EPSON WOWS AT VISUAL IMPACT

HOW TO BE A MORE SUSTAINABLE PRINT SHOP AND IMPROVE YOUR BOTTOM LINE! (PART 2)

FEATURE ARTICLE

KISSEL + WOLFAUSTRALIA’S MOST DIVERSIFIED PRINT SUPPLIER

EPSON WOWS AT VISUAL IMPACT

HOW TO BE A MORE SUSTAINABLE PRINT SHOP AND IMPROVE YOUR BOTTOM LINE! (PART 2)

KISSEL + WOLFAUSTRALIA’S MOST DIVERSIFIED PRINT SUPPLIER

Welcome to the June issue of Textile Image Magazine.

It’s been a busy time attending trade shows with Visual Impact, FESPA Munich, and ITMA Milan, all in the space of 8 weeks, bringing with them a swathe of new products being showcased for the first time.

Domestically, Visual Impact was held in Sydney in May for the first time since 2018. Visual Connections reported that attendance was up 10% on 2018 and 20% on 2017, and it was pleasing to see even more focus on textile printing and garment decoration than previous shows, not only from exhibitors but also in the forum presentations.

Regarding product categories, direct-tofilm is still going from strength to strength,

with more new product releases in this space than ever before, including Mimaki’s first foray into DTF, which was shown for the first time at FESPA Munich.

In this issue, Pamela Mannell, founder of T-1 Print, brings us part two of her series on how to become a more sustainable print business and improve your profitability. We also speak with Greig Wood, Managing Director of Kissel + Wolf to learn more about the evolution of one of our textile printing industry’s oldest and most trusted suppliers.

As always, we love to hear about your latest projects, so feel free to reach out to us at editor@imagemagazine. com.au. You can also subscribe to our weekly newsletter for all the latest news and events, and follow us on LinkedIn, Instagram and Facebook.

PUBLISHER

Janet Maitland Image Publications Pty Ltd

PO Box 613 Brighton SA 5048

E info@imagemagazine.com.au

P 1300 001 393

W imagemagazine.com.au

EDITOR

E info@imagemagazine.com.au

P 1300 001 393

ADVERTISING

Janet Maitland

P 1300 001 393

E info@imagemagazine.com.au

SUBSCRIPTIONS

Available FREE to all IMAGE MAGAZINE subscribers

DEADLINES

TEXTILE IMAGE is published

3 times per year.

Next issue: October 2023

Booking & material deadline: Friday September 8, 2023

DISCLAIMER

The opinions expressed in this magazine are not necessarily the views of the publisher. While every effort has been made to ensure the accuracy of information contained in this magazine no responsibility is accepted by the publisher for any omissions, inaccuracies, typographical errors or printerʼs errors. No responsibility will be accepted for any changes to information after publication.

Best Regards, Janet

Maitland

system, all ensure that processes are carried out efficiently with minimal intervention needed.

As the company’s first entry into a new segment, Mimaki has created its own range of water-based pigment inks (PHT50) especially for this solution. These inks will be OEKO-TEX ECO PASSPORT certified from March 2023, guaranteeing safety and environmental standards are met, in line with Mimaki’s sustainability pledges.

Mimaki’s first foray into DTF technology, the TxF150-75 has made its international show debut at FESPA. DTF printing provides an easy and affordable process for decorating apparel, most commonly T-shirts. The design is initially printed directly onto a special transfer film, which is then sprinkled with hot-melt powder. Once heated and dried, the transfer sheet is ready to be applied to the fabric using a heat press.

Based on Mimaki’s existing 150 Series, one of its best-selling models, the new TxF150-75 responds to the market, providing a reliable, stable DTF technology. Built-in ink circulation system and degassed ink pack design prevent

common DTF issues, such as poor ink ejection and white ink clogging. These core technologies, which also include the nozzle check unit and nozzle recovery

The printer also comes with Mimaki’s RasterLink7 RIP software, allowing users to have full oversight and the ability to streamline the process from the design to the final product. Like with all Mimaki technologies, buyers can expect extensive in-house support from Mimaki throughout the initial set-up and use.

STAY INFORMED REGARDING THE LATEST ANNOUNCEMENTS, NEW APPOINTMENTS, INDUSTRY TRADE SHOWS, EDUCATION AND INDUSTRY TRENDS.

Featuring six staggered Brother industrial print heads with internal cooling fans for continuous printing. The staggered print heads, means that white ink is printed first, followed by orange and green, with CMYK as the top layer. The inks are filtered and degassed to guarantee optimum print quality up to 1200 dpi. In addition, the built-in air filter ensures perfect working conditions in all printing environments.

The water-based innobella inks are OekoTex Pass and GOTS certified and come in 9l tanks with less packaging material.

The Brother GTX600 direct-to-garment printer has been further refined to include orange and green for even more colours and more vibrancy. Two extra tanks and two extra print heads offer orange and green ink which increases the colour gamut.

The printer has plates in different sizes up to 24 inches designed to handle a wide range of textiles and promotional products, and are quick and easy to change. The printer can automatically adjust the plate height to create an optimum distance between print heads and textile.

DTF is a method that rivals Direct to Garment printing (DTG) as it is capable of printing onto non-treated cotton, silk, polyester, denim, nylon, leather, 50/50 blends, and more. It works equally well on white and dark textiles. The process is simple: Print onto the coated PET film. Apply the lightweight powder either manually or by using an automatic powder shaker. Bake the powder coated print resulting in an image ready for transfer now or at a later date.

At just 24 inches wide, the Japanese made Mutoh STS VJ628D fits into any size print shop

STS DTF inks are ECO PASSPORT, OEKO-TEX certified, nontoxic and environmentally friendly. Made in the USA STS DTF inks have consistent colour from batch to batch, deliver high colour density with excellent print performance and great wash fastness.

With a low price point and perfect size, the Mutoh STS VJ-628D is the best option for anyone entering the custom apparel marketplace.

“This new system is a good fit for KIWO”, says Andrew Marrs from Kissel + Wolf, “it’s the traditional technology of DTG [Direct -to-garment] and heat transfer materials partnering with the reliability of Mutoh, giving added support to our customers, with the back up of Mutoh.”

Epson has launched the new SureColor F2200, at FESPA Munich direct-togarment printer tailored for medium volume printing.

Epson has strengthened its position in the DTG (Direct to Garment) market with a significant upgrade to its SureColor F2100 Large Format Printer. The new SureColor F2200 is ideal for start-up companies or medium-volume businesses that need high levels of flexibility and accuracy, with fast turnaround times.

Designed to produce complex designs on a variety of garments, the SureColor

F2200 uses Epson’s advanced PrecisionCore MicroTFP printhead technology to provide faster printing and data processing speeds, resulting in a productivity increase of up to 25%* over its predecessor, while maintaining extremely high print quality. With a highly compact, flat top design that allows easy installation into smaller spaces, flexibility is further enhanced through Epson’s bundled GarmentCreator2 software, which not only enables the printing of both DTG & DTFilm but improves the quality of fine lines and small text.

Offering a range of enhanced features designed with ease of use in mind, the SureColor F2200 allows businesses to maintain high levels of production and quality without the need for specialist operators. A transparent lid and internal light, for example, enable easy printstatus checking, while an intuitive 4.3-inch touchscreen makes operation fast and simple. With automatic carriage height adjustment, the F2200 remains stable with minimal adjustment by the user, and

The SC-F6460 is designed for medium to high production volumes. It combines a large 1.33” Epson print head with advanced Epson Dye Sublimation ink, a high-capacity tray-loaded ink system, and advanced Precision Dot image processing. All components work together to enable superior imaging with fine gradation, an expanded gamut, and high colour density. The engine and ink system enable cost-effective production at speeds up to 70.8sqm/hr. The integrated autocutter enables cut-sheet output for operation with a flat heat press while an optional Auto-Take-Up (ATU) enables fast and efficient roll-to-roll production for operation with a calendar style heat press.

It features the latest 1.33" Epson PrecisionCore™ (TFP) print head with Epson UltraChrome™ DS ink enables superior and consistent colour at resolutions up to 600x1200dpi. employs Epson precision dot image processing with new LUT, HTM and print modes for even finer gradation and a wider gamut.

the platen can be easily removed and attached by hand, making adjustment for printing different garments quick and straightforward. The GarmentCreator2 software, features faster data processing well as 600dpi resolution, to deliver exceptional colour output.

With a very low TCO, the F2200 uses new UltraChrome DG2 Ink Pouches, instead of cartridges. These 800ml pouches (previously 600ml) mean a lower change frequency, and significantly reduce wastage, in terms of space and weight, compared with ink cartridges. Epson’s DG2 ink also reduces bleed between yellow and black, which is important for applications such as light T-shirts, and maintains colour consistency with DG ink.

Straightforward to set up and start printing, the F2200 is supplied as a complete package, including consumables, warranty, servicing and support.

* Light garments only. 15% for darker garments. Compared with SureColor F2100

The SureColorF6460 comes with a comprehensive warranty (including print heads) and flexible coverPlus for up to 5 years total on-site service. features an integrated Epson Cloud Solution PORT server for convenient web/app based remote management and reporting along with enhanced back-end support.

range of industry experts and educators such as Epson, The Hanes group and Bonds with ongoing feedback from the Indigenous creative community.

Craig Heckenberg added, “Our partnership with FNFD is built on a shared vision of promoting cultural and economic sustainability. Through directly supporting inclusive and authentic initiatives such as THE ICONIC x FNFD Incubator Program we will add value by providing access to the world’s most advanced textile printing technologies. We will also share new skills and knowledge to help First Nations designers understand how they can digitally translate their designs into high quality fashion.”

EPSON HAS SIGNED A LANDMARK TECHNOLOGY AND SUSTAINABILITY AGREEMENT TO SUPPORT FIRST NATIONS FASHION + DESIGN (FNFD), THE NFP INDIGENOUS CORPORATION WHOSE GOAL IS PROMOTING THE GROWTH OF THE INDIGENOUS FASHION SECTOR.

Epson Australia MD, Craig Heckenberg said, “We are very excited to be working with Grace and her team at FNFD to promote the growth of Indigenous fashion and provide new skills and knowledge to help First Nations designers tell their stories through the art of fashion using Epson digital printing technologies.”

A big part of the discussion around a potential partnership between Epson and FNFD came from the fact that Epson had just launched their Monna Lisa ML-8000 direct-to-fabric printer.

Lee said, “FNFD’s vision is to partner with organisations that can support First Nations designers, businesses and communities in the fashion industry in

order that they can grow and develop their skills and businesses to become commercially self-sufficient. Then allow the value they have created to flow back into their communities - thus creating a self-supporting ecology.”

THE FNFD has developed an Incubator Program with THE ICONIC and recently awarded the first places in the program to Gunggandji designer Elverina Johnson of label Pink Fish, Mt. Isa designers Dale Bruce, Cheryl Perez, Glenda McCulloch and Jaunita Doyle of label Myrrdah and Kuranda based designer Briana Enoch of label Jarawee.

Over the next eight months, the designers will participate in workshops, events and experiences developed by a

Heckenberg continues, “Epson’s products, services and technologies in digital print and projection will enable First Nations designers to tell their stories by converting their designs into commercially sellable items. This includes printing their canvasses, printing fabrics for the making of fashion garments using direct-to-fabric printers such as the Monna Lisa ML-8000 and using direct-to-garment printers for items such as t-shirts, dye-sublimating designs on fabrics for soft furnishings and printing on to hard surfaces such as mugs and key rings.”

Lee concludes, “Having Epson as a partner of FNFD gives us access to experts in the industry who can create new opportunities, boost skill development and industry engagement. Also, Epson is a company committed to helping further sustainability in fashion. Their printers offer on demand solutions which reduces waste and over production. This is also a partnership that allows Epson Australia to play a key role in a number of FNFD strategic initiatives that supports First Nations designers and businesses who work within the Australian fashion industry.”

GJS, in conjunction with its partner, Brother International Australia (BIA), have announced a new award and sponsorship program to support students studying Certificate II in Printing and Graphic Arts at TAFE NSW and to encourage the next generation of print entrepreneurs.

The new accolade, titled the BIA Excellence in Digital Decorating Award, will be awarded yearly based on demonstrated excellence in digital decoration to a student studying Certificate II in Printing and Graphic Arts. The winner will also receive one full year of their TAFE tuition (or equivalent) paid for by Brother. The winning student’s name will also be placed on an honour roll that is permanently displayed in the TAFE classroom.

“We really appreciate GJS facilitating the connection between Brother International Australia and TAFE NSW so that we could create this new industry award and sponsorship. It’s wonderful to be involved in the education and growth of prospecting digital decorators and garment designers and to provide them with the technology to learn with and to push the industry forward,” said John Timmins, National Sales Manager (DTG).

The Certificate II in Printing and Graphic Arts course provides students with a strong foundation to launch their careers in printing with a variety of media, one of which being garment production, where Brother’s involvement will greatly enhance the learning outcomes of the course.

“TAFE NSW has always done wonderful work educating our industry, and Brother is glad to further assist with the democratisation of digital print education and enable its future vision to become a reality,” added Timmins.

GJS has been working alongside TAFE NSW for over 30 years, providing training, support and equipment for the various printing methods taught within the classrooms.

The recent installation of a Brother GTXpro Bulk direct-to-garment (DTG) printer marks the most recent investment from TAFE NSW towards gearing students towards a future in digital printing.

Similarly, GJS has been working beside Brother for more than ten years of collaboration and market education on DTG printing, recently being awarded for a decade of commitment to DTG.

To further assist all students studying Certificate II in Printing and Graphic Arts at TAFE NSW, Brother has also agreed to provide free ink each year, allowing the students to maximise the potential learning opportunities of the new Brother GTXpro Bulk direct-togarment (DTG) printer.

“The partnership brokered by GJS between us here at TAFE NSW and Brother is a significant step in enhancing the learning outcomes of students pursuing a career in printing and graphic arts, specifically in the digital decoration field,” said Craig Rollins, Head Teacher of Printing TAFE NSW.

The BIA Excellence in Digital Decorating Award is a great opportunity for students to showcase their talents and receive recognition for their hard work.

“The continued commitment from Brother will also be incredibly valuable for TAFE NSW, allowing us to provide our students with supplies to use with professional print equipment and to get a head-start in the industry, whether they aspire to be digital print operators, designers, print salespersons or print managers,” concluded Rollins.

smoother, brighter print results. They are pre-degassed and available in user replaceable one litre bags for continuous, longer run production. Importantly, the film and ink are coated and chemically matched for high release and have antistatic properties to ensure consistent, reliable results. The initial heat press transfer time is just 10 seconds, with the final press decreased to 10-15 seconds at 145˚C to 160˚C (290˚F to 310˚F).

"The main point of difference when it comes to this system is in the workflow", explains Jerry Erich, Business Development Manager, Impression Technology. "Whilst there are some great roll-to-roll solutions available, a business must have a high enough volume of transfers to schedule them appropriately to reduce film wastage. A flatbed offers a completely different workflow. A decorator can run off a few transfers or a batch of transfers in a reasonable time, as the QO-T has a reasonably high print speed. They can produce a sample on the fly, using it as a sales tool to show their customer exactly what the finished product will look like and win the job".

KNOWN AS THE MERCH FACTORY, THE QO-T IS THE FIRST DESKTOP FORMAT HIGH-VOLUME COMMERCIAL DTF PRINTER CAPABLE OF PRINTING FULL 16" X 20" (40 X 50CM) DTF TRANSFER SHEETS IN UNDER THREE MINUTEs.

The Merch Factory is a complete DTF production kit comprising the QO-T Printer, Powder Applicator and Cure Oven. It has dual print heads for highspeed throughput, and the printing hardware has the same industrial-grade features as the company's successful Q Hybrid Series DTG/DTF Hybrid models. The QO-T Printer has a built-in vacuum platen to secure the DTF film sheets in place during the print cycle. This

feature improves registration accuracy and ink droplet placement, resulting in best-in-class DTF print quality. WIMS white ink management automatically circulates, filters and pressurises white ink in the printer reducing white ink maintenance. The auto white ink flush system refreshes all critical white ink components with touch button control for predictable and repeatable white ink prints.

DTF consumables available with The Merch Factory include Kodak transfer film, EFTF inks and powder adhesive. The new EFTF transfer inks are OEKO-TEX approved and designed to match the latest precision core print heads with regard to viscosity and temperature requirements guaranteeing

Ben Carroll, Founder of Velflex, says, "When we look at the market, there are two main types of customers: transfer printers and garment decorators. Our customers are predominantly the uniform stores, the workwear stores, and the garment decorators, who make money from selling uniforms. We want to ensure we offer them a solution that enables them to make enough transfers to sell as many garments as possible. Without worrying about printing as many transfers as they can to pay off a machine, which is why we find the sheet-fed solution appealing. We've been supplying our customers with consumables and heat transfer solutions for over fifteen years. It's a long-term relationship that we have with our customers, and we want to deliver a product and a solution that works and is backed by a company with a good reputation, and for us, that is Impression Technology", concludes Ben.

STUNNING FABRIC & MERCHANDISE PRODUCTION MADE SIMPLE

With unprecedented productivity and image quality, these advanced new models give you the power to say ‘yes’ to more work.

• Outstanding print speed with exceptional image quality

• Vibrant and consistent colour, job after job

• Industrial strength, user replaceable print heads*

• High capacity ink supplies with heavy duty media support

• Cloud-based production tool for managing your print business*

• Remote monitoring and diagnostics for pro-active service and support*

• On-site CoverPlus service packages up to 5 years

WHAT BREAK? SUCH WAS THE EASE WITH WHICH EVERYONE INVOLVED AT VISUAL IMPACT 2023 RESUMED BUSINESS AS USUAL, YOU COULD BE FORGIVEN FOR THINKING THE CANCELLED SHOWS AND DISRUPTION OF RECENT YEARS WERE A FIGMENT OF OUR COLLECTIVE IMAGINATION.

We know, of course, that they were all too real, and that made the triumphant return of Visual Impact to Sydney recently even more special, especially for Epson, who celebrated in style with a whole new look and a display that not only showcased the broadest product range of any manufacturer, but also took out the show’s best custom stand award!

Eschewing the typical corporate look, the Epson display went for a more relaxed, colourful presence inspired by beach and surf lifestyle as the company

demonstrated the very best in digital printing and signage solutions. As print businesses look to diversify, the stand was underpinned by the idea that the more options you offer your clients, the more work you can say ‘yes’ to. Moreover, with recent advances in design, workflow and usability, print companies can reduce their equipment footprint to fit more in smaller spaces, and reduce waste to limit their burden on the environment while still providing products and services that customers demand.

Epson Australia MD, Craig Heckenberg, said, “Due to the impact of Covid-19, businesses have opted to bring more print back to Australia. As a result, and to help businesses embrace this change, we have further expanded our print range to provide a solution for any requirement. Epson are also striving to further reduce wastage and water requirements. For example, we are placing more emphasis on inherently more efficient digital print processes for natural and synthetic fibres alike. You saw a range of these products and

solutions on show and demonstrated at Visual Impact 2023 in Sydney.”

One of the stars of the show was Epson’s SureColor V7000 UV flatbed printer. Leveraging decades of colour and imaging expertise, the SC-V7000 is powered by no less than eight PrecisionCore® printheads and a new UltraChrome UV ink to deliver outstanding print quality and low cost of ownership on many types of media including paper, film, board, Corflute, vinyl, canvas, aluminium, timber and acrylic up to 80 mm thick.

Epson's resin ink range was also on display with the SureColor R5000L, which not only offers a low running cost, but also brings accurate and repeatable colour to a platform optimised for rapid job turnaround. The SureColor R5000L is designed to produce signage, décor and promotional material. It uses aqueous (water-based) ink that is like latex but formulated for enhanced scratch resistance and a lower curing temperature. Enhanced print durability is matched with enhanced mechanical reliability for a dependable, costeffective solution.

Alongside these flagship signage and décor machines Epson also showcased several other offerings, including the SureColor T7760D, a new large-format colour drawings and poster platform that boasts an extremely compact footprint, the venerable SureColor S80660L, the popular eco-solvent

solution for PANTONE® certified POS and signage, and the SureColor F6460 dye-sublimation printer for customised fabric, décor, merchandise and soft signage.

Rounding out Visual Impact 2023 for Epson was the new SureColor F2260 direct-to-garment (DTG) and direct-tofilm (DTF) printer. Representing the third generation of Epson’s best selling DTG platform, the SC-F2260 wowed showgoers with a host of upgrades that make it faster and more efficient while also enhancing support for the increasingly popular DTF (direct-to-film) production workflow.

Overall and by all reports, Visual Impact 2023 was a tremendous success and

testament to an Australian print industry that is going from strength to strength. Epson would like to thank the show organisers and everyone who attended for the opportunity to showcase the industry’s most comprehensive line-up. If you were unable to attend Visual Impact and would like to learn more about Epson solutions, don’t hesitate to contact us to book a free demonstration tailored to your business. PLUS, for a limited time, Epson has special pricing, extended CoverPlus service package and other promotions running. Contact your Epson representative, call 02 8899 3666 or email marketingassistant@ epson.com.au to learn more.

While there is a lot of attention on DTF as direct-tofilm, there is also a lot of buzz around the other DTF, direct-to-fabric. Epson is a pioneer in this space, having partnered with Italian manufacturer Robustelli to develop the Monna Lisa series of industrial digital textile printers. Now having landed in Australia with the ML-8000, this technology offers local companies a cost-effective way to onshore production of textiles and fabric, and the ability to provide short-run, highly customised offerings. While the full Monna Lisa range will be on display at ITMA in Milan this year, the ML-8000 is ready for demonstration right now at Epson’s Sydney showroom. To learn more and arrange a free demo, contact Epson on 02 8899 3666 or at monnalisa@epson.com.au.

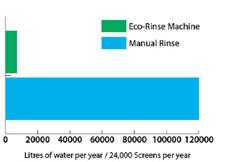

“To clean screens T-1 Print uses the Eco Rinse Automatic Screen Rinsing System which improves our productivity and reduces our labour costs”, says Pamela. “It also recycles and reuses water which significantly reduces our overall water consumption”.

Pamela Mannell, founder of T-1 Print in Marrickville, Sydney, is one of Australia’s leading apparel decorators and has championed the development and implementation of sustainable practices for printing businesses for over fifteen years. Pamela sat down with Textile Image Magazine to share her experience and practical insights that can be implemented in any print shop to improve both sustainability and profitability. Following on from the first article in the February Issue which focussed on packaging, in this issue we focus on opportunities to print more sustainably.

“There are an ever increasing number of options available from suppliers designed to make printing more sustainable”, says Pamela. “While each business needs to do their own analysis in terms of return on investment, we have implemented a number of products and processes that make our business more sustainable, and improves our productivity and profitability”.

T-1 Print only use water based inks. Water based inks have a lower environmental impact compared to traditional solvent-based inks. Waterbased inks are free from or have significantly reduced VOC content,

making them a more eco-friendly option. Water based inks reduce the amount of water required for ink preparation and cleanup, minimising water consumption and the potential for water pollution. Additionally, water-based inks are easier to clean from screens, reducing the need for strong solvents during the cleaning process.

“When it comes to manufacturing screens T-1 Print use the i-Image Computer to Screen Image System. The image is digitally printed direct onto the screen using water based inks. The cost per screen is significantly lower, the process is quicker and it reduces labour costs, or, frees up that person to work on something else. It eliminates the need to send film waste to landfill, and it also means that you need less space for storing screens as the image files are saved digitally”, explains Pamela.

Source: T-1 Print

To clean squeegees T-1 Print use the Ozzy Mat Smart Washer, which uses biological agents such as microbes or plants to break down or neutralize hazardous substances or contaminants thereby removing dangerous chemicals in the environment.

Source: T-1 Print

“Wherever you look there are opportunities in your business to be more sustainable, whether it be in printing, packaging or other business practices. Just pick one thing at a time to focus on so it doesn’t become too daunting”, concludes Pamela

VELFLEX IS STRENGTHENING ITS POSITION AS THE LEADING AUSTRALIAN HEAT TRANSFER SUPPLIER WITH A NUMBER OF NEW INTRODUCTIONS TO THEIR RANGE, INCLUDING CUSTOM TRANSFER PRODUCTION.

At the recent Visual Impact Sydney show the Velflex stand was a constant hub of activity, an indicator of the growing interest in heat transfer within the wider print industry. Since launching 17 years ago, heat transfer specialists Velflex have made sure they are at the forefront of innovation in the industry,

but, they have always maintained a relatively small footprint.

However, all that is about to change “this show marked an important evolution in Velflex’s journey” says Managing Director Ben Carroll “the growing interest into in-house

garment decoration, and all the new technologies gives us a prime opportunity for growth. We are truely becoming a ‘one stop shop’ for businesses when it comes to reliable, quality transfer solutions, whether they are dipping their toe in or looking to expand a growing operation.”

Providing a quality end-to-end solution has long been the goal for the team at Velflex and although they’ve built their business on selling heat transfer vinyl, they could not ignore the increasing demand for direct-to-film solutions. Now after a couple of years researching they have finally released their range - a sheet fed system developed here in Australia by Impression Technology and a roll-to-roll system by Manprotek exclusive to Velflex in Australia.

“Direct-to-film is undoubtedly the future of our industry and we want to be onboard” explains General Manager Mandy Olivier. “However, we didn’t want to sell our customers a problem. We want to sell them a solution, these two machines cover a spectrum of production needs. The sheet-fed system for small businesses looking to do short, sporadic runs. And, for big producers looking to do big runs we have our new Manprotek roll-to-roll machine that we are very excited about. For those not ready to invest they can outsource and get their ready-to-press transfers from UltraColour.”

Their US built Stahls' Hotronix presses are the last step in the production journey and are one of the key weapons in Velflex’s growing arsenal. The team had three of their machines on the stand at Visual Impact: the Hotronix STX clam press, the Hotronix 360IQ cap press, and the Hotronix Dual Air Fusion.

The Hotronix presses are a high demand item for Velflex. So much so they recently sent a team to the US to conduct training with the techs at Stahls’ on machine servicing/repair. “Our after service has always been a key point of difference for us” Carroll, who attended the training emphasises, “we want our customers to know that we’re not just going to sell to them and disappear. We are going to support them through install and the lifetime of that machine”.

There were a number of significant new introductions for Velflex at the show, including the Direct-to-film printers, and Jones Brother screen-printing supplies. However, the the most significant news was that they would be bringing Carroll’s other company UltraColour Transfers under the Velflex brand allowing them to offer custom transfer capabilities.

“The businesses have always complimented each other well”

continues Carroll, “it makes perfect sense for users to be able to buy their heat transfer equipment, their consumables, and their custom transfers all from one supplier. Our new online store launching in July will offer customers the opportunity to do just that”.

Launching July 1st Velflex’s new online platform will allow their customers to purchase HTV vinyls, and equipment, access their education resources, and for the first time ever order their UltraColour transfer entirely online.

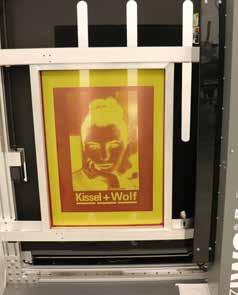

WITH A HERITAGE SPANNING MORE THAN 35 YEARS, TEXTILE IMAGE MAGAZINE, GOES BEHIND THE SCENES WITH GREIG WOOD, MANAGING DIRECTOR, KISSEL + WOLF, TO EXPLORE THE EVOLUTION OF AUSTRALIA’S OLDEST, MOST TRUSTED AND DIVERSIFIED PRINT SUPPLIERS.

TIM: Tell us about the history of Kissel + Wolf?

GW: My father John (Snr) had spent his entire adult life in the printing industry, having completed an apprenticeship as a printing machinist at the Royal Mint in Melbourne. He left the Royal Mint to take a job as a lithographic machinist at Spicers in Melbourne, but when the opportunity arose to move into the supply side of the industry, he joined ink manufacturer Collie & Co, where he remained for the next 30 years.

John loved working at Collies, saying that the company and those working there was like family, a core value that remains true at Kissel + Wolf to this day.

John rose through the ranks at Collies to become national sales manager, which gave him the opportunity to travel interstate and overseas and form relationships that would prove beneficial in later years.

At age 56 his spirit of adventure saw him, along with sons John, Peter and myself, founded a company called Sias Screen Printing Products – which then went on to become lntergraphic Technologies. The company became the Australian distributor for the highly regarded screen printing equipment range from Italian company, Sias. Importing the Italian manufactured SIAS screen-printing machinery, Marabu

Consumables and Sefar Mesh out of Europe. The partnership with SIAS Italy proved to be an incredible opportunity for the company who went on to capture a very large portion of the Australian Screen-Printing Machinery market with top of the line machinery and equipment throughout this time.

An amusing side story to that partnership was that there was never a written document between the two companies, it was a handshake agreement between former CEO, the late Umberto Brassa, and John Wood (Snr) that built an amazing legacy that has now blossomed into Kissel + Wolf Australia. John (Snrs) foresight,

experience and skill in predicting market trends laid the foundation for lntergraphic Technologies' (now known as Kissel + Wolf), current success in the screen print, wide format digital, offset and packaging markets.

A major customer back in the 80’s was Adval Australia, they purchased the first SIAS 5 Colour UV in line Screenprinting machine in Australia. All of our customers at this stage focused primarily on screen-printing for various markets.

GW: During this time the company formed many exclusive distribution partnerships with trusted and innovative suppliers, who were leading the way in intuitive and progressive printing within Australia at the time. One of the partnerships formed was with Kissel + Wolf Germany.

In the Year 2000 the business was handed over to John Wood (Junior), Peter and myself, who were all already

working in the family business at the time.

In 2004, after some substantial growth the company was sold to Sefar AG, a Swiss company who are a leading manufacturer of Screen Printing Mesh.

The subsequent years saw some huge developments across the entire printing industry resulting in many customers looking at the advancements in digital printing technologies. A major part of this change was happening within the large format point of sale screen printing market and we knew that at this stage that we had to pivot the business model slightly and embrace the change in technology, whilst also staying focused on our original markets and customers.

In 2014 Kissel + Wolf Purchased the company from Sefar AG, therefore forming what is known as Kissel + Wolf Australia. This was a fantastic step for the business with the Kissel + Wolf owners recognising the changes in the industry and, being a medium sized, nimble company they were happy to embrace and tap into new market technologies. This has allowed Kissel + Wolf Australia to grow as a whole into new and sectors of the Australian print market, while still keeping in touch with our roots in screen-printing. We now supply products in a range of sectors including Metal Decoration, Corrugated Printing and finishing, signage and all forms of textile printing.

TIM: What are some of the more recent milestones for the business?

2008

• Acquisition of Wilflex Australiasia and integration into Kissel + Wolf & Wolf team.

• Move to Bayswater

• Trading as KUW (Kiwo, Ulano, Wiflex).

2013

• Acquisition of Sefar printing solutions.

• Move to Tullamarine warehouse

• Established NSW office in Revesby.

• Team increases to approx. 25 people as a result of the acquisition.

• Trading as KIWO Australia.

• Main focus on screen and offset printing equipment and consumables.

2014

• Enter DTG market becoming master distributor of Kornit in ANZ

• Marabu digital inks is the second product range to be added for digital applications

2017/18

• Re-branding KIWO worldwide into the Kissel + Wolf + Wolf Group.

• Celebrate 30 years of Kissel + Wolf + Wolf Australia

• 125 years of Kissel + Wolf + Wolf group of companies

TIM: What were the early days like compared to today?

GW: Chuckling ‘How times have changed.’ In the 1980’s and 1990’s major customers such as VDO Instruments were printing car instrument clusters via the screen-printing process. Until almost overnight, the manufacturing of cars within Australia disappeared. During this period the company was also a major supplier of UV screen inks and consumables to companies like Sony Music & Technicolour, who focused primarily on the manufacturing and printing of millions of CD’s & DVD’s - until the day that people began to be able to download music and stream media. These were major customers whom we serviced with our long term partner Marabu UV Screen-printing Inks & Sefar screen-printing screens. Large-Format Point of sale Screen-printing was also a major focus supplying KIWO chemistry, Inks & Consumables. Industrial ScreenPrinting markets were still very solid throughout this period.

Over the past few years through our partners Zeller & Gmellin Uv Offset Inks, Salchi Metal-coat Coatings, Marabu Inks and Birkan Blankets, who are all quality European manufacturers, we saw an opportunity in metal decoration and its potential for growth within Australia. These partnerships now see Kissel + Wolf Australia as a major supplier of inks and consumables to the Food & Packaging market in Australia.

When the company began in the 80’s we focused primarily on importing screen-printing equipment. Today we still cater to this market but with a whole digital catalogue that provides for the Textile, Digital Finishing, Software, Workflow Solutions, Packaging, PointOf-Sale (POS), industrial and signage markets.

To give you a sense of the breadth of our range and the number of categories we play in, we recently held a highly successful Open House at our Melbourne showroom where customers could see a wide range of solutions. The textile category featured our new DTF product, the Mutoh Valuejet 628 Direct-to-film Printer and Shaker. Also on show was, the Epson 2160 DTG, printer as well as the Kornit Avalanche and Kornit Atlas Max for higher volume print shops, a solution for every garment decorator.

In the signage, industrial and screen printing categories, visitors could see the Mutoh 661 ValueCut 2-600 Sign Cutting Plotter, the Mutoh ValueJet 1300 Wide Format Printer and the iECHO Range of Digital Cutters as well as the KIWO XTS - Computer to Screen machine.

We have established multiple divisions throughout Australia with offices in Revesby New South Wales, Geebung Queensland and Tullamarine Victoria, equipped with our specialist service and sales team who provide support

nationwide to our customers of all shapes and sizes. We pride ourselves on our level of technical support to our customers and our ability to be ‘small enough to care & big enough to deliver’.

TIM: What does the future hold for Kissel + Wolf?

GW: With some of the third generation of our family coming into the business, the reality is more of the same in terms of technology, family values and technical support and service. Kissel + Wolf is continuously looking for growth opportunities. With the market ever changing we keep our ear to the ground, visiting suppliers and travelling regularly to overseas trade shows to critically evaluate the variety of trends and technological advancements that can help the Australian print market. We have established ourselves as a trusted supplier to many Australian printing companies and will continue to provide world-class products and equipment to support them in delivering their goals.

Ricky Richards stocks a diverse range of printable textiles that provide acoustic absorption and upholstery benefits for bespoke indoor pieces. With impressive features across the range, including a 3D honeycomb textured option, metallic finish, and the ability to create 3-dimensional fabric installations.

Silencio, Akustico, and Shape are designed and manufactured by Rickys' long-term supply partner Pongs Germany. With their extensive knowledge, longstanding industry presence, and innovative approach, Pongs is undoubtedly a leader in the printable textiles space worldwide.

Silencio is a unique acoustic fabric. This sound-absorbing textile features a detailed 3-dimensional honeycomb structure and has known benefits on sound perception and quality. Silencio

uniquely unites function and aesthetics; it can be digitally printed, making it ideal for interior design.

Like Silencio, Akustico has soundabsorbing properties. It is flexible, hardwearing, fire retardant and printable. Ideal for producing curtains and ceiling

sails and for covering design features for sound-optimized interior décor and art. The intricate weaving process ensures a uniform-looking surface from any angle.

The third product from the Pongs range is Shape. Uniquely interwoven with metal threads, Shape is made with 50% polyester and 50% stainless steel. The strength and versatility of Shape allows this textile to be reversibly shapable by hand; Ideal for drapes and surfaces with an artistic approach - let your imagination run wild.

Lastly, Aluminate, while not manufactured by Pongs, this printable textile stands out due to its soft hand feel with a unique metallic finish. This product has exceptional image quality and is ideal for banner stands, roller blinds, and tablecloths for events.

Customers of Ricky are generally familiar with printable textiles and soft signage options; however, they are always looking to add products with creative points of difference to ensure a diverse range of problemsolving solutions for their projects. This includes 3D textures, sound-absorbing properties, and metallic finishes.

Silencio, Akustico, Shape and Aluminate are all exclusive to Ricky and are available to order now. If you would like further information or a digital version of the Ricky printable product catalogue, contact your Print Media experts today at www. rickyrichards.com.au.

Inspire

projects with Ricky’s diverse range of printable textiles. From acoustic options to reverse hand-shapable fabrics, create impactful spaces with sound absorption benefits with ease.

Explore acoustic essentials like Silencio which features a distinct 3-dimentional honeycomb texture and sound quality benefits, or luxurious Akustico which is ideal for curtains, ceiling sails and for covering design features with a sound-absorbing function. In search of something that will test boundaries? Be bold with Shape, an artistic three-dimensional fabric or Aluminate a 50% stainless steel weave with eye-catching metallic finish. Explore the full Ricky Printable Media range, endless opportunities for inspired creatives.

Arrange

Born in Italy, perfected in Japan, the Monna Lisa direct-to-fabric series has landed in Australia. Powered by no less than eight Epson PrecisionCore industrial printheads, the ML-8000 packs power and performance into a single affordable package with full local support, and the Epson GENESTA pigment inks meet global standards for sustainable textile printing, both synthetic and natural. Print on demand is now big business. Are you ready to grow?

Learn more at www.epson.com.au/direct-to-fabric