IN THIS ISSUE:

Twinstar rides the wind

Peikko keeps wastewater project on track

R20 million electrical modernisation programme

IN THIS ISSUE:

Twinstar rides the wind

Peikko keeps wastewater project on track

R20 million electrical modernisation programme

AVOID CONCRETE STRENGTH DELAYS. As winter approaches, the colder ambient temperatures can cause delays in concrete strength development as well as finishing aspects. Rest assured, this challenge can be easily overcome using CHRYSO’s Premia Range of admixtures and demoulding agents.

With 2024 drawing to a close, this final issue of Precast for the year reflects on a tumultuous, uncertain – but hopeful – 12 months. The industry has been impacted by power and water cuts, corruption, disinvestment and socio-political instability, as well as the construction mafia, which is alarming not only because of its violence and intimidation, but because of the apparent lack of response to it. The thought that it could become accepted as just another ill is terrifying on every level.

Normalising the risk of organised crime by making it a standard clause of project contracts is that it creates a precedent for tolerating other forms of crime as unavoidable and, indeed, inevitable. This becomes the foundation for a society where anarchy and impunity triumph over ethics. Once “anything goes”, it is not long before “everything’s gone”. We hope that our law enforcement and anti-corruption agencies will prioritise eliminating this scourge and our article on ASAQS in this issue expands on that.

We also celebrate the strides made by Twinstar into the solar power sector and Peikko’s success in completing a crucial project months before the deadline. In addition, we offer an intriguing glimpse of a US project which drew on the architecture of the industrial past to create a strikingly modern iron works.

We wish all our readers a joyful and safe holiday season, as well as a healthy, happy and prosperous new year and look forward to connecting with you again in 2025.

15

AfriSam’s relocated Ulco cement plant in the Northern Cape will be capable of providing security of supply for about 40 years and will need to deliver around two million tons of limestone to Ulco each year. The supply of readymix will include AfriSam cement.

Twinstar has identified the need for customised wind energy solutions – and is supplying them with the excellence for which it is renowned

AfriSam’s relocated Ulco cement plant in the Northern Cape will be capable of providing security of supply for about 40 years and will need to deliver around two million tons of limestone to Ulco each year. The supply of readymix will include AfriSam cement.

PRECAST is independently published by Isikhova Media (Pty) Ltd Tel: +27 (11) 883 4627 www.isikhova.co.za

PRECAST is independently published by Isikhova Media (Pty) Ltd Tel: +27 (11) 883 4627 www.isikhova.co.za

PRECAST is independently published by Isikhova Media (Pty) Ltd Tel: +27 (11) 883 4627 www.isikhova.co.za

Operations director: Thuli Majola

Operations director: Thuli Majola

E-mail: thuli@isikhova.co.za

E-mail: thuli@isikhova.co.za

Operations director: Thuli Majola E-mail: thuli@isikhova.co.za

Design and layout: Yoland Crator

Design and layout: Yoland Crator

E-mail: yoland@edgehosting.co.za

Sales Director: Ruwayda Mahomed E-mail: ruwayda@isikhova.co.za

E-mail: yoland@edgehosting.co.za

Managing director: Imraan Mahomed

E-mail: imraan@isikhova.co.za

Design and layout: Phumi Vilakazi E-mail: phumi@candymustache.co.za

Managing director: Imraan Mahomed

E-mail: imraan@isikhova.co.za

Copy editor: Anne Phillips Media sales: Tel: +27 (11) 883 4627 / 083 450 6052

Copy editor: Anne Phillips Media sales: Tel: +27 (11) 883 4627 / 083 450 6052

Managing director: Imraan Mahomed E-mail: imraan@isikhova.co.za

Media sales: Tel: +27 (11) 883 4627 / 083 450 6052

South Africa’s power crisis is hardly news – and the option of wind energy has long been on the table. So, true to its enterprising spirit, Twinstar has identified – and is supplying – a need for its innovative, custom-made products in this burgeoning sector.

Why wind energy?

• Wind energy is sustainable and abundant, reducing reliance on fossil fuels and contributing to energy security.

• Wind farms help lower greenhouse gas emissions, supporting South Africa’s commitments to combat climate change and improve air quality.

• The development of wind farms can boost local economies by creating jobs in construction, maintenance and operation.

• Wind energy contributes to a more diversified energy mix, enhancing resilience against fluctuations in energy supply and prices.

• Many wind farms are located in

rural areas, bringing infrastructure improvements and economic opportunities to local communities.

• Investment in wind energy fosters technological innovation and skills development in renewable energy sectors.

• Wind farms can enhance grid stability by providing a source of electricity that can be scaled up as needed, especially when integrated with other renewable sources.

• Unlike coal and nuclear power plants, wind energy production does not require significant water resources, helping to conserve water in arid regions.

Overall, wind farms play a crucial role

in promoting sustainable development and addressing energy disruptionss in SA. However, each wind farm experiences different challenges and layouts, as well as different investors with different approaches. Therefore each new farm requires newly designed items.

Enter Twinstar Precast as a market leader for the casting of precast items for these farms.

Precast concrete offers several advantages when used for bases and plinths, including the following:

Quality control: Precast concrete is manufactured in a controlled environment, ensuring consistent quality and minimising defects, compared with on-site mixing.

“Some of these enclosures or bunkers have been designed by the clients and brought to us to cast and test their durability. Others have been designed by us, after a client has approached us with a problem and asked us for a solution.”

in the country. The latest plinth being manufactured weighs 9,3 tons and is 6,4m long and 2,8m wide.

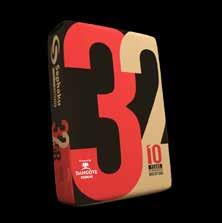

Over the past 10 years, Twinstar has supplied plinths to wind farms in Loeriesfontein, Kangnas, Gibson Bay, Khobab, Noupoort, Oyster Bay, Paardekraal and Garob. Since January this year, it has manufactured plinths for wind farms in Ummbila Emoyeni, Umsobomvu, Brand Valley, Witberg and Impofu East and West.

A proud legacy

Speed of construction: Precast components can be produced simultaneously with site preparation, significantly reducing overall construction time.

Durability: Precast concrete is resistant to weathering, corrosion and other environmental factors, resulting in longlasting structures.

Cost-effectiveness: Although initial costs may be higher, the reduced construction time and labour costs often lead to overall savings.

Design flexibility: Precast concrete can be moulded into various shapes and sizes, allowing for customised designs that meet specific project requirements.

This is Twinstar’s forte. It specialises in helping both civil engineers and civil engineering contractors dealing with difficult worksites, where currently available precast concrete products are simply unsuitable. The company is fully equipped to handle once-off jobs which many precasters avoid due to their complexity, size and resource-intensive nature.

Twinstar is the only company in SA specialising exclusively in custom-made and one-off, unconventional precast concrete products, including those needed on wind farms. Any sizes can be manufactured on request.

It is currently manufacturing plinths, junction boxes and distribution boxes for various wind farms under construction

Twinstar’s products are known and respected throughout the construction industry for their durability, versatility and cost-effectiveness. They are manufactured using advanced techniques and undergo stringent quality checks before becoming available to clients. They also come with meticulous manufacturer’s guidelines

for installation, ensuring correct positioning, proper alignment and stability.

The company is a respected and trusted industry leader, with a reputation for expertise and excellence in both its service and products, as well as foresight in identifying and fulfilling needs in the sector.

Little wonder, then, that Twinstar has the wind behind its back.

TWINSTAR: Unit 21, Hunky Dory, Business Park, 9 Goedehoop Avenue, Olifantsfontein, Gauteng

Tel: 012 670 9083

E-mail: info@twinstar.co.za. Website: www.twinstar.co.za.

Centurion’s thriving business district just reached a new milestone. Westend Office Park recently welcomed its latest tenant, financial solutions giant Hello Group, which now officially occupies the entirety of Building E. As part of the celebration, a “roof-wetting” event commemorated the occasion, signifying not only Hello Group’s arrival, but also the continued growth of the precinct.

Westend Office Park’s allure is tied to its strategic location. Nestled on the edge of Centurion’s CBD, it is within walking distance of the Centurion Gautrain Station, which provides effortless access to Pretoria, OR Tambo International Airport, Midrand, Sandton and Rosebank. The office park’s direct exposure to the N14 freeway and the Gautrain line offers great business visibility and accessibility that

few other locations can match. Its parklike environment, serene landscaping, bird life and views of the Hennops River further boost its amenities, which include a park coffee shop, a car wash and shuttle services. Westend Office Park also looks to the future with the ground-breaking of Building F. This A-grade office building will offer approximately 5 000m² of prime office space in a secure office park. Like Building E, it will enjoy all the strategic benefits that make the precinct an attractive business address, including proximity to key transport routes, ample amenities and robust infrastructure, while boosting the local economy by offering numerous job opportunities. In addition, its design will be sustainable, emphasising energy-efficiency and environmental responsibility, thanks to architects MWLF

Development kicked off in October 2023, with Mike Buyskis Construction. The property manager is Strive and the precinct’s shareholders include Centurion Investments, the Moolman Group and Abcon Group.

“Westend Office Park recently welcomed its latest tenant, financial solutions giant Hello Group, which now officially occupies the entirety of Building E.”

Learn more at mapei.co.za

Tel: +27 11 552 8476

Email: info@mapei.co.za

the sacrificial admixture that deals with the “GREMLINS” in your aggregate.

DYNAMON MS100 is an innovative, high-quality sacrificial admixture which is ideal for use with super absorbent aggregate on site.

It has been developed to accommodate various site conditions and raw material characteristics and should be used with your chosen superplasticizer.

When your aggregate is not working with you, trust DYNAMON MS100 to get it back in line.

From the foundation to the roof - MAPEI is your solutions partner

Leader in advanced precast concrete construction technology, Peikko South Africa, assisted in reducing the construction time for the development of the extensive upgrade to the City of Cape Town’s sewage and wastewater system to just three months. The expansion of the Potsdam wastewater treatment works involved the construction of a new structure to house a membrane technology system.

Under intense time pressure, main contractor H&I Construction reached out to precast concrete specialist Cape Concrete in an effort to find a more time-efficient method of constructing the column and beam structure which had to

support the weight of a travelling crane.

Cape Concrete immediately contacted Peikko, having worked with it on numerous projects, where its innovative structural solutions and connection technology for precast construction techniques had proved a winner.

“When Cape Concrete contacted us requesting assistance with the precast design of the new structure, we knew the project design was ideal for our advanced technology approach,” says Winston Visser, project engineer at Peikko.

“The original design called for castin-situ column and beam construction

with column heights of 15m and beams which had to support a 60-ton capacity travelling crane. We responded with our initial precast designs and confirmation that, if these were adopted, they would not only comply with all structural and seismic specifications, but restore the main contractor’s construction schedule, cutting off weeks compared with cast-insitu construction.

“After extensive discussions between H&I Construction, Cape Concrete and the client, our design was approved and Cape Concrete began the off-site manufacture of the precast concrete elements, which incorporate Peikko’s

plant’s foundations. Furthermore, as the structure could now be effectively modular, it was unnecessary to execute the construction in a traditional process. This allowed other trades and sub-contractors to access sections of the building earlier than was first envisaged under a cast-in-situ solution.

This was particularly valuable for the mechanical contractor, who was able to schedule the installation of a myriad of pipework in a more timeeffective way.

“The upshot of this switch to Peikko’s connected precast elements instead of in-situ construction resulted

in H&I Construction being able to finish construction of the plant in just three months, bringing the project back onto the client’s timelines for the development of this extensive upgrade to the city’s sewage and wastewater system.

“The project elicited praise from the client for the contractor’s performance, quality of work, finish of the precast elements and minimal snags, and –above all – the speed of construction,” says Visser.

“When Cape Concrete contacted us requesting assistance with the precast design of the new structure, we knew the project design was ideal for our advanced technology approach.”

Our range of locally produced superior quality cement is designed for specialised applications demanding high early strength, enhanced durability and superior concrete. Supported by our dedicated expertise, our superior products are the ultimate choice when compromise is not an option and time is of the essence. Cement Your Legacy and Ask for AfriSam.

The construction mafia has become so entrenched in South Africa that the risk of organised crime is increasingly factored into project contracts – suggesting that these criminal activities are a legitimate part of doing business. To restore the rule of law and revitalise the construction industry, the Association of SA Quantity Surveyors (ASAQS) is calling for collaborative action between built environment professional associations and the SA Police Service (SAPS) to combat these criminal extortion rings.

“Although government and various industry stakeholders are working to address the issue, the challenges remain and have now reached the point where many legitimate businesses are forced to cut jobs or scale back operations due to the financial pressures from extortion and intimidation,” says Mosha Senyolo, president of ASAQS. “This contributes to higher unemployment, particularly in locations where construction and infrastructure development are key. Workers and businesses are threatened, which breaks down community trust and safety. Construction mafias are creating a climate of fear – and its ripple effect is giving rise to more opportunistic criminal behaviour.”

Ethical and existential dilemma

It has been estimated that the construction mafia has cost SA’s economy approximately R68 billion over the past decade. The impact on quantity surveyors is significant, as they have to account for potential extortion payments and increased security measures within their budgets. “Additionally, intimidation and disruptions lead to project delays, making it challenging not only for the contractors, but also for the project quantity surveyor to manage the complexities while trying to maintain their professional reputation,” says Senyolo.

The increased call by contractors to incorporate the risks associated with organised crime into project contracts further complicates risk management strategies and drives up costs. “Moreover, dealing with clients or contractors who may be coerced causes an ethical dilemma, putting our members in a difficult position,” says Senyolo. Consequently, the relationships between quantity surveyors, contractors and clients suffer, fuelled by anxiety over project security that often erodes communication and trust.

Sharing insights and encouraging whistle-blowing

To effectively root out construction mafias, ASAQS is calling for a collaborative platform between built environment professional associations and the SAPS. Since many members are directly impacted and face an existential risk, ASAQS is ideally positioned to create a safe space for industry professionals to submit tip-offs and blow the whistle on corruption. “Such a collaborative platform would enable us to share insights and potential approaches to combatting the construction mafia together with the SAPS, based on the lived realities of our members on the ground,” says Senyolo. Furthermore, ASAQS leadership is considering engaging directly with the special unit established by the SAPS. These measures – as well as regular meetings and information-sharing platforms with local communities during the planning phase of projects – are expected to encourage the reporting of suspicious activities without fear of retribution. By working more closely and establishing a platform to share insights, industry bodies and the SAPS have the power to successfully fight the construction mafia.

A.Shak Construction Chemicals offers a wide range of products:

- Bonding Agents

- Chemical anchors

- Concrete Bonding

- Concrete crack repair

- Concrete release agents

- Concrete repair mortars

- Curing compounds

- Epoxy adhesives

- Epoxy grout

- Joint sealants

- Non-shrink grouts

- Precast repairs

- Waterproofing

Trusted suppliers to the construction industry for 66 years

Konecranes and Demag SA’s modernisation programme includes the replacement of all key electrical components, as well as the reprogramming of the variable speed drives.

Konecranes and Demag SA was recently awarded a R20 million crane electrical modernisation contract for an industrial company based in Southern Africa. The 18-year-old Demag crane which was orig-

inally purchased from Konecranes and Demag SA had started to show signs of wear by mid-2024.

The company contacted Konecranes in Johannesburg, which travelled to site

“The

cost of maintaining crane electrical and control systems increases over time. An electrical system modernisation not only helps improve the performance of a company’s existing equipment, but extends the lifespan of a crane without the major capex expenditure of purchasing a new crane.”

to conduct an assessment.

“Once at site, we conducted a full electrical and mechanical evaluation of the crane. This assessment showed that the downtime and resulting breakdowns experienced by the client were the result of the age of the electrical system, which was no longer performing optimally. We recommended that an electrical modernisation programme be undertaken,” says Alwyn Rautenbach, modernisation and sales support specialist at Konecranes and Demag SA.

The modernisation programme included the replacement of all key electrical components, as well as the reprogramming of the variable speed drives. “As we hold a large supply of mechanical and electrical components for our products at our premises, we were able to supply all of the parts required to complete the modernisation upgrade from our Johannesburg distribution centre,” says Ian Grobler, Konecranes and Demag SA sales manager.

Components such as variable speed drives, encoders and auxiliary panels, as well as brake and hoist resistors, formed part of the consignment of components. Full functionality testing, as well as a factory acceptance test, were conducted before the complete electrical upgrade was delivered to site. The modernisation installation process took one month, with ongoing monitoring of the crane’s performance ongoing for a further two months.

“Despite the removal of the crane’s complete electrical system, the modernisation transition was smooth and efficiently conducted. We’ll continue providing assistance on site and conducting unscheduled maintenance that limits downtime for the customer, while ensuring that all components of the new system are performing as they should be.

“The cost of maintaining crane electrical and control systems increases over time. An electrical system modernisation not only helps improve the performance of a company’s existing equipment, but

extends the lifespan of a crane without the major capex expenditure of purchasing a new crane,” says Grobler, adding that new safety features and positioning capabilities can simply replace high-maintenance, obsolete components with newer technology offering a tailored and fully integrated system.

“We’re proud to have resolved the customer’s crane challenges as cost-efficiently and timeously as possible. The end result has delivered a modernised and fully operational ‘new’ crane. We’re also delighted to have been the preferred supplier to the same customer for a further two to three

electrical crane upgrades over the next two years.

“Konecranes receives a substantial number of enquiries from clients based in Southern Africa, no matter what make of their cranes, and a key factor in our successful resolution of any mechanical or electrical performance issue is our quick technician-to-site response time for assessment purposes. We’re able to supply spare parts and components from our distribution centre easily to site to ensure that the refurbished crane equipment is fully operational speedily, without cutting any safety requirements,” adds Grobler.

“As we hold a large supply of mechanical and electrical components for our products at our premises, we were able to supply all of the parts required to complete the modernisation upgrade from our Johannesburg distribution centre.”

PRODUCTS

Storm Water

Electrical

Markers

Water Reticulation

Outdoor & Building

Polymer Products

Mining Solutions

Kerb Inlet & Road Products

Custom Products

SERVICES

Moulds Drawings

Concor once again showcased its remarkable ability to execute complex, fast-track projects with exceptional efficiency and safety during the construction of the new drop-off and pick-up facility, along with the reconfiguration of an underground parking area into a taxi holding facility at Menlyn Park Shopping Centre. The company was honoured by Master Builders Association (MBA) North, winning in the regional category for projects under R15 million. The MBA North regional safety competition saw 67 entries, including 60 principal contractors and seven sub-contractors.

Menlyn Park Shopping Centre – one of the largest in South Africa – boasts a diverse array of over 500 shops, restaurants and entertainment facilities. The centre attracts a vast number of shoppers and visitors each month, necessitating a significant workforce to support its operations. While some commuters use personal

vehicles, the majority rely on minibus taxis for transportation. To streamline this process and enhance the commuter experience, a publicprivate partnership was established for the construction of the taxi holding facility.

Concor contract manager Martin Muller explains that the company is known for managing high-pressure construction programmes effectively and applied attention to planning. underpinned by effective programme management, to ensure that every phase of the project dovetailed

seamlessly, meeting tight deadlines without compromising quality or safety.

The project, initiated in February 2024 this year and completed by April, was delivered on time and within budget, ready for the official opening by the Tshwane mayor.

Despite the tight timeline, the project was executed without any incidents, a testament to the rigorous safety protocols implemented. The construction site, active within a live retail environment, required meticulous traffic management and pedestrian safety measures. A full-time safety

officer ensured compliance with all safety procedures, leading to a five-star safety rating from MBA North.

Another of Concor’s significant strengths lies in involving local SMMEs and individuals from the communities in which it operates. On this project, the company engaged with community representatives to source, vet and employ SMME sub-contractors, offering opportunities in trades such as brickwork, plasterwork, painting, paving and plumbing.

Muller says that while the contract period was too short for a formal skills development programme, local labourers were given the chance to work on the project, gaining valuable experience and mentorship.

The drop-off and pick-up facility is strategically located on the northern side of the centre, accessible from Atterbury Road. This facility enhances the movement of taxis, allowing for safe drop-off and pick-up of passengers. Commuters benefit from a designated pedestrian walkway leading directly into the mall, which is both safer and sheltered from the elements.

The facility can accommodate around 40 taxis at any given time within its spacious footprint. The construction involved extensive groundwork, soil stabilisation and paving to ensure durability under high traffic volumes. Security measures include fencing around the area and structural steel canopies with reinforced concrete foundations. The pedestrian walkways were also designed with aesthetic landscaping.

In addition to the primary logistical infrastructure, provisions were made for registered informal traders to set up kiosks, offering food and other goods in a secure and sanitary environment with shelter from inclement weather. Nearby, 24/7 accessible ablution facilities ensure safe and hygienic conditions for commuters and taxi operators.

Muller explains that previously, taxis lined Lois Avenue on the eastern side of Menlyn Park Shopping Centre, creating hazardous conditions for both commuters and other vehicles. “The

new facility alleviates these issues by providing a controlled environment for taxi operations and commuter safety,” he says.

The taxi holding facility was integrated within the centre’s existing parking structure. It includes 165 parking bays, with 135 for standard minibus taxis and the remainder for larger long-distance minibuses. Access is controlled via licence plate recognition, with separate entrances for shortand long-distance operators. The area is secured with fencing and the parking layout was upgraded with energy-efficient LED lighting and clear demarcation of bays.

The holding facility also features utility areas, including a rest area with a kitchen, ablution facilities catering to disabled individuals and a wash bay. With a focus on the environment, sustainable design elements were

incorporated such as sensor-based lighting and water-efficient fixtures to reduce resource consumption. The dedicated wash bay encourages water conservation among taxi operators, while providing a suitable vehicle cleaning area.

As with all its contracts, Concor’s commitment to community upliftment extended beyond the project site, with the company identifying needs within local communities. In this instance, it donated building materials to a nearby school for an upgrade project, collaborating with the professional team to support local education infrastructure.

“This project not only improved the commuter experience at Menlyn Park Shopping Centre but also, once again, showcased our dedication to quality, safety, and community engagement,” says Muller.

“Menlyn Park Shopping Centre – one of the largest in South Africa – boasts a diverse array of over 500 shops, restaurants and entertainment facilities. The centre attracts a vast number of shoppers and visitors each month, necessitating a significant workforce to support its operations.”

AfriSam Starmix®, a premium ready-mix concrete solution, answers the need for high-quality, reliable and efficient building materials.

AfriSam Starmix®, a premium readymix concrete solution, answers the need for high-quality, reliable and efficient building materials. Available from leading construction materials company AfriSam, it is designed to cater to a wide range of construction applications.

This versatile ready-mix concrete combines the finest raw materials with advanced technology to ensure superior quality and consistency. It is specifically formulated to meet the stringent demands of modern construction projects, offering unmatched durability, workability and strength.

One of the standout features of AfriSam Starmix® is its exceptional workability. The mix is designed to flow easily and settle smoothly, making it ideal for a variety of applications. This improved workability also reduces the time and effort required for placement, ultimately speeding up the construction process.

AfriSam Starmix® is engineered to provide outstanding durability and strength, ensuring that structures built with this concrete can withstand the test of time and harsh environmental conditions.

Another key advantage of AfriSam Starmix® is its versatility. The product is highly adaptable and can be customised to meet specific project requirements.

AfriSam is committed to sustainable practices – and Starmix® is no excep -

tion. The product is designed with environmental considerations in mind, incorporating eco-friendly materials and production methods that minimise the carbon footprint. This aligns with AfriSam’s broader commitment to sustainability and responsible construction.

“This versatile ready-mix concrete combines the finest raw materials with advanced technology to ensure superior quality and consistency.”

AfriSam not only provides a superior product, but offers exceptional customer support and service. The company’s team of experts is available to assist with mix design, technical advice and on-site support to ensure that every project runs smoothly and efficiently.

One of the biggest enemies of parking ramp longevity is corrosion. Whether a parking ramp is in a warm coastal area subject to sea breezes and salt spray, or in winter snow-prone areas where cars frequently need de-icing salts, the basic story is the same. Chloride-induced corrosion leads to premature deterioration and early repairs on the reinforced concrete structure.

To change this story, Cortec® recommends adding Migrating Corrosion Inhibitors (MCI®) into routine maintenance to slow down the corrosion process.

Advantages of preventive maintenance versus repair

Preventing a problem is usually easier and less expensive in the long term than repairing one. When it comes to reinforced concrete parking ramps, corrosion prompts repair because it swells the size of the rebar, placing pressure on the concrete overlay and eventually causing it to crack and spall off. The further this process goes, the more damage is done and the more material- and labour-intensive the repair.

While adding corrosion protection to a repair is important to help it last longer, slowing down corrosion as part of routine maintenance is even better, because it can delay and reduce the damage. MCI® Surface Applied Corrosion Inhibitors (SACIs) are ideal for parking lot maintenance because they penetrate and migrate through concrete pores and can be combined with water repellents or traffic membranes. MCI® molecules are attracted to reinforcing metal, where they adsorb and form a hydrophobic layer which inhibits the ability of the metal to interact with corrosives such as moisture and chlorides. This molecular barrier delays the time to corrosion initiation and slows down the

rate of corrosion that has already started. MCI® can be applied at any stage of a parking ramp’s life-cycle – before, during and after repairs.

Selecting the right MCI® SACI Contractors and parking garage management companies can take a variety of paths when incorporating MCI® into their preventive maintenance plan. Those aiming for a 20-year MCI® re-application rate will typically want to choose MCI®-2020, with a traffic membrane applied on top. Traffic membranes often have a 20-year warranty; however, when the membrane inevitably fails, it can allow water and chlorides to seep underneath and attack the concrete anyway. Applying MCI®-2020 to the surface first will enhance protection by introducing the highest concentration of migrating corrosion inhibitors of any SACI on the market.

For those who are open to a corrosion preventive maintenance period of seven to 10 years, MCI®-2020 followed by MCI®2018 X is a good choice. This combination takes advantage of the highest concentration of surface-applied migrating corrosion inhibitors topped by a 100% silane water repellent to keep MCI® within and slow the ingress of corrosives.

Adding Migrating Corrosion Inhibitors (MCI®) to routine maintenance slows down the corrosion process in parking ramps.

For those wanting to apply a two-inone product, MCI®-2019 or MCI®-2018 are good options. MCI®-2019 combines MCI® with a 40% silane water repellent, making it ideal for tighter budgets. MCI®2018 combines MCI® with a 100% silane water repellent for even better water repellency. These two SACIs are best applied in two coats, wet on wet, so there is no need to wait for dry time.

If a surface still has residual silane from a previous water repellent application and the scope of the project does not include its removal, MCI®-2019 can be used. This is because MCI®-2020 and MCI®-2018 may not penetrate a concrete surface which is partially covered with water repellents. However, MCI®-2019 can be applied over residual silane water repellent with better penetration through the substrate.

Whatever a parking ramp’s age, it is never too early to start creating a corrosion preventive maintenance strategy. Through routine application of a water repellent and Migrating Corrosion Inhibitor™, parking ramp owners can push back the need for corrosion-related repairs and keep their parking structures in better condition longer to preserve property value.

As the year draws to a close, companies across various industries begin to think about how to recognise and reward their employees, particularly top performers. Traditionally, many opt for year-end bonuses or grocery vouchers. However, a more strategic approach is gaining traction. Steve Mallaby, CEO of adumo Payouts, advocates businesses considering card-based incentive schemes as an alternative payout solution for year-end rewards.

“Year-end awards and incentives are common practice in many organisations,” notes Mallaby. “These rewards aren’t necessarily tied to the financial year-end, but are a way to recognise employee performance and effort throughout the year.”

He believes that year-end incentives should go beyond traditional bonuses, encouraging HR, sales and marketing heads to explore more personalised options. adumo Payouts’ card-based solutions offer this flexibility, empowering employees to choose how they want to spend their reward.

“Many companies still hand out grocery vouchers or performance awards at their year-end functions,” says Mallaby. “However, offering employees a choice –

allowing them to use their reward in a way that suits them – creates a more personal and valued experience.”

It is also an option that makes sense, particularly during the holiday season, when shopping malls are crowded and crime is rampant. A card-based option is safe and could also be used after the excesses of the silly season, when the requirements of a new academic and working year are looming. Using a reward for what is truly needed in a household can be a truly significant blessing.

This sense of personalisation is at the heart of adumo Payouts’ incentive offering. By allowing employees to decide how and where to spend their rewards, companies can foster a deeper connection between their people and their brand.

“When employees have the freedom to choose how to use their reward, it reflects well on the brand and demonstrates how much the company values them,” notes Mallaby.

The appeal of adumo’s incentive system extends beyond its flexibility. It transforms rewards into memorable experiences. “You want the reward to feel meaningful, not like just another line item in their bank account,” says Mallaby. “It should feel significant, something employees truly

appreciate and remember.”

The personalisation of these rewards adds another layer of value, instilling a sense of pride and achievement. “Recognition matters; it isn’t just about compensation,” emphasises Mallaby. “This kind of incentive has a lasting impact, showing that the company cares enough to provide a reward that suits each individual’s preferences.”

In addition to being flexible and customisable, adumo Payouts’ cardbased incentives also offer practical benefits. Unlike cash or money into a bank account, which are often subject to debit orders or garnishees, these cards provide a secure and convenient option.

“Why are businesses still doing the same old year-end bonus routine, but expecting a different result?” asks Mallaby. “We’re encouraging companies to think outside the box. With adumo, we offer a fresh, impactful approach to year-end incentive payouts that’s both simple and meaningful.”

Mallaby believes this innovative approach is suitable across all industries, making it a versatile payout solution for businesses wanting to elevate their yearend rewards. “We position ourselves as the go-to partner for companies looking to optimise their year-end incentive payouts,” he says.

For businesses looking for novel ways to incentivise their teams, adumo’s card-based incentive solutions offer a fresh, flexible and impactful payout option.

Jason Griessel, head of Cushman & Wakefield | BROLL Strategic Risk Services.

By Jason Griessel, head of Cushman & Wakefield | BROLL Strategic Risk Services

The construction industry is a powerhouse, reshaping skylines and revitalising communities. However, beneath the scaffolding, a growing threat is emerging.

In recent years, tragedies like the George building collapse in South Africa, the L’Aquila earthquake in Italy, the devastating earthquakes in Haiti and Christchurch, New Zealand, and the horrific Grenfell Tower fire in the UK have

exacted a staggering toll: over 200 000 lives lost and nearly $70 billion in damages. These disasters were more than accidents –they were the result of overlooked risks and failure to prepare for the worst.

The construction industry is not alone in its vulnerability. The oil, gas and extractives sectors have long understood that loss of life impacts share value. It is only a matter of time before SA’s construction companies are held to the same standard and some already are, due to reputational impacts.

Insurers, who play an integral part in

the construction ecosystem, growing wary of unchecked threats, are pushing for better risk management and targeted regulation enforcement. And they are not alone. As 50- and 100-year weather events become the new norm, the entire sector must adapt, taking novel approaches to the construction of assets in order to withstand such severe weather conditions and environments.

Risk is a part of life, something we all intuitively assess every day. From the moment we roll out of bed and decide whether we are well enough to face the

day, we constantly weigh threats and vulnerabilities. Yet in construction, where the stakes are highest, this intuition is often abandoned. The way many in construction approach risk is broken – and the cost of inaction could be catastrophic.

Threats, vulnerabilities and risks

A threat is anything with the potential to cause harm. Vulnerability is our susceptibility to that harm. Risk is the intersection and outcome of the two – the resulting damage and picking up the pieces afterwards.

“Risk” is often used as a catch-all phrase. However, in construction, a game lodge and an office building face different types of threats, while both ultimately being the same underlying asset – property. Marauding elephants may be a risk for the former, but not the latter. Nuance matters.

Real estate investors and speculators understand this. They conduct rigorous risk assessments for every deal, knowing that without them, they will not survive. Yet this mindset often does not extend to the actual building process. Many in the construction industry consider risk assessments a burden; a grudge purchase. Worse, they leave our biggest assets in the hands of the lowestpaid workers with the least training. This must change.

At Cushman & Wakefield | BROLL, we use models and international standards for risk management. It is an accessible, affordable and comprehensive framework that we have designed into deployable commercial frameworks which increase the likelihood of organisations achieving objectives,

identifying opportunities and threats, and effectively allocating resources to deter catastrophes or manage them better. It is a model that can be used by any organisation, regardless of size or sector.

Successful organisations and entities operating in challenging environments all deploy risk engineering. It is about using the least cost to achieve the greatest benefit. No-one wants to spend R50 to save R1, but it is worth spending R100 to save R1 000 000. This principle is at the heart of smart risk management.

Exposure analysis takes risk assessment a step further, using environmental and historical data to anticipate potential disasters. In an age of big data, there has never been more information available to learn from past mistakes and make informed decisions.

Preparedness is about taking proactive measures to prevent hazards and prepare for the worst. For example, just as you would expect from a completed building, a construction site should be prepared by having space for evacuation and responders. On the other hand, it is not about having an emergency response plan somewhere on a shelf gathering dust. If you do not know who your crisis team is, and cannot assemble them in 10 minutes, you are not prepared. If your plan is not integrated with your insurance, you are leaving yourself exposed and potentially ignoring a variety of tools to support you, either via expertise or service provision.

Response plans must be swift,

coherent and considerate. It is about communication, both with those impacted and with partners like insurers and vendors. Non-compliance is a ticking time-bomb.

The trajectory of construction’s approach to risk is unsustainable. If things do not change, insurance costs will skyrocket, making development prohibitively expensive. This will stall projects and prevent much-needed construction. The community will suffer, as will the industry itself. The status quo is no longer an option. The time for the entire construction industry to get serious about risk is now.

What more can we do to ensure safer construction?

Insisting on well-trained workers and artisans reduces construction risk. Embracing new, safer technologies, materials and equipment, where training and education are part and parcel of their use, can also make sites safer.

Then, building management systems in the design and construction of buildings, particularly for air quality control, heating, ventilation, airconditioning (HVAC) and fire, should be a prerequisite and certified. HVAC and its ongoing importance in ensuring building integrity, occupant health and safety cannot be overstated. With the advent of significant environmental events, which have culminated in rising damp in the built environment across southern Africa, I foresee dramatic changes in compliance with these systems and their impacts in the near future.

Fibre-reinforced concrete minimises labour, time and waste, resulting in long-term savings for infrastructure projects.

In today's construction industry, the twin imperatives of sustainability and efficiency are driving transformative innovations. One such advancement making waves is the use of fibre in concrete, replacing traditional steel reinforcement. This shift not only results in substantial time and labour savings

leading to significant cost-efficiencies, but also plays a pivotal role in reducing the carbon footprint associated with construction projects.

Steel reinforcement, while indispensable for its strength and durability, exacts a heavy toll on the environment. The production of steel

involves substantial energy consumption and emits significant amounts of carbon dioxide (CO₂). According to the World Steel Association, the steel industry accounts for approximately 8% of global CO₂ emissions, making it a prominent contributor to climate change.

Michelle Fick, BU development

manager: Concrete Aesthetics at Chryso Southern Africa, says that fibres, in contrast, are made from synthetic and natural materials and offer a far more sustainable alternative. Concrete containing fibres is thus easily recycled for re-use as crushed aggregates for other projects.

The environmental benefits of this shift are significant. The production of fibre materials, particularly synthetic ones, generates considerably less CO₂ than steel production. In addition, the energy requirements for manufacturing fibres are significantly lower.

“By substituting steel with fibres, construction companies can markedly decrease their carbon emissions,” says Fick, “and, unlike steel reinforcement –which often involves cutting and fitting, leading to substantial scrap material that needs to be managed – our Advil fibres can be precisely mixed into concrete, minimising waste on construction sites. This reduction in waste contributes further to the sustainability credentials of fibre-reinforced concrete.”

Beyond the environmental advantages, fibre-reinforced concrete offers several practical benefits that enhance construction-efficiency. Integrating fibres into concrete is straightforward and can be done during mixing, eliminating the labourintensive steps of placing and tying steel reinforcement.

This streamlined process significantly accelerates construction timelines. The simplicity of using fibres reduces the need for specialised labour typically required for handling and installing steel reinforcement. This not only cuts down on labour costs, but mitigates the risk of on-site injuries associated with traditional steel handling.

Fick says that while the initial cost of fibres may be close to that of traditional steel reinforcement, the overall savings in labour, time and reduced waste translate into lower total project costs over the life-cycle of the construction project.

Fibre-reinforced concrete has been successfully deployed in numerous projects, both globally and locally, highlighting both its practical and

environmental benefits. Infrastructure projects like roadways and bridges have reported enhanced durability and reduced maintenance costs due to the use of fibres.

Moreover, residential and commercial buildings have benefited from faster construction times and improved structural performance, highlighting the versatility and effectiveness of fibre-reinforced concrete across diverse applications.

Available from Chryso, Adfil’s range of high-quality fibre reinforcement solutions are designed to enhance the performance of concrete by improving its durability, reducing cracking and increasing its structural integrity. By integrating Adfil fibres into concrete, construction projects can achieve superior results. while also benefiting from the environmental advantages of reduced carbon emissions and lower energy consumption.

Adfil offers a range of fibres tailored to various construction needs, including macro-synthetic fibres, micro-synthetic fibres and steel fibres. These products are engineered to provide optimal reinforcement, ensuring that concrete structures can withstand the demands of modern construction without the drawbacks associated with traditional steel reinforcement.

“We believe that the adoption of fibre in concrete represents a paradigm shift in the construction industry and offers contractors a sustainable and efficient alternative to traditional steel reinforcement,” says Fick. “By reducing carbon emissions, minimising energy consumption and cutting down on waste, construction companies can significantly lessen their environmental impact, while bolstering their operational efficiencies.

“As the construction sector continues to prioritise sustainability, embracing innovative materials like fibre will be pivotal in fostering a greener future. These advancements not only align with global environmental goals, but position construction companies at the forefront of sustainable practices, driving both environmental stewardship and economic viability.”

“We believe that the adoption of fibre in concrete represents a paradigm shift in the construction industry and offers contractors a sustainable and efficient alternative to traditional steel reinforcement.”

The region called the Research Triangle, incorporating the North Carolina cities of Raleigh, Durham and Chapel Hill, is known as a high-tech magnet, thanks to the advances that have come out of its namesake, Research Triangle Park, which is essentially a massive, mixeduse office park focused on technology and life sciences research companies. However, one of its most recent draws is capitalising on architecture from the area’s history. The Raleigh Iron Works, a remake of an old iron foundry district, opened in 2023 to resounding

success. Its design, not surprisingly, leans heavily on its past, making ample use of architectural metal roof and wall panels to emphasise its industrial history.

The centrepieces of the new development are two former foundry structures, each named for their distinctive rooflines. The Bow Truss building, with its eyebrow roof, dates back to the 1800s, when it originally was located in downtown Raleigh. In the 1950s (just a few years before ribbons were cut at Research Triangle Park), local manufacturer Peden Steel bought

the structure and moved it to its current location for use as a welding shop. The company then erected the adjacent Double Gable building to house steel fabrication facilities. However, plant operations ceased in 1984 and the site was used for several functions, including a waste management facility, before being mostly abandoned by the early 2010s.

Developers Grubb & Ellis brought designers from the local firm LS3P and New York City’s S9 on board to design plans for the two buildings, along with

“The Raleigh Iron Works, a remake of an old iron foundry district, opened in 2023 to resounding success. Its design, not surprisingly, leans heavily on its past, making ample use of architectural metal roof and wall panels to emphasise its industrial history. ”

a new mixed-use, multi-family structure. Now the formerly derelict structures are home to a range of retail, restaurants and offices, bringing new life to an increasingly vibrant area of Raleigh.

Metal plays a prominent role in the designers’ plans, hearkening back to the site’s long history as an iron and steel producer. Both buildings

feature standing-seam metal roofs and the Bowtruss Building also features PAC-CLAD architectural metal wall cladding from Petersen. The architects, along with installers from Garner, North Carolina-based Hamlin Roofing, specified products from Petersen for the project. Today, 3 716m² of the company’s Tite-Loc Plus roofing panels in a zinc

finish top the two structures, while the Bowtruss’s walls feature an additional 2 787m² of M-36 corrugated wall panels, finished in 2022.

Reprinted with permission of BNP Media: https:// www.buildingenclosureonline.com/articles/92747metal-roof-wall-panels-connect-mixed-use-complex-toindustrial-past

• Precast concrete plasticising admixtures

• Ready-mixed concrete plasticising admixtures

• Extended workability polymers

E LTON'S REA dY MI x CONCRETE www.eltonreadymix.co.za info@eltonreadymix.co.za 082 401 8635

• Set retarding admixtures

• Hardening accelerators

• Viscosity modifying admixtures

• Form release agents

www.afrisam.co.za

• Synthetic fibres

• Pozzolan-activity mineral additions

• Permeability-reducing admixtures

CORROSION I NSTITUTE OF SOUTHERN A FRICA

011 670 5941

www.afrisam.co.za

• Water-repelling admixtures

www.cemcon-sa.org.za CEMENT & CONCRETE I NSTITUTE

• Anti-washout admixtures

debbie.harvey@za.afrisam.com 011 670 5941

• Expanding agents

hanlie.turner@cemcon-sa.org.za

The consolidated cement and concrete industry body is soaring to new heights Become a member –be part of the future

Drying shrinkage-reducing admixtures

www.corrosioninstitute.org.za admin@corrisa.org.za 0861 267 772

PAN M I x ERS SA www.panmixers.co.za quintin@panmixers.co.za 011 578 8600

www.panmixers.co.za quintin@panmixers.co.za 011 578 8600

2354 • e-mail: cindy@ashak.co.za A SHA k CONSTRUCTION www.ashak.co.za sales@ashak.co.za 011 822 2320

Air entraining and foaming agents

Evaporation-retarding admixtures

TECHNOLOGICAL INNOVATION IN THE CONCRETE INDUSTRY STARTS WITH MAP PRODUCTS.

debbie.harvey@za.afrisam.com

A SHA

• Precast concrete plasticising admixtures

• Ready-mixed concrete plasticising admixtures

• Extended workability polymers

E LTON'S REA dY MI x CONCRETE www.eltonreadymix.co.za info@eltonreadymix.co.za 082 401 8635

www.corrosioninstitute.org.za

• Set retarding admixtures

• Hardening accelerators

• Viscosity modifying admixtures

hannelie@chrysosa.co.za 011 395 9700

The consolidated cement and concrete industry body is soaring to new heights Become a member –be part of the future

• Form release agents

• Synthetic fibres

CONSTRUCTION www.ashak.co.za sales@ashak.co.za 011 822 2320

• Pozzolan-activity mineral additions

• Permeability-reducing admixtures

www.cemcon-sa.org.za CEMENT & CONCRETE I NSTITUTE www.cemcon-sa.org.za hanlie.turner@cemcon-sa.org.za 011 315 0300

• Water-repelling admixtures

• Anti-washout admixtures

• Expanding agents

• Drying shrinkage-reducing admixtures

• Clay mitigating admixtures

• Precast concrete plasticising admixtures

• Pumping aides

• Ready-mixed concrete plasticising admixtures

• Air entraining and foaming agents

• Extended workability polymers

• Concrete rescue packs

hanlie.turner@cemcon-sa.org.za

CONCRETE MOUL dS www.concretemoulds.co.za nigelbrown@mweb.co.za 082 774 4657

011 883 4627

J ESSOP & A SSOCIATES www.jessop.co.za info@protile.co.za 016 421 2521

• Set retarding admixtures

• Evaporation-retarding admixtures

• Hardening accelerators

• Viscosity modifying admixtures

• Form release agents

• Synthetic fibres

• Pozzolan-activity mineral additions

• Permeability-reducing admixtures

www.cemcon-sa.org.za CEMENT & CONCRETE I NSTITUTE www.cemcon-sa.org.za hanlie.turner@cemcon-sa.org.za

• Water-repelling admixtures

• Anti-washout admixtures

• Expanding agents

• Drying shrinkage-reducing admixtures

CHRYSO www.za.chryso.com hannelie@chrysosa.co.za

• Clay mitigating admixtures

• Pumping aides

www.ppc.africa ContactUs@ppc.co.za 0800 236 368

CHRYSO

M APEI www.mapei.com j.lewis@mapei.co.za 011 552 8476

• Air entraining and foaming agents

• Concrete rescue packs

• Evaporation-retarding admixtures

CONCRETE MOUL dS www.concretemoulds.co.za nigelbrown@mweb.co.za 082 774 4657

AVOID CONCRETE STRENGTH

www.za.chryso.com

SEPHA k U CEMENT www.sephakucement.co.za sales@sepcem.co.za 0861 32 42 52 ROCLA www.rocla.co.za info@rocla.co.za 011 670 7600

TECHNICRETE www.technicrete.co.za info@technicrete.co.za

Annemerie@Twinstar.co.za 012 670 9083

www.concretemoulds.co.za nigelbrown@mweb.co.za 082 774 4657

hannelie@chrysosa.co.za 011 395 9700

ONCRETE MOUL dS

www.concretemoulds.co.za nigelbrown@mweb.co.za 082 774 4657

M ASTER BUIL dERS SOUTH AFRICA www.masterbuilders.org.za info@masterbuilders.org.za 011 205 9000

www.twinstar.co.za

Annemerie@Twinstar.co.za 012 670 9083

TECHNICRETE www.technicrete.co.za info@technicrete.co.za 011 674 6900

High performance crystalline waterproofing admixture that enables concrete cracks to self-heal and therefore block water, even when under extreme hydrostatic pressure. It will continue to reactivate whenever water is present.

KEEPING WATER OUT:

■ Basements

■ Habitable basements

■ Parking garages

■ Utility/plant rooms

■ Tunnels

www.sika.co.za

KEEPING WATER IN:

■ Swimming pools

■ Water retaining structures

■ Dams

■ Water structures

■ Waste water treatment structures