Powerful Transformations

Unleash your potential with tech-savvy strategies that improve productivity and increase profitability.

Unleash your potential with tech-savvy strategies that improve productivity and increase profitability.

FOUNDED FOR FABRICATORS BY FABRICATORS TO LEARN MORE ABOUT THE BENEFITS OF MEMBERSHIP, VISIT WWW.ISFANOW.ORG.

Editor: Sarah Peiper

Contributors:

Stephen Alberts

Nancy Busch

Paul “Max” Le Pera

Austin Maxwell

Jessica McNaughton

Tim Saddoris

Louise Scott

Travis Sterrett

Ed Young

Proofreader: Marsha Jo Scott

Design:

V2 Marketing & Management

Printing and Distribution: LSC Communications

Countertops & Architectural Surfaces (ISSN 2372-983X) is published quarterly by the International Surface Fabricators Association (ISFA), with a fifth edition, a Buyers Guide, publishing in October.

Individual copies of Countertops & Architectural Surfaces magazine are available at the nonmember newsstand price of $14.95. Countertops & Architectural Surfaces magazine is also available by annual subscription (five issues) for $30.00. ISFA members receive a complimentary annual subscription with every membership renewal. Special rates and charges apply for orders outside of the United States. To subscribe, call (888) 599-ISFA.

For change of address, please include old label with new information, including both old and new ZIP codes. Allow 3-6 weeks for address change to take effect.

Countertops & Architectural Surfaces magazine is proudly printed in the United States of America. Copyright © International Surface Fabricators Association 2023. All rights reserved. No part of this publication may be reprinted or otherwise reproduced without the publisher’s written consent.

Countertops & Architectural Surfaces magazine and the International Surface Fabricators Association assume no responsibility for unsolicited manuscripts or photographs. Materials will be returned only if accompanied by a stamped, self-addressed envelope.

Opinions expressed by contributors in this magazine are not necessarily the opinions of Countertops & Architectural Surfaces magazine or the International Surface Fabricators Association, but rather those of the individual writers.

Photos in this publication may not depict proper safety procedures for creative purposes. ISFA and Countertops & Architectural Surfaces magazine support the use of proper safety procedures in all cases and urge readers to take steps to institute such procedures.

Photography/graphics provided by:

ActionFlow

Alexander Volkmann

Aristech Surfaces

BB Industries

Breton

Caesarstone

Cambria

Crystallyne Enterprises

Daltile

Daniel Stauch

Darius Ramazani

DG Innovations

Durasein

Edel Photography

Emmanuel Raab

ETemplate Systems

Fabricator’s Choice

Groves, Inc.

Heiko Stahl

Jan Bitter

Laminam

Lapitec

Laser Product Industries

LX Hausys

Mans Berg

Moraware

Park Industries

Paul Moore

Pipedrive

Pinpoint Status

Porcelanosa

Prodim

Quote Countertops

Rosskopf + Partner

Slab Caddy

Slabsmith

Spanish Ceramic Tile

Manufacturer’s Association

Speedlabel

Steffen Spitzner

Vadara

POSTMASTER: Send address changes to:

LSC Communications

c/o Countertops & Architectural Surfaces magazine

3401 Heartland Drive

Liberty, MO 64068

THE OFFICIAL PUBLICATION OF THE INTERNATIONAL SURFACE FABRICATORS ASSOCIATION

A housewarming invitation like no other, this fuss-free lineup features sepia-inspired whites with both warm and cool veining so often found in natural stone. Well-loved in both traditional and modern design stories, these ultra-versatile tones work as well on an oversized waterfall island as they do in a tiny bath. Visit one of over 45 MSI showrooms and distribution centers to make your dream surfaces a reality.

CALACATTA IDILLIO

CARRARA MIKSA

CALACATTA ABEZZO

CALACATTA IDILLIO

CARRARA MIKSA

CALACATTA ABEZZO

Learn how industry professionals are turning to technology to help them reach their expansion goals despite economic downturns.

Make the most out of your sales processes by working smarter, not harder.

Discover the latest and greatest software solutions that support today’s fabricators.

A true champion of solid surface, this German fabricator innovates extraordinary solutions in the pursuit of progress.

Trinseo is excited to announce the Riverine Collection by AVONITE Solid Surface, a new addition to our material solutions portfolio resulting from the acquisition of Aristech Surfaces. Thermoformable and hygienic, due to its nonporous physical properties, AVONITE Solid Surface offers seamless assembly and the possibility to create intriguing light effects, thanks to its subtle translucency. The Riverine Collection is modern yet timeless, featuring the appearance of soft, free-flowing marble patterns with warm, neutral and cool palette options to enhance any décor.

To learn more, visit www.aristechsurfaces.com

Follow us on social media!

@ISFAnow.org @ISFAnow @ISFAnow @ISFA

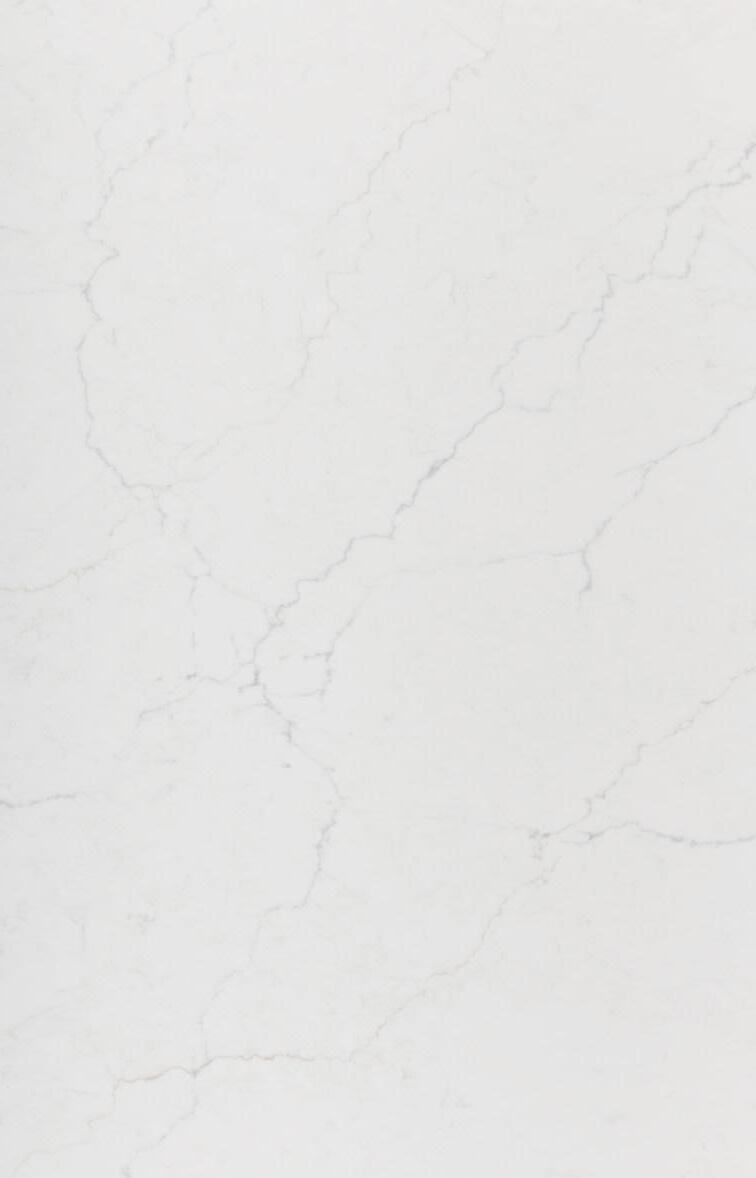

The advent of artificial intelligence and sophisticated language models like ChatGPT has undoubtedly revolutionized how we interact with technology. These models have shown incredible capabilities in understanding and generating humanlike text, leading some to speculate about the potential for these AI systems to replace people in various applications. However, despite their impressive abilities, there are several fundamental reasons ChatGPT and similar technologies cannot fully replace humans.

First and foremost, the human element encompasses qualities that are difficult to replicate in an AI system. Humans possess empathy, intuition, creativity, and the ability to understand complex emotions and nuances in communication. These underlying qualities allow us to connect with others on a deeper level, provide emotional support and navigate ambiguous situations. While ChatGPT can mimic humanlike responses, it lacks our deep understanding of each other — subliminal communication including tone, touch, visual cues, proxemics, and even silence — that help us relate to situations and each other.

Further, the human element involves contextual understanding and real-world experience. Humans have lifetimes of experiences, cultural knowledge, and personal biases that shape their perspectives and decision-making processes. These unique backgrounds enable humans to consider the broader implications of their actions and make informed judgments in complex situations. ChatGPT, on the other hand, lacks personal experiences and relies solely on preexisting data to create responses. This limitation restricts its ability to fully comprehend the context and make judgments that consider the complexities of the real world.

Another crucial aspect of the human element is ethics and moral reasoning. Humans possess a moral compass and an understanding of right and wrong, which guides their decisions and actions. While AI systems can be programmed with ethical guidelines, they cannot truly comprehend the underlying principles and values that inform ethical decision-making. As a result, AI systems may make decisions that are technically correct but morally questionable.

Furthermore, the human element encompasses subjective experiences and perspectives. Individuals have unique thoughts, emotions and perspectives shaped by their personal lives and identities. This diversity of perspectives fosters creativity, critical thinking and innovation. ChatGPT, on the other hand, lacks personal experiences and subjective viewpoints. It generates responses based on patterns in data and lacks the ability to truly think outside the box or offer fresh insights.

In situations where empathy and understanding are crucial, the human element is irreplaceable. Consider customer service. Humans can build trust, establish rapport and provide genuine emotional support. While ChatGPT can simulate conversation and provide information, it lacks the emotional connection that inspires. Many of you may have implemented customer service chatbots on your website to funnel users shopping for your services and products. There’s always a layer of skepticism around it: Am I talking to a real person or a robot? For many, trying to reason with a robot is a huge turnoff — more work trying to connect than it’s worth. Here’s looking at you, automated phone systems! No matter how much frustration I impart in my pleas for help when my information is mistaken, or the options don’t match my needs, you just repeat yourself and cycle through the prompts like some kind of twisted prank — the definition of insanity. Please just connect me to a real person.

The fact of the matter is technology is all around us, and it is constantly innovating. The good far outweighs the bad. It helps keep us safe in the shop and on the road and analyze and run our businesses with more clarity than ever. This issue presents more than a dozen software solutions for fabricators that can increase profitability, create efficiency and improve accuracy (page 26); a digital marketing strategy that funnels leads (page 18); ways in which you can increase sales with fewer people using tech (page 22); and a fabrication company that takes pride in its ability to embrace automation and innovate new products (page 38).

And while ChatGPT and similar AI systems are remarkable tools, it remains to be seen how they can fully replace the human connection. Although my brain can’t possibly hold all the information cataloged in ChatGPT’s database, it’s good to know that there is something inherent in me that it can’t replicate … yet.

Behind the Surface Podcast: Marketing Tools that Lead to Growth

September 4 www.ISFAnow.org

2023

ISFA Webinar: The Right Way To Do Discovery in Your Sales Process

September 6 www.ISFAnow.org

ISFA Mineral Surfaces Fabrication Training

September 13-14

Massillon, Ohio www.ISFAnow.org

Behind the Surface Podcast: B2B Lead Generation

September 18 www.ISFAnow.org

BACA Systems Fabrication Seminar

September 21

Farmington, N.Y. www.bacasystems.com

Missouri Stone Summit: Know Your Business

September 21 St. Louis www.naturalstoneinstitute.com

Cersaie

September 25-29

Bologna, Italy www.cersaie.it

Marmomac

September 26-29

Verona, Italy www.marmomac.com

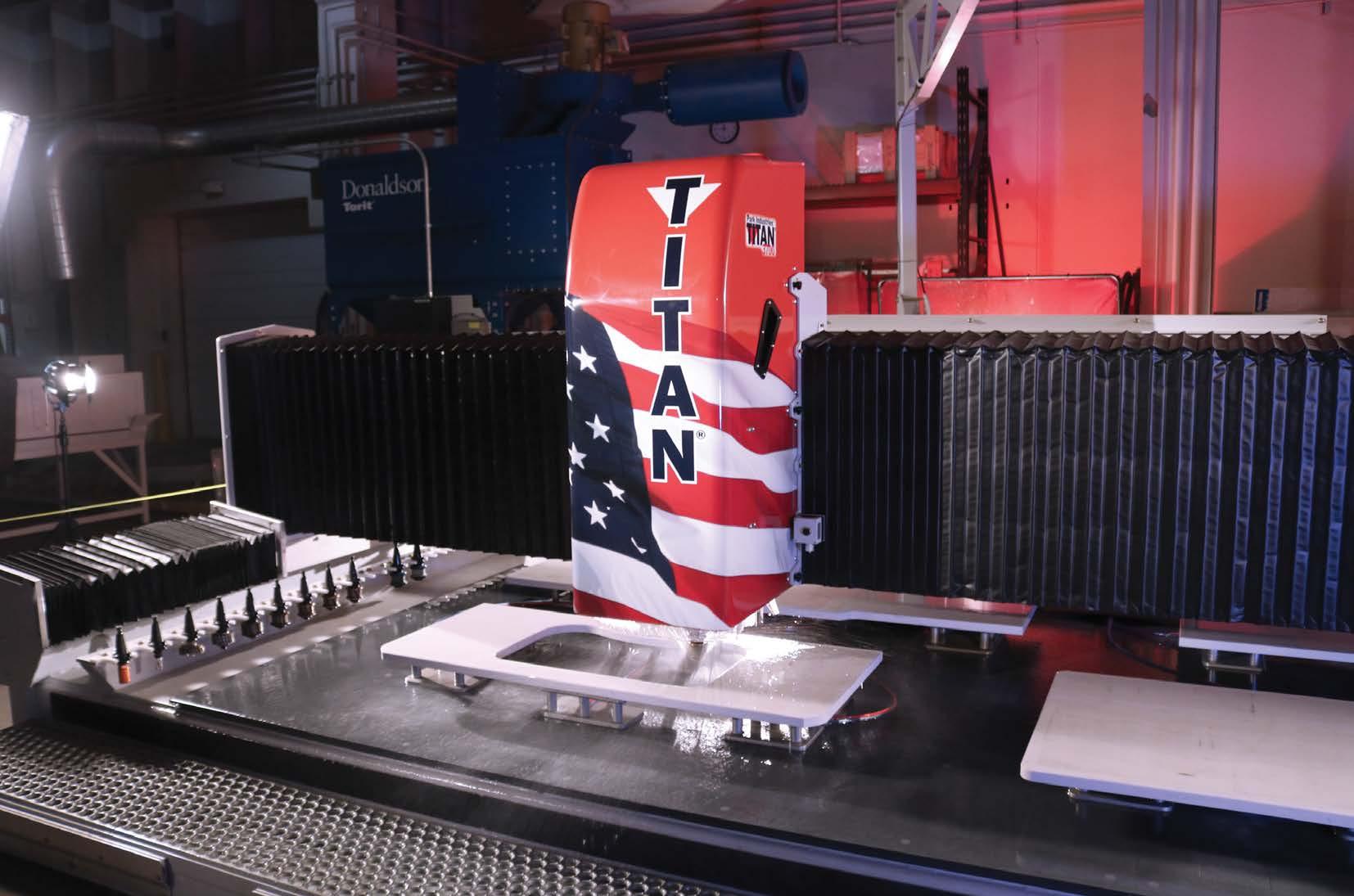

ParkFest 2023 by Park Industries

October 3-4 St. Cloud, Minn. www.parkindustries.com/parkfest

ISFA Webinar: Selling Identity Transformation vs. Countertops

October 4 www.ISFAnow.org

Behind the Surface Podcast: Mindful Materials and Sustainable Products

October 9 www.ISFAnow.org

ISFA Annual Conference

October 16-19, 2023 Sint Maarten www.ISFAnow.org

Connecticut Stone Summit: Dynamic Intentionality

October 19 New Haven, Conn. www.naturalstoneinstitute.com

Behind the Surface Podcast: Using Data To Find Opportunity in Your Business

October 23 www.ISFAnow.org

ISFA Solid Surface Fabrication Training

October 24-25

Addison, Ill. www.ISFAnow.org

BACA Systems Fabrication Seminar

October 25-26

Orion Township, Mich. www.bacasystems.com

ISFA Webinar: 3-Step Framework To Close Deals More Quickly & Easily

November 1

www.ISFAnow.org

Woodworking Machinery & Supply Conference + Expo

November 2-4, 2023

Mississauga, Canada www.woodworkingnetwork.com

Behind the Surface Podcast: Entrepreneurial Operating Systems: Reflect and Review November 6 www.ISFAnow.org

ISFA New Member Workshop

November 8 Virtual www.ISFAnow.org

Texas Stone Summit: Take Your Organization to the Next Level November 9 Austin, Texas www.naturalstoneinstitute.com

Behind the Surface Podcast: Checking in with Eric Tryon November 20 www.ISFAnow.org

Middle East Stone Show December 3-6 Dubai, U.A.E. www.middleeaststone.com

Behind the Surface Podcast: The New NEO Consumer December 4 www.ISFAnow.org

ISFA Webinar: Creating Raving Fans & Loyal Customers with Gratitude Campaigns

December 6 www.ISFAnow.org

ISFA MemberConnect Meeting

December 14 Virtual www.ISFAnow.org

Behind the Surface Podcast: The Art of Upselling December 18 www.ISFAnow.org

The International Surface Event (TISE) 2024

January 24-26

Las Vegas www.intlsurfaceevent.com

KBIS 2024

February 27-29

Las Vegas www.kbis.com

NAHB International Builder Show 2024

February 27-29

Las Vegas www.buildersshow.com

The Spanish Ceramic Tile Manufacturer’s Association (ASCER) announces the call for entry for the 2023 edition of the Tile of Spain Awards of Architecture, Interior Design and Final Degree Project. This year marks 22 years of honoring innovation in design.

Celebrating the excellence in precision and progression of ceramic craftsmanship, the Tile of Spain Awards highlights the careful consideration, meticulous installation and design enhancements of ceramic tiles, in projects from around the world. With the awards open for entry, ASCER invites architects, designers, specifiers, installers and trade professionals, to submit their completed work for consideration in this year’s accolades.

The jury presiding over the awards will be led by architect Carme Pinós and is made of esteemed architects and interior designers including Inma Bermúdez, Jesús Olivares, Gracia Cardona, Susana Babiloni, Luis Rojo, José Juan Barba, Ángel Pitarch and Agnès Blanch.

The Tile of Spain Awards have a total prize fund of €35,000 (approx. $38,500), to be shared among three categories. The two main categories, Architecture and Interior Design, each have cash prizes of €15,000. The Final Degree Project award has a cash prize of €5,000. The panel of judges is also entitled to give up to two special mentions in each category.

Project submissions from around the world will be accepted now through Wednesday, October 18, 2023. The awards ceremony will be held during Cevisama 2024. Visit www.tileofspainawards.com/current-edition/ to review entry guidelines, enter the design contest or learn more about the Tile of Spain Awards.

The European Commission and European Organization for Technical Assessment have adopted a new European Assessment Document (EAD) that defines a new product category known as Sintered Stone. The definition is as follows:

“An industrial product consisting of a wet mix of minerals, without using resin or cement. The material is cold-formed by vacuum vibro-compression and then consolidated, after drying, by sintering at temperatures between 1,100 and 1,200°C. The production process is reversible. The material can be used in architecture and design for various interior and exterior applications and can be installed by means of adhesives, structural bonding or mechanical fixings.”

The material is produced in large slabs and boasts high levels of resistance against scratches, temperature changes, fire, salt water, humidity, UV rays and more. Above all, it is environmentally sustainable, as it is produced without the use of petroleum derivatives. As specified in the EAD, the material is the result of a reversible process, enabling it to revert to its original state at the end of its lifespan and be reused. These properties make it a valuable material for construction and design, both on land and at sea, and it is compatible with numerous global certifications for quality and sustainability.

The EAD 090142-00-0404, which will soon be cited in the Official Journal of the European Union, contains the list of essential characteristics and specifies the test methods necessary to verify the performance of this innovative surface. It’s a significant breakthrough that sheds light on the different specificities of the sintered stone and ceramic product categories to avoid overlaps, confusion and misuse of terms. From now on, surfaces that meet the requirements of the new EAD can be CE marked and circulated even more easily within the European Community’s borders.

According to the Freedonia Group study, Global Countertops, demand for engineered stone is expected to grow at a strong pace through 2027; it will surpass both laminate and granite to become the second most popular countertop product in the world.

Global demand for engineered stone countertops is projected to advance 9.3% per year to 128 million square meters in 2027. Engineered stone has rapidly increased its share of the global countertop market over the past decade — rising from 7% of sales in 2012 to 14% in 2022 — and has become the most popular countertop material in the large U.S. market due to its aesthetics, durability and ease of maintenance when compared to natural stone. Strong sales increases and increasing market share will continue due to:

• A growing array of colors in line with current design trends from both domestic and foreign suppliers.

• The increased availability of non-Breton equipment, largely made in China, which has allowed producers to significantly boost capacity (The market was previously limited by Breton’s dominance in engineered quartz fabrication equipment and its strict quality control standards.)

• An abundant supply of low-cost quartz slabs from the Africa/ Mideast region and other locations in the Asia/Pacific region, such as India.

• Broader distribution networks for engineered stone.

In 2022, North America accounted for the largest share, or 35%, of global engineered stone countertop demand. The Asia/Pacific region was the second largest regional outlet for engineered stone countertops, accounting for 26% of global sales.

Porcelain will be the fastest growing countertop product — albeit from a small base — in the world, with demand rising at a rate of 27% annually through 2027. This robust growth will be fueled by rising consumer awareness of porcelain slab’s favorable performance properties.

Park Industries, the leading manufacturer of stone CNC machinery, announced the promotion of Meagan Hegland as national sales director and the addition of Jeremi Cowman as national sales manager. These strategic moves reflect Park Industries’ commitment to prioritizing customer success and strengthening its sales force to deliver unparalleled service.

As national sales director, Meagan will play a crucial role in driving the company’s customer-centric sales strategies and expanding its market presence. “Meagan’s promotion is a testament to her exceptional skills and her steadfast commitment to customer success,” said Joan Schatz, CEO of Park Industries. “Under her leadership, we are confident that our sales team will continue to thrive.”

Joining the Park Industries team as national sales manager, Jeremi Cowman brings a wealth of experience from his 18-year tenure at a global distribution company. Throughout his career, Jeremi has excelled in sales management and developed a deep understanding of customer needs. He is known for his ability to build strong relationships, develop effective sales strategies and ensure customer satisfaction.

“Jeremi’s extensive background in sales and his customer-centric approach make him a valuable addition to the Park Industries team,” said Hegland. “His commitment to understanding and addressing customer needs aligns perfectly with our company’s focus on delivering exceptional value and success to our clients.”

Alongside Meagan and Jeremi, the sales team at Park Industries includes a talented group of professionals, including 12 experienced sales consultants, four dedicated sales support specialists and two skilled sales application specialists. Together, this robust team is well-equipped to deliver personalized support, technical expertise and comprehensive solutions.

By reducing their carbon footprint an impressive 17% since 2018, leading tile company sister brands Daltile, Marazzi and American Olean were key contributors to their parent company, Mohawk Industries, being named to USA Today’s recent America’s Climate Leaders list. Substantial reduction in carbon emissions is just one of many sustainability accomplishments the brands have achieved to date, providing their customers with tile that is not only beautiful and durable, but sustainably and responsibly manufactured.

“As a company, we create beautiful tile designs responsibly,” said Paij Thorn-Brooks, vice president of marketing, Dal-Tile LLC. “Under our brands’ ‘Our Promise’ sustainability platform, we are focused on creating a more climate positive future by being dedicated stewards of our global impact, leveraging our resources to shrink our footprint and reduce our waste.”

The Daltile, Marazzi, and American Olean environmental sustainability efforts include, but are not limited to, the following:

• 99% — Over 99% of tile collections contain recycled or reclaimed materials.

• 300 million — On average, the company’s North American facilities recover and reuse over 300 million pounds of recycled or reclaimed material per year.

• 17% — Reduction in carbon footprint by 17% from 2018 to present.

• 84% — Recover and reuse 84% of all process wastewater in U.S.- and Mexicobased facilities.

• 125 million — Prevented over 125 million gallons of wastewater from entering local municipal water treatment facilities annually.

• 11% — Reduced energy consumption by 11% at all sales service centers and distribution facilities.

• 0% — Tiles are made from only natural materials: water, clay, sand, feldspar and other minerals. Tiles contain zero VOCs, plastics, PVCs, allergens or formaldehyde.

• Developed and maintain productspecific EPDs and product-specific HPDs for each of our core companies.

• 341 tons — Recycled over 341 tons of cardboard and office paper, averaging 68 tons per year.

• 9 — Nine manufacturing facilities have achieved Mohawk’s internal Zero Landfill Certification.

• 6 out of 11 — U.S.- and Mexico-based facilities are zero-discharge facilities (meaning they recover and reuse a full 100% of their process wastewater).

• Millions — Sent millions of pounds of materials to state-approved beneficial reuse programs.

I get a lot of questions from shop owners about how to price their products. They see advertisements from competitors touting incredibly low price-per-square-foot numbers and wonder if they have priced their products incorrectly.

“How are their prices so low?”

“Should my prices be that low?”

“How do I make a profit at that price?”

I also run across a lot of shop owners who want to close every quote opportunity regardless of the work. For them, it’s all about selling as much as possible. They think, “If the shop is busy, shouldn’t I be making money?”

Unfortunately, they are both asking the wrong questions. They should ask, “What kind of work makes the most money for my shop the fastest?”

To answer this question, you need to know how much money each order generates for your business (Throughput Dollars or $T) and how much cash the business burns daily (Operating Expense or $OE). Additionally, you need to understand how quickly you can fabricate and install different jobs.

Here’s an example of what happens when you ask the right question and use these metrics to get the answer:

I was working with a shop that was limping along at about break-even financially and had some unfilled capacity. Just filling the capacity would have added profit, but the owner was struggling with low-price competition in the area, hampering his ability to increase sales.

We analyzed his market segments: retail, kitchen and bath, contractors, etc. To do this, we calculated the $T as a percentage of the sales price for each kind of job. As expected, the $T percentage varied between the market segments and within each segment. However, there were a few surprises. Most of the contractor orders had a similar $T percentage as most of the retail jobs. The owner had expected the contractor work to have a lower percentage of $T. Through this exercise, he discovered he was doing better with the contractor work than he thought.

We then discussed which market segments he could get more sales from and what actions were required to get that work. There were various challenges with each market segment: high advertising costs, fierce low-cost competition

for a couple of segments, and other issues. These challenges were significant barriers to increasing his sales volume.

Then the owner recalled one market segment he hadn’t evaluated yet. Recently, he had taken on some production builder work at a really low price because he needed to keep the shop busy. Sure enough, the $T percentage was the lowest of all the market segments. It was easy to see why he felt beat up by that customer.

Next, we discussed how many jobs of each market segment he could fabricate and install each week. The way we approached it was to ballpark fabrication and installation of typical retail jobs for an entire week and then do the same for the other market segments. We talked about how the various characteristics of the types of jobs impacted how many he could get fabricated and installed in a week.

The retail and contractor jobs were typically larger and more complex than the production builder jobs. This meant he couldn’t get as many retail jobs fabricated and installed in a week as the production builder jobs. The question was whether the higher $T for the retail and contractor jobs would make up for the lower quantity completed per week.

The aha moment came when we looked at the production builder work. As expected, the number of these jobs he could process per week was the highest of all. When we multiplied the typical $T for production builder jobs by the number of those jobs he could fabricate and install in a week, this segment outperformed all others. We had a winner! Not only was this

work good for his shop, but he also knew how to get more of this work so he could fill his shop. We now had a recipe for this shop owner to start making a significant profit.

This rough calculation helped the owner understand how quickly each type of job generated $T relative to other types of jobs. While not true for every shop, in this instance, the simple production builder work generated cash faster than any other type of work this shop was doing. We also talked about how he might start to adjust his pricing to reflect this impact and start to drive total $T for the business even higher.

Another client recently sent me a note. She had bid on a sizable multi-unit job a year ago and had just learned she had won the bid, but now she was concerned about the ultimate profitability since this was an unusual job for her workflow. When she went through the same evaluation for her market segments, she realized this job could be quite profitable. Now she just had to focus on making sure the logistics for the job were managed well rather than worrying about profitability. Now she has the data and the confidence to bid on this type of work in a way that makes her company money.

Remember, you cannot take the results in this article and assume they are true for your shop. Each shop is different, and you have to do your own analysis. But knowing how to

Ed Young is the owner of Fabricator’s Business Coach, a consulting firm designed to strengthen and elevate fabrication shops of all sizes. A former shop manager, Ed fully understands the challenges of today’s professionals. He has consulted with a range of businesses, from one-person startups to international Fortune 100 corporations, covering a broad array of products and processes. As a result, Ed knows that each business needs an appropriate structure for its unique situation. To learn more about how Fabricator’s Business Coach can take your shop to the next level, visit www.fabricatorscoach.com or reach Ed directly at Ed@fabricatorscoach.com.

With each episode, Behind the Surface inspires fabricators to take their business to the next level by addressing challenges, sharing strategies and gathering insights from leading industry experts.

MINERAL SURFACE

PORCELAIN, SINTERED & ULTRA-COMPACT MATERIALS

SEPTEMBER 13-14, 2023 | MASSILLON, OHIO

SESSION INCLUDES:

MATERIAL ORIENTATION + HANDLING

CUTTING TECHNIQUES

MITERS

OVERHANGS

SEAMING

POLISHING INSTALLATION

REPAIR TECHNIQUES AND MORE!

REGISTER TO ATTEND AT ISFANOW.ORG.

Get the skills you need to fabricate these increasingly popular materials and meet growing customer demand.

In the world of online marketing, having a well-designed website is crucial for converting visitors into leads. Regardless of how successful your pay-per-click campaigns or search engine optimization strategies are, you risk losing potential customers to your competition if your website fails to engage users and convey a compelling message. To maximize the profitability and revenue of your online marketing efforts, it’s essential to focus on website conversion fundamentals.

One of the key factors in website conversion is authenticity. People relate to real people — not staged environments — so it’s important to avoid using stock photography whenever possible. Instead, incorporate photos of your team, showroom, or even your trucks. These visuals help create a personal connection with your audience, making them feel more comfortable and confident in choosing your company. When it comes to content, craft messaging that resonates with visitors; for example, if someone is looking for a countertop, the first message they see on your homepage should reinforce trust and reliability — an emotional connection. Highlight your company’s values and include a call to action, such as encouraging them to call for an estimate or book an appointment. Remember, they have multiple options, so provide compelling reasons they should choose you.

Your company logo should be in the top

left-hand corner. A brief blurb emphasizing that the company is family-owned and operated adds a personal touch. The main navigation should be easy to find, with clearly descriptive links that guide visitors through your site. Use social media to drive traffic to your website by showcasing videos, project photos and community interactions. Lastly, make sure your website is mobile-friendly and make all important information easily accessible. Incorporating web forms throughout your website is essential for capturing leads. Ensure that each page has a web form or, at the very least, have one on the “Contact Us” page. This enables visitors who may not be ready to make a phone call to provide their contact information. Ensure your phone number is prominently displayed in the website’s top right-hand corner, along with a clear call to action telling visitors what to do next. For our clients, we like to put the phone number at the top and then add a button that says, “Get Estimate” or “Get Quote.” Also, remember to leverage your reviews, testimonials and videos to provide additional proof of your company’s credibility. Videos are incredibly effective, catering to both visual and auditory learners.

When writing content for your website, address the specific concerns of your target audience. For instance, if someone wants to refresh their kitchen, include messaging that speaks directly to their needs. After each

Digital marketing can be confusing, but it can completely change your countertop company when done correctly. This article is adapted from chapter 7 of Stephen’s book, The Complete Guide to Internet Marketing for Countertop Shops. To learn more about how to up your online game, get a free copy of the book at countertopmarketingco.com/ book/.

block of text, provide clear calls to action, such as scheduling an appointment or getting an estimate. Include links to other relevant pages, such as your “About Us” section, special offers and before-and-after images of completed projects. Provide content that showcases your expertise and professionalism, making visitors think, “This shop knows what they’re doing.” Emphasize why they should choose your company over the competition.

When considering the conversion factors of a website, it’s essential to optimize the content “above the fold.” This is the top half of your website, what’s visible to the user when they land on your page without scrolling down. Include attention-grabbing headlines, bullet points, calls to action and lead-capture forms. Incorporate a dedicated section for user engagement, focusing on your company profile to establish credibility.

A blog section keeps visitors informed and enhances your shop’s credibility. Testimonials are crucial for earning trust, and including a “Read More” link that redirects to a testimonial page provides additional social proof.

Optimizing your website for conversions is a fundamental aspect of online marketing success. By incorporating authentic visuals, compelling messaging and clear calls to action, you can increase the likelihood of converting visitors into leads and leads into jobs. Address their specific concerns, provide external proof of your credibility, and make it easy for visitors to contact you. Analyze and optimize the various conversion factors on your website to ensure a user-friendly interface and maximize conversions. With a well-structured and persuasive website, you can effectively convert visitors into valuable leads for your shop.

No relief cut is necessary when working with Crossville’s 100% porcelain slabs. That saves fabricators 45 minutes on average.

Because our porcelain is completely resistant to stains, scratches, frost, and fire, you’ll never have to compromise on creative solutions again.

Get free samples fast at Crossvilleinc.com/Products/Slabs-and-Countertops

Stephen Alberts is the owner of the Countertop Marketing Co. and STONE ENGAGE. They specialize in helping countertop companies grow the retail side of their business outside of wordof-mouth and referrals. They also offer software to help you engage more with customers and close more countertop projects. To learn more, visit www.countertopmarketingco.com or www.stonengage.com. You can also email Stephen at steve@ countertopmarketingco.com.

The construction industry is facing significant challenges, such as scarcity of skilled labor, rising material costs and lead delays that have carried over from pandemic-driven supply chain issues like transport bottlenecks and geopolitical uncertainties. But despite these challenges, contractors, subcontractors and material suppliers are moving forward with an optimistic mindset.

A recent survey conducted by PlanHub found that eight in 10 (82%) of general contractors and 80% of subcontractors plan on growing their business in 2023. Also, according to the American Institute of Architects, commercial construction is expected to grow by 6% in 2023, and industry professionals are turning to technology to help them prepare to reach their expansion goals amid an economic downturn.

Greater use of technology across the construction industry helps companies increase efficiency, streamline operations and mitigate labor shortages. To weather the economic slump and labor scarcity, construction professionals rely on digital solutions that increase collaboration and improve margins through greater productivity. And the proof is in the pudding, with 91% of general contractors and 82% of subcontractors planning or considering using new technology in 2023.

A cloud-based preconstruction platform connects general contractors, subcontractors, owners and material suppliers to build relationships and improves how they collaborate, manage their business and win more projects.

In addition, this advanced technology helps streamline the bidding process, accelerate takeoff and secure more leads, so contractors and subcontractors can spend more time enhancing their skills and hiring quality talent to move their business forward.

By leveraging a comprehensive cloudbased preconstruction platform, suppliers are connected directly with general contractors, and subcontractors can get their products in front of them as quickly and efficiently as possible. In addition, by having an easy-to-use sales and collaboration platform, suppliers and other construction professionals can boost their revenue and focus on building their teams and hitting the ground running with new client projects.

One significant and long-standing challenge confronting the construction industry is a profound shortage of skilled labor. According to Associated Builders and Contractors (ABC), contractors must hire approximately 546,000 workers in 2023 to be in a healthy place to meet the demand for jobs and grow their businesses as the construction worker shortage hits half a million.

Added to this challenge is the coming construction worker retirement cliff. The aging of our workforce is a problem for many industries, but the construction industry will be hit particularly hard. ABC reports that nearly one in four construction workers is currently

through greater productivity. And the proof is in the pudding, with 91% of general contractors and 82% of subcontractors planning or considering using new technology in 2023.

over 55, meaning the labor gap will widen year by year as this generation steps into retirement. This means longer hours and less downtime for current skilled construction workers, causing burnout and frustration while adding pressure to wages.

To help respond to this labor crisis and get quality, skilled talent on the payroll, certain best practices provided by technology can be implemented to take full advantage during the hiring and onboarding of new employees.

First, employers must have quick access to a broader talent pool. Technology can help contractors and subcontractors find and hire skilled workers from anywhere in the world, which can be especially helpful in areas with a shortage of workers, allowing contractors to tap into a wider pool of talent to fill critical roles.

Regarding onboarding, a preconstruction solution accelerates the process and provides employers with necessary data on their workforce securely and in good time. This comes in handy for companies low on HR professionals and in need of quickly moving forward on new bids.

One of the best ways to implement substantial and consistent growth is by having a competitive advantage. Technology can help contractors, subcontractors and material suppliers stay competitive in an increasingly challenging market. Why? Companies that adopt new technologies and processes are more likely to win contracts and attract top talent, ultimately driving growth and profitability.

According to PlanHub’s industry report, since the beginning of 2021, a 324% increase was seen in the number of general contractors posting their first projects on PlanHub’s platform, and projects with activity increased by 231%. By leveraging preconstruction technology platforms, general contractors have been able to expand their invitations to bid by 35%.

Not only are more contractors leveraging tech to grow their businesses, but they are proving to know the importance of being able to offer well-rounded services by expanding their skill set and services. As such, the aforementioned survey report shows that 44% of subcontractors said they plan to provide more trades in 2023. In addition, subcontractors have responded to adversity by seeking new ways to find business. They expanded their reach by listing up to 20% more trades and boosted their service area by nearly 50%.

Another bright spot for contractors, subcontractors and suppliers is the positive effects of the passage of the Infrastructure Investment and Jobs Act in November 2021. According to PlanHub’s Q2 Thriving in the Dynamic Construction Market report, there was a 500% increase in civil construction projects posted to the platform in Q1 2023 over Q4 2022.

In short, technology has significantly impacted and transformed the construction industry, allowing for increased efficiency, accuracy and productivity. Preconstruction bidding technology has enabled the industry to improve talent recruitment and retention, reduce costs and minimize waste. In addition, integrating such technologies has revolutionized how construction projects are planned, designed and executed by growing their talent pool amid staffing shortages, winning more bids by building stable relationships within the industry, listing more trades, and developing and retaining skilled talent. As the industry continues to evolve, companies must stay abreast of emerging technologies and incorporate them into their operations to remain competitive. The future of construction is increasingly reliant on technology, and those willing to embrace it will undoubtedly be at an advantage as they return to work. C C C C

A A A A

Ro Bhatia is the CEO of PlanHub, the leading cloud-based preconstruction platform that enables general contractors, subcontractors and suppliers to connect and collaborate on construction projects across the United States. PlanHub was created by contractors, for contractors, to simplify the construction bidding

B B B B

2 2 2 D V V

Without sales, your business is going nowhere fast. The incredible downpour of new orders during COVID is starting to end, and you need a dynamic sales team to maintain as much momentum as possible. With today’s labor shortage, it’s nearly impossible to find salespeople, and keeping the sales funnel full is a real challenge. So how do we prepare for what’s ahead with limited resources? The answer isn’t just finding more staff but making the most out of your process, creating efficiency and that adage — work smarter, not harder.

Recently, my team was hired to work with a stone fabricator to help grow their revenue. While they were focusing on their online leads to generate more prospects into their sales funnel, sales weren’t increasing relative to the number of leads coming in. Something was wrong.

I also noticed how hard it was to schedule meetings with their sales team. They were always unavailable and struggled to get back to me on outstanding questions we had for them. Salespeople said they were simply too busy.

You’d think the phone was off the hook all the time because of how busy they said they were, but whenever I walked through the showroom, maybe

one of six phone lines was busy. The plot thickens!

So, I asked the owner if I could pull their phone records. Across six salespeople, they averaged — wait for it — a whopping 24 minutes on the phone daily for both inbound and outbound calls. What?!? If they were busy, they were busy with things that prevented them from selling.

We took a deep dive into this company’s sales process to find ways to free up time and make the team more efficient. From that, we found five practices you can implement to grow your revenue.

If you haven’t invested in a customer relationship management (CRM) platform, do it now. In this case, when someone walked in the door at the shop, the sales team used Post-it notes or emails as reminders. Handwritten notes or entries in a spreadsheet make it challenging to find and stay on top of customers, especially if a salesperson has to help with a customer working with a different sales team member or someone is out on vacation.

A CRM lets you capture all the contact information you need and keep it in one place that any authorized user can access. It helps you:

• Keep track of who the customer is and any notes about them.

• Automatically log all emails and texts sent.

• List what the next activity should be.

• Know you need to follow up.

If a salesperson is working with 30 prospects, how are they supposed to remember all that? And what happens when a former customer needs help?

A CRM solves this problem and stops having to pull paper records.

There are plenty of CRM solutions out there — about 300. We prefer Pipedrive for stone fabricators. It’s affordable and straightforward to use; no engineering degree is required.

This may sound strange, but bear with me for a minute. While controlling the foot traffic at your location so you can anticipate the flow

and manage those customers effectively, it goes without saying a more specific approach can yield better results.

We listened to more than 1,000 stone fabricator calls and learned an interesting thing. Most calls from new prospects asked about the hours the showroom was open. Most salespeople simply gave them the answer and moved on.

But here’s where it gets good: The most successful salespeople — those earning six figures — knew an important hack: They didn’t tell callers the store hours. Instead, they started asking questions and building what we call a social contract.

They might open with a question like, “Before you waste your time driving to our shop, may I ask you a few questions about your project?”

By framing it this way, the salesperson shows they are being helpful and trying to save time for the customer. They are also gaining information about the customer and building a relationship. They can learn so much about the projects, like the types of materials and colors they have in mind and whether they have talked to any competitors.

Then, they set a time to meet. When customers show up, the salesperson has already gotten some basic info so they can steer the visit more effectively. A good salesperson will take all this information and provide a customized experience with samples already pulled out.

shop for a car, they provide you with a quote when you come in to try to close the deal. With stone fabrication, if you can’t provide a quote, there are no onecall closes.

This process turns into multiple back-and-forth interactions, taking the numbers, giving them to the pricing person (and then reminding them to give you the quote), forwarding it to the customer and dealing with it potentially getting stuck in their spam filter, etc., then, reaching out to make sure they got the quote and what they think.

No wonder your sales team feels like they’re too busy.

In the meantime, your customers are probably shopping your competitors. In the end, the most efficient process might win the job.

• 40% to lock in the materials and hold them.

• 40% to lock in the installation days.

• 10% on the day of the install.

• Remainder on the day of completion.

This gets you paid faster, helps with your cash flow, and reduces your team’s time chasing payments.

How many times have you called someone, the call went to voicemail and the mailbox was full? Or you sent an email, but the customer said they never saw it? While phone and email are important, they can be a time suck.

Most salespeople love building beautiful kitchen designs, helping customers make the right choices — and making money. They didn’t go into sales to become debt collectors. Yet, in most cases, the sales team is responsible for building a relationship, closing the deal and chasing the check. It no longer makes sense to ask for 50% upfront and the rest when the job is done. After the installation, the sense of urgency to pay disappears.

Many shops don’t let their salespeople quote, which adds an extra layer to the process and takes time. It can also frustrate customers. Think about it for a minute. When you order furniture or

You don’t buy high-ticket items without providing a down payment and arranging for financing for the remainder of the deal. Savvy home remodelers, construction companies and fabricators have moved toward progress payments. There are many variations of this, but here’s one strategy you might consider instead of 50/50:

The average sales rep can spend hours each day trying to hunt customers down to follow up on a conversation, leaving messages or emails. Sales can get stalled or put on hold hoping the customers reengage.

Yet, there’s a better way. Here’s how texting can accelerate the sales cycle:

• Text messages get seen: 98% of texts are read.

• Text messages are seen right away: 60% of texts are read within five minutes of receipt.

• Text messages get responses: 45% of texts get a quick response.

When you get a response, you can quickly answer questions and keep the sales process moving forward. Plus, you know when the customer is active and can quickly convert the text into a phone call. There’s no more phone tag or waiting for an email response.

Here’s an advanced course for stone fabricators that can be a significant time saver. Use artificial intelligence. You don’t need a degree in computer science or even a budget anymore. ChatGPT is free, and it can do amazing things.

I was coaching a sales team, and they had some questions I wasn’t exactly sure how to answer. I went to ChatGPT and asked it to act as the vice president of sales for a large fabrication shop. I told it that this persona was kind, caring, to the point and dedicated to making their sales team better.

scenario. While you may need to work with the output a bit to get it right, it can help get your brain moving and even come up with suggestions you may not think about otherwise. It’s like having a consultant available 24/7 (for free!) to help you think things through.

2 2 2 D ENTIRE digital process. The

Now, I have this avatar that can be used to craft emails to unhappy customers, respond to negative reviews, and even provide coaching advice for tricky situations. I can ask the avatar how to be a better coach or leader in a specific

digital templating EVOLUTION begins now...

V V V V LT3Raptor

is a new digital templating platform designed with a robust

not only in templating, but

also

other areas of your process!

In today’s digital age, there are all sorts of software and technology solutions designed to augment the fabrication workflow while providing growth opportunities that enable you to streamline processes, monitor material inventory, track jobs, review metrics and provide a richer experience for your customers — all of which lead to better margins and more sales. Here are some of the latest and greatest tech solutions that support today’s fabricators.

With ActionFlow’s countertop fabrication software, you can complete more jobs, enhance communications, increase accountability, manage inventory more accurately and increase sales while devoting less time and effort to each task. This stone fabrication software has modules designed to simplify each aspect of your business. Whether you’re looking for a customer relationship management tool or a mobile app with cloud-based storage to give your team remote access to critical information, ActionFlow optimizes your daily operations.

From efficient scheduling and routing to convenient and customer-friendly payment options, ActionFlow’s business management solutions make it easier to manage projects by automating tedious day-to-day tasks that take your focus away from high-priority objectives. Learn more at www.actionflow.net.

CounterGo is a straightforward drawing and estimating solution that allows fabricators to become more efficient, accurate and professional. This industry-leading software makes quoting

countertops in as little as 3 minutes possible while taking the business side of a countertop shop to the next level. With clear communication, accurate and consistent pricing, and easy accounting using the QuickBooks Integration, fabricators quickly see an increase in bid output and countertop sales. Learn more at www.moraware.com.

ETemplate Systems, experts in digital measuring, are the makers of the ELaser Xpress 3D Templating System. Powered by award-winning ETemplate Measure Manager software, templates are faster and easier, and the software provides seamless compatibility with all CNC machinery. The ELaser Xpress 3D system features auto-start software, an industry-best three-year warranty, enhanced speed averaging one second per point, accuracy of 1 to 2 mm for a standard-size space, horizontal and vertical fine adjustment knobs, digital leveling, hand-held remote, Bluetooth connectivity, rechargeable batteries with charger, and compact design with a rugged case for easy portability. These enhancements, along with automated countertop functions and new manual design updates within Measure Manager, allow users to create templates

faster than ever before. Set up, shoot your points, press enter and you’re done! This solution integrates with popular cabinet design software such as Mozaik, Cabinet Vision, KCD and 2020. For more information, visit www.etemplatesystem.com.

Whether it be supersizing a meal, a wheel shine with a car wash, or an extended warranty on an appliance, everyday consumers are introduced to options that upgrade a sale. These offerings, called “Hot Sauce,” are deemed a little something extra that can enhance a purchase. The same holds true for countertops. Hot Sauce can dramatically improve your profitability with the most immediate earnings boost you can do for your company. The Hot Sauce selling software provides content, images and pricing so that every consumer-facing employee can be your best salesperson. Hot Sauce selling software offers meaningful metrics that enable you to track sales, integrate with Moraware and automate communications with your customers and team. Visit www.hotsauceyourtops. com to learn more about this powerful selling tool and how users are increasing their profitability with every sale.

LT3Raptor is a new digital templating platform designed with a robust cloud-based management hub to make you faster and more efficient in templating and other areas of your process, including job management, programming and more. LT3Raptor has built-in Templating Intelligence to make quick even quicker. From Edge Detection to One-Touch technology, finish fabrication-ready files in fewer clicks easily and intuitively. In addition, LT3Raptor has taken the user-friendly foundation of the current LT software and enhanced it. The new UX and UI feature workspace customization, improved Quick Actions and more. Easily view and manage jobs, edge styles, drop-ins, user permissions and workflows. Learn more about LT3Raptor at www.lt3raptor.com.

PHOTOTOP 5 from Fabricator’s Choice just keeps getting better with added power capabilities. Functionalities include the ability to auto-create miter strips, auto-create lamination, auto-dimension on PDF output and more. PHOTOTOP 5 makes templating fast and accurate, and is easy to use. Professional training and online support are available. Integrate templating with office inventory, job management systems, and shop equipment. Multiple software licenses are not required

to expand PHOTOTOP 5 to additional templaters. Simply order ORGANIZE Field Kits, which include a laptop, camera and markers.

The exclusive Organize On-site Tool provides immediate confirmation and file delivery of the most highly detailed digital templates in the business. PHOTOTOP users enjoy frequent upgrade options due to ongoing developments. For more information, visit www.fabchoice.com.

There’s never been a better time to transform your customer experience. PinPoint Status’ mobile app and platform sync with your scheduling software to:

• Automate appointment reminders and reduce call volume with two-way texting.

• Eliminate missed appointments. Customers get an accurate estimated arrival time via service tech GPS location monitoring.

• Build customer loyalty. Customer experience is transformed through simplified two-way text communications, service technician photo identification and bio, and requests for customer feedback.

• Measure employee performance and build online reviews. Automatically ask customers to review their service after a job is done. Generate employee performance reports and help capture positive online reviews.

PinPoint Status eliminates communication gaps between in-home service providers and the homeowners they serve. Low flat rates and a userbased monthly subscription model make PinPoint Status a simple, affordable solution for companies of any size. For more information, visit www.pinpointstatus.com.

Whether you fabricate laminate, solid surface, wood, granite or engineered stone, QuickQuote Countertop Estimating Software from Crystallyne Enterprises can save time, eliminate errors, and entice new customers with faster, easier countertop quoting and drawing. It features a uniquely intuitive interface that creates a fully-labeled scale drawing alongside every quote. Its flexible pricing system offers multiple pricing methods so virtually any material can be quoted, and it allows customization of items and services to fit a particular business. Quotes can be printed alongside the drawings on a single page, exported to different formats such as PDF, and transferred directly to QuickBooks. The built-in schedule provides a place to keep track of everything from fabrication to installation, and the internal slab inventory lets users lay out the parts on the slabs for more accurate material counts. For more information and a free trial of QuickQuote, visit www. quickquotecountertops.com.

This award-winning kitchen and bathroom industry software offers 3D kitchen and bathroom visualization and instant quoting for consumers and sales teams. Quickly design and quote a new kitchen or bathroom countertop, room renovation, cabinet reface, tub shower conversion and more using this integrated and easy-to-use software, which generates leads, streamlines the sales process, increases average ticket sales, and serves as an invaluable tool for sales team training. Quote Countertops’ focus is on their clients’ success, and that means you’ll benefit from unparalleled and personalized onboarding, training, and technical and marketing support. To learn more, visit www.quotecountertops.com.

The Pathfinder workstation is designed to capture precise, fully calibrated images of slabs in high resolution. Whether you want to build a visual slab inventory library or create scaled images for further programming on your CNC saw, Fab Center, or CNC saw/waterjet, the Pathfinder workstation is a rock-solid platform for consistent, accurate imaging. The Pathfinder is the tool that will reduce your material costs by enabling you to efficiently and effectively manage your full and partial slab inventory while also giving you the ability to accurately veinmatch slabs and provide 3D rendering visualization for your clients. For more information, visit www.parkindustries.com/ stone/slab-imaging/pathfinder/.

QuickBooks, JustCall and Google Drive. Learn more at www.pipedrive.com.

Prodim Factory Software connects field, office and production teams. With four available versions of the software with increasing levels of functionality, businesses can choose the software that matches their requirements best. For instance, the innovative Factory Draw Advanced provides an easy as-is multiple-plane design with insightful 2D and 3D views and solid collision alerts. By entering details like the material type, thickness and glue offset, Factory Draw Advanced can be used to make calculations, identify potential problems and make design decisions. With Factory Full Fabricator, you can even build your digital slab library and match all your slabs in your designs. Prodim’s Factory Fabricator is the complete solution for exactly what it says: fabrication! For more information and demonstration videos, visit www.prodim-systems.com.

Winner of numerous best-in-class awards in 2023, Pipedrive’s visual sales pipeline makes customer relationship management a breeze by allowing you to track leads, spot opportunities, measure key activities, streamline sales workflows and focus on sales success. The cloud-based CRM solution includes automated reminders and follow-ups that increase productivity and eliminate repetitive, time-consuming tasks. Real-time reports

Let your clients see what you have in stock. This Slabsmith Inventory software offers up-to-date inventory with accurate slab dimensions and high-quality images for each product. Slabcloud offers automatic synchronization with Slabsmith to allow for 24/7 inventory accessibility. You will have access to the latest technology, ensuring your clients will correctly see your entire range of products on all your devices. The Slabcloud Kitchen Visualizer is unmatched by offering a unique, real-time stone preview feature. Allow your customers to visualize their dream kitchen using your inventory of products. Slab Inquiry allows your clients to ask questions about any specific slab in your inventory with quick customer service. With Slabcloud Inventory Integration, your website will benefit from consistent updates that will improve your search engine optimization. Learn more at www.slabcloud.com.

show your sales reps and managers what business processes to prioritize. Use dashboards, CRM analysis, and reporting tools to identify customer trends and assess sales performance. Create and send customizable email campaigns with pro templates built to get more clicks. The software integrates with over 350 other applications, including Zoom, Microsoft Teams, DocuSign,

Slabsmith is an integrated system that creates tight links among the office, showroom, warehouse and shop. It includes the most powerful inventory management solution, which provides accurate and detailed slab inventory status. By producing digitized slabs that are true-to-life in both color and dimension, it captures all the relevant properties of the original slab that was photographed. It provides the ability for anyone in a company to quickly locate and view the slabs in inventory based on any of the properties of the slab. The Perfect Match layout module provides tools that are customized for the specific needs of users to lay out countertops efficiently. Incorporating Slabsmith into your business can increase profits and lower operating costs; yield increases of 8-10% are typical. For more information, visit www.slabsmith.com.

Since 2017, SPEEDlabel has changed how fabricators label and track materials in production. It can be used with hand drawings or CAD files and works automatically with most countertop software. The labels are waterproof and tear-proof and come off easily at installation. There are customized label designs, including top, bottom and edge formats. SPEEDlabel provides a quick understanding of the status of every part in the shop and helps ensure entire jobs are kept together, improving accuracy and efficiency. SPEEDlabel was developed by fabricators to help other fabricators streamline processes, stay organized and improve quality control. For more information, visit

With the Speroni STP Essentia, you can efficiently measure tools easily and independently of the operator achieving full machining productivity. Robust, spacesaving and long-lasting, the Speroni STP Essentia is ready to deliver quality results right beside your CNC machine. Clear, concise and easy-to-use controls are designed to optimize all tool presetting and measuring operations. An attractive multi-touch display efficiently complements Speroni STP Essentia’s design and ergonomics. Tool presetting essence is delivered on a Windows-based display and sensor system with high definition camera. The automatic Run-Out, MaxP, Comparator, Base Post Processor and the top-level Tool Database are only some of the functions included. The online help function provides additional assistance for users. Learn more at www.bbindustriesllc.com/speroni-stp-essentia-cnc-tooling-presetter.

Introducing six new aesthetics that combine the beauty of the great outdoors with the hygienic, thermoformable, virtually seamless, and repairable benefits that you can only get from solid surface. Each of these Terrains and Terrazzos are made in the USA, and also contain recycled content* to help make an impact on design, not the environment.

*

Pending SCS certification in Q4 2023. Scan to see the new Corian® Solid Surface collection.

Available in Corian® Solid Surface –Archeologic, Excavage, Laguna Terrazzo, Pebble Lane, Peppered Terrazzo, and Stonique

A central pillar of Sustainability Matters is to suggest ways and incite conversation around how we can weave into the fabric of the industry the four R’s of environmental sustainability: Reduce, Reuse, Recycle and Reform. As we continue the journey with a holistic focus, it is clear that not all strategies are endemic to each business. Furthermore, as we move to construct a more defined framework around Leadership in Energy and Environmental Fabrication (LEEF), a concept we introduced in the previous issue, we insist that some efforts require teamwork. Waste is one of these conundrums that is profound in size and poorly understood, yet it continues to grow at a rate many times faster than the expended efforts to remediate it.

Waste comes in many forms: excess water usage, lights we forget to turn off when we leave a room, office workflows that heavily rely on paper products, or a lack of protocols to recycle within an organization. But dig deeper, and you’ll find more subtle forms of waste such as cardboard, lumber, yield loss, cutout remnants and material samples that end up in the trash. While businesses may ignore these waste streams’ impact, the waste summation of everyone — fabricators, distributors and manufacturers — is alarming.

The solid surface industry may have the highest degree of the circular economy because sheets can be hard-seamed together, and yield loss can be kept at a minimum — for the popular colors at least. Further, due to the nature of this material, it requires carbide tooling, which is relatively easy and less

expensive. Converting cutouts and remnants into something of value is quite possible. Finally, the repairability of solid surface means the life of this material is easily extended. Every effort to reuse anything otherwise destined for a landfill poses a win for the environment.

At the local level, some fabricators are doing what they can and addressing the problem in their own way – every effort counts. For example, material otherwise destined for the dumpster can be donated to organizations such as Habitat for Humanity or passed along to paving companies that grind the material down to aggregate for roads and landscaping. Additionally, for solid surface, some of you may be creating cutting boards, signage and other marketing materials that can be easily made from remnants and cutouts. While all these efforts are fantastic, they represent only a nano-fraction of the waste remediation policies we need.

Further, as we look beyond solid surface into the other two main engineered materials categories — quartz and mineral surfacing — we see a distinct step change in how effective the four R’s are represented. These materials have a hardness about them that, on the one hand, gives them performance benefits that are so appealing, but on the other, makes reusing, recycling and reforming a significant challenge.

The massive quartz waste, for example, starts at the manufacturing level. Given the profound proliferation of the quartz category since 2006, when quartz, for the first time,

took the crown away from natural stone as the best overall choice for countertops, the world has seen an explosion of quartz manufacturing facilities whose manufacturing, research and development of the material, has raced to innovate designs, but in the process created an abundance of out-of-spec material and slow-moving and discontinued colors. Add fabricator yield loss that often winds up in a dumpster, and the tonnage is almost incalculable.

The mineral surfaces category, which includes sintered stone, porcelain and ultracompact materials, is rapidly growing, although relatively smaller by volume than quartz. The value proposition is becoming clear that mineral surfaces are the next big surfacing category whose application, colors and aesthetics steadily increase every year.

Sintered stone, for example, is purely a mineral mix and can be reground back into its base mix and reformulated into new slabs. This is unique to sintered stone, unlike large format porcelain, which can use inks and dyes that compromise its ability to be reground into a pure mix. Porcelain can also use mineralbased colorants, which would be reground, but many manufacturers do not make this claim. Recycling and reclamation programs are all impressive in theory, but in reality, the programs’ implementation needs attention. Fabricators will need to bin and sort the offal from quartz, mineral surfaces and stone to keep them separate for individual processing, depending on if there are resins or if it is a mineral composition like stone or sintered stone.

In addition, regrinding does not come without concerns, including respirable crystalline silica, which, while safe to consumers when installed in a slab form, would need proper safety and protection equipment and infrastructure in place. Any facility constructed must have the appropriate

systems and machinery to keep all operators and occupants safe. Both stone and engineered stone like quartz have crystalline silica; some sintered stones do not, and some new quartz formulations, like that introduced by Breton (Bioquartz), do not have crystalline silica in their mineral mix.

Back to this idea of teamwork. Viable, sustainable solutions that combat waste is front and center. The problem emanates from the cost of conversion for engineered materials. That is, what it costs to reuse or reform waste in terms of skilled labor alone, exceeds any realized value. Hence, little to no effort is invested, and the waste stream gets wider and deeper.

Industry teamwork, however, could be a viable solution for waste remediation. Oftentimes, a process does not become economically feasible unless done at scale. Engineered waste could likely fall into this category. Where one fabricator trying to convert all engineered waste into something of value is not in the least viable, perhaps a regional specialized processing center, for example, can repurpose (a combination of reuse and recycle) the materials at scale. Why scale? Mainly because a processing center would be highly operationally leveraged due to the nature of the material and the large scale and volume needed to reach and surpass break-even. Such a theoretical plant could make quartz bricks, create aggregate for paving, and a host of other assets that help to minimize waste accumulation and, at the same time, reduce demand for new materials and thereby preserve natural resources.

If we all banded together to support the operation, perhaps fabricators could get rebates based on the tonnage they contribute. After all, the operation’s raw materials could be included at a negative cost on their financials. For example, the operation charges to pick up the waste — the very raw material they need

to make a new product — hence a negative cost. As an incentive to guarantee their supply chain, a discount or rebate could go to the fabricators who contribute their waste and are proactively part of an industry-wide solution — theoretically, a huge win/win.

Yes, this is big-picture thinking, but it’s necessary because the dilemmas grow and increase in severity without it. Participating in this sort of venture or anything similar would be crucial to being a LEEF. As we design the constituent parts of the certification, actions like these are highly aligned. A good next step is perhaps forming an industry waste alliance network with participants at every level — manufacturing, distribution and fabrication — to brainstorm and participate in solutions that significantly mitigate the waste dilemma and create an economically and environmentally viable solution.

Paul “Max” Le Pera is the president and founder of Proprietary Ventures, LLC, a boutique-style global firm devoted to researching, discovering and deploying disruptive and sustainably oriented proprietary products and technologies. He serves on the ISFA board of directors as vice president of standards. He can be reached at paul.l@ proprietaryventures.com.

While the industry is evolving and iterating, and materials are becoming healthier and safer for people and the planet, the surfacing industry is woefully behind in contributing to environmental health. In its inadvertent stockpiling of slabs, partial slabs, remnants and waste across thousands of fabrication shops, material manufacturing and distribution facilities should look at ways to mitigate adverse environmental impacts. With seemingly little to no economically viable solution to reuse, recycle or repurpose at the moment, perhaps the awareness we drive here is a first step in calling all parties to the table to start the conversation. There is much truth applicable here; it does, in fact, take teamwork to make the dream work. C C A A B B 2 2 V

Jessica McNaughton serves as president at CaraGreen, a provider of sustainable building materials, including many alternative surfacing materials. She has 20 years’ experience in sales, marketing, business development and strategy. Previously the director of sales and marketing at CaraGreen, Jessica has maintained her status as a LEED Accredited Professional since 2009 and she hosts a podcast, Build Green Live Green. She can be reached at jessica@caragreen.com.

Imagine a home that seamlessly integrates breathtaking design aesthetics with a deep-rooted commitment to environmental sustainability. A net-zero home is so energy efficient that it produces as much renewable energy as it consumes annually. In addition, design elements are chosen to ensure things like temperature management with minimal energy consumption, water conservation, air purification and healthy natural light exposure. Products manufactured using sustainable processes are prioritized.

Then consider how you can contribute your knowledge, skill and experience to such an endeavor. Cambria, the leading American-made, family-owned quartz surface producer, did just that by being a part of a groundbreaking net-zero home

— the first-ever sustainability show house in the nation. By providing the purest quartz in the marketplace, Cambria perfectly complemented the sustainable ethos of the home, showcasing a beautiful harmony between innovation and nature-inspired beauty.

The home is nestled in Cave Creek, Arizona, and spans 3,000 square feet. Meticulously crafted using environmentally conscious processes and products, its construction focused on minimizing the adverse effects on the environment. A net-zero home is renowned for its exceptional insulation and energy efficiency. Beyond its eco-friendly features, this residence boasts a captivating layout and modern architectural design, accentuated by exquisitely appointed spaces. Notably, the home showcases the stunning beauty of environmentally conscious products.

Mark LaLiberte, the founder of Construction Instruction, is the owner and driving force behind this project. According to LaLiberte, a high-performance home encompasses

exceptional indoor air quality, outstanding energy efficiency, captivating aesthetics and impeccable durability. Achieving net-zero status begins early in the planning and design phase by making sustainable home design decisions that align with ecofriendly objectives. The entire team recognized and embraced this responsibility wholeheartedly.

The construction of this remarkable home was a collaborative endeavor involving teams from Construction Instruction; Cosan Studio, an architecture firm specializing in high-end residential design; Refined Gardens, a landscape design company; K & Q Interiors, an interior design firm; and A Finer Touch Construction (AFT). Together, they have pushed the boundaries of what can be achieved in net-zero homes, resulting in an unprecedented masterpiece.

AFT procured the quartz slabs directly from the Phoenix Cambria Sales and Distribution Center. With 22 distribution centers spread across the United States and Canada, Cambria’s network aligns with the objective of minimizing carbon footprint during the home construction process.

Taking steps toward sustainability, Cambria addresses

transportation, water usage, power generation, lighting design, tooling and materials in its operations. By prioritizing sustainable practices, it plays an active role in safeguarding the land and its people for generations to come. Its commitment to minimizing the environmental impact throughout its operations showcases a company dedicated to a brighter and greener future.

The masterful design of the home seamlessly blends beauty and functionality, creating a harmonious living experience that transcends expectations. The home features Brittanicca, Brittanicca Warm and Ironsbridge, which draw inspiration from organic forms found in nature. By integrating these designs into the kitchen and baths of the home, the quartz surfaces beautifully bring the outside in, creating a space that harmonizes with the surrounding environment.

As a country, we continue to move forward in our quest for sustainable living. This net-zero home stands as a testament to the boundless possibilities when innovation, design and sustainability converge. C

In 1984, Helmut Rosskopf founded Helmut Rosskopf Construction and Furniture Joinery. Located near Frankfurt, Germany, he worked with borrowed machines in an old barn. Since the company’s expansion to the German states of Thuringia and Saxony, it has changed considerably, not only in its location but also in terms of scope. What started as a millwork company has become well-known for fabricating all kinds of materials, including solid surface, quartz, sintered stone and natural stone for high-end kitchen countertops, custom commercial casework and architectural installations for a variety of applications. Today, Rosskopf + Partner is well past its early days in the barn working with borrowed machines. Offering a complete range of services, including engineering, product development, fabrication and installation, the company’s customer base extends from Germany throughout Europe to Africa and North America.

Raiffeisenbank (Zurich, Switzerland): This consulting area

of the bank features one-of-a-kind wall paneling and office furniture made of solid surface.