Food Safety

SCIENCE & RESEARCH:

CRONOBACTER IN AFRICA

DR. ROY MUGIIRA

NATIONAL BIOSAFETY AUTHORITY

We are ready to regulate GM foods in Kenya

SA’S LABELING REGULATIONS

REGULATORY: FORMULATION:

SALT

INDUSTRY FOCUS:

WATER RE-USE IN DAIRY INDUSTRY

SCIENCE & RESEARCH:

AOAC AFRICA DEBUTS PLATFORM

WWW.FOODSAFETYAFRICA.NET YEAR 3 | ISSUE NO. 1 MARCH 2023

Meet & Network with the leading manufacturers and distributors of ingredients technologies from across the World at the Food Ingredients Africa Expo. Discover the latest market trends for your next new products innovation project. WWW.AFMASS.COM A SPECIAL PAVILLION AT: WWW.AFMASS.COM Food Colours & Flavours • Enzymes and Flour Improvers • Sugar, Fat & Salt Replacers • Emulsifiers & Antioxidants • Vitamins, Minerals & Supplements • Thickeners, Stabilisers, Humectants & Gums • Specialty Starches, Proteins & Oils • Sweeteners & Acidulants • Herbs & Spices • Antioxidants & Preservatives • Flavour Enhancers • PLUS MANY MORE . . . . FOOD EXPO INGREDIENTS AFRICA FOOD Afmass EXPO The Future of Food in Africa JUNE 15-17, 2023 SARIT EXPO CENTRE, NAIROBI, KENYA

Safari Park Hotel, Nairobi, Kenya

AFRICA’S MOST INFLUENTIAL FOOD INDUSTRY AWARDS

ENTRIES

DEADLINE: MAY 1, 2023

FOOD

JUNE 16, 2023

A. COMPANIES OF THE YEAR 1. Company of the Year 2. Start-Up of the Year B. PEOPLE OF THE YEAR 3. CEO of the Year 4. Lifetime Achiever of the Year 5. Entrepreneur of the Year 6. Young Person of the Year (below 35 years) C. NEW PRODUCTS OF THE YEAR 7. Innovative Food Products of the Year 8. New Product with Most Outstanding Use of Ingredients 9. New Product with Most Outstanding Packaging 10. New Product with Most Outstanding Nutrition Application D. SUSTAINABILITY CHAMPIONS OF THE YEAR 11. Renewable Energy Initiative of the Year 12. Water & Waste Management Initiative of the Year 13. Local Sourcing Initiative of the Year 14. Community Initiative of the Year 2023 AWARDS CATEGORIES www.awards.foodbusinessafrica.com

CEREMONY

Food Safety

In this issue

4 Editorial 5 Events Calendar

10 News Updates:

• FDA to restructure Human Foods Program to establish proactive approach in tackling crisis

• National Agricultural Research Organization finds grains in Uganda laden with 10 times more aflatoxin

• Research shows Listeria species developing resistance to disinfectants used in food industry

• Kenya leads Africa in automating phytosanitary certification

• Ghanaian scientists working on inserting a second gene into Bt cowpea to strengthen pest resistance

• AOAC Sub-Saharan Africa expands scope to cover entire continent

• Screen-printed electrodes to aid in real-time detection of E.coli in milk

• Harvestplus Nigeria, Nigeria government unveil national Biofortification Recipe guide to address malnutrition

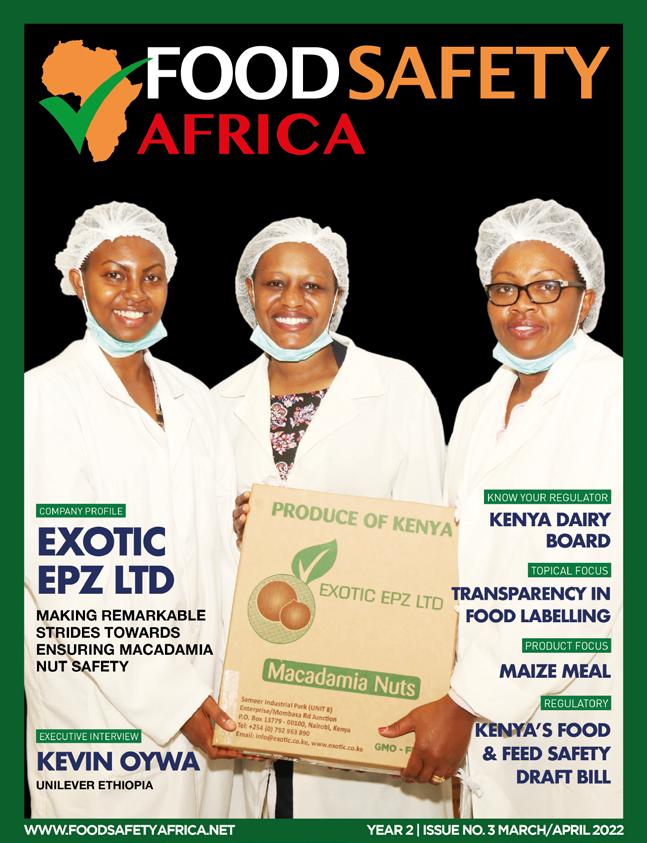

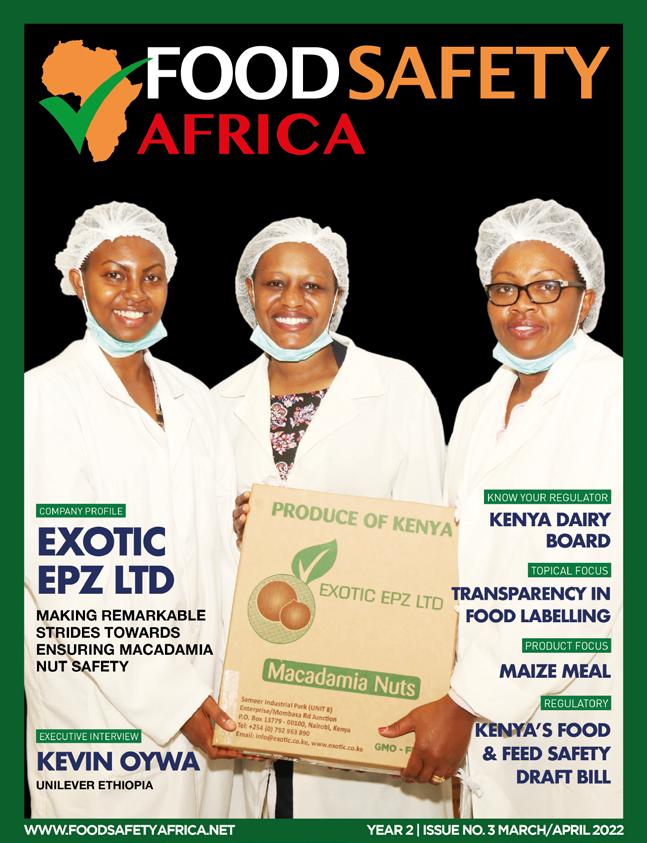

ON THE COVER

Dr. Roy Mugiira, CEO, National Biosafety Authority

19 Supplier News & Innovations:

• bioMérieux develops kit to simultaneously detect Listeria, Salmonella

• Enartis partners with WINEGRID to introduce “Smart Enology” hence increasing efficiency in wineriesw

• iFoodDS launches consultancy division to help firms implement FDA traceability rule

• Danfoss partners with Lizard Monitoring to assist North American stores reduce food waste

20 Appointments Update

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 2

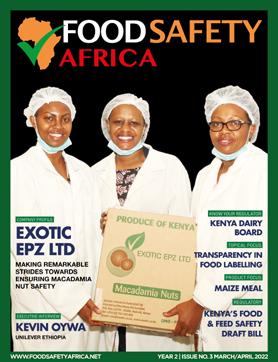

23 30 WORLD FOOD SAFETY DAY

NATIONAL BIOSAFETY AUTHORITY DR. ROY MUGIIRA We are ready to regulate GM foods in Kenya CRONOBACTER IN AFRICA SA’S LABELING REGULATIONS SALT SCIENCE & RESEARCH: SCIENCE & RESEARCH: REGULATORY: FORMULATION: INDUSTRY FOCUS: AOAC AFRICA DEBUTS PLATFORM WATER RE-USE IN DAIRY INDUSTRY WWW.FOODSAFETYAFRICA.NET YEAR 3 ISSUE NO. MARCH 2023

30

23 38 40 44 47 50

KNOW YOUR REGULATOR: National Biosafety Authority

Out of the freezer, into the limelight to take charge of the biotech sector

SCIENCE & RESEARCH: Foodborne Pathogens in Africa

Foodborne pathogens in Africa: Understanding Cronobacter sakazakii

OPINION: World Food Safety Day 2023

World Food Safety Day 2023 theme highlights the importance of food standards in protecting public health

FORMULATION: Salt

Salt, an all-time source of flavour proves to be a rising tingle of death, WHO report indicates

REGULATORY: South Africa's Labeling Regulations

South Africa’s draft labeling regulations envisioned to encourage better food choices

INDUSTRY FOCUS: Water Re-use in the Dairy Industry

Practical guidance on risk-based approaches to assess and manage fit-for-purpose water in the Dairy Industry

SCIENCE & RESEARCH: AOAC Africa

A collaborative approach to driving and delivering effective and sustained improvement in analytical laboratories

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 3 MARCH 2023 | Year 3 Issue 1. No. 6

50 WORLD FOOD SAFETY DAY 40 47 38 44

Year 2 | Issue 1 | No.6

FOUNDER & PUBLISHER

Francis Juma

SENIOR EDITOR

Paul Ongeto

EDITOR

Catherine Odhiambo

BUSINESS DEVELOPMENT DIRECTOR

Virginia Nyoro

BUSINESS DEVELOPMENT ASSOCIATE

Hellen Mucheru

HEAD OF DESIGN

Clare Ngode

VIDEO & DESIGN ASSISTANT

Newton Lemein

ACCOUNTS

Jonah Sambai

PUBLISHED BY: FW Africa

P.O. Box 1874-00621, Nairobi Kenya

Tel: +254 20 8155022, +254725 343932

Email: info@fwafrica.net

Company Website: www.fwafrica.net

Exploiting GM technology’s food security potential, Africa waits to see Kenya’s game plan

If it's not safe, it's not food. You probably remember that phrase from the 2022 Africa Food Safety Summit where it was repeated by almost every speaker until it was impressed permanently on our minds. With the recent lifting of the ban on GM crops in Kenya, I couldn’t help but wonder: are GM crops safe? And if not, do they qualify as food? The potential for GM Crops to possibly relieve food shortages, particularly in sub-Saharan Africa where 146 million people are suffering from acute food insecurity and require urgent humanitarian assistance, is enormous.

The use of high-yielding, diseaseand pest-resistant crops, is for instance projected to have a direct bearing on improved food security, poverty alleviation, and environmental conservation. GM crops will hopefully produce more yield on less land. This may increase overall productivity and may offer developing countries a means to sustain themselves and reduce worldwide hunger.

However, serious questions surrounding its safety still linger with many associating GM crops with negative health outcomes some as bizarre as men growing breasts and women growing beards! This just shows the level of negative perception towards GM crops. As Kenya works to adopt GM technology, the task is on the National Biosafety Authority to assure the public of their safety when consuming GM

foods. The pressure on the Authority is immense as Africa is watching Kenya’s steps closely, and its failure or success will play a key role in determining whether widespread adoption of the novel technology will become a reality during our lifetime.

In this Magazine, we explore the ups and downs of rolling out GM technology in Africa with National Biosafety Authority’s CEO, Dr. Roy Mugiira. As food recalls associated with Cronobacter sakazakii spike, we also explore how food processors in Africa can prevent transmission of the bacteria along the food production chain.

We sure believe these along other articles on water reuse in dairy plants, labeling regulations, and sodium reduction will be worth your read.

We wish you an insightful read,

Paul Ongeto, Senior Editor FW Africa

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 4 Food Safety Africa is published 4 times a year by FW Africa. Reproduction of the whole or any part of the contents without written permission from the editor is prohibited. All information is published in good faith. While care is taken to prevent inaccuracies, the publishers accept no liability for any errors or omissions or for the consequences of any action taken on the basis of information published. EDITORIAL WWW.FOODSAFETYAFRICA.NET CEO BUSINESS AFRICA WWW.HEALTHCAREMEA.COM WWW.SUSTAINABLEPACKAGINGAFRICA.COM WWW.CEOBUSINESSAFRICA.COM OUR PUBLICATIONS MILLING MIDDLE EAST & AFRICA WWW.FOODBUSINESSAFRICA.COM WWW.MILLINGMEA.COM

Business HealthCare MIDDLE EAST & AFRICA

Food Africa

WWW.FOODSAFETYAFRICA.NET

AOAC Africa Section Annual Conference

29-31 March 2023

Johannesburg, South Africa

www.foochemistry.www.aoac-africa. org/2023-annual-meeting

Australian Food Microbiology Conference

30 Mar 2023

Parramatta, Australia

www.aifst.asn.au/AIFST-2023-FoodMicrobiology-Conference

Annual American Food Sure Summit

30 - 31 Mar 2023

Chicago, USA1 www.americanfoodsure.com

International Conference on Food Microbiology

05 - 06 Apr 2023

Barcelona, Spain

https://foodmicrobiology. foodtechconferences.com

Annual Canadian Summit on Food Safety

18 - 19 Apr 2023

Mississauga, Canada

www.foodsafetycanada.com

World Congress on Food Safety and Nutrition Science

27 - 28 Apr 2023

Rome, Italy

https://foodcongress. conferenceseries.com/

2023

International Conference on Food Microbiology and Food Safety (ICFMFS)

29 – 30 Apr 2023

Bali, Indonesia

http://theires.org/Conference2023/ Indonesia/3/ICFMFS/

Food Safety Summit Conference & Expo

08 - 11 May 2023

Rosemont, USA.

https://www.food-safety.com/foodsafety-summit

Food Safety Congress

25 - 26 May 2023

Berlin, Germany

https://live.handelsblatt.com/event/ food-safety-kongress/

International Conference and Expo on Food Science and Food Safety

12 - 13 Jun 2023

Paris, France

https://hilarisconferences.com/ foodscience

Africa Food Safety & Nutrition Summit

14 - 17 June

Nairobi, Kenya

https://summit.foodsafetyafrica.net

The International Conference on Agriculture, Food Security and Safety (AgroFood)

14 - 15 Jul 2023

Colombo, Sri Lanka

2023

https://agrofoodconference.com/

Meat Industry Food Safety Conference

17 - 18 Aug 2023

Denver, USA.

https://www.meatinstitute.org/ht/d/ sp/i/181624/pid/181624

International Conference On Food Science and Nutrition (ICNSFT)

25 - 26 Aug 2023

London, UK.

https://www.aconf.org/conf_189395. html

North American Food Safety & Quality (NAFS)

26 - 27 Sep 2023

Buffalo Grove, USA

https://foodsafetyna.com/

Food Safety Consortium Conference & Expo;

16 - 18 Oct 2023

Parsippany-Troy Hills, USA

https://foodsafetyconsortium.org/

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 5 EVENTS CALENDAR

2023

JUNE 15-17, 2023

Nairobi, Kenya

www.summit.foodsafetyafrica.net

DISCOVER THE FUTURE OF FOOD SAFETY, NUTRITION & FOOD SECURITY IN AFRICA

REASONS TO ATTEND THE SUMMIT

Provide a platform to exchange the latest knowledge, experience and expertise in food safety, food nutrition, food processing and new technologies within the food and agro value chains in Africa

Improve local, regional and global collaboration initiatives on food nutrition, food security and food safety initiatives;

Provide a platform where technology and service providers can showcase their latest products and services to the industry, Goverment/NGOs and other stakeholders, hence improving the adoption of the latest technologies in Africa’s food and agro sector;

Improve the quality and food safety aspects of the food, agricultural and processed food and feed products in Africa, hence boosting trade and market access to local, regional and overseas markets;

Amplify the awareness of consumers on food safety, regulatory and public health issues and how each stakeholder can contribute to a safer food environment in the Continent.

7 info@fwafrica.net +254 725 343 932 www.summit.foodsafetyafrica.net Sign up to Sponsor, Attend & Speak SCAN ME

FAO harmonizes antimicrobial resistance frequently used vocabulary to ease communication

of frequently used terms on the subject of antimicrobial resistance (AMR) to better align technical internal communications and materials for external audiences.

The terms are now available, in addition to other languages, in all six of the UN’s official languages: Arabic, Chinese, English, French, Russian, and Spanish.

led the working group to define the terms.

The vocabulary is also accessible in Khmer, Korean, Mongolian, and Nepali, the four official languages of the nations participating in the “Action to support implementation of Codex AMR Texts (ACT)” project.

Soon, it will be accessible in Punjabi and Urdu.

GLOBAL – The Food and Agriculture Organization (FAO) has created a glossary

”Having clear and precise definitions of words, and using them carefully, is particularly important when diverse stakeholders engage in discussions so that everyone has the same understanding of the intended message,” said Jeffrey LeJeune, FAO Food Safety Officer, who

“Words matter. Considering the complexity of the AMR issue, having harmonized terminology is a helpful contribution when working together in the fight against AMR,” said Jorge Pinto Ferreira, FAO Food Safety Officer.

FDA to restructure Human Foods Program to establish proactive approach in tackling crisis

U.S – To better assist the organization as a whole, the U.S. Food and Drug Administration (FDA) has unveiled a new, transformative vision for the Human Foods Program and the Office of Regulatory Affairs (ORA).

The concept calls for the establishment of a consolidated Human Foods Program with a single Director reporting directly to the FDA Commissioner, eliminating

DISEASES, OUTBREAKS & RECALLS

duplications, and empowering the organization to regulate human food more effectively and efficiently.

Interestingly, these changes come hot on the tail of the FDA’s Deputy Commissioner, Food Policy and Response, Frank Yiannas’s resignation.

While penning his resignation, the Deputy Commissioner cited that the decentralized structure of the foods

UK records dramatic rise in norovirus cases

U.K – The UK Health Security Agency (UKHSA) has reported a dramatic rise in confirmed norovirus cases, registering a 66 percent rise higher than the seasonal norm.

The total number of lab reports for weeks 3 and 4 of the 2022–2023 norovirus season was 527, which is more than the 318 reports seen on average during the previous five seasons for the same twoweek period.

People 65 and older are experiencing the largest increase in lab-confirmed norovirus cases. UKHSA noted that such high levels in this age range had not been observed in over ten years.

Hospitals, schools, and nursing homes have all seen an upsurge in norovirus outbreaks, with nursing facilities

program significantly impaired the FDA’s ability to operate as an integrated food team and protect the public.

As such, he recommended the creation of a more integrated operating structure and a fully empowered and experienced Deputy Commissioner for Foods, with direct oversight of those centers and offices responsible for human and animal foods.

reporting the majority of cases. In hospitals, 78 outbreaks were lab-verified as norovirus up until week 4 of the 2022–2023 season.

To this end, UKHSA notes that maintaining proper hand hygiene is among the best strategies to stop the spread.

“Regular handwashing is really important to help stop the spread of this bug, but remember, alcohol gels do not kill off norovirus so soap and warm water are best,” said Lesley Larkin, Surveillance Lead for the Gastrointestinal Infections and Food Safety (One Health) Division at UKHSA.

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 8 NEWS UPDATES

REGULATORY & POLICY

National Agricultural Research Organization finds grains in Uganda laden with ten times more aflatoxins

good fungus, it displaces the bad one in a process known as competitive exclusion and this is the principle we used to develop aflasafe,” Dr. Godfrey Asea, the Director of Research at the National Crops Resources Research Institute (NaCRRI), said in reference to a biological product used to reduce aflatoxins.

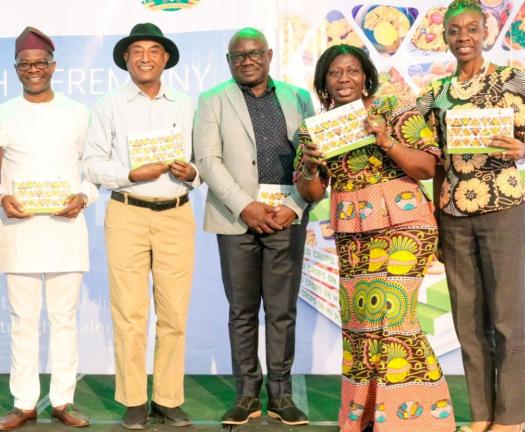

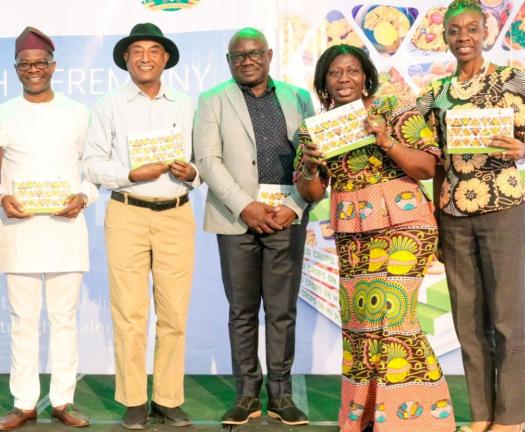

Harvestplus Nigeria, Nigeria government unveil national Biofortification Recipe guide to address malnutrition

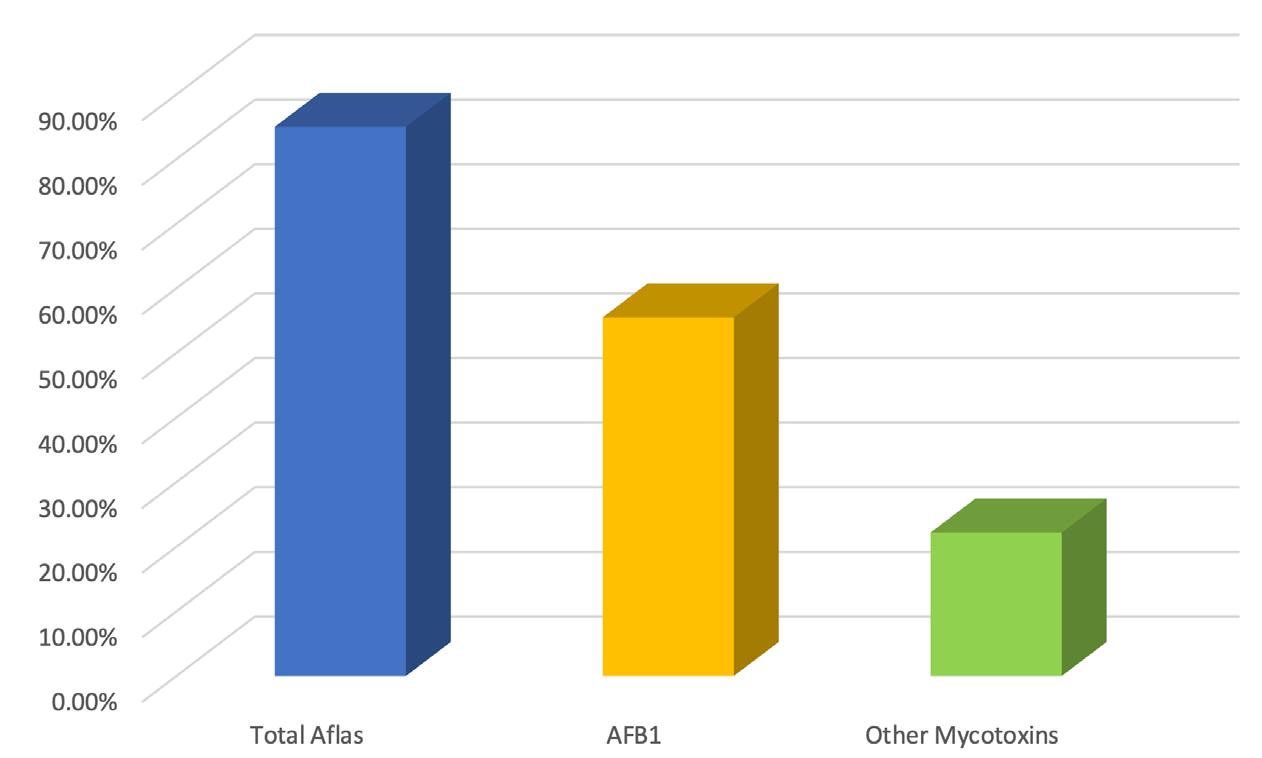

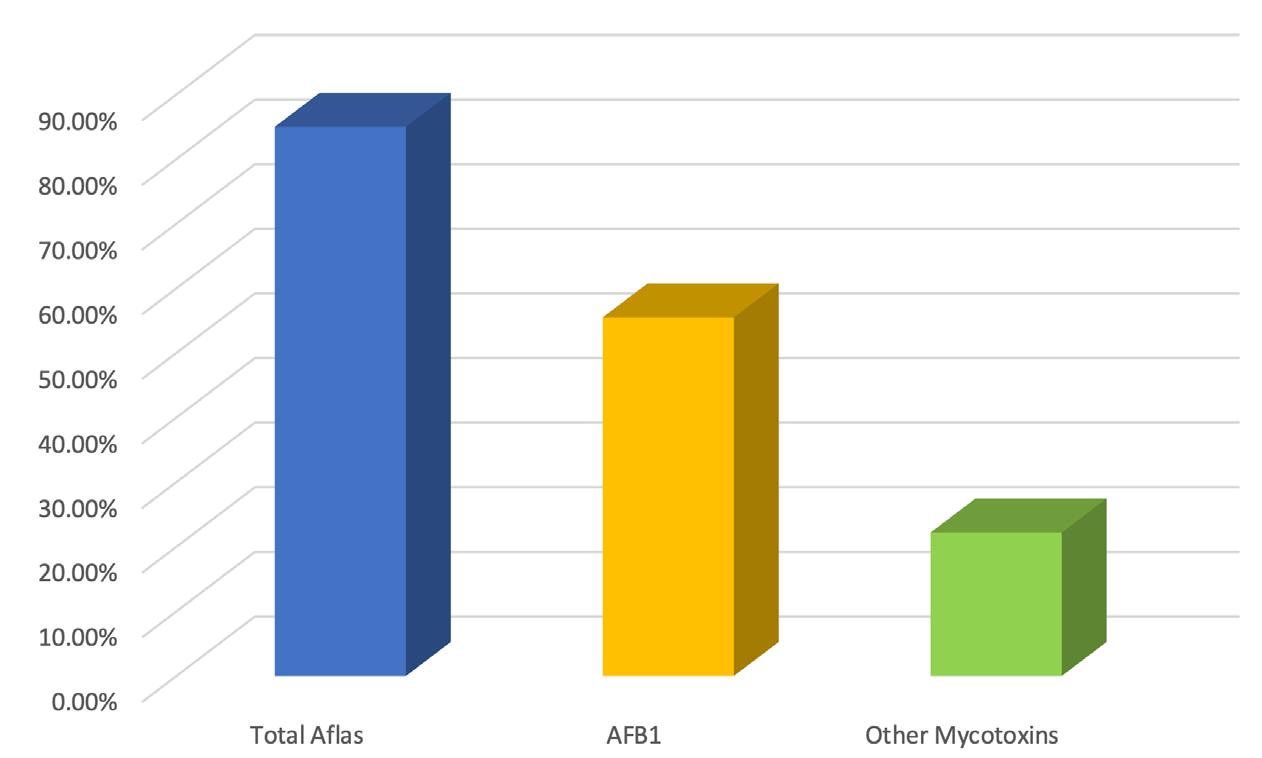

UGANDA – Scientists at the National Agricultural Research Organization (NARO) have found that maize, sorghum, and groundnuts in Uganda have aflatoxins concentrations that are 10 times or greater than the safety level advised by the World Health Organization (WHO).

The investigation was carried out by government experts in collaboration with the International Institute of Tropical Agriculture to determine the aflatoxin level in the grains from 2007 to 2023. Both the soil and the grains were examined as part of the investigation.

“We got both good and bad fungi. When you have a high concentration of

He revealed that the country produces about five million metric tonnes of grain per year and from the research, samples of these grains contain up to 100 parts per billion of aflatoxins, which is higher than the 10ppb recommended by WHO.

Ghana Artisanal Palm Oil Millers and Outgrowers Association launches app to curb palm oil adulteration

GHANA – The Food and Drugs Authority (FDA) in cooperation with the Artisanal Palm Oil Millers and Outgrowers Association, has launched the Artisanal Palm Oil app in Accra to ensure that only authentic and healthy palm oil is sold in the Ghanaian market.

The event organized by the Artisanal Palm Oil Millers and Outgrowers Association was under the theme, ‘Introducing Digital Technology into the Palm Oil Industry to curb the menace of Sudan IV’.

Sudan dyes are classified by the International Agency for Research on

Cancer (IARC) as Group 3 carcinogens and are banned as food additives worldwide (IARC, 1987).

The dye is widely used during the processing of non-food products such as textiles, leather, plastics, papers, hair, mineral oils, waxes, and cosmetics.

The app has tools to determine whether the FDA has approved the brand of palm oil represented by the QR code. It may also show details about the palm oil producers, including their locations and photos so that customers can quickly determine where the product came from.

NIGERIA – Bio-fortification giant, HarvestPlus Nigeria, in collaboration with the federal government and development partners, has launched the first national nutritional guide to help Nigerians reduce the risks of malnutrition that has been grappling Africa’s most populous country.

The Minister of Agriculture and Rural Development, Dr. Mahmood Abubakar has termed the National Biofortification Recipe Book titled ‘Biofortification on my Plate’ a game-changer.

He expressed confidence that the information contained in the book addresses the healthy eating and dietary diversity of Nigerians.

The first national 201-page recipe book includes nutrient-enriched foods and features a collection of practical and traditional dishes that have been cleverly adapted to meet the daily nutrition needs of all family members and to provide a diverse menu using bio-fortified crops, aiming to improve nutrient intake and reduce malnutrition.

The book offers over 50 recipes using vitamin A cassava, vitamin A maize, and vitamin A orange sweet potatoes as the main ingredients, Abubakar said.

“BIOFORTIFIED CROPS ON MY PLATE’ features a collection of practical and traditional dishes that have been cleverly adapted to provide added nutrition and fight malnutrition through bio-fortified foods,” said Chief Nutritionist of HarvestPlus, Erick Boy.

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 9

SCIENCE & RESEARCH NEW TECHNOLOGY

UGANDA'S CEREALS HAVE AFLATOXINS CONCENTRATIONS THAT ARE 10 TIMES OR GREATER THAN THE SAFETY LEVEL ADVISED BY THE WHO

The Future of Food in Africa

www.afmass.com

JUNE 15-17, 2023

Sarit Expo Centre, Nairobi, Kenya

SIGN UP TO ATTEND EASTERN AFRICA'S LARGEST FOOD, BEVERAGE & MILLING INDUSTRY TRADE SHOW

Co-located with:

Sign up today to Sponsor, Exhibit, Speak or Attend AFMASS Food Expo

Hosted at the Sarit Expo Centre in Nairobi, Kenya on June 15-17, 2023, AFMASS Food Expo has over the last 7 years grown into the most influential trade show for the food, beverage and milling industry in Eastern Africa.

This year, look forward to a larger Expo Hall with more exhibitors, a larger variety of exhibitors from more than 20 countries and more food companies showcasing their latest products

And to cap it all, join us as we debut the AFMASS Baking Championship at the Expo. See you in June!!

FOOD Afmass EXPO

info@fwafrica.net +254 725 343 932 www.afmass.com Sign up to Sponsor, Attend & Speak SCAN ME

FOUR PAVILLIONS THAT COVER THE FOOD INDUSTRY FROM A-Z

AFMASS BakingChampionship

• The AFMASS Baking Championship is a new initiative by the organisers of the AFMASS Food Expo that is focused on promoting excellence in the bakery industry in Africa.

• The Championship’s main goal is the advancement of the baking and baking profession in Africa and to create vibe and celebration at this pan-African Expo.

In the first edition, the Championship will focus on the cake making and decoration – where creativity, science and art converge, thereby enabling attendees to experience the wonderful art of baking.

The competitors will be judged by a Panel of Judges with vast experience in the field of pastry, cake making and baking, with each entry evaluated on originality and creativity in the use of ingredients, decoration and the use of technical skills. They will also be judged on cleanliness and overall presentation of the final cake.

FOOD

AFMASS DRINKS

PACK AFRICA EXPO Process &

FOOD EXPO INGREDIENTS AFRICA

MARKET

NEW

AOAC Sub-Saharan Africa expands scope to cover entire continent

Screen-printed electrodes to aid in realtime detection of E.coli in milk

UK/NETHERLANDS – Escherichia coli can now be detected in milk without sample preparation thanks to the development of a unique thermal biosensor for real-time detection.

The approach is based on screenprinted electrodes (SPEs), which are functionalized via a straightforward surface-imprinting method. This method is an easily scalable method for producing synthetic receptors.

Due to their affordable and scalable production procedure, SPEs have recently grown in popularity for use in biosensor applications. The SPEs were used in combination with the heat transfer method to detect E. coli.

The sensor was tested in milk samples

that had been inoculated with E. coli without the requirement for sample preparation in order to demonstrate the sensor’s usefulness. The outcomes matched those of a buffer experiment.

Overall, the sensor enables the labelfree quantification of the pathogen using experimental protocols that call for little to no apparatus, as well as the real-time detection of E. coli.

The study was a combined effort of researchers from the Sensor Engineering Department, Faculty of Science and Engineering, Maastricht University, and Faculty of Science and Engineering, Manchester Metropolitan University, United Kingdom.

SOUTH AFRICA – Analytical scientists working throughout the African continent will now be included in AOAC Africa’s purview following considerable consultation with its 300+ members and ultimate approval from AOAC INTERNATIONAL.

Formerly known as the AOAC SubSaharan Africa Section, AOAC Africa focused, as the name suggested, on scientists in the nations south of the Sahara.

Building trust in analytical results, the AOAC Sub-Saharan Africa Section is a premier regional professional scientific association committed to furthering knowledge and best practices in the analytical sciences throughout the region.

It comprises not only industry veterans, but also young scientists who participate in its annual meetings, ensuring recognition of AOAC, and succession in the future.

AOAC Africa will from now onwards serve individuals working to ensure food safety and compliance with applicable regulations throughout the continent.

Dr. Owen Fraser, President, AOAC Africa, noted that the expansion comes at an opportune time when the African Continental Free Trade Area (AfCFTA) is bringing with it regulatory challenges and opportunities that are not restricted to one region but apply to Africa as a whole.

REGULATORY & POLICY

WHO report on global trans fat elimination 2022 shows 2023 target unachievable

to track progress towards the goal of trans fat elimination in 2023.

Population coverage of best-practice policies has expanded about six-fold since WHO initially advocated for the global eradication of industrially produced trans fat in 2018 with an elimination target set for 2023.

As per the report, 2.8 billion people are now safeguarded worldwide thanks to 43 nations that have adopted best-practice laws to combat trans fats in food.

However, despite significant progress, this still exposes 5 billion people to the devasting health effects of trans fat, making the global target for its complete eradication in 2023 now unachievable.

SWITZERLAND – The World Health Organization (WHO) status report has revealed that about five billion people globally remain unguarded from harmful trans fat, increasing their risk of heart disease and death.

The report, called “Countdown to 2023 – WHO report on global trans fat elimination 2022”, is an annual status report published by WHO in collaboration with Resolve to Save Lives,

“Trans fat has no known benefit and huge health risks that incur huge costs for health systems. By contrast, eliminating trans fat is cost-effective and has enormous benefits for health.

“Put simply, trans fat is a toxic chemical that kills and should have no place in food. It’s time to get rid of it once and for all,” said WHO Director-General, Dr. Tedros Adhanom Ghebreyesus.

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 12

NEW TECHNOLOGY

NEWS

UPDATES

FDA publishes draft guidelines for labeling plant-based foods

statement that describes how the product compares with milk using the U.S. Department of Agriculture’s (USDA’s) Food and Nutrition Service fluid milk substitutes nutrient criteria.

For instance, the label might read, “Contains lower amounts of Vitamin D and calcium than milk.”

The FDA is also developing a draft guidance to address the labeling and naming of other plant-based alternatives and is seeking comments on the same.

U.S – The U.S. Food and Drug Administration (FDA) has published draft guidelines for the industry on the naming of plant-based foods marketed and sold as milk substitutes.

The draft guidance titled Labeling of Plant-based Milk Alternatives and Voluntary Nutrient Statements: Guidance for Industry, also suggests that some plant-based milk substitutes’ labels include voluntary nutrient claims.

SCIENCE & RESEARCH

The proposed guidance was created to address the enormous rise of plantbased milk substitutes that have occurred over the past ten years in the market. The guidelines are designed to give consumers clear labeling.

According to the draft guidance, a plant-based milk alternative product with the term “milk” in its name (such as “soy milk” or “almond milk”) and that has a different nutrient composition from milk should include a voluntary nutrient

All 15 samples of water that were randomly obtained from the butcheries and eateries tested positive for E. coli, salmonella spp., and Shigella bacteria, according to the report written by principal investigators Dr. Hillary Odeckh Indago, Prof. Joseph Wafula Matofari, and Dr. John Masani Nduko.

“These results indicate a public health risk for consumers of RTE meat products in Nakuru County,” the report stated.

“The presence of these bacteria points a direct finger to bad handling and poor hygiene practices because they indicate that the products have been in contact with faecal matter.”

Research shows Listeria species developing resistance to disinfectants used in food industry

SOUTH AFRICA – A study conducted in South Africa and recently published in the journal Microbiology Spectrum has concluded that Listeria innocua strains are developing resistance to temperature, pH, dehydration, and other stresses.

The study used whole-genome sequencing to provide insights into two species of presumed nonpathogenic Listeria—L. innocua and L. welshimeri.

Some of the L. innocua and L. welshimeri strains tested for the study exhibited three genes for resistance to a common disinfectant from the class of chemicals known as quaternary ammonium compounds (QAC or QUAT).

The study included 258 isolates from butcheries, abbatoirs, retail

establishments, cold storage facilities, and processing facilities located throughout South Africa.

Of these, three isolates of nonpathogenic L. welshimeri and 38 isolates of nonpathogenic L. innocua were identified. Additionally, two of the L. innocua strains examined in the study had three or more pathogenic traits that were alarming, including CRISPR CAStype adaptive immune systems.

“The Listeria innocua that we tested has some of the genes that are also found in pathogenic Listeria monocytogenes.

“These shared genes between L. innocua and L. monocytogenes are also responsible for disease in humans and stress tolerance such as resistance to the disinfectant Benzalkonium chloride,”

said Thendo Mafuna, Ph.D., a Lecturer at the University of Johannesburg, and coauthor of the study.

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 13 REGULATORY & POLICY

THE LISTERIA INNOCUA THAT WE TESTED HAS SOME OF THE GENES THAT ARE ALSO FOUND IN PATHOGENIC LISTERIA MONOCYTOGENES.

Thendo Mafuna, Ph.D., a Lecturer at the University of Johannesburg

Kenya leads Africa in automating phytosanitary certification

problems with documentation.

The ePhyto platform is anticipated to decrease the cost experienced by exporters with physical documentation as well as the time it takes for the document to be transmitted from Kenya to the Netherlands and other markets.

KEPHIS backs the system to also improve phytosanitary certification compliance by at least 99%.

KENYA – Thanks to a platform created in conjunction with the Netherlands Food and Consumer Safety Authority (NVWA) that has automated phytosanitary certification, the Kenya Plant Health Inspectorate Service (KEPHIS) anticipates an increase in the volume of horticultural exports from Kenya.

Prof. Theophilus Mutui, the Managing Director of KEPHIS, claimed that the ePhyto platform will assist in reducing instances of missing documentation, inaccurate information, incomplete documentation, and forgeries that have

plagued Kenya’s export process and resulted in losses for producers and income for the government.

“Previously we have had challenges where there is fraud. People have defaced the phytosanitary certificates which has led to our products being intercepted at the destination market. This is the reason why we came up with this innovation to be able to address that challenge,” said Prof. Mutui.

According to KEPHIS, horticulture exports are typically seized in at least 54 consignments each year because of

Ghanaian scientists working on inserting a second gene into Bt cowpea to strengthen pest resistance

GHANA – The National Biosafety Authority (NBA) has received a new application from researchers at the Council for Industrial and Scientific Research (CSIR) and the Savanna Agricultural Research Institute (SARI) in Ghana asking for permission to add a second gene to the cry1Ab that has already been inserted into the Bt cowpea.

According to them, the new cry2Ab gene will strengthen and increase the Bt cowpea’s resistance to the Maruca pest and any potential future mutations.

SARI has spent more than ten years working to genetically alter the popular cowpea variety songotra to withstand the pod-boring bug Maruca vitrata.

Insects do evolve into new biotypes

and dismantle any previously developed resistance, according to SARI Director Dr. Francis Kusi.

“So, with this approach, we are just trying to build up the level of genes in there so that if a particular insect can overcome one, the other one will be able to knock it out.

“This is the approach, and that is why we are now asking for the second gene to add to make it more robust, and then the resistance can stay longer for the farmers,” he said.

The biosafety authority authorized the release of the Bt cowpea into the environment on June 30, 2022.

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 14

TECHNOLOGY

NEWS UPDATES

THE EPHYTO PLATFORM IS ANTICIPATED TO DECREASE THE COST EXPERIENCED BY EXPORTERS WITH PHYSICAL DOCUMENTATION AS WELL AS THE TIME IT TAKES FOR THE DOCUMENT TO BE TRANSMITTED FROM KENYA TO THE NETHERLANDS AND OTHER MARKETS.

AFRICA

BUSINESS SUMMIT

MARCH 13-15, 2024

Nairobi, Kenya

Accelerating Businesses Innovation, Strategic Leadership & African Transformation through new Technologies

The Africa Business Summit is the ground-breaking conference and exhibition that brings together the key decision makers to define the future of business innovation, strategic leadership and the transformation of Africa, as we approach 2030 and beyond.

KEY AGENDAS

The conference program at the 3-day Summit will comprise of highlevel keynote speeches and panel discussions plus sponsored industry and country-focused sessions. It will also feature fireside chats with influential people and change makers who are making waves –and who are also inspiring the next phase of business leaders in the Continent.

The Africa CEO & Leadership Forum

The Africa CEO & Leadership Forum

Digitizing Africa Strategic Leadership in Africa Connecting & Trading In Africa Healthier Africa Industralising Africa Investing In Africa Sustainable Africa Powering Africa Feeding Africa

* * www.africabusinesssummit.biz

Neogen’s Reveal 3-D for Gluten receives AOAC certification

U.S – The AOAC Research Institute has awarded the Performance Tested Method Certification to Neogen Corporation for their Reveal 3-D for Gluten test.

The Reveal 3-D for Gluten test has been independently verified as meeting the AOAC standard for screening gluten residues in environmental samples by the AOAC certification (No. 122201).

Neogen’s Reveal 3-D for Gluten is a single-step lateral flow immunochromatographic assay that utilizes a simple, rapid methodology to qualitatively detect gluten residues in environmental and food samples as low as 5 parts per million (ppm).

develops kit to simultaneously detect Listeria and Salmonella

U.S – bioMérieux, a global pioneer in invitro diagnostics, has developed a firstof-its-kind testing kit that simultaneously detects Listeria and Salmonella from environmental swabs, with PCR confirmation.

The technology reduces laboratory waste, lowers costs, and streamlines the workflow to enable quick and accurate quality decisions.

Separate enrichments are used in the market-available processes and tests for Salmonella and Listeria.

With the help of GENEUP ENVIROPRO, users may test environments for both Salmonella and Listeria with just one swab, one enrichment, and one sample preparation, increasing total sampling efficiency and sustainability.

The GENE-UP ENVIROPRO assay is the outcome of bioMérieux’s xPRO program, an innovation engine within bioMérieux that collaborates directly with industry leaders to quickly develop, validate, and commercialize cutting-edge molecular assay to address new market

AWARD

“With this certification, we once again demonstrate the continued reliability of our assays and our commitment to providing trustworthy, dependable solutions for producers around the world.

“Our customers can confidently utilize our Reveal 3-D for Gluten tests to help gluten-intolerant and allergic customers minimize exposure to allergens,” said John Adent, Neogen’s President and Chief Executive Officer.

The assay delivers results in just 5 minutes and can be used in virtually any environment to screen environmental swabs and clean-in-place rinses.

The Reveal 3-D line of food allergen test kits is uniquely designed to guard against oversaturation and false negative results, with results displayed in three visual lines on the lateral flow test strip.

needs and improve their overall quality programs.

“The evolution of ENVIROPRO demonstrates our commitment to innovation through our xPRO program and our success in building gamechanging assays.

“Bringing much-needed efficiencies to routine environmental monitoring will not only reduce costs for our end users but do so in a far more sustainable way, a key focus in the market,” said Ben Pascal, Global Head xPRO Program, bioMérieux.

SGS India receives 13th Food Safety Award 2022 for Outstanding Laboratory Performance

INDIA – SGS Testing laboratory based in Ambattur, Chennai has been awarded the 13th Food Safety Award 2022 for Outstanding Laboratory Performance – Food Testing Laboratories by the Confederation of Indian Industry (CII) –Food and Agriculture Center of Excellence (FACE) – India’s leading resource center for driving food safety and nutrition in the food processing industry.

The CII Award for Food Safety, which was introduced by CII in 2010, fosters the development of capacity along the food value chain while promoting globally recognized practices in food safety in small, medium, and large food businesses.

The performance of food testing laboratories is assessed using ISO

17025:2017 standards, best practices, leadership efforts, and social and legal compliance.

SGS’s state-of-the-art food testing laboratory in Ambattur, Chennai is ISO/IEC 17025:2017 accredited for a scope covering a wide range of tests on agriculture and food products. It is also certified for ISO 9001:2015, ISO 45001:2018, and ISO 14001:2015.

The lab can conduct nutritional analysis, pesticides (+1000), mycotoxins, heavy metals, illegal dyes, antioxidants, preservatives, pathogens, and nonpathogens in food as well as digital sensory evaluation, species identification, and shelf-life studies to test the quality of agricultural and food products.

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 16 NEW TECHNOLOGY

bioMérieux

SUPPLIER NEWS & INNOVATIONS

Enartis partners with WINEGRID to introduce “Smart Enology” hence increasing efficiency in wineries

Enartis is now distributing will allow winemakers to make better decisions, enhancing the efficiency of their wineries in keeping with Enartis’ aim to support wineries throughout the world in achieving ever-higher wine quality.

Due to advanced forecasting and analytical capabilities, the company notes that winemakers will be able to quickly take remedial action in situations where the parameters are not optimal.

Enartis.

ITALY – Enartis, an Italian multinational operating in the market of enological products and services, has partnered with WINEGRID, a Portuguese engineering company specializing in winemaking monitoring solutions, to distribute WINEGRID innovative solutions worldwide which detect critical production data in real-time during the various stages of winemaking.

The WINEGRID technology that

A proprietary information system on a SaaS (Software as a Service) platform analyzes and interprets the acquired data using cutting-edge algorithms and Artificial Intelligence (AI) technology.

“This partnership meets our primary vocation of always being one step ahead in our industry. The interaction with the most advanced forms of technology proposed by WINEGRID, including Artificial Intelligence, allows us to offer, not only solutions and control but the strategic design of wines with a systematic and scientific approach,” says Piermario

Ticozzelli, Strategic Business Director of

THE INTERACTION WITH THE MOST ADVANCED FORMS OF TECHNOLOGY PROPOSED BY WINEGRID, INCLUDING ARTIFICIAL INTELLIGENCE, ALLOWS US TO OFFER THE STRATEGIC DESIGN OF WINES WITH A SYSTEMATIC AND SCIENTIFIC APPROACH.

Piermario Ticozzelli, Strategic Business Director of Enartis.

Danfoss partners with Lizard Monitoring to assist North American stores reduce food waste

DENMARK/U.S – To assist North American stores reduce food waste, Danish multinational company Danfoss has established a cooperation with U.S retail technology company Lizard Monitoring.

The Alsense monitoring system from Danfoss is reported to be supplemented by The Lizard’s sensor networks to enable continuous temperature monitoring and deliver in-depth information on environmental compliance and refrigeration performance to store managers and food safety executives.

Retail managers can monitor refrigeration performance using Danfoss’ Alsense, an Internet of Things (IoT) platform developed within Microsoft Cloud for Sustainability. This platform

tracks alarms ensures continuous monitoring of food conditions and lowers energy use.

Lizard offers reliable wireless sensor networks to gather information from

retail settings and deliver it to the cloud where it is mined for trends that will cause food waste before they occur.

To this end, customers can now get more thorough records of each event and what shop personnel did in response, along with early warnings and fewer alarms.

“Our customers are looking for sustainable solutions and more automation to reduce product loss and labor and energy costs.

“The Lizard solution is highly complementary to the Danfoss Alsense platform and together gives a 360-degree view of your store’s refrigeration performance,” commented Peter Dee, Danfoss North America Sales Director of Food Retail.

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 17 DISTRIBUTION PARTNERSHIP

Energis Solutions develops technology to reduce pathogens in meat

Document Compliance Network releases new edition of its food safety software traceability rule

U.S – In order to help food safety teams in the food and beverage sector work more efficiently and with less work, Document Compliance Network (DCN), a cloudbased solution that makes managing food safety documentation easier, has released a new edition of its food safety software.

There are 14 languages supported by DCN’s food safety software, including Arabic, Chinese, English, French, German, Hindi, Italian, Japanese, Korean, Portuguese (Brazil), Russian, and Spanish.

U.S – The Voltai technology for the meat protein sector invented by biotechnology company Energis Solutions, has been independently validated and submitted to the Food and Drug Administration (FDA) for clearance.

The solution is manufactured onsite using a machine that can be simply integrated into almost any current production process and significantly reduces food-borne pathogens that continue to pose a threat to the meat sector.

“The Voltai machine produces a patented unique, highly energized fluid that carries the same EPA toxicity rating as tap water, Category IV. The technology can be used as a carcass spray or poultry dip, which is far safer than acid-based alternatives that are often used in the industry today,” said Darin Jensen, Vice President of Food Safety, Quality & Regulatory, Energis.

The Voltai solution targets STEC, Salmonella, Campylobacter, and Listeria amongst other pesky pathogens.

It is Kosher and Organic compliant and is in current trials validating shelflife extension characteristics for protein products.

Voltai has conducted multiple 3rd party side-by-side studies that prove double the reduction of STEC and Salmonella when compared to legacy Peracetic and Lactic acid treatments.

In addition, you can designate the preferred language of your business partner (customer or vendor) to streamline communication and efficiency in the global supply chain.

DCN also modified its internal

document area to incorporate a history and change log, making it simple to track updates to Standard Operating Procedures (SOPs) as required by various auditing organizations and food safety requirements.

For the supplier side of the platform, the upgrade also adds a history and advanced note system that will automatically move earlier iterations of documents into history and keep track of who approved them.

Food and beverage businesses can submit their most recent papers to the program, which will automatically deliver them to associated customers before they expire, and send one-way fillable PDFs to suppliers.

launches consultancy division to help firms implement FDA traceability rule

iFoodDS

U.S – In order to help businesses achieve operational compliance with the FSMA 204 mandate, iFoodDS, the industry leader in connected traceability, quality, and food safety solutions for the fresh food supply chain, has announced the formation of a consultancy division called New Era Partners.

The Food Safety Modernization Act Section 204 Food Traceability Rule, recently published by the FDA, establishes new traceability recordkeeping requirements for firms that manufacture, process, pack, or hold certain foods on the Food Traceability List.

New Era Partners will be coled by Matt Regusci, a co-founder of Azzule|PrimusGFS, and Andrew Kennedy, a former FDA traceability expert who worked on the development of FSMA 204.

According to iFoodDS, no team is better suited to assist businesses with the regulatory and practical implications of the new regulation and the best ways to comply.

“FSMA 204 is complex, especially

for grocers, foodservice operators, and processors. With our deep understanding of the rule and the supply chain, New Era Partners can quickly help enterprises understand the rule’s impact on their operations and objectively identify paths to compliance,” said Andrew Kennedy, Principal Traceability Advisor at New Era Partners.

Some of the services offered include executive briefings for enterprise operations, IT, and legal executives on the rule and its impacts, and Supply Chain Traceability X-Ray.

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 18

CAPACITY BUILDING TECHNOLOGY UPDATE SUPPLIER NEWS & INNOVATIONS

FOOD AFMASS DRINKS

MARKET

The AFMASS Food & Drinks Market showcases packaged food products from Africa and the World. Sign up today to engage with consumers, corporate buyers from hotels, restaurants and catering (HORECA) and other institutions and more . . .

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 19 WWW.AFMASS.COM JUNE 15-17, 2023 SARIT EXPO CENTRE, NAIROBI, KENYA

Dairy Products • Coffee & Tea • Poultry & Fish • Fresh Produce • Soft & Alcoholic Beverages • Flours, Legumes & Grains • Baked Goods & Snacks • Nuts, Oils & Oilseeds • Animal Feed & Pet Food • Savoury & Condiments • Fats & Oils etc . . . A SPECIAL PAVILLION AT: FOOD

EXPO The Future of Food in Africa

Afmass

Cindy McCain to head United Nations World Food Programme

Comoros President Azali Assoumani elected new AU Chair

AFRICA – The President of the Union of Comoros, H.E. Azali Assoumani, has been chosen by the Heads of State and Government of the African Union (AU) to serve as the new Chairperson of the African Union for the year 2023.

President Azali of Comoros is taking over the baton of command from H.E. Macky Sall, President of the Republic of Senegal, who has concluded his term as the Chairperson of the African Union for the year 2022.

Azali expressed his gratitude for the honor, responsibility, and trust placed in him and the other members of the new Bureau to guide the Organization’s course for the upcoming year in his acceptance address.

AOAC International appoints new Deputy Executive Director and Chief Science Officer

ITALY – United Nations World Food Programme (WFP), the world’s largest humanitarian organization, has tapped the current United States Permanent Representative to the UN Agencies in Rome, Cindy McCain as its new Executive Director, effective April.

McCain will succeed David Beasley as Executive Director, who will have served six years when his term ends on April 4.

She is the former Chair of the Board of Trustees of the McCain Institute for International Leadership at Arizona State University.

She also served on the Board of Directors of Project C.U.R.E., CARE, Operation Smile, the Halo Trust, and the advisory boards of Too Small To Fail and Warriors and Quiet Waters.

McCain holds an undergraduate degree in Education and a Master’s in Special Education from the University of Southern California.

Commenting on her appointment, McCain said: “I am ready to roll up my sleeves and spend time both in Rome and in the field, deepening my understanding of WFP’s vital work, and making sure it continues to grow to meet the needs of a hungry world.”

Kenya had earlier withdrawn its candidature from the elections, paving the way for Comoros to rise to the leadership ranks for the very first time in history.

“By allowing the Union of Comoros to lead the African continent, our Organization has just proved to the world its conviction that all countries have the same rights and enjoy the same freedoms,” underscored the incoming Chair of the Union.

U.S – AOAC International has appointed Dr. Katerina (Kate) Mastovska as the new Deputy Executive Director and Chief Science Officer.

AOAC International is a wellknown, impartial, third-party, notfor-profit organization that creates voluntary chemical and microbiological consensus standards.

“I’m delighted to join the AOAC staff and lead the team of dedicated scientists. AOAC has a critical role in food safety, and I’m inspired to continue to be a part of this important work,” said Dr. Mastovska.

Since joining AOAC International in 2004, Dr. Mastovska has actively participated in the organization. In 2021, she was given the Harvey W. Wiley Award, the association’s highest scientific accolade.

She has a wealth of experience in research chemistry, having held positions with the U.S. Department of Agriculture, the University of Chemistry & Technology in Prague, and her own independent consulting firm, Excellcon International.

The most recent position Dr. Mastovska held was as a Chief Scientific Officer for Eurofins’ American Food Division.

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 20 APPOINTMENTS UPDATE

David Tharp to culminate 30-year stint at IAFP in April

U.S – Following 30 years of service, David Tharp, the Executive Director of the International Association for Food Protection (IAFP) is set to retire on April 26, 2023.

David joined IAFP in 1993 as Director of Finance and Administration, and served as Interim Director in 1995 until he was appointed to his current role in 1997.

He successfully directed and represented IAFP at dozens of key food safety meetings worldwide, helping grow IAFP’s international status.

The association also saw a significant increase in membership, as well as Annual Meeting attendance, exhibitors, and sponsors, during David’s years as Executive Director.

USDA swears in new Food Safety Under Secretary

Frank Yiannas bows out from his role as FDA’s Deputy Commissioner, Food Policy and Response

U.S – Frank Yiannas, Deputy Commissioner, Food Policy and Response, FDA has submitted his resignation from the agency citing his concern that the decentralized structure of the foods program significantly impaired the FDA’s ability to operate as an integrated food team and protect the public.

Yiannas took the mantle as the FDA’s Deputy Commissioner for Food Response and Policy in December 2018.

U.S – The U.S. Department of Agriculture (USDA) has appointed José Emilio Esteban, Ph.D., as the organization’s new Under Secretary for Food Safety.

Dr. Esteban joined the USDA Food Safety and Inspection Service (FSIS) in 2001 and held the roles of Laboratory Director for the Western Laboratory, Scientific Advisor for laboratory services and research coordination, and Executive Associate for laboratory services.

In 2018, he was appointed Chief Scientist of FSIS. In his role, Dr. Esteban provides scientific advice to support agency policies including the disciplines of microbiology, chemistry, and pathology.

He has since served as the FDA Commissioner’s main advisor in the formulation and implementation of food safety regulations, including

His leadership, according to IAFP, was crucial during the trying years of the COVID-19 pandemic, when IAFP 2020 transitioned to a virtual event for the first time in its history and the European Symposium had to be cancelled, all without any staff turnover.

During his 30-year stint at IAFP, David played a transformative role that resulted in a name change, an increase in international conferences and workshops, a greater emphasis on student scholarships, and a solid financial foundation.

He leaves the association in a great position with a staff that is quite competent, says IAFP.

He has held positions as an Epidemic Intelligence Service Officer, Staff Epidemiologist, and Assistant Director of the Food Safety Office at the Centers for Disease Control and Prevention (CDC).

He is also the current Chair of the Codex Alimentarius Commission Committee on Food Hygiene, the committee that establishes global food hygiene standards for international trade. Moreover, he is serving as the International Association for Food Protection’s (IAFP’s) Vice President.

“Serving as the next Under Secretary of Food Safety is an opportunity to give back to a nation that has given me so much,” he said.

the historic FDA Food Safety Modernization Act (FSMA).

Food safety priorities like epidemic response, traceback inquiries, product recall operations, and supply chain innovation, have fallen under his purview.

“In December 2018, I joined the FDA with the goal of helping to modernize the food safety oversight system in the United States and protecting the American people from contaminated food.

“I wanted to build on my work of protecting consumers by elevating food safety standards and building more effective, modern, and innovative food safety approaches, something I did in the private sector for more than 30 years,” said Yiannas.

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 21

NATIONAL BIOSAFETY AUTHORITY STEPS INTO LIMELIGHT AS KENYA OKAYS GM FOODS

Mixed reactions have followed Kenya's lifting of the 10-year ban on GMOs, bringing to light the National Biosafety Authority (NBA). The Food Safety Africa Magazine team had a seat-down with the Authority’s CEO, Dr. Roy Mugiira, in a bid to dissect their role in the industry.

By Catherine Odhiambo

The National Biosafety Authority (NBA) was established by the Biosafety Act No. 2 of 2009 to exercise general supervision and control over the transfer, handling, and use of GMOs. GMOs are products of modern biotechnology that involve the manipulation of the genetic material of organisms through genetic engineering procedures.

“GMO is either a plant, an animal or a microorganism that has new genetic composition, or that has been altered through modern biotechnology,” elaborates Dr.Mugiira.

When GMOs initially gained notoriety, customers expressed concern about their safety. Additional elements like socioeconomic status, cultural practices, and religious convictions also impacted how people perceived these new breeds. Consequently, the international community negotiated a protocol called the Cartagena Protocol on Biosafety that is anchored under the Convention on Biological Diversity, to

which Kenya is a party.

“We want to assure our consumers and particularly the Kenyan public that that which we have checked and put our seal of approval on is indeed safe,” he reiterates.

HIERARCHY OF LEADERSHIP

The Authority was founded with the goal of regulating the research and commercial use of genetically modified organisms in order to protect the environment and ensure human and animal health.

The Authority is governed by a Board of Directors comprising nine members. They include a Chairperson; representatives of four Principal Secretaries from the Ministries of Education (as the Ministry responsible for Science and Technology), The National Treasury, Ministry of Agriculture and Livestock Development, and the Ministry of Health; Two experts in the biological, environmental, and social sciences respectively, one member with financial expertise, and the Chief Executive Officer (CEO) who is an ex-

officio member.

The CEO is backed by two Directors in the Technical area, one Director in Corporate Services, another Director in Planning and Strategy, and a Director in the Legal and Cooperation area, collectively known as the "Cooperation Secretary Office.”

In addition to an operational border post in Namanga, NBA also maintains outposts at the Jomo Kenyatta International Airport (JKIA), which is overseen from the Nairobi headquarters, one in Mombasa, and the final one in Busia. These outposts are used to monitor products entering the country and guarantee compliance.

“We hope to expand but we are limited by resources. The 10-year ban didn't see quite a bit of movement in this space. That is why you have seen after the lifting of the ban, it is like we have been taken out of the freezer. Now we are out there and we hope to fall back on track quickly enough so that we can pick up our mandate as is required,” notes the NBA boss.

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 23

REGULATOR HIGHLIGHT | National Biosafety Authority

ROBUST REGULATIONS TO MAN GMO SECTOR

Nonetheless, a number of stakeholders have expressed concern over whether the nation is prepared to end the embargo. According to Dr. Mugiira, Kenya laid down the groundwork for biotechnology way before the year 2000 when the Cartagena Protocol was signed into law by the late former President Daniel Arap Moi and later ratified in the year 2003. In 2006, Kenya published the National Biotechnology Development Policy followed by the enaction of the Biosafety act which now established the National Biosafety Authority.

In 2011, the country published three sets of regulations. One such regulation was the Contained Use Regulations published in August 2011 to guide activities involving GMOs under containment and confinement. These regulations are applied during research on GMOs while still in the laboratory, greenhouse, growth chamber, and confined field trials.

“We also published regulations for Environmental Release. If we are releasing a GM crop into the environment for cultivation, these regulations clarify the forms to be filled, any costs to be incurred, and safety evaluation procedures,” says Dr. Mugiira.

The third regulation was the Import, Export, and Transit

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 24

Staff at the National Biosafety Authority lab in Nairobi

WE WANT TO ASSURE OUR CONSUMERS AND PARTICULARLY THE KENYAN PUBLIC THAT THAT WHICH WE HAVE CHECKED AND PUT OUR SEAL OF APPROVAL ON IS INDEED SAFE.

Dr. Roy Mugiira, CEO, National Biosafety Authority

Regulation which as the CEO points out is a hot topic of discussion currently. They give explicit protocols on importing, exporting, and transportation of GMOs and guidance on steps to undertake in case of unintended release of the items into the environment while in transit. Under the regulations, any person(s) involved in GMO import for consumption or research, GMO export to any country, and GMO transit from one country to another through Kenya is/are required to seek approval from the Authority.

Later in 2012, the Authority released the Biosafety Labeling Regulation to ensure that consumers are made aware that the food, feed, or product is genetically modified so they can make an informed decision. The regulation also facilitates product traceability to assist in the implementation of the necessary risk management strategies when necessary. The regulations aim to make it easier to accurately label products, monitor their impacts on the environment and, when necessary, human health, and put in place the necessary risk management strategies, such as pulling products off the market.

Subsequent to the release of the Biosafety Labeling Regulation, the government banned the importation and use of genetically modified crops, thanks to a publication publicized by a French scientist by the name Professor Séralini. This effectively put the NBA's regulatory system on ice.

“For 10 years, we have just been dealing with research work, except the approval of Bt cotton, which was approved in 2020 responding to the

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 25

National Biosafety Authority buiding

need to revitalize the cotton apparel value chain. So in essence, therefore, we have been ready way before 2000.

“We have the capacity, both in our research institutions, and also our regulatory framework, which includes eight other regulatory agencies,” echoed Dr. Mugiira.

IMPORT PROTOCOLS AND SAFETY TESTS

Following the lifting of the ban, the NBA updated some facets of the Export, Import, and Transit Regulation including digitizing the application process. They also updated a platform known as KenTrade and identified a seven-step procedure to be followed by potential GM food importers. All import procedures begin with the completion of an Import Declaration Form (IDF), which details the products the importer plans to bring in, who the products are from, where they are coming from, and what components of the products are GM or non-GM. Dr. Mugiira claims that when that is indicated, it raises a flag for NBA inspection.

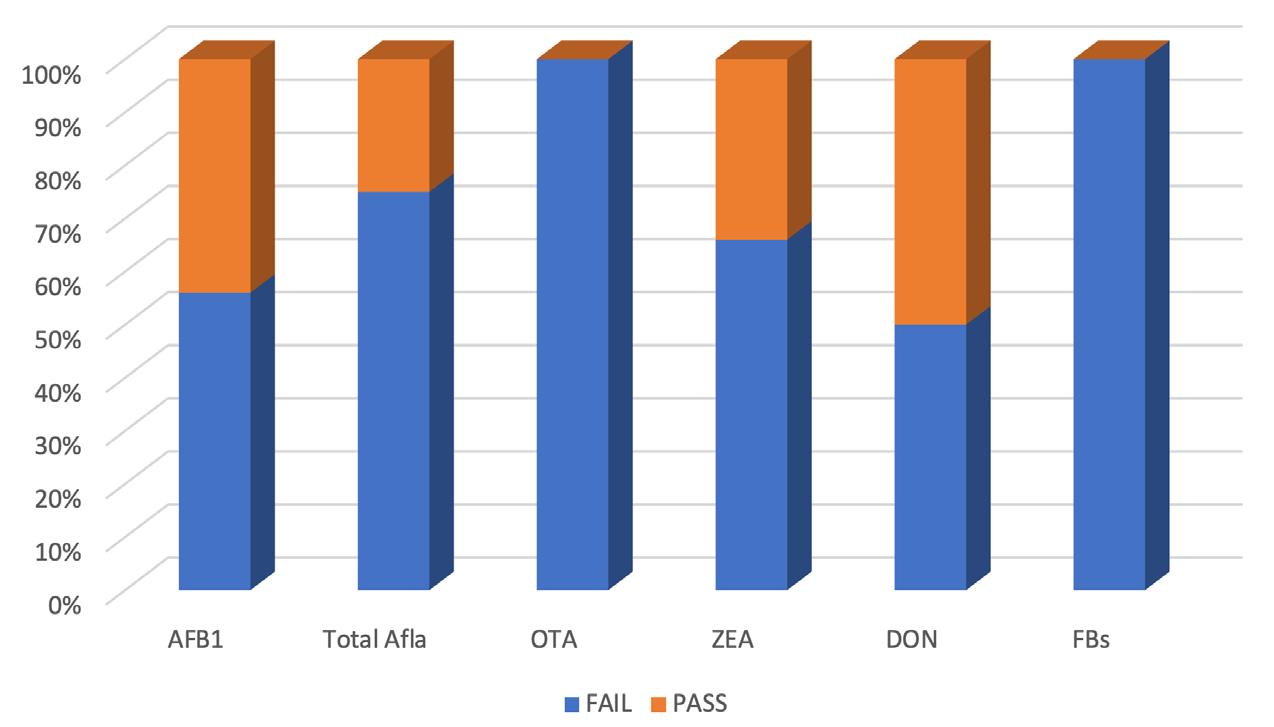

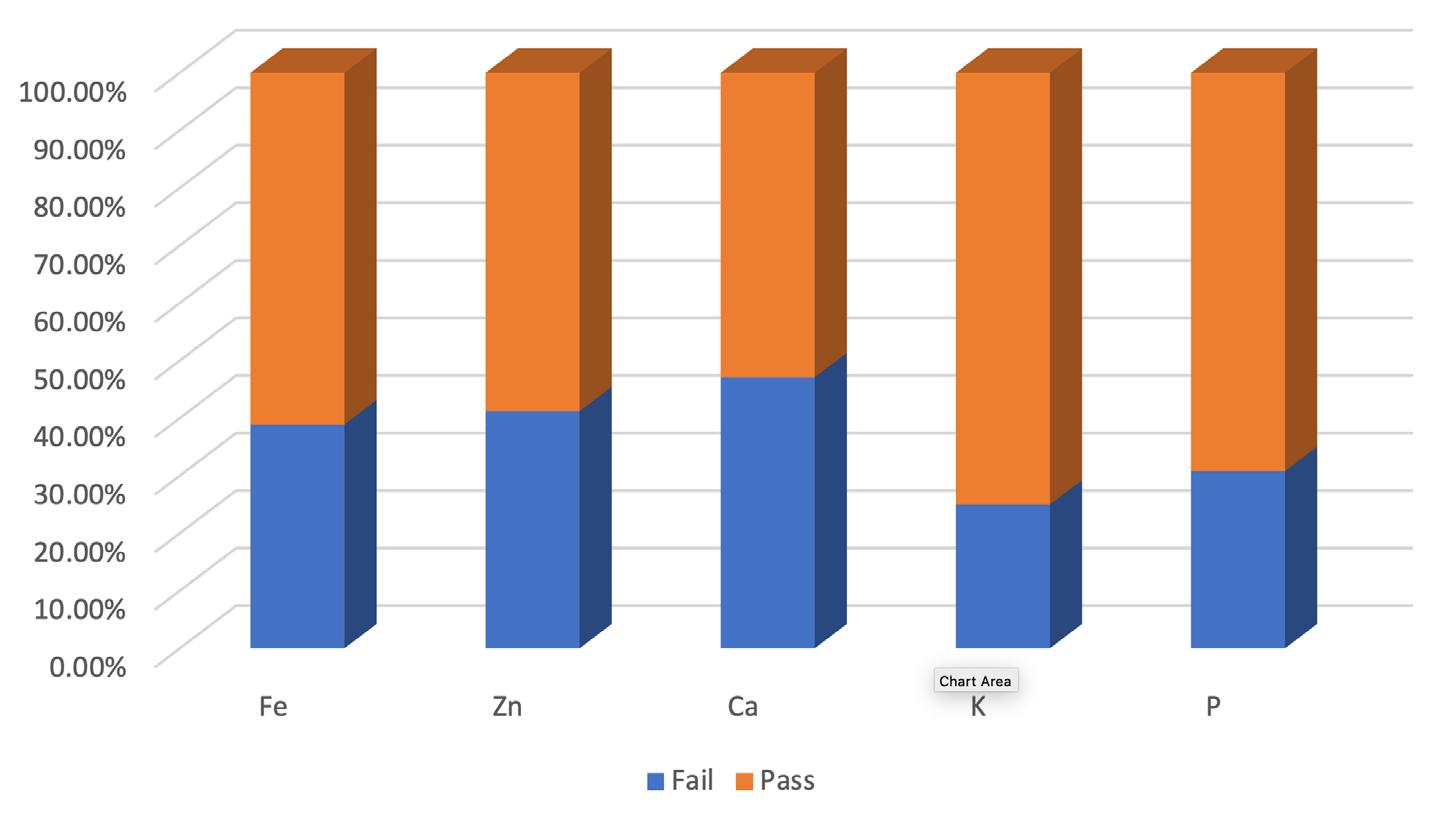

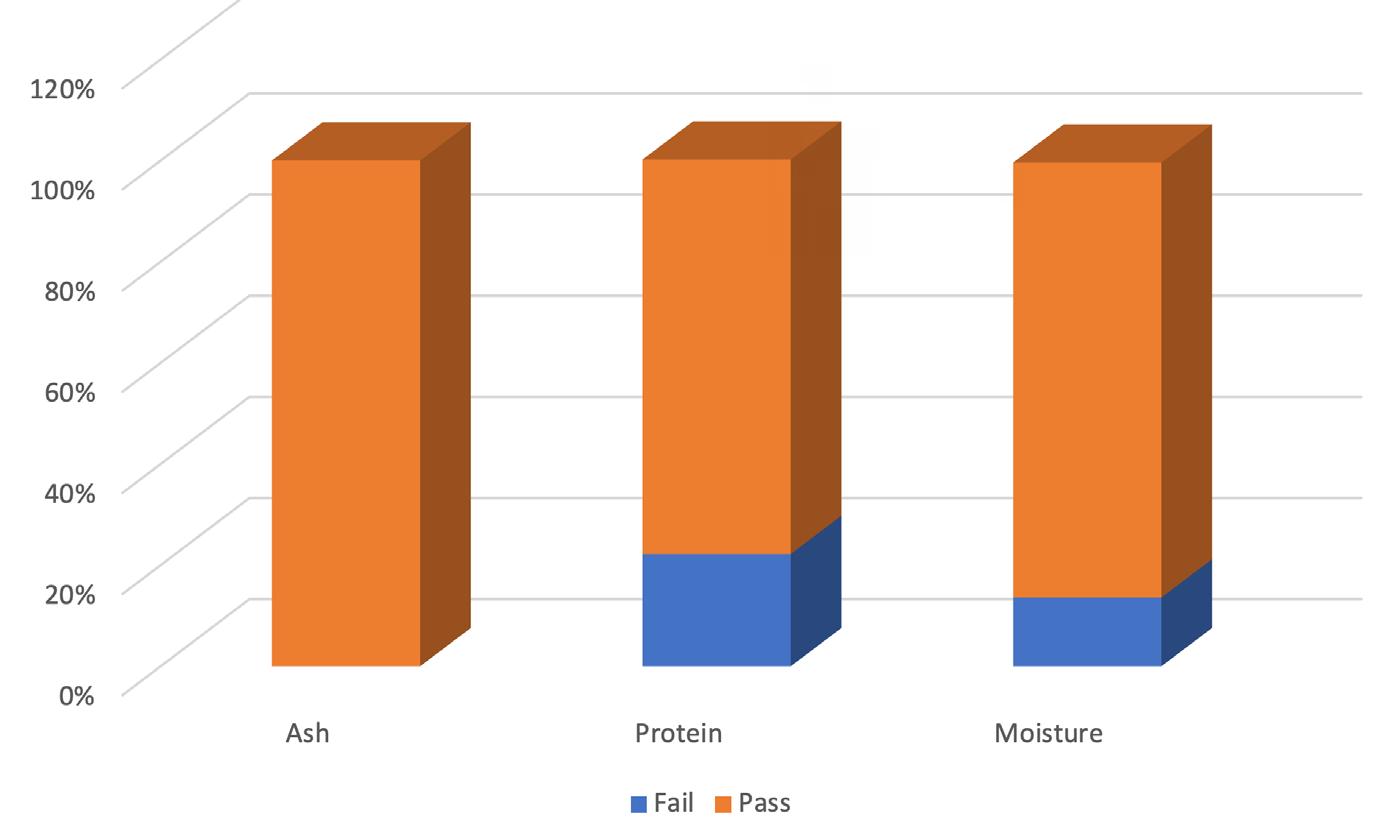

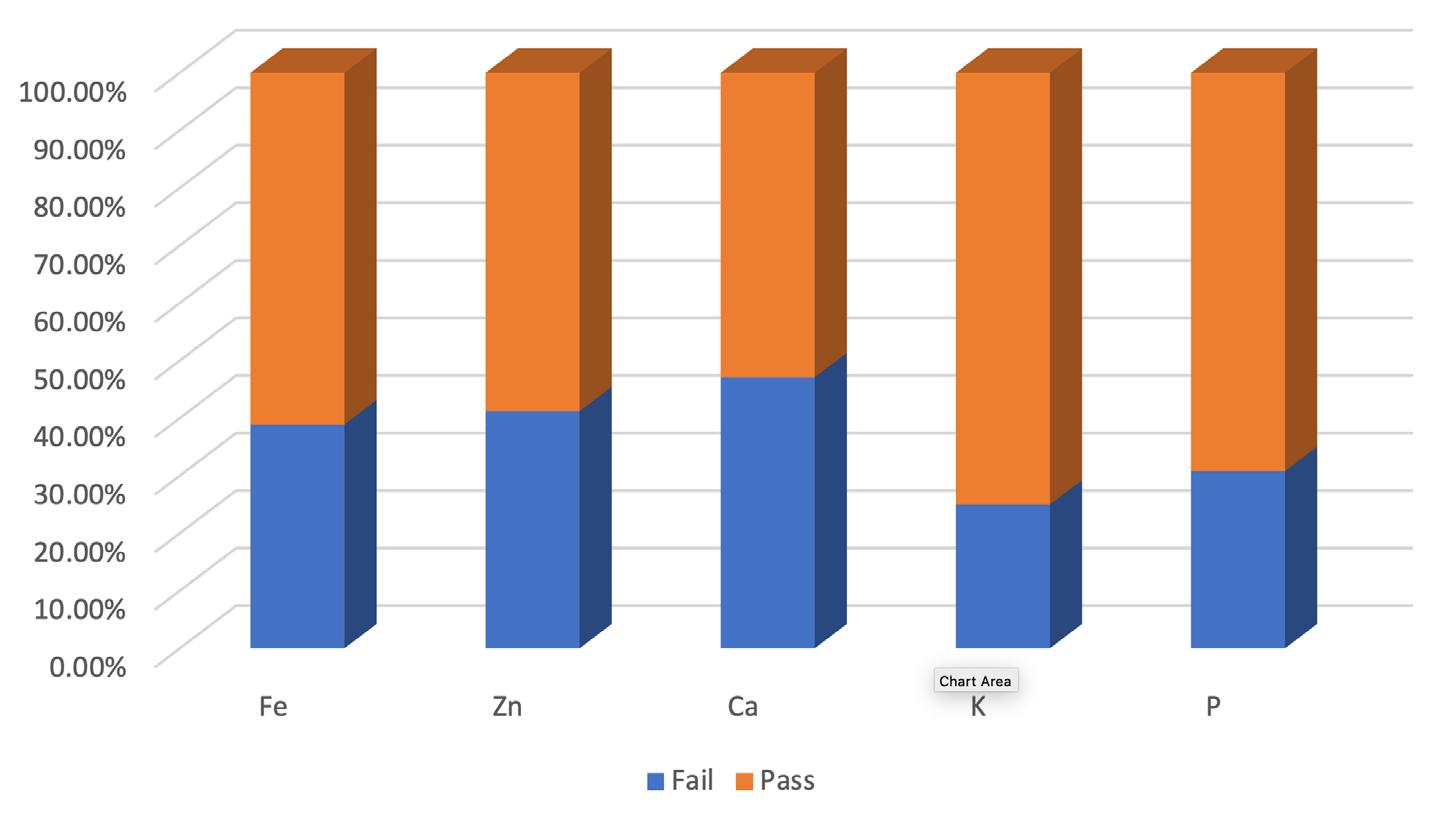

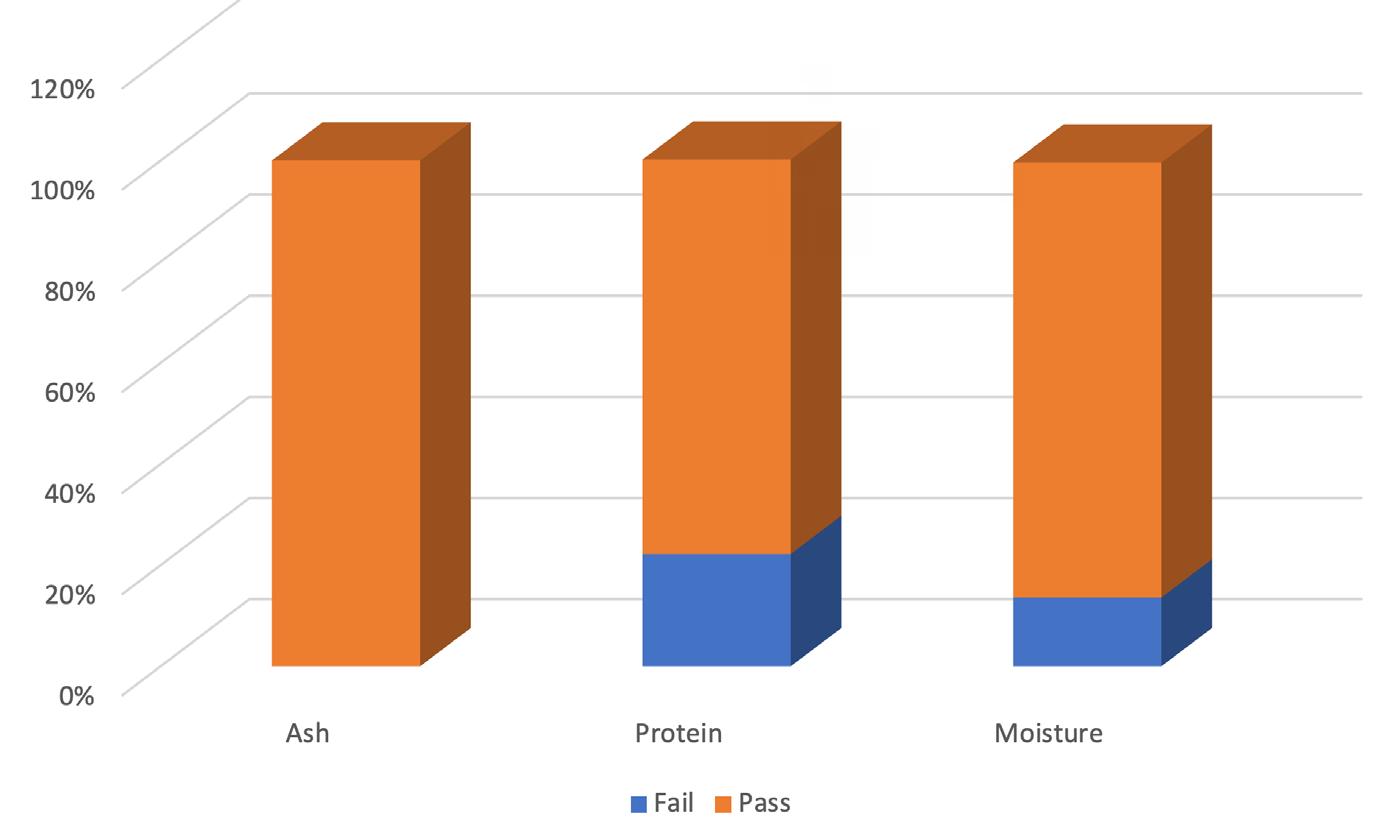

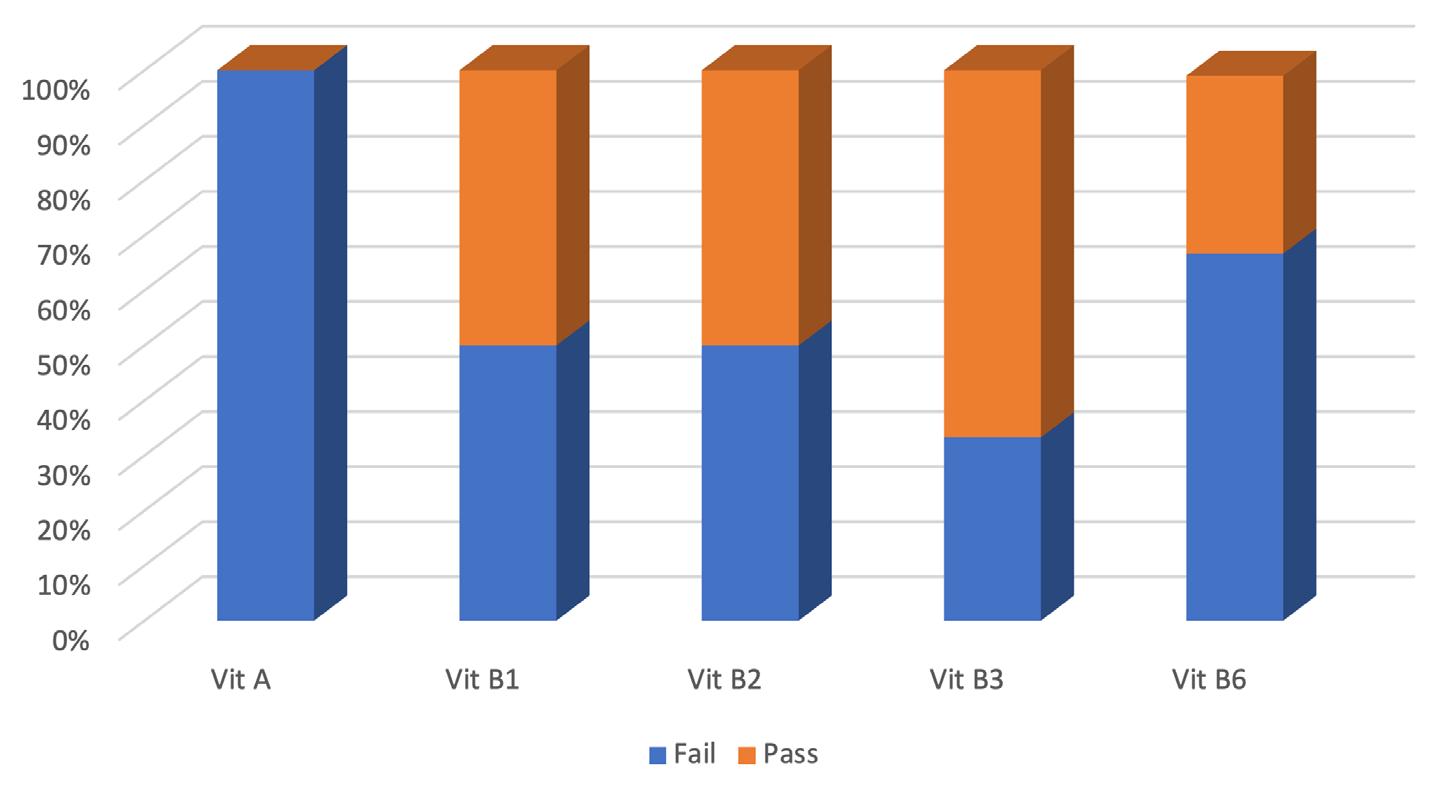

“So within the KenTrade platform, as KEPHIS is looking at the potential for insect pests and diseases, as KEBs is looking at moisture and aflatoxin among other things, we are looking at what GM is in that commodity,” he informs.

Subsequent to clearance from the partner organizations, NBA doesn’t conduct repeat tests owing to the large costs and a potential delay to trade. Instead, they only verify the approval of the specific gene in the commodity for use as food, feed, and processing in its country. Once verified, the findings are posted in the Biosafety Clearing House, a virtual Clearing House, where state parties to the Cartagena Protocol post all decisions. This then paves way for the release of the product

for use in the country.

“However, if the product is coming as a seed which will be required to germinate in our environment, it will be required to have been approved here for environmental release,” he points out.

GENOME EDITING UNPACKED

Last year, Kenya joined its Nigerian counterpart in establishing guidelines for the Genome Editing (GE) technology, a more recent innovation that does not involve the transfer of genetic material from one organism to another. Nonetheless, one can question the need for GE regulations given the existence of GM ones. What defines the difference between these two?

Dr. Roy clarifies that in GE, instead of bringing a gene fragment from another source, the scientists go into the organism, identify the genome of interest and edit it either by removing it or modifying it constitutively.

“Hence the crops are not classical GMOs as they

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 26

REGULATOR HIGHLIGHT | National Biosafety Authority

FOR 10 YEARS, WE HAVE JUST BEEN DEALING WITH RESEARCH WORK, EXCEPT THE APPROVAL OF BT COTTON, WHICH WAS APPROVED IN 2020 RESPONDING TO THE NEED TO REVITALIZE THE COTTON APPAREL VALUE CHAIN.

don’t have the novel gene from another source and should not be regulated in a similar manner,” he explains.

The guidelines were developed to provide technical guidance to applicants and reviewers on which genome editing organisms and/or products are regulated under the Biosafety Act 2009 or not, as genome editing can result in either a GMO or non-GMO depending on the pathway followed in the editing process. The applicants are supposed to consult with the Authority early enough for them to assess their research and issue a verdict on the product category.

The other feature of the GE regulations is the three pathways where if the researcher ends up with GMO it becomes the NBA’s interest, if not, it becomes the interest of other regulatory agencies.

“Where there are transient stages that are GM, we regulate up to the point

KEY NUMBERS

where it has exited the GMO component. That approach resonates well with several other jurisdictions including Argentina, Nigeria, India, and Malawi.

“It is an approach that is universally agreed upon. And that has made us reasonably popular. We are now being invited to share our experiences with that approach,” says Dr. Mugiira.

NBA has so far taken three products through that process, and two others are in the pipeline. This begs the question of whether the rumored GM crops circulating in the Kenyan market are really GM…the CEO terms these crops as hybrid since they result from the crosspollination of two plant varieties to create a new plant with desired traits.

COLLABORATION WITH OTHER ENTITIES

NBA works hand in hand with several regulatory agencies as stipulated in the first schedule of the Biosafety Act. Key among them is the Kenya Plant Health Inspectorate Service (KEPHIS) which also deals in crops. Others include the Department of Public Health, Department of Veterinary Services (DVS), Kenya Bureau of Standards (KEBS), Pest Control Products Board (PCPB), National Environmental Management Authority (NEMA), Kenya Wildlife Service (KWS), and Kenya Industrial Property Institute (KIPI).

Internationally, the Authority has partnered with the African Union Development Agency NEPAD (AUDANEPAD) which manages a program called the African Biotechnology Network of Expertise (ABNE).

“This program helps African countries to develop regulatory frameworks. They’re supporting us a lot in developing our regulations around genome editing and also in the rollout of biotechnology,” he says.

They also work with an institution called the Program for Biosafety Systems, a program under the International Food Policy Research Institute (IFPRI) of the U.S., in the development of frameworks and especially in the coordination framework for the regulatory agencies. In terms of food safety assessment, they work with the Food and Agriculture Organization (FAO) of the United Nations, the World Health Organization, and the Codex Alimentarius Commission. Debunking the myths through public education

Besides the NBA’s regulatory role, the Authority is also mandated to provide public education and awareness. A lot

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 27

THE YEAR NATIONAL BIOSAFETY WAS ESTABLISHED

2009

REGULATOR HIGHLIGHT | National Biosafety Authority

Dr. Roy underscored the need for the public to be made aware that GM farming is not the opposite of organic farming since one can grow GM crops that are also organic. Just like farmers utilize organic chemicals/fertilizers on their nonGM crops, the same can be adapted to their GM counterparts. To avoid cross-pollination with nonGM crops, the Authority recommends distancing. In the event that cross-breeding actually happens, the transgene is lost in the second generation.

“Where we want to maintain purity is at the seed production level. At the crop cultivation level, we are saying this is safe, it can go to the cultivation and we will progressively see it not appearing in the non-GM crop production system after generations of cultivation,” he explains.

REGULATORY OVERLAP AND LIMITED RESOURCES STILL A CHALLENGE

of myths and misconceptions have flooded the internet with no voice of authority to set the record straight, an issue Dr. Mugiira attributes to the 10year silence occasioned by the ban on GM foods.

“You cannot tell a story if you have nothing to tell. We are now able to tell a story because we can talk about Bt cotton, which is already with farmers. Farmers can come out themselves and even tell us their experiences generally.

“And the best way of communicating is people sharing experiences. So the 10 years, have been really quiet. And that is one of the reasons why our role in public education, public awareness, and Public Communications has been low,” he says.

In a bid to up that game, NBA is mulling on revitalizing a program launched by His Excellency, President William Ruto, when he was serving as Minister for Agriculture in 2008, known as the ‘Bio Aware program’.

“Hence, public education and awareness have long been recognized as being necessary. I have already requested financial facilitation from the government so that we can roll out a structured, coordinated public education, public engagement, public communication program,” Dr. Mugiira revealed noting that the authority currently only engages in ad hoc modes of awareness creation, an initiative that has earned him the title, ‘GMO man’.

While NBA jubilates the country’s move to open its doors to GMOs, the Authority is still left to grapple with the impacts of staying underground for over a decade. Making do with a 2010-2011 budget is no mean feat given the current economic status not only of the country but of the global community at large. This has restricted the NBA’s capacity to carry out public education and awareness and in turn, limited the potential uptake of the technology.

“Today, if you ask somebody, ‘if I made ugali from GM corn, would you partake of that meal?’ Somebody would want to run away. So it means therefore even the acceptance of the technology is low,” Dr. Mugiira says.

The Authority also has to battle with an overlap in the regulatory framework that hinders the seamless coordination among partner institutions.

“For example, within the Environmental Management Act (EMCA), there is a provision for subjecting projects of biotechnology, particularly testing of GM commodities or crops to environmental impact assessment, while we have already conducted environmental risk assessment. So it becomes like a duplication, or even an unnecessary kind of undertaking,” comments the CEO adding that there are a number of other gap areas in legal provisions that NBA intends to address with the country’s legislature.

CONTINUOUS LEARNING TO STAY ON THE RADAR OF TECHNOLOGICAL ADVANCES

To continuously keep up with the rapidly evolving scientific and technological innovations, NBA takes its staff through incessant training sessions that also encompass short courses. These training sessions are backed by partner organizations

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 28

Mr Harry Kimutai, PS Livestock Development, Ministry of Agriculture & Dr. Roy Mugiira during the 11th Annual Biosafety Conference

like the AUDA-NEPAD. The UN has also come in handy in facilitating the Authority’s human technical capacity building. NBA has thus far held two training sessions on genome editing and the proposed regulatory framework for the Board and top policymakers in the government.

“We are also embracing IT in our operations so that we step out of the paper and file processes. Our clients who need us to clear them for GMO-free certificates can access our services virtually. This has enabled us to enhance our service delivery. So it is training, training, and some more training and also setting up the infrastructure for ICT,” informs the NBA Head.

DELICATE BALANCE BETWEEN INNOVATION AND SAFETY

As new technologies emerge, there is a risk that they could fall into the wrong hands and end up being utilized as bioweapons. Dr. Mugiira informs of the existence of a sister institution called, the ‘National Commission for Science Technology and Innovation (NACOSTI) established to specifically regulate science research and innovation. NACOSTI implements the requirements of the Biological Weapons Convention (BWC) which prohibits the development, production, acquisition, transfer, stockpiling, and use of biological and toxin weapons.

of enhancing the virulence of a disease-causing pathogen for example, for use in biological warfare, or even in hostile activities of terrorists and groups like those,” he says.

SOLDIERING ON DESPITE THE HURDLES

According to Dr.Mugiira, NBA has been able to put in place a robust science-based regulatory system that has been tested and tried over time. It is on account of this robust framework, that the former CEO, Professor Dorington Ogoyi shepherded the approval of Bt cotton amidst a very hostile environment.

“By demonstrating how Bt cotton can contribute to socioeconomic development, the Authority was able to take it through all the phases up to the doorstep of the farmer, which is a major achievement, and it has been a big test for our regulatory system,” he highlights when asked some of their achievements.

The Authority has also been able to oversee the National Performance Trials for Bt maize and was almost releasing it to farmers were it not for the obstruction by the court. Moreover, it has 32 GMO projects for contained use and 12 for confined field trials in various research facilities in the country, to date.

However, he affirms that there is a delicate balance between innovation and safety, and regulations alone cannot bridge that gap. As a result, he urges scientific professionals to self-regulate. Just as food safety is everyone’s business, responsible innovation should also be everyone’s business.

“Our role, therefore, is to ensure that this technology doesn't find itself in the wrong hands and be used for purposes

With an eye toward the future, NBA seeks to control and direct new bioscience fields including synthetic biology and the militarization of biotechnology. In the medium term, the authority has a strategic plan running through 2025 and an upto-the-task management team which Dr. Roy is confident will ensure it remains relevant in an ever-changing technology and regulatory landscape.

FOODSAFETYAFRICA.NET MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE 29

YOU CANNOT TELL A STORY IF YOU HAVE NOTHING TO TELL. WE ARE NOW ABLE TO TELL A STORY BECAUSE WE CAN TALK ABOUT BT COTTON, WHICH IS ALREADY WITH FARMERS. FARMERS CAN COME OUT THEMSELVES AND EVEN TELL US THEIR EXPERIENCES GENERALLY.

Dr. Roy Mugiira, CEO, National Biosafety Authority

Foodborne pathogens in Africa: Understanding Cronobacter sakazakii

By Ifeanyi Michael Mazi, Helen Onyeaka, Nnabueze Darlington Nnaji

Cronobacter sakazakii is an emerging and opportunistic foodborne pathogen that causes severe infantile diseases, including meningitis, necrotizing enterocolitis, and septicemia. It has been reported in numerous countries around the world, including those in Africa. Although it has been isolated from food, environmental and clinical samples across Africa, the most implicated source of the C. sakazakii infection outbreaks across the globe has been the consumption of contaminated powdered infant formula (PIF).

PIF contamination can occur during the production stage for several reasons, such as poor Good Manufacturing Practices (GMP) and contaminated equipment. Owing to its high food safety risk and severity of C. sakazakii infections, especially for infants, the International Commission on Microbiological Specification for Foods in 2002 categorized Cronobacter spp. as “a serious hazard for restricted populations, life-threatening or with significant chronic sequelae over a long duration”. Neonatal infections associated with C. sakazakii have been reported to have a mortality rate as high as 80%, often leading to irreversible

MARCH 2023 | FOOD SAFETY AFRICA MAGAZINE FOODSAFETYAFRICA.NET 30

SCIENCE & RESEARCH | Foodborne Pathogens in Africa

neurological disorders for survivors

Cronobacter has many unique characteristics that contribute to its survival in harsh environments and transmission along the food chain from production to consumption. These features include the formation of biofilm; the ability to withstand critical food control steps during food production such as osmotic stress, thermal treatment, pH, detergents, starvation, disinfectants, antibiotics, and sanitizers. In addition, the organism also possesses the ability to significantly resist high temperatures (the minimum, maximum, and optimum temperatures for growth are 6, 45, and 37–43°C) and desiccation that allows it to stay up to 2–5 years in an encapsulated form in dehydrated food products (with water activity range from 0.30 to 0.83).

CRONOBACTER IMPACT GOES UNNOTICED IN AFRICA

Based on the current surveillance systems across the globe, available data shows that there is no active surveillance system for diseases caused by E. sakazakii (Cronobacter spp.), implying that most national foodborne disease surveillance centers of the world are yet to identify cases of C. sakazakii infection. Because C. sakazakii infection is rare, most sites where Cronobacter spp. disease has been reported have very low populations, and several years of monitoring/surveillance will be needed to develop a valid incidence estimate across affected populations

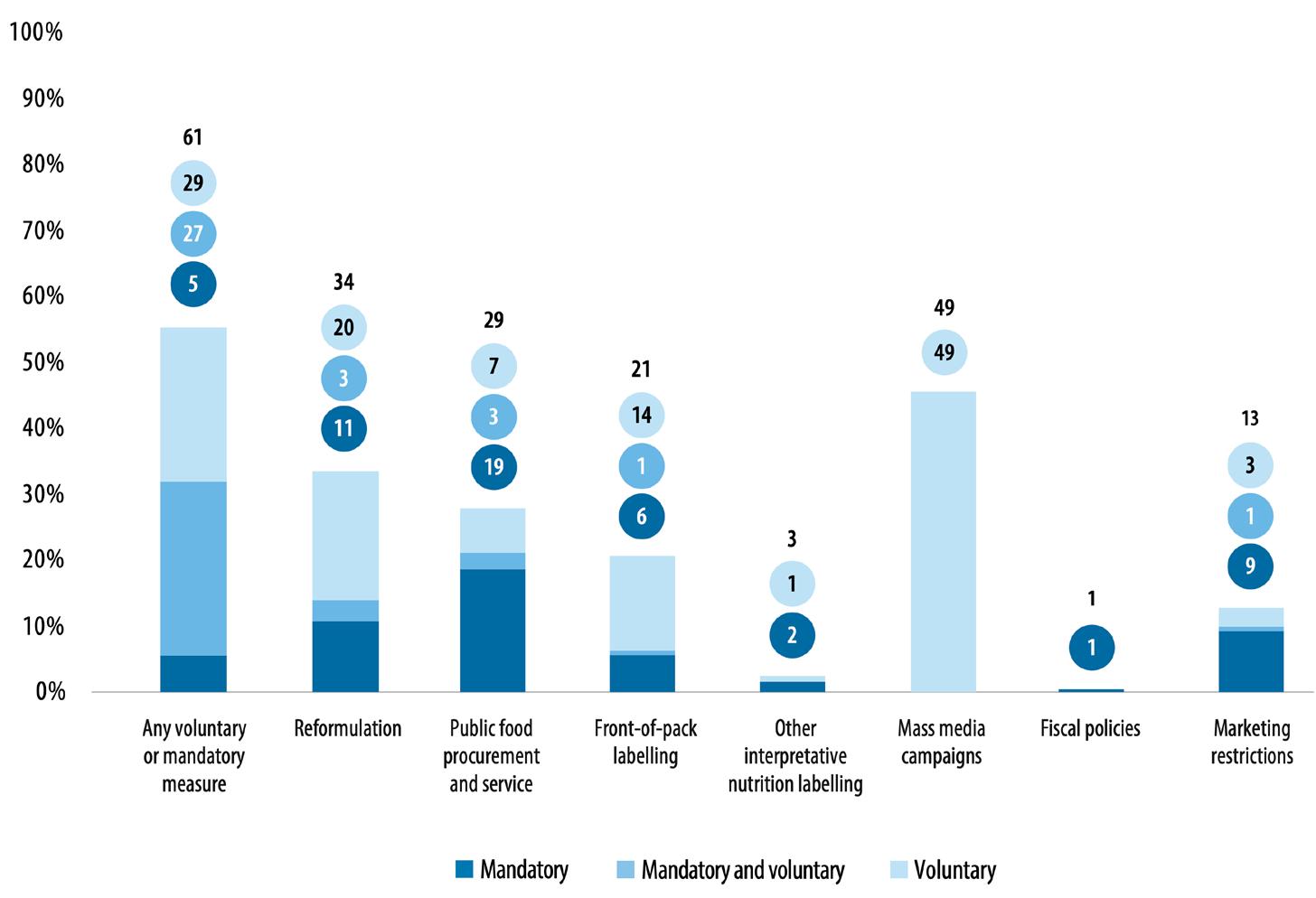

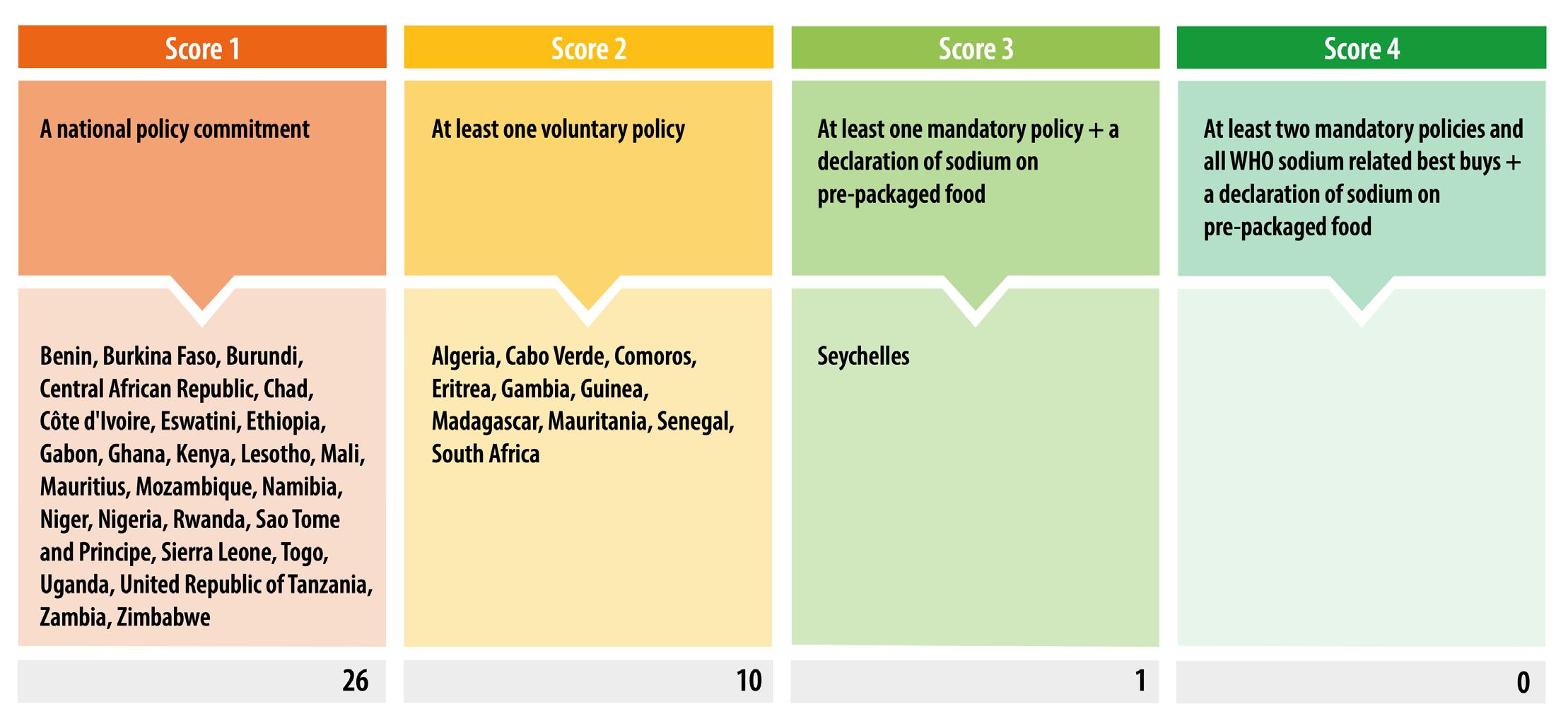

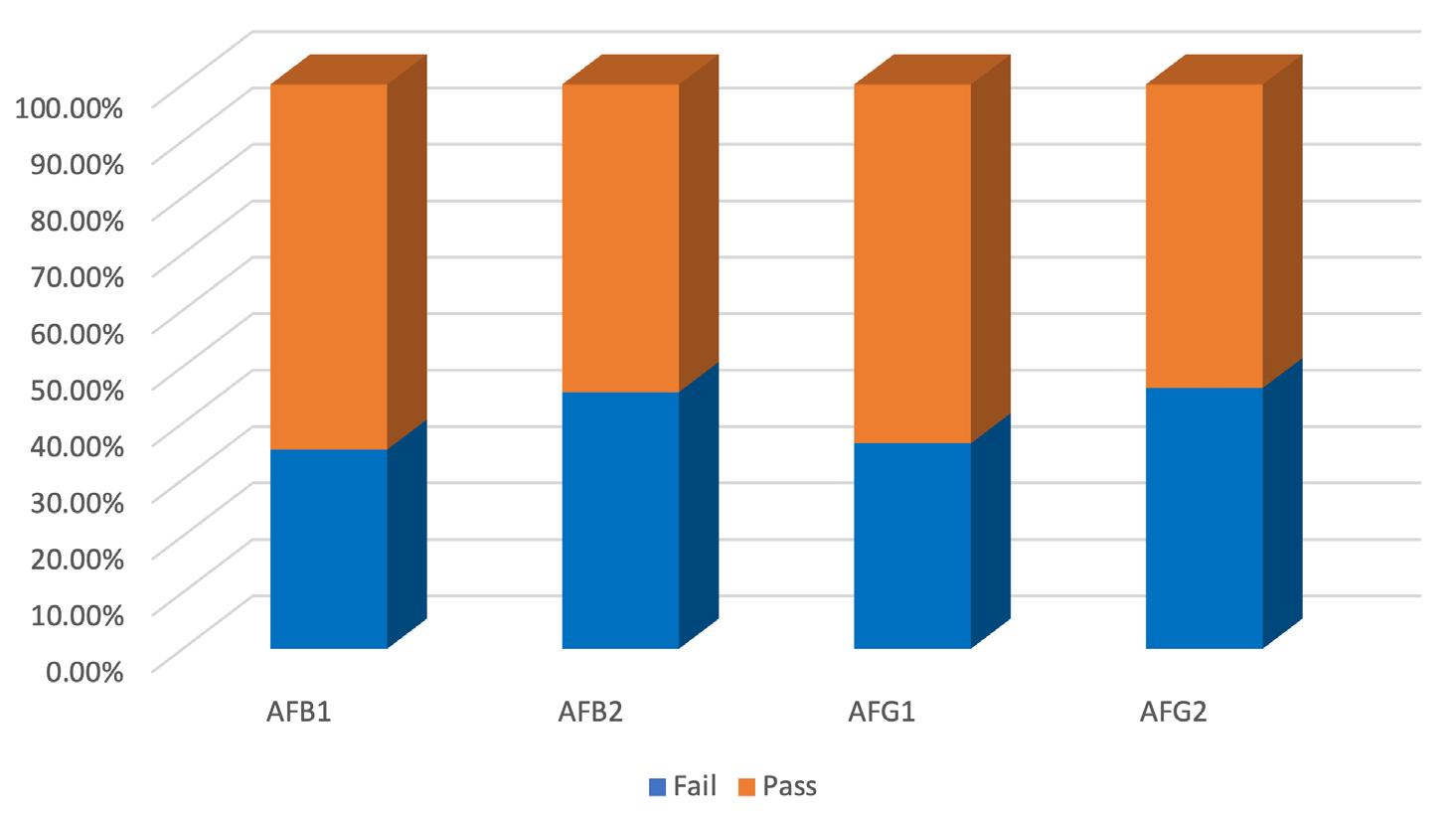

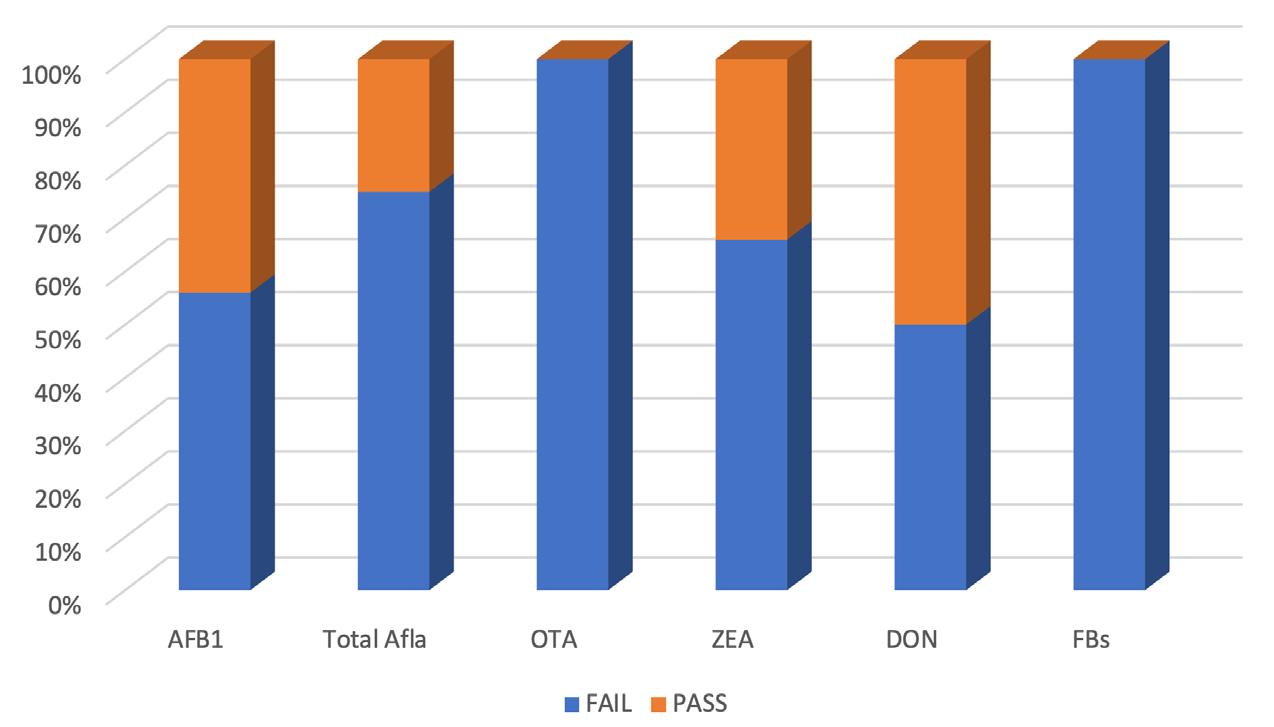

Generally, in less developed nations, including Africa, the impact of Cronobacter spp. often goes unnoticed.