The AFMASS Youth Summit, a new addition to the AFMASS FOOD EXPO events, is Africa’s first event focused on improving capacity, building networks, and

mentoring young people in Africa’s food industry.

In the spirit of oneness, government institutions such as the Ministry of Health, Ministry of Agriculture, Livestock, Fisheries and Co-operatives, Kenya Bureau of Standards, and Kenya Dairy Board, also graced the occasion. The Summit would have been incomplete without the presence of professional bodies such as the Institute of Public Analysts in Nigeria (IPAN), Kenya Institute of Food Science & Technology (KIFST), Food Science & Technology Platform of Kenya (FoSTeP-K), and industry association body Consumer Goods Council of South Africa (CGCSA).

EXPERTS DISSECT A DIVERSE RANGE OF TOPICS

Topical issues deliberated upon over the 3 days by some of the industry heavyweights and delegates included food safety regulations, entrepreneurship, career growth, food safety, quality concerns, and technology.

The first day of the Summit kicked off with a panel that dissected the “Status Of Food Safety Regulation & Practice In Kenya”.

Steven Carlyon – Managing Director, Simplify Foods, and Campbell Mitchell – Regional Quality & Food Safety Director, Middle East, Indian sub-continent & Africa, Kerry lent their voices to the topic, “Transformational Leadership In Food Business Organisations To Mainstream Food Safety In Africa’s Food Industry.”

Dr. Augustine Okoruwa, FNIFST - Head of EatSafe Country Programs, GAIN Nigeria; Doreen Lugalia – Managing Consultant,

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 26

Mantra Consulting and Careen Biwott – Quality Assurance Lead, KwikBasket provided insights into how their organizations have implemented food safety measures and how food industry stakeholders in Africa should adopt new strategies in the new normal under the topic, “Digitalisation & Supply Chain Transformation To Deliver On Food Safety, Quality & Conformity In Africa’s Food & Agro Industry”.

Day 2 of the Summit, specifically dedicated to the youth, took off with a Panel discussion on “Tapping into the Youth Potential in Africa’s Food & Agriculture Sector” where the panelists called for a change in perception to help Africa’s young population gain opportunities to grow and thrive.

Food industry professionals were also able to share their career journeys right from the start to inspire the youth on the value of hard work, tenacity, and how to get the best out of their potential. The panelists agreed that, regardless of the huge gap between graduates and available job opportunities, education is still a necessary tool to be armed with. As Walter Bruce Opiyo, Quality Assurance Manager, at Golden Africa put it, “It’s like the degree opens the door for us, but our personality widens the boundaries of what we can achieve inside.”

A chat with Khadija Mohamed, Founder & CEO of Kwanza Tukule, took us into the world of entrepreneurship. At the end of the day, the need for passion in whatever you undertake couldn’t have been driven home more clearly.

We also had a town hall discussion on some of the food safety incidences, new regulations, and technologies making headlines in the news - a topic that threw the house into a frenzy. Owen Paul Fraser, Ph.D. – President Africa & Board Member, AOAC International, climaxed the day with a mind-blowing presentation on “Advances In Laboratory Design & Infrastructure”, an area that is seldom given consideration.

The third day drove us into the technical aspects of things where our exhibitors took to the stage to enlighten the audience on some of their ground-breaking solutions in the analytical world on the topic, “Advances in Microbial & Physicochemical Testing of Food Products”. We were able to see how microbial testing has shifted from the laborious traditional plating techniques to more rapid ones such as ready-to-use plates and Polymerase Chain Reaction (PCR) techniques. Laboratories and manufacturers have also adopted the use of Artificial Intelligence and Machine Learning technology in psycho-chemical testing. The issue of Aflatoxins was another hot topic that roused a highly contentious

debate with people realizing that mycotoxins could very well be a part of our daily meals.

With the world constantly being faced with emerging food safety and quality issues such as antimicrobial resistance and animal welfare issues, the Summit would have been found wanting were these issues not addressed.

“Thinking about the future of food safety in our region takes me straight to a starting point that is absolutely certain. And that is, change will happen as we progress. Technologies are and will continue to change, circumstances will change, and ideas will change,” stated Jim Tozer, Managing Director, Kenchic.

The Summit came to a glorious end with a panel of academicians from Kenya and Nigeria on “Capacity Building & Training of Africa’s Next Food Safety Champions”. The panel highlighted the need for mentorship and bridging the skills gap from theory to practice. They also advised the youth to put themselves out there and demonstrate what they bring to the table.

You are probably reading and wondering why you missed such an important conference. Not to worry, as next year’s edition is around the corner and this time around, we also feature nutrition, an important part of food security. See you in 2023!

Jim Tozer, Managing Director, Kenchic

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 27

THINKING ABOUT THE FUTURE OF FOOD SAFETY IN OUR REGION TAKES ME STRAIGHT TO A STARTING POINT THAT IS ABSOLUTELY CERTAIN. AND THAT IS, CHANGE WILL HAPPEN AS WE PROGRESS.

03 SPONSORS

African Development Bank is an international entity established in Africa during the 1960s with the objective of supporting the economic development and social progress of countries in Africa.

Address: 6, avenue Joseph Anoma, Abidjan, Côte d'Ivoire

Telephone: +225 20 26 10 20 Website: www.afdb.org

Kerry is the world’s leading taste and nutrition company, bringing technology leadership and sustainable growth to the food and beverage industries.

Address: Crater Auto building | Mombasa Rd | South C | Nairobi | Kenya

Telephone: +254 793326878

Email Address: regis.manyange@kerry.com Website: www.kerry.com

04 EXHIBITORS

Bureau Veritas is a recognized world leader in testing, inspection and certification services (TIC).

Address: Delta Corner, Tower A, 5th Floor, Along Waiyaki Way, Westlands

Telephone: +254 20 366 9000

Email Address: contact.ken@ bureauveritas.com Website: www.group.bureauveritas.com

Nesvax Innovations Limited is an analytical laboratory equipment distribution company in East and Central Africa.

Address: Akshrap Properties Limited ,Gate C, Godown no 5,Mombasa Road,Opposite JKIA Junction, Nairobi, Kenya

Telephone: +254707965100

Email Address: info@nesvax.co.ke Website: www.nesvax.co.ke

ESTEC LTD is the market leader in East Africa for the supply and servicing of analytical equipment.

Address: West 1 Building 4th Floor, Corner of Wambugu Grove off Parklands Road

Telephone: 254-20-6537709

Email Address: info@esteckenya.com Website: www.esteckenya.com

AOAC INTERNATIONAL brings together government, industry, and academia to establish standard methods of analysis that ensure the safety and integrity of foods and other products that impact public health around the world.

Address: Crater Auto building Telephone: +1 301-977-7626

Email Address: customerservice@aoac. org Website: www.aoac.org

World Animal Protection is an international non-profit animal rights organization working to end the needless suffering of animals.

Address: Westside Tower, 9th Floor - No. 901, Lower Kabete Road, Westlands, off Brookside Roundabout.

Telephone: +254 20 3673 456

Email Address: worldanimalprotection. or.ke

Website: www.worldanimalprotection. or.ke

CASELAB offers holistic solutions to manufacturing and scientific sectors.

Address: Ruaraka Housing Estate, Unit No. 7, USIU Road, off Thika Superhighway Ruaraka, Nairobi, Kenya

Telephone: +254722776286

Email Address: caselab@caselabafrica.com Website: www.caselabafrica.com

Ingredients Laboratory Solutions Specialty Chemicals

05 SPEAKERS

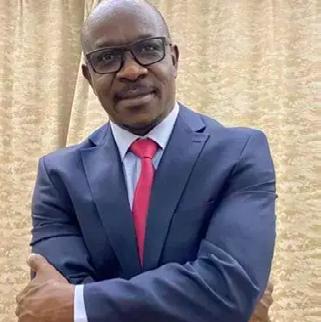

IHEDIOHA

PhD - Division Manager, Agribusiness Division, African Development Bank Group

Regional Quality & Food Safety Director – Middle East, Indian Subcontinent & Africa, Kerry

Humane & Sustainable Agriculture Campaign Manager, World Animal Protection

Innovations Marketing Manager, Eastern & Southern Africa, Upfield

ISAAC MUGENYA

Manager, Testing Services, KEBS, Lake Region, Kenya

District Chief Executive, Eastern Africa, Bureau Veritas

Regional Food Safety & Quality Specialist, World Food Programme

OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 30

DAMIAN ONYEMA

DR. VICTOR YAMO

MARY MUREITHI

CAMPBELL MITCHELL

MARGARET KIBOGY Managing Director, Kenya Dairy Board

COLLINS MARANGU Director Plant Protection and Food Safety in the Ministry of Agriculture, Livestock, Fisheries and Cooperatives in Kenya

STEPHEN CARLYON MD, Simplifine Foods

MATLOU SETATI Executive: Food Safety, CGCSA

ALIYU ANGARA

Registrar/CEO, Institute of Public Analysts of Nigeria (IPAN)

TOM OUMA Business Development Manager, ESTEC

DR. HERMOGENE NSENGIMANA Secretary General, African Organisation for Standardisation, ARSO

JIM TOZER Managing Director, Kenchic Ltd

DR. BLAISE OUATTARA, DMV, Ph.D. Regional Food Safety and Quality Officer for Africa, FAO

DR. JOHN K. MUORIA Lecturer JKUAT & Chairman, KIFST

OWEN PAUL FRASER, Ph.D President Africa & Board Member Aoac International

LINDA CAPWELL

CYPRIAN KABBIS

SPEAKERS

WILLIS MITULA

Head, Governance & Technical, Kenya Breweries Ltd

R&D Manager, Capwell Industries

CAREEN BIWOTT

Quality Assurance Lead, KwikBasket

DOREEN LUGALIA Managing Consultant, Mantra Consulting

Milling Executive, CCB – National Milling Zimbabwe

Chief of Party, Land O’Lakes Venture 37

Quality Control Manager, Golden Africa

JOHNES

VIVIAN OCHIENG Production Manager, Simplifine Foods

FOODSAFETYAFRICA.NET OCTOBER 2022 | FOOD SAFETY AFRICA MAGAZINE 31

EVANSON MWANGI Laboratory Manager, Kenya Dairy Board

KEZIAH WACHUKA

Head of Research and Development, Bio Foods

LAWRENCE ALOO Chief BioChemist, National Public Health Laboratory, Kenya

CHARITY MAGWENZI

LABAN KABIRU Manufacturing and Logistics Director, Bio Food Products

WILLIAM KAPFUPI

06

DR. ANDREW EDEWA Director, Standards and SPS Measures, TradeMark East Africa

AUGUSTINE OKORUWA, PH.D, FNIFST Head of EatSafe Country Program, GAIN