Designed and Built in Great Britain Supplied Across the World Manufacturer of materials handling systems and automation solutions for all industries CONVEYOR SYSTEMS FOR: PRODUCT FINISHING PLANTS | LOGISTICS | INDUSTRIAL EQUIPMENT | POINT OF DISPLAY | AUTOMOTIVE Midland Handling Equipment Ltd. Stretton Road, Great Glen, Leicester, LE8 9GN, England T: +44 (0)116 259 3175 F: +44 (0)116 259 2820 E: enquiry@mhel.co.uk W: mhel.co.uk Materials handling equipment for Spraying, Powdering, Curing, Treating, Dipping, Flipping and more ... ... we have everything covered JUNE 2023 4th &5th October 2023 NEC, BIRMINGHAM www.surfaceworld.com read online @ www.surfaceworld.com – follow us on twitter @surfaceworldmag – visit www.surfaceworld.com Years Celebrating 1973 2023

MANAGING DIRECTOR & ADVERTISEMENT DIRECTOR

Nigel Bean

t: +44 (0) 1442 826826

e: nigelbean1@aol.com nigelbean@surfaceworld.com

EDITOR & GRAPHIC DESIGNER

Jane Soones

e: janesoones@aol.com janesoones@surfaceworld.com

CIRCULATION & SUBSCRIPTION DEPARTMENT

Sheena Burrus e: sheenaburrus@hillmedia.com

EXHIBITION ORGANISER

Sheena Burrus e: sheenaburrus@hillmedia.com

Hill Media Ltd, Marash House

2-5 Brook Street, Tring, Hertfordshire HP23 5ED, United Kingdom.

The Surface World magazine is published 12 times a year by Hill Media Ltd. Although every effort is made to ensure the accuracy and reliability of material published in Surface World, Hill Media Ltd and its agents accept no responsibility for the veracity of claims made by contributors, manufacturers or advertisers. Copyright for all material published in this journal remains with Hill Media Ltd and its agents.

© Hill Media Ltd – 2022 ISSN 1757-367X

1 JUNE 2023 COMPANY SPOTLIGHT The new Dalby EQ Spray Booth, with Pro Active energy saving technology. 4 INDUSTRY NEWS Midland Handling Equipment Celebrates 50th Anniversary. 8 QUALICOAT Members Meet in Cork. 12 Engineering should be made more visible in schools, says poll of academics. 14 Industry Recognised Training Courses from the IMF. 16 HMG Paints Ltd Honoured as the 2023 Manufacturing Family Business of the Year. 18 SURFACE WORLD 2023 Trade shows can be a vital business platform for companies. 22 CONVEYORS & MATERIALS HANDLING Is it time for some conveyor TLC?. 26 Improve your efficiency using an overhead conveyor. 28 ELECTROPLATING, ANODISING & GALVANIZING Rare Rhinos Housed for the Future Thanks to State-of-the-Art Enclosure. 30 TESTING & MEASUREMENT Reduce Costs With Inline Measurement For Electroplating Reel-To-Reel Applications. 32 Paint Cure Monitoring – PhoenixTM Helping drive Quality and Coating Oven Economy. 34 PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING Equipment Modernisation Programmes E.M.P. 40 Should you automate your cleaning process? 42 Offering Intelligent Cleaning Solutions for Demanding Applications. 44 Achieving substantial annual cost savings and improving sustainability. 48 PAINT & POWDER Datalec is always looking at ways to better service its customers. 52 PRODUCTS & PROCESSES Innovations in greener manufacturing and technology. 56 First life cycle analysis of ultraviolet/electron beam curing shows benefits over other coil coating technologies. 60 MATERIAL & EQUIPMENT SUPPLIERS 66

Specify QUALICOAT for all your architectural aluminium powder coating requirements qualicoatuki.org JUNE 2023 VOLUME 30 NUMBER 6

Hadleigh Enterprises Limited Unit 11, Buckingham Square Hurricane Way, Wickford Essex, SS11 8YQ Tel: 01268 572255 Fax: 01268 572121 Email: sales@hadleightapes.co.uk Web: www.hadleigh-tapes.co.uk Certificate No. FM10409 • AS9100 APPROVED • NO MINIMUM ORDER QUANTITY • ALL PRODUCTS FOR ALL PURPOSES • 48 HOUR DELIVERY SERVICE The Adhesive Tape Specialists

SUPERIOR TECHNOLOGY Significant Savings Nordson HDLV ® Dense-Phase Technology Enhance productivity and maximize your product quality with Nordson powder coating equipment and HDLV technology. Our Encore® HD powder spray systems deliver superior efficiency and coating uniformity. Tight control of the coating process yields significant powder savings. Proven long-lasting performance maximizes up-time and productivity. Explore the unique features of our powder coating systems online www.nordson.com/hdlv or get in contact with us today for more information! www.nordson.com/ics | ics.eu@nordson.com

The new Dalby EQ Spray Booth, with Pro Active energy saving technology

The new Dalby EQ Spray Booth, with Pro Active energy saving technology. Now with game changing cost per job software to give accurate cost analysis of gas and electric consumption on each individual job.

The new Dalby Evolution EQ combination spray booth oven incorporates the very latest technology, providing the optimum paint application environment, whilst minimising running costs.

The ‘Pro Active’ control system constantly monitors the activity within the spray booth and automatically adjusts airflow, temperature and lighting to optimise overspray clearance and bake performance as efficiently as possible.

The control system allows the booth to operate in Performance, Smart and Economy modes. With invertor controlled automatic pressure

balancing, the airflow is automatically controlled to provide power consumption as low as 1kW in Economy mode. This unique spray booth technology will provide your

business long term cost savings without compromising the quality or performance of the equipment.

With the high visibility LED mode indicator and countdown timer display fitted above the 3 leaf, large vision panelled doors, the booth operating mode and count down timer is easily visible across any workshop.

The factory-built air handling unit incorporates the fans, dampers and pilotless burner into a single unit, enabling a fast installation and unrivalled levels of reliability. Access to the plant for maintenance is gained from inside the EQ booth. This allows for corner positioning within the workshop with no side or rear access required. This space saving design helps maximise usable floorspace and is a major benefit for clients with limited room.

With rear extraction as standard, there is no requirement for a pit. However, if you prefer, the Dalby EQ can also be supplied with downdraft air movement via pit extraction or with an internally ramped raised floor.

4 JUNE 2023 COMPANY SPOTLIGHT

elcometer.com blast it inspect it paint it High performance abrasive blasting equipment Spray equipment engineered for the most demanding bodyshops test it Ultrasonic NDT equipment for accurate corrosion & flaw assessment Industry leading coatings inspection & physical test equipment

surface preparation to final inspection, we make sure your equipment works as hard as you do.

believe in our workmanship, so you can have confidence in yours. NIEDAM RG E A T BRITAIN MADEINGREAT BRITAIN MADEIN GRE A T RB I NIAT TAERGNIEDAM NIATIRB engineered TAIN FABRIQUÉ EN GRANDE-BRETAGNE PE FABRIQUÉ ENEUROPE engineeredYTILAUQ I N TEGRITY SERVICE EXPERTISE SUPPO R T YGOLONHCET GNINIART Surface World - Brand Advert April 22.indd 1 13/04/2022 14:33:01

From

We

Pro Active Energy Saving Technology

The Dalby ‘ProActive’ touch screen control system enables full control of all the booth’s functionality and allows the user to switch between modes at a touch of the screen.

PERFORMANCE mode, is ideal for spray and flash off processes where maximum airflow is required.

PERFORMANCE mode will offer 20,000m3 / hour airflow whilst ECONOMY mode will deliver 10,000m3 / hour, dramatically reducing the energy consumption, saving you money.

SMART mode enables the booth to actively reduce energy consumption without affecting productivity. This is done by targeting periods when the booth is running without spraying activities taking place.

The Dalby control system constantly monitors operations inside the booth and will actively switch between modes to reduce electricity and gas consumption where possible. The EcoSave mode further reduces power consumption with active use of stop/start technology when the booth is not being used for spraying or curing activities, such as when masking up or paint mixing is taking place.

Cost Per Job Analysis

The Dalby evolution booths now have game changing technology which can monitor the real time running costs of

your booth. New software means you can now track the usage of the booth, recording data against each individual or job reference number and monitor how long the booth is operational in each mode giving you accurate energy costings per job.

This data is displayed on screen and can also be downloaded onto your laptop for more detailed performance analysis. With the rapid cost of energy increases we have seen recently this is an innovative, new way to monitor costs in real time and see where operational improvements can be made to make further energy savings.

The ‘ProActive’ control system has a number of other innovative features designed to optimise the performance and efficiency of the booth. These include:

Automatic Pressure Balancing, this automatically maintains the negative pressure balance in the booth cabin.

Integrated Mist Clearance Indicator. When spraying has finished, the ‘ProActive’ control displays the mist clearance time remaining.

Automatic Filter Condition Monitoring. The control system warns you when the input and extract filters require replacement.

Maintenance Scheduler, this gives you advance warning of when the next scheduled service is due.

Fault Finding and Diagnosis. The ‘ProActive’ control system provides fault diagnosis information in the event of a breakdown.

Customisable Display. You can also select from a library of car images to customise your display.

“HighLight” LED Lighting System with PIR Control

The EQ booth has The Dalby “HighLight” LED lighting system fitted as standard. This system significantly reduces power consumption, with typical power savings in excess of 60% versus traditional lighting systems.

The “HighLight” LED light boxes are mounted at corner roof level and shine through our unique, laser cut, highly efficient light shaping diffuser to provide diffused light inside the booth which replicates daylight. The diffused light reduces spotting and decreases vision issues as operators do not see the individual LEDs.

With average light levels at the spraying face in excess of 1400 lux and with excellent colour rendering, the “Highlight” LED lighting creates an optimally lit spraying environment.

With heat control designed into the light, the “Highlight” LED lighting has a much greater life span that traditional fluorescent lighting leading to very low

6 JUNE 2023

COMPANY SPOTLIGHT

ongoing maintenance costs and minimal reduction in light output.

PIR control saves energy by ensuring that the lights dim and then turn off when no movement is detected in the booth cabin, and instantly turn on when an operative enters the booth.

Spray Booths

Manufactured In the UK

Harry Dalby Engineering is proud of its tradition of manufacturing in the UK. Operating from our two factories in Leicester with a combined area of 49,000 sq ft, we manufacture almost every part of our spray booths in house. The process starts in our drawing office where, using the latest 3D CAD software and our modular design concepts, we specify each and every spray booth to suit our client’s individual requirements. The designs are then issued to our factory floor where, using state of the art CNC machines such as our Fibre Laser, CNC Punches, 6 Meter CNC Press Brake and Robot Welders, we manage production from start to finish.

We manufacture in house all the major components such as the insulated booth enclosure panels, vehicle and personnel doors, fans, dampers, control system (including state of the art PLC controls), direct gas fired burners, and we even have our own ducting shop and spiral duct forming machine.

By manufacturing these components in-house we are able to constantly evolve our designs to ensure that every part of each spray booth is perpetually reviewed and optimised for its function within a paint application environment, thus ensuring the highest performance and long term reliability of our Spray booths.

Dalby spray booths are recognised by many of the UK’s major OEM’s and Tier 1 industries who work with Dalby

because of our reputation for Quality, Technological Innovation and the ability to offer a complete package from concept to installation and commissioning.

To find out more about our new cost per job software or our EQ energy saving spray booth please contact us on telephone: 0116 2916000 or email: enquiries@dalby.co.uk or visit our website www.dalby.co.uk

Dedicated stand-alone unit is ready to measure right out of the box Fast measurement speed—ideal for moving lines and swinging parts Scan Mode continuously takes measurements—ideal for analyzing large areas Storage of 999 readings with onscreen averaging. Stored readings can be downloaded to PosiSoft Desktop Software Affordably measures uncured powder coatings using non-contact ultrasonic technology to predict a cured thickness 16A Long Drive, Meadway, Berkhamsted, Herts HP4 2PN t: 01442 879494 www.dftinstruments.co.uk e: sales@dftinstruments.co.uk Non-contact Uncured Powder Thickness Gauge Powder Inspection Kits Complete solutions for measuring powder coating before and after cure are available

Powder Checker

Midland Handling Equipment Celebrates 50th Anniversary

February 2023 saw the 50th Anniversary of Midland Handling Equipment Ltd, a leading manufacturer of Material Handling Equipment, especially Overhead Chain Conveyors.

Founded in 1973 by brothers Keith and Mike Deacon, who had already established themselves as sub contract installation engineers for many conveyor companies of the period, they decided to begin manufacturing their own conveyor products.

And so Midland Handling Equipment was formed to supply a range of conveyors mainly to the Paint Finishing Industry. The Trakmaster range of

Overhead Chain Conveyors quickly became a firm favourite in the industry, and remains so today, with ranges from the light duty ‘152’ to the heavy weight ‘406’.

As customer demands and manufacturing techniques evolved so too did Midland Handling’s products with the development of a range of Power and Free Overhead Conveyors which is now amongst the most

popular product range, with capacity to handle loads from a few kilos to 10 tons.

But in addition to Overhead Conveyors the company produces a wide range of Belt, Roller and Slat Conveyors, as well as special purpose bespoke handling equipment.

With such clients as JCB, BAE Systems, Bosch Rexroth, Airbus, Jaguar Landrover & Toyota, amongst many others over the years, Midland Handling is able to meet the demands of modern manufacturing to supply quality and reliable products on time and within budget.

8 JUNE 2023

INDUSTRY NEWS

Today the company occupies a 10,000 sq ft manufacturing facility in Great Glen, Leicestershire and is staffed by a dedicated team of experienced engineers and management team. From here the company can take an initial concept idea through the design stage, manufacturing and installation, with after sales service for spare parts and maintenance.

The company looks forward to the future with the recent accusation of

the firm by Richard Deacon and John Donohoe, the company remains very much a family business that still offers a personal and dedicated service, backed up by the skills, knowledge and manufacturing capabilities gained over decades of experience in the material handling industry.

For more information please visit www.mhel.co.uk or contact us on: Telephone 0116 2593175 Email: info@mhel.co.uk

10 JUNE 2023

INDUSTRY NEWS

Years Celebrating 1973 2023

Solutions for recycling SOLVENTS Save Money | Recycle Any Solvent High Yield | Low Waste ASK FOR A FREE QUOTE SYSTEMS Units available for any quantity and application Safe and easy to use Recycled solvent as good as new Atex certified for flammable solvents The number one choice with over 38,000 units worldwide BUY OR LEASE info@solutex.co.uk | 01691 622 225 For more information visit: www.solutex.co.uk

INDUSTRY NEWS

QUALICOAT Members Meet in Cork

By Angus Mackie - QUALICOAT Chair

As the Association covers both the UK and Ireland, the second members council meeting of the year was held at Architectural & Metal Systems (AMS), based in Cork, who kindly offered their meeting room facilities for the event which was attended by thirty members.

AMS was established in Cork in January 1990 by Chris Martin, Pat O’Hara and the late Dave Rawlings to supply fenestration systems across the region. The company has grown significantly since 1990 and now offers system design, aluminium extrusions, powder coating, anodising thermal break and fabrication services. Early members of QUALICOAT UK & Ireland, this year marks AMS’s twentieth year in membership. As early adopters on new technology, AMS have utilised only chrome-free pretreatment since joining QUALICOAT for all of their architectural aluminium powder coating, citing chrome free technology as a robust pretreatment system.

The meeting took place within the AMS offices, overlooking the ‘Lough Mahon’ on Little Island and despite the warm weather outside, the meeting was opened by Chair, Angus Mackie, who welcomed everybody to the meeting and thanked AMS for their hospitality and assistance in organising the meeting.

Following a round table delegate introduction, the Chair welcomed two new member companies at the meeting, Ross Hartshorn & Eddy Webb from Garnalex and Declan Deane from Deane Roofing. Both companies were awarded their licences in early 2023. After matters of business were covered, the Members discussed the upcoming Surface Live Show at the NEC on the 4th & 5th of October and attendance at the ZAK World of Facades in London later in the year on the 8th November. The Surface World Live show brings people together from all the surface coatings businesses and associations to discuss and review the Industry. Supporting the event, QUALICOAT Members will be present to discuss the benefits of membership of the Association.

The ZAK World of Facades event, which takes place in London, brings together the complete facade supply chain including specifiers who are working on projects in the UK and overseas. QUALICOAT is taking a tabletop stand at the show and will be on-hand

during the conference break-outs to offer guidance on specification of architectural powder coatings which adorn the majority of facades around the globe.

Most UK & Ireland members are now using chrome-free pretreatment systems and the Members were reminded that the use of hexavalent chromate in the UK for pretreatment will be banned by the HSE from September 2024 due to its carcinogenic properties. Pretreatment systems Members confirmed that their products will be withdrawn for sale in the UK at that time but that the product will continue to be used in other countries around the globe as it remains within QUALICOAT approval. Two further companies applying for QUALICOAT application licences are very close to being awarded. One UK systems company in the West Midlands and an applicator business in the South East. Both companies have recently cleared initial inspections, with these two companies in membership later in the year, twenty eight of the UK’s leading architectural powder coat applicators will be QUALICOAT approved licensed applicators.

12 JUNE 2023

Training for the members laboratory technicians, which takes place once a year and is obligatory for members to attend at least once every two years, will be held in the Midlands on the 21st November and be run by the independent German test house IFO. More information will be available on the website prior to the event.

On the technology, front there will shortly be a further appendix added to the QUALICOAT Specification. The new appendix will cover post forming of powder coated profiles. As technology in the metal curving world has advanced allowing specifiers freedom in design, there has been little research undertaken to determine the life expectancy of the coatings on the profiles that have been shaped after powder coating. The appendix will cover the appropriate specification of powders and pretreatment systems that will ensure powder adhesion on such profiles. Some powder formulations are more flexible than others, using a more brittle coating, could cause issues over time for a coated curved profile. The appendix will offer specification advice which has been researched by a QUALICOAT working group of members from around the globe. The appendix will be launched later this year.

QUALICOAT 3.0 continues to gain traction with specifiers where the aluminium itself forms part of the coating specification. Whilst the mechanical properties of extrusions

with high recycled content is well understood, the level of trace elements and the structure of the aluminium at the molecular level is less so. With some slight adjustments in the extrusion process, mainly around the heating of the billet and die, a more consistent grain structure can be achieved and this, together with the reduction of ‘tramp’ elements in the aluminium, can further extend the life of powder coating by several decades.

The next Members Council Meeting, to be held on the 22nd November, will be the Members 2023 AGM which also coincides with the UK & Ireland Associations twenty fifth year anniversary. The event is to be marked with a dinner and meeting in the West Midlands.

The meeting closed at lunchtime and after a short lunch break, Members were treated to a guided tour of AMS extensive facility.

The current QUALICOAT Specification is freely available for download via the Association website, qualicoatuki.org and offers an up-to-date list of licensed UK and Ireland Powder Suppliers, Pretreatment Suppliers and Applicators. Telephone support is available from QUALICOAT UK & Ireland Head Office in Birmingham on 0330 236 2800, the Association can also be followed on Twitter @ Qualicoatuki or on Linkedin www. linkedin.com/company/qualicoatuk-&-ireland.

JUNE 2023 PASSION FOR MASKING SOLUTIONS www.global-mask.com WHEELS CUSTOM STANDARD

Engineering should be made more visible in schools, says poll of academics

Plus, universities are adapting courses to spotlight sustainability

The UK’s engineering academics have called for greater visibility for the subject in schools as a way of tackling labour shortfalls and the need to find environmental solutions, following a poll by NMITE (New Model Institute for Technology & Engineering) and the Engineering Professors’ Council (EPC).

NMITE and the EPC worked together to conduct the survey of the nation’s engineering academics in advance of the EPC’s ‘Engineering Academics Network Annual Congress’ which NMITE hosted in Hereford from 12th June. The three day event saw engineering academics from universities all over the UK come together to explore issues in education and engineering.

When asked what should be done to elevate the status of engineering, almost two thirds (63%) of respondents felt that engineering should be made more visible in schools, with one commenting: “help to educate parents about what a fantastic career choice a Professional Engineer is.” This emphasises the importance of raising awareness of engineering as a career choice, as many school leavers are either unaware it’s an option, think they must have maths or science qualifications to be considered, or hold the view that it’s a career path just for certain types of people.

James Newby, CEO at NMITE, gave his thoughts on the results: “It’s clear that more needs to be done to help inform young people about engineering as an option, earlier in their learning journey. This is not a finger pointing exercise targeted at schools. They have enough on their plates. It’s important that the national curriculum reflects the diversity of careers available to school leavers within STEM. In September 2022, T level courses started in Engineering, which is a promising sign that things are moving in the right direction.

“We are also seeing impressive initiatives from industry trying to assist with the education piece, alongside institutions like ours going into schools and engaging directly with students. It’s about putting engineering on their radar and changing some of those perceptions that engineering is only for boys, or for those who excel at maths for example. Our new model of education is open to new and different kinds of thinkers and the old stereotypes don’t apply.”

Johnny Rich, Chief Executive of the EPC, commented: “The UK has a skills shortage in engineering running into tens of thousands every year. Without plugging that gap, we cannot hope to address the environmental, technological, economic and social challenges we face and that many young people care passionately about. But you cannot be what you cannot see. We need to be clearer in schools about what engineering is – a creative subject that applies

science and design to real-world problems and which leads to fulfilling and rewarding careers for all kinds of students.”

Not far behind the need for more visibility of engineering in schools, the EPC research also revealed that 60% of respondents felt that making ‘engineer’ a restricted professional title in the UK, as it is in many other countries, could elevate the status of the profession.

Demonstrating just how important climate considerations are for the industry, 61% said they last changed their curricula to place a greater emphasis on sustainability, followed by 54% who did so to improve student satisfaction. This emphasis is certainly true of NMITE, with its Centre for Advanced Timber Engineering which aims to create a new workforce skilled in the use of sustainable construction materials and techniques, to drive the development of a much more sustainable built environment.

In line with the theme of the Engineering Academics Network Annual Congress, which was ‘New Models’, when asked what the most promising new models for engineering education are, over half (54%) answered project-based learning, with 49% choosing problem-based learning. Either way, both show that practical, hands-on learning by doing is the way forward, something that NMITE embraces wholeheartedly. Newby comments: “We teach our courses in studios, not lecture theatres, and in small teams –not large groups. Most importantly, the programmes involve, at every stage, engagement with employer partners and work on real life projects.”

The EPC and NMITE research also included an open-ended question around the gender gap in the engineering workforce, which highlighted a strength of feeling around the topic. While some rallied against the question and argued that women do prosper, others felt that concerns around unconscious bias and the industry being maledominated were a barrier. Off-putting workplace attitudes and culture, inflexible working patterns and a lack of accommodation for family commitments still present an issue for many women in engineering.

Fittingly, as part of the programme of events for the Engineering Academics Network Annual Congress, worldrenowned physicist Prof Dame Athene Donald DBE gave a lecture on 12th June, at Hereford Cathedral chaired by Karen Usher DL, NMITE Founder. The lecture, entitled: ‘Innovation: new ideas & new people’, explored the disadvantages and gender bias women face and explored common myths which could deter women from science. She made a compelling case for greater diversity in modern research to improve science and tackle the great challenges we face today.

For more information about the Engineering Professors’ Council visit https://epc.ac.uk and for more information about NMITE visit: https://nmite.ac.uk

14 JUNE 2023

INDUSTRY NEWS

ECONOMICAL COATING. FLEXIBLE APPLICATIONS. GM 5000 & GA 5000 Manual & automatic electrostatic guns • High transfer efficiency with wrap-around effect • Suitable for water-based & solvent-based paint • Excellent finishing results wagner-group.com Contact Wagner Spraytech (UK) Ltd a Member of WAGNER GROUP Telephone: 01327 368410 enquiries@wagner-group.com

Become an Acknowledged Leader in Surface Engineering and Materials Finishing: Industry Recognised Training Courses from the IMF

Are you involved with the application of coatings to enhance and protect your products? Do you need to meet client specifications to ensure the longevity of your components? Does the complex world of surface engineering and materials finishing cause you headaches?

If so, the courses offered by the Institute of Materials Finishing (IMF) could be your solution!

The IMF have been promoting knowledge in the surface finishing industries, both inorganic surface treatments including plating and the application of organic paints, lacquers and varnishes for many years. Large numbers of engineers and technicians across a multitude of industries have benefitted from the knowledge gained to enhance their careers, their standing within industry and the ability to

problem solve the many challenges they face in their daily working lives!

Starting with the Foundation level course, students gain knowledge on all aspects of materials finishing, specifically aimed at their own industry requirements, but to include sections on Health & Safety, the Environment and Surface Finishing and Corrosion Protection. There is no need for a

science background to be able to successfully complete a foundation course.

The Foundation Course requires study of 15 sections and requires the submission of 2 marked assignments followed by an end examination. The course, conducted by distance learning will take 16 weeks to complete. There are three specific study routes to choose from; electroplating, organic coatings and aerospace finishing. On successful completion, the student is awarded the Foundation Certificate. To follow on, students can then elect to progress to the Technician level modules, which give more in-depth knowledge for key finishing technologies, their application and best practice methods. Again, both inorganic and organic technologies can be studied to match the industry requirements. There is a choice of eight modules, which provide study in applicable areas of surface finishing best matched to your needs.

Like the Foundation course, study is by distance learning, and the student is required to complete four marked assignments and pass an examination. Passing two technician modules leads to the award of Technician Certificate; passing four modules leads to the award of an Advanced Technician Certificate.

If you feel your career could benefit from being a recognised specialist in your particular branch of Surface Engineering or Materials Finishing, then contact the IMF today. Speak with our training manager Karen Yates on +44 (0)121 622 7287 or e-mail at karen@materialsfinishing.org.

Move your career to the next level and join the finishing community and all the benefits that gives through the IMF.

16 JUNE 2023 INDUSTRY NEWS

HMG Paints Ltd Honoured as the 2023 Manufacturing Family Business of the Year

HMG Paints, a leading manufacturer of paints and coatings, has been named the Manufacturing Family Business of the Year at the prestigious Family Business of the Year Awards 2023. The awards, hosted by Family Business United, took place in the serene Medicine Garden located within the grounds of the Royal College of Physicians. The event aimed to recognise and celebrate the invaluable contributions made by family firms to the national economy.

“Family businesses are the engine room of the UK economy and with 6 million family firms employing around 14 million people in all corners of the country they make a massive impact each and every day” commented

Paul Andrews, Managing Director of Family Business United. “Incomes are generated, jobs provided and wealth created but as one of the family members said to me, ‘That is just the tip of the iceberg. Family businesses care

and want to be seen as doing the right thing, doing business the right way.’”

The accolade of Manufacturing Family Business of the Year is a testament to HMG Paints’ commitment to excellence, innovation, and the preservation of its family legacy, with the judges also recognising the companies support for the wider family business community. As a multi-generation family-owned business, HMG Paints has consistently demonstrated its dedication to producing high-quality paint products and industry-leading solutions for over nine decades.

18 JUNE 2023

INDUSTRY NEWS

C M Y CM MY CY CMY K

URBAN FURNITURE APPLIANCES

GENERAL INDUSTRIAL FUNCTIONAL COATINGS

Markets:

AGRICULTURE & CONSTRUCTION EQUIPMENT (ACE)

ARCHITECTURAL TRANSPORTATION

FURNITURE

TAILOR-MADE SOLUTIONS

PRODUCT INNOVATION

EXPERT TECHNICAL SUPPORT

“OVER 100 NEW ENQUIRIES FROM SURFACE WORLD LIVE 2022” - WE’VE GOT YOU COVERED!

John Falder, Chairman of HMG Paints, expressed his gratitude for the recognition received by the company, stating, “Being named the Manufacturing Family Business of the Year is an incredible honour for HMG Paints. We are immensely proud of our heritage and the values that have guided our family business since its inception. This award is a testament to the hard work and dedication of our team, who consistently strive for excellence in everything we do.”

HMG Paints Ltd has been at the forefront of the manufacturing industry, continuously delivering innovative

products and solutions to a diverse range of customers. The company’s commitment to sustainability, customer satisfaction, and community engagement has further strengthened its reputation as an industry leader.

Paddy Dyson, Marketing Manager “Being able to collect the award on behalf of all the team back at Riverside Works is an honour. We’re extremely proud just to be nominated for the award and be in the company of so many fantastic family businesses but to receive the Manufacturing Family Business of the Year Award was a fantastic surprise.”

Family Business United, the host of the Family Business of the Year Awards, is a leading resource centre and advocacy group dedicated to supporting and promoting family businesses throughout the United Kingdom. The awards ceremony provides a unique opportunity to highlight the importance of family enterprises and their significant contribution to the nation’s economy, you can find out more about FBU and the awards by visiting www.familybusinessunited.com.

For more information on HMG Paints and their range of products visit www.hmgpaint.com.

20 JUNE 2023

INDUSTRY NEWS

Trade shows can be a vital business platform for companies

Trade shows offer a unique opportunity for companies to showcase their products or services to a targeted audience of potential customers and industry professionals. They can also be a great way to network with other companies in the industry, learn about the latest industry trends and developments, and gain valuable insights into customer needs and preferences.

Why you should consider

brand awareness and reach a larger audience than they would through traditional marketing channels. This is particularly important for new businesses or those looking to expand their reach into new markets.

2. Generate leads

By exhibiting at a trade show, you have the opportunity to engage with potential customers, demonstrate your products or services, and collect contact information for follow-up after the event. This can lead to increased sales and revenue for your business.

3. Network with industry professionals

Trade shows also provide an opportunity for businesses to network

1. Build brand awareness

Trade shows provide a platform for businesses to showcase their products and services to a targeted audience of potential customers. By exhibiting at trade shows, businesses can build

with industry professionals. This can lead to valuable partnerships and collaborations that can benefit your business in the long term.

4. Showcase new products or services

By exhibiting at a trade show, businesses can get feedback from potential customers and industry professionals on their new products or services. This can help businesses refine their offerings and make improvements based on customer feedback.

5. Stay ahead of the competition

Businesses can learn about their competitors’ offerings, pricing, and

22 JUNE 2023

exhibiting at trade shows and how they can benefit your business:

SURFACE WORLD 2023

UK’S LEADING MANUFACTURER PYROLYSIS & BURN OFF OVENS Call Longworth today for a no obligation meeting on how we can help you and your business Longworth’s pyrolysis & burn off ovens are second to none in design and build quality, built to last and have the latest in technological features. Our ovens provide a quick and highly effective process for the removal of plastics, paints and resins from jigs, filters, shelving, food trays, motors, automotive parts and a multitude of other components. Our Pyrolysis ovens provide you with a quick and highly effective process for the removal of plastic, paints and resins Accreditations BS EN ISO 9001:2008 visit www.bmlongworth.com call 01254 680501 email enquiries@bmlongworth.com

marketing strategies. This can help businesses identify areas where they can improve and stay competitive in their industry.

In conclusion, exhibiting at trade shows can be an effective way for businesses to build brand awareness, generate leads, network with industry professionals, showcase new products or services, and stay ahead of the competition. If you’re looking to grow your business and reach a larger audience, consider exhibiting at trade shows as part of your marketing strategy.

as it needs to be eye-catching and memorable. Make sure it stands out from the other booths and is visually appealing.

5. Marketing materials

and distributors of surface coatings. This targeted audience provides businesses with the opportunity to showcase their products and services to the right people who are interested in their offerings.

1. Audience

Check the profile of the attendees expected to be at the trade show. Are they the right fit for your product or service? Will they be interested in what you have to offer? Make sure the trade show attracts the kind of audience you’re targeting.

2. Competition

Research and identify your competitors who will also be exhibiting at the trade show. You want to understand their marketing strategy, product offerings, and pricing to be able to position yourself effectively against them.

3. Booth location

Consider the location of your booth. Is it in a high traffic area? Will your booth be easy to spot? Is it located near any key players in your industry? These factors can all impact the number of visitors you receive.

4. Booth design

The design of your booth is important,

Ensure you have plenty of marketing materials on hand, such as brochures, flyers, business cards, and samples. Make sure they are high quality and visually appealing to attract potential customers.

6. Networking opportunities

Trade shows provide an excellent opportunity to network with other professionals in your industry. Take advantage of this by connecting with other exhibitors and attendees.

7. Follow-up strategy

Have a plan for following up with potential leads after the trade show. Collect contact information and ensure you have a system in place to track and follow up on these leads in a timely manner.

By considering these factors, you can ensure that attending a trade show is a productive and valuable experience for your business.

2. Networking opportunities

The trade show provides an excellent opportunity for businesses to network with other industry professionals, potential customers, and suppliers. Networking can lead to new business partnerships, collaborations, and sales opportunities.

3. Product launches and demonstrations

The trade show provides businesses with an opportunity to launch new products and demonstrate their products to potential customers. This can help businesses generate buzz around their offerings and attract new customers.

4. Market research

Surface World 2023 allows businesses to conduct market research by observing industry trends, competitor offerings, and customer preferences. This information can be used to improve business strategies and offerings.

Overall, the Surface World 2023 is a valuable platform for businesses in the surface coatings industry to showcase their products, network with industry professionals, launch new products, and conduct market research.

Surface World 2023 is being held at The NEC in Birmingham on 4th & 5th October 2023.

1. Exposure to a targeted audience

Surface World 2023 attracts a specific audience of industry professionals, including manufacturers, suppliers,

If you are interested in exhibiting or visiting this event, please contact Nigel Bean at:

Telephone: +44 (0) 1442 826826

Email: nigelbean1@aol.com

24 JUNE 2023

As an exhibitor attending a trade show, there are several things you should look out for. Here are some key considerations:

Surface World 2023 is a leading international trade show for companies in the surface coatings industry. This event is considered a valuable platform for businesses connected to this industry for several reasons:

SURFACE WORLD 2023

elcometer.com Everything you need for fast and accurate coating inspection in one cost-effective, easy-to-use kit. climatic conditions | surface cleanliness | coating thickness surface profile | weld inspection | surface inspection INSPECTION KITS Elcometer3045 · FAST · REPEATABLE · ACCURATE · DURABLE COATING Surface World - Kit - April 22.indd 2 04/04/2023 08:09:57

Is it time for some conveyor TLC?

Regular service and maintenance of your conveyor belts and equipment will save you in the long run. Breakdowns due to infrequent servicing and lack of spares can lead to down time and major disruption. By ensuring your equipment receives regular service and maintenance you are sure to save yourself a lot of hassle.

If there is one thing our many years of experience here at Midland Handling Equipment Ltd have told us it is that even the most reliable and highest quality conveyors will eventually break down. Regular maintenance and servicing may be viewed by some as unnecessary, but the reduced output and capacity can cost a lot.

Planning Maintenance

Here at MHEL we offer full installation, service and breakdown cover for our customers. To ensure your conveyor system is running at full capacity and reduce unnecessary faults and damage, it is key that you regularly service the machine. Our trained engineers will ensure the machine is fully working and safe. If any issues are found, we are happy to quote to fix the fault for you. The majority of faults we find are able to be fixed on site and on the first visit. We also offer a ‘Service Contract’ giving you fixed service costs over the year (we would advise two services a year), priority breakdown response and 5% discount on spares.

Spare Equipment

It is advisable for customers to carry some spare equipment in the event of breakdowns. We can send you a list of essential spares for your system. Our conveyors are also backed by our comprehensive spares stock, quick delivery and fast breakdown response time.

Are you interested in acquiring a conveyor system for your workplace? Have you a system in place that requires servicing to ensure it continues to run smoothly in future? Or perhaps you wish to guard against future problems by acquiring some spare equipment for your system?

If so, you have come to the right place. Contact the conveyor system experts here at MHEL for all your conveyor needs.

Telephone: 0116 259 3175

Email: enquiry@mhel.co.uk

Visit: www.mhel.co.uk

26 JUNE 2023

CONVEYORS & MATERIALS HANDLING

Touch the color with color2view The revolution in color management

The new color2view is your objective eye to evaluate total color impression: 45°c:0° Geometry – 20° & 60° Gloss – Built-in fluorimeter to predict lightfastness – Jetness

The new color2view is focused on easy and intuitive operation – an unprecedented user experience: Color touchscreen like your smart-phone – Smart sample clamp – Integrated standard storage – Exchangeable apertures

The new color2view has a superior technical performance to set-up a global color QC system: Digital standards exchange among portable & benchtop without extra profiling

Improve your efficiency using an overhead conveyor

The Railtechniek van Herwijnen Group of companies, which Stewart Gill Conveyors Ltd have been a long time member of, provides complete solutions for complex requirements in the field of materials handling. They produce a wide range of overhead conveyors and materials handling products, such as manual conveyors, chain conveyors, power and free conveyors and crane systems. For the surface finishing industry the most frequently delivered systems are Power and Free conveyors. P&F conveying systems offer a high degree of flexibility and they can be completely automated.

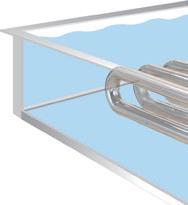

P&F systems are equipped with load bars to attach the products. The products can be transported through the complete process (Power) or stopped for buffering or treatment (Free) without stopping the complete system. Stewart Gill Conveyors Ltd offer a wide range of P&F systems, suitable for carrying capacities up to 9.000 kg per load bar.

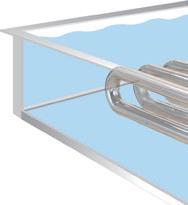

They specialise in systems for wet paint and powder coating lines, blasting installations, assembly lines, logistic and storage systems. A system that they offer specially for the surfacetreatment industry is a dipping tank crane system. Dipping cranes transport metal products in and out of a series of pre-treatment tanks.

Advantages of a Power & Free Conveyor

Compact and save design with movable parts inside the tack

Modular system with standard parts

Flexible design for optimal lay-out planning

Advanced automatic control system with touch screen user interface and remote access.

Components

Different standard components are available to design the most optimal conveyor lay-out. The track sections are available as Power & Free, Free or only Power in standard or cut-tolength sections.

Bends can be horizontal or vertical. The radius of the bends is often standard. Non standard bends can be made on request.

The power chain comes in standard chain link pitches and can be fitted with open or closed bearings.

Depending on product dimensions and the conveyor lay-out the product carrier can have different trolley configurations. Using multiple trolleys the load capacity of carrier can be increased.

A Power & Free system needs a drive system. Depending on system parameters the drive mechanism can be a caterpillar drive or a screw drive unit. For safety all drive units are utilised with a torque limiter that disconnects the drive force between the drive unit and gear motor.

Stop stations are available as standard design, ATEX or high temperature for curing ovens. Stop stations are controlled and monitored by the PLC/PC control system.

Switches are installed at the position where carriers must divert to other directions. Pneumatic cylinders with position sensors are used to actuate the switches. Depending on the position in the lay-out switches can also be self-switching. Switches are also controlled and monitored by the main control system.

To avoid as much as possible wear of the chain and trolleys a lubrication unit can be used. This automatic controlled device lubricates parts such as the chain links and bearings on a pre-set interval. Special parts are available such as lift- and drop sections, transfer chains, pneumatic pushers and product rotation units.

There are also solutions to have a dipping tank crane system take over the products from the carriers and after the dipping process hang them back onto the carriers.

To find the best conveyor solution for your needs contact Stewart Gill Conveyors Ltd.

Telephone: +44 (0) 1926 641424

Email: info@stewart-gill.co.uk

Visit: www.stewart-gill.co.uk.com

28 JUNE 2023

CONVEYORS & MATERIALS HANDLING

Product Overview

Manual Monorail Systems

Unit loads up to 3000kg

Handling Solutions

Stewart Gill Conveyors Ltd have been supplying overhead conveyors into all sectors of industry for over 70 years.

As a long time member of the Railtechniek van Herwijnen BV Group based in the Netherlands, Stewart Gill Conveyors can offer a comprehensive range of overhead conveyor products which are capable of handling unit loads up to 7000kg.

Monorail Chain Conveyors

Unit loads up to 300kg

Stewart Gill Conveyors Ltd offer complete manufacture, installation and commissioning, coupled with fully documented instruction, operation and maintenance manuals.

We do:

In-House 3D CAD engineering

In-House manufactoring in the UK and EU

Power & Free Conveyors

Unit loads up to 7000kg

In-House design of PLC/PC control systems

Industry 4.0

Worldwide installation and commissioning

Remote support, service & inspection

Part of the

Floor Conveyors

Unit loads up to 500kg

Gill Conveyors Ltd

3&4 Brook Business Park Brookhampton Lane Kineton, Warwickshire CV35 0JA, United Kingdom Tel: +44 (0)1926 641424 info@stewart-gill.co.uk www.stewart-gill.co.uk

Stewart

Unit

ELECTROPLATING, ANODISING & GALVANIZING

Rare Rhinos Housed for the Future Thanks to State-of-the-Art Enclosure

A new rhino enclosure at Knowsley Safari has been protected for decades to come thanks to two firms involved in its major redevelopment.

CLM Services Ltd were asked by the park’s team to provide assistance with the design, fabrication, and installation of six new paddock fence lines, four keeper areas, a dedicated veterinary area, and a VIP area for the brand-new rhino enclosure.

One of only a few fabrication companies registered as a Member with the British & Irish Association of Zoos and Aquariums (BIAZA), CLM Services called on its long-standing partners, Merseyside Galvanizing Ltd, to galvanize the steel and ensure the structures would be protected against corrosion and rust.

Eight white rhinos are now housed in the new enclosure, including a rare southern white rhino which was born shortly after work was completed.

“As a family-run business and member of BIAZA, we’ve worked on many zoological projects over the last 15 years,” explained Matt Hayes of CLM Services. “To be asked by the team at Knowsley Safari to develop a permanent new environment for its endangered white rhinos has been a real privilege, and we’re pleased to have

been able to deliver a fit-for-purpose solution for each of their requirements.”

A fence line structure was part of the scope of works, consisting of over 50 tonnes of precast concrete panels and 15 tonnes of galvanized steel, which allows staff to safely access the rhinos and undertake a range of vital animal welfare activities.

Six sliding gates, each weighing 500kg, were also installed along the fence line to allow keepers to transfer the rhinos safely from paddock to paddock, including a keeper porch designed to provide them with close access whilst remaining fully protected by a solid partition.

“One of the most innovative parts of the overall design was the vet area, which weighed five tonnes and included two manual and fully adjustable sliding gates to safely contain rhinos, allowing staff to adapt the size of the area based on the individual rhino’s size and conduct hoof inspections and weigh-ins,” Matt added.

“It’s always beneficial to use galvanizing for an environment like this where steel is open to the elements, and often harsh weather conditions. It can also

be washed down with ease and without worry of damaging the structure, helping keepers to maintain a clean habitat and ensure the continued welfare of animals. The team at Merseyside Galvanizing once again delivered on the brief and provided us – and the safari team – with the reassurance that the steel structures will last for decades to come.”

Richard Smetham, Sales Manager at Merseyside Galvanizing (part of Wedge Group Galvanizing Ltd), added: “We always look forward to working with CLM Services as we know the structures we’re galvanizing play such an important role – whether it be for animals, or for key construction projects and ariel amusement rides.”

Merseyside Galvanizing Ltd is part of Wedge Group Galvanizing Ltd, the largest hot-dip galvanizing organisation in the UK with a history dating back over 150 years. With 14 plants strategically placed across the country, the firm offers a truly national galvanizing service.

For further information, please contact Wedge Group Galvanizing on 01902 601944 or visit www.wedge-galv.co.uk.

30 JUNE 2023

Hot dip galvanizing provides you with long-term protection against rust and corrosion of steel products. With 14 plants across the UK, Wedge Group

Galvanizing is the UK’s largest hot dip galvanizing organisation offering a national service, collection and delivery and 24hr turnaround on request. The group can process anything from small components to 29m structural beams.

Solutions for Parts & Paint Spray gun cleaning WASHERS ASK FOR A FREE QUOTE Manual | Automatic Our high quality, advanced range of equipment provides the best way to clean paint spray guns or industrial parts. With numerous options, you can be sure that there is a model in our extensive range that meets your cleaning requirements using either solvents or water. ATEX certified • High quality alloy pumps Stainless steel construction • Wash cycle controlled by timer • Wash & rinse • Hot water wash • Inbuilt water recycling • Inbuilt solvent recycling Air extraction • 2 year warranty BUY OR LEASE www.solutex.co.uk info@solutex.co.uk | 01691 622 225 For more information visit: Head Office: Stafford Street, Willenhall, West Midlands, WV13 1RZ ISO 9001 Quality Management FM 00382 E: info@wggltd.co.uk T: 01902 601944

WEDGE GROUP GALVANIZING Your Galvanizing Partner WASHING SYSTEMS EFFICIENT - ROBUST - RELIABLE INNOVATION FOR ALL YOUR WASHING NEEDS • SMALL BATCH WASHING TO CONVEYORISED SYSTEMS • SPRAY, SOAK , ULTRASONIC OR COMBINATION MACHINES. • FULL AFTER SALES SUPPORT • IN HOUSE TEST FACILITY • EUROPEAN WIDE CUSTOMER BASE • STANDARD AND BESPOKE SYSTEMS AVAILABLE • COMPLIMENTARY CHEMICAL RANGE AVAILABLE Call 01543 675800 or visit our website www.unitechwashers.uk.com

Reduce Costs With Inline Measurement For Electroplating Reel-To-Reel Applications

Keeping the tolerance limits for layer thicknesses

Electroplating reel-to-reel production lines need to maintain minimum and maximum tolerance limits for the applied coatings. To save costs, layers are coated as thin as possible - especially when using precious materials. However, a certain margin between the minimum limit and the nominal applied layer thickness is necessary to ensure the adherence of the lower tolerance limit due to process variations.

Efficient Coating Processes

Usually, strips at the beginning and at the end of a reel are cut out manually and measured offline. This is time consuming for the staff and the reaction time is too long: If a tolerance limit is violated, it is too late to interfere since the coating process is finished and the reel already left the production line.

The X-ray fluorescence method (XRF)

Inline measurement equipment –based on the x-ray fluorescence (XRF)

principle – provides continuous data about the applied coating thickness and allows immediate production process control. Feedback loops can be set up either with automatic communication between XRF instrument and coating line or manually by the operator. Therefore, the nominal applied thickness can be chosen to be closer to the minimum tolerance limit which significantly saves costs. Obviously, this is most effective for valuable metals but it also adds up for other coating materials. Additionally, products with rather tight tolerance limits can be manufactured only if there is a measurement system in the production line to determine the actual applied coating.

Saving Cost and Time with the Right Measurement Technology

The following example where a gold (Au) coating of 2 – 4 µm needed to be applied shows the cost saving effects of such inline process control: Using offline instruments for quality control the nominal coating thickness was set to 2.8 µm Au to ensure not to violate the tolerance limit. After installing the inline measurement system FISCHERSCOPE® X-RAY 4000, the nominal coating thickness could be lowered to 2.3 µm Au.

Just by saving the 0.5 µm gold coating, the investment was amortized within half a year! Additionally, the production is now 100% documented. Every customer buying an electroplated reel gets a protocol with a statistical summary and a profile ensuring that the whole strip is coated properly within defined tolerance limits.

The Optimum Measurement Device for Production-Lines

Using the FISCHERSCOPE® X-RAY 4000 production cost can be lowered significantly by reducing material consumption, especially effective for precious materials, and by eliminating scrap production. Additionally, 100% of the applied coatings on the product are recorded and therefore traceable to comply with ISO9000 standards. For further information, your local FISCHER partner will be glad to assist you.

For more information, please contact your local FISCHER representative:

FISCHER INSTRUMENTATION (GB) LTD

12 Goodwood Road, Keytec 7 Business Park, Pershore, Worcestershire, WR10 2JL.

Telephone: +44 (0)1386 577370

Or visit: www.fischerinstrumentation.co.uk

32 JUNE 2023

TESTING & MEASUREMENT

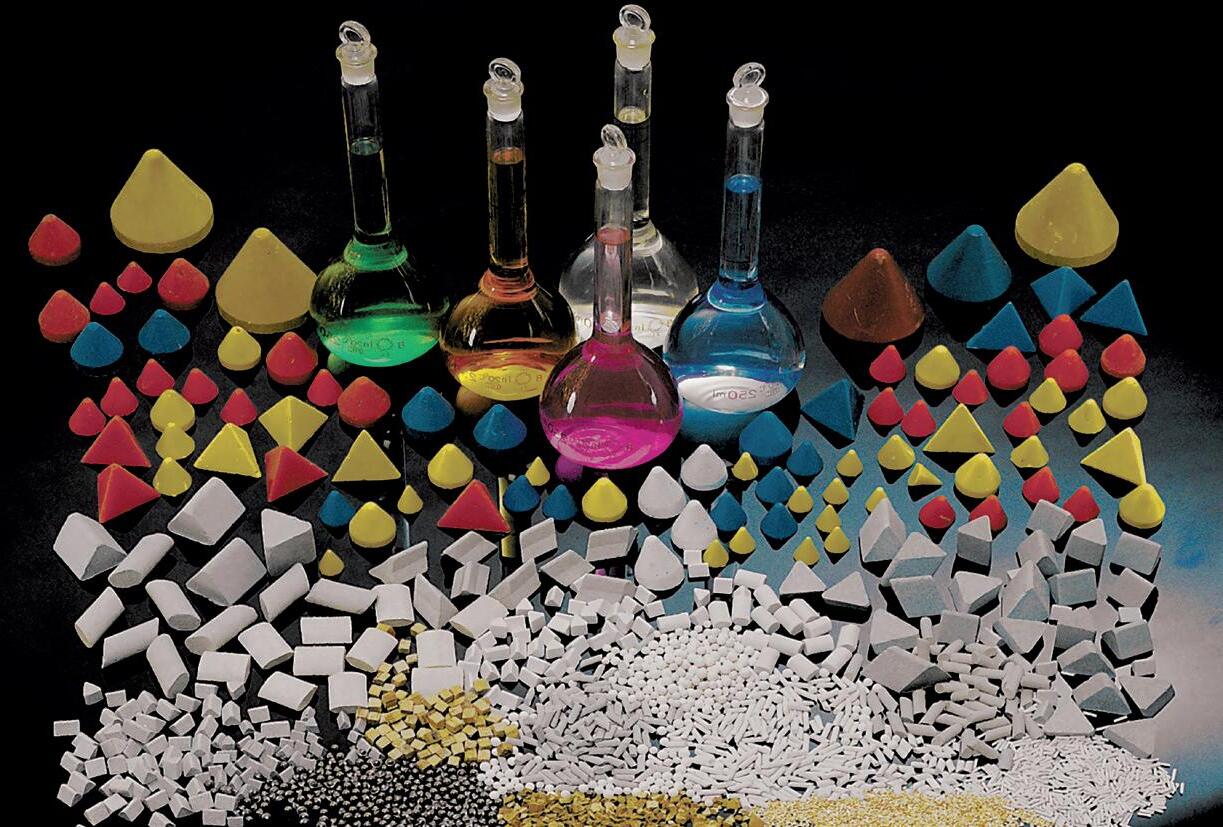

WE’RE OBSESSED WITH COLOR YEARS OF EXPERIENCE IN RESEARCH & DEVELOPMENT OF CUSTOMIZED INDUSTRIAL COATINGS brands of The Sherwin-Williams Company A complete range of industrial coatings Waterborne | Powder | Solventborne | High solid | E-coat The Sherwin-Williams Company, Goodlass Road, Speke, Liverpool, L24 9HJ, United Kingdom | T: +44 (0)151 486 0486 | e-mail: liverpool.sales@sherwin.com

Paint Cure Monitoring –PhoenixTM Helping drive Quality and Coating Oven Economy

Monitoring what is happening inside your cure oven is critical to understand how your paint or powder coating operation is working. PhoenixTM understands the challenges you face running your operation, to not only get the coating cure quality you need but keep your oven technology up and running as economically as physically possible. With energy costs and ever increasing labour costs you need to make your operation run efficiently and make those costs savings wherever possible. To help you get the best out of your oven PhoenixTM offer a monitoring toolbox to suit your specific needs.

Comprehensive Product Temperature Profiling

consistent Phoenix Factor. A value close to 1.00 equals perfect theoretical cure with < 1.00 potential under cure >1.00 potential over cure.

With the current energy crisis, the tool provides a further benefit in that is allows operational characteristics of the oven (zone set temperatures / line speeds) to be optimised with confidence and with no risk to the cure quality. Consider what effect potentially dropping your set-point temperatures by 10 °C could make to the operating cost of the oven over a month or year! When setting up new processes or changing energy / heating sources you can monitor your process to permit quick effective optimisation. As they say look after the pennies and the pounds will look after themselves. Even in coating every little counts!

Oven Temperature Uniformity Surveying (TUS)

The PhoenixTM Thru-process temperature profiling systems provide you with an accurate record of what temperature your product experienced in the cure oven. Thermal View Finishing software provided with the system converts the raw temperature profile data into meaningful information. The software is designed with all the analysis and process documentation tools to fully interpret and communicate paint cure performance.

To provide an accurate method to quantify cure PhoenixTM have developed its own mathematical index of cure calculation referred to as the Phoenix Factor. The Phoenix Factor gives the paint technician a perfect numerical tool to easily and accurately confirm that the cure process is working to the coating supplier specification, guaranteeing quality of cure and eliminating rejects or need for rework and corresponding cost. Irrespective of the profile shape, as all profile data is utilised, it’s as simple checking for a correct

To perform a TUS to comply with CQI-12, PhoenixTM have developed a software package specifically designed to allow efficient surveying of the oven. At critical TUS temperature levels data logger recorded data can be analyzed to check that at all points on the TUS frame (oven working zone) are within a specified tolerance (Target TUS temperature ± Tolerance) and remain in tolerance for the period of the specified TUS test. Graphical tools and analysis tables allow easy clear data interpretation.

34 JUNE 2023

TESTING & MEASUREMENT

THIS IS HANGON

HangOn is a partner who helps customers to nd smart solutions to increase the e ciency in their coating process and improve their pro tability. We develop and produce in own factories. Our products are distributed from our warehouses into more than 40 countries.

HangOn Ltd. Leintwardine, Craven Arms, Shropshire, SY7 0NB WEB www.hangon.co.uk EMAIL sales@hangon.co.uk TELEPHONE 01547 540 573

Accuracy of data can be maximized through auto application of both data logger and thermocouple correction factors. All analysis and reporting requirements of the CQI-12 are provided by the software to verify full compliance.

For continuous processes the data logger can travel safely, protected by a suitable thermal barrier, with the TUS frame through the process. Live data can be transferred if RF telemetry is used, otherwise, the TUS run can be simply downloaded post run for full TUS analysis and reporting.

For batch oven processes the data logger can be used externally to the oven trailing TUS thermocouples without need for thermal protection. Each thermocouple is fixed to the designated location on the TUS frame positioned in the oven cavity. Live data generated during the run can be viewed in real time in the survey software during the TUS run. Data transfer from data logger to PC can be performed by either a hardwired comms cable, Bluetooth or optional RF telemetry feature.

Oven Optical Profiling

Thru-process temperature profiling provides a great understanding of what temperatures the product sees travelling through the cure oven. In terms of paint quality

though, in particular cosmetic finish and paint defects, this is not the complete story. During the journey through the oven the painted part can experience many problems that are not temperature related that can affect the quality of the cured paint. Problems such as paint runs, drips, or paint inclusions from dust or particulates can only be detected post process without any specific knowledge of the root cause / location in the oven of the problem. The Optic system developed by PhoenixTM travels through the paint cure oven with the product capturing a live video of exactly what the product sees on its journey. The optic system shown above can combine temperature and optical profiling in a single run. The technology is perfect to detect the source / root cause of paint inclusions. Dust contamination in the oven can be detected as streaks of light passing across the torch illuminated video image, just like a shooting star across the night sky. The same system can detect damage to the inner oven walls / insulation which may be the cause of heat losses resulting in inefficient operation and wasted energy.

To understand, control and optimise your coating operation why not PhoenixTM your finishing oven today!

Email: sales@phoenixtm.com

Visit: www.phoenixtm.com

36 JUNE 2023

&

TESTING

MEASUREMENT

PosiTector ® Inspection

Unrivaled probe interchangeability for all of your inspection needs.

Coating Thickness Probes

n Ferrous n Non-Ferrous n Combination n Ultrasonic

Surface Profile Probes

n Depth Micrometer n Replica Tape Reader

Environmental Conditions Probes

n Integral n Cabled Magnetic Probe n Anemometer Probe

n 1/2” NPT n Infrared

Hardness Probes

n Shore n Barcol

Salt Contamination Probe

n Bresle Method

Ultrasonic Wall Thickness Probes

n Corrosion n Multiple Echo Thru-Paint n Precision

DesignandFeatures

Customized Inspection Kits... Build your own kit from a selection of gauge bodies and probes to suit your needs.

Coating Thickness Surface Profile

Conditions

Backwards Compatibility! The redesigned PosiTector gauge body accepts ALL coating thickness (6000/200), environmental (DPM), surface profile (SPG/RTR), salt contamination (SST), hardness (SHD/BHI), and ultrasonic wall thickness (UTG) probes manufactured since 2012.

DFT Instruments UK LTD

DFT Instruments UK LTD

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN

Long Drive, Meadway, Berkhamsted, Herts HP4 2PN

01442 879494

01442 879595

Proud

supplier of DeFelsko Inspection Instruments

16A

t:

f:

www.dftinstruments.co.uk e:

sales@dftinstruments.co.uk

Ultrasonic

Environmental

Wall Thickness HardnessSalt Contamination

NEW

Proud

DeFelsko

16A

t:

f:

www.dftinstruments.co.uk e:

n Low Frequency n Xtreme NEW

supplier of

Inspection Instruments

01442 879494

01442 879595

sales@dftinstruments.co.uk

DesignandFeatures

PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING

Straaltechniek UK Shot Blast & Shot Peen Equipment Modernisation Programmes E.M.P.

With over 150 years of combined experience Straaltechniek UK can offer extensive Equipment Modernisation Programmes for all types of Surface Preparation Blasting & Shot Peening Equipment at a fraction of the cost of new installations.

Why EMP? Jay Dorling (Sales Director) at Straaltechniek UK explained ‘that many of our customers we service and supply spare parts to have older generation shot blast and shot peening machines and although well maintained by the Straaltechniek UK Service Division for various reasons do not fulfil the latest health & safety legislation and increased production demands of improved modern day processes.

This usually results in the request for significant capital investment for the latest new design modern replacements.

However, in highly competitive industries this investment may not be forthcoming straight away but in the short & medium term all is not lost! Older machines can be retrofitted and upgraded with the latest technology.’

What are the Main Drivers for EMP?

1. Health & Safety

2. Manufacturing Method Changes

3. Inability to meet Output Demands

4. Increased Cycle Times

5. Superior Cleaning Standards Required

6. Higher Levels of Contaminant to be removed.

7. Production Demands V Preventative Maintenance

8. Dust Emissions legislation changes.

9. Increase Profitability of Older Equipment

10. Limited Investment Budget in difficult times

Straaltechniek UK have a wide range of EMP programmes to assist customers when legislation and production demands require more from their existing equipment. Health & Safety, Dust Filtration, House-keeping, Handling & Ergonomic issues are classic examples. The health & safety of all employees is paramount in any modern businesses who must comply with the latest H&S regulations. Straaltechniek UK can assist these businesses with advice and upgrades to meet with these mandatory demands. Whether it is working from heights, near to powered moving machinery, excessive noise, dust or ergonomic issues

Straaltechniek UK can provide the latest bespoke solutions. Many customers are operating without suitable Simple Safety Interlock

Guarding, Light Guarding, Laser Guarding, Maintenance

Access Ladders & Platforms, Bulk

40 JUNE 2023

Simple Safety Interlock

Bulk Abrasive Replenishment

Minimum Manual Handling of 25kg bags

Automatic Abrasive Replenishment, Acoustic Enclosures, Handling Systems and ATEX Dust Filters.

Jay went on to say ‘that if Companies are unsure of their obligations

Straaltechniek UK would be happy to help with any issues they may perceive they have including any other process, production or operational issues with their shot blasting equipment that our EMP Programmes may help them with’.

Telephone: +44 (0) 1142 571077

Email: info@straaltechniek.co.uk

Visit: www.straaltechniek.co.uk

41 JUNE 2023

Acoustic Enclosures & Noise Attenuation >85DBA

Access Platform & Ladder

Two Dimensional Laser Beam Guarding System (Costly Mechanical Guards Eliminated)

Should you automate your cleaning process?

Well, that depends on the type of cleaning process you have, but the good news is, they can all be automated in some way, but the bigger question is, what are the benefits of automation in a cleaning process? Initially it is probably the usual most common issue of operator costs to load and unload parts into the cleaning system. This is an easy one, just compare the cost of the operator with the cost of automation.

A lesser understood reason to automate the cleaning process is “Process Control” and this can be a more difficult justification depending on the application. Many applications have a forgiving process however if corners are cut or untrained operators are asked to pick up the slack during busy times this can lead to problems much further down the production line. In addition, many applications require a clearly defined and repeatable process to comply with either a customer’s specification or to ensure the cleanliness specification is consistently met and it is critical the components go through the correct predefined process. For example, some components may not be allowed to go through a process with Ultrasonics while others can, some parts may require to only go through a certain limited process or miss out one tank or other components require longer to dry. With basket flagging or bar code recognition, automation can control all these variables, in addition you can process multiple components through different processes in the same system saving time and money. Add to that data logging, remote access and data downloads you can rely on the automation to select the correct process every time, insuring repeatability and have full traceability.

A lesser known advantages of many automation systems in the cleaning sector is process monitoring. While the equipment may well do this, the automation can control whether or not to process parts depending on the input from the cleaning system its self, for example, chemical

temperature can greatly affect the performance of a process, likewise chemical concentration, with a go/no go option depending on the criteria of the process this can be controlled and baskets held until these parameters are met. Additionally, DI water quality can be a good indicator of effective final rinsing and depending on the mix of component or quantity which can vary from batch to batch the recovery time of a DI water tank can vary, again, automation can control this element as well.

There are many variables and cost benefits to automating a cleaning process, some are obvious however some are more subtle but can have significant cost implications further down the line if the controls are not put in place.

Having spent over 30 years in this business it is amazing to see how automation has moved on from the early pick and place systems to todays fully automated and connected systems however, it is vitally important to not get carried away and over specify a system and you should always keep one eye on the cost, performance benefits.

With over 55 years of experience in component cleaning, across all areas of manufacturing, Fraser Technologies is the name to trust. For more information, visit www.frasertech.co.uk or call 01506 443058.

42 JUNE 2023

PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING

PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING

Offering Intelligent Cleaning Solutions for Demanding Applications

Kemet International is a leading provider of intelligent aqueous cleaning solutions that cover a wide range of industry-demanding applications. With a complete turnkey solution to your cleaning requirements, Kemet can help you find the optimal solutions to your cleaning needs, whether it’s a completely new cleaning project or a review of an existing one.

Achieving effective and efficient aqueous cleaning can be difficult, and it requires a harmonious interplay between chemistry and equipment. To address this challenge, Kemet offer more than 300 cleaning solutions, tailored to meet the specific needs and regulations of new applications. Additionally, Kemet has the resources of

its partners at NGL’s Laboratories, where chemists study, formulate, develop, and manufacture cleaning solutions. This partnership assists in process validation and approval of preliminary tests, saving time in the development of customer projects, and guidance and assistance in preparing specifications for equipment investment.

In addition to Aqueous Ultrasonic Cleaners, Kemet also offers; Vacuum Solvent Cleaning machines operate in a complete vacuum treatment cycle in all phases, ensuring excellent cleaning of finished products from wastage and oily substances, without releasing harmful substances into the environment. Utilising modified alcohols with a flash point exceeding 60°C under vacuum, eliminates the need for manufacturing machines with ATEX approved ratings, resulting in reduced construction expenses.

Passivation machines are designed to comply with ISO 7 clean room standards, ensuring that your parts are

properly prepared for their intended use. The machines are furnished with validation software compliant with ‘21 CFR part 11’. This software guarantees adherence to the stringent regulatory standards imposed by the aerospace and medical sectors, making them the perfect choice for deployment in these tightly regulated domains.

Fluorescent Penetrant Inspection machines are specifically engineered as a highly efficient NDT method for detecting surface-breaking flaws, cracks, and defects that may remain undetected by other means. Engineered to adhere to the widely recognised ASTM E1417 FPI standard, extensively utilised in the aerospace and medical sectors.

Vapour Degreasing Cleaner is designed for efficient and safe degreasing using compatible solvents. This innovative cleaner offers a highly effective method for removing oils, grease, contaminants, and other unwanted substances from various surfaces. By harnessing the power of vapour degreasing, this system ensures thorough cleaning while minimising environmental impact and promoting operator safety.

Spray Washing machines for cleaning parts before maintenance or between production phases. Offers an optimal solution for swift and efficient part cleaning within a closed chamber, promoting a better working environment.

Contact Kemet International today for intelligent aqueous cleaning solutions. Benefit from their expertise and the feature-packed Versa Genius+ ultrasonic cleaning system at their dedicated test centre. Kemet, in partnership with NGL’s Laboratories, delivers tailored cleaning solutions for a wide range of industry applications. Trust Kemet International for exceptional cleaning solutions.

Visit www.Kemet.co.uk or contact +44 (0) 1622 755287 or Sales@Kemet.co.uk for more information and to arrange cleaning trials.

44 JUNE 2023

ultrasonic-cleaning

Innovative-Cleaning-Solutions

We solve our customers filtration, chemical transfer and treatment needs.

PUMPS & FILTERS

L SERIES | Medium flow rate filter

P SERIES | Ultra-high flow rate filter

A SERIES | Mechanical seals pump

M SERIES | Magnetic drive pump

T SERIES | Vertical pump [...]

FILTER MEDIA

L-TECH | Pleated cartridge

BAGTECH | Filtration bag

QUALITHERM | Extruded cartridge

QUALIBOB | Wound cartridge

ANODTECH | Anode bag [...]

SPECIAL SYSTEMS

ACIDPURE | Acid recycling

EASYPURE | Fluid recycling

IONPURE | Ionic filtration

ACIDVAC | Acid draining vacuum

EDUCTORS | Bath agitation [...]

Contact us SIEBEC UK Ltd, Stafford +44 (0) 1785 227700 sales@siebec.co.uk www.siebec.co.uk

“The Professionals” email info@pros trip.co.uk phone 01 1 5 91 1 2240 “Save up to 20% on your monthly s tripping cos ts” Send your enquir y today!! Sub contract specialists in Paint & Powder coat removal to the finishing industr y JIG CLEANING PAINT BOOTH GRID CLEANING COMPONENT RECLAMATION EST . 1989 Pro-Strip Ltd. Trent Lane, Daleside Road, Nottingham NG2 4DS web www.prostrip.co.uk

Surface Finishing is our DNA AM Solutions Shot Blasting Individual systems engineering and intelligent process solutions –reliable and energy efficient The full solution provider for 3D post processing equipment and 3D printing services Mass Finishing Efficient systems engineering and innovative technologies – powerful and economical Rösler UK Limited| 1 Unity Grove | Knowsley Business Park | Prescot | Merseyside | L34 9GT Tel: +44 (0)151 482 0444 | Fax: +44 (0)151 482 4400 | rosler-uk@rosler.com | www.rosler.com

PRETREATMENT, SURFACE PREPARATION, DEGREASING & CLEANING

Cleaning of industrial pre-treatment liquids with centrifuges Achieving substantial annual cost savings and improving sustainability