IN THIS ISSUE:

IN THIS ISSUE:

Despite the current despondency about the economy pervading all sectors of industry in South Africa, industry leader AfriSam is upbeat about overcoming any hurdles, according to its 2024 budget breakdown, which also took into account the recent national budget speech.

The resiliance of the entire South African construction industry is inspiring. It has weathered storms ranging from economic crises to political unrest, and has unfailingly overcome these, aware that it plays an indispensable role in the future of the country. We have no doubt that it will do so again.

Equally positive have been some remarkable projects showcasing the ingenuity and efficiency of the construction sector, such as AfriSam’s new limestone quarry and Peikko SA’s completion of a school sports stadium in a near-incredible two days. Achievements such as these reinforce the power of the industry and the talent it brings to bear.

Further afield, we showcase other noteworthy achievements, including DPR taking on the tallest building in Texas, USA, the innovative use of stringless cement paving near Munich on Germany’s autobahn and a collaborative water management project between Gaza and Israel – a particularly inspiring story, given the ongoing hostilities in that region, demonstrating that the most certain way to achieving sustainable peace is through construction which serves people’s essential needs, regardless of their political affiliations.

Ultimately, our industry is the one most associated with the resolution of conflict and the creation of a peaceful future. Cause for pride indeed!

AfriSam’s relocated Ulco cement plant in the Northern Cape will be capable of providing security of supply for about 40 years and will need to deliver around two million tons of limestone to Ulco each year. The supply of readymix will include AfriSam cement.

PRECAST is independently published by Isikhova Media (Pty) Ltd

Tel: +27 (11) 883 4627

www.isikhova.co.za

Operations director: Thuli Majola

E-mail: thuli@isikhova.co.za

Design and layout: Yoland Crator

E-mail: yoland@edgehosting.co.za

Managing director: Imraan Mahomed

E-mail: imraan@isikhova.co.za

Copy editor: Anne Phillips

Media sales:

Tel: +27 (11) 883 4627 / 083 450 6052

As the important mineral component of its cement, limestone will soon be mined from a new deposit by AfriSam’s Ulco cement plant in the Northern Cape.

The relocated quarry will be capable of providing security of supply for about 40 years and will need to deliver around two million tons of limestone to Ulco each year. According to Gavin Venter, manager of Saldanha and strategic projects at AfriSam, the enabling infrastructure for this quarry has been significant.

“After conducting a number of widespaced prospecting campaigns – as well as close-spaced drilling across 100ha – we identified the best limestone reserves on our mining right on the opposite side

of the R31 national road, which runs between the new site and the plant,” he says. “This means it’s necessary to construct tunnels under the road to facilitate safe access between the new quarry site and the existing plant. Adding to the complexity is the fact that the large Gamagara water pipeline runs parallel to the road.”

The R31 which runs between Kimberley and Postmasburg carries high volumes of large ore trucks and abnormalload mining equipment. It will be diverted early this year to accommodate that traffic for about six months while extensive excavation and civil engineering work is undertaken to construct the tunnel

underpass system.

“In compliance with the road authority’s requirements, the tunnels will traverse the full 32m width of the road reserve. This will allow for future road-widening, in addition to the pipeline servitude,” says Venter. “The two tunnels themselves will be over 50m long and will be separated to enhance safety, as there’ll be counter-flow traffic to and from the plant.”

The 5m-high by 5m-wide tunnels will be excavated to 12m below the R31 road level and constructed as large culverts with steel-reinforced in-situ cast concrete. The design work ensured a tunnel alignment to suit the future possibility of an in-pit crusher and conveyer belt. If such an

option were financially justified in future, it would provide an alternative method of feeding crushed material to the existing pre-blending stockpiles.

The civils works also has to accommodate the 700mm-diameter Gamagara pipeline, supplying the Northern Cape with water from the Vaal River. To avoid the risk of disrupting this water supply, a concrete bridge was constructed parallel to the existing pipeline, inside of which a new 100m stretch of pipeline was laid.

“This provided the necessary support for the pipeline so that excavation and controlled blasting can be conducted underneath,” explains Venter. “As a further precaution, there’s a 100mm-per-second vibration limit applied to any blasting activity around the pipeline bridge.”

Work on the pipe bridge began in late 2022 and excavation work began in the third quarter of lastt year, creating the initial slot on the south side of the R31. Once the road is diverted, the excavation of the tunnels can begin and this is expected to have been completed

by March 2024. This will be followed by the construction of the two tunnels. The supply of ready-mix – which will include AfriSam cement – will come from Kimberley, about 80km south. With ambient daytime temperatures that can rise to 40ºC, this will require the careful use of admixtures to achieve the required slump by the time ready-mix trucks arrive on site.

“Mining’s expected to begin in the second half of this year, with an unusual topography in which the quarry will be mined into an escarpment,” says Hannes Meyer, cementitious executive at AfriSam. “Transportation of mined material is therefore mainly downhill. With the gradient of the haul road slopes limited to 5º, AfriSam’s truck-trailer combinations have been designed to be much more energy-efficient than conventional off-road dump trucks.”

AfriSam commissioned various specialist studies as part of its environmental impact assessment to investigate the new quarry’s potential effects on wetlands, terrestrial life, hydrology, heritage and traffic.

Authorisation was granted to mine in the vicinity of water features on the proposed mining area, with a seasonal drainage line that had to be diverted to avoid the exit slot of the new haul road.

(Below): The existing Ulco operation with the new mining area outlined.

It was a sombre tone at this year’s annual AfriSam budget breakdown event, but sales and marketing executive Richard Tomes reminded stakeholders that the company’s 90 years in business should be inspiring because the construction sector remains so resilient.

A regular contributor to the budget breakdown, Econometrix chief economist Dr Azar Jammine, highlighted that the construction and building industries were still in the doldrums, with little sign of emerging from them soon. He pointed to the low economic growth rate and the poor level of gross fixed capital formation as key culprits of the challenging milieu. While President Cyril Ramaphosa’s budget speech contained a theoretical commitment by government to focus on infrastructure, there was not much to boost confidence.

Jammine noted that private-sector capital investment in South Africa had shown some improvement, but this was mainly in machinery and equipment. Investment in construction – including civil engineering – and building had declined by 40-45% over the past decade. The slight recovery in residential building from 2020-2022, as a result of the Covid-19 pandemic, had faded.

“This is horrific and there’s little sign of it recovering,” he said. “The big loser is in the commercial space, which has fallen by 80% in terms of plans passed.”

Employment in the construction industry also continued to drop and is now 40% down from 2019 figures. The sector’s contribution to national employment is today only about 4,5%, having been over 6,5% in around 2017.

“No other sector in the economy has been performing as badly,” said Jammine. This was also reflected in the retail sales at builders’ merchants, which now ranked as

the weakest segment of the retail sector. He reiterated that crime was also a central factor in holding back progress in the construction industry and was encouraged by Business Leadership SA’s workstreams to work with government on energy, transport and crime.

“I don’t need to remind members of this audience of the debilitating effect that the construction mafia is having,” he said. “I only hope that government will listen to the private sector and involve it more in finding solutions.”

With the “semigration” of many South African professionals to the Western Cape, he noted that this province had recently taken the lead over Gauteng in terms of residential building plans passed. There

had been a slight rise in numbers in Gauteng recently, however, which could point to a revival.

According to Richard Tomes, AfriSam sales and marketing executive, the insights from Jammine confirmed that the construction industry would remain under pressure for some time. “However, what we can learn from AfriSam’s 90-year legacy is that the industry’s very resilient,” he said. “Over the past 90 years, we’ve seen good times, but have also survived very tough ones.”

He said he believed the construction sector – as with AfriSam – would come through this challenging period and continue to create concrete possibilities for SA.

The most recent incident of a fire breaking out in the Johannesburg CBD in the early hours of 3 February highlights the importance of the rational design of performance-based fire safety systems for residential buildings in particular, according to ASP Fire CEO Michael van Niekerk.

The latest fire broke out in a building at the intersection of Kerk and Goud Sts. Fortunately, no fatalities were reported, as Emergency Management Services (EMS) responded swiftly.

The incident follows the tragic fire in Nugget Street two weeks earlier, which resulted in two fatalities and four injuries. In August 2023, the Usindiso building in Marshalltown was engulfed in a fire that claimed 76 lives.

“It’s crucial to address fire safety measures and support those affected during such challenging times,” says Van Niekerk. “Proactive planning, education and collaboration are essential to prevent building fires and enhance overall safety in urban areas.”

Mitigation measures include adhering to stringent building codes and inspections. Regular building inspections must be carried out to ensure compliance with fire safety regulations. Strict enforcement of building codes, including the use of fire-resistant materials, correct electrical wiring and emergency exits, is equally vital.

Public awareness campaigns can educate residents, business-owners and building occupants about fire hazards, evacuation procedures and the importance of basic interventions such as smoke detectors and the presence of fire extinguishers.

Building managers,

security personnel and emergency responders must receive adequate training in fire prevention and response. “Conduct regular fire drills so that occupants are familiarised with evacuation routes,” urges Van Niekerk.

It is also important for the city to upgrade ageing infrastructure, including electrical systems, to prevent electrical fires. Fire hydrants, water supply systems and fire-fighting equipment need to be maintained and inspected on a regular proactive basis.

Van Niekerk urges architects and engineers to prioritise fire safety during building design. The process commences with a fire-risk consultant such as ASP Fire visiting the premises, or reviewing a set of new building plans, to undertake a comprehensive evaluation of all areas of the property and inspect all areas of fire safety and risk in detail.

All buildings in SA need to comply with the requirements of the National Building Regulations and Building Standards Act, 1977 (Act No 103 of 1977), Fire Protection, as set out in SANS 10400 Part T: 2011.

Upon completion of the fire-risk assessment and drafting the rational design report, ASP Fire provides the client with practical actions to implement.

Other measures include compartmentalisation and adequate escape routes. Fire suppression systems should focus on automatic sprinkler systems, fire alarms and smoke detectors. High-rise buildings should have pressurised stairwells for safe evacuation.

Collaboration with EMS can mean the difference between lives lost or saved. This calls for bolstered co-ordination between the fire department, police and other emergency services.

Daniel Petrov, MD of Peikko SA, a specialist company in advanced solutions for precast concrete applications, outlines its new system’s details, quality and applications in a growing African market where robust walling provides security, safety and peace of mind in both commercial and residential applications.

Precast concrete construction techniques have many advantages over conventional on-site concrete construction, particularly in repetitious elements such as wall panels and support foundations and columns. These default advantages are present in the company’s latest offering to the marketplace – the Slimline Wall System.

These benefits include ease and speed of on-site installation, dimensional accuracy, consistent quality, durability and finish, no maintenance and economy in comparison with other walling materials and construction methods.

Precast concrete walls provide high-quality assurance, as the concrete elements are manufactured in factory conditions.

Peikko is an ISO-accredited company with quality control and quality assurance measures in place which meet both local and international standards. Peikko’s mechanical connections carry CE Marking and ETA testing certifications.

Optimum quality control means that when highdensity precast concrete is produced, the result is a very durable product that can withstand impact, corrosion and acid attack almost indefinitely. The outstanding corrosion-resistant properties of reinforced concrete and mechanical connections make it ideal for precast concrete bases, columns and wall panels.

With mechanical connections added, precast elements provide lifelong support of heavy loads, whether below or above ground. As precast concrete is made in a controlled factory environment long before it is needed, curing adds strength before final erection. Final testing is undertaken, also in a controlled environment, before precast concrete walling components are dispatched to site to ensure they meet design criteria to bear the weight of the required load.

Depending on the design of a walling project, the precast concrete can be moulded to practically any size and shape, allowing architects or designers to shape it into many aesthetically pleasing designs, taking into account the structure and mechanical characteristics of each unique shape.

Perhaps Slimline precast walling’s biggest advantage is in the saving of labour and erection time on site. Eliminating the need for casting concrete at the construction site allows other construction work to be carried out unhampered while the precast concrete walling is snapped together like Lego, saving time and money.

A well-drilled assembly team and a fluid assembling technique require fewer labourers on site, lowering construction costs, which means that the process will be more cost-effective and save money. As precast concrete walling only needs a one-time installation and mechanical lifting on the site, not as many workers are required as for cast-in-place concrete.

Specialised lifting equipment and accessories are specified, detailed and used for handling (eg loading, offloading, handling and installation of all precast concrete walling elements). Over and above this, highly trained operatives are assigned to handle and install various elements by strictly adhering to processes and procedures to ensure safety on and off site.

The precast concrete walling system consists of PAD foundations, columns and walling panels. It is simple to manufacture and handle, enabling quick installation with significant cost-savings.

The Slimline Walling System is suitable for any walling projects where low, medium or high levels of security are required. Peikko recently completed a walling project which not only secured the infrastructure, but fulfilled safety considerations, preventing access by members of the public.

Cement and Concrete SA (CCSA) and its members are driving technical competence, innovation, sustainability and high standards across the cement and concrete value chains.

“CCSA provides an immense opportunity for our members to gain a holistic view of our industry by connecting with leaders and experts in their fields, while also contributing their own unique perspectives and experiences to the benefit of the larger SA cement and concrete industry and the local economy,” says Hanlie Turner, CCSA’s business development manager.

Since its inception in 2021 following the consolidation of the Concrete Institute, the Concrete Society of Southern Africa and the Association of Cementitious Material Producers, CCSA has grown its membership.

Through this large network of influencers, the body is fulfilling its mandates, which include promoting the value propositions of cement and concrete. Another priority obligation is raising awareness of the immense value that the SA cement and concrete industry creates. CCSA also supports research to increase the continuous expertise base, as well as

promoting industry standards and audit compliance among members and industry stakeholders by a cement proficiency scheme.

Members across all tiers of membership have access to CCSA’s comprehensive portfolio of services which are either free of charge or at member-discounted rates.

These include courses presented by the School of Concrete Technology, which keeps pace with the constantly evolving skills demands of the industry. A case in point is the depth of knowledge which is now needed to build more robust concrete structures that can withstand extreme climate events due to global climate change, as well as designing concrete mixes with smaller carbon footprints.

Meanwhile, new technologies are improving the design and application of concrete, placing additional demands on the skills pipeline. These include advanced admixtures, drone technology, thermal imaging and remote sensing. This is in addition to sophisticated Fourth Industrial Revolution technologies such as 3D concrete printing, with their disruptive potential that will radically revolutionise conventional building and civil engineering construction value chains.

Members also have access to CCSA’s information centre, which houses the largest resource of cement and concrete research in sub-Saharan Africa. This includes more than 150 000 pamphlets, articles and papers, more than 4 000 books, the latest conferences and symposia proceedings and subscriptions to 120 local and international periodicals.

Moreover, members attend CCSA’s CPD-accredited technical events and webinars, as well as events of local interests arranged by the three branch committees. Members also receive mention in Concrete Beton, CCSA’s quarterly electronic magazine.

Corporate membership provides access to affordable and targeted marketing for companies to broaden their reach, create brand awareness and remain competitive and relevant in the market. Included on CCSA’s database, nominated representatives of these organisations are eligible for the benefits accruing at the particular membership level.

However, at the core of CCSA’s success are the many individual members and representatives of company members. These professionals – specifiers, contractors, industry enthusiasts, academics, students and retired construction stalwarts – all value acquiring relevant current knowledge and the opportunity to collaborate and network with peers to stay abreast of the latest cement and concrete industry developments.

“We encourage more individuals and companies to connect with cement and concrete leaders and experts, while also building their professional networks. There’s strength in numbers, with collaboration between industry stakeholders even more important during difficult economic conditions. This is when academics, other professional bodies, companies spanning the entire cement and concrete industry value chain and professionals must work together to find solutions to wider industry challenges. We’re providing a platform for that, while also serving as a single voice for our industry to address industry concerns at the highest level,” says Turner.

The World Cement Association (WCA) has endorsed global government efforts to advance low-carbon cement and concrete production, announced at the 2023 UN Climate Change Conference (COP28) in Dubai.

The commitments made by Canada, Germany, the UK and the USA, member countries of the Industrial Deep Decarbonisation Initiative (IDDI), include adopting time-bound commitments to procure low-emission cement and concrete, as well as steel. This pledge aligns with the WCA’s initiative to support a sustainable cement industry, encouraging technical development and innovation by its members to help achieve full

decarbonisation by 2050.

The collective commitment of IDDI members to leverage their considerable national purchasing power to drive demand for low- and near-zero emission materials is a welcome pledge to accelerate the decarbonisation efforts of heavy industries globally.

Despite these commitments to addressing and mitigating the environmental challenges associated with industrial activities, a substantial gap exists in sustainable infrastructure financing for developing countries, requiring an estimated $15 trillion by 2040. It is not currently clear how this gap will be bridged, with measures announced so far

unlikely to have a significant impact. The cement industry has reduced per ton emissions by 23% since 1990, with the majority of this reduction coming between 2000 and 2012. To meet 2050 net zero goals, we need to see an acceleration of progress. With nearly 90% of cement produced in emerging economies, it is essential that this is a worldwide effort.

“The WCA has always emphasised the need for immediate and collaborative action between government and industry to make carbon-negative concrete a reality at scale. Creating demand for low-emission materials is essential for decarbonisation. Now is the time to work together to make necessary progress this decade,” stresses Ian Riley, WCA’s CEO.

At the end of 2023, some 30 000 building industry employees in the Western Cape received more than R200 million in bonuses and leave pay, thanks largely to the efforts of the Building Industry Bargaining Council (BIBC).

The BIBC in the province has been instrumental in ensuring hundreds of thousands of workers continue to benefit financially, despite a stagnant national economy still battling the fallout of the Covid-19 period.

Danie Hattingh, principal officer of the BIBC, says the Western Cape sector has been a shining example to the rest of the country.

Over the past eight quarters, the Western Cape has performed best among the country’s largest construction employment contributors, boasting an average growth of some 8%.

The council’s resilience was severely tested at the height of the pandemic, yet it was still able to sponsor retirement fund contributions of compliant employers and employees for seven months. Its unwavering commitment to stakeholders has remained as the industry has stabilised in the past two years.

The BIBC’s effectiveness lies in its model of holding employee benefits in provision

and paying workers directly. This means that the employer is released from the burden of having to find funds for annual leave pay and holiday bonuses because the business already pays a proportion of the daily labour rate for this purpose.

Furthermore, the body – which boasts 97 staff – carries tremendous weight in terms of its legislative standing. In addition to the council’s accreditation with the Commission for Conciliation, Mediation and Arbitration (CCMA) in February 2023, the Financial Sector Conduct Authority issued new regulations to give the council further power to not only enforce, but report under the Pension Funds Act 24 of 1956.

However, the BIBC also embraces an approach of trying to help so that employers do not fall foul of dispute resolution procedures.

According to Hattingh, it has embarked on multiple projects to ensure fair treatment for all.

This is particularly relevant to employees who, for example, have worked for 30-35 years and suddenly find themselves retrenched. By having their pension fund contributions paid over for reinvestment purposes, they have some money to fall back on in the event of a

sudden loss of income.

The organisation is also playing an important role in guiding building industry stakeholders through recent developments that may affect their financial contributions.

One of these recent developments is the “two-pot system”, where employees will be able to draw against their retirement funds savings from September 2024.

Another development is the proposed National Health Insurance (NHI) plan, but the council has again pulled out all the stops to establish any potential impacts on beneficiaries and guide them through the process.

Hattingh adds that this year, the BIBC will be focusing on increasing membership of employer organisations and trade unions and building these relationships. It will also emphasise the importance of the BIBC as the recognised collection agent that overcomes delays in the collection and distribution of employee benefits and party levies.

“By registering with the BIBC, we can create a fair and sustainable building industry. We’re stronger together,” says Hattingh.

Sungrow, the leading force in smart energy solutions worldwide, remains dedicated to alleviating South Africa’s persistent struggle with load-shedding, a challenge which appears to be ongoing, despite the heroic announcements from government that it is making progress in ending the crisis.

With recent extreme weather conditions in summer and more extreme weather expected in winter (if the record-breaking highs and lows experienced in Europe are anything to go by), frequent and impactful power disruptions must be expected – and provided for.

In response to this, Sungrow introduces an innovative residential solution which not only ensures uninterrupted power during load-shedding stages, but also maximises the returns on consumers’ photovoltaic investment.

Sungrow’s residential solution is strategically designed to align with the specific power cut landscape in the country. It is a purpose-built system that caters to the back-up needs at every stage of load-shedding, delivering a reliable and noise-free power supply.

Sungrow’s residential solution now boasts a state-of-the-art high-voltage lithium iron phosphate (LFP) battery. This advanced energy storage technology ensures high performance, enabling up to 30A continuous charging and discharging

current with exceptional efficiency. The multi-stage protection design and extensive safety certifications guarantee a secure and reliable power source for homeowners.

The organisation’s high-voltage LFP battery offers unparalleled flexibility, allowing for an extendable lifetime and support for three to eight modules per unit. With a maximum of four units in parallel, the system provides a wideranging capacity from 9-100kWh. This adaptability ensures that the solution meets the unique energy needs of each household, promoting energy independence.

The high-voltage LFP battery is engineered for convenience, featuring a compact and lightweight design that allows for single-person installation. The plugand-play functionality eliminates the need for cumbersome cables between battery modules, streamlining the installation process for homeowners.

“We’re committed to providing sustainable and hassle-free living solutions to every household in South Africa. We also offer customers a 24/7 service hotline on which homeowners can rely for assistance whenever needed, ensuring continuous support for a hassle-free experience,” says Sungrow.

In what is believed to be the first of its type in South Africa, specialist designer, manufacturer and supplier of structural and precast concrete construction elements Peikko SA reports on the construction of a school sports pavilion in the record time of just two days.

Winston Visser, Peikko’s project engineer, says the company was approached by the professional team’s quantity surveyor with a proposal to construct a new sports pavilion at the Springvale Primary School in Centurion. The school currently has 1 800 pupils and requires infrastructure to accommodate its growing numbers during sports days.

“A major concern of the school’s management was that erecting a sports pavilion by conventional on-site construction methods was both timeconsuming and presented safety hazards from inquisitive onlookers. The Peikko SA team presented the inital design and gave the assurance to the professional team and the school’s principal that the pavilion would be erected in just two days, with no compromise to safety,” explains Visser.

He adds that the design, which incorporated both male and female changing rooms and ablutions, 120m2 of storage space for sporting equipment and an aesthetically pleasing off-shutter finish to the seating panels, found favour and construction commenced off site.

“Close co-operation with the contractors of the raft foundations ensured that the placement for the precast column’s anchor

bolts were accurately positioned – a critical element in the build. Columns and seating panels, as well as the later addition of stairways on each end of the pavilion, were all manufactured off site in a factory environment, which ensured quality control and element accuracy while minimising environmental emissions normally found on site with conventional construction. This was appreciated by the school’s management in a setting where children are present.”

Visser adds that the manufacture of the building elements with all the necessary cast-in Peikko mechanical connections was scheduled to coincide with the completion of the raft foundations and after the delivery of just five loads of precast elements, the erection of the pavilion was completed in the promised two days, to the astonishment of both the principal and the professional team.

“The speed of the on-site installation is a major advantage of the Peikko system of precast element design and its system of the mechanical connections is that site erection is both quick and easy, with each ‘piece’ fitting like a glove.

“The school’s management were so impressed with the fit and finish of the final product that they’ve ordered a second pavilion to be built this year. The overseeing architects have also concluded a marketing agreement with Peikko to promote its technique, which is expected to find favour in rural communities seeking similar sporting facilities,” says Visser.

Infrastructure projects provide essential services and other benefits to people from all walks of life and play an integral role in the welfare and economic stability of a nation. However, it is often difficult for developers and clients to measure how impactful and successful a project will be once completed.

“While every precaution is taken in the planning and construction phases to ensure the structure’s long-term durability and utility, the only true measure of a project’s capabilities is how people use it every day,” explains Olebogeng Manhe, chairperson of the Gap Infrastructure Corporation.

“Post-analyses help determine whether what we deliver is of value and meets the needs of the client and especially the communities we serve. It further identifies potential future issues that the system may experience, what the longterm maintenance requirements will be, what additions need to be made and how developers can improve upon their processes in future projects.”

Post-project analyses are systematic and comprehensive assessments of the project’s performance, outcomes and impact after

its completion. These assessments can be conducted at different levels and stages, depending on scope and evaluation.

For example, some analyses may focus on the technical aspects of the project, such as the design, construction, operation and maintenance of the infrastructure. Others may focus on the economic, social, environmental or institutional aspects of the project, such as the cost-to-benefit ratio, stakeholder satisfaction, environmental impact, or governance and accountability.

There is no one-size-fits-all method for measuring the impact and success of infrastructure projects. Different projects may have different objectives, characteristics, contexts and challenges that require different approaches and indicators. However, some general steps and principles can guide the process of developing and applying appropriate methods.

Firstly, it is important to define clear and relevant measures of success that reflect the project’s objectives and

value. These measurements should be aligned with the expectations and interests of the stakeholders involved. For example, a public-sector client may be more concerned with the social and environmental benefits of an infrastructure project than a private-sector contractor who is more focused on financial returns.

Secondly, it is essential to collect reliable and valid data to support the measurement of success. This may involve using various sources and methods of data collection, such as surveys, interviews, observations, records or sensors. Some data may be

quantitative, such as numbers or statistics. Others may be qualitative, such as opinions or stories. The data collection should be planned and conducted in a systematic and ethical manner.

Thirdly, data must be analysed and interpreted to draw meaningful conclusions and recommendations. This may involve using various tools and techniques of data analysis, such as descriptive statistics, inferential statistics, regression analyses or content analyses. The analysis should be rigorous and transparent, with clear assumptions, limitations and declarations of uncertainties.

There are a few methods that can help both infrastructure developers and their clients measure the impact and success of a project.

A fault-tree analysis is a graphical technique which identifies and analyses possible causes that may lead to an undesired event once the infrastructure is

in use. The method uses logic symbols and rules to represent the relationships between events and to calculate their probabilities. A fault-tree analysis can be drawn up directly after a project’s completion, using simulated data to determine what future issues may come to pass.

Georeferenced data, in combination with demand peak indicators, reflect the highest level of demand for or usage of a completed project, using real-time geographic location data. This analysis can be used, for example, to monitor peak traffic periods and high traffic loads to estimate how well a road or bridge will function in certain circumstances, what future maintenance requirements will be and when the said road or bridge will need large-scale repairs or replacement.

Similar to demand peak indicators, a demand forecast analysis can be used to estimate future demand for an infrastructure project based on various factors such as population growth, local

income level changes, user behaviour and other trends that would affect how people will use the infrastructure.

Finally, an accessibility analysis measures how accessible infrastructure is, whether the service is easily or conveniently reachable or available to users, whether there are any gaps or disparities in access coverage and whether there are opportunities or challenges to be improved upon.

“By using some of these methods to measure the success of our projects, project developers can improve the quality and functionality of future projects, enhance decision-making processes, optimise resource allocation and increase client and user satisfaction. By being more aware of our successes and failures, we’re able to improve and implement enhanced techniques with every new project, ensuring that South Africa’s infrastructure continues to improve over time,” says Manhe.

It has been said that everything is bigger in Texas – and Waterline is no exception. It will be the tallest building in Austin, taking the city’s skyline to new heights. As the general contractor, DPR must self-perform the concrete for the 74-storey mixed-use “super-tall” with higher predictability, less rework and reduced risk.

Topping out at 311m tall, it is the most challenging self-perform concrete project in the history of DPR Construction, a global self-performing commercial contractor based in Austin. Bringing the super-tall to life is a complex orchestration of workflows, people and technology that must come together with precision.

The Waterline site is congested, surrounded by busy streets and another construction project to the south, making planning and co-ordination an important aspect of keeping the project on target. From bid to build, data-rich, constructible models and collaboration in a common data environment are foundational to DPR’s approach.

A clear plan, early alignment, virtual design and construction In a workflow, the company describes as “left of the line” DPR’s bidding process for Waterline, which began with modelling the structural design in Tekla Structures. Going beyond traditional cost projections and value engineering to create a constructible model engages project teams early and establishes a clear plan from the very beginning.

“This part of our workflow is focused on getting as much accurate data into the model as possible,” says Rafael Valles, virtual design and construction (VDC) engineer at DPR. “In Tekla, we can model to a high level of detail, so we aren’t just modelling the concrete, for example. We’re modelling the rebar elements within the concrete and the pour breaks to ensure that the square metreage is accurate. We’re bringing in our scheduling team to ensure that the production rate, schedule and crew sizes are feasible. It’s this level of effort and engagement upfront that makes us different.”

DPR’s VDC and project teams use the

Tekla model to visualise what they have been asked to build. Trimble Connect is the common data environment used to collaborate in the model and identify and solve issues and discrepancies – before the work is won. DPR considers this early alignment essential for establishing trust and bidding with confidence.

“Bringing key project teams into the Trimble ecosystem to review the model early on breaks down silos and builds trust from the very beginning,” says Matt Lagusis, central SPW VDC manager at DPR.

“Modelling the project to a high level of detail in the bidding process is more than just creating a source for accurate quantities – it sets the tone for everything we do after the job’s won. It allows us to adjust and align early so that when it’s time to build, we can rock ’n roll. Field teams don't have to stop and think about how it’s supposed to be done, because those stones

have already been turned over.”

When DPR has cross-team alignment on the Tekla model, its estimating team brings the data into WinEst, where accurate quantities are combined with the company’s project and cost history to generate the bid.

For DPR, every bit of data incorporated into the model is another step closer to optimising speed, efficiency and accuracy. A driving force behind the company’s emphasis on constructible models is the vision to work within a common data environment that everyone involved in the project can access.

“We truly believe that constructible data and the ability for it to flow up- and downstream sets the tone for a successful project,” says Rayya Karaa, VDC project manager at DPR. “As we transition from modelling in Tekla to consuming in

“We used virtual mock-ups in Tekla & Trimble Connect to reduce the risk of project delays and ensure that all of the #18 bars would fit together with all of the beam rebar and post-tensioned cables.”–

MattLeguisis,concreteVDClead:CentralRegion

Trimble Connect, every trade involved in Waterline can access co-ordinated information and share, review and comment on data-rich models. We’re pulling everyone out of silos and into Trimble Connect to collaborate across trades and avoid problems in the field. Having a common data environment to push data back and forth across different file types has been transformative, especially as we’re co-ordinating across numerous trades and partners on Waterline.”

DPR uses the concrete model for building information modelling coordination and QA checks against other models. Using Trimble Connect, DPR brings models across trades together to visualise and resolve conflicts between them before construction begins.

“We’re able to bring file types from different applications into Trimble Connect and use them for reference and co-ordination,” says Adam Cieslak, project manager at DPR. “It allows us to see the project come together from various disciplines and opens the door

to constructibility conversations. With Trimble Connect, we can easily see when things don’t match up across disciplines and address them a lot sooner.”

The teams working on Waterline also use the ToDo feature in Trimble Connect to assign, track and resolve issues across trades. For Reuben Flores, a steel detailer with Patriot Erectors, ToDos has been instrumental in keeping the project on track.

“We’re working on tight timelines and staying on track to get material to the site has been a challenge,” he says. “Trimble Connect has streamlined communication and co-ordination among our detailing team and with DPR. Trimble Connect allows us to overlay trades in the model and zoom in on potential issues. From there, we create and assign ToDos to get problems resolved. The person assigned to the task can visualise the issue at hand, which makes the conversation much more efficient. For example, we don’t have to explain that on level 5, area B, we have an issue. It eliminates hours of sending e-mails back and forth trying to describe

the location of the problem. With Trimble Connect, we’re able to work much faster.”

Accurately modelling formwork and planning pours

“Planning the slickline in order to pump concrete was very important. We’ll be wrapping up level one while pouring concrete up top. Everything has to run smoothly because we’re going to get to a point where we’ll be pumping concrete over 305m high into the building. We need to visualise what’s going on”, says Doug Nettles, Concrete VDC lead.

Concrete pours are planned in Tekla Structures. Using the model, DPR’s selfperform concrete team runs animations for various scenarios to verify that schedules and quantities are aligned. Concrete pours for Waterline will span two years and construction on lower levels of the building will still be underway when the concrete is pumped across a bridge, over 64m through a high-pressure pipe, up through the core wall which will eventually be 311m. The pipe carries the concrete through the core wall to the top level,

where it is pumped through a placing boom and goes into the active pour. When one truck finishes, another one is waiting behind it.

Although the pipe is temporary, its placement is critical. “Everything we needed to ensure the pipe wouldn’t interfere with other trades was already in the model,” says Nettles. “We sat down with the concrete pumping sub-contractor, pulled up the model in Trimble Connect and turned on every trade. This allowed us to ensure, for example, that drilling a hole to accommodate the pipe wouldn’t cross an electrical line or interfere with other trades. This alignment across trades is incredibly important and informs us where the pipe is placed and how we should plan and sequence the pours. When we’re planning concrete pours, we have to look at the big picture – and Trimble Connect allows us to do that.”

DPR also modelled all of the complex locations of Waterline’s formwork, including custom formwork to accommodate the building’s sculptural columns and sloped columns, and cantilevered decking and shoring in Tekla Structures.

Working in 3D, DPR can visualise and organise formwork quantifications according to location, pour type and sequence. The models are shared with the formwork supplier, who uses the data to

inform the CNC machine and produce the formwork components. Downstream, field teams access the formwork models on tablets in the field using Trimble Connect to streamline installation, keep formwork moving and eliminate guesswork.

Most recently, DPR simplified its technology stack with a subscription to Trimble Construction One, a connected stack of Trimble solutions that bring people, data and workflows across the company together in a shared environment.

“With Trimble Construction One, we don’t have to worry about purchasing licences when we want to bring a new team member into a workflow,” says Jacob Skrobarczyk, VDC technology leader at DPR. “It’s been easy to scale and bring in other team members.”

From the office to the field, a wide range of Trimble solutions are helping DPR deliver Waterline on time and within budget. “We’re using a combination of WinEst, Tekla Structures, Tekla Structural Designer and Trimble Connect, all of which are connected through Trimble Construction One,” says Skrobarczyk.

“Trimble solutions are an essential part of our workflow across every project

phase, from the initial pursuit, when we’re conveying the benefits of our selfperforming concrete team to the owner, all the way to the craft and foremen working in the field.”

With access to a full stack of Trimble solutions through its Trimble Construction One subscription, DPR can easily explore bringing other technologies into its workflow. “We’re always pushing forward and trying new things,” says Skrobarczyk. “We’re testing Trimble Connect AR and FieldLink on a project now and it’s amazing. The collaboration on multi-trade models and being able to co-ordinate steel, rebar and concrete on three separate models at the same time is going to be a game-changer for us. We’re barely scratching the surface of what it can do and looking forward to applying it to new workflows.

“Being able to bring a wide range of Trimble technology into our workflows allows us to push the envelope, try new things and optimise project delivery.”

The Middle East is an arid region which is highly vulnerable to the effects of climate change. There is an essential need for solutions that offer equitable access to water and sanitation, and that protect Israel and the Palestinian territories’ shared water resources.

A dry region with a growing population

Israelis and Palestinians living in Israel, Gaza and the West Bank have a combined population of roughly 14 million. Both populations are growing at nearly 2% annually, compared with 0,4% per year for high-income countries. As the populations grow, so does the demand for water.

The average yearly per capita water supply for the region is less than 500m3/ per capita. According to the UN and other experts, this amount is at the upper threshold of absolute water scarcity – the level at which nations cannot meet all demand, especially the large amounts needed for agriculture, and have to restrict water use. For comparison, in 2015 the USA used 1 207m3/per capita of water.

Israel and the Palestinian territories’ main freshwater resources are the Jordan River system and two groundwater aquifers – one along the Mediterranean coast and the other beneath the central Judean Mountain range. Palestinians in the West Bank have access mainly to the mountain aquifer system, while those in Gaza use the coastal aquifer. Israel uses both.

The 1993 Oslo Peace Accords included

provisions allocating water between Israelis and Palestinians, but ongoing conflict and continued disagreements have hindered updating these agreements to reflect rising water demand.

Since the foundation of the state of Israel, access to water resources has been as central to the nation’s conflict with the Palestinian people as competing claims to land. Israel has partially decoupled itself from water scarcity by building desalination plants along the Mediterranean coast.

In the West Bank, Israel’s continued occupation has impeded Palestinians’ ability to develop their own water network that could distribute water across the population. The situation in Gaza is even more dire.

Even before the current Israel-Hamas war, Gaza had a massive water deficit. Its main source is groundwater, which has been significantly over-pumped and is now so salty as to be undrinkable due to seawater intrusion into the aquifer.

Before the war, most Gazans relied on private water vendors and a few small desalination plants for drinking water.

Israel also piped about 10 million cubic metres of water each year into Gaza. Yet, all told, the water supply is not large enough to meet the entire population’s needs. Now, because of the war, no fuel is entering Gaza to run the desalination plants, leaving them inoperable.

Israel has turned off water and fuel shipments to Gaza in order to punish Hamas. This strategy has turned a disaster into a catastrophe that is only likely to get worse.

It is unlikely that the lack of access to drinking water and sanitation will cause Hamas to lay down its arms. However, it is already bringing additional misery to the civilians of Gaza and giving them further reason to hate Israel, and will add to international condemnation of that country.

UN officials are warning that lack of water and sanitation will precipitate an enormous health crisis which will particularly affect women and children. It could lead to outbreaks of waterborne diseases that will spread rapidly across Gaza’s crowded and besieged population.

Gazan hospitals are already overwhelmed with casualties and lack water and electricity.

Studying approaches to managing water and other environmental resources, the Arava Institute for Environmental Studies is a non-profit teaching and research centre in the south of Israel. At the institute, students and academics from Israel, the Palestinian territories and Jordan come together to learn from

each other and work together, developing technologies and programmes that meet the region’s water needs. This collaboration creates understanding and friendships which defy the ongoing conflict.

From 2019-2023, the Arava Institute has worked together with a Palestinian non-profit group, an Israeli water tech company called Watergen and the Friends of the Arava Institute, a USA-based nonprofit, to install seven atmospheric water generators to Gaza. These devices, which pull humidity from the atmosphere and turn it into high-quality drinking water, run on solar power to ensure round-theclock operation in the energy-poor Gaza Strip.

The institute also installed the first generator in a small municipality in central Gaza, along the border with Israel, in 2019. The second, larger generator was installed in a major hospital in central Gaza in 2020. During the hostilities between Hamas and Israel in May 2021, when water supplies were cut off to many communities, these generators were the only sources of drinking water for many people in the surrounding communities.

In 2023, funds were raised to install five more water generators at medical facilities throughout Gaza. According to David Lehrer, director of the Arava Institute’s Track II Environmental Forum, two generators in southern Gaza are still working and are the only sources of clean drinking water in the region. The fate of the other units is unclear.

In a separate project in 2020, Arava and its Palestinian partners installed a pilot mobile wastewater treatment plant in a Gazan village. The plant treats 100m3 of

“People from both sides have histories of trauma and grief and, in most cases, very little experience of each other. However, working together on shared water challenges can bring people together.”

wastewater per day, serving around 1 000 residents, and produces treated wastewater which is of sufficiently high quality to be used in agriculture. It is estimated that about 25 of these mobile treatment plants could cover all of the village’s needs.

Many rural villages in Gaza have no centralised wastewater treatment system. Wastewater is collected in unsanitary cesspits in the middle of the road between houses. Raw sewage runs in open ditches from homes to the cesspits, which residents pump out around once a month.

Sewage then would normally be

Weaponising water – one of the most crucial requirements of both warring sides.

transported to a wastewater facility to be treated. However, now, because of the war, without fuel for electricity, wastewater plants in Gaza are not working. Raw sewage is being dumped into ecologically important coastal wetlands called wadis and into the Mediterranean Sea.

This environmental and public health catastrophe also affects Israel. The Israeli seawater desalination plant in Ashkelon is only a few kilometres north of Gaza and cannot operate if it risks pulling in polluted seawater. Over the years, lack of adequate sewage treatment in Gaza has caused the plant to periodically halt operations.

Working closely with Israeli and Palestinian partners is not easy. People from both sides have histories of trauma and grief and, in most cases, very little experience of each other. However, working together on shared water challenges can bring people together.

An alternative future is possible – a future that is grounded in a sense of shared humanity and respect. Indeed, we believe it is the only future that is possible for the intertwined reality of Israelis and Palestinians.

Applying

Is it possible to give concrete too much protection against reinforcement

corrosion? Research indicates that this is so, although no consensus exists on the exact mechanisms and how to avoid it.

However, following logical reasoning, Cortec® recommends applying migrating corrosion inhibitors to mitigate the problem.

Over-protection occurs when metal reinforcement in one part of the concrete is more protected than in another. This can happen when a new concrete

patch is laid, replacing contaminated or carbonated concrete with uncontaminated concrete that has a high pH and therefore a naturally protective alkaline environment. The resulting difference in corrosion potential between the patch and the adjacent concrete eventually leads to corrosion in surrounding areas, thus transferring the original problem elsewhere. This is known as the ring anode/halo effect.

Over-protection can also happen in a variety of other ways. One is through

the common practice of cathodic protection. The challenge of calculating the appropriate number of anodes for an area and removing concrete to install them is compounded by the fact that it is impossible to gain access to and treat all parts of the rebar equally. This leaves some portions of the metal reinforcement with more protection than others, an imbalance that could show itself over time by corrosion in areas with less protection. A similar effect may happen with the application of an epoxy coating to one part of a rebar and not to another. Using other corrosion protection measures may

cause a similar imbalance when over-applied.

The use of MCI® Surface Applied Corrosion Inhibitors (SACIs) makes it easier to balance the corrosion potential. Rather than leaving a well-protected patch surrounded by chloride-contaminated concrete, contractors can apply MCI® SACIs to the undisturbed concrete in an effort to reduce the difference in corrosion potential between two portions. Fortunately, MCI® SACIs are easy to apply by spraying onto the concrete like a standard surface treatment. As time progresses, migrating corrosion inhibitors in the MCI® SACI work their way deeper in through the concrete pores toward the metal reinforcement. Their affinity to metal allows them to form a protective molecular layer on the embedded rebar when they encounter it.

MCI®-2020 contains the highest

concentration of surfaceapplied migrating corrosion inhibitors on the market and is therefore the primary recommended SACI for this purpose. Typically, a coating or water repellent should be applied on top of this to keep moisture out and MCI® in. Two-in-one MCI®/water-repellents are also available for greater convenience, albeit with smaller doses of migrating corrosion inhibitors (MCI®-2018 combines MCI® with a 100% silane water-repellent and MCI®2019 combines MCI® with a 40% silane water-repellent).

Concrete repairs are too labour-intensive to make the mistake of over-protection. By being sure to protect the concrete around the patch area with migrating corrosion inhibitors, contractors can take one step ahead of the chain reaction of corrosion that is common in less protected areas.

Innovation, quality and capability are hallmarks of a Pan-African trailblazer, so it came as no surprise that Macsteel, a leading manufacturer, merchandiser and distributor of steel and value-added steel products, was first in line to take up the highly sought-after Pan-African Trailblazer sponsorship opportunity at the 2023 SA Institute of Steel Construction (SAISC) Steel Awards.

Trailblazing innovation was also the mainstay of one of the awards’ most exciting category winners. The Azmet Reactors project – which won the Mining and Industrial as well as the Best Export Project categories – comprised a combination of six colossal reactors in the Democratic Republic of Congo (DRC).

This distinctive project was recognised for its precision engineering, use of steel and ability to overcome seemingly insurmountable logistical challenges. It also represented the innovation, tenacity and foresight which Macsteel’s CEO Mike Benfield believes reflect the spirit and essence of what it means to be a panAfrican trailblazer.

In addition, the project is closely aligned with Macsteel’s operational ethos of “Pursuing Reinvention”, which in turn reflects and supports the Pan-African Trailblazer sponsorship concept.

Benfield believes it is important to support organisations such as the SAISC, which provides a platform for members of the steel value chain to drive a common agenda in the sector, while also fostering a “Team Africa” ‘approach to quality and collaboration across the continent. This is increasingly important, as the African Continental Free Trade Area (AfCFTA) agreement becomes a reality.

“The SAISC Steel Awards also encourage innovation, which is the ethos and mantra we live by. We’re roleplayers in a very old field, so we need to continuously innovate and improve the way we do things. The whole steel sector needs to reinvent itself. We need to make people think about steel in different ways,” he says.

In the Macsteel ethos, steel touches every aspect of people’s lives and, indeed, society as a whole. The best feature of the Steel Awards, according to Benfield, is that the entire steel supply chain is recognised: not just suppliers, but also the architects, fabricators and contractors involved in projects.

“Furthermore, in pursuing reinvention, Macsteel advocates for the entire steel value chain – including clients – to consider steel in ways which are different, unusual and more cost-effective. We have to begin thinking of steel as more than only a material of construction: rather, it can be a construction innovation, or an architectural feature, emphasising safety and aesthetics. Any construction – from the mining to the residential sector – can showcase the innovative use of steel, elevating and reinforcing its relevance throughout a broad spectrum of sectors,” says Benfield.

“There are several examples in our own operations where we’ve successfully combined innovation and reinvention. A recent high-profile example is the Pick n Pay Distribution Centre East Port project, joint winner of the 2023 Steel Awards Factory and Warehouse category, the Innovation and Sustainability category and recipient of the Best Project Gauteng award.

“One of the stand-out features of this project was the need for extremely long roofing sheets and a unique roof curvature. Both of these challenges were easily overcome through the application of Macsteel’s innovative ‘sky-forming’ method to roll and shape the roofing sheets accurately and cost-effectively. A crowning achievement was that this earned the project a place in the Guinness Book of Records for the longest continuous roof sheet.

“Another innovation example is a product we produce, cellular steel beams, a modern version of the traditional castellated beam, made from a patented double-cut profiling process to achieve greater load-carrying capacity and

stiffness. Cellular beams offer a far wider range of applications to achieve long, clear spans, service integration and shallow floor depths. The product’s also aesthetically pleasing – an appealing trait for architects! These are the kinds of solutions we can provide while steel projects are still in the design stage,” he explains.

Another key factor in Macsteel’s eagerness to be the Pan-African Trailblazer sponsor is the fact that it focuses on Africa and the capabilities of the SA steel sector in completing excellent Pan-African steel projects. Benfield emphasises that with a vast amount of infrastructure required, Africa is still “under construction” – which creates massive opportunities for local steel companies.

“In Africa, the fundamental building blocks are there, but further beneficiation must be targeted for the continent to achieve its fullest potential. Only basic commodities are currently being produced. However, beneficiation is now almost a requirement for viable Pan-African economic growth. Therefore, innovation and reinvention are needed more than ever before. Beneficiation will grow the economy and, when this happens, it drives the demand for steel. This then becomes a self-fulfilling cycle of demand.

“African economies depend on commodities and steel has a crucial role to play in driving further beneficiation, downstream of the basic commodity. The use of steel is integral to mining and the lives of mines can be extended when costs reduce. Through the use of steel and innovating around it, this can also be achieved. The ore body becomes

more viable when a mine becomes more efficient. In this way, the entire future of the mine is extended, along with the entire mining community which it supports,” Benfield points out.

However, he concedes that in Africa, the greatest challenge is that cost remains a determining factor. “The prevailing view seems to be that ‘tomorrow will be better, but today there’s only so much to spend’. As a result, from the SA steel sector perspective, we should be fabricating and supplying innovatively, highlighting the benefits of steel as a material of construction. We need to focus on the pain points our clients will encounter during design and construction – and set about finding creative, new ways to use steel to meet those challenges.”

As Benfield notes, most African governments tend to be vague and contradictory when it comes to economic policy and its consistent application, which can be a grave impediment to the contribution of steel in growing the economy. On this point, although the evolution of a buoyant steel industry can create jobs, stimulate manufacturing and localisation, a stable local economy is definitely a prerequisite.

There is also a pervasive distrust of the private sector, which often prevents governments from working together with companies to constructively address pressing infrastructural and developmental issues.

“Governments need to collaborate with the private sector to build PanAfrican economies. The private sector has

capital, can secure financing and absorb a certain amount of risk. It also has the relevant experience and skills to invest in a discernible trajectory. However, when economic growth is predicated on stateowned enterprises which are hamstrung by corruption, progress stalls. Governments need to change the way they think,” he says.

This brings him back to the importance of the Steel Awards.

“When excellence and high standards become the baseline of a project, opportunities abound as the demand for quality grows and the cost of quality reduces due to economies of scale. This needs to start right at project inception, with the architects, specifiers, designers and fabricators. By setting high standards from the outset and investing in lowering the total cost of the project, over its entire duration, a far higher value is achieved for its owners and stakeholders,” he emphasises.

He also acknowledges that local steel sector companies cannot compete with their Asian counterparts when it comes to the price of the material. This requires Africa to fix its internal issues to become more competitive and build an export footprint. Here, the “Team Africa” concept will play an important role.

“By working together, we can pool our skills and resources, build relationships and improve competitiveness. South Africanbased steel value chain participants must also remember that their greatest asset is that they’re resilient, resourceful – and that they know and understand the continent,” says Benfield.

To allow Eastgate Shopping Centre in Gauteng to upgrade its heating, ventilation and air-conditioning (HVAC) facilities for greater energy- and water-efficiency, Concor is carefully strengthening the structure on which the heavy new chillers will rest.

Concor contract manager Martin Muller explains that the HVAC system is located on top of a building on the centre’s roof parking area, in which tenants are active – and need to continue trading during the renovation. Aside from the technical elements of the contract, therefore, clear and ongoing communication with the client and the tenants is a crucial aspect of success.

“The construction work includes the demolition of an existing roof, walls and slab above tenants,” says Muller. “The

structure will then be strengthened to ensure that it can safely carry the seven 10-ton HVAC chillers which are to be installed on the rooftop building.”

Due to the presence of a tenant running a call centre in the adjacent building, demolition can only take place outside of normal working hours. Muller highlights the importance of Concor’s safety culture in ensuring safe working practices at night.

What is important is for the considerable load of the new installation to be effectively transferred into the centre’s existing concrete columns under the roof parking – and hence down into the foundations. This is being done through the construction of interlinking stub columns which will create a grid to support the chillers. These columns are being cast

systematically, working in a direction of priority for the HVAC specialists, so that they can start their installations on the network of support steelwork and grating which Concor will provide.

The new structure will also include a transformer room and a perimeter louvre closure around the HVAC area. At about 3,5m high, the louvre will improve the rooftop aesthetics by concealing the installation from view. Concor’s team and sub-contractors receive working-at-height training and work strictly according to safety protocols – especially since the HVAC rooms are 8,5m above ground on one side of the structure and 20m high on the other. Completing the project will be a steel roof, louvres to allow fresh air to cool the installation, access doors and a steel staircase.

The structure is being strengthened to ensure it can safely carry the seven 10-ton HVAC chillers which will be installed on the rooftop building.

The construction of interlinking stub columns will create a grid to support the chiller, with columns being cast systematically in a direction of priority for the HVAC specialists so that work can begin.

In future, the east- and westbound lanes of the A43 autobahn near the city of Münster, Germany, will be separated by a poured-in-place concrete safety barrier. The effectiveness and permanence of such construction elements for the passive protection of road-users make them the preferred vehicle restraint system, especially on sections of roads with heavy traffic.

The monolithic profile was paved by an SP 25i using the slipform paving method. The use of AutoPilot 2.0 on this project eliminated the need for the paving crew from VSB infra GmbH & Co KG to set up a stringline for controlling the machine.

Developed by Wirtgen, the control system enables precise, stringless control of slipform pavers. It comprises a control system integrated in the machine, a base station and a tablet computer that can be used together with the Field Rover survey pole and on the slipform paver. As the system completely eliminates the need for setting up and removing the stringline conventionally used for machine control, it also reduces the associated project times and costs. Instead, the machine is guided along a virtual stringline by satellite-aided navigation. This makes the entire paving workflow faster, more efficient and, in

turn, more cost-effective. At the same time, it makes the paving of complex geometries such as tight radii or S-bends much easier.

“This is another project on which we’re using stringless paving. We’ve been using the AutoPilot system since it came onto the market. It saves us so much time that we use it on both of our machines whenever we can,” says Kay Petersen, CEO of VSB infra GmbH & Co KG.

As is typical for construction sites on major highways like the A43 autobahn, the working area offers very little room for the paving crew. Using a stringline in front of the machine in situations like this would limit this space even more. Yet there is no stringline here apart from what is shown on the screen of the AutoPilot tablet. The hand-held control unit displays the course of the virtual stringline and provides precise information to the machine operator at every point along the predefined track. This also means that there is plenty of free space in front of the slipform paver. Concrete mixers have room to manoeuvre and can drive right up to the paver to deliver their load. The free space in front of the machine gives the paving crew more room to work in, resulting in greater safety on the project

site. The absence of a stringline also removes the risk of tripping and injuries because of falls.

The AutoPilot 2.0 3D control system takes control of the production of all kinds of offset and inset profiles. There is also no longer any need for a surveyor to create a geodetic data model in advance. If a 3D data model already exists, this can be uploaded from the tablet and integrated in the system. Time-consuming surveys and the time and effort involved in setting up and removing stringlines are no longer required.

The AutoPilot comes into play before the actual construction work begins. Relevant points on the project site are recorded with the Field Rover survey pole and form the basis of the digital data model for the generation of the virtual stringline on the tablet computer. This eliminates the need for an additional surveyor on the project site.

The AutoPilot then takes control of the slipform paver, after which the machine works its way along the pre-determined virtual stringline with absolute precision. The existing sub-base of the A43 was sampled by an ultrasonic sensor and used as a reference datum by the machine control system. The result of this is extremely precise paving of the required concrete profile.

“Thanks to the Field Rover, I can perform a quality check on the paving results right behind the machine. I also really like the fact that everything comes from a single manufacturer – the machine, the AutoPilot system and the customer support, says site manager Meike Teuwsen.

NB: Only attendees who are members of ECSA will be able to claim these CPD points from the ECSA website.

The CASI Construction Academy’s series of live online courses offers cost-efficient, customised training in essential aspects of construction contract management, estimating, tendering, financial management and financial project appraisal for employers and employees alike. All you need is a laptop and a good Internet connection to attend. Please note that sessions are limited to 20 per session,

so application and registration must be done as soon as possible.

Construction Contract Management Masterclass: jb CC, NEC, gCC, f IDIC (3 CPD)

Johannesburg: 25-27 March 2024

Cape Town: 25-27 March 2024

Durban: 25-27 March 2024

This workshop covers conditions for international contracts for civil and industrial projects. The above four contracts are a recurring theme in our country for contractors and consultants alike, as they form part of the standardisation of the Construction Industries Development Board of SA. This makes these contracts compulsory when government entities contract for built environment projects. These standard contracts are also widely in use

in the commercial contracting sector and two of them, FIDIC and NEC, are used internationally. JBCC and GCC 2010/2015 are created by South African entities and mainly used in SA for building and engineering works. Participants will also learn how pandemics like Covid-19 and natural disaster affect construction contracts.

Project Management in Construction Workshop (3 CPD)

Johannesburg:

18-20 March 2024

Cape Town: 18-20 March 2024

Durban: 18-20 March 2024

This workshop will provide some new and additional insights into project management approaches, human behaviour, interdependencies and relationships that facilitate successful projects. Managing and executing projects that are on time and within budget can be done by identifying, exploiting and managing project improvements and changes.

For costs, session details, terms and conditions and further information, or to register for any of the above masterclasses, tel: 087 700 5633, e-mail: register@casits.co.za or visit: www.casits.co.za.

AFRISAM

www.afrisam.co.za

debbie.harvey@za.afrisam.com

011 670 5941

CORROSION I NSTITUTE OF SOUTHERN A FRICA

www.corrosioninstitute.org.za admin@corrisa.org.za

PAN M I x ERS SA

www.panmixers.co.za quintin@panmixers.co.za

011 578 8600

0861 267 772

A SHA k CONSTRUCTION

www.ashak.co.za

The consolidated cement and concrete industry body is soaring to new heights

Become a member –be part of the future

sales@ashak.co.za

011 822 2320

TECHNOLOGICAL INNOVATION IN THE CONCRETE INDUSTRY STARTS WITH MAP

• Precast concrete plasticising admixtures

www.cemcon-sa.org.za

• Ready-mixed concrete plasticising admixtures

E LTON'S REA dY MI x CONCRETE www.eltonreadymix.co.za info@eltonreadymix.co.za

• Extended workability polymers

082 401 8635

• Set retarding admixtures

• Hardening accelerators

• Viscosity modifying admixtures

• Form release agents

• Synthetic fibres

• Pozzolan-activity mineral additions

• Permeability-reducing admixtures

• Water-repelling admixtures

CEMENT & CONCRETE I NSTITUTE

• Anti-washout admixtures

• Expanding agents

• Drying shrinkage-reducing admixtures

www.cemcon-sa.org.za hanlie.turner@cemcon-sa.org.za

011 315 0300

Learn more at mapei.co.za

Tel: +27 11 552 8476

Email: info@mapei.co.za

• Clay mitigating admixtures

• Pumping aides

• Air entraining and foaming agents

J ESSOP & A SSOCIATES www.jessop.co.za info@protile.co.za

016 421 2521

• Concrete rescue packs

• Evaporation-retarding admixtures

M APEI

CHRYSO

www.za.chryso.com hannelie@chrysosa.co.za

011 395 9700

CONCRETE MOUL dS

www.concretemoulds.co.za nigelbrown@mweb.co.za

082 774 4657

SEPHA k U CEMENT

www.sephakucement.co.za sales@sepcem.co.za

0861 32 42 52

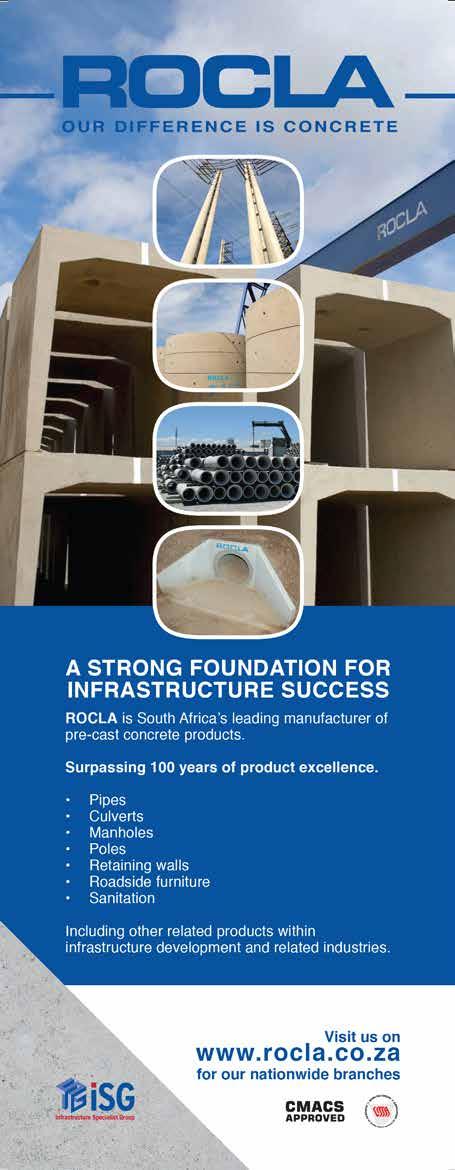

ROCLA

www.rocla.co.za info@rocla.co.za

011 670 7600

TECHNICRETE

www.technicrete.co.za info@technicrete.co.za

www.mapei.com j.lewis@mapei.co.za

011 552 8476

M ASTER BUIL dERS

SOUTH AFRICA

www.masterbuilders.org.za info@masterbuilders.org.za

011 205 9000

011 674 6900

T WINSTAR

www.twinstar.co.za

Annemerie@Twinstar.co.za

012 670 9083