By Margie Smithurst

The first ROKLive event in Australia, hosted by US giant Rockwell Automation in Sydney in August, was a resounding success for the 350 customers and 150 employees and partners who attended and took part in the technology lab sessions.

“[ROKLive] is a unique event,” said Rockwell Automation’s President of Asia Pacific Scott Wooldridge, speak ing to Industry Update.

“From our perspective, we do simi lar events in different global hubs, but it’s one of the few industrial events where we get people hands-on with technology.

“...whether it’s augmented reality or digitisation, artificial intelligence

or analytics, people are able to get immersed in hands-on lab environ ments and really understand how it might translate to their individual-use cases or manufacturing sectors.

“It really speeds up that digital isation transition because it takes the theory from a PowerPoint slide and makes it reality in a face-to-face environment.”

Students’ sustainable designs could win $15,000

RS Pro & Engineers Without Borders Australia (EWB) are running a student competition focusing on environmental, sustain ability and social impacts.

Students or student groups who can address sustainable design and positive environmental outcomes could win $3,000 worth of RS Pro components, tools and accessories. Entrants have five chances to win the RS Pro products, tailored for use on their projects. and accessories tailored for use on their projects.

With the company already well-es tablished in Australia, Wooldridge says most attendees who used the 25+ hands-on lab sessions at the event were existing customers, with a strong showing from food and bever age companies as well as miners. Continues on page 14

Continues on page 50

AUSTRALIA'S LARGEST CIRCULATING MANUFACTURING MAGAZINE Issue 128 Oct/Nov 2022 $12.00 inc. GST

STRATEGIC PLANNING IN JUST ONE HOUR

Buck Hour is designed to help middle-market businesses

their current position, realign thinking and maximise their

potential. In just one hour, we’ll guide you through a

structured around a range of key fundamentals.

the

our advisors will conduct an analysis of your business using commercial insights, professional experience and best practice standards to develop a prioritised action plan for your business.

end result is a fresh perspective and a focused strategy to help you move forward. 1The William Buck Hour In your lifetime, you will spend: 45,000 27,000 2,550 hour focusing on your business? 18 Capral Aluminium — Bespoke bodies for Australian trade vehicles

The William

assess

business’s

detailed discussion

Following

session,

The

27 ROKLive 2022: Australian companies need to get smarter with automation

ACCESS OVER 25,000 L APP CABLES, CABLE GL ANDS & CONNECTORS ONLINE. Make the right connection with L APP Australia. lappaustralia.com.au sales@lappaustralia.com.au 1800 931 559 LEADER IN CABLE AND CONNECTIVIT Y SOLUTIONS Our top stories Running on hydrogen: retro tted diesel engines at Engineers from UNSW Sydney have converted diesel engine to run as a hybrid hydrogen-diesel engine — reducing CO2 emissions by more than 85% ...Read more More from the industry Online symposium: working with RCS Although respirable crystalline silica (RCS) has been recognised as an occupational risk for century or more, Manufacturing jobs jumping at Ampcontrol Electrical engineering company Ampcontrol Group is set to the next 18 months, after winning contracts ... Product news ciency with the right torque Choosing the most suitable torque sensors from ZHYQ’ range can help to maximise ef ciency and accuracy Torque is measure of the force that Read more Moving right along with Turck roller conveyor These staples of material handling play critical role in throughput and plant Featured products Australian Made 32 Check out Industry Update’s e-news banner ads attracting high hundreds of clicks TO M OR ROW’S PLAN S STA RT TO DAY Westpac Business Loan Our Business Relationship Managers are here to help you expand, grow and get your manufacturing business moving forward. Things you should know: T&Cs, fees, charges and eligibility and credit criteria apply © Westpac Banking Corporation ABN 33 007 457 141 AFSL and Australian credit licence 233714. DB 0641

Scott Wooldridge - Rockwell Automation’s President of Asia

Pacific

Your Global Automation Partner

Monitor Critical Flow and Temperature Conditions

Reduce system downtime with more accurate measurement of critical flow and temperature conditions with the FS+ sensor from Turck. Detect leaks or blockages with this easy-to-use sensor. Not only does the FS+ measure the flow rate of liquids in pipes, it also monitors temperature. Plus, no moving parts or rotating sensor components reduce the chance of failure or introducing contamination into the system.

• Accurate and easy to use

• Rated to IP69K for harsh conditions

• Rugged, rotatable stainless-steel housing

• Switching or analog outputs

• Long lasting - no moving parts to wear out

Contact your local Turck sales representative to learn more.

1300 132 566 www.turck.com.au

SENSORS | CONNECTIVITY | FIELDBUS TECHNOLOGY

Publisher Scott Filby

Publisher Scott Filby

As Australian companies come out of Covid and face a skills shortage for their workforces, there’s a shift towards an increased and smarter use of automation.

This edition of Industry Update examines some of the challenges and solutions that companies are facing and seeking out: from getting the most out of the large amount of data that automation produces, to digital emulation software that can build a ‘digital twin’ of production plant plans, thereby saving considerable commissioning time and risks.

Skills shortages have pushed businesses towards novel solutions, such as cobots, or collaborative robots - which were on show at the Modern Manufacturing Expo. Welding, for example, is an industry that could benefit from the use of cobots for the more menial, time-consuming tasks, freeing up other workers.

At the Smart Manufacturing Conference which ran alongside the Expo, innovative companies from Australia and beyond talked about how they’re keeping up with the challenges of a shifting supply chain and consumer environment, and designing their fac tories to be able to pivot quickly to new products when demand changes.

The bright crop of university

graduates continues to be a boon to the manufacturing industry, with more companies aligning themselves with universities in order to engage the young engineering talent that’s emerg ing and pragmatically solve the skills shortage. Whereas a food and beverage sector job might not have seemed sexy in the past, the technology and innova tion now involved is appealing to some of the brightest engineering graduates.

Attracting both men and women into the sector at this point continues to be a challenge, one that may be helped by overseas skilled migration. Redefining how manufacturing is perceived is a good start - it’s not all hard-hats and factory floors, it’s also problem solving in pre and post production.

As Lana Van Wyck, Principal at Hatch engineering services told the magazine, she’s encouraged by seeing more female graduates drawn to work in the renewable technologies sector, and points out that working as a min ing engineer doesn’t mean every day is spent in safety gear on a mine site.

There’s an energy and intelligence in the Australian manufacturing sector right now that’s been invigorated by Covid supply chain issues. Recognising and harnessing that is the grand challenge facing the government and industry leaders.

Editor Christine Powis

Editor Christine Powis

Collaboration is increasingly the name of the manufactur ing game. Putting together ideas, expertise, capabilities and funding is the forte of the Australian Manufacturing Growth Centre (AMGC) an industry-led not-forprofit which works with 4,000 members.

At last month’s Jobs and Skills Summit, AMGC’s Managing Director Dr Jens Goennemann told govern ment, business and associated leaders that they had manufacturing all wrong: it’s not a sector but a capability which can apply to every sector. It’s a more flexible way of thinking that is producing great results, and these are outlined in its 2022 Project Report (see article in this issue).

This solid document outlines the actual impact of the 31 completed projects and the anticipated impact of all the co-invested projects under AMGC management (total 141).

It is very much worth close inspec tion by anyone who would like to know more about how collaboration works and its positive results on projects’ bottom lines, expansion of markets, products or services, job creation and upskilling.

Yet AMGC’s report also measures its collaborative projects in finer

terms of qualities such as improve ments in research efforts, better designs, better logistics, manufac turing, packaging and distribution, improved business development and knowledge management — and more.

The report shows the first 31 com pleted projects, which include flying cars (or personal hybrid or electric vertical-takeoff-landing vehicles), have returned 9:1 on combined indus try and government investment.

As for government investment, the AMGC calculates that just $16,600 of federal funding was required to create an ongoing, highly skilled, resilient local job, and for every federal govern ment dollar invested there was $26 returned.

As part of the federal government’s Industry Growth Centre Initiative, since 2015 the AMGC has worked as an industry-led, membership-based NFP to match and guide research-led organisations and industry and their advanced manufacturing projects according to ideas, expertise, capabil ities and needs — including funding and export hub opportunities.

The success of its diverse projects speaks for the collaborative approach and I look forward to putting a spot light on some of its projects in future issues.

FROM THE PUBLISHER

Treotham has all your VSD cable & glands needs covered ANNIVERSARY th 1992-2022 1 A Own 1 nMna Treotham Automation supply an extensive range of high quality electrical flexible cables and accessories from . The range is available from stock in Sydney, Melbourne, Brisbane & Perth. With a full range of industrial products, our technical engineers are able to provide fast and reliable service and custom-built solutions for special applications. 100% Australian owned & managed | www.treotham.com.au | info@treotham.com.au | 1300 65 75 64 6 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

Manufacturing jobs to grow at Ampcontrol

Electrical engineering company

Ampcontrol Group is set to create at least 200 manufacturing roles across Australia in the next 18 months, after winning contracts with a total value of $41m with BHP, Western Power and others such as telcos.

Ampcontrol company CPS National has also been named a key partner in the Western Power contract won by Boundary Power for the roll-out of 101 stand-alone power systems (SPS).

Boundary Power is a joint venture between Ampcontrol and West Australian utility Horizon Power.

The Western Power contract is Australia’s biggest single roll-out of SPS: it will replace 762km of overhead powerlines, improve land for farmers and reduce risk of bushfires.

Ampcontrol Managing Director & CEO Rod Henderson said the new projects demonstrate Ampcontrol’s ability to provide optimal solutions for utilities, communications and industry.

The roll-out of power and battery upgrades and solar skids for BHP provide the key first steps in elec trifying mine sites and eliminating safety risks to workers while keeping manufacturing within Australia.

“At Ampcontrol, we have always felt strongly about keeping manufacturing

jobs here in Australia. By winning these contracts with BHP and other businesses, it further reinforces the capabilities of the Ampcontrol Group,” says Mr Henderson.

“Ampcontrol is proud to play an integral role in the uptake of innovative solutions such as SPS across Australia, supporting remote communities by

Driving your performance to the next level

providing a more reliable and cost-ef fective option through renewable tech nology rather than traditional poles and wires,” said Mr Henderson.

“This is just the beginning for jobs growth within the Ampcontrol Group as we scale up our operations.”

Founded in Newcastle NSW in 1968, Ampcontrol already has more

Oxy Combustion for Glass Melting Oxy Combustion for Glass Conditioning

INDUSTRY NEWS OXY-COMBUSTION TECHNOLOGY AIR LIQUIDE ACTS FOR A SUSTAINABLE FUTURE -33% Carbon emissions by 2035, Neutrality by 2050

us today to discover more with one of our experts www.airliquide.com.au

Contact

perfecting the use of oxygen

melting processes.

At Air Liquide, we have helped to move the glass industry forward for over 30 years,

in

than 950 employees across 30 opera tions worldwide.

Industry Update Issue 128 October / November 2022 | 7 industryupdate.com.au

Ampcontrol Group ampcontrolgroup.com

www.greasemax.au

MANUFACTURING MAGAZINE

Industry Update Media Pty Ltd ABN 25 083 502 783 Suite 403, Level 4, 116-118 Christie Street, St. Leonards NSW 2065 +61 2 9439 1288 / sales@industryupdate.com.au

Circulation 17,754 Readership 71,016 as at September 2022

All material in this publication is copyright to the publisher and/or its contributors. No material may be reproduced in part or in whole without the written consent from the Publisher. It is a condition of purchase or acceptance of this magazine that the Publisher does not assume any responsibility or liability for any loss or damage which may result from any inaccuracy or omission on this publication or from the use of the information in this publication or from the use of the information and illustrations contained herein and the Publisher makes no warranties, express or implied, with respect to any of the material contained herein.

© Copyright Industry Update Media Pty Ltd 2022

Publisher SCOTT FILBY scott@industryupdate.com.au

Editor CHRISTINE POWIS editor@industryupdate.com.au

Writer MARGIE SMITHURST writer@industryupdate.com.au

Universities & Collaboration Editor DAVID SLIGAR unieditor@industryupdate.com.au

Sub Editor WILLIAM POOLE subeditor@industryupdate.com.au

Advertising Sales Director SCOTT FILBY scott@industryupdate.com.au

Marketing Manager DUMI UDESHIKA marketing@industryupdate.com.au

Creative Director EDWIN KWONG production@industryupdate.com.au

Production Manager DUMI UDESHIKA copy@industryupdate.com.au

Video Editor & Producer CHARLIE LOUGHLIN video@industryupdate.com.au

Office Manager NICOLE CHARLES nicole@industryupdate.com.au

Finance & Accounts MICHELLE ALCOCK michelle@industryupdate.com.au

Consultant TRACY FILBY tracy@industryupdate.com.au

Accounts Receivable LYN SLIGAR lyn@industryupdate.com.au

Subscription Assistant SAM HICKS info@industryupdate.com.au

Sales Assistant RUBEN PANDEY salesassist@industryupdate.com.au

Circulation Assistant TAYLOR PARSONS circ@industryupdate.com.au

Printer

CONTENTS

OVATO Web Developer JINI M R

simply superior! single point lubrication WHAT’S POOR LUBRICATION COSTING YOU? PRESENTED BY Join us at the Modern Manufacturing Expo at Sydney Showground on the 20th & 21st September. WIN - A 2 hour strategic review with Coleman Greig Lawyers, William Buck Accountants and Advisors and St. George Bank. Manufacturing LAB Ad.indd 1 2/09/2022 1:52:56 PM MANUFACTURING MEDIA MEDIA KIT 2023 MANUFACTURING MEDIA AUSTRALIA’S NO.1 MANUFACTURING & INDUSTRIAL EQUIPMENT MAGAZINE & DIRECTORY DOWNLOAD 2023 MEDIA KIT 6 Publisher’s Note 10 Minister Husic’s Column 11 Universities, Research and Development 16 Industry News 20 Business, Finance and Accounting 24 Employment 28 Women in Manufacturing 32 Australian Made 38 Machinery 44 Workplace Health & Safety 49 Packaging & Labelling 52 Energy, Waste & Recycling 56 Products 61 Events 8 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

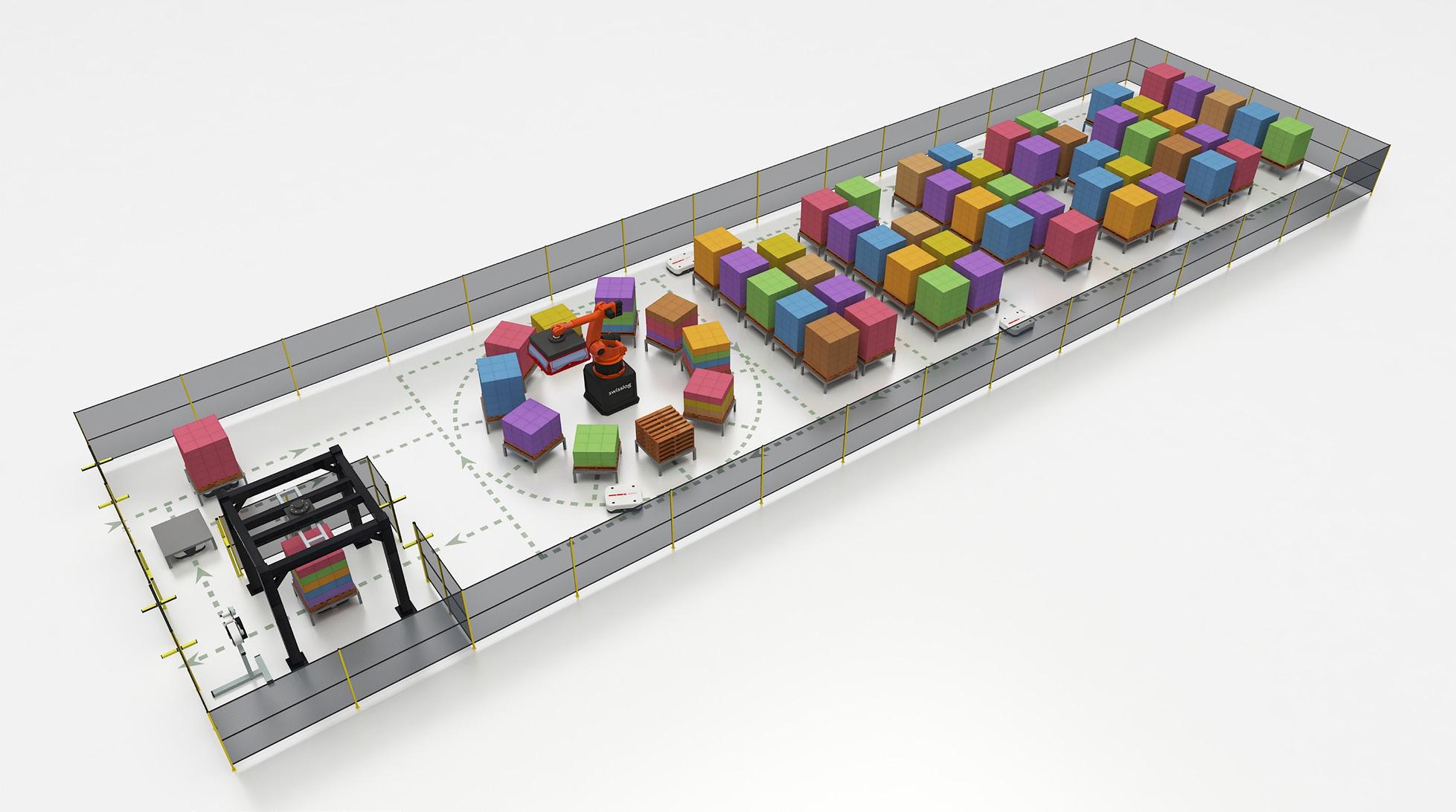

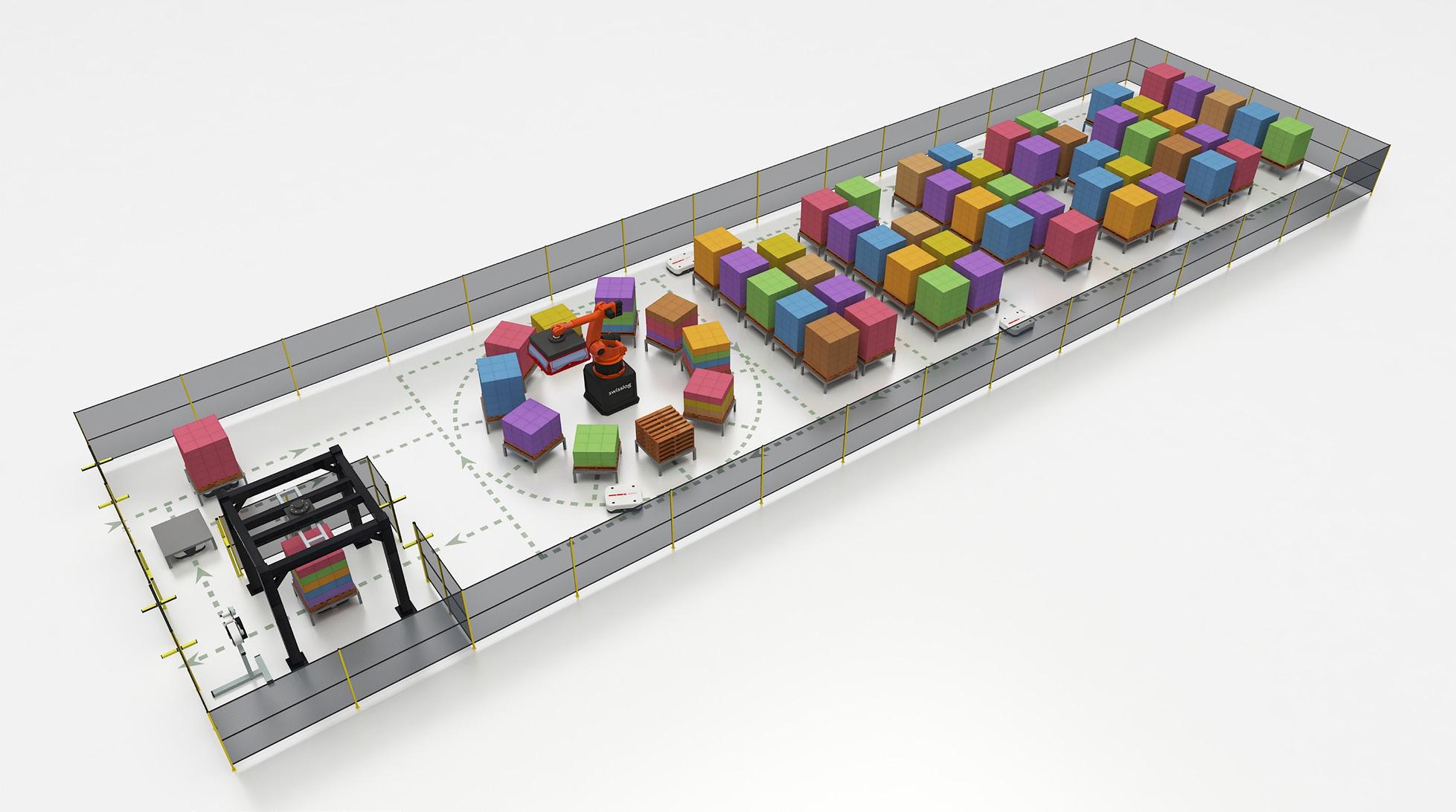

Swisslog’s innovative warehouse automation technology wins materials handling Mercury award

which not only manages the system, but collects valuable data and uses this to recommend further efficiencies.

“I’d like to thank the dedicated ANZ team for all their hard work in developing new solutions tailored to our customers’ needs,” said Dan.

About Swisslog

Swisslog’s innovative auto mated warehouse technology has won the ‘Best Technology Application’ award at the 2022 MHD Materials Handling Mercury Awards.

The technology that received the accolades in the award presentation in Melbourne involved Automatic Mobile Robots (AMRs), KUKA Robots, and the latest Swisslog SynQ Warehouse Management Software (WMS), which combined to deliver optimum efficiency, flexibility, reliability, and sustainability for order fulfilment.

“It’s a great honour to be rec ognised in the materials handling and supply chain industries for our innovative solutions that are helping customers locally and globally,” said

Dan Ulmamei, Managing Director, Swisslog Australia and New Zealand (ANZ).

“Globally, the industry is experienc ing a range of new challenges, and it is through innovation, problem-solving, and collaboration that we will be able to overcome these challenges together,” he said.

The technology involved in the award win complements Swisslog’s comprehensive range of warehouse automation and intralogistics solu tions, including automatic storage and retrieval systems (ASRS), transport and conveyors, picking and palletis ing, and automation software.

The scalable and modular solution that won the Mercury Award was a

fully-automated solution suitable for small, mid-size and large layer and stack picking operations. With min imal fixed infrastructure required, and the ability to grow as a business expands its operations, the innovative solution is ideally suited to food and beverage, grocery, FMCG, and phar maceutical companies looking for a cost-effective, hygienic and efficient warehouse automation solution.

The solution from Swisslog also enhances productivity and sustain ability through negative picking, which allows for the conversion of source pallets into order pallets to minimise wastage.

The entire system is driven by Swisslog’s intelligent SynQ software,

Swisslog shapes the future of intral ogistics with robotic, data-driven and flexible automated solutions that achieve exceptional value for our cus tomers. Swisslog helps forward-think ing companies optimise the performance of their warehouses and distribution centres with future-ready automation systems and software. Our integrated offering includes consult ing, system design and implementa tion, and lifetime customer support in more than 50 countries.

Swisslog swisslog.com/en-au

INDUSTRY NEWS

Industry Update Issue 128 October / November 2022 | 9 industryupdate.com.au

Minister for Industry and Science Ed Husic

As Industry and Science Minister, I often speak about the importance of science and technology for developing our industries.

Central to that is an adequate supply of workers with education and skills in science, technology, engi neering and mathematics (STEM).

During September’s Jobs and Skills Summit, participants highlighted the need to promote the importance of STEM education and careers in meet ing our current and future workforce needs.

One clear way of increasing the number of workers with STEM skills is by widening the pipeline of talent.

We need to create more pathways for women, First Nations people, migrants, mature workers and those living with disability.

The 2022 edition of the Australian Government’s STEM Equity Monitor issued in late September shows that while there has been progress in increasing the participa tion of women, there is still a lot of work to be done.

The data showed that the number of women enroll ing in univer sity STEM courses increased by 24% between 2015 and 2020. However, as a proportion of all people working in STEM-qualified jobs, women’s participation grew by just 2% to 15% in 2021.

Moreover, only 23% of senior man agement and 8% of CEOs in STEMqualified industries are women and, on average, women still earn 18% less than men across all STEM industries.

Frankly, that’s not good enough.

More effort has to be made to increase diversity in STEM and tech nology sectors, not only because it is the right thing to do, but because it is needed to meet the growing demand for skilled workers.

Research shows that diverse businesses are strong and successful businesses.

The Government is committed to making that effort and succeeding. And we want to work closely with industry to make sure real change is achieved.

Following the Jobs and Skills Summit, we announced a review to determine how existing government programs to support women and girls in STEM can be reformed to support greater diversity in Australia’s science and technology sectors.

We are also determined to remove cultural and structural barriers that

limit participation and retention of women and other under-represented groups in STEM.

To further develop skills, the gov ernment is also supporting a Digital and Tech Skills Compact between government, unions and technology employers.

Working with industry, unions and training organisations, the govern ment will develop a pilot scheme offering a blend of employment and training to support workers entering the tech industry.

This could form the basis of digital traineeships or ‘digital tradies’ enter ing businesses across the economy.

The Digital and Tech Skills Compact is an important step towards achieving our target of 1.2 million long-term, tech-related jobs by 2030.

In the past month I have also cleared the way to introducing new National Science and Research Priorities. These were last updated in 2015 and I don’t need to tell you that the world is a completely differ ent place. We will work with industry and the science and research commu nity to develop new science and research priori ties that are fit for purpose.

These priorities won’t just be win dow-dressing but will help us target funding where it’s needed, through projects like our transformative National Reconstruction Fund.

This fund will help rebuild and transform Australia’s industrial base.

The $15 billion fund includes $1 billion in dedicated support for advanced manufacturing and a further $1 billion to support critical technologies investment, such as for AI, robotics and quantum technology.

As part of our renewed purpose to support these industries, we are updating the List of Critical Technologies in the National Interest.

To consult on this review, I have been visiting a range of companies that make up our diverse manufactur ing industry. I have been impressed with the innovative work of these businesses which, like all companies involved in critical technologies, are built on STEM education and skills.

I will play my part in opening up opportunities in STEM to Australians of all backgrounds. And I will con tinue to work closely with industry and researchers to help create the high-value, high-wage and high-tech manufacturing jobs of the future.

INDUSTRY NEWS

Liftco Industrial Supplies Pty Ltd sales@liftco.com.au www.liftco.com.au (02) 9829 4411 REDUCE MAINTENANCE COSTS ON OVERHEAD CRANES LOAD LIMITERS ROPE AND CHAIN CRANES AND HOISTS • Helps reduce the risk of accidents • Protects against overloading of Crane and supporting structures • Quick and easy installation and available for all capacity cranes • Available preset or easily calibrated on site • Helps reduce maintenance costs • Minimizes down time • Automatic reset by reducing the load CONDUCTOR BAR • Available in steel & copper • Quickly and easily installed • Supports required only every 1.5m • Also available in a compact cluster range SIDE PULL PREVENTERS / ROPE GUIDE PROTECTOR Prevents side pulling and protects rope guides and drums on most multi-fall cranes & hoist Prevent dragging of loads Easily fitted to any crane/hoist Helps reduce down time 10 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

“The Digital and Tech Skills Compact is an important step towards achieving our target of 1.2 million long-term, tech-related jobs by 2030.”

UNSW’s retrofitted diesel engines run on hydrogen

timed hydrogen direct injection controls the condition of the mixture inside the cylinder of the engine and this resolves the problem of harmful nitrogen oxide emissions which had been a major hurdle for commerciali sation of hydrogen engines.

“If you just put hydrogen into the engine and let it all mix together, you will get a lot of nitrogen oxide (NOx) emissions, which is a significant cause of air pollution and acid rain,” Prof. Kook said.

“In our system, we have shown if you make it stratified — that is in some areas there is more hydrogen and in others there is less hydrogen — then we can reduce the NOx emissions below that of a diesel-only engine.”

Compared to existing diesel engines, an efficiency improvement of more than 26% has been shown in the die sel-hydrogen hybrid. That improved efficiency is achieved by independent control of timing of hydrogen direct injection, as well as diesel injection timing, enabling full control of com bustion modes — premixed or mix ing-controlled hydrogen combustion.

Engineers from UNSW Sydney have converted a diesel engine to run as a hybrid hydrogen-diesel engine — reducing CO2 emissions by more than 85% in the process.

Professor Shawn Kook and his team from the School of Mechanical and Manufacturing Engineering devel oped the patented Hydrogen-Diesel Direct Injection Dual-Fuel System in 18 months.. They believe any existing diesel engines in trucks or power equipment — for manufacturing, transportation, agriculture and min ing industries — can be retrofitted this way in just a couple of months to use 90% hydrogen as fuel.

by clean, renewable energy so it reduces emissions during its produc tion as well as its use as a fuel.

The team aims to convert exist ing diesel engines at about half the replacement cost of a new diesel engine and anticipates their system will compete against hydrogen fuel cell systems, a widely demonstrated CO2 reduction technology. Prof Kook believes theirs has several advantages over hydrogen fuel cells.

“Our advantage of our system is that is easier to adopt, it uses existing infrastructure and skills, and has lower costs on both development and fuel,” said Prof Kook.

“Hydrogen used for fuel cells must be of extremely high purity which makes it higher cost. In our system the hydrogen can be lower purity and therefore less expensive because the impurities are being burned out during the combustion process.”

“Retrofitting diesel engines that are already out there is much quicker than waiting for the development of completely new fuel cell systems that might not be commercially available at a larger scale for at least a decade,” said Prof. Kook, stressing that climate change means we need more immedi ate solutions.

“This new technology significantly reduces CO2 emissions from existing diesel engines, so it can play a big part in mak ing our carbon footprint much smaller, especially in Australia with all our mining, agriculture and other heavy industries where diesel engines are widely used,” said Prof. Kook.

High-pressure hydrogen direct injection

The research team hopes to be able to commercialise the new system in the next year or two and is keen to consult with prospective investors. They say the most immediate potential use for the new technology is in industrial locations where permanent hydrogen fuel supply lines are already in place.

That includes mining sites, where studies have shown that about 30% of

The International Journal of Hydrogen Energy has published the UNSW researchers’ paper which shows their hydrogen injection system reduces CO2 emissions to just 90 g/kWh — 85.9% below the amount produced by the diesel-powered engine. Green hydrogen is produced

Resulting from a collabora tion with Dr Shaun Chan and Professor Evatt Hawkes, the new system maintains the original diesel injection into the engine but adds a hydro gen fuel injection directly into the cylinder. Their research found that

greenhouse-gas emissions are caused by diesel engines in such items as mining vehicles and power genera tors. And the Australian market for diesel-only power generators is cur rently estimated to be worth around $765 million.

“At mining sites, where hydrogen is piped in, we can convert existing die sel engines that are used to generate power,” said Prof. Kook.

“In terms of applications where the hydrogen fuel would need to be stored and moved around, for example in a truck engine that currently runs purely on diesel, then we would also need to implement a hydrogen storage system to be integrated into our injec tion system.

Prof. Kook believes the technology for mobile hydrogen storage needs to be developed further.

UNIVERSITIES, RESEARCH AND COLLABORATION

“The Australian market for dieselonly power generators is estimated to be worth around $765 million.”

Industry Update Issue 128 October / November 2022 | 11 industryupdate.com.au

The Hydrogen-Diesel Direct Injection Dual-Fuel System has been developed by the UNSW Engine Research Laboratory’s team led by Professor Shawn Kook (right), and including Xinyu Liu (back left) and Jinxin Yang (front left).

Co-investment in Australian manufacturing drives real growth

The Advanced Manufacturing Growth Centre (AMGC) has released its 2022 Project Report –demonstrating manufacturing trans formation and revealing a significant positive industry impact. The report provides an overview of the organisa tion’s 141 co-invested manufacturing projects and showcases the economic contribution from its first 31 com pleted projects. All AMGC projects involve collaboration between indus try and a research-led organisation.

Analysis of the organisation’s 141 projects provides evidence of real jobs and revenue growth generated from the initiative. Overall, the projects are expected to generate $1.62 billion in additional revenue and the creation of 4,288 new jobs. The returns reflect a combined industry and government co-funded pool of $137.2 million.

Of the 31 completed manufactur ing projects, a total of 430 new or upskilled roles have been created while an additional $188 million in revenue was injected into the Australian economy via domestic and export sales. The revenue creation

represents an average return on investment of 9:1, based on a co-fund ing investment of $20.26 million ($7.15 million derived from federal funding and the remainder from industry in cash and in-kind).

Speaking of the Project Report’s impact, Federal Minister for Industry and Science, Ed Husic, said, “Crucially, it [AMGC] has a focus on funding innovative projects that have the potential to make Australia’s manu facturing industry more productive and competitive, but might be in areas where companies may not have the capacity or expertise to tackle the task on their own,

AMGC’s portfolio of co-invested projects incliudes projects in resources, agriculture, forestry, and fisheries, transport, medical sciences, renewables, and low emissions tech nology, defence, space and, enabling technology – such as AI and robotics.

Some of the first 31 projects locally manufactured, include flying cars, solid-state rocket motors and fuel, prescription eyewear from recy cled materials, invasive ventilators,

track-and-trace system for the prov enance of the wine, carbon fibre rein forced geopolymer to displace concrete, and carbon composite bike wheels.

Managing Director of AMGC, Dr Jens Goennemann said these successes are proof of the manufacturing indus try’s readiness to invest, advance, scale, and export if highly targeted assistance is afforded to those who wish to com mercialise and scale.

“We can manufacture amazing things in Australia, provided we focus on being better, not cheaper, that we add value to our abundant natural resources, and we embrace advanced practices and processes – our 2022 Projects Report is proof that we can do so much better than Australia’s current ranking of 91st in global

complexity rankings, “AMGC has demonstrated time and time again that by empowering man ufacturers, through appropriately sized and supported initiatives, we can create prosperity for Australians and establish the country as a manu facturing powerhouse – we just need long-term commitment at all levels of Government to give the industry the confidence to invest where it mat ters”, said Goennemann.

About Advanced Manufacturing Growth Centre (AMGC)

The Advanced Manufacturing Growth Centre (AMGC) is an indus try-led, not-for-profit organisation.

KEY FORECAST IMPACT FROM AMGC PROJECTS

• 141 co-funded industry projects

• $137.5 million in co-funding investments

• 4,288 direct and 15,436 indirect jobs are expected to be created

• $1.62 billion in estimated revenues generated

• 434 nation-wide collaborations

OUTCOMES FROM FIRST 31 COMPLETED PROJECTS

Upon completion of a co-funded project, participants contribute to a substantive finalisation process. The data collated revealed:

• Increased revenues of $188 million from local ($136M) and inter national ($52M) sales

• The creation, or upskilling, of 430 direct jobs

•

•

•

• Average Return on Investment (ROI) 168%

• Participants reported an increase in - Profit – 77% of participants - Range of products and services – 83% of participants - Productivity – 83% of participants - Profit Margin – 57% of participants

• The majority of project participants reported improvements at all points along the manufacturing value chain

• Many project participants engaged in collaborative endeavours, with: - 75.8 per cent of completed project participants rating working with research institutions as ‘positive’ or ‘very positive’

• Of the 31 completed projects, 89 per cent of participants increased activities around exports, niche or underserved markets

• All projects reported an increase in their business resiliency

UNIVERSITIES, RESEARCH AND COLLABORATION

strategies

Hey! Have you checked your air filters? In October, SMC is spreading awareness around the importance of changing the filters on your factory floor. Chat to our team to arrange an inspection! #SayNotoNoFilter #doyoureallyknowSMC Why?

It removes liquid water at the point that it is installed.

It helps machinery to run more efficiently and economically.

It helps keep contaminants out of cylinders, valves and other pneumatic components. It’s quick and easy, and it makes a big difference to the life of your equipment. We are here to help - it’s as easy as 1,2,3… SMC! Expertise - Passion - Automation Join the conversation: SMC Corporation Australia I New Zealand SMC - more than pneumatics

12 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

The AMSL Aero Electric VTOL (Vertical Take-off and Landing) aircraft has some design attributes that are viewed as significant advantages over other eVTOL concepts and make it adaptable to a range of different missions.

Students’

“The last two years has been a strange and stress ful year for the

“The opportunity to submit your concept and potentially be given the tools to build the project is a kick-start for any entrant into 2023. The sustain able and environmental criteria is commensurate with current expectations in the industries applica ble to these projects.”

The competition criteria include: Socio-technical skills

Sustainable design skills, including the environ mental, economic and social impacts

The demonstration of effective communication skills through the design pitch application and the outline of teamwork and skills for the project

A demonstration of how the prize will help the entrant achieve social, economic, and environmen tal impacts

The five winners will be announced later in the year and entries close Monday 31st October, 11:59pm (AEST). To be eligible you must be aged 18 or over living in Australia & NZ and enrolled in a full or part-time university-level academic, engi neering, or technology-related programme.

‘Not sexy but fascinating’: uni students fill skills gap in food sector and beyond

The skills shortage in Australia right now is driving a shift towards ‘dark factories’: ones that are so heavily automated they need mini mal human involvement.

However, to get the skills the company does need, Sydney based food manufacturer Beak & Johnston told the Smart Manufacturing Conference in September it now targets university graduates rather than bringing people in from Europe, said Pool, a shift that’s become more critical since Covid closed the borders.

“We network extensively with universities and students. Many find the food industry fascinating, despite the fact it’s not considered particularly sexy.

“Some who we’ve brought on board have been with us for 30 years now.”

Mikael Sandell, of leading global pneumatic manufacturer SMC Corporation, also spoke at the

conference, and said they take a similar approach to getting the skills they need.

“We see the future as university graduates, and we try to catch them when they start their courses.”

“We offer training that sets them up so that they’re already being introduced to SMC technolo gies while they’re at university.

“Our business model is heavily focused on R&D. We have 1771 R&D engineers globally, and five tech nical centres. This explains why we have managed to stay at the top of the market.”

Alan Lipman from bespoke high-tech manufac turer Romar also attested to the quality of students who go on to work in the industry.

He told the conference the advanced manufac turing sector will continue to grow and become more efficient with help from the “incredibly high” standard of young engineers graduating from Australian universities.

UNIVERSITIES, RESEARCH AND COLLABORATION

Scott Philbrook, Managing Director ANZ for RS, the parent company of RS PRO, says he is looking to support future generations of engineers through programs such as this.

evolution of design and engineering in many sectors,” he said.

To enter or for more information visit

sustainable designs to win $15,000

Free education, guidance and leadership for Australian manufacturers seeking advancement, competitiveness and growth. SCAN TO FIND OUT MORE manufacturingacademy.org.au 9 learning modules 20 real stories of Australian success 4+ hours of content COMPETITIVENESS PRODUCT VALUE INDUSTRY 4.0 MARKET REACH MANUFACTURING WITH ROSIE WORKFORCE THE CIRCULAR ECONOMY THE STATE OF MANUFACTURING RESILIENCE

au.rs-online.com/web/content/m/rs-pro-student-fund 14 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

Continued from first page

Australia

Manufacturing: misunderstood, mismeasured & miscommunicated

When Dr Jens Goennemann

addressed the Jobs and Skills Summit last month, he didn’t pull any punches, telling attendees they did not understand manufacturing.

The Managing Director of Australian Manufacturing Growth Centre said it was wrong to think

of manufacturing as a sector and nor was it all about making finished goods. Rather, he told them, it is a capability that cuts across every sec tor where anything is being made.

“This misunderstanding is com pounded because we also use outdated measures,” he said. “These measures

Capral now offers lower-carbon aluminium with a certified CO2e content of 8kgCO2e/kg AL or below. Make a responsible choice; choose locally extruded, lower carbon aluminium from Capral.

For more information visit: capral.com.au

By Christine Powis

ignore roles in pre-and post-produc tion, although these roles account for more than half of manufacturing jobs and are higher-paying, more resilient manufacturing jobs, which are also a growth category and where women’s participation has tripled.”

The misunderstanding, Goennemann told Industry Update, has had a profound impact on all aspects of Australia’s manufactur ing capability—from ways many manufacturers think of their own businesses, to how government policy works, and to the way Australians, especially job seekers, think of manu facturing as a career—or not!

“If you get it wrong from the start how can any policy be well informed— it’s impossible. If policy makers and the public believe manufacturing is production, or assembling products from overseas, then we will not extract maximum value from manufacturing.

“So, subsidies to assemble cars designed and engineered overseas will never have a lasting impact –because we don’t engage in all steps of their manufacture.

“Whereas, if an industry depart ment has a project proposal, for exam ple with AMGC, where we take $57m to create $1.6bn revenue and along the way create 4,000 local jobs with local manufacturers, that’s policy at its best—informed by profound research and real, impactful outcomes.”

Australian Bureau of Statistics (ABS) figures show manufacturing employs about 900,000 Australians, yet AMGC has found the ABS doesn’t count crucial roles in pre- and post-production.

Based on AMGC data, manufac turing employs circa 1.3 million Australians (3.5 times the mining sector) which creates an average of 3.5 jobs—in food and other retail, child care, education, and support services.

“We mismeasure it, so we end up mis communicating it and portraying jobs

as blokes in overalls and hi-viz— not the case but it’s what the public thinks and what our children are led to believe.”

Goennemann believes the mismea surement creates a distorted picture which not only affects government policy but has led to worker shortages: manufacturers are having trouble finding people for roles from talented skilled labour to digitisation experts.

Recent generations have been losing interest in manufacturing, says Goennemann, because we keep hearing manufacturing is shrinking and don’t know about the variety and expertise it often involves.

“We get it wrong before the work begins,” says Goennemann, “and it impacts the pipeline of people looking to a manufacturing career, but manufactur ing indeed can offer a job for anyone, of any skill set, from any background.”

He says misconceptions about manufacturing are deeply wired in Australians so that we favour finished goods and production lines when thinking about manufacturing.

Finished goods are easier to under stand, and great for ribbon-cutting photo opps. But all 141 manufacturing projects co-financed by AMGC have a digitisation component— they’re high-tech businesses.

Scaling up

Rather than a dearth of research, ideas, or the capability to turn them into real ity, the capacity to scale up is the biggest problem for many Australian manufac turers, and therefore a focus of AMGC’s support. Of the 47,000 manufacturers in Australia, about 90% are small busi nesses employing less than 20 people— who often wear several hats.

“It’s difficult for small businesses to scale up to international sales where they could have 7.5 billion global customers, not 25 million locals,” says Goennemann. “Yet that is what an Australian company is doing with carbon fibre wheel rims.”

Importantly, building scale in manu facturing is among the 36 outcomes from the Jobs and Skills Summit to which the government has already committed.

The government also committed to support jobs growth and resilience in the clean energy supply-chain by increasing Australia’s value-adding, clean energy manufacturing industries.

AMGC research shows that 95% of Australia’s manufacturing exports are generated by just 5% of local man ufacturers. This means that even a small uplift in growing the scale of local manufacturers could have an immense impact on jobs and GDP.

INDUSTRY NEWS

Greener. More sustainable

for your

Cleaner,

aluminium

projects.

Continues on page 21 16 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

Goennemann expects AMGC’s mantra is sinking in, and there will be good results from the summit.

IS AN INITIATIVE 1674AMWMEL23INDUPDATEOCT22 AUSTRALIANMANUFACTURINGWEEK.COM.AU THE JOURNEY TO INTELLIGENT MANUFACTURING AMW MELBOURNE 2023 SPACE SELLING FAST. BOOK NOW! For enquiries please contact Anne Samuelsson (Head of Sales) On 0400 115 525 or email asamuelsson@amtil.com.au 9TH – 12TH MAY 2023, MELBOURNE • MCEC AUSTRALIA’S PREMIER MANUFACTURING SOLUTIONS EVENT

Bespoke bodies for Australian trade vehicles

thicknesses, grades and widths.

Park believes that the ability to design custom extrusions with Capral is part of what differentiates Bull motor bodies in the market.

“It takes all the complexity out of the day–to–day build but adds all the smarts of the design into it.”

As a long-term Capral customer, reflects on the relationship as more of a partnership, commenting that transparency has become one of the great benefits to both parties.

“We have cooperation as to future needs, warehousing and logistics so we work more as partners rather than a distant supplier. Capral is the most important part of our supply chain.”

Park stresses that a highly skilled, stable workforce capable of crafting high-quality vehicle bodies has been central to Bull’s success.

When Andy Park and his busi ness partner began a Perth metal fabrication business 20 years ago, they looked for a gap in the market where they could apply their creativity.

Then, badgered by an electri cian friend, they built the first Bull canopies and were soon creating a small run of bespoke canopies. They had identified a need in the vehicle build-up market for a standardised, scalable solutions for heavy industry vehicles used in mining, and by emer gency and utilities services.

They worked at perfecting Bull Motor Bodies’ manufacturing pro cesses and automated production. The team designed a new way of fabri cating vehicle canopies to streamline the process, shed excess weight and create a more stylish body. The result ing AeroBody range led to interstate contracts with large fleets.

But managing director Park says they realised there was scope for their business to innovate further.

“In 2007, we decided to take all we’d learned so far and start again with design. We invested in 3D software and looked at the whole thing differently.

“How would a car manufacturer

make this product? How could we use new technologies?

They wanted to use their essential material, aluminium, more smartly, using engineering, adhesives and new processes.

Using a clever mix of technology, premium aluminium and automo tive plastics, they created a range of strong yet lightweight, stylish chas sis-mounted modules to suit all light utilities on the market.

Fast forward to 2013, and Bull Motor Bodies opened its first interstate operation in Queensland and then its national distribution centre in 2018.

Today, a generation on from its mod est start, Bull Motor Bodies is a pre ferred provider for some of Australia’s largest fleets. Bull has literally built up more than 13,000 vehicles.

Bull motor bodies withstand Australia’s harshest conditions. For instance, their bespoke northwest mining utilities run 24 hours on offroad corrugated tracks.

Bull’s biggest client sector is min ing: the company builds directly for large mining companies and busi nesses servicing the mining sector.

“We work long and hard with our big clients to understand what their technicians do on-site, what tools and weights they carry, what terrain they travel over and how it’s going to be compliant,” says Park.

“We sit with them, visit their sites, talk to their people and try to understand what works, what doesn’t, what is essential and what is nice to have.”

Bull provides design concepts for review before

creating prototypes to trial in the field for evaluation, with feedback inform ing final designs. Its bespoke solutions draw on a wide range of standardised and proven parts, saving its clients time and money.

“Every time we touch any part of our work, we are thinking how it could be better and what we can improve. We have a culture of innovation; everyone feeds back, and in, we push forward.

“We live and breathe crafting our products; we are all dedicated

Park says the Bull team found aluminium the best medium to work with from its earliest days.

In 2007 Bull looked for a supply partner which ticked the right boxes as to who they were and what they could do and offer.

“We knew we needed lots of extrusions; we needed an experi enced Australian company with local die-making facilities able to turn things around quickly, with the capa bility to advise us on aluminium use. An Australian company that could service us as we grew.”

Capral Aluminium matched their brief and has become the most important part of Bull’s supply chain, providing more than 30 unique and standard extrusions along with aluminium sheet in different

to making sure our products are perfect when they go out the door. The laser-cutting, 3D designs and extru sions give us a head start.

“We don’t lose people. When they join us, we look after them, and they hang around. It’s a good place to be.”

Park’s focus is on pushing the busi ness forward by making things easier to do, making Bull a better place to work and producing designs others only dream about.

“We challenge ourselves daily to be more sophisticated as a supplier.”

capral.com.au

INDUSTRY NEWS

18 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

Capral

Deputy Leader of the Opposition and Shadow Minister for Industry Sussan Ley

As the federal opposition con siders our next set of industry policies, I want to take this opportunity to thank the manufac turers of Australia and let them know my door is always open to hear what is going on in their neck of the woods.

Australian manufacturers have walked a difficult road through this pandemic. They have had to pivot all the way. Manufacturers have had to run workshops and change the way their businesses operate. They’ve had to split rosters, divide up teams and separate production lines.

Manufacturers have faced supply chain shocks and unpredictable hits to margins. It has been tough. But equally manufacturers have been up to meeting these challenges the pan demic has posed to our nation.

Manufacturers changed their

products to help Australia mask up and stay sanitised. They built new capabilities and shifted to support sovereign need over business sense.

It’s no stretch to say Australian man ufacturing kept the nation moving.

Manufacturers have come through a storm — many survived thanks to the support of government assistance through programs like JobKeeper.

This was always the plan. We needed to insulate our economy from the shocks so we could grow through the post-pandemic period.

With the major impacts of the pandemic behind us, many manu facturers now face new risks and a cost-of-business crisis that isn’t just brewing – it’s erupting. As the Federal Treasurer himself has said, storm clouds are on the horizon.

Travelling across the country in recent

Green shipping with Treotham tech

Global shipping needs to reduce environmentally harmful emissions. With this goal in mind, the Spanish start-up bound 4blue has developed a novel propul sion technology – fully automated sails that significantly reduce fuel consumption, by up to 40%.

A large proportion of ocean-going, coastal and inland vessels still run heavily on fuel oil and diesel. It’s a burden on the environment that’s no longer sustainable for shipping com panies worldwide.

To help the international shipping industry achieve the common goal of climate neutrality by 2050, engineers are frantically developing greener drive technologies, such as electric motors or methanol- and ammo nia-based fuels.

However, bound4blue from Barcelona is going in a completely different direction. Their idea is to use the power of the wind, combined with a novel drive system, to reduce fuel consumption.

To make this work, robust and durable components are needed that can with stand a harsh environment - such as igus’ plain and deep groove ball bearings

Lubrication and maintenance-free, the igus ball bearings are available

Electric suction draws wind

The Spanish engineers’ invention consists of two complementary drive systems: wing sails and eSAILs.

The 20m high giant eSAILs are mounted on deck and automatically adjust to the wind – similar to a clas sic sail.

The wing sail looks like an aero plane wing and is based on the same aerodynamic principles. The advan tage is that it is a collapsible system that takes up little space on deck.

The column-like eSAIL comes with a special technical feature: an electric suc tion mechanism on the back of the sail draws in wind while the boat is moving.

This significantly reduces turbulence that is otherwise common. As a result, the airflow literally surrounds the sail, creating enormous lift with low drag.

That lift is up to seven times higher than that of a conventional sail, with minimal power consumption, and therefore strong enough to take the strain off the engines.

With the help of wing sails and eSAILs, fuel consumption can be reduced by up to 40%.

According to the company, a pay back period of less than five years is

months, I’ve heard a great deal from manufacturers and small businesses.

Inflation is hitting all parts of our economy. We have rising energy costs, an inability to get skilled workers, soaring input costs and massive supply chain disruptions. These are serious problems that need serious solutions.

Previously we sought to support industry with partnerships. Our $1.3 billion Modern Manufacturing Initiative (MMI) did just that. These grants enabled manufacturers in sectors of comparative advantage and strategic importance to scale up.

The MMI initiative targeted man ufacturers in defence, space, national security, food security, recycling, clean energy and importantly medical products, which have become crucial in recent years as we responded to the pandemic.

I welcome the Labor government’s commitment to this important initia tive and am looking forward to seeing the projects which get underway over coming months.

An additional $52.8 million was committed to expanding the Manufacturing Modernisation Fund, and a further $107.2 million in our Supply Chain Resilience Initiative. These flagship programs were tar geted and achieved in partnership.

Another key issue facing manufactur ing is the cost of congestion at our ports.

According to the ACCC and the World Bank, Melbourne and Sydney ports are

ranked in the lowest 15% for efficiency in the world. Out of 351 global ports, Melbourne ranked 302, Fremantle 326, Sydney 337 and Adelaide 339.

The ACCC has said it consid ers that industrial relations have played a pivotal role in inhibiting productivity and efficiency gains at Australian ports, exacerbating delays and increasing costs to Australian importers and exporters.

CEO of the Australian Chamber of Commerce and Industry Andrew McKellar said the Maritime Union of Australia maintains a choke-hold on Australia’s ports, trashing any mea sures that would encourage a more flexible and responsive workforce.

This is an issue on which we need to see action and an area we will be examining carefully. Yet our focus is not just in one sector – we are exam ining the pressures right up and down the supply chain.

On balance I think we got the set tings right when it came to supporting Aussie manufacturers through the pandemic and I’ll be watching closely to make sure the balance is maintained as we face this cost-of-business crunch.

So thanks to all manufacturers for their hard work which kept Australia strong!

We have to keep at it … Because we aren’t out of the woods yet and we can’t afford to take a backward step when it comes to supporting Australian industry.

therefore guaranteed.

To convince shipping companies of the benefits of this new drive system, the engineers also want to keep main tenance costs as low as possible.

The system has to withstand high loads, salty seawater, high humidity and changing temperatures for years – with out frequent repair interventions.

These are demands that must be met not only by the largest but also by

the smallest parts, such as the plain bearings. Hence, components from igus are used in the eSAIL.

The designers use cylindrical plain bearings made of the iglidur X mate rial for the gear shafts and support rods of the sail.

The advantage compared to metal bearings is that the polymer bearings don’t corrode, even in direct contact

INDUSTRY NEWS

from Treotham Automation.

Continues page 37 Industry Update Issue 128 October / November 2022 | 19 industryupdate.com.au

Make the most of ‘temporary full expensing’ incentive

October 2020 and 30 June 2023

• Used principally in Australia for the principal purpose of carrying on a business

Note - the TFE measures only apply to depreciating assets, as defined in the income tax legislation. Three important asset classes are not included under these measures as they fall under other provisions of the Income Tax Act:

• Capital works - Capital works are deductible under the Capital Works Expenditure measures. While many people colloquially refer to these deductions as ‘building deprecia tion’, it is important to remember that buildings and similar struc tures are not depreciating assets for tax purposes.

• Depreciating assets that would oth erwise be allocated to a low-value pool or a software development pool. These assets continue to be allocated to these pools (since the election to use such pools is irrevo cable) and are therefore not eligible for TFE.

• Primary production assets such as water facilities, horticultural plants, fodder storage assets and fencing assets. These assets are otherwise dealt with under Subdivision 40-F of the ITAA 1997 and are not eligible for TFE.

One size does not fit all

application of the measure creates a significant difference between tax and accounting income.

Additionally, the TFE can get particularly complex in its interaction with other tax provisions and give rise to unintended consequences that could be hard to foresee with cer tainty at the relevant time. Therefore, you may sometimes need to think of doing the unthinkable – opting-out of the measure in some circumstances.

How do I apply?

Equipment and machinery are among the biggest expenses for a manufacturing business, and gauging the right time to invest in new or second-hand equipment can have a significant impact for both productivity and cashflow.

Now may be the time to purchase new or second-hand equipment by making use of the federal govern ment’s Temporary Full Expensing (TFE) incentive - but it does not come without pitfalls.

Introduced in the October 2020 federal budget as part of the gov ernment’s COVID relief measures, the TFE has effectively replaced the decade-long Instant Asset Write-off.

The TFE measure provides for a full deduction in respect of the cost of eligible assets by eligible entities in the income year in which the asset is first held, first used or installed ready for use for a taxable purpose.

In a significant departure from the Instant Asset Write-off (which had a threshold of $150,000), the TFE is unlimited in amount. As such, it can prove very lucrative for manufacturers.

The TFE measure was originally meant to apply until 30 June 2022, but the May 2021 federal budget extended it to 30 June 2023.

Who is eligible?

The TFE is one of the Government’s

most far reaching incentives. Your business may be eligible for the measure if it meets the following requirements:

• the relevant entity carries on a business

• the relevant entity has ‘aggregated turnover’ of less than $5 billion

While the $5 billion turnover test is very generous, it applies to all ‘con nected entities’ and ‘affiliates’ inside and outside of Australia. Therefore, an Australian subsidiary of a multi national group may well be excluded under this wide-ranging definition, however it may be able to access TFE through an alternative test if it has more than $100 million in assets.

Additionally, recent cases have led to uncertainty around the concept of ‘carrying on a business’ in recent years. If you are unsure as to whether your business qualifies, it is import ant to get expert taxation advice before making a purchase.

Which assets are eligible?

To be eligible for the TFE, the depre ciating asset must be:

• new or second-hand (if it is a sec ond-hand asset, your aggregated turnover must be below $50 million)

• first held, first used or installed ready for use by you for a taxable purpose (such as a business pur pose) between 7.30pm AEDT on 6

Because the TFE measure extends to very large businesses that were not previously eligible for any pre-COVID or initial COVID concessions, its application differs for different sized businesses.

You can apply for the TFE in your tax return. However, as outlined above, due to the complexity of the provi sions, it’s important to seek expert taxation advice prior to making any large investment in depreciating assets to ensure that you qualify, and to avoid any unintended conse quences of accessing the incentive.

To

opt-out or not to opt-out?

Notwithstanding the advantages of the TFE measures, there are some circumstances in which applying TFE may be detrimental. Examples include where the TFE creates tax losses, if the business is being sold in the future (which may create issues for the purchaser), if there is an intention to create a tax consolidated group in the future, and where the

BUSINESS, FINANCE & ACCOUNTING

For further information on how William Buck can assist you in assess ing the suitability of the TFE or other tax advice contact them at 02

4000.

Buck

Small businesses Aggregated Turnover < $10 Million TFE is available for most assets, including second-hand assets. The measure is available until 30 June 2023. Medium Businesses Aggregated Turnover $10 - 50Million TFE is extremely attractive because eligible assets, including second-hand assets, can apply this measure until 30 June 2023. Large Businesses Aggregated Turnover $50 - 500Million The general availability of TFE is only for new assets and improvements to new and existing assets acquired between 2020 Budget Night and 30 June 2023. Very Large Businesses Aggregated Turnover $500Million to $5 billion The TFE measures are relatively rigid –namely, the assets acquired must be new assets or improvements to new and existing assets (i.e., second element costs).

8263

William

williambuck.com

Raffi Tenenbaum - Tax Director at William Buck Accountants and Advisors

20 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

Rhiannan Canto - Senior Tax Manager at William Buck Accountants and Advisors

Manufacturing: misunderstood, mismeasured and miscommunicated

Continued from page 14

From car industry ashes

Australians often mourn the loss of our car ‘man ufacturing’ industry. Yet a growing auto parts industry has arisen from the ashes of assembling cars for others. These days Australia’s auto parts manufacturers create 100 line items that are all intermediate and finished parts, and crucially are sold all over the world, and are resilient because they are not waiting on parts from overseas “Australia is better served by seeking oppor tunities to supply components into global supply chains—taking a smaller piece of a big pie rather than a big piece of nothing,” says Goennemann.

The auto parts industry today includes expansion and advances by companies such as Omni Tanker in Sydney and the world-first active wheel align ment system from Doftek in Melbourne. Some of the world’s best vehicle radiators from PWR (used in Formula 1 racing cars) and ARB or air-actuated differential lockers, are Australian designs, made here and exported internationally.

Combining component-makers worked well when a virus shone a spotlight on the need for Australia to make entire products, too.

In 2020, when hospitals were desperate for invasive ventilators for Covid patients who couldn’t breathe, AMGC and Grey Innovation pulled together 53 local manufacturers to make them in Australia under the Notus Invasive Ventilator program. None of them had made a medical device before, let alone an invasive ventilator.

The message is sinking in The 140-odd summit attendees were clearly told they need to re-think manufacturing, its value and what it offers Australia, to help change the mindsets of government, industry, educators, families and the potential workforce. Goennemann expects AMGC’s mantra is sinking in, and there will be good results from the summit over time.

“When you get a new government, which, very early in its term, puts people from all walks of government, business and industry in a room, it’s a good sign. And we have a pro-manufacturing prime minister and an industry minister who is extremely interested in manufacturing, so my expectations are high.”

Goennemann describes Australia’s recent ranking by Harvard Growth Lab in its Economic Complexity Index, way down at 91st (between Namibia and Kenya) from 133 OECD countries as “disgusting” for a rich country. He says the index is highly relevant because a country’s ability to make complex things is its most important capability.

“If Australia keeps making basic items and selling commodities without value-adding, without intellec tual property, we are not resilient— we risk losing to anyone who can make a similar, simple product.

“Every country that makes complex things does better than a country which does not. If you are better off economically, you have an opportunity to be better off socially; you are baking a bigger cake so you have more to share.”

hour focusing on your business?

STRATEGIC PLANNING IN JUST ONE HOUR

The William Buck Hour is designed to help middle-market businesses assess their current position, realign thinking and maximise their business’s potential. In just one hour, we’ll guide you through a detailed discussion structured around a range of key fundamentals. Following the session, our advisors will conduct an analysis of your business using commercial insights, professional experience and best practice standards to develop a prioritised action plan for your business.

The end result is a fresh perspective and a focused strategy to help you move forward.

BUSINESS

1The

williambuck.com In your lifetime, you will spend: 45,000 27,000 2,550 hours handling emails hours in Zoom meetings hours making coffee

William Buck Hour

amgc.org.au • article too long please trim Industry Update Issue 128 October / November 2022 | 21 industryupdate.com.au

Australian Manufacturing Growth Centre

Evergreen looks to a wider market for its Australianmade Asian food products

by Margie Smithurst

David Zhang, “The majority [of the market] is Western food.”

But Zhang says they’re currently in the lucky position of being able to capture a growing vegetarian market, with soya a high protein alternative to meat.

That said, the smell, taste and tex ture of soya products is a challenge for Western palates, says Zhang.

Investment in R&D to meet market needs

As a result, the company has invested significant amounts of money this year in building a new state-of-theart R&D factory on its Bankstown premises.

“We know what the Asian mar ket wants in Australia,” says Kerry Zhang. “We’re one of the top sellers for tofu and noodles for Asian people.”

“Now we’re trying to adapt that to the western audience, especially for hard tofu. For example, the taste: western people don’t like the soy fla vour being too strong, and they prefer a chewier texture, so we’re doing R&D on that.”

Funding for the new facility, which is due to come online in six months’ time, has been helped by St.George Bank.

Kerry Zhang says St.George’s rela

lot of instances, we’re there to have ideas bounced off of us and bring our industry expertise into the relation ship. Whether it’s new machines that expand the business and help it grow, or investment in cost-saving innovations, we know that the real way we can make a difference is by understanding our customers and their operations to add value beyond just finance.”

When Shanghai-born engi neer David Zhang set up his first small tofu factory in Western Sydney’s Greenacre in 1991, he had his sights set on Australia’s Asian food market.

At the time, the quality of Asian food in Australia was poor, says Zhang, and he saw a niche for a healthy option.

Using soya and wheat products from Australia and doing all the manufac turing locally, Zhang gradually built a customer base for fresh tofu, beancurd, noodles and dumpling sheets.

“Slowly, slowly customers came to us,” he says, and they kept coming back wanting more.

Within the next few years, he had opened a distribution centre in Melbourne, and expanded opera tions to Brisbane, WA, the NT and Tasmania.

The company faced a major setback in 2006, when, after moving their fac tory to Sydney’s Bankstown, it burnt down. Their ability to quickly rebuild and restart production led to them winning a Phoenix Award that year.

When Woolworths asked to stock the product 11 years ago, and Costco a

few years later, Evergreen Foods was well and truly on its way.

Now, David’s son Kerry has joined the company as Evergreen’s manag ing director.

Constantly updating their factories

David Zhang’s engineering back ground means he is constantly innovating and updating his factories, combining biology and food science to keep ahead of competitors.

With a reliance on automation, the company is still quite small, with under 100 employees.

“The thing with automation is that the quality is very consistent,” says son Kerry.

products

The Zhangs put their success down to always striving for the highest quality and most nutritious food, and adapt ing to fit the market’s needs.

They spend very little on market ing, because as David says, “make the best products and the market will come”.

“We’re still a niche market,” says

tionship with the family’s business has been very solid.

“They have always been supportive of our requests since we switched to them a year and a half ago.”

St.George Relationship Director, Industry Banking NSW, Daniel Galofaro said “It’s more important than ever to have a strong relation ship with your bank manager. In a

such an exciting time to be helping David and Kerry with their plans for expansion with their new R&D facility.”

BUSINESS, FINANCE & ACCOUNTING

“Make the best

and the market will come”

“It’s

St.George Bank stgeorge.com.au

22 | Industry Update Issue 128 October / November 2022 industryupdate.com.au

David Zhang, Founder, and Kerry Zhang, Managing Director

Rates: what lies ahead and how to counter it

by Colin Cooper, director of Australiawide Finance

The upward march of interest rates continues unabated, presently with no end in sight, writes Colin Cooper, director of Australiawide Finance

The world’s central banks in each country seem to be in lockstep, with the goal of taming rampant inflation, but the early signs are that rises have had a minimal impact, and there will be more to come.

Central bankers, usually circum spect, have announced their firm intent to continue to do ‘whatever it takes’ to bring inflation back to a target of 2% - while currently it ranges between Australia’s 6.1% to almost 10% in the UK. The US and Eurozone fall in the middle but closer to the UK upper range.

Perhaps the most concerning part is the commentary from the US Federal Reserve Chairman Jeremy Powell acknowledging that the fight against inflation ‘may cause a reces sion,’ and the World Bank President David Malpass quoted as saying that inflation could ‘last for years’.

We hope it is not the case. Meanwhile, the Australian Reserve Bank Governor Philip Lowe has said Australia is well placed to avoid recession.

Three commonly referenced economic indicators offer some per spective. Pricing of semiconductors, shipping container movements and fertiliser production form some of the most relied upon forward indicators of activity, and the news is that all may have peaked.

Much of the inflation outcome has been caused by supply chain, pro duction and transport challenges, which are beginning to show signs of a

return to normality.

Semi conductors have been in serious short supply for several years for a variety of reasons: ranging from factory shutdowns caused by the pandemic, to the increased sales of telephones, personal computers and gaming devices as people stayed at home.

One outcome was an estimated 100,000 unfinished cars waiting for chips before they could be delivered. The previously estimated large upturn in demand for chips has been downgraded, partially due to an expected fall in demand for mobile telephones and computers.

Shipping container movement prices monitored by the Drewry World Container Index show the 30th consecutive weekly price fall - of 10% to $4,472 US for a 40 foot container, having fallen 57% from the high of $10,377 US in September 2021, although still 21% higher than the 5 year average of $3704 US.

Fertilisers for agriculture are in serious short supply, partially caused by the Russian Ukraine war, causing major price hikes both in fertiliser and the materials used to produce them.

Russia, Belarus and Ukraine are among the world’s largest exporters after China, which ceased export of fertiliser in December last year to avoid domestic shortages and price spikes.

Sanctions, shipping delays, insur ance problems and Russia’s exclusion from the SWIFT payment system have resulted in massive price spikes and supply shortages, contributing to the expectation of a significant food short age and price crisis across the world.

However, from July, a series of

exemptions from sanctions have been combined with encouragement from the US government to increase Russian exports.

How to counter the impact of interest rate rises

There has been a vast change in the supply of finance in the past several years. Banks being less willing to sup ply a retail presence and the prolifer ation of fintech lenders has changed the landscape.

While rates have been low, it has been convenient to accept the most available finance offering. Despite rates having increased, it may be pos sible to get a far lower rate than before

– just by shopping around.

Shop around, ask questions and compare

costs

Interest rates may provide a headline indicator but the real cost of finance is more nuanced.

Establishment fees, monthly and any other fees commonly present an added cost to the interest charges contained in a finance contract and the best way to compare is to request a schedule of the total cost of your proposed loan.

Australiawide Finance austwidefinance.com.au

BUSINESS, FINANCE & ACCOUNTING

Colin Cooper, Director of Australiawide Finance

GO AHEAD AND GROW MEMBERSHIPS austwidefinance.com.au 1300 367 327 Australian Credit Licence number 508530 LOOKING FOR FINANCE? We specialise in commercial asset finance. Buy your business assets with confidence and arrange fast, competitive finance with one call Vehicles, Plant & Equipment and Machinery Personal Finance for Cars, Caravans, Marine, Motorbikes, Jetskis etc. Finance for Technology & Green Energy Assets New & Used, Older Goods, Dealer, Auction & Private Sales Full Service: from Consultation to Application, Approval, Settlement and beyond Wide & lengthy experience, ongoing customer service BRING YOUR BUSINESS VISION TO LIFE! australiawide FINANCE offers a wide and varied range of finance products, tailored for business asset purchases SCAN FOR PRODUCT RANGE

Industry Update Issue 128 October / November 2022 | 23 industryupdate.com.au

Quiet quitting: disengaged employees are doing the bare minimum

Have you ever worked in a job where you simply did the bare minimum to get paid? You were probably turning down extra shifts and wanted nothing more than for the day to end.

Chances are that some of your employ ees are doing the same. Quiet quitting.

It’s a phenomenon that’s beginning to trend due to the same factors that caused the Great Resignation and Great Reshuffle.

Although it is only beginning to trend now, the concept is by no means new behaviour. Quiet quitting is a result of employees not feeling engaged in their roles or appreciated at work.

More and more people are choosing to stop working harder for no extra pay or incentive.

Quiet quitting is linked to low productivity and business stagnation, and manufacturers with large work forces will lose the most if they don’t pay close attention to their employee engagement levels.

Research has shown that quiet quit ting and low engagement correlates with poor management. Managers who don’t invest in the wellbeing and interests of their employees will see no extra investment or commitment from their employees in return.