millingandgrain.com March 2024 In this issue: Milling and Grain . Volume 135 . Issue 3 . March 2024 Proud supporter of Download the Milling and Grain app to your smart phone YOUR GLOBAL PARTNER Volume 135 Issue 3 A revolution in yeast: Our visit to ICC Brazi - World Flour Day: Millers Unite for Global Giving Campaign - Nitrogen fumigation: The organic way for safe longterm storage of grain, pulses, and vegetables - Energy-efficient and foodsafe grain moistening Take part in one of our conferences at the event Meet the Milling and Grain Team on stand i044 at:

WHAT WE DO Designing FLOUR MILLING Manufacturing Turnkey project Service +86 371 68631308 info@g-grain.com www.g-grain.com SCAN ME FOR BROCHURE

Handle bulk with efficiency and reliability

Pneumatic and mechanical ship (un)loaders

Up to 2500 tph for loaders and up to 1200 tph for unloaders.

Low noise & no dust emission

Turnkey solutions for cereals, soy flour, fertilizer, pellets and more...

Perendale Publishers Ltd

7 St George’s Terrace

St James’ Square, Cheltenham, Glos, GL50 3PT, United Kingdom

Tel: +44 1242 267701

Publisher Roger Gilbert rogerg@perendale.co.uk

International Marketing Team

Darren Parris

Tel: +44 1242303792 darrenp@perendale.co.uk

Asia Marketing Team

Dante Feng

Tel: +886 227930286 dantef@perendale.com

Latin America Marketing Team

Cristina María Roldán Otero

Tel: +44 1242 267700 cristinaot@perendale.co.uk

Nigeria Marketing Team

Nathan Nwosu

Tel: +234 8132 478092 nathann@perendale.com

Egyptian Marketing Team

Mohamed Baromh

Tel: +20 100 358 3839 mohamedb@perendale.com

Turkey, Eurasia and Middle East Marketing Team

Mehmet Ugur Gürkaynak

Tel: +90 537 3646457 mehmetg@perendale.com

Editorial Manager

Joy (Jyothsna) Nelloolichalil joyn@perendale.co.uk

Editorial Assistant

Shannon Parsons shannonp@perendale.co.uk

Niamh Cassidy niamhc@perendale.co.uk

Social Media Journalist’ David Harvey davidh@perendale.com

International Editors

Dr Roberto Luis Bernardi robertob@perendale.com

Professor Wenbin Wu wenbinw@perendale.com

Mehmet Ugur Gürkaynak mehmetg@perendale.com

Design Manager

James Taylor jamest@perendale.co.uk

Circulation & Events

Tuti Tan tutit@perendale.co.uk

Development Manager

Antoine Tanguy antoinet@perendale.co.uk

ISSN

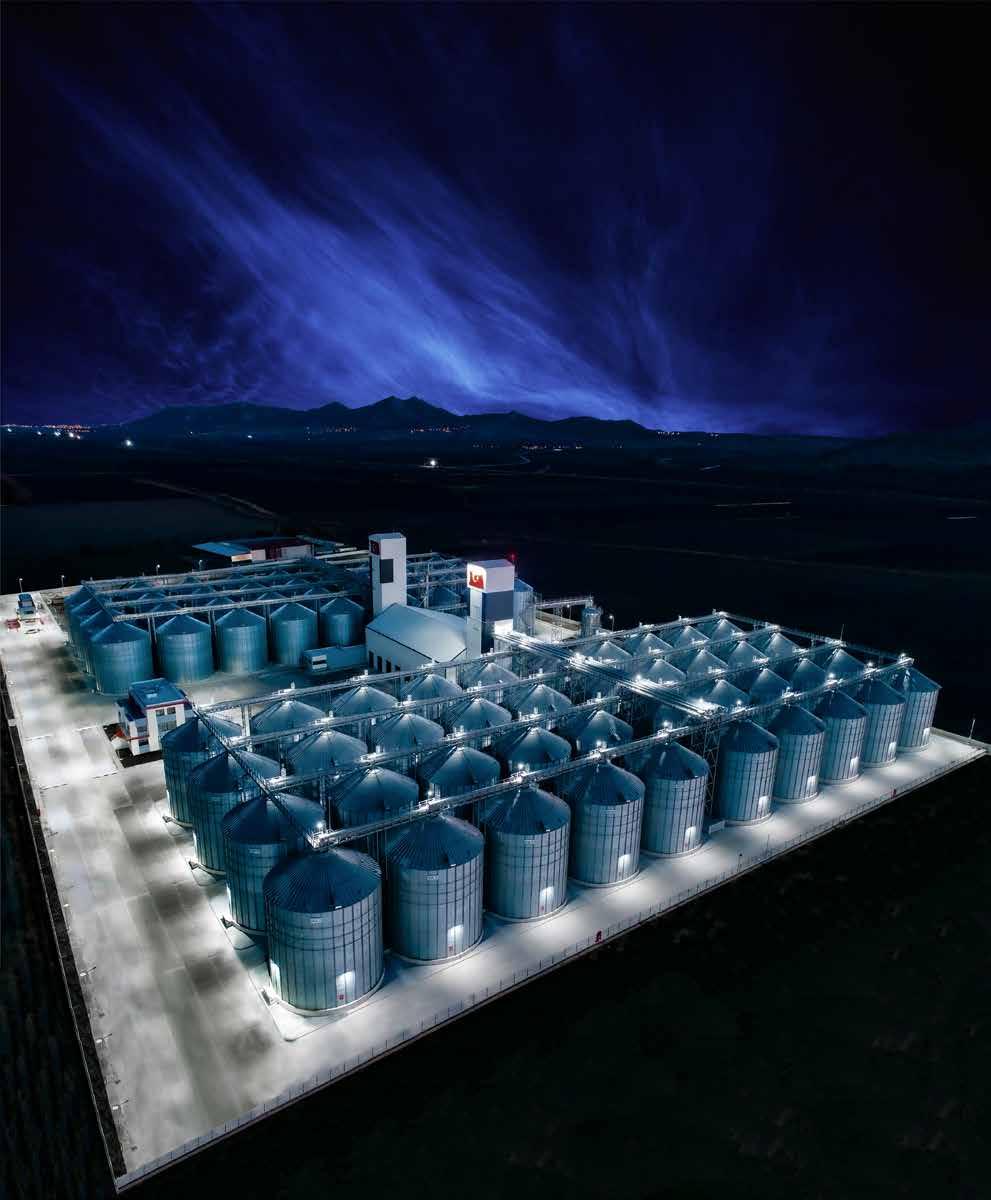

VOLUME 135 ISSUE 3 NEWS 10-41 54 Sustainability - The business case for sustainability in the milling industry 50 Nitrogen fumigation: The organic way for safe long-term storage of grain, pulses, and vegetables 68 A revolution in yeast: Our visit to ICC Brazil 74 Perfect synergy of brewers‘ yeast and fibre STORAGE 78 Energy-efficient and food-safe grain moistening 8 PUBLISHER Roger Gilbert 108 INTERVIEW Mildred Cookson ©Copyright 2019 Perendale Publishers Ltd. All rights reserved. No part of this publication may be reproduced in any form or by any means without prior permission of the copyright owner. More information can be found at www.perendale.com Perendale Publishers Ltd also publish ‘The International Milling Directory’ and ‘The Global Miller’ news service EVENTS 96 Event listings, reviews and previews COLUMNS 18 MAG TV 18 The Global Miller 26 Mildred Cookson 31 Dr Mahmoud Riyad 36 Nathanael Hodge FACES 110 People news from the global milling industry TRAINING 45 Industry training news PRODUCT FOCUS 48 CASE STUDY 92 INDUSTRY PROFILE 90 Grain & Feed Milling Technology magazine was rebranded to Milling and Grain in 2015 March 2024 COVER IMAGE: Bakha Söhne oat mill - Kazakhstan’s most high-tech oat mille - see more on page 76 FEATURES millingandgrain.com

No: 2058-5101 WORLD FLOUR DAY - Millers Unite for Global Giving Campaign See more on page 10

82 MARKETS

March is an extremely important month

March is an extremely important month in a miller’s calendar. That’s because the 20th of March each year is ‘World Flour Day.’

It’s a time when we should all do something special for our industry, especially when it comes to awareness of the work we do to deliver a highquality, safe and nutritious food staple to a global population.

All too often consumers and others do not know anything about our industry nor what is involved in producing flour-based foodstuffs that we have come to rely upon. Bread – along with baked gods, etc - have become the most dominant source of protein, vitamins, minerals and complex carbohydrates - and not to ignore fibre – in our daily diets.

Roger Gilbert

Roger Gilbert

While we should not diminish the contribution other grains, including rice, make to the human condition, we know that ‘bread’ is at the centre of our existence. Every seventh calorie we consume comes from wheat. When combined with other grains and cereal crops we can only imagine the wider implications of what the milling industry delivers. And that is without taking into account the important animal feed processing sector that feeds the domesticated terrestrial and aquatic animals that in return provide us with the proteins we need for a complete diet.

We need to be more appreciative of what our milling industry does dayin and day-out to ensure we have enough of these essential foodstuffs on our plates to satisfy our nutritional needs and which we expect to sustain future generations.

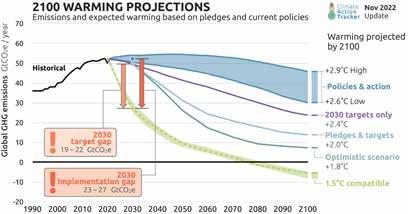

It was interesting to learn from a keynote presentation late last month that independent North American Indian tribes work with their environment so that it can meet the needs of their peoples seven generations ahead.

Looking into the distant and considering what life might be like on our planet in two or three hundred years’ time might result in a different approach to progress, development and sustainability. We are no longer protecting this plant for our grandchildren, but for the children of our genetic offspring in hundreds of years from now.

That sounds almost too difficult to contemplate, but looking to the past and understanding how we got to where we are today (see our report on Göbeklitepe in the February edition from page 50 written by our Turkish representative Mehmet Ugur Gürkaynak), will help us recognise the likely challenges of the future and how we might pre-empt disaster and protect human life on earth for many centuries into the future.

Therefore, the milling industry not only has quite a challenge in front of it, but also a huge responsibility in considering longer-term goals that will not only meet the demands from population growth but provide food in an ever more efficient manner in terms of energy usage, food safety, affordability and availability.

Having one day in the year set aside to get our messages out to the wider public is a great start and it is cognisant on all of us to in this industry to actively speak up about who we are and what we should be doing to preserve this most valuable industry.

Giving your best

I’m also pleased to say that in this edition and for World Flour Day we are starting the publication of our Charities Directory (which also includes not-for-profit charitable organisations and others), listing those working specifically from within the milling sector. As I

explained in my editorial last month, we will feature one charity a month to help you pin-point a charity you might like to support (see page 10).

All links for information and donation making go direct to the charity in question.

Our charity, the Milling 4 Life CIO, is hosting this directory within Milling and Grain, which the magazine is very pleased to do.

We feature the work being done by Bastak Instruments of Turkey ‘Empowering African Agriculture’ to kick-off the Directory's first report.

I encourage you all to think in terms of supporting people and families in other parts of the world and who might not be as well-off in their environments as you are in yours when it comes to food and feeding families. The Charities Directory is a great way to start to explore where you might like to help others. Thank you for taking the time to consider this option on World Flour Day!

Meet with us in Asia

I’m hoping I will see many of you in Thailand at the upcoming Victam Asia 2024 / VIV Animal Health and Nutrition event which is a co-located show being held in Bangkok in the middle of this month (March 12-14, 2024) at the BITEC and which is easily reachable by Skytrain from the centre of the city.

Milling and Grain will be hosting multiple conferences including the renowned ‘Build My Feedmill’ which is jointly host with VIV and can be located in Room MR 220-221.

There are two earlier events on aquaculture which are well worth the time to attend. But please note they take place on March 11, the day prior to the opening of the joint expos.

They are two one-day conferences involving the production of aquatic feeds: 1) Aquafeed Extrusion Conference (to be held in Room MR223) and 2) Aquatic Asia Conference (in Room 224). Both start at 10:00 in the morning. Please be sure to register via either the Victam or VIV websites.

Finally, on the last day of the event (March 14) from 09:30-12:30 we host a new conference under the GRAPAS banner called ‘Flour Milling Maximised’ (in Room MR 214-215). GRAPAS is an expo within an expo which is offered free to attendees by Victam which is targeting the flour and rice milling industries.

‘Flour Milling Maximised’ is a three-hour session that features two keynote presentations along with exhibition companies highlighting technologies that will improve flour and rice production.

This is a unique opportunity to not only learn about newer technologies but to hear from two of the largest flour millers on the planet – Bogasari of Indonesia and Wudeli of China. Come along and be impressed!

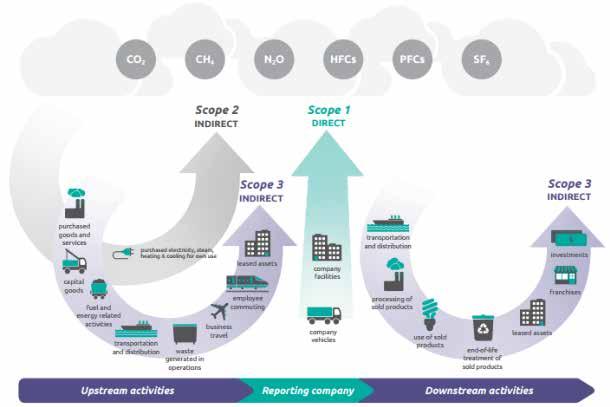

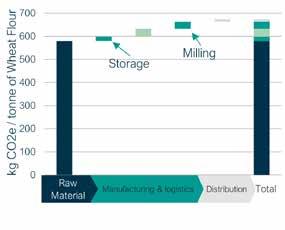

• Ad Witono will be addressing ‘The Sustainability Journey Within Our Bogasari Group’ and

• Raymond Ma will provide an ‘Introduction of Wudeli - A revolution of equipment and technology’

In my experience there has been too few occasions when millers from these extremely large milling organisations are happy to share their experiences. It’s never too late to book your place to be in attendance. See elsewhere in this edition for further information and links. Happy reading!

Milling and Grain has a cooperative partnership with COFCOET

Annual Subscription Rates

Inside UK: UK£100

Outside: US$150/€133

More Information

www.millingandgrain.com

http://gfmt.blogspot.co.uk

WORLD FLOUR DAY

Millers Unite for Global Giving Campaign

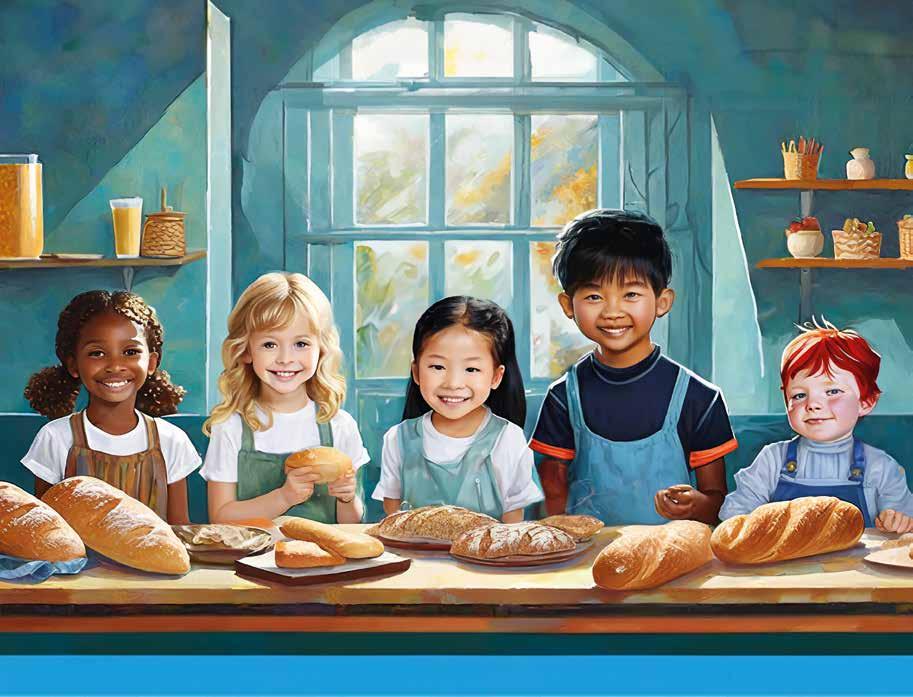

As the world prepares to celebrate World Flour Day on March 20, 2024, the global milling community is gearing up for a special campaign under the theme ‘World Flour Day – Giving Day.’ Organized by the FlourWorld Museum in Wittenburg, this initiative aims to highlight the social commitment of millers worldwide by focusing on campaigns for donations to support needy children.

Flour, often referred to as the ‘White Gold,’ holds a significant place in human nutrition and development throughout history. World Flour Day serves as an occasion to recognize the importance of flour and the invaluable work of the milling industry. This year, the FlourWorld Museum is emphasizing the social impact of flour with a call for collective social engagement.

Under the motto ‘Millers meeting social challenges,’ mills across the globe are encouraged to actively participate in the Giving Day campaign by donating flour to charitable institutions such as children’s aid foundations and orphanages. This campaign not only provides practical assistance to those in need but also sheds light on the essential role millers play in society. The FlourWorld Museum sets an example by donating 500kg of flour to kickstart the initiative.

Peter Steiner, Global Head of Business Unit MC Mühlenchemie, underscores the profound significance of this year’s World Flour Day, stating, “Flour is much more than just a staple food. It symbolizes life. With our global charitable initiative, we aim to raise awareness of the crucial role the milling industry plays in global nutrition. When we donate flour, we donate life.”

Mills and millers worldwide are invited to join this noble initiative by contributing goods to orphanages and youth

foundations, with the shared goal of making the world a better place. The FlourWorld Museum will showcase and highlight these initiatives on March 20, 2024, through its website www.worldflourday.com and social media platforms using #worldflourday.

March 20 was selected for World Flour Day due to its symbolic significance, aligning with the beginning of spring in the Northern Hemisphere, signifying a time of planting, and autumn and harvest in the Southern Hemisphere. Since its inception three years ago, World Flour Day has become an integral event in the calendars of millers worldwide.

The FlourWorld Museum, located near Hamburg, Germany, houses the world’s largest collection of flour sacks from 150 countries, portraying the traditions, history, and myths of flour under the unifying idea of “Flour, Power, Life.” Dedicated to celebrating flour and the contributions of millers globally, the museum continues to champion initiatives like World Flour Day to support communities in need.

10 | March 2024 - Milling and Grain Milling News

your actions speak On March 20, many millers around the world focus on social engagement and relief efforts for children in need. Join our call to action and donate flour to charitable organizations. For more information and the opportunity to participate in this initiative by the FlourWorld Museum, visit www.worldflourday.com. Picture created with Ai

World Flour Day – Giving Day Let

Bastak Instruments’ Journey of Innovation and Social Responsibility Empowering African Agriculture

Bastak Instruments, with a quarter-century expertise in food safety, quality control in food, and sustainable agriculture, is taking significant steps to contribute to the development of the agricultural sector in Africa. As part of these efforts, Zeki Demirtaşoğlu visited Africa to examine the company’s recent projects on the continent and to meet with local farmers. During his visit to Africa, Zeki Demirtaşoğlu had the opportunity to personally observe projects aimed at increasing the productivity of local farmers through the company’s agricultural innovation and technology solutions. These projects encompass a wide range, including the teaching of modern farming techniques and the training of blue and white-collar personnel working in the food and agriculture sectors.

Innovative solutions with agricultural innovation and technology

Agriculture is a key factor for the future of Africa. The African continent hosts most of the world’s arable land, and half of the population works in the agricultural sector, contributing the largest share to the total gross domestic product. However, Africa has not seen a significant increase in productivity since the 1980s, producing

insufficient food and low-value-added products.

Wheat, being one of the world’s most important cereal crops after rice, is a subject of international trade and a crucial component of industrial and food grain in sub-Saharan African countries. Wheat is also a strategic product generating farmer income. Ethiopia is one of the largest wheat producers in terms of total wheat-cultivated area and total production.

Demirtaşoğlu, emphasizing the critical role of laboratory quality control devices used in the food, grain, seed, and oilseed sectors in ensuring product quality and safety, stated that Bastak Instruments aims to support farmers and local agricultural organisations in Africa with state-of-the-art 72 types of quality control devices, expert and academic staff, and training activities under Bastak Academy to enhance the quality of agricultural products in the region. They aim to elevate the region’s food safety standards. During his visit, Zeki Demirtaşoğlu observed the use of these devices and engaged in significant discussions with local laboratories and agricultural organizations on integrating these technologies.

Empowering communities with education and capacity development project

Demirtaşoğlu also examined education and capacity development projects aimed at empowering local communities during his trip to Africa. These projects seek to support the adoption of sustainable

CHARITIES DIRECTORY 12 | March 2024 - Milling and Grain F

farming practices by providing education to farmers on modern agricultural techniques and laboratory quality control applications under the Bastak Academy. He mentioned their efforts to establish the Milling and Sector Machinery Manufacturers Association (DESMÜD) and Ankara Metropolitan Municipality partnership to create the Milling and Bread, Pasta, Biscuit Training Center, which will provide education in both English and Turkish - a first in Turkey and globally. They aim to offer innovative technologies and best practices to tens of thousands of learners who have not received formal education and have not fully adapted to the requirements of the times, coming from Africa, Turkic Republics, Latin America, the Middle East, and other countries.

Demirtaşoğlu, acknowledging Africa not only as a geographical continent but also as a home to diverse cultures, rich histories, and strong connections, expressed that the challenges and disadvantages in the region deeply influenced him during his visit. He mentioned their desire to make a positive impact by reaching out to people’s lives, taking a step towards education, and helping

them look towards the future with hope. Zeki Demirtaşoğlu emphasized that Bastak Instruments is focused on creating an impact not only in the business world but also in the field of social responsibility. He added that, through social responsibility projects for African agricultural communities, they aim to improve the living standards of people in rural areas by providing support in health, education, and infrastructure.

Zeki Demirtaşoğlu’s journey in africa through his eyes

Zeki Demirtaşoğlu believes that true change in Africa’s agricultural sector, sustainability, and technology is possible when they converge. Following his visit to Africa, he expressed that their company has initiated efforts to provide support to local farmers and communities, aiming to facilitate the transfer of knowledge and technology. He stated that, with love and support, they hope these efforts can bring about positive contributions to the agricultural future of the continent, ultimately working together to bring about change in Africa.

www.vav.nl contact@vav.nl Stand E041 Milling and Grain - March 2024 | 15 F

Elevator parts Conveyor chains

Milling and Grain is hosting a directory of milling industry charities and charitable organisations working in the milling sector under its UK Milling 4 Life CIO Charity. The aim of the directory is to build greater awareness of the work these charities do and how you might be able to donate funds to their specific projects and activities. Milling 4 life is not affiliated with these charities, but lists those working in the milling sector here along with their contact details for information and direct donations. Milling and Grain will feature each charity in turn in this section of the magazine in order to provide background information on each

Flour to the People by Scotland the bread Scotland

REGISTERED CHARITY No.-SC048892

https://scotlandthebread.org

Scotland The Bread is a collaborative project to establish a Scottish flour and bread supply that is healthy, equitable, locally controlled and sustainable. Our idea is simple: grow nutritious wheat and bake it properly close to home. Donations to support our work are urgently needed and very welcome. Thank you for your contribution.

Milling 4 Life

UK / International

REGISTERED CHARITY No. 1172699

https://millingforlife.com

Our goal is to help relieve malnutrition and poverty through the development and uptake of food and feed milling technology and processes; by encouraging agricultural improvements in the first instance followed by encouraging the adoption of the proper handling and storage of raw material and the uptake of milling processes to provide safe and affordable food products for both people and livestock (including fish) in transitional countries.

The George Family Foundation UK https://whitworthbros.ltd.uk/charitable-foundation

The George Family Foundation was established in 2020 as a registered charity independent of the Whitworths Holdings Group. It is run by three trustees, two of which are members of the George family and one who is independent. Currently the Foundation plans to donate a minimum of £100,000 per year to individuals and organisations whose purposes align with the values of the George Family.

The Green's Windmill Trust UK REGISTERED CHARITY No. 1163116 www.greensmill.org.uk

Green’s Windmill Trust started over 13 years ago as a small group of people who wished to help preserve the milling heritage of the windmill, promote George Green’s reputation as one of the greatest scientists of his age and further the educational and public activities of the Science Centre.

In 2012 we became a registered charity and began taking over day-to-day operations at the Mill and Science Centre from Nottingham City Council.

The Mills Archive Trust UK REGISTERED CHARITY No. 1155828 https://new.millsarchive.org/

The Mills Archive is a permanent repository for the documentary and photographic records of traditional and contemporary mills and milling, as well as similar structures dependent on traditional power sources. It makes that material freely available for public inspection and use in research and learning.

The Mills Archive is one of the world’s great mill collections. It has rescued over the million documents and images that might otherwise have ended up in a landfill site. It is an Aladdin’s cave filled with memories and free to users. The collections show the rich and diverse crafts, buildings, machinery, equipment and people involved with mills in the UK and around the world.

Flour World Museum

Germany

REGISTERED CHARITY No. 1155828

https://mehlwelten.de/english/index.php

The FlourWorld Museum in Wittenburg is an invitation to millers and friends of flour and bread from all over the world to rediscover this vital basic food with all their senses.

The FlourWorld Museum in Wittenburg is also a tribute to the millers of the world and a gesture of thanks for our close partnership with the international Milling Family, whose inspiration and active support enabled us to transform an eccentric idea into a museum that is unique in the world.

THE JORDAN TRUST UK

https://jordansmill.com

The Jordan Trust, run in association with Jordans Mill is registered as a charity, limited by guarantee and is based on the River Ivel at Holme Mills, Biggleswade.

The objectives of the Trust are to protect and preserve the character of the River Ivel site where flour milling was recorded in the Domesday Book of 1086.

Central to Holme Mills is the unique water driven Mill building which was last rebuilt following a fire in 1899. Visitors to the mill are able to gain an understanding from staff and volunteers about the process involved to produce a variety of flour products from wheat varieties grown in the Ivel Valley over the last 1000 years. In its day, this mill was a technologically advanced example of a milling system based on steel rolls rather than the millstones which had been powered for centuries by the power created by a six foot drop in water level on the Ivel river.

If you would like to list you charity under this directory, please email us at editorial@ perendale.co.uk

CHARITIES DIRECTORY

BESTMIX® Software: The best solution in challenging times Reduce costs and prevent risks Optimize your entire production chain Guarantee higher quality products BESTMIX® Feed Formulation, Quality Control, Ration Calculation and ERP solution. Scan to learn more: www.bestmix.com PEAK PERFORMANCE WITH NEXT GENERATION TECHNOLOGY Stay tuned LinkedIn SWISCA 16 | March 2024 - Milling and Grain

NewsMilling

Renate

Wiendels at VIV MEA 2023

Roger Gilbert, Publisher of Milling and Grain magazine, talks to Renate Wiendels, Senior Project Manager for VIV at VNU Exhibitions, at VIV MEA 2023, which took place in Abu Dhabi from November 20-22, 2023.

Renate tells us how comprehensive the show is this year, with a new horticulture and agriculture element added, brining plant protein to the discussion with animal protein. She notes how the 2023 show reached a wide range of countries from all over the Middle East and Africa, stating governments in the region are particularly interested in investing in food security.

The next VIV MEA will be taking place in 2025, from November 25-27 in Abu Dhabi, see https://www.vivmea.nl/

Nath Morris at IPPE 2024

Nath Morris, President of the Association of US Poultry & Egg, speaks to Roger Gilbert, Publisher of Milling and Grain magazine, at the 2024 edition of IPPE, in Atlanta, Georgia, USA.

Nath has 10 years’ experience running the show at IPPE and has seen how the show has developed and significantly expanded over the years. The attendance goal this year was 31,000, which has since been met and raised in registrations. The international presence this year has increased, with the show being around 29 percent international, from 131 countries worldwide. 40 percent of the International presence has been from the LatAm alone. Evident from crowds, including 8000 International visitors, the show is getting busier than ever, so don’t miss out on next year’s show!

Learn more about IPPE 2025 – taking place January 28-20, in Atlanta, Georgia, USA. https://www.ippexpo.org/

Welcome one and all, to the third edition of Global Miller for 2024, ergo, the March edition of Milling and Grain. The first quarter of the year is ending, and it flew by. Who knew time could go by so fast? It only gets faster the older we become too.

It is International Women’s Day on March 8, a day of celebration for women worldwide and a reminder to all that women deserve to be treated with equality and equity. The theme for this year according to United Nations Women is ‘Invest in women: Accelerate progress’. As the world suffers through crisis after crisis, by investing in women, whether it be financially or by providing jobs or services that allow women to be able to work, the world can grow and a future can be created where everyone thrives as women will provide an economical growth, new innovations, boundless opportunities and more. As a sign that Milling and Grain are also investing in women, we wish to honour one our long-standing friends within the milling industry, Mildred Cookson, who we have a double page interview of in the back of our magazine.

March is also celebration for World Flour Day on March 20. A significant day for flour millers as it’s a day to celebrate the challenges we have overcome and the global solidarity that marks the efforts we have put in to get to where we are now regarding milling. This year World Flour Day is focusing heavily on ‘Giving’. Giving to the community, to charities, organisations and more. We want to provide children with a tangible difference and to do so, World Flour Day would like the global milling community to showcase their spirit and ability to work together by participating and donating towards causes that benefit our future generations.

As for news for this month, you’ll be able to learn more on how AFIA welcomes the FDA’s move toward modern claim regulations. You can also discover how dsm-fimenich plan to separate out Animal Heath & Nutrition business from the group and how the Italian company Ocrim acquired SIMA with is wonderful news. More can be read about this in both the magazine and our website. This isn’t all of our news either, so there are still some surprises for you to read about too in this edition.

This month, we also have a very large event that will be happening- VICTAM 2024 co-locating with Animal and Health Nutrition Asia in Bangkok, Thailand. If you’re attending then do find Milling and Grain at our stand I044. Mentioning large events, you will find the report of IPPE 2024 in this edition and discover all the latest information on the event along with what the President of IPPE has to say regarding their event.

gfmt.blogspot.com

18 | March 2024 - Milling and Grain

Introducing Horti Agri Next (HAN) Asia 2025

VNU Exhibitions Asia Pacific, renowned for its expertise in organising successful trade fairs and conferences in Southeast Asia, is thrilled to announce the launch of HAN ASIA 2025, a trade exhibition dedicated to Horticulture and Agriculture that covers the entire supply chain.

With the strategic re-branding of horticultural and agricultural exhibitions in Asia, VNU Exhibitions Europe and VNU Exhibitions Asia Pacific are positioned as the leading and complete Seed to Food trade hub for Asia Pacific and beyond. With the launch of HAN ASIA, VNU Exhibitions Asia Pacific simultaneously introduces regional satellite events in the countries of Vietnam (May 2024) and Indonesia (September 2025), co-locating the events under the name HAN Select, with the successful livestock trade shows of the ILDEX Series.

The new international platform for Asia, HAN ASIA, will be held during March 12-14, 2025 at IMPACT, Bangkok, Thailand, parallel to VIV Asia 2025, focusing on the latest products, innovations and advances in the fields of horticultural food production, landscaping, controlled environment practices, environmental conservation, arable land planting, harvesting, and processing of crops, as well as land and water resources management and new enhancing technologies. The fusion of HAN ASIA and VIV Asia creates Asia’s largest Agri-food trade fair – a

powerful collaboration of innovation and excellence.

HAN ASIA follows the success of HAN MEA 2023 that took place in Abu Dhabi, UAE from November 2022, 2023, in co-location with VIV MEA 2023 and was organised by VNU Exhibitions Europe. With 10,080 visitors from 113 counties and nearly 500 exhibitors from around 50 nations, the events showcased the global interconnectivity of the animal husbandry and the agribusiness industry. Spanning five halls at Abu Dhabi’s ADNEC venue, the exhibitions covered over 17,500sqm of space, drawing attendees not only from the UAE, but also from countries such as Egypt, Iraq, Iran, Pakistan, and Saudi Arabia. The remarkable 67 percent interest overlap between the co-located events underscored the dynamic networking and information exchange that characterised this triumphant showcase.

“HAN MEA was a testament to our commitment to promoting innovation and collaboration within the agricultural and horticultural sectors in the Middle East and Africa and across the different regions in which we operate. Our decision to extend this initiative to Asia with HAN Asia and the satellite HAN Select events stems from the positive impact witnessed in the MEA region and the growing potential we see” stated Ms Birgit Horn, Managing Director of the Agrifood Portfolio of VNU Exhibitions Europe.

Get insights in the quality of your steam process With the IVS Smart Steam Dosing Unit www.ivsdosingtechnology.nl Recommendations for optimisation Anticipating data facilitates predictive maintenance Increases user expertise of steam dosing Insight into the quality of the steam network 20 | March 2024 - Milling and Grain Milling News

The print edition the trusted information source for the industry NEW EDITION - OUT NOW! 2024 www.internationalmilling.com ANDRITZ FEED & BIOFUEL andritz.com/feed-and-biofuel-en Upgrade your operations with ANDRITZ Feed & Biofuel’s advanced, risk-free automation and digitalization integration. Leveraging our 25 years of cross-sector success, our platform blends human and digital intelligence to enhance processing efficiency and support growth, while delivering 7%-16% throughput increases. Our solution encompasses an evolving, vendor-neutral solution supported by state-of-the-art automation and digitalization technology. Send us a request to get a personal consultation: fb-automation@andritz.com FEED & BIOFUEL AUTOMATION & DIGITALIZATION NEVER STAND STILL ANDRITZ WILL BE WITH YOU EVERY STEP OF THE WAY IN YOUR DIGITALIZATION JOURNEY, ENSURING YOUR PLANT AND YOUR BUSINESS NEVER STAND STILL. Milling and Grain - March 2024 | 21 Milling News

AFIA welcomes FDA’s move toward modern claims regulations, but says legislation is still needed

The American Feed Industry Association applauds the Food and Drug Administration Center for Veterinary Medicine’s (CVM) decision to revoke an outdated regulatory policy spanning almost three decades, which has deterred animal food ingredient manufacturers from investing in the US marketplace.

This move could catalyse significant enhancements in livestock, poultry and aquaculture production, as well as advancements in food safety, environmental sustainability and animal well-being by allowing feed additives to be reviewed through the appropriate ingredient review processes versus the CVM’s animal drug review process. AFIA’s President and CEO Constance Cullman issued the following statement:

“The AFIA welcomes the CVM’s intention to withdraw its nearly 30-year-old regulatory policy, which shows its commitment to partnering with animal food innovators. This action signifies progress toward fixing a broken process and will allow our industry to start providing innovations for animal production, but the need does not end here. Congress, now it’s your turn to act by swiftly

passing the bipartisan Innovative Feed Enhancement and Economic Development (Innovative FEED) Act and providing the FDA with the tools it needs to codify a regulatory pathway and support American animal food manufacturers.”

Over the recent years, the FDA’s 1998 Program Policy and Procedures Manual Guide 1240.3605 has faced criticism, particularly from the AFIA, animal producers, lawmakers and federal officials, who argue that it hindered timely and cost-effective introduction of animal food ingredients with beneficial properties. The CVM’s strict interpretation categorised these products as animal drugs. This categorisation subjects them to lengthy drug review procedures rather than more suitable ingredient review processes, needlessly prolongs the evaluation period and, in many cases, stops companies from seeking product approval in the United States. The Innovative FEED Act, endorsed by nearly 190 stakeholders, would codify a regulatory review pathway that demonstrates safety and effectiveness for animal food ingredients impacting the microbiome of animals, food safety or the environment.

FEED FOCUS

Milling and Grain - March 2024 | 23 Milling News

SHIPLOADER SPECIALIST

NEUERO produces the most reliable and high-quality bulk ship loaders worldwide | neuero.de/en

DLG quality seal for farm inputs: Register new products for the 2024 tests now

Quality-conscious companies use the independent and practical control of the DLG (German Agricultural Society) for their products to show their customers that they can trust their products. The DLG Test Centre Technology and Farm Inputs offers manufacturers and distributors the opportunity to take part in the 2024 quality tests for farm inputs with new products. Products that pass the extensive expert tests receive the DLG quality seal, the renowned industry award for above-average product quality.

The quality tests carried out by the DLG experts are based on test criteria of high practical relevance. The test frameworks on which the tests are conducted are drawn up for each product group by neutral and independent

test commissions consisting of experts from agriculture, science and consultancy and cover all value-determining characteristics of the respective product group. The effectiveness is analysed in the laboratory and in practice, as is any possible negative impact on animals and/or stable facilities, which must be ruled out. The consistently high quality of the tested products is ensured by annually recurring control tests.

“The DLG quality seal has an outstanding reputation in agricultural practice,” says Dr Michael Eise, Project Manager at the DLG Test Centre Technology and Farm Inputs.

“Our test criteria are regularly updated and reflect the current requirements for the respective farm inputs. Thanks to our efficient and regular inspections, companies have the opportunity to position themselves precisely in the market and the ‘DLG quality seal’ guarantees an excellent product quality when agricultural investment decisions are to be made.”

FEED FOCUS

Industriestrasse 32, 8200 Gleisdorf, Austria Tel.: +43 3112 38580-0 E-Mail: office@statec-binder.com www.statec-binder.com more than more than 1800 85 countries years 45 fully automatic packaging systems YOUR SPECIALIST & PARTNER FOR BAGGING & PALLETIZING SOLUTIONS Milling and Grain - March 2024 | 25 Milling News

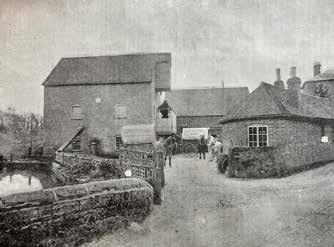

JH Burrows & Co Salford Mills, Horley

Milling journals of the past at The Mills Archive

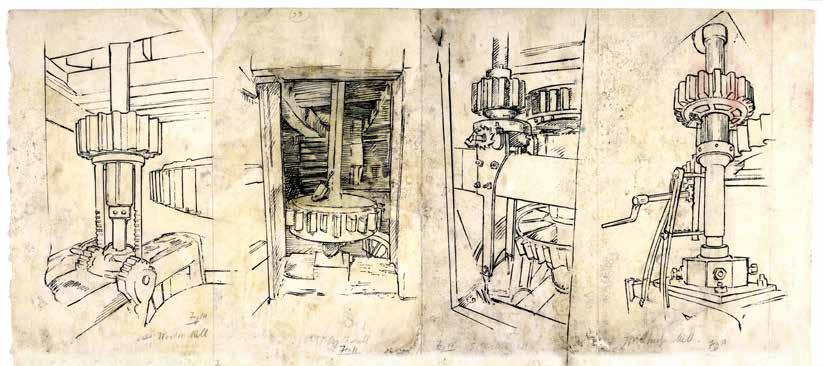

by Mildred Cookson, Mills Archive Trust, UK

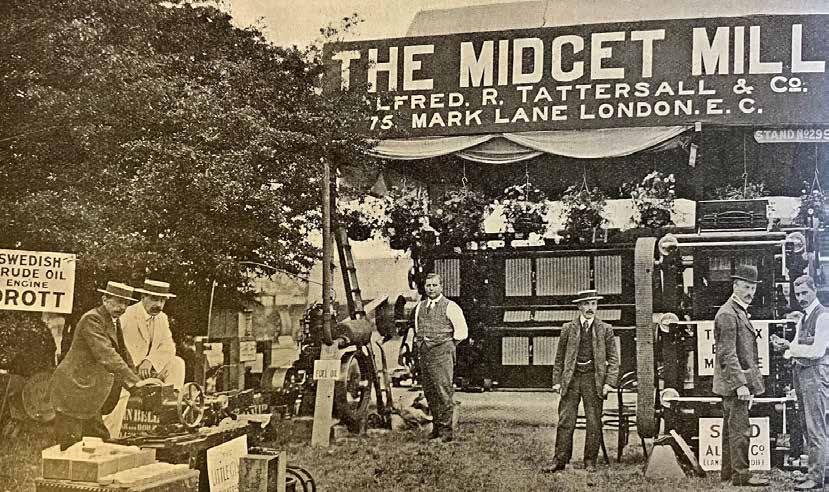

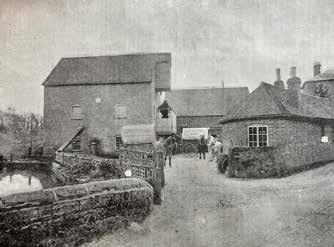

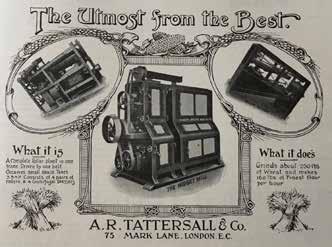

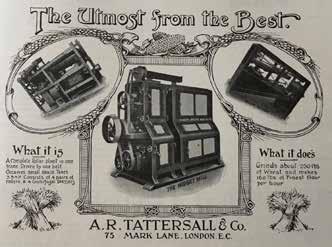

By the 1895 report in “The Miller”, this Surrey mill had been owned by Mr Burrows for several years. The illustration shows it from the road to Earlswood. This building replaced an earlier one destroyed by fire in the early part of 1887. After rebuilding, the mill was to work on Tattersall’s system.

The Tattersall machine consisted of three pairs of rolls, grooved suitably for effecting the first, second and third breaks. The product treated by the first set of rolls fell onto a sieve covered with wire and inclined at an angle which could be regulated as required. This sieve was carried on ash springs at the sides. It was moved by the rotation of a cam of 8 sides, which imparted a vertical vibration and lightly throwing the products upwards, then falling at a right angle. The sieve was remarkably effective in the rapid separation of the bran from the broken floury

particles. The overtails fell to the second break where the products went to a second sieve and then to a third pair of rolls underneath which was a centrifugal for taking out the flour.

The overtails of this machine were treated on a sifter, dividing the bran into three sizes. The throughs of the first and second break sieves fell to another centrifugal which ran parallel with the bran centrifugal, the flour joining the bran flour in a worm common to both. The overtails of this centrifugal were semolina to be treated on a middlings purifier on the third floor, where they would be reduced on smooth roller mills. The wheat was cleaned on a scourer and brush installed on the first floor. A Dickey sieve was also here to separate the germ.

The mill was driven by a 10hp high and low pressure condensing engine of the beam type built by Thomas Horn and Sons, engineers and millwrights of Waterloo Road, London S.E. The engine was fed from a boiler made Whitmore & Binyon of Wicken Market and Mark Lane.

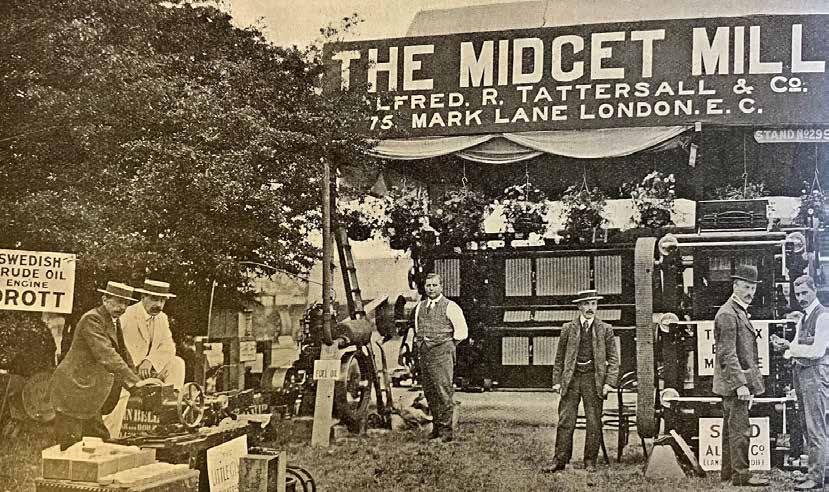

Drott crude oil engine driving Tattersall’s Midget Mill at Bristol Show

Drott crude oil engine driving Tattersall’s Midget Mill at Bristol Show

advertisement

Tattersall 1896

26 | March 2024 - Milling and Grain

Tattersall’s Midget Mill (1925)

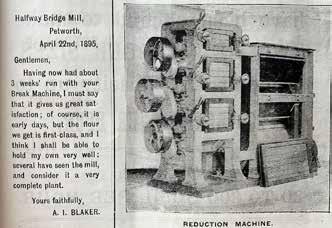

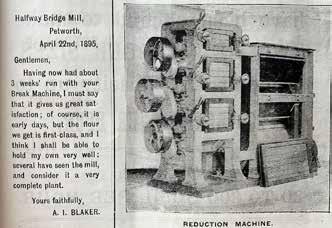

AJ Blaker’s Halfway Bridge Mills, Selham

In 1896 “The Miller” considered that nothing was more remarkable at that time in the history of flour milling than the resurrection of the small country mill. The roller revolution had taken place and automatic roller plants of from five to 20 sacks capacity were being erected at all points of the compass. Although many country mills ceased to be, roller systems made their way into many such mills until the humble but thriving 1-2 sack roller plant was no longer a rarity.

A typical mill of the time was the Halfway Bridge Mill, situated in the pretty county of Sussex. The mill, owned by Mr Blaker, stood in Lodsworth parish about a mile and a quarter from Selham station. Besides this mill, Mr Blaker also worked another mill, Lodsbridge Mill, about three quarters of a mile away on the Selham Road.

Lodsbridge mill was on the river Rother, and powered by a pair of waterwheels which provided all the motive power needed. Here all the gristing and barley grinding was done; the equipment included 3 sets of millstones. There was also a wheat cleaning system, a scourer, a trieur cylinder and a smutter through which all the grain intended for use at the Halfway Bridge Mill was first passed.

This gristing mill also served the useful purpose of a granary and preliminary cleaning department for the Halfway Bridge Mill. A tablet let into the wall could be seen by visitors entering the yard and dated the mill from 1872. A bakery, shown on the right foreground in the illustration, turned 50 bushels, or 10 sacks of flour into bread. The window at the end of the building was Mr. Blaker’s office. The building in the background, at right

Blaker’s endorsement for Tattersall

Blaker’s endorsement for Tattersall

Milling and Grain - March 2024 | 27

Tattersall 1896 advertisement

angles to the mill, was the warehouse for both flour and grain.

Motive power was provided by both water and steam. The water drove a breastshot waterwheel, which, with a full 14 ft head, could give around 7 hp. Added to this, a semi portable combined boiler and engine by Marshall Sons & Co., of Gainsborough, was installed in a building parallel with the mill but separated by a stout wall.

In 1896 the millstones were supplemented with smooth rolls for treating the semolina and middlings, whilst a purifier was added as well as centrifugal reels. This combination succeeded so well that Mr Blaker resolved to equip his mill with an allroller plant and chose the ‘Tattersall’ complete break machine.

On the ground floor a purifier stood beside an offal divider, consisting of a rotary sieve hung from the ceiling. There were three double elevators in the mill, two of which were on this floor, while the feet of the other were hidden by the flooring. The ‘Tattersall’ mill combined break machine of one sack per hour capacity, which was fitted three pairs of rolls 12 inch by 6 inch. The mill stood in the middle of the floor behind which were two sets of reduction mills fitted with two pairs of smooth rolls each, to do the four reductions of the semolina and middlings. Over the second roller

fed to the fourth reduction, while the tailing passed to the offal sack.

On this floor remained two pairs of millstones that could be used as needed. A ‘Victor’ smutter was fed from the dirty wheat bin on the floor above was also installed here. On the second or top floor a lucam provided the means of hoisting the grain into the mill where there were three bins. The equipment on this floor also included four centrifugals.

I have included two illustrations of Tattershall’s Midget Marvel

Tattersall’s catalogue

Tattersall’s catalogue

Milling and Grain - March 2024 | 29

H Burrows & Co Salford Mills, Horley

Looking to reinvent your feed mill? We’re listening.

As industry experts, we understand the unique challenges you face in the animal feed industry. That’s why we are committed to assist you throughout the entire journey, from concept to complete installation So, what’s on your mind?

Let’s talk opportunities

Fane Valley, Ireland

www.ottevanger.com

»

rising 39.5 percent to 7.56 million tons, accounting for 69.5 percent of total wheat imports.

Wheat imports from Ukraine have increased to 1.28 million tonnes after dipping to 845,587 tonnes in 2022, with last year’s shipments accounting for 11.8 percent of imports.

Soliman added that imports rose partly because GASC was buying more wheat to sell to the private sector through a new commodities exchange.

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

by Dr Mahmoud Riyad, Secretary-General, Egyptian Milling Association, Egypt

Egypt’s wheat imports rebound after a dip in global prices

Egypt’s wheat imports rose by more than a million metric tonnes in 2023, data seen by Reuter shows, with traders citing a dip in global prices from highs reached after Russia invaded Ukraine.

One of the world’s top wheat importers, Egypt uses the grain it buys for heavily subsidized bread available to more than two-thirds of the North African nation’s 105 million population.

The data showed that Egypt imported about 10.88 million tonnes of wheat in 2023, up 14.7 percent from 9.48 million tonnes in 2022.

That was mainly because shipments delivered to state buyers, the General Authority for Supply Commodities (GASC), jumped by 26 percent to about 5.6 million tonnes.

Imports by the private sector rose 1.3 percent to 5.12 million tonnes.

“Imports in 2022 were extraordinarily low because of high prices and the FX crunch following the war in Ukraine when importers couldn’t buy as much,” said Hesham Soliman, president of Egyptian merchant Mediterranean Star.

The growing population and rising demand could have led to a bigger increase in wheat imports but for Egypt’s chronic shortage of foreign currency, he said.

Egypt’s total wheat imports fell 18.7 percent to about 9.5 million tonnes in 2022, estimated to be the lowest since 2013, as the war in Ukraine disrupted GASC’s wheat purchases, caused a spike in global prices, and exacerbated a foreign exchange crisis in Egypt that left private importers unable to pay for wheat stuck at ports.

Most of Egypt’s 2023 imports came from Russia, with shipments

Trading on the Egyptian Mercantile Exchange(EMX) began in November 2022 to tackle private-sector price distortions after a spike in the price of unsubsidised bread.

GASC, mainly responsible for importing subsidised bread, can help private sector mills by selling them wheat from its reserves.

The authority has sold 1.2 million tonnes since the launch of the exchange, about 1.1 million tonnes of it in 2023, EMX Chairman Ibrahim Ashmawi told Reuters.

“GASC increases its purchases to secure the country’s needs,” said Ashmawi. “Part of boosting reserves is maneuvering when there’s a market shortage, so it sells on the exchange.”

Ashmawi added that he does not expect GASC to increase purchases specifically for the commodities exchange but it would do so if needed.

The data seen by Reuters shows total deliveries, not purchases, of wheat shipments to Egyptian ports in the previous calendar year and are not official figures.

However, Ashmawi this month told domestic media that the total 2023 imports were about 11 million tonnes.

Egypt doesn’t plan to implement a hedging policy against wheat imports in the new fiscal year 2024-2025, because of the recent drop in prices, Supply Minister Ali El-Mosilhy said.

“Current wheat prices have decreased to levels nearing those before COVID-19 and the war between Russia and Ukraine,” the minister told Bloomberg in an interview.

Egypt, one of the world’s top wheat importers, has signaled numerous times in recent years that it planned to start hedging the grain in order to protect itself against higher prices. The country relies on subsidised wheat to feed its population.

Egypt’s stockpiles are sufficient for 4.2 months, with the country importing 6.5 million tons to seven million tonnes of wheat per year, El-Mosilhy added.

Separately, according to the minister, vegetable oil inventories are sufficient for 5.1 months and sugar stockpiles for 5.4 months.

5 continents 30+ years of evolution 300+ projects delivered The technology that pushes the limits of storage Vibrafloor Z.A. 27 rue de la Tuilerie 71640 Dracy-le-Fort Tél: +33 (0)3 85 44 06 78 vibrafloor@vibrafloor.com www.vibrafloor.com UNIVERSAL RECLAIM SYSTEM Together, let’s prepare your future projects! Milling and Grain - March 2024 | 31 Milling News

dsm-firmenich to separate out Animal Nutrition & Health business from the group

dsm-firmenich has announced the initiation of a process to carve-out and separate out the Animal Nutrition & Health (ANH) business from the Group. ANH is driven by different dynamics from the rest of the group, which has become even more apparent with the unprecedented challenges in the vitamins market. The company believes that the full potential of the ANH business could be best realised through a different ownership structure for which all potential separation options will be considered. The company would expect to be in a position to separate the business in 2025.

Dimitri de Vreeze, CEO of dsm-firmenich, commented: “Our purpose at dsm-firmenich is to bring progress to life, as we boost innovation in premium, high-growth and resilient segments. ANH is a fantastic business that over the years we have built to be a true leader in the industry. This is a difficult moment, but we strongly believe that a separation would be better for both businesses and their employees, and ultimately generate better value for all our stakeholders.”

A separation would enable dsm-firmenich to strengthen its position as a world-leader in nutrition, health, and beauty. By fully focusing on Perfumery & Beauty (P&B); Taste, Texture & Health (TTH); and Health, Nutrition & Care (HNC), the company can further develop its complementary world-class scientific research,

technologies, and manufacturing excellence. Full focus on these businesses is expected to enhance their commercial potential and synergies, supporting an attractive and consistent growth outlook alongside robust margins.

The perimeter of the ANH business expected to be separated out is being reviewed as part of this process. Given Beaver’s critical role in reducing emissions across the dairy industry, an important segment for TTH, and Veramaris’ significant potential in dietary supplements, it is expected that both businesses would remain part of the group.

Ivo Lansbergen will continue to lead the ANH business. He joined in 1997 and led ANH since 2019.

Ivo Lansbergen, President, Animal Nutrition & Health, commented: “We have an amazing team within ANH that has built a global leader with scale, a unique portfolio and unrivalled innovation capabilities to help our customers tackle some of the most challenging food security issues and with a strategy that is strongly focused on making animal farming sustainable. It is an exciting prospect for our world class team to pursue our ANH strategy.”

ANH is a world leading business with the most complete ingredients portfolio ideally positioned to support a growing population through more sustainable animal farming. Headquartered in Kaiseraugst, last year ANH delivered more than EU€3 billion in revenues with

BECAUSE IT’S ABOUT TIMING

Determine the nutritional quality of your feeds and raw materials – fast, reliably, and at the best quality.

Reliable and timely information about the nutritional value of your raw materials and products allows you to optimize your processes and gain a competitive advantage based on verifiable superior quality. AMINONIR ® is the number 1 in amino acid analysis with a track record of over 20 years.

Sciencing the global food challenge. aminonir.evonik.com

9804-02_AZ_AMINONir_190x132_EN_Milling-and-Grain_240108-1.indd 1 08.01.24 15:33 32 | March 2024 - Milling and Grain Milling News

approximately 6000 employees. It helps its customers to deliver healthy animal proteins efficiently and sustainably whilst harnessing the power of data to make animal farming practices more sustainable, productive, and transparent. The business has a unique premix network across the world that helps deliver global products with local solutions and benefits from precision services capability.

The global vitamins market has experienced a prolonged downturn which has been driven primarily by unprecedented cyclical pressure on vitamin prices in the animal markets. This has been partly mitigated by strong outcomes from the performance solutions business which provides important tools for farmers to deliver feed efficiency yield management. By separating ANH, dsmfirmenich’s exposure to future vitamin earnings volatility would be reduced.

As part of the vitamin transformation program announced in June 2023, the company continues to make significant progress on its cost reduction plan including plant closures, route-to-market simplification, and optimised service levels. The company remains confident in realising a contribution of EU€100 million in adjusted EBITDA in 2024 and the full benefit of EU€200 million in 2025.

During the process, dsm-firmenich remains committed to the ANH business, its market-leading team and to providing excellent service to customers as the business transitions to a new ownership structure to deliver its full potential.

Milling and Grain - March 2024 | 33 Milling News

Omas Industries announces expansion into UK and Northern Europe

Omas Industries, the Italian company specialising in machinery and plants for the milling industry based in San Giorgio delle Pertiche, Padua, is excited to announce its entry into UK and Northern Europe market. This strategic move comes at a time of remarkable growth, with the company experiencing a consistent increase in orders and pursuing an ambitious hiring plan to strengthen its international presence.

Omas Industries stands as one of the few Italian companies operating in the milling industry. The newly formed entity, ‘Omas Northern Europe’, will be spearheaded by Peter Marriott, former Sales Manager EMEA of a leading global manufacturer of equipment for the rice, wheat, and corn industry, with over 30 years industry Experience.

“I am very honoured that such a remarkable and experienced milling expert like Peter chose Omas and I’m sure that he will contribute to promote our technologies and presence in the market, providing support to the customers”, said Pietro Barbalarga, Sales Director of Omas Industries. This expansion decision reflects a bold step in line with the growing market demand for innovative solutions in the grain milling sector. Now more than ever, the industry requires efficient and flexible production

through the adoption of automation and digitalisation processes within the facility. This translates into increased energy efficiency, improved production quality, energy savings, and waste prevention. Notably, this vision aims to modernise a traditionally conservative sector, leading to a smart factory capable of providing technological advances to customers around the world.

34 | March 2024 - Milling and Grain Milling News

Luigi Nalon, CEO of Omas Industries, states:

“The milling industry must embrace new production methods and products, making it easier to adapt to changes in consumer lifestyle, achieving global goals of carbon reduction and protecting the environment”. “It is a great pleasure for me to join Omas” comments Peter Marriott, the new General Manager of Omas Northern Europe “I was deeply impressed by Omas’ technologies, especially the Flexy Mill, which allows the modification of different parameters during the grinding process, adapting the mill to various types of grains and legumes without compromising performances and product quality. Thanks to permanent magnet torque motors, the miller can increase or decrease the peripheral speed of both grinding rollers, change the grinding ratio and the rollers’ operating position, adjust the grinding gap,create recipes, and more. I strongly believe Omas’ innovative solutions

1 27/01/22 10:59

can bring significant enhancements in the UK and Northern European market”.

The success of Omas Industries’ machinery and Flexy Mill has been recognized by some of the world’s most renowned producers of flours and industrial machinery, including Moulins Soufflet, EB Bradshaw & Sons, Panhandle, Agricultural Commodities and, in Italy, Molino Favero. For these projects, Omas has provided machinery or implemented turnkey plants, contributing to improve turnover and profitability.

In addition to pursuing commercial success, Omas is deeply committed to sustainable innovation. Ongoing research and development not only enhance production efficiency but also contribute to reducing environmental impact, showcasing a tangible commitment to a more sustainable future in the cereal transformation process. Gabriele Nicoletti, Omas Technical Director, explains “Omas continuous innovation and development is focused to enable customers to produce new products with advanced milling machinery. More than ever, it is imperative to meet the requirements of food safety, energy efficiency and traceability during the production process”.

“Omas is ready to offer its expertise and cutting-edge technology to a market thatcontinues to show growing interest in advanced solutions, carving a niche among traditional milling methods” continues Nalon. “With the addition of Peter Marriott to our team, we believe that our products will benefit from his expertise, making a positive impact in the UK and Northern European market”.

pubblicità italiana_MOD.pdf

Milling and Grain - March 2024 | 35 Milling News

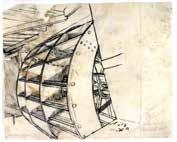

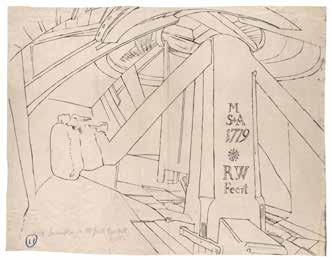

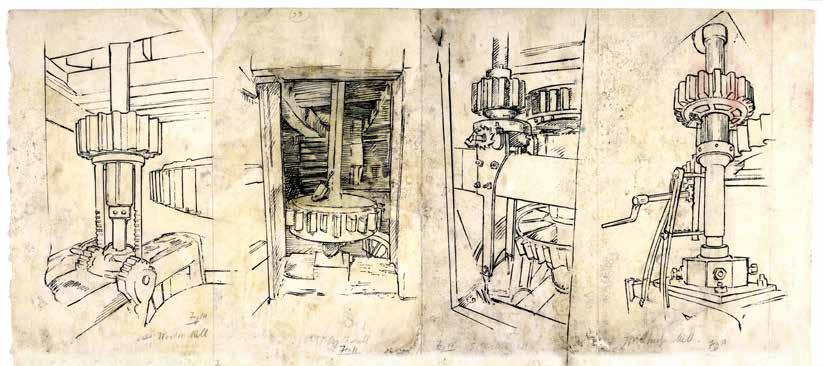

Gems from the Mills Archive Mill sketches by Thomas Hennell

by Nathanael Hodge, Mills Archive, UK

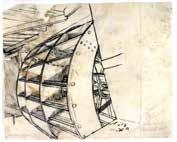

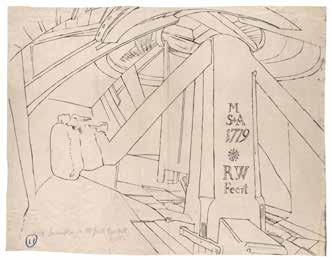

These sketches, showing the machinery in wind and watermills, were drawn by artist Thomas Hennell and rescued as part of the Rex Wailes collection, now preserved by the Mills Archive.

Hennell was born in 1903 at Ridley in Kent, the son of a vicar. His happy childhood in idyllic countryside surroundings gave him a deep love of rural England and its historic crafts. He studied drawing and painting and sought to capture the traditions of farming and country life in his art, publishing his first book of illustrations, Change on the farm, in 1934.

Hennell first made contact with Rex Wailes in 1927, writing I understand that you are interested in the subject of windmills, and are thinking of writing a book on them, and offering his services to provide illustrations. This was the beginning of a long correspondence, interrupted only by Hennell’s period of mental illness and time in a psychiatric hospital in the early thirties. Hennell later wrote about the bizarre and surreal hallucinations and delusions he experienced during this time in his book The Witnesses.

The planned book with text by Wailes and illustrations by Hennell sadly never saw the light of day. Commissioned as a war artist, Hennell was sent to work in Iceland, and after D-Day to depict the invasion of Europe. In 1945 he was sent to the Far East, visiting Burma, India, Sri Lanka and Singapore. With the surrender of Japan the war was now over, but Hennell went on to Indonesia, arriving in Surabaya, Java, in October 1945. Here a conflict was brewing between the Dutch colonists of what had been the Dutch East Indies and Indonesian nationalists. It seems the nationalist fighters surrounded the house where Hennell was staying and took him captive. He was never heard of again.

The sketches shown here were part of a mass of material left by Rex Wailes in the sheds at the bottom of his garden. Unsurprisingly storage in these conditions for many years did not leave the material in a good state – when Alan Stoyel took it upon himself to rescue the collection, he reported that “much of the

material was damp, quite a lot was actually sopping wet and full of mould and small animal life, and some had been attacked by mice”.

Alan spent many hours drying and cleaning the material, and then sent part of it to the Science Museum. Eventually in 2019 the whole collection was reunited at the Mills Archive.

Thanks to a grant from the National Manuscripts Conservation Trust, we were able to get this and a number of other drawings professionally cleaned and conserved.

www.millsarchive.org

36 | March 2024 - Milling and Grain

If you can think it, we can pack it!

With over 150 years of combined experience, we help you find your individual packaging solution. Over the years, we have developed machines that cover a range of weights from 50 grams to 25 kg for flour based products. In addition, we help you meet global environmental challenges without compromising on performance.

The Packaging Group GmbH · Germany · www.tpg-packaging.com

Let’s create your perfect flour packaging solution!

55 million m3 built Projects in 150 countries

New pendular and rotative sensors

ATEX 20 certified, the zone with the highest risk

· SY-DP1 Pendular . Robust and simple. It does not require power and maintenance.

· SY-DR1 Rotative . Sensitive. It has 2 operating modes depending on the density of storage material.

Top Project worldwide Flexibility and adaptability

symaga.com • +34 91 726 43 04 • symaga@symaga.com

A reliable

reliable

YOUR RELIABLE PARTNER

team for a

project

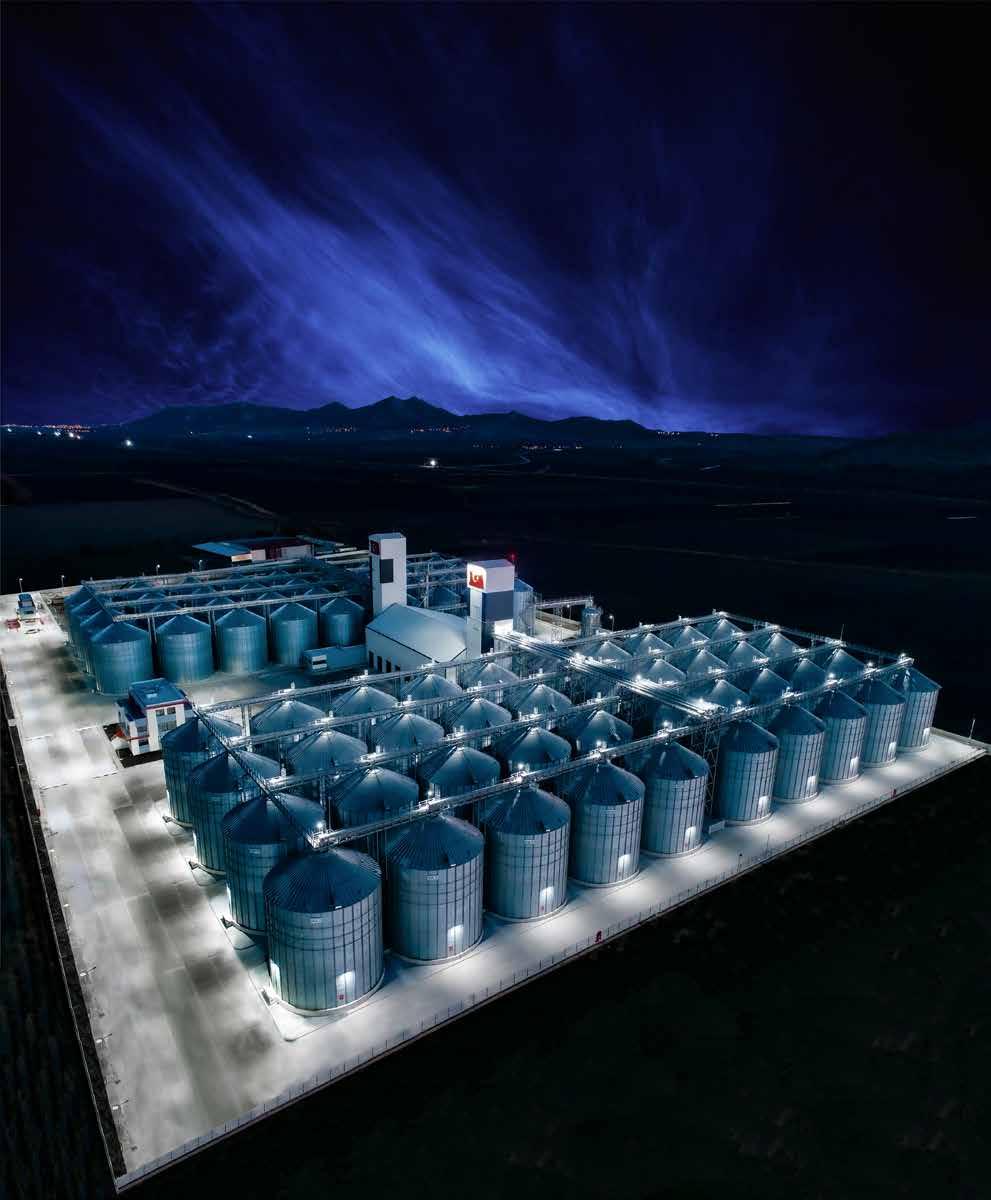

Cesco CEO delivers keynote address at IAOM MEA

Martino Celeghini, CEO of Cesco,

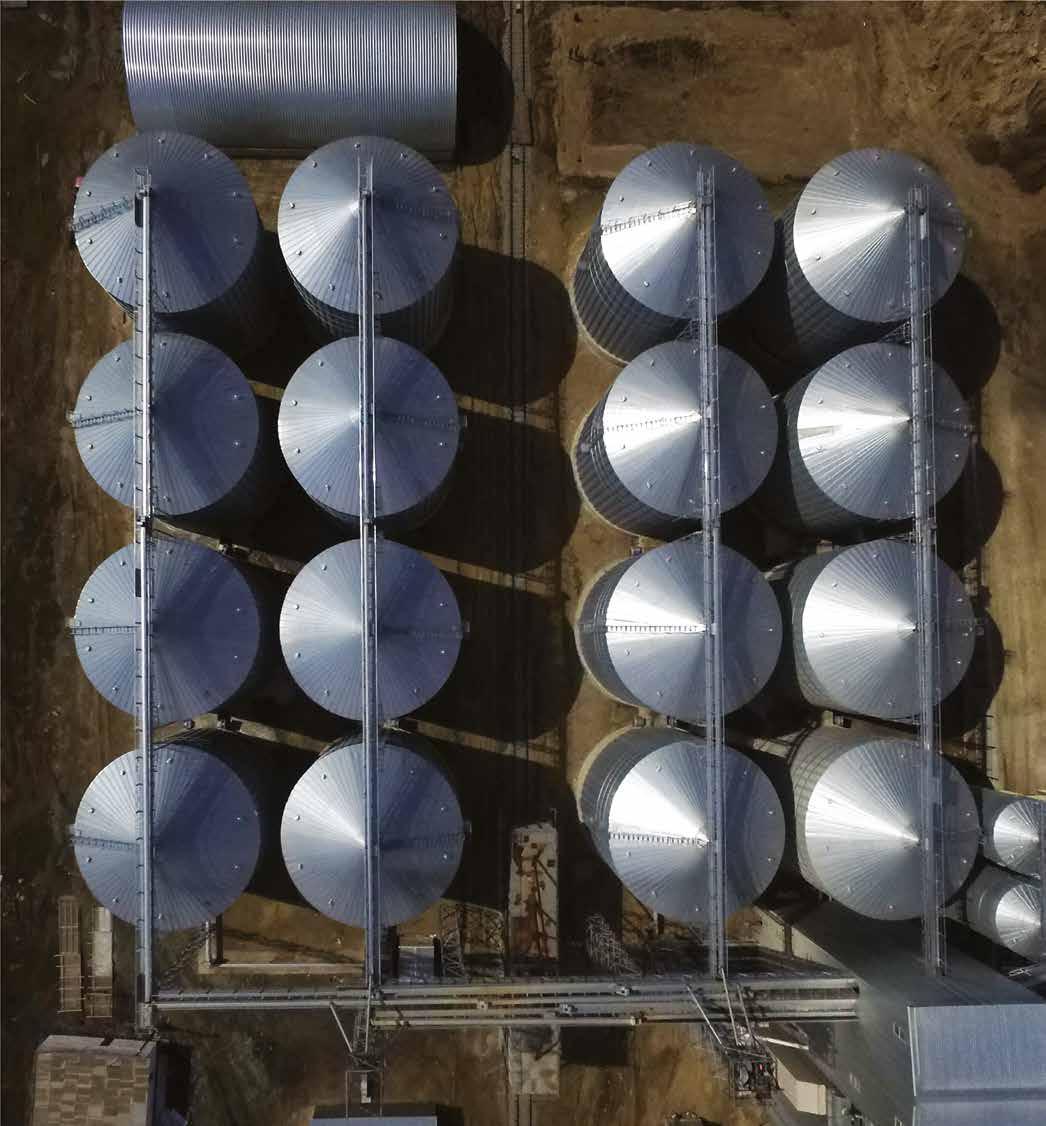

shared insights at the IAOM MEA Regional Milling Forum on crucial aspects of silo design and operation in industrial storage plants. Focusing on enhancing food security through efficient grain storage, the presentation explored various considerations from soil evaluation to operational safety measures.

The discussion began by stressing the vital role of grain storage in food security. Traditional methods, such as using gunny bags in warehouses, were deemed inadequate due to losses from rodents, grain deterioration, and pilferage. Modern storage facilities were presented as offering comprehensive solutions to protect grains and address food security concerns.

The significance of integrated plant design in silo operations was underscored, emphasising structural, architectural, and management design criteria as foundational elements for successful investments. Additionally, functional and operational design considerations, including process flow, product nature, and automation levels, were outlined.

Key factors influencing silo design were thoroughly examined, highlighting the importance of soil evaluation, including deep-water level analysis, to optimise excavation and foundation costs. Local regulations, particularly structural calculations for wind and seismic loads, were emphasised for their impact on design and investment costs.

Various types of silos, including raw material and process silos, were explored, discussing the advantages of different bottom designs in terms of investment, loading cycles, and contamination risks. Operational measures for safe storage were thoroughly examined, covering FIFO (First In, First Out) management, regular monitoring, effective cleaning, and pest control. Strategies for maintaining proper moisture content, controlling temperature, and implementing monitoring systems were highlighted to ensure material integrity and safety.

The presentation concluded with a call for integrated design approaches that consider both silos and steel structures, aiming to optimize static cooperation, simplify foundation design, and reduce unnecessary costs.

• Protection against insects & fungi • Without chemical treatment • Short amortisation period • Independent of ambient wheather • Low energy demand • No respiratory losses The natural way of grain preservation frigortec.com Made in Germany GRANIFRIGOR™ Grain cooling Milling and Grain - March 2024 | 39 Milling News

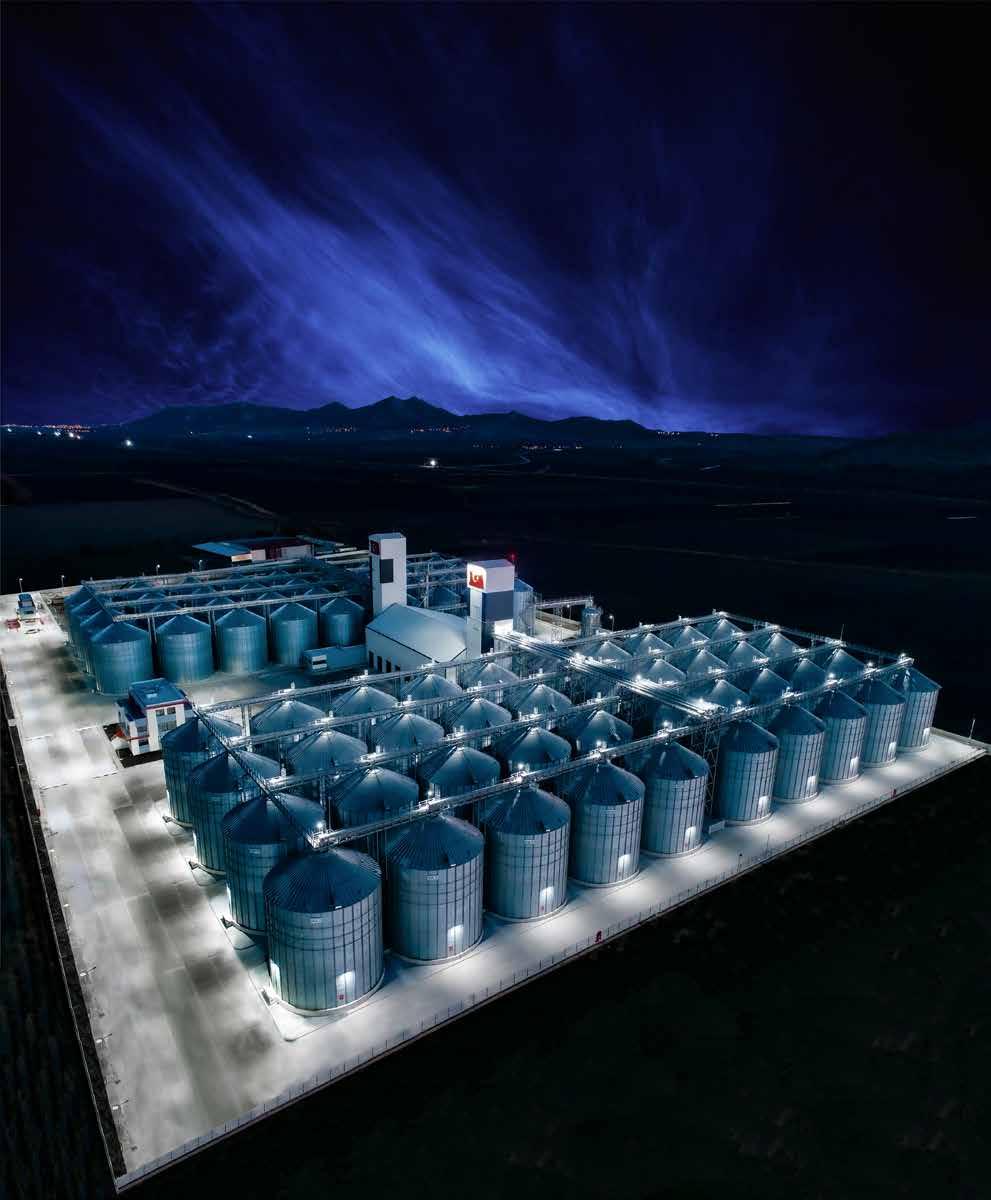

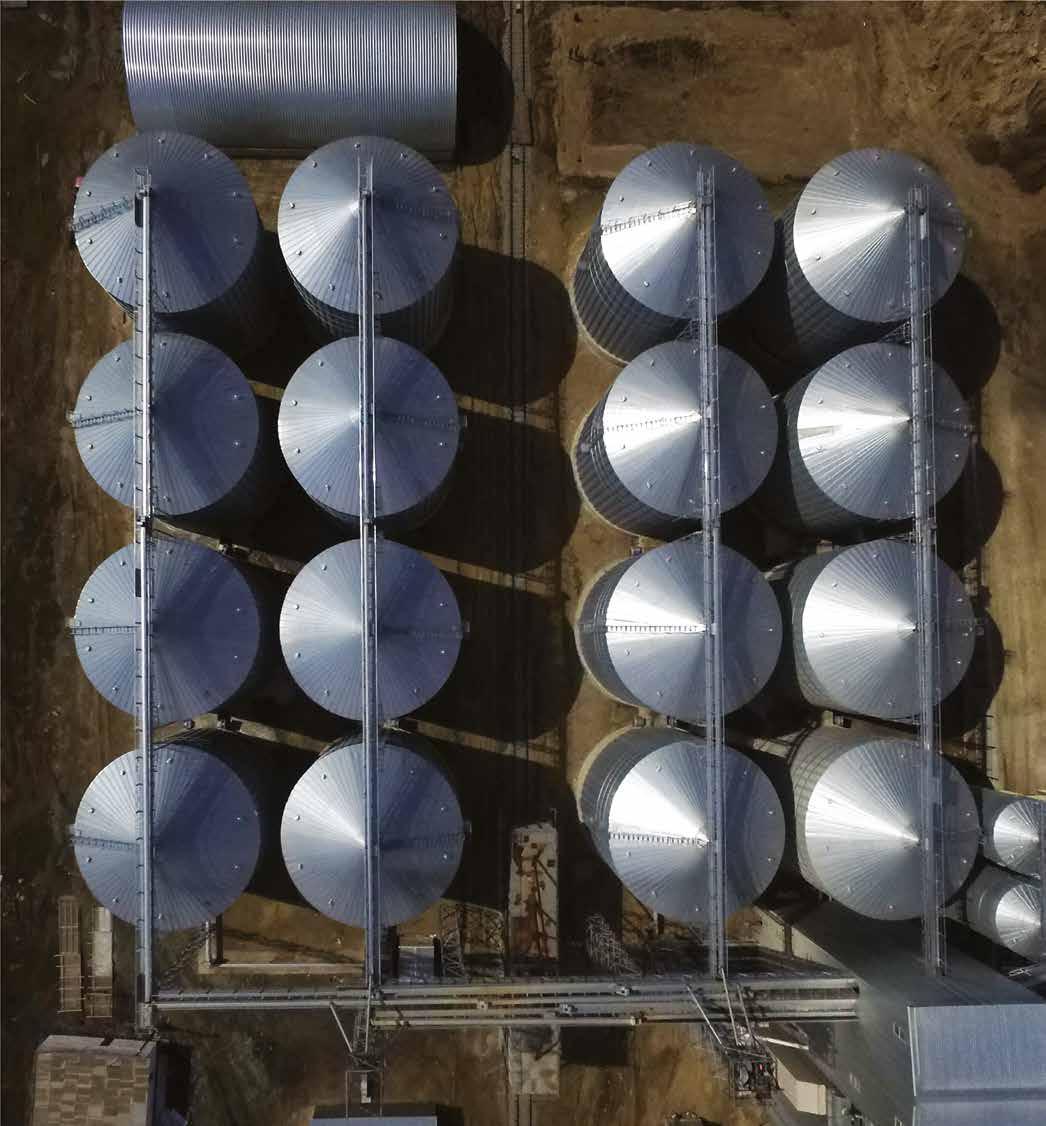

Ocrim acquires SIMA

Ocrim S.p.A., a Cremona-based company, top player in the milling sector, announced the acquisition of SIMA s.r.l. (Spresiano - TV, Italy), another key player in the panorama of storage facilities. This operation marks a significant step in Ocrim’s growth strategy, consolidating its position as a key player in the construction of milling plants, through the direct and specialised offer of complete solutions for storage plants.

Over the years, Ocrim has earned a global reputation for providing advanced technologies and cutting-edge services in the milling industry. The company has been a pioneer in integrating technological innovation with the practical needs of milling companies, offering tailor-made solutions that improve efficiency, quality, and sustainability in the processing of wheat, corn and cereals in general.

The acquisition of SIMA s.r.l. - specialised in the design and construction of storage systems that guarantee the optimal conservation of raw materials and finished products - was a strategic move aimed at expanding Ocrim’s offer and responding to the growing needs and requirements of the market. The integration of the skills of SIMA - present in the sector for over forty years - will allow Ocrim to offer complete solutions, covering the entire production chain, thus integrating the storage of cereal and finished products in the mill.

Ocrim CEO Alberto Antolini says “This acquisition represents an important step in our growth strategy.

Above: One of Sima’s plants

Below: From left: Sergio and Alberto Antolini, respectively President and CEO of Ocrim

With SIMA’s experience and expertise, we are ready to reach new levels of excellence and meet the growing needs of our customers and to respond to the increasingly complex requests of the market which is looking for loyal, strong, and complete partners”.

The acquisition represents an exciting chapter in Ocrim’s success story. With a future-oriented vision and an ongoing commitment to innovation, Ocrim is preparing to reach new heights of excellence in the global milling market.

A SQUARE APPROACH FOR A WORLD WITHOUT FOOD WASTE.

DISCOVER OUR TAILORED SOLUTIONS ON OUR WEBSITE SCE.BE Milling and Grain - March 2024 | 41 Milling News

APPROX 40 MILLION TONS OF GRAIN IS SAFELY STORED IN MYSiLO SILOS.

CONTINENTS more COUNTRIES than 5 80’

more more CUSTOMERS PROJECTS than than 2000’ 2500’ HAPPY WITH MYSiLO GRAINS MYSiLO GRAIN STORAGE SYSTEMS INC.CO. Erenler OSB Mah. R. T. Erdoğan Blv. No: 30 Aksaray / TURKEY info@mysilo.com | www.mysilo.com | +90 382 266 22 45

Distance learning Distance learning PROGRAMME

We will be seeking enrolments from June ...

Spread over the study year, the cost of a module is less than £12 a week

Study increases competence thereby freeing up your time

All students are allocated a tutor with a wealth of specialist knowledge

C O S T E F F E C T I V E

T I M E E F F I C I E N T I N D U S T R Y E X P E R T I S E

F I N D O U T I F S T U D Y W I T H U S I S R I G H T F O R Y O U A N D Y O U R T E A M W E ' R E H E R E T O H E L P - F I N D O U T M O R E O N L I N E O R E M A I L U S : W W W . U K F L O U R M I L L E R S . O R G | T R A I N I N G @ U K F L O U R M I L L E R S . O R G

28th Annual Practical Short Course on Snack Food Processing

A one-week Practical Short Course on Snack Food Processing in cooperation with SNAC International will be presented on April 8-12, 2024, at Texas A&M University by staff, industry representatives and consultants.

The program will cover establishment of snack food facilities, operating principles of the three major types of extruders. This hybrid course offers an extensive look at the principles

and characteristics of extruders and support systems (drying, coating, packaging) for effective selection and operation. During this 4.5-day course, attendees will learn about establishment of snack food facilities, operating principles of the three major types of extruders, supporting equipment, fried corn and corn tortilla chips, friction extruder-puffed fried and baked snacks, single, twin-screw extruder snacks, high protein and whole grain snacks, cereal chips, fryers and ovens, packaging, and quality assurance. Participants completing the course will be awarded a certificate and are eligible for 30 professional development hours (PDHs). Reservations are accepted on a first-come basis. For more information, programs and application forms, contact: Mian N. Riaz, Ph.D, CFS, at mnriaz@tamu.edu

Milling and Grain - March 2024 | 45 TRAINING Mill

TRAINING Mill

KSU–GEAPS Grain Elevator Managers

The KSU–GEAPS Grain Elevator Managers course benefits individuals who are responsible for supervising grain managers. The course focuses on the science behind the practices used in grain management. It provides new managers with the information they need to correctly interpret the experiences they will have when managing grain quality, and the insight they will require when evaluating the practices used by their predecessors.

Course topics include personnel management; grain quality management; grain handling equipment; grain drying; grain operations costs; grain inventory management; grain receiving

and shipping; grain condition monitoring; grain aeration strategies; and fumigation.

Who Should Attend

Industry professionals who work in operations, procurement, management, or other grain holding roles.

Registration Information

The course date for this upcoming course is April 30 – May 3, 2024. The course fee is US$1,300, GEAPS members receive a 20% discount.

About the Organiser

The IGP Institute serves Kansas and U.S. commodity organizations through its global education centre housed in the Grain Science Complex on the campus of Kansas State University. This complex is home to the International Grains Program Conference Centre, Hal Ross Flour Mill, O.H. Kruse Feed Technology Innovation Centre and the Bio-processing and Industrial Value-Added Program.

We train the workforce of tomorrow. Expand your knowledge, exchange ideas and gain experience in our academies around the world.

Scan the QR code for more information.

millingacademy@buhlergroup.com

Let’s shape the future together

.

Innovations for a better world. 46 | March 2024 - Milling and Grain

Product Spotlight - The Holmen

NHP100 Portable Pellet Durability Tester

The Holmen NHP100 is Tekpro Limited’s entry level pellet durability tester used for calculating the Pellet Durability Index, also known as the PDI, of feed pellets by simulating pellet transportation environment from mill to trough.

Mesh pellet hopper

Pellets

Airflow

The complete Holmen range of Pellet Testers represent the culmination of over 20 years involvement within the pellet manufacturing industry

The range consists of four models including the ever popular Holmen NHP100, which is supplied complete with a 2.5mm diameter mesh hopper as standard, although other mesh sizes are also available to suit aqua, poultry and larger cattle feed types.

Versatile Pellet Test Machine

The Holmen NHP100 portable pellet durability tester is a truly versatile entry level machine. Being portable it can be easily transported between different testing locations, requiring only to be placed on a flat stable surface to provide basic results for the operator It works by loading a pre-sieved sample of pellets into the test chamber which cascades them in an air stream causing the pellets to collide with each other and the perforated hard surfaces within the test chamber When testing is complete the pellets are removed for manual weighing. The 'pellet durability index' (PDI) is the difference between pellet weight before and after the test recorded as a percentage. The tester provides the ability to manually calculate test results with limited repeatable accuracy The operation is totally manual with a basic timer function only, unlike the manufacturers more advanced Holmen NHP200 where test length is adjusted according to pellet diameter

Holmen Testers Increasing In Demand Globally

The basic NHP100 is a popular machine for smaller companies, but quality focused feed mills typically now prefer the NHP200, this is due to its ease of use and the repeatable accuracy of the test process. For larger companies who manufacture pellets in bulk, Tekpro can also provide the Holmen NHP300, together with inline samplers to test directly after the press, before too much product has been produced, this can significantly help reduce the need for rework, and optimise production efficiency

The NHP100 has always been a very popular machine since it’s original launch, but as feed mills further strive for greater levels of automation and consistent repeatability of processes, both the Holmen NHP200 semi automatic and NHP300 inline pellet durability testers from Tekpro have significantly increased in demand from all around the globe.

To access further free information on the entire range of Holmen Pellet Durability Testers, exclusively Made in Britain by Tekpro, or to find out how you could join the growing number of pellet manufacturers already using Holmen to check their PDI, scan the following QR code:

Made in Britain, Trusted Worldwide. We

are

FOCUS Product March 2024

In every edition of Milling and Grain magazine, we dedicate this page to taking a look at the products that will save you both time and money in the food and feed milling process.

Should you have a new product or service that you would like to feature on this page in a future edition of our magazine, be sure to contact us at editorial@ perendale.co.uk

NEW SIMILAGO II by Alapala

Alapala’s NEW SIMILAGO II roller mill is equipped with high technology electronic control systems for a continuous and consistent performance in the grinding of cereals, such as wheat, maize (corn), rye, spelt, barley and sorghum. The product level at the inlet bunker is controlled by using load cells, which sends signals via PLC to adjust the feed roll speed accordingly. Rotational speed of feed rolls is monitored against an unexpected stop due to belt problem, etc. Manual feeding gap adjustment mechanism ensures a uniform flow on feed rolls. The main motor load is constantly measured for protection against any possible damage, and the rotational speed of grinding rolls is monitored against an unexpected stop due to belt problem, etc.

The NEW SIMILAGO II is built to comply with the high sanitation standards and ensure food safety. The roller mill’s all front structure is isolated and smoothened against adhering and condensation risk.

Vane axial fans by GSI

For applications requiring high airflow at static pressures below 6” (depending on bin diameter), GSI offers vane axial fans in 12” diameter (1 HP) through 28” diameter (15 HP). Vane axial fans 18” and smaller use cast aluminium blades. Vane axial fans 24” through 28” use durable composite airfoil blades that are lightweight for easy starting and function well in this type of environment.

The 12” through 28” (1-15 HP) units feature a 3450 RPM motor for increased fan performance and energy efficiency. Close fan blade tip clearance and straightening vanes provide maximum air flow and reduced turbulence to ensure smooth and consistent airflow. All 24” and 28” vane axial fans also include a durable plastic inlet venturi which funnels air more efficiently into the fan.

Polybutadiene Rubber Ball by Rubtech Mech INDIA LLP

The company has conveniently developed Rubber Ball Sieve cleaners for edible materials which are for human consumptions; the basic Rubber compounds and specimen were duly tested by SGS & passed with distinction inconformity to all of the US FDA & EU regulations. This ball cleaners have been developed after consistent research in compound (recipe) designing with base elastomer Polybutadiene.

The resilience of this rubber balls is exceptional; thus, it leads to an extra yield of the sieving process. The abrasion resistance is very high; thus, the wear rate is minimal, leading to enhanced service life. The rubber compound used for these balls is Certified Food Grade as per US FDA, EU & Japan Regulations.

www.rubtechmech.com

“SF” Volumetric Screw Feeders by Essmueller

Volumetric Screw Feeders are used to control the flow rate of bulk material from a bin or hopper. They are designed to be flood fed, so that regardless of the amount of material in a hopper above the inlet, the outlet rate will remain consistent. Screw feeders are available to feed a wide range of materials.

Essmueller screw feeders are available in standard trough lengths, and in sizes to suit almost any need. They are available in single, double, triple and live bottom configurations. Multiple screws are used to control the flow rate of bulk material that tends to bridge a bin or hopper. Live bottom screw feeders are designed to be mounted under bins to control the flow rate of material that tend to pack or bridge. Tapered pitch or variable pitch screws are used in screw feeders to draw the bulk material evenly from all areas of inlet opening.

GRANIFRIGOR™ Europe by FrigorTec

The GRANIFRIGOR™ Europe range of grain cooling units are performance- and energy consumption-optimised for the temperature and humidity of European temperate conditions. They can be used to reliably cool grain in temperate climates (rain, fog, head and cold) - assured control of air humidity due to HYGROMAT™ automatic. Complete suitability and reliable operation even at high ambient temperatures due to safe refrigerants. The units have a standard medium pressure version - ideal for tower silos too.

FrigorTec grain cooling units are based on a sophisticated modular system and offer the following features:

Fully automatic Siemens S7 controller

Remote-controlled operation via FrigorTec app

Rigid, welded frame construction

Partially soundproofed housing UV-resistant external cable

Eyelets for lashing on every housing corner

Pressure-stable cooling air high pressure fans

Filters for the cooling air supplied to the grain

Compressors, for example from Bitzer/ Germany

Multi-coated steel parts

48 | March 2024 - Milling and Grain

mymag.info/FVCq www.frigortec.com www.alapala.com mymag.info/DcAR mymag.info/WoIG www.grainsystems.com www.grainsystems.com

http://essmueller.com mymag.info/ghaz

FOCUS Special

Sweep Auger

Decades of Sweep Augers by Denis

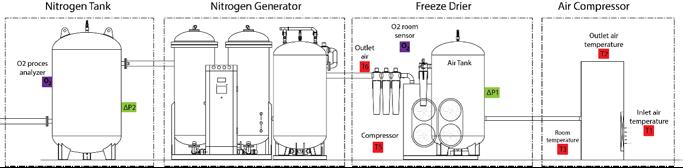

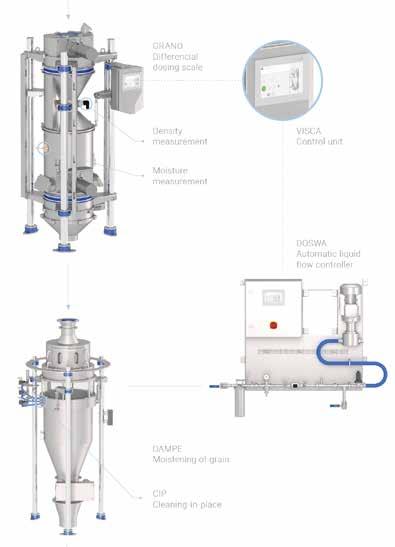

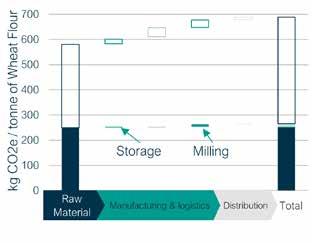

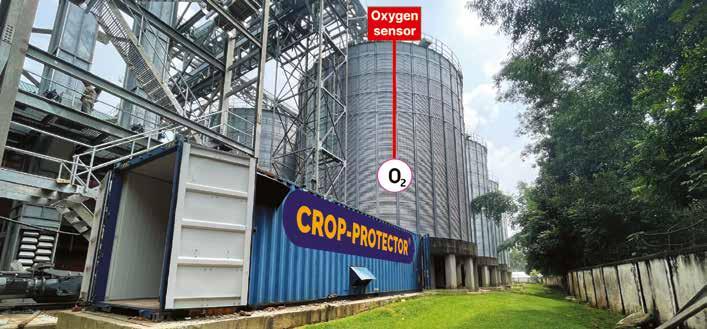

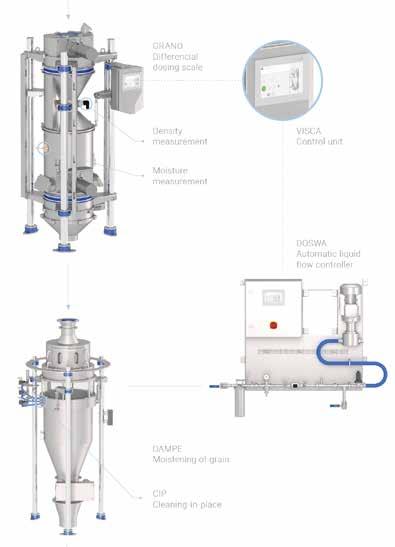

In 1973, the Sweep Auger version A was developed to empty grain cone in silos equipped with raised floors. This consisted of a Tubular Screw Conveyor, installed under the floor, driving a Sweep Auger via bevel gears and a clutch.