Use Crafco HP ER Asphalt Cold Patch and Stop Repairing the same area.

Crafco High Performance (HP) ER Asphalt Cold Patch is specially formulated to be flexible, provide a strong bond with the surrounding pavement, and resist raveling and rutting. Where other cold patch products fail to remain in place, Crafco HP ER Asphalt Cold Patch establishes a firm grip in the repair area. In addition to its enduring performance, Crafco HP ER Asphalt Cold Patch is easy to apply. No mixing, heating, or special equipment required and no messy clean-up to deal with when you’re done. Crafco HP ER Asphalt Cold Patch can be applied in a wide range of temperatures and climates and opens to traffic immediately.

Performance that last. Performance that’s easy to apply. Learn more at Crafco.com/hp-er

ON THE COVER This Wacker Neuson vibratory, wheeled roller is busy compacting base aggregates in NE Ohio. This job, completed by Northern Erie is part of our cover story on managing your business.

whether you’re new to the field or a long time veteran. There’s something for everyone. The next NPE is just around and the corner and there’s still time to register.

is a

balancing act between

and reward. Hear the stories from five different entrepreneurs and how they grew their business while knowing what kind of risks to take, and when to take them.

It’s time to recognize the 2023 Pavement Top Contractors! Fill out the survey categories for your Paving, Sealcoating, Striping, Sweeping and Pavement Repair business. Applications close on Feb. 3, 2023.

Formoreinformationvisit http://asphalt.com/1rgkqm

With two hybrid-electric models and counting, Elgin Sweepers aims to help contractors meet their sustainability goals today, and well into tomorrow

Formoreinformationvisit http://asphalt.com/tz0wgx

A construction site can be dangerous for a lot of reasons, and measures should be taken to mitigate them whenever possible. This includes on-thejob harassment, threats, racial or other kinds of discrimination. What can we do about it?

Formoreinformationvisit http://asphalt.com/be1ven

Published and copyrighted 2023 by AC Business Media. All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording or any information storage or retrieval system, without written permission from the publisher.

Subscription policy: Individual subscriptions are available without charge in the U.S. only to pavement maintenance contractors, producers and government employees involved in paving or pavement maintenance; dealers, and distributors of pavement maintenance equipment or materials; and others with similar business activities. Complete the subscription form at www.forconstructionpros.com or use your company letterhead giving all the information requested. Publisher reserves the right to reject nonqualified subscribers. One year subscriptions for nonqualified individuals: $35.00 U.S.A., $60.00 Canada and Mexico, and $85.00 all other countries (payable in U.S. funds, drawn on U.S. bank). Single copies available (prepaid only) $10.00 each (U.S., Canada & Mexico), $15.00 each (International). Pavement Maintenance & Reconstruction (ISSN 1098-5875), is published eight times per year: January, February, March/April, May, June/July, August/September, October/ November, December by AC Business Media, 201 N. Main St., Fifth Floor, Fort Atkinson, WI 53538. Periodicals postage paid at Fort Atkinson, WI and additional entry offices.

POSTMASTER: Please send change of address to Pavement, PO Box 3605, Northbrook, IL 60065-3605. Printed in the USA.

PAVEMENT MAINTENANCE & RECONSTRUCTION is proudly supported by these associations:

The IGNITE 2022 Construction Summit was a crash course of the very best kind.

I'm sitting on Clearwater Beach, under an umbrella at the Sand Pearl Resort where a handful of IGNITE 2022 attendees and other event staff are soaking up the last few rays of sunshine before decamping back to our respective places of origin. I want to list a few of my key takeaways from the event, and mull them over a bit:

EDITORIAL

Editor Brandon Noel bnoel@acbusinessmedia.com

Contributing Editor Jessica Lombardo jlombardo@acbusinessmedia.com

Managing Editor Gigi Wood gwood@acbusinessmedia.com

Technology Editor Charles Rathmann crathmann@acbusinessmedia.com

Audience Development Manager ........................ Angela Franks

PRODUCTION

Senior Production Manger Cindy Rusch crusch@acbusinessmedia.com

Art Director April Van Etten

Publisher Amy Schwandt aschwandt@acbusinessmedia.com

Brand Director Sean Dunphy sdunphy@acbusinessmedia.com

Sales Associate Tadashi Soma tsoma@acbusinessmedia.com

bNoel@ACBusinessMedia.com 234-600-8983

It didn’t come up during a specific panel, however, every night during our networking sessions out near the beach (pictured above), people discussed it. They argued different secrets, tricks, tools or materials that produce the best results. Some are purely cut and replace, others are all-in on infrared, but almost everyone agrees the real problem is the "throw and go" repair jobs that aren't doing anybody any favors. It's something I intend to cover more during 2023, because it generated so much conversation.

One thing everyone was saying in almost every setting, whether in a panel or on a barstool, was that things have changed a lot, very quickly, and even more change is coming. There was agreement that these changes will reshape the traditional business models. Agreement that new solutions will need to be developed to deal with coming waves of regulation. Agreement that sustainable solutions like electrification are net positives.

Despite all this agreement, there was little consensus about what to do with all these changes, or what they will ultimately mean in a material sense. In one panel about materials and supply, a representative from NAPA, Jay Hansen, spoke matter-of-factly that the future will force the industry to evolve.

I had an extended conversation with an owner/operator who is 21 years old. It made me feel ancient. I spoke with an operations manager from a repair company who is only 23. Both were energetic, hopeful and brimming with ideas. But it wasn't just them. The opening night roundtable was co-opted by a veteran of the industry sharing success recruiting young people, especially young women, from school-based programs. He praised the next generation's potential, he said, "They aren't lazy, they respond to what you invest in them."

There was a hunger from everyone I spoke with to connect, learn and engage with the industry. If they had something to share, they were eager to share it. If they were unclear about something, they were interested in networking with someone who did. Their passion extended beyond the success of their own individual business, and into the community itself. It's this last takeaway that tells me that IGNITE and other annual gatherings for the industry have real value far beyond people getting together to showoff their latest gadgets, or brag about their success.

These are educational, truly. I came away from it myself, with a long list of topics, ideas and concepts that will carry me through the whole year. I, for one, can't wait for NPE coming up next, where I will meet even more amazing people.

See you on the road! ■

Sales Associate Kris Flitcroft kflitcroft@acbusinessmedia.com

AC BUSINESS MEDIA

Chief Executive Officer Ron Spink

Chief Financial Officer JoAnn Breuchel

Chief Revenue Officer Amy Schwandt

Chief Digital Officer Kris Heineman

Brand Director, Supply Chain & Green Industry Jason DeSarle

Brand Director, Construction Sean Dunphy

VP, Audience Development Ronda Hughes

VP, Operations & IT Nick Raether

Content Director Marina Mayer

Director, Online & Marketing Services Bethany Chambers

Content Director, Marketing Services Jess Lombardo

Director, Demand Generation & Education Jim Bagan

Director, Enterprise Sales Kay Ross-Baker

CIRCULATION & SUBSCRIPTIONS

P.O. Box 3605, Northbrook, IL 60065-3605 (877) 201-3915 | Fax: (847)-291-4816 circ.pavement@omeda.com

LIST RENTAL

Sr. Account Manager Bart Piccirillo | Data Axle (518) 339 4511 | bart.piccirillo@infogroup.com

REPRINT SERVICES

Tadashi Soma (800) 538-5544 ext. 1267 | tsoma@ACBusinessMedia.com

Published and copyrighted 2023 by AC Business Media.

All rights reserved. No part of this publication may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopy, recording, or any information storage or retrieval system, without written permission from the publisher.

Published by AC BUSINESS MEDIA 201 N. Main Street, Fort Atkinson, WI 53538 (800) 538-5544 • www.ACBusinessMedia.com

Hilltip, a leading manufacturer of snowplows, spreaders, deicing sprayers, sweepers and other road maintenance equipment, has acquired all assets of Industrial Metal Products, Inc., an Indiana-based manufacturer of truck beds and other quality metal products. The arrangement provides growth opportunities for both companies’ products, while aiding Hilltip’s expansion in the North American market.

The acquisition of Industrial Metal Products will allow Hilltip to manufacture its products in North America using the company’s Fort Wayne facility, which will immediately get a remarkable expansion for increased production and storage capacity. In addition to the logistical benefits of production at the Indiana location, Hilltip will establish staff resources and a customer service team to better serve dealers and customers in the U.S. and Canada.

“We are now able to manufacture all our industry leading products in the United States and distribute throughout North America,” said Craig Sandmann, managing director of Hilltip, Inc. North America. “This includes our complete line of spreaders, sprayers and brooms, as well as established Hilltip products lines we have yet to offer domestically.”

Industrial Metal Products will continue production and development of its existing product line as a separate division of Hilltip, and it will still carry the Industrial Truck Beds brand name.

“It’s an exciting development for our employees, dealers and customers,” Sandmann said.

For the latest Pavement Maintenance and Reconstruction news, bookmark ForConstructionPros.com/ Pavement

For more information visit https://asph.link/bc1eue

Schwarze Industries LLC announced that it was proud to welcome the addition of their newest dealer, Tampa Crane & Body, to the Schwarze Trusted Dealer Network. Effective immediately, Tampa Crane & Body will be providing Sales, Service, and Parts for Schwarze products for the state of Florida.

Tampa Crane & Body will be responsible for supporting the Schwarze-branded products in the areas of new whole goods sales, parts, warranty, factory-trained service and reconditioned units. Schwarze is focused on quality, performance, public safety, value and customer support. They said that having the right dedicated dealer is crucial to delivering the exceptional support their customers expect. Schwarze also said that they were highly pleased to have Tampa Crane & Body as a trusted dealer.

Despite ongoing inflation, the U.S. economy experienced many bright spots in 2022. That includes the construction industry, which saw record-low single-family vacancy rates and a burgeoning crop of planned commercial projects for 2023. Avoiding a recession in 2023, however, will require taking a narrow road, one economist said recently.

Dodge Data & Analytics Chief Economist Richard Branch delivered the company’s “On the Razor’s Edge: Will the U.S. Economy Enter Recession and How Will Construction Starts Respond in 2023” via an online webinar on Nov. 15. The analysis was based on several data categories the company tracks throughout the year. Some of that outlook was based on historical data through the end of September.

Looking at the big picture – or skimming through any news site – it’s clear there is a lot going on in the world. From election results, to bitcoin, to tech layoffs, it can be a challenge to predict what will happen next with the U.S. economy.

Former Boston Federal Reserve President Eric Rosengren told CNBC recently that the U.S. is likely headed for a mild recession going into 2023. Branch told his online audience on Tuesday that a recession may not happen, and if it does, it will not be as severe as the Great Recession of 2008 or the downturn of 2001.

“The key thing here to remember I think, is we view this as fairly V-shaped here. We don't view this as anything similar to what happened during the Great Recession,” Branch said. “A couple of key reasons I would say that we feel this way is No. 1, the banking system is in great shape. And No. 2, the housing market is undersupplied.”

There are a handful of issues that Branch is watching and considers potential recessionary events:

• Increased China and Taiwan tensions or conflict

• A real further violent escalation in Ukraine and Russia

• Production cuts for OPEC plus that push oil prices to $115-$120 a barrel “We're walking the razor's edge here,” Branch said. “In our estimation, there is a very, very, very narrow path to avoiding a technical recession in 2023.”

Gemseal, a manufacturer of sealers and complementary pavement products, offers PROSTRIPE PLUS paint for asphaltic parking lots and low volume roadways. This fast-dry traffic paint features an 100% acrylic binder in conjunction with powdered pigments, binders and liquid drier. The lead-free, low VOC paint is especially designed for airless walk-behind stripers.

• Dry Time: No Tracking (open to traffic) 190 seconds at 77°F ; DryThrough (early washout) 120 minutes at 73°

• FLead Content:0.06%

• Viscosity:80-90 Krebs Units

• Pigment Percent:60% – 62%

• Dry Opacity Ratio:.94 – 100

• Reflectance:85% White

• VOC:75 - 85 g/L

• Heat Shear Consistency:68-105 KUs

www.ForConstructionPros.com/22512080

Ammann America’s eAPX 68/95 vibratory compactor with multidimensional movement for construction sites includes four working shafts in an X shape combined with a curved base plate to provide the 620-kg compactor with high maneuverability. It has the ability to go in an arc, circle or turn on the spot. The eAPX 68/95 has an operating height of 700 mm. The height and the machine’s ability to move in all directions enables trenching applications. The plate can also be used in open spaces. Remote-control features dictate the eAPX 68/95’s movements, so at a safe distance, individuals can operate the machine. The plate can run continuously for approximately 80 minutes before recharging is needed. Recharging only takes about 30 minutes.

www.ForConstructionPros.com/22484466

The new Panasonic TOUGHBOOK G2 is a fully rugged 2-in-1 detachable tablet with optional keyboard that features a modular design and user-removable expansion packs (xPAKs). With three modular expansion areas and up to 36 different xPAK combinations, users can customize the TOUGHBOOK G2 with features and functions such as a serial port, thermal camera, barcode reader, quick-release SSD and more. Despite its modular design, the device is backwards compatible with most TOUGHBOOK 20 and G1 docks. Featuring a 10.1-in. display and powered by Intel CoreTM i5 and i7 vPro processor (with Intel vPro technology). To accommodate longer work schedules, the TOUGHBOOK G2 offers 18.5-hour battery life as standard for operations across manufacturing plants, utility fields, in federal civilian agencies and on the front line. Additionally, the TOUGHBOOK G2 now features three programmable buttons for customizing access to applications.

www.ForConstructionPros.com/22578261

Read more at: https://asph.link/orqb8o

Crafco Patchers have been a leader in the industry for more than 20 years. Built to the highest quality standards, Crafco Patchers provide the ultimate in performance, reliability, and productivity. Built using innovative construction, Crafco’s Engineers were able to maximize the tank size while keeping the loading height low for safety and provide a daily melting capacity of 24,000 pounds.

• Large 395-gallon capacity material tank.

• Additional material loading door on the driver side, offering two intake areas for greater efficiency. Includes a third area for bucket storage.

• Optional powered auger chute to dispense material extends outside the wheel path for safer and more efficient application.

• Integrated digital control system ensures mastic temperatures are always kept within specifications.

• Angled and staggered agitation blades provide superior material agitation and aggregate suspension

www.ForConstructionPros.com/22526013

of the Zenith X2 – an ANSI Type II compliant safety helmet. Making slight modifications to the popular Zenith X helmet, introduced a little over a year ago, enabled KASK to achieve additional safety standards.

While the Zenith X2 still retains certifications for the ANSI Type I and EN 12492 clauses it has always met, KASK made an adjustment to the Zenith X to comply with the ANSI Type II requirements. The Zenith X helmet gained acceptance in the market recently. Because of this, KASK felt it was an acceptable platform when developing an ANSI Type II compliant safety helmet for the U.S. market. The result was a slight modification to the internal structure – and everything else about the helmet remains the same – from the outer-shell to accessory integration.

www.ForConstructionPros.com/22526172

An 18-year-old saw a display for seal coating that inspired him to launch a multi-location asphalt paving enterprise.

@vm2002 - adobe.stock.com

The value of sealcoating asphalt to preserve it and improve its aesthetic appeal are easy to understand, and one day in 1998, this simple value equation hit one young man hard, leading to a lifelong career as a paving entrepreneur and a national business footprint.

“I was 18 years old and getting ready to get done with high school,” William “Nick” Yoss said. “I was at Home Depot and saw the sealcoat display, went across the street to Staples and had business cards made. Now, we have sealcoating work all over the country for Home Depot, Walmart and Menards. We always subbed out pavement up until 2020, but we could not get subs with COVID-19 happening. So, we jumped into paving the same way we did the sealcoating.”

Today, Yoss is president and founder of Synergy Pavement Group, a family of companies that employs 32 and delivers asphalt paving, repair and maintenance from locations in South Beloit on the Wisconsin-Illinois border and Lake Placide, Fla. Synergy Asphalt performs paving and Asphalt Maintenance Systems performs asphalt repair, maintenance and line striping.

The company tends to keep its South Beloit and Lake Plaza operations separate.

“We used to move capacity around between the two offices,” Yoss said. “It did not work very well.

Every time we get a large project, we would send a couple people down. Between the distractions that Florida may offer a northerner in the winter and time spent away from family, the

arrangement did not stick. Separate crews and equipment pools deliver the full spectrum of Synergy Asphalt Group’s service offering from each office.

“We strive to be the best in pavement maintenance and asphalt paving,” Yoss said. “Today, we do everything in house — no sub work for concrete milling or pavement overlays.”

Scaling a company in a constrained labor market means there is one glaring top priority for Yoss.

“The biggest technology we are waiting for right now are robot employees.” Yoss quipped. That may be feasible for some disciplines with emerging technologies like robotic

Stay ahead of the game with Dynapac’s decades of experience in the world of compaction and paving. The compact line of equipment gets the job done in confined spaces, small parking lots or landscaping projects. From sand to soil, rock to asphalt, Dynapac’s plate compactors, mix spreader and walk-behind rollers are the preferred choice for contractors

paving stripe pre-lining. But Spectrum Pavement Group is well past the whiteboard-and-Excel stage in the construction technology maturity curve.

The company uses multiple different software-as-a-service (SaaS) business applications to streamline its backoffice processes including Clockshark, a timesheet management and capture application that caters to small and middle market businesses. This gives Yoss visibility and control over hourly time clocks for employees and crews.

Workers and supervisors in the field access Clockshark on a mobile device to log time. Supervisors can clock in and out for an entire crew or switch them from one account to the other if they do not have individual accounts. Meanwhile, back-office users or administrators use a desktop browser application

personnel with a national paving contractor — Manassas, Va.-based Brothers Paving and Concrete. Shawn Boyce serves as secretary of PavementSoft and chief revenue officer for Brothers.

“We have designed and built out PavementSoft really to meet our own needs,” Boyce said. “That is what we use to run our field, for our crews and sales — everything runs through PavementSoft.”

PavementSoft can be considered ERP because it gives contractors a single, digital workflow for the full value lifecycle from lead to bid to project and crew management to invoicing — from quote to cash. This supports more accurate estimating by exposing actuals. It also delivers control and the ability to modify invoices before they go out. There are integrations with both

payroll reports. ClockShark and a couple others do a little bit more.”

“You can be on the job taking photos of progress, upload job pictures, generate and fill work orders, do time tracking and cost tracking,” Boyce said. “The foreman can see all the work orders and all the pictures. At the end of the day, they run a job report that shows paving cost, materials used and hours for each member of the crew, along with a profit and loss statement.”

Photos in PavementSoft can be attached to a variety of different documents ranging from invoices to estimates or internal work orders. During work-in-progress, the application automates weather alerts that affect schedule. At project close

PavementSoft has about 400 customers across the United States and Canada, and takes on a limited number of new customers each year, positioning the software subscription like a selective fraternity or sorority.

“We are very selective,” Boyce said. “They need to be willing and able to change their philosophy about how they do things. Sometimes, the customers don’t want to do that. We start each year by taking about 100 names of companies that want to join. We pick the best 30. Then, we watch everyone’s sales improve immensely because of how quickly they can process estimates and capture cost.”

to set up these accounts, collect data for accurate payroll and track and manage employees and crews. The software banks time transactions for later upload if there is no internet connection, making it ideal for a contractor working on linear assets between towns and cell towers. A combination of geofencing in Clockshark that records where employees are as they clock in and out on projects and internet protocol (IP)-based two-way radios help Yoss track where his crews and equipment are located at a given time.

Synergy Pavement Group also uses a paving industry-specific enterprise resource planning (ERP) application from PavementSoft, a software company that actually shares ownership and

Quickbooks Desktop and Quickbooks Online. An integration with Netsuite is coming, according to Boyce. There is also a Docusign integration to support proposal submissions.

Contractors can license portions of or the entire application — PavementSoft does have an internal timeclock, for instance but a ClockShark user like Synergy Pavement Group does not need to use it.

“Our clock manager is pretty good — it does include geofencing,” Boyce said. “There are some other that are a little bit better because they do more. But ours clocks all of the employees in when they get to the job, logs them out when they leave and rolls up into

Integrated CRM and estimating can help contractors increase revenue by letting them pursue more projects without a corresponding increase in time or effort. Invoices with photos help document completion and the software even collects a net promoter score (NPS) survey to help find, fulfill and bill the next customer.

Synergy Pavement Group has a progressive technology footprint for a small contractor, but Yoss says the software is no silver bullet.

“You are not going to see a return on it right away, and you have to get everyone using it,” Yoss said.

“But PavementSoft is very simple to use. When you get your call in

regarding new business, you can enter info into the application and send out an email estimate in less than five minutes. We do our maps right in the application, our coding for pricing and descriptions are all in PavementSoft. We also get the ability to update a bid with a nice map and send it to customer as a Docusign file. Once it is sent back, we can do work order off of that. As long as there are no change orders, it is one click of a button to invoice it off of the estimate.”

In projects that do involve change orders, they are hand written in the field but use a similar workflow to the estimate if they originate in the back office.

“In the field, we have tried to equip our crews with tablets,” Yoss said. “But they don’t get plugged in and charged, or they get dropped.”

Synergy Pavement group is not involved in the scale of civil work that would make 3D asphalt paving, milling or compaction attractive.

“We have something similar to that on our grading and milling machines, but not on the actual paving machines,” Yoss said.

Synergy Pavement Group relies for milling on the Bomag 1330, giving them access to a number of productivity technologies including the BOMAG TELEMATIC app that:

• Monitors fuel consumption

• Tracks operating hours against duty cycle-based maintenance activities

• Captures and exposes location

• Prevents theft by triggering alerts when the equipment moves outside of a defined geomap

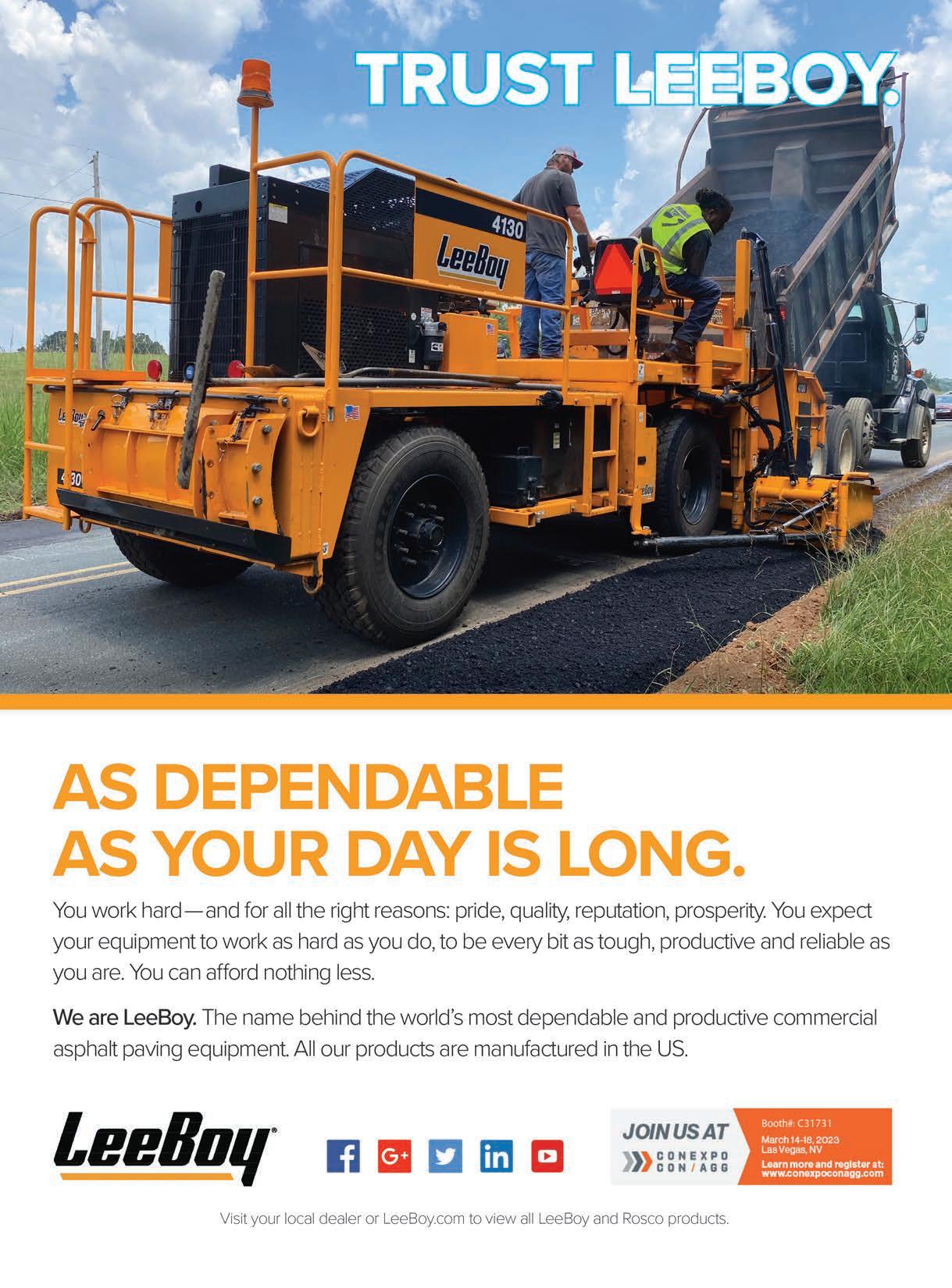

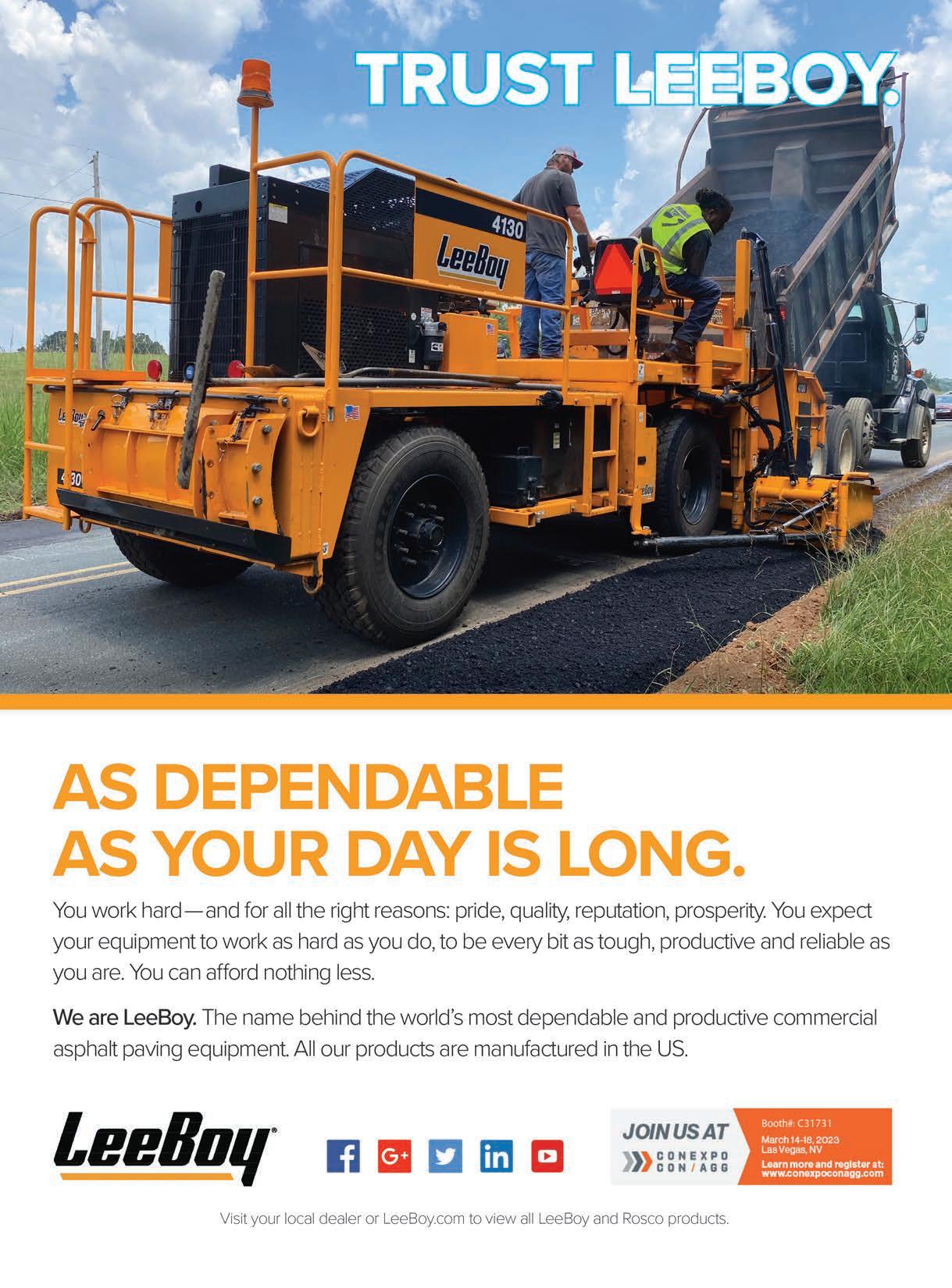

The company also runs LeeBoy pavers, Dynapac rollers, Case skid loaders and Sealmaster seal coating equipment. Actual autonomous

equipment — those “robotic workers” Yoss mentioned, are high on his list.

“We’ve got to see more automation in our line of work,” Yoss mentioned. “Nobody wants to work out in the heat or do anything difficult. The older guys that have done it are retiring. A lot of our stuff already has some automation — BOMAG is looking to have a selfmanned roller.”

the Mavic Mini. We could carry it anywhere, but the video footage was not very good. Most of what we use the drone footage for is really just for marketing purposes. With Pavement Soft’s program, we can get a picture of the site by satellite. But if we have a larger project where you can’t get good image off of Google Earth, we use the drone.”

Drone-related technology Yoss wants to explore next includes smaller drones that can launch from a truck bed or can hover or follow another object. Less interesting is advanced drone photogrammetry software that unites the drone images with a geographic information system (GIS) or building information model or use machine vision to process photogrammetry into progress reporting.

“The progress reporting would be kind of cool,” Yoss said.

“We could follow crew and use that to inform people. But we don’t do a lot where we are on the job for three weeks at a time and need to deliver those progress updates.”

A modern contractor should be as much a technologist as a tradesperson, able to identify and use technologies to deliver value. Yoss’s credentials as this type of practical construction technologist become even more apparent given his group’s early use of drone technology.

“We were one of the early ones to start using drones and including maps with estimates,” Yoss said.

The company has relied mostly on unmanned aerial vehicles (UAVs) from DJI.

“Our first drone was through them — was a very large drone,” Yoss said. “Then we got the Mavic — which was about the size of a VHS tape, then

Technology is a pivotal tool for Synergy Paving Group from an operational perspective, but also helps Yoss and his team meet customer expectations that are more and more demanding.

“I am seeing more of that since COVID started rather than just a change over time,” Yoss said.

“Customers want things done right now — and want it done to a standard that may be difficult. Someone may sign that Docusign agreement for the work and expect you will be on the site a couple days later.” ■

For more information visit https://asph.link/9ywso6

Events like NPE are a vital resource for industry pros. Whether you're new to the field or a long-time veteran, there's something for everyone.

Winter weather slows or even halts paving in many parts of the country, but slower times offer the perfect opportunity to think about the new year and implement fresh ideas. Todd Eichholz, owner and CEO of A&A Paving, Roselle, Ill., is one of those operators who is essentially done with outside work for the year.

Back inside the cozy office it’s a different story. “Now we get to plot and plan and figure out how to conquer

2023,” says Eichholz, who also serves on the Educational Advisory Board (EAB) for the National Pavement Expo (NPE) and Conference.

Eichholz and pavers throughout the country will look to match their motivation with a bit of inspiration when NPE convenes Jan. 25-27, 2023, in Charlotte, North Carolina. The show brings together vendors and contractors who make their living from asphalt and concrete paving, sealcoating, striping, sweeping, crack repair, pavement repair

and snow removal.

NPE delivers more than 55 conference sessions over a four-day span, and there is much to be learned. Outside of the structured sessions, networking events provide a chance to chat with speakers and cement relationships with professionals (mostly non-competitors) who face many of the same challenges.

Three Talk Shop: NPE Speaker Meet And Greet events are scheduled for: Thursday, Jan. 26 from 1 p.m. to 2 p.m.; Friday, Jan. 27 from 11 a.m. to

noon and Friday, Jan. 27 from 1 p.m. to 2 p.m. As an NPE speaker, Eichholz will be available to chat with attendees in a casual setting that may prove to be more comfortable than in-session or post-session Q&A.

“The Speaker Meet And Greet is a little more personable,” Eichholz says. “It's more relaxed and you can do some networking with the speakers and ask questions. Sometimes people are hesitant to ask questions at the end of a class or during a class. They don't want to say something that they may think is obvious and/or they should know. There's also a pretty good line after educational sessions are over, and sometimes you can't get to everybody. The Meet And Greets are great opportunities to ask those questions and get to know the speakers.”

Located within the Charlotte Convention Center, the NASCAR Hall of Fame will host another networking event, a three-hour party from 6 p.m. to 9 p.m. on Thursday, Jan. 26. It’s a great way to have fun and learn about the best drivers in the history of professional racing. “It's relaxing and you can get to know people,” Eichholz says. “I've solidified some of my best working relationships at these types of networking parties, and those relationships have lasted a decade.”

As attendees prepare for the trip to Charlotte and still others are on the fence, Eichholz has a final word of encouragement that involves a new mindset, particularly when it comes to the rationale for NPE attendance. He explains: “Rethink the word ‘spend’ when it comes to time, money and effort. Replace the word with ‘invest.’ I am going to bring about a dozen people from my team to NPE, and that is not inexpensive, but it is a wise investment.

We are investing in learning and in growing the company. If team members go in open-minded and humble enough to ask questions and learn, they are going to get 10 times whatever they spend out of it. I've gotten a 100 times

my investment back from NPE. I attribute a lot of our success to the things I've learned year over year, not just going once or twice.” ■

For more information visit https://asph.link/vw0w7r

Starting a business and managing a business aren't the same thing. While they both require a certain amount of boldness and selfdetermination (and perhaps just a dash of brazenly-acquired luck), once you have your idea up and running, the running part is what can burn you out, trip you up, or spell the end.

Maybe you're at the point where you've started the side-hustle, making ends meet with extra work, and it's doing well and you're considering growing or taking things full-time. Maybe you're considering launching the startup, but things haven't come together yet. Or maybe your business has been sitting on idle for a little while now, and you want to know how to take it to the next level. Whatever point you are at on the spectrum, your business journey will require not only taking risks, but taking the right risks at the right time.

That's a daunting task, to be sure, but in this month's cover story we went out and spoke to a number of business owners who all came into their parts of the industry through different methods. One started from nothing, one rescued a struggling group from closure, and another bet big on a often misunderstood piece of pavement repair technology that paid off in a huge way. They all share a lot of commonalities, but one of the most relevant is their willingness to forge their own pathway toward their goals, even when the decisions they made might have seemed unconventional or too risky at the time.

Entrepreneurs know that the work of managing a business is a constant balancing act between risk and reward.

The day that I caught up with James, he was fixing a site of one of Ohio's new electric vehicle (EV) charging stations along the I-80 Turnpike. It was all set to be paved, when sudden rains came in and washed everything out. It was well below freezing that day so, between laying "1s and 2s" and compacting, we warmed up in our cars and talked about how he got his start and worked up to where he is now.

James is the owner of Erie Northern, a site preparation company that completes excavation and base/sub-base work, often hand-in-hand with local paving contractors like Holland Paving in Northeast Ohio. When he launched the company in 2018, they had only one tandem axle hauling truck to their name. It wasn't new, but it ran, and it got the job done. But in those early days, there was just one problem. Ed James' company couldn't afford Ed James.

"Back at the time we started, I couldn't pull a paycheck to provide for me and my family and the company be profitable," James told me from the seat of his excavator.

The solution was one I never would have imagined. He ran Erie Northern, while working full time for other companies. James explained, "Yeah, I'm a member of the Local 18 International

Union of Operating Engineers, and so I took work for Carron Asphalt Paving and The Shelly Company, all union outfits, as I worked to build my business at the same time." James' company utilizes Local 18, as well.

I told James, whom I was meeting for the first time, that it was the wildest thing I'd heard. Standing there in the icy cold temperatures I said, "I bet they don't teach that one at business school."

How did he do it? Not easily. It was a constant battle, juggling cell phones, dispatchers, and schedules — but in the end it paid off. Just four years later, the company now has a fleet of seven trucks and growing. Best of all, James no longer works for anyone else simultaneously. He now just works for himself.

There are other paths for aspiring business owners to take, however, because not everyone goes all-in the way Ed James did. What works for some, doesn't work for others. There are many contractors who got their by just doing the work on the side, by themselves, out of the back of the pickup truck. This is especially true of people who work as asphalt pavement sealers. Everyone has seen trucks, now and then, driving around their neighborhoods with large tanks in the back. Lots of start-up sealing businesses get into the industry this way, according to Girish Dubey, the president of Star Seal, a company that produces a variety of sealants and additives.

Dubey has been in and around the industry for more than 50 years, and the president of Star Seal since 1987. I asked him directly, about what percentage of contractors who are successful sealers and maintenance outfits started out of the back of just one truck. "Oh, I would say well more than half likely get their start that way," Dubey told me.

Over the years, he has seen lots of contractors come and go, along with hosts of changes in the industry itself. Shifts in environmental regulations, materials and economic environments all play a huge role in the ups and downs of a business, especially in the pavement maintenance industry.

However, he felt that the thing that mattered most, consistently amidst all the other changes, was properly educating yourself on the materials and the tools at your disposal.

"It doesn't matter if all you have is that one truck and a squeegee," Dubey said, "The quality of the work will speak for itself to whomever your client base is. It grows from there."

From Dubey's side of the desk, I couldn't help but ask what he could share about running a large business with 22 locations, that smaller, locally owned businesses could take and apply to how they operate.

serve your customers better, it lays the groundwork for real success.

Taking risks always comes with one certainty. There will be no shortage of people who feel it is there role to come and explain to you what you're doing wrong. I have found that it is a lot easier to be a Monday-morning quarterback, than to actually put some skin into the game. When it's your time and money on the line, you can't subject yourself to the whims and opinions of ever single outsider that comes your way. Sure, every business manager should have a trusted circle of people they can count on to "tell it like it is" with them, but that's not what I mean. Sometimes, you've got to make your own way and tune out the noise.

Heroes to grow into a hugely successful pavement repair and maintenance network, which has spread nearly statewide, and that speaks for itself.

Young said that the infrared technology hasn't been the only divergence in running his business that draws the odd look from those on the outside looking in. He has his own approach to operations management that is a far cry from the traditional methods, but he makes a compelling argument. "If our crews have five days worth of work to do," Young said, "and they get it done in three days. Then-BYE! Have a nice two days off then."

I couldn't help but laugh along with him. The idea is so strikingly simple, that it borderlines on the absurd when you say in the context of the way a business might operate. However, Young says it has proven successful.

"It is the same," Dubey said. "The same things still apply, no matter what your size. Taking the time for proper education, the correct methods-these are the difference makers. In our industry there is a huge amount of turnover. About 10-15% don't stay with it. This is a big problem, and I think that it can be partially addressed by making resources more available to those who are serious and want to learn. And many of them are hungry to learn."

Taking advantage of the resources is a major factor, like participating in industry functions, events, webinars and conferences like the IGNITE Construction Summit, NPE, as well as many others. Businesses of every size, growing or established, need to stay informed on the most up-to-date products and industry standards to best serve their client base. And when you

For instance, I spoke with Dynamic Chief Operating Officer Zach Young of Potholes Heroes, a pavement patching and repair contractor based out of southern Florida. What's interesting about Young's approach to growing his business, was the tools he chose to invest in, as well as how he utilizes them differently than most other contractors in his field do. Frequently, it is the case that pothole repair and asphalt pavement patching is a side portion of business for pavement contractors who's primary focus and source of business is paving itself. Young's company takes a different approach, utilizing an array of infrared tools, hot boxes, and reclaimers--it's their whole business.

What surprised me was how much pushback Young described getting from other contractors in the industry. Young said, "I was in the Nashville airport, talking to a guy and he just straight up tells me that infrared isn't as good, that it takes too much time, or that it doesn't last as long. I mean, to me it just made me want to know more, but that's my nature. If someone gets that way about something like that, I'm kind of contrarian that way. I've got to find out for myself, and I did." That personal investigation led Young and Potholes

"We aren't looking to squeeze our crews for every possible minute, that just burns people out, they leave, and then you have to start over again with new hires," he said. "I think that's a reason we've had some success in our recruitment and turnover, as well."

Another way to find avenues for business growth is to find gaps or needs in a given market, and devise a way to either solve the problem better than it's currently being addressed or to solve one that seemingly is being overlooked. The place to start is always with the target audience of your given market, doing a little investigation and research goes a long way.

Mike Blake, marketing director of KM International, a manufacturer specializing in pavement repair and recycling machines, and based out of North Branch, Michigan, described the way the company wholly developed a new product based simply on a customer asking if it was possible. At first, they weren't sure that it was, but, rather than turning them away, they just got to work on figuring it out. This too carried some risk. Expending resources and time on a project that wasn't guaranteed to result in success.

Blake recounted it, "A lot of the hot box trailer variations we sell started just like that. A lot of the solutions we come up with happes by just saying let's go out on the floor and start welding, and see what we can come up with."

That's a potential avenue for people on the hardware side of things, but in today's pavement and pavement maintenance world, the software you choose (or the lack thereof) to incorporate as your business grows can be the difference maker due to the volatility in the supply chain. The better you can plan, the better possibility of success. But building software is, also, about meeting the needs of those who use it. As a business, establishing open channels of communication with your clientele is a vital component to growth.

Kerin Hughes, the CEO of Pavement Management Pro, a recently-launched management platform designed to support contractors in the paving and

pavement maintenance sector, spoke about their team's development process.

"We're continuing to get the customer feedback even now on a monthly basis," Hughes said. Leading up to launch they went through several rounds of testing and refinement until they felt the product was something actually useful to contractors.

"What it came down to is: what do they need right where they're at," Hughes continued. "Let's create a program that will actually help these guys out based on their workflow. How do they actually do business? Let's create a program that makes that easier and connects the paving guy with a stripping guy, with a sign installation guy, and so on. It's one big circle."

Every business is a system. They are complex. What that means is that there

does not exist simple, easy answers to how to grow, increase sales, and, ultimately, be more successful. Any secret answers that are easy and sound too good to be true, are too good to be true. That doesn't mean that there aren't any answers at all, it's just more than likely that those answers will require you take a risk.

A risk of more of your time. A risk of greater capital investment. A risk of trying something outside the established norm. It won’t guarantee success, nothing truly will, but there is one guarantee you can count on in your business. If you don't take any risk at all, you severely limit the possible future of your business. ■

For more information visit https://asph.link/uf44sz

Engineered and built to exceed the demands of commercial paving, Weiler pavers, compactors and tack distributors incorporate proven designs with new innovations to provide performance, reliability and outstanding results in a wide range of applications. Weiler equipment is sold and serviced exclusively at Caterpillar dealers throughout North America, providing unmatched support with factory trained technicians and readily available parts to keep your operation up and running.

Asingle cab truck. A 300-gallon, hand-agitated sealcoat tank in the back. A hand blower, stiff broom, a couple gallon jugs of crackfiller and a squeegee. If you have had to climb up from the bottom in this industry, you recognize the outfit.

Now, to take you back, remember the end of the day in the cab of that truck on your way home from slaying a couple $350 driveways? No air conditioning, you’re sweaty, but you have the windows down, taking in some desperately-needed air. Radio, if you were like me, blasting “We Takin’ Over” by DJ Khaled. Remember that feeling?

Whether you were alone or had another person in the cab with you for the day, unbeknownst to you, that atmosphere was/is what’s known as company culture. That’s where it starts, and depending on how, and if, you focus on it and/or nurture it, it grows from there.

That is how culture was started at Wis-Coat. I’m sure there are some similarities and differences in your story of the climate within your business, especially if you have grown it from there.

I, Marvin, believe I was born with something that makes me naturally take action to control the environment I am in so that I am comfortable. That may be a good thing, but it is also a bad thing if a person gets too comfortable and stops focusing on their goals.

I didn’t change that “culture” you heard me describe earlier for eight years or so when I started. It took me to a certain level, but then I plateaud.

It wasn’t until I started to desire more growth within my business that I realized something. We had more employees and I had less time to be on the sealcoat crews> This meant I was needed to impress upon the company my focus on integrity, quality, drive, goals, satisfaction, and sense of pride. I was going to have to do it at a larger scale. I needed to create an atmosphere that oozed this “culture” from every aspect.

It seemed a daunting task to translate what existed everyday in my mind, out into my team, and thus, out into the community we aimed to thrive in.

I started, of course, with social media. If you have seen any of my videos, you know that I express exactly what separates us from any competition: What we expect from ourselves as a company and what we promise to deliver to our customers. Oh, and another thing, we make what we do fun. On purpose. The leaders at Wis-Coat do everything we can to make this not feel like work, and it shows in our content. It showed through our content the first three years after we plateaud, when it was just me and one other guy. What did that create? I’ll share.

Whether it was online comments or in-person customer interactions, I would often hear, or see (for the insecure jerks in the comment sections on posts) things like, “We thought you were a BIG company”, “You guys work for them. So, we wanted you to work for us”, “On your video we seen your work and you sounded like you know exactly what you are talking about.” And simply “We Trust You.”

All the types of things you would want to hear if you finally build up the

nerve to put yourself on camera and show your work to the world through your posts. I noticed something, though. My only helper at that time, who had been with me for two years, started to emulate me. He would repeat to customers what we are about here. He would tell them what they can expect and even took time during his off hours to read articles, look in Facebook groups and more. I know this because he started to talk about things we hadn’t spoken about in our company yet. I noticed a change in his actions outside of the company, in a positive way, not all, but some. He was really living what we believed here in the company. Our core values were becoming his personal core values.

Once we started taking on more employees, I watched the process repeat. My crew lead Chris makes me feel as if I am in two places at once. He does not compromise anything that we are about culturally, and he emulates our core values to the people he leads.

I have been able to scale Wis-Coat off this foundation. More people, more crews, more work being done and more of the culture we desire being fostered within our company and out into our community and for our customers.

People seek us out, to work at our company, because they can see and hear the difference we make in our community and in our employees’ lives. It has grown beyond myself having to be the only one focusing on the culture. My team wants more success all around and they have seen the tactic pay off. We all want to have more of what makes us feel good about our lives. Your culture in your life, mind, and business is where that starts and where the key is. If you

want to see different results, change your culture.

If you walk into the Wis-Coat office in Lone Rock today (which I encourage you to do, we love visitors), you will see four sentences painted on the floor just as you walk in:

1. Be Positive Here.

2. We Have Goals Here.

3. Don’t Half-A** It Today.

4. You Get What You Give.

This is culture has gotten Wis-Coat to this point — from a small company in a single cab truck to a mid-size company on its way to a big one. There is still work to be done to get us there, and adaptations to be made along the way. But we will, again, learn and implement the culture of the larger companies that led the way before us, to get there, while staying true to the culture that got us here.

-Marvin Joles, owner at Wis-Coat, host of the Blacktop Banter podcast

It's interesting how similar Marvin’s and my story align, as far as, our humble beginnings, the trajectory we are both on, and how it all happened. It appears that the only difference in our two stories is that Marvin is primarily on the maintenance side of the asphalt industry. ADC Paving is full spectrum paving and pavement maintenance, which has allowed for greater revenues and ultimately led us to become a larger company at a faster pace.

That doesn't mean bigger or better by any stretch of the imagination. Culture is culture, and small-time culture is culture that lasts and gets in the veins of your teams, to the point where I know that when my team shows up to the field, that they're playing for the name

on the front of the jersey instead of the name on the back; the blood flowing through their veins is black and orange.

The reason I know this is because over the past six-and-a-half-years we diligently developed, fostered, nurtured, and modeled being humble servants as our culture here at ADC Paving.

It hasn't always looked like it looks today, and it won't look the same five years from now, because culture is one of those things that is ever-evolving and ever-changing. It’s almost like a living organism, because it consists of living, breathing, evolving, and changing people; as well as their thoughts, their ideas, their creativity, and their passions.

You see, culture is created by every member of the team, yet it is up to the leader to cast the vision. They tell the story and breathe life into what the culture and workplace can become.

”

The single most important duty for me in this lifetime is to be and become the ultimate role model to my two young boys, Jack (12) and Phoenix (5). Fortunately, being the prime example for two boys, who will one day become men, has helped me stay the course in creating and nurturing a business culture of our own at ADC Paving.

There are so many qualities in my father that have stuck with me through the first 41 years of my life. They remind me to operate and carry myself with integrity, treat others with respect, be kind, be compassionate, and, overall, just be a really good human being. One whose heart is most full when he is serving others around him.

Couple that with a diligent work ethic, and a motor that just won't stop until the task is done, and I believe that some of the greatest cultures known

to the business world are formulated. Being the owner and operator of this company, I knew that culture change was going to take my ultimate attention and I was going to have to live out by example each and every day.

Luckily, my passion for serving people and helping people live up to their

fullest potential has helped me build a company that is rich with culture.

We operate with a mentality that we will do whatever it takes to deliver our customers the experience they deserve, but better yet, to improve the lives of those who wear the black and orange uniform with pride. During the early

years, I'm not sure that I understood that this would become my ultimate goal, passion and purpose for operating this business.

As each year passes and as our culture grows, not only in depth but in width, it becomes more and more clear that changing lives, providing opportunities for others to better themselves and to be able to coach, teach and mentor those both young and old, within the organization, with some of my favorite philosophies and principles on life, purpose and humanity has paid me back over the years in dividends beyond measure.

We have been on the journey here at ADC Paving to change the culture during the past five years and I understand that it could take five more to get it where we really, and I mean really, want it to be. When I first met with

my mentor who owns a large general contracting business here in Louisville, who also operates a paving division, he explained to me that their culture change happened over a course of 10 years. That absolutely blew me away when I first heard that.

Now that we're five years in, I can completely understand and appreciate the dedication that truly changing a culture or establishing a culture takes. Culture is based on the morals, values and the things most important to you that you believe in. For us here at ADC Paving, those look like passion, respect, integrity, dedication and excellence.

When you stand back and look at those five words, the first letter in each of those also spell the word pride. Things that require zero talent, like being on time, showing effort, being coachable, having a good attitude and staying humble yet hungry, can lead to a workforce and team filled with amazing

individuals who in turn are taken care of and responsible for the direct happiness of your customers.

To create and maintain an unbreakable culture, you absolutely must stick to the non-negotiables that are established within the team and organization and there must be accountability. The accountability of the leader is the most important. He or she is the ultimate example of the culture and their actions, their words, the way they carry themselves, the way they treat people, the way they handle conflict, the way they celebrate wins and how they handle themselves in defeat, will ultimately begin to shape and mold the culture of the entire organization.

For years, I didn't understand that I would have to endure a lifestyle change and show up as the best version of myself day in and day out for this culture change to begin even remotely, but as I figured that out it became my mission, my

purpose and in turn also made me a better father. The thing I believe is the hardest with culture change and implementation of culture is the accountability piece, because no one likes to let go of decent or even good employees, but if they are unwilling to carry themselves in a manner that line up with the non-negotiables, the core values or the 10 things that require zero talent, in our business, then they simply do not fit.

The process of holding those things accountable is meant to weed out the weak. Also, one of the hardest things I had to learn and accept was this didn't mean those people were bad people or even bad employees, they just weren't a good fit for ADC Paving, for our customers or for their other teammates. Our philosophy is to hire on personality and character rather than talent. Give me great people and we can enable them to be phenomenal asphalt technicians, operators, sales staff, administrative,

management, etc. “People over talent” and “Actions Over Words” are statements that we live and die by. Ultimately it is what our customer experience lives and dies by and we must protect what we have, hold each other accountable and foster healthy communication to give us the feeling of being unstoppable.

That said, culture is a two-way street between company and employee. It is unlikely that you were going to get much in the way of reciprocation from an employee if you're not willing to be all-in on culture from the company side and that can look a lot of different ways. The message always starts, “they don't care how much you know until they know how much you care.”

Write that down, store it in your memory bank and hold it tight for the rest of your career if you want to be a respected and emulated leader and the

true evangelist for your company and the members of it. Culture starts with understanding your people and going above and beyond to figuring out who they are, what makes them tick, what makes them feel appreciated, what may turn them off and so many other key emotional triggers. Most say in big business that you can't mix business and personal, but I couldn't disagree more.

Most larger businesses miss this sentiment when they are wondering why they can't get the production, efficiencies and/or quality from their workforce. Some ways that we do this with our team is to have them fill out a “how I want to be coached” form, which ask questions like what they need most from a coach, what motivates them, what they expect from their coaches, what their triggers are, etc. Answering simple questions like these really help us to understand how unique each individual member of our team really is.

We also like to conduct a core values index on our folks to understand them on some of the deepest levels possible, again so that we may be better coaches, leaders and teachers for our people and gain their full trust and absolute buy in to the company’s mission and core values. We take regularly scheduled meetings very seriously, along with quarterly team building activities and are very consistent and transparent on all the social media platforms, which all our employees tune into. By the way, the messages in these social media platforms should also be derived to reach potential new hires and not only customers.

We have found many of our very best employees through social media platforms because our message consistently gives a transparent look into who we really are and what we stand for. People with common goals, vision and morals tend to flock to companies they can align with these capacities. Some other

techniques we're mindful to use are surprising our team members whether it be monetarily or with some other gesture because there is a direct connection between surprises and happiness.

My favorite technique to use when working on improving the culture is the teaching and training aspect, and providing education and skills training as frequently as possible. Therefore, it is very important to foster open communication and finding employees that are open and approachable.

In closing, culture is one of my absolute favorite aspects of owning and operating a business. It is the aspect I am most passionate about and the aspect that gives me the opportunity, each day, to be who I really am and act out my qualities that best serve our company. Those of you who have followed our journey on social media know I have spent a large portion of my career out in the field with my teams. Although I

don't believe doing that is necessary to creating and maintaining a positive culture, I do know that it is a very efficient means to gaining respect and trust for members of your team in the field. Fortunately, the words I speak and the things I preach to our teams are things that I am absolutely willing to do whenever duty calls and in the end I think that is what a great culture is all about, doing whatever it takes for the betterment of each other on the team, the improvement and well-being of each other’s lives, ultimately leading those

teams to treat your customers with the utmost passion, respect, integrity, dedication and excellence. My hope is that they not only treat our customers in that fashion, but they act in this manner in each and every facet of their personal lives, as well, because for me that is the true reward. ■

Kevin Gray, president/partner at ADC Paving

For more information visit https://asph.link/yarqq9

How

There are several factors contributing to the current labor shortage. COVID-19, a worldwide pandemic affecting literally everyone. The great resignation. A skills gap where not enough skilled workers are available to fill job openings. A generational gap with more Baby Boomers leaving the workforce. Many organizations are struggling to fill positions because of the labor shortage. In fact, hiring and retaining employees has become the largest HR challenge organizations face today.

Statistics show that one of the reasons employees stay at their jobs is because they are recognized and appreciated. Happy employees report they are actively engaged, feel connected and have a voice.

What makes employees happy? How can your organization work to become an employer of choice? How do you retain employees, especially after you have worked so hard to hire them?

Organizations who incorporate values of diversity, equity and inclusion (DEI) in the workplace position themselves for

successful recruitment and retention. So, what is DEI, and why is it important? DEI is simply understanding that all people deserve to work in a safe environment, are offered the same opportunities and are recognized for their contributions. That’s simple, right?

I will be the first to say, introducing DEI initiatives is not a once-and-done “project.” DEI is not simply a belief that you profess without acting on it. It is quite the contrary. DEI principles take root in the organization’s culture and span through every layer of the organization. Therefore, DEI is a commitment that is ongoing and evolving.

Think about it this way. Have you ever worked with a problematic coworker or a mean boss? What effect did that experience have on you? Did you feel accepted or valued? Did you like your job? Probably not. This is an example of a situation in need of some culture shaping!

How do organizations implement diversity, equity and inclusion initiatives? The following are some ways to get started:

Start the conversation with key members of your organization.

Envision the advantages or outcomes of building a DEI culture. You may wish to revise or revamp your values and mission statement to incorporate your DEI goals.

Conduct management and employee training on the company’s equal employment opportunity and non-discrimination policies. (In some states, annual training is required.)

Identify the different perspectives and ideas individuals bring to the organization. In other words, talk to your employees. Hold regular meetings and invite employees to present or contribute. Create focus groups or committees dedicated to company projects or initiatives. Conduct employee surveys, communicate the results, and take appropriate actions.

This is the most important step. Follow up and evaluate to ensure goals are being met. Based on your findings, assess and redirect your plan or start on a new path altogether. Do not be afraid to change things for the better, especially when it is the right thing to do.

Consider acting on one or two of the suggestions above, and then build on it. You may also want to discover the greatest need and focus on that first. Talk with an HR professional or use outside resources for further ideas and assistance.

■

For more information visit https://asph.link/nvq38x

do organizations implement diversity, equity and inclusion initiatives?

8 reminders to make your next trade show visit easy –and successful!

It’s that magical time of year – no, not Halloween or Christmas – it’s trade show time!

Trade shows are an extremely important part of growing your business. They are filled with the latest and greatest equipment and dozens of educational opportunities. Trade shows come in all shapes and sizes, from national level shows, to smaller regional events, to even those directed to owners and executives.

I have been attending shows regularly for more than two decades. I can’t even begin to tell you all that I have learned at each show (we have bought countless pieces of iron, as well). One of the biggest benefits is the networking with others in the industry. I absolutely love to talk with contractors from all over the country about their company – and I’ve learned quite a bit about how others do business.

How to find the shows? Right here in Pavement Magazine – the go-to source for upcoming events. Don't let the size of an event scare you away. Nothing is too big for even a beginner, and nothing is too small for even a seasoned pro. I also post information on upcoming shows at the ever-popular www.pavementguru.com site.

Here are some tips from a trade show veteran to make attending an event easy, enjoyable, and productive.

• Research the city and see if you can squeeze in a day-or-two of extra vacation time. You’ve already spent the travel dollars, so taking a few extra days of R&R can be a nice break. That’s something I love to do each year. I’m known to fly in days before, and be one of the last to leave town.

• Plan to take advantage of educational classes, and for larger shows scope out various sessions in the show guide. (If you’re attending a smaller regional event where sessions don’t require tickets, plan to participate in all of them!) Don’t be afraid to branch out. Sign up for sessions about services you don’t offer, or management you don’t think you need. It’s often those sessions that can have the biggest impact. Bring something to take notes with as you attend each class. You will hear from the industry’s top professionals, so the more you absorb, the better.

• Register early and secure your tickets to educational sessions as some do sell out. Most trade shows and conferences offer a form of earlybird registration, so be sure to take advantage of those discounts.

• Book your hotel. Often show management has secured the best rates (available only through the show’s registration), so check out the rates at the various convention hotels. Check Airbnb as well, and don’t be afraid to book directly with convention hotels or with nonconvention hotels. You never know the deals you might find.

• Book your flights. Flying is getting a tad harder these days, so planning is key. Most events are near a national airport. I suggest flying in a day prior.

• Have plenty of business cards on hand. This might be considered old school by some, but they are still very convenient to pass along to exhibitors and new friends you meet. I also like to order some fresh company polo or T-shirts.

• Watch for free events, such as everpopular roundtables. Open to all, the roundtables are moderated by an industry expert and generate questions and interactions from contractors from throughout the country. Information gleaned, and even questions asked, can be enlightening – and you might just meet a peer from across the country with whom you can compare notes.

• Locate hospitality events with your favorite vendors. Often at the national shows, the top vendors will have free events. In addition to free food and drinks, they are excellent ways to network with salespeople and other contractors. It might seem tricky to score an invite to these events, but a visit to the exhibit floor booth and asking nicely might get you a pass in.

Overall, these industry-focused trade shows will boost your entrepreneurial energy like no other. You will network and learn so many things about your business that you just can’t go wrong. Hope to see you at some shows! ■

For more information visit https://asph.link/yarqq9

Nick Howell, president of T & N Asphalt Services, Salt Lake City, UT, has been a regular presenter at National Pavement Expo since 2008 and a member of the Pavement Advisory Board since 2007. Let him know your thoughts on “From the Owner’s Desk,” and if you have a question or topic you’d like covered – let him know that too! You can reach Nick at nick@tnasphaltservices.com.

National Pavement Expo 2023 brings vendors and suppliers together with contractors who make their living from asphalt and concrete paving, infrared pavement repair, seal coating, striping, sweeping, crack repair, pavement repair and snow removal.

well as inform. Sweepers Night Out offers all paid-attendees an associationsponsored excuse to let their hair down and socialize. This is where the real networking happens!

Over four days and multiple tracks, NPE2023 offers workshops and seminars highlighting the topics and skills necessary to operate a successful business in this industry: management skills, operator performance and safety, risk management, leadership strategies, asphalt design, crack sealing, paving, sealcoating principles, striping, and sweeping topics. As you know, or might expect, that last category — sweeping topics — is handled by conference partner North American Power Sweeping Association. Who’s better than NAPSA to organize that information-packed track?

To give you a taste of what will be included, the NAPSA-sponsored power sweeping track will include sessions on these evergreen topics:

• The power sweeping standard

• Best practices

• Certification

• Management and human resources

• Roundtable discussions

• Keynote speakers

• Sweepers Night Out Best practices seminars are led by acknowledged experts in the power sweeping industry. Keynote speakers deliver hard-hitting and often entertaining speeches that inspire as

How to Register? Registration for the NAPSA program (Sweepers Night Out and Annual Meeting) is separate from NPE registration. A separate registration will be sent for NAPSA. The full 2023 NPE full-conference pass includes any conference workshop or general session, as well as admission to the exhibit hall. NAPSA members have a specific discount code for free and greatly reduced sessions.

Sweepers Track Courses

NAPSA encourages members to take full advantage of the “Sweepers Track” and select the following sessions:

• NAPSA Keynote: Elizabeth McCormick – Stay Alert Stay Alive: Course code: W07 Generously sponsored by TYMCO

• NAPSA Best Practices: Course code W06

• 3 NAPSA (FREE) selected sessions:

• Josh Ferguson – Using the ANSI Power Sweeping Standard To Protect Your Business and How To Use It As A Sales Tool (Wednesday, January 25 at 1 p.m.) Course code: A05

• Derek Rayburn – The Complete Internet: Strategies To Grow Your Company (Wednesday, January 25 at 3 p.m.) Course code: A10

• Bryan Young – Environmental Benefits of Sweeping (Friday, January 27 at 2 p.m.) Course code: C11 NAPSA has a separate landing page for registration for Sweepers Night Out and the NAPSA annual meeting, as those events are not part of the NPE program. NAPSA Sweepers Night Out Sponsors will have tickets for the premier networking event.

To date, those sponsors include Stewart Amos Sweepers, Nite-Hawk Sweepers, Schwarze Industries, Elgin Sweepers, TYMCO, Keystone Plastics, Sweep Inspect, 1-800 Sweeper, World Insurance Associates and Scenic City Studio.

See you there!

As always, NAPSA will be fully represented at NPE2023. If you haven’t met the association’s executive director, Nancy Terry, that’s your chance to get to know the administrative powerhouse who keeps NAPSA organized and its business running. Find the NAPSA booth in the exhibit hall at space #1637.

NPE2023 will be held January 25-27 at the Charlotte Convention Center, Charlotte, North Carolina. The annual trade show typically attracts up to 20,000 attendees and more than 150 exhibitors. The audience profile typically includes corporate decision makers: company owners, CEOs, project managers and presidents. Attendees come from around the globe, although most of the foreign visitors are from China and India.

Built in 1995 and renovated in 2021, the Charlotte Convention Center itself is equipped with cutting-edge technology and world-class facilities. It offers over 400,000 sq. ft. of convention space with 41 meeting rooms. ■

For more information visit https://asph.link/5u0eka

The North American Power Sweeping Association (NAPSA) is a nonprofit association made up of 200+ contract sweepers, service providers and sweeping equipment dealers, manufacturers and suppliers. NAPSA is dedicated to providing beneficial support to the membership and enhancing services to the sweeping industry. NAPSA is committed to promoting and educating the power sweeping community while enhancing the environment. For more information on NAPSA membership, please visit www.powersweeping.org or call (888) 757-0130.

Executive Committee and supporting members have made

and industry-wide

and key stakeholders.

by Brian RiggsAs we look toward 2023, two of the most immediate opportunities will occur in January with additional studies and research scheduled for late spring and early summer.

In January, our research partners at Exponent will present at the 2023 Sediments Conference in Austin, Texas.

Their presentation, titled “Evaluation of Generic PAH Profiles Used in Sediment Source Characterization Modeling,” will present a case study where the results of CMB and other receptor models were used to support product bans and permitting requirements, a

major source of discussion over the past several years.

In addition, the Exponent team will undertake a massive research project related to the recent USGS ruling.

This scope will include an Evaluation of rougly 170 computer files PCTC received from the U.S. Geological Survey as a result of a Freedom of Information Act request and litigation. Most of the files contain outputs for EPA’s Chemical Mass Balance (CMB) model.

The goals for this project include comparing the results to those described in Van Metre and Mahler 2010, and developing an approach for

summarizing the large amount of data. A technical memorandum will follow. As a result, PCTC’s work will continue to ensure we keep our members and the industry at the forefront of our efforts. ■

For more information visit https://asph.link/x79ud3

For more about PCTC visit www.pavementcouncil.org.

When profit margins for sweeping contractors are already razor thin, are third party vendors helping or hurting the bottom line?

by Ranger Kidwell-RossOne of our WSA members recently contacted our office about one of the third party vendors (TPV) he was contracted with for sweeping the parking lots of some Home Depot stores. The middleman company — one of the many that are so prevalent these days for regional and national sweeping accounts — said they needed a price reduction of $5/sweep. His question tp us: Should he do that?

TPV contracts typically provide very little margin to start with. Contractors have to really sharpen their pencils to bid a price that still provides them with a normal profit margin. An unmistakeable message is given when a reduction from the contracted price is agreed to.

In essence, when an ethical contractor bids at a particular price per sweep, they are telling the client that the bid

price reflects them covering their costs, plus only the normal profit needed for equipment repair and their other expenses that allow long-term growth.

When the contractor later agrees to a discount of even $5/sweep, that indicates to the customer that the contractor was actually price gouging a little bit with their initial pricing.

Due to inflation, the margin on a pre-existing contract has probably eroded since it was signed. However, if a price increase was requested to a TPV, there’s little likelihood it would be granted.

TPV’s are notorious for finding ways to nickel-and-dime the contractors they hire, with slow payments, bogus service complaints and suspect requests like “The client has asked for a $5/sweep reduction.” For these reasons many top contractors refuse to work for TPV companies.

At WSA, we catalog all of the known TPVs and allow our members the opportunity to comment on their experiences with them. This knowledge has allowed them to find out from other members which have proven unreliable and which have not. ■

For more information visit https://asph.link/5u0eka