March/April 2023 SPECIAL REPORT WRAPPING-UP WORLD OF CONCRETE 2023 20 ➜Contraction Joints New Developments for Slabs-On-Ground Save BuildMoney, Faster: Synthetic Macrofibers in Concrete Construction Exploring Your Concrete Screed Options Surface Prepping Blades Which Tool Is Best?

ALL MX FUEL™ BATTERIES ALL MX FUEL™

NEW

FUEL™ Vibratory Screed Kit

LEARN MORE BATTERIES FIT ™ EQUIPMENT

MX

MXF381-2CP

22 Save Money, Build Faster: Synthetic

One of the benefits is that it can cut time from the project schedule. But then, how do you know which macrofiber to use?

HOW TO

Now that the ACI Committee on Residential Concrete recognizes early contraction joints, here’s how the Trak Joint early contraction joint method can help reduce random cracks in your concrete slab.

FEATURES

We

How the right blade tooling choices can impact floor removal rates.

An

The ins and outs of antimicrobial surface protection.

Technology in the form of accounting software, project management software and AI has changed the construction processes and is constantly increasing the production for construction companies at their sites.

4 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete

10 Tips & Strategies

GFRP Composites in Construction

for Working with

SPECIAL REPORT

World of Concrete 2023 Wrap-Up

A few tips and strategies for contractors to work with glass fiber-reinforced polymer composites safely and efficiently.

16

saw

much, we couldn’t

EQUIPMENT FEATURE

Exploring

Concrete

Options

so

possibly include everything.

26

Your

Screed

Editor’s Letter

New Products 34 Product Focus Battery & Electric-Powered Tools & Equipment 42 The Last Placement INSIDE THE ACI

Contraction Joints: New Developments for

overview on how to carefully consider the screed types available to maximize ROI when purchasing this crucial equipment. DEPARTMENTS 6

8

30

Slabs-On-Ground

Best?

38 Surface Prepping Blades: Which Tool Is

39 Contamination Safety, From the Concrete Floor-Up

WHAT’S INSIDE MARCH/APRIL 2023 | Issue 2, Volume 24

Image courtesy of The Euclid Chemical Company

Macrofibers in Concrete Construction

FORM YOUR BUSINESS

How Technology is Increasing Productivity on Jobsites

40

COVER STORY Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher. Concrete Contractor (USPS 021-799, ISSN 1935-1887 (print); ISSN 24712302 (online) is published 6 times a year:January/February, March/April, May/June, July/August, September/October and November/December by AC Business Media, 201 N. Main Street, Ste 350, Fort Atkinson, WI 53538. Printed in the U.S.A. Periodicals postage paid at Fort Atkinson, WI, and additional entry offices. POSTMASTER: Send address changes to Concrete Contractor, PO Box 3605 Northbrook, IL 60065-3605 March/April 2023, Issue 2, Volume 24 One year subscription to non-qualified individuals: U.S. 1 year: $35, 2 years: $70. Canada & Mexico 1 year: $60, 2 years: $105. All other countries 1 year: $85, 2 years: $160 (payable in U.S. funds drawn on U.S. banks). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). Canada Post PM40612608. Return Undeliverable Canadian Addresses to: Concrete Contractor, PO Box 25542, London, ON N6C 6B2. Printed in the U.S.A.

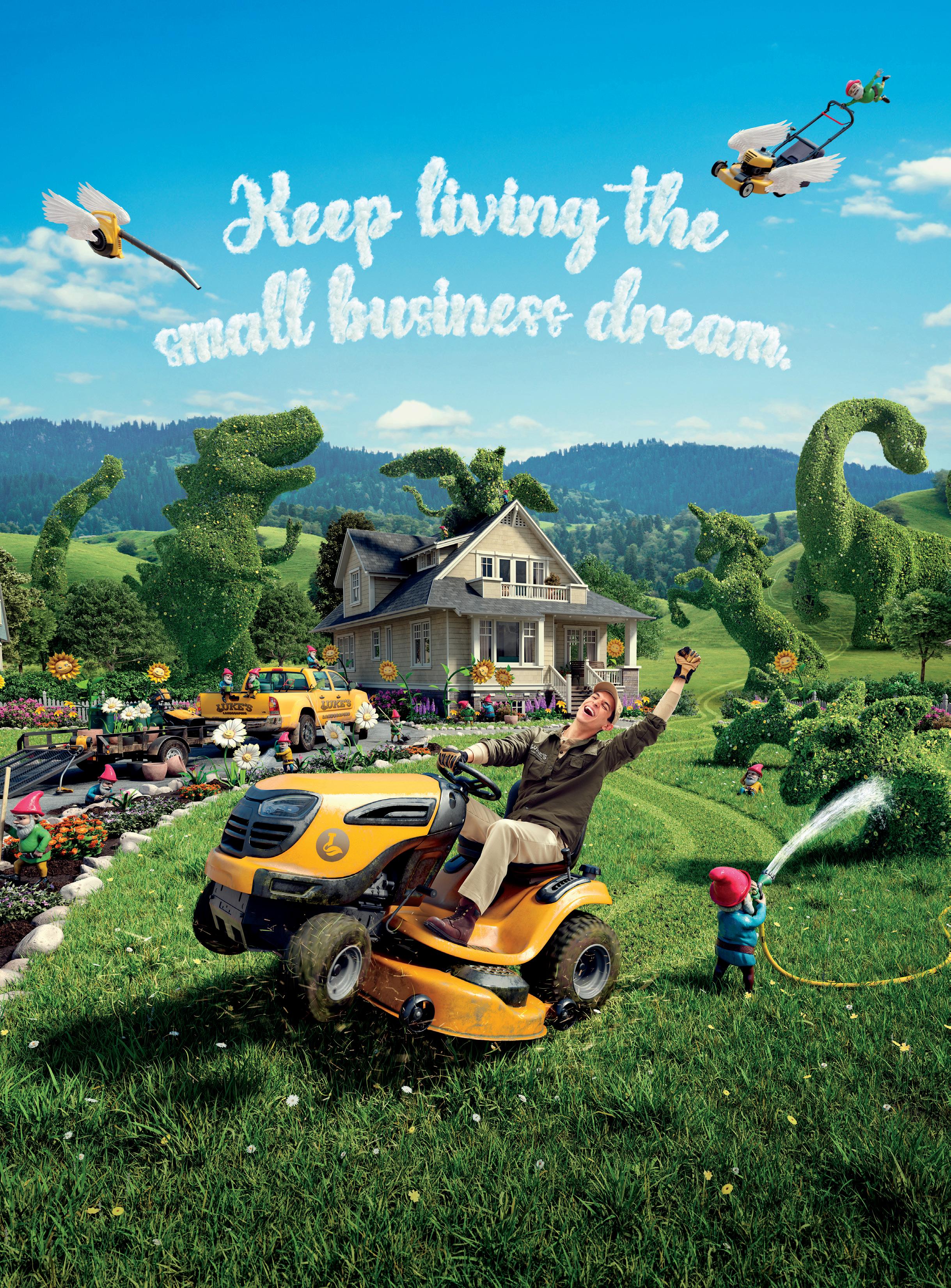

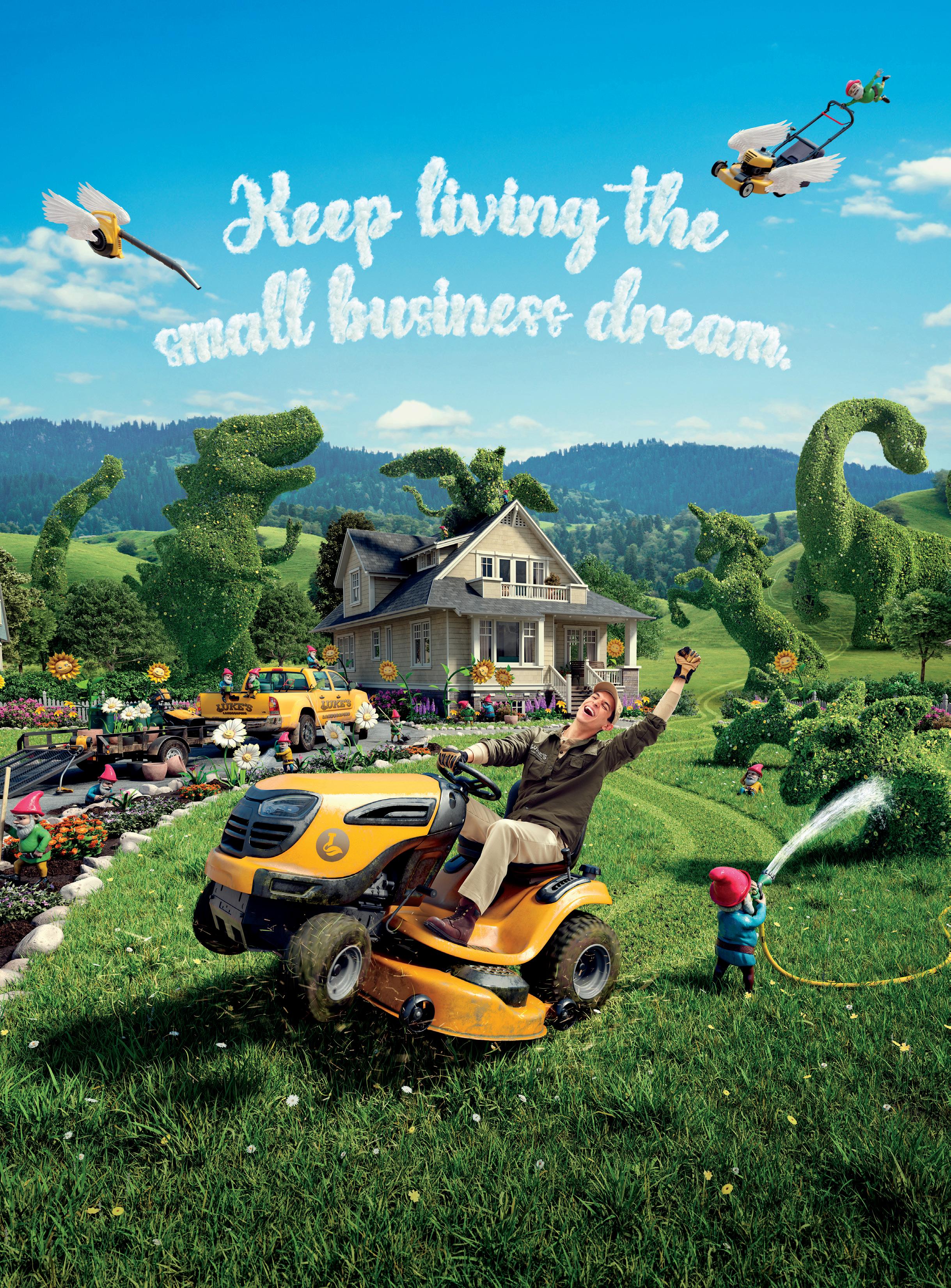

Progressive Casualty Ins. Co. & affi liates. Coverages and discounts not available in all states or situations, for all vehicles or coverage selections. Protect your small business from reality with over 30+ customizable coverage options and personalized discounts. Get a quote in as little as 6 minutes at ProgressiveCommercial.com

With Feet Sore, We Are Home

Welcome home from World of Concrete! I hope you’ve recovered, taken stock of the stack of business cards, and maybe even signed that purchase of a new machine, tool, or product. Later in this issue, you’ll find a handful of pages of the many happenings we saw during the show (see page 16). But with the show taking up three convention center halls and three outside lots, we aren’t able to fit in everything. Check out the pages and then find more in an online collection with additional images and happenings.

Despite doing as much as we could—we weren’t able to see EVERYTHING from the show. (There’s only so much time in the day.) For that, I pose a question: What was the one thing that stood out for you?

It’s been years in the making, but one thing we did notice was the doubledown on the battery-powered tools and equipment. Lithium-ion batteries have been around for sure but each year manufacturers seem to take advantage of the comments customers like yourselves are telling them. It’s working. Keep it up.

From just off the top of our heads, expect 50+ new cordless tools and likely more major equipment machines to be battery-powered by the end of the year (and we’re greatly underestimating). On top of that, it’s the further advancement and integration of communication technology for asset management and tracking. These solutions are becoming more intuitive and smart. Not only will they allow contractors to know how much battery life a pack has, but its location, what it’s powering, how long, maintenance reports, and more. One brand even gave us a chance to preview a collection of prototypes.

How far will cordless take us? We don’t know until we find that bubble, but the further expansion of battery technology is clear. While there are some advantages— the solution has to be right for you, the work you do, and your company.

Yes, we put in miles every day. Maybe next year we’ll track. Anyone up for a challenge? World of Concrete 2024 returns for its 50th year, January 23-25. It’ll be your chance to be in Vegas before the city hosts the Super Bowl.

But wait! There’s More!

Don’t think our tradeshow season is over; we’ve only just begun. It’s been years since but 2023 marks the return of CONEXPO on US concrete. I don’t know about you but our calendar is getting packed and meeting requests are filling our inboxes. To help us all out keep everything straight, our friends at Equipment Today put together a guide for the show. Find the digital edition through our library at issuu.com/forconstructionpros.com. See you out there!

ADVISORY BOARD

Kim Basham

KB Engineering Cheyenne, Wyo.

James Baty II Concrete Foundations Association Mt. Vernon, Iowa Dennis Purinton Purinton Builders, Inc. East Granby, Conn.

Jim Cuviello Cuviello Concrete Polished | Stained | Crafted Stevensville, Md.

Chris Klemaske T.B. Penick & Sons, Inc. San Diego, Calif.

EDITORIAL

Editor Jonathan Kozlowski jkozlowski@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

AUDIENCE

Audience Development Manager Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director Marcy Murphy

ADVERTISING/SALES

Sales Representative Mike Worley mworley@acbusinessmedia.com

Sales Representative Nikki Lawson nlawson@acbusinessmedia.com

Sales Representative Tadashi Soma tsoma@acbusinessmedia.com

Sales Representative Kristin Pride kpride@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer ...................................... Kris Heineman

Brand Director, Supply Chain & Green Industry Jason Desarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director ............................................ Marina Mayer

GM, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.ConcreteContractor@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 tsoma@ACBusinessMedia.com

EDITOR’S LETTER

6 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete

JONATHAN KOZLOWSKI, EDITOR JKOZLOWSKI@ ACBUSINESSMEDIA.COM

WWW.FORCONSTRUCTIONPROS.COM/CONCRETE Published by AC BUSINESS MEDIA 201 N. Main Street, Suite 350 Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com Concrete Contractor is the Official Media Sponsor of the CFA Foundation Company Certification Program

Backed by the industry’s best service. Industry-leading pumping pressure. Unparalleled quality. Unrivaled customer service. This is the kind of innovation you’ve come to expect from Blastcrete. The RMX-5000 allows contractors to pump harsh materials and longer distances, and features twice the mixer capacity of competitive machines. All this plus user-friendly features for easy maintenance make the RMX-5000 the most productive — and profitable — mixer-pump on the market.

CALL TODAY to learn more ways Blastcrete ingenuity can work for you. Blastcrete .com | 866.899.2418 | International 256.371.4950 RELENTLESS INGENUITY

D6536 Concrete Pump Attachment Piccola Rotary Gunite Machine

RMX-5000 Concrete Mixer-Pump

Schönox FP & HS Sturdy

The Schönox FP, one-part filling and priming compound, allows flooring professionals to prime and fill substrates in one step. The second product introduction provides a 10-lb. bag version of Schönox HS Sturdy, the company’s repair and smoothing compound with its patented hybrid active-dry technology. Tight project timeframes and limited numbers of skilled flooring professionals necessitate effective subfloor products and processes. Schönox FP, filling and priming compound, combines tasks, dries fast and works with a wide variety of substrates. Schönox FP integrates with Schönox repair, patching, smoothing and self-leveling compounds, providing contractors with a new technology, matching their fast-paced schedules.

https://CONC.me/u4nd9a

Panasonic TOUGHBOOK G2

The Panasonic TOUGHBOOK G2 is a rugged 2-in-1 detachable tablet with optional keyboard that features a modular design and user-removable expansion packs (xPAKs). With three modular expansion areas and up to 36 different xPAK combinations, users can customize the TOUGHBOOK G2 with features and functions such as a serial port, thermal camera, barcode reader, quick-release SSD and more. Despite its modular design, the device is backwards compatible with most TOUGHBOOK 20 and G1 docks. Featuring a 10.1-in. display and powered by Intel CoreTM i5 and i7 vPro processor (with Intel vPro technology), the TOUGHBOOK G2 is available with Windows 10 Pro. An evolution of the TOUGHBOOK G1 tablet and TOUGHBOOK 20 laptop, the TOUGHBOOK G2 combines computing power with enterprise security and device management benefits. To accommodate longer work schedules, the TOUGHBOOK G2 offers 18.5-hour battery life as standard for operations across manufacturing plants, utility fields, in federal civilian agencies and on the front line. Additionally, the TOUGHBOOK G2 now features three programmable buttons for customizing access to applications and shortcuts.

https://CONC.me/3pqopy

3D Silicate-Free Concrete Densifier by Ameripolish

Ameripolish’s 3D SF Densifier is a non-silicate densifying agent designed to add improved abrasion resistance, stain resistance and water repellency to exposed, colored and polished concrete with ion-exchange technology.

• Offers superior performance

• Improves the slab’s overall durability

• Designed for warehouses and retail floors

Ameripolish 3D SF is great for grind and seal or traditional polishing jobs, minimizing dust for healthier indoor air quality, and offers improved abrasion and stain resistance over conventional silicate densifiers. 3D SF was designed using ion-exchange chemistry to harden concrete surfaces. It is ready to use and covers 500-700 sq. ft. per gallon, depending on concrete porosity.

https://CONC.me/u96dts

The iQ1550 Dry-Cut Masonry Saw from iQ Power Tools

Milwaukee Tool WORKSKIN Warm Weather Hardhat Liner

Milwaukee Tool has expanded its lineup of workwear with the introduction of the WORKSKIN Warm Weather Hardhat Liner. The custom-built fabric is engineered to be breathable and wick moisture away from the body. This solution dries quickly and keeps users cool while working in warmer conditions. Constructed with flatlock seams and a four-way stretch fabric, the new hardhat liner is designed for next-to-skin comfort. To prevent odor-causing bacteria, the liner features anti-microbial technology and moisture-wicking layers. The WORKSKIN Warm Weather Hardhat Liner is designed for use with hard hats and safety helmets.

https://CONC.me/s5bssz

iQ Power Tools’ iQ1550 masonry saw is a huge leap forward in cutting technology. This is not your grandfather’s masonry saw. Whether materials to-be-cut are small or large, this tool is designed to save cutting time and increase productivity. The iQ1550 can tackle any jobsite, dry cutting and eliminating the dust cloud, allowing workers to increase their efficiency and productivity while maintaining a safe work environment. Equipped with a 230v Super Duty 3 HP saw motor and 3HP vac motor, it can handle cutting through 8” wall blocks and capture the dust. It’s integrated dust collection chamber holds 75 pounds of dust and with the automatic filter cleaning system maintenance is simple. Highly portable, the iQ1550 is equipped with high-floatation tires, forklift pockets, and a center lift point to make transportation easy.

• 21.5 in. Q-Drive blade with a 8 in. depth and a full 16 in. length of cut

• Saw Dimensions: 32-in. wide by 67-in. high by 51-in. length

• Unmatched cutting speed

Designed with soft start technology, the iQ Power Management System controls the power ramp up without the spike and the automatic filter cleaning system. Easily transported around the jobsite, the cutting performance and speed of the iQ1550 along with integrated dust collection makes it the ultimate saw for serious masonry and hardscape professionals.

https://CONC.me/f3upco

8 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete

NEW PRODUCTS

ACI Resource Centers — Southern California, Chicago/Midwest, and Mid-Atlantic (Coming Soon!)

Helping meet the increasing need for ACI knowledge through hands-on training, educational offerings, and on-demand access to ACI Certification programs. Designed for the trades, contractors, inspectors, designers, and engineers, ACI Resource Centers are a great fit for new-hire onboarding, employee education, and customer or member training. Learn more at ACICertification.org

How To Work With GFRP Composites

184,000 pieces of 38 mm GFRP

Mateen Pultron dowels were supplied In the construction upgrade project for the Port of Rotterdam Container Terminal, Netherlands (2019).

Pultron Composites

Concrete contractors are increasingly turning to GFRP (glass-fiber reinforced polymer) products as the building material of choice for concrete structures.

GFRP products are 1/4 the weight of steel which can often mean less need for heavy lifting equipment or extra labor. This can be factored into your scheduling when planning your labor, project timeline, and equipment requirements.

These composite materials are commonly used in concrete construction projects like retaining walls, foundations, and other reinforced structures.

The most common types of GFRP products used in these applications include rebar, rock bolts, dowels, form ties, and thermal insulation pins. They are corrosion-resistant, lightweight, nonelectrically conductive, excellent thermal insulators, easy to work with, have high durability, and have a long service life. They also provide excellent resistance to cracking, shrinking, and thermal expansion/contraction. With just a few tips and strategies, you can work with GFRP composites safely and efficiently to create long-lasting structures including bridges, concrete panels, seawalls, and more.

HOW TO STORE GFRP COMPOSITES

Take reasonable care and use common sense. Ensure the products aren’t damaged during storage. Products that are

designed to be buried in concrete do not need any UV resistance for the application, so typically do not have any UV inhibitors added. If they are to be stored for a long period of time, they should be covered or otherwise kept out of direct sunlight. They should be kept clean and inspected before use.

PURCHASE QUALITY GFRP PRODUCTS

With the right knowledge and the proper precautions, you can find reliable and high-quality GFRP products that will meet your needs. Choose a manufacturer with a comprehensive quality program and a laboratory equipped with a differential scanning

calorimeter (DSC) and a dynamic mechanical thermal analyzer (DMTA, photo on page 12). These specialized instruments are used to determine the glass transition temperature and degree of cure of composites. Both test methods are critical components of any pultrusion quality control program.

The strength, durability, and quality of the GFRP product you purchase are one of the most important criteria to consider, as it will directly affect your end product. Some GFRP products may be cheaper, but may not last as long or perform as well as higherquality materials.

10 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete HOW TO

Similar to steel rebar, GFRP reinforcement bars must be correctly placed and held firmly for the concrete pour. ACI 440 covers the design codes, product performance, and quality. Pultron Composites

A few tips and strategies for contractors to work with glass fiber-reinforced polymer composites safely and efficiently.

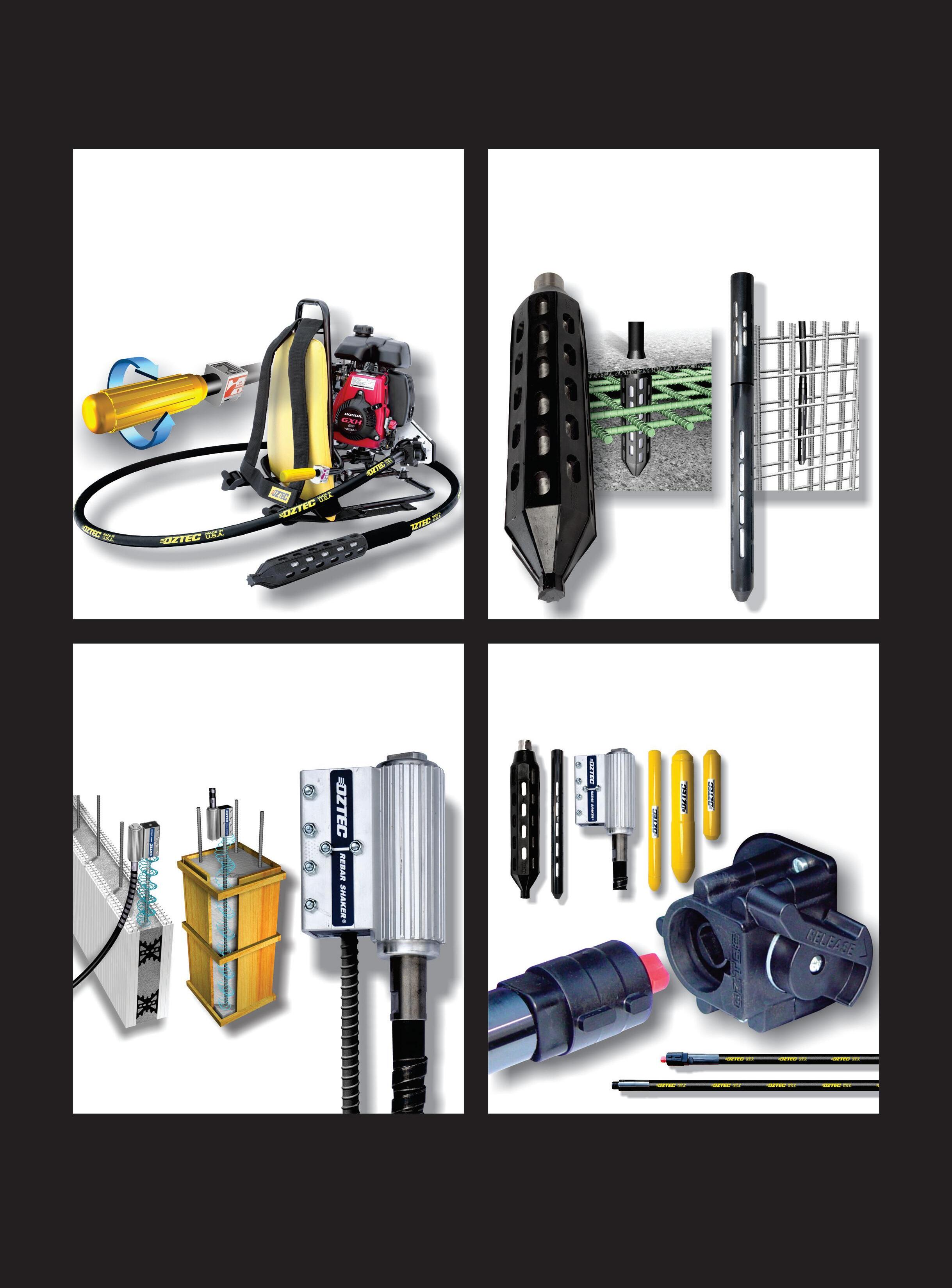

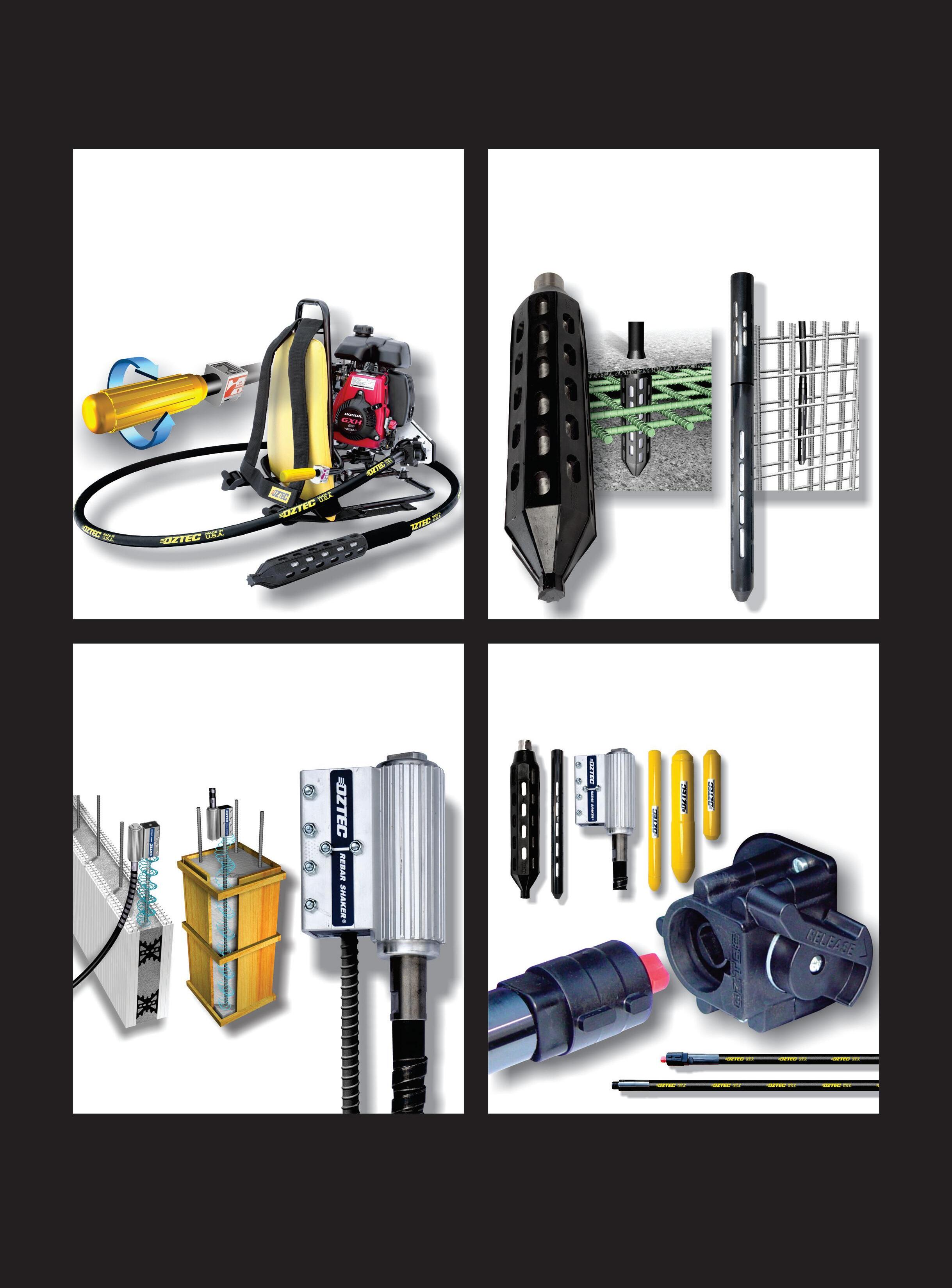

THE STINGER

The Stinger electric flex shaft vibrator is rugged, lightweight, and powerful. The 115v electric motor has been designed to run cool with the power and torque to handle todays concrete loads. The stinger attaches to competitor core and casing with quick disconnect adapters.

www.minnich-mfg.com

HOW TO WORK WITH GFRP PRODUCTS IN CONCRETE CONSTRUCTION

When working with GFRP composite products, there are some distinctions to be made. Rebar, dowels, and forms are good examples of how working with GFRP differs from working with steel or stainless steel.

Working With GFRP Rebars

The design of the structure and the differences between GFRP and other materials must be considered. For example, you can’t simply swap steel rebar for GFRP. The material properties are different, and these must be considered in the design. Fortunately, there are codes such as the ACI 440 series of documents, which covers design codes, product performance, and quality. The engineers should become familiar with these codes.

Similar to steel rebar, it must be correctly placed and held firmly for the concrete pour. Bars, except those to be placed in vertical mats, should be tied at every intersection when the spacing is more than 30 cm (12 in.) in any direction. Where the spacing

is less than this, the bars should be tied at every intersection or at alternate intersections. Ties maintain the position of the reinforcement during the pouring and setting of concrete. They do not need to provide permanent strength to the structure. Always ensure bars do not float upwards and out of position during concrete placement and consolidation. If movement is detected, the pour should be halted whilst additional support or fixtures are added. GFRP rebar can be used and tied in with steel bars. The same tying method as steel should be used in order to achieve the best performance.

Nicks, scrapes, and cuts that do not exceed 5% of the depth of the bar are acceptable. Beyond 5% we recommend the

replacement of the bar or using a lap splice on either side of the damaged bar. However, GFRP rebar is not like coated steel rebars, so small surface scratches do not need to be repaired to protect the bars from corrosion; they are corrosion-resistant all the way through.

Due to the nature of GFRP rebar, bends cannot be bent on-site. All bends are factory-made and delivered to exact

GFRP rock bolts can be installed with bolts in tunnels and mines. Pultron Composites

A dynamic mechanical thermal analysis test is done for quality testing of the GFRP’s full cure.

12 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete HOW TO CONTINUED

Pultron Composites

The Worldwide Leader in Concrete Paving Technology

GOMACO offers the full range of concrete slipform pavers, curb and gutter machines, trimmers, placer/ spreaders, texture/cure machines and bridge/canal finishing equipment. GOMACO equipment features our exclusive and proprietary G+® control system, created in-house by our software engineers from the wants and needs of contractors paving in the field. At the heart of GOMACO equipment is our passion for concrete and our commitment to our customers. We look forward to visiting with you about your upcoming paving projects and your concrete paving equipment needs. Our worldwide distributor network and our corporate team always stand ready to serve and assist you.

CONCRETE STREETS AND HIGHWAYS x AIRPORT RUNWAYS x CURB AND GUTTER x SIDEWALKS RECREATIONAL TRAILS x SAFETY BARRIER x BRIDGE PARAPET x BRIDGE DECKS x IRRIGATION CANALS GOMACO CORPORATION IN IDA GROVE, IOWA, USA x 712-364-3347 www.gomaco.com x info@gomaco.com

Central Hall -- C30280 Las Vegas Convention Center

specifications. A variety of shapes, stirrups, and bespoke bends can be produced.

Working With GFRP Dowels

GFRP dowels are designed for low bond strength, so do not require greasing or

other bond-breaking preparation methods. This makes them quick to install and long-lasting. GFRP dowels can be installed using standard installation methods including slip-form pavers, baskets, and dowel insertion machines.

Working With GFRP Form Ties

Most form-ties within the concrete are designed to be broken off or unscrewed. The remaining holes are then filled with mortar or ready-made plugs. This slows the process considerably, leading to lost production time and increased costs.

BOOTH #C32575

Copyright 2022 NLB Corp. | PSale_Hydro_22_001_v1 ™

©

14 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete HOW TO CONTINUED

Here, the GFRP for the Port of Rotterdam project, Mateen Pultron dowel are supplied ready for construction professionals. Pultron Composites

GFRP form-ties are designed to stay in the concrete and are sawn off when the concrete is set, leaving a concretecolored ‘plug’ that blends well with the concrete. No filling of holes with mortar is required.

SAFETY MEASURES FOR WORKING WITH GFRP PRODUCTS

Dust and fibers may cause temporary skin itching due to the glass fibers. When working with GFRP products during construction follow these health and safety tips. Standard health and safety practices used on construction sites are usually appropriate.

• Always wear protective eyewear, gloves, long sleeves, and long pants when handling any GFRP product.

• When cutting or drilling GFRP composite products, always wear a dust mask and eye protection to prevent irritation. Where possible, cut in a ventilated area.

• If glass fibers or dust come into contact with your eyes, flush with water for at least 15 minutes and contact a physician if the irritation persists.

Pete Renshaw is the Business Development Director at Pultron and serves as the Chief Technical Officer for Mateenbar Limited. He has over 25 years of experience working with pultruded composite product development.

Scan here for insight and announcements on rebar and accessories: https://CONC.me/rebar.

GFRP Rebar Plays Important Role in Weightman Bridge Reconstruction

The City of Niagara Falls, Canada, conducted a 4 million dollar project on the Weightman Bridge. The project included replacement of the complete bridge deck, the sidewalks, and the steel railings. The deck joints of the existing bridge were replaced by continuously reinforced flexible links.

Schock ComBAR was used for the reconstruction of the bridge deck and the sidewalk slabs. The rebar was used to reinforce the top layers of the deck and sidewalk slabs.

Find the full project profile at: https://CONC.me/be2kjt

This is the natural habitat for Brokk’s compact giants. With the perfect combination of power, operability and accessibility our demolition robots provide efficient solutions to increase profits. OUR KIND OF PLAYGROUND Brokk Inc. | Monroe, WA | 1-360-794-1277 | info@brokkinc.com | www.brokk.com

www.ForConstructionPros.com/Concrete MARCH/APRIL 2023 CONCRETE CONTRACTOR 15

BY JONATHAN KOZLOWSKI, EDITOR

World of Concrete 2023 Wrap-Up

We saw so much, we couldn’t possibly include everything.

With over 48,000 registered professionals, the 49th World of Concrete marked a banner year for the show. After a tough couple of years, I think it’s safe to say that the event is back on track. Jackie James, vicr president of WOC says the results exceeded their expectations, noting that “in-person attendance is on its way back to pre-pandemic levels.”

Wausau, Wisconsin-based Michael Schlund and Arron Kowalski won the SPEC MIX BRICKLAYER 500 competition, laying 759 bricks in one hour. This effort earned Schlund “World’s Best Bricklayer,” a new Ford F250 4x4 Super Duty truck, an Essick Pro12 Mixer, and more than $15,000 in cash and prizes.

Join us and the rest of the concrete industry in celebrating the 50-year anniversary of the show, January 23-35, 2024 (with education sessions starting on Jan. 22).

THE NEXT GENERATION OF CONCRETE

Hosted by Rick Yelton, editor-in-chief of WOC, students within the Concrete Industry Management (CIM) program were invited to present on their experiences and what they learned from their respective internships throughout the concrete industry. Students from California State University – Chico; Middle Tennessee State University; New Jersey Institute of Technology; and Texas State University presented an eightminute speech and answered two minutes of questions from the audience.

Student presentations were judged by three industry leaders to receive the 2022 Bob Weatherton Award plus a $2,500 scholarship. Afterward, one of the judges was so impressed with the quality of the presentations that they put up $5,000 of their own money providing a $1,000 scholarship to the next five runners-up.

16 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete SPECIAL REPORT » COLLECTED

The CIM auction broke records (again) this year rasing more than $2.1 million in gross revenue. Auction items included cement, fly ash, aggregate, concrete saws, drills, safety equipment, training sessions, reference books and software subscriptions, laptop computers, sports travel packages and golf and vacation travel packages and much more.

BREAKING THE BOOTH

Remote-controlled demolition machine manufacturer Brokk was busy during the show with the launch of the new My Brokk online support platform, two breaker attachments for the Brokk 900, (the BHB 1500 and BHB 1300) and the new Brokk 70—the smallest electric robot in the company’s range.

EQUIPMENT TRACKING, MADE EASIER

Dustin Garry, a 22-year construction industry veteran and CEO of DM Gary Holding Co., launched Rooster—a Kansas-based Construction Technology company—with the Rooster Asset Tracking System, an equipment management tool that captures powered, unpowered and heavy equipment activity and automates reporting for $1/month.

CALIBRATE YOUR CONCRETE SENSOR, QUICKER

From weather conditions, scheduling issues, or even last-minute changes to your mix order and delivery, since you never know what changes will come your way, Giatec’s new SmartRock Pro is a selfcalibrating maturity sensor with seven years of research behind it. Sensors detect the mix and utilize an AI algorithm to determine maturity and strength.

LONG LAG TIMES, BUT NO RECESSION

During his presentation, Portland Cement Association Chief Economist and Senior Vice President of Market Intelligence, Ed Sullivan, projected a gradual weakening of the U.S. economy under high inflation, rising interest rates and geopolitical turmoil. He cautioned that the impact of the infrastructure bill on the construction industry and the U.S. economy as a whole, will not be as much of a boon as many were hoping for either.

He stressed that there are long lag times to take into account when creating a forecast. These lag times range anywhere from 12-18 months, meaning the economy could possibly not reflect the impact of interest rate increases made by the Federal Reserve last spring, until winter 2023.

Plus, Sullivan says there’s a chance that the Fed could become more aggressive in its rate hikes because the economy has shown near-term resilience over the last year. If further hikes are made, the impact timetable can stretch into 2024. Find the full report at https://CONC.me/fj8c5a

COLLECT $200 AS YOU PASS THE BATCH PLANT

Founded by Mike Murray in 2012, Concrete Cares is a 501/c3 charitable group helping families and children battling cancer. The group is led by Mike and Donna Murray, Katie Murray, Bob and Laurie Banka, Kevin and Cathy Brunnemer and Rick and Leslie Hite. The goal is to help parents who have children going through cancer treatments by walking with them and assisting them with necessities such as rent, car and utility payments and food.

Banka’s company, Concrete Management Solutions decided that he could help raise funds for scholarships to the five Concrete Information Management programs as well as support Concrete Cares, by creating a “concrete” themed Monopoly board game, “ConcreteOpoly®,” revolving around the concrete and construction industry. Instead of the racecar, top hat, or dog, players can use a concrete truck, work boot, hard hat, and more landing on sponsored spaces or “jobsites” from companies supporting the organization ranging from small concrete contractors, admix and cement companies and ready

www.ForConstructionPros.com/Concrete MARCH/APRIL 2023 CONCRETE CONTRACTOR 17

https://www.gofundme.com/f/fight-cancer-the-concrete-way

mix producers. No detail was spared. Even the chance cards include concretethemed bonuses and penalties. You can find the game at https://concreteopoly.com

WHY USE A ROTATING TELEHANDLER?

Austin Bailey, sales manager of Merlo USA (photo at left) gave us a tour of the ROTO 50.35 S Plus featuring an 11,000 lb. capacity, a 115 ft. lift height, and stabilizers that extend out from below the machine. Sensors tell the machine where the stabilizers are located and automatically adjusts the load chart making the job that much easier with realtime information on their screen. That’s not all! Check out this video online at https://CONC.me/hws91i

EFFICIENT WORK ON THE JOBSITE

Mark Hanson and Alex Vollrath from ANA Inc. (photo page 20) the supplier of AIRMAN and (new for this year) MAC3 air tools spoke with us about the story behind the how the company became one the best players in the generator, air compressor, and power storage markets. With a focus on customer support and values, they use their experience to ensure products are the lowest cost of ownership, strong reliability, and jobsite performance. Alex walked us through the new Energy Boss hybrid energy system and how they can help contractors be more efficient. Watch the interview at https://CONC.me/j8h6vi

BROOM & CURE IN ONE MACHINE

Somero’s new Broom and Cure machine (page 17, bottom) combines a 14-ft. proprietary broom, spray-bar, and channel float head with precision-engineering to follow ACI curing guidelines. It was designed with space for 55-gallon

18 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete WORLD OF CONCRETE CONTINUED

Donations to Concrete Cares can be made through

FINISH TOUGH SURFACE PREP JOBS FAST

Tackle the most demanding removal jobs with SMITH FS351 DCS

Heavy-Duty Scarifiers.

SMITH FS351 DCS heavy-duty scarifiers are ideal for challenging removal applications such as leveling floors, grooving, and removing thick epoxy coatings.

PRODUCT FEATURES:

¡ Remove path up to 16 inches wide

¡ Precisely control cut depth with SMITH’s electronic DCS Depth Control System

¡ Self-propelled with variable speed drive for precise speed control

¡ Wide variety of cutters available, including PCD shaving drums

¡ Propane, Gasoline, and Electric models

© 2021 Graco Inc. 3J0220A 1/21 Printed in the U.S.A. Product covered by issued and pending patents, see graco.com/patents Gasoline 38 HP Kohler® EFI Propane 25 HP Kohler EFI Electric 20 HP 380/480v 3ph A GRACO COMPANY ®

AVAILABLE MODELS:

MADE IN THE USA WITH GLOBAL COMPONENTS LEARN MORE AT SMITHMFG.COM/FS351DCS DEPTH CONTROLSYSTEM PCD Shaving Drum

ADDING TO THE NURON TOO FAMILY

Hilti launched 30 new cordless tools adding to the Nuron battery platform (which now counts to over 100). The NCV4-22 Pencil concrete vibrator (above, right) was lightweight and moved the motor to the head. It was designed to help enable operators to vibrate concrete in the hardest to reach parts of the concrete pour with its narrow head and more than enough power to finish the job.

WOMEN OF CONCRETE 2023

Sponsored by the Women’s Association of Concrete Professionals, the featured artists of Diane Duncklee, Felicia Julien, Elise Yoder, and Caressa Roberts Bray, displayed their skill in the decorative concrete lot with a beautiful installation (photo page 18, bottom).

COMFORT & CONCRETE

A work boot as tough as concrete In an attempt to make a work boot as comfortable as a hiker, KEEN launched its new Fort Wayne style (above, left). Features include a direct-attach PU construction, carbon fiber toe, electrical hazard/electric shock resistant protection, and KEEN.DRY waterproof and breathable membrane.

PORTABLE PRECISION POWER

The Makinex 32kW Power Generator (above, center) is the smallest in its class containing advanced alternator technology, flexibility, and reliability. With less than 3% harmonic distortion, no transients, or voltage spikes on load rejection, this 32 kW Power Generator boasts clean, brushless, three-phase power.

20 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete WORLD OF CONCRETE CONT.

Tracer technology helps ensure accurate head height during the boom and cure process.

World

Concrete 2023

Find these and more photos from

of

https://conc.me/WOC

drums

to keep spraying consistent and help make refills easy. Dual Sonic

Curb Roller Manufacturing

Save Money, Build Faster: Synthetic Macrofibers

in Concrete Construction

One of the benefits of macrofibers is that it can significantly cut time from the project schedule. But then, how do you know which macrofiber to use?

In the wake of a global pandemic, widespread supply chain issues, and inflation on the horizon, the construction industry has had more than its share of speedbumps over the past few years. Fortunately, builders were considered essential in most places, allowing the pace and volume of construction projects to weather the storm relatively well. While all this has been occurring, many engineers, architects, owners, and contractors have increasingly realized that synthetic macrofibers can replace steel in a number of applications, speeding their construction schedules and reducing overall construction costs.

Decades ago, I served on the Strategic Development Committee at the American Concrete Institute (ACI). During this time, the committee produced a report stating that most innovations in the concrete industry take almost two decades to become a common practice. Innovations face particularly strong headwinds in the concrete construction industry. Engineers and architects must manage the risk of liability, so few want to be the first to try anything new. Contractors, on the other hand, prefer to do things

the way they have been done in the past as this familiar routine generally makes it easier to estimate and construct. That said, synthetic macrofibers have been around for more than 20 years, increasingly gaining market share (versus steel) even before the last few years’ disruptions. However, when recent inflation impacted steel prices, the growth of macrofiber usage has only accelerated as a result.

Why has the demand for synthetic macrofibers exploded? Cost is certainly one of the key drivers. When macrofibers are used in slabs-on-grade, elevated slabs, pavements and other applications, this eliminates the labor costs associated with #3 or #4 bar and welded wire fabric. In other words, no labor is needed to install steel, place it on chairs or move it to the upper floors. Add in the cost of steel you don’t have to buy, and the savings can be significant. On projects in the South Central U.S. alone, I have seen $0.50 to $1.10 savings—per square foot! That’s a $100,000 savings on a 100,000 ft.2 project. It is easy to see why the market is shifting to macrofibers at a significant rate.

Who is using macrofibers in lieu

of steel rebar? One such company is Tesla, which recently used 5,000,000 ft 2 of macrofibers for the construction of their new gigafactory. Amazon has also used macrofibers on countless large distribution centers. Similarly, FedEx, Tractor Supply, Walmart, and many other retailers are increasingly building with macrofiber as well.

CHOOSING A SYNTHETIC MACROFIBER

With the economic case so strong, the market is shifting rapidly. Speed of construction continues to drive the concrete construction industry, while macrofibers significantly cut time from the project schedule. So, the question becomes: how do I know which macrofiber to use?

To answer this question, there are significant intangible factors that must be considered. For instance, how does the concrete finish with the macrofiber in it? Is the macrofiber creating a “furry” slab? Does it pump well? Does the manufacturer support the contractor at the site when the placement begins? (This is a critical point, especially if the construction crew has not placed macrofiber concrete before.)

22 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete COVER STORY

Self-fibrillating macrofiber provides threedimensional reinforcement against cracking. All

SOME OF THE BIGGEST FACTORS TO CONSIDER:

1. Macrofiber Pumpability. What can be done to improve the pumpability of a macrofiber mix? For most cases, a good pumpable mix can accommodate fibers with little to no adjustments made. Oftentimes in the field, because fiber-reinforced concrete functions differently, users will want to add water to make the concrete more workable. This can worsen the situation, as too much water will actually cause a mix to segregate and can ultimately block a pump hose.

When discharging a fiber-reinforced concrete (FRC) mix into a hopper assembly on a pump truck, raise the chute to 18 in. (300450 mm) above the grate on the pump to allow for the fibers to “impact” the grate and help them pass through. A working vibrator on a grate will also improve the concrete’s ability to pass through the grate.

2. Finishing Macrofiber-Reinforced Concrete. If reducing the visibility of macrofibers on the finished concrete surface is desired, it’s important to start with a properly proportioned concrete mix to accommodate fibers, as well as ensure that a mix is not overwatered to improve flow. The use of water-reducing admixtures to maintain strength while improving workability is always recommended. Timing of the finishing operation can sometimes be tricky because the FRC may look like the concrete is setting up more quickly due to the cohesive nature of the material.

How the finishing of this concrete is actually completed will make a huge impact

UTILIZING MACROFIBER-REINFORCED CONCRETE

SoFi Stadium—Home to the Los Angeles Rams and Los Angeles Chargers

The SoFi stadium, located in Inglewood, California, was constructed by a joint venture between two general contractors. The stadium seats 70,240 spectators for most events, with the ability to expand it with 30,000 additional seats for larger events. It is located at the former site of the Hollywood Park Racetrack, three miles (4.8 km) from the Los Angeles International Airport.

As opposed to conventionally reinforced slabs, these fiber-reinforced concrete slabs:

• Prevents corrosion over the lifetime of this facility;

• Provides improved crack control for this topping slab;

• Allowed construction time to be reduced, as the use of macrofiber eliminated the time to crane lift and install welded wire fabric or reinforcing steel;

• Improved job-site safety by eliminating tripping hazards for the concrete placement crew.

Highway Rehabilitation in Fowler, Indiana

The Indiana Department of Transportation (INDOT) is also utilizing macrofiber reinforcement with thin concrete overlays for highway rehabilitation. Constructed in 2018, the section of US 52 outside of Fowler, Indiana, was rehabilitated with a 4 to 4.5-in. concrete overlay using a 4 lb./ yd3 (2.4 kg/m3) dosage of macrofiber. This four-lane highway was previously surfaced in asphalt and had reached a deteriorated state that required a long-term solution and improved ride quality.

The project utilized a twin-shaft portable mixer placed at its local dry batch plant location. This combination of mixers allowed for the production of up to 100 yd3 per hour, with the placement of between 500-900 yd3 per day. In total, over 18,500 yd3 of macrofiber-reinforced pavement was placed without the use of any dowels or reinforcing steel. This showcases a major market potential for future FRC and pavement projects in the industry.

images courtesy of The Euclid Chemical Company

www.ForConstructionPros.com/Concrete MARCH/APRIL 2023 CONCRETE CONTRACTOR 23

Synthetic macrofiber reinforcement

Macrofiber reinforcement provides cost savings over rebar and welded wire.

on its appearance. First, it is critical to hit the surface with a vibratory screed. If not done, this will likely result in “furry” concrete, no matter what fiber you choose. After this step, you can finish the surface with pans or trowels, just like you would do with regular concrete.

If you are looking to achieve a broom or tine finish, it is very important that you do it in one pass and in one direction. Ensure that the equipment used to apply the broom finish is maintained in a clean state and that the angle of the broom is low. Broom finishes will usually pull fibers of any type to the surface of concrete, but experience has shown that “practice makes perfect.” Self-fibrillating macrofiber does not have as much of a tendency to be pulled to the surface during finishing operations, making this type of fiber an ideal candidate over steel fibers, which tend to be more rigid and can cause problems along joints when saw-cutting operations are underway.

It is always good to have the fiber manufacturer on site for the first day of placement and, if necessary, perform a trial or mock-up prior to concrete placement to assist the contractor in obtaining the desired surface appearance.

3. Flexural Strength. Another important differentiator between macrofiber types is flexural strength. The same dosage rate does not provide the same flexural strength when comparing most fibers. ACI and the American Society of Testing & Materials (ASTM) have standards that make this part easy to understand.

Macrofibers should be tested in accordance with ASTM C 1609, Standard Test Method for Flexural Performance of Fiber-Reinforced Concrete, which will provide a residual strength based on the dosage. The results of this test method are used for comparing the performance of various fiber-reinforced concrete mixtures, monitoring concrete quality, verifying compliance with construction

specifications or evaluating the quality of concrete in service. It is especially important to have ASTM C 1609 results if you are considering more than one supplier of macrofiber.

Over the past several years, we have seen an increased interest in the use of macrofiber-reinforced concrete in concrete pavement applications, such as parking lots, bridge decks and roadways. ACI, the American Concrete Pavement Association and the National Concrete Pavement Technology Center have each developed guidelines and recommendations on how to properly select and use fiber-reinforced concrete:

• ACI PRC-544.4-18: Guide to Design with Fiber-Reinforced Concrete

• NCPTC Fiber-Reinforced Concrete for Pavement Overlays

• NCPTC Overview of

Fiber-Reinforced Concrete Bridge Decks

Synthetic macrofibers have passed the test of time and are being used on hundreds of projects of every size. With cost savings of as much as $1.10 per ft2, the use of macrofiber is booming in the concrete construction industry— meaning we will likely continue to see its rise in 2023 and beyond.

24 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete COVER STORY CONTINUED

Vance Pool is manager of the National Business Development Group at Euclid Chemical. He has been actively involved in the concrete construction industry for four decades.

Techniques used to finish FRC will impact its final appearance.

Access more information on concrete materials at https://CONC.me/materials

Broom finishing macrofiber-reinforced concrete.

Finish faster with a code-listed, corrosion-resistant anchor.

The Simpson Strong-Tie ® Titen HD ® heavy-duty mechanically galvanized screw anchor.

Build anchoring strength indoors and out with the Titen HD heavy-duty mechanically galvanized screw anchor. Now code listed for exterior use, Titen HD is designed for cracked and uncracked concrete, as well as uncracked masonry. It’s ready for sill plates, ledgers, post bases, seating and other wood or metal-to-concrete applications. A hex-washer head eliminates the need for washers, and serrated teeth reduce torque. Titen HD also is easy to remove, making it ideal for temporary jobs like bracing and formwork, or when relocating a fixture.

To learn more, visit go.strongtie.com/THDMG or call (800 ) 999-5099.

©2023 Simpson Strong-Tie Company Inc. THDMG-C Anchoring Solutions | Products, Software and Service for Smarter Building

Exploring Your Concrete Screed Options

For concrete contractors, screeds are an essential purchase and a critical tool for providing the smooth, level finish for concrete work. By carefully considering the screed types available, contractors can see maximum productivity from their investment.

The most common screed categories include roller, truss, laser, power, and hand screeds. Each screed has unique features that, when aligned with project goals, can improve ROI. Here is a breakdown of the features and benefits of the most widely available screeds on the market.

HAND SCREEDS FOR LOW COST

Classic hand screeding, which traditionally uses a wooden board, might cut it for the one-off small concrete job, but any serious contractor knows the life-long pains that come from years of stooping over a heavy board and sawing it back and forth along forms to screed concrete. Although the materials have evolved over time from hefty two-byfour lumber to lighter-weight aluminum alloy bars, the design and method has largely remained unchanged.

In addition to the back-breaking labor, hand screeding methods using boards require the skill of an experienced professional to remain true to grade and achieve consistent results since there’s no mechanical assistance. This can prove challenging on large pours, even with decades of experience.

POWER SCREEDS FOR SINGLE OPERATORS

In what could be considered an assisted hand screeding method, power screeds, also known as wet screeds, consist of an engine or electric battery-powered motor and an extended handle placed in the center of a traditional board/blade that is in contact with the concrete. Power screeds use vibration to help the blade

level the concrete. These require a lot of skill and experience by the operator. Although more ergonomic and efficient than traditional hand screeding, power screeds require the operator to stand in the poured concrete while screeding. The vibration has similar benefits and drawbacks to that of the truss screed. Due to their one-man operation and center support, manufacturers typically limit the blade widths to around 15 ft.

ROLLER SCREEDS FOR VERSATILITY

Roller screeds broadly consist of a detachable pipe connected to a drive head with an extended handle for upright, ergonomic operation. These screeds are known for their minimal setup, low learning curve, and consistent, quality results with less reliance on the operator’s skill level. Roller screeds use a spinning motion to move concrete, a method that reduces operator fatigue and allows for improved integration of aggregate throughout the pour compared to vibratory methods that cause the aggregate to settle. These screeds are versatile and can be used for a variety of pours, often up to 22-30 ft. wide, depending on the power source.

The roller screed’s detachable design also makes for a highly portable option. Some manufacturers even offer linkable pipe sections to increase portability and versatility. General features like a 3-way adjustable and lockable handle for improved ease of operation and a kickstand to keep the drive head and handle out of the concrete allow crews

Adobe Stock Images | By Kadmy

26 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete

Battery-powered roller screeds provide a convenient and maneuverable screed option. Some even use the same rechargeable 60-volt lithium-ion battery found in common handheld power tools. Curb Roller Manufacturing

EQUIPMENT FEATURE

to quickly adapt to various jobsite needs. Contractors have four different power options to choose from: battery, corded, hydraulic, and gas-powered.

Battery-powered roller screeds are easily maneuverable and can handle pours up to 22 ft. wide. These versatile machines can be especially useful for contractors working in basements or factory settings indoors, at farms, or in communities in remote locations.

Depending on the slump and pipe length, a contractor can screed off 1,800-2,500 sq. ft. of concrete with just one fully charged battery. Since the battery operation provides fume-free screeding for those working in any closed-off environment where fumes may be a concern, no additional power source such as gasoline, hydraulics, or a generator is required. That means fewer transportation needs, reduced setup time, and no cords or hoses in the way. Some battery-powered roller screeds can also provide cross-platform use by utilizing the same rechargeable 60-volt lithium-ion battery that is found in common handheld power tools.

For special projects such as circular pours, battery-powered roller screeds provide a convenient single push-button directional change. This allows contractors to easily change their screeding direction to avoid cold joints or other structural flaws that can occur with an uneven cure.

Corded electric roller screeds enjoy many of the same benefits and capabilities as battery-powered roller screeds. They are fumefree for indoor jobs and some provide a single push-button directional change for screeding unique pours. With a nearby outlet or reliable generator, contractors can have the reassurance and convenience of seemingly endless power.

While enjoying the convenience of power, contractors must consider proper care to ensure the cords don’t become tangled, unplugged, or damaged while on the jobsite. And relying on a separate power source, like a generator, can come with its own worries. That can include staying on top of fuel availability, general maintenance, or fume concerns.

Some heavy-duty applications, like road drainage and ditch liner pours, require large custom drums and a screed powerful enough to drive them. This is where hydraulic roller screeds shine.

Hydraulic-powered roller screeds have the power to move up to 6 in. of concrete along a pour while the operator remains in a standing position. Additionally, most hydraulic roller screeds accept 6-in. tube length up to 30 ft. while some manufacturers also offer custom drums made to various job specifications such as sidewalks, parking lots, residential streets, large highway ditch liners, and more.

Like corded screeds, hydraulic screeds require a separate power source. Look for a manufacturer that provides a portable hydraulic power pack to match their hydraulic screed’s exact specifications. With this option, contractors don’t have to tie up a host machine to power their hydraulic screed. To take on heavy-duty jobs, these are also generally heavier at 2-3 times the weight of battery- and corded roller screeds. Contractors should consider how to accommodate the additional weight before committing to these powerful screeds.

Gas-powered roller screeds have a similar setup as the other roller screeds but with a motor attached to the drive head. These screeds offer another option

Hydraulic-powered roller screeds have the power to move up to 6 in. of concrete along a pour while the operator remains in a standing position. Additionally, they accept any 6-in. tube length up to 30 ft. while some manufacturers also offer custom drums made to various job specifications such as sidewalks, parking lots, residential streets, large highway ditch liners and more.

for contractors who typically screed large pours that require a longer pipe, often up to 30 ft. wide. The motor produces screeding power that rivals that of hydraulic screeds and offers a viable, familiar alternative for those preferring a gas engine.

More care is required as a gas-powered screed motor needs to be in an upright position to avoid gas and oil from leaking out. This can prove even more challenging due to the weight of the engine on the drive head. These screeds have location limitations as well, as they cannot be used indoors due to the exhaust and fumes from the engine. Engine vibrations present another area of concern. The high vibration from the engine can cause the throttle cable to slip and need continuous readjusting.

TRUSS SCREEDS FOR LENGTH

Truss screeds level off the concrete often featuring a vibration motor. These screeds are expandable and come in multiple sections that resemble a truss design to help maintain rigidity for longer widths, even beyond 60 ft. Due to this ability to screed such a width at the same time, truss screeds can be an excellent

Curb Roller Manufacturing

www.ForConstructionPros.com/Concrete MARCH/APRIL 2023 CONCRETE CONTRACTOR 27

The WSH-Series Vibratory Truss Screed from Multiquip.

EQUIPMENT FEATURE CONTINUED

Vibrations from a motor attached to the truss carry throughout the screed as contractors guide it on concrete forms, flattening and settling the concrete to remove trapped air, increase concrete strength and provide a

Born with a long reach and a wide pass, the Ligchine SCREEDSAVER ULTRA PLUS was built to screed more and screed faster. Complete with an ultra heavy-duty boom reaching 20 ft. with an all-new Ultra Performance 14 ft. 6 in. screed head.

Powering the ULTRA PLUS is a 45-hp Kubota turbocharged diesel engine. For increased maneuverability and traction, it includes selectable four-wheel drive with a 2-speed drive range and four-wheel independent steering.

Ligchine

option for the larger jobs, like screeding an entire roadway, slabs-on-grade, bridges, and more.

Roller screeds are known for their easy operation, low learning curve and the consistent, quality results they provide with less reliance on the operator’s skill level.

smooth finish. However, due to the vibration, it is generally not recommended to utilize a truss screed on a slope. The aggregate in concrete

A flexible repair solution for concrete.

TechCrete is a flexible and extremely strong repair mastic with proven performance of 10+ years. Its exceptional ability to bond to concrete and remain flexible with thermal movement and extreme weather conditions makes TechCrete an ideal repair solution for wide cracks, joint deficiencies, surface defects, and many other distresses.

To learn more, visit Crafco.com/techcrete-appeal

tends to settle with vibration and unevenly dispersed aggregate can create spots of varying strengths that can result in structural flaws and damage over time.

Truss screeds can be powered by an engine or air, with the latter preferred for indoor jobs or tunnels when a combustible engine would be prohibitive.

Giving contractors the ability to expand the truss and screed blade needed for the project, it’s common for truss screeds to come in sections of various lengths. Additional sections can be added to achieve a maximum width and some models may have limits. Best practices suggest selecting a screed width that allows a minimum of a 6-in. overhang past your concrete form.

LASER SCREEDS FOR EXTREME PRECISION

Laser screeds are growing in popularity for larger concrete pours and those that require a high degree of precision. This category of screed equipment can be found in various styles

28 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete

Curb Roller Manufacturing

ranging from telescopic (boom), ride-along (drive-in), and lightweight machines. The screed’s laser arm ensures a precise, accurate, and evenly leveled surface while reducing the need for excessive labor. Some of the widest laser-guided boom screeds available on the market can have a maximum working width of 20 ft.

An average laser screeding work can range from to 130 to 220 sq. ft. of concrete in a single pass depending on the size of the machine and head—making this equipment a game-changer for the concrete industry.

Options can include a roller head, various widths, paver screed, front drive tracks, or high-float wheels. However, the tracks are likely available for select models. Some modern screed heads can be replaced in minutes instead of hours—providing another time and labor savings at the jobsite.

Some common specs per screed classification:

TELESCOPIC

• Head widths can range from 8-12 ft. 6 in. (some models include a travel distance for their screed heads, shorter and wider head options may be available for some models)

• Telescopic boom reach range: 12 ft. 5 in. to 50 ft.

• Machine weight range: 2,840-22,000 lbs.

• Some models are controlled by wireless remote control and/or ride-on operator

RIDE-ALONG / RIDE-ON

• Head widths can range from 6-10 ft.

• Machine weight range: 1,107-1,775 lbs.

• Controlled by on-board control system

LIGHTWEIGHT

• Head widths can range from 6 ft. 8 in. to 10 ft.

• Machine weight range: 546-1,280 lbs.

• On-board control

A CASE FOR QUALITY

Jobs in a concrete season can vary as much as the tools themselves. Contractors should carefully consider the advantages of each type of screed, which screed will work best with the majority of their jobs, and how a screed will pair with existing support equipment as well as their crew’s skill level. No matter the method, choosing a manufacturer that offers not just options, but high-quality construction, parts, and service will help limit problems to small, logistical inconveniences.

Always confer to your equipment’s operations manual and follow all official safety guidelines.

www.ForConstructionPros.com/Concrete MARCH/APRIL 2023 CONCRETE CONTRACTOR 29

Find this article at https://CONC.me/fc43l2

Seth Ulmer is the sales manager at Curb Roller Manufacturing. He joined the company after spending over a decade in the concrete and construction industries.

Contraction Joints: New Developments for Slabs-On-Ground

The ACI Committee on Residential Concrete now recognizes early contraction joints, here’s how an early contraction joint method called “Trak Joint” can help reduce random cracks in your concrete slab.

Two new developments have recently occurred regarding the installation of contraction joints in slabs-on-ground. First, the ACI Committee on Residential Concrete now recognizes joints, installed soon after concrete placement, as early contraction joints. The types of joints that meet this category are tooled joints, inserts, and early entry saw-cuts. The depth requirement for these joints is 1/5 the thickness of the slab or a minimum of 1 in.

Second, a “Trak Joint” insert type of contraction joint is now available on the market. This joint is installed at the time of bull floating, which makes it a very early contraction joint, and an effective method to minimize random cracks.

Historically, the joint depth of 1/4 the thickness of the slab applied to all types of contraction joints for slabson-ground. In the 1980’s with the introduction of early-entry sawcuts, a new criterion evolved. Joints could be 1-in. deep for slab thicknesses of up to 9 in. These joints were installed shortly after the slab was strong enough to support foot traffic. The age of the concrete was about one hour in summer and four hours in winter. This was in contrast to conventional wet or dry sawcutting where the concrete needed more strength prior to sawcutting. Conventional sawcuts required the concrete to have an age of about four hours in summer and 12 hours in winter. Many times, the conventional

sawcuts were installed the day following concrete placement. This delay often allowed cracks to develop overnight. Field experience showed a significant improvement in reducing random cracks by using earlyentry sawcuts.

Interestingly, the criterion for the reduced sawcut depth, that is 1 in. for slabs up to 9 in. thick, applied only to early-entry sawcuts. Tooled and insert joints were required to meet the joint depth of one-fourth the thickness of the slab. Yet, tooled and insert joints are installed sooner than early-entry sawcuts. This oversight is now corrected in the ACI Code Requirements for Residential Concrete (ACI 332-20), where tooled, inserts, and early-entry sawcut joints are treated equally. The new joint depth is one-fifth the slab thickness, or a minimum of 1 in. Conventional sawcut joints, either wet or dry, remain at the depth of onefourth the slab thickness, or a minimum of 1 in.

There are technical reasons why contraction joints installed earlier are more effective in activating than joints installed after the concrete is hard.

TECHNICAL DISCUSSION

Random cracks in slabs are primarily caused by volume decreases to concrete. Three mechanisms exist that cause concrete to decrease in volume. The most well-known mechanism is drying shrinkage. Here, water in the pores of hardened concrete needs to evaporate. As water evaporates, the water remaining in the partially filled pores forms a meniscus. The occurrence of menisci means that the surface tension of the water has increased. The more water evaporates, the greater the surface tension becomes. The surface tension of water pulls on the solid particles. The hydrated cement particles are forced

30 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete INSIDE THE ACI

Deep groover for installing a tooled joint. Haynes & Associates LLC

closer together, which results in a volume decrease. Drying shrinkage occurs slowly from days to years.

On the first day of concrete placement, plastic shrinkage of concrete may occur due to water evaporation. Plastic shrinkage is a form of drying shrinkage, only the shrinkage occurs while the concrete is “plastic” or very weak. The formation of menisci in the pores cause volume decreases, which can lead to cracking of the young concrete.

The second mechanism is thermal contraction. On the first day of concrete placement, the internal temperature of concrete can become high at 150º F and greater. Factors influencing the maximum temperature are initial temperature of concrete in the ready-mix truck, ambient air temperature, solar insolation, and amount of portland cement in the mix. As portland cement hydrates, the chemical activity is exothermic. Substantial amounts of heat are generated by cement’s heat of hydration, particularly on the first day. Concrete hardens when its internal temperature is high. The initial volume of concrete is established at a high temperature. When the temperature of concrete decreases, a volume decrease occurs. The coefficient of thermal expansion is the material property that permits calculation of the amount of contraction expected due to temperature change. The first night is a vulnerable time for concrete, where its strength is still low and decreases in volume occur due to cool evening temperatures. Thermal contraction is a major cause of random cracks in slabs-on-ground.

The third mechanism is less well known. It is chemical shrinkage. When portland cement is exposed to water, the cement particles partially dissolve, and the atoms and molecules, now swimming around in solution, combine to form various types of crystals. A rapidly forming crystal, ettringite, is responsible for the setting and stiffening of concrete and are composed of calcium, aluminum, sulfate, and water. The next important crystal to form is responsible for the strength development of concrete. These crystals are called calcium silicate hydrate, and consist of calcium, silicates, and water. The volume of crystals is less than the volume of the individual elements because of attraction forces between the atoms and molecules. As cement hydrates, volume decrease occurs in the concrete by chemical shrinkage. Once a strength-giving structure is developed for the concrete, water continues to be consumed by hydration. Some pores start to become partially filled with water, so menisci form. Cracks can occur in concrete on the first day due to chemical shrinkage. Once concrete is hard and water consumption continues due to hydration, the volume decrease is called autogenous shrinkage.

Normal concrete mixtures are usually not affected by cracks developing due to chemical shrinkage. As a consulting concrete engineer, I have encountered projects where cracks in slabs occurred on the first day, and those cracks could not be explained by drying shrinkage or thermal contraction. For those cases, the concretes contained a high cement content and low water-to-cement ratios, and other factors which resulted in rapid hydration during the first day. In any event, chemical shrinkage can have a contributing effect to the development of cracks because volume changes by chemical shrinkage, thermal contraction, and drying shrinkage are additive.

EFFECTIVE CONTRACTION JOINTS

Tooled and insert joints are installed prior to the occurrence of all three volume change mechanisms; hence, these joints are most effective in having cracks develop where desired—in the contraction joint. From an effectiveness standpoint, the best joints are installed in fresh concrete (tooled and inserts), next are those installed in recently stiffened concrete (earlyentry sawcuts), and last are those installed in hardened concrete (conventional sawcuts).

TOOLED JOINTS

Early contraction joints are now recognized as tooled, inserts, and early-entry sawcuts. The depth of joint needs to be 1/5 of the slab thickness, with a minimum depth of 1 in. for each of these methods.

Conventional wet or dry sawcut joints still need to be 1/4 the thickness of the slab.

These joints are also called scored or grooved joints, and the tools used to form the joints are jointers or groovers. The top image of this article shows a deep groover, where the bit is usually about 1.5 in. but tools with bits about 3/4-in. deep are also common.

These tools are used for relatively small jobs, such as, driveways, patios, and sidewalks. In residential work, garages typically show tooled joints. The slab to the residential part of the house may also have tooled joints. Some contractors use the deep groover to push aside the coarse aggregate particles and then fill the groove with cement paste during bull floating. This type of joint is only partially effective as a contraction joint. It is not recognized as an official contraction joint.

Tooled joints have edges that are rounded to various radii. The appearance is neat and clean.

Insert joint using Trak Joint flexible plastic tape.

www.ForConstructionPros.com/Concrete MARCH/APRIL 2023 CONCRETE CONTRACTOR 31

Photograph courtesy of Aaron Hilbert LLC

INSIDE THE ACI CONT

INSERT JOINTS

Insert joints have a rigid or flexible material embedded into the fresh concrete. In the past, Masonite strips were inserted into the concrete. Today, rigid plastic strips (Zip Strips) are more common and typically 10-ft. long. Workers walk in the fresh concrete to insert the strips by hand. Sometimes a long metal angle is used to make a groove prior to inserting the strips. This assists in establishing a straight line and assuring that the insert has a vertical orientation in the slab. Without the prior groove, problems can arise with lack of straightness of the joints or the inserts may not be vertical. Strips, which are installed at a slant, have a top edge that is less than 90 degrees. The thin edge is vulnerable to breaking off. These inserts are used in relatively small slabs, such as residential houses, retail stores, and utility slabs.

The new insert method, called Trak Joints, are installed using a tool called a Traker. The Traker is used to embed a continuous, folded, flexible plastic strip into fresh concrete—either before or immediately after bull floating. The plastic strip is pulled off a roll and then folded in half by an insertion disc, just as it is embedded in concrete. A long-handled pole or rope is used to push or pull the Traker across the slab. The strip remains in the slab as concrete finishing operations occur over the strip. The appearance of the Trak Joint, after the joint activates, is a relatively straight crack in the slab.

Applications for Trak Joints are limited to uses where straight-crack joints are acceptable. Such applications are residential house slabs (where floor coverings are used), utility slabs, pathways, parking lots,

and roads. A few advantages of Trak Joints are: no silica dust is created; the embedded plastic tape adheres to the walls of the crack, so curing of concrete in the joint is effective; rainwater is deterred from entering the joint and wetting the subbase soil; and, after the slab is in use, moisture vapor emissions are prevented from rising through the joint. The most significant advantages are reduction in random cracks and reduced cost over that of other joint methods.

CONVENTIONAL SAWCUTS

Conventional sawcut joints have been used for a long time so the equipment and blade technology are well understood. These joints can be cut dry or wet. The appearance of the joints is neat and clean. The main disadvantage is that due to the wait time for the concrete to become sufficiently strong, so that aggregate particles are not dislodged by the sawblade, the timing for joint installation can easily occur too late. For certain jobs, sawcutting needs to occur after workday hours, so a decision is made whether to wait until the following morning to cut. This overnight delay can result in the formation of random cracks.

Harvey Haynes established Haynes & Associates LLC in 1982 to provide concrete consulting services to the construction industry and legal firms. He focused his career of over 55 years on the study of concrete as a construction material and applies his knowledge to the investigation of concrete problems. Mr. Haynes is a Fellow of the American Concrete Institute.

Traker for installing an insert joint in fresh concrete. Photograph courtesy of Aaron Hilbert LLC

32 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete

Insert joint using Zip Strip rigid plastic strip. Photograph courtesy of Superior Profiles Inc.

Find this article at https://CONC.me/dtrjdt

Earth-moving prices Save big on wheel loaders. www.ebay.com/heavyequipment

BATTERY & ELECTRIC-POWERED TOOLS & EQUIPMENT

PowerPusher E-750 Electric Wheelbarrow

The Power Pusher E-750 Electric Wheelbarrow is designed for transporting heavy loads weighing up to 1,000 lbs. It improves safety by eliminating ergonomic challenges and unnecessary production delays that are associated with manually operated wheelbarrows.

• Available with multiple tubs and quick-change attachments to handle material handling applications

• Silent motor with zero emissions for indoor or outdoor use

• Moves at speeds up to 4 mph

• Powered dump feature unloads materials with touch of a button

• The motor is powered by two 12V rechargeable Group 27 Deep Cycle Marine Batteries and can run five miles on one charge

• A bed capacity up to 12 cubic feet allowing for hauling of large loads in one pass

• Durable, reliable construction for rocks, bricks, sand and concrete, fertilizer, sod, soil, mulch, construction debris, feed, hay and other materials

• Foam filled tires, never go flat

• Custom attachments available

https://CONC.me/m9l9ec

Makita’s 40V MAX XGT 8.0AH BATTERY

Makita’s 40V max XGT 8.0Ah Battery gives contractors higher output power for high-demand applications. It is compatible with all products in the expanding XGT System and is designed for use with XGT equipment and tools taking on high-demand applications. It reaches a full charge in only 76 minutes or less for increased efficiency on the XGT Rapid Optimum Charger. The smart charging system includes built-in chips that allow communication between the battery and charger to control current, voltage and temperature. In addition, the XGT Charger has two built-in fans that circulate air through the battery and circuit board during charging.

https://CONC.me/8hczov

Briggs & Stratton

Lithium-ion Commercial Battery Packs

The three new commercial battery options include: 3.5

kWh* Diecast Commercial Battery, 5

kWh* Diecast Commercial Battery and the 7 kWh* Diecast Commercial Battery. The lithium-ion 1.5 kWh* Swappable Battery Pack is engineered to provide users with reliable battery power. The battery’s exchangeable design allows customers to swap freshly charged packs from application to application. The Swappable Battery Pack can be used in tandem with other Vanguard packs to meet larger power needs and will be available for order in May 2023.

*Total energy measured using a 0.2C discharge per IEC 61960-3:2017

https://CONC.me/jp8p2z

GOMACO CC-1200e Battery powered Curb Machine

The CC-1200e is equipped with a 48VDC lithium-ion battery pack that provides enough power for a full day of paving.

• Charging options include the standard eight to 10-hour normal charge rate or optional two-hour fast charge system

• G+ control system with full-function radio remote control puts all machine operations in the operator’s hands

• Able to slipform a 24-in. radius, depending on mold profile

• Features a 19-cu.-ft. hopper capacity with up to 15 in. of horizontal sliding capabilities for easy alignment with ready-mix trucks

• Curb molds can be interchanged easily and can be positioned on either side for right-side or left-side paving https://CONC.me/pes02n

DEWALT 60V MAX Cordless SDS MAX Chipping Hammers

Curb Roller Batt Screed 6000

The Curb Roller Batt Screed 6000 is powered by a removable, rechargeable 60V lithium ion DeWalt FLEXVOLT battery that is estimated to screed off 1,800 to 2,500 sq. ft. on a full charge, depending on slump and pipe length. The unit can accommodates jobs from 3 to 22 ft. with expandable tube inserts. It spins concrete into shape so more and larger aggregate remains near the surface of the slab for increased structural integrity. Features include adjustable right- or lefthand speed control, variable speed in both high and low ranges, a three-position foldable handle and heavy-duty kickstand. A single pin connection on both ends allows pipe to be removed from the handles in less than 60 seconds.

https://CONC.me/y5yvga

The 60V MAX Cordless SDS MAX chipping hammers deliver precision chipping with seven-position variable speed control and consistent speed under load through built-in constant-speed electronics.

• Integrated SHOCKS Active Vibration Control system minimizes vibration felt at the handles

• WIRELESS TOOL CONTROL connectivity for remote activation of the available DCV585 60V MAX Dust Extractor

• 22-lb. model delivers up to 19.4 joules of impact energy and tackles horizontal and downward chipping

• 15-lb. model delivers up to 10.5 joules of impact energy and is highly maneuverable for horizontal chipping

https://CONC.me/1ldxah

Lavina Electric Power Trowel

Superabrasive’s LAVINA LP30E electric model power trowel is designed for concrete polishing with free planetary drive and the proven Trowel Shine pan system. The LP30E is a 5 ft. ride-on power trowel, offered in 220V and 380/480V electric models. With 2 x 7.5 hp motors and 8 x 9 in. heads, it can get serious work done, fast. It was designed to be very easy to transport and operate, and it goes through standard doors.

https://CONC.me/y9itrw

34 CONCRETE CONTRACTOR MARCH/APRIL 2023 www.ForConstructionPros.com/Concrete

Milwaukee Tool’s M18 FUEL 1 1/4-in. SDS Plus D-Handle Rotary Hammer

• Faster 3/4 in. holes and lighter vs the 1 9/16 in.

S DS Max

• AUTOSTOP Control, Enhanced Safety

• Up to 25 3/4 in. by 4 in. holes per charge