Central Hall -- C5176

Las Vegas Convention Center

January 17-19, 2023

Central Hall -- C30280

Las Vegas Convention Center

March 14-18, 2023

Central Hall -- C5176

Las Vegas Convention Center

January 17-19, 2023

Central Hall -- C30280

Las Vegas Convention Center

March 14-18, 2023

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/spreaders, texture/ cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

Featuring Concrete Strategies, creating a safety culture for your construction company is built from a foundation of great leadership.

The right mentorship goes beyond emotional support and advice. It can be imperative in helping growing female leaders understand and successfully navigate the political minefields that every organization encounters.

Concrete Contractor (USPS 021-799, ISSN 1935-1887 (print); ISSN 24712302 (online) is published 6 times a year:January/February, March/April, May/June, July/August, September/October and November/December by AC Business Media, 201 N. Main Street, 5th Fl., Fort Atkinson, WI 53538.

Printed in the U.S.A. Periodicals postage paid at Fort Atkinson, WI, and additional entry offices. POSTMASTER: Send address changes to Concrete Contractor, PO Box 3605 Northbrook, IL 60065-3605

January/February 2023, Issue 1, Volume 23

One year subscription to non-qualified individuals: U.S. 1 year: $35, 2 years: $70. Canada & Mexico 1 year: $60, 2 years: $105. All other countries 1 year: $85, 2 years: $160 (payable in U.S. funds drawn on U.S. banks). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International).

Canada Post PM40612608. Return Undeliverable Canadian Addresses to: Concrete Contractor, PO Box 25542, London, ON N6C 6B2.

Printed in the U.S.A.

It’s January, which means it’s a new year—which means it’s a new season for tradeshows, conferences, and expos. As we all return to Las Vegas, there are a few lessons learned from walking tradeshow floors for the past 15+ years.

EDITORIAL Editor

Jonathan Kozlowski jkozlowski@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Marcy Murphy

Kim Basham

KB Engineering Cheyenne, Wyo.

James Baty II

Note: These thoughts are on attending not exhibiting. “Exhibiting” is a whole different can of beans. Searching online for quick lessons for tradeshow attendees results in some fairly decent general advice. At top of the list of many of these is planning. I’ve tried “winging it” a couple of times; trust me, it doesn’t work well. Check out the schedule and use whatever tools that you know are going to be effective for you. I’ve written my days out in notebooks and attempted to rely on Outlook to alert me of my next appointment. I don’t recommend being solely reliant on this second option. Service is too spotty and popping out your phone mid-conversation is just awkward. Download the World of Concrete app. If anything, having a map in your pocket can be handy.

Sales Representative Mike Worley mworley@acbusinessmedia.com

JONATHAN KOZLOWSKI, EDITOR JKOZLOWSKI@ ACBUSINESSMEDIA.COM

JONATHAN KOZLOWSKI, EDITOR JKOZLOWSKI@ ACBUSINESSMEDIA.COM

Speaking of maps, part of a successful expo walkabout is direction. Before you go, ask yourself what you are looking for. Ask your team about inefficiencies or problems. Have a short list of brands that you want to visit and bring your questions. See if you can reserve a spot for a more personal conversation with a representative, though this might need to be done ahead of time to get on the schedule.

Remember to flip that coin on your busy schedule. Slow. Down. Leave time to wander the aisles and visit booths that catch your eye. Stop by the association and institution booths to chat. Watch a demo on something you’ve never seen before. Go back to that schedule and sign up for a seminar or two, or ten. On that note, check out the evening events to catch up with old friends and make a couple new ones.

What else? … you’ll be walking a lot so wear comfortable shoes. Bring two if you can and switch every other day.

Oh, and before I forget, and I think something quite important—if you have one, recharge or replace your watch’s battery.

As you read this, I’ll probably be walking the World of Concrete 2023 floor. If you find me, let’s talk. Grab my attention and let me know what issues are on your mind and what answers you’re looking for. Not at the show? My inbox is open, jkozlowski@acbusinessmedia.com.

It’s Vegas, so, good luck and stay safe. Thank you.

Jim

Cuviello Concrete Polished | Stained | Crafted Stevensville, Md.

Chris Klemaske

Concrete Foundations Association Mt. Vernon, Iowa

Dennis Purinton Purinton Builders, Inc. East Granby, Conn.

T.B. Penick & Sons, Inc. San Diego, Calif.

Sales Representative Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Kristin Pride kpride@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer ...................................... Kris Heineman

Brand Director, Supply Chain & Green Industry Jason Desarle

Brand Director, Construction Sean Dunphy VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director ............................................ Marina Mayer

GM, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

Director, Enterprise Sales Kay Ross-Baker

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.ConcreteContractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

Tadashi Soma (800) 538-5544 ext. 1267 tsoma@ACBusinessMedia.com

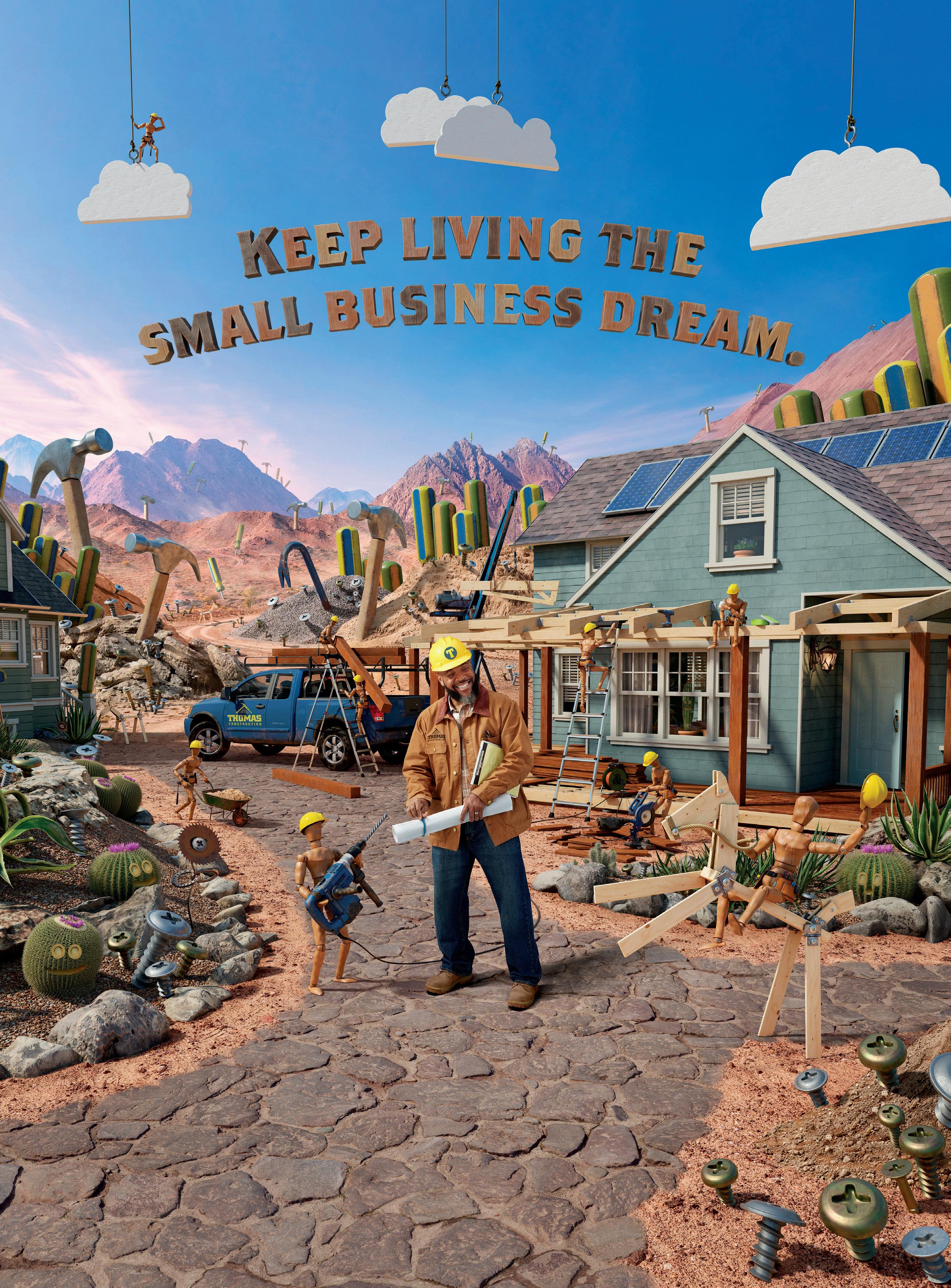

Protect your small business from reality with over 30+ customizable coverage options and personalized discounts. Get a quote in as little as 6 minutes at ProgressiveCommercial.com

Progressive Casualty Ins. Co. & affi liates. Coverages and discounts not available in all states or situations, for all vehicles or coverage selections.

Progressive Casualty Ins. Co. & affi liates. Coverages and discounts not available in all states or situations, for all vehicles or coverage selections.

With the world’s first configurator for 3D construction printers made by COBOD International, contractors and developers can now estimate the time to 3D print a specific building and calculate the amount of concrete materials needed. Users can start by configuring their 3D printer, modifying the printer width, length, and height. The configurator also makes it possible to calculate the time it takes to print out a specific structure and calculate the quantity of materials needed. Available as an app for Android and iOS devices and as a web app edition.

https://CONC.me/8v4s4e

Designed for aggregates, construction and demolition recycling, as well as site preparation, McCloskey International’s J4 jaw crusher includes new features for hard rock applications. Designed to withstand tough conditions, the J4 delivers high production due to its jaw chamber design and material flow. The large 42 in. by 28 in. jaw opening accommodates large feed sizes, contributing to production in material processing. The material path is enhanced with the 41.9 in. by 167.2 in. grizzly pan feeder under the hopper that allows for sizing of material with a variety of mesh options. Options of either a short pan feeder to suit the pre-screen or a double deck grizzly pre-screen are available for sizing of material based on the required end product. The J4 offers a choice of either a two deck or one and a half deck system.

https://CONC.me/oqmt45

Toro’s 2500 Electric Ultra Buggy features a compact design, zero emissions, zero-turn-radius steering, full recharge in eight hours with a 120-v wall outlet and hauling capabilities of up to 2,500 lbs. of material. Featuring a narrow width of 31.5 in., the electric Ultra Buggy can fit through a 3-ft. door with a crash bar. Built to be versatile and agile, it’s equipped with a fold-up platform so operators can choose to stand on or walk behind the unit. The fold-up platform serves a second purpose, as well, allowing the unit to fit inside elevators or on trailers for easy transport. The polyethylene tub has an increased thickness of 3/8 in., allowing operators to haul more than just concrete, and a steel tub is also available for applications that require it.

https://CONC.me/pbxv4k

For use on loaders and skid steer loaders from 4.5-11 tons, the MB Crusher padding bucket attachment features 1-ton weight and load capacity of 0.6 m3. The 2.20-m inlet mouth opening helps keep the tracks or wheels of the carrier machine clean. Greasing is centralized and done onsite. The coupling system promotes freedom of movement of the operating machine. . The MB-HDS-220 allows the rotors to be changed directly onsite by the operator. The bucket facilitates work on construction sites where there is a need to aerate packed topsoil.

https://CONC.me/4l54ca

KASK made adjustments to the Zenith X for the Zenith X2 ANSI Type II compliant safety helmet— though it still retains certifications for the ANSI Type I and EN 12492 clauses. The result was a slight modification to the internal structure. KASK will manufacture the Zenith X2 for the U.S. market and has begun production in their Chicago facility. “We believe the switch from the Zenith X to the Zenith X2, will have the best benefit for our customer,” says Alex Dabelstein, VP of sales KASK Safety. “There is essentially zero learning curve, and no risk as the product has proven itself in the market across all types of applications globally. “

https://CONC.me/jz21lp

The DEWALT POWERSTACK 20V MAX 5Ah Battery builds upon the POWERSTACK platform providing performance for many DEWALT cordless power tools.

• 50% more power

• 50% more work per charge making it DEWALT’s most efficient battery in its class

• Provides up to 2x longer lifespan

• The non-marring over-molded rubber base helps to protect finished surfaces

Compatible with all DEWALT 20V MAX tools and chargers, it features a 3-LED fuel gauge that displays the battery’s state-of-charge, helping users avoid unplanned work stoppages.

https://CONC.me/61d4qr

From troweling competitions, equipment demos, concrete pumps on display, thousands of concrete tools, and innovative decorative concrete solutions; find these booths, events, and happenings at World of Concrete.

While cruising the show, take a moment and stop by our booth—we’d love to hear from you!

With 2022 marking the 20-year history of the Concrete Contractor magazine, we’re celebrating during the show. Attendees are welcome to pop on by and get their photo taken as if they are on the cover themselves, sponsored by Milwaukee Tool. Come join us in some fun! Find us at C4137.

Curb Roller Manufacturing, one of the world leaders in shaped concrete roller screeds, will offer hands-on product demonstrations and provide an opportunity to see and operate the innovative concrete equipment, including the patented Lynx Screed modular system and the battery-powered Badger Curb Maker for monolithic pours. Find these and other products and technologies that improve productivity for curb and gutter work as well as flatwork. Get hands-on with Curb Roller at O31934.

The Concrete Industry Management Program have announced the donation of a 2023 Peterbilt Model 567 with a Con-Tech Manufacturing extreme-duty mixer. The silent auction will be held from 11 to 12:45 p.m. with the live auction beginning at 1 p.m.

The family-owned and operated company will feature its SafetyTech Outrigger Pads, FiberMax Crane Pads, ProStack Cribbing, SlatTrax, and other Ground and Access Mats at the show.

Find a group of brand-new concrete solution launches at Milwaukee Tool! They’re excited to continue revolutionizing the light equipment market with their cordless system MX FUEL providing even more solutions to increase performance and productivity while removing the frustrations and limitations of gasoline and power cords. More details will be released at O30361 and online.

• 115-in. BBC set back front

• PACCAR PX-9 diesel engine rated with 380 HP and 1,250 lb.-ft.

• CARB Emissions Warranty included

• 236-in. wheelbase

• 10.5-yard HP drum with 46-in. discharge opening

• Tip-up hopper

• R/E electric cab controls with Omnex wireless option

• PMP Gearbox with 52,000 ft./lbs. of torque

Join the auction at room N262, Jan. 18.

FiberMax Crane Pads are designed to withstand extremely high pressures from construction equipment like concrete pump trucks. They effectively spread outrigger loads and create stability when extra rigidity is needed and weight is a concern.

DICA’s SafetyTech Outrigger Pads and ProStack Slot Lock Cribbing Blocks can be used together to help keep concrete pumpers level when working in tight spaces and uneven terrain.

Find DICA’s showcase of products at C4864.

AC Business Media | Photo by Jonathan Kozlowski

Milwaukee Tool

Curb Roller Manufacturing

The Concrete Industry Management Program

AC Business Media | Photo by Jonathan Kozlowski

Milwaukee Tool

Curb Roller Manufacturing

The Concrete Industry Management Program

Watson-Marlow Fluid Technology

Solutions is showcasing its Bredel hose pumps for handling of concrete. Abrasive grouting mix is no problem for Bredel pumps, which can be used to replace progressive cavity and centrifugal pumps for a variety of applications. Bredel hose pumps offer reduced downtime, maintenance, and costs for spare parts. Visit Booth C6454 to view heavyduty pumps ideal for handling abrasive concrete.

WORK TRUCK LIVE!

Work Truck Live! will highlight innovations in the design and configuration of work trucks and accessories that will help contractors increase safety and productivity. Work Truck Live! is designed to bring attention to companies that manufacture chassis and supply up-fitting accessories, as well as develop technologies with which contractors can customize their vehicles to the job.

World of Concrete is debuting a Ride and Drive experience that provides attendees the opportunity to test-drive select Class 1- Class 7 vehicles. Approved drivers and passengers experience the feel of the vehicle in a closed, short loop located near the Las Vegas Convention Center. Ride and Drive will take place on Tuesday and Wednesday. Look for the Work Truck LIVE! pavilion in the Central Hall.

The Concrete Foundations Association worked with ViewPoint to develop a national campaign designed to promote workforce development and career opportunities in the concrete construction industry. Check out the video first-hand and more at C4605.

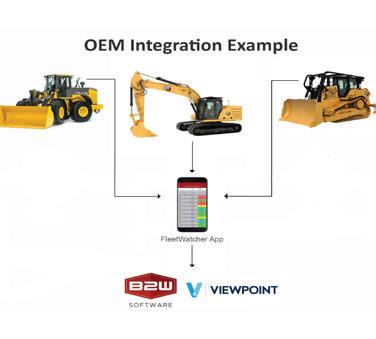

As paving contractors and heavy construction contractors increasingly adopt technology for greater efficiency, FleetWatcher is one of the leaders by seamlessly integrating with popular software programs. Providing a seamless flow of data further enhances the functionality of programs like Viewpoint, B2W, OnStation, and many more.

Representatives will be on hand to demonstrate the telematics platforms and discuss integration with B2W, Viewpoint, OnStation, and many other popular software programs. Connect with FleetWatcher at N1869.

Catch the Briggs & Stratton (Vanguard) swappable batteries in action on concept applications right on the show floor. Contractors can see why lithium batteries are more scalable, serviceable, and sustainable for any application. Sign up and reserve your spot to see a live demo! Find the Vanguard 10kWh Lithium-Ion battery, the NEW lithium-Ion Diecast Aluminium Casing Battery, Vanguard 400 EFI/ETC Engine, the 40.0 Gross HP EFI/ETC V-Twin Engine and more. Explore Vanguard’s solutions at O31434.

A first for World of Concrete—Join a distinguished panel of women who have gained success in the concrete and construction industries and represent diverse areas of expertise such as concrete materials, specifications and performance; jobsite scheduling, productivity and generational workforce; finance management, job costs, profitability and cash flow; and managing field supervisors, foremen and field personnel.

These frequent presenters and contributors to the World of Concrete Education Program will share their history, perspectives, challenges, and growth experiences in the male-dominated construction industry. This session is scheduled for Jan. 17, 1-4 p.m. There is a fee to attend.

Find these and more World of Concrete coverage at https://CONC.me/WOC

Watson-Marlow Fluid Technology Solutions Briggs and Stratton (Vanguard)

Water and water infiltration is the natural enemy of concrete causing below-grade reinforcement corrosion, surface scaling, aggregate expansion, mold, etc. Here are three methods you can use to protect against water-related damage in concrete Concrete has been used as a strong, durable building material for thousands of years, dating back to many ancient concrete structures that are still standing to this day. Yet, it has one fundamental enemy it can’t escape—water. With increased humidity and rainstorms, water infiltration can lead to issues such as below-grade reinforcement corrosion, surface scaling, aggregate expansion, mold growth, and more.

In order to provide sufficient workability for proper placement, compaction, mixing and transportation to the jobsite, most plant-batched concrete will contain excess water required to hydrate or chemically react with the cement. As concrete hardens, this excess water evaporates from the concrete and creates a network of fine capillaries and internal pores—essentially forming a “dense sponge” that allows water to transport through the surface, causing damage as a result.

Crystalline waterproofing and silane and siloxane water repellents are three innovative reactive technologies that concrete contractors can use to combat water-related damage and ensure optimal concrete protection.

Crystalline waterproofing materials can be applied as a slurry coating to the surface of an existing concrete structure, such as a foundation wall or floor slab, and broadcast onto fresh horizontal

concrete and troweled into the surface. An alternative approach involves adding the admixture directly into the concrete at the batch plant. In all cases, the waterproofing function includes both complex chemical and physical mechanisms that take place within the concrete surface.

As concrete hardens, the reaction between water and cement generates chemical by-products, which reside in the capillaries and pores of the concrete. When crystalline waterproofing materials are applied, the by-products of cement hydration and the crystalline chemicals produce a chemical reaction with very dense, non-soluble crystal formations. This crystalline formation will only occur where moisture is present, forming in the pores, capillary tracts, and shrinkage cracks of the concrete— the same routes susceptible to water ingress. Chemical diffusion can carry these crystalline materials deep into the concrete, plugging the voids in concrete and becoming an integral, permanent part of the structure.

In lieu of penetrating from the surface as seen with a coating application, adding crystalline waterproofing chemicals to the concrete at the batch plant ensures that the crystalline formation occurs uniformly throughout the slab

or structure. In addition, by adding crystalline chemicals directly to the concrete mix at the time of batching, the same crystal growth and waterproofing functions take place in a quicker, more cost-effective manner because labor associated with a surface treatment application is eliminated. Procedural sequence for addition will vary according to the type of batch, plant operation, and equipment. For most mixtures, the dosage rate of integral crystalline waterproofing admixture is 1-2%, based on the amount of cementitious material in the mix.

The use of a waterproofing coating can be undesirable in some cases due to aesthetics or the desire for a simpler application process. Certain concrete applications do not need to be fully waterproofed but instead can function properly with a water repellent treatment, such as silane and siloxane.

Derived from the silicone molecule, silane and siloxane create an envelope of protection that can extend the life of substrates even in difficult environments. Both are UV stable, reduce efflorescence and freeze-thaw damage, are highly wear-resistant, and permit the

Contractors can use a masonry brush, spray, or trowel to apply a crystalline waterproofing coating to concrete. The coat should be thick but even.

Contractors can use a masonry brush, spray, or trowel to apply a crystalline waterproofing coating to concrete. The coat should be thick but even.

substrate to breathe—in turn allowing interior moisture vapor to escape. Water repellent sealers can be used to impart water repellency to a variety of porous substrates, including poured-in-place or precast concrete.

Silane and siloxane sealers reveal little to no change in the appearance of the substrates to which they are applied. There is no gloss, color change, or hiding of the substrate underneath. This is important when water protection is required for architectural finishes where a waterproofing coating would hide the decorative feature.

While silanes and siloxanes provide excellent water repellency to surfaces, each has its own performance differences.

Corrosion and scaling due to exposure to salt spray and chemical deicing products is a primary cause of concrete deterioration. Silane-based sealers provide an extremely effective solution to prevent deterioration from water and salt. Silanes penetrate deep

because of their extremely small molecular size and ability to chemically bond with silica to form a permanent attachment to the water-repellent molecule. This creates a deep hydrophobic layer that prevents water and waterborne contaminants from entering the substrate and causing premature deterioration, while simultaneously leaving the surface with a completely invisible finish and providing a chemical “screen” that prevents chloride ions from reaching embedded steel in concrete.

Crystalline waterproofing uses the available water in concrete to allow crystals to grow and self-seal cracks and keep water at bay. This crystalline formation will only occur where moisture is present, forming in the pores, capillary tracts, and shrinkage cracks of the concrete—the same routes susceptible to water ingress.

The Euclid Chemical Company

Once applied, silane water repellents penetrate into the s ubstrate and react chemically with calcium hydroxide to form a

The Euclid Chemical Company

The Euclid Chemical Company

hydrophobic, water-repellent resin within the pores and on the surface. In order for this chemical reaction to take place, the substrate must be alkaline (high pH) and contain calcium hydroxide. Because silanes do not change the skid or slip resistance of concrete, they are ideal for surfaces such as walkways, bridges, and roadways. Silanes are not effective in sealing other substrates such as natural stone, clay, brick, or wood.

Because silanes consist of smaller molecules than siloxanes, they will typically penetrate deeper than siloxanes and thus perform better on dense surfaces such as poured-in-place and precast concrete. A consequence of this molecular size is that silanes are quite volatile. Therefore, the solids content of a silane water repellent should be high enough to compensate for the evaporation of reactive material during application and curing.

Siloxanes have a slightly larger molecular structure and are somewhat effective on substrates up to medium porosity, such as heavyweight, smooth-faced, and concrete block. Despite being closely related, the siloxane-based chemical composition does not encourage rapid evaporation. The solids content and cost of a siloxane-based sealer is typically lower than that of silanes.

Unlike silanes, siloxanes are not dependent on substrate pH to react. They can react with atmospheric moisture, as well as any moisture in the substrate, to form the hydrophobic resin. For this reason, siloxanes are ideal for treating non-cementitious building materials such as brick, stucco, and stone.

Jennifer Crisman is director of marketing services at The Euclid Chemical Company, a leading manufacturer of specialty concrete and masonry construction solutions. A 20-plus-year industry veteran, Crisman manages the marketing communications activities for Euclid’s expansive line of admixtures, fiber reinforcement, concrete repair products, flooring materials, and decorative concrete systems.

Use this QR code to download the FREE whitepaper, “Moisture in Concrete: An Essential Guide to Protect Concrete Structures.” https://CONC.me/bll7ul

The Stinger electric flex shaft vibrator is rugged, lightweight, and powerful. The 115v electric motor has been designed to run cool with the power and torque to handle todays concrete loads. The stinger attaches to competitor core and casing with quick disconnect adapters.

Trimble and Hilti have announced that the Hilti ON!Track asset management system will integrate with Trimble Viewpoint Vista, an ERP solution within the Trimble Construction One suite. The integration is Hilti’s first North American integration with an enterprise resource planning solution, which provides a solution for unified tool tracking and automatic job allocation, giving contractors one source of truth for tracking and managing their tools and equipment. Now instead of having to manually look, call or guess where tools are or how much to invoice based on their use, contractors can more easily track their tools and equipment in one place and automatically know how much—and where—they were used so that an accurate amount of equipment time can be invoiced. This eliminates the need to spend clerical time manually inputting utilization data, and even manually tracking it in the field.

https://CONC.me/5telq6

Verizon Connect released updates to the Reveal fleet management platform. The features are designed to help mobile workforce managers looking to make investment and planning decisions as they consider moving to electric vehicles (EVs) from their gasoline-powered ones. For those customers who have already made the leap to EVs, the new updates to Reveal enable customers to manage their EVs and gas-powered vehicles, as well as monitor uptime by seeing charging and battery status information all from one platform.

https://CONC.me/4me8il

StructionSite launched its Locations tool. Capable of analyzing reality capture health based on project locations, the tool gives users the ability to filter and view images by different parameters like date range, location, tags and image quality for an understanding of what happened on a jobsite and when. Many construction projects are broken down by a location hierarchy: building, floor, area and room. The Locations feature in StructionSite matches this model, thus integrating with the customer’s project management and scheduling workflows. This enables teams to search a location and see all the latest images, RFIs and work status to make critically informed decisions.

https://CONC.me/ri9csi

4M Analytics offers the 4Map solution for locating underground utilities including oil and gas lines, water pipes, electricity and telecommunications lines and renewable energy infrastructure. This software does not require hiring labor onsite. The company is in the process of making the data of underground utilities available through a single dashboard that will eventually cover the entire U.S. Using this, engineers will be able to see exactly where utilities are, no matter where in the U.S. they’re working, reducing the time it takes to locate them. The solution is designed for civil engineering firms, engineering procurement construction firms, contractors and subsurface utility engineering firms in industries including transportation, oil and gas, water and electricity, renewable energy, telecommunications and more.

https://CONC.me/gb8j27

Software-as-a-service (SaaS) and a new generation of powerful apps are finally putting sophisticated business tools in the hands of even the smallest mom-and-pop contractors. Maybe your contracting business is competing directly with much larger organizations with formalized and rigorous business processes that give their customers visibility and predictability.

Or maybe you are just trying to match customers’ expectations for Amazon-like ease of doing business. Regardless, now is a great time to be alive.

This is because the business software tools that deliver best-in-class business processes are now affordable to the masses of contractors who need them. Business software can help a small contractor:

• Present a more professional face to the customer with digital tools on the web and on mobile devices on the job site

• Increase utilization of employees and equipment

• Increase total throughput and productivity

• Achieve project visibility and controls with regard to cost and timeline

• Schedule work, people and equipment more intelligently

• Track, manage and make decisions based on profit

This affordable but powerful software suite addresses the entire quote-tocash lifecycle starting with customer relationship management (CRM) including online service booking,

marketing automation, quoting, scheduling, reporting, job checklists and invoicing.

“We still believe there is a huge opportunity—and we are not near being done with the product,” says Jobber Senior Director of Marketing Nick Keyko. “There are a lot more services like consumer project financing that we can embed in our product—capital to help our users maintaining cash flow as they wait to get paid. The core of Jobber is the operations side, but we see a lot more opportunity for technology that has historically only been available to the big and bring the cost way down to the smaller businesses.”

This addition of third-party services and offerings embedded in SaaS software products—a business equivalent of in-app purchases in consumer apps—is interesting for a few reasons. First, it can put valuable services like gap financing for contractors or project financing for customers, in the hands of contractors in the most convenient way.

But the heart of Jobber from a functional standpoint is job scheduling, where they compete most often with Quickbooks Time, formerly Tsheets, which Intuit acquired in 2017 and is not as deep or robust as Jobber.

“Quickbooks is an accounting package, and we do not aspire to replace them for that,” Keyko says. “It is not built for contracting, and you are taking an accounting platform and using it in a way it is not meant to be. It is not exactly the best way to run a business. What we are trying to do is educate the businesses out

there that there is something now built directly for you. It understands how your business works and that it is different from, say, a restaurant or a hair salon.”

Jobber’s market is broad, and they have identified 40 different subindustries within contracting that their product will address. The software will address the needs of a one-person operation up to a company with several dozen employees.

“Anything where you are servicing a house or small commercial business is a good fit for Jobber,” Keyko says. “A handyman doing some concrete, for instance, can find a solution with Jobber. In terms of the contracting side of the business, contractors tend to use the whole suite. From the front end of winning the job, to strong quoting and estimating. We give contractors the ability to add optional line items in their quotes so they can upsell customers to new features and can pay for Jobber just like that.”

Hippo.Build helps small and mediumsized (SME) construction companies connect existing siloed software solutions into one single cloud space with the competitive advantage of Enterprise Resource Planning (ERP).

Most ERP applications work by consolidating business data in a single, centralized application. What makes Hippo.Build different is that it works more by connecting data and processes from the handful of technologies a contractor already uses, reducing complexity.

The product should be understood in terms of what the product does in its current state and where it will be functionally in a short space of time. Right now, the software is pulling inventory or stock information from the jobsite through chatbots back into a dashboard. Hippo. Build integrates with project management software to send reminders to on-site staff of tasks that need to be completed and then pulling back into the system a report of the results or productivity. Hippo.Build also handles punch in/punch out of the on-site staff to support payroll.

The inventory management tools help with placing orders before contractors need the material, timing orders and arrival to dovetail material arrival to synchronize with when they are needed on site. Currently, the BIM model is supported directly with the inventory management model, so that in an as-built, a contractor can provide deep information including serial traceability, incept date, amount of time a material or component was on site, and more. While it is not a sophisticated supply chain management application, the inventory module is an alternative to guesstimating on inventory—something that may happen a lot in smaller contracting environments. The tool is normally used to track bigger materials allotments like PVC piping, cement, sand, metal, with guidance on what to track often coming from a product owner.

The software includes a document management system similar to Dropbox or Google Drive that automatically pulls documents in from systems Hippo.Build integrates with.

Task management functionality in Hippo.Build is focused on delegating tasks to workers on a job site with information on what the task entails. At the end of the day, the worker can confirm they have completed the task and upload a photo of their work. The software can accommodate 3D scans, Lidar and other visual evidence and documents, but most users are now just uploading standard JPG photos. Analytics then call out tasks that are on track versus delays, enabling management by exception.

Payroll functionality should have functionality for simple time and work codes, generating a time sheet report for each person at the end of the month with the ability to switch between time codes.

Dibbs is a digital marketplace for bidding, buying, and selling products and services targeted at home repair services. The tool delivers a verticalized construction market of homeowners, contractors, suppliers and retailers and also gives a contractor a central place to manage the entire quote-to-cash process, including online payments.

“Quotes, contracts, payments and supplies, all in one place,” touts a YouTube video from Dibbs. This ability to facilitate the quote-to cash lifecycle is what makes Dibbs more than a marketplace, yet more affordable from a fees and percentages standpoint than Angi, formerly Angie’s List. This tool, which is currently rolling out nationwide, may give the small home contractor a system of record that formalizes business processes better than ad hoc approaches they currently may be using.

Hippo.BuildBefore founding Dibbs, CEO Luke Fleury was rehabbing homes, and from that front line vantage point noticed a real gap in the industry that could be filled by transformational technology.

“Bidding is disorganized and time consuming,” Fleury says. “I am not tech savvy at all—but with our co-founders, we came up with the solution of a digital marketplace for service and materials. A project owner can enter a budget and timeline, location, what they need done and upload building plans. And then a seller can bid on that material that is being requested… contractors so far have really not used technology. Our goal is to get contractors on our site to see how easy it is to source their bids in a more efficient way.”

What sets Dibbs apart from standard online service directories is its inclusion of materials, so construction materials vendors can bid for their portion of the job and coordinate availability of materials on site according to the plan. Co-founder Case Olszewski brought a background in technology and digital customer experiences, augmenting Fleury’s street cred as a residential contractor. A third co-founder, Rob DeSantis, brought board and tech startup experience and helped architect the company.

While the initial product launch will focus strictly on service and material bidding transactions, the company does have on the roadmap an analytics offering that will give contractors the ability to track bids that are received to do things like determine what an attractive market price for a service or materials expenditure would be in that local market.

By virtue of the way it facilitates transactions, Dibbs will also serve as a contract management solution, and contractors can lay out in the tool payment terms, including up-front and milestone payments and final payment after inspection.

Unsure which technology will help your business? Try this assistant at IronPros.com! We’ll recommend the best construction specific solutions.

https://CONC.me/CONTECH

Business software tools that deliver best-in-case business processes are now affordable to the masses of contractors who need them.

Creating a safety culture for your construction company is built from a foundation of great leadership. The strategy behind the safety program at Concrete Strategies.

Workers can feel it when a company believes in safety.

For ready-mix concrete supplier Concrete Strategies, “safety” is a living, breathing concept. An unfaltering but ever-adapting entity that places a palpable net throughout the construction jobsite.

“We’re not perfect. Nobody in the business is perfect, but we have placed a great deal of emphasis on building a safety culture that’s lasting, viable, and is real,” says Joe Rock, Vice President of Risk Management for Concrete Strategies.

With over 1,000 employees nationwide, the St. Louis, Missouribased company is a full-service concrete contractor with a nationwide footprint and subsidiary of the national designbuild firm Clayco. They’ve been listed in the Top 20 Firms in Concrete by Engineering News Record for two years running (#8 in 2022 and #11 in 2021), was one of the Top 600 Specialty Contractors, and received the 2021 “Excellent In Achievement” Tilt-Up Achievement Award for their work on a $52 million, 160,000 sq. ft. Benson Hill facility in Creve Coeur, Missouri.

From a safety standpoint, the company has high expectations in terms of how people are to perform. They call it their “rules to live by.” This expectation starts at the top with the executive leadership and continues throughout the company all the way down to the apprentice laborer or carpenter, finishers, etc. “Our

expectations are that people are going to be personally responsible,” says Rock. After training and providing personal protective equipment, each person is personally responsible for their own safety. They’ve integrated a simple process for addressing non-compliance or people putting themselves in harm’s way.

Further reinforcing its safety strategy, the company has over 30 full-time safety professionals on staff. Not only that but the president, Pat Moriarty, and executives of Concrete Strategies makes it a focus through their words and actions while on jobsites and meeting workers. They call this process “management safety audits.” Leaders of the company will visit jobsites and engage with the workforce via a twoway dialogue regarding what’s going well, the challenges, the struggles, and discuss what they can help with.

“This demonstrates the commitment from leadership that has to be in a company that is placing safety at the forefront of their goals and objectives,” says Rock. “We want to be the safest concrete company in the nation. And if we’re the safest company in the nation, we’ll be the safest concrete company in the world—that’s our goal.” Concrete Strategies has been recognized in 2022 by the American Society of Concrete Contractors as a “Four Star” company in their “Safety Training Assessment & Recognition (S.T.A.R.) Program. One of only a very few in the Nation to earn this recognition. The company’s OSHA

• Daily safety meetings covering previous concerns and the day’s plans

• Create a safety culture where workers are able to bring attention to hazards and/or hazardous practices

• Provide stop-work authority should conditions or behaviors be unsafe

• Invest in leadership training, for communication, coaching, and guiding your crew

recordable rate has been less than 50% of the national average for the concrete industry overall for the last two years and counting.

There’s a litany of considerations and actions that they go through each and every single day. Each morning, explains Josh Ross, Safety Manager of Concrete Strategies, St. Louis division, the crews gather to conduct “stretch and flex” exercises. From there, the general contractor announces any issues they had the previous day, upcoming events, anything safety-related, where every trade will be working, and what they’ll be doing. “From there, we break off in a pre-task safety analysis (PTSA) huddle where we go through what we’re going to be doing that day, the hazards involved and what we’re going to do to mitigate those hazards,” he says.

These groups allow everyone to have a voice with the more experienced workers sharing their experience with the new hands and the newer workers sharing their knowledge obtained from working for other companies. Notes are then added to the PTSA. Doing this allows everyone to be involved and workers “own” the scope of work that day.

Constantly looking to improve, the team encourages anyone to bring anything to their attention so it can be corrected. Everybody on the jobsite also has “stop work” authority where anyone, from the most experienced superintended to the brand-new apprentice, can stop work if they feel there’s an unsafe condition or unsafe behavior.

The safety conversation is constant and it starts from the top. Concrete Strategies wants to lead by example and places special emphasis on leadership training. They’ve heavily invested time and money over the last few years for leadership training for field leaders, foremen, and superintendents. While great at their job, someone may not have the “soft skills” of leadership like how best to communicate, coach, mentor, and guide. The company has integrated several programs: a bi-weekly construction leadership video series; an annual meeting with speakers to discuss leadership; and a weekly call to focus on key metrics and objectives that they want leaders to focus on.

“[These] initiatives have paid dividends. Not only for developing our safety culture but also for improving productivity and quality as well as the general alignment between senior management and field leaders and workforce,” says Rock.

Concrete Strategies has made a commitment to achieve a vibrant— living—safety culture. As part of that commitment, when hiring safety professionals Rock looks for three qualities: passion for the work, ability to communicate effectively, and leadership skills. “When I first came here, we had just got to illustrate graphically. We had four fulltime sales professionals. We’re now up to 30,” says Rock. “This is a challenging time in the construction industry to hire

and keep employees. We’re constantly on the lookout for good safety pros.”

But if a concrete construction company only has safety people that care about safety, it won’t make much of a safety culture. You need coaches and people at hand who are available, a subject matter expert people can go to when personnel have questions. In order to create a safety culture, you need people whose primary focus everyday is coaching for safety performance, not only the hazards.

The development of the company’s safety culture comes from two elements. “It’s recognition by top management that safety has a role to play and with the understanding that it has to be more than just the safety professionals focused on safety if we’re going to have a real, vibrant, living safety culture,” says Rock.

Part of their corrective and preventative action is the encouragement to suggest ideas. They reward a $100 gift card for the best ideas on a weekly basis. “I have guys bringing issues up to me that we get corrected out in the field,” says Ross.

He continues, “We’ve had people stop work because of an unsafe condition. Just because you’re working safely doesn’t mean the people next to you are. We had a worker stop plumbers [that] were in an excavation over 10 ft. deep with no protection whatsoever. Our worker went over, stopped the work, and told the guy to get out of the hole. They brought it to the attention of the general contractor who made the worker do it the correct way, the safe way. Maybe saved that guy’s life.”

Additional stopped work examples include a superintendent noticing that the crane road had been flooded and stopped work until rock was placed and stabilized, another was on a tilt-up project when one of their truck drivers stopped plumbers from working near the braces that could be damaged or destabilize a panel.

Despite their effort, they aren’t working in a Nirvana where everything’s perfect, but it’s the little things that can add up to create a different kind of company. “That’s one of our goals. Our motto is ‘More to the pour.’ And part of that is when we show up on a jobsite, we bring that safety component with us,” says Rock.

Many construction companies may

focus on popular indicators like the OSHA recordable rate, Dart rate, insurance rating, and EMR. While Concrete Strategies does track these “lagging” metrics, they go a step further by looking at “leading” indicators such as safety audits, management involvement, training, and corrective and preventative actions. They use EHS Insight, a mobile application to house all the company’s paperwork, policies, procedures, training, toolbox talks, etc. It’s where they document observations and record corrections.

“Obviously we are going to be compliant with all OHSA regulations, but I think we go over and above the regulations in a lot of areas,” says Rock.

One of the first things Concrete Strategies does for corrective and preventative actions is documentation and communication. According to Rock, writing a corrective action and EHS Insight takes about two minutes. A small investment of time to keep everyone and the site safe.

For contractors developing their own safety programs, Rock sees that the work starts at the top. “First and foremost, ownership needs to get with the people that are running work and explain that safety is the top priority. If the person that signs the checks and the person that assigns the work every day have a high level of care and concern for their workforce, everybody else will too.”

For smaller contractors who might not have the budget to have a full-time safety professional on staff, Rock suggests considering contacting their insurance company to conduct an audit and provide recommendations. The cost of prevention greatly outweighs the price of lost production, workers’ compensation expenses, as well as the hidden costs like decreased morale.

“If it’s [safety] important to the people that run the company, it’s going to be important to the workers,” he says.

“And that doesn’t cost a dime.”

For more information visit https://CONC.me/gi2pd4

The dead load was reduced by 25-30% using lightweight concrete in the floors of the Comcast Center. Courtesy of the Expanded, Shale, Clay and Slate Institute

Choosing a concrete that can maximize our favorite building material’s potential is one step, but are there benefits from structural lightweight concrete (SLC)?

So much depends upon a structure’s foundation. This mostly unseen element can mean the difference between a long-lasting building and one that will need substantial repairs over its lifetime. As such, it’s important that concrete professionals take every step possible to ensure a foundation that can withstand all the forces of nature that act on a building. Doing so will increase their customer’s long-term satisfaction with their work and improve their reputation within the industry—both of which can unlock more business overall.

But other than following best practices for foundations, what can contractors do to improve the quality of foundations they pour? Choosing concrete that maximizes its potential is one step toward more resilient foundations. Structural lightweight concrete (SLC) made from expanded shale, clay or slate (ESCS) aggregate not only provides several benefits to make foundations more durable, but it also alleviates concerns about tensile strength associated with other lightweight concretes. The following will explore these qualities and how they can improve the quality of all concrete elements, including foundations.

SLC has a lower density than standard concrete, which can reduce the deadload of an entire structure. A lighter building will reduce pressures exerted on the soils beneath the foundation, thereby reducing the degree to which the ground below the structure will compress. This mitigates the tendency of foundation failure due to settling, since the soil will endure less pressure. Of course, the amount of deadload reduction depends on

A comparison of 1 lb. of lightweight concrete aggregate to other conventional options. Courtesy of the Expanded, Shale, Clay and Slate Institute

A comparison of 1 lb. of lightweight concrete aggregate to other conventional options. Courtesy of the Expanded, Shale, Clay and Slate Institute

how much concrete is used throughout a building. However, given that SLC is typically 25-35% lighter than normal-weight concrete, it can contribute to a lighter structure even when used only in the floors and foundation.

Additionally, the coefficient of thermal expansion is lower and the thermal conductivity of SLC can be half that of normal-weight concrete. As a result, it reacts to temperature change more slowly, thereby lowering the risk of cracking caused by extreme differences in temperature. While these characteristics are often touted as contributing to more energyefficient and fire-resistant structures, they also contribute to foundations that resist cracking due to temperature differences between internal and external temperatures because SLC more uniformly distributes the temperature-related stresses.

Both qualities improve the long-term resiliency of a foundation for longer-lasting structures. This can lead both to more satisfied building owners and potentially more business from word-of-mouth recommendations.

In addition to SLC’s physical characteristics, the material also benefits foundation construction due to its compositional properties. Early age shrinkage and cracking can be the first steps toward a crumbling foundation. However, because SLC cures internally, it reduces the tendency of concrete to shrink and crack during curing. Essentially, the absorbed moisture within the ESCS aggregate is released as the cement hydrates, contributing to a more uniform curing process. It also strengthens the bond at the interface between two materials (aggregate particles and cementitious paste), furthering mitigating concrete’s tendency to crack.

The increased bond strength between lightweight aggregates and cementitious paste also reduces SLC’s permeability. As reported in a 2008 paper presented at the Concrete Bridge Conference, SLC can have an average chloride permeability rating of 989 coulombs, less than half of the code-driven limits for commercial and infrastructure projects. Generally, highly permeable concrete allows ingress of harmful chemicals, which can lead to the corrosion of steel

rebar via chloride attack. This weakens the structural integrity of the concrete. For foundations, a less permeable concrete is more able to evade chloride and sulfate attack from the soil. It also contributes to foundations that more readily resist damage from freeze-thaw cycles, since there would be fewer chances for water to find its way into and widen micro-cracks.

These benefits are both immediately noticeable and detectable over the course of a foundation’s service life—offering crucial proof points to the improved quality of concrete used.

While the above qualities can help maximize the immediate and long-term potential of concrete foundations, it is important to note that SLC has a lower tensile strength than standard concretes. This can increase the likelihood of cracking when soils shift from settling, frost heave or other forms of movement. However, the similarity of the stiffness of the cementitious paste and the lightweight aggregate particle reduces stress concentrations within the concrete. This can be readily seen, as cracks in normal-weight concrete tend to go around the aggregate, while cracks in SLC often propagate through the lightweight aggregate. This “strain compatibility” reduces the tendency for SLC to crack under normal loading.

According to a 2003 paper by Frank Dehn, building materials and concrete construction professor and director of the Material Testing and Research Laboratory, SLC made with ESCS lightweight aggregate displays fracture behaviors somewhere between other SLCs and standard concretes. This translates to a ductility that is closer to that of normal-weight concrete, which can be improved further through the incorporation of fibers or steel reinforcements. Though these methods for improving the ductility can be used on all types of SLC, the SLC made with ESCS requires minimal adjustments, reducing any significant changes to the material’s performance capabilities.

By reducing the ductility differences

between SLC and normal-weight concrete, ESCS lightweight aggregates help contractors pour more resilient foundations while offsetting a major concern some professionals have when considering types of concrete. As such, SLC made with ESCS can drastically improve the quality of concrete foundations, and high-quality foundations often require fewer repairs and maintenance through the years, potentially saving building owners money on the long-term cost of a project. Communicating these benefits during negotiations can improve the efficacy of a contractor’s bid (even when that bid includes higher material costs).

Pouring the most structurally sound foundations largely depends on following best practices for a given site and environment. That said, contractors can improve the immediate and long-term performance of their foundations by looking at the type of concrete they use. SLC mitigates the tendency of concrete to crack during curing and the material’s overall permeability. Further, it improves concrete’s thermal resilience for reduced strain from differences between internal and external temperatures, all while lessening the deadload a structure places on the soil.

These qualities sideline many issues that crack concrete, which improves a foundation’s long-term structural viability. When SLC is made with ESCS, it also increases the material’s ability to mitigate the damage a crack can cause. Contractors can use this information both to improve the concrete they pour and to increase the satisfaction of their customers.

Jeffrey Speck is the General Manager of Marketing and Technical Sales at Arcosa Lightweight. Jeff has more than 30 years’ experience in the lightweight aggregate industry. He serves on the Expanded Shale, Clay and Slate Institute (ESCSI) Board of Directors and actively participates in numerous committees.

Article provided by the Expanded Shale, Clay and Slate Institute.

For more information visit https://CONC.me/t3fj3o

When constructing the second largest cement plant in North America with an eye toward not only increasing capacity and meeting current market demands but also achieving sustainability goals, the entire building team brought creativity and innovation to the task. Heidelberg Materials, formerly known as Lehigh Hanson, expects to begin clinker production at its new state-ofthe-art facility on the Mitchell Cement Plant and Terminal grounds, located in Mitchell, Indiana, in early 2023. Construction of the Mitchell K4 project, which required approximately 1,000 workers, broke ground in late 2019, but experienced delays due to COVID-19 and resumed in September 2020 at an accelerated pace. The $600+ million project is the largest capital investment in the history of Heidelberg Materials.

“We really have an all-star team working on the project. The Heidelberg Materials team overseeing the plant construction operated as the general contractor and this group has done an exceptional job managing the many challenges presented by COVID-19 and supply chain issues. Additionally, the construction team and plant team have cooperated at a high level to keep construction moving and minimize the impact to current operations,” says Tracy Crowther, Mitchell Plant Manager, Heidelberg Materials.

The construction team and trade workers, along with Heidelberg Materials’ employees and vendors, accomplished several “firsts” on the project. Noteworthy was a clinker storage dome that measures 219 ft. (66.8 m) in diameter and 164 ft. (50.2 m) high with a storage capacity of 169,000 metric tons. Dome Technology, a specialty contractor based in Idaho Falls, Idaho, developed the proprietary shotcrete construction method used on the dome and was also responsible for setting the deep foundations and ring beams as well as constructing tunnels and an at-grade entry for front-end loaders. According to Dome Technology, the Mitchell plant dome is the largest clinker storage in the Western Hemisphere and second in the world only to a Romanian structure Dome Technology built in 2008. The erection process included inflating a customsized, air-supported PVC airform, installing rebar inside the membrane, and applying shotcrete in layers to its surface. The membrane stayed in place as a permanent waterproof membrane. Prior to the dome’s construction, contractors evaluated mix pumpability and ease of placement using mockups and test panels, as well as conducted strength tests and pulled core samples. The finished dome is high-strength, resilient and long-lasting, and has a high tolerance for differential settlement.

Allowing a substantial increase in production capacity, the Heidelberg Materials’ Mitchell Cement Plant (Mitchell, Indiana) project brought approximately 1,000 construction jobs into the area and 50 new full-time jobs. Heidelberg Materials

The site’s current three kilns were replaced with a single kiln that measures 80 m long and has a 5.4-m diameter. The kiln will have a production capacity of 7,000 metric tons per day. Construction also included a 170 ft. (52 m) tall blending silo that was slip-poured and required 1,900 cubic yards of concrete to construct; a 416 ft. (127 m) tall five-stage steel preheater tower whose foundation is constructed of 3,400 cubic yards of concrete; and a 29,400-sq.-ft. packhouse.

“Everyone on the Mitchell team, from operations to project management to government affairs, is constantly

The building team of the second-largest cement plant in North America had an eye toward not only increasing capacity and meeting current market demands, but also achieving sustainability goals.

A “topping out” ceremony for the Mitchell Cement Plant was held in August 2022. It is expected to be commissioned in early 2023. Heidelberg Materials

searching for new and innovative ways for the company to lower our energy use as well as our carbon emissions,” says Axel Conrads, Midwest Region President, Heidelberg Materials. “Although we have a lot of ‘firsts’ associated with the facility already, we believe those are only the beginning and there are many more ‘firsts’ yet to come.”

Sustainability targets for the K4 facility are in line with the Portland Cement Association (PCA) Roadmap to Carbon Neutrality and include increasing the use of portland-limestone cement (PLC), continuing energy efficiency improvements, and fueling the plant with natural gas with a continued effort at innovations using alternative fuels.

According to the PCA, universal acceptance of PLC— a type of blended cement that contains a greater percentage of limestone than traditional portland cement— will reduce clinker consumption and decrease emissions. The Mitchell plant not only produces, but used in its construction, a proprietary PLC known as EcoCemPLC, which has as much as 10% more limestone content than ordinary cement. It uses the same components and has the same yields as ASTM Type I-II/AASHTO Type I portland cement and has equivalent performance, meeting ASTM C595 Type IL standards. It requires less energy to produce, thereby lowering the carbon emissions associated with cement production. EcoCemPLC is available in bulk and bag and is ideal for use in the production of concrete block and pavers, for concrete pavement and soil stabilization and for ready-mixed concrete applications. For the clinker dome alone, crews sprayed 7,000 cubic yards of EcoCemPLC-enhanced shotcrete.

The PCA encourages improving energy efficiency during cement production as a means of reducing the amount of CO2 emitted for each ton of product. The Mitchell kiln will produce clinker using 100% natural gas, reducing carbon emissions of clinker production by 25-30%.

Carbon capture, utilization, and storage is identified in the PCA Roadmap as one of the pathways for unlocking emissions reductions along the cement and concrete value chain because it directly avoids a significant portion of cement manufacturing emissions. The Mitchell facility was selected by the U.S. Department of Energy’s Office of Fossil Energy and Carbon Management to conduct a front-end engineering design (FEED) study on carbon capture. The Department awarded Heidelberg Materials (then Lehigh Hanson) approximately $3.7 million toward the project, and the company will contribute about $1.1 million in additional funds, bringing the total project value to around $4.8 million.

The FEED study will involve retrofitting Mitsubishi Heavy Industries America Inc.’s carbon capture technology, which is expected to capture and sequester approximately two million metric tons of CO2 per year, or 95% of the facility’s CO2 emissions. The study will evaluate the cost and performance, including site-specific considerations for fullscale implementation as well as examine the positive social, economic, and environmental benefits.

The new Mitchell plant is significant for its geographic region, being one of the largest investments ever made in Lawrence County. It is expected to provide approximately 50 new fulltime jobs, growing to more than 170 full-time employees. It will also help ease cement supply constraints in the industry, producing four times the amount of cement compared to the existing facility, with total annual cement production expected to be 2.4 million tons.

All of the Mitchell Cement Plant’s clinker is channeled through its dome, providing:

• 2.4 million tons annual cement production (expected)

• 169,000 metric tons of storage capacity

• 140,000 live metric tons (minimum)

• Plus a reserve of 29,000 tons

Construction efforts included implementation of smart motor control centers and other cuttingedge technologies that will improve plant operations, as well as enhanced bulk loading and package output. The distribution terminal will accommodate 32,000 tons of additional cement storage and the company expanded its terminal network to bring cement closer to customer locations.

For bagged products, the plant has an automated rotary-type packing machine capable of filling 3,600 full-sized (92 lb.) bags per hour. Capacity was also added to the company’s rail network, with approximately 1,000 additional rail cars leased to move the additional product volume and ensure transport availability. An abandoned rail yard near the site was purchased and renovated, providing the infrastructure necessary to house the additional cars.

At a time when the concrete industry is making every effort to reduce carbon emissions, Heidelberg Materials’ Mitchell plant represents a major stride forward. Its four-fold increase in cement production will also mean a significant easing of current cement supply constraints.

As a member of AOE, a subsidiary of the American Concrete Institute, Kristin Dispenza has 30 years of writing and editorial experience in the architecture/engineering/construction industry.

For more information visit https://CONC.me/3s00km

Attachments allow concrete to be economically recycled on site, saving on aggregate, trucking and dedicated crushing plants.

Equipment used to process concrete on site typically includes various kinds of crushers, whether it be a jaw crusher or a crusher plant, or pulverizers, hammers and universal processor attachments. Crusher and shaft screener buckets and drum cutters can also be used to accurately size concrete materials. According to MB Crusher, crusher buckets reduce hauling fees by crushing the material directly on site for immediate reuse.

Many attachments can be used for processing concrete on a jobsite. “The product that is most useful for this process will be determined by the specific task to be accomplished and the jobsite conditions,” says Rich Elliott, product and application specialist, Epiroc. “Taking down a concrete structure (building, bridge, foundation, etc.) may require a different attachment than processing concrete that is in a pile.”

For example, deconstruction of a building, bridge or structure will be best suited for a multi-processor or concrete cracking attachment. Yet, other contractors may prefer a hydraulic breaker for this task.

Understand options and the tradeoffs before choosing the attachment. “We have the Combi Cutter with three separate jaw sets,” says Elliott. Universal, steel and pulverizer jaw sets can be changed in 30 minutes or less on site to easily adapt to the job requirements. “We also offer a Concrete Buster [for] where noise pollution and

vibration are an issue when working on structures and/ or foundation demolition. There is the Demolition Pulverizer, which has a single moving jaw and is configured as a straight jaw, and the Bulk Pulverizer, which has a curved jaw like a bucket.”

No single attachment is the best solution for every job. “This is completely dependent on the end use for the concrete,” says Chad Wood, Genesis product development engineer. “Are you feeding an on-site crusher, or pulverizing concrete to a reusable size?

In many applications, mobile crushing buckets are an alternative to mobile crushing plants. Throughput varies and is a function of the material hardness and density. REMU

pulverizer attachment and a universal processor, consider the pros and cons associated with each choice.

“If feeding a crusher, a dedicated concrete cracker-style tool will most efficiently get the concrete down to a size that you can feed a crusher or haul off site,” he points out. “If you are processing concrete to a size that is reusable on site, then a dedicated pulverizer or linkage pulverizer would be your tool of choice. These tools would downsize the concrete into 3-in. minus, if necessary, as well as make clean rebar that can be taken directly to a recycling center.”

When choosing between a dedicated

According to Wood, the dedicated pulverizer offers a larger jaw size, more power and a lighter weight in some instances. The universal processor offers more versatility in processing multiple types of material. Without the universal processor, a contractor may need multiple attachments or machines on a site, which may be difficult on small sites or for smaller contractors.

“There is a trade-off with a universal processor,” says Wood. “To have the versatility of being able to process multiple materials with one tool, you give up some performance and productivity. Universal processors typically will have a smaller jaw or less power than a similar-size dedicated tool.”

Elliott adds, “Typically, for the same

size carrier that a dedicated pulverizer would fit on, it would have a larger jaw opening to allow larger pieces of concrete.”

It makes a difference whether the attachment is being used to pull a concrete structure apart or process concrete that has been piled up. “A dedicated pulverizer is typically best used for material that is loose (already on the ground),” says Elliott. “These have one stationary jaw and one moving jaw. They come in two different styles — a straight jaw configuration and one with a curved jaw to assist with grabbing concrete that is in a pile.

“The universal pulverizer is a better product to use for demolition of concrete structures because there are two moving jaws,” he continues. “If one jaw contacts the material first, the other jaw will quickly catch up. Once the pressure is equalized, then both jaws will start to crush/cut/ pulverize the material.”

Separating concrete and rebar is possible with both the dedicated pulverizer

attachment and the universal processor with a pulverizer jaw set. “If you have a concrete cracker-style jaw set installed in a universal processor, you may not be able to separate all the rebar as this type of jaw typically makes larger chunks of concrete,” says Wood.

Note that the pulverizer should not be relied upon to remove all metal from the concrete. “There may be small pieces of rebar that may get mixed into the concrete and a magnet would be helpful to gather the smaller steel pieces,” says Elliott.

It’s worth noting that hydraulic-powered attachments are not the only solutions for processing concrete. “Mechanical pulverizers can be very effective at downsizing concrete and can work very quickly compared to a hydraulically powered attachment,” Wood states. “Also, they are typically a significantly lower upfront investment cost. The downside to a mechanical pulverizer is it relies on the bucket cylinder and linkage of the excavator for its power, which is less than the power generated by a hydraulically

Sealing concrete cracks, joints, and other distresses with a rigid repair material often fail as they grow brittle and break over time. The ideal solution provides both strength and flexibility.

TechCrete™ is a highly flexible concrete repair material that not only adjusts with the pavement but delivers the strength to support heavy loads, and the durability to resist cracking, delamination, and spalling.

Have your concrete and repair it, too, with TechCrete™. The most advanced, flexible, long-term repair solution for concrete.

Nationwide sales, service, and rentals. Learn more at crafco.com/sales

be mounted to, as well as the thickness and reinforcement inside of the concrete that needs to be processed,” says Elliott.

“This may also be a factor in the hydraulic kit that is on the specific carrier being used,” he points out. “The Combi Cutter (multiprocessor), Concrete Buster (concrete cracker) and Demolition Pulverizer all require a bidirectional auxiliary circuit and rotation circuit. The Bulk Pulverizer

will require a bidirectional circuit also, but can be fitted with or without the rotation device.”

Using pulverizing attachments is usually the first step in recycling concrete on the jobsite.

“The pulverizer does not produce any specific size material,” says Elliott. “The use of this product is strictly to reduce the size of concrete to manageable sizes and/or to separate the reinforcement from the concrete. This means that the material will vary in size from dust on up.

“If there is a specific size material than can be used on the same jobsite, then a crusher bucket can be used to process the larger pieces of concrete to a specific size,” he notes. “You could also use a bucket screener to separate material of a specific size or smaller.”

According to Wood, “With a dedicated pulverizer or a universal

processor with a pulverizer jaw set installed, you can achieve 3- to 4-in. minus material. This may take some additional time to achieve as you may need to take smaller bites of the concrete each time.”

Portable crushers, crushing buckets and screening attachments are necessary to produce accurate aggregate specifications on the jobsite. While production requirements on larger jobsites may require a portable crushing plant and the necessary support equipment, crusher buckets can prove an economical alternative on smaller projects.

Crusher bucket attachments allow concrete to be accurately sized and reused as aggregate on smaller jobsites with minimal support equipment.

“The advantages of bucket crushers are they are compact and can easily be transported and installed on any carrier with an auxiliary circuit,” says Elliott. “If the material can be used on

site, this will reduce transport costs. Limitations are they will not be able to produce as much as a portable crusher. Bucket crushers can produce material size from 3/4 to 6 in.”

With the right attachments, you can set up a cost-effective concrete recycling operation on even small or confined jobsites, saving the cost of trucking in expensive aggregate while reducing the amount of construction debris leaving the jobsite.

Curt Bennink has been writing about the construction industry for over 20 years.

Find crusher bucket benefits and limitations with this article at https://CONC.me/ktukqt

The 18V LXT lithium-ion brushless cordless rebar tying tool (XRT01ZK) takes the rebar tying process from two-hand to single-hand operation. It has a tying capacity of up to 5,300 ties of #3 x #3 diameter rebar on a single charge of an 18V LXT 5.0Ah battery, and can tie two #5 diameter bars or four #4 diameter bars in under 1 second.

• Digitally adjust tying strength to match various tension strength requirements

• Features two-mode operation (single or continuous wire tie actuation) and an easy-load design for wire reel changes with an automatic locking mechanism

https://CONC.me/yeq10u

The TyBot autonomous rebar tying robot is construction’s most advanced rebar installation equipment. With autonomous navigation of the working area with no pre-mapping, programming or calibration required, it is working on the jobsite within an hour of arrival and continuously identifies and ties up to 1,100 rebar intersections per hour. Operating day or night, rain or shine, it dramatically enhances workforce productivity, reduces schedule risk and increases capacity to perform more work while keeping crews safer. It is available as a leased option staffed with a trained and dedicated quality control technician.

https://CONC.me/fwga2t

SkyTy consists of a control station and a swarm of drones that automate rebar tying for concrete flatwork and other slabs. The swarm size can be varied with the size of the jobs and the schedule for completion. The technician manning the system identifies the rebar installation area and a divided section of the work area is assigned to each drone. After the technician selects the percentage of ties (50%, 75%,100%) and tying pattern, multiple drones are deployed. The drones can identify rebar intersections without using CAD files or programming utilizing computer vision technology. Each drone operates independently of others, is easily replaceable and will come back to the landing station for spool and battery replacement. Upon project completion, the control station provides a report of successful ties for quality control and archival.

https://CONC.me/ysu2d7

Diablo’s complete range of SDS-Plus and SDS-Max Rebar Demon 4-cutter full-carbide head hammer bits withstand the stress of high powered hammer drills and the impact of rebar cutting. Produced with Tri-Metal Diffusion Bonding technology, the full-carbide head resists heat and prevents breakage. Precision tip delivers the stability and accuracy required to produce fast, precise holes in concrete with rebar for ANSI approved anchor setting. Featuring a four-flute design for speed, this range provides faster dust removal, less wear, cleaner holes and faster drilling. Diablo hammer bits are optimized for maximum performance in corded and cordless SDS Plus and SDS Max rotary hammers.

• Diablo’s Rebar Demon range includes (74) hammer bits, covering a range of sizes:

• SDS-Plus range: 5/32 to 1-1/8 in.

• SDS-Max range: 3/8 to 2 in.

https://CONC.me/tajqzb

The 10.2-lb. RB401T-E’ has an automatic contact mechanism/switch that automatically forms a tie when pushed down over a rebar intersection.

• 4,000 ties per charge with a tie speed of approximately 1/2 second

• Handles applicable rebar size of #3 x #3 to #6 x #6

• Two-position handle adjustment enables user to find the most comfortable position for their height

• Long nose attachment allows tool to glide into rebar intersections with minimal effort

• Battery charge time of 65 minutes for a full charge or 50 minutes for 80% charge

https://CONC.me/jmopqg

Diablo’s complete range of SDS-Plus and SDS-Max Reba