millingandgrain.com September 2023 In this issue: Milling and Grain . Volume 134 . Issue 9 . September 2023 Proud supporter of Download the Milling and Grain app to your smart phone INARECEN T POLL, MILLINGANDGRA I N W A S V O#DET LLIMDETSURTTSOMI GN MEMYBENIZAGAM SRE O F U K F L OU MILLERS YOUR GLOBAL PARTNER Volume 134 Issue 9 Up-coming Milling and Grain conferencesfind out more on page 84 FOOD SECURITY the need for strong relationships - Determination of gluten fractions - A holistic approach for feed hygiene and mycotoxin control - Is the future of animal nutrition in postbiotics? - Rice washing technology - Getting the most from extraction systems

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

Perendale Publishers Ltd

7 St George’s Terrace St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267701

Publisher

Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris Tel: +44 1242303792 darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Cristina María Roldán Otero Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Social Media Journalist’

David Harvey davidh@perendale.com

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

ISSN No: 2058-5101

VOLUME 134 ISSUE 9 NEWS 10-31 44 Determination of gluten fractions 46 Food security - the need for strong relationships 50 A holistic approach for feed hygiene and mycotoxin control 56 Is the future of animal nutrition in postbiotics? 60 Rice washing technology STORAGE 66 Getting the most from extraction systems 8 PUBLISHER Roger Gilbert 104 INTERVIEW Martino Celeghini ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service EVENTS 84 Event listings, reviews and previews COLUMNS 10 MAG TV 10 The Global Miller 20 Mildred Cookson 24 Dr Mahmoud Riyad 30 Gems from the Mills Archive FACES 106 People news from the global milling industry TRAINING 35 Industry training news PRODUCT FOCUS 34 CASE STUDY 80 INDUSTRY PROFILE 76 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 September

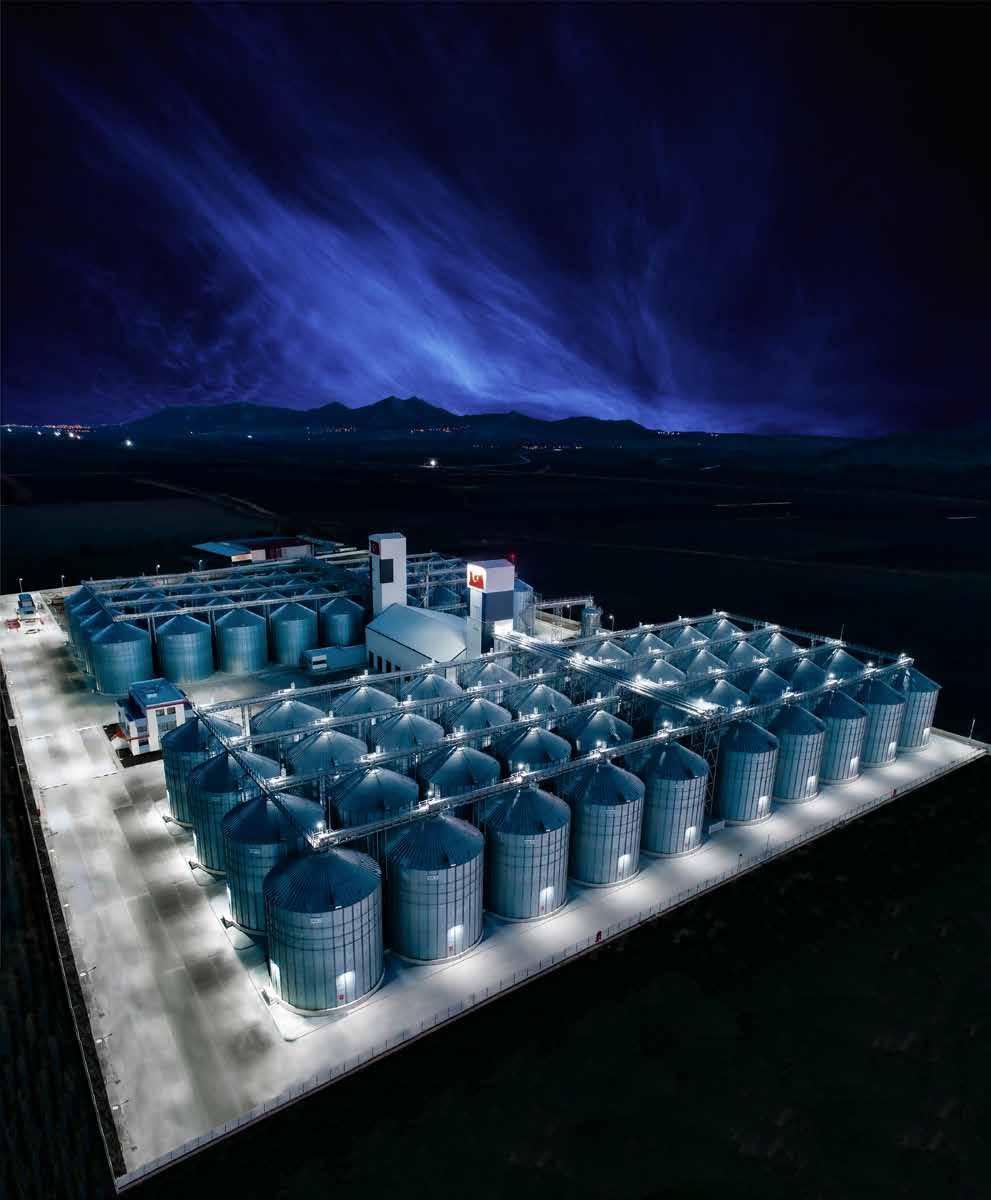

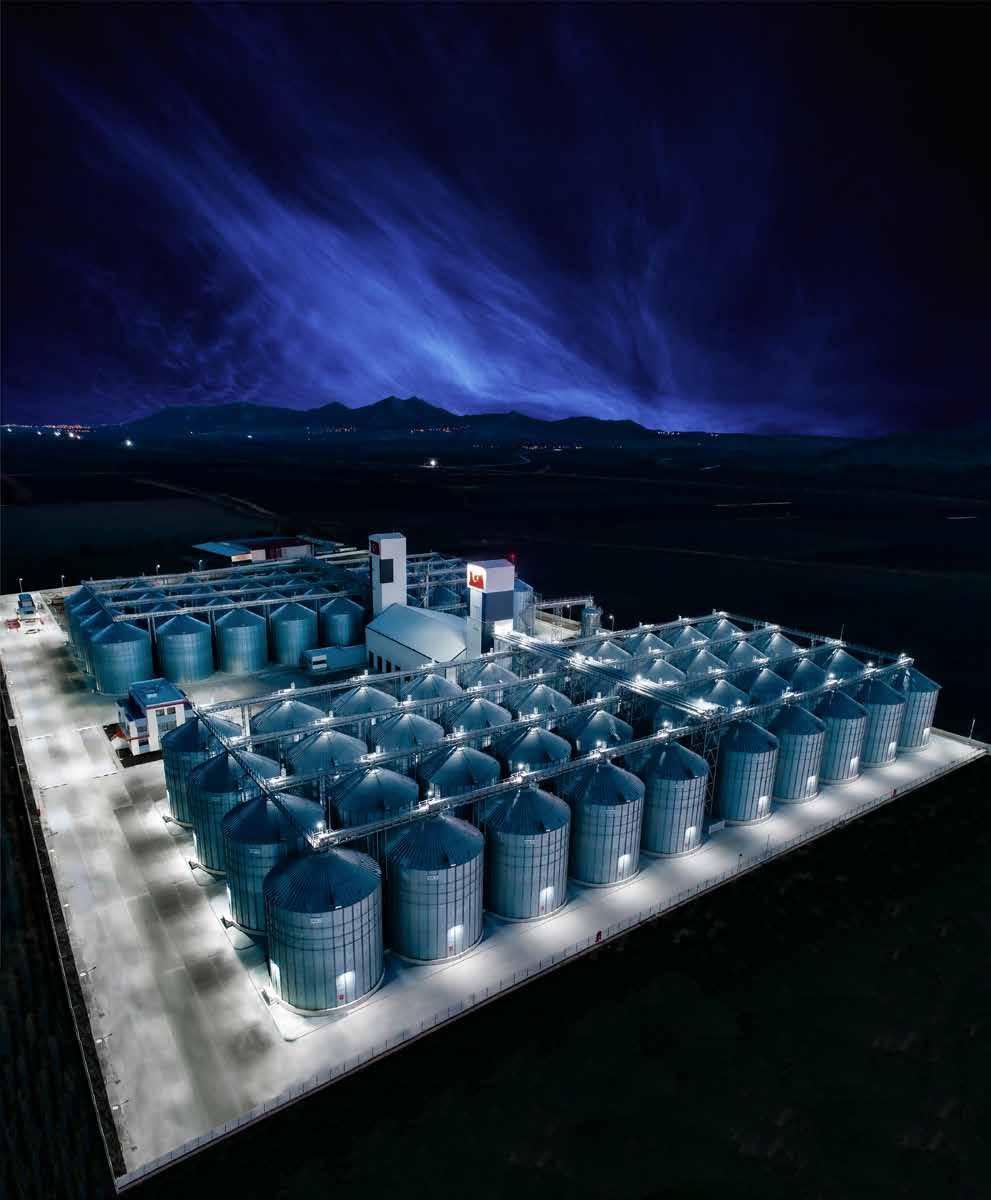

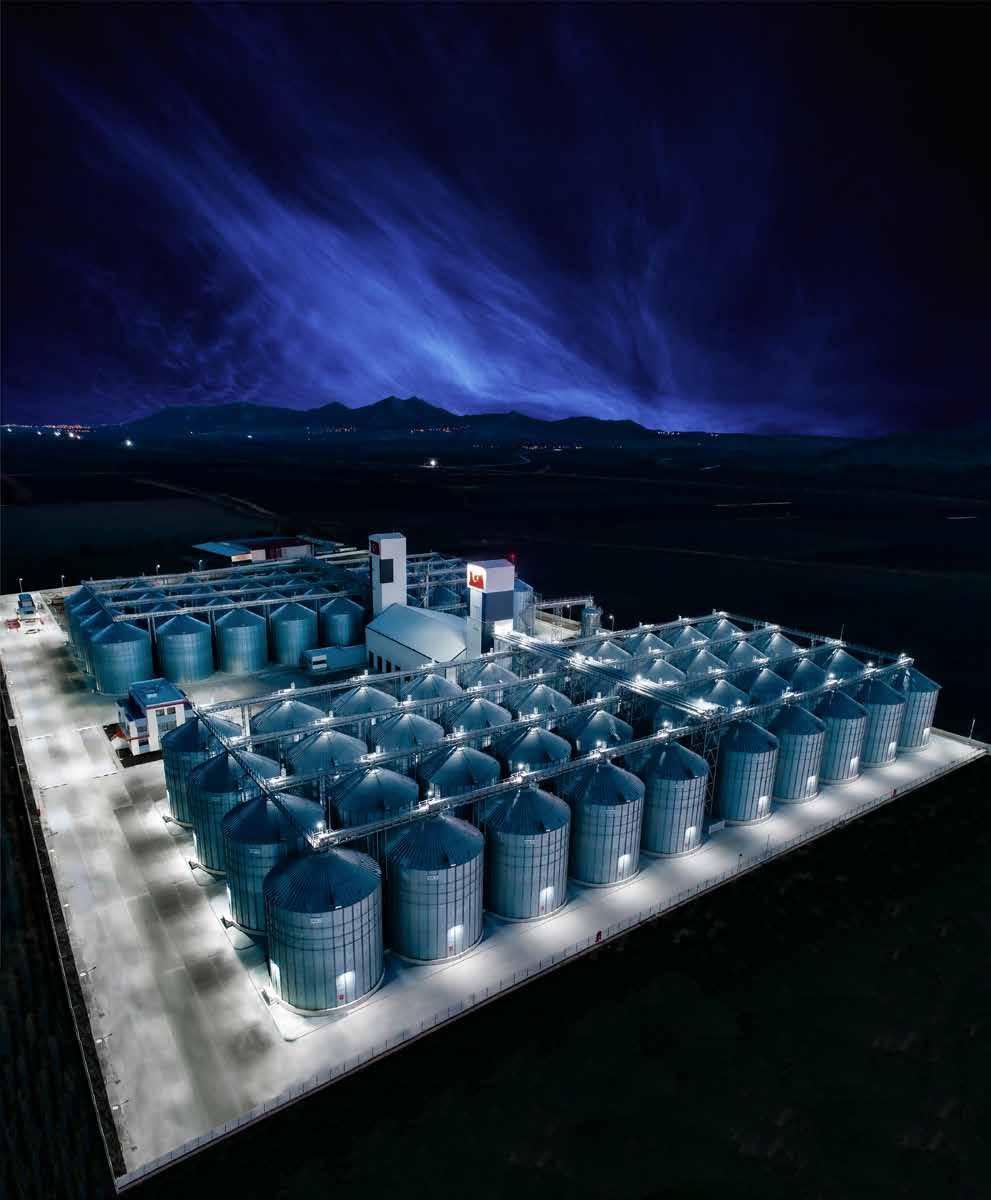

COVER IMAGE: Company Profile: Simeza Silos - Manufacturing of storage silos for grains, flours, and other industrial products for over 45 year - see more on page 76 FEATURES millingandgrain.com

Food security - the need for strong relationships See more on page 46

2023

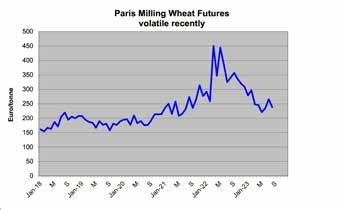

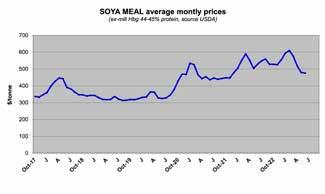

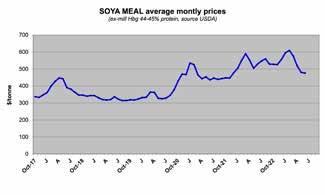

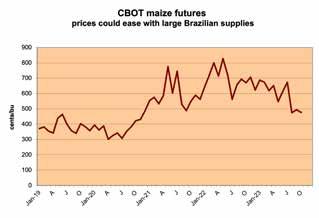

70 MARKETS John Buckley

Stepping into the future

This is our summer edition of Milling and Grain, given we are in the Northern Hemisphere. While it’s a time for many industries to close for holidays - and this is particularly true in countries such as France, Italy, Spain and Germany - it is not true of us involved in the production of grains, cereals and other crops that go into the production of foodstuffs nor for flour millers and feed production for livestock.

Harvesting gets underway shortly and indicators on yields and supply levels for the coming year will be keenly awaited, given the constraints that still apply due to the conflict in Ukraine and challenging global weather conditions that seem to change dramatically and without warning.

John Buckley, our resident contributor, reports on the world’s grain and oilseed production is being more keenly followed by readers of late. His report starts with reference to this critical Ukraine-Russia war and its impact on global trade and the supply of wheat and oilseeds plus the related impact on other commodities. Please turn to John’s report on Page 70 to get his interpretation of what this all means to supply and prices across the board.

I have also asked our staff to report on the Ukraine-Russian war which might not be an update of the most recent developments but will record the consequences that are occurring for industries such as ours which involve flour, rice and feed producers globallyafter all for over 130 years Milling and Grain has been a ‘record of note’ for the development of the milling industry and the way the world is going about feeding itself - and as this European conflict is having significant impact on the livelihoods of not only those in developed countries but also on the lives of those in poorer parts of the world and needs to be noted in the historical record which we consider ourselves to be.

Just-in-time

Globally, mankind has survived and developed where it has had with a sound nutritional base that includes a large dependence on grains and cereals that may at one point been grown locally or regionally, but today are grown and traded internationally over long distances and governed by an international accepted market price basis.

We are becoming increasingly aware that our food-production and consumption strategy is closer to an industrial ‘just-in-time’ approach than independent and secure local supply chains.

Outside China many countries do not hold large quantities of grain reserves and depend on grains arriving on a regular schedule, often from the other side of the world, to meet basic food needs for some of their staple food products.

In my travels in recent month, I find I’m more frequently talking about food security issues with those I meet. It’s surprising how many countries are now more engaged with where and when and at what price their food raw materials they depend upon, arrive.

In this edition you will also find our Case Study (Page 80) of the Mulino Mill, Ukraine which is operating on the ‘front-line’ in the Ukraine-Russia war. It’s a sobering story of a mill that is determined to keep production going despite energy supply interruption, damage to the factory, depleted workforce, etc. The mill is supported by owners and equipment manufacturers from Turkey.

Dust explosions

On a lighter note, and talking of explosions, we cover dust explosions in facilities handling grains. The feature is on page 66 and reports that some 500 grain explosions have occurred in US facilities over the past 15 years. Stephane Harding, the MD at Gough Engineering here in the UK tackles this topic for us.

Another interesting feature in this edition is our Rice Washing Technology article on page 60 that supports Japanese cuisine by the president of Rice Techno Products in Japan, Mr Masafumi Haramoto.

RongoRongo Live

Well, I’ve finally set up a video studio. A studio where I can invite individuals into a workspace and record a conversation about critical issues facing our food producing industry that will not only reach the readership of our sister magazine and those subscribing to our language editions in the first instance, but also with a potential to reach a far wider audience. Since before Covid the RongoRongo interviews have been conducted online and not in person. I’m wanting to change that approach and provide an atmosphere that is conducive to the exploration of a topic chosen.

I’ve posted my first RongoRongo Live interview which has the link on this page. Please let me know what you think and the issues you might like to see covered.

If you are wondering what the word RongoRongo means then take a look at this - https://www.cabinetmagazine.org/issues/64/ mikanowski.php RongoRongo is an ancient language of Easter Island and adopted by New Zealand Maori to mean ‘chant out, debate or recite’ among many other meanings that also reflect food from animals and plants. It’s an original work from a lost language created in the South Pacific. As a New Zealander, I’m extremely proud to name our video studio RongoRongo Live.

bit.ly/rongorongo1

Annual Subscription Rates

Inside UK: UK£100

Outside: US$150/€133

More Information

www.millingandgrain.com

http://gfmt.blogspot.co.uk

Milling and Grain has a cooperative partnership with COFCOET

Roger Gilbert

Milling and Grain has a cooperative partnership with COFCOET

Roger Gilbert

PINGLE.

PROFESSIONAL MANUFACTURER

★ INTEGRATED MILLING SOLUTION PROVIDER

★ ISO 9001:2015 CERTIFIED

Аdd: Zhengding, Shijiazhuang,Hebei,China

Tel: +86-311-88268111 Fax: +86-311-88268777

E-mail:pingle@pingle.cn / www.pinglemachine.com

OF GRAIN MACHINERY

NewsMilling

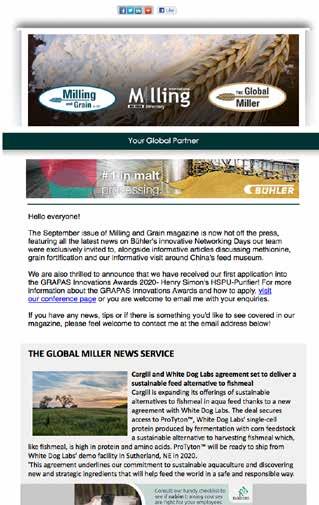

Warm greetings from the September 2023 edition of your Global Miller, and from the Milling and Grain magazine. I hope that you’re well and that you’re preparing for Autumn, it’s an incredibly important season for the industry.

The end of summer approaches as the autumnal equinox arrives on September 23 for the Northern hemisphere. (It’s finally time for the spring equinox for those of you in the Southern hemisphere. I hope you’re all excited for the warmer weather!)

Milling and Grain magazine talks to Simon Shaw, Industrial Products Manager for Alvan Blanch at this year’s Cereals event, held in Nottingham, UK in mid-June 2023.

He says as machinery manufacturers the focus of the company is predominantly on dryers and drying technology. Its dryers are one of the most efficient worldwide, incorporating heat recovery and best retention for optimum process control – these machines can dry any crop or any material made available to them.

I hope everyone in the northern hemisphere has unpacked their sweaters ready for the colder seasons, the weather is about to get cold so enjoy those final moments of warmth that you can grab.

The autumn equinox is an important part of the year for farmers and has been for centuries. The rise of the moon during the sunset gave farmers additional light which offered them more time to complete their harvests before the cold weather destroyed what was left. The first full moon after the autumn equinox was even titled the Harvest Moon, indicating its importance to the farmers and the harvest. The Harvest Moon usually takes place either in September or October, with this year it being held on September 29. Use this chance if you can to admire the moon and think back on all the people who would use this moment to complete a harvest under the bright light.

Milling and Grain magazine talks to Saurabh Malhotra, Product Manager at Bühler, at this year’s Cereals event, in Nottingham, UK. Mr Malhotra talks us through the company's optical sorter, the Sortex H Spectra Vision. The machine offers improved performance, connectivity (with its monitoring system) and easeof-use with its pre-set modes and recipes for each product along with a simple user interface.

https://millingandgrain.com/category/mag-tv

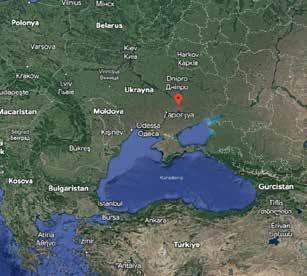

For global news, Russia has pulled back from the grain corridor deal and have threatened to attack any ship that passes Ukrainian ports. This will contribute to the scarcity of grains along with India’s temporary stoppage of export of non-Basmati rice and deepen the worry about global food supply. The global cereal price index rose 10 percent in late July after Russia torpedoed the Black Sea grain initiative blocking a route that carried 32 million tonnes over a year, more than half Ukraine’s total grain exports. Some say, after failing to conquer Ukraine through conventional ways, Russia has resorted to one of the oldest forms of warfare - turning food into weaponry. We cover more on this further in the magazine if you would like to read more details on Russia’s attack on the Ukrainian grain storage.

For more news around the world, you can read how Özpolat Grain Processing Technologies is taking a step forward in supporting our future technical experts with special internships. We also cover how UK£14 million from the British Government will be used to further agricultural innovation in the UK.

Regarding events, you can find information about future events such as VIV Nanjing in Nanjing, China, IAOM Eurasia in Instanbul, Türkiye, and Taiwan Smart Agriweek in Taipei, Taiwan within the magazine. We have all the latest information on these events so you can stay updated on it all and know exactly what you’ll be getting at each event. If you have important news that you would like to share, please send it to us at editorial@perendale.co.uk

Alvan Blanch

Buhler – Saurabh

gfmt.blogspot.com See more videos from all aspects of the industry at millingandgrain.com/videos

10|September2023-MillingandGrain

Anton Paar acquires Brabender GmbH & Co KG

Anton Parr has acquired the German company Brabender, which will be integrated into the Anton Paar Group as Anton Paar TorqueTec GmbH. The effective, retroactive date of the acquisition is January 1, 2023. The company, based in Duisburg, Germany, offers measurement and process engineering solutions for the testing of various raw materials and for recipe and process development. It covers a wide range of applications – from food and feed to plastics and rubber, and even batteries and other special applications.

The signing of the acquisition took place on August 1, 2023. The parties have agreed not to disclose the purchase price. A smooth integration of Brabender into the Anton Paar Group is planned. As before, products and services can be purchased directly via the Brabender website and sales organisation.

Development, growth, and position on the market

For Anton Paar, the acquisition of Brabender is a promising addition to the product portfolio, especially in the area of material characterisation – one of Anton Paar’s strongest growth markets.

“The decisive factor for Anton Paar’s decision to purchase Brabender was the know-how in the development and production of world-leading measuring instruments, which the company has built up since its foundation 100 years ago,” says Anton Paar CEO Dr Friedrich Santner. “In line with its own long-term strategy, Anton Paar will sustainably expand and further strengthen Brabender’s sites in Duisburg and Hackensack, USA.”

Brabender’s approximately 200 employees will become part of Anton Paar. The acquisition represents a clear commitment to progress, according to Brabender Executive Director Dr David Szczesny: “Being part of the Anton Paar Group opens up many opportunities for us – in research and development of our innovative products as well as in sales and service. For us, this is a great move that will definitely benefit our employees and customers.”

The Milling Journal

A wide range of products – from farinographs to extruders

Brabender’s best-known instrument is probably the farinograph. Developed by company founder Carl Wilhelm Brabender in 1928, it was the first – and is still the most widely used – instrument for testing the quality of flour. It is mainly used in flour mills, by baking agent manufacturers, and large bakeries. The farinograph is a component of the three-phase system developed by Brabender to investigate and describe the processes involved in the production of baked goods (dough preparation, proofing, gelatinisation): The farinograph measures the potential water absorption of flour and the kneading properties of dough. The extensograph analyses the stretching properties of dough and the amylograph examines the gelatinisation properties of starch in flour. Another extremely successful Brabender product group includes various models of single-screw and twin-screw extruders. The machines, which are offered as compact or modular versions, are mixing and conveying devices that press solid or viscous materials under pressure through a shaping orifice. Industries in which they are used include the food industry, for pasta production, and the plastics industry. Extrusion technology also plays an important role in achieving global sustainability goals: Brabender extruders are used to develop, among other things, alternative protein sources for meat-substitute applications.

Milling Journal is a new online publication by Perendale Publishers Ltd., United Kingdom with its distinguished track record of technical and trade magazines in the agricultural, aquaculture and food sciences. This new peer-reviewed scientific journal will serve academia and the commercial milling sectors and related cereal and grain industries with high-quality papers. Milling is at the heart of products for both the human and the animal feed sector. It is envisaged to address fundamental and advanced technologies in the conversion of grain, cereals, pulses and legumes via milling to create diverse and bespoke secondary products. For example, ground wheat, corn, oats, barley, sorghum, beans and peas are widely used for human foods. The downstream by-products of bioethanol and potable alcohol from fermentation of ground grain are notable areas for research findings towards provision of sustainable animal feed ingredients.

12 | September 2023 - Milling and Grain Milling News

Promtek to launch innovative cloud process control solution

Automation specialist

Promtek Ltd will showcase its pioneering new inthe-cloud process control solutions for intelligent weighment management, recipe handling and production monitoring on stand H52 at this year’s PPMA Show, which will be held from 26-28 September 2023, NEC Birmingham.

For the very first time, Promtek will demonstrate the company’s Condor Cloud alongside the MicroMan control system. Together they provide a complete strategic overview of every aspect of production, including ingredient reformulations, equipment utilisation, climate impact and energy costs, demonstrated using Promtek’s miniature railway and MicroMan hand-weighing game.

As a cloud-based alternative, Condor Cloud offers the same IT/ OT integration for ingredient and recipe handling as its native version without the need for expensive IT infrastructure, making it ideal for fastgrowing SME manufacturers with a weighing process. With no onsite servers or network requirements, the browser-based Condor Cloud will help grow a business, reduce costs, and optimise production facilities.

Promtek’s peerless all-in-one platform uses predefined algorithms to calculate energy efficiency accurately, bringing enterprise-level manufacturing systems to smallerscale facilities. Condor provides access across the organisation to be

stored centrally, it creates customised batch and production reports with critical information by connecting systems such as process control, ERP or PLC/SCADA.

Condor’s time-in-motion capabilities provide systemic observation, analysis and measurement of each step in the production process, establishing a standardised time for each, improving performance and increasing productivity. By analysing the data in Condor from each connected monitor and input, the MES can trim down production waste and reduce energy usage by fine-tuning individual equipment settings, significantly lessening the amount of kWh/t.

The platform is always running the latest software version, as the maintenance and administration for a Condor server, including updates and security patching is handled remotely by Promtek engineers – tapping a business into Promtek’s exceptional customer service and aftercare offerings.

MicroMan, a portable version of Promtek’s signature platform StoraWeigh collates all production information using its systems and

graphics integration suite to generate bespoke production control and support. Businesses can use the data to create customer-specific trusted records of weights and measurements of ingredients and materials, manage recipe control, improving ingredient traceability, prevent crosscontamination and assist with order scheduling.

Promtek’s Marketing Manager, Lani Scholtz, explained, “Promtek is thrilled to be at PPMA for the first time – we love meeting new people from across different industries. Interacting with potential new customers and catching up with a few current customers is one of the best parts of the job, as we get genuine, unfiltered feedback in person. You get an excellent feel for a testimonial, feedback or praise if you’re standing right next to someone”

“We are truly excited to showcase our next-level, class-leading innovations. We can’t wait to show manufacturers what benefits they will bring to the manufacturer’s process controls and how they can grow and develop to support any business strategy.”

BOURNE AES R C H & RECRUITMENT SELE C T I NO � CHIEF COMMERCIAL OFFICER � GENERAL MANAGERS � MANAGING DIRECTORS � CHIEF MILLERS � FEED & POULTRY MANAGERS � MAINTENANCE MANAGERS � R&D NEWPRODUCT DEVELOPMENT � SALES & MARKETING � PLANT MANAGERS � CFO’S ���� bournerecruitment.co.uk ���� +44 7764 465 897 THE EXPERT IN FEED, FLOUR MILLING AND FOOD PRODUCTION RECRUITMENT POSITIONS RECRUITED: RECRUITING GLOBALLY Milling and Grain - September 2023 | 13 Milling News

Growing Into Performance.

INNOVATIVE OPTICAL SORTING SOLUTIONS.

Better than the human eye, Cimbria sorting technology is the most advanced and reliable solution to meet the high quality standard of the grain and seed processing industry.

The all-new optical system integrates Full-Color RGB and NIR cameras, that can be combined with SWIR and UV technologies to ensure the total removal of any foreign body like stones, wood and glass, as well as the best separation of nonconforming or unwanted grains.

Great purity, optimized yield and food safety are so granted by Cimbria optical sorters.

Growing into performance is easy and effective, thanks to the extraordinary technology signed by Cimbria.

Cimbria.com Cimbria Srl Imola, Italy Tel +39 0542 361423 seainfo@agcocorp.com

United States establishes USMCA dispute panel on Mexico’s agricultural biotechnology measures

United States Trade Representative Katherine Tai today announced the United States is establishing a dispute settlement panel under the United States-Mexico-Canada Agreement (USMCA) regarding certain Mexican measures concerning biotech corn.

The United States is challenging measures set out in Mexico’s February 13, 2023 decree, specifically the ban on use of biotech corn in tortillas or dough, and the instruction to Mexican government agencies to gradually substitute the use of biotech corn in all products for human consumption and for animal feed. Mexico’s measures are not based on science and undermine the market access it agreed to provide in the USMCA.

“The United States has used the tools provided by the USMCA in attempting to resolve concerns with Mexico’s biotechnology measures. Today, the United States is taking the next step in enforcing Mexico’s obligations under the USMCA,” said Ambassador Katherine Tai. “Through the USMCA dispute panel, we seek to resolve our concerns and help ensure consumers can continue to access safe and affordable food and agricultural products. It is critical that Mexico eliminate its USMCA-inconsistent biotechnology measures so that American farmers can continue to access the Mexican market and use innovative tools to respond to climate and food security challenges. Our bilateral relationship with Mexico, one of our oldest and strongest trading partners, is rooted in trust and honesty, and there are many areas where we will continue to cooperate and work together.”

“Mexico’s approach to biotechnology is not based on science and runs counter to decades’ worth of evidence demonstrating its safety and the rigorous, science-based regulatory review system that ensures it poses no harm to human health and the environment. Innovations in agricultural biotechnology play a key role in advancing solutions to our shared global challenges, including food and nutrition insecurity, the climate crisis and the lingering effects of food price inflation.” said Agriculture Secretary Tom Vilsack.

“By requesting the establishment of a dispute settlement panel with Mexico, the United States is continuing to exercise its rights under the USMCA to ensure that US producers and exporters have full and fair access to the Mexican market. We will continue to support fair, open, science- and rules-based trade, which serves as the foundation of the USMCA as it was agreed by all parties.”

Welcome to The website for the International Milling Directory has been totallly redeveloped for a faster and more accurate user experience, with new and improved features available for all of our members! internationalmilling.com Milling and Grain - September 2023 | 15 Milling News

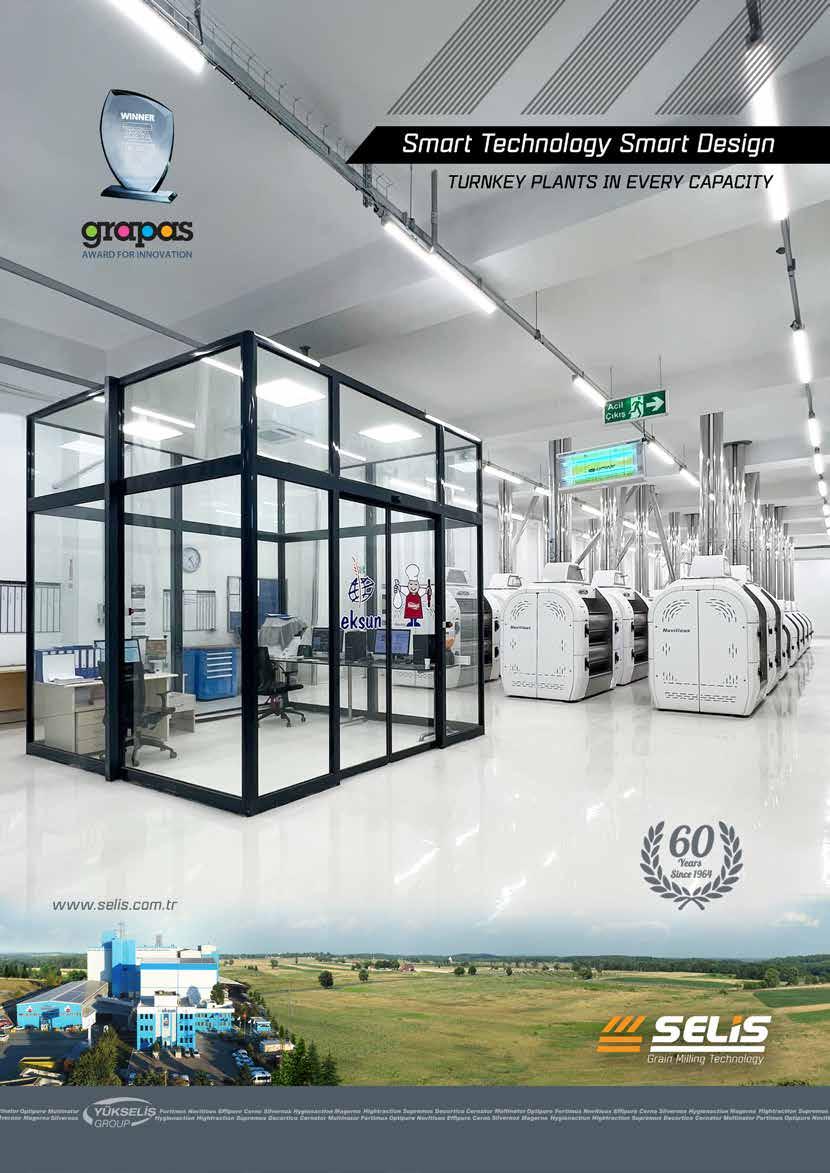

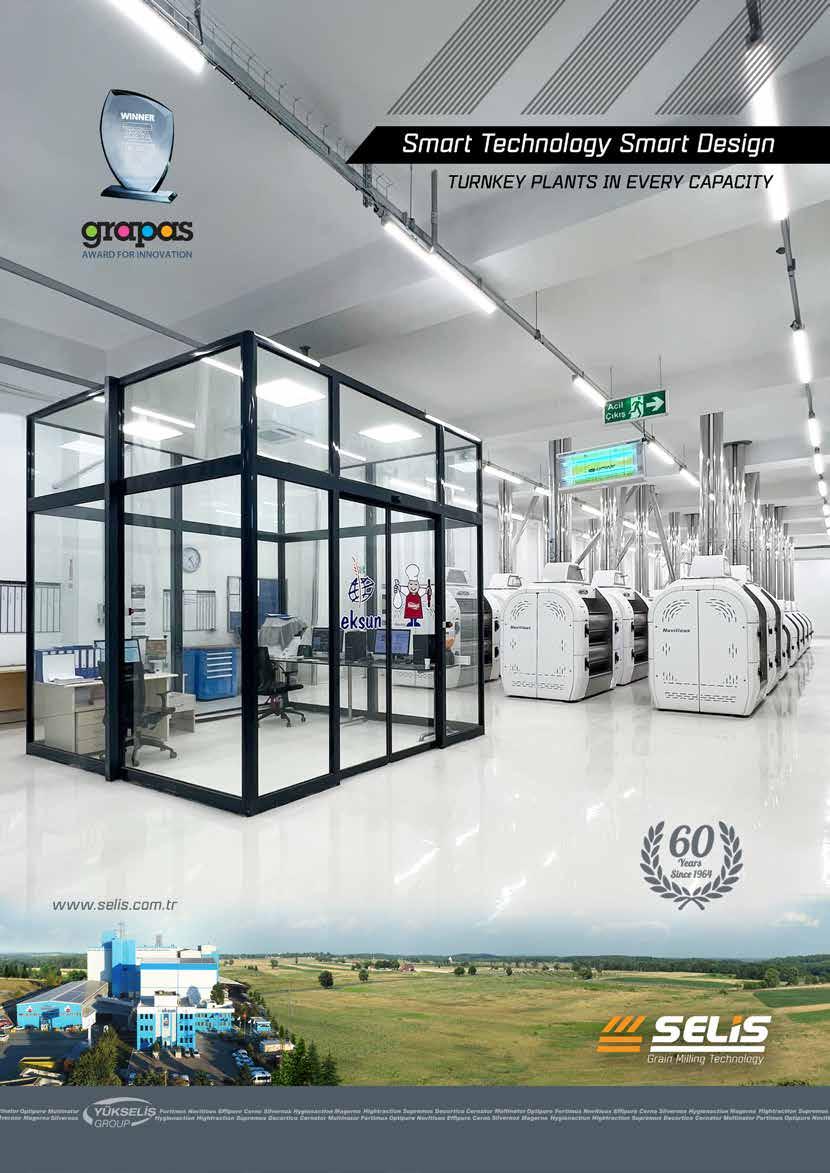

LESS EFFORT AND ENERGY IS MORE PRODUCTIVITY

The age of dark factories has arrived that offer more productivity with less consumption. With +1000 turnkey projects in 120 countries, Alapala is one step ahead of the era...

alapala.com

CF Fertilisers UK announces proposal to close plant

CF Fertilisers UK Ltd, a subsidiary of CF Industries Holdings, Inc (NYSE: CF), recently announced a proposal to permanently close the ammonia plant at its Billingham complex in order to secure the long-term sustainability of its business in the United Kingdom and more efficiently serve its customers in the country. The Company intends to continue to produce Ammonium Nitrate (AN) fertiliser and nitric acid at the Billingham site using imported ammonia, as it has for the last ten months following its decision to temporarily idle the plant in August 2022.

CF Fertilisers UK has made this proposal due to its forecast that producing ammonia at Billingham will not be cost-competitive for the long-term compared to importing ammonia due primarily to projected high natural gas prices in the United Kingdom relative to other regions and the impact of carbon costs. Additionally, shutdowns in recent years of industrial customers’ UK operations that had consumed significant ammonia volumes for their businesses have created a supply-demand imbalance for ammonia production at the Billingham Complex. The Company believes that ample global availability of ammonia for import, including from CF industries’ North American production network, will enable more cost-competitive and efficient production and sales of ammonium nitrate fertiliser and nitric acid for its UK agriculture and chemicals customers moving forward.

The Company’s proposal to permanently close the ammonia plant at its Billingham Complex could result in up to 38 redundancies at the site in relation to which it will be entering into the required collective redundancy consultation process with its recognised union, Unite, and elected employee representatives. The Company anticipates that some of the proposed redundancies might be avoided by redeployment opportunities.

Russia attacks Ukrainian grain storage on the River Danube

The strikes have begun since Russia pulled out from the UN grain deal in July.

On Wednesday, Russia attacked the Ukrainian port of Izmail on the river Danube, a key port for Ukrainian grain exports. The attack follows Russia pulling out of the UN grain deal last month, which was allowing Ukraine to export 33 million metric tonnes of grains and oilseeds over the past 12 months.

Ukrainian Deputy Prime Minister Oleksandr Kubrakov said that almost 40,000 tonnes of grain destined for Africa, China and Israel were destroyed in the bombings. The BBC reported that Grain warehouses and elevator shafts were damaged by the drone strikes, however no casualties have currently been reported.

Ukraine’s Ministry of Defence made a statement on X (formerly twitter) saying that “Ukrainian grain has the potential to feed millions of people worldwide. However, Russia chose the path of killing, starvation, and terrorism”.

Romanias President has also taken to X to condemn the actions of Russia calling them “Unacceptable” and stating that “These are war crimes and they further affect UA’s capacity to transfer their food products towards those in need in the world.” The bombings took place in close proximity to Romania.

Russias President Vladimir Putin has been accused by the West of “weaponising” food. However he stressed during a phone-call with Turkey’s President on Wednesday that he would not return to the UN Grain deal until Russias own exports of grain and fertiliser were also guaranteed. During peacetime, Ukraine produced enough food exports to feed 400 million people.

Milling and Grain - September 2023 | 17 Milling News

AB Agri partners with Aceae Nutra to provide tomato-based animal health solutions

AB Agri is working with agri-tech company Aceae Nutra on the development of a novel nature tomato Based product.

AB-Agri has partnered with agri-tech company Aceae Nutra on the development of an innovative product made from tomatoes that could offer a new natural way to reduce traditional treatments in animals.

AB Agri and Aceae Nutra are now working together to assess its application in livestock animals. AB Agri is currently growing the tomatoes for use in trials which will determine the product’s effectiveness in animals as a feed material.

Aceae Nutra is an IP focused SME founded in 2018 specialising in research, innovation and product development of plant-based solutions. The company’s approach incorporates plant sciences and agronomic expertise to generate viable solutions for conditions affecting human and animal health.

Natasha Whenham, Head of Innovation, AB Agri, said “We’re committed to nurturing new technologies that have the potential to make a real impact in the production of responsible, affordable food – and turning those ideas into industry-relevant solutions.

“The industry is looking for ways to responsibly reduce the use of traditional treatments that bring either environmental or resistance concerns and this product is an exciting new prospect that offers real potential to achieve this goal.”

Andrew Bottley, Director, Aceae Nutra, said: “The data we have generated from initial lab-based trials is really promising and we are delighted to be working with AB Agri to take the product to the next stage and assess its effect on animal health.”

Satake at Cereals Event

Roger Gilbert, Publisher of Milling and Grain magazine talks to General Manager for Satake, Peter Marriot, about their experience at this year’s Cereals Event held in Nottingham, UK from June 13-14, 2023.

The annual Cereals Event is key for Satake, says Mr Marriot, who says it is “a great way of connecting with the UK industries and customers.” Having attended Cereals for around 20 years now, Satake is a longstanding supporter of the event. The key products Satake presented at this year’s event included the company’s full range of colour sorter machinery and supporting milling equipment. For example, it displayed rice cleaning equipment that

can be readily adapted to beans and pea processing, along with flour milling from the company’s Henry Simon subsidiary.

To prove the capabilities of its sorting machinery, Satake gave practical sorting demonstrations throughout the three days to give a clear example of how effective sorting can be. Stay tuned for the live demonstration of their FMS-2000 Optical Sorter at the end of the video! In it, you’ll see some sample of rye contaminated with wheat, ergot and various products being sorted. Once it completes the passage through the machine, the sample has been quickly separated into a ‘rejects bin’ and a bin for accepted materials.

Milling and Grain - September 2023 | 19 Milling News

Two 19th Century European Engineering Works

Milling journals of the past at The Mills Archive

by Mildred Cookson, Mills Archive Trust, UK

Eastern European innovations in the milling processes spread rapidly during the latter half of the 19th century. The demand from millers for more efficient equipment resulted in the creation and expansion of engineering companies well-placed to service this rapidly expanding market with an emphasis on innovation and improvements in ease of operation and the quality of flour produced. Two of these companies were featured in The Miller in 1886; Messrs Hoerde and Co, founded in 1874 in Vienna, and Alessandro Calzoni & Sons, established in 1836 on the outskirts of Bologna.

Hoerde & Co, Vienna

The invention of the middlings purifier, one of the most essential advances in modern milling, was claimed by Austrians. Ignaz Paur worked in Leobersdorf, a village some twenty miles south of Vienna, about 1786. The machine he constructed in 1810 was built by a carpenter, N. Winter and was said to be reverently preserved by his countrymen as one of the most precious relics of Austrian industry.

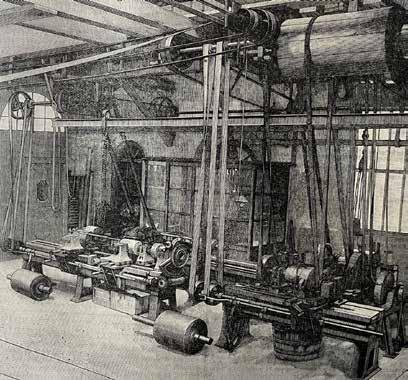

Herr Hoerde was well known and had secured many customers locally and as far away as Russia and Romania. His firm employed 200-300 men and the frontage of the works looked onto the Taborstrasse, one of the main thoroughfares of Vienna. The workshops were at the back of the offices, as may be glimpsed in the illustration, with a range of buildings measuring 120 yards, around twice the length of the front.

The ground floors were filled with smithies and turners’ shops as well the metal frames and other parts of the roller mill machinery that were bored out and prepared for the fitting and erecting departments. Hoerde & Co. were famous for the manufacture of the steel roller mills and by 1886 thousands were working in various parts of the world.

The steel rolls in their ‘Fortuna’ model were thrown apart by a simple arrangement. A balanced lever was placed outside the hopper, its position dependant on the feed. The lever was brought in or out of contact with a short spindle. By turning the latter, the ends of the levers carrying the bearings of the rolls were thrown apart, the clutch on the axle of the reed roll was disconnected from its pulley and the feed roll was stopped. The loose pulley continued to revolve and acted on a little bell attached at the end of the feed roll axle, which at each revolution was touched by a small hammer and rang until the machine was stopped or fresh feed supplied.

On the first floor the carpenters’ shop covered 800 square yards and was filled with every species of machine for woodworking. The ‘Phoenix’ decorticator, and its parts were made of the same

Hoerde's show rooms and workshops, Viennna

Hoerde's show rooms and workshops, Viennna

20 | September 2023 - Milling and Grain

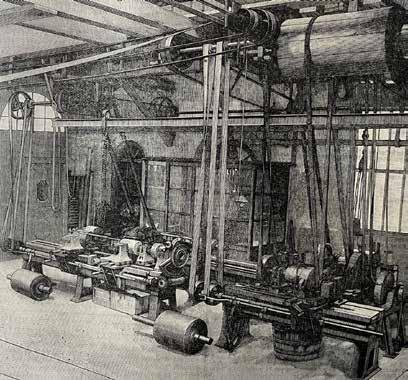

Calzoni's roller grooving shop

hard steel used for the rolls in the mills. The floor also carried the celebrated “Austria” middlings and dunst purifier which was claimed to thoroughly purify at one passage coarse and fine middlings as well as dunst or the fine particles of the semolina.

Alessandro Calzoni & Sons, Bologna

The house was originally founded in 1836 by Alessandro

Calzoni, a highly regarded Italian engineer, who died in 1855 when the business passed to his five sons, who continued running the firm. The works pictured in the bird’s eye view of the premises were in a convenient position to the railway station. In 1886 210 craftsmen were employed in the workshops, with 30 people in the offices. The firm also owned a warehouse and showroom in the centre of Bologna. The works covered 5600

V I S I T U S Milling and Grain - September 2023 | 21

Calzoni's workshops, Bologna

YEARS IN MILLING

MORE THAN 400 COMPLETE PROJECT PERFECTLY RUNNING AROUND THE WORLD

We manufacture, flour, semolina, wheat, maize milling plants, feed mills, seed production plants, oilseeds and pulses processing plants, storage and handling systems.

R O L L E R M I L L

square metres and the city warehouse 850 square metres.

Among the various kinds of machines manufactured were water and steam motors, turbines of every description as well as almost every kind of agricultural machinery and implement. The firm paid particular attention to the construction of pumps and artesian wells, and to service two of the staple industries of Italy, an array of wine and olive presses.

For 20 years, Calzoni had been engaged in the manufacture of flour milling equipment and with the inevitable spread of modern milling in the Italian peninsula, it was expected to become even more important in the future. They made nearly every machine and apparatus used in modern flourmills, including wheat aspirators, Eureka brush and smut machines, stone mills, roller mills, centrifugal reels, middlings purifiers and bran dusters.

The break roller mill made by the firm was furnished with two rolls, 13¾ by 15¾ inches, grooved to a suitable pitch and working at differential speeds, one roller driven by a belt and the other by gears. The passage between the rolls of any foreign body was absorbed by springs, and it was claimed that the heating of the

bearings had been reduced to a minimum by a careful system of lubrication.

For middlings reduction the firm recommended Wegmann ‘Victoria’ porcelain roller mill and they sold a considerable quantity of these machines. The works had a complete plant of machinery for the turning, grinding and grooving of rolls and the illustration shows the interior of the roller grooving shop.

Milling and Grain - September 2023 | 23

The Fortuna Roller Mill Wegmann Victoria roller mill

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

Egypt signs US$500 million financing deal with UAE to import wheat

The Egyptian Ministry of Finance on Tuesday, Aug. 15 signed a US$500 million five-year financing agreement with the Abu Dhabi Exports Office (ADEX) of the United Arab Emirates (UAE) to finance wheat imports, the ministry said in a statement.

"This is the first deal signed with ADEX, a financial arm of the Abu Dhabi Fund for Development (ADFD), in light of the two countries' strong relations and the joint cooperation for promoting development and boosting food security," the statement quoted Egyptian Minister of International Cooperation Rania Al-Mashat as saying.

The funds will be disbursed in five tranches, each valued at 100 million dollars, she added.

Noting that food security is a vital issue and a matter of national security, Al-Mashat said Egypt has enough wheat reserves for five months' consumption and the funding will help meet the local market's needs for wheat amid the state's efforts to maintain food security via soft funding.

Since its founding in 1971, ADFD has financed 20 projects in Egypt that cover various priority sectors, said the minister.

During the signing ceremony, Egypt's Finance Minister Mohamed Maait said Egypt seeks more cooperation with the ADFD to accomplish social and economic development, provide a decent life to citizens, and improve the people's living conditions as well as reduce burdens of inflationary impacts.

Egypt, the world's largest wheat importer, suffers from global supply chain interruption and price hikes due to the RussiaUkraine conflict.

The country imports two-thirds of its annual consumption of 18 million tonnes of wheat, according to the state-run Ahram

newspaper.

According to this statement released Egypt will get imported milling wheat under the five-year deal, valued at US$100 million annually, "at competitive prices." This is according to a report by the American news agency, Reuters.

The nation began delaying payments for wheat imports and is now having a harder time generating money to pay off its foreign debt. "The low-cost financing package from ADEX helps us procure high-quality wheat at the lowest cost financing available, with comfortable payment terms," Egypt's supply minister Ali Moselhy said in a statement.

Recent wheat purchases have frequently been financed by loans from the World Bank and the International Islamic Trade Finance Corporation (ITFC), which this year increased a credit line given to Egypt to US$6 billion. The financing for food subsidies, primarily bread, would increase by 41.9 percent to 127.7 billion Egyptian pounds (US$4.1 billion) in the fiscal year running from July 2023 to June 2024, according to the finance ministry.

Al Dahra will start supplying Egypt with imported wheat this year as per the agreement. Through its Egyptian affiliate, which cultivates wheat on 28,000 hectares in Egypt, the Emirati Corporation already provides the government with locally produced wheat. The government organization Abu Dhabi Fund for Development's export finance division is called ADEX.

Egypt, a significant consumer of basic goods, has been experiencing a foreign exchange crisis as a result of the Ukraine War's widespread shock to its economy. In terms of the dollar, Egypt's currency has fallen by approximately 50 percent, and official headline inflation has reached an all-time high of 36.5 percent.

and use the Promo Code HNY2023 This offer entitles you to a 12 month digital subscription to Milling and Grain magazine on our app and desktop versions. This offer is on a first come first served basis and will run until 01/12/2022 Would you like a complimentary digital subscription to Milling and Grain magazine? Simply visit: https://flickread.com/edition/Milling-and-Grain

24 | September 2023 - Milling and Grain

Feeding the world is a daily commitment in which technical and practical knowledge must be precise, synchronized, and balanced. It’s a microbiome that requires the right nutrients, information, advise, and high performing solution that are simple for you and your animals.

At Jefo, it’s more than a gut feeling; it’s science, it’s partnership. We know you . You aim for the You follow the

jefo.com

Milling and Grain - September 2023 | 25 Milling News

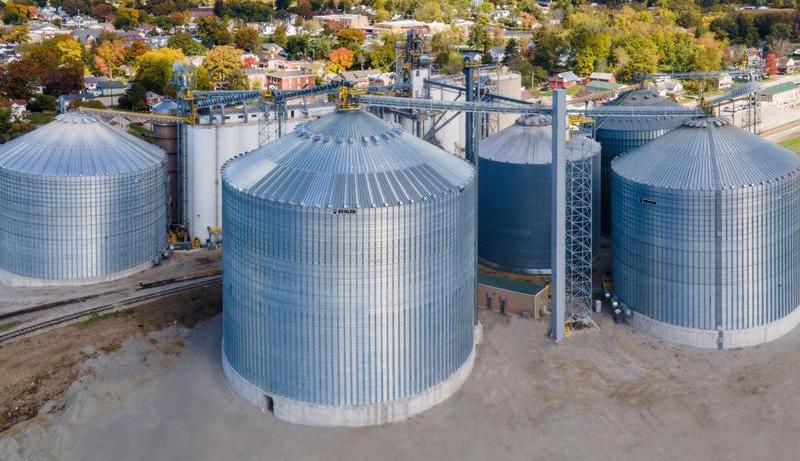

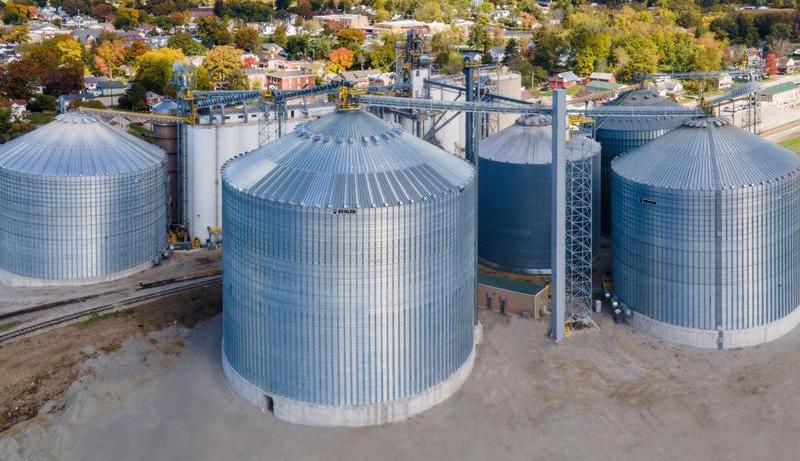

Behlen bins range in size from 85 to 66,000 cubic meters. These silos feature a unique trapezoidal wall panel design. COMMERCIAL GRAIN BINS Behlen hoppers are designed to ensure strength, ease of assembly, and trouble-free operation. COMMERCIAL HOPPER TANKS Behlen Steel BUILT TO LAST Behlen Grain Systems... Standing the test of time with competitive prices and Customer Service second to none. CONTACT US TODAY TO DISCUSS YOUR PROJECT! Call 1-402-564-3111 or Visit www.behlengrainsystems.com Bigger and Better than Ever!

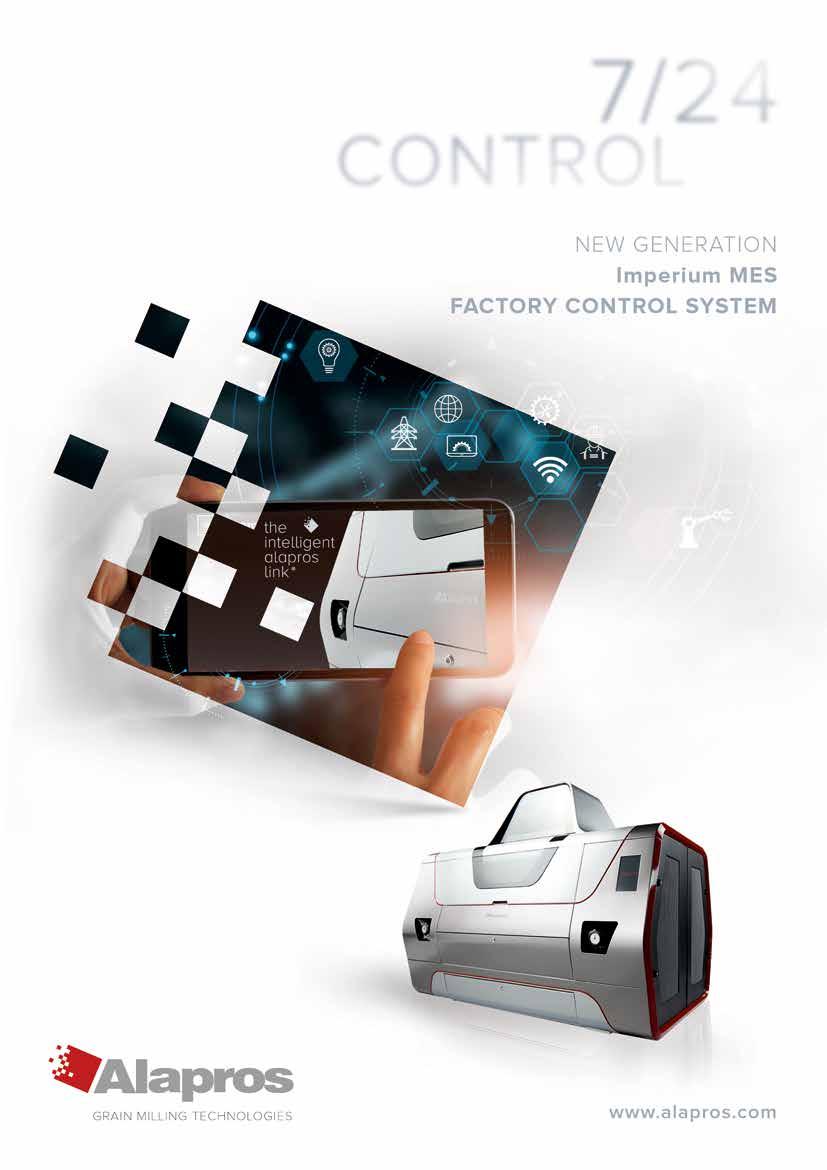

Alapros to build a flour mill for the Italian Casillo Group

Alapros, which is preparing to sign an important project in Trieste, Italy, announced a strategic cooperation with Casillo Group. Within the scope of this cooperation, a turnkey flour milling contract with a capacity of 300 tonnes/ day has been signed and the project is planned to be commissioned in April 2024. Casillo Group expresses its satisfaction for choosing Alapros and emphasizes the innovation and quality that this cooperation will bring to the sector.

Alapros stands out as a professional company offering integrated solutions in grain milling and processing technologies. The company is led by an experienced team with a passion for innovation and production and shapes all its products and services with the goal of global leadership. Alapros focuses on the production of Industry 4.0 compliant factories and competitive products by offering integrated solutions such as design, diagramming, automation and commissioning, as well as wheat milling

machines and equipment.

Casillo Group, on the other hand, has been offering a broad perspective from wheat production to processing and marketing with the principles of quality, innovation and sustainability for years.

Molino Casillo's roots began in 1958 when Vincenzo Casillo started his own business, learning the secrets of wheat and milling from his father. With an innovative approach, the Casillo Group is a leader in the market, producing a variety of flours and semolina as a result of the valuable work of the Research and Development department.

Casillo Group's choice of Alapros was driven by Alapros' innovative approach and pursuit of excellence in production. The 300 tonnes/day capacity flour mill project, which will be built as a result of the cooperation, will increase competitiveness in the sector and stand out with its innovative production approaches.

It is certain that this plant to be built by Alapros for Casillo Group will breathe new life into the sector.

Milling and Grain - September 2023 | 27 Milling News

Bühler and Entocycle partner to deliver end-toend technology solutions to insect farms

Bühler, one of the world’s leading processing technology groups, and Entocycle, an insect technology company have joined forces to drive adoption of large-scale black soldier fly (BSF) farms. The companies will provide solutions and expertise to serve customers in this segment, covering the multiple steps of the journey, from concept and basic engineering to execution of BSF facilities worldwide.

The non-exclusive partnership creates a highly complementary offering with Entocycle delivering proprietary breeding technology and Bühler bringing proven industrialscale technologies in feedstock processing, larvae rearing and product processing.

One of the challenges of the highly promising, emerging insect industry has been how to ensure a steady supply of young larvae at an industrial scale. “While the pioneers in the industry had to develop their own technology out of necessity to ensure a robust BSF breeding, companies now venturing into this industry will be able to rely on a proven and scalable solution,” says Andreas Baumann, Head of Market Segment Insect Technology at Bühler. Although there are specialised breeding service companies in certain regions, in large parts of the world, there is no alternative to having an in-house brewing operation. With this partnership Bühler and Entocycle address this challenge by offering scalable end-toend solutions that significantly reduce the time to market for companies building an insect facility.

During the last 10 years, Bühler has been developing its capabilities in the insect protein industry and has already completed a number of relevant projects in the field. In 2019, Bühler supported Prolix in the realisation of the world’s first commercial BSF plant in the Netherlands and this year Bühler delivered Agronutris’ first industrial BSF plant in France.

“We are incredibly proud to partner with Bühler, a company with 163 years of illustrious history. Our team is really excited to work with Andreas Baumann and his team to deliver largescale BSF facilities around the world and make the impact that we know BSF farming can make in creating a more sustainable and efficient global food system,” says Keiran Whitaker, Founder and CEO of Entocycle.

“The industrial use of BSF is rapidly gaining traction among businesses seeking alternative feed protein sources and more sustainable practices. To accelerate scaling in this industry we must contribute to lowering the hurdles for companies to enter this business,” says Andreas Baumann. “That is why we are very pleased to cooperate with the Entocycle team in future projects, as they share the same philosophy as Bühler in ensuring the quality and reliability of their solutions.”

“It’s going to be a great partnership, not only in the way that our businesses and teams complement one another in terms of respective skill sets and experience but also in the strong alignment of values around building a better and more sustainable world,” says Matthew Simmonds, Managing Director of Entocycle.

SETS THE STANDARD IN SQUARE SILOS

www.tsc-silos.com Check out our references:

“In Tasmania, they had plans to convert a former cardboard factory into a fish feed factory. And so it happened.”

Location: Wesley Vale, Tasmania, Australia Application: Aqua Feed, dosing

Capacity 2.900 m³ Bins 36 Height 29,8 m Width 12 m Length 20 m 28 | September 2023 - Milling and Grain Milling News

block

Gems from the Mills Archive A miller’s retirement certificate

by Nathanael Hodge, Mills Archive, UK

by Nathanael Hodge, Mills Archive, UK

This month’s gem from the collections of the Mills Archive is the beautiful calligraphic certificate shown here. Miller William Cornwell received this certificate at the end of a long and successful milling career. Born in Littlebury, Essex, in 1851, Cornwell witnessed first-hand the dramatic revolution in milling caused by the transition from stone grinding to roller flour milling.

As a young man he was employed in a traditional stone mill in Ickenhem, Essex, learning the art of milling and marrying into his master’s family. By 1879, he was managing a small mill with five pairs of millstones in Waltham Abbey, Essex, working first for George Wright of Ponders End and then for Charles Brown, before a new company, the Sun Flour Mills Co Ltd was founded in 1887. The company ran mills in Waltham Abbey and Chelsea, and invested in the new roller milling machinery, noting that stone milling could not compete.

It wasn’t long, however, before unexpected setback occurred when a disastrous fire broke out at the Waltham Abbey mill on Christmas Eve, 1888, completely destroying it. However, the company turned this into an opportunity, purchasing a mill in a much more convenient location for transport – a former rice mill at Bromley by Bow, London, now renamed the Sun Flour Mill. Machinery was installed by Henry Simon with a steam power plant by Pollit & Wigzell, and the mill began work in September 1889.

Under William Cornwell’s management the mill went from strength to strength, upgrading and improving its machinery

30 | September 2023 - Milling and Grain

regularly. By the time of his retirement in 1926, he had been promoted to Managing Director.

William Cornwell was clearly not one to sit back and relax; although he was in his 70s, he went on to purchase another mill, the William King Flour Mill in Uxbridge, which he worked with his sons until his death in 1933.

The Uxbridge mill was later incorporated into Associated British Foods, giving its name to ‘Kingsmill’ bread. The Sun Flour Mill was purchased by J W French in 1941. Badly damaged by an explosion in 1965 which killed four people, it was then reconstructed. The buildings were finally demolished in 2013.

www.millsarchive.org

pubblicità italiana_MOD.pdf 1 27/01/22 10:59

The Mills Archive is a permanent repository for the documentary and photographic records of traditional and contemporary mills and milling, as well as similar structures dependent on traditional power sources. It makes that material freely available for public inspection and use in research and learning.

The Mills Archive is one of the world’s great mill collections. It has rescued over 3 million documents and images that might otherwise have ended up in a landfill site. It is an Aladdin’s cave filled with memories and free to users. The collections show the rich and diverse crafts, buildings, machinery, equipment and people involved with mills in the UK and around the world.

Milling and Grain - September 2023 | 31

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS

more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Product Spotlight - The Samplex CS90

Bulk Truck Sampling Probe

Samplex is the UK's leading brand on the truck probe market, with many of the originally manufactured machines still in use worldwide today The Samplex CS90 is robust, reliable, highly adaptable, and able to provide a truly representative sample of a bulk load.

The entire Samplex range of bulk samplers uses time proven electromechanical technology, completely eliminating the use of hydraulics and the associated risks of pressure hoses splitting, which could contaminate valuable loads.

Fully Automatic Sequential Sampling

Using the simple setting procedure, a customised set of sequences from 3 to 15 sampling positions can be programmed and saved by the operator to suit varying specifications of delivery vehicles. This ensures accurate consistent sampling analysis in full accordance with I S O 24333:2009 (E)

More representative Sample

Samplex truck probes deliberately don't use the more common and potentially flawed method of suction to collect product, as this has been demonstrated to possibly bias the collected sample with dust. Instead, they use positive air in conjunction with cyclonic action, and the design of the Unispear probe allows the product to fall directly into the airflow under gravity, and therefore provide a smaller, but importantly, more representative sample. Uniquely, Samplex fit all their probes with a twin variable aperture, to allow more or less product to be sampled as required.

The 340° rotation and telescopic arm allows for the variable sampling patterns required to meet ISO 24333:2009(E) standards.

Wide Range of Products

The C S90 and Unispear system is unique in its ability of being able to accurately sample, without modification, a range of dry powders including meal and flour, small seeds such as oilseed rape and linseed, plus cereals, maize, sorghum, soya beans, rice, pulses and animal feed pellets up to 16mm x 30mm. Due to the clever design of the spear, it is possible to vary the amount of product sampled to help to prevent excess product building up in the laboratory

To access further free information on the entire range of Samplex mechanical samplers, exclusively Made in Britain by Tekpro, or to find out how you could join the ever growing number of companies already trusting Samplex equipment to sample their bulk products, scan the following QR code:

Made in Britain, Trusted Worldwide.

We are

Online Milling School at Victam LatAm

We will be hosting a seventh Credo OMS Off-Line Session at the Victam Latam event in Sao Paulo, Brazil from 13.3015.30 on October 5, 2023.

VICTAM LatAm is a ‘one-stop’ show for the decisionmakers within these industries. Each visitor will be able to find what they are looking for, all under one roof over three days. The event also focuses on a series of high-quality industry conferences and business matchmaking with colleagues and clients.

VICTAM LatAm and GRAPAS LatAm 2023 in co-location with GEAPS will take place from October 3- 5,2023 at Expo Centre Norte, red pavilion, São Paulo, Brazil. The elaborate conferences program and technical seminars will

take place simultaneously in the conference rooms in the same venue.

The OMS-Offline event follows the Online Milling School’s that took place this August-September 2023. The topics will comprise of a discussion panel and a Q&A session from the Autumn Courses and from within the room.

During this Off-Line Session we will be awarding Certificates of Attendance to those who have completed one of the 2023 six-week courses and who are in attendance. Training is fundamental to developing a business’ efficiency and ensuring a return on your investment.

The event is organised by Milling and Grain Magazine and VICTAM, with thanks to our sponsors: Wenger, Tietjen, Andritz, and PLP Systems.

Milling and Grain - September 2023 | 35 TRAINING Mill

One-Day Workshop: Practical Flour Milling

The society for the protection of Ancient Building (SPAB) is holding a one-day workshop, looking at the practicalities of traditional flour milling. The workshop, taking place on 13 October 2023, at Fosters Mill in Cambridgeshire, will provide attendees with hands-on experience running the mill under the supervision of experienced traditional millers.

This workshop is introductory, and ideal for mill volunteers, trainee millers, and more experienced millers who wish to develop their skills and have a general interest in milling. On the day, attendees will learn a variety of skills and knowledge,

including how to dress flour, how to mill different grades and types of flour, how to operate a mill safely, including starting and stopping the mill, as well as learning all about food hygiene, and trading standards relevant to milling and selling flour.

The workshop fee is UK£90 with the early bird offer, which is valid until 22 September, which will change to UK£120 after that date. The location is Fosters Mill, Swaffham Prior, CB25 0JZ.

The course price includes course notes, lunch and refreshments during the day. Attendees are asked to let SPAB know of any dietary requirements when booking.

TRAINING Mill SQUARE SILO EXPERTS BELGIUM HQ +32 51 72 31 28 ASIA SALES OFFICE +65 8222 90 96 SCE.BE

36 | September 2023 - Milling and Grain

ENGINEERING A WORLD WHERE NO MORE FOOD IS WASTED.

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

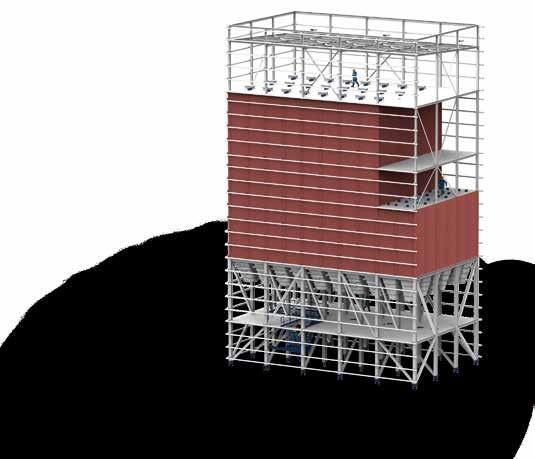

Tanks by Simeza

Simeza’s Tanks are used for the storage of liquids. They are designed according to the Euro-Code European norms and are manufactured to withstand stress caused by continuous use, extreme temperatures, high winds and heavy snow. They also offer greater resistance to corrosion through thicker galvanisation on the steel sheets.

They are entirely manufactured in galvanised steel with the possibility of choosing between a galvanised or pre-painted finish. The joints are sealed with unalterable putties to the weather. To give a greater tightness to all the junctions, a layer of impermeable painting based on cement and resins is applied. Subsequently and to give it a perfect finish, a primer to the entire interior surface and a waterproof paint to all interior joints is applied.

Simeza’s tanks cover a wide range of models from 2.3 meters to 42.8 meters in diameter.

EAPR pellet mill control system by Amandus Kahl

With the innovative, electronic automatic pellet mill control EAPR, the Reinbek-based mechanical engineering company ensures optimum operation with low personnel requirements and long service lives.

The EAPR is a pellet mill control system for automatic operation of flat die pellet mills made by Amandus Kahl. This system enables users to control all relevant process parameters. It consists of a local control cabinet with graphic touch panel and intuitive software user interface. For more energy efficiency, Amandus Kahl thus considers the entire plant and equips all pellet mills with corresponding switching and control systems. If desired, the customised software enables the user to control and monitor the pellet mill, the dosing screw, the mixer, the auxiliary units - the cooler if required - and the respective upstream and downstream elements at any time. As an option, up to four additional liquids can be added to the continuous mixer and included in the processing.

Chain conveyors CC 550 650 900 by CESCO

Cesco chain conveyors CC are designed with a flexible concept and modular design, for horizontal or slightly inclined conveying of grain, grist, pellets, and granular products in general. They understand the completely closed conveying of the product, with the possibility of loading and unloading the product in several places, even in reversible mode, with zero loss during the conveying, easy cleaning, maintenance, and safety during operation thanks the fully bolted system used.

General characteristics

• Drive and tensioning stations with rounded shape.

• Tensioning station equipped with screw chain adjustment and spring-loaded length and shock absorber.

• Chain sprocket bolted to shaft and divided into 2 parts for easy maintenance.

• Chain flights equipped with UHMW-PE scrapers every 3 m.

• Fully outboard supports for both drive and tensioning shaft, allowing for easy bearing maintenance.

Pegasus Conditioner by Dinnissen

The Pegasus Conditioner is a double-axis mixer that uses steam or hot air to adjust the moisture percentage in a product. Different types of products, such as powders, steam, water and fats can be mixed homogeneously. The steam or hot air can be used as pre-treatment or salmonella control. The amount of product to be mixed and the mixing time can be controlled manually. Maintenance and inspection are quick through the easily accessible hatches. Various products come together in the Conditioner's sealed mixing chamber. The double-axis mixer quickly and precisely realises a homogeneous mixture and uses steam and heat to determine the temperature within this mixture. The mixed product passes from the outlet to the next step in the production process. With the Pegasus Conditioner you easily mix different types of bulk materials such as powders, water, steam ad fats without segregation. The substances remain homogeneously mixed by combining the mixing process with product heating. In addition, by adding steam you can accurately determine the temperature of your product.

Advanced Feature Dryer by Extru-Tech

Extru-Tech horizontal dryers are the leading industry tool for the production of a diverse range of food and feed products, including pet and aquatic foods and foods for human consumption. Extra-Tech has taken dryer technology to the next level with the new Advanced Feature Dryer, which features improved performance and new sanitary dryer features.

The Advanced Feature Dryer is renowned for its balanced Air Circulation System. The addition of variable frequency direct drive fans provides uniform airflow across the entire width of the beds minimising moisture deviation and providing flexibility to maintain even efficient drying regardless of product size, shape and density. The result is a finished product with less than 0.5 percentage point variation in moisture. Their new, redesigned cute is complete with span and speed controls for 'in-process' adjustments, providing accurate product spread for even bed depth.

FOCUS Product September 2023

38 | September 2023 - Milling and Grain

www.extru-techinc.com www.akahl.com www.dinnissen.com https://simeza.com

https://cesco-group.com

Get longer lasting bucket elevators with solid-welded flange connections and all-galvanized construction from Brock Grain Systems. An extra 1/2-inch lip on the head seals out water and dust. The adjustable bonnet discharge on the throat minimizes back-legging.

headstrong.

We’re

brockgrain.com/handling-commercial BUCKET ELEVATORS Storage | Handling | Drying & Conditioning | Structures +1 866.658.4191 sales@brockgrain.com

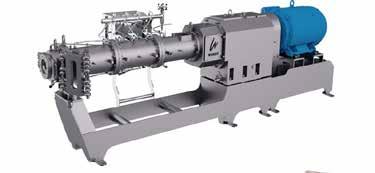

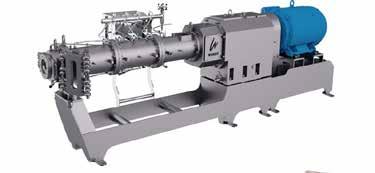

Magnum ST: Twin Screw Series Engineered for High SME ratings & unsurpassed versatility

The Magnum ST Series redefines versatility for smaller extruders with no loss of capacity. It has the ability to use higher SME (Specific Mechanical Energy) settings to take extruded products to the next level, can reach speeds of up to 1200 rpm, and power levels of up to 165 kWhr/t SME at volumetric capacity.

The benefits of higher SME inputs include the potential for lower bulk density, higher absorbency levels of liquid coating, smaller cell structure, enhancement of textural properties, and higher cook levels. There is also a higher torque at lower speeds for extreme processes.

Utilising parallel-shaft twin screws, the Magnum ST series extruders are ideal for unique processes that require extreme operating parameters. With their increased process flexibility and rate potential, the Magnum ST series is especially suited for:

Applications with extreme product viscosities

Processes requiring high SME inputs

Continuous physical and chemical reactions

Dispersive mixing applications

The Magnum ST Series is ideal for applications requiring high torque at low extruder shaft speeds and for jobs that require increased rate potential, where rate is dependent on SME and shaft speed. It provides an increased process flexibility and rate potential, redefining versatility.

The equipment has applications in a number of areas. One potential application is for Food, including plant-based textured proteins, meat analogues, snacks, cereals, and breading’s. It can also be applied to Pet foods and treats, such as dry, semi-moist, high meat, co-extruded, multi-coloured, and novelty shapes. It has its uses in aquatic feeds also, for floating, sinking, slowsinking and specialty products. Lastly, it had industrial uses, such as biodegradable packing material, oilseed processing, starch-based products, and detergents.

The application has specific design features, including a highintensity preconditioner (HIP), Roll away feature, dry ingredient feed system, and convenient barrel/shaft removal.

FOCUS Special

Milling and Grain - September 2023 | 41

www.ai-lati.com

Our essence lies in the forms through which we show ourselves. We offer just what we are. Always.

Determination of gluten fractions

by Ayşenur Akpınar, Food Engineer, Bastak Instruments, Türkiye

Wheat, one of the cereal crops, which is the most important staple food in our diet, ranks first in the world and in our country in terms of cultivation and production area among plants.

In Turkey, cereals and cereal products are of great importance both in terms of consumption habits and their share in the economy, and our interest in wheat in particular stems from our nature of being the gene centre of Anatolia beyond our traditional eating habits. It has been determined that all wheat has its origin in the Karacadağ foothills near Urfa Göbeklitepe, the first settlement centre in the world. 198 bread and 61 durum registered varieties were identified as of 2016. In 2015, 22.6 million tonnes of wheat, corresponding to 3.3 percent of world production, was produced and four out of every five farmers in Turkey grow wheat.

Wheat quality is evaluated according to its suitability for the final product and one of the most important quality control criteria is protein content. Gluten, which is the most important component of gluten protein obtained from wheat flour or crushing, constitutes approximately 40 percent of the endosperm proteins in wheat flour.

Proteins determine many characteristic properties of the dough and gluten, which is hydrated in the mixture of flour and water and forms a network, spreads to the dough mass. Gluten protein hydration, which plays a role in gaining volume by keeping carbon dioxide bubbles in the dough during fermentation, has a great effect on oxidation.

The necessity for high quality gluten

According to the proportions of gluten in flour; it is classified as very strong, strong, powerful, extensible and weak. Rheological properties of proteins such as hydration capacity, oxidation and elasticity reflect the strength of flour. In this classification, the strength of flour is determined according to the amount and quality of gluten.

Wheat producers want to have the highest wheat yield, while wheat industrialists want to have the highest protein concentration at the lowest possible price.

Bakers want wheat to have a high gluten content; the higher the quantity and quality of gluten, the higher the gas holding capacity and the higher the bread yield and quality.

In the pasta industry, it is desired that minimum dry matter passes into the cooking water and that the pasta does not fall apart and stick during cooking. For this reason, protein quantity and quality of durum wheat is a very important issue.

In the biscuit, pastry and cracker industry; controlled rising of the products produced is desired. For this reason, it is desired that the protein ratio should be weak and soft at around 10 percent during the process.

The gluten feature in the total protein in wheat and flours is mainly effective on the rheological and technological properties of the dough and the research are still continuing. International standards have been developed for the determination of gluten index value and quality and the gluten index value, which expresses the percentage by weight of the wet core remaining in the sieve after the gluten obtained is subjected to centrifugal force, has an important place in determining the quality.

One of these international standards is the ICC No.192 Standard (International Cereal Science and Technology Association (ICC)) for the determination of wet gluten, gluten index and dry gluten of wheat flour and whole wheat flour using Bastak Instruments' Bastak Quality Control Instruments: 6100 model Gluten Cheq, 2100 model Centrifuge Cheq and 2500 model Dry Cheq.

Bastak’s solution

Bastak Gluten Quality System Instruments are used in thousands of flour, bread, pasta, biscuit, cereal industry manufacturers, universities, research institutes and quality control analysis laboratories worldwide. Bastak Gluten Quality System Devices is an approved world standard for determining the gluten amount, gluten index and dry gluten values in flour and semolina used in bread, pastry, biscuit and pasta in accordance with world standards, final product volume, baking and cooking quality.

Wet gluten, gluten index and dry gluten values obtained from flour, whole wheat flour, semolina, bulgur, vital gluten and vermicelli are determined in international standards with the Gluten Quality System. The Gluten Quality System is produced with 0.001 micron precision , the world's highest quality machine park and with the latest technology in Bastak factory with a closed area of 7000 square metres.

In addition, Bastak Teknoloji Systems Company's method study on the determination of 'Falling Number' depending on the Alpha-Amylase Activity level based on viscosity using the Falling Number Cheq device was presented to the world by the International Cereal Science and Technology Association (ICC) with the standard number 189.

44 | September 2023 - Milling and Grain F

Fane Valley, Ireland Looking to reinvent your feed mill? We’re listening. www.ottevanger.com As industry experts, we understand the unique challenges you face in the animal feed industry. That’s why we are committed to assist you throughout the entire journey, from concept to complete installation. So, what’s on your mind? Let’s talk opportunities »

FOOD SECURITY

by Selin Chua, Product and Marketing Manager Maize & Pulses, Bühler, Switzerland

THE NEED FOR STRONG RELATIONSHIPS

For a food producer that makes a major contribution to its nation’s food security, minimising downtime is essential because every minute means lost production. This requires modern and efficient production technologies, but that is not all. Pembe Flour Mills, one of Kenya’s largest millers, also relies on a strong relationship with its solution providers. With a deep understanding of the stress points in Pembe’s business, Bühler is able to provide not only the solutions but also the support that this important food producer needs.

If you sit down to a traditional Kenyan meal, you will probably be eating ugali, one of the most popular dishes in Kenya, also served across the African continent. Maize or corn flour, poured into boiling water is mixed until it thickens into a doughlike consistency. Ugali then takes center stage on any Kenyan table, surrounded by smaller plates of stews, as diners tear balls of the ugali, role it between their fingers and use their thumbs to make a small indentation with which to scoop up the accompanying curries and vegetable dishes.

If you eat ugali in Kenya’s capital, Nairobi, the maize was probably milled by Pembe Flour Mills Ltd. A family business that originated in Kenya, Pembe Flour Mills has today spread across East Africa through a network of sister businesses in Uganda, Tanzania, Zambia, Mozambique, Burundi, and Rwanda. Pembe Flour Mills is one of the largest producers of maize in Kenya, meaning it plays a key role in protecting the country’s food security. Maize provides one of the most affordable sources of calories among the cereal grains. Research published in the American Journal of Food and Nutrition shows that maize provides around 65 percent of the total staple food calorific intake in Kenya. Producers are also required to fortify the maize they mill with vitamins and minerals providing additional health benefits.

“Physical access to sufficient, safe, and affordable food is very important for an economy and Pembe Flour Mills is one of the lead manufacturers of feed and food and one of the main manufacturers of a staple product in the country, which is maize meal,” explains Suad Salim Abubaker, Director of Pembe Flour Mills Ltd. “This makes it very important that we have quality and efficiency in our production to ensure we have sufficient product to feed the nation.”

Pembe processes a range of different raw materials at its

Nairobi milling site, including animal feed, millet, sorghum, wheat, and wholegrain wheat. Despite very stiff competition in the fast-growing African milling sector the company’s relationship with Bühler stretches back over twenty years, during which it has been using a mix of Bühler technologies along with solutions from other providers.

Minimising downtime

Pembe has relied on Bühler for technologies and solutions since the 1980s, including a maize mill and sorghum plant, a feed mill, and wheat mills. A new maize mill and an Atta plant were commissioned in 2021. Bühler has, over the years, also retrofitted newer technologies into Pembe’s older mills on the Nairobi site. One of the drivers to modernise processes for Pembe has been rising energy prices across East Africa. Improving energy efficiency with new generation technologies is a sound commercial decision for Pembe. It is also in line with Bühler’s commitment to have solutions ready to multiply by 2025 that reduce energy, waste, and water by 50 percent in the value chains of its customers.

In recent years, Pembe had experienced problems with its nonBühler feed plant, which impacted productivity. Bühler’s local services team retrofitted the feed mill and, as a result, downtime has been reduced significantly. “Prior to working with Bühler we were having more downtime due to a lack of efficient technical support from our other suppliers. We were also having various issues in the procuring of spare parts from them,” explains Suad Salim Abubaker.

In 2019 Pembe decided to build a maize mill on its Nairobi site, choosing to go for a total Bühler solution. The deciding factors in choosing Bühler were the existing long-term relationship between the two companies as well as Pembe’s desire for a strong customer support network to cut its production downtimes.

46 | September 2023 - Milling and Grain F

Mercury Solomon and Salim Abubaker

Bühler has had a presence in East Africa since the early 1960s. Today it offers its East African customers access to a network of engineers based in Ethiopia, Uganda, and Tanzania, with the head office based in Nairobi also offering engineering backup. It means regional offices support each other whenever skills are required so that customers can receive timely backup when they face production challenges.

“A maize mill provides a staple food in Kenya so in terms of food security it matters a lot that Pembe is always running, to help maintain the nation’s food supplies,” explains Salim Abubakar, family member and fellow director. “Bühler having an East African office has been a game changer for us as we get spare parts in good time, which has resulted in our profitability going up as our downtime is reduced.”

Keeping food affordable

Reducing production downtime is becoming increasingly important for all East African maize producers. Data from the Kenya National Bureau of Statistics shows that between 2018 and 2021 Kenya’s maize production fell from 44.6 million bags to 34.3 million bags as drought, rising temperatures, and climate related pest infestations impact crop yields. At the same time demand for maize is increasing as the population grows. Currently at 55 million, according to the United Nations World Population Prospects, Kenya’s population is growing by two percent adding a million more mouths to feed annually. This growing mismatch between supply and demand, compounded by rising fertilizer and energy costs, has led to price increases.

Solomon Mwangi, Bühler Sales Director for Kenya and Somalia, has been watching the rising price of maize on the open market. “We are in a region where supply of the raw material is

Milling and Grain - September 2023 | 47 F

THE REVOLUTION IN PELLETING TECHNOLOGY Progress MonoRoll HE

Optimum pellet quality

Please contact us for the possibilities within your company info@ptn.nl - www.ptn.nl Scan de QR-Code for more information

T/H

Guaranteed 20% energy saving 10-15% higher throughput

decreasing, and demand is rising. I have seen the average price of a 90 kilogram (kg) bag of maize rising from 2000 Kenyan shillings three years ago to 6000 shillings today,” explains Mwangi. “When this is happening to a staple food it is worrying, which is why it is so important for millers to be at their most efficient when it comes to the processing of the raw material to ensure the maximum extraction at the highest quality. In the end our customer is the end consumer and if they can’t afford the product because our process is inefficient, we are in trouble, so we need to make the process as efficient and therefore as affordable as possible.”