Politecnico di Milano

AUIC School - Architecture and Urban Design

Construction and Sustainability Design Studio A.A. 2021/22

Professors: D. Fanzini, G. Dall’O

Politecnico di Milano

AUIC School - Architecture and Urban Design

Construction and Sustainability Design Studio A.A. 2021/22

Professors: D. Fanzini, G. Dall’O

Francesca Cisaria Alessandra Colombo Simona Horakova David Peralta

Francesca Cisaria Alessandra Colombo Simona Horakova David Peralta

Access to quality transit

Bycicle Facilities

Reduced parking footprint Green veichles

Surrounding density and diverse uses

High priority site

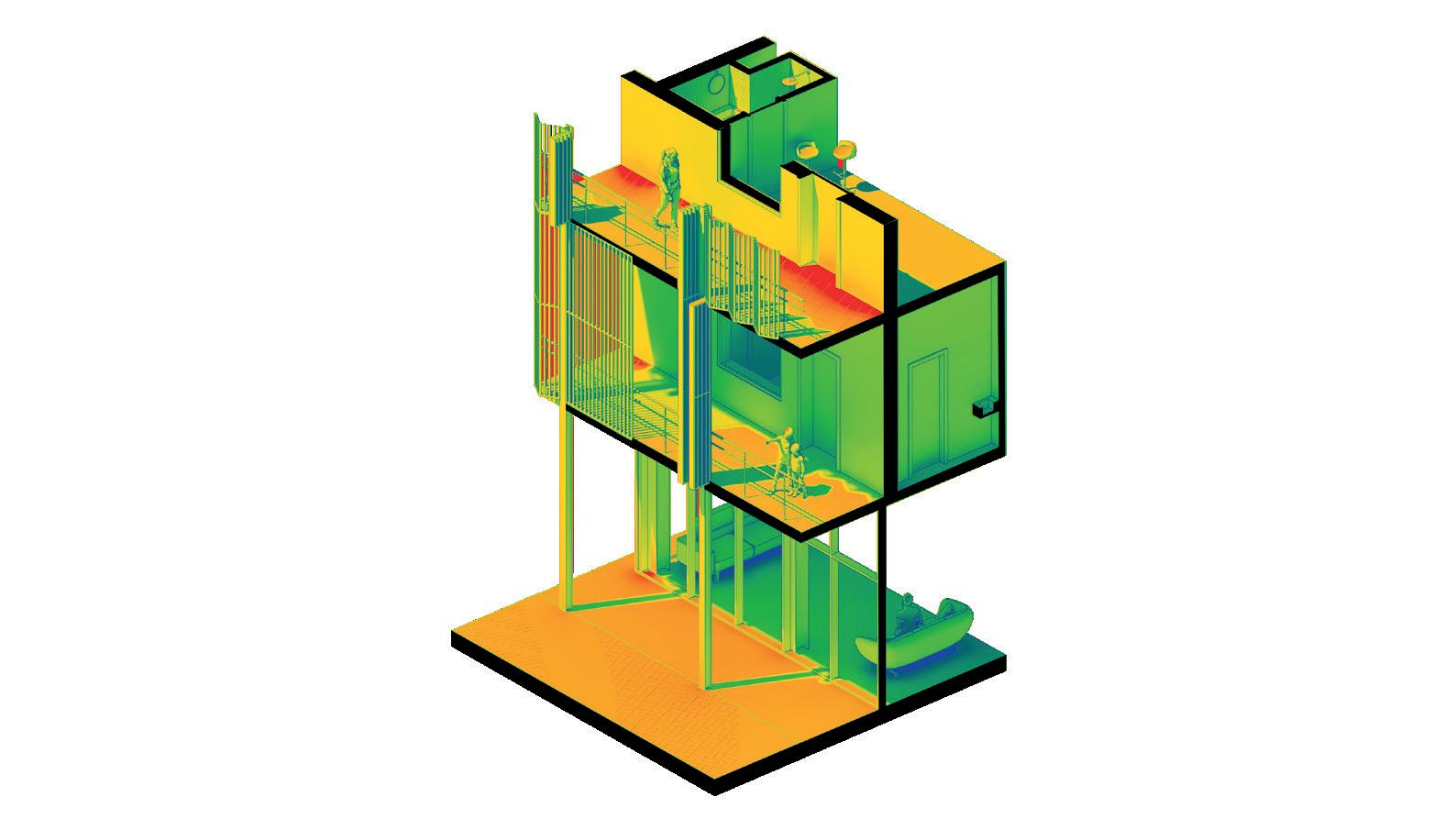

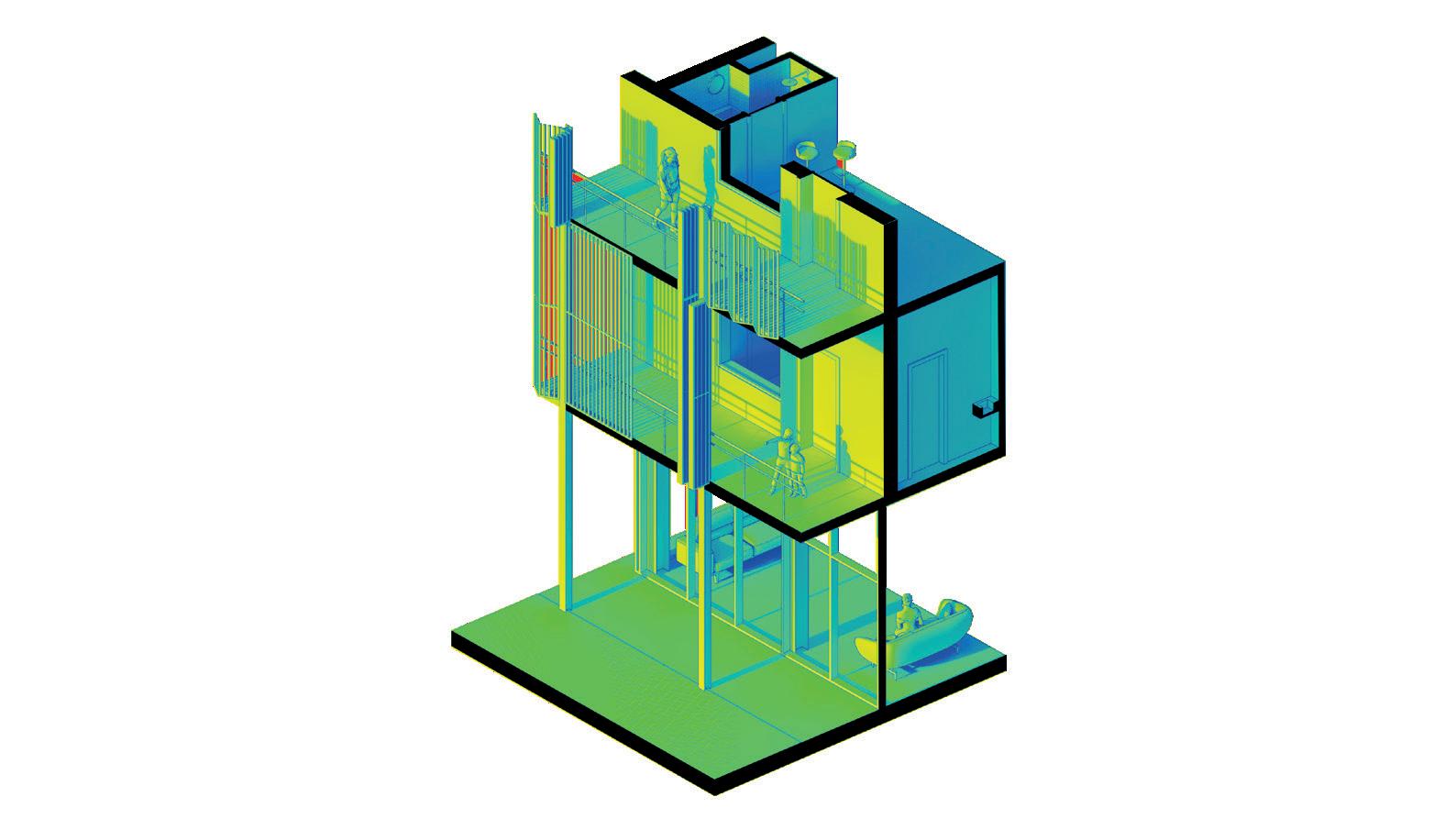

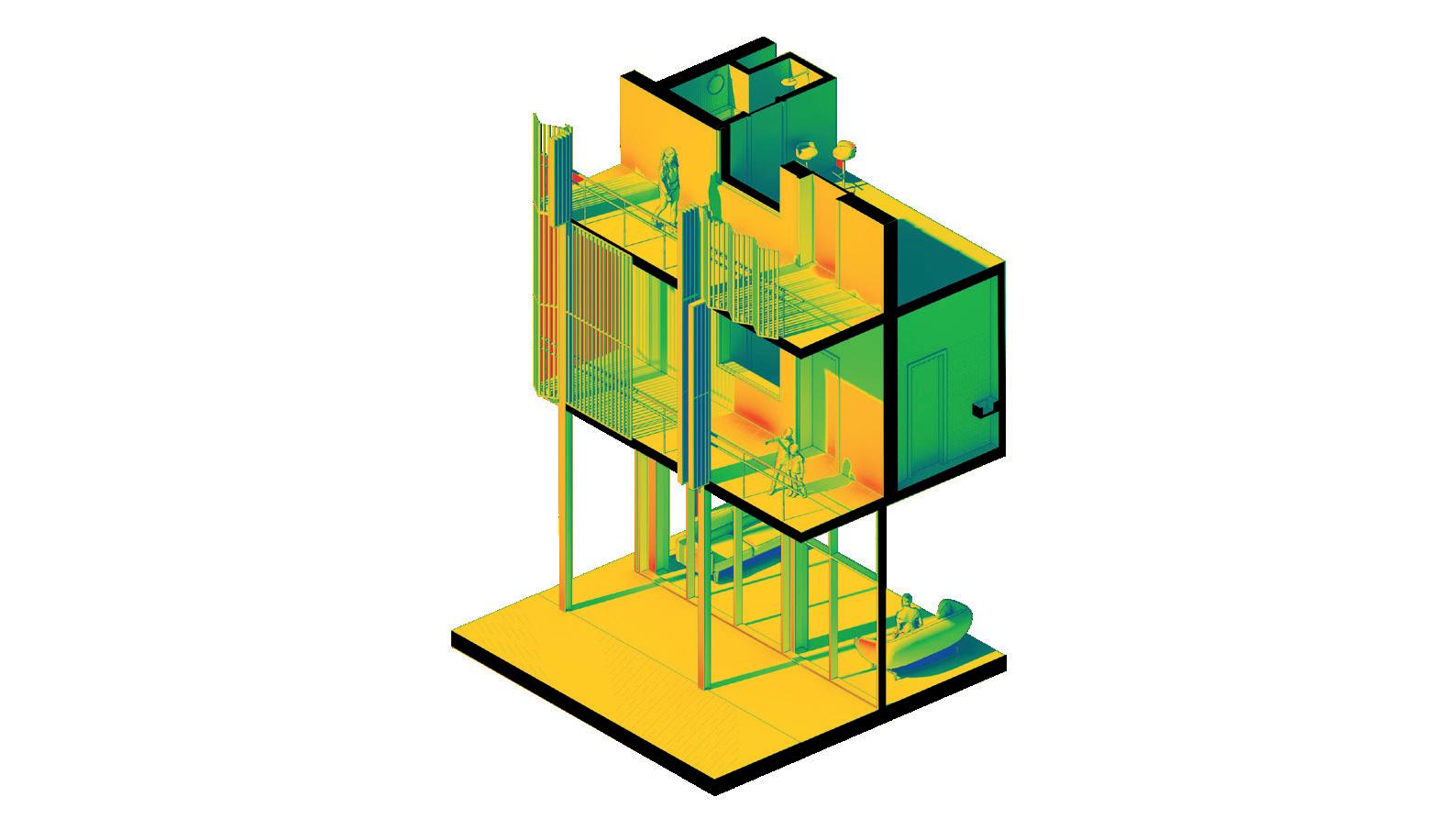

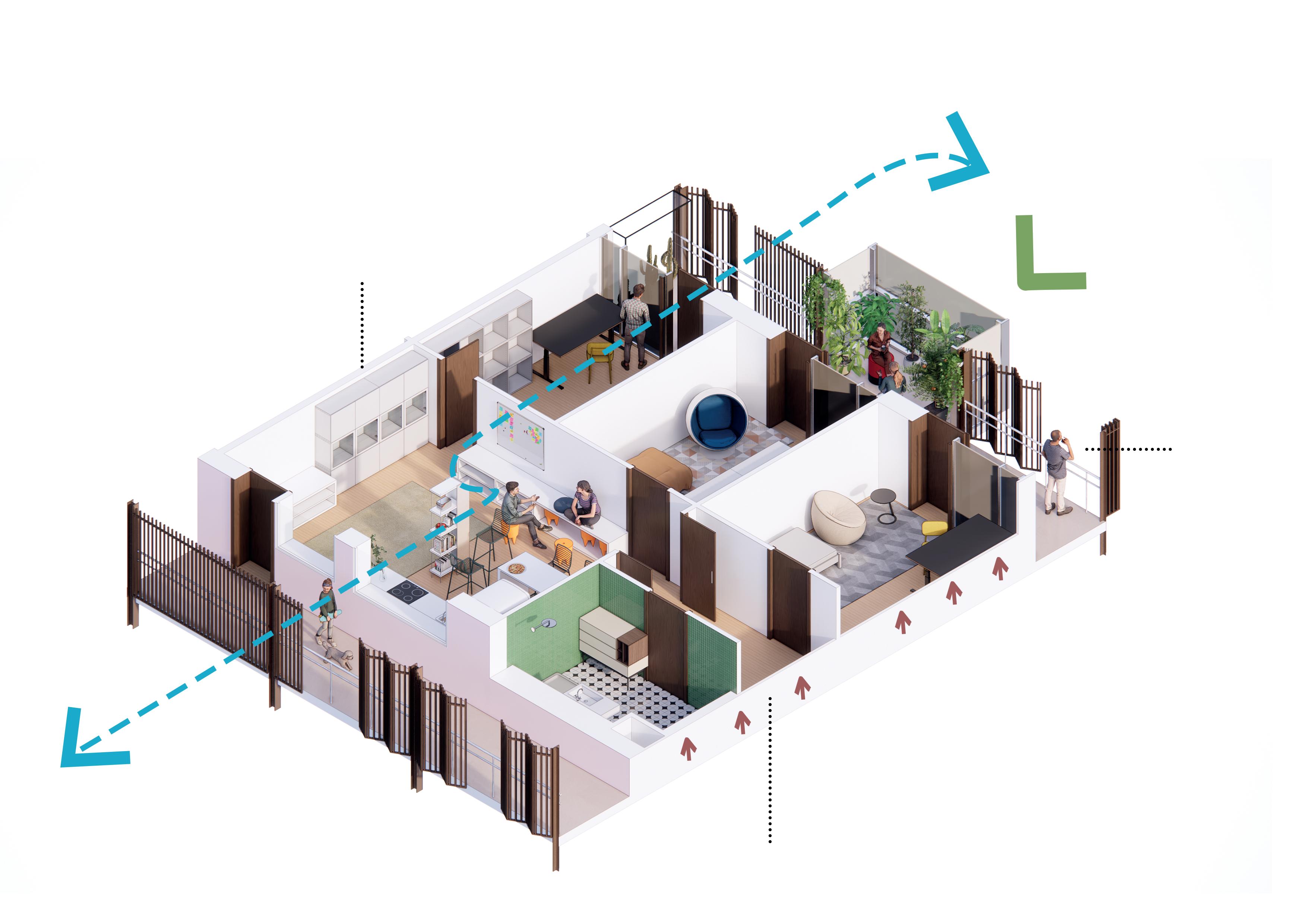

Enanched indoor air quality strategy

Low-emitting materials

Indoor air quality assessment

Thermal comfort

Daylight

Enhanced indoor air quality strategies

Low-emitting materials

Construction indoor air quality management plan

Indoor air quality assessment

Thermal comfort

Interior lighting

Daylight Acoustic performance

Site assessment

Open space

Rainwater menagement

Heat island reduction

Light pollution reducion

Optimize energy performance

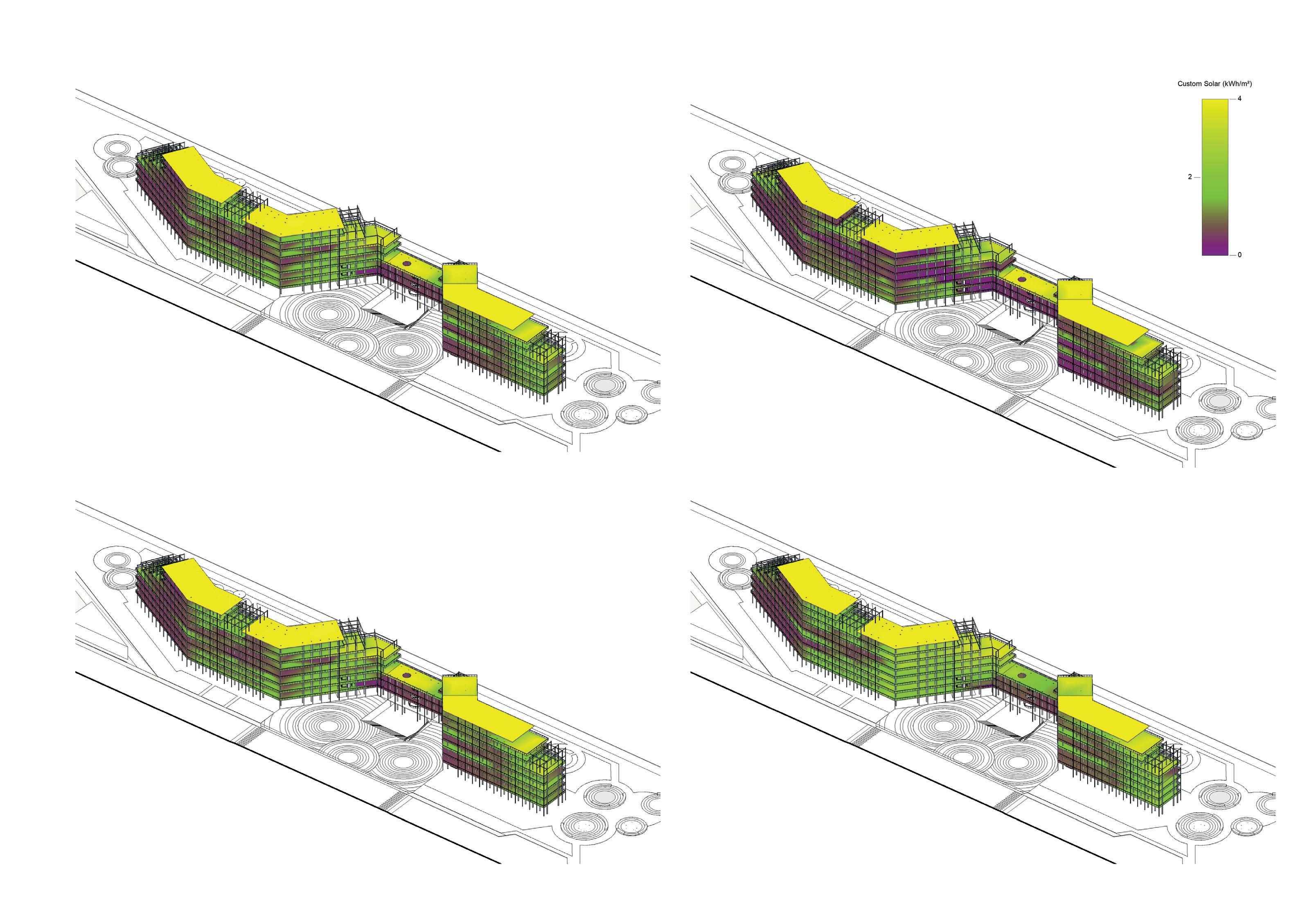

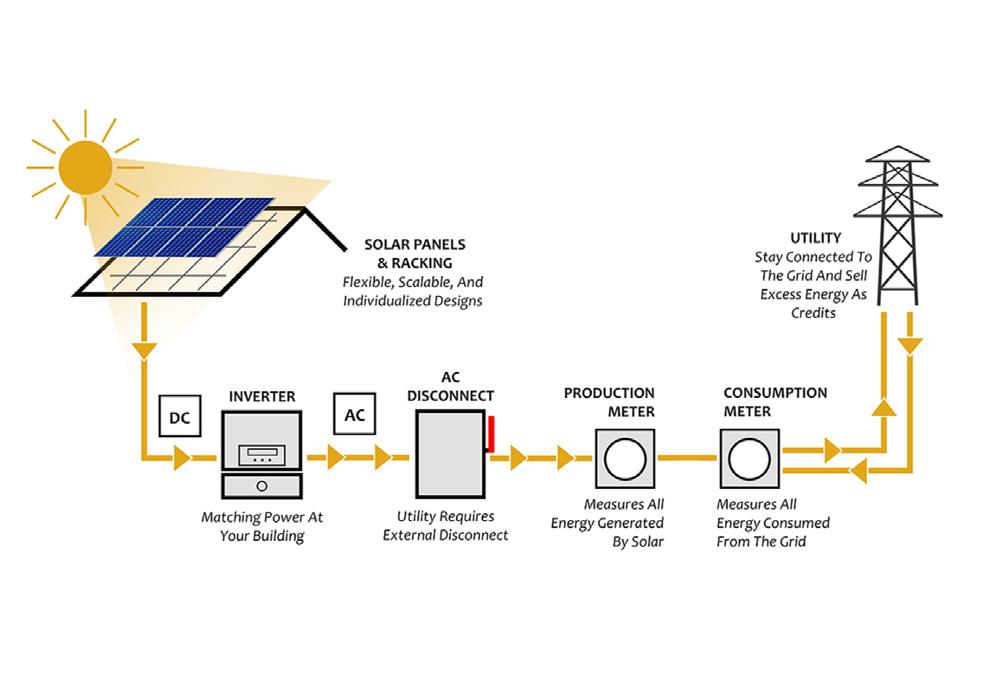

Renewable energy production

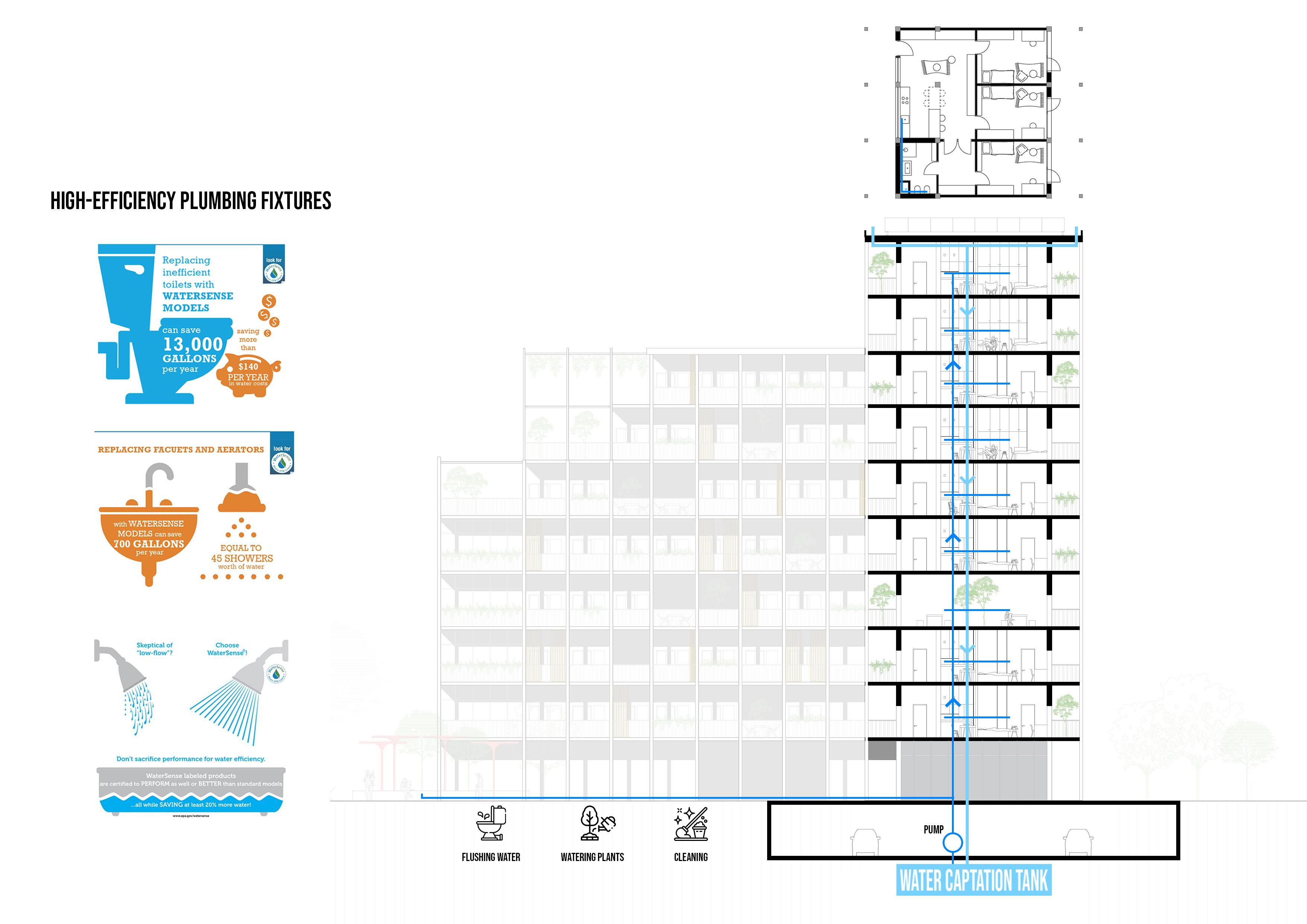

Outdoor water use reduction

Indoor water use reduction

Cooling tower water use

Water metering

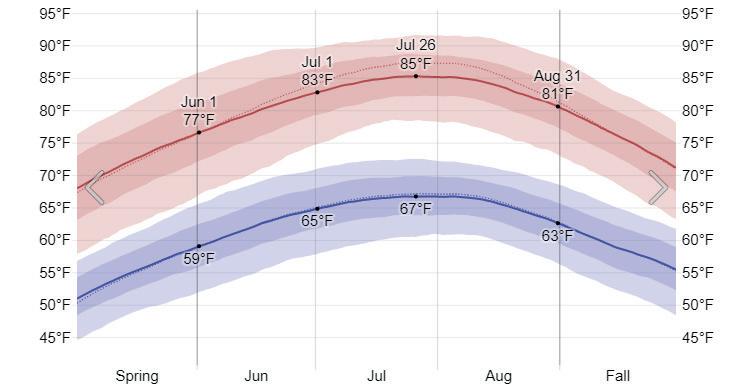

Daily high temperatures increase by 4°F, from 77°F to 81°F, rarely falling below 67°F or exceeding 92°F. The highest daily average high temperature is 85°F on July 26. Daily low temperatures are around 63°F, rarely falling below 52°F or exceeding 73°F. The highest daily average low temperature is 67°F on July 29. For reference, on July 26, the hottest day of the year, temperatures in Milan typically range from 67°F to 85°F, while on January 12, the coldest day of the year, they range from 31°F to 42°F.

Average Hourly Temperature in the Summer in Milan

Average High and Low Temperature in the Summer in Milan

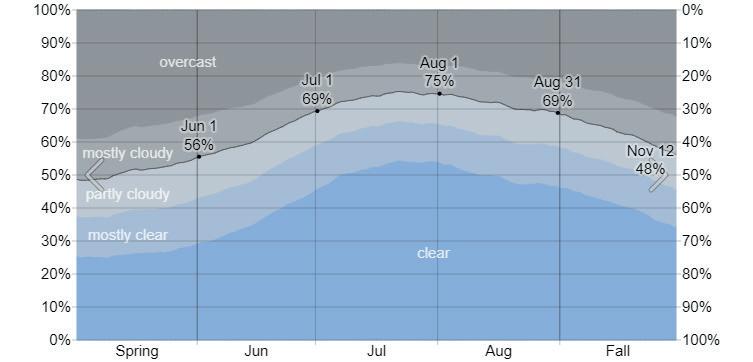

Cloud Cover Categories in the Summer in Milan

Average Hourly Temperature in the Summer in Milan

Average High and Low Temperature in the Summer in Milan

Cloud Cover Categories in the Summer in Milan

Rainfall and rainy days 20 30 40 50 60 70 80 90 100 0

Gen Feb Mar Apr Mag Giu Lug Ago Set Ott Nov Dic

Humidity and overcast days 20 30 40 50 60 70 80 90 100 0

Gen Feb Mar Apr Mag Giu Lug Ago Set Ott Nov Dic

Average daily incident solar energy

9 kWh 8 kWh 5 kWh 4 kWh 3 kWh 2 kWh 1 kWh

dark

7,1 kWh 11 Mag 13 Feb

2,5 kWh

6,0 kWh

light dark 7 kWh 6 kWh 15 Dic

5 Lug 1,4 kWh

Gen Feb Mar Apr Mag Giu Lug Ago Set Ott Nov Dic

Annual solar radia�on in Milan: 1408 kW / h per year

Humidity and temperature 20 30 40 50 60 70 80 90 100 0

Gen Feb Mar Apr Mag Giu Lug Ago Set Ott Nov Dic

14 km/h 12 km/h 10 km/h 8 km/h 6 km/h 4 km/h 2 km/h

40 C°

30 C°

20 C°

10 C°

0 C°

ventoso 8,7 km/h 6,0 km/h 7,3 km/h

Average wind speed The average hourly wind direc�on in Milan is from the east during the year.

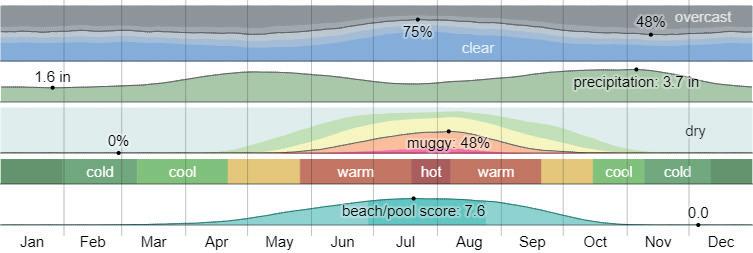

Analysis of the climatic context of insertion. Maximum and minimum temperatures

Gen Feb Mar Apr Mag Giu Lug Ago Set Ott Nov Dic

Wind speed

0 > 1 > 38 > 28 > 50 > 60 km/h > 5 > 12 > 19

1

5

4

3

2

6 0 Gen Feb Mar Apr Mag Giu Lug Ago Set Ott Nov Dic

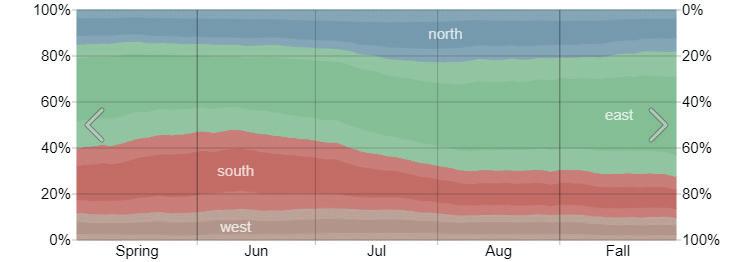

Wind Direction in the Summer in Milan

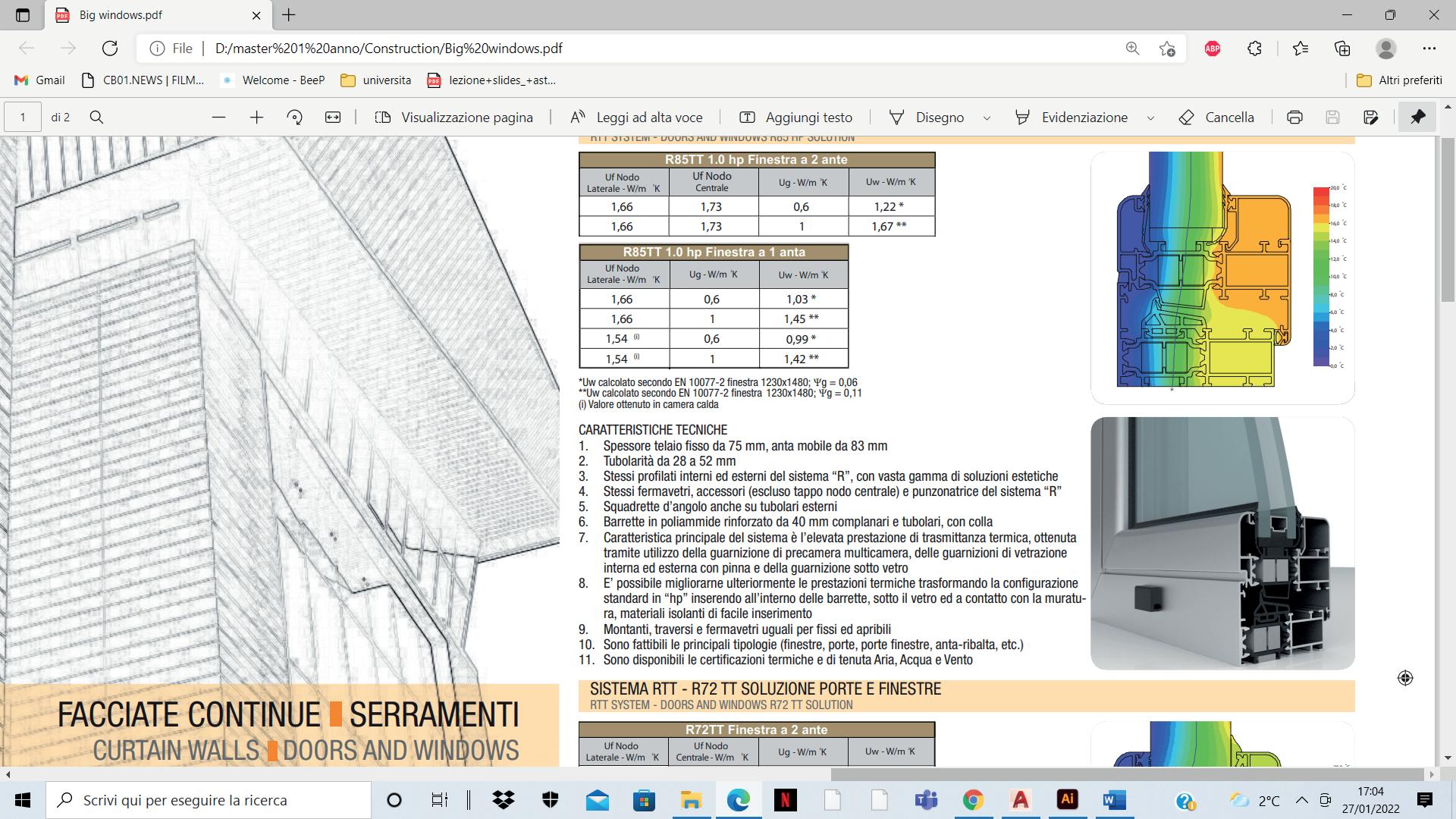

- Spessore telaio fisso da 75 mm, anta mobile da 83 mm

- Tubolarità da 28 a 52 mm

- Stessi profilati interni ed esterni del sistema “R”, con vasta gamma di soluzioni estetiche

- Squadrette d’angolo anche su tubolari esterni

- Caratteristica principale del sistema è l’elevata prestazione di trasmittanza termica

EQUITONE is a through coloured panel with no coating. As the panel has an honest, pure and natural appearance, colour di erences are possible. The surface of the sheet is characterised by fine sanding lines and white spots. The EQUITONE features grooves to the front face of the board. The rear receives no back-sealing coating. The board receives a hydrophobation which prevents moisture ingress into the core of the panel.

Durability classification

Strenght classification

Fire Reaction Water impermability Test

Warm Water Test

Dry Test

Thermal Movement Thermal Conducivity

Category A Class 5

A2-s1, d0 Pass Pass Pass 0.01 0.39

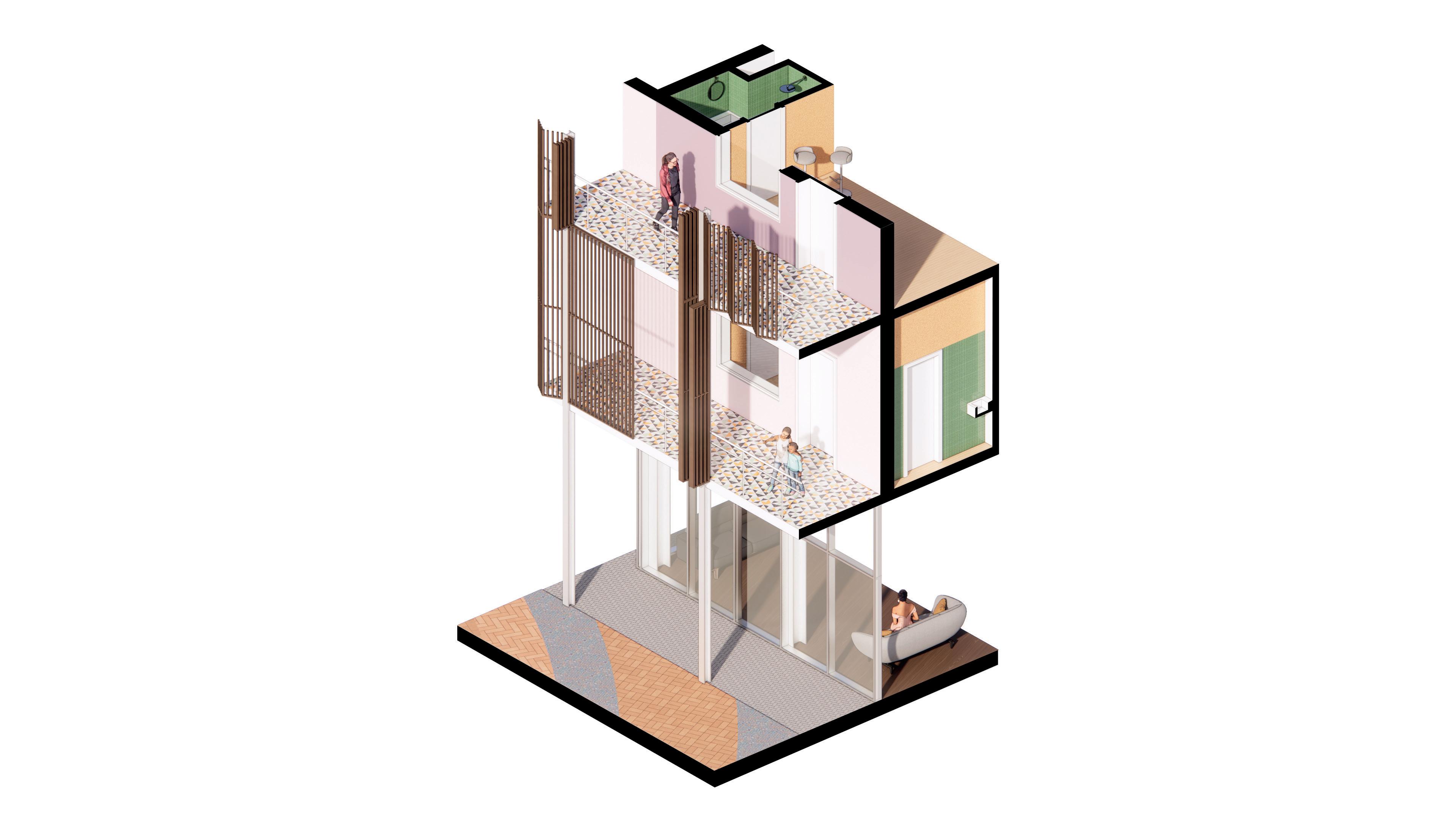

WOODEN SUN SCREENS CURTAIN WALLS - DOORS AND WINDOWS SISTEMA RTT - R85 HP SOLUZIONE PORTE E FINESTREThe housing solutions are enriched by greenhouses at high altitude - in fact winter gardens - which represent a natural extension outdoors.

Decorative and flowering plants, small vertical gardens, shrubs, vines and citrus fruit.

Building Product Disclosure and Optimization

Environmental Product Declarations Materials reuse

Building Product Disclosure and Optimization - Sourcing of Raw Materials

FALL EQUINOX 22 SEPTEMBER

SUMMER SOLSTICE 21 JUNE

SPRING EQUINOX 20 MARCH

WINTER SOLSTICE 21 DECEMBER

SUMMER SOLSTICE 21 JUNE

WINTER SOLSTICE 21 DECEMBER

ACOUSTIC INSOLATION IN THE EXTERIOR WALLS OF THE FLATS

Exterior louvers allow people to control the amount of sunlight they will receive in their rooms

FLOORING CENTRAL HEATING

composite wood Products FOR FLOORING, CEILINGS, WALLS AND FURNITURE. USING THEM, iMPROVE THE AIR QUALITY

Decorative and flowering plants, small vertical gardens, shrubs, vines and citrus fruit

composite wood Products FOR FLOORING, CEILINGS, WALLS AND FURNITURE. USING THEM, iMPROVE THE AIR QUALITY

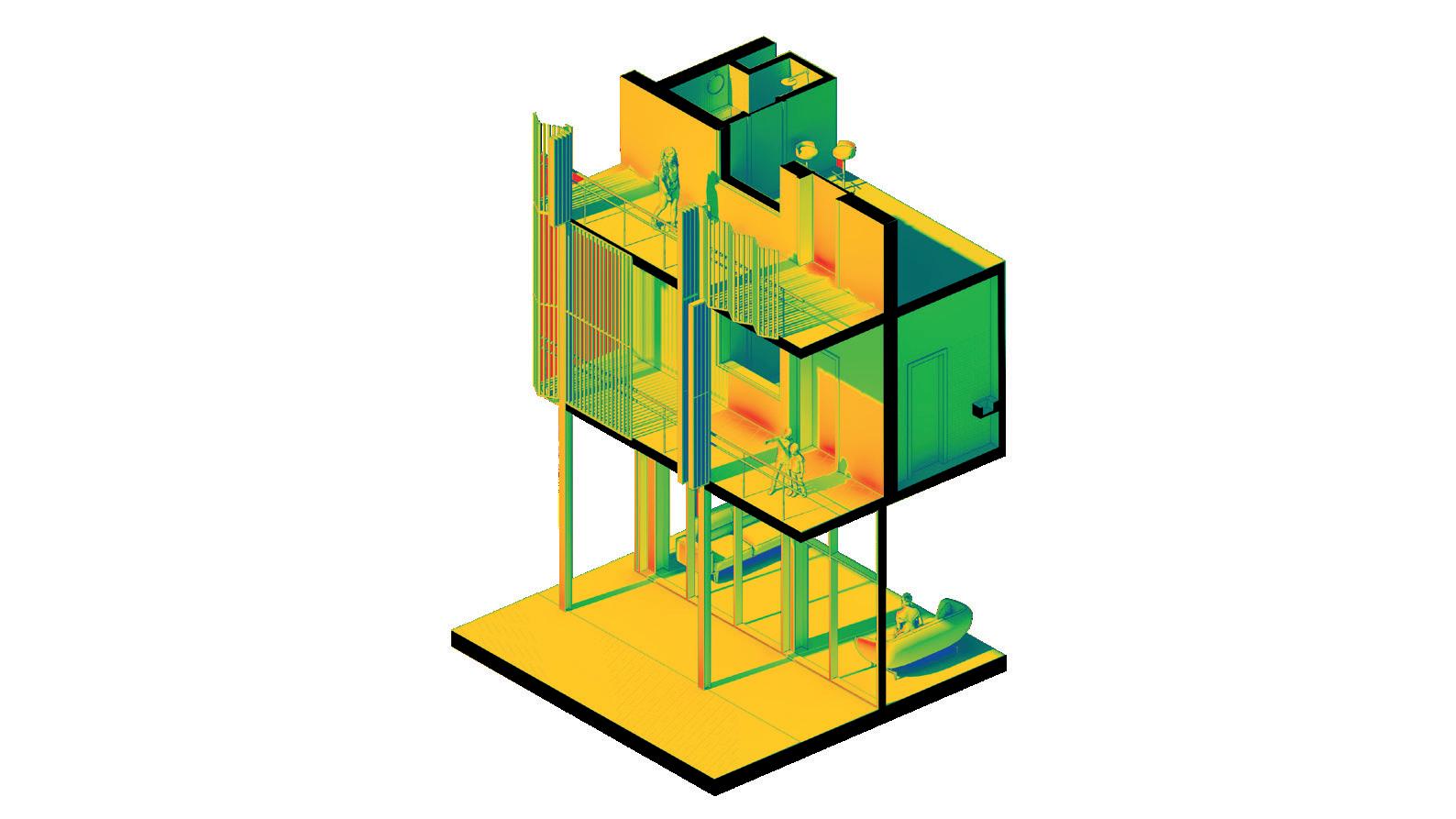

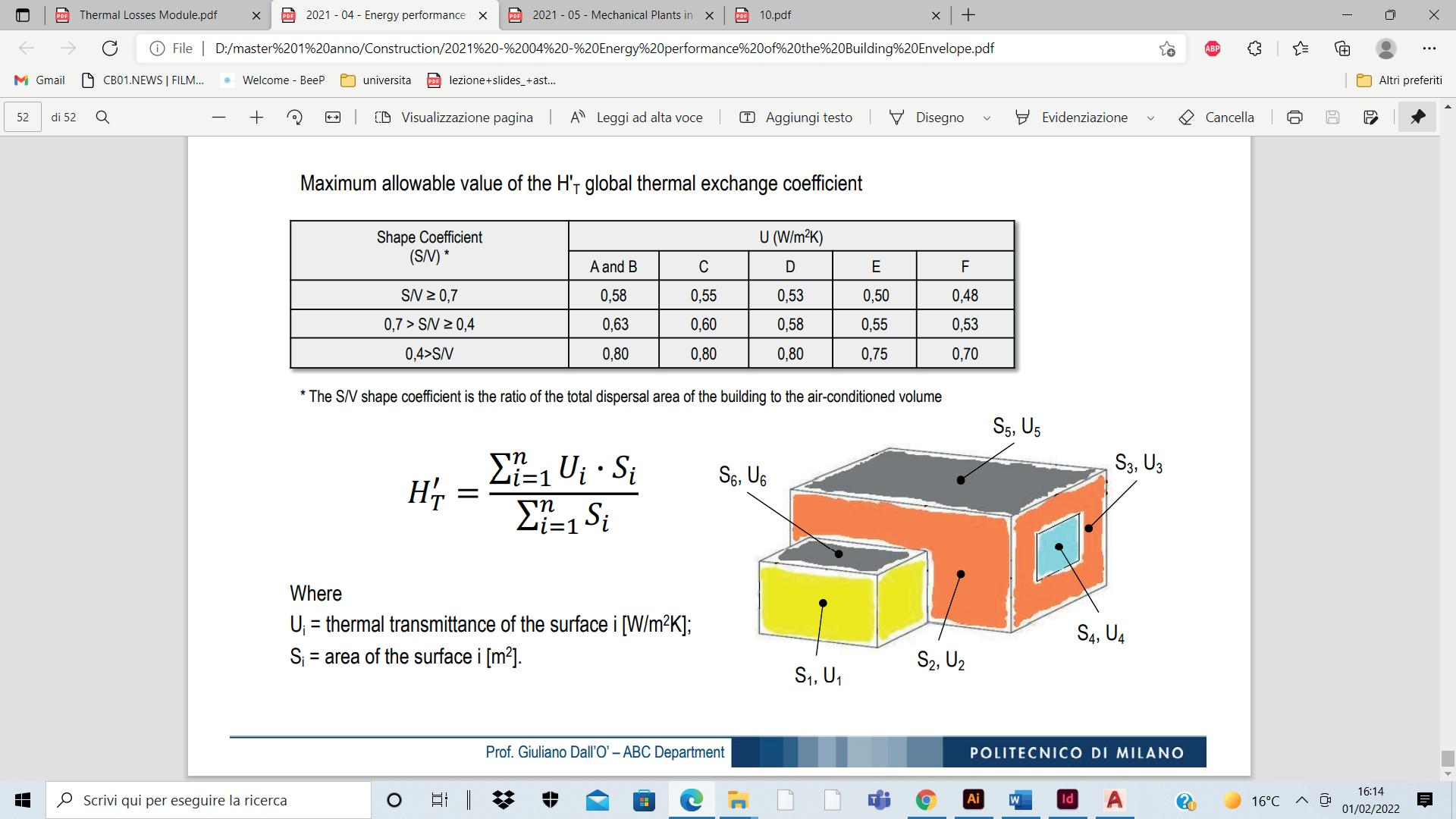

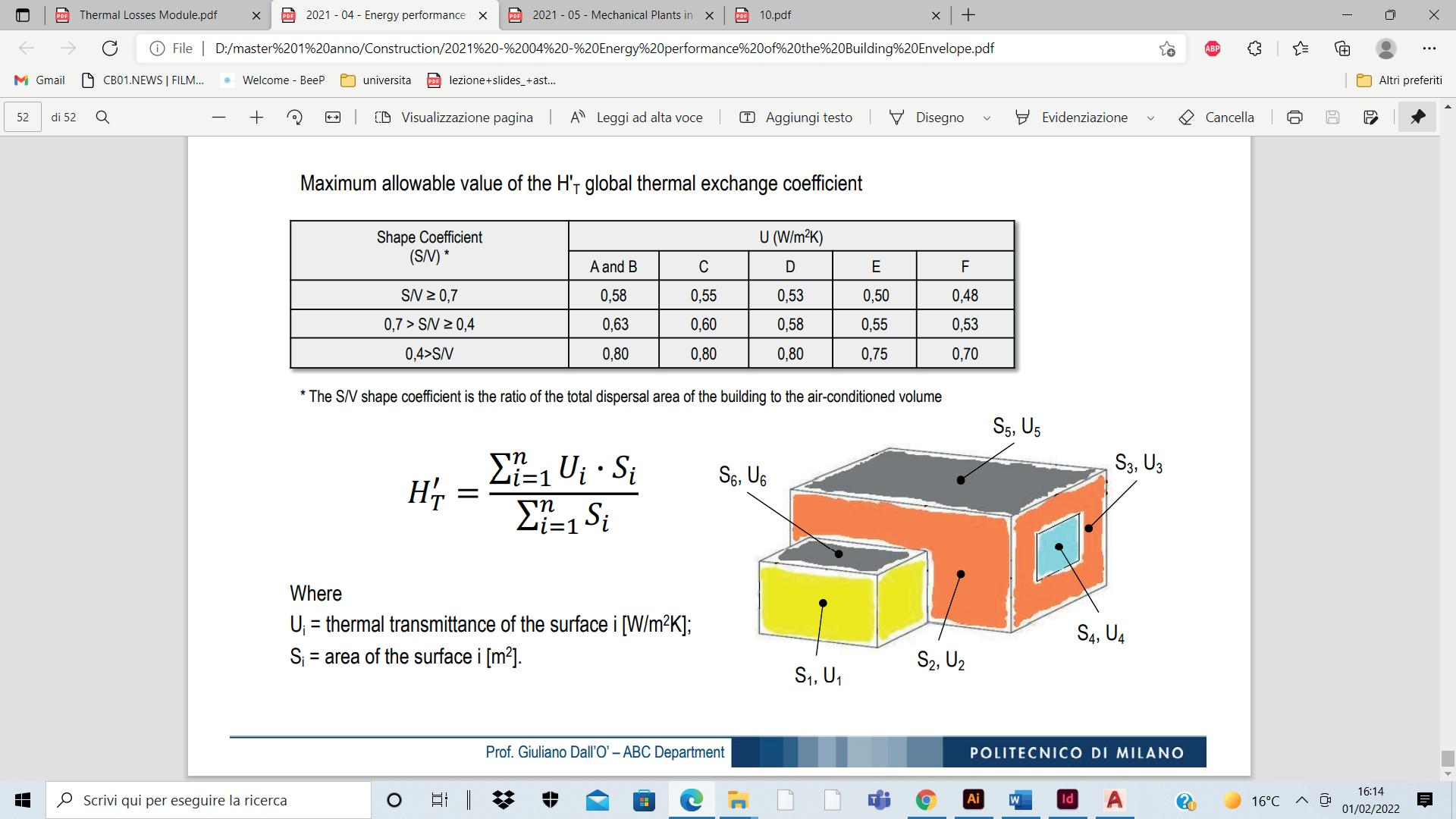

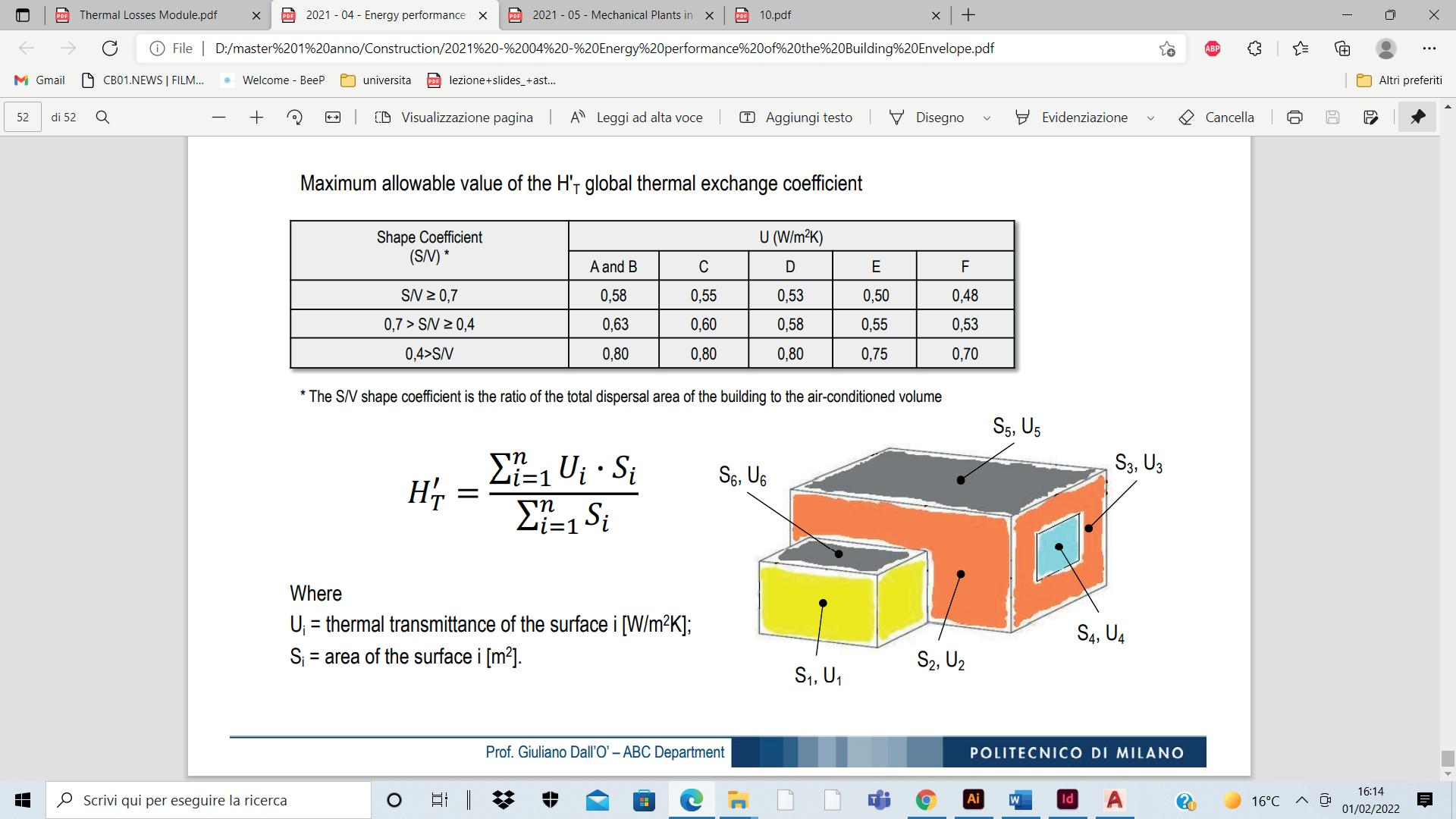

H’T= 0,46

Shape Coe cient

S/V= 15465/35384= 0.44

Maximum allowable value= 0.55

Room Intended use Ti (°C) Te (°C) Δ T

20 -5 25

Heat Losses coe cient for transmission through walls Hd Hd = UK · AK · fK

N Description U (W/m2K) A (m2) Hd (W/K) 1 Groundfloor to garage 0.85 1 1 1

0.18 0.12 0.14 1,1 1,3

3240 7991 3068 3396 1010

2 Walls 3 Roof 4 Windows 5 Winter garden Total

1

Heat Losses coe cient for transmission through thermal bridges Hpt Hpt = Ψ · l · fK Hpt= 20% of Hd

Design Heat Losses for Transmission QT QT = (Hd + Hpt) · ∆T W

Thermal Losses coe cient for ventilation Hv = 0,34 · Vi · nmin Net volume Vi m3

Minimum ventilation rate n min h-1

Design Heat Losses for Ventilation QV QV = Hv · ΔT

495,72 958,92 429,52 3735,6 1313 6932,76 1386,55 207982,75 14070,56 351764

Overall Design Thermal Losses QT + QV 559746,75

F1

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Fibrocement Panel EQUITONE 0,02 0,39 0,025

Fibergypsum Acquapanel outdoor 0,013 0,3 0,043 Vapor barrier 0,04 0,4 0,1 Rockwool Insulation 0,15 0,037 4,05 Rockwool Insulation 0,15 0,037 4,05

F1 - EXTERNAL WALL MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Fibrocement Panel EQUITONE 0,02 0,39 0,025 Fibergypsum Acquapanel outdoor 0,013 0,3 0,043 Vapor barrier 0,04 0,4 0,1 Rockwool Insulation 0,15 0,037 4,05 Rockwool Insulation 0,15 0,037 4,05 Fibergypsum panel 0,013 0,3 0,043 8,32

Fibergypsum panel 0,013 0,3 0,043 8,32 Coefficienti Resistenza 1/coefficiente hi 7,68 0,13 he 25 0,04 Ca Air 6,4 0,15 T O T A L R 8,64 U v a l u e 0 , 1 2

F2 - PARTITION WALL with stairs

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Fibrocement Panel EQUITONE 0,02 0,39 0,025

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Coefficienti Resistenza 1/coefficiente hi 7,68 0,13 he 25 0,04 Ca Air 6,4 0,15 T O T A L R 8,64 U v a l u e 0 , 1 2

Fibergypsum panel 0,013 0,3 0,043

Rockwool Insulation 0,125 0,037 3,38 Concrete 0,2 1,1 0,18 3,60

Fibergypsum Acquapanel outdoor 0,013 0,3 0,043 Vapor barrier 0,04 0,4 0,1 Rockwool Insulation 0,15 0,037 4,05 Rockwool Insulation 0,15 0,037 4,05 Fibergypsum panel 0,013 0,3 0,043 8,32

F2 - PARTITION WALL with stairs MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Coefficienti Resistenza 1/coefficiente hi 7,68 0,130 he 7,68 0,130 Ca Air 6,4 0,156 T O T A L R 4,02 U v a l u e 0 , 2 5

Coefficienti Resistenza 1/coefficiente hi 7,68 0,13 he 25 0,04 Ca Air 6,4 0,15 T O T A L R 8,64 U v a l u e 0 , 1 2

Fibergypsum panel 0,013 0,3 0,043 Rockwool Insulation 0,125 0,037 3,38 Concrete 0,2 1,1 0,18 3,60

F3 - INTERNAL WALL between units MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Coefficienti Resistenza 1/coefficiente hi 7,68 0,130

Rockwool Insulation

Rockwool Insulation 0,125 0,037 3,38 Concrete 0,2 1,1 0,18 3,60

0,12 0,03 4,00

Fibergypsum panel 0,013 0,3 0,043 4,09

F3

Ca Air 6,4 0,156 T O T A L R 4,02 U v a l u e 0 , 2 5

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Fibergypsum panel 0,013 0,3 0,043

F3 - INTERNAL

Coefficienti Resistenza 1/coefficiente hi 7,68 0,130 he 7,68 0,130 Ca Air 6,4 0,156 T O T A L R 4,02 U v a l u e 0 , 2 5

Rockwool Insulation 0,12 0,03 4,00 Fibergypsum panel 0,013 0,3 0,043 4,09

Coefficienti Resistenza 1/coefficiente hi 7,68 0,130 he 7,68 0,130 Ca Air 6,4 0,156 T O T A L R 4,50 U v a l u e 0 , 2 2

between units

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

MATERIAL

S06 - GREEN ROOFTOP SLAB (80cm) U = 0,19 W/m2K 01. Lightweight cultivation soil 02. Impermeabilization plaster 03. Drainage layer 04. Slope screed 05. Impermeabilization plaster 06. Rockwool insulation 07. Vapor barrier 08. Reinforced concrete 09. Shaped steel 10. Plasterboard

spessore (m) �� (W/mK) R (m2K/W)

Fibergypsum panel 0,013 0,3 0,043

Rockwool Insulation 0,12 0,03 4,00

Coefficienti Resistenza 1/coefficiente hi 7,68 0,130 he 7,68 0,130 Ca Air 6,4 0,156

Gravel Rock (Ghiaia) 0,08 1,2 0,07 Slope screed 0,075 0,072 1,04

Fibergypsum panel 0,013 0,3 0,043 4,09

T O T A L R 4,50 U v a l u e 0 , 2 2

Impermeabilization plaster 0,009 0,4 0,02 Insulation 0,1 0,037 2,70 Vapor barrier 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70

6 7

1 2 3 4 5 S05 - ROOFTOP SLAB (62cm) U = 0,16 W/m2K 01. Gravel 02. Impermeabilization plaster 03. Rockwool insulation 04. Vapor barrier 05. Rockwool insulation 06. Predalles type floor 07. Light brick

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Gravel Rock (Ghiaia) 0,08 1,2 0,07 Slope screed 0,075 0,072 1,04

Reinforced Concrete 0,06 1,1 0,05 Shaped Steel 0,0012 80 0,00 Plasterboard 0,013 0,19 0,068 6,67

Coefficienti Resistenza 1/coefficiente hi 7,68 0,130 he 7,68 0,130 Ca Air 6,4 0,156 T O T A L R 4,50 U v a l u e 0 , 2 2

S4

Rockwool

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Gravel Rock (Ghiaia) 0,08 1,2 0,07 Slope screed 0,075 0,072 1,04

Impermeabilization plaster 0,009 0,4 0,02 Insulation 0,1 0,037 2,70

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14 T O T A L R 6,95 U v a l u e 0 , 1 4

Impermeabilization plaster 0,009 0,4 0,02 Insulation 0,1 0,037 2,70 Vapor barrier 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70 Reinforced Concrete 0,06 1,1 0,05 Shaped Steel 0,0012 80 0,00 Plasterboard 0,013 0,19 0,068 6,67

Vapor barrier 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70

S6

Reinforced Concrete 0,06 1,1 0,05

MATERIAL

6 7 8

Shaped Steel 0,0012 80 0,00 Plasterboard 0,013 0,19 0,068 6,67

spessore (m) �� (W/mK) R (m2K/W)

Lightweight cultivation soil 0,15 1,08 0,14

Impermeabilization plaster 0,009 0,4 0,02 Drainage layer 0,04 0,035 1,14

1 2 3 4 5 S04 - ROOFTOP SLAB (74cm) U = 0,14 W/m2K 01. Gravel 02. Impermeabilization plaster 03. Rockwool insulation 04. Vapor barrier 05. Rockwool insulation 06. Reinforced concrete 07. Shaped steel 08. Plasterboard

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14 T O T A L R 6,95 U v a l u e 0 , 1 4

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14

Impermeabilization plaster 0,009 0,4 0,02 Slope screed 0,075 0,072 1,04

Impermeabilization plaster 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70

spessore (m) �� (W/mK) R (m2K/W)

0,01

1 2 3 4 5

,

Impermeabilization plaster 0,009 0,4 0,02

Drainage layer 0,04 0,035 1,14

Shaped Steel 0,0012 80 0,00 Plasterboard 0,013 0,19 0,068 5,08

Impermeabilization plaster 0,009 0,4 0,02 Slope screed 0,075 0,072 1,04

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Lightweight cultivation soil 0,15 1,08 0,14

Impermeabilization plaster 0,009 0,4 0,02

Drainage layer 0,04 0,035 1,14

Impermeabilization plaster 0,009 0,4 0,02 Slope screed 0,075 0,072 1,04

Impermeabilization plaster 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70 Vapor barrier 0,0045 0,4 0,01

Reinforced Concrete 0,06 1,1 0,05

Impermeabilization plaster 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14

rigid

S03 - FIRST FLOOR SLAB (60cm) U = 0,22 W/m2K 01. Pavement 02. Serpentine heating 03. Soundproof barrier 04. Reinforced concrete 05. Shaped steel 06. Rockwool insulation 07. Plasterboard

1 2 3 4 5

Shaped Steel 0,0012 80 0,00 Plasterboard 0,013 0,19 0,068 5,08

MATERIAL

Vapor barrier 0,0045 0,4 0,01 Reinforced Concrete 0,06 1,1 0,05 Shaped Steel 0,0012 80 0,00 Plasterboard 0,013 0,19 0,068 5,08

T O T A L R 5,36 U v a l u e 0 , 1 9

spessore (m) �� (W/mK) R (m2K/W)

Gravel Rock (Ghiaia) 0,04 1,2 0,03

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14 T O T A L R 5,36 U v a l u e 0 , 1 9

S5

T O T A L R 5,36 U v a l u e 0 , 1 9

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Impermeabilization plaster 0,009 0,4 0,02 Insulation 0,1 0,037 2,70 Vapor barrier 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70 Reinforced Concrete 0,3 1,1 0,27 Plasterboard 0,013 0,19 0,068 5,81

Gravel Rock (Ghiaia) 0,04 1,2 0,03

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Gravel Rock (Ghiaia) 0,04 1,2 0,03

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14 C 2,7 0,34 T O T A L R 6,43 U v a l u e 0 , 1 6

Impermeabilization plaster 0,009 0,4 0,02 Insulation 0,1 0,037 2,70 Vapor barrier 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70 Reinforced Concrete 0,3 1,1 0,27 Plasterboard 0,013 0,19 0,068 5,81

Impermeabilization plaster 0,009 0,4 0,02 Insulation 0,1 0,037 2,70 Vapor barrier 0,0045 0,4 0,01 Insulation 0,1 0,037 2,70 Reinforced Concrete 0,3 1,1 0,27 Plasterboard 0,013 0,19 0,068 5,81

S2 -

Coefficienti Resistenza 1/coefficiente

to garage

MATERIAL spessore (m) �� (W/mK) R (m2K/W)

Ceramic pavement 0,02 1,3 0,015

Coefficienti Resistenza 1/coefficiente hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14 C 2,7 0,34 T O T A L R 6,43 U v a l u e 0 , 1 6

hi 10 0,1 he 25 0,04 Ca Air 6,98 0,14 C 2,7 0,34

Serpentine Heating 0,04 0,048 0,83 Soundproof Plaster 0,004 0,4 0,01 Horizontal shaft 0,075 0,072 1,04 Insulation 0,06 0,037 1,62

T O T A L R 6,43 U v a l u e 0 , 1 6

Reinforced Concrete 0,3 1,1 0,27 Plasterboard 0,013 0,19 0,068

1 2 3 4 5

6

S06 - GREEN ROOFTOP SLAB (80cm) U = 0,19 W/m2K

01. Lightweight cultivation soil 02. Impermeabilization plaster 03. Drainage layer 04. Slope screed 05. Impermeabilization plaster 06. Rockwool insulation 07. Vapor barrier 08. Reinforced concrete 09. Shaped steel 10. Plasterboard

01. Lightweight cultivation soil 02. Impermeabilization plaster 03. Drainage layer 04. Slope screed 05. Impermeabilization plaster 06. Rockwool insulation 07. Vapor barrier 08. Reinforced concrete 09. Shaped steel 10. Plasterboard

6 7 8 9 10

S06 - GREEN ROOFTOP SLAB (80cm) U = 0,19 W/m2K

1 2 3 4 5 S02 - GROUNDFLOOR SLAB (50cm) U = 0,22 W/m2K 01. Pavement 02. Serpentine heating 03. Soundproof barrier 04. Rockwool insulation 05. Predalles type floor 06. Light brick

1 2 3 4 5

6 7

1 2 3 4 5

S05 - ROOFTOP SLAB (62cm) U = 0,16 W/m2K 01. Gravel 02. Impermeabilization plaster 03. Rockwool insulation 04. Vapor barrier 05. Rockwool insulation 06. Predalles type floor 07. Light brick

S05 - ROOFTOP SLAB (62cm) U = 0,16 W/m2K 01. Gravel 02. Impermeabilization plaster 03. Rockwool insulation 04. Vapor barrier 05. Rockwool insulation 06. Predalles type floor 07. Light brick

1 2 3 4 5 S01 - BASEMENT (88cm) 01. Pavement 02. Reinforced concrete 03. Ventilated crawl space 04. Lean concrete 05. Natural ground

6 7

6 7 8

6 7 8 9 10 1 2 3 4 5 6 7

7 1 2 3 4 5 S04 - ROOFTOP SLAB (74cm) U = 0,14 W/m2K 01. Gravel 02. Impermeabilization plaster

W2 - WINDOWS

Material

W2 - WINDOWS

Material

Ag 3,5 m2 1,75 Af 0,82 m2 2,624

W5 - GROUNDFLOOR WINDOWS

Material

Wood-aluminium Steel

Ug 0,5 W/m2K 0,48 Uf 3,2 W/m2K 4,854 ��������g 0,6 W/m2K 4,32 lg 0,8 m Uw 1,1 W/m2K

Ag 3,5 m2 1,75 Af 0,82 m2 2,624 Ug 0,5 W/m2K 0,48 Uf 3,2 W/m2K 4,854 ��������g 0,6 W/m2K 4,32 lg 0,8 m Uw 1,1 W/m2K

W5 - GROUNDFLOOR WINDOWS

Material

Wood-aluminium Steel

Ag 28,9 m2 17,34 Af 6,1 m2 13,42 Ug 0,6 W/m2K 0,6 Uf 2,2 W/m2K 31,36 ��������g 0,6 W/m2K 35 lg 1,00 m Uw 0,9 W/m2K

Ag 28,9 m2 17,34 Af 6,1 m2 13,42 Ug 0,6 W/m2K 0,6 Uf 2,2 W/m2K 31,36 ��������g 0,6 W/m2K 35 lg 1,00 m Uw 0,9 W/m2K