BRICKS AND THE FUTURE30 GETTING AHEAD OF THE GREEN ECONOMY42DEMOLITION ROBOTS34 NOVEMBER 2022 | No 1165 CELEBRATING 99YEARS • GNITARBELECSRAEY99 •

Features Driver Identification & Driving Behaviour Monitoring Engine Performance Monitoring (RPM & Idling) Fuel Level & Consumption Monitoring Iris Camera Solution Front-Back-Side Facing Camera Option Onboard Weighing Breathalyser Tip Sensor Improve your building operation with dynamic Ctrack Solutions. www.ctrack.co.za | sales@ctrack.com | Call Centre: +27 (0)860 333 444 Always Visible

FROM THE EDITOR

to build

with Musa Shangase

MBSA NEWS

safety on construction sites

network is your net worth: getting the most out of association membership

Westown urban development breaks ground

MBA REGIONAL PROFILE

Getting to know the East Cape Master Builders Association

INDUSTRY NEWS

Flexible pricing in renewable energy projects: how to strike a balance

Higher-efficiency electric motors will drive down energy consumption

Inspiring SAISC Steel Awards 2022

HDPE pipes for Polokwane waste water treatment plant

CESA Infrastructure Indaba 2022: procurement crisis impacting service delivery

of mortar mix important for sustainability

winning in construction

South African Builder is the official journal of Master Builders South Africa, established in 1923. The opinions expressed by contributors are not necessarily those of Master Builders South Africa. SA Builder is a registered trademark of Master Builders South Africa. Any use of this trademark without the express and written approval of Master Builders South Africa is prohibited. No material contained herein may be reproduced in whole or in part without the prior written permission of the publisher. SA Builder © 2022. All rights reserved.

PUBLISHER

Isikhova Media (Pty) Ltd 10th Floor, Metal Box, 25 Owl Street, Milpark, Johannesburg, South Africa

Tel: +27 11 883 4627

/www.isikhova.co.za

CONTRIBUTIONS

Master Builders South Africa Tel: +27 11 205 9000 E-mail: editor@sabuilder.co.za www.masterbuilders.org.za

AND CREDITS

FEATURES

Personal protective equipment –the right footing

The sustainability economy: why are we so behind?

Future-proofed with brick

Plugging into the right electrical contractor

Demolition robot wars

Pulling down construction silos key to digital transformation

Foundational knowledge BUILDER’S VIEW

Achieving net zero and the role of carbon tax

Uganda’s waste opportunities

CAPTAINS OF CONSTRUCTION

Meet Refilwe Lesufi

Publishing Director/ Editor-in-chief: Jason Aarons E-mail: jason@isikhova.co.za

Editor: Nicholas McDiarmid E-mail: nicholas@isikhova.co.za

Director: Brand Strategy: Jenny Justus Tel: 083 450 6052 E-mail: jenny@isikhova.co.za

Managing Director: Imraan Mahomed E-mail: imraan@isikhova.co.za

Creative Director: Joanne Brook E-mail: joanne@isikhova.co.za

Operations Director: Thuli Majola E-mail: thuli@isikhova.co.za

Copy Editor: Anne Phillips

Advertising sales: Tel: +27 11 883 4627 Mobile: 072 383 3203 / 083 450 6052

MESSAGE

02 Planning

COVER STORY 04 Interview

06 Prioritising

08 Your

10

11

12

14

16

19 19km

20

22 Quality

24 Women

26

28

30

ASSOCIATIONS 32

PRODUCTS 34

INNOVATION 36

TECHNICAL 39

42

GLOBAL VIEW 44

47

NOVEMBER 2022 SOUTH AFRICAN BUILDER 01 CONTENTS

CONTENTS

www.sabuilder.co.za

26 10 44 36 Free download available on: www.sabuilder.co.za Twitter: @Builders_SA | Facebook: @SouthAfricanBuilder savvy thinkers smart doers together people Proud Media Partner

PLANNING TO BUILD

As we all continue to adjust to the ongoing stream of challenges thrown up by loadshedding, project constraints, lower margins and environmental realities (to cite more general issues), we know there are certain realities that we can depend on. We will survive, we will grow and we are learning. It is never foolish to be tenacious.

The disciplines required through this period can be looked upon in a positive light, as they reflect many trends filtering through global best practice in business and project management. LEAN, for example, might be a project acronym, but South Africans understand its implementation as a survival adaption, rather than as remnants from a pricy training seminar. Training our sights on effective

business survival strategies is always a winner, and builders know that there are always better ways of solving a problem.

SA Builder continues its drive to seek out winning alternatives to business as usual, from more effective equipment, plant and vehicle solutions to finding methods and materials cut to this new cloth. Now is the time to consider the unconsidered; to try out out new things. We also encourage everyone to network more than ever before. Opportunities generally come from unexpected sources and resources are everywhere to be found. Partners, friends, associates and mentors should be put firmly at the top of your survival strategy.

Nicholas McDiarmid: editor

Nicholas McDiarmid: editor

EDITOR'S NOTE

Western

Cell: +27 (0)83 505 1819 Office: +27 (0)21 535 4455

Nathan

Cell: +27 (0)72 778 3449 Office: +27 (0)11 822 7242

KwaZulu-Natal

Yvette

+27 (0)83 524 3879

+27 (0) 31 705 7733

Eastern

Cell: +27 (0)83 452 4031 Office: +27 (0)41 451 3944

www.technicalfinishes.com

Cape Chester Laas

chester@technicalfinishes.com Gauteng

Calitz

nathan@technicalfinishes.com

Watters Cell:

Office:

yvette@technicalfinishes.com

Cape Tobie Vosloo

tobie@technicalfinishes.com SPECIALIST CONSTRUCTION SOLUTIONS Technical Finishes’ leading range of specialist construction solutions include: • Concrete curing compounds and sealers • Epoxy flooring and coatings • Epoxy adhesives and repair products • Construction grouts • Waterproofing products • Joint sealants

INTERVIEW WITH MUSA SHANGASE

Musa Shangase was inaugurated as the new president of Master Builders SA (MBSA) on 9 September 2022 at this year’s congress held in KwaZulu-Natal. He talked to SA Builder about the seemingly uncharted road facing the construction sector and the economy as a whole, as well as his plans for expediting the recovery ahead

With Shangase having been a director of Corobrik for nearly nine years now, it is difficult to imagine a more qualified candidate to guide the MBSA and its members through what can only be described as a uniquely challenging economic landscape. He has a long history with the association and was elected president of MBA North in 2017.

SA Builder: Congratulations on your inauguration; you are uniquely positioned to understand the work of the association and what makes it so effective for its members and the industry. What are the most important factors for members to keep in mind at this critical juncture for the sector?

MS: MBSA is the umbrella body for all the regional Master

Builders Associations (MBAs) and specialised affiliate members. It utilises the power and cohesion of this united voice to effectively represent the best interests of our industry on key national bodies and lobbies national government on legislative and policy issues.

You have mentioned the importance of your relationships in the sector in tackling challenges. What are the priority issues for your plan of action?

A workable solution to the prob lem of the so-called “construction mafia” is the most urgent priority. We must provide as much assis tance to the Department of Public

Works as possible to unblock its project pipeline, while using our influence and leveraging our alliances to put enough muscle behind the Finance Minister’s Infrastructure Budget and get it endorsed by National Treasury. Then we need to build consensus throughout the MBAs on employ ment equity targets and timelines, and engage the Department of Employment & Labour in getting them implemented.

What needs to change in the industry’s public and private sectors, both singly and jointly, to establish the co-operative partnership which can achieve the levels of activity required of a growth economy?

Private-public partnerships are key to the success of our country’s economy and our industry. Privatesector technology and innovation need to be aligned and combined with public-sector incentives to complete works and projects on time and within budget. We need to stop the financial haemorrhage characteristic of the very initiatives intended to stimulate growth.

We’d like to see the public sector sharing risk with the private sector, especially in matters of procurement and on-time payments. The sole point of this model of partnership is to unlock the development of industrial processes, products and services beyond the capacity of either party acting alone. It’s a symbiotic partnership for the national benefit

SOUTH AFRICAN BUILDER NOVEMBER 202204 COVER STORY

“I ALWAYS TRY TO RECOGNIZE AND DEFINE FEAR AS IT COMES UP, BECAUSE THEN I CAN DEAL WITH THE FEAR, INSTEAD OF ALLOWING THE FEAR TO DEFINE HOW I ACT.”

and it’s time for a mutual vision, with both parties on the same side.

What should members be doing right now to both steer their businesses through this rocky time and positively effect the changes we need to see as a whole?

On balance, I’d say that while there are grounds for optimism, contractors must be very cautious going forward. The industry’s made some recovery from the dip experienced during the lockdowns: from June 2020 to May 2021, the monthly average value for building plans registered was R6,3 billion. It was R9 billion for the June 2021-June 2022 period. However, reports are being made of commercial building activity slowing down, decreasing the likelihood of a full recovery from the 2020 lockdowns this year.

Reflecting on your own journey, what actions and attitudes have worked for you, both personally and professionally, when facing particularly difficult challenges?

I accept my life for what it is in the here and now. Acceptance can be fleeting, but it normally helps me let go of stress, anxiety and fear. When I face a particular challenge, I take a step away from my feelings and make a plan. While it’s important to still acknowledge my feelings, I want my actions and decisions to be objective

I regard the taking of action to be one of the biggest steps in over coming challenges. A big part of whatever I’m facing probably feels so challenging due to underlying fear. I always try to recognise and define fear as it comes up, because then I can deal with it, rather than allowing it to define how I act.

Ultimately, I tend to exist in my comfort zones, so when something new happens or presents itself, it can appear hard to deal with. Practising gratitude also allows me to reframe my definition of a challenge

You’ve referred to the wonderful resilience in the sector. Are

there developments from within government to keep up the motivation and inspiration we all need at this time?

In May 2020, Cabinet approved the establishment of Infrastructure SA (ISA), a programme under Minister of Public Works and Infrastructure Patricia de Lille. Prof Kgosientso Ramokgopa heads the ISA and advised the MBSA Congress that R2,2 trillion had been put aside for this 10-year programme.

The ISA incorporates several mandates from bodies like the Presidential Infrastructure Coordinating Commission Technical Team and the broader public institution framework for delivery of public infrastructure. This single point of entry for accelerated infrastructure investment, with a particular focus on both publicand private-sector catalytic social and economic infrastructure projects, is overseen by De Lille, representing the executive and reporting to President Cyril Ramaphosa.

What do you most enjoy about the work you do and the sector itself?

I came across this passage written by Jennifer Younes, a senior product marketing specialist: “Construction is a phenomenal industry to be in. There are new and unique opportunities each day and the industry’s constantly challenging the status quo with technological advancements. It’s an amazing feeling to be part of building incredible projects and positively impacting communities.” I subscribe to her thinking.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 05 COVER STORY

PRIORITISING SAFETY ON CONSTRUCTION SITES

Statistics published by the Federated Employers Mutual Assurance Company (FEM) reveal that 6 423 workplace accidents requiring medical attention were reported in 2021. Of these, 56 resulted in fatalities. In addition, the report indicates that 11 761 days were lost in 2021 as a result of employees being injured and five people were permanently disabled.

In light of this, the Master Builders’ Association Western Cape (MBAWC) urges its members, employers and employees in the construction industry to prioritise safety both on and off site at all times with a view to eliminating accidents.

A CLEAR IMPERATIVE

Deon Bester, health and safety manager at the MBAWC, believes that the FEM figures are concerning. “Not only is any death, injury or disablement unacceptable, but the downtime that occurs as a result of accidents impacts the overall delivery of projects,” he says.

“This is why employers and employees need to work together when it comes to health and safety compliance. The Occupational Health and Safety Act states that all employees have the right to work in a safe environment, but with that comes the responsibility of complying with the health and safety standards that have been put in place.”

RISK PREVALENCE

A closer look at the most common accidents that occur within the construction industry reveals that motor accidents are among the largest contributors to the issue.

“This is a very difficult area to control, but people who make use of company transport, especially those being transported in open vehicles, must know the rules of the road. These employees shouldn’t allow themselves to be transported in unsafe modes of transport. Employers operating

these vehicles should always ensure that they abide by the requirements of the National Road Traffic Act, as well as the requirements of section 23 of the construction regulations,” says Bester.

FROM TRAINING TO ADHERENCE

While many contractors and employers invest significantly in training their staff in health and safety compliance, it is up to all parties to ensure adherence to the safety learnings and on-site measures.

The MBAWC offers assistance to its members to ensure compliance with the Occupational Health and Safety Act. “We believe that nobody should lose their life while at work, which is why we offer advice on how our members can ensure that safety is constantly prioritised – both on and off site,” says Bester.

MBA NEWS

(Right): Off site and on, adherence to safety regulations and procedures is a priority.

“NOT ONLY IS ANY DEATH, INJURY OR DISABLEMENT UNACCEPTABLE, BUT THE DOWNTIME THAT OCCURS AS A RESULT OF ACCIDENTS IMPACTS THE OVERALL DELIVERY OF PROJECTS.”

Ndia

For more information contact +27 (0) 11 326 2501 or email to amrita@intelligencetransferc.co.za or fax: +27 (0) 11 326 2960 or visit: www.intelligencetransferc.co.za Pg 1

Magadalela CEO EVERLECTRIC Portia Nkuna Managing Director FAZI RAIL ACADEMY Dr Thelma Ngwenya Engineer: Advanced Materials Division MINTEK Mazande Ntshanga Local Economic Development Project Manager Capital Projects Unit-Economic Development & Planning Cluster ETHEKWINI MUNICIPALITY Confidence Tshilande PrEng. Founder & Director PRESTIIO APP UJ AND SHRA COUNCIL MEMBER Claudia Ngwekazi Geology Manager MARULA PLATINUM Asavela Sigonya Engineer OPENSERVE Mulalo Nemataheni CEO IMPOWERX ADVISORY SERVICES CONFIRMED SPEAKER FACULTY INCLUDE: Dates: 23, 24 & 25 November 2022 Venue: Indaba Hotel, Fourways WOMEN IN ENGINEERING AFRICA NETWORK CONFERENCE & EXPO 13th Annual Media Partners: MENTAL HEALTH PANEL DISCUSSION CONFERENCE HIGHLIGHTS Senzekile Shongwe Counsellor & Mental health Facilitator Victoria Mkhize Trauma Informed Systems Researcher OCCUPATIONAL SOCIAL WORK CPDS PTY LTD Dorah Tlala Group Chief HR Officer PROCONICS KEY STRATEGIES • Developing the next generation of Women in Leadership within this ever-changing engineering field • Women empowerment through Innovation: Department of Agriculture Case study • Investing in mental health care for women in engineering • Education tailored for Women in Engineering • Catalysis and your role in it: Techno-social aspect • Electric mobility is South Africa • Looking at electric mobility is South Africa • Discussing the use of technology and social media for career advancement and global impact • A Woman Kind of Leadership • Discussing experiences in STEM at NASA Begoña Vila, PhD Lead Systems Engineer JAMES WEBB SPACE TELESCOPE NASA GODDARD SPACE FLIGHT CENTER/KBR Lisa Bartusek Deputy Mission Systems Engineer NANCY GRACE ROMAN SPACE TELESCOPE NASA GODDARD SPACE FLIGHT CENTER TELESCOPE Jody Davis Systems Engineer NANCY GRACE ROMAN SPACE TELESCOPE NASA GODDARD SPACE FLIGHT CENTER Dr Angela Tabiri Research Associate Academic Manager (Girls in Mathematical Sciences Program) AFRICAN INSTITUTE FOR MATHEMATICAL SCIENCES-GHANA Florence Jedidiah Mulenga Projects Manager ZAMBIAN NATIONAL STEM FOUNDATION INTERNATIONAL PERSPECTIVE NASA PANEL DISCUSSION AFRICAN PERSPECTIVE Dr Maneshree Jugmohan-Naidu Director: Agricultural Bioinnovation DEPARTMENT OF SCIENCE AND TECHNOLOGY Ayanda Ndlovu Managing Director HUBA EMPOWERMENT HUB Lusanda Dlamini Director-Project Management DEPARTMENT OF WATER & SANITATION Pfumelani Mbulayeni Owner and MD PM AVIATION CONSULTING Dr Thandiwe Sithole Senior Lecturer UNIVERSITY OF JOHANNESBURG Michelle Nxumalo Exhibition Director AFRICA AEROSPACE AND DEFENCE Dr Emma Molobi Technology Management Principal Engineer (Rolling Stock Technology) TRANSNET FREIGHT RAIL Register and enjoy a restorative and energizing morning or afternoon Half Day Mangwanani SPA VOUCHER that can be used at any Mangwanani Nation wide, valid for a YEAR Your experience includes unrivaled entertainment, delicious light breakfast at the morning session or lunch with decadent desserts at the afternoon session, beverages, and chocolate to round off your experience NB* This voucher is valued @ R1299. Ts & Cs apply WHEELCHAIR CHARITY BUILD PROJECT NETWORKING FUNCTION FOR ONSITE ATTENDEES AWAITING CPD POINTS Researched&DevelopedBy:

GETTING THE MOST OUT OF ASSOCIATION MEMBERSHIP

During periods of high economic activity, businesses tend to subscribe to various publications and services. Challenging economic conditions often cause businesses to reduce nonessential expenditure. Some of the first items to be considered expendable are subscriptions. Not all subscriptions are the same and this article seeks to explore the value of association memberships.

PROFESSIONALISM

AND CREDIBILITY

Firstly, membership of respected

organisations is an indication of the value that you attach to yourself and the service that you provide. Members of respected organisa tions are governed by a code of conduct and can be held account able to agreed-upon standards. This fact gives peace of mind to prospective clients. It is noted that funders also prefer contributing to businesses that are members of respected organisations. Your membership of an association with good brand exposure sends a message that you are serious about the service that you offer.

REPRESENTATION

It is not always possible to represent your business on all platforms that impact your business. Recognised membership organisations establish capabilities to lobby on behalf of their membership with government, suppliers and other key stakeholders.

NETWORKING

The value of meaningful networking cannot be overstated

SOUTH AFRICAN BUILDER NOVEMBER 202208 MBA NEWS

YOUR NETWORK IS YOUR NET WORTH:

(Above): Education and training keep you relevant and engaged with leading trends.

in the business context. Wellestablished and respected organisations have a broadly represented membership and are capable of bringing together a diverse range of entities and stakeholders that can positively impact business prospects. The ability to bring business entities together with prospective private and public clients and those with information for the success of your business is internal to a value proposition of a membership organisation. Social media networking has its place, but it cannot replace the opportunities afforded by local networking.

EDUCATION AND TRAINING

A membership organisation should recognise the value of education and training and invest in the development of such programmes. Development events such as workshops and webinars are offered and valuable content for the benefit of their membership is provided.

RECOGNITION

To be recognised by your peers for outstanding work and excellence shines a positive light on your business and has the potential of exposure to clients who seek service providers with proven excellence. Wellestablished and recognised

(Above): Nothing compares with networking when it comes broadening the scope of opportunity.

membership organisations see value in hosting and sponsoring industry initiatives in their quest for brand exposure and partnering with relevant stakeholders.

REFLECTION

When negative economic conditions force you to rethink membership subscriptions, remember the benefits provided by your respected and industryleading membership association.

CONCLUSION

Master Builders KwaZulu-Natal exists to represent the interests of members and provide them with specialist support services to assist in the successful running

of their businesses. It prides itself on being the voice of the KZN construction industry, representing the interests of its members through effective lobbying and advocacy, promoting best practices, skills development and construction excellence by providing relevant services and a diverse range of business solutions. In this way, it creates an empowering and enabling environment for the sustainability of the construction industry.

The association is further involved in a range of activities and services which complement its core operations.

These include:

• Building and contractual advice and assistance.

• Occupational health and safety consulting.

• Mediation and dispute resolution.

• Fund administration.

• Conference facilities.

• Café Indaba.

• Print studio.

• Occupational health clinic.

• Property portfolio.

• Training academy.

• Recruitment agency.

• Business support consultancy. Contact your membership manager to ensure your continued and enhanced utilisation of the association’s services.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 09 MBA NEWS

“WELL-ESTABLISHED AND RESPECTED MEMBERSHIP ORGANISATIONS HAVE A BROADLY REPRESENTED MEMBERSHIP AND ARE CAPABLE OF BRINGING TOGETHER A DIVERSE RANGE OF ENTITIES AND STAKEHOLDERS THAT CAN POSITIVELY IMPACT BUSINESS PROSPECTS.”

WESTOWN URBAN DEVELOPMENT

BREAKS GROUND

By Victor Smith, membership manager: MBA KwaZulu-Natal

The breaking of ground on the first phase of the Ntshongweni Urban Development, known as Westown, is the start of a long-awaited stimulus of the eThekwini economy.

The development, which covers over 2 000ha of land, will include a retail and urban core precinct and a significant residential area. Associated social facilities, as well as commercial, logistics and recreational components, will be developed in phases. It is an integrated human settlement development conceptualised by Tongaat-Hulett Developments, a company responsible for numerous high-profile projects including Umhlanga Ridge, Zimbali Coastal Resort and Riverhorse Valley.

“The R30 billion development is a nine-phase urban mixed-use project that aims to create a new

economic hub in the region,” says Mxolisi Kaunda, the mayor of eThekwini.

JOB CREATION AND SOCIAL DEVELOPMENT

The development will be a catalyst for job creation and further invest ment. It is being developed by the Fundementum Property Group in partnership with eThekwini Munici pality and Tongaat-Hulett.

The Westown component is phase 1A of the project and is valued at R2,5 billion. Phase 1 will be completed in the third quarter of 2024. R200 million will be allocated to local suppliers and 8 000 jobs will be created.

According to Carlos Correia, CEO of the Fundementum Property Group, tender calls have gone out for the first key infrastructure components.

Infrastructure development will be the first priority for developers,

with the first phase focusing on upgrading Kassier Road to a two-lane road with medians and sidewalks. This upgrade has been awarded to Stefanutti Stocks and engineering consultants SMEC South Africa. Work began in September 2022 and will take place in tandem with the construction of a 45 000m2 shopping centre.

SOUTH AFRICAN BUILDER NOVEMBER 202210 MBA NEWS

(Above): The Ethekwini Municipality is working with numerous partners on the development of an ambitious mixed-use development project.

(Top): Aerial view of a similarly specified mixed-use development in the USA.

GETTING TO KNOW THE EAST CAPE MASTER BUILDERS ASSOCIATION

The first inaugural meeting of master builders in Port Elizabeth was held on 8 January 1898 at 8pm on a Saturday. The meeting was called by Jass Williams by circular and advertisement to master builders and contractors “for the purpose of discussing the advisability of establishing a Master Builders‘ and Contractors‘ Association in this town” (Port Elizabeth). That first meeting was attended by some 16 contractors and L Mackay was unanimously elected to the chair. Williams became the association's first secretary. A number of meetings were held in that year which laid the foundations of the association.

During 1982 the association amalgamated with the Master Builders' Associations of East London, Southern Cape, Queenstown, King William's Town and Grahamstown to form the Master Builders' and Allied Trades Association, East Cape.

On the eve of its centenary and with the advent of the new Labour Relations Act, the association resolved to revert back to its former name with one slight variation: the East Cape Master Builders' and Allied Industries Association (East Cape MBA).

EDUCATION AND TRAINING

Qualified skills development facilitators assist companies to

become self-sufficient in the development of their training plans (workplace skills plans) and the implementation thereof, as well as reporting to the Construction Education Training Authority (CETA) on previous training being done.

Skills development facilitators engage with our member companies in order to achieve the vision of developing a skilled and motivated construction workforce whose skills are recognised and valued in order to improve competitiveness, employment creation and a sustainable skills base across the entire sector.

APPRENTICESHIP PROGRAMME

The East Cape MBA has secured funding from the CETA to financially assist companies who would like to indenture their employees for apprenticeships in any designated trade such as plumbing, carpentry, bricklaying and plastering, painting and decorating, and other critical artisan skills.

HEALTH AND SAFETY SERVICES

• Members receive a free audit every year.

• Weekly or monthly audits with detailed reports for a minimal fee.

• Compiling of Health and Safety Files and other Safety documents.

• Assisting sub-contractors with health and safety files.

• Monthly sub-contractor audits on behalf of the principal contractor.

• Free general site visits and assistance.

• Safety workshops.

• Regular safety legislation updates and articles in the weekly bulletin.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 11 MBA REGIONAL PROFILE

(Above): Greg Steele, executive director: East Cape MBA.

FLEXIBLE PRICING IN RENEWABLE ENERGY PROJECTS: HOW TO STRIKE A BALANCE

By Megan Jarvis and Tyron Theessen, partners at Webber Wentzel

Volatile input costs pose a threat to the viability of developers of renewable energy projects, which may require offtakers to be more flexible in contract negotiations.

Soaring costs of commodities and energy have resulted in an unprecedented level of cost uncertainty in the inputs needed for developing renewable energy projects. Cost uncertainty is compounded by the logistical woes being faced by developers in South Africa and elsewhere. Even where component parts are available, they may not be at a cost that is recoverable in terms of the contracts in place with buyers or sustainable for suppliers.

RISING COSTS

According to the International Energy Agency in its Renewable Energy Market Update 2022 released in May this year, prices of raw materials and freight costs for renewable energy projects have been rising since the beginning of 2021. By March 2022, it

(Above): Megan Jarvis and Tyron Theessen, partners at Webber Wentzel.

(Top): At this time of slim margins, the financial details of any commercial agreement need great care.

stated: “The price of PV-grade polysilicon more than quadrupled, steel increased by 50%, copper rose by 70%, aluminium doubled and freight costs rose almost five-fold. The reversal of the long-term trend of decreasing costs is reflected in the higher prices of wind turbines and PV modules as manufacturers pass through increased equipment costs. Compared with 2020, we estimate that the overall investment costs of new utility-scale PV and onshore wind plants are 1525% higher in 2022.”

SOUTH AFRICAN BUILDER NOVEMBER 202212 INDUSTRY NEWS

DEALS DELAYED

These cost increases have further compounded difficulties, initially arising from pending litigation, in closing projects bid under the Risk Mitigation Independent Power Procurement Programme (which was gazetted on 7 July 2020). Similar issues may be faced if other programmes are delayed and could apply equally where private offtaker deals suffer from their own delays.

In this uncertain environment, where fixed pricing on long-lead items cannot always be secured, developers may be unable to sell power at the prices they bid and still make a profit. The same phenomenon affects other privatesector power projects underway, such as those being developed to supply renewable energy to offtakers in the mining and other industries, where the developer has undertaken to supply power at a certain agreed price. The client, in turn, has budgeted for that price and may also have limited room for cost escalations.

BUILDING COST ESCALATIONS INTO CONTRACTS

Many contracts may have prudently allowed for an annual escalation in tariffs of the Consumer Price Index (CPI) plus a certain percentage, or in line with a formula for certain items. However, although the CPI may be a measure of the shifting costs of a basket of goods, the composition of capital costs in renewable energy projects is not reflected by that basket. The CPI is also not an immediate measure of international commodity fluctuations, so cost escalations

linked to it will deliver little comfort if project development timeframes are more limited than the realised effect on the basket.

Even though buyers of power may be sympathetic to these cost pressures (since they are being felt broadly across many industries), a buyer cannot be expected to give a developer a blank cheque. On the other hand, a developer would be hard-pressed to continue with an uneconomic project and it is not in the client’s interests if the developer of the project goes into business rescue and work is suspended indefinitely – which

that are currently being negotiated. These include clauses allowing cost price adjustments that are based on industry-specific formulae. Invariably, a level of risk will have to be assumed by the buyer in agreeing to flexible pricing, but this may be mitigated by allowing for re-pricing of components at specified thresholds, termination for convenience provisions and other commercial arrangements where this risk is shared and managed.

ALL THINGS CONSIDERED

When a contract is already in place, the developer and client would need to consider the terms and may need to discuss, and possibly renegotiate, terms to ensure a via ble project. This may not be possi ble and such discussions may not go well. However, in the absence of a commercial compromise, there is a real risk of the developer repudi ating the uneconomic arrangement or being run into insolvency. The same considerations will apply between the developer and its contractors and further down the procurement chain.

has happened on more than one renewable project. Similarly, suppliers and original equipment manufacturers, whose costing is more directly affected by these fluctuating input costs, cannot necessarily absorb this risk and certainly cannot do so indefinitely without being pushed into uneconomic arrangements.

To take some of the guesswork out of making provision for these uncertain costs, pre-emptive clauses can be built into contracts

Affected parties may also find some relief in taking out forward cover, but this may only be available on certain items, such as steel.

The key is to conclude a commercial arrangement that is fair to all parties. It needs to balance the interests of all project participants and adequately manage the risk. In this environment, some flexibility must be considered, as fixed positions will invariably lead to at least one party being compromised and likely litigation.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 13 INDUSTRY NEWS

“IN THIS UNCERTAIN ENVIRONMENT, WHERE FIXED PRICING ON LONG-LEAD ITEMS CANNOT ALWAYS BE SECURED, DEVELOPERS MAY BE UNABLE TO SELL POWER AT THE PRICES THEY BID AND STILL MAKE A PROFIT.”

HIGHER-EFFICIENCY ELECTRIC MOTORS WILL

DRIVE DOWN ENERGY CONSUMPTION

The adoption of new Minimum Energy Performance Standards (MEPS) for electric motors in South Africa will provide significant energy savings and, in doing so, alleviate pressure on the country’s electricity supply crisis, while improving operational competitiveness.

NATIONAL ENERGYSAVING POTENTIAL Entitled Cost-Benefit Analysis to Introduce MEPS for Electric Motors in SA, the report found that national electricity demand could potentially be reduced by as much as 0,25% in 2023, should the inefficient IE1 motors be replaced with more efficiently rated IE3 ones. IE3 electric motor units have a premium efficiency rating of 94,2%, with potential energysavings of 15-16%.

SA’s economy depends on energyintensive industries such as mining, chemicals, agriculture, iron and cement-making. These industries all run electric motors for extended periods, even up to 17 hours a day. The CBA’s study revealed that about 32 companies in these sectors consume about 40% of the country’s electrical energy.

COLLECTIVE ACTION

It is therefore imperative that the country adopts MEPS and energy labels which are supported by government bestpractice awareness programmes. Collectively, these actions will

accelerate the transition to more efficient motor system applications.

BARRIER TO EFFICIENCY

The repair of motors and the preused sales sector were identified as barriers to the government’s energy-efficiency efforts. Standard and labelling programme do not typically regulate the second-hand market. This significantly slows down the pace at which standard and labelling policy objectives can be achieved.

Some South African distributors are already making the shift towards IE3 electric motor units and support the government’s intention to forge ahead with the new efficiency standards programme, which is now long overdue.

ABSENCE OF RATING

In line with international standards, the report recommends that the DMRE proceed in implementing MEPS for level IE3 electric motors in the 0,75-375kW range for two-, four-, six- and eight-pole motors.

(Below): The trade in used motors is having a negative impact on many industries in SA.

In its research, it considered the Urban-Econ Feasibility Study of 2019 to help reach its conclusions. This study suggested that 200 000 electric motor units are sold each year in SA, with at least 69% of them in the 0,75-11kW size range. Of these, 40-50% have no stated energy rating, suggesting that they are the most inefficient motors available on the market.

Eskom’s own integrated annual report for the year also finds that more efficient MEPS will have the potential to reduce electricity demand by 0,25% in 2023. This will increase as older electric motors are replaced with the newer IE3 models over time.

BENEFITS CONCLUSIVE

The CBA report concludes that if the electric motor MEPS programme is effective, it should offer meaningful electricity savings which will directly benefit Eskom. It will not only assist the power utility with its current supply challenge, but improve the competitiveness of SA’s industrial base by reducing load-shedding risks and operational costs.

SOUTH AFRICAN BUILDER NOVEMBER 202214 INDUSTRY NEWS

PERI OUTPERFORMS IN MBA NATIONAL SAFETY AWARDS

PERI Bloemfontein's safety audit won first place in the regional and national health and safety competitions to take the award. The PERI team attended the annual Master Builders Association congress hosted in KwaZulu Natal to receive their trophy.

PERI has long established safety as its value: ‘Acting safe and staying safe’.

IMPOSSIBLE PROJECTS MADE POSSIBLE PERI SA has taken on the most daunting construction challenges in high-profile projects around South Africa, making possible seemingly impossible structural manoeuvres involving record weights, record heights, and record times. Innovating extraordinary systems, like the VARIO GT 24 wall formwork system, DOMINO Walling System, HANDSET Alpha panel formwork, and the PERI MULTIFLEX and QUICKSTAGE systems.

FORMWORK SCAFFOLDING AND CIVIL ENGINEERING PIONEERS

Combined with expertise, experience, and training, the company has lifted, hoisted, fitted, and created the structural walls, the load-bearing columns and beams; and the girders at new heights and under previously uncharted conditions.

Without PERI’s pioneering achievements, many nowiconic buildings and infrastructures would likely not have achieved their ambitious designs.

The PD 5 shoring system's simple design features only six components with integrated locks that enable it to perform to its fullest potential. This easy shoring solution is suited for building and infrastructure projects, offering simple assembly and disassembly for slab, beam, and light bridge formwork. It also has adjustable height configurations, which can be done quickly and continuously.

ADVERTORIAL

Formwork Scaffolding Engineering www.peri.co.za

The PERI PD5 Shoring System A SHORING SYSTEM

WITH RELABLE FLEXIBILITY

PERI

HAS THE ANSWER

INSPIRING SAISC STEEL AWARDS 2022

Innovation, ingenuity and a sense of community within the steel construction industry were showcased on the evening of 13 October, when participants across the local steel value chain gathered to attend the highlight of the annual steel industry calendar – the 2022 Steel Awards, presented by the Southern African Institute for Steel Construction (SAISC) and held at Emperor’s Palace, Gauteng.

This event, which demonstrates excellence in the use of steel in construction, was the first in-person Steel Awards held since 2019, prior to the Covid-19 pandemic. The 2022 awards very effectively highlighted how the local steel sector has triumphed over adversity in the past two years, as well as showcasing a typically South African “cando” approach to the challenges endured during this time.

The annual SAISC Steel Awards provide an opportunity for stakeholders across the industry

- including engineers, fabricators, designers, architects, processors, merchants and fabricatorsto present their work and be honoured for their outstanding achievements. The eveningknown in the steel sector as the “Oscars of the steel industry” – was an elegant gala-style gathering with a “red carpet” feel and a growth-related theme this year of ‘green shoots’.

THE STEEL AWARDS CATEGORY WINNERS

Automotive

• Ford Package E - as part of a R3 billion investment by vehicle manufacturer Ford, an automotive assembly plant was erected in Rosslyn, Pretoria as part of the company’s highvolume export programme. The project used extensive steel supplies and comprised a 12 400m² warehouse, 14,6m in height. The project was completed ahead of schedule, despite the Covid-19 pandemic and related supply challenges.

Agri-Industrial

• Woodridge Packhouse - this project presents an interesting form, clever use of natural light and a design which allows for natural ventilation, therefore saving on energy costs.

Mining

• Benguela Gem Treatment Plant – this project not only won the Mining category but the 2022 Steel Awards overall.

Residential

• House Vingos - the innovative use of steel - combined with all the other elements of construction - delivers a statement piece of architecture and a warm, welcoming family home.

Sports Facilities

• KES Aquatic Centre - while retaining the heritage component of the previous swimming pool complex, the roof structure is of particular interest: an apex running diagonally across the structure, requiring meticulous attention to ensure leak-proof sealing.

SOUTH AFRICAN BUILDER NOVEMBER 202216 INDUSTRY NEWS

Sculptural/Architectural

• Eastgate Solar Trees - in addition to its aestheticallypleasing design and how this cleverly reflects a renewable energy focus, the access to the site during the construction phase was challenging, making for a complicated installation process.

Light Steel Frame (LSF) Building

• Jubilee Hospital - at the height of the Covid-19 pandemic, the innovative use of light steel framing in this field hospital in Hammanskraal, north of Pretoria, allowed for the addition of a significant number of hospital beds to increase existing capacity, using this speedy construction methodology.

Metal Cladding and Roofing

• KES Aquatic Centre - this project won both the Metal

Cladding and Roofing, and the Sports Facilities categories.

Tubular Steel

• Babanango Travellers Camp - this innovative tourist accommodation is situated within the Babanango game reserve in northern KZN. A number of interesting technical details included reconciling complex issues regarding the use of different materials of construction and geometrical factors, to achieve the project’s architectural objective: roofing reflecting shapes used in traditional African shields.

Community Enrichment

• Gary Kirsten Sports Centre Khayelitsha - featuring ease of construction and sustainable materials, this structure also has the capacity to extend, if need be.

Regional Awards

• Best Project GautengHouse Vingos.

• Best Project Western Cape - Benguela Gem Treatment Plant.

• Best Project Eastern CapeWoodridge Packhouse.

• Best Project LimpopoFresh-mark Polokwane.

• Best Project KwaZulu-NatalBabanango Travellers Camp.

• Best Export Project - New Biox Plant in Zimbabwe.

Best Project Limpopo: The project, carried out for the Freshmark distribution centre in Polokwane, made use of particularly innovative cladding: atypical of a warehouse building and technically challenging to achieve. The result was aesthetically pleasing, with a design element of curved bullnoses from roof to cladding.

Best Export Project: Biological oxidation (“biox”) is a technology that ensures the optimal processing of high-sulphur gold ore, thereby increasing the achievable gold recovery. This technically challenging structural framing project entailed detailing, fabricating and constructing a gold processing biox plant. The primary objective thereof was to provide access to the various areas of the biox plant – and to its piping support system.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 17 INDUSTRY NEWS

“THE 2022 AWARDS VERY EFFECTIVELY HIGHLIGHTED HOW THE LOCAL STEEL SECTOR HAS TRIUMPHED OVER ADVERSITY IN THE PAST TWO YEARS.“

ALL-IN-ONE SOLUTION FOR ENTRY-LEVEL FORMWORK SYSTEMS

PERI has introduced the HANDSET Alpha as a robust and economical formwork system for crane-independent applications. It is a universal formwork system for walls, foundations, and columns. The system has an efficient profile consisting of a low number of sophisticated components and

multifunctional panels that take handling to an intuitive level. This streamlined, integrated portfolio minimises the need for on-site training and requires just two people to assemble the system, with no crane required.

The high-quality steel and powdercoated panels make HANDSET Alpha particularly durable and reduce maintenance costs.

The design minimises loose system parts by integrating features like brace connectors and handles into the profile, as well as the amount of timber required. The high allowable concrete pressure of 60 kN/m² for walls and up to 75 kN/m² for columns reduces the margin for error and allows you to concrete faster.

HANDSET Alpha

efficiency and Intuitive handling

HANDSET Alpha

You can ensure a cleaner construction site as you reduce the number of different systems needed on hand with the multipurpose features of the PERI HANDSET ALPHA. Meaning you can move from multiple columns and wall sizes to foundations and retaining walls, all with one product. You can be sure that site workers will assuredly keep up as few components and intuitive handling make the HANDSET ALPHA easy to use across all levels of experience, saving you on excessive training costs.

Formwork

ADVERTORIAL

Scaffolding Engineering www.peri.co.za

Experience

19KM HDPE PIPES FOR POLOKWANE WASTE WATER TREATMENT PLANT

Waste water treatment plants play a crucial role in the removal of contaminants from waste water and sewage in order for its conversion into an effluent that can be returned to the water cycle in an environmentally friendly way or can be reclaimed for other purposes. It is a critical process in the supply of safe water to local communities.

The project, which was sub-divided into three phases, is based in the Seshego area in Polokwane. It was initiated to upgrade the existing sewerage system, to meet the increased requirements of the Seshego local communities. Each phase of the project had a separate starting point with a common joining at a single point.

Rocla regional sales manager Andrew Kruger says: “The project was commissioned by the Polokwane Municipality to upgrade a now outdated sewerage system

which no longer met the local community’s requirements in the Seshego area of Polokwane. We worked closely with site contractor Safcrete Construction so that the quality of the pipes would be to the standard required and delivery scheduling would be as seamless as possible.

“The pipes were 2,5m silica rolling joint pipe, comprising a 3mm sacrificial layer. Five sizes of pipe were required, namely 900mm, 1 000mm, 1 200mm, 1 400mm and 1 500mm, which if placed end-to-end, would mean that the HDPE piping was over 19 km. The placement of each pipe required the insertion of a rubber ring and the welding of a “capping strip” on the inside of each individual joint to ensure proper sealant,” says Kruger.

“In order for our Polokwane factory to manufacture the various sizes of pipes and the required quantities, Rocla Polokwane underwent

an overhaul in terms of the manufacturing sections needed to accommodate the upgraded equipment. We also made use of special vertical cast moulds which were required for use with the insertion of the sacrificial layer within the pipes. It was these changes that enabled us to meet the quantities of HDPE pipes required for the Polokwane Waste Water Treatment Plant, projects as they allowed us to increase our production schedules and deliver to site timeously.”

Concrete pipe with a cast-in HDPE lining has all the advantages of a strong, rigid pipe that keeps its shape, as well as those of a plastic pipe that is inert to acid attack. It is the best pipe for large-diameter gravity pipelines in almost any conditions. Standard HDPE lining is light green and 3mm thick. Different colours and thicknesses can be supplied.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 19 INDUSTRY NEWS

CESA INFRASTRUCTURE INDABA 2022

PROCUREMENT CRISIS IMPACTING SERVICE DELIVERY

The second day of the Consulting Engineers South Africa (CESA) Annual Infrastructure Indaba kicked off with discussions centering largely on procurement and public infrastructure projects, engineering capability and technology, and water security. A strong message carried through across both conference days focused on the serious impact of the procurement crisis and the crucial need for the implementation of a capable infrastructure project pipeline for the sustainability of the industry, as well as the impact on the economic recovery of the country.

PROCUREMENT AND PUBLIC INFRASTRUCTURE PROJECTS

The session entitled “Procurement and Public Infrastructure Projects” included the presentations “Building a Capable Industry and State: A Holistic Anti-Corruption Approach”, presented by Julian Rumbelow, co-founder and director at GIACC-SA, “A Fresh Approach to the Procurement of Public Infrastructure Projects” by Ivor Chipkin, Government and Public Policy, “Implementing an Integrated Strategy for the Reconstruction, Growth and Development of the Construction Industry” by Bongani Dladla, CEO of the CIDB and “A Global Approach: Procurement Magnifying the Impact of Consulting Engineers on Projects

and Societal Needs” by Malani Padayachee-Saman, consulting engineer at MPAMOT.

“We have a huge procurement crisis,” said Chipkin. “We’ve lost control, with the consulting engineering industry bearing

the brunt of the chaotic consequences. We need to push it forward by depoliticising, professionalising and bringing transparency to the public service. Pressure needs to be put on the government to reform.”

INJURING INDUSTRY AND THE DISASTROUS COST OF CORRUPTION

Dlada presented several challenges affecting the construction sector. “We’re facing the severe consequences of unemployment and without meaningful transformation, the construction sector isn’t

SOUTH AFRICAN BUILDER NOVEMBER 202220 INDUSTRY NEWS

(Above): Malani Padayachee-Saman, MPAMOT; Julien Rumbelow, GIACC-SA; Ivor Chipkin, GAPP; Bongani Dladla, CIDB.

“WE NEED TO BUILD AN ANTI-CORRUPTION CULTURE IN SA THROUGH TRAINING AND VARIOUS INTERVENTIONS, PUTTING IN MEASURES THAT MAKE IT DIFFICULT TO HAPPEN IN THE FIRST PLACE.”

sustainable. Tender cancellations are a major issue. We need more punitive measures, as it’s killing businesses. In addition, the longer we delay projects, the more they cost,” he stated. He also called for the implementation of a capable infrastructure project pipeline as being critical for the sustainability of the construction industry.

Padayachee-Sanab discussed global trends, including the climate crisis, socio-economic risks, the debt crisis, supply chain bottlenecks and issues of diversity and inclusivity. “We need to have strategic alliances with both the public and private sectors in dealing with issues of procurement,” she said. In relation to the current skills crisis in the country, she added that the challenge was to keep professional engineering skills within SA.

SAVING LOCAL GOVERNMENT

Other key insights offered by the presenters included: “Service delivery, particularly related to infrastructure, is the major challenge for all municipalities, due to numerous issues including lack of technical capacity, procurement processes causing delays, underfunding and lack of maintenance with massive infrastructure backlogs.”

“SALGA has created a detailed plan of priorities for a digital future focused on smart solutions related to infrastructure and revenue management strategies. We’d like to change the narrative of municipalities focusing on driving key priorities that include

procurement and funding to reconfigure for technology and innovation.”

“Don’t let technology take the engineer out of engineering. We need to use technology to enhance our work, not replace it.”

RESOURCES AND THE ENVIRONMENT

In the session focused on water security, facilitated by Uzair Osman, YFP deputy chairperson from Bosch Projects, panellists included Dr Sean Phillips, director-general: NWS, Prof Mbangiseni Nepfumbada, codirector: Joint Research Center – Water, Environmental Science & Technology (JRC-WEST) and Andi Rweqane of Royal HaskoningDHV.

“Water scarcity is now one of the leading challenges for sustainable development,” said Rweqane. She discussed “smart water” and the need to optimise and automate

designs through the use of digital twins for the future.

In closing, CESA CEO Chris Campbell said that discussions over the two-day conference had inspired thinking about approaching infrastructure development from an entire lifecycle perspective. CESA president Olu Soluade concluded the event by presenting resolutions which were developed over the course of the indaba.

(Below): Ivor Chipkin of GAPP, Julian Rumbelow of GIACC-SA, Gift Mphefu of Med-Tech Engineer, Bongani Dladla of the CIDB, Malani PadayacheeSaman of MPAMOT and Olu Soluade, CESA president.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 21 INDUSTRY NEWS

“SERVICE DELIVERY, PARTICULARLY RELATED TO INFRASTRUCTURE, IS THE MAJOR CHALLENGE FOR MUNICIPALITIES.”

QUALITY OF MORTAR MIX IMPORTANT

FOR SUSTAINABILITY

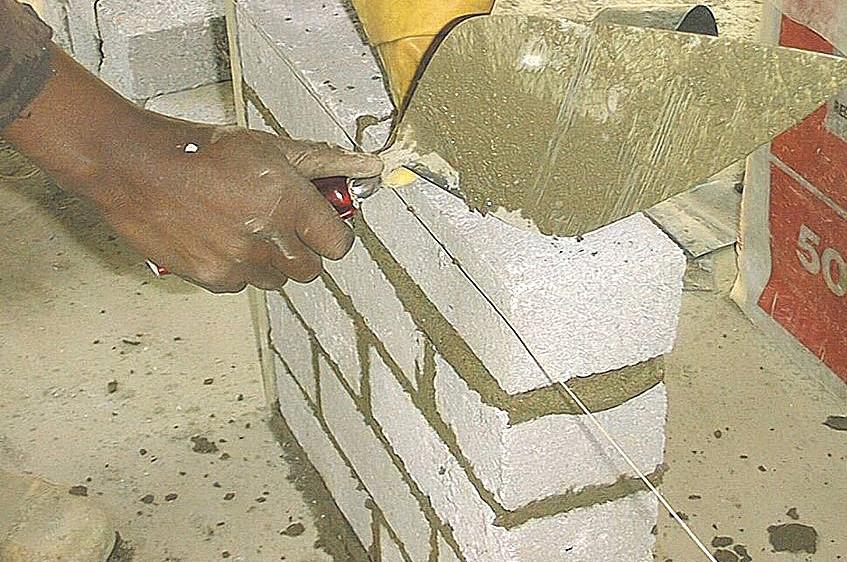

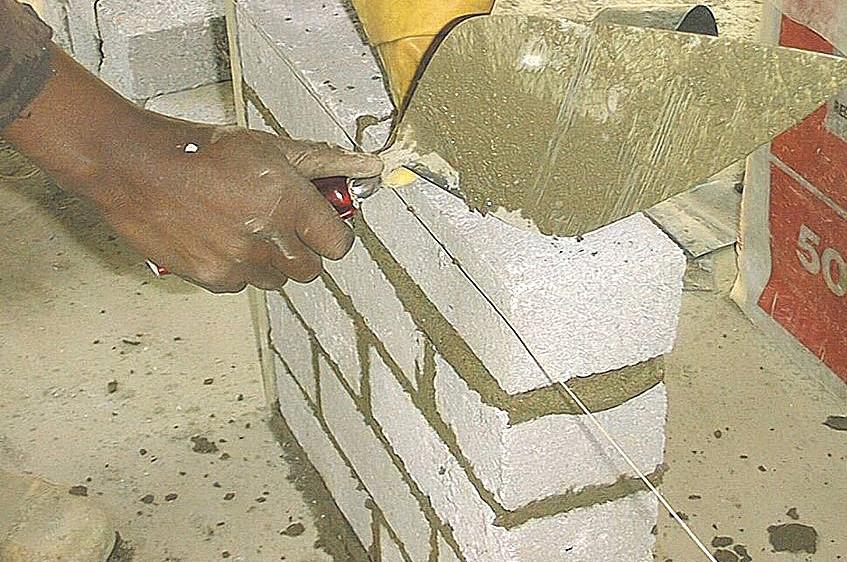

The quality of the mortar invariably determines the durability of any new structure, says Matthews Magwaza, lecturer at Cement & Concrete SA’s School of Concrete Technology.

“Mortar binds bricks and blocks together to give strength and stability to a wall and in developing countries, where contractors tend to produce their own mortar rather than factory-purchase it, the importance of correctly produced mortar is extremely important to ensure sustainable structures,” he states.

Magwaza says freshly mixed mortar must be soft and plastic so that it spreads easily and makes good contact without becoming too strong. Mortar that is

too strong may crack and is wasteful and expensive. “The proportion of each material in the mix should suit the type of work being done. In general terms, the classes of mortar commonly used in South Africa are Class I for high-strength structural units such as multi-storey load-bearing buildings

SOUTH AFRICAN BUILDER NOVEMBER 202222 INDUSTRY NEWS

“THE PROPORTION OF EACH MATERIAL IN THE MIX SHOULD SUIT THE TYPE OF WORK BEING DONE.”

or reinforced masonry and Class II mortar for normal load-bearing applications, as well as parapets, balustrades, retaining structures, free-standing and garden walls, as well as walls exposed to possible severe dampness.”

Magwaza says the preferred cement types for quality mortars are:

• Common cement complying with SANS 50197-1; and

• Masonry cement complying with SANS 50413-1; strength class 22,5X.

“The addition of lime in the mortar mix is optional. Lime should be used if the sand lacks fine material or is single-sized, as such sands tend to produce mortar with poor workability unless lime is included in the mix. Lime also helps the fresh mortar to retain water when it's placed against dry masonry units and helps to prevent cracking of the hardened mortar. Use only building lime complying with SANS 523 and don't use quick-lime, lime

wash or agricultural lime. Lime should also never be used with masonry cement.

“The sand in the mix mustn't contain organic material produced by animal or plant activities, nor particles retained on a sieve of nominal aperture size 5mm. When 2,5kg of cement is mixed with 12,5 kg of air-dry sand, the mixture won't require more than 3 litres of water to be added to reach a consistency suitable for the laying of masonry units. When mixed with the cement in accordance with the mix proportions, the sand must have workability suitable for the laying of masonry units. Sands which require the addition of more than 3 litres of water to reach a consistency suitable for the laying of masonry units can in some instances be blended with a coarse sand for compliance. The proportion of the blended sand can be determined by trials. Some pit sands are suitable. River, dune and beach sands are often too uniform in size or too fine to give

good results without being blend ed with another suitable sand.

“When it comes to batching, a 65-litre builder’s wheelbarrow is a convenient measure for large batches. Steel drums of 20- or 25-litre capacity and buckets are useful for small batches.

“Mixing should be done on a clean, hard surface such as a smooth concrete floor or a steel sheet. Small batches may be mixed in a wheelbarrow provided that the volume of the batch is no more than half the capacity of the barrow. Sand and cement, and lime if used, should be mixed dry until the colour of the mix is uniform. Then add water in small quantities, mixing after each addition, until the mix is soft and plastic,” he explains.

Magwaza says if mortar is left in the sun before being used, it should be covered with plastic sheeting or a wet sack. Mortar that has stiffened so much that it is impossible to restore workability without adding more water should be discarded.

“Mortar mustn't be used after it's started to set, which usually occurs about two hours after it's been mixed. Don't use too thick a layer of mortar between bricks or blocks; this is wasteful and may lead to cracking,” he cautions.

For more information, including strength requirements and mix proportions recommended by Cement & Concrete SA, download the CCSA free leaflet on MORTARS at www.cemcon-sa.org.za or tel: 011 315 0300.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 23 INDUSTRY NEWS

WOMEN WINNING IN CONSTRUCTION

The Construction Industry Devel opment Board (CIDB) hosted the prestigious Empowerment and Recognition of Women in Con struction (ERWIC) Awards on 24 August 2022. This year’s awards had 12 categories that recognised companies and individuals who support the gender transforma tion, development, and mentor ship of women in the construction industry.

The ceremony was attended by the Department of Infrastructure and Public Work’s Deputy Minister Noxolo Kiviet, who in her impassioned keynote address congratulated the nominees and winners, and stated that

the event held during Women’s Month celebrated the strength, dedication and resilience of women dedicated to building the country. “These awards should always stand as the clarion call for gender transformation within the construction sector, showcasing the strength of women and serving as a vision of what women can achieve when given the necessary support,” she said.

CEO of the CIDB, Bongani Dladla stated: “The ERWIC Awards were developed by the CIDB to celebrate and encourage the development of women in the construction industry. He explained that the competition

at the ERWIC Awards had always been fierce and this year was no different. “The winners are all welldeserved and stand out in their respective categories,” he said.

THE WINNERS

The winner for Project Delivery Excellence of the Year – Grade 1 was Boitsholo Trading and Projects CC for its Coega Feltex Trim Factory Pretoria project. Coming in at second place was Sbonzin Trading for its Upgrading of Gravel Roads to Surface Roads, including the associated Stormwater project.

Winning the Project Delivery Excellence of the Year – Grade 2 –4 was Tumagole Trading Enterprise

SOUTH AFRICAN BUILDER NOVEMBER 202224 INDUSTRY NEWS

for the Renovations of the City of Johannesburg Recreation Centre project. In second place was Magiya Women’s Developers for its Construction of Stormwater in the Mhluzi Ward 25 project, while third place was awarded to Letsogo Trading Enterprise for its Upgrading of the Hans Coetzee Road project.

The Project Delivery Excellence of the Year – Grade 5 – 6 was Mam pumi Trading for its Buhlebuyeta Primary School (Refurbishment of 13 classrooms) project. In second place was the Philcorn Group for the Electrification of Driekoppies, Makaung, Malepetleke, Ngha lalume project.

The Project Delivery Excellence of the Year – Grade 7 upwards was Oakantswe Construction & Projects for the Nellmapius Ext 22 (erf 1223 & 12224) project. In second place was the Motheo Construction Group for the new Graaff-Reinet TVET College project.

The Rural Project of the Year award winner went to Kgothatso Electrical for the Electrification of 50 Households in the Boikhutsong Village project. The second place was awarded to Africa Hlahla Investments for Upgrading of Arlington Access Road project, while third place went to Quantum

Leap Investments 656 (Pty) Ltd for the Imvani 145 Low-Cost Housing project.

The Mentoring Entity of the Year was awarded to Thabomeleng Construction Group. In second place was Masoko Construction CC and third place was awarded to Kgothatso Electrical.

The first-place winner for Transformation Entity of the Year went to Thabomeleng Construction Group, while KNM Projects was awarded second place.

The Innovative Entity of the Year was awarded to Bashoeshoe Investments and Projects, second place went to Siphumelele Business Enterprice and the third-place award went to the Thabomeleng Construction Group.

The Business Resilience of the Year (Covid-19) was awarded to Quantum Leap Investments 656 (Pty) Ltd, while Moshiki and Letsogo Trading Enterprise awarded second and third place respectively.

The exciting Youth-Owned Women Construction Entity of the Year award was given to Yibanathi Mtirara from Magz Projects (Pty) Ltd, while second and third place were awarded to Mpumelelo

Angel Lekhuleni from Mpumistone Projects and Kgothatso Matsogo from Kgothatso Electrical.

The Women-owned Construction Entity of the Year award went to Malebogo Lobelo from Lobelo Building Contractors, while Lynette Mazibuko from Lenda Construction & Supply Services and Mafani Nelly Dasheka from Quantum Leap Investments 656 (Pty) Ltd came in a close second and third place.

Itumeleng Mohoang from the Thabomeleng Construction Group won the Women Mentor of the Year award.

The Exceptional Woman in Construction Contributor of the Year award went to Itumeleng Mohoang from the Thabomeleng Construction Group. In second place was Mafani Nelly Dasheka from Quantum Leap Investments 656 (Pty) Ltd, while third place was awarded to Faith Tshepiso Mabena from Nokhanya Services (Pty) Ltd. The awards concluded with the prestigious Chairman’s Award that went to Portia Tau Sekati.

Dladla indicated that the ERWIC Awards were a resounding suc cess, with the quality of entrants improving yearly. The quality of projects delivered, proven leadership through mentorship programmes, the resilience of some construction companies and the winners of the awards of the coveted women-owned Construc tion Company of the Year showed the intent and purpose that the awards aimed to celebrate – that women belonged and thrived in the construction industry.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 25 INDUSTRY NEWS

“THESE AWARDS SHOULD ALWAYS STAND AS THE CLARION CALL FOR GENDER TRANSFORMATION WITHIN THE CONSTRUCTION SECTOR SHOWCASING THE STRENGTH OF WOMEN AND SERVING AS A VISION OF WHAT WOMEN CAN ACHIEVE WHEN GIVEN THE NECESSARY SUPPORT.”

PERSONAL PROTECTIVE EQUIPMENT –THE RIGHT FOOTING

By Dr Anette Thompson, specialist podiatrist at SISI Safety Wear

By Dr Anette Thompson, specialist podiatrist at SISI Safety Wear

The culture of “zero harm” is about much more than preventing workplace accidents. Holistically speaking, it is about nurturing a workforce who are adequately equipped, properly educated and know that workplace safety does not end when their shift is over. It includes personal health, safety and well-being, and extends around the clock.

As awareness increases of the importance of having the correct personal protective equipment (PPE), it is important for individuals to acknowledge that health and safety requires more than wearing the gear on site, particularly when it comes to footcare. For workers who are on their feet all day, foot health is critical. While employers have an obligation to provide the correct PPE footwear for the job, workers also have a responsibility to ensure their own personal foot health.

AWARENESS IS THE FIRST STEP TOWARDS SAFETY

There are many ways to educate the workforce on foot health. Effective teaching methods include workshops and presentations from experts, in which workers are exposed to common foot ailments and how to prevent them.

Posters in washrooms and change rooms about how to practise good foot hygiene are also useful ways of teaching footcare. In mining, particularly, where working conditions can be hot, humid and sweaty, foot hygiene is extremely important. It includes proper and thorough washing and drying of feet once safety footwear has been removed. In caring for the feet properly, the skin barrier is properly maintained and in this regard, it must be noted that when moisturising the feet, it is unnecessary to apply lotion between the toes. If skin is dry and flaky, this is often an indication of another ailment such as eczema

and will require medical attention. Cracks or fissures in the skin barrier of the feet must not be ignored and if heels are dry, it is necessary to use heel balm specially formulated for footcare.

HYGIENE INSIDE AND OUT Hygiene also extends to the footwear itself. Workers need to understand that cleanliness inside boots is just as important in preventing bacterial, fungal and viral infections. This includes regularly wiping out boots with a damp cloth and a 10% bleach solution to eliminate bacteria and odour. Ultraviolet light from the sun is also effective for eliminating fungus and bacteria. Workers should leave their inner soles and boots in direct sunlight to dry after cleaning. Proper hygiene requires individuals to wear flip-flops in communal washing areas such as showers, as these are places where bacteria and fungus generally thrive and are easily transmitted. Ingrown toenails are a common ailment and should not be addressed without proper medical intervention, as there could be an underlying infection that requires attention.

FEATURE

SWEAT HAPPENS

While there are many different types of safety shoes and boots, all designed to prevent injury from hazards that cannot always be prevented, the importance of correct socks is severely underestimated. PPE footwear manufacturers are paying attention to the role of socks in foot health and designing socks that are fit for purpose. The inside of a work boot can be very sweaty, since feet sweat 200-250ml of water vapour every day as part of the body’s normal thermoregulatory function. It is therefore necessary to choose the correct socks. Workers should never wear their work footwear without socks, as this is extremely unhygienic, not to mention uncomfortable.

Almost as bad as not wearing socks at all are all-nylon ones, which act like plastic bags on the feet, increasing temperature and perspiration. For socks to be effective, they need to contain approximately 70% natural fibres to adequately absorb sweat, while 30% consists of man-made fibres to help draw moisture away from the skin. For workers who sweat excessively, the 72-hour anti-perspirant available at most

supermarkets can be sprayed onto the soles of their feet before putting on socks. With regular use, the antiperspirant reduces the size of the sweat glands, but does not block them.

FOOT HEALTH IS PROACTIVE CARE

Human beings have a tendency to ignore problems and hope they will resolve themselves. When it comes to feet, however, it is vital to address symptoms of ailments immediately. Workers should not be embarrassed to visit the on-site clinic, as these healthcare practitioners have been trained to assist and have likely already seen it all, or will refer workers to a foot health professional such as a podiatrist.

Protective clothing and footwear care must include effective management of bacteria and fungi, as well as personal hygiene

PROTECT YOUR FEET, PROTECT YOUR LIVELIHOOD Any compromise in foot health can be extremely detrimental to an individual’s ability to perform their job. This puts their livelihood at risk. While people in labour-intensive industries such as mining do work with their hands, one cannot overlook the importance of the feet. Accordingly, it is critical for construction organisations to do more than supply the correct footwear. They need to educate their workforce on the importance of footcare and how to achieve and maintain foot health, particularly in challenging underground working conditions.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 27 FEATURE

“HUMAN BEINGS HAVE A TENDENCY TO IGNORE PROBLEMS AND HOPE THEY WILL RESOLVE THEMSELVES.”

THE SUSTAINABILITY ECONOMY: WHY ARE WE SO BEHIND?

By Brondwyn Douglas, senior ESG officer: Spear Capital

The UK shooting past its record high daytime temperature in July was a powerful reminder that the effects of climate change will not be felt in the distant future, but are with us here and now. There have been many of these powerful reminders in 2022.

PASSING MILESTONES

Whether it is the wildfires raging across Europe, the floods that ravaged parts of Australia and South Africa earlier this year or the mega-drought which has enveloped the south-western areas of North America, the signs are now too glaring to ignore.

Acknowledging the problem and addressing it, however, are two different things. There has been much discussion about the net-zero commitments made by some of the world’s biggest governments, as well as the fact that the combined assets of companies committed to achieving net-zero emissions had risen to US$130 trillion by the end of 2021.

However, in the quest for a netzero world, is Africa being left behind? Is it getting the support it needs not only to develop sustainably, but to live with the effects of the climate catastrophe?

ADDRESSING SIGNIFICANT VULNERABILITIES

Africa is, after all, disproportionately affected by climate change, with rising global temperatures already triggering food insecurity, poverty and displacement across the continent. There will be other impacts too, including the destruction of heritage sites and a rise in conflict.

In many ways, the continent is suffering from the actions of others, particularly in the developed world. Africa itself is only responsible for less than 3% of global CO2 emissions. Despite that, and despite the fact that

large parts of the continent still have a lot of ground to make up when it comes to growth and development, Africa is under massive pressure to reduce its own emissions.

FUNDING A LEVERAGE: CARROT OR STICK?

In fact, as an article in Foreign Policy points out, some richworld nations have gone as far as leveraging development aid and threatening to cut off finance in order to push African countries into adopting climate change mitigation strategies. At surface level, it is possible to understand why the rich world is putting this kind of pressure on the continent.

SOUTH AFRICAN BUILDER NOVEMBER 202228 FEATURE

Having seen the rapid economic rise of China, India and other large emerging markets result in matching increases in carbon emissions, it fears that the same will happen in Africa. That, too, makes a modicum of sense. While population growth in other parts of the world is plateauing or even shrinking, it is still accelerating across the continent. In fact, 2020 research showed that the world’s 15 fastest-growing cities were all in Africa.

LOW DEVELOPMENT LEVELS AND LEAST EMISSIONS

The trouble is that both of those views ignore a few realities. The first is that the continent is starting from such a low energy usage base (with the notable exception of SA, which has the world’s most polluting power company in the shape of Eskom) that, even on the continent’s accelerated growth path, its contribution to global emissions is likely to remain lower

than that of the developed world for some time to come.

The second is that Africa has a long history of adopting innovations without needing all the preceding stages other countries experienced. The story of how the continent “leapfrogged” fixed-line telephony with mobile phones is well known, as is its embrace of mobile money. Less well-known is how it has used those innovations to embrace things like off-grid solar power.

As countries across the developed world try to figure out how to change their power systems from one-way, centralised grids to smart, two-way ones, many parts of Africa have the chance to take such an approach from the beginning.

LEAP-FROG DEVELOPMENT

FROM THE GROUND UP Africa, in other words, needs different ways of thinking to

guarantee a greener future. To our mind, that looks like investment in the companies which are already making a difference on the ground, fostering development and advancing sustainability.

These companies understand the realities of the markets in which they operate and are in a much better position to push Africa towards sustainable development and even net-zero emissions than paternalistic handouts and punitive threats.

While limiting the effects of the climate catastrophe is and should be a global effort, it should not be informed by misconceptions that Africa represents some kind of existential climate threat. In fact, with the right investments in the right places, it might just offer models that the rest of the world can follow.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 29 FEATURE

“IN MANY WAYS, THE CONTINENT IS SUFFERING FROM THE ACTIONS OF OTHERS, PARTICULARLY IN THE DEVELOPED WORLD.”

(Above): Africa’s development status means it contributes less than 3% of global emissions, a huge advantage when it comes to leap-frogging sustainable development technologies.

FUTURE-PROOFED WITH BRICK

Face-brick and paving from Corobrik played a prominent role in the future-proofed design of the new state-of-the-art Waterkloof Hills Combined School in Rustenburg, North West. The 11 500 m2 project was built by Royal Bafokeng Platinum (RBPlat) in partnership with the North West Department of Education (NWDoE). Mzansi Wealth was the lead consultant and project manager.

The Waterkloof Hills Combined School was officially opened by Minister of Basic Education Angie Motshekga and Minerals & Energy

Minister Gwede Mantashe in a high-profile unveiling ceremony on 5 August.

“Face-brick is durable, longlasting and keeps its appearance for an extended period. In addition, there is the benefit of no maintenance, which is important

in the context of a school,” comments Floris van der Walt from Olivehill Architects.

The school can accommodate 2 155 pupils, with 1 280 pupils in the primary school (with four streams) and 875 pupils in the secondary school (with five streams). A feature of the school is that there are 32 “smart” classrooms equipped for remote learning and teaching.

DURABILITY OF BRICK: BEYOND FACE VALUE

A total of 180 000 Onyx Satin FBX and 480 000 Ruby Light FBS face-bricks, 27 000

Nutmeg pavers and 110 000 plaster bricks for the internal walls were supplied from Corobrik’s Midrand and Springs factories, according to Gary Westwood, sales manager for Mpumalanga, North West and Botswana.

A key requirement from RBPlat and NWDoE was durability. This resulted in choosing face-brick for all high contact and hightraffic areas. For example, in the classrooms themselves, only the front and back walls are plastered brick to cater for the necessary internal services, while all the side walls are face-brick.

Face-brick was a natural choice in terms of its price point and aes thetic contribution. The architects

FEATURE

opted for the combination of Onyx Satin face-brick, a dark brown high-end product, contrast ed against the lighter orange Ruby Light face-brick.

Westwood says that Onyx Satin is the “Rolls-Royce” of Corobrik’s face-bricks, used extensively for detailed highlighting work. “Onyx Satin is a simply stunning facebrick that we used in very specific focus areas and feature walls,” he adds.

THE AESTHETIC PROPERTIES

Commenting on the thoughtful design that went into the project, Van der Walt says simply that

even a school building can be inspirational and, in turn, inspire its eventual end users. “Even though we had a limited budget, face-brick allowed us to heighten the aesthetic appeal of the project and also to future-proof it.”

Westwood says that Corobrik’s collaboration with Olivehill Architects on this project is typical of the extra mile it goes for its architectural clients. Its business development team discussed various options for the

school, with husband-and-wife design team Floris and Irma van der Walt eventually selecting their final combination based on various samples.

Full-size sample walls were then built on-site to give the architects a better impression of the end product in terms of quality, sizing and colour. Corobrik also supplied a bricklayer trainer to train local bricklayers, thereby assisting with skills development and empowering local communities.

“Not only does this translate into better quality at the end of the day, but it means a project in which all stakeholders can take pride,” says Westwood.

NOVEMBER 2022 SOUTH AFRICAN BUILDER 31 FEATURE

“FULL-SIZE SAMPLE WALLS WERE THEN BUILT ON-SITE TO GIVE THE ARCHITECTS A BETTER IMPRESSION OF THE END PRODUCT IN TERMS OF QUALITY, SIZING AND COLOUR.”

PLUGGING INTO THE RIGHT ELECTRICAL CONTRACTOR

By ECA member Juan Beyneveldt, MD, Atom Electrical