SUPPLIER SHAKE UP

From the world’s leader in diagnostic leak detection technology, the Battery + Coolant Leak Detector ensures that EV battery enclosures, battery coolant systems, and EV powertrain components are safely sealed to prevent intrusion of water, dust, and other contaminants that could cause a catastrophic thermal event.

BCLD pinpoints the precise location of all leaks with 100% accuracy. Innovative PurgePulse™ technology allows technicians to vacate all coolant fluid from the battery pack before testing. Live graphing and logging.

BCLD is mandated essential by OEMs in 160 countries and used by the makers of Amazon, Walmart, and UPS commercial fleet vehicles.

TO LEARN MORE CALL +1 (714) 451 - 1411 OR EMAIL SALES@REDLINEDETECTION.COM

May 17-18

Toronto, Ontario

The first EV & Charging Expo was held at the Enercare Centre at Exhibition Place in Toronto. It was hosted by Electric Autonomy Attendees were able to take in sessions on a variety of topics, listen to key industry figures and political leaders and check out dozens of booths from exhibitors offering charging equipment, advisory services, whole system solutions and more. There was also a test track for e-bikes and scooters, along with various electric vehicles from pickup trucks to cargo vans for attendees to experience.

Publisher | Peter Bulmer (585) 653-6768 peter@turnkey.media

Managing Editor | Adam Malik (647) 988-3800 adam@turnkey.media

Contributing Writers | Mike Bailey, Mark Sessions, Creative Director | Samantha Jackson

Video / Audio Engineer | Ashley Mikalauskas, Nicholas Paddison Sales | Peter Bulmer, (585) 653-6768 peter@turnkey.media Delon Rashid, (416) 459-0063 delon@turnkey.media

Production and Circulation | Delon Rashid, (416) 459-0063 delon@turnkey.media

EV World magazine is published by Turnkey Media Solutions Inc. All rights reserved. Printed in Canada. The contents of this publication may not be reproduced or transmitted in any form, either in part or full, including photocopying and recording, without the written consent of the copyright owner. Nor may any part of this publication be stored in a retrieval system of any nature without prior consent.

Canada Post Canadian Publications Mail Sales Product Agreement No. 43734062

“Return Postage Guaranteed” Send change of address notices, undeliverable copies and subscription orders to: Circulation Dept., CARS magazine, 48 Lumsden Crescent, Whitby, ON, L1R 1G5

CARS magazine (ISSN# 2368-9129) is published six times per year by Turnkey Media Solutions Inc., 48 Lumsden Crescent, Whitby, ON, L1R 1G5

From time to time we make our subscription list available to select companies and organizations whose product or service may interest you. If you do not wish your contact information to be made available, please contact us.

The move to a future of electric vehicles isn’t just a business change for the automotive aftermarket or the automotive industry as a whole.

The electrification movement is attracting what feels like every imaginable industry to automotive. From payment terminal companies to property management to business advisory services, those are just a few examples of organizations seeing an opportunity to cash in thanks to the expanding EV marketplace.

They’re hearing industry experts like Guido Vildozo, senior manager of Americas light vehicles sales forecasting at S&P Global Mobility, who advise that regulators are “not joking” when it comes to the mandate to stop the sale of gas-powered consumer vehicles by 2035.

The road to get there can be debated — does the deadline move; or are internal combustion engine vehicle sales held back to increase the percentage of zero-emission vehicles and make the math work? But we’re moving forward, of that there is no doubt.

So outside industries see opportunities. Which leads one to wonder: What about those inside the industry? What is the future of automotive aftermarket suppliers whose business relies on its components working with an internal combustion engine? There are fewer parts in an electric vehicle so we will eventually see a drastic reduction in demand for their parts.

This is not an attack on them but a hope that plans for the future are being made. Their market share still dominates. EVs make up not even a full percentage of vehicles in operation. So they’re doing fine today. But their market isn’t growing. How much longer will they be "fine?"

A special report from S&P Global Mobility, included as part of the cover story in this issue, highlights the need for suppliers to, in essence, get on with it. Make robust plans. End the denial.

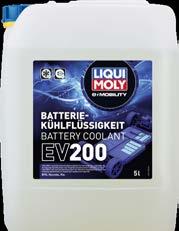

We’re seeing that from some traditional aftermarket players. Liqui Moly, which has made its name as an oil specialist, is one example. As it has expanded to other areas of chemicals, lubrication and additives, it's examining what liquids are needed for electric vehicles. It has developed several options.

Mahle is seeing opportunities in thermal management and electrification in general. It expects electrification to be a major driver of its bottom line as it offers more solutions in the area. It has teamed up with another company for battery services.

President & Managing Partner | Delon Rashid

Head of Sales & Managing Partner | Peter Bulmer

Corporate Office

48 Lumsden Crescent, Whitby, ON, L1R 1G5

Those are just two examples. There will be others. There should be others. There are many opportunities to transform as we move through the electrification cycle. There are emerging business prospects for a variety of industries. I bumped into two friends outside the industry at a recent EV expo because their companies are looking for opportunities pretty much in our backyard. Will we sit back while they move in?

Apart from shifting, S&P sees the following options for suppliers: Aim to be the dominant parts supplier, milk the cash cow dry and turn off the lights on the way out or set up to be acquired. Let’s see which path they take.

Adam Malik Managing Editor, CARSISSN 2368-9129 Online 2368-9137

There are a whole bunch of 1st gen BEVs out there with mileage above 60,000 km and will probably need some repairs. In areas where salt usage is high in the winter, brakes will corrode no matter what. The aftermarket needs parts now, not in 2030. The volume might not be high, but it is a real opportunity to secure customers early. We are having the conversations now with customers.

Shawn Greenberg, Seamless Auto CareWhy has nobody looked into the long-term costs of owning an electric vehicle? Raw material commodity prices are rising steadily causing price increases in new vehicles midyear. What is the long-term prognosis for future battery replacement costs? These projections will definitely hurt longterm ownership. Used EV sales will be an interesting topic after vehicles are five years old.

Bob Ward, The Auto GuysI’m sure it’s just a coincidence that Quebec is offering major cash bribes to customers buying EVs. It’s also nice that the rest of Canada is subsidizing such spending, as well as their cheap electricity. Everything is easy when someone else is paying the bills.

Geoff, reader

At the turn of the last century when the automobile was first invented, multiple forms of power were introduced concurrently. What developed were the technologies that made sense for the applications. It has never worked when change is legislated. There are too many applications where electric simply won’t work without negative economic impacts. Let technology develop the future.

Kim Stankiewicz, Performance InitiativesWith the government mandating these changes is there going to be some sort of subsidy or buy out for shop owners? When tobacco was deemed "bad" by the government, the farmers in my area received a buy out. It would only seem fair in this case to offer something since it is the government that has deemed the ICE as “bad.”

Doug Dykstra, Dykstra AutomotiveOur governments and manufacturers have done a tremendous job marking this commodity as a green vehicle. The truth is it is not only far from green but also it is not affordable for the average consumer. While EV technology has a place in our society, it is not for the average consumer. Our government and manufacturers are dependent on the average consumer to purchase this commodity for our economic stability. If the average consumer holds on to their vehicles longer than normal or gives up this commodity altogether because they can not afford an EV, our government and manufacturers are going to be in a whole world of hurt.

Rob Nurse, Bob Nurse MotorsNOW THAT CONSUMERS have more options for buying a battery electric vehicle, their focus is turning to more traditional factors that make up vehicle satisfaction, according to J.D. Power.

Factors like styling and quality are now top of mind as more mainstream — and affordable — options hit dealerships, the J.D. Power 2023 U.S. Electric Vehicle Experience (EVX) Ownership Study found.

“The electric vehicle landscape is changing quickly, and newer models are bringing in more mainstream, first-time EV buyers,” said Brent Gruber, executive director of the EV practice at J.D. Power. “Recent vehicle launches from both new brands and traditional automakers have had a profound effect on what factors are most important in the ownership experience. Today’s EV owners are looking for quality, reliability, driving enjoyment, safety and technology features.”

The study found a difference in what’s most problematic when comparing mass market and premium EVs. For the mass market segment, most vehicle owners reported most issues with the vehicle’s infotainment system. For premium EVs, most complained about squeaks and rattles

Public charging options also divided the segment. As Tesla is the leader in the premium segment, the company has its own network of chargers. Owners in this category to give a score of 589. But mass-market EV owners are relying on those installed by private companies or the government, giving this area a score of 341.

“The EV marketplace is dynamic and the important factors that manufacturers need to watch will vary based on their history and experience,” Gruber said. “First-time EV buyers who are more mainstream will compare their EV’s build quality to what they know about gas-powered vehicles.”

Towing satisfaction is up; notably, those who use their EV for towing are more satisfied than those who have not towed.

“Truck manufacturers that proactively communicate the effect that towing has on range — like they do with gas mileage — seems to help set owner expectations,” J.D. Power’s report said.

ABOUT ONE OUT OF every 11 vehicles bought in Canada in the first quarter of 2023 was a zero-emission vehicle, up almost a full percentage point compared to the same time last year.

While year-over-year data from S&P Global Mobility shows overall increases, a quarter-by-quarter analysis shows a possible shifting trend as the trajectory moves upward.

Battery-electric vehicles accounted for almost 7 per cent of market share, with total volume jumping by 19 per cent, S&P reported. Hybrids had an adoption rate of 8.7 per cent while plug-in hybrids had a share of 2.2 percent in the first quarter. The total number of ZEVs jumped by 18.2 per cent.

Internal combustion engines made up 82.2 per cent of the total share last quarter — a drop from 86.1 per cent reported in the first quarter of 2022.

However, when comparing S&P’s data from the first quarter of 2023 to the last of 2022, there has been a shift in which vehicles Canadians are moving towards. At the end of last year, BEVs had an 8.4 per cent share, hybrids had a 7.1 per cent adoption rate, while PHEVs were at 1.8.

So while year-over-year comparisons show growth across all segments, quarter-by-quarter analysis suggests Canadians are moving more towards a hybrid option.

Looking ahead, S&P observed that 41 new BEV models are scheduled to be launched in the Canadian market in 2024.

“These new models aim to target various vehicle segments, including the introduction of new entrants in the light-duty pickup truck segment, which addresses specific challenges for adoption where product availability is lacking (e.g. GMC Sierra EV, Hummer EV and Chevy Silverado EV),” it said.

That means there will be a greater number of options for Canadian consumers, S&P added.

A 1,400-KM corridor for electric vehicle charging stations is set to be built from Michigan and stretch into Quebec.

The joint binational alternative fuel corridor agreement was announced by federal Minister of Transport Omar Alghabra and U.S. Secretary of Transportation Pete Buttigieg. It will see EV charging stations every 80 kilometres along highways from Kalamazoo, Michigan to Quebec City.

Each station along the corridor — covering the I-94 through the Detroit-Windsor border tunnel, Highway 401 across southern Ontario, Highway 20 through Montreal and Highway 40 through to Quebec City — will be required to have at least one direct current (DC) fast charger along with combined charging system (CCS) ports.

There will be 61 stations between Detroit and Toronto and 154 between Toronto and Quebec City.

This new plan will expand travel capabilities for EV owners as well as reduce concerns around range anxiety.

“This first cross-border alternative fuel corridor will help drivers to travel across the border and charge or refuel worry-free,” Alghabra said in an announcement. “It contributes to bringing us another step closer to making our air cleaner while helping people save money on traditional fuels.”

AN INCREASING NUMBER of battery electric vehicles are being serviced at dealerships, leading to a decrease in overall customer service satisfaction, a study recently found.

Overall customer satisfaction with the service experience dropped, according to the J.D. Power 2023 U.S. Customer Service Index (CSI) Study. But the drop was led by owners of BEVs — owners of internal combustion engines were more satisfied.

Recall rates are more than double for BEVs compared to their ICE counterparts. Service advisor knowledge is also not as strong

when it comes to electrics. Both were reasons for customer service satisfaction among owners of BEVs being 42 points lower than among owners of ICE vehicles.

Overall satisfaction sits at 846 on a 1,000-point scale in this year’s study, a drop of two points.

A leading factor is that, as noted, recall rates are more than double for BEVs than their gas and diesel counterparts. Additionally, service advisor knowledge continues to be a major satisfaction issue among BEV owners who provide a rating of 8.01 (on a 10-point scale) compared with 8.59 among owners of ICE vehicles.

“As the electric vehicle segment grows, service is going to be a ‘make or break’ part of the ownership experience,” said Chris Sutton, vice president of automotive retail at J.D. Power. “The industry has been hyper-focused on launches and now these customers are bringing their electric vehicles in for maintenance and repairs.

“As training programs for service advisors and technicians evolve, EV service quality and customer experience must address both the vehicle and the unique customer needs. The EV segment has the potential to spur massive convenience improvements in how customers service their vehicles — but we’re not seeing the benefits yet.”

FORD AND TESLA HAVE agreed on a partnership that will see the Detroit-based automaker adopt Tesla chargers on its electric vehicles, making them accessible to Tesla’s network.

It’s a move that surprised many industry analysts who have noted Tesla’s preference to operate in its own bubble and ignore attempts to standardize the industry in areas such as chargers.

CEOs from both companies announced that future Ford EVs — such as the Mach-E and Lightning — will incorporate the Tesla connector from 2025. Current Ford EV owners in Canada and the U.S. will be able to access 12,000 Superchargers starting in the spring of next year via a CCS-to-Tesla connector.

Days later, GM announced a similar deal with Tesla. The move gives the automakers access to Tesla’s own network of charging

infrastructure, giving them a market advantage over other automakers that are only able to rely on public infrastructure.

In return, Tesla will keep a large portion of revenue from the charging stations.

COMMON CONSUMER complaints about electric vehicles seem to go by the wayside after purchase, a study has found.

Calling it the largest-ever survey of Canadian EV drivers, the Canadian Automobile Association also reported that an overwhelming majority would buy an EV again. But they are concerned about the lack of public charging options.

Other concerns like including driving range, cold weather performance and battery degradation drop after purchase, CAA found when asking more than 16,000 EV drivers across the country.

These drivers told CAA they spend 30 per cent of their time charging away from home. That’s why 44 per cent of them still worry about public infrastructure.

CAA also found that more than a third (36 per cent) are not confident about in taking road trips in their EV. Most EV drivers (67 per cent), it observed, still own a gas vehicle, which they are more likely to use for longer journeys.

"We know EVs are gaining sales, but a lot of people still have questions,” said Ian Jack, vice president of public affairs for CAA National. “We think this research — into the actual experiences of EV drivers in Canada — sheds an important light into where the real pain points are, and where potential buyers can perhaps worry less."

As for the concerns that did reduce, those around range fell 37 percentage points to 30 per cent; cold-weather performance concerns dropped 25 percentage points to 33 per cent; and fears about battery degradation fell 41 percentage points to 13 per cent.

The survey also found high satisfaction rates among Canadian EV drivers. Nearly all (97 per cent) reported that they will purchase another EV when it’s time to replace their existing one. Almost nine in ten (89 per cent) said they enjoy driving their EV more; 95 per cent say their EV is more affordable; and 92% say their EV is a quieter ride than their gas vehicle.

AS VEHICLE ELECTRIFICATION grows, jobs in the bays will be impacted, a panel of experts agreed. But there may not necessarily be a loss of jobs, but a call for different skills for new jobs.

A panel of speakers were asked at Centennial College’s recent Driving the Future 2.0 event about what the future of technician jobs was going to look like as electric vehicles grow. With fewer parts and components to work on, how concerned should the industry be?

“We’re going to definitely eliminate some of the more simpler jobs, for lack of a better term,” observed Rob Morrison, Canadian fixed operations manager at Phaff/Lithia.

With electrification, oil and changes will go by the wayside, he noted as an example. Instead, being able to work with electrification will be a required skill set beyond what you find in many bays these days.

“We’re talking about battery repairs and battery specialists, high voltage experts; we’re talking about the ability to work on incredibly complex and advanced vehicles and systems,” Morrison added.

He brought up LiDAR and radar — it’s hard enough to understand how they work, let alone fix it. But technicians need to know.

“That’s what’s changing,” Morrison said. “This is an incredible lift in the skill set and to recognize that skill set is of value.”

David Cochrane, regional sales manager at Delphi, said there will be many new jobs popping up. He pointed to a company that is doing ADAS calibrations. Being able to do this type of work is fairly new.

“So there is a shift, but there’s still going to be a large amount of positions available,” he added.

Pierre-Hugues Comiré, regional field technical manager at Hyundai Canada, agrees there will be a shfit — there won’t be less work, just different work. Technician jobs will be replaced by a different type of position.

Careers lost by the reduction of jobs related to ICE vehicles “will be made up by analytical thinking skills needed for diagnosing networks, for dealing with electrification and driver assistance technology that’s in vehicles,” he said.

A NEW REPORT IS highlighting the continuing affordability of electric vehicles in addition to the fact that running costs remain stable when compared to internal combustion engine vehicles.

The Zero Emission Transportation Association (ZETA) released a report showing that EVs continue to be more affordable for drivers. It also highlighted that EVs are more price stable when looking at cost to operate as gasoline prices have fluctuated greatly for more than a year while the cost per kilowatt-hour of electricity has remained stable.

In other words, electricity is more insulated from price fluctuations compared to gas-powered vehicles, noted Albert Gore, executive director of ZETA. “Ensuring that [families] can travel affordably requires better protection from fluctuating oil prices. Electric vehicles provide that protection.”

EVs, the group highlighted, operate independently of global oil and gas markets, making their operating costs not subject to fossil fuel price shocks, disruptions and supply shortages.

It also noted that driving an EV can be 4.5 times cheaper than a gas-powered vehicle. “EVs are markedly cheaper to drive per mile — and experience far greater price stability — than gas-powered vehicles,” ZETA’s report synopsis said.

EXPERTS ARE WARNING that older parking garages may not be able to handle the added weight of electric vehicles.

As they grow in popularity — and as mandates ensure a higher EV population — concerns are being raised over whether current infrastructure can handle the weight.

A report out of the UK noted that aging parking garages should have the minimum weight they can hold raised, along with improved maintenance as neglect of the structures has experts concerned for their ability to hold the weight.

An electric vehicle can weigh much more than its internal combustion engine counterpart — the Ford F-150 Lightning can weigh 2,000-3,000 pounds more than the ICE version.

Structural engineer Chris Whapples, who helped author the report, observed that the situation could be disastrous in some cases.

“I don’t want to be too alarmist, but there definitely is the potential for some of the early car parks in poor condition to collapse,” he said, according to British newspaper The Telegraph. "Operators need to be aware of electric vehicle weights and get their car parks assessed from a strength point of view, and decide if they need to limit weight.”

RISING ELECTRICITY RATES have resulted in lower satisfaction with home charging, according to the J.D. Power 2023 U.S. Electric Vehicle Experience (EVX) Home Charging Study

More than two-thirds (68 per cent) of EV owners use a Level 2 permanently mounted station. But overall satisfaction declined 12 points year-over-year to 740 on a 1,000-point scale.

“Whether you’re an automaker, dealer or utility company participating in the EV ecosystem, improving the EV owner experience with respect to home charging should be a common goal shared by all,” said Brent Gruber, executive director of the EV practice at J.D. Power. “There are programs available today that will help EV owners with the startup costs, such as installing or upgrading to a faster Level 2 charger. There are also programs designed to save EV owners money with the ongoing costs of charging their vehicle, like scheduling to charge during the most affordable time of the day. However, J.D. Power sees that there is little awareness and utilization of these benefits.

“As the EV marketplace continues to grow, brands that help owners take advantage of these offerings will be in a much better position down the road.”

Stats that put the North American automotive aftermarket into perspective

14.9%

British Columbia leads the way in Canada with the highest rate of battery electric vehicle adoption among all provinces.

68%

97%

There is high satisfaction among Canadian EV drivers. Nearly all reported that they will purchase another EV when it’s time to replace their existing one.

43%

media, accounting for nearly half the share. Ford was second at 13 per cent. GlobalData

Many EV owners use a Level 2 permanently mounted station at home. Rising electricity rates reduced satisfaction with home chargers, however.

67%

3X

Mahle expects the sales potential of components tied to electric vehicles to be three times higher when compared to internal combustion engines.

Many EV drivers still have a gas-powered vehicle in their driveways. They are more likely to use it for longer journeys.

Those without a clear goal for adjusting to the future will be the losers when the next chapter of the auto industry is written, a special report warns

recent special report from S&P Global Mobility gently asks if the last throttle body manufacturer would kindly turn out the lights.

What’s ahead of the automotive industry is clearly problematic for internal combustion engine (ICE) suppliers. The world is moving to electrification. Expect a shakeout, S&P predicted.

So for how long can those suppliers reliant on gasoline propulsion go on and count on being in business? There’s no use ignoring the 2035 mandate to outlaw passenger ICE vehicles.

Guido Vildozo, senior manager of Americas light vehicles sales forecasting at S&P Global Mobility, told attendees of this year's AIA Canada’s National Conference that the feedback he’s received is that regulators would rather have lower vehicle sales volume

Even in a country that is fragmented when it comes to electrification policies — such as British Columbia and Quebec being the only provinces offering a rebate on zero-emission vehicle purchases — the mandate will come into effect.

“So they're not joking,” Voldozo said of regulators. But where Canada may differ from the rest of the world is the type of zero-emission vehicle consumers lean towards between now and then. Few countries have weather like Canada so it stands to reason Canadians would prefer to choose a hybrid electric vehicle when looking at all options.

Globally, hybrids represent about 4-5 per cent of any market share in the future. In Canada’s case, that number sits at about 8-9 per cent.

“The main reason behind it is weather,” Vildozo explained. “We know that there's an infrastructure challenge up north; 5 per cent of the population is in the northern territories [and] in the Prairies. Battery performance is not the same in this kind of weather.”

So Canadians will buy future vehicles with that in mind. “So we now forecast that Canada will actually have the highest plug-in hybrid ratio of any market around the world because of weather conditions here,” he observed.

This doesn’t just cater to areas where infrastructure is lacking but to the fact that last-mile delivery can’t be counted on in a battery electric vehicle if the weather doesn’t co-operate. And that extends beyond parts or grocery delivery.

“You can't depend on battery electric for an ambulance given whether here or a fire truck, for example, further down the road,” Vizdolo pointed out.

So the existence of PHEV may keep some suppliers afloat for some time. Nevertheless, the ultimate goal is full battery electrification. Will they adjust their business or wither away?

To hear Gino Amador, president of Snap-on Equipment, tell it, it’s time for suppliers to stop being scared.

“What are you all so worried about?” he asked during a session at this spring's MEMA Aftermarket Suppliers Vision Conference in Chicago.

This is the automotive aftermarket, not the new car dealers group, Amador added. They’re worried about what may or may not happen this year, next year and the year after that. The aftermarket doesn’t need to worry as much because it already knows what’s going to happen.

“That's sort of baked already. We know how many cars got sold three and four years ago. We know how many cars are coming off of warranty. We know how many cars are in that perfect space of four to 11 years,” he said. “That's the spot we

There are many factors influencing change among suppliers, Amador observed. If you’re the head of a supplier to the automotive aftermarket and you’re not thinking about how you’re going to adapt to that change, you’re facing tough times.

“If you consider the trichotomy of climate change advocacy, of road safety initiatives and trade policy that is at best questionable, for most of you in this room, if you don't reinvent yourselves, you're going to have some trouble,” he told attendees of the session

He’s not sure how long companies will have to reinvent themselves; it’s difficult to put an exact number on it. But “stochastic events” will come into play, he said, and every business is different with its own set of variables.

“But I feel fairly comfortable in saying that the event horizon for being deep into change is somewhere in the neighbourhood of 20 to 30 years,” he predicted.

What follows is an edited excerpt from S&P Global Mobility’s special report. It makes mention of the automotive aftermarket — indeed, the aftermarket stands to gain from an ICE-dominated marketplace for many years. As Paul McCarthy, president and CEO of MEMA Aftermarket Suppliers, put it, the industry will enjoy a long, fat tail for years, if not decades to come.

But it starts with acknowledging the future, says S&P’s report. Here are the actions it recommends suppliers take.

The time for denial is over. There are still suppliers of parts related to internal-combustion engines that are steadfast in their belief that the looming (and eventual) shift away from ICE toward any number of battery-electric propulsion formats is just a passing fad.

In their view, scores of OEMs, suppliers, dealers, and infrastructure partners have it completely wrong. That the billions in investment earmarked in virtually every major global market to build a new ecosystem is capital that is misallocated. That years of industry strategic moves and government regulations to position both nations and organizations for success in a battery-electric vehicle future are in haste.

Or, conversely, these legacy players may recognize that change is coming, but their corporate strategy is paralyzed by the surge of electric vehicle introductions.

They will be the losers when the next history of the auto industry is written.

While the pace and timing of this transition will be variable (read: lumpy), working under the premise of, "When, not if," should be the rallying cry among the supplier base. This existential threat

is already separating winners from losers — whether they know it or not.

That's not to say the shift will be immediate, or that there won't be strong revenue streams to be had during this transformation. It will be protracted, and there are still tremendous profits to be made in the internal combustion space over the next couple of decades — especially in the aftermarket.

After all, there are 1.3 billion internal combustion cars on the world's roads today, according to S&P Global Mobility estimates, and they aren't going to just vanish. Nor will BEVs take a dominant share of the vehicles in operation for many years to come. But the shift is happening.

There are thousands of moving parts in the internal-combustion powertrain; battery electric vehicles have only a couple dozen. As a result, there will be a brutal shakeout and consolidation among engine, transmission, and driveline suppliers in addition to those in the fuel and exhaust systems sectors. The victims will be those who failed to plan ahead and listen to their customers.

As S&P Global Mobility sees it, those suppliers have four strategic choices:

Divest from ICE, and shift to BEV components

Milk the cash cow dry, while shrinking to an eventual shutdown

Double down to become the dominant part supplier

Position to be acquired

Even if it were the best of the times, an industry experiencing this sort of transformation from ICE to BEV propulsion would have its fair share of participants throwing in the towel. Add financial pressures and risk dynamics impacting the industry since 2019, and you have a recipe for significant industry turnover.

This frantic pace of change and its inherent risks for capital in a rising interest rate environment, the skills/process transition required, and the advantages gained by innovators and first movers in this new environment is head spinning. Emerging from this unfortunate timing combination of significant competitive challenges will be an ecosystem which will not resemble the one in which we entered this century. Despite the challenges, nimble industry participants — be they OEMs, suppliers or dealers — will leverage this tumult to their advantage.

Early evidence of a looming propulsion transition emerged even before 2019. Both China and the European Union understood (albeit for differing reasons) that legislating vehicle emission reductions through the coming decade was going to upend the competitive dynamics of their home market vehicle manufacturers and the suppliers which served them.

As a result, OEMs will be required to devote a substantial share

The emerging BEV production ecosystem has few similarities to that of rationalized industry were touted as optimal — the tide is now turning.

of capital expenditures to battery-electric propulsion systems and platform structures. They are understandably reducing their focus and resources on traditional ICE systems due to limited payback and slowly abating volumes/utilization.

Some ICE powertrain suppliers may discover they are unable to pivot to a BEV world. One option for entrapped medium-sized suppliers may be to ride an ever-decreasing ICE revenue stream until the business is unsustainable; Wall Street tends to look unkindly on that business model.

Another path is to become the dominant supplier in a niche segment — be it for throttle bodies, ignition coils, exhaust manifolds, or some such — and hope that the aftermarket business is sufficient to keep the business afloat.

While traditional propulsion systems suppliers face these challenges, an opportunity is emerging for others to build new value chains and differentiate innovations and competitive advantages as first movers.

Though the number of new BEV platforms (all-new structures and processes) has primarily been initiated in China and the European Union through this decade so far, North America is catching up quickly. Installation of new, highly flexible BEV platforms is already underway in North America.

According to S&P Global Mobility, 84 BEV nameplates, built at 47 vehicle production lines, are forecast by 2025 — and North American numbers may surge due to benefits incurred under the U.S. Inflation Reduction Act (IRA). For many of these offerings, development and component sourcing occurred years ago.

The emerging BEV production ecosystem has few similarities to that of today's ICE-focused version. For decades the advantages of a globally rationalized industry were touted as optimal — the tide is now turning.

For instance, the days of efficiently sourcing engines and transmission from over an ocean has given way to propulsion systems (battery cells and enclosures) produced regionally. We are entering a BEV chain based on localism — usually within a couple hundred miles of the final-assembly plant. While this new supply chain was forming well ahead of the recently enacted IRA, financial incentives will drive even greater value-add through the upstream battery inputs (anode & cathode material) within North America.

What's more, geopolitical risks, potential trade frictions (such as between the United States and China), sustainability and ESG concerns, and growing logistics issues will drive tomorrow's supply chain even closer to home factories. Suppliers will need to adapt to nearer supply networks, an even-greater concentration on efficiency, and labor stability to build robust upstream chains.

There also is a danger in changing course too quickly. What happens to suppliers that go all-in on an electrification push that does not meet expectations?

After all, it's an industry truism that, if you added up each automaker's calendar year sales projections, the U.S. market would be 22 million vehicles. Of course, it has never come close to that.

Mike Wall, executive director of automotive analysis, warns that sort of overexuberance in sales projections seen with internalcombustion vehicles could happen just as easily with electric vehicles. And suppliers could end up holding the bag.

"Automakers are making some big production projections. One will say, 'We're going to sell 1 million EVs.' Then the next one says, 'We're going to sell 2 million.' And suppliers are being told to plan for this much capacity," Wall said.

"If you are a supplier told to plan for a vehicle with 150,000-unit volume, what if it happens to come in at 50,000? Besides altering the basic profit potential for the part, if you amortize tooling and development costs into your piece costs, it will take much longer to recover those costs, if it ever happens. If you are a supplier, you won't be selling at 100 per cent capacity at job one," Wall added.

These are important considerations as suppliers venture into the quoting process for any new business, particularly electrified vehicles.

Additionally, going it alone may not be the optimal path. Reacting to new opportunities through alliances and partnerships will be key as the speed of vehicle development rises. A new competitive dynamic will emerge as reliance on past advantages gives way to a new definition of success or failure.

Those suppliers slow to transition to BEV technologies have missed the initial surge. Remember that there are three timelines in the industry:

Development (which occurs up to five years before start of production)

Tooling for production (two to three years before start of production); and

Service/aftermarket requirements once in service.

It's a harsh assessment, but given the time-factors involved, a supplier's strategic perspective needed to be in play years ago. In an industry built on relationships, the need to break into the BEV supplier base will be frenetic. But BEV propulsion uses a fraction of the parts required for internal combustion, and as a result, more than a few suppliers will be left standing without a chair when the music stops. The level of displacement and disruption will be significant. Planning ahead is critical to survival.

today's ICE-focused version. For decades the advantages of a globally

As you explore setting up your shop for EV repair, here are important considerations around the physical workspace

The adage “fool me once” has reared its head again. Lately, owners and technicians are asking a question about hybrids and electric vehicles that takes me back to the introduction of emission testing: “How much to get into this?” This is a valid question as nobody wants to get burned again, though there is a larger picture to consider.

The first part is easy. If you decide your shop will service and repair hybrid and EVs, it makes sense to seriously consider the financial investment. Some owners and managers have likely performed a rudimentary search to identify the tools and equipment required. Others may have taken a deep dive down the rabbit hole and have an exact list of items they want.

Consider your shop setup. Most common service work on hybrids and EVs can be performed in any service bay, provided the hoist is up to the lifting task — some EVs are heavy! From tires to brakes, steering and suspension, it’s unlikely that the highvoltage system will be touched … until the repair requires the high-voltage system to be powered down. When service information requires a ‘main disconnect’ to be removed or turned off, the larger picture comes into play.

Does it make sense to service and repair a hybrid or EV in a high-traffic area of the shop? That is a firm “no.” People are naturally curious about these vehicles. Some can’t help themselves and touch things, while others may be inquisitive to the point of distracting the technician.

Staff can usually be trained to recognize and avoid an area where high-voltage service is taking place. However, lapses in judgment or common sense are common. Reminders, and what we call ‘attention-grabbers,’ are required to reinforce that it may not be safe to approach or touch a technician or hybrid/EV that is in for service.

When high voltage is involved, the vehicle should be cordoned off. Every employee should be made aware of what this means. Tall (45-inch) orange ‘delineator posts’ strung with danger tape or red plastic chain placed to isolate the vehicle get the point across. Add a “Caution, high voltage” sign for good measure. Unfortunately, some see these warnings as a challenge to overcome — this should be addressed immediately.

Shop policy should state that the servicing technician is always present when high voltage is exposed, and he or she shall remain with the vehicle until it is ‘safed-down.’ Leave the barriers up for the entire service operation.

Customer control is another consideration. This topic has been around for decades. We all know the type. Intercept these customers at the reception desk to keep them out of the service area. Summer is on its way and bay doors may be open. Ensure the cordoned-off area extends around and behind the vehicle as necessary, and that customers are respecting the safe zone.

Speaking of safe zones, ensure the cordoned-off area extends around high-voltage dangers removed from the vehicle. EV battery packs can be half to three-quarters the length of the vehicle when removed and are almost as wide. They are large, heavy and dangerous if not respected.

A separate room to service or store battery packs is the best, but not always an option. Battery packs should never be left unattended when high voltage is exposed. Covers should always be reinstalled if work stops while waiting for parts or service.

Storage of removed interior panels and pieces should be addressed. Many hybrids require seat backs, seats, panels, cooling ducts and storage compartments to be removed to access the high-voltage battery. Consider providing a storage area for this ‘clutter’ to keep it clean and the work area organized.

Speaking of storage, under-vehicle splash panels are abound on EVs. A storage area for these panels (other than inside the vehicle) is helpful. A stocked assortment of plastic panel clips will help to speed up the reassembly process. However, drilling out the broken m6 panel bolts will slow your technician down. Remember to add clips and drilling/tapping time to the estimate.

Mike Bailey is chief technical and developmental officer and co-founder of Environmental Motorworks. He is a licensed 310S and 310T Technician in Ontario and is certified to deliver HRAI’s Ozone Depletion Certification Program, as well as the EPA Section 609 Automotive Refrigerant Training Program in the U.S.

Tools and equipment are some of our favourite things. The following list will help to identify those that your shop will need to service hybrids and EVs. This basic list is in addition to standard first aid and fire response tools and equipment. How much to get in? It depends on what you need on a list such as this…

Scan Tool

▶Shop choice

Insulation Tester/DVOM

▶Required CAT III 1000v rating

▶You probably have a meter that meets this specification but does not test wire insulation. A ‘megger’ performs HV wire insulation tests by applying 50-1000v and measuring “electron leakage” through the insulation. Most are also a DVOM

Long test leads and extended grippers

▶CAT III 1000v rating required for all leads and probes

Class “0” High Voltage Glove Kit w/leather outer gloves

▶Class “0” glove certification lasts for six months

▶Certified for 1000 volts AC

Precision Milliohm Meter or 3-Phase Motor Tester

▶Accurately tests motor-generator stator windings

Charge Port B.O.B.

▶Break-out Box connects between the charge port and charger to provide access to the charge port circuits during use for level 1 and 2 charging diagnostics.

Insulated Hand Tools/Small Items (Working on live HV circuits is rare)

▶Certified 1000v (double triangle) Screw drivers, 1/4” and 3/8” ratchets, sockets, and pliers

▶Slip on anti-spark lug covers (to cover wire end lugs after disconnecting)

Non-Conductive Work Surface

▶To be used during battery pack service and repair

Battery Module Lifting Table (recommended)

▶Appropriate weight rating is important

Lab Scope

▶Diagnosis is challenging without one

▶Differential probes are required to directly measure high voltage

Technician Disconnect Pole

▶Visual Warnings

▶Signage

▶Pile-Ons or

▶Perimeter tape (commonly says “Danger” or “Caution”)

Technician and support staff training

High-voltage training is essential for technicians’ safety — and your shop’s success //

By Mark Sessions

By Mark Sessions

As the number of electrified vehicles (EVs) on the road continues to rise, the number making their way into repair shops is steadily increasing as well. With EV sales forecasted to account for 50 percent of new car sales by 2033, the repair shops that will thrive in the future will be the ones whose technicians know how to service new technologies — and importantly know how to do so safely.

The responsibility to train employees in safe working practices is paramount for any business. When it comes to EV repair and maintenance, technicians often come in with a misunderstanding of what the dangers really are.

Electrified vehicles are engineered and built to meet vehicle safety standards and undergo the same rigorous safety testing as conventional internal combustion engine (ICE) vehicles. These standards ensure that the high voltage system is safe for drivers, passengers and anyone who encounters them. There can be dangers, however, if multiple isolation faults occur within a vehicle.

As a trainer for ZF Aftermarket, I teach highvoltage training that equips technicians with the proper knowledge and procedures to work on electric

vehicles safely. ZF’s training applies to any and every EV application and is built on the foundation of the Occupational Health & Safety Act, the German Road Vehicle and DGUV 200-005 regulations. These standards for employee and public safety cover every aspect of working on battery-operated vehicles, guiding the technician to work to the highest safety standards, using specific work-based instruction.

Now adapted for North America, the training integrates the elements of the NFPA-70E regulation in a combination of online and in-person, hands-on sessions. Certification is active for two years from the date of completion.

Pure battery-electric vehicles, plug-in hybrids, and hybrid electric vehicles have high-voltage electrical systems that typically range from 300 to 850 volts. Importantly, bodily contact poses a danger to health in as little as over 60 volts DC or over 30 volts AC. Exposure is directly affected by bodily resistance and the skin's moisture content. This resistance has a direct influence on the amount of electrical current that could pass through the body, and the severity of the outcome is directly

proportionate to the amount of time the technician is exposed to the current and possibly the frequency.

One additional important consideration is that these vehicles will continue to operate with one isolation fault on the high-voltage circuit; the vehicle will warn the driver and continue to function normally until it comes to a complete stop. If a second fault occurs, the vehicle will deactivate as soon as it is detected. Even then, the ground or PE (protective Earth) circuit is constructed in such a way as to prevent the risk of injury. This is important because a technician can be at risk when working on a system that has a PE and an isolation fault. But this risk can be safely negated by following proper procedures.

ZF’s five-stage process of what we call a Certified

Deactivation of the high-voltage system must be followed to ensure the technician’s safety. This includes specific signage, labelling, lock-out tag-out procedures & NFPA-70E Reg. Personal protective equipment and importantly, the passive discharge time of any remaining energy stored in the system capacitors.

Once the system is safely and properly deactivated, it is essential to inspect it by identifying and correctly using precise measuring equipment to define any system tolerance defects. This allows for accurate diagnosis and repair of any faults, clearing the way for the safe installation of any replacement components before final re-activation.

Of course, no job is complete without a detailed report that defines the original state of the vehicle, with all measurements and findings, as well as the condition in which it was handed back to the customer. Understanding the need for accurate and concise historical data is key to a quality work structure.

Electric vehicles pose new challenges and requirements, but they are cleaner and require significantly fewer moving components than traditional ICE vehicles, offering consumers a more sustainable mobility experience. Aftermarket shops and technicians should be preparing now for a future dominated by EVs. There’s no better place to start than with high-voltage training to ensure your employees’ safety on the job.

Mark Sessions is senior product technical trainer and ZF high voltage expert for ZF Services North America.

When it comes to EV repair and maintenance, technicians often come in with a misunderstanding of what the dangers really are.

Juice Americas Inc., the U.S. subsidiary of Swiss-based Juice Technology AG announced the Canadian availability of the portable two-in-one EV charger, J+ Booster 2. The portable charging station allows for indoor and outdoor home charging. The UL certified, NEMA 14-50 EV charger includes a wall bracket for compact use at home and a carrying case for use on the road. It’s available in 21-foot and 25-foot length options and includes NEMA 14-50 and 5-15 wall socket adapters. Additional adapters are also available. www.juice.world

Mevotech announced it added 173 new part numbers to its extensive catalogue with new chassis, control arm and wheel end solutions. Several are for Tesla vehicles: Rear lower rearward lateral arms for 2017-2021 Tesla Model 3s, rear upper rearward lateral arm for the 2017-2023 Model 3 and 202-2021 Model Y. Rear lower lateral arms are also available for the 2016-2021 Model X. These options provide exact fit, anti-corrosion coatings for longer service life and restore vehicle suspension geometry.

www.mevotech.com

Liqui Moly has released the Battery Coolant EV 200 to act as a thermal manager. The ideal lithium-ion battery temperature is between 15 and 40 degrees Celsius in an EV. The vehicle’s range depends on its energy consumption and temperature affects the service life of the battery and engine. The coolant ensures that the battery never gets hotter than 60 degrees in summer and that the temperature constantly remains within the ideal range, even in winter.

www.liqui-moly.com

VW COILOVER SUSPENSION

KW Automotive released the V3 coilover suspension for the rear-wheel drive VW ID. Buzz. Made of stainless steel, the coilover kit can be customized to adjust the damping characteristics in the compression and rebound stages and lowering height. The ground clearance of the VW ID. Buzz can be lowered on the front axle by 25 to 45 millimeters and on the drive axle by 15 to 35 millimeters. The kit currently only supports shorter wheelbase and rear-wheel drive models. www.kwsuspensions.net

Nothing brings the automotive aftermarket community together like AAPEX. It’s the only event where hands-on training meets expert-led business education. Where professionals and industry leaders from around the world gather to make connections, catch the latest demos, and find the perfect products. And it’s where you belong. Secure your sopt today.