Introduction to Jingoli Power Material Management

Introduction to Jingoli Power Material Management

Introduction to Jingoli Power Material Management

Introduction to Jingoli Power Material Management

WHO WE ARE?

WHAT WE DO?

HOW WE DO IT?

JINGOLI is a nationally ranked contractor / construction manager with over 100 years of experience servicing power, industrial, healthcare, gaming and educational clientele. JINGOLI has built a solid reputation by providing a full spectrum of services to the private sector, as well as municipal, county and state governments.

JINGOLI’s unique combination of professional expertise, personal attention to detail and financial stability enables them to continually support their clients’ construction goals by delivering a high quality project, on-time and on-budget.

Jingoli Power, LLC provides professional services staffing, project management, materials and construction management services for complex electrical transmission, distribution and substation projects and programs. Our flexible model and vertical integration capabilities guide a client’s project from conceptual phase through engineering, procurement, construction and commissioning.

EMR Ratings:

2023-2024 = 0.504

2022-2023 = 0.438

2021-2022 = 0.344

2020-2021 = 0.373

2019-2020 = 0.444

OSHA Citations = 0

Bonding Capacity

Aggregate: $2,000,000,000

Single Project: $500,000,000

Our Veteran led Materials Operations Group employs a Cradle-to-Grave life cycle approach to managing Projects.

Services include constructability analysis, inspections of key materials during fabrications, receiving and issuing material, trucking material to the right-of-way, and maintaining an electronic repository of all project quality control deliverables.

Our services ensure 100% traceability of every single piece of material.

JPOW - Proud Recipient of 2022 US Department of Labor HIRE Vets

Platinum Medallion

JPOW - Proud Recipient of 2022 US Department of Labor HIRE Vets

Platinum Medallion

The program is referred to internally as CGIP (Carolinas Grid Improvement Program). Over the next 5 years, CGIP will roughly double the amount of construction and materials management volumes.

Material Management for a 100 mile 345kV transmission project including inventory control, constructability analysis, laydown yards, QA/QC on receipt, load out

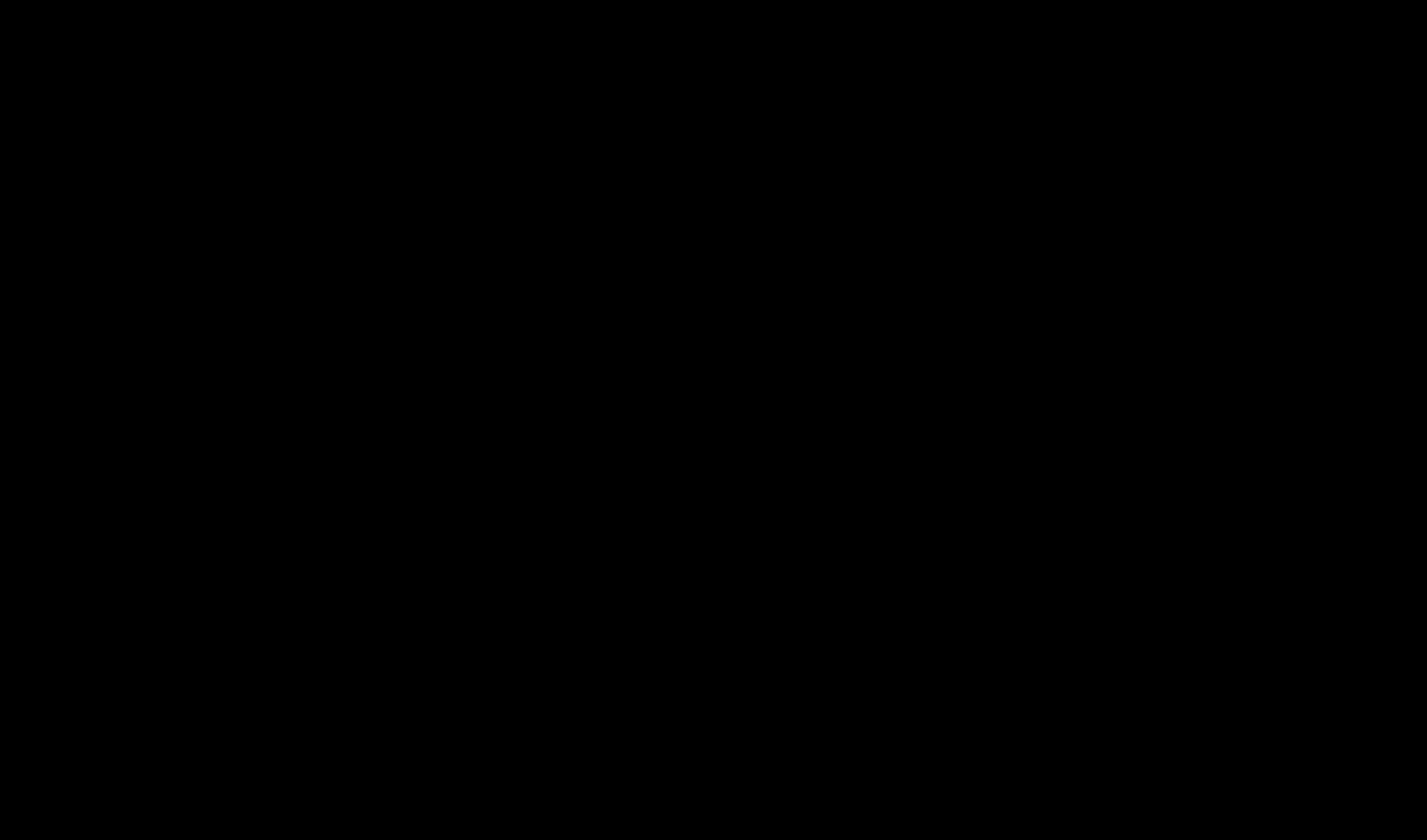

Jingoli Power is directly contracted with PSE&G to perform material logistics, QA/QC, and source inspection. Our approximate contract value is $19 Million. Our anticipated material throughput is $200 Million US Dollars. Total project estimated cost is $739 Million.

Duke Energy Carolinas Capital Growth Program Material Management Services Quanta Services – NIPSCO Reynolds-Topeka Transmission Line PSE&G Metuchen-TrentonBurlington Project (MTB)Construction Management, Material Management, and Site Control on the new indoor four-bay breakerand-a-half GIS switching station in center city Newark, NJ. The Newark Switch Project is valued at over $350M.

Our U.S. Veteran-led Materials Operations Group employs a Cradle-to-Grave life cycle analysis to inform our materials selection and distribution to ensure optimum value and guarantees 100% traceability of every single piece of material.

Services include inspections of key materials during fabrication, trucking material to the right-of-way and an electronic repository for all project quality control deliverables from all.

Strategic Program Material Logistics Management and Procurement

Field/Site Material Care and Setup of Material Distribution Centers/Yards

Material Financing/Inventory Carrying

Carry material inventory at the Material Distribution Centers/Yards at the request of the Owner/Utility, for the purposes of anticipating the upcoming immediate needs of upcoming projects, without invoicing the Owner/Utility under normal payment terms.

Acceptance of Risk

Our material logistics management program accepts “assumed risk” in performing our proposed scope of services including:

+ Material loss, damage, and theft

+ Material availability

+ Material on-time delivery

+ Safety of Material Operations

+ Material quality

Financial Strength

Bonding Capacity of One Billion Dollars ($2,000,000,000) with single projects in upwards of $500,000,000.

q Materials Management

q Laydown Yard Planning

q Constructability Planning

q Safety Services

q Inventory Control

q Procurement Support/Expediting

q Fuel Management

q QA/QC Services

q Project Logistics

We can manage materials from source to delivery.

We have integrated our quality management and material management systems.

We have experienced and dedicated material management personnel.

Material Management data base updates real time to ensure schedule adherence.

Proactively assess potential shortfalls and react accordingly in the best interest of the organization and the customer.

We accept risk of loss and take risk on performance.

Lessons Learned

Project Right-Sizing

Custom Database Tools

Initial Project Workshop

Detailed

Project Estimation

Deep Scope Review

Experienced Personnel

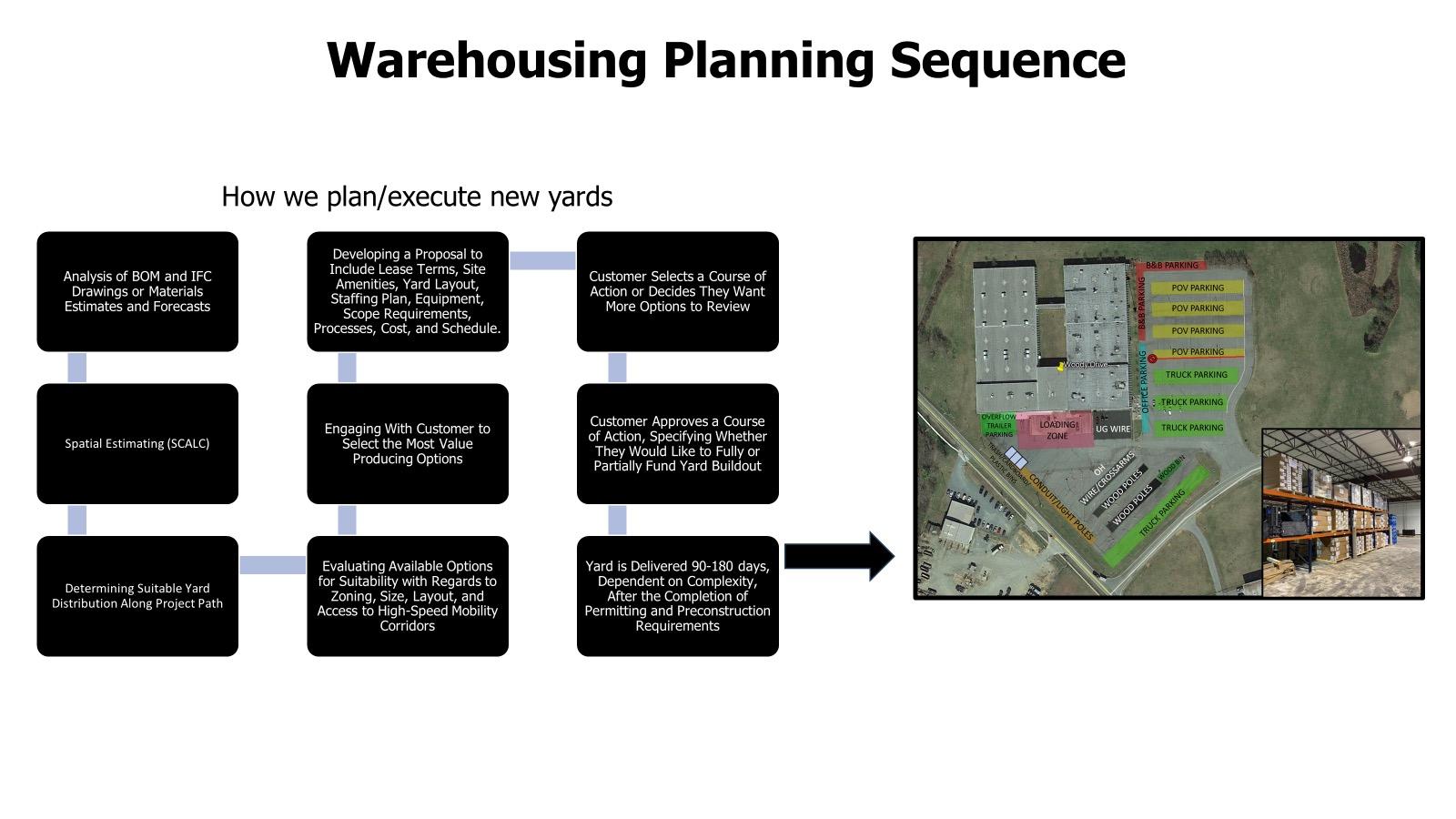

Analysis of BOM and IFC

Drawings or Materials

Estimates and Forecasts

Spatial Estimating (SCALC)

Determining Suitable Yard

Distribution Along Project Path

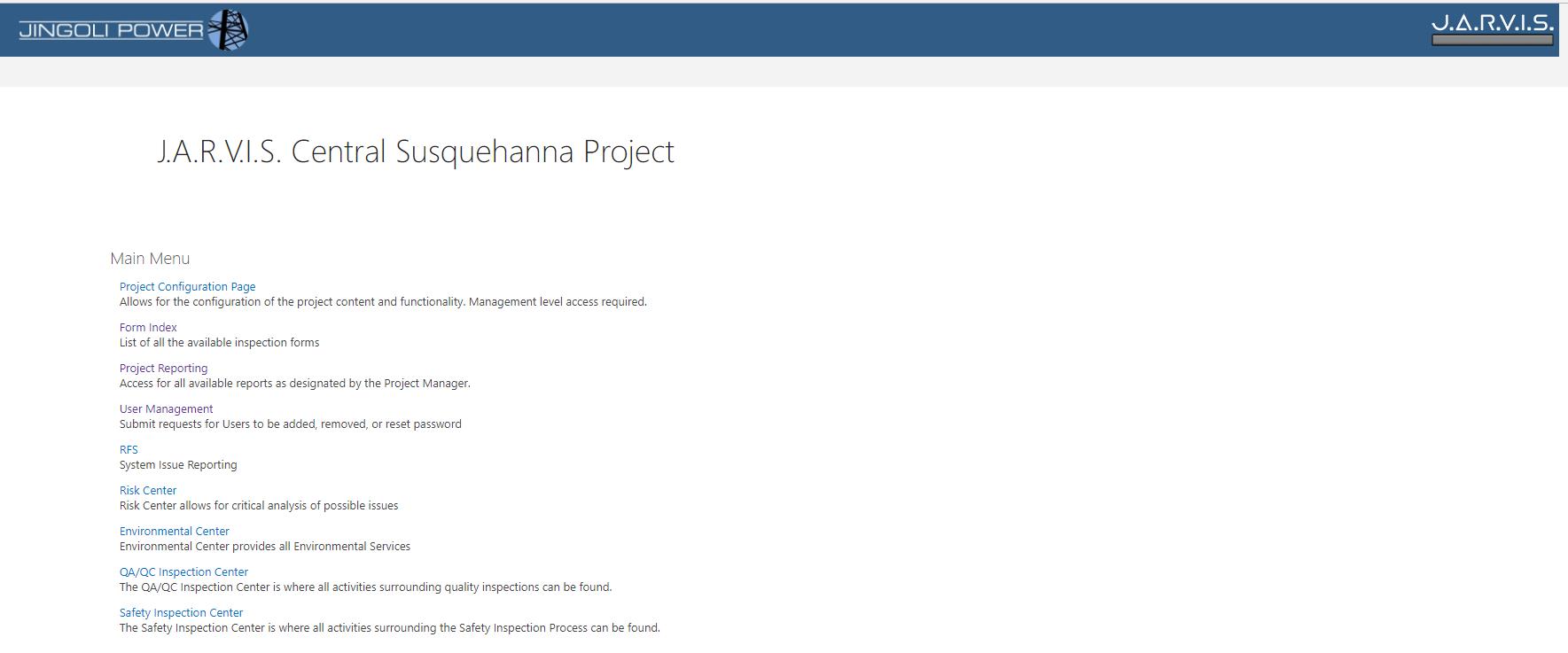

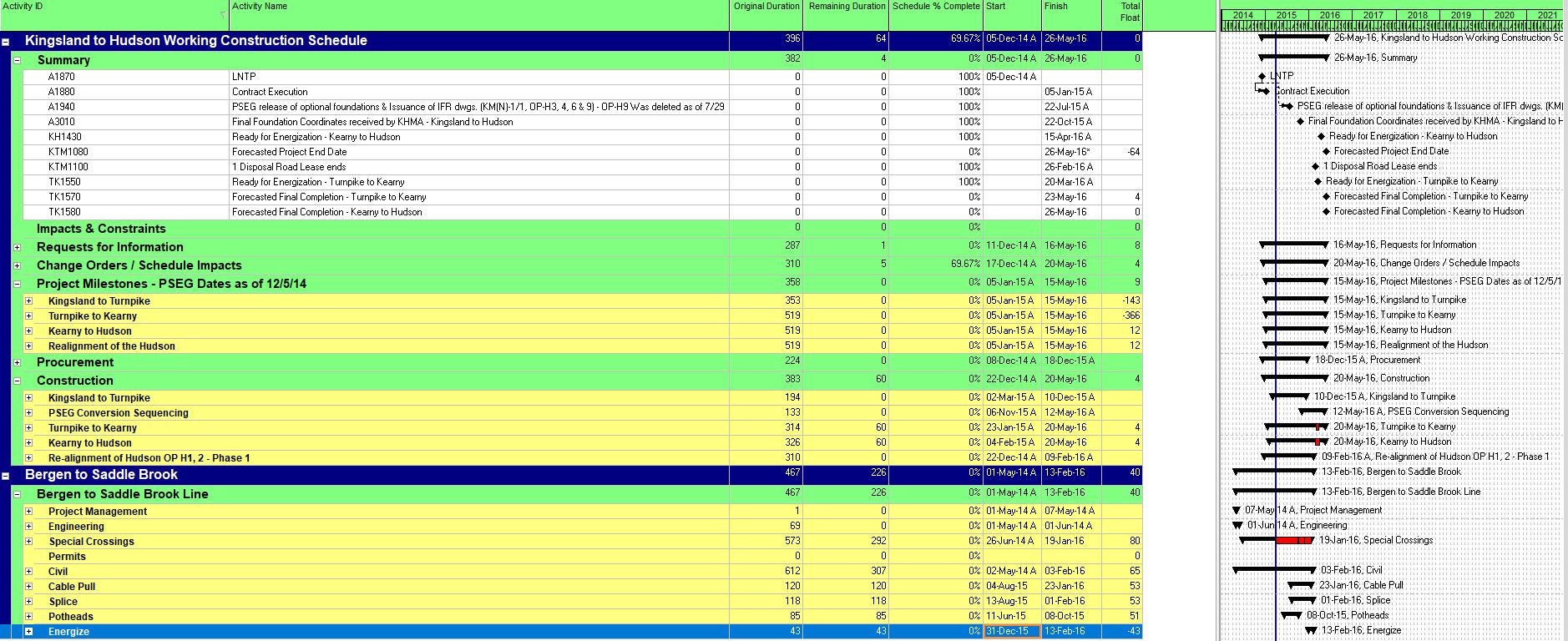

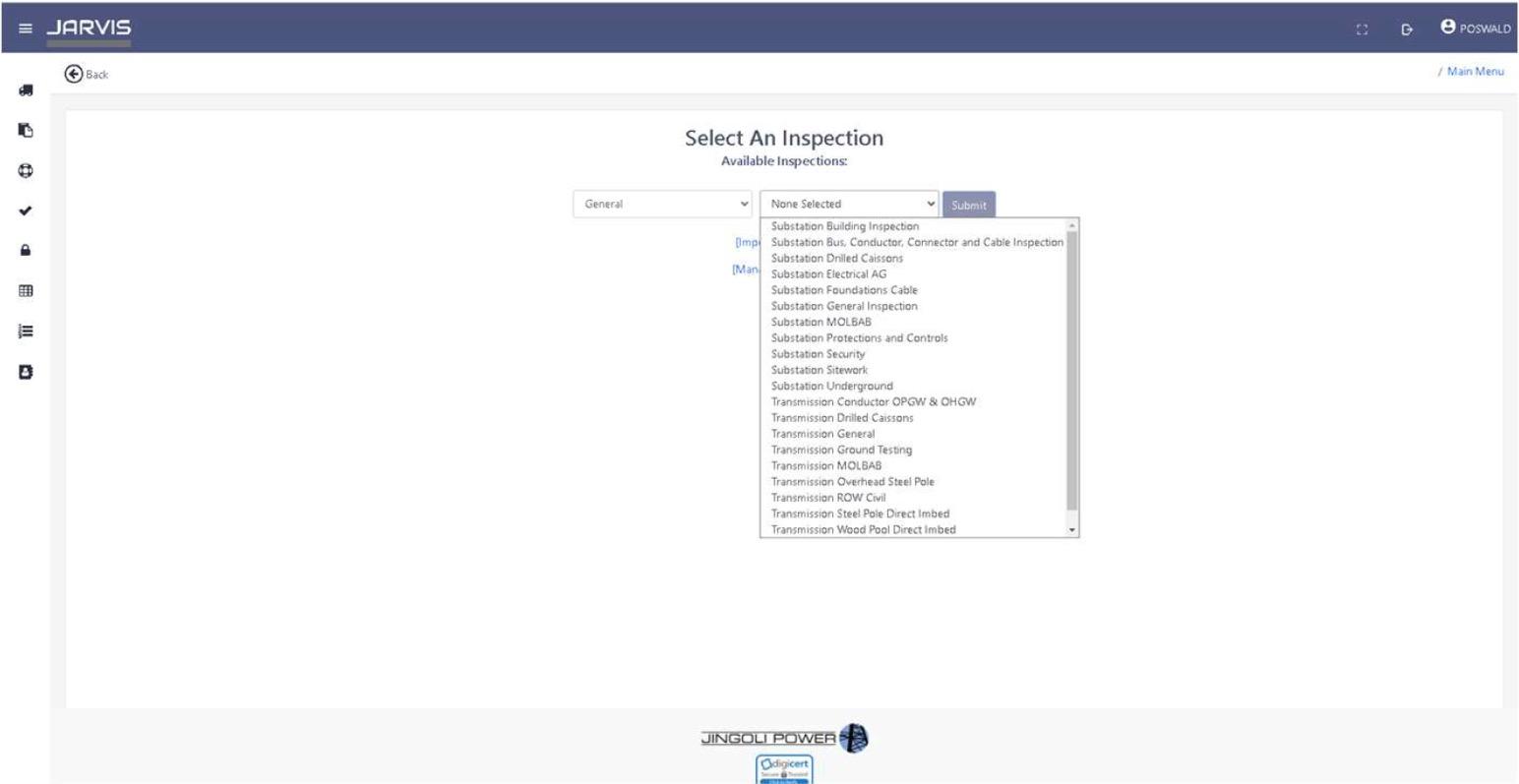

Jingoli Power uses JARVIS, its proprietary application to track and aggregate QA/QC inspections and testing data, to provide users a real-time analysis of deficiencies during construction to refine and optimize the final product. So at the project’s completion, our customers know that the asset they added to their system is comprised of the materials that were properly specified by the Engineers and properly installed by the Contractors.

qLifecycle QA/QC down to component

qWork with the contractor to proactively engage QA/QC into the plan

qDocument and learn from non-conformances

qEvaluate Extended Conditions

qSoftware that provides real-time dashboards and status’

qTablets and phones to document inspections and photos.

Receive/Issue Logs (MSE/PDF/Online)

Item Inventory (MSE)

Constructability (MSE)

A detailed report designed to inform decision-makers of how and where to best deploy their current inventory.

Purchase Order Fulfillment (MSE/PDF/Online)

Inventory Snapshot (Online)

Locate items by ICN with their most current information.

Hot List Item (MSE/PDF/Online)

Items identified as required but not on-hand.

Transaction History (MSE/PDF/Online)

Procore (Document Control)

JARVIS QA/QC (KAREN) Inspection Module is a based digital inspection system that is built to be customized to your organization’s quickly and with lower setup cost.

JARVIS stands for Jingoli Automated Reporting and Virtual Information System. Designed to bring information to user’s quickly while allowing for adaptation during the project.

It was built to work for our teams. This was not built with the intention of selling it. We built this to use.

Jingoli Power built a proprietary solution to provide actionable insight for managers and teams in the field, eliminating the need for physically transferring data from paper formers into PM dashboards. JARVIS aggregates operational data to predict problems before they happen so crews can adjust and avoid a costly breakdown or work stoppage. JARVIS modules offer real-time data over the life of a project, including solutions that enhance:

q Procurement

q Materials management

q Quality assurance

q Risk management

q Safety

q Environmental impact assessments

Jingoli Power’s in-house technology development team can adjust these solutions and reconfigure JARVIS to meet a customer’s unique data requirements

True Mobility: JARVIS forms work on iPads, iPhones, and Android tablets and smartphones

Real Time Connectivity: Inspection forms can be submitted right into your SharePoint from the field, in real time, over any data network

Advanced Data Collection: Put modern technology to work for your inspectors. Snap a photo directly into the form. Collect a signature and GPS place stamp to the form.

Enhanced Data Precision: JARVIS forms are intelligent. Your custom forms are able to offer the inspector different questions based on previous answers, to auto-fill fields, validate data, and to perform calculations in the field.

Total Flexibility: Every JARVIS form and report can be uniquely customized to your needs. Every project has its own unique challenges and priorities. We specialize in obtaining the data you need in the format you require.

JINGOLI is proactive about conducting community outreach through service, education and mentorship so residents, businesses and youth in those areas benefit from JINGOLI’s presence and involvement.

TALENT

Finding Local Employees for Job Sites

Identifying SBEs, WBEs & MBEs to Provide Services at Job Sites

LIVE CLASSROOM

Educating High School Students Interested In the Industry

ACE Harbor Beach –(18) Local Craft and Professional Interns

PSEG NEWARK SWITCH – (13) Local Hires; (3) accepted into the Union Trades (Carpenters, Heavy Highway and Electrical)

SDGE FCA PROGRAM –

DoD Skillbridge – Veterans to Work

CAMDEN WATERFRONT –(118) Local Hires, $22 mil. awarded to Local Businesses