PRECAST

Unleash the power of your sand.

IN THIS ISSUE:

Chryso's new addition to concrete solutions

Cutting carbon with extenders

Mix ratio key to precast concrete Big

Unleash the power of your sand.

IN THIS ISSUE:

Chryso's new addition to concrete solutions

Cutting carbon with extenders

Mix ratio key to precast concrete Big

Our range of high quality locally-produced cement is designed for specialised applications where high early strength, improved durability and superior concrete is needed. Backed by our dedicated and highly skilled expertise our range of superior quality products are the ideal choice when there is no room for compromise, and no time to waste. Together, we make it possible. Ask for AfriSam.

WITH YOUR HIGH STANDARDS, UNCOMPROMISING QUALITY IS NOT NEGOTIABLE.

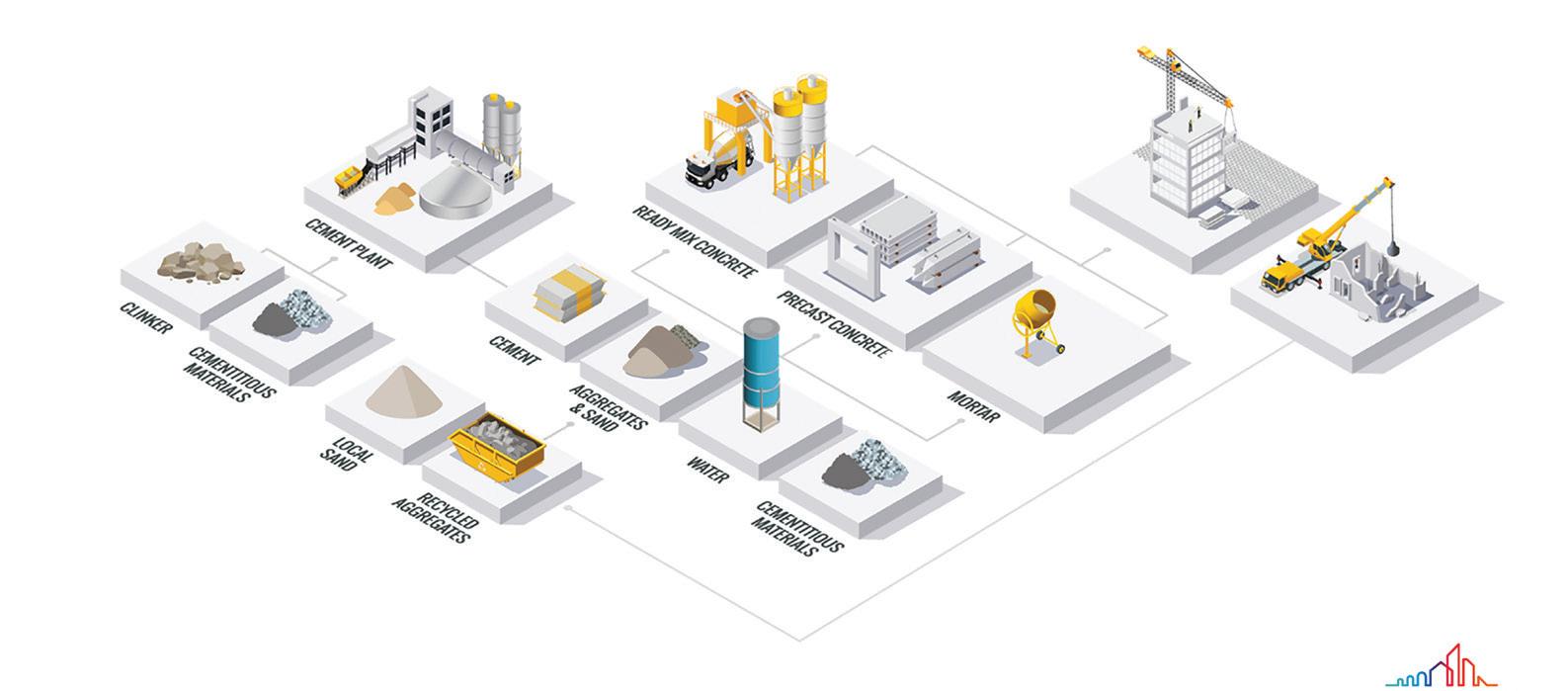

A summary of current dynamics in the global precast market and a brief look at circular economic applications to the industry are useful in terms of how we, in SA, consider moving our own sector forward.

Consulting firm McKinsey’s reported quite extraordinary gains to the concrete industry in its recently-released research document The Circular Cement Value Chain: Sustainable and Profitable. Its findings, in global terms, reflect the concrete industry as a whole, but notably provide a detailed assessment of key market dynamics and comprehensive information about the structure of the global precast concrete industry. This reflects the intense market penetration of our segment and the nearlimitless applications of precast concrete components and structures across the entire built environment, which have been so rapidly opened up by innovative and integrative technologies, methods, transport and material.

From energy recycling stored in waste materials to the recirculation of materials and minerals across the built environment, an estimated R2,2 trillion in net value can be unlocked. Adoption of circular technologies could also decarbonise 80% of all cement and concrete emissions by 2050.

Precast magazine continues to explore the opportunities inherent in these strategic adjustments, pinpointing the most available and meaningful applications in our country’s growing precast segment. The most important door we can all open immediately is inter-sectoral co-operation and exploration of those opportunities and what each player can do to yield all parties’ maximum value and reward.

So, as Joan Rivers always asked, can we talk?

4 Chryso’s Quad range solves concrete challenges

6 The SAICE 2023 National IP showdown –an incubator of excellence

8 African infrastructure benefits from Chryso’s growing footprint

10 Concrete knowledge vital for sustainable infrastructure

12 Is your coating a good match for corrosive chemicals?

13 Sika successfully closes MBCC acquisition and strengthens it's position as a sustainability champion

14 Sam Ntuli Mall boosts property portfolio

15 Corobrik Student Architecture Awards crowns its 36th winner

16 Big 5 Construct Southern Africa: Driving economic growth, recovery and transformation

Leading from the front in sustainability, Chryso's Quad range gives concrete users another opportunity to raise their sustainability performance to the next level. The range broadens the scope of sands available for concrete mixes, while retaining concrete quality.

20 Local and

PRECAST is independently published by Isikhova Media (Pty) Ltd

10th Floor, Metal Box, 25 Owl Street, Milpark, South Africa

Tel: +27 (11) 883 4627 www.isikhova.co.za

Editor: Nicholas McDiarmid

Tel: 067 672 2503

E-mail: nicholas@isikhova.co.za

Director: Jenny Justus

E-mail: jenny@isikhova.co.za

Operations director: Thuli Majola

E-mail: thuli@isikhova.co.za

Creative director: Joanne Brook

E-mail: joanne@isikhova.co.za

Managing director: Imraan Mahomed

E-mail: imraan@isikhova.co.za

Copy editor: Anne Phillips

Media sales: Tel: +27 (11) 883 4627 / 083 450 6052

The views and statements expressed in this publication are not necessarily those of the editor or the publishers and neither the publishers nor the editor accept responsibility for them. No person connected with the publication of this journal will be liable for any loss or damage sustained as a result of action following any statements or opinions expressed herein. The same applies to all advertising. Precast© 2023. All rights reserved. No part of this magazine may be reproduced or transmitted in any form or by any means, electronic or mechanical, including photocopying, recording, or any information storage retrieval system, without prior written permission from the publishers.

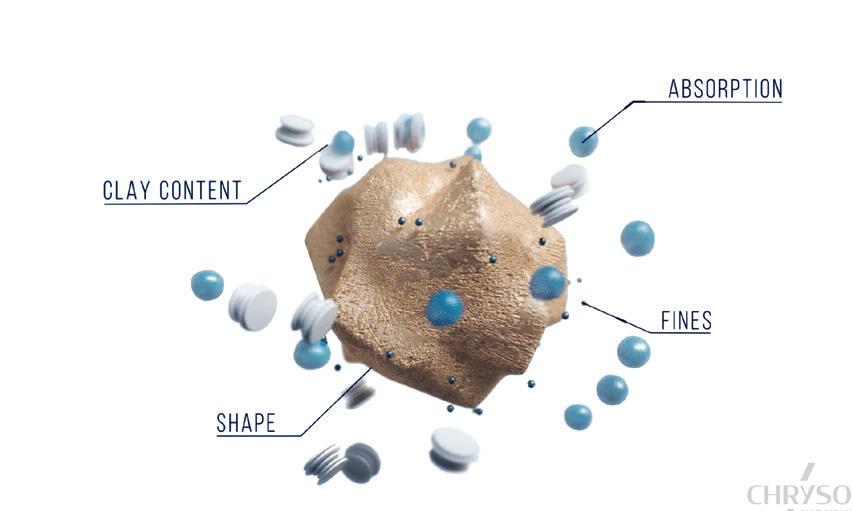

Leading from the front in sustainability, Chryso is giving concrete users another opportunity to raise their sustainability performance to the next level. Its Chryso® Quad range allows concrete mixes to incorporate challenging sands without affecting concrete quality – including sand that contains swelling clay and sand with too much or too little fines.

According to Patrick Flannigan, technical manager in the Concrete Business Unit at Chryso Southern Africa, the use of crusher or manufactured sand in construction has been prevalent for many years as it is a cost-effective and more readily available alternative to natural sand.

“However, there’ve been issues with grading, which often prompt contractors to

supplement with natural sand from sources such as rivers and dunes,” he explains. “This is where the challenges lie: less availability of natural sands increases costs, while the presence of clays means that less

(Above): The shortage of natural sand, a nonrenewable resource, is a growing environmental issue for concrete production.

of this material can be used or it has to be excluded completely.

“Our Chryso® Quad range allows customers to reduce their use of natural sand while making better use of crusher sand, without compromising the quality of their concrete mixes. Successful laboratory trials have been concluded, with customers in various market segments already realising the benefits,” he says.

“Working with customers such as contractors, ready-mix suppliers and precast manufacturers, Chryso’s making significant contributions to industry sustainability and a reduced carbon footprint.”

Chryso’s supporting role in building a sustainable construction industry is evident across its product range. Flannigan points to how the organisation’s vital partnership with contractors has developed and increased the role of admixtures in conservation across the board. The sophistication of applying water-reducing admixtures to concrete, controlling evaporation with its evaporation reducers and controlling shrinkage of concrete structures with shrinkage control agents, illustrates the way Chryso has made a science of water conservation of maximal impact.

While these vital impacts on water conservation are to be prized on their own terms, Chryso’s partners in the construction industry prize the increased workability which its products deliver. The construction of the Vlakfontein Reservoir near Standerton in Mpumalanga is a perfect example of combining sustainability with workability.

With an inner diameter of 154m and a heavily reinforced 11,8m-high wall, it is believed to be one of the largest cylindrical post-tensioned concrete reservoirs in the world. Flannigan says the project made use of several Chryso admixtures to reduce water and improve workability.

Once again, Chryso is first off the starting blocks, having introduced its Chryso® Quad range of concrete admixtures to

the market in 2022 – helping customers promote sustainable practice in their use of challenging sands.

Flannigan highlights the fact that using less natural sand gives the industry a lower environmental impact on sources like rivers. Where natural sand is still being used, Chryso® Quad CLEAR® (Clay Enabling Admixture Response) allows a wider choice of sources – even challenging sand that contains swelling clay. This can allow contractors to source from locations closer to site, reducing the carbon footprint and cost of transporting sand over a long distance.

“The challenge is that swelling clays absorb newer-generation plasticisers, thereby preventing them from delivering benefits such as water reduction or slump retention,” he explains.

Chryso Southern Africa also offers the quick and innovative Chryso® CLEAR Test to identify where these swelling clays could present a problem for concrete users. Where they are identified in the source material, Chryso® Quad CLEAR® can be added as a liquid to the relevant plasticiser.

Another important contribution to sustainability in the construction and concrete manufacturing sectors is Chryso® Quad GRAFT® (Gap Gradation Fixing Technology), he notes. This can solve the challenge of an excess or lack of fines in source material – which often occurs in crusher sand.

“The industry’s seeing the environmental benefit of moving away from natural sand and more towards crusher sand, but this product often has varying levels of fines,” says Flannigan. “In the past, this could have compromised the performance of concrete, but Chryso® Quad GRAFT® now solves that challenge.”

The SA Institution of Civil Engineering (SAICE) recently joined forces with leading universities across the country to recognise excellence among civil engineering students for their research efforts. The SAICE 2023 National IP Showdown took place on 4 April, when students presented their finalyear research projects.

They were invited to present their civil engineering university research and investigation project, which is part of the national curriculum for final-year civil engineering undergraduates.

Through this project, students are required to select an issue which is topical in the industry and then conduct research in accordance with pre-set deliverables. Once the research is complete, the student teams present their findings to a panel of judges comprised of both selected industry leaders and non-engineers. The presentations are then adjudicated by:

• Identifying whether the teams have gained an in-depth understanding of the research project.

• Determining whether the teams showcase adequate communication skills by presenting their work to a diverse audience.

• Exposing these top students to the industry and key players within it.

The main objective of the event is to create a platform for winners from the various universities to compete on a national level.

Steven Kaplan, 2023 SAICE president, enthusiastically summed up the National IP Showdown as an invaluable platform for upcoming civil engineering professionals to demonstrate their understanding of the issues faced in the environment by embarking on initiatives to find solutions to highly complex engineering topics.

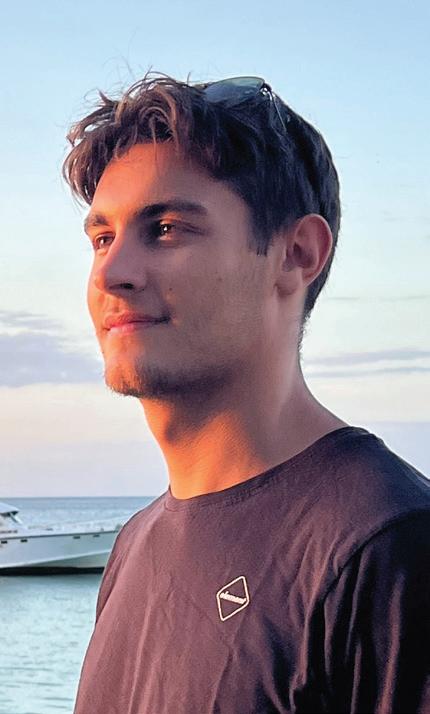

The first prize, sponsored by BVI, was awarded to Bukani Ndebele from the University of KwaZulu-Natal, for his project on biofilm control in water supply pipes.

This research investigated the bacteria build-up – biofilm – which is trapped in water pipelines that affect water quality, increase frictional losses and subsequently increase pumping costs. His research centred on methods to break down the microbial cells that make up the biofilm. “The benefits of my research will result in a better understanding of how to improve water safety and quality, while simultaneously reducing the cost of transportation in pipelines,” Ndebele explained.

The second prize, sponsored by the SAICE, was awarded to Herbert Nyoni from the University of Pretoria, who presented his project titled Optical Crack Width Detection and Analysis in Concrete Using Python, OpenCV and Machine Learning Algorithm.

Traditional methods of concrete crack detection and analysis are time-consuming and require very complex engineering skills. Nyoni’s research centred on the analysis using an image of the defect and employing a combination of commonly found software programs and a machine learning algorithm to determine the cause and consequence of cracks in concrete structures.

In third place, sponsored by Leica Geosystems, was Etienne-Pierre Skein from

Stellenbosch University for work on the development of a high-modulus concrete for 3D printing applications.

Skein aimed to make a difference to the traditional methods of concrete construction against a background of numerous reports of failing infrastructure by investigating the effects of increasing Young’s modulus or stiffness of concrete members using 3D concrete printing.

Friedrich Slabbert, director at Sciendum Academy, who was a judge at the event, applauded the contestants and their ability to present their research findings to a daunting panel of judges. “Being able to communicate and present effectively is essential for selling a new or revolutionary concept, especially to an audience of professionals with traditional or no concepts of civil engineering,” he said.

“I’m immensely proud of our young graduates’ attitude and commitment in undertaking demanding research projects. These are our future engineers to whom the built environment is entrusted, and their enthusiasm and approach inspire confidence that they can meet the challenges of the many projects that lie ahead,” said Kaplan.

The event was accredited for 0,2 CPD points.

Co-located with:

27 - 29 JUNE 2023

GALLAGHER CONVENTION CENTRE, JOHANNESBURG, SOUTH AfRICA

Get ready to experience the ultimate construction event of the year. Big 5 Construct Southern Africa is celebrating its 10th edition and you’re invited!

Big 5 Construct Southern Africa is a significant contributor to the economic growth, recovery and transformation within Southern Africa’s construction industry with a special focus on facilitating buyer/seller face-to-face connections and showcasing the most innovative solutions for the region.

Join thousands of your construction industry peers for three days of valuable business and gain FrEE access to:

Grow your network with over 8,500 construction industry professionals

DISCoVEr the most innovative products and technologies available

ENGAGE with public and private sector stakeholders over the most critical issues

LEArN about the latest trends, best practice and upcoming construction projects

Simply scan the QR code with your phone’s camera app

Co-located with:

www.thebig5constructsouthernafrica.com

With a firm base of technical expertise and infrastructure in South Africa, construction chemicals and admixtures specialist Chryso Southern Africa has been increasingly serving markets in Central, East and West Africa. The company’s active growth strategy into the continent over more than a decade means that customers there can expect the same high standards of product and support.

According to Armand van Vuuren, commercial manager: exports at Chryso Southern Africa, the company’s expansion strategy has been pursued for almost a dozen years – with great results. There are now distributors in a range of key markets, including

“An important element of Chryso’s presence is the stock held by distributors in their respective regions – giving customers easy access to products as and when they are required.”

Angola, Botswana, Ghana, Mozambique, Nigeria, Zambia and Zimbabwe.

“We also have an established office in Nairobi, Kenya and are expanding into Tanzania,” he says. “Through our extensive presence across Southern, Central, East and West Africa, we supply not just the ready-mix and precast sectors, but also specific construction and infrastructure projects.”

The expertise and resources of Chryso Southern Africa’s distributors in these countries are supported by the technical team in Johannesburg, who can step in whenever necessary with the required specialised input. Van Vuuren stresses that these partners are carefully chosen to act as extensions of the company, delivering the same high level of service wherever their clients work.

“Africa’s an exciting continent and this is where future economic growth’s going to come from,” he says. According to the African Development Bank, the expected growth rates in West and Central Africa are expected to be 4,2% and 4,6% respectively this year, while East Africa will reach 5,5% in growth terms.

Van Vuuren notes the extent to which many countries have invested heavily in infrastructure in recent years – demanding large volumes of concrete for civil engineering projects. The construction work involved in the Decongestion Project for Zambia’s capital Lusaka, for instance, has changed the face of that city in a matter of years.

“Chryso Southern Africa and our distributors have been working with a range of contractors and other businesses

to ensure that their concrete meets the exacting specifications of the contract,” says Van Vuuren. “Whether the application’s bridges, dams, mining infrastructure or precast manufacturing, we continue to play a vital and growing role in the continent’s development.”

An important element of Chryso’s presence is the stock held by distributors in their respective regions – giving customers easy access to products as and when they are required. Endcustomers are provided with full site support from a technical perspective, including access to the specialist team in SA.

“With our current momentum, we’re planning to set up more of our own offices and production facilities in key regions, paving the way to serve larger and more complex requirements,” says Van Vuuren. “Africa’s leading countries have their plans in place for future development and, despite the occasional setbacks, they’re on track for long-term growth. Chryso Southern Africa’s working with the concrete and construction industries on the continent to help make this happen.”

This strategy is bolstered by its parent company, Saint-Gobain’s acquisitions of companies such as GCP Applied Technologies, which will offer access to innovative products. Firmly committed to customer-centricity and proximity, the organisation has local operations in 45 countries and this footprint provides its service offering to more than 100 countries.

A thorough knowledge of concrete and its full potential is essential for municipal engineers to design, construct and maintain safe and reliable infrastructure that meets the needs of South Africa’s communities and ensure sustainability, says Bryan Perrie, CEO of Cement & Concrete SA (CCSA).

Perrie says municipal engineers are responsible for designing and maintaining public infrastructure, such as roads, bridges, sidewalks, water systems, wastewater plants and buildings. “As concrete’s one of the most commonly used materials in municipal construction projects, it’s essential that municipal engineers have a strong understanding of its properties and benefits,” he explains.

He says among the reasons why civic engineers should know more about concrete are:

Material selection

Municipal engineers should know how to choose the right materials for the job and be aware that concrete is the best choice for its sustainability, versatility and lowmaintenance requirements. “Concrete can be manufactured to an enormous range of specifications to suit a wide variety of applications by using different mix designs or adding different materials. By fully understanding the properties of concrete, engineers can make informed decisions about how to use it in their designs,” he says.

Concrete has a unique design capacity with important factors that can impact and enhance the aesthetics and performance of infrastructure. Concrete can be cast into different shapes and sizes to suit various applications in infrastructure, such as for the construction of new buildings, bridges, tunnels, roads, dams and a wide variety of other structures. “By understanding these factors, municipal engineers can design concrete structures that are safe, reliable and sustainable.”

Construction management

Municipal engineers are responsible for managing construction projects from beginning to completion, including

overseeing the concrete processes. By having a thorough understanding of concrete, they can ensure that it is designed properly and applied correctly and that any issues are addressed promptly.

“Concrete also provides faster construction, which means reduced carrying costs and faster revenue generation. This facilitates more timely payback of financing charges and faster revenue generation for any developer or owner, including municipalities,” says Perrie.

Municipal engineers are also responsible for the maintenance and repair of public infrastructure and, as concrete structures require periodic maintenance and repairs, the engineers should have a solid understanding of concrete properties and repair techniques to help extend the lifespan of these structures and ensure public safety. “Eventually, when it comes to re-use, concrete is an inert material that’s easily recyclable. Old concrete, which has reached the end of its service life, can be re-used as aggregate for new concrete mixtures. The addition of industrial by-products such as fly-ash, silica fume and blast furnace slag enhance the various performance properties of concrete, while incorporating waste materials that would otherwise be deposited in landfills,” says Perrie.

He adds that for centuries, concrete has been a crucial material for sustainable infrastructure and advancements in concrete technology are continually improving its performance and reducing its environmental impact.

Among the vital qualities of the world’s most popular and perennial building material are:

Concrete is a sustainable material that can be produced with lower carbon emissions than other construction materials. Additionally, concrete structures can be designed to reduce energy consumption, lowering carbon footprint.

Concrete is a strong and durable material that can withstand high compressive forces and resist weathering, erosion and many other adverse environmental factors. This

makes it ideal for use in infrastructure that needs to last for many decades.

Concrete can be cast in different shapes and sizes, making it ideal for various applications in infrastructure. It can be used to construct buildings, bridges, tunnels, roads, dams and a wide variety of other structures.

Concrete is a cost-effective material compared with other construction materials and can also be produced using locally available materials, reducing transportation costs.

Concrete is highly resistant to fire, making it ideal for use in structures where fire safety is a concern.

Concrete structures have good thermal mass properties, which means they can retain and release heat slowly, leading to substantial energy-savings in buildings.

“Concrete is one of the oldest and most widely used construction materials in the world and possesses many unique qualities that benefit the owner, developer and designer. Due to its versatility, aesthetic appeal, cost-effectiveness and availability, concrete’s changing the face of Southern Africa’s landscape. Increasingly, cuttingedge engineers and architects are making it their material of choice,” says Perrie.

“Concrete is a strong and durable material that can withstand high compressive forces and resist weathering, erosion and many other adverse environmental factors. This makes it ideal for use in infrastructure that needs to last for many decades.”By Tara Benn, executive director: ESAMPMA

If you are a facility or maintenance manager, you probably know the importance of a good epoxy coating to protect surfaces from chemical attack and abrasion. The right coating can mean the difference between a concrete floor that lasts for decades and one that starts to disintegrate and corrode shortly after a chemical spill. It is therefore critical to ask whether the coating you are considering has what it takes to resist the substances to which it will be exposed. Our “MCI®-2026 Floor Coating Chemical Resistance Guide” makes that easy when looking at the Cortec® option.

Highly versatile epoxy coating

MCI®-2026 is a 100% solids, twocomponent novolac epoxy coating designed for areas that need high chemical- or abrasion-resistance. It can be used on concrete floors, concrete counters and even on metal tanks (when used with MCI®-2026

Concrete Primer WB). Possible applications include chemical processing plants, manufacturing plants and just about any industrial facility that gets heavy traffic or is at risk of chemical spills. Since MCI®-2026 meets all USDA/FDA guidelines for use in federally inspected facilities, it is also a good option for coating floors in commercial kitchens and food processing sites.

Finding the perfect fit

Anyone interested in using MCI®2026 can check the “MCI®-2026 Floor Coating Chemical Resistance Guide” to see whether MCI®-2026 is a good match for the substances it is likely to encounter in their facility. This list is sorted by the following categories:

• Organic acids.

• Inorganic acids.

• Chlorinated solvents.

• Aromatic and aliphatic solvents.

• Alcohols.

• Ketone esters.

• Alkalis and salts.

• Miscellaneous.

• Oils.

From chemicals to foods

With almost all of the more than 100

chemicals on the list falling in the range of fair to excellent resistance (most in the excellent category), this guide reflects the tough make-up of MCI®2026 for chemical processors or other manufacturers. For those considering using MCI®-2026 in commercial food processing facilities, the list even includes resistance ratings for several food substances, including mayonnaise, milk,

mustard, peanut butter and vinegar that could easily fall on the floor.

Chemical resistance is an important part of many concrete and metal coatings applications. Simplify your search for the right epoxy coating by starting with this guide, which can be found at: https://www. cortecmci.com/product/mci-2026-floorcoating/.

Sika has completed the acquisition of the MBCC Group after having received all the necessary regulatory approvals. With this highly complementary transaction, Sika strengthens its footprint across all regions, reinforces its range of products and services across the entire construction life-cycle and drives the sustainable transformation of the construction industry further and faster.

The MBCC Group, headquartered in Mannheim, Germany and formerly owned by an affiliate of Lone Star Funds, is active in the field of construction systems and admixture systems. To close the transaction and comply with regulatory requirements, Sika sold the group’s chemical admixtures assets in the UK, the USA, Canada, Europe, Australia and New Zealand to international private equity firm Cinven. The business now acquired by Sika generated sales of CHF2,1 billion in 2022, employs 6 200 people, operates in over 60 countries and has 95 production facilities.

“We’re delighted to welcome the MBCC employees to the Sika family,” says CEO Thomas Hasler. “We’re on an exciting journey and will continue to drive Sika’s growth story. Thanks to our extensive experience in integrating companies, we’ll successfully bring Sika and MBCC together and combine our strengths to create the new reference in the construction chemical industry. Together we’ll deliver world-class performance for our customers and develop innovative, sustainable solutions.”

With this transaction, Sika strengthens its growth platform by broadening its product and solution offerings in four of five core technologies and seven of eight target markets. Customers will benefit from an enhanced and more efficient distribution network across all construction markets. The organisation expects to generate annual synergies in the range of CHF160-180 million by 2026. The combined group is set to reach sales in excess of CHF12 billion in 2023.

The Futuregrowth Community Property Fund (“Comprop”) has acquired the Sam Ntuli Mall, which brings the Comprop portfolio to 24 shopping centres, with a total gross lettable area of more than 420 000m2, valued at more than R7,3 billion.

The Sam Ntuli Mall is a recentlydeveloped, high-quality regional shopping centre situated in the large township of Katlehong, approximately 28km south-east of the Johannesburg CBD. The 30 276m2 hub is anchored by Shoprite, Pick n Pay, Boxer and Cashbuild, with an internal mall, as well as a number of line shops trading directly onto an expansive parking area that includes several drive-through offerings.

The Sam Ntuli Mall is centrally located and easily accessible via Tugela and Masakhane Sts. The shopping centre has excellent commuter access, with an onsite taxi rank servicing local routes and the main taxi rank located less than 1km away, servicing commuters to and from Johannesburg. There is extensive parking available for customers and a pedestrian crossing allowing easy access to shoppers

from the neighbouring community.

“The acquisition of the Sam Ntuli Mall is in line with our long-term strategy of investing in high-quality retail shopping centres across SA which are underpinned by strong income growth potential for our investors and service low- to middleincome households by delivering highquality goods and services at affordable prices,” says Smital Rambhai, fund manager of Comprop. “The acquisition makes Comprop one of the biggest specialist property funds in SA.”

Comprop is a flagship fund in Futuregrowth Asset Management’s suite of developmental investments and has been in existence for more than 25 years. All its shopping centres are located in prime locations within townships and rural areas around the country.

Capital Land Asset Management, its appointed property and asset manager, is a leading investment property boutique involved in the asset and property management of institutional and private commercial property portfolios in SA.

Describing it as “such a moment”, Luzuko Funda from Nelson Mandela University was declared winner of the 2022 Corobrik Student Architecture Awards. The event was at a special in-person ceremony at

Langhams in Johannesburg on 16 May and also live-streamed.

Funda won a R70 000 grand prize and joins a prestigious list of awards alumni. “I'm deeply honoured by the recognition, as I'm striving to make architecture accessible to all. I hope to be an inspiration for the next generation,” he said.

Ané Meyer from the University of the Free State received a Special Commendation and a R20 000 prize. “This year the judges felt it was such a close competition that they wanted to commend a student who delivered outstanding work,” commented Corobrik chairperson Peter du Trevou.

The finalists were selected from the eight major universities, based on architectural Master’s theses from the class of 2022.

Speaking at the awards ceremony, Corobrik CEO Nick Booth said the leading clay brick and paving manufacturer remains “steadfast and stalwart” in its support of the Corobrik Student Architecture Awards. Highlighting the dearth of awards and bursaries in the building and construction industry in general, he said: “The lack of recognition of students and the excellent work they're doing is actually to the detriment of the built environment and the architectural profession.”

He added: “There's no doubt that the present economic environment in South Africa has had a deleterious effect on the building industry, which hasn't helped investment in future generations. Funding has also become a major driver for academia. That's why we need to continue to have events like this to recognise excellence. Corobrik remains committed to the awards and to the architectural profession.”

The Southern African construction industry is resilient and has an optimistic future, with its output expected to increase by 3,2% this year, surpassing the 1,7% growth achieved in 2022. Recognising this progress and positivity is the next edition of the Big 5 Construct Southern Africa expo, with co-located events African Smart Cities Summit, the Big 5 Southern Africa Construction Impact Awards and the inaugural Big 5 Southern Africa Construction Leaders’ Summit taking place at the Gallagher Convention Centre in Johannesburg this June.

“These events not only promote upcoming projects, trends and opportunities in Southern Africa’s construction market, but celebrate the great work being done in the industry, inspire even greater things and strive towards a future-proofed industry,” says Tracy-Lee Behr, portfolio director: built environment at organiser DMG Events.

“There are many opportunities and many professionals in the industry with exciting ideas and fresh perspectives to share.”

“The construction industry has faced challenges, but is in recovery. There are many opportunities and many professionals in the industry with exciting ideas and fresh perspectives to share. These events will provide the chance to explore opportunities to collectively ensure industry resilience and growth.”

The 10th annual Big 5 Construct Southern Africa, taking place from 27-29 June, offers contractors, engineers, architects, quantity surveyors, designers and propertyowners a one-stop shop to identify viable opportunities and materials to complete projects efficiently and on budget.

The African Smart Cities Summit takes place on 28 June 2023 and is Africa’s only dedicated conference exploring the benefits of smart cities enabled through economic growth in the Internet of Things, technology and creative thinking.

The first Big 5 Southern Africa Construction Leaders Summit takes place on 29 June and will unite high-

level decision-makers, essential industry stakeholders and premier service providers to converse, deliberate and propel the advancement of infrastructure construction and development within the SACU region.

An invitation-only event, the Big 5 Southern Africa Construction Leaders’ Summit promises a gathering packed with experts from government to specialist funding institutions leading interactive panel discussions and keynote sessions on leadership, investment and partnership opportunities, and more.

Project-owners across sectors, institutional and private investors, funders and financiers will benefit from attending this event.

The Big 5 Southern Africa Construction Impact Awards on 27 June have been created as a platform to celebrate the achievements and transformation of the construction industry that go beyond traditional measures of project delivery.

These events serve as a hub for the Southern African construction industry and combine more than 200 exhibitors and more than 30 associated partners.

The Concrete Manufacturers Association (CMA) is among the associated partners with this year’s Big 5 Construct Southern Africa. “It’s a privilege to be affiliated with events that are tailored to our industry and promote innovation and professionalism. We look forward to engaging with the many stakeholders and representatives who’ll come together to showcase new ideas and determine the way forward to ignite further progress in the construction sector within the subcontinent,” says Henry Cockcroft from the association.

“Uniting as an industry to address and solve the current problems and realities allows us to reflect on how far we’ve come and what we can do together to make the most of the future. These events will offer unrivalled networking and deal-making opportunities, combining all facets of construction infrastructure in Southern Africa, and shouldn’t be missed,” adds Behr.

Register to attend Big 5 Construct Southern Africa and co-located events at: https://www.thebig5constructsouthernafrica.com

Twinstar Precast is a recognised industry leader in both custom and standardised precast concrete production. Owneroperator Annemerie Coetzee is a generous custodian of her extremely valuable knowledge and expertise.

Within this story, the chances of finding the precious nugget of information, inspiration or motivation needed for that next step on your precast journey are high.

With her years of hard work, practically acquired skills, committed study and in-depth industry consultation, Coetzee wants to share her experience, strength and hope. Also known to be one of the most innovative individuals in the industry, she jointly received the 2012 CMA Award for Excellence in innovation for her contribution to the design and development of a bomb-proof ATM enclosure.

Knowing its express aims

Once-off jobs are typically avoided by precasters due to their complexity, size and resource-intensive requirements, but Twinstar has made this a specialty and is uniquely geared to undertake such work, in which it has excelled for many years.

“I recognised a gap in the precast concrete market for custom-made prod -

ucts and once-off items,” recalls Coetzee.

“In the concrete pipe and manhole cover market, for example, the emphasis is on high volumes. The effort and time required to design and build once-off moulds for non-standard products disrupt the normal well-oiled production line and require additional skills and supervision.

“Not all building contractors have the necessary expertise, manpower and facilities to manufacture such products

on site,” she says. “That’s why our express aim is to assist specifying civil engineers and civil engineering contractors with complex projects for which currently available precast concrete products just won’t work.

“We strive to be a problem-solver and are solution-driven in all aspects of precast concrete. We’re able to manufacture products ranging in weight from 2kg-6 tons quickly and affordably.

“We only keep a few fast-moving products in stock which are standard specifications in tenders and drawings. Companies which previously made them have either stopped doing so or have closed down. This has largely given rise to our unique relationship with mainstream precast concrete companies who make use of certain non-standard products,” says Coetzee.

Twinstar saw value in manufacturing polymer products with no steel or cast iron elements, reducing risk of theft replacement costs. It offers both mediumand heavy-duty polymer products, in line with the SANS 1882:2003 specification. These components can be bought as loose items or cast into the required precast concrete slabs.

Twinstar became as comfortable manufacturing standard products as it was manufacturing non-standard ones by seizing the opportunity to supply the demand for custom manhole covers when numerous precast companies closed down. It is now the preferred supplier of numerous public water utilities.

The skills and commitment of its staff are central to the exceptional standards for which it is known. Sixty-five percent of its clients have been with the company for five years or longer, thanks to the service and products they receive from Twinstar’s true artisans who are skilled in the subtleties of specialised production processes.

The company keeps its operations and facilities to a size that enables the precision changes required for short lead times to be met without compromise.

Its aesthetic commitment is equally uncompromising. No product leaves its doors without Coetzee’s sign-off. “This is one of the reasons we won’t create other

branches or franchises: I won’t allow anything to leave our premises that isn’t perfect and aesthetically pleasing,” she says. Twinstar has expanded, however, having tripled the size of its factory since 2015.

Passion: a non-negotiable One of Coetzee’s favourite projects was stepping in to manufacture bicycle

stands for the Ekurhuleni municipality’s recreational park in Springs.

“It was a very complex product and certainly one of our most difficult ones,” she recalls. “We received a 3D drawing from an architect and basically worked by trial and error.”

The complexities of creating a mould that would allow for correct tapering of a design into which bicycles wheels could fit without breaking the concrete product was a challenge for Twinstar. Nevertheless, thanks to its skills and production management expertise, it perfected the required product.

“My most memorable project was the work we did on closing the Grootvlei mine shafts. The contractor was employed by the Department of Mineral Resources to ensure the safety of the communities around the defunct shafts,” explains Coetzee. “Some of the shafts were very deep and posed great safety risks to the township. Mothers were especially welcoming and supportive of the work we did there, as was the whole community. The slabs we manufactured to seal the shafts needed a lot of reinforcement and had to be designed to be impenetrable. It was highly satisfying to deliver something so life-enhancing to that community.”

Since the installation of mine shaft slabs manufactured by Twinstar Precast, the shafts have remained closed and are still completely intact.

The environment we build around us increasingly depends on precast concrete elements. Whether stand-alone products or hybrid construction elements, precast concrete has undeniable advantages. The sky is the limit when it comes to realising new ideas; all it takes is a feasible concept, a sketchbook and a conversation with Twinstar Precast.

“The skills and commitment of its staff are central to the exceptional standards for which it is known. Sixty-five percent of its clients have been with the company for five years or longer, thanks to the service and products they receive from Twinstar’s true artisans who are skilled in the subtleties of specialised production processes.”

Musina Mall, the dominant shopping centre in Limpopo’s heritage-rich town of Musina, is notching up excellent performance and continues to increase its trading metrics, shopper appeal and convenience

Despite the background of the prevailing tough times in South Africa, Musina Mall continues to show significant growth. Its total turnover grew a whopping 34% in 2022 over 2021 and was also a significant 23% higher than 2019’s pre-Covid-19 levels. Footfalls at the mall increased by 6% in 2022. Its shopper numbers exceeded 900 000 in December, approaching the one million mark for the first time.

External factors contributing to this include the completion of the N1 ring road last year and the Zimbabwe border formally opening in September 2022. The mall is a mere 10km from the Beit Bridge borderpost, which is the second-biggest port of entry into Zimbabwe and a gateway to other SADC countries. Offering superb accessibility, the mall is situated on the N1, from which it enjoys direct access.

Astute tactical management improvements to the asset for tenants and shoppers alike have also made a significant contribution to its mounting success. Strategic leasing has ensured that Musina Mall and its original section, the Great North Plaza, are fully let to specially selected tenants who create a unique retail mix that appeals to its market. Newer retailer additions include Roots Butchery and Roots Home, Telkom, American Swiss, Spec-Savers and Hi-Fi Corporation.

With 35 000m² of retail space, the mall houses almost all the area’s recognised

national retailers and popular brands. Musina Mall is anchored by Checkers and Shoprite and offers Woolworths, Clicks, Dis-Chem, Mr Price, The Foschini Group, Ackermans, Truworths, Pep and many others. It is also home to all five major banks: Absa, Standard Bank, Nedbank, FNB and Capitec.

In 2017, the Great North Plaza underwent a major redevelopment to add the brand-new Musina Mall, the largest part of this retail asset by far. This was a

redevelopment by the Moolman Group (30%) and listed property company Investec Property Group in 2017, and the result went on to outperform expectations. In August 2020, based on the mall’s track record of excellent performance, Moolman increased its stake to 50%, with Flanagan & Gerard acquiring the other 50% co-ownership.

The co-owners have since rebuilt the parking area at the mall’s Entrance 1 to ease traffic congestion and have also created more outdoor seating. In addition,

the taxi rank at the mall has been embraced by the community and is now being fully utilised.

There are more exciting plans on the cards, including the addition of a drivethrough and some tenant relocations and updates.

“From our experience with Musina Mall, we know it’s a great asset that delivers particularly pleasing perfor mance. It’s recovered well in the past two years post-pandemic, which is very positive and rewarding. We believe there’s even more potential to unlock at this shopping mall and look forward to an exciting road ahead. We plan to continue meeting the high demand for shopping and trading opportunities in its prominent business, social and tourist node,” says Pieter Lombaard, CEO of the Moolman Group.

Paul Gerard is MD of Flanagan & Gerard, which develops and invests in mostly dominant regional shopping centres that can maintain their market positions over time. “The improvements to Musina Mall build on its unparalleled convenience for its immediate community and many customers from over the Beit Bridge border in Zimbabwe and beyond.

including diamonds. The zone is intended to accelerate economic growth and President Cyril Ramaphosa has identified it as a focus area in SA’s postCovid-19 economic recovery.

Moolman and Flanagan & Gerard enjoy a long-standing association. In addition to Musina Mall, they have partnered in numerous award-winning retail property developments and are currently co-owners in quality retail assets that include Middelburg Mall in Mpumalanga and the Mall of the North (co-owned with Resilient REIT) in Limpopo.

“Strategic leasing has ensured that Musina Mall and its original section, the Great North Plaza, are fully let to specially selected tenants who create a unique retail mix that appeals to its market.”

Some people seem to be destined to find solutions to common problems. That was certainly the case for Bulali Mdontsane, whose path led him to becoming the developer, aided by uMaStandi, of Singleton Heights, located at 17 Casper Street in Protea Glen, Johannesburg.

Originally from the Eastern Cape, Mdontsane began his career by obtaining a degree in engineering with a focus on chemical engineering. He then obtained a Pr-Tech Engineering designation with the Engineering Council of SA, followed by a Master’s degree in engineering management at the University of Johannesburg. More recently, he obtained an MBA from the Wits University Business School.

However, instead of ending up in engineering, Mdontsane’s passion led him

to becoming a property entrepreneur. “I consider myself an African child and I saw all these problems, one of which was the issue of human settlements,” he explains. Together with uMaStandi, he is now doing his part to address the need for safe, comfortable accommodation in the townships.

“The Singleton Heights project is particularly significant to me. The building’s a tribute to my uncle, who was a migrant worker in the mines and had to endure living in hot, unpleasant conditions,” says Mdontsane.

The main aim of the Singleton Heights development is to provide clean, comfortable accommodation for people who are working in Johannesburg, but

“The accommodation’s for people who move out of the homes they grew up in and don’t want a back room type of space; they want a safe space where they can park their cars, but they also like the communal lifestyle of the township,” he explains.

The double-storey property consists of 30 bachelor apartments which are 25m² in size and each have their own dedicated parking bay. Designed to be lock-up-andgo accommodation, 29 of the apartments are let, while the remaining one is for a live-in caretaker.

On the cards for the near future is a laundromat and Mdontsane is also considering adding a space in which

pre-cooked, hot food can be sold. Both facilities would create entrepreneurial opportunities for other small businesses in the community.

“I was brought up observing the philosophy of ubuntu, which I still believe in and with these plans, I believe there’d be shared value and a real example of ‘lift as you rise’. I’d garner greater value as the landlord, my tenants would have greater convenience and the entrepreneurs involved would be able to share the market. The aim is to uplift the community together,” he says.

He explains that for the most part, the development of the apartment block proceeded smoothly, with construction beginning in February 2022 and finishing in July. After final inspections were completed in August, the apartments were ready to be let. A notable achievement of the project was that it was completed two months ahead of schedule.

Singleton Heights is not Mdontsane’s first foray into property development and ownership, but it is his most ambitious to date, which is why he turned to uMaStandi. Previously, he acted as the project manager on his first two developments, sourcing the required contractors on his own. Those developments were smaller in scope, involving the conversion and extension of existing structures and consisting of six units in Durban and Soweto, respectively.

Mdontsane’s comprehensive academic background served him well, with his engineering experience helping him manage the various puzzle pieces that go into successful development, while the MBA helped him deal with the management and financial aspects. However, he says that working with uMaStandi has helped him manage his property portfolio in a more professional manner, as well as avoid some of the major traps and pitfalls involved in an owner-run development.

No project is without its challenges and Mdontsane had to contend with two major ones. The first was dealing with the inefficiencies of the municipality and utilities, which he acknowledges

“construction mafia” – third parties who demanded a 30% stake in the project. He had taken steps to sidestep that challenge by ensuring that his construction team was locally sourced. He also ensured that he communicated extensively with the local councillor and community ahead of time, which forestalled individuals’ attempts to hijack the project for their own gain.

“I learnt that rule number one is to always obtain community involvement before bringing development into the area,” he relates.

Speaking from experience

Mdontsane’s advice to anyone wanting to get into property development is to bear in mind that every phase of the industry is about connecting with people, from aligning with the neighbours to ensuring one has buy-in from political leaders and the community. He also stresses the importance of looking beyond one’s own financial gain, a value which aligns him with uMaStandi’s purpose.

“As developers, we have a role to play in changing the face of the spaces we walk across and addressing the housing problem in South Africa. My own chosen space is the township and I believe that my mission and what the Trust for Urban Housing Finance does through uMaStandi are linked. Noone’s coming to save us. People need safe living spaces and I think we can be the solution they’re waiting for,” he says.

Recognising the short lead times and reduced cost of installing substations in a modular format, many sectors are choosing this option over the bricks-and-mortar structures traditionally used for that purpose. The reasons are not hard to see, says Trafor Power Solutions MD David Claassen, who designs and supplies these modular substations fitted with dry-type transformers.

Modular substations are fast becoming the format of choice in many applications, from industrial sites to data centres, mining and the oil and gas sector, delivering benefits such as quick deployment, lower installation costs and more flexibility.

“The trend towards modular substations is now well established in many sectors – and with good reason,” says Claassen. “There are many different options and designs, from shipping containers to larger or more

(Above): This modular substation is fully equipped and includes dry-type transformers, switchgear and instrumentation.

(Right): Trafo Power Solutions provides modular substations for data centres, corporate offices and commercial facilities. They are engineered to offer a high-quality, affordable solution to power needs.

Standard shipping containers – in either 6m or 122m configurations – provide an economical and compliant format for substations that must be transported via land or sea, he notes. The dimensions facilitate cost-effective logistics and generally ensure quicker availability of on-board space when

arranging shipping on container vessels. Indeed, the containerised concept was where the modular idea originated, as it could be moved around easily.

“More recently, though, we’ve seen the concept develop into much larger substa-

tion sizes – but the benefits remain,” says Claassen. “These can generally be constructed quite simply using structural steel with fire-rated insulation to enhance the safety rating of the installation.”

Compared with constructing a normal building on site, with all the related civils work, the modular option quickly shows a range of benefits. Any building work can become complex, costly and time-consuming, especially in remote locations. These costs include transporting various building materials to site over long distances, as well as finding and employing scarce skills and supervision.

“This traditional route also involves taking all the electrical components to site – and then installing, testing and commissioning them in conditions that are often less than ideal,” he explains. “By contrast, a modular substation can be constructed for the most part in a fully-equipped factory, which is more conducive to quality and speed.”

Once shipped to site, there is minimal work to be done before the modular substation can be commissioned and put to work. Modular substations can also be designed with state-of-the-art technology for improved reliability, easier maintenance and reduced running costs.

Claassen highlights that dry-type transformers add considerable value to the modular substation concept, as they can be installed inside a container or e-house. He explains that the safety levels intrinsic to dry-type transformers mean that they do not need a separate enclosure outside the modular structure.

“Effectively, the dry-type transformer is just another aspect of the electrical

arrangement in a substation that can be readily modularised,” he says. “For safety and other reasons, an oil-filled transformer would still need its own infrastructure due to the risk of fire, explosion or oil spills.”

Claassen highlights that this is counter-productive to the modular philosophy which makes this format of substation so popular. By using a dry-type transformer instead, the installation can avoid having a separate transformer bay, fire protection and suppression facilities, as well as outside cabling. With a drytype transformer inside the substation, there is also a reduction in the overall footprint size.

“Once shipped to site, there is minimal work to be done before the modular substation can be commissioned and put to work. Modular substations can also be designed with state-of-the-art technology for improved reliability, easier maintenance and reduced running costs.”(Above): The integration of dry-type transformers into a modular substation offers additional advantages, such as being suitable for installation inside a container or e-house, where they are also less exposed to inclement weather.

The Trevenna Basement project in Sunnyside, Pretoria is well underway, being built by black-owned principal contractor Concor. The project comprises a large five-level basement to serve the Trevenna Campus precinct, part of a larger venture driven by the Public Investment Corporation (PIC).

The project is a precursor for A-grade office buildings on the campus.

According to Martin Muller, senior contracts director at Concor, the contract is part of a multi-phase development and began shortly after the major earthworks were completed. Concor will carry out the first and second phases of the project, which comprises the five-level,

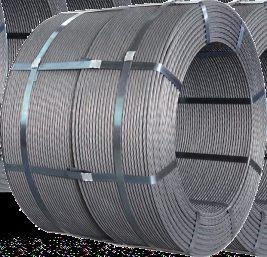

68 000m² super-basement with all services, lobbies and finishes. The basement extends some 20m below ground level and will be constructed with post-tensioned concrete slabs.

The full scope

“The scope of work also includes extensive underground services such as sewer and stormwater infrastructure, electrical reticulation, lifts to the ground floor and access control,” says Muller.

Phase 1 of this 11-month project began in February 2022 and Phase 2 started in March. The third phase, which is yet to be awarded, will comprise four A-grade office buildings some five storeys high, making

In line with local procurement principles, the project will rely heavily on local subcontractors, suppliers and labour, with a considerable workforce of 500-600 people active on site. Among the key subcontractors are specialists in excavation, formwork, concrete, post-tensioning and reinforcing.

Muller explains that Concor deployed four tower cranes on the site to facilitate the fast pace of construction required, ensuring the safe and expedited movement of steelwork, formwork and other construction materials. Space is at a premium, as the footprint of the basement extends across almost the entire site. “This necessitated the pumping of ready-mix concrete insitu for the post-tensioned slabs,” he says, noting that dealing with the challenges of congested urban environments is one of Concor’s many strengths.

“This is the first contract we’re undertaking for the PIC and we look forward to delivering excellence and demonstrating our extensive capabilities,” says Muller.

“The scope of work also includes extensive underground services such as sewer and stormwater infrastructure, electrical reticulation, lifts to the ground floor and access control.”

Driven for decades by its overarching sustainability commitment, AfriSam maintains a leading role in industry efforts to reduce carbon dioxide emissions. A key aspect of this is its pioneering technology to replace a growing proportion of clinker in cement with cementitious materials which are by-products of other industrial processes.

The science of substituting clinker in cement with a portion of alternative cementitious materials has paved the way for substantial gains in decarbonisation.

According to AfriSam process engineer Marieta Buckle, the company has reduced its carbon dioxide emissions per ton of cement by 33% since 1990. An important factor in this sustainability journey has been the use of extenders – mainly fly-ash and granulated blast furnace slag.

“We embarked on this journey many years ago, before buzzwords like ‘net zero’ were in common use,” says Buckle. “Our Project Green Cement began in 2000, involving significant research and development being invested. Among the outcomes, we were able to launch our Eco Building Cement in 2010 as the lowest carbon footprint product.”

AfriSam became arguably the world’s first construction material supplier to

“carbon-footprint” all its production operations, including cement, aggregate and ready-mix concrete, she notes. Its carbon dioxide rating system indicates each product’s carbon footprint relative to Ordinary Portland Cement (OPC).

Buckle explains that producing clinker is the most energy-intensive aspect of cement manufacturing – and is therefore a prime driver of carbon dioxide emissions. A central strategy at AfriSam has therefore been to promote decarbonisation by reducing the portion of clinker in cement, while maintaining its strength and other

properties. As an added advantage, the utilisation of extenders enables formulation of cement products that have improved characteristics specific to the application.

“AfriSam’s extensive research and development effort has resulted in the production of a cement mix that comprises up to 70% of alternative materials,” says Buckle. “Such a mix would contain only 30% of clinker, while still providing the required cementitious properties for the application. Importantly, it consumes less energy – and generates fewer carbon emissions – in the production process.”

The company’s ongoing achievements in this field are reflected in the statistics. AfriSam’s carbon emissions per ton of cement produced – at 598kg in 2021 – are considerably lower than the 671kg average among South African cement-producers, measured in 2016. It is also lower than the global average of 642kg of carbon emissions per ton of cement.

“By using what are essentially waste materials like fly-ash and slag, we can leverage the energy that’s already been consumed in generating them as byproducts,” says Buckle. “Apart from the value of recycling a waste product, we can make our cement production gradually more sustainable by reducing the energy that’s required.”

“A central strategy at AfriSam has therefore been to promote decarbonisation by reducing the portion of clinker in cement, while maintaining its strength and other properties.”(Above): AfriSam launched Project Green Cement in 2000 as a concerted effort to produce more environmentally responsible cement. (Above): AfriSam has reduced its CO₂ emissions per ton of cementitious material by 33% since 1990.

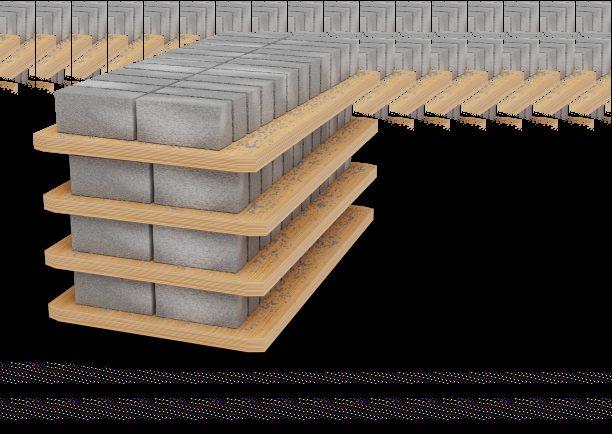

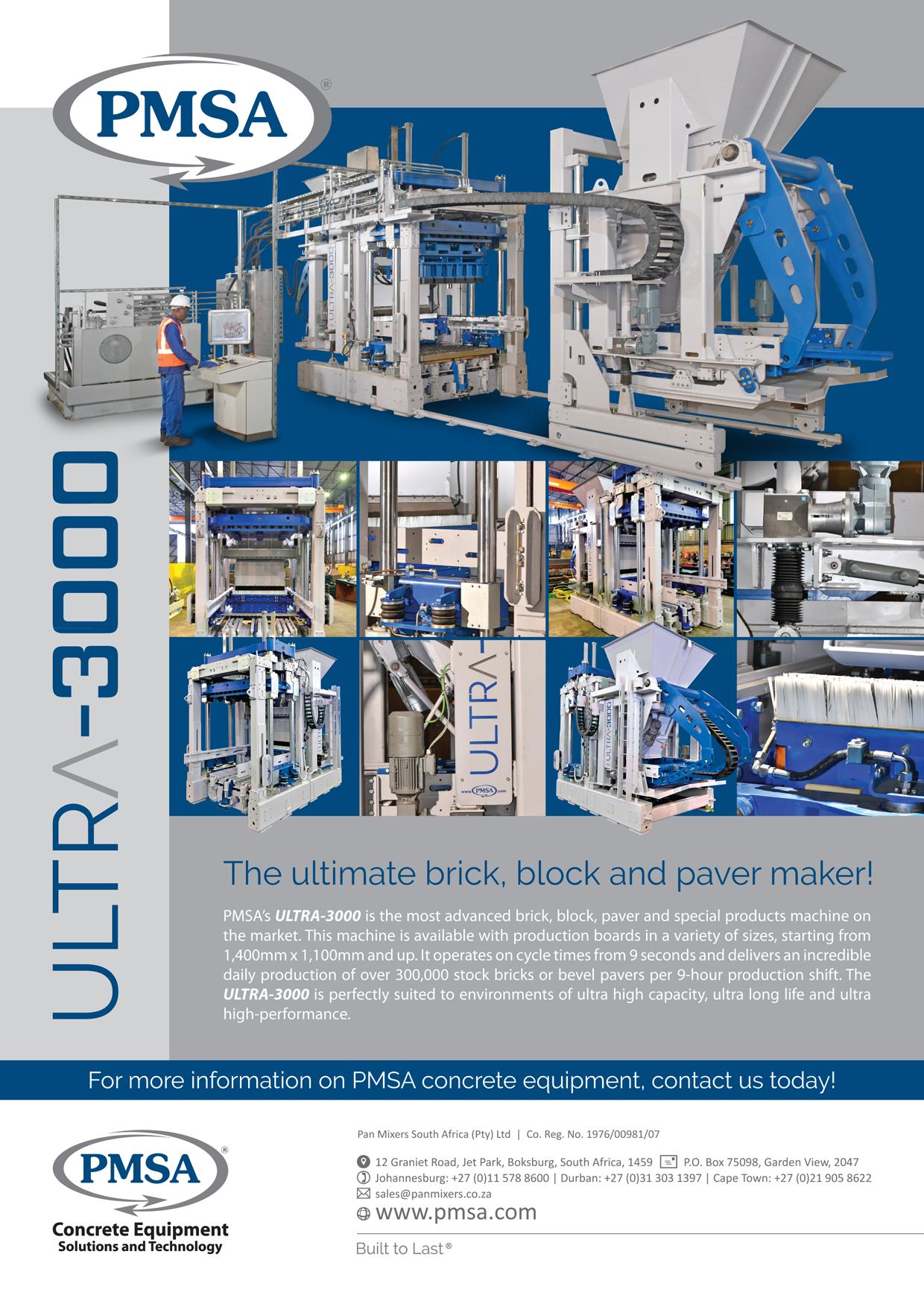

The construction industry is a crucial sector of the economy in South Africa and the production of cement bricks, blocks and pavers is an essential component of this industry. However, the quality and durability of these building materials depend largely on the correct mix ratio of the raw materials used in their production. It is therefore imperative to understand the importance of the correct mix ratio for such products.

The mix ratio refers to the proportion of different raw materials used to make the cement mixture. The raw materials commonly used in the production of cement bricks, blocks and pavers include cement, sand, gravel and water. The correct mix ratio ensures that the right amount of each of these raw materials is used to produce a concrete mix that is strong, durable and able to withstand the elements.

Different areas in SA produce different raw materials for use in the concrete mix. For instance, the sand found in one area may have a different texture or colour from that found in another area. The same applies to the gravel and cement used in the production of cement bricks, blocks and pavers. It is essential to take into account the variations in these raw materials when determining the correct mix ratio to use.

Failure to use the correct mix ratio can result in building materials that are weak and prone to cracking or breaking. Such materials are not only unsightly, but can pose a safety hazard. In addition, poorly mixed cement bricks, blocks and pavers are more likely to deteriorate quickly and require frequent repairs, which can be costly.

The mix ratio for cement bricks, blocks and pavers can vary, depending on the intended use of the building materials. For instance, building materials used for loadbearing walls may require a different mix ratio from that used for non-load-bearing walls. It is therefore important to consider the specific requirements of the building project when determining the correct mix ratio to use.

By considering all these factors and their consequences, we can ensure that our buildings are strong, durable and able to withstand the test of time.

DID KNOW? YOU

“Different areas in SA produce different raw materials for use in the concrete mix.”

However, the mix ratio is not the only element to consider: the type of mixer used can affect the consistency or pace at which the mix is made, possibly leading to a production delay or overflow.

Pan mixers: Pan mixers are horizontal, stationary mixers that have a circular mixing pan with a vertical rotating shaft in the centre. The pan is fitted with one or two mixing stars that rotate around the vertical shaft. Pan mixers are ideal for mixing dry and wet concrete, as well as for mixing refractory materials and powders.

Revaro 350L pan mixer

Revaro 500L pan mixer with or without a skip

mixing paddles rotate around their own axis. They are ideal for mixing highquality concrete, as well as for mixing other materials such as glass, ceramics and resins. They can handle both dry and wet materials.

Revaro RPM500-2 500 planetary mixers (500-2 500L)

• More affordable than other types of mixers.

• Can handle a wide range of materials, such as refractory ones and powders.

Cons

• Limited mixing capacity.

• Mixing quality may not be as consistent as that produced by other types of mixers.

• Not suitable for largescale production.

Pros

• High mixing efficiency and consistent quality.

• Ideal for mixing high-strength and high-quality concrete.

Twin-shaft mixers: Twin-shaft mixers are also stationary, but they have two horizontal shafts with mixing blades that rotate in opposite directions. This produces a thorough and even mix, making them ideal for mixing highquality concrete. They can handle both dry and wet materials.

Revaro RM-500-1 500 twin-shaft mixers (500-1 500L capacity)

When it comes to Revaro brickmaking machines, the type of mixer used depends on the machine model. For example, the Revaro REL range of manual and electric egg-layers uses the 350L pan mixer with almost all machines, while the Revaro RS static range of concrete brick-, block- and paver-making machines uses the bigger 500L pan mixer with or without a skip.

Twin-shaft mixers are ideal to use with the Revaro RE range of medium hydraulic brick-making machines. The company’s range of large hydraulic brick-making machines functions best with its range of planetary mixers to ensure that these automatic robust plants run optimally, without losing a beat.

Choosing the right mixer for a brickmaking machine will ensure that one gets the best-quality concrete mix possible. Factors such as the size of the mixing batch, the type of material being mixed and the required mixing time also need to be considered.

Pros

Planetary mixers: Planetary mixers are vertical and have a mixing bowl that rotates around a central axis while the

• Simple design, easy to operate and maintain.

• Ideal for mixing dry and wet materials.

• Can handle both dry and wet materials.

• Can mix large batches of concrete.

Cons

• More complex design and more expensive than pan mixers.

• Requires more maintenance than pan mixers.

• May not be suitable for certain types of materials.

Pros

• High mixing efficiency and consistent quality.

• Ideal for mixing high-strength and high-quality concrete.

• Can handle both dry and wet materials.

• Can mix large batches of concrete.

• Can mix a wide range of materials, such as glass, ceramics and resins.

Cons

• More complex design and more expensive than pan mixers.

• Requires more maintenance than pan mixers.

• Mixing bowl and paddles can be difficult to clean.

• May not be suitable for certain types of materials.

Sustainability of environmental responsibility and renewability is at the forefront of many minds today. When it comes to construction, multiple pieces fit into this puzzle, especially the materials used and the overall durability of the structure. In the case of reinforced concrete, Cortec® has been offering a unique answer to ready-mixers for more than two decades – the opportunity to add a biobased corrosion-inhibiting admixture, MCI®-2005, to their concrete mix.

How do MCI®-2005, concrete durability and sustainability fit together? The longer a concrete structure lasts, the better, because it reduces the need to make replacement concrete, which is an energy-intensive resource. Since cement, a main component of concrete, is blamed for as much as 8% of global CO₂ emissions, this reduction could have significant implications for sustainability. This may be one reason it is becoming more and more common to hear about structures being built with a service design life of 100 years or more.

One of the biggest threats to concrete longevity is corrosion. Under static conditions, reinforced concrete is at very low risk of corrosion. However, when adding cracking, chloride exposure from seawater or deicing salts and long-term carbonation

to the equation, the vicious cycle begins. Corrosion causes reinforcing metal to expand, pushing on the concrete cover and causing it to spall off, subjecting the reinforcement to additional corrosives and deterioration. For this reason, corrosioninhibiting admixtures are often used in the construction of concrete buildings in harsh environments such as sea coasts or regions that use heavy deicing salts. MCI®-2005 is an admixture that meets the corrosion inhibitor requirements under ASTM C1582 and promotes greater concrete longevity.

Along with the search for greater durability is society’s quest to use products made from renewable resources instead of relying so heavily on petroleum-based substances. In this respect, MCI®-2005 truly stands out

from the crowd as a corrosion-inhibiting concrete admixture that contains 67% USDA-certified biobased content and is therefore a great way to earn credits toward LEED certification through the use of renewable materials.

In addition to extending concrete service life predictions and using renewable materials, MCI®-2005 has a variety of other practical advantages. It is certified to meet ANSI/NSF Standard 61 for use in large drinking water system components. Workability is excellent; unlike calcium nitrite (CNI), which accelerates set time and makes it difficult to finish the job well, MCI®-2005 actually delays set time, giving workers a wider time-frame for finishing. Dosage is relatively low at 1pt/ yd³ (0,6L/m³), independent of expected chloride levels in the concrete, whereas CNI must be dosed higher for larger expected levels of chloride.

For the past two decades, MCI®-2005 has been used in structures around the world, exposed to everything from the high watertable/saline-soil conditions of the Middle East to the intense brine of desalination processes. As the only USDA-certified biobased product of its kind (that comes with minimal impact to concrete physical properties and no increase in concrete shrinkage), it is an outstanding choice for contractors and engineers seeking extended service life and sustainability.

“For the past two decades, MCI®-2005 has been used in structures around the world, exposed to everything from the high water-table/saline-soil conditions of the Middle East to the intense brine of desalination processes.”

Orania, a Karoo town in the Northern Cape named after the Orange River flowing alongside, has experienced rapid population growth in the past few decades. Consequently, the wastewater plant did not have adequate capacity to cope and a new one had to be built. The appointed contractor was Orania Infrastruktuur, which conducted the project from March to mid-December 2021.

Watertight concrete construction Sika SA was approached to consider solutions and then supplied the relevant specified materials to the project. It was important to ensure that the concrete works and joints were totally watertight. The basic methodology initially required the installation and fastening of SikaWaterbar® DR EG, an expansion joint sealant for watertight concrete construction, prior to casting of the concrete. SikaPlast® 220VX, a water-reducing multi-purpose admixture, was dosed at the readymix supplier and Sika® WT-200 P, a waterproofing admixture, was then added to the load just prior to discharge and thoroughly mixed.

The Sika-Waterbar® DR EG range is made of thermoplastic PVC and can therefore easily be heat-welded, as adhesive jointing is not permitted. Further advantages include high-tensile strength and elongation, permanent flexibility, resistance to hydrostatic pressure/stress and a resistance to natural soil and groundwater mediums. It is also available in a range of different sizes to suit various structures and applications. The selection of a suitable Sika-Waterbar® is governed by the type of joint, the concrete thickness, grade of concrete, reinforcement position, expected movement (expansion/shear) and the waterhead to which it will be exposed. The correct consistency of the concrete itself is also important, and the aggregates must be well graded. The Sika-Waterbar® solution performs only if both sides are well embedded in the concrete, centrally placed and heat-welded. Sika provided all the information and conducted training in the use of its products.

“It was important to ensure that concrete works and joints be totally watertight.”

SikaPlast®-220 VX is a multi-purpose water-reducer and superplasticiser which can be used in both ready-mix and onsite batching applications. It is ideal for use with lean, harsh concrete mixes and concrete-containing slag, fly-ash or microsilica. The superplasticising action of SikaPlast®-220 VX provides high-slump, flowing concrete that maintains excellent workability and may be placed with minimal vibration. It has been formulated to provide controlled and predictable extended slump life, allowing good slump retention without significant loss in early strength development. The combined highrange water reduction and superplasticising action of SikaPlast®-220 VX provides the following benefits in hardened concrete:

• Higher early compressive strengths for earlier removal of forms and structural use of concrete.

• Higher ultimate strengths allow for greater engineering design flexibility and structural economies.

• Reduced water cement ratios produce more durable, dense concrete with reduced permeability.

• It does not initiate or promote the corrosion of steel present in the concrete.

Successful delivery, four times more powerful

Sika® WT-200 P is a combined waterresisting and crystalline waterproofing admixture used to reduce the permeability of concrete and enhance the self-healing abilities of the concrete. The active mixture of cements, amino alcohols and fillers forms non-soluble materials and seals the concrete permanently against penetration of water and other liquids. In addition, the special Sika formula of ingredients in Sika® WT200 P provides the following benefits:

• Improved ability to heal cracks in concrete.

• Reduced water penetration under pressure.

• Reduced water absorption. Despite rain delays, the project was successful and the new wastewater plant

now has four times the processing power of its predecessor. Sika SA was there to ensure that no resources went to waste – except, of course, what was intended to be wasted!

MAPEI offers a complete range of high-quality adhesives for ceramic, porcelain and stone materials. MAPEI stays up to date with growing trends and technology within the market, making it the ideal application solution.

The range includes:

• Polymer modified cementitious adhesives

• Deformable cementitious adhesives

• Fast-setting levelling compounds

• Reactive resin polyurethane and epoxy adhesives

• Water repellent cementitious grouts

• Water based epoxy grouts

Tel:

A Japanese contractor which is one of Lintec & Linnhoff Concrete’s long-time customers has bought a second Eurotec ECO60 concrete batching plant for Madagascan port development.

The contractor bought the plant to support its work on the Toamasina Port Development Project (Phase 2) on the island’s east coast.

The ECO60 is an affordable, simple and functional concrete batching plant that produces up to 60m³ of concrete per hour.

The contractor was already familiar with the ECO60, as it had been using the same model before.

The decision to buy the second plant was based on quality and reliability, as well as effective levels of after-sales support. “This customer always has a need for high productivity, which is why it took advantage of the ECO60 plant’s performance and reliability. In order to meet the new project’s requirements for more complex concrete mix designs, it upgraded that first ECO60 model from three aggregate bins to five bins,” explains R Sakthi, CEO of Lintec & Linnhoff Concrete.

The ECO60’s modularised structure provides fast installation and easy maintenance. It has started producing a consistent mix of concrete volume for a range of tasks on the Toamasina Port Development Project.

The new quay and container storage area, already the largest commercial port in Madagascar, is expected to increase Toamasina’s port-handling capacity.

Moreover, the deepened berths allow more and larger cargo and container ships to dock.

The stationary Eurotec ECO60 provides an affordable and reliable solution for customers who demand an economical concrete batching plant with high-quality concrete production. The customer can also customise the number of aggregate bins (three to six inline bins) according to the project’s concrete mix requirements.

The model produces ready-mix concrete in batches of 1m³. The consistency of the mix is ensured by the weighing and batching systems that are metered using load cells. This is managed with Eurotec’s in-house ECS process-control system software, which runs on Windows OS for fully automatic operations.

A twin-shaft mixer, 100% manufactured in Italy, supports high-volume production and rigorous mixing intensity. Its robust steel structure and thick,

“The model produces ready-mix concrete in batches of 1m³. The consistency of the mix is ensured by the weighing and batching systems that are metered using load cells.”

interior abrasion-proof linings ensure durability. Located at 90° intervals, the double-mixing spiral paddle structure delivers greater abrasion-resistance and high-performance production than conventional mixers. This is a valuable advantage when blending materials with particle sizes from 120-150mm.

The ECO60’s work was completed without incident in July 2022, although the project is expected to continue for another two to three years.

The long-running Toamasina Port redevelopment programme has already witnessed major improvements, with porthandling capacity rising from just 60 tons to 2 500 tons per

Africa, Asia, Europe and the Gulf states.