millingandgrain.com June 2023 In this issue: Milling and Grain . Volume 134 . Issue 6 . June 2023 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volume 134 Issue 6 Flour is artFlourWorld Museum opens a new chapter - The World Nutrition Forum 2023 - Regenerative agriculture: The role of mills and food producers in sustainable supply chain - Grain management for reliable Feed Milling - Seed cleaning: Crop value increase when cleaning standards met

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267700

Publisher

Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Clarissa Garza de Yta

Tel: +52 669 120 0140 clarissag@perendale.com

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Digital community manager

Levana Hall levanah@perendale.co.uk

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

No: 2058-5101

VOLUME 134 ISSUE 6 NEWS 10-28 42 Flour is artFlourWorld Museum opens a new chapter 48 The World Nutrition Forum 2023 54 Regenerative agriculture: The role of mills and food producers in sustainable supply chain 58 Grain management for reliable Feed Milling 62 Antibiotics in weaned piglets and dietary protein’s role in reducing it STORAGE 68 Seed cleaning: Crop value increase when cleaning standards met 8 PUBLISHER Roger Gilbert 104 INTERVIEW Ivo Lansbergen ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service EVENTS 84 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 20 Mildred Cookson 24 Dr Mahmoud Riyad 30 Gems from the Mills Archive FACES 106 People news from the global milling industry TRAINING 33 Industry training news PRODUCT FOCUS 38 CASE STUDY 80 INDUSTRY PROFILE 76 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 June 2023 COVER IMAGE: Flour is art - FlourWorld Museum opens a new chapter - see more on page 42 FEATURES millingandgrain.com ISSN

The World Nutrition Forum 2023 See more on page 48

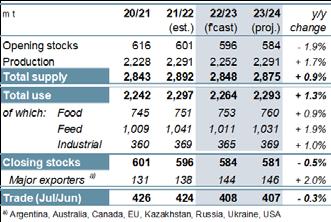

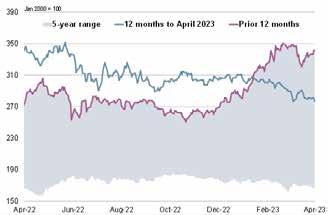

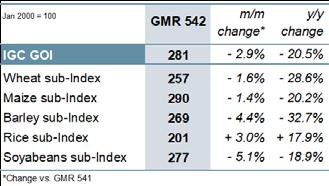

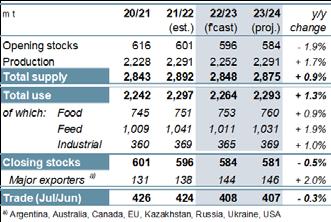

70 MARKETS

Looking back and looking forward

Events - expos and conferences

- are a great source of valuable information.

Roger Gilbert

Roger Gilbert

They are not only valuable for providing an opportunity to catch up on the latest developments in a region or globally, but also accommodate an exchange of ideas and provide the impetus for us to take action.

Two events that have taken place in the recent past include among others, IAOM’s 127th Annual Convention and the 2023 World Nutrition Forum.

We were able to include a timely but brief reference to IAOM’s USA event in our May 2023 edition, but we have re-visited the event in our show report section in more detail this month. This was a significant coming together for the flour milling industry in North America in Minneapolis, Minnesota at the end of April and had an extending attendance that include delegates from 21 countries among its 1100 attendees (see page 92).

The focus was clearly on inclusion for all involved in milling and this was reflected in the keynote presentation made by Meredith Nelson from the General Mills company when she referred to the success of IAOM’s Women in Milling group.

We congratulate Steve Matson, director of operations at Bay State Milling, on becoming the 2023-24 IAOM President and who intends to support greater diversity and inclusion along with industry recruitment and education during his tenure.

It was a vibrant and engaging event that conveys a message of strength within our industry at both nation and international level.

The second event, the 2023 World Nutrition Forum (see page 48), took place in Cancun, Mexico, in the second week of May from the 8-10. It attracted over 800 attendees from around the world.

This was the fifth outing for the WNF following a two-year interruption due to the Covid pandemic. Despite this delay and the fact that its organisation has transferred from the former Biomin company to DSM, when the former was taken over by the latter, it has lost none of its focus and appeal under new management.

A number of keynote speakers dealt with topics ranging from data gathering, to sustainability, to climate change, to industry image challenges from those critical of the intensive livestock and aquaculture industries.

Our report from page 48 in this edition goes some way to

highlighting key aspects of the event although ‘being there’ delivered more than expected for discerning delegates.

It is clear our industry needs both these types of events - those arranged by organisations such as IAOM, as well as those offered by companies.

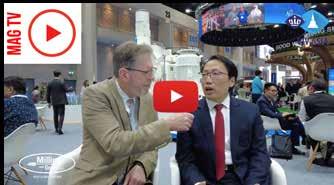

Milling and Grain was fortunate to have the opportunity at the event to talk with Ivo Lansbergen, Executive Vice-President for Animal Nutrition and Health at the newly named dsm-firmenich, which you can see on our MAGTV Channel; Mr Lansbergen made the announcement of the merger on the second day of the conference that DSM had merged with Firmenich of Switzerland and hence creating the new name dsm-firmenich! see page 13.

Also in this issue

This month our columnist Mildred Cookson (see page 20) recounts the first mill to be driven by electricity - and it was a mill operated by Matarazzo and Co of Saõ Paulo, Brazil - funded by a British bank in 1900. Mr Matarazzo had emigrated to Brazil from Italy and was destined to become the fifth richest man in the world by 1937. This is an intriguing insight into the history of our milling industry and our thanks go to Mildred for unearthing this international historic gem.

Another ‘gem’ is highlighted by her colleague Nathanael Hodge who manages the Rex Wailes Collection at the Mills Archive. He features a conical lump of rock that is believed to be over 2000 years old and was once used in the production of flour by hand, another fine feature (see page 28).

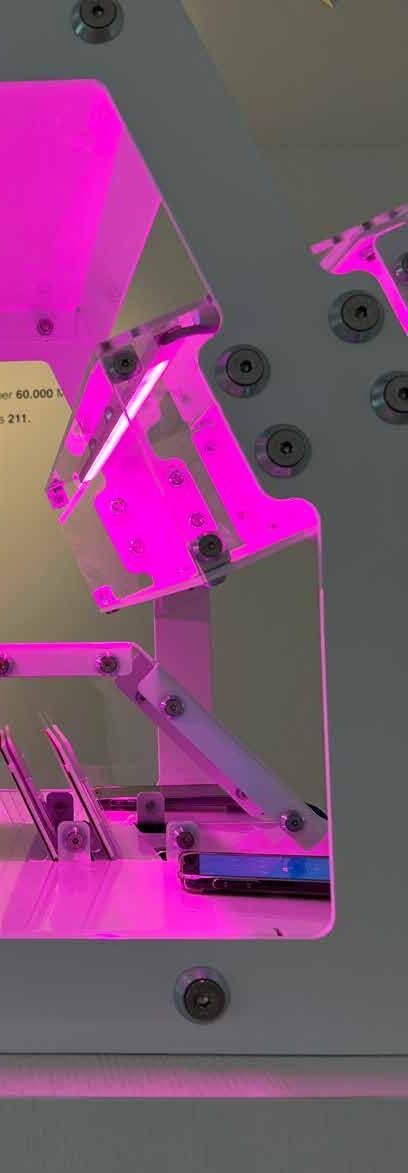

Our cover

You may be forgiven for not being able to figure out our cover image this month.

Don’t worry it’s part of a colour sorter that is not often seen as its internal structure is hidden below its casing.

This unit is being displayed in the ’new room’ recently opened at the FlourWorld Museum in Wittenberg, Germany - that illuminates a further chapter in human history - dedicated to the industrial revolution and which has allowed the world’s population to grow.

The creation of new technical solutions has been critical in supporting population growth with the foodstuffs needed, particularly around bread and other milled flour-based foods that have come to sustain almost all societies on the planet.

The room is dedicated to the Industrial Revolution and was conceived by Dr Oliver Seifert of the museum in co-operation with the Bühler Group and Mühlenchemie. The optical sorter is just one of the working models on display. Others include a roller mill and a plansifter.

World Nutrition Forum 2023 – Interview with Ivo Lansbergen

In this months magazine we have two interviews with Ivo Lansbergen, you can read the first interview on page 104, and view the second on the MAGTV page of our website.

“It’s a big theme, sustainability. We need to take it seriously as it’s going to be a theme driving this value chain. The good news is we have the power and the means, but now we need to join forces and start acting on it.”

To see more of this interview, go to our MAGTV YouTube Channel, at: https:// millingandgrain.com/category/mag-tv/

Annual Subscription Rates Inside UK: UK£100 Outside: US$150/€133 More Information

and Grain has a cooperative partnership with COFCOET

www.millingandgrain.com http://gfmt.blogspot.co.uk Milling

PINGLE.

PROFESSIONAL MANUFACTURER

★ INTEGRATED MILLING SOLUTION PROVIDER

★ ISO 9001:2015 CERTIFIED

Аdd: Zhengding, Shijiazhuang,Hebei,China

Tel: +86-311-88268111 Fax: +86-311-88268777

E-mail:pingle@pingle.cn / www.pinglemachine.com

OF GRAIN MACHINERY

NewsMilling

Hello and welcome everyone to the June edition of Milling and Grain magazine and to the Global Miller. The seasons have begun to change this month and we’re moving onto hotter weather here in the Northern Hemisphere.

Greg Liu - Famsun

Greg Liu, Vice President of Famsun, talks to Roger Gilbert, Publisher of Milling and Grain magazine, whilst attending VIV Asia 2023, held over three days in Bangkok, Thailand from March 8-10, 2023.

The Famsun stand displayed its impressive automation systems, as Greg Liu told Milling and Grain magazine about the important of automation and storage due to the high price of raw materials. This year’s VIV Asia has proved incredibly valuable to Famsun, who’s imports/ exports have been impacted alongside everyone else from Covid 19. Mr Liu tells us how helpful and productive it is to now be able to have the opportunity to meet with customers, old and new, face-to-face.

BK Chew

BK Chew, Vice President of Feed Additives, Ingredients & Amino Acids, APAC, ADM, talks to Roger Gilbert, Publisher of Milling and Grain, whilst attending VIV Asia 2023, held over three days in Bangkok, Thailand from 8 –10 March, 2023.

BK emphasises the opportunity the event has provided to reconnect with customers and industry partners and discuss ongoing challenges such as supply chain disruption, increasing prices of raw materials and microbial resistance. He addresses ADM’s holistic approach to their services and how they keep in mind the importance of sustainability. Sustainability is a core area for ADM, and it always strives to give the best nutrition to animals whilst lessening negative environmental impacts. ADM has many specialists covering areas of nutrition, formulators, veterinarians and experts in analytical work, with every ingredient and feed additive trialled in-house. Regarding microbial resistance, ADM seeks to lessen the impact antibiotics have on people and livestock production, looking at solutions and programs to assist customers in restricting their use and ultimately providing alternatives which are more beneficial

Summer begins on June 21 which is also the longest day of the year for the Northern Hemisphere (sorry Southerners, you’ll have to wait till December 21). This day is also known as the Summer solstice, or Winter solstice for the Southern Hemisphere. The specific date for the solstice changes over the years but tends to stay between June 20 – 23 whereas Midsummer is on June 24 this year. The difference in the days for these holidays’ stems from the Julian and Gregorian calendars.

The summer solstice has been a celebrated holiday for centuries in Northern and Central European Neolithic cultures with the holiday relating to the timing of crop cycles as it is the high point of summer. The solstice was ordinarily marked by Celtic, Slavic, and Germanic people by lighting bonfires and hosting festivals to both celebrate and boost the sun’s strength for the remainder of the crop season and ensures a healthy harvest.

The solstice also sits in a wider celestial framework that compliments the seasonal equinoxes that mark spring and autumn, as well as daily, monthly, and annual cycles. These helped to track the timings of the harvests and planting of crops by acting as the midpoint between these two events. Farmers, recognising this day as the half-way point towards harvesting their crop, would celebrate at the Midsummer festivals.

Midsummer is the holiday period of the solstice originating from Celtic, Slavic, and Germanic people with Pagan preChristian roots. Once the Christian Church was established, solstice and midsummer celebrations were tied with the commemoration of John the Baptist, St Johns Day.

Due to the varying origins of Midsummer, the methods of celebration between the solstice and Midsummer tends to be some form of festival with bonfires, large feasts, and rituals and prayers. In Viking tradition, Nordic communities would use the longest day as a method to maximise their productivity by hunting, settling disputes and conducting raids.

Mentioning productivity, DSM is now dsm-firmenich, having merged with Firmenich, launching a new company together. Along with this, CPM have announced the acquisition of IDAH and Alltech and Agolin partner to provide eco-friendly solutions for supporting cattle production. This is quite the month for companies getting together, let’s hope for more successful partnering and mergers in the future. For more detailed information on all this news then read on as we have it all in our magazine.

For news on the events around the world, we will have some detailed reports on the DSM World Nutrition Forum and the 127th Annual IAOM, two events that members of our team will have visited. We also have an interesting preview for Cereals 2023 that we plan to attend.

Share your experiences at these events with us at editorial@ perendale.co.uk, we would love to share them on our blog or in our magazines.

gfmt.blogspot.com

mymag.info/e/1593 10 | June 2023 - Milling and Grain

Looking for Milling and Grain in your language? Find links to all of our editions in one place

See more at:

http://flk.bz/xxsY

The Milling Journal

Milling Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with its distinguished track record of technical and trade magazines in the agricultural, aquaculture and food sciences. This new peer-reviewed scientific journal will serve academia and the commercial milling sectors and related cereal and grain industries with high-quality papers. Milling is at the heart of products for both the human and the animal feed sector. It is envisaged to address fundamental and advanced technologies in the conversion of grain, cereals, pulses and legumes via milling to create diverse and bespoke secondary products. For example, ground wheat, corn, oats, barley, sorghum, beans and peas are widely used for human foods. The downstream by-products of bioethanol and potable alcohol from fermentation of ground grain are notable areas for research findings towards provision of sustainable animal feed ingredients. The Journal will particularly embrace scientific and technical

information on novel processes enabling the generation of ingredients for manufacture of bread, cakes, confectionary, pasta and a plethora of applications for diverse types of breakfast cereals, beverages and the infant formula markets. We also consider papers on complete animal feed manufacture as a core topic. These usually require pre-grinding and milling/flaking of grain and cereals for terrestrial animal feeds such as for poultry, swine, ruminants and equine. Animal feed production can involve drying, milling, pelleting, steam and pressure conditioning, shaping and texturisation dependent on specific machinery. Processes such as extrusion, cooking and expansion are of paramount importance with much research being undertaken on engineering, both mechanical and electrical. Effective storing and preservation methods offer opportunities for papers.

Please do not hesitate to get in touch with any queries at journal@perendale.co.uk.

2023

Useful links

dsm-firmenich launches as innovators in nutrition, health, and beauty

dsm-firmenich is excited to confirm the successful merger of DSM and Firmenich and the resulting launch of a new company that brings together one of the largest innovation and creation communities in nutrition, health, and beauty. With a nearly 30,000 strong team and unparalleled capabilities built on more than a century of cutting-edge science, dsm-firmenich will be a trailblazer in the reinvention, manufacturing, and combination of vital nutrients, flavours, and fragrances.

Combining the essential, desirable, and sustainable

By creatively applying proven science and drawing on data-driven innovation capabilities as well as exceptional standards of operational excellence, dsm-firmenich seeks to tackle the tension between what society needs, what people individually want, and what the planet demands in the areas of nutrition, health, and beauty. By working closely together with customers to create what is essential for life as well as desirable for consumers yet simultaneously more sustainable for the planet, dsm-firmenich is poised to bring progress to life for billions of people around the world.

Geraldine Matchett and Dimitri de Vreeze, Co-CEOs of dsm-firmenich, comments, “Today marks a new beginning for us all that is the culmination of more than a century of ground-breaking science from two great companies. dsm-firmenich now stands out as a category of one, uniquely working at the intersection between what people individually want and what we collectively need, without costing the Earth. After all, what is essential has limited impact if it is not desirable, and that impact is not positive if it is not sustainable. And sustainable things that people don’t want or need don’t help much! We are truly global, built on an incredible foundation of proven world-class science with the broadest portfolio of nutrients, flavors, and fragrances. We are delighted to embark on this journey together as a single force for good as innovators in nutrition, health, and beauty.”

Structured for success

dsm-firmenich is organised in four distinct high-performing businesses, rooted in complementary world-class scientific research and manufacturing excellence. Together they are uniquely positioned to help our customers realise their ambitions and address evolving consumer needs and wants.

Perfumery & Beauty creates superior scents with proven benefits – always with the consumer in mind. Creating fragrances that smell amazing and make people feel even better, using the best and largest palette of natural, synthetic, and biotech ingredients.

Taste, Texture & Health helps customers create food and beverage products that are delicious, nutritious, affordable, and sustainable. Providing enjoyment and nourishment for consumers, business success for customers, and better health for people and planet.

Health, Nutrition & Care provides people

a way to look after their health by adding critical nutrients to diet. Driving medical innovation forward, speeding up recovery, and enhancing quality of life.

Animal Nutrition & Health delivers healthy animal proteins efficiently and sustainably, harnessing power of data to make animal farming practices more sustainable, productive, and transparent.

Delivering for all stakeholders

dsm-firmenich is a purpose-led company where people and planet as well as financial success are at the core of its strategy. As a company formed of two growth companies that are also global sustainability leaders, dsm-firmenich is determined to keep growing its positive impact and keep raising the bar in helping to tackle climate change, protect nature, and care for people all along the value chain. Working together with customers and partners, the company strives to tackle the challenges of today and tomorrow while making a positive difference for the planet and enhancing the lives of millions.

A new name and identity

To mark the launch of the new company, dsm-firmenich has revealed a new brand that captures the spirit of bringing two iconic organisations together in a merger of equals. The brand reflects the company’s purpose and values and is the expression of a shared identity. The brand symbolises the company’s mission to combine what is essential for life, desirable for consumers, and more sustainable for the planet. The purpose of dsm-firmenich is to bring progress to life, together with customers and partners, to achieve positive change and make a difference in the world.

Geraldine Matchett and Dimitri de Vreeze, Co-CEOs of dsm-firmenich, adds, “We honour the legacy of DSM and Firmenich by taking the best of both companies in creating a fresh, new identity. It’s lively. It’s vibrant. It’s led by our purpose. Just like dsm-firmenich. This is the beginning of an exciting new time for our employees, our customers, and our partners as we go above and beyond in shaping a positive future for all and as we bring progress to life.”

Following the successful completion of the merger, Geraldine Matchett has decided this is the right time to further her career elsewhere and will move on, as of September 1, in full alignment and with the thanks of the Board of Directors. Dimitri de Vreeze will be the dsmfirmenich CEO.

Milling and Grain - June 2023 | 13 Milling News

You Have A Vision For Your Business.

Cimbria can bring it to life.

We’ve been doing it for over 75 years. With dedicated experts at your side from start to finish and beyond, Cimbria will help you grow with confidence. So you can look forward to a prosperous future.

Do you have a unique grain or seed processing challenge? From customized plant design to turnkey installations and expert support, Cimbria can help find the right solution for your success.

Cimbria.com A/S Cimbria Thisted, Denmark Phone +45 96 17 90 00 cimbria.holding@agcocorp.com

İmas Receives ‘Product Showcase 2023’ Award by IAOM

Multimilla Roller Mill, offering higher operational reliability and extended long term durability with its new Polymer Base Construction®, has been awarded in Product Showcase 2023 innovation awards during IAOM USA event in Minnesota, USA.

The 127th of annual IAOM USA Conference & Exhibition was held in Hyatt Regency Minneapolis Hotel between 17-21 April 2023, as three days of education, networking and fellowship meeting for all North and South American milling professionals. In addition, the show gives opportunity milling equipment producers to introduce their innovations each year.

İmas team excited to announce that this year Multimilla Roller Mill with its new Polymer Base Construction® receives Product Showcase 2023 innovation award by IAOM USA.

The presentation of Multimilla Roller Mill was given at the İmas booth by Mr Diwakar Modakam – General Manager of İmas North America. And after the selection of jury, he also received the award on behalf of the İmas team.

Polymer Base Construction®

İmas R&D and Engineering team has developed an alternative roller mill chassis construction material to the steel or cast iron, with the use of polymeric composites as being the first application in milling industry.

The major advantage of using patented polymeric composites in the roller mill chassis is that they have a great vibration resistance, enabling a more reliable operation and extended long term durability of the machine.

The new Polymer Base Construction® material has actually ten times better vibration damping ability than the cast iron, and even 20 times better than the welded steel chassis. Moreover, it has comparatively lower thermal conductivity, higher rigidity and corrosion resistance, and better production flexibility advantages with reduced production time, cost, and footprint.

Stay up-to-date with the latest news Read the online version of Milling and Grain for FREE! Find our archive content by topic millingandgrain.com Comparison Chart Welded Steel Cast Iron Polymer Base Vibration Damping Rates 0.0005 0.001 0.01 Milling and Grain - June 2023 | 15 Milling News

CPM announces the acquisition of IDAH

CPM, a leading solutions provider of process equipment and engineered technologies, has announced the acquisition of IDAH, a move that unites two industry leaders behind a shared mission to sustainably feed, fuel and build a better world.

“The joining of these two successful enterprises will bring a new dimension of solution and service offerings to our customers thanks to the perfectly complementary nature of our product portfolios,” says David Webster, CPM President & CEO. “We look forward to utilising the strong team and capabilities of the IDAH business to expand our global position in the aqua feed, petfood and plant-based protein processing markets. We are very excited to welcome the IDAH team to CPM.”

Founded in 1974 by James Chang, IDAH has grown from a small plant in rural Taiwan to six global offices serving more than 21 countries. IDAH specialises in pelleting, extruding and drying equipment, most notably for aqua feed, petfood, snack food, and plant-based protein markets. The IDAH brand has a reputation for high-quality spare parts, machines and services and today is the number one shrimp feed machine solution provider in the world and the number one provider of aquafeed equipment in Southeast Asia.

celebrate this milestone of joining CPM,” says Mr Chang. “Today, two industry leaders unite as one, accelerating our shared vision to sustainably feed, fuel, and build a better world and driven by our passion to innovate and create robust solutions that meet the evolving needs of our global customers.”

Integration activities are already underway with IDAH joining the CPM Process Solutions business unit, a centre of excellence focused on innovative solutions for the consumer food, animal feed and advanced materials industries. CPM Process Solutions is led by Charlie Spearing, General Manager, and comprises the following product brands: Century Extrusion, Extricom, Ruiya, Wolverine Proctor, Planet Dryers, TSA Griddle Systems and IDAH.

Customers and business partners will continue to be served through their current contacts. CPM and IDAH remain committed to delivering the highest level of service

16 | June 2023 - Milling and Grain Milling News

Alltech and Agolin partner to provide eco-friendly nutrition solutions

As a global leader in animal nutrition, Alltech is proud to partner with companies that share its commitment to Working Together for a Planet of Plenty™. Today, Alltech announced it has acquired a majority interest in Agolin. Founded in 2006 in Switzerland, Agolin has developed and produced plant-based nutrition solutions that improve herd performance, profitability and sustainability, according to a 2020 meta-analysis in the journal Animals.

Agolin’s high-quality essential oil blends are scientifically proven to optimise feed intake and performance, including improved milk and meat production. Furthermore, Agolin® Ruminant was the first feed additive certified by The Carbon Trust for methane reduction in ruminants (2018). Today, organisations such as Verra and Gold Standard are including it in their major international climate protection projects.

“Agolin’s essential oil blends are a complement to Alltech’s proven nutritional technologies, such as Yea-Sacc® and Optigen®,” says Dr Mark Lyons, Alltech’s president and CEO. “Governments, consumer brands and retailers are making important commitments to reduce their environmental impact. These commitments rely upon farmers and ranchers, and we are dedicated to supporting them with the best available nutritional technologies to achieve more milk and meat while reducing their environmental footprint.”

The alliance between Alltech and Agolin will empower farmers and ranchers to reach their sustainability goals while also supporting the performance and profitability of the cattle in their herds and supply chains. The synergistic use of Alltech and Agolin nutritional technologies leads to benefits such as improved animal welfare, greater feed efficiency and conversion, enhanced milk and meat production, increased profitability, and a reduced environmental footprint, including a boost in nitrogen efficiency. The partners will also be exploring opportunities to develop new technologies that bring together the best of Alltech’s proven nutrition and Agolin’s essential oil blends. Agolin has a presence in Europe, Asia and North America. Alltech’s majority interest in the company will expand the availability of Agolin to additional markets.

“We at Agolin are delighted with this strategic alliance to grow synergistically through the added technical expertise and global reach of Alltech,” says Kurt Schaller, managing director of Agolin SA. “This represents a new era for our business, and we look forward to breaking new ground in our industry.”

Agolin focuses on research and development to produce and market innovative feed additives based on plant active ingredients, which are effective and easy to use. Its essential oil blends are backed by a strong quality management system (FAMI-QS), which ensures safety and guarantees traceability.

Milling and Grain - June 2023 | 17 Milling News

Andritz introduces comprehensive solutions to produce alternative proteins

International technology group Andritz is expanding its role in the food and feed industries with solutions to produce alternative proteins. The company will help customers scale up alternative protein production to a commercial level and provide support over the entire equipment life. The new project will initially focus on alternative protein sources such as peas, pulses, lentils, insects, and animal residues, with more to come soon.

ANDRITZ experts are working side-by-side with customers to find the optimal solution for their alternative protein production needs based on wet or dry processing. The tailored end-to-end solutions include concept design, process engineering, realisation, automation, and service. Andritz has proven technologies for all key process steps available in the group, including milling, conditioning, dewatering, drying, extrusion, and pelleting – all backed by innovative process automation and proven global service. To produce alternative proteins, Andritz will draw upon the broadest product portfolio worldwide as well as its expertise in project management by dedicated and experienced teams.

“We are thrilled to officially announce the birth of this new offering,” says Christian Kling, Head of Alternative Protein Solutions at Andritz. “The field of alternative proteins is an exciting market but moving from lab to industrial scale can be challenging. Andritz – as the trusted partner on your side – not only has the production technology but also helps customers speed up commercialisation and bridge the gap to full-scale production. With a history of 170 years, we have been engineering and implementing solutions for many industries including food and feed for decades.”

To support customers in realising their ideas, Andritz is also building an innovative test centre at Waddinxveen, The Netherlands. The “Food Innovation Xperience” will open in the 4th quarter this year, enabling customers to validate their concepts by scaling up production and testing quality, consistency, and energy efficiency at industrial levels.

Stay up-to-date with the latest news Read the online version of Milling and Grain for FREE! Find our archive content by topic millingandgrain.com

Milling and Grain - June 2023 | 19 Milling News

The First Mill to be driven by Electricity: Matarazzo & Co’s Mill, São Paulo

by Mildred Cookson, The Mills Archive, UK

by Mildred Cookson, The Mills Archive, UK

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

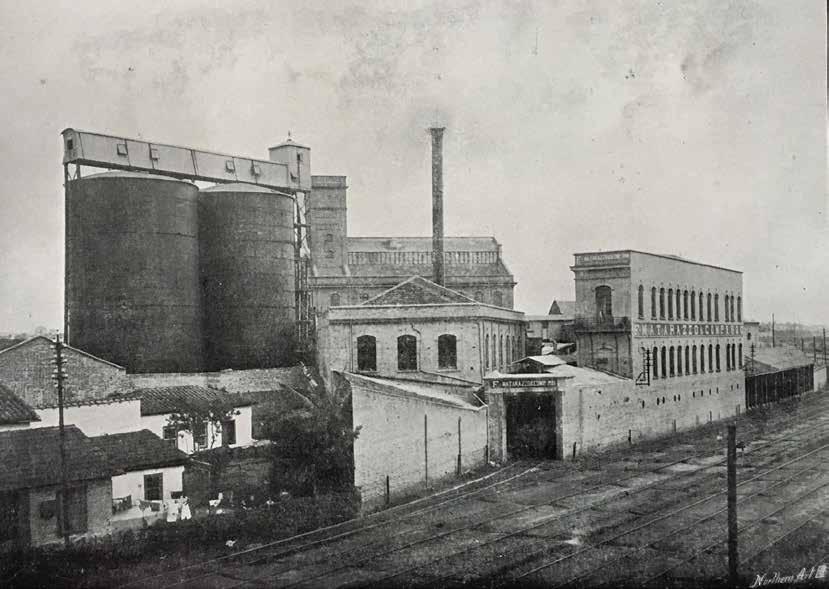

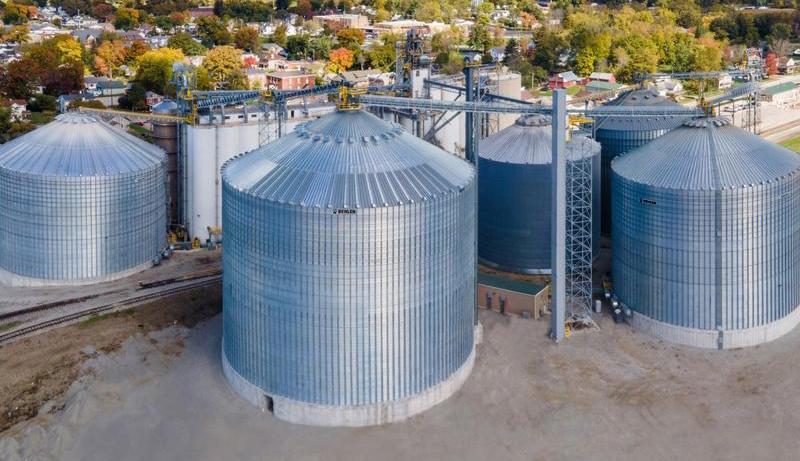

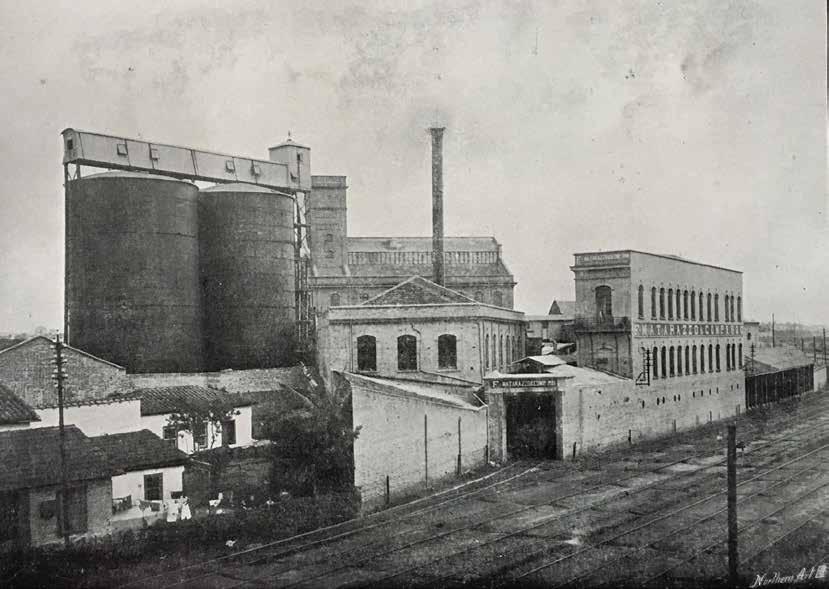

This title headed an article in the Christmas edition of Milling in 1902. Twenty years earlier Francesco Matarazzo had emigrated to Brazil from Italy and was destined to become the fifth richest man in the world by 1937, the year he died. In 1900 a British bank had provided the finance for him to build a modern mill in Sao Paulo and by 1902 electricity was becoming more and more used for running machinery. It was not so surprising that the whole plant in a large flour mill would come to be powered this way and Matarazzo & Co were early adaptors.

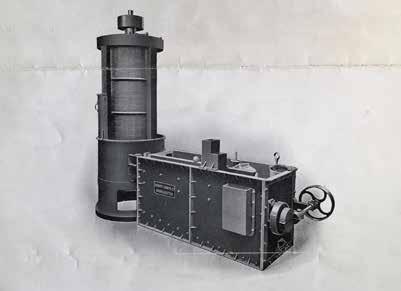

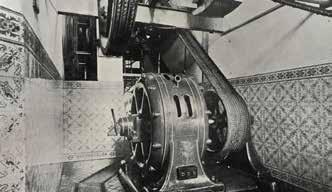

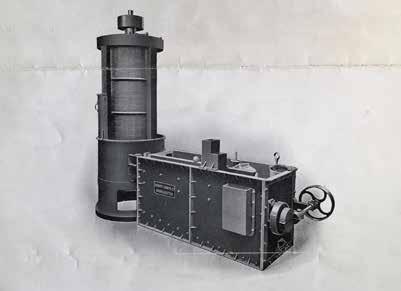

Originally the setup was driven by steam, and although coal was abnormally expensive in Brazil, the mill was still a great success. It used “Monitor” wheat separators and scourers, “Simon” patent wheat washing, stoning, and drying machines, a ventilated whizzer and “Cyclone” dust collectors, cylinders, graders, sieves, and fans. The roller plant of the first mill had 50inx10in Simon 4-roller mills for the breaks, and smooth 4-roller mills for the reductions, with a full complement of scalpers, purifiers, graders, and centrifugal dressing machines. Band conveyors were also installed for conveying grain from the railway cars to the silos.

During 1902 Henry Simon of Manchester had erected the firm’s second roller plant of 20 sacks capacity, comprising a complete set of machines for cleaning the wheat, as well as for grinding, purifying the middlings and dressing the flour. As a result of this success, Mr. Matarazzo called in the Manchester firm to erect a

duplicate twenty sack plant bringing the total up to 40 sacks per hour. In addition, a splendid range of steel storage silos for grain were made in England, put together, marked, then taken apart to be shipped to Brazil where they were erected by Simon’s own superintendent mill erectors.

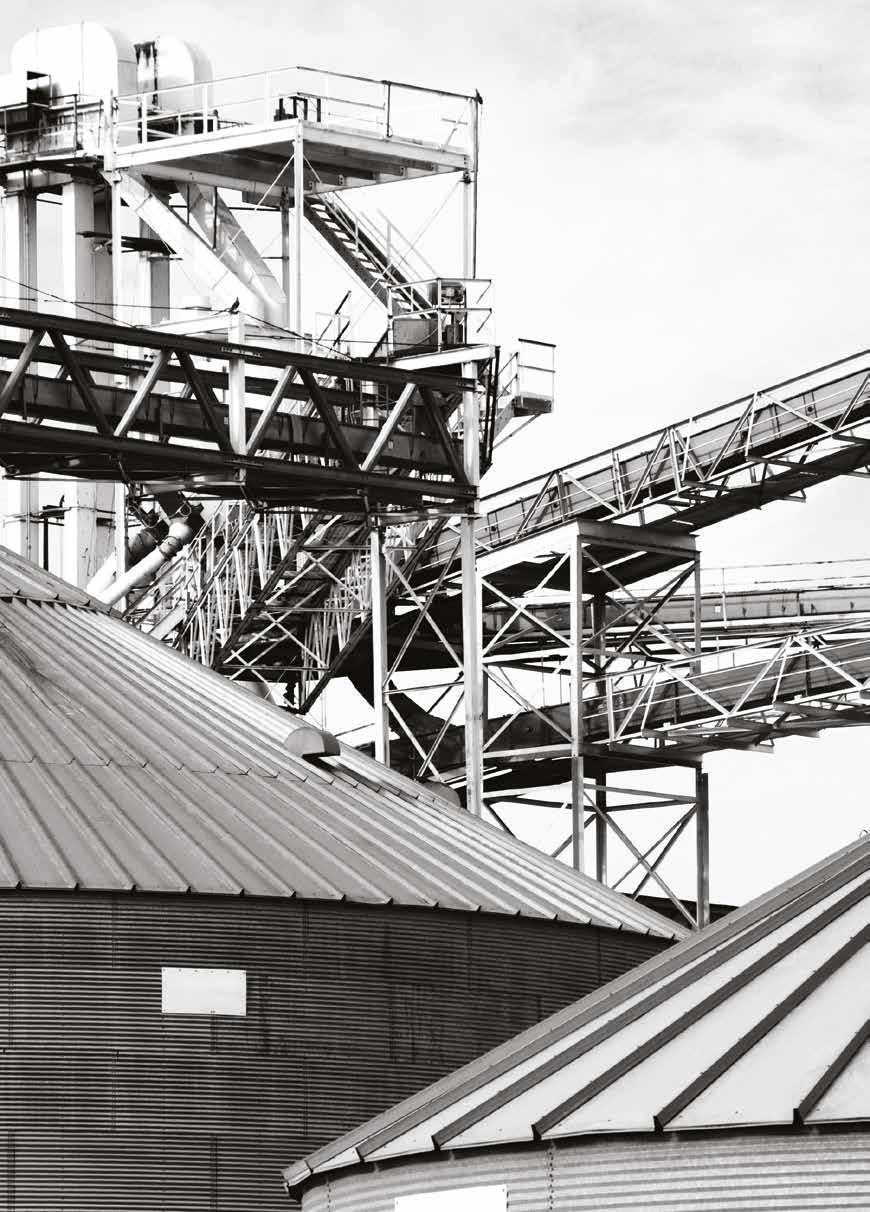

The silos were 76ft, high from the outlets at the bottom to the tops of the domes and held 15,000 quarters. Band conveyors were provided which ran parallel to the railway siding by which the grain could be transferred direct from the cars to the silos at the rate of 50 tons an hour. The high tower seen in the illustration contained a main elevator for lifting the wheat at the same rate as band conveyors moved it from the railway cars. Other bands were located below the silos for transporting the grain to the cleaning house.

The mill manager was Mr H Rishworth, scion of the wellknown firm Rishworth, Ingleby & Lofthouse of Hull UK, and was trained on Henry Simon’s staff. He was not only general manager for the mill from the first but had the responsibility of supervising the various engineering problems that took place.

The whole of the premises formed one of the finest properties of the kind in Brazil. They constituted the second largest mill in the country, the largest being those of the Rio de Janeiro flour Mills and Granaries Ltd., situated at Rio de Janeiro, which were also built and equipped by Henry Simon.

The city of Sao Paulo is fifty miles from the port of Santos, resulting in a very high price of coal for deliveries up-country. This was the prime motivation to move to electrical power.

Fortunately for Mr. Matarazzo, the Light and Power Company

20 | June 2023 - Milling and Grain

The grain silos viewed from the railway at the rear of the mill

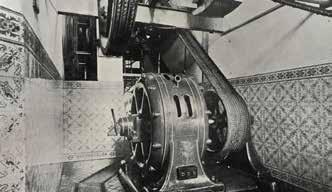

of Sao Paulo had developed a power station by a waterfall in the adjacent mountains, and by means of turbines, dynamos and electric cables, were able to supply the milling firm with electric current to drive their mill at a much lower cost than could have been done by steam power. The journalist believed that price negotiated was UK£17 per horsepower, per annum, with a discount of 5 percent if 250 hp was consumed, and 10 percent

for over 300 hp. The charge for the use in 1902 for lighting the premises and for the electric oven amounted to £300 per year. One large motor of 2-300 hp was arranged for each of the two roller plants. The power was transmitted from them to the main line shafts of the mills by means of cotton ropes. The speeds did not vary even when switching off the cleaning plant. Although the motors were close together there was no vibration, and

EXTRUSION AND EXPANSION TECHNOLOGY YOU CAN TRUST

The Cyclone dust collector

One of the large motors installed by Henry Simon

The Cyclone dust collector

One of the large motors installed by Henry Simon

The mill from the street Scan the QR-Code for more information www.almex.nl

The two large motors, each 300hp and 2080 volts

www.almex.nl

The Almex AXT 220 Single screw extruder consists of a robust base frame that supports the main motor, gearbox, and extruder barrel. This frame can be executed in mild steel or stainless steel for extended lifetime. The direct coupled inline geared motor ensures the optimal energy efficiency.

Capacity: 10,0 - 12,0 t/h (indication only)

Milling and Grain - June 2023 | 21

with the Extruder AXT 220

YEARS IN MILLING

MORE THAN 400 COMPLETE PROJECT PERFECTLY RUNNING AROUND THE WORLD

We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

R O L L E R M I L L

the bearings gave no trouble. Financially they proved their worth by saving between UK£3,000 and UK£4,000 per year compared with the cost of working with a steam plant.

Milling considered that there were many sites in Britain and Ireland where electrical power could be adopted to advantage. As coal was cheaper, the economy of steam engines was difficult to beat for mills and factories where their machinery was near the main engine. The point where it paid to transmit power by wire, instead of by belt depended on this distance. The heavy drag of a mill running empty with widely spread, ill placed machinery, contrasted starkly with the light power load required to run a more compact mill. Shafting alone in some mills took considerable power, and a wire would never get out of line like shafting, nor would it need oiling!

Milling and Grain - June 2023 | 23

The Simon Reform combined washer, stoner and whizzer

A good start to the Egyptian wheat season

The Egyptian government has purchased 1.2 million tonnes of wheat from local farmers in this season since mid-April 2023, according to a report filed to Minister of Supply Ali Al Meselhi on Saturday 6 May 2023.

The purchased amount of wheat was sent to 420 places nationwide, the report said, noting that the wheat quality of this season is superior, besides the increase in the rates of supply this year compared to last year at the same time, the report said, indicated that the payment takes place 48 hours after the supply.

Hussein Abdul Rahman Abu Saddam, Head of the General Syndicate of Farmers, said in a statement that the authorities aim to purchase a total of four million tonnes of wheat from the local farmers.

He added that the supply of wheat will continue until the end of next September, and about 50 percent of the cultivated areas have been harvested so far, while about 25 percent of the harvested quantities have been threshed.

Abdul Rahman added that the high rate of supply is attributed to several reasons, the most important of which are the increase in the price, the high number of wheat receiving points (430 nationwide), and the ban on sealing wheat to another place without approval from the Ministry of Supply.

In April 2023, the Egyptian Ministry of Finance allocated 45 billion EGP to purchase local wheat from farmers this year, with an increase of more than 19 billion EGP compared to the last year, said Minister Mohamed Maait in a statement.

The government has started to buy the local wheat from the beginning of this April to the mid-August, with an additional cost to increase the price of one ardab (150 kilograms) by 74 percent from 865 EGP (US$ 27.90) to 1,500 EGP (US$ 48.39), Maait added.

This year’s wheat harvest will be one of the best in terms of area under cultivation, according to the head of the Egyptian Farmers Syndicate Hussein Abu Saddam. Some 3,650,000 feddans (a feddan is slightly larger than an acre) were cultivated this season, the largest area ever, according to Abu Saddam. Wheat is a priority crop because the more abundant the local crop, the less wheat the country needs to import.

The government has also taken a number of measures to make it easier for farmers to deliver wheat to government silos. “It has set up 439 collection points for wheat close to harvest areas in order to ease the transport and freight burden on farmers,” said Abu Saddam. “Also, it has accelerated the payment process so that now farmers can receive their payments within 48 hours. Obstacles have been minimised, and farmers are given encouragement through guidance seminars.”

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

The Ministry of Supply had taken better decisions this year than last year, he said. Last year it required farmers to deliver a minimum of 12 ardabs of wheat, whereas this year delivery is optional. The government has also prohibited using wheat in fodder manufacture and to feed livestock and fish, and it has cautioned against shipping wheat from one governorate to another without notifying and receiving approval from the Ministry of Supply. The purpose is to curb stockpiling and monopolistic practices on the part of some traders.

Haj Galal, a wheat farmer from Upper Egypt, agreed that LE1,500 (US$ 48.39) per ardab was a fair price for wheat this year when compared to LE850 (US$ 27.90) last year, especially for farmers who had large areas of land under cultivation. He also approved of the government’s decisions regarding the distribution of subsided coarse bran, a milling by-product.

Minister of Supply Ali Moselhi has announced that the government will disburse 10 kg of coarse bran from the ministry’s wheat mills for every ardab of local wheat received at collection points. The farmer or trader will be required to submit a photocopy of the document that certifies the delivery of the harvested wheat to the collection point, stating the quantity, place, and date.

According to Ashraf Kamal, professor of Agricultural Economy at the Academy of Agricultural Research, one of the greatest problems farmers face, apart from bad weather conditions, is the fragmented structure of land tenure. “A small farmer, with only a quarter or even three-quarters of a feddan of land, finds it hard to afford to hire a special truck to take his harvest to the silos. So, his only option is to sell it to a trader to deliver it for him even though he will receive a smaller amount of money for his wheat than he would directly from the government.”

Mohsen, a small farmer from Qalioubiya who owns half a feddan of land, is in the position Kamal described. He told Al-Ahram Weekly that “I’ll sell my crop to a trader who’ll pay me LE1,430 (US$ 46.13) per ardab, which is less than the government rate, to deliver it to the government silo. But then, I’ll have a problem getting the coarse bran to use for animal feed because the government gives the bran directly to the people who deliver the wheat.”

“I’m not sure how the trader is going to deal with us. Will he agree to give me the subsidised bran? Normally, it costs LE11 a kg in the market.”

On 7 May, Moselhi cautioned traders and anyone else who delivered wheat on behalf of small farmers against trading in the subsidised bran that the government distributes in exchange for local wheat deliveries. The intermediaries are obliged to turn over the bran to the farmers and could be subject to legal action if they fail to do so, he said.

24 | June 2023 - Milling and Grain

Richard Sellers Receives AFIA’s Distinguished Service Award

The American Feed Industry Association (AFIA) honored Richard Sellers, formerly of the AFIA, with its 2023 Distinguished Service Award for his contributions to the feed industry. Leah Wilkinson, AFIA’s vice president of public policy and education, presented the award to Sellers at the AFIA’s May Board of Directors meeting on Wednesday evening.

The Distinguished Service Award is AFIA’s highest honor and is typically given to the elite members of the U.S. animal food industry who have provided outstanding support to the AFIA and the entire animal food industry throughout their careers.

“Richard played a major role in shaping the AFIA into the successful organization that it is today,” said Wilkinson. “Richard prided himself on ensuring that our industry’s voice was heard and considered during several shifts in regulatory programs. No one has provided as much expert advice to the animal food industry over their career as Richard Sellers.”

Prior to retiring in 2018, Sellers joined the AFIA in 1991 and throughout his tenure at the association, he oversaw the AFIA’s legislative and regulatory efforts, growing the team from a team of two to the seven individuals it is today. He was the industry’s advocate before the Food and Drug Administration, state feed control agencies, the Association

wet milling technology

of American Feed Control Officials (AAFCO) and Congress, and relayed information to AFIA’s membership to help them comply with all state and federal feed laws and regulations. Sellers served as the staff contact for the AFIA Aquaculture, Nutrition and Feed Regulatory Committees during his tenure, impacting many individuals through those roughly 160 committee meetings he staffed over the years.

During his career, he was a part of or advocated for industry during several monumental changes and shifts in authorities and regulation of the industry, including: the Animal Drug Availability Act, which overhauled animal drug approvals, medicated feed mill licensing, Veterinary Feed Directive and the Food Safety Modernization Act and its regulations. He guided the industry through the finding of bovine spongiform encephalopathy (BSE) in Europe, the resulting feed ban regulations and inspections and then the finding of BSE in the United States in 2003. He helped develop the current model pet food regulations by AAFCO and oversaw the updates of numerous state commercial feed laws.

• Made from high-quality whole-grain brown rice, our gluten-free flour is versatile and ideal for baking or use in food business

• Long shelf life and wide range of uses make it a smart investment to expand your offerings and increase profits

with Maxx Brown Rice Flour

Diversify and increase profits

by

Don't miss out on the endless possibilities for your business try our Brown Rice Flour today! Learn more insights information on our website www.maxtex.net Milling and Grain - June 2023 | 25 Milling News

Ÿnsect and the LOTTE R&D Centre sign Memorandum of Understanding

Ÿnsect, the world leader in insect production, signs a Memorandum of Understanding (MOU) with the LOTTE R&D centre, a Korean leader in the Tech industry. The MOU was signed by Guillaume Daoulas, Ÿnsect Food & Plant Sales Director, in the presence of Cho Juhyeon, Korean Vice-Minister for SMEs and Startups, at the “France – Korea” event organised by French Tech and the French Embassy in Korea on April 26th.

The agreement includes conducting joint research to develop insect-based food products, working together to increase knowledge of edible insects’ health claims, and conducting and sharing surveys on “insects in human food” among consumers in Europe and South Korea. This partnership will enable Ÿnsect to accelerate its development in human food and expand its activity in Asia.

The MOU between Ÿnsect and the LOTTE R&D centre represents a significant milestone in the development of insect-based food products and highlights the importance of cooperation between France and Korea in the Tech industry.

“The signing of this MOU with the LOTTE R&D centre, the Korean leader, is a major step forward in Ynsect’s development. We aim to accelerate our presence in high value-added markets, with natural, healthy and sustainable ingredients. Through LOTTE R&D centre, we now benefit from the support of a key player to better understand the different markets in which we are establishing ourselves across

the Asian continent and thus be able to meet the demand for local proteins,” says Guillaume Daoulas, Ÿnsect Food & Plant Sales Director.

Ÿnsect aims to accelerate its presence in high value-added markets with natural, healthy, and sustainable ingredients –this partnership is a clear step in this direction. Lee Gyeong Hweon, president at the LOTTE R&D centre, believes that insect proteins are a key option to meet the food and climate challenges of our time, and Asia is already keen on insectbased foods for human nutrition.

In a 2011 report, the FAO highlighted that to feed the planet by 2050 we will have to produce 70 percent more ingredients with only five percent of available land. The FAO already mentioned insects as a solution. Ten years later, with its industrial know-how and scientific knowledge, Ÿnsect began developing the human food market.

Insects are an environmentally sustainable and healthy protein source that can meet the world’s food and climate challenges. Studies conducted by Maastricht University show that mealworm proteins are as beneficial as milk proteins in terms of digestion, nutrition, absorption, and muscle production. Additionally, the protein content of insects is naturally high, requires 30 times less land, emits 40 times fewer CO2 emissions than beef, and uses 40 times less water than pork.

FILIP GmbH • Müllereibürsten • Anemonenweg 4 • D-33335 Gütersloh Telephone: +49 (0)5241 29330 • Telefax: +49 (0)5241 20321 E-mail: info@filip-gmbh.com • www.filip-gmbh.com SIEVE CLEANERS … because that’s what we do, too. On every single FILIP cleaner, we monitor every detail throughout the entire manufacturing process. We know that our proven quality will guarantee effective sieve cleaning within your plansifters. And that, in turn, will ensure a high yield from your passages. Efficient. Quality. Cleaning. PCE PELLETING CONSUMABLES EUROPE YOUR PARTNER FOR TOP QUALITY RING DIES available for all major pellet press brands WWW.PCE.EU Scan the QR-Code to find your die!

26 | June 2023 - Milling and Grain Milling News

Product Spotlight - The Samplex Inline sample & transfer system

The Samplex Inline Transfer System from TekPro Ltd. is a reliable and efficient solution for sampling and transferring products from the production line to the reception chamber. Using Air Flow Motors, the system draws the product along transfer lines from the IL50 or IL55 Sampler/s at the production line. The sampled product can then be removed and tested to meet the manufacturer's requirements.

Made in Britain, Trusted Worldwide. We are

Capable of working with a wide range of dry products

The system is capable of transferring a vast range of products using standard Reception Chambers and 1.5" hoses. For larger products, special Reception Chambers and 2" hoses are available upon enquiry at TekPro Ltd.

The system can be operated in two modes - single or multiple. Single mode allows for one transfer operation to take place, while multiple mode will continue to carry out transfer operations at timed intervals once started. The system is fully programmable, allowing for customization of transfer time, number of samples, time between samples and time between sample operations.

In addition, the Transfer System has an optional external start facility, allowing each transfer operation to be started remotely by a simple switch or signal from mill operations. With its advanced capabilities and features, the Samplex Inline Transfer System from TekPro Ltd. is a valuable tool for product sampling and transfer

To access further free information on the entire range of Samplex inline samplers, exclusively Made in Britain by Tekpro, or to find out how you could join the ever growing number of leading companies already trusting Samplex equipment to sample their products, scan the following QR code:

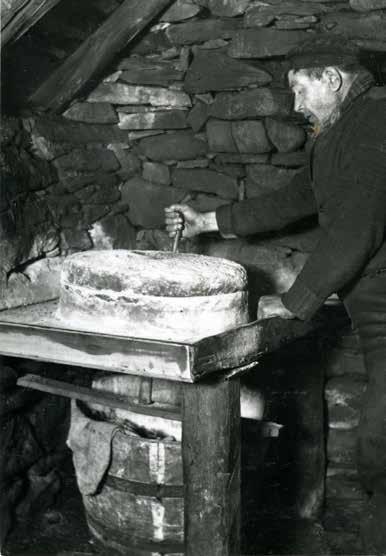

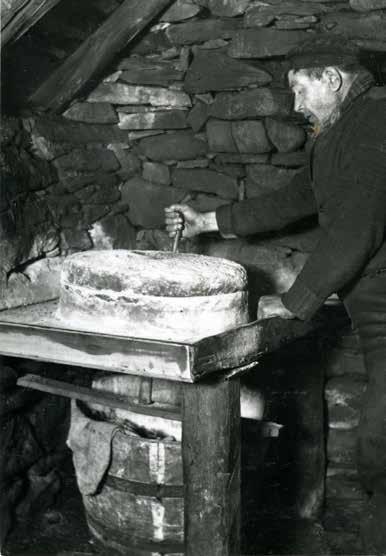

Gems from the Mills Archive An ancient milling revolution

by Nathanael Hodge, Rex Wailes Collection, Mills Archive, UK

It’s the oldest item in our collections – a heavy, smooth, conical lump of rock, about nine inches across and four and a half inches high. Known as a beehive quern (due its similarity in shape to a traditional dome-shaped wicker beehive), it was found in north west Essex in the Stansted area and is made of Hertfordshire puddingstone. Although this ancient artefact is probably over 2000 years old, in its day it was a revolutionary new form of technology, both literally and metaphorically.

Today we are so familiar with each new year bringing new technological advances, we can hardly imagine what it was like to live in a time when most of the tools people used as part of their everyday lives were the ones they had inherited from their parents and grandparents before them, and when a new form of technology would have seemed wholly unprecedented. For thousands of years, from perhaps as early as 4000 BC or before, the form of millstone used the world over was the saddle quern, consisting of a large flat stone with a smaller upper stone which would be rubbed back and forth across it. Grinding enough flour for the daily bread at a saddle quern was very strenuous work. Research from the University of Cambridge in 2017 indicates that Neolithic women had stronger arms than today’s elite rowers due to spending up to five hours a day grinding wheat.

In the Iron Age, for the first time in thousands of years a completely new type of mill appeared – the rotary quern. It was significantly more efficient, taking perhaps only hour to grind the wheat for the day’s bread, and made de-husking the grain much easier. The new type of mill was only made possible by the introduction of iron, enabling the creation of both the iron tools used to shape the stone and the iron spindle around which the upper stone rotates. Grain was fed into the ‘eye’ in the centre of the upper

28 | June 2023 - Milling and Grain

stone, which was turned using a wooden handle inserted into a hole at the side. Grain is crushed between the rotating upper stone and the stationary lower one, exiting as meal all around the rim.

The exact time and place of the rotary quern’s origin is not certain; however they seem to have arrived in Britain in around 400-300 BC. We can only guess at the effects the new type of mill had on society, but in providing a means to produce flour much more quickly and in greater amounts, it must have led to significant social changes, comparable to the effects of the introduction of the even more efficient water powered mills in the Roman period, and the development of modern roller milling technology in the 1800s. Beehive querns continued to be used into the Roman period, gradually being replaced by larger and thinner stones. Even with wind and water powered mills, handmills still continued in use into the Middle Ages, and for grinding oats in the Scottish isles into the 20th century.

The Mills Archive is a permanent repository for the documentary and photographic records of traditional and contemporary mills and milling, as well as similar structures dependent on traditional power sources. It makes that material freely available for public inspection and use in research and learning.

The Mills Archive is one of the world’s great mill collections. It has rescued over 3 million documents and images that might otherwise have ended up in a landfill site. It is an Aladdin’s cave filled with memories and free to users. The collections show the rich and diverse crafts, buildings, machinery, equipment and people involved with mills in the UK and around the world.

www.millsarchive.org

pubblicità italiana_MOD.pdf 1 27/01/22 10:59

- June 2023 | 29

Milling and Grain

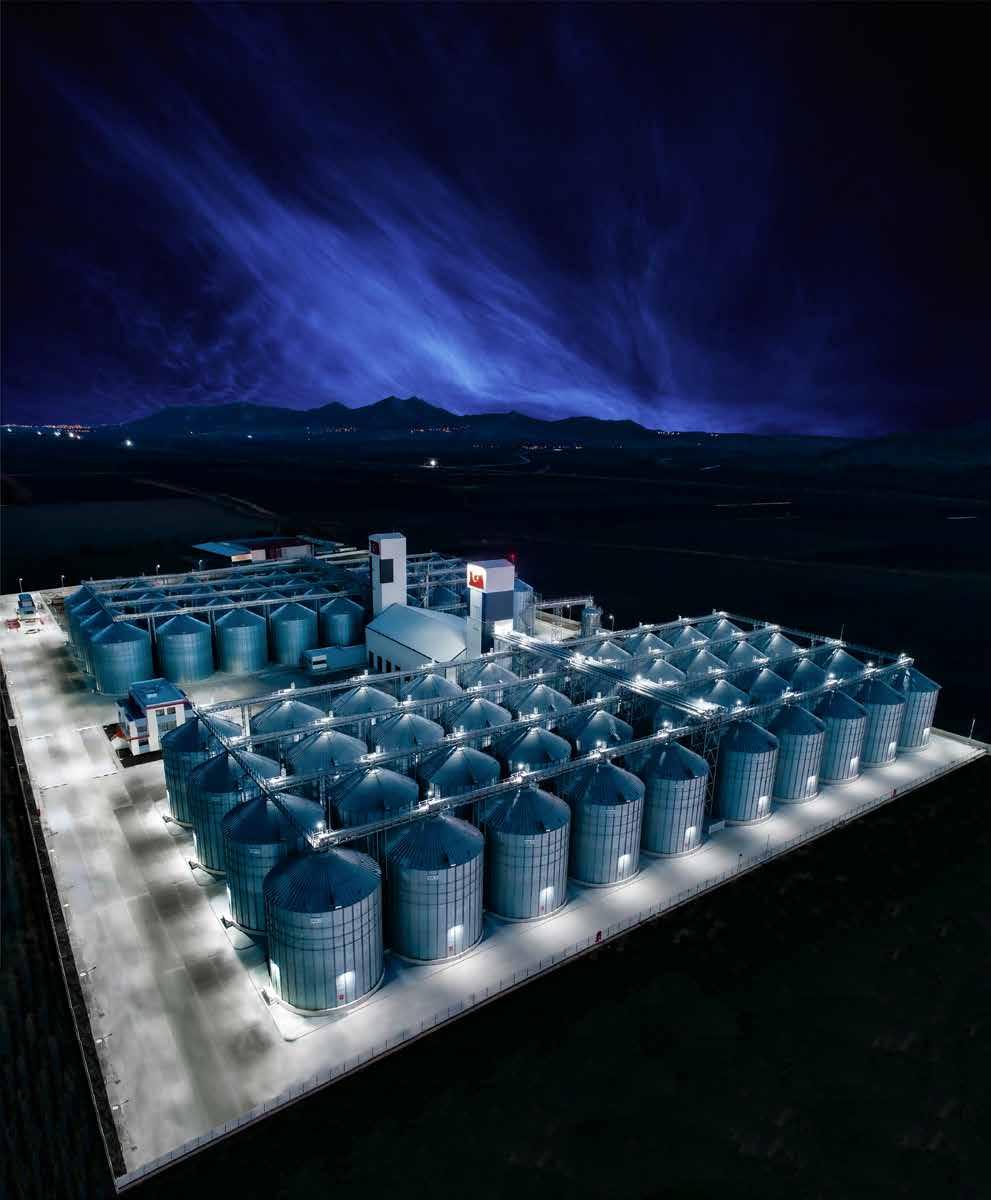

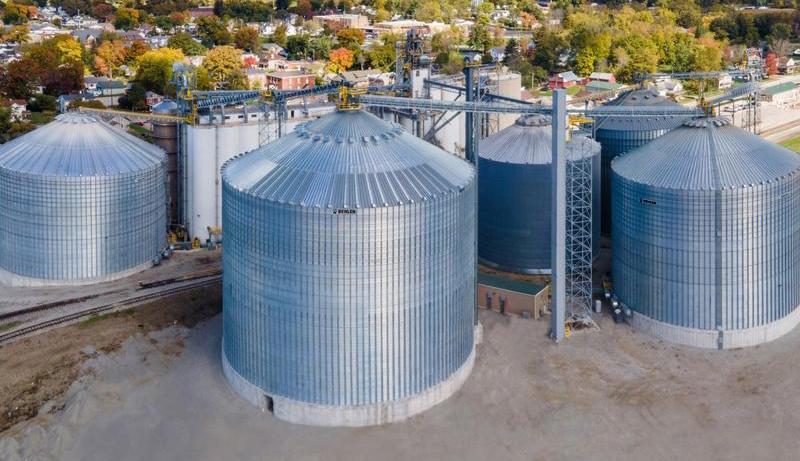

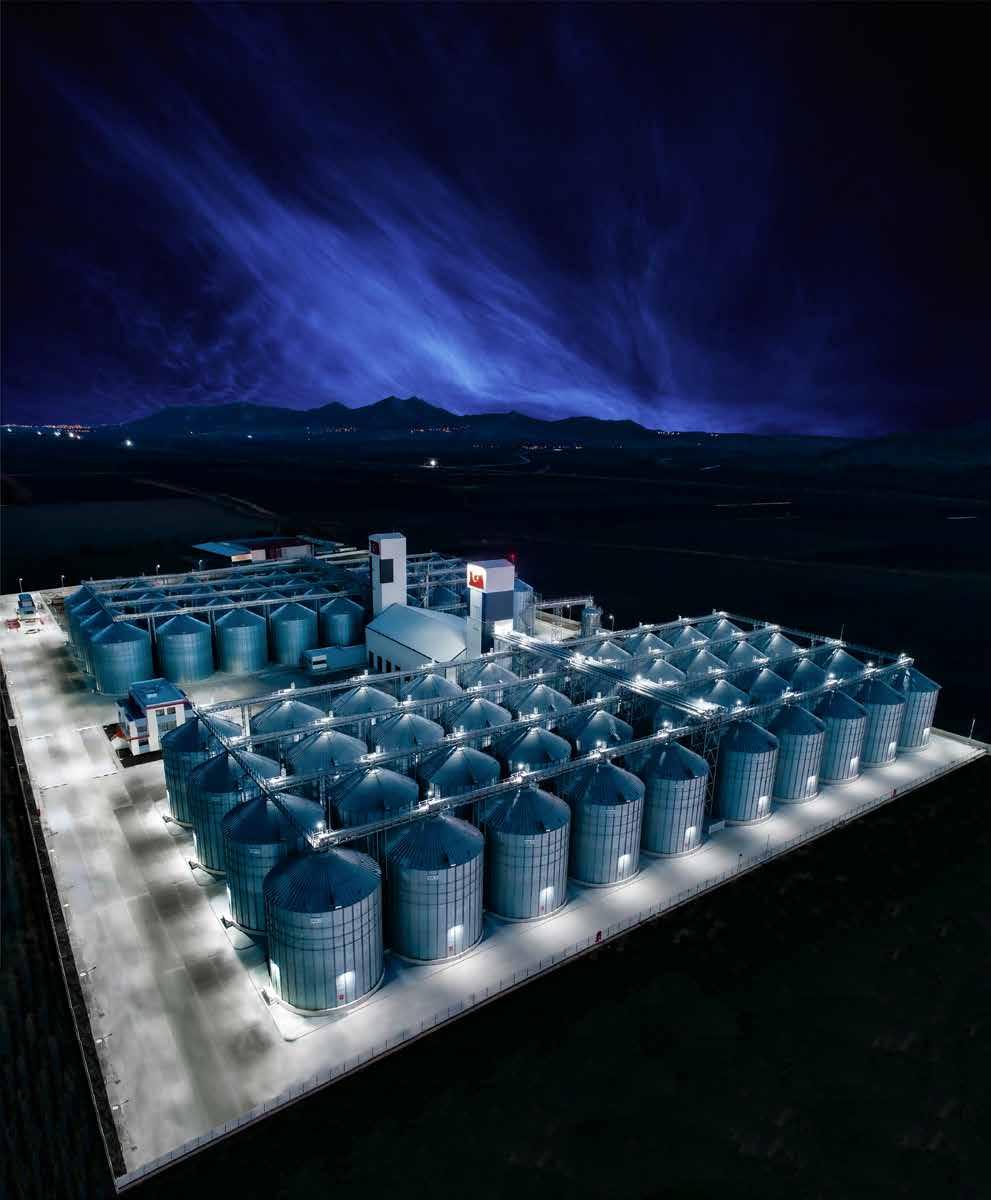

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS

more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Food Extrusion Workshop

The workshop will take place at Extrusion Application Centre, Bühler, Uzwil, Switzerland, on 13 - 16 June 2023. The course, conducted in English, will cover an introduction on the basics of extrusion technology using hands-on workshop teaching. This will encompass:

• The principles of extrusion technology: Extrusion Basics, function of screw elements, effects of mechanical and thermal energy input, screw configurations for direct and indirect expanded food products.

• Extrusion process related equipment: Steam addition into extruder and preconditioning as a means of thermal energy addition, de-gassing and application of vacuum as a means of thermal energy removal, co-extrusion process and remotecut technology, colouring and coating of extruded products, drying and toasting technology.

• Presentations of various extruded food products: Direct and indirect expanded RTE breakfast cereals and snacks, dry and wet texturised plant-based proteins, modified flours, and extruded breadcrumbs.

• Analytical methods to analyse raw materials and final products: Conversion of starch and proteins during extrusion cooking process, and a demonstration in Bühler’s Analytical Laboratory.

Between the theoretical sessions there will be live demonstrations of various extruded products in Bühler’s stateof-the-art extrusion pilot plant. Those attending need to be actively involved in the technological aspects and feasibility of extrusion production for food.

The cost of the training course is CHF 4’900, which includes:

• Hands-on training with our experienced extrusion experts

• Training documentations

• Lunch on all full training days

• Transportation between hotel and training facilities (hotel fees not included)

• Certificate of participation

• Invitation letter for visa application

For more details, visit: https://www.buhlergroup.com/content/ buhlergroup/global/en/training/Extruded-products-workshopfor-food.html

Milling and Grain - June 2023 | 33 TRAINING Mill

Ocrim milling school

A company, and in general any industrial reality, is well balanced and competitive when profound technical knowledge is combined with the indispensable entrepreneurial skills of intuition and imagination.

The task of our school is precisely to help milling companies enrich their human resources, placing the most advanced technical know-how at their disposal as a company that designs and manufactures the machines and systems it teaches, through its dedicated courses, functions, use and maintenance. All the teachers at our school, including technicians, engineers, technologists, skilled workers and chief erector, are part of the OCRIM team. OCRIM's International Milling Technology School has been providing training to students from all over the world for over 58 years, as evidenced by the different courses that take place every year.

In March and April, for example, we hosted respectively students from "La Pasta S.A." company (Cameroon) and Cargill Deutschland GmbH (Germany), who attended a course with theoretical and practical courses in milling technology. The school courses’ agenda does not stop there. In fact, other dedicated courses are already scheduled for September and October.

Furthermore, basic training is provided for beginners in the sector - who desire to have a concrete approach with the milling reality - upon reaching a minimum number of members, to have the best training experience. For more information, please send an email. Let's retrace together the historical stages of the most important International Milling School

1965 – OCRIM sets up training courses for its customers aimed essentially at learning the maintenance techniques of the mill machines. For the theoretical lessons, the classrooms of the Industrial Technical Institute of Cremona were used; the company's assembly and maintenance departments were used for the practical lessons.

1979 – OCRIM physically creates the school in Cavatigozzi, Cremona province, equipping an area with classrooms, laboratories, a workshop and a pilot mill.

1995 – The school, almost completely renovated, was transferred from the suburbs to the headquarters (where it is still located), becoming its flagship.

2018 – Bonifiche Ferraresi, OCRIM and other realities, including research institutions and universities, sets up a training center at Jolanda di Savoia (Italy) which offers training courses and masters on agriculture 4.0.

2020 – Establishment of the futuristic Milling Hub Masterclass milling academy, whose courses focus on knowledge of seeds up to the marketing of the finished product.

TRAINING Mill 34 | June 2023 - Milling and Grain

C O S T E F F E C T I V E Spread over the study year, the cost of a module is less than £12 a week T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E Study increases competence thereby freeing up your time All students are allocated a tutor with a wealth of specialist knowledge Distance learning Distance learning PROGRAMME

. . . F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

We will be seeking enrolments from June ...

FOCUS Product June 2023

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

The speed, accuracy and flexibility of the STORM PRO seed treater provides the ultimate seed treating solution for your operation. Industry leading speed and capacity propels your business to the next level, allowing true just-in-time treating. The STORM PRO is a completely selfcontained, turn-key seed treater that uses an auto-calibration system and is safe enough to use on all seed types, including soybean, pulse and cereals. The STORM PRO offers the versatility of treating seed when you need it, where you need and can be controlled by the easy-touse touchscreen controls or by phone or tablet. It also meets the new industry requirements for commercial application.

Unlike other seed treaters, STORM PRO accurately measures untreated seed directly from the bin, precisely meters and applies the seed treatment, gently mixes the seed for consistent, even coverage and then transfers the treated seed into the truck, ready to be planted in the field.

NEW SIMILAGO II by Alapala

Alapala’s NEW SIMILAGO II roller mill is equipped with high technology electronic control systems for a continuous and consistent performance in the grinding of cereals, such as wheat, maize (corn), rye, spelt, barley and sorghum. The product level at the inlet bunker is controlled by using load cells, which sends signals via PLC to adjust the feed roll speed accordingly. Rotational speed of feed rolls is monitored against an unexpected stop due to belt problem, etc. Manual feeding gap adjustment mechanism ensures a uniform flow on feed rolls. The main motor load is constantly measured for protection against any possible damage, and the rotational speed of grinding rolls is monitored against an unexpected stop due to belt problem, etc.

The NEW SIMILAGO II is built to comply with the high sanitation standards and ensure food safety. The roller mill’s all front structure is isolated and smoothened against adhering and condensation risk.

https://alapala.com

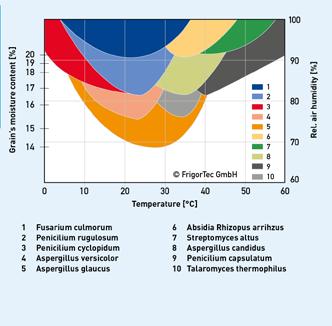

STANDARDFRIGOR Air purifier deviro™ by FrigorTec

The deviro™ cleans room air of fine dust, viruses and other elements that are harmful to health using a three-phase filtration system. The downstream HEPA H14 filter removes 99.995 percent of impurities from the air. Despite its powerful fan, the deviro™ is one of the quietest filtration devices in its class and can therefore also be used in work rooms. Three filter stages remove 99.995 percent of air impurities

Sound insulation enables use in noise sensitive surroundings

Simplified transport with handles and fixed castors

Every deviro™ is produced at our German plant and undergoes a factory test run before delivery Easy operation, timer can be selected with app Optional UVC technology for additional safety

www.frigortec.com

Absograph 500 by Bastak

Absograph 500 measures water absorption capacity of dough and transfers the data to graphic, besides it prepares the dough sample for the next test (resistograph test). It gives information about flour properties if it is suitable for bread, pasta, biscuits.

It is easy to use with an ergonomic design, it has a touchable screen, internal computer system, and saves data. If required possible to use with mouse and keypad. It has connection ports RS232 and Ethernet. The software can be updated with remote connection. Absograph also complies with World standards. It has standard 300 gr dough mixing capacity and it is possible to record the results as PDF File. The results of Absograph comparable and equivalent with the Farinograph device and the temperature of dough mixing container is adjustable

ETI Batch Coating System by Extru-Tech

The ETI Batch Coating System was designed to handle up to 40,000 lbs/ hour at batch sizes of 2,500 pounds at 63 percent fill level. Even at this high rate, the batch coater provides 3.75 minutes of product retention time, which far exceeds the retention time of a traditional, continuous coating system. Batch retention times of up to 5 minutes are seen when operating near 24,000 lbs/hour production rates.

A multi-functional time/pressure spray design provides optimal liquid application uniformity across the entire batch. The automated control system determines the optimal spray time for each liquid and then sets the spray pressure for each of the pressure supply tanks. This allows the spray time to be extended to the maximum length of time, thereby providing the most even and accurate coating possible. Since 1985, the Extru-Tech name has been synonymous with versatility and efficiency among food and feed manufacturers.

www.extru-techinc.com

STORM PRO by AGI

STORM PRO by AGI

36 | June 2023 - Milling and Grain

www.aggrowth.com

www.bastak.com

AgroLog The Ultimate Wireless Crop Moisture and Temperature Probe

The industry has longed for an accurate crop moisture and temperature probe that combines precision and ease of use in a single package. Addressing this demand, crop storage specialists Martin Lishman Ltd have introduced the AgroLog moisture and temperature probe to their comprehensive line-up of crop quality equipment. Timed perfectly for the 2023 season, this cutting-edge 2-metre probe offers instant temperature and moisture readings, serving as the ultimate portable monitoring solution. Equipped with five on-board sensors and an extensive calibration process, it can accurately determine the moisture content of stored grain.

The probe's standout feature is its seamless wireless capabilities. Once positioned in the crop, it automatically collects moisture and temperature data and sends it via the cellular network to the cloud for further analysis. The data can be conveniently accessed and manipulated using the AgroLog app, available for iOS and Android. Additionally, a web-app version is accessible on any internet-enabled device.

"The AgroLog probe is an exciting addition to our crop quality range," explains Joel Capper, Managing Director for Martin Lishman Ltd. "We believe this probe fills a gap in the market, and we are confident that farmers across the UK will find it a valuable tool to use in their stores."

With its advanced sensor technology, the AgroLog probe provides users with crucial knowledge of the equilibrium moisture content (EMC) specific to their grain. Understanding the EMC is essential for effective grain drying. Farmers and grain handlers can ensure

safe storage conditions while avoiding unnecessary energy consumption and economic losses associated with over-drying. The multiple sensors inside the AgroLog Probe assist in identifying the location of the drying front. By confirming when the lower levels of grain have reached their target moisture content, the probe helps users decide when to turn off heaters so that fresh airflow can be utilised, reducing the risk of over-drying and saving energy.

Pete Waudby, Farm Manager for J.E. Atkinson & Son, trialled the new AgroLog probe earlier this year. "I was fortunate enough to trial this probe during the testing stage. I was surprised at how easy it was to set up and use, and the unit's accuracy coincided with our moisture metres. This will be a handy tool for any farmer looking for an instant guideline moisture reading."

Constructed from the highest quality materials, the AgroLog probe is designed to withstand the rigours of farm use. Its construction incorporates aluminium, fibreglass, and ABS, ensuring its durability, and it is weatherproof to withstand the harshest storage conditions.

Milling and Grain - June 2023 | 39 FOCUS Special

www.ai-lati.com

u r ess enc e lie s i n t h e for m s t h ro ugh wh i ch w e s how o u rsel v es.

offer j u st wha t we a r e .

wa y s . www.paglierani.com

O

We

Al

www.ocrim.com

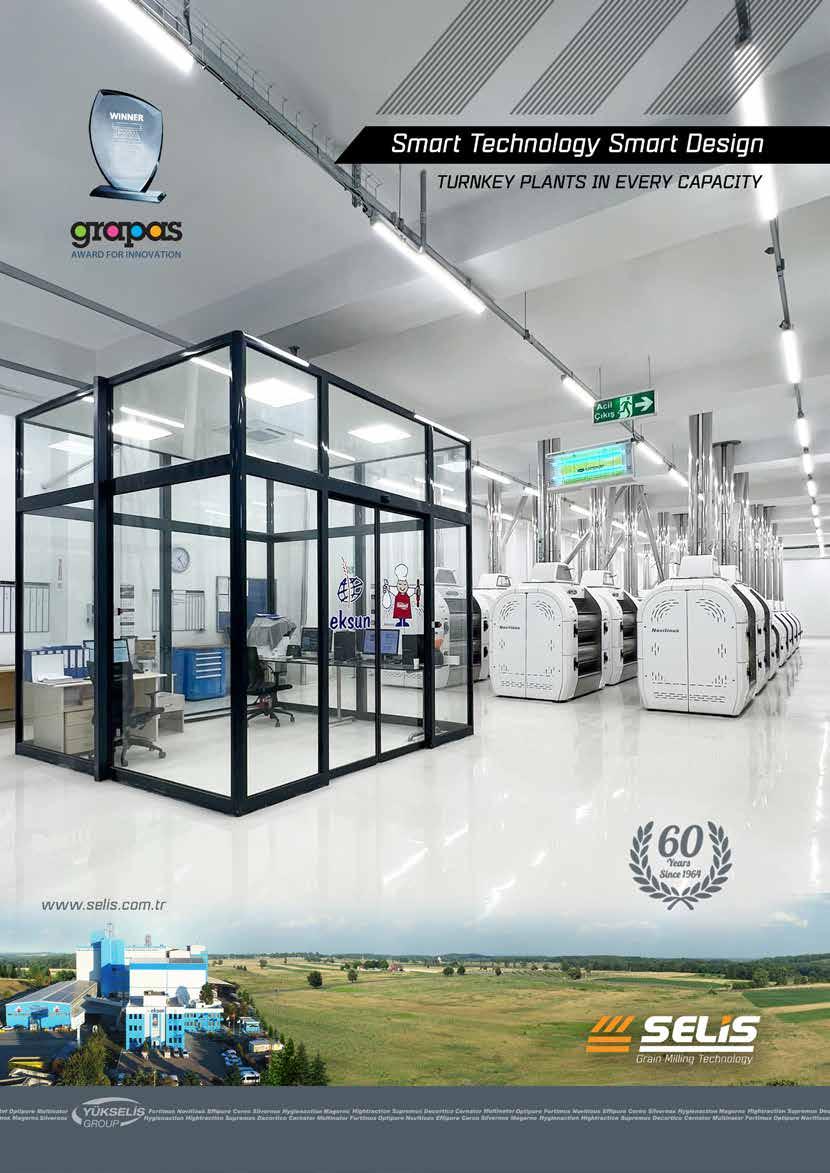

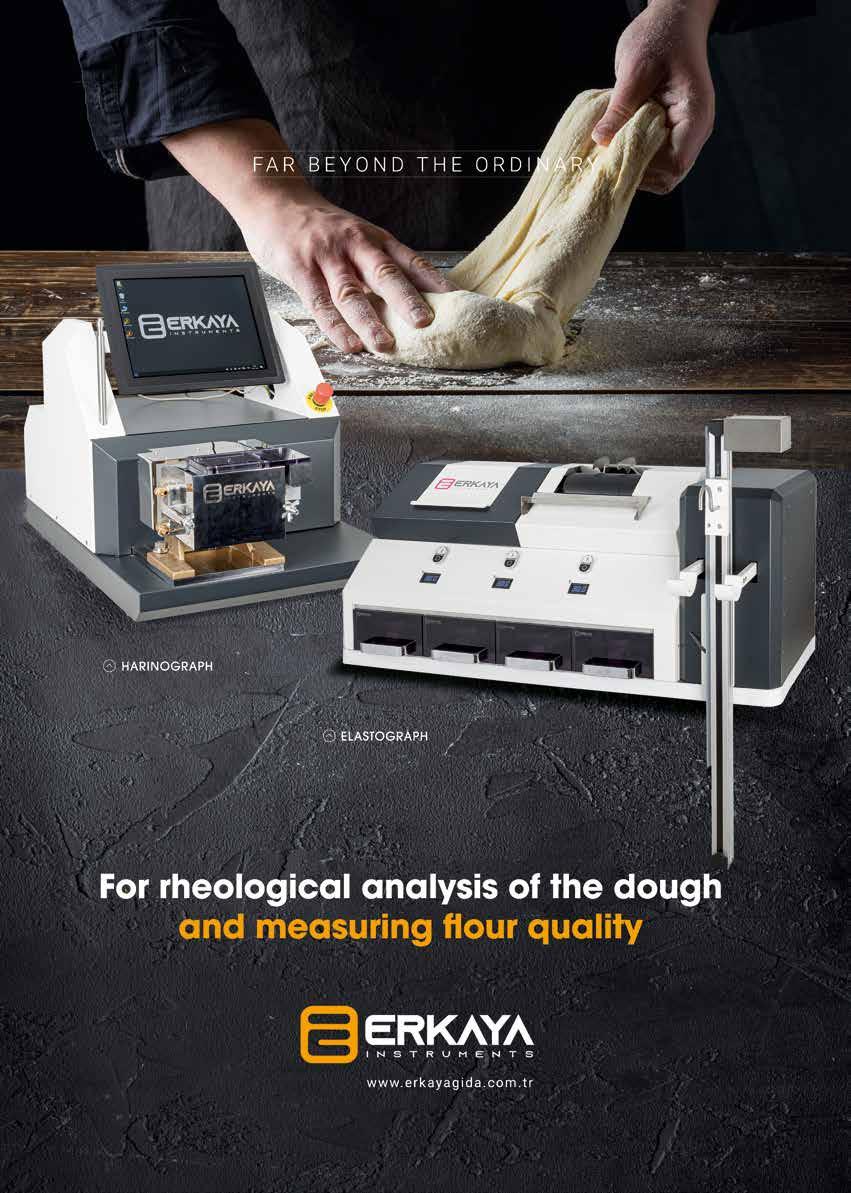

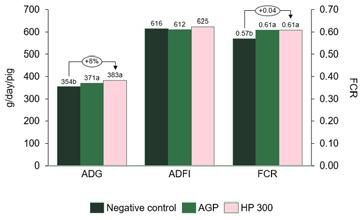

Flour is art

FlourWorld Museum opens a new chapter

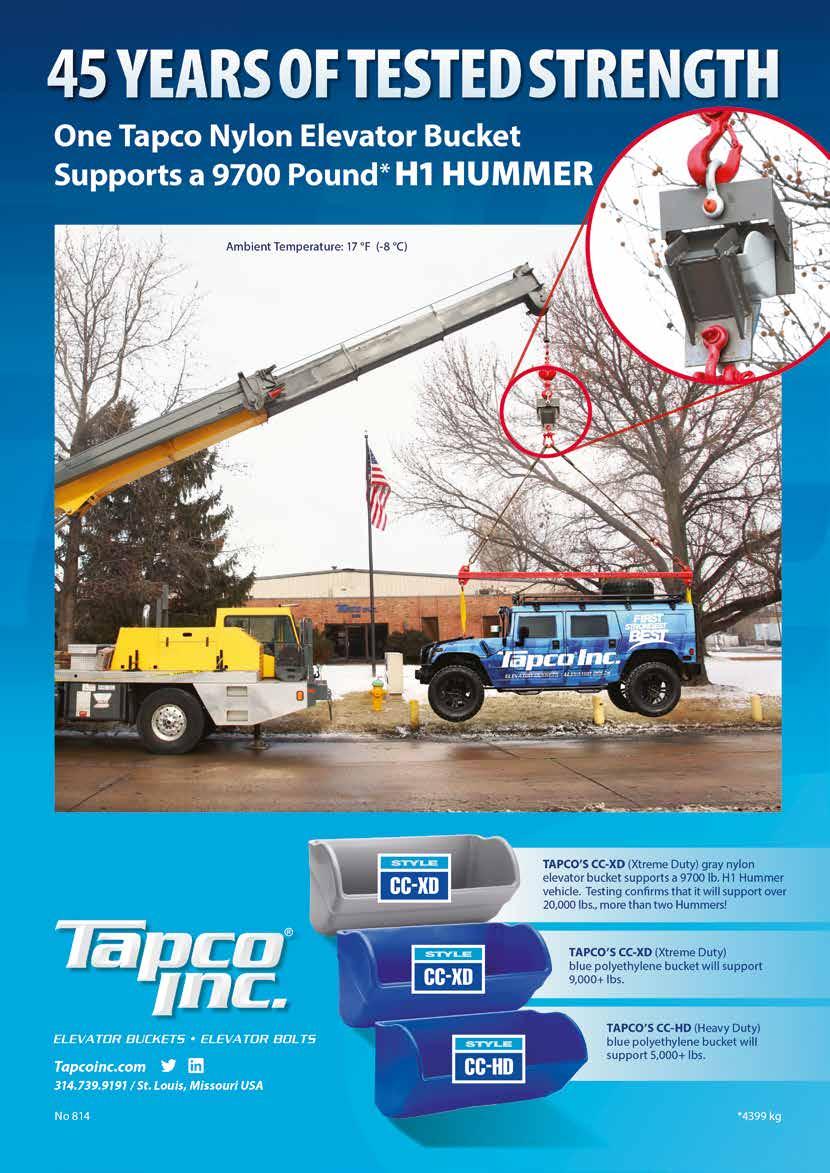

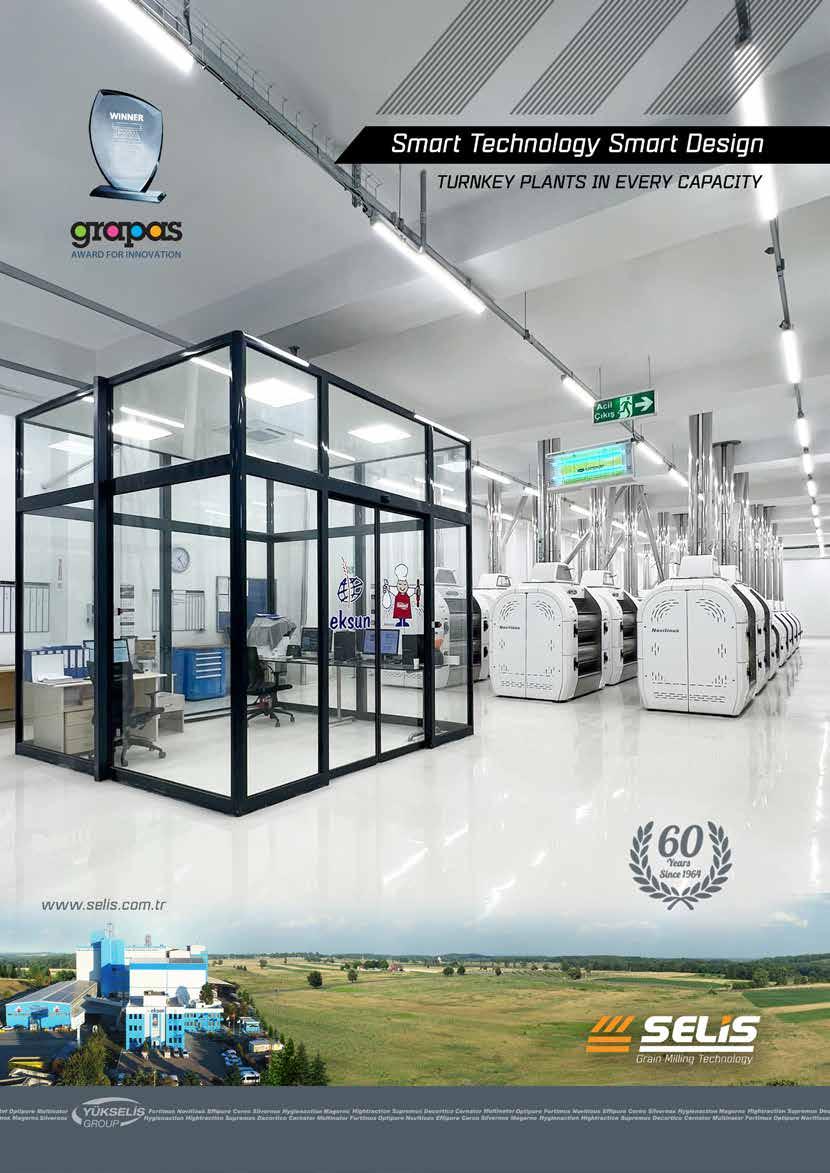

The FlourWorld Museum in Wittenburg illuminates a further chapter in human history, opening a new room dedicated to the Industrial Revolution. An epoch that allowed the world population to grow, while at the same time creating new technical solutions to provide for it. The modern industrial milling presentation was conceived and designed by museum curator Dr. Oliver Seifert, in cooperation with Bühler Group, a worldleading Swiss technology leader in grain processing, and Mühlenchemie GmbH & Co. KG. An audiovisual installation and working models of an optical sorter, roller mill and plansifter show interested visitors the individual steps in the industrial production of flour, the worldwide staple food.

42 | June 2023 - Milling and Grain F

The “Flour.Power.Life” exhibit concept at the FlourWorld Museum revolves around the importance of flour as a staple food in the history of humanity. This history reaches from the first cultivation of grain 10,000 years ago during the neolithic revolution, when humans became sedentary, until today. The new “Milling Room” addresses the other major revolution in human history –the industrial revolution of the 19th century. It changed the world even more radically than the neolithic revolution of 10,000 years ago. What is remarkable is that both revolutions were intimately associated with grain.

Before the Industrial Revolution there were over 60,000 mills in Germany. Today there are only about 200, although the population has quadrupled. The story in other parts of the world is similar. The new exhibition shows the technical achievements and devices that led to the development of the modern industrial mill. Three machine models are centrepieces and take visitors through the process of flour production. An optical sorter, roller mill and

The “Flour.Power.Life” exhibit concept at the FlourWorld Museum revolves around the importance of flour as a staple food in the history of humanity

Milling and Grain - June 2023 | 43 F

Plansifter and multimedia installation wall.

plansifter demonstrate the mechanical processes of cleaning, grinding and sifting. The models were developed and built during the last three years by 37 apprentices of the deep-rooted Swiss company Bühler in Uzwil. They give a detailed look at the functioning of a modern mill. In addition, a schematic presentation shows all the fully automated work steps in today’s industrial milling.

“The room is designed to present the technology of modern flour milling, the power and the dimensions that make industrial manufacturing processes so revolutionary. When you visit a modern mill today, even with its steel machinery, high tech and sealedoff cleanrooms, it’s hard to comprehend the quantities that are processed every second to get a consistently high-quality product like flour,” said Volkmar Wywiol, founder of the FlourWorld Museum.

The art of milling!

The exhibit designers used artistic means to make these energies tangible. The link to art was obvious. In the 17th century, due to the technical sophistication of mills, mill construction was called “the art of milling.” A multimedia grid wall with 80 moving panels that slowly turn around – almost like the blades of an old-style windmill – transforms into a mysterious machine. Crystalline objects appear, first a few, then more and more, and the machine starts to eject the objects from the grid. Sorting, grinding, and then the dancing movements of the particles on the screens of the plansifter – the grid wall shows the processes demonstrated by the models in modified, highly reductive visual and acoustic form. The apparently irrational change of the aggregate state from crystalline to fluid stands for the transformation of indigestible grains in the mill to the pure white product we call flour. A

44 | June 2023 - Milling and Grain F

Simply visit: https://millingandgrain.com/magazine and use the Promo Code HNY23 This offer entitles you to a 12 month digital subscription to Milling and Grain magazine on our app and desktop versions. This offer is on a first come first served basis and will run until 01/09/2022 Would you like a complimentary digital subscription to Milling and Grain magazine? YOUR GLOBAL PARTNER

transformation that still has something magical to it, despite all the science.

When Volkmar Wywiol, the former owner of Mühlenchemie, stumbled over an empty flour sack washed up on the beach in Dubai in 1998 there was no way he could guess the consequences this encounter would have. But he could not get the idea of the flour sack as part of our international cultural heritage out of his mind, and so the collection grew and grew until it comprised over 3,600 flour sacks from more than 140 countries. This was due above all to the enthusiasm of Mühlenchemie’s customers and employees; it was their many contributions that ultimately raised the flour sack to the level of a real art form, with a museum of its own.

But the FlourWorld Museum is more than just an exhibition building. It is the first institution to study flour sack motifs for their cultural significance and reveal their symbolism.

The new Milling Room can be viewed during a visit to the museum in Wittenburg every other Saturday and every Sunday from 12:00 to 17:00. An audioguide explains all the displays and exhibits. The FlourWorld Museum in Wittenburg is an initiative of Mühlenchemie.

https://mehlwelten.de

The new Milling Room in the FlourWorld Museum in Wittenburg

The new Milling Room in the FlourWorld Museum in Wittenburg

Milling and Grain - June 2023 | 47 F

Flour pic 1 - The new Milling Room is opened by sponsors and initiators. Left to right: Peter Steiner, Global Head of BU Mühlenchemie GmbH & Co. KG; Alexander Schnelle, Sales Director Europe Bühler AG; Flavio Diaz, President Europe Bühler AG; Volkmar Wywiol, founder of the FlourWorld Museum and the Stern-Wywiol Gruppe; Dr. Matthias Moser, CEO Food Ingredients Division of the Stern-Wywiol Gruppe

The World Nutrition Forum 2023

by

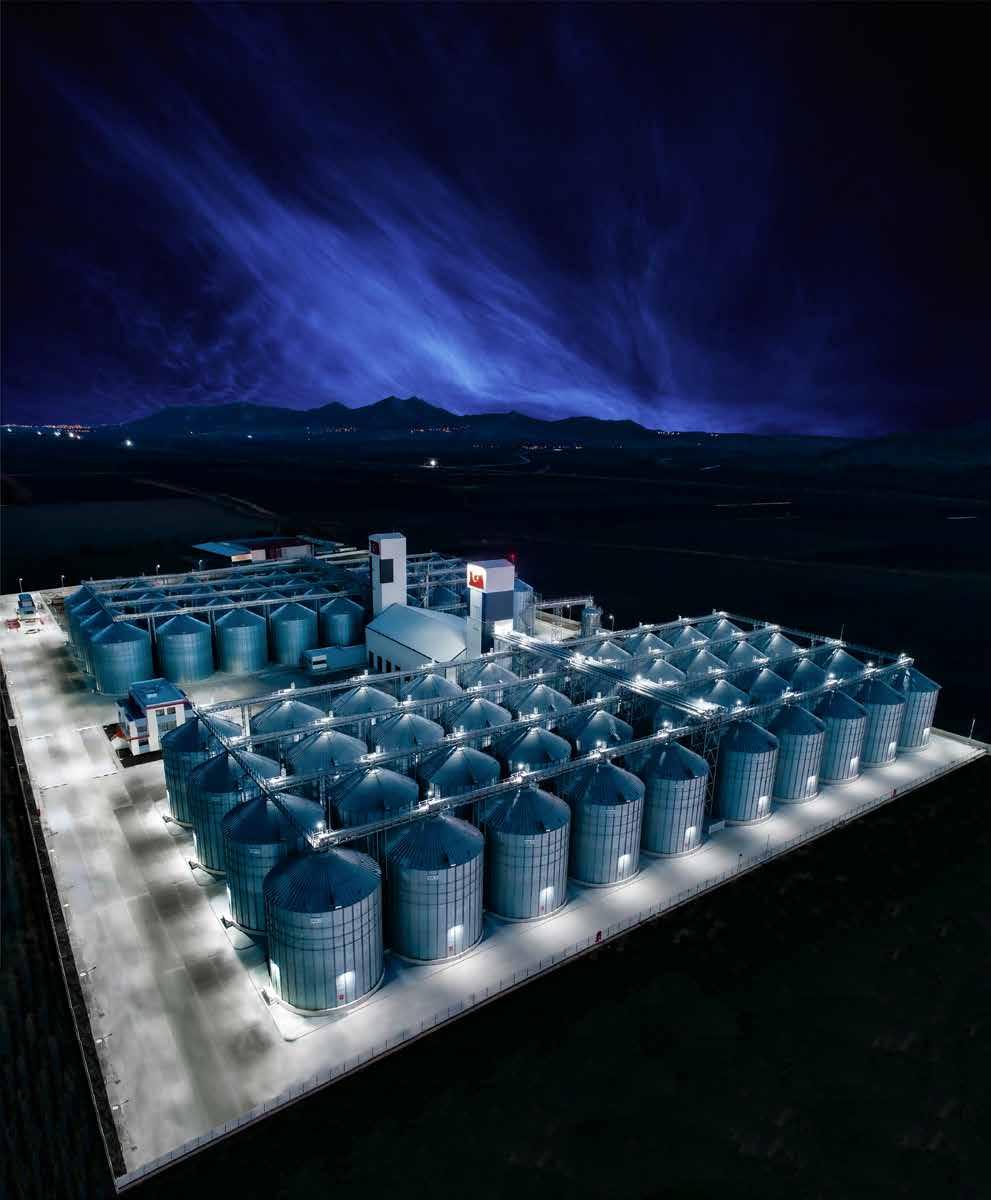

The World Nutrition Forum (WNF), hosted by dsm-firmenich, saw more than 800 delegates gathered for this the fifth hosting of this unique, biannual international event, which served as a platform to discuss modern advances in intensive livestock production, its trends and challenges.

The theme for this year’s WNF was ‘GENiUS’, which specifically focused on the need for new technologies and research.

First launched by Biominn in 2004, WNF has become more than just a company-sponsored conference. Introduced by Biomin as a platform for critical thinking, opinions and addressing challenges, it has become widely regarded as a much-attend event by leading decision makers in animal nutrition and related fields.

It is a global opportunity for industry professionals to engage with each other, address important issues, and look to create a successful future which addresses a growing global population and has been fully embraced by dsm-firmenich which acquired Biomin in October 2020.

Previous editions have taken place across the globe, from places

such as Salzburg and Munich in Europe, Singapore in Asia and prior to the Covid pandemic in Cape Town South Africa. This year’s three-day event took place in Cancun, Mexico from May 8-10, 2023.

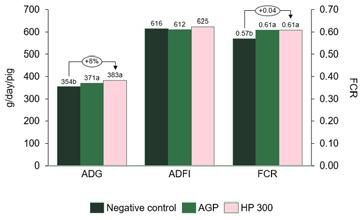

The event, located in a picturesque spot overlooking the Caribbean Sea, at the Cancun International Convention Centre, was dsm-firmenich’s first opportunity to host the event and presented a thought-captivating conference with significant opportunities for delegates to meet and exchange views - what a phenomenal job it achieved. All this while as DSM announcing on day two its merger with the Swiss company Firmenich, which operates in the fragrance and flavour business, to become dsmfirmenich.