DGTronik - PCB

ASSEMBLY EXPERTS

DG Tronik - PCB ASSEMBLY EXPERTS

LA MAREHOUSING ON THE WATER

LA MAREHOUSING ON THE WATER

RELPOL S.ARELAYING SUCCESS

R ELPOL S.ARELAYING SUCCESS

NEW TECH HUB TO ACCELERATE NEXT GENERATION AIRBUS WINGS

NEW TECH HUB TO ACCELERATE NEXT GENERATION AIRBUS WINGS

VOLUME 33/2 – 2023

IMAGE: ©AIRBUS

A Too-Hot Tango: Europe's Dance with Climate Change & the Persistent Wildfires

Ah, Europe. When one imagines this eclectic continent, we often envision Parisian streets filled with fashionforward individuals, Italian piazzas bursting with mouth-watering aromas, or the vibrant streets of Barcelona humming with energetic nightlife. The last thing one expects to think about is an unbearable sauna, yet here we are. Europe is turning up the heat, and unfortunately, we're not talking about the latest summer styles or fiery flamenco.

Europe, renowned for its cultural diversity, its timeless architectural marvels, and its palate-pleasing cuisines, is currently caught in a fervent embrace with a heatwave, sparking off wildfires across the continent. The sun-dappled piazzas of Italy and the picture-perfect chalets of France, usually abuzz with lively chatter and laughter, are now uncomfortably simmering under the relentless summer sun. From the lavender fields of Provence to the vineyards of Tuscany, this relentless heat is relentless, casting a worrisome shadow over Europe's beautiful landscapes.

Surprisingly, even the snow-clad expanses of Sweden, a country where the concepts of 'hygge' and 'lagom' provide a counterbalance to the icy winters, is now facing a blazing predicament. The usual winter wonderland is wrestling with wildfires, swapping snowmen for sandcastles, and adding a rather unexpected and unwanted twist to their summer narrative.

Interestingly, even the Vatican City, a holy enclave known more for spiritual warmth than physical heat, isn't exempt from this situation. As the Pope contemplates from his balcony, the trials of fire mentioned in biblical texts might be feeling a bit too close for comfort. From his pulpit, the call for climate action may resonate stronger, backed by a vista of a city grappling with a temperature crisis.

In the Iberian Peninsula, Spain and Portugal, usually lauded for their passionate performances of Flamenco and Fado respectively, are dancing a different kind of duet. The usual sun-drenched landscapes, typically the backdrop for idyllic holiday memories, have been thrust onto a blazing stage, transforming the region's picturesque beauty into a scene straight out of Dante's Inferno.

have milder summers. Rather, it's a wakeup call, a call to arms. It's a reminder that we, as global citizens, need to put forth a unified front against this warming enemy.

The soul of Europe is not encapsulated in the current sweltering conditions. Instead, it thrives in its rich cultural tapestry, its diverse gastronomic delights, and the warm hearts of its people. The goal is to ensure that the only things heating up in Europe are the delectable pastries in the bakeries of Vienna, or the intense football rivalries that unite and divide in equal measure.

Tackling climate change is a marathon, not a sprint. We need to change the narrative from Europe's climate crisis to Europe's climate solution. It's high time we bid farewell to the era of sweat-soaked shirts and sunburn and welcome the era of sustainable solutions and innovative adaptations.

The French Riviera, an unparalleled destination for sun and sea lovers, might need to rethink its brand. The 'Côte d'Azur', famed for its crystal-clear waters and golden beaches, might soon have to contend with an unwelcome addition to their summer ensemble - smoke from wildfires. This is not the plot twist sunbathers or yacht enthusiasts signed up for when booking their summer getaway.

Climate change, once a subject debated in the hallowed halls of academia and environmental forums, is no longer a distant threat. It's here, and it's turning up the temperature. Europe, in response to the global warming reports, seems to have thrown down the gauntlet, as if challenging the sun to a duel. And currently, it seems like the sun is gaining the upper hand.

Yet, this is not a time to pack up your winter gear and plan for a vacation in the usually sunny Greece, now expected to

The responsibility is heavy, but it's not insurmountable. Each one of us can contribute to the solution. Together, we can replace the sizzling heat with a spark of hope, exchange apprehension for proactive action, and ensure a brighter, cooler, more sustainable future for everyone.

Europe has always been a testament to resilience, diversity, and unity. Even though the current temperatures seem to be hitting an all-time high, the spirit of its people is far from diminished. Together, we can and will make a difference. Let's ensure that our future remains 'cool' in every sense of the word, where the only heat we encounter is the warmth of European hospitality.

After all, the sizzling summer is a challenge, but it's also an opportunity - a chance for us to come together, unite in our efforts, and make Europe a beacon of sustainable practices. So, let's rise to the challenge and ensure that the only 'fire' we associate with Europe is the passion and zeal of its incredible citizens. n

Industry Europe 3

Europe has always been a testament to resilience, diversity, and unity. Even though the current temperatures seem to be hitting an all-time high, the spirit of its people is far from diminished.

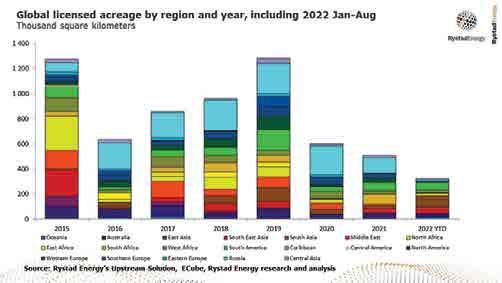

4 Industry Europe CONTENTS VOL 33/2 Comment 3 Editorial: A Too-Hot Tango: Europe's Dance with Climate Change & the Persistent Wildfires. Focus on – Aerospace & Defence 5 NMARSAT to launch I-8 satellites to power L-BAND network. 6 New Tech Hub to Accelerate Next Generation Airbus Wings. 7 Electric ‘Air Taxis’ One Step Closer. Focus on – Technology & Innovation 8 Nokia site solutions enhance power efficiency Aerospace & Defence 10 Aerospace & Defence news The latest developments in the sector Chemicals & Biochemicals 12 Chemicals & Biochemicals news The latest developments in the sector Construction & Engineering 14 Construction & Engineering news The latest developments in the sector Consumer Goods 16 Relaying success RELPOL S.A 22 Housing on the water La Mare 26 Consumer Goods news The latest developments in the sector Energy & Utilities 28 Energy & Utilities news The latest developments in the sector Healthcare 30 Healthcare news The latest developments in the sector Metals & Mining 32 Metals & Mining news The latest developments in the sector Politics & Economics 34 Politics & Economics news The latest developments in Politics and Economics Technology & Innovation 36 PCB assembly experts DGTronik 42 Technology & Innovation news The latest developments in Tech and Innovation Transportation 44 Transportation news The latest developments in the sector Editorial Director Roger Sullivan Profile Writers Romana Moares Dariusz Balcerzyk Emma-Jane Batey Director of Sale & Business Development Katarzyna Pozoga Business Partner, Poland Magdalena Grzempczyńska Art & Design studio@industryeurope.net Editorial Office editor@industryeurope.net Accounts accounts@industryeurope.net Industry Europe 110 Boundary Road, Norwich NR6 5JE, United Kingdom Tel: +44 1133 281 173 Email: studio@industryeurope.net Web: www.industryeurope.com LinkedIn: www.linkedin.com/company/industry-europe MAX MEDIA GLOBAL LTD. INDUSTRY EUROPE © Industry Europe 2023 No part of this publication may be reproduced in any form for any purpose, other than short sections for the purpose of review, without prior consent of the publisher.

The satellite operator has announced its new Inmarsat-8 small satellites will launch in 2026 to provide crucial safety services and support advances in emergency tracking.

NMARSAT TO LAUNCH I-8 SATELLITES TO POWER L-BAND NETWORK NMARSAT TO LAUNCH I-8 SATELLITES TO POWER L-BAND NETWORK

Inmarsat, a world leader in global, mobile satellite communications, has announced that SWISSto12, one of Europe’s fastest growing aerospace providers, will develop its new eighth-generation of spacecraft. The three I-8 satellites will provide additional network resilience, securing the future of Inmarsat’s global L-band safety services.

SWISSto12, headquartered in Switzerland, will use its HummingSat satellite platform - in conjunction with unique 3D-printing technologies and specialised Radio-Frequency (RF) and payload products - to develop and manufacture the geostationary satellites, which will launch by 2026.

Just 1.5 cubic metres in volume, the I-8’s will use SWISSto12’s innovative new class of spacecraft which has a form factor up to five times smaller than conventional geostationary satellites yet can still deliver critical safety services with certainty.

The three l-8 satellites will continue to provide the extra layer of resilience to complement the existing constellation and Inmarsat’s two I-6 generation satellites, which were launched in December 2021 and February 2023. In March 2023, Inmarsat announced the first, I-6 F1, had successfully completed testing with ground stations in Western Australia and has now started to provide Ka-band services for the fast-growing Asia Pacific region. The company will begin introducing its L-band capacity and transitioning services to the new satellite throughout 2023.

The second, I-6 F2, which launched in February 2023, is expected to enter operational service over Europe, Africa, and much of the Americas in early 2024.

Each I-8 will also extend Inmarsat’s history of launching and operating radionavigation transponders for Governments and international space agencies. These transponders can enable Satellite-Based Augmentation System (SBAS) services around the world, for example for air traffic controllers or coastguards. SBAS systems use satellite connectivity, land-based infrastructure, and software to enhance standard GPS/Galileo accuracy of 5 to 10 metres to as little as just 10cm.

Such precise tracking could enable pinpoint safety navigation on aircraft, help emergency services reach vessels in distress more quickly, or allow a raft of industrial innovations, like device tracking in agriculture or advanced, automated transport management systems.

The I-8 satellites will continue to secure Inmarsat’s global safety services into the 2040’s. The company was founded in 1979 under the auspices of the United Nations specifically to provide highly reliable safety communications. Today some 1.6 million seafarers and over 200 airlines rely on Inmarsat’s global L-band network to deliver 99.9% availability every day.

The Inmarsat-8 programme forms part of Inmarsat’s fully funded technology roadmap, which will include five new satellite payloads added by 2025 to further Inmarsat’s high-

speed broadband Global Xpress (GX) network with the launch of the software defined satellites GX 7,8, and 9, aimed for 2025, and the polar coverage satellites GX10a and b, which are aimed for the first half of 2024.

Peter Hadinger, Chief Technology Officer, Inmarsat, said: “Every single day people around the world depend on Inmarsat services. Our customers have demanding, and often safety critical, missions that rely on our satellite technology for links that can make the difference. The I-8’s will not only underpin our existing capabilities for the future; but enable ever more advanced safety innovations like SBAS that can ultimately help save more lives. We have chosen SWISSto12 because they have the ground-breaking technology that can make it a reality.”

Emile de Rijk, CEO, SWISSto12, said: “We are delighted that Inmarsat has selected SWISSto12 as its partner for its landmark l-8 program. It demonstrates that, with HummingSat, we have created a highly advanced new class of small geostationary spacecraft that delivers world-leading connectivity capabilities at a fraction of the cost. Our proprietary 3D-printing of Radio Frequency payload technology allows us to push the limits of existing capability and service new and existing business cases for geostationary satellite communications. This is an important step in our journey to better connect and protect every corner of the world.”

Industry Europe 5 FOCUS ON – AEROSPACE & DEFENCE

n

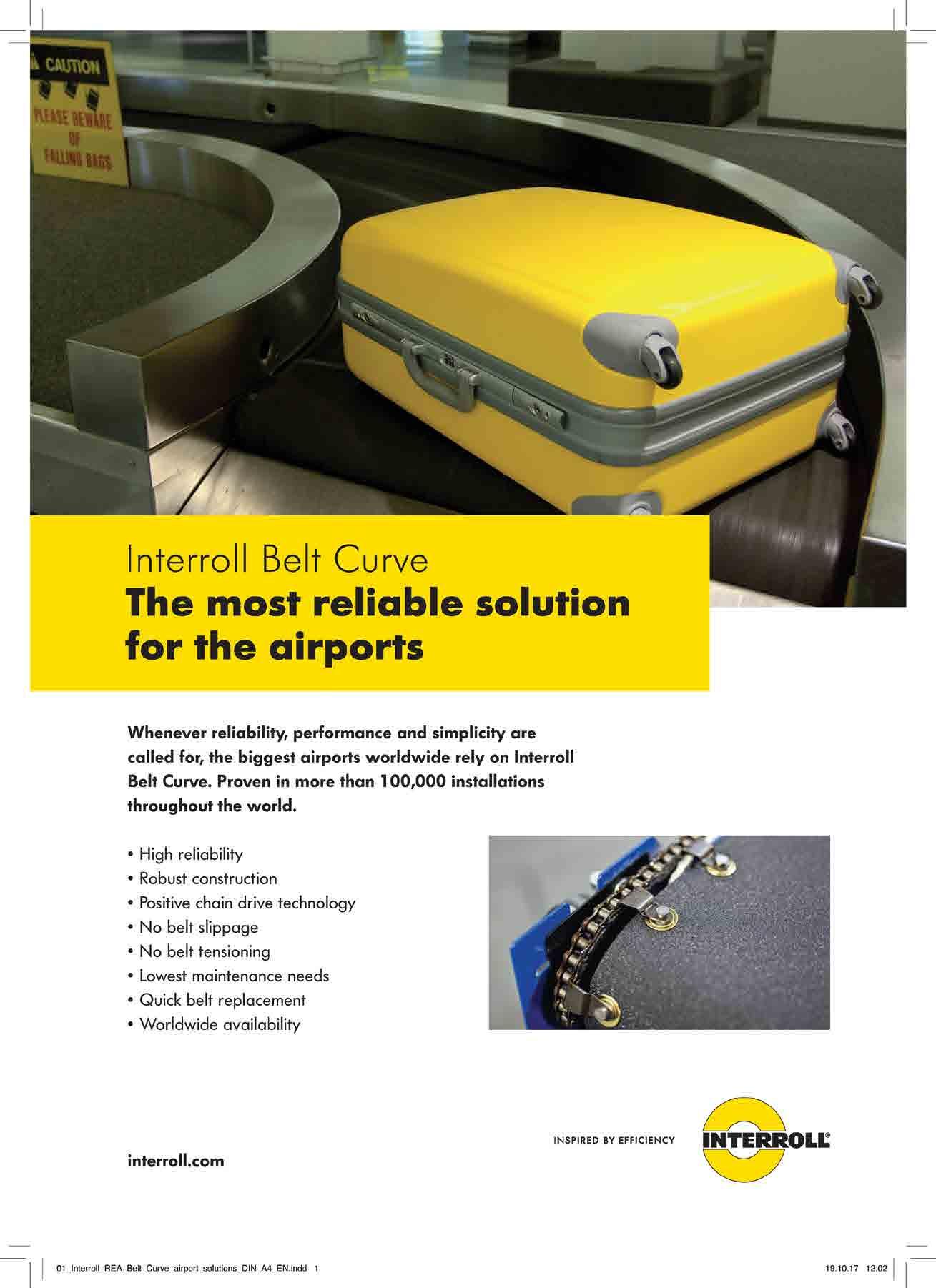

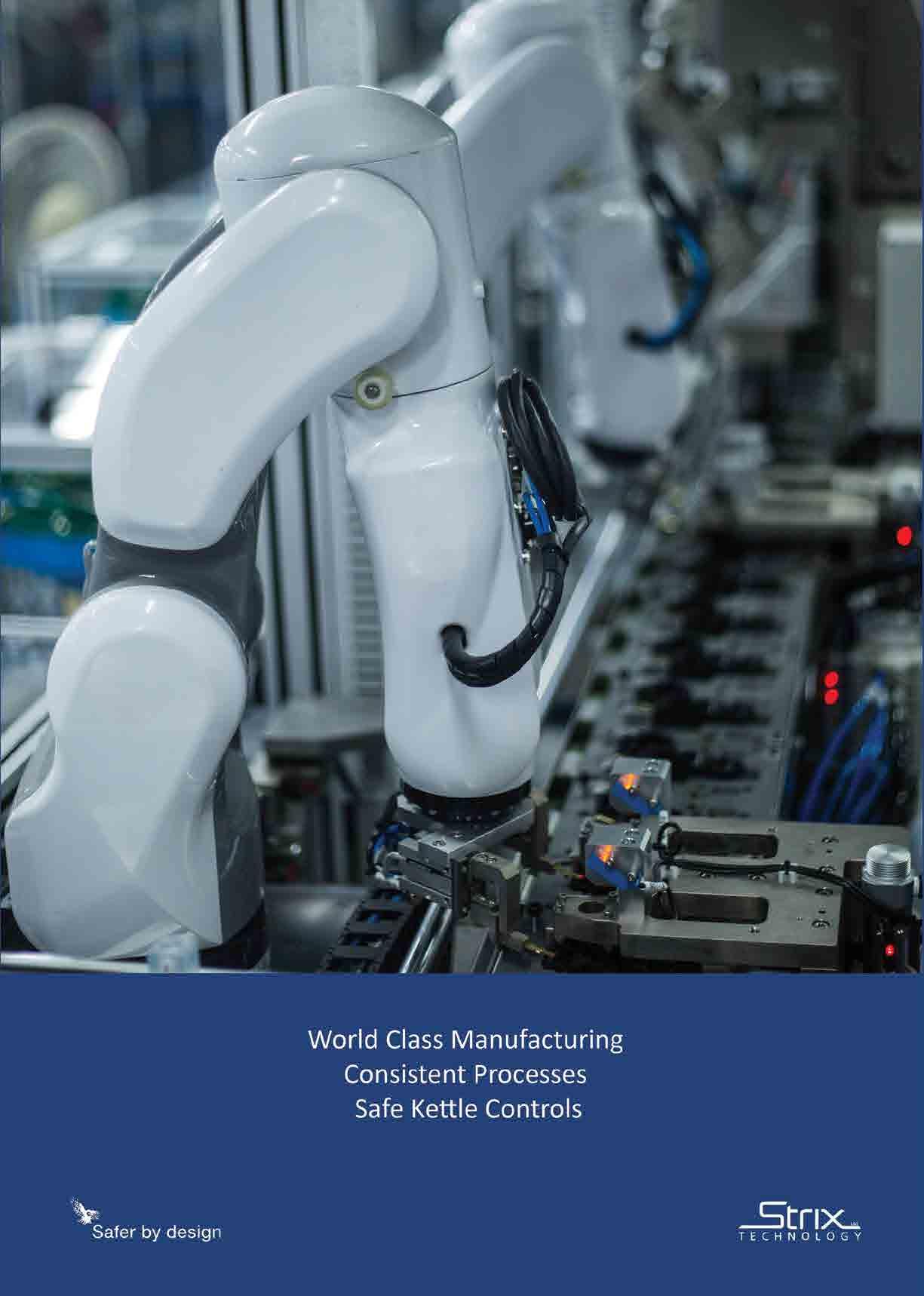

NEW TECH HUB TO ACCELERATE NEXT GENERATION AIRBUS WINGS

Airbus says the new facility will help accelerate the design, build and testing of wings for next generation aircraft, by using the latest technology and world-leading demonstrators to further improve the performance of its wings.

Alongside engine optimization, making wings longer, leaner and lighter is one of the biggest opportunities to improve fuel efficiency, reduce CO2 and ultimately work towards the aviation industry’s ambition to achieve net zero carbon emissions by 2050.

“The new Wing Technology Development Centre will help us to ground our research in practicality,” said Sue Partridge, Airbus head of Filton site and Wing of Tomorrow Program. “A key element of how we deliver technology for next generation aircraft wings is through Wing of Tomorrow (WoT), our largest research and technology program led by the team in the UK. Last week, we achieved a critical milestone in the program when our second wing demonstrator was completed by the team in Broughton, Wales and delivered to the WTDC. Here it will be prepared for structural testing in our Aerospace Integrated Research and Technology Center (AIRTeC).”

The WoT program allows Airbus to explore new manufacturing and assembly technologies so future generations can continue to benefit from flying.

“It’s about preparing our people, technology, industrial system, supply chain and digital and physical capabilities for next generation aircraft. We’re leveraging industry partners and the very best digital tools and automation to identify potential technology bottlenecks that may slow us down in the future. The foundations we

lay now will help us build better and faster when the time comes.”

The WTDC adds to Airbus’ existing research and technology footprint in the UK, including the Advanced Manufacturing Research Center (AMRC) in Broughton and both the ZEROe Development Center and Aerospace Integrated Research & Test Center (AIRTeC) at its Filton site.

Since 2014, Airbus has been awarded £117 million by the Aerospace Technology Institute for Wing of Tomorrow related research. n

FOCUS ON – AEROSPACE & DEFENCE 6 Industry Europe

Nusrat Ghani, UK Minister of State at the Department for Business and Trade opening the Wing Technology Development Centre with Airbus team. Image: ©Airbus SAS 2023

Credit: Shutterstock (Ceri Breeze)

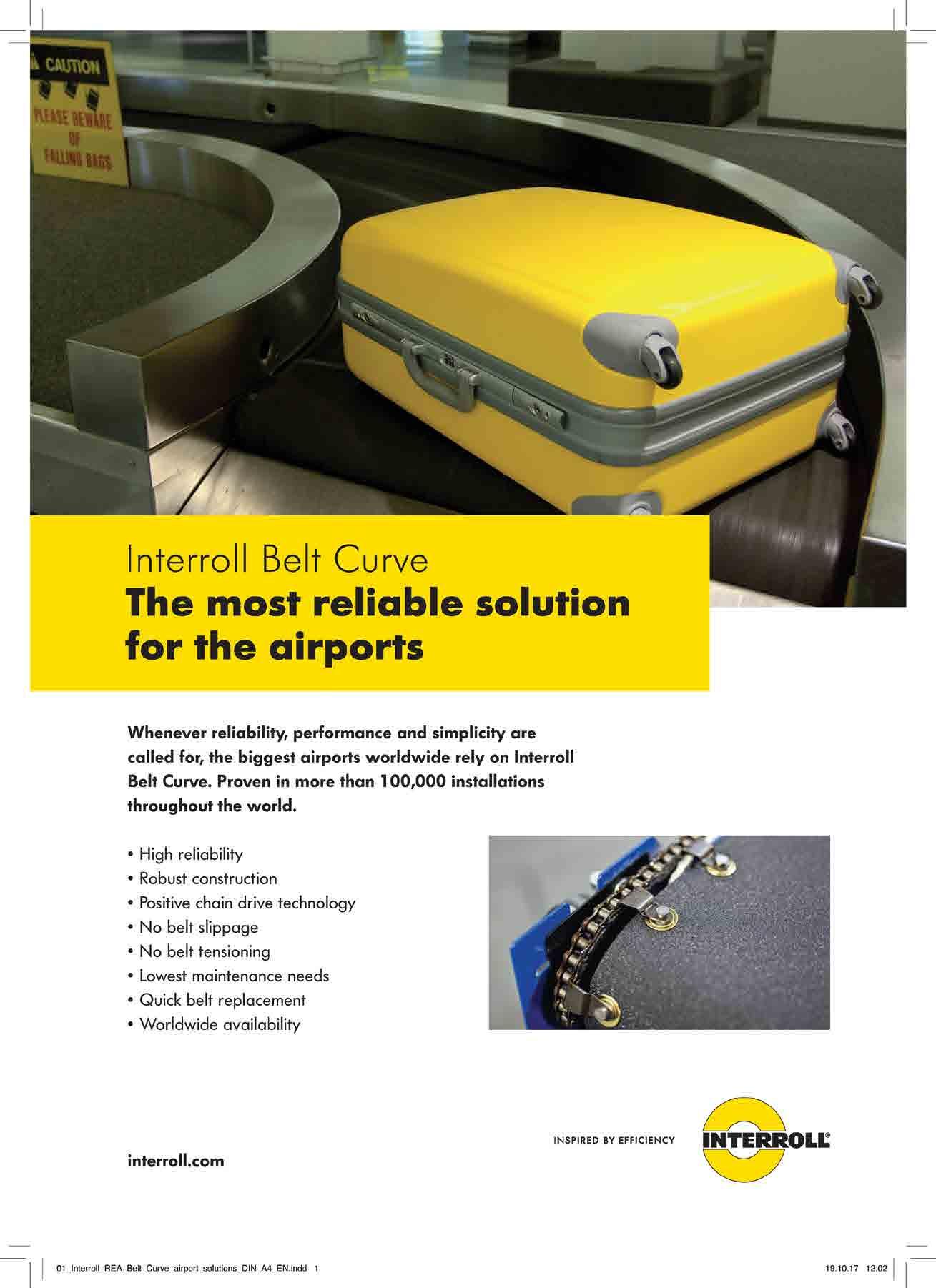

ELECTRIC ‘AIR TAXIS’ ONE STEP CLOSER

Node4 Set To Support Skyports Infrastructure in Delivery of Global Network Infrastructure and CloudBased Data Analysis Capabilities.

Once the stuff of science fiction, passenger-carrying electric urban air taxis could soon be a reality in major cities across the world. This revolutionary form of transport is one step nearer to reality after Skyports Infrastructure, the leading provider of vertiports for the advanced air mobility (AAM) industry, commissioned Node4 to deliver the underlying IT network components and data analysis capabilities needed for vertiport operations. Under the terms of the agreement, Node4, the cloud-led digital transformation Managed Services Provider (MSP), will support Skyports Infrastructure by building a global SD-WAN capability. Due to go live at its first UK location later this year, SD-WAN will eventually cover further UK sites and extend to other Skyports Infrastructure facilities in the USA, Dubai and France. Ultimately, SD-WAN will also provide the enabling technology and connectivity for Skyports Infrastructure’s global vertiport operations — supporting safe and efficient integration of electrical vertical take-off and landing (eVTOL) aircraft and ground infrastructure. Adopting SD-WAN will reduce time to deployment at each of Skyports Infrastructure’s vertiport facilities while centralising

and streamlining remote operations — allowing the company to monitor and manage a network of vertiports in near real-time while maintaining a cost-effective, lean and agile IT team. Once operational, SD-WAN will deliver consistent availability and performance, as well as centralized management and strong network security.

“Everyone at Node4 is so easy to work with,” explained Dan Lambeth, site reliability engineer at Skyports Infrastructure. “The team are approachable and flexible — always offering to go above and beyond for us. Node4 also provides invaluable guidance to build Skyports Infrastructure’s in-house expertise.”

Lambeth continues: “We have a long technology journey ahead of us, but with the support of key technology partners such as Node4 and the insight they provide, the journey will be smooth. Looking to the next 12 to 24 months of technology development, we’re in an excellent position to continue at pace with our vertiport technology product.”

Skyports Infrastructure’s IT team is also drawing on Node4’s extensive cloud-based knowledge – and Node4 has already helped

Skyports Infrastructure build and configure several Azure landing zones to support the development of bespoke vertiport IT systems and software. They will also enable the development of the APIs needed to allow vertiport partners and operators to connect, collaborate and share data easily. Node4 is also supporting Skyports Infrastructure with a large-scale, cloud-based data warehousing project that’s designed to store, capture and facilitate analysis of aircraft telemetry and journey data, including weather and optimal route information.

“We’re delighted to be playing a pivotal role in helping Skyports Infrastructure realise its mission of making electric air taxi travel a reality – and supporting the development and operation of its vertiports,” comments Iain Shearman, COO, Node4. “Network infrastructure solutions, in combination with our Azure and Database experience, have the potential to bring about such a reimagining of urban travel. I can’t wait to see how this project develops and, who knows, to take one of the first eVTOL flights from a Skyports Infrastructure vertiport in the nottoo-distant future.” n

Industry Europe 7

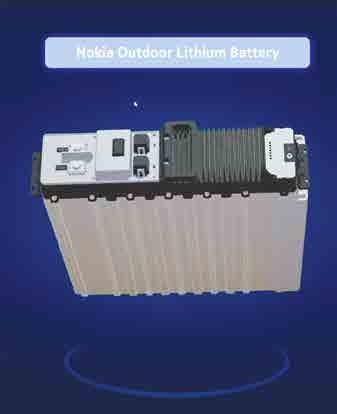

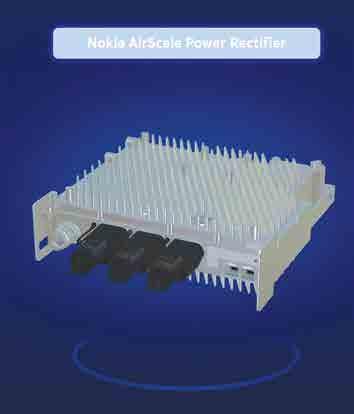

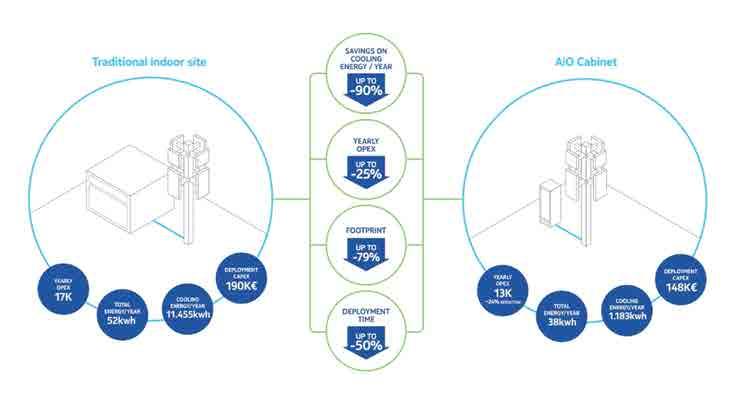

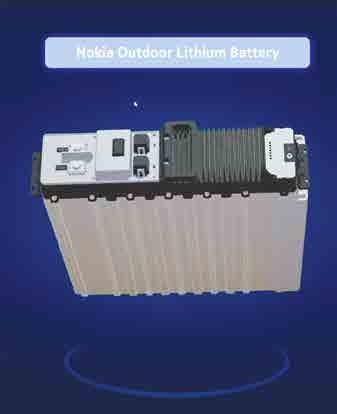

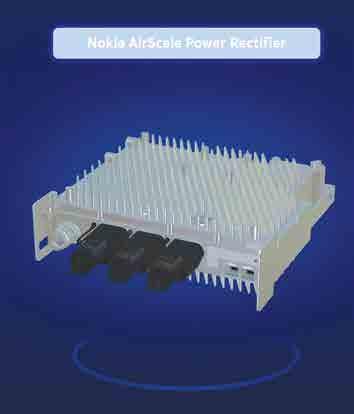

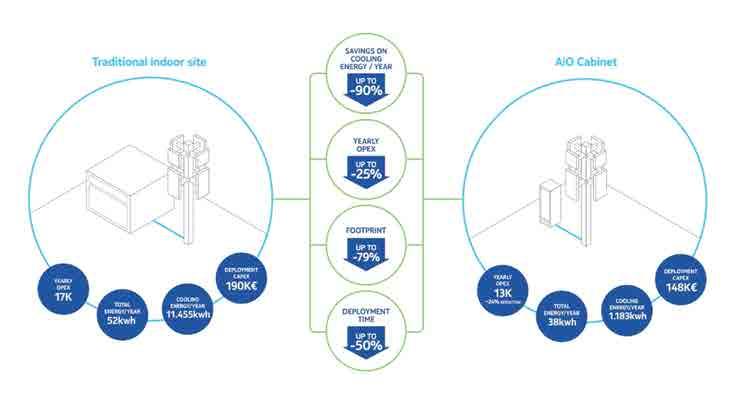

NOKIA SITE SOLUTIONS ENHANCE POWER EFFICIENCY OF AIRSCALE DEPLOYMENTS BY UP TO 30 PERCENT

• Nokia’s all-in-one portable, outdoor cabinet solution is designed for all deployment scenarios saving on time, cost, and energy consumption

• Nokia’s advanced energy solutions can reduce total energy consumption on sites by up to 30 percent and cooling power consumption by 60 to 99 percent; also reduces installation time and simplifies maintenance over a product’s lifetime

• Nokia's NetAct network management solution can control energy systems; new market-leading rectifier combines 6kw capacity with 97 percent power efficiency

Nokia today announced the availability of its new expanded portfolio of energy-efficient site solutions designed for its industry-leading AirScale baseband portfolio, including a pre-integrated ‘all-inone’ cabinet solution and a zero-footprint site solution that features a high-capacity

(6kw) power rectifier with market-leading, 97 percent power efficiency. The optimized outdoor solutions reduce the total energy consumption on sites by up to 30 percent. The zero-footprint deployments use up to ninety-nine percent less cooling energy due to natural outdoor temperatures, avoiding

site rental costs and requiring minimal space and installation time.

The easy-to-deploy ‘all-in-one’ outdoor, modular cabinets are available in different variants covering all site conditions. They can seamlessly accommodate preintegrated components such as baseband

FOCUS ON – TECHNOLOGY & INNOVATION

units, Nokia’s advanced dual bay cooling systems enabling optimized cooling for electronics and batteries separately, as well as its latest high-performance, industry-leading rectifiers and batteries. Pre-integration means there is less demand for civil work as well as easier maintenance and reliability.

The zero-footprint solutions give mobile operators the option to install all equipment directly to a mast or wall, eliminating the need for air conditioning. This minimizes the consumption of energy and space as well as integration and maintenance costs for a wide variety of radio site deployment scenarios. Zero-footprint solutions are ideal also for noisesensitive areas where solutions with fans and active cooling may not be an option.

These solutions are designed for NetAct, Nokia's network management platform, and support many additional energy-saving features such as load shifting as well as solar power.

Energy consumption major driver of network transformation

Network energy costs account for approximately half of the costs facing network operators. In particular, the radio access network (RAN) accounts for approximately 80 percent of all mobile network energy consumption. The exponential growth in mobile traffic means that the number of

sites and related power consumption is rising, and at the same time, energy prices are increasing. At traditional indoor radio sites, up to half of the energy consumption can be used by auxiliary components such as fans, cooling systems, lighting, and other power supplies. Nokia’s new site solutions can minimize this energy consumption while helping operators slash both their energy bills and their carbon footprints.

Nokia has set sustainability goals to reduce its environmental impact and help its customers to do the same. The company has committed to reducing its greenhouse gas (GHG) emissions across its value chain (Scope 1, 2, and 3) by 50 percent between

2019 and 2030. Nokia’s technology is designed to be energy efficient, contributing towards the climate and environmental targets of mobile operators

Samir Kumar, Head of Mobile Network Services at Nokia, said: “Nokia’s expanded site solutions portfolio minimizes the energy consumption and deployment costs for virtually every radio site deployment scenario. Increased energy expenditure is a pain point for mobile network operators and our solutions help reduce these costs as well as having a significant environmental impact. This is another example of our commitment to ensuring we act sustainably throughout every area of our business.” n

Industry Europe 9

Image: cabinetzero-footprint. Credit: Nokia

New developments in the Aerospace & Defence

NATO army division in Europe.

Germany's Army Chief, Alfons Mais, expressed confidence that the nation would possess the most advanced army division among its European NATO allies by 2025. This determination comes as countries are urgently bolstering their military capabilities following Russia's invasion of Ukraine.

Presently, Berlin lacks a single combat-ready division, which typically comprises over 20,000 troops. However, the plan is to have the first of three divisions operational by 2025, with the second division following suit in 2027.

Mais conveyed his optimism, stating that the division for 2025 would initially be staffed with 80% to 90% of the required personnel, and these plans were agreed upon with NATO.

Germany's approach involves providing two mechanized brigades initially, followed by a more lightly armed medium brigade, with additional support from a Dutch brigade. Each brigade consists of approximately 5,000 troops. The goal is to collaborate with Dutch partners

and establish the best equipped division among all European NATO members by 2025.

Divisions serve as the fundamental building blocks of land forces, essential for handling conflicts with peer adversaries. Western nations, having focused on smaller wars in Iraq and Afghanistan, have been neglecting, dismantling, and depleting the weapons and ammunition of their divisions.

Mais acknowledged the challenge of sup plying enough ammunition to the division by 2025, given that Western countries are provid ing substantial ammunition to Kyiv, further depleting already low stocks since the end of the Cold War. He emphasized that this was a common problem faced by all NATO partners.

Despite the urgency in establishing the division, supporting Ukraine remains a top priority, as emphasized by NATO Secretary-General Jens Stoltenberg.

Regarding the second German division, scheduled to be combat-ready in 2027, its

full equipping depends significantly on purchases from the 100 billion euro special fund, which aims to modernize the long-neglected German military. German Chancellor Olaf Scholz's announcement of a "Zeitenwende" (historical turning point) after Russia's invasion of Ukraine signified a major shift in policy, leading to the establishment of this special fund.

Apollo Global Management, the private equity firm, has provided Air France-KLM with a substantial cash injection of $560 million.

funding sources has sparked increased competition for conventional leasing companies.

The newly acquired funding from Apollo will be allocated to support the French company's Engineering and Maintenance (MRO) components activity. It's crucial to note that this injection will not result in any change of ownership for the division, nor will it impact the existing employees' contracts, according to the company's statement.

As part of the agreement, Apollo will be subscribing to perpetual bonds that carry an initial interest rate of 6.9% for the first three years. Subsequently, there will be gradual step-ups and caps applied to the interest rate. Additionally, Air France will retain the option to redeem these bonds at any point after the initial three years.

Air France-KLM has officially announced the completion of a definitive agreement with private equity firm Apollo Global Management for a substantial capital injection of 500 million euros ($561 million) into one of its vital engineering and maintenance units.

In the aviation industry, sale and leaseback deals are frequently employed as financing mechanisms. However, the emergence of new

This is not the first collaboration between Air France-KLM and Apollo Global Management. In a similar move last year, the private equity firm had invested 500 million euros in the company, aiding in the repayment of French state aid.

Visit: www.airfranceklm.com/en

10 Industry Europe NEWS

Berlin's objective for 2025 is to possess the most technologically advanced

Thales to buy Cobham Aerospace Communications for $1.1 billion.

French defense and technology group Thales announced on Wednesday that it is currently in exclusive negotiations to acquire aerospace supplier Cobham Aerospace Communications for $1.1 billion. This move has propelled Thales shares up by over 3% as the company places its bets on connected cockpits.

As the world's third-largest producer of avionics for civil jetliners, Thales expects this all-cash acquisition to enhance its sales growth and operating profitability significantly. Furthermore, it positions the company to capitalize on the consistent demand for secure connectivity.

Based in Paris, Cobham Aerospace Communications specializes in manufacturing antennas and communication systems. According to Thales' statement, the company is projected to generate around $200 million in revenue in 2023. Among its products are satellite and digital radio systems installed on popular Airbus and Boeing aircraft, facilitating data handling and improved audio connections.

Connected cockpit systems play a crucial role in integrating data from various aircraft and ground applications. Establishing continuous

and secure connections is vital for achieving more efficient flight trajectories, thereby reducing delays and lowering emissions. Additionally, this technology may support increased pilot autonomy in the future.

Thales has valued the acquisition at approximately 17 times the forecasted 2023 operating profit before synergies or 15 times after considering synergies, which amount to $10 million per year in costs and $40 million per year in revenues through cross-selling opportunities.

Moody's Investors Service senior analyst Vitali Morgovski commented that while the valuation multiple appears rich at 17 times, the profitability and strong revenue potential of the acquired business help offset it.

The deal is expected to boost Thales' operating margins from the first year, with profit margins estimated to be above 30%, which is approximately double Thales' current avionics margins.

The acquisition aligns with the increasing production by planemakers and the development of the next generation of single-aisle planes that are expected to incorporate greater connectivity features.

The Aerospace Xelerated programme has announced that it has opened calls for applications. Following three cohorts headed up by Boeing and supported by industry partners, the programme will now be run in partnership with the Tawazun Economic Council, the defence and security acquisitions body of the United Arab Emirates.

Startups from anywhere worldwide working on digital services and solutions are encouraged to apply. Applications open today and close on 25 September.

Aerospace Xelerated and Tawazun highlight their shared focus on innovation and point out that the partnership is part of their joint mission to "empower entrepreneurs" to develop ideas that solve real-life problems and move the aerospace sector forward.

Based in Abu Dhabi, Tawazun acts as a catalyst for economic growth and the further development of the defence and security industry in the UAE.

Part of its role in Aerospace Xelerated will be to advise and partner with startups as they navigate their way into new markets in the Middle East. Tawazun will also serve as a guide to companies and provide support for market expansion, developing new products, and facilitating local industry connections.

Startups accepted into the programme will have the option to benefit from a £100,000

(€118,000) investment from Boeing, with the potential for additional funding from partners throughout the region. They will also have access to strategists and technical experts from industry to support the development of proof of concept opportunities.

Startups taking part in the 12-week programme will also be introduced to a network of angel investors, venture capitalists and key stakeholders in the aerospace sector.

Mentoring will also be available from a global network of experienced entrepreneurs, as well as more than £100,000 in perks from partners including Oracle, Amazon, HubSpot, and Digital Ocean, amongst others.

Aerospace Xelerated is looking for startups in the field of digital services and solutions. Companies must be mid-late seed stage; preferably working on software solutions; and at a traction stage with proof of concepts, contracts already in place, revenue and/or letter of intent. The programme does not require the startups to be operating in the aerospace sector.

Nichola Bates, Managing Partner at Aerospace Xelerated and Head of Global Accelerators and Innovation Programs at Boeing, said: "This partnership between Aerospace Xelerated, Tawazun and Boeing is a further testament to our global presence and our commitment to supporting entrepreneurs and innovation irrespective of their country of origin.

"When it comes to global startup hotspots, few places are as exciting as the UAE. It’s hard to match the extraordinary mix of dynamism, growth, tech, strategic location, and government incentives that the Emirates has to offer. Having the programme launch out of the UAE will provide further market access not only to the UAE but to all of the Middle East, Turkey and Africa regions thanks to the strategic geographical location, as well as the global expansion initiatives that the UAE has accomplished to date."

Abdullah Al Awani, Executive Director of Economic Partnerships at Tawazun Economic Council, added: "Tawazun is committed to the promotion of innovation. Through a continued focus on technology, we aim to increase efficiency, drive industry best practices and support SME growth. We are very excited and proud of our partnership with Aerospace Xelerated on their fourth Cohort as it perfectly aligns with our mission to drive economic value, facilitate ecosystem growth and empower technology and people who are innovating."

Since launching in 2019, startups involved in the three previous Aerospace Xelerated cohorts have gone on to raise over £100 million in additional funding and create over 150 jobs across the UK and globally. Organisations to work with past cohorts as partners or mentors include PWC, Frazer-Nash, Chevron Technology Ventures and EasyJet.

Industry Europe 11 NEWS INDUSTRYNEWS

AEROSPACE & DEFENCE

Aerospace Xelerated cohort 4 opens to digital services startups worldwide.

New developments in the Chemicals & Biochemicals

from Zhanjiang to KHUA

BASF and Zhejiang Guanghua Technology Co.,Ltd. (KHUA) have signed a Letter of Intent (LoI) for the supply of Neopentyl Glycol (NPG) from BASF’s Zhanjiang Verbund site to KHUA. This agreement marks a significant milestone in the long-term partnership between both parties.

BASF und Zhejiang Guanghua Technology Co.,Ltd. (KHUA) haben eine Absichtserklärung (Letter of Intent, LoI) über die Lieferung von Neopentylglykol (NPG) vom BASF-Verbundstandort Zhanjiang an KHUA unterzeichnet. Diese Vereinbarung stellt einen wichtigen Meilenstein in der langfristigen Partnerschaft zwischen beiden Parteien dar. Das Foto zeigt die Unterzeichnungszeremonie. Vordere Reihe, von links nach rechts: Haryono Lim, Senior Vice President, New Verbund Site China, BASF, Yao ChunHai, General Manager, KHUA, hintere Reihe, von links nach rechts: Vasilios Galanos, Senior Vice President, Intermediates Asia Pacific, BASF, Hong Tao, stellvertretender Sekretär und stellvertretender Leiter des Joint Party Committee of Advanced Manufacturing Key Project Construction Taskforce von Zhanjiang Economic & Technological Development Zone (ZETDZ) und Fenyong High-Tech Zone, Jeffrey Sun, Vorsitzender, KHUA. / BASF and Zhejiang Guanghua Technology Co.,Ltd. (KHUA) have signed a Letter of Intent (LoI) for the supply of Neopentyl Glycol (NPG) from BASF’s Zhanjiang Verbund site to KHUA. This agreement marks a significant milestone in the long-term partnership between both parties. Photo shows the signing ceremony. Front row, left to right: Haryono Lim, Senior Vice President, New Verbund Site China, BASF, Yao ChunHai, General Manager, KHUA, Back row, left to right: Vasilios Galanos, Senior Vice President, Intermediates Asia Pacific, BASF, Hong Tao, Vice Secretary and Vice Chief Commander of Joint Party Committee of Advanced Manufacturing Key Project Construction

Taskforce by Zhanjiang Economic & Technological Development Zone (ZETDZ) and Fenyong High-tech Zone, Jeffrey Sun, Chairman, KHUA.

KHUA, a reputed manufacturer of saturated polyester resins for the powder coatings industry in China, is planning to build a 100 kilotons per annum (KT/a) production plant for high-end powder coatings resins in Donghai Island, Zhanjiang Economic & Technological Development Zone, where BASF is building a world-scale NPG plant with an annual production capacity of 80,000 metric tons.

“We have high hopes of BASF’s Zhanjiang Verbund site, which will set a new standard in the petrochemical industry by utilizing clean energy, conserving energy, and reducing emissions. Leveraging our competitive advantages, backed by the strategic partnership with BASF, one of the world’s leading NPG suppliers, as well as Zhanjiang’s unique geographical location, we are confident in the success of our 100KT/a powder coating resin expansion project. This will enable us to reduce VOCs and contribute to a sustainable future with clear blue skies and white clouds,” said Jeffrey Sun, Chairman, KHUA.

With the new NPG plant at the Zhjanjiang Verbund site expected to be available from Q4 2025, BASF’s global NPG capacity will be boosted from 255,000 metric tons to 335,000 metric tons annually, strengthening its position as one of the world’s leading NPG manufacturers. Upon completion, this will be BASF’s fifth NPG plant, following the ones in Ludwigshafen, Germany; Freeport, Texas, United States; as well as Nanjing and Jilin, China.

NPG is an intermediate mainly used in the production of powder coating resins, which are particularly successful for the coating of household appliances and in the construction industry. Due to their low volatile organic compounds (VOC), powder coatings enable their users to comply with VOC emission standards by reducing the release of VOCs by up to 50% compared to liquid coatings. Other applications for NPG include the manufacture of lubricants, plasticizers and pharmaceuticals.

Asahi Kasei and Mitsui to Establish Supply and Procurement Systems for Biomethanol

Asahi Kasei Corporation and Mitsui & Co., Ltd. will establish a supply and procurement scheme for bio-methanol produced in the United States. Through this scheme, Asahi Kasei plans to use the bio-methanol procured from Mitsui to produce in Japan engineering plastics with a lower carbon footprint than existing products.

Today, companies in Japan are increasingly stepping up their efforts to reduce GHG emissions throughout their product supply chains, including raw material-derived greenhouse gases, known as Scope 3 emissions, in order to achieve carbon neutrality by 2050, as advocated by the Japanese government. In this context, Asahi Kasei is working to reduce GHG emissions by manufacturing various engineering plastics, such as TENAC™, a polyacetal (POM) resin, using biomass-based materials with low GHG

emissions. Asahi Kasei and Mitsui are working together to find solutions to various issues related to material procurement.

In the United States, Mitsui procures RNG (renewable natural gas) generated from municipal waste landfills in the form of biogas and uses it in the mass balance approach*2 to produce biomethanol at Fairway Methanol, a local joint venture. Asahi Kasei and Mitsui have acquired the International Sustainability & Carbon Certification (ISCC PLUS certification) for their supply chains in order to prove the raw material’s sustainability features for use in final products.

This will enable Asahi Kasei to procure biomethanol manufactured by Mitsui, and to sell various types of engineering plastics which contain the correct amount of biomass raw material allocated under the mass balance approach.

The Asahi Kasei Group aims to contribute to a carbon-neutral and sustainable world under its slogan of “Care for Earth” by focusing on initiatives such as the use of biomass raw materials, recycled raw materials, and renewable energy. The company strives to meet the expectations of its customers and society by further advancing the provision of products and services with such sustainable characteristics while deepening collaboration with other companies based on its medium-term management plan for fiscal 2024, under the theme of "Be a Trailblazer".

Mitsui is striving to reduce the Scope 3 GHG emissions of its customers by using the expertise, knowledge, and products of a variety of its businesses, including the provision of low-carbon methanol, such as bio-methanol, and to contribute to the sustainable development of all society.

12 Industry Europe NEWS

BASF to supply Neopentyl Glycol

Indaver Chooses Coperion Twin Screw Extruder for Plastics2chemicals Plant

Coperionwill deliver a ZSK Mc18 twin screw extruder and corresponding peripherals for a Plastics2chemicals (P2C) plant that Belgian waste management company Indaver is building to chemically recycle plastic waste. The P2C plant is currently under construction in Antwerp, Belgium and is expected to annually transform 30,000 tons of so-called end-of-life plastics into high-quality basic chemicals.

Indaver decided upon Coperion’s twin screw extruder technology to ensure energy-efficient, continuous reactor loading in the chemical plastics recycling process. Along with the ZSK extruder, the order includes Coperion K-Tron gravimetric feeders, a vacuum unit, a closing valve, and the melt line to the reactor.

Where mechanical plastics recycling reaches its limits, Indaver picks up with its innovative Plastics2chemicals depolymerization process. The company reclaims materials from mixed polyolefin and polystyrene streams, closing the loop for these plastics with no loss in quality.

In the P2C recycling process, plastics are broken down into shorter carbon chains or

monomers. Base products such as naphtha (raw benzine) and wax result from polyolefins (PE and PP). Polystyrenes are split into monomers that can be reused as raw material.

The Coperion ZSK Mc18 twin screw extruder assumes a central function in Indaver’s innovative P2C process. Before plastic waste can be fed into the reactor, it must pass through the ZSK extruder’s process section at throughputs of up to 3.7 tons per hour. Using intensive shearing and dispersion, the ZSK extruder’s twin screws introduce a large amount of mechanical energy into the material stream in a very short period of time. In just 30 seconds, the agglomerated post-consumer waste is transformed into a homogeneous, up to 350°C (660°F) hot melt in an energy-efficient process.

A Coperion K-Tron gravimetric feeder continuously feeds agglomerated plastic waste into the twin screw extruder. The melt exits the ZSK extruder just as uniformly, ensuring constant loading of the likewise continuously operating P2C plant’s reactor.

An additional Coperion K-Tron gravimetric feeder regulates the addition of additives into

the ZSK extruder’s process section, where they are homogeneously mixed in. At the same time, the remaining moisture in the agglomerated plastic is reduced via the ZSK extruder’s devolatilization.

The high added value of the ZSK extruder in Indaver’s Plastics2chemicals depolymerization process has been proven in comprehensive tests at Coperion’s Test Center. According to Frank Lechner, General Manager Process Technology and Research & Development at Coperion: “ZSK twin screw extruders possess numerous advantages that are especially beneficial in chemical recycling. Thanks to the twin screws’ effective operation, plastic energy dissipation takes place in no time – one core advantage for energy efficiency. In chemical recycling, ZSK technology covers a very wide throughput range of 1 kg to 20 tons per hour, allowing high-capacity product streams to be processed, even those anticipated in the future.

Paul De Bruycker, CEO of Indaver, explained: “Our innovative Plastics2chemicals project positions us to recycle plastics and successfully transform them into basic chemicals for industry. In so doing, we will achieve our goal as a waste removal company of playing an important role in the circular economy. We will reclaim valuable raw materials from plastics which will generate added value for society and for our customers.”

Sulzer Chemtech’s crystallization technology helps drive DSI’s growth

Prior to the delivery of the purification unit, Sulzer Chemtech completed extensive feasibility and pilot testing ahead of its basic engineering package. This helped ensure DSI to produce different concentrations, including levels of up to 99.9 wt% at an overall production capacity of 7’000 metric tons per annum.

Tthat can be used for applications with stringent quality requirements.

DSI’s facility in Serang processes naphthalene from coal tar to deliver the valuable chemicals. To this end, the plant has been producing naphthalene related products.

In order to increase the purity level of its raw materials and end products as well as serving the broader downstream sector, the company selected Sulzer Chemtech’s proven falling film crystallization technology. This is currently used by leading naphthalene producers and processors worldwide, enabling them to deliver high quality aromatics.

Song Ho Kim, President of DSI, says: “We are extremely happy with the collaboration established with Sulzer Chemtech. Their solution for crystallizing naphthalene is a leader in the market, so when looking at advancing our offering, we were confident we should invest in this technology. The flexibility of our operations will also be improved, helping us address different market needs while optimizing operational expenses and profitability. We look forward to installing the unit and beginning our first-grade naphthalene operations shortly.”

Etienne Rigaut, Head of Crystallization at Sulzer Chemtech, adds: “For decades, we have been supporting the most challenging separation processes with state-of-the-art crystallization equipment. Thanks to our extensive expertise, combined with testing and engineering capabilities, we have been able to deliver a customized unit that will help DSI enhance its competitiveness in the marketplace. We strive to support our customers and the entire sector with cutting-edge technologies.”

Industry Europe 13 NEWS INDUSTRYNEWS

CHEMICALS & BIOCHEMICALS

Atlas Copco expands its vacuum range with DB Side Channel Blowers

required. This makes the dry rough vacuum of the DB models suitable for rough industrial processes - such as drying, pneumatic conveying or suction processes. The modular design ensures high efficiency, reliable performance and quiet operation.

Avacuumsolutions, is expanding its comprehensive vacuum pump portfolio with the side channel blowers DB series. Based on an efficient operating principle, the vacuum is created by the kinetic energy of the rotating impeller. The impellers are connected to the motor shaft and enable suction of the pumped medium, which is accelerated in the side channel.

Side channel blowers are designed for applications where high flow rates are

Thanks to the dry, non-contact pumping principle, the exhaust air of the DB vacuum pumps cannot be contaminated; the vacuum is completely free of oil and dust, without any emissions or impurities. The models are equipped as standard with IE3 motors in eco-design and comply with cURus standards. This certification meets all safety requirements for the Canadian and American markets.

Depending on the required vacuum performance, Atlas Copco offers the DB series in single-stage and two-stage versions, optionally with one impeller or twin impellers each. The single-stage version release the pumped

Thelatest research from McKinsey & Company (McKinsey) emphasizes that procurement in construction companies will play a pivotal role as they navigate uncertainty and aim for sustainability targets. The insights come as McKinsey publishes its latest report: The strategic era of procurement in construction.

40 to 70 percent of a construction company’s total spending stems from procurement, and McKinsey’s research reveals that many chief procurement officers (CPOs) in the industry believe that consistent application of best-in-class procurement practices could lead to up to 12 percent cost savings. Despite this, and the significant margin impact, the construction industry is far behind others in implementing these best practices.

The role of Procurement is also rapidly elevating in strategic importance. The construction industry is directly and indirectly impacting 25% of global carbon dioxide emissions mainly through the production processes of the ingoing materials and the energy efficiency of the structure through its lifecycle. As 90% of emissions for construction companies are Scope 3, our report highlights that procurement, as the main interface with the construction value chain, should be in the driver’s seat to reduce the carbon footprint of construction projects and meet corporate sustainability targets.

McKinsey points that Procurement will play a pivotal role in making cost and sustainability trade-offs, identifying the most sustainable suppliers, and securing access to many sustainable materials and technologies that will be in short supply. That requires new skill sets, data and insights, and new decision-making process and involvement in the construction projects by the procurement professionals.

In the near-term, procurement teams of construction companies will need to create transparency and estimations for the CO2 footprint across

medium after it has gone through just one stage, while in the two-stage version it enters the second stage after the first one. Operation with twin impellers increases the blower's capacity. The two-stage version 2 (4) achieves a higher vacuum level. The combination of both results in larger air flows and higher vacuum level with just one machine.

Atlas Copco takes care of maintenance planning and regular servicing of the DB pumps, if required. "Our 'Preventive Care Plan' is tailored exactly to the pump's needs. Since the vacuum pumps are maintained using state-of-the-art technologies, we also achieve a high level of energy efficiency as a result," Carol Pignatelli, the responsible product manager at Atlas Copco, emphasises. Thus, regular maintenance ultimately helps to reduce operating costs and increase process productivity by minimising unplanned downtime.

the value chain, gain granular perspective on costs and emissions from different materials and available suppliers and work with engineering and project management teams to manage trade-offs of cost / value vs emissions to prioritize solutions that can drive both profits and sustainability.

These actions will be enabled by three key themes:

· Talent and expertise - construction companies will need new expert roles focused on collecting reliable information, guiding, and recommending trade-offs between alternative materials and technologies - tailored to each category and project - assessing design simplifications against impact on value and assessing risks / assessing unproven approaches.

· Roles and mandates – new roles should not only be embedded in the procurement organization but also integrated closely with engineering and design functions and project teams to drive recommendations or alternatives, optimize trade-offs between profitability and sustainability targets, as well as securing access to scarce materials (potentially recommending M&A opportunities).

· Data and market intelligence - procurement teams will need to collect and curate reliable information on the different existing alternatives. This should be built in partnership with suppliers but will require to build own databases, conduct research, and even perform tests when needed. This needs to be complemented with new digital tools, such as dashboards (similar to those used to manage customer relationships) to collect, display, and interpret data.

Procurement function will raise to a strategic role as construction companies navigate the dual mission of improving profitability in volatile times whilst decarbonizing construction

14 Industry Europe

NEWS

New developments in the Construction & Engineering

Up to 50% drop in orders for construction machinery sector despite sales growth

recorded a 23% drop. Western Europe, especially the building construction machinery sector, saw a stark 50% reduction in orders.

Vrecordfor the current year with real growth potentially reaching up to 10%. This optimistic forecast is credited to the increased availability of components, facilitating better delivery capabilities for manufacturers, as deduced during the VDMA Construction - Equipment and Plant Engineering board meeting on July 14, 2023. Nonetheless, a continuous decrease in new orders is gradually diminishing the order backlog. Between January and May 2023, there was a 19% total drop in new orders in the construction machinery sector, while building materials plants

The economic downturn induced by heightened interest rates in Europe and North America has negatively impacted residential construction and machinery suppliers. Unless there's an improvement in order intake, VDMA warns of a potential significant drop in turnover starting in Q4 2023.

Excessive bureaucracy, over-regulation, and stringent documentation requirements like the Supply Chain Sourcing Obligations Act are posing key challenges to European production companies, hindering competitiveness, according to VDMA. Franz-Josef Paus, the trade association chairman, stressed that the limits of manageability have been reached in these areas.

Rising construction and material costs, along with persistent interest rate hikes, are further complicating the industry. To attract more invest-

ments, the VDMA argues that Europe needs to be more attractive, as investors are currently favouring North America and China due to these economic developments.

China presents another source of challenge with its increasing competitive pressure. China's drive for self-reliance and the fusion of political goals and economic policies have resulted in significant overcapacities, leading to increased exports to Europe. Joachim Strobel, Chairman of the VDMA Construction Equipment Section, warned that European competitiveness could be disrupted if Chinese companies receive state subsidies.

“The situation in the real estate sector continues to be worrying, the risk of the real estate bubble bursting there hangs over us like a sword of Damocles. There is enormous overcapacity in Chinese residential construction.” expressed Dr. Jürgen Blumm, Chairman of the VDMA Construction Materials Plant Engineering Section.

BUMAX continues to deliver fasteners that are out of this world

Specialist

fastener manufacturer BUMAX has been selected to provide crucial fasteners to be used on the International Space Station (ISS). BUMAX 88 fasteners will be used to secure a new payload going to the ISS to measure the speed of sound.

BUMAX premium fasteners include some of the strongest in the world and are being used in a variety of extremely demanding and cuttingedge scientific applications, such as at the scientific research institute CERN in Switzerland and for the world’s largest optical telescope in northern Chile.

The space sector continues to benefit from the BUMAX fastener range with various applications. BUMAX extra strong and fatigue resistant model 88 has been selected to securely fasten the housing of a new payload on the ISS called Granular Sound.

The customer is OHB System AG, a subsidiary of the European space and technology group OHB SE, under contract of the European Space Agency (ESA). OHB SE is a European multinational technology corporation. Headquartered in Bremen, Germany, the corporation consists of the three business divisions: Space Systems, Aerospace and Digital. At present, OHB is the third largest corporation in Europe's space sector.

Granular Sound is an experiment in space to measure the speed of sound through a cube filled with glass balls (a so-called package) in microgravity at different package pressures. The experiment uses thousands of glass balls to simulate granular media like sand or concrete.

“The housing of this package will be securely fastened by BUMAX 88 fasteners to avoid the balls from flying around the ISS,” said Lukas Pfeiffer, Project Manager & Systems Engineer at OHB System AG. “The microgravity experiment will provide valuable data for various terrestrial and space applications – from more effective concrete processing to 3D printing in space or on the moon.”

The enhanced properties of BUMAX 88 fasteners are achieved through a combination

of unique BUMAX manufacturing processes and the highest quality European steel.

Since January 2022, BUMAX 88 screws have also been used for the ANITA-2 trace gas monitoring system to ensure good air quality for the ISS astronauts. The system has been simultaneously measuring more than 40 gases every six minutes on the ISS. The system was developed by OHB System AG. BUMAX 88 screws were used for the ANITA-2 payload to securely seal a safety containment and fasten crucial optical components.

“Being trusted with supplying fasteners for projects such as CERN and ISS, which are essential to the evolution of mankind, is of course a source of immense pride and a testament to the quality of our products and BUMAX as a whole,” said Lars Holm, Managing Director, BUMAX. “Being chosen again and again for the most demanding applications means that all our existing and new customers can rest assured that they are getting the best of the best.

The International Space Station was launched in 1998 to gain more knowledge about space. It is crewed by up to seven people. The ISS orbits the Earth at an altitude of 400 kilometers and a speed of 28,000 km/h, which means it orbits the Earth every 90 minutes.

Industry Europe 15

NEWS INDUSTRYNEWS CONSTRUCTION & ENGINEERING

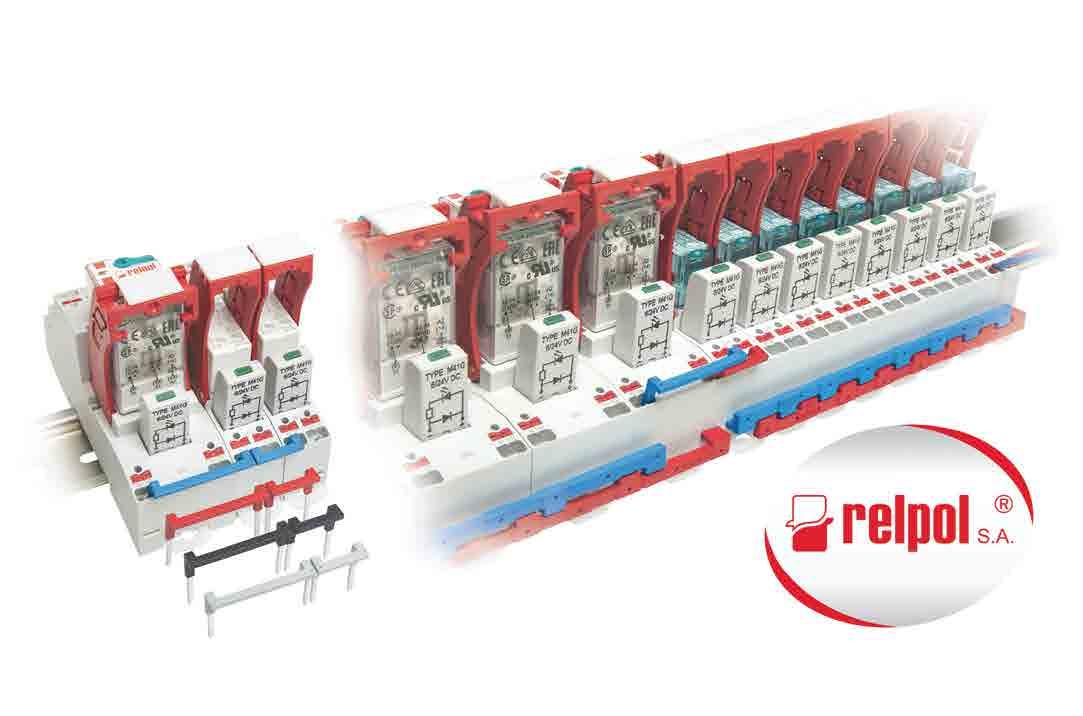

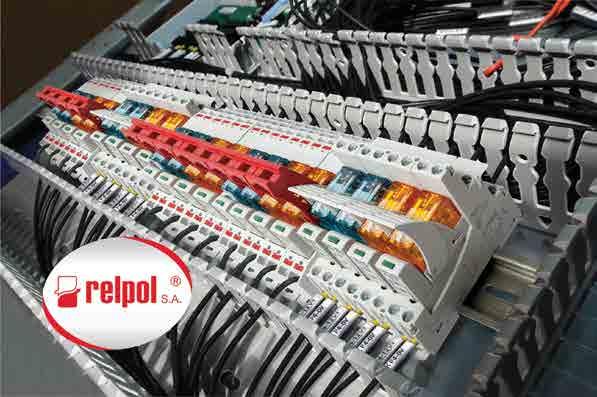

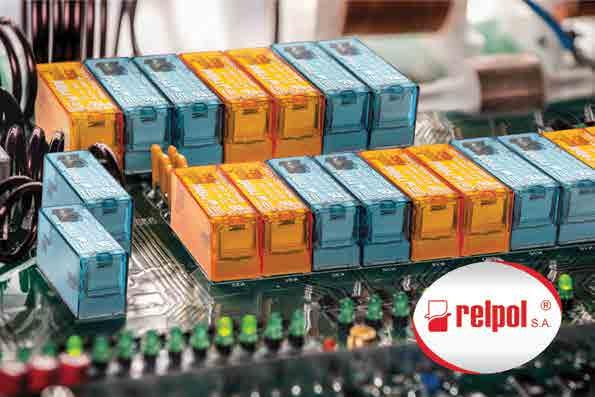

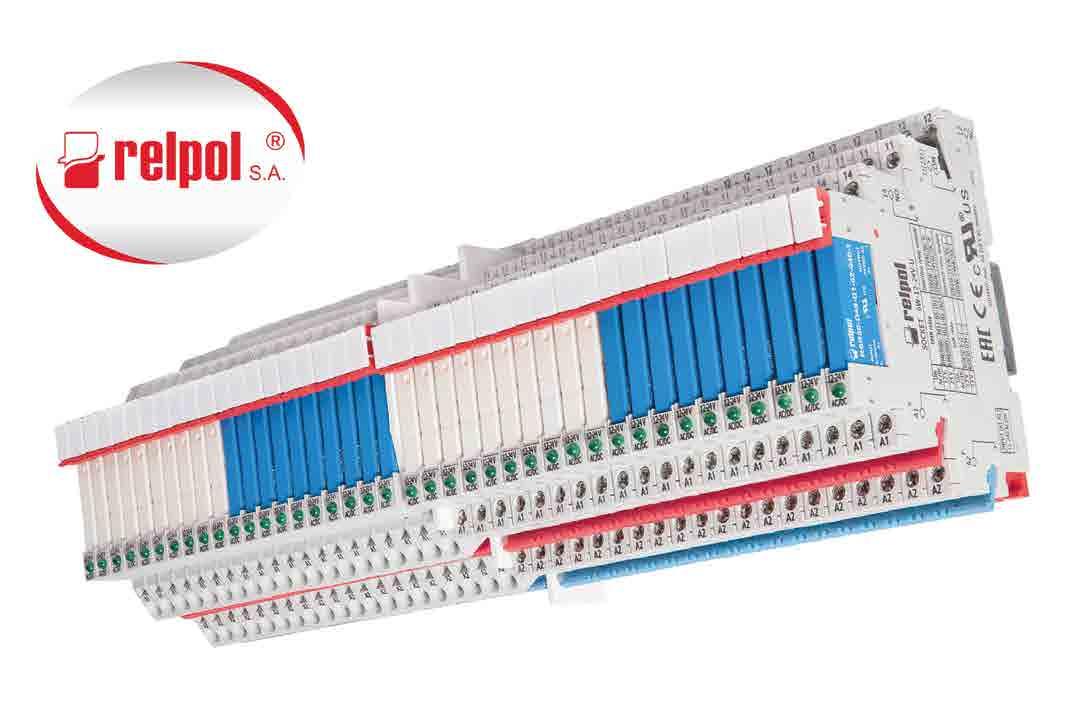

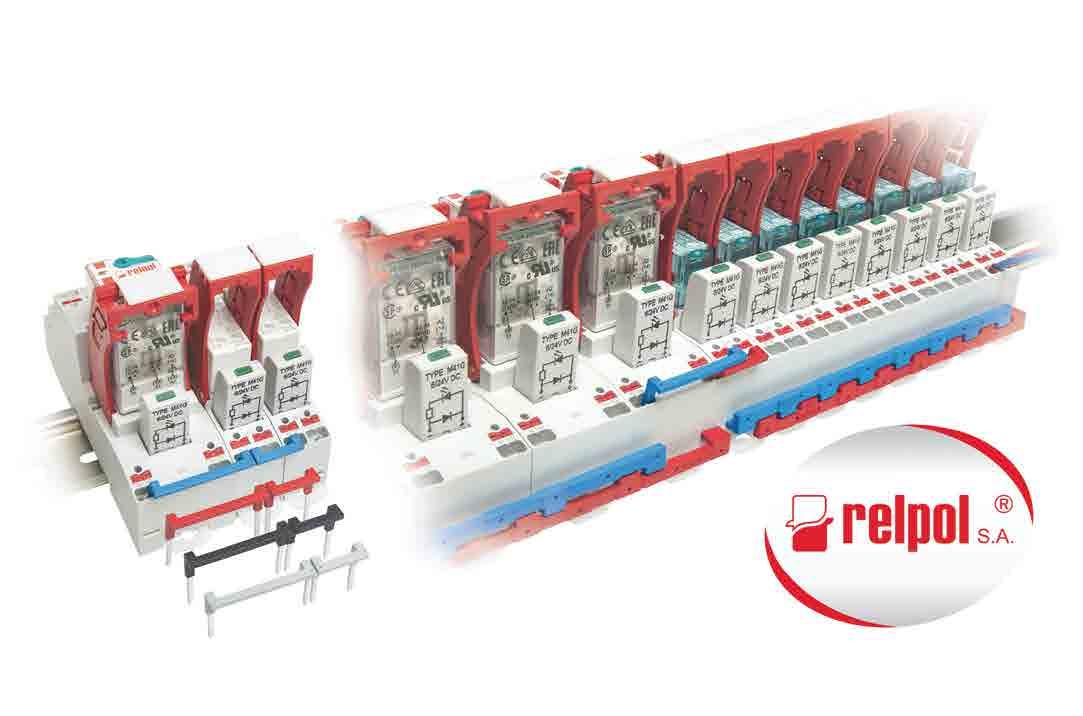

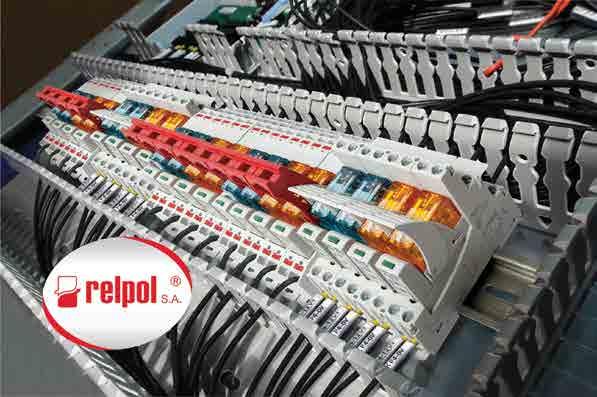

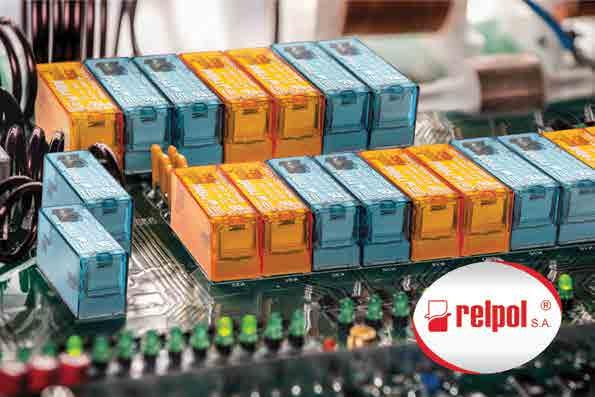

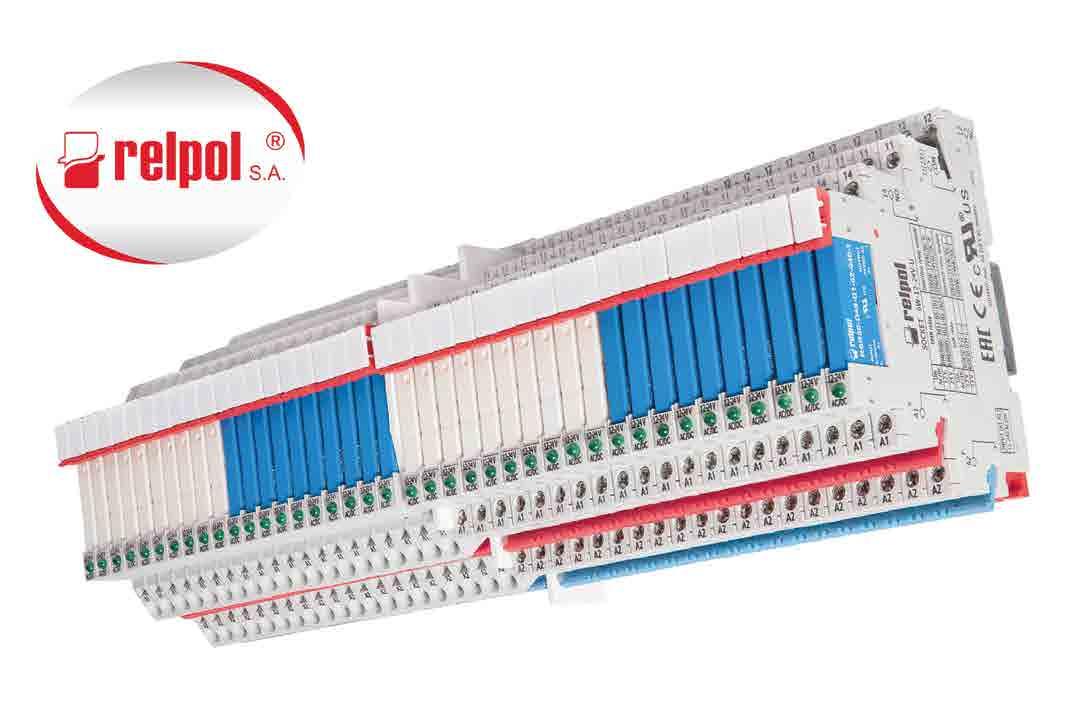

RELAYING SUCCESS

RELPOL S.A, from Żary, Poland- is the largest manufacturer of electromechanical relays in Poland and one of the leading companies on the European relay market. Interview with Mr. Bartłomiej Szydłowski –Sales/Marketing Director and Board Member, it will bring everyone closer not only to the history of the company, but also to the strategy and vision, and above all, plans for the present and future years.

The history of RELPOL. What are the origins of the company?

The company has its beginnings in 1958. On 1st of January 1965 the company became a part of MERA-LUMEL Lubuskie Zakłady Aparatów Elektrycznych. The company became fully independent in July 1982, when the Zakład Przekaźników in Żary started operating. In December 1990, a decision was made to privatise the company. In 1996, as the 55th company in Poland, the company debuted on the Warsaw Stock Exchange. The Relpol brand, known for its design quality, flexibility, and product customisation, proved to be very competitive with Asian manufacturers.

Originally, Relpol S.A. specialised in products for the reconstruction of industry and the energy sector. It mainly manufactured large electromechanical relays, such as the R15 series, which is still well-known to many engineers.

What is the secret of the company’s success in summing up its experience and activity on the market?

The basic factor in Relpol S.A.’s success is its flexibility in relation to business partners, the availability of our products to a wide group of recipients through the distribution market, a solid European brand

built up over many years of quality and reliability on the Polish and European markets, as well as the technical and technological knowledge, experience and commitment of its employees.

However, an important role in the business success of Relpol S.A. is played by the range of products on offer, as relays intended for the power and industrial automation sectors formed the basis of the company’s offer.

What is the current position of RELPOL S.A. on the domestic and European markets?

We supply our products to many foreign markets (more than 50 countries). 70% of our turnover is export, the majority of which is in Europe. While we sell domestically through local distributors and reach out directly to OEM customers, in the case of exports our strategic partners and distributors are key. Our annual sales are approximately 31.3 million Euros (2023), with more than 90% of our turnover achieved in Europe. In particular, we sell on the German market, which accounts for 39% of our revenue, and in Poland, where the proportion of total turnover is 32%.

CONSUMER GOODS

The business environment is currently uncertain. What tools are necessary to maintain business stability?

It should be remembered that one of the strategic entities for the capital group is the factory in Ukraine, which has already reached almost full production capacity from the start of the war until today. Nevertheless, the situation is very dynamic and, given the military activities, this may change at any time. On this basis, decisions are taken to minimise the impact of negative factors and to safeguard the company against these risks in the future. One example is the construction of a twin machine park at the factory in Poland, which is currently being used at the plant in Ukraine.

This is to safeguard the continuity of the production process against a possible escalation of the conflict, which could halt the operations of the Ukrainian factory.

What investments increasing the company’s production capacity and competitiveness has RELPOL made in recent months?

The ongoing major investment of a production line for industrial bistable relays is scheduled for completion in 2024. We consider this project to be very innovative, as none of our competitors has such a product on offer. The task of this product in practice will be

18 Industry Europe

to reduce the electricity consumed in the supply of power switchgear and control cabinets in industrial automation processes. This is a large project worth more than 31 million PLN, thanks to which we will be ready at the end of 2023 with the new product and the entire process of its automatic production. There is also an interesting project in progress for a critical rail infrastructure relay, which is currently in the design phase. This is also a funded project with a total value of nearly 8 million PLN.

What factors distinguish RELPOL’s offering from its competitors?

By focusing on quality, completeness of assortment, as well as flexibility of production itself, Relpol SA strives to create a competitive advantage in relation to the largest companies on the market, where gigantic amounts of money are invested in production automation. With a much smaller production scale, Relpol is a recognisable European brand. Production processes are based on the best materials supplied by European suppliers, which, together with the flexibility of customer service, allows us to remain competitive. We plan to open up new sales prospects in the future in markets where our share has so far been very small, with the USA being one example.

What is the selection of the right raw material (relays) and how does their manufacturing process work?

Relpol SA employs over 50 engineers, about 20 of whom work in R&D departments. The accumulated constructional and technological knowledge allows us not only to create new product groups and continuously improve the current ones, but also to flexibly adapt

products to emerging needs. The company has its own test laboratory, where a few tests are carried out with the products. We test mechanical cycles, shock, and vibration resistance, check electrical parameters and the impact of environmental parameters through the use of climate chambers.

The most important to the manufacturing process is the selection of the right raw materials, which must pass several tests during the production validation process before they can be used. Only positive results allow a given raw material to be used in production. Relpol S.A.’s production process consists of several stages, which are always completed with a 100% test of semi-products or already finished products. It should be noted that each product is subjected to 100% quality control in terms of electrical and mechanical parameters.

What is the company’s current strategy and, above all, for the next few years?

A long-term strategy was designed for Relpol S.A. in the previous year. The objectives set in this strategy are based on investments in building bigger production capacity and market expansion (mainly export) to take advantage of production opportunities. Expansion of the machinery park and investments in new production technologies are an ongoing process resulting from the company’s outlined plans. However, the company’s commercial offer will also develop goods that will complement electromechanical relays in practical applications.

The company’s management is also focusing on building employee awareness of the challenges the company faces. This is aimed at awakening the initiative for ideas and actions that will help the company to overcome adversity.

Industry Europe 19 CONSUMER GOODS

Exports - what share does it have in the company’s production/sales, as well as the main export markets.

Foreign markets for Relpol S.A. account for the largest percentage share of the company’s revenues - approximately 70%. Currently, the company is experiencing sales growth in this channel, however, the key challenge is to cover the complete suspension of sales in the markets of Russia and Belarus. Significant growth is being generated in other territories, mainly in Germany, where the key markets are energy, renewables and the booming electromobility industry. The plan for the coming years in export sales will be to continue market expansion in the area of new countries and new industries.

How many people are employed by RELPOL S.A. and what profit/turnover the company generated in 2021/2022?

There are two factories in the Relpol S.A capital group - in Żary (Poland), where approximately 500 people work, and in Ukraine, where more than 306 people are employed. Relpol generated

146.5 million PLN in sales revenue in 2022, an increase of 14% compared to 2021, with sales to the domestic market increasing by 18% and exports by 12%.

What are the company’s vision and mission for the coming years?

The budget plans for the coming year include several key operational activities, such as process optimisation in all areas of the company to reduce costs of electricity and heat consumption, monitoring of the situation at the production plant in Ukraine, implementation of investment schedules and active commercial activities to acquire new projects to cover production capacity. In the coming year, new product series launches are planned, such as a new series of modular contactors, which will be broader than the current one with additional configurations and a wider range of switching capacities. Our most important priority objective in the design and technology strategy is to search for market niches where the need for specialised electromagnetic relays is expected to grow rapidly in the coming years. These areas should also be specific enough that our competitors will not be interested in them.

For more information, visit: www.relpol.pl/en

CONSUMER GOODS

n

20 Industry Europe

INDUSTRYEUROPE.COM INDUSTRYEUROPE.COM

LA MARE: HOUSING ON THE WATER LA MARE: HOUSING ON THE WATER

La Mare, a company from Bydgoszcz, Poland, is a manufacturer of houseboats. Its mission is to provide customers with top-class, tailor-made solutions, which ensure full safety and the highest comfort. Mr. Witold Witkowski, the La Mare’s CEO, speaks with Industry Europe.

What are the origins of La Mare, the company with a history that goes back to 2010?

In its current form the La Mare’s operations started 13 years ago. Initially, before 2010, we were making steamboats powered by wood briquettes. Unfortunately, they were not very popular, and we soon would realise that the age of steam was over. So, we looked for another idea related to water. I managed to observe a certain niche: houseboats, in other words - houses on the water. At that time, there were no luxurious or elegant units in this segment of the market, houseboats were very simple: no comforts, no electricity, no water connection. So, I decided to create a kind of fashion for the houseboating in Europe. Mobile houses are very popular, so why not to promote floating houses? I really wanted to breathe the spirit into this idea. Now I can say with complete confidence that we have succeeded.

What is the La Mare’s current position on the market?

We are absolute no. 1 producer of houseboats in Europe. Comparing to our competitors our annual production is two times bigger. We have all the necessary certificates such as ISO 9001/2015; we employ more than 30 employees and cooperate with hundreds of companies and subcontractors. Currently, we manufacture more than 100 units a year and sell it on all major European markets, actually to all the EU countries. The exports account for 95 per cent of our total sales, with Germany, the UK, the Netherlands, Portugal and Scandinavian countries being our most important markets. The company’s annual sales exceeded in 2021 to PLN 41 million (EUR 9 million); in 2022 they were more than PLN 47 million (EUR 10.2 million).

Which houseboat model is the most popular in Poland and among foreign customers? Are there any differences?

22 Industry Europe

Witold Witkowski - CEO LaMare

The customers’ preferences are rather similar. I would rather divide it into the floating units (with engines) and stationary units. The interest is divided half and half and it depends on individual regulations in different countries. For example, in the UK a vessel such as houseboat cannot have an engine and can’t sail, as the local canals are too small, and the bridges are too low. However, there are favourable tax conditions for living on the water, so many people buy our products as stationary houseboats. At that time, they were a complete novelty in the UK, since the traditional narrow, metal barges had the apartments partially submerged under the line of water. It means that a lot of moisture enters there, which translates into bad smell of the interior and interfere with the comfort of staying in it. This made our houseboats a great hit, people.

live in them even all year around, since they are dry, warm and cosy. I know marinas with more than 20 of our vessels.

The situation in Germany is completely different. There is a need for houseboats with engine, mainly in the vicinity of Berlin. Houseboat charters start in late March, and customers sail usually for 3-7 days. The unit must therefore be energized and existential independent to enable the client live there with no need to any external utilities.

What is behind of the company’s success on the market?

The first and most important thing is to have an idea, then to observe a niche and launch a product. People are the other matter, in two respects. Firstly, the invaluable contribution of our dealers. On their shoulders is to sell our units. We have an extensive dealer network, with more than 10 dealers in Europe. Secondly, the people in the plant, i.e., our employees who perfectly learned the houseboats manufacturing and do it well. Our crew is constant, we rarely say goodbye to anyone. We care about a good working atmosphere.

Observing the market and adapting to the customer’s needs is another factor contributed to our market success. We are open to any proposed solutions and suggestions. Colloquially speaking, we try to fulfil all the customers’ whims. Maybe it slows us down a bit, because there is no longer a serial production, but a search for the best solutions to meet the client’s needs is worth it.

Of course, stubbornness and faith in your vision are also important. The promotion of the La Mare brand, which take place mainly at European fairs, brought us a great success.

Industry Europe 23

CONSUMER GOODS

Which fairs are the most important for LaMare?

Definitely BOOT World’s Fair Dusseldorf in Germany, but we also take part in regional fairs. I believe that physical presentation of our houses on the water is also the way to success, as this product is not sold from a catalogue. You have to touch it, to step inside, to feel the atmosphere, to check what impression it makes on you.

The best way is to experience it all on the water. That’s why we offer our customers the option to charter a houseboat to able them literally fall in love with the product. Then, the customers often come to us to buy a houseboat for private or investment purposes, as purchasing a houseboat is also a great investment. It pays off much faster than any real estate, in 4-5 years. It has the advantage over yachts that are dedicated only to the summer

period, two or three months. The season for houseboats lasts the whole year, as our units are fully prepared for winter conditions: they are insulated, have heating, and double glazing.

What distinguishes La Mare’s offer from its competition?

When we started our business, there was a little competition, mainly in Germany. Currently, Poland’s companies are our main competitors. They have, like us, a very attractive price offer. However, an attractive price is not everything for us. A very good quality of the product is a must, and we offer it; we combine a good price with a great quality. The rightness of this direction is confirmed by the fact that our products are often copied. Even recently we have won a court case for infringement of our intellectual property.

24 Industry Europe

La Mare is constantly developing, working on new models, expanding its offer, which also increases our competitiveness. We provide a 2-year service throughout Europe.

How long does the production process take?

It takes about 3 months. We are able to produce about 20 houseboats at one time, monthly appr. seven units. For a client the waiting period is from four to six months, since before the production starts, the time is needed for ordering all the necessary components.

Have you made recently any investments to increase the company’s production capacity and its competitiveness?

For the last four years, our annual production has increased more than 100 per cent. Hardly any company is able to get out of it unscathed, to cope with the excess of orders. Fortunately, we made it. Three years ago, I introduced the company’s branches in various towns, where we organized the production. From 2023 we have been developing and expanding the production in the parent company, in Bydgoszcz. Even as we speak, an additional hall of 1000m2 is growing, which is due to open in July this year. We have also permission to build another hall, 600m2, and a port with a crane, partially subsidized from Norwegian funds.

We are near the production of a unit completely independent of external media, external energy sources and municipal connections. So far, waste has been pumped to an external network, and we came up with an in-built sewage treatment, which is powered by five stationary houseboats. Now we are working on a treatment microplant that would be installed individually for a given unit.

We are also in a process to invent river/lake water filters so that you do not have to connect to the municipal network. It is also worth

mentioning that we are the only company in the world to start the production of floating houses in a metal structure. We are planning to launch a metal module factory, which would give us the opportunity to produce land houses.

What is your vision of the company’s further development?

In the next three years, we should like to improve the company’s profit. We need to take full advantage of the new processing capacity that will appear on the occasion of the completion of the two previously mentioned halls. We are also thinking about introducing two-story units or small hotel buildings on water. Our plan includes the enter to two new markets: USA and Middle East. n

Visit: https://lamare.pl

Industry Europe 25 CONSUMER GOODS

New developments in the Consumer Goods

Dematic Delivers Enhanced Processes for Spanish Third-Party Logistics Operator Factor 5

Third-partylogistics operator Factor 5 recently commissioned a goods-to-person solution featuring an AutoStore™ automated storage and picking system provided by intelligent automation solution provider Dematic. The solution enhances its order process for perfumes and cosmetics products with the aim of boosting sales and strengthening its ability to compete in the long term. The solution went live this past March at Factor 5’s Alovera site northeast of Madrid.

Headquartered in Spain’s mid-section in Guadalajara, with 2,000 employees and over 400,000 square meter of warehouse space, Factor 5 is one of Spain’s leading third-party logistics operators.

According to Maria de Jesús, the Supply Chain director at Factor 5, Dematic was selected for its flexibility, global reach and reliability. “We wanted an international technology partner who could offer us a selection of solutions that meet the needs of customers looking to transform their supply chains and looking for increasingly efficient and scalable logistics operations to reduce costs and accommodate growth of online

sales. And we wanted a solid service partner who would be there for us to support our own growth projections for the coming years.”

Factor 5 opted for a modular automation solution from Dematic, which features a high-performance storage system that is easily scalable, has very low energy consumption and provides excellent inventory security. The solution significantly reduces the amount of space required for storage and improves order preparation process times. The project got underway in March 2022 and was completed in just under 12 months.

Dematic Software manages and runs the entire automated system. The AutoStore™ automated

storage and picking system includes nearly 4,400 containers for storage and seven R5 robots for collecting and delivering the containers with the requested items to one of five workstations where operators collect the items to complete orders. The goods-to-person concept is anticipated to substantially increase productivity as Factor 5 employees no longer need to cover long distances to collect individual order items.

“Our goal has been twofold with this project. Of course, we wanted to deliver a robust solution to Factor 5 that meets their requirements from top to bottom, but we also wanted to establish a strong relationship with them that provides added value where they view Dematic as a reliable technology partner for the long term”, explains Sonia Bello, Sales Director at Dematic Iberia.

Santiago de Vicente, CEO at Factor 5, states, “We are convinced that the Dematic solution perfectly meets our business needs, and as we face an increasingly complex market, Dematic can provide advanced and structured technology solutions to support our company’s growth and development in the years to come.”

are typically used for volume production. Importantly, they come at a mid-market price point, yet there is no compromise on build quality or functionality.

Leading UK packaging specialist Xact is set to expand into new markets with state-of-the-art, multiformat packaging machines supplied by Spanish packaging technology innovator IRTA Group Packaging under a new partnership to help brands and retailers “future-proof” their packaging processes.