words & pictures

saws

your next replacement

dark trends

The Hawa Concepta RangeNow whisper quiet!

Ultra-quiet sliding doors have been the trademark and recipe for success of Hawa for over 50 years. With the latest generation of Concepta - the last possible sources of noise have been eliminated. If you listen carefully, you will be able to hear... nothing at all, actually.

Soft Closing.

Hinges now come standard with soft-close to ensure the most smooth and silent action.

Increased Stability.

The new torsion panel that increases the stability of the Hawa Concepta 25 and 30 system while closing.

Completely Silent.

The soft close dampener and other subtle improvements in the components ensure a totally smooth movement and absolute silence.

View

for a perfect finish start with GoldenEdge HMR0

GoldenEdge HMR0 is the proven MDF that provides a perfect paint finish. It’s that simple.

Eco friendly GoldenEdge HMR0 (high moisture resistance zero emissions) is rated E0 and comes in 9mm, 12mm, 16mm, 18mm and 25mm thicknesses.

It’s recommended for kitchen units, cabinets,

bathroom vanities - everywhere a perfect paint finish is required.

GoldenEdge HMR0 is just one of the many MDF products provided by Nelson Pine Industries using the advanced technology of the Küsters continuous press and offering an unsurpassed range of board densities and thicknesses.

Eco Friendly helpingtheenvironment

COLUMNS

Master Joiners 4

Master Joiners President Andrew Reilly talks about the importance of reaching out, education and succession planning.

Laminex Update 15

Mike Arthur engenders optimism with the latest residential and commercial consent figures showing record numbers being processed.

Steering a Course 76

Ian Featherstone acknowledges current stress levels and offers a few thoughts on how we might minimise the risk and impact.

Due Process 78

Geoff Hardy asks - how are joiners going to protect themselves against their profitability being eroded by prices rises in the aftermath of the pandemic?

NKBA report 86

NKBA president Nick Thompson gives a wrap on a year which saw covid restrictions, the forming of Designers of NKBA and record numbers at conference.

REGULAR

News & Info 4 - 14

Education 74

NZJMF membership 80

State of the Industry 84

Classifieds 88

Advertiser index 88

form and finish 18

The sheer range of styles and finishes available means handle selection causes as much comment and uncertainty as any component within the kitchen. We provide some pictures to help.

the next move 26

Peter Hay Kitchens have always been at the forefront of the NZ kitchen manufacturing community. The recent purchase of three edgebanding lines from German machinery supplier Homag has continued that tradition.

saws & hybrids 30

Drill bits have taken over many of the functions of the saw blade in processing panel and solid timber. But sometimes the saw remains the best option - we look at the place of the saw in the modern factory.

hinges 46

While looks are important, function is critical and durability is necessary, a big plus for cabinetmakers when it come to hinges is that they are simple to fit and easy to adjust. We look at options that cover all criteria.

vortek spaces 54

3D presentation software has been creating a bit of talk in the New Zealand design community lately. We spoke to several users of Vortek Spaces who are finding the software useful in helping them share the vision.

$20,000.00 cash giveaway from Evostone - p.68

Reaching out and planning

FirstlyI’d like to shout out to all of our members in the Auckland, Northland and Waikato areas, our heart goes out to you guys. You’ve certainly had the short end of the stick with all the restrictions you’ve had to work under and try keep your hardearned businesses afloat.

I take my hat off to all of you and don’t forget to reach out to your fellow Master Joiner community for support if needed, you’d be surprised how much difference a phone call can make to someone who you know is struggling with all of this. In this digital age a text or email may be the quickest way to communicate but nothing beats a real phone conversation. Master Joiners are there to help in any way possible you just need to reach out.

On a lighter note. Master Joiners recently reached out to a good cross section of our members to

attend an education retreat with the aim to better educate our members on the benefits of being a member of the association and to get a better understanding of what head office and the executive do to support our membership.

This was the first exercise of its type and was rated a great success by all who facilitated and attended, so if you’re ever invited to attend one of these workshops in the future please don’t hesitate to put your hand up and participate. The only downside was that several participants from Auckland and Waikato were unable to attend due to covid restrictions but we plan to take this to them as soon as we are able to.

Education plays a major role in our industry, from the importance of training apprentices without whom our trade would simply die to training ourselves on better business practices to training

our key staff in growing more knowledge about business the industry and better practices all of which will grow our own businesses. This leads into surrounding yourself with skilled staff which makes succession planning a much simpler process. Succession planning just like myself is not something we prioritise to prepare ourselves for until sometimes it's too late or you’re getting to a stage in your working life where you want to take a backwards step from the day to day grind and start passing the torch to the next generation coming through. This isn’t something you can start too early and we need to ensure we’re passing our knowledge down the chain because believe it or not you probably know a lot more than you give yourself credit for.

That’s all from me, I hope you all have a good lead into the stupid season and just remember

the world doesn’t actually end at Christmas and restart at New Years so those jobs you can’t get done can most probably wait until next year. Hope you all have a good break and forget about work and Covid for a while.

Andrew Reilly National President Registered Mastered Joiners

JOINING IT ALL TOGETHER

Partnering with CARTERS makes it simple to get the pieces of the puzzle sorted for that perfect finish, every time.

You can count on us to stock the market’s best-known brands. We’ve been servicing the joinery market for decades and understand the special requirements needed by a joiner, not a one size fits all approach.

Let’s partner together on your next project. The full range of Bestwood Melamine colours available at your local CARTERS.

ount the market’s been by a not artner togeth ext range od s you ARTERS.

r on r

Editor Michael Goddard michael@joiners.net.nz

Publisher Bob Nordgren bob@joiners.net.nz

Of Hinges & Handles ...

At last Winter has gone and Summer is upon us. We have a truly bumper Christmas issue for you this time to see you through the holiday break. Easily fitted and adjusted hinges are key attributes of the modern hinge in the kitchen (and anywhere else). We have a few of the latest from the leading suppliers for those who are either building new or renovating their kitchens (and there are a lot of people doing this). Despite the handle less look in the kitchen remaining popular there is still great demand for handles as well. We have a look at some of the latest offerings. In the machinery sector we have a look at the use of saws and the related tool supply scene. There are new offerings from a number of suppliers as well. Of note are Fisher & Paykel, Amorini, Cardona and Halliday & Baillee.

An interesting item is the latest from well known kitchen manufacturer Peter Hay Kitchens. Always a forward thinker, he has put his money up front and made a significant investment for his business. They say everybody wants to know what Peter Hay is doing, well find out in this issue. We have our 2022 Wall Planner enclosed as well so you’ll be able to scope out the year from the kick off! A note here about the State of Industry reports in this issue: make for real interesting reading as to how the joinery, cabinetmaking and kitchen industries are faring and where they see themselves in 2022.

Well 2021 has been a colourful year with Covid ever present. It has seen us in and out of lockdown especially in Auckland so I think we are all looking forward to more freedoms over Christmas. Business has been, despite Covid, surprisingly resilient thanks in large part to a ongoing strong construction sector. Here’s hoping it continues into next year. Michael and I wish to thank all those who have advertised in the magazine (and those who have supplied editorial), all our column writers and of course you the readers for your ongoing support. All of you have a great Christmas and New Year break and see you again next year.

Bob NordgrenAUTO MA TION

VERSATILE EFFICIENCY.

Easy use, optimisation of the production process, constant top machining quality on every type of material - even the most delicate. Automated solutions for panel movement to reduce standby time and eliminate the risk of

Blum E-SERVICES

E-SERVICES is our online service centre for cabinetmakers, installers, designers - and more. Find up to date and immediate information on all things Blum. E-SERVICES will support you and your team.

Order Management 2.0. Did you know Kiwis make up the largest percentage of users for this online tool worldwide? It's something we are incredibly proud of, and the automation of getting orders into the system faster helps our team on the ground to get more orders out the door every single day! It frees us up to update ETA's on the system when we get delays from the ports, meaning you can log in and find your most up-to-date lead time instantly!

Cabinet Configurator. The best way to plan, order and manufacture cabinets with Blum fittings. Use the "My projects" function to save, access and manage personalised configurations, and because it's an online service, there's no need for manual updates. Produce parts and cutting lists, production drawings and CAD/CAM data with just a few clicks.

Product Configurator. New Zealand's most used E-SERVICE! Quickly and easily find fitting solutions, assembly instructions or planning information. Product Configurator will help you to select the correct hardware components for your job. Save your progress to "My library" or send your product configuration selections directly to Order Management to place an order for even greater efficiency.

Sign up to E-SERVICES and learn why thousands of other Kiwis log in every day at e-services.blum.com or talk to your Blum Account Manager to discover the E-SERVICES package that best suits you.

Eumabois General Assembly 2021

A successful restart despite the Corona pandemic

Eumabois, the European Federation of woodworking machinery and tools manufacturer, held its annual General Assembly in November. After substituting the onsite event with a “Digital General Assembly” in 2020, the delegates and board members gathered again in person in Vienna.

The opening topic was the general outlook on the woodworking industry which has been showing a rapid and very positive recovery. The figures, despite the fact that also the woodworking industry suffers from high material costs and lack of raw material, indicate a sustained growth rate in the mid-term. The global demand remains high, as evidence of the good resilience of the sector in response to the crisis triggered by the Corona virus. Megatrends such as digitalization and industrial automation, as well as a growing demand for home furniture and kitchens, stimulated by travel restrictions and the cocooning effect, are driving the woodworking industry, too.

Looking at the Eumabois Exhibition Network 2021, most of the shows have been canceled. On the other hand, a full calendar of trade fairs is planned for 2022 with two top exhibitions events: HolzHandwerk in Nuremberg in March and Xylexpo in Milan with a new date in October. The positive signals coming from the exhibition sector are an important step towards the normality confirming the value and relevance of face-to-face events.

The meeting in Vienna was also used to officially launch the new Eumabois website with completely renewed and modern graphics. There were also important news on the technical projects side.: OPCUA (Open Platform Communication Unified

Architecture) got the marketing name “IZY”, which was officially presented to the market during LIGNA.Innovation Network on September 27th, 2021.

At the end of the Assembly, the president Jürgen Köppel expressed his sincere thanks to the hosting association FMTI and to all the present national associations, stating: “ … I firmly believe that one of the key pillars for the growth of our industry is our joint European approach.”

The next Eumabois General Assembly will be held on 22nd23rd of September 2022 in the city of Krakow, Poland.

JacksTech 2021 2022!

Along with many other events in Auckland, JacksTech 2021 was a victim of the COVID lockdown, so it’s been rescheduled for March 15-17, 2022.

It will still showcase the latest innovations in our industry from across the globe, with much of the technology displayed on show for the very first time in New Zealand. Highlights include the latest developments in laser edge processing and 5-axis CNC machining, along with Felder Group’s revolutionary (PCS) panel saw safety system.

Also on show will be the world’s fastest CNC nesting line, the Anderson GS-612; Fimal’s Concept 350 hybrid beamsaw/panel saw; and the Vitap K2 compact CNC machining centre.

The furniture industry finally met up once again at SICAM

Held in Pordenone, Italy, from 12th to 15th October, the twelfth edition of SICAM enjoyed a success that outstripped the most optimistic forecasts. With over 540 exhibitors from Italy and 28 other countries, the event marked a true confirmation of the strength of the sector of components and accessories for the furniture industry.

Everyone was extremely eager to meet up again at trade shows: see each other and come face to face, work out thought processes together, exchange ideas and assess projects. Indeed, this is the very point of trade fairs. And at SICAM it was made easy, with attention paid to all leading global markets. Furniture industry professionals attended from as many as 97 foreign countries in addition to Italy, representing over 7200 companies. 66% came from Italy and 34% from abroad. This widespread representation was hard to imagine in the weeks

leading up to the event due to all the restrictions imposed to curb the spread of the pandemic and with international flight schedules still far from 2019 levels.

“And yet many companies believed in us and invested with us,” explained Carlo Gobbi, SICAM founder and organiser.

“They kept fully abreast of the market situation and had a real desire to return to in-person trade shows, aware that new business can be tangibly developed in

this format.” By all accounts the atmosphere in the halls was similar to that seen in pre-pandemic times and there was a clear eagerness to reconnect and get back to working as normal, with even higher intensity.

“This year more than ever, it is true that those who came to Pordenone and chose to take part in SICAM in person had a very fulfilling experience,” Carlo Gobbi revealed. “The number of registrations to return in 2022

trade fairs held as in-person events in this initial period of recovery have all clearly showed that the world of business cannot do without this time-honoured tool that is still so current and vital

received at the event plainly prove this. We aren’t ones to blow our own horn, instead it is the actions of the companies themselves that show us whether the event works or not.”

SICAM 2021 certainly demonstrated that it was very effective. The trade fairs held as in-person events in this initial period of recovery have all clearly showed that the world of business cannot do without this timehonoured tool that is still so current and vital.

The date is set for October 2022, from Tuesday 18th to Friday 21st. The furniture industry already has its next meeting scheduled with the global business world in Pordenone.

Jacks are having a spring clean that’s going to last all year…

During their 75 years of trading Jacks have accumulated a large number of spare parts, accessories and tooling. Some of these remain invaluable to customers who are still using older machinery – being able to get parts for a machine that you seldom use is a lot more affordable than having to replace the whole machine with a modern version. Where they can match an older part or accessory with someone still operating the relevant machine, Jacks will get in touch directly.

The many shelves of older but still new tooling will be listed online. So if you’re looking for something from the past, out of the ordinary, or just keen to grab a bargain, keep an eye on the Jacks website. Listings have already started and will continue as long as there’s stock. And there’s a lot of old stock ….

www.jacks.co.nz

Good FIT

The team at Fit are delighted to welcome Mark Bartlem to the team as Business Development & Specification Manager.

Many of you will be very familiar with Mark via his 13 years of service with Hafele, as Account Manager and as Regional Sales Manager. Initially he’s spending time ‘behind the scenes’ checking out Fit’s processes, systems and workings and getting to know the folk at Fit.

Fit figure they must be doing something right to attract the experience and talent that Mark offers. Welcome to the Fit family, Mark!

NEW TRADE RESOURCES

NEW AND IMPROVED FISHER & PAYKEL TRADE RESOURCES INCLUDING A RANGE OF 3D FILES, SPECIFICATION GUIDES AND DATA SHEETS TO SUPPORT JOINERS IN THE DESIGN, SCHEDULING AND BUILDING OF THEIR PROJECTS.

Stay in the loop with new product releases and technical content by signing up to receive Trade Resources updates. Use the QR code on this page to sign up to Trade Resources before 31 December 2021 and be in to win a Fisher & Paykel 144 bottle Wine Cabinet valued at $5,729*

The purpose-built technical content now includes:

• 3D files for Revit, ArchiCAD, Sketchup and Rhino

• 2D CAD in dxf and dwg

• Specification Guides

• Data sheets

• Planning Guides

New and improved technical content has been developed to help you by:

• Prioritising accuracy and clarity of information to give you confidence

• Delivering purpose built files specifically developed for the construction industry, not repurposed product engineering files which can be unsuitable to architecture

• Detailed data sheets, hinge articulation files, or alternative installation files gives a level of dimensional information that is unique to Fisher & Paykel, giving designers and cabinetmakers better clarity and fewer opportunities for install mistakes

• Providing high resolution models for real time rendering, parametric design in BIM and sophisticated scheduling giving you the ability to create schedules quickly and easily and identify clashes

• Supporting various stages and needs of your project from concept through to documentation with a range of documentation and downloads

*For full Terms & Conditions, visit fisherpaykel.com

Contract Services Engineering & Upholstery

Inspiration the difference between good and great

Without inspiration, there's no pushing forward. It motivates us to become better - removing boundaries and sparking new ideas. At Blum, we love hearing your thoughts and dreams because it inspires us and our future products. Your ideas become our reality.

Titan can function as a part of your operation. We can work in combination with your processes as a complimentary manufacturing source.

In the current fast-moving market, Titan recognizes that it needs suppliers and customers who have the same can-do attitude as us. We know that we are only as good as the companies we have to support us. We recognize your company image is based on the last fit-out and we all must continually demonstrate our highest standard.

Using Titan to complete your subcontract services will only increase your exposure as market leaders in the fit-out arena.

36 Honan Plc, Avondale, Auckland. Phone 09 828 1079

www.titanfurniture.co.nz

Blum Inspirations is our platform to showcase real innovations created by our customers worldwide to help spread inspiration using Blum products and opens up the world of cabinetry with Blum hardware. A custom clothes horse using MOVENTO runners, a SPACE TWIN integrated into the sofa arm, or ergonomic storage solutions in a wardrobe or bathroom. Blum Inspirations is the next generation of sharing ideas.

If you've created something inspiring with Blum products, email socialmedia. nz@blum.com to find out about being featured on our NZ Instagram channel or online at blum-inspirations.com. All of these inspiring spaces can be viewed in person at our Christchurch Showroom in Wigram.

update

Rising Consents

Festive greetings, I hope the run up to Christmas is going well for everyone in industry, given the supply constraints, alert level changes and disruptions we all continue to navigate.

Despite the challenges we have all faced the industry continues to experience strong demand. The latest Residential consent data for the year to September 2021 set a record of 47,331 consents. The market value for the 12 months to September is $20.1b, up 26% year on year. September also saw 4,483 new homes consented, close to the highest number set the previous month of 4,490 new homes. Townhouses remain the hot favourite in Auckland, making up 47% of all Auckland’s new consents in the year to September 2021, vs 21% of all new consents for the rest of New Zealand.

Non-residential (commercial) consents for the year to September 2021 also rose by 10% to $7.7b year on year. This data indicates the potential for sustained strong demand for our industry and is positive news.

To ensure you have the best possible selection of product and decors Laminex has launched several exciting updates. First cab off the rank is expanding our popular Laminex Acrylic Panel range to include a 26mm panel. We are also launching 31 x 1mm ABS and 31 x 1.2mm laser, to edge these sheets. Our Laminex Woodgrain Collection range will also be available in 25mm panels with matching 31 x 1.2mm laser edgetape for all decors and 31 x 1mm ABS edgetape. We are building stock now with all decors available by the end of January.

Last month we launched exciting new Melteca colours across Melteca Standard, Jumbo and Hi-Gloss ranges. The new Standard decors take inspiration from international ‘light & bright’ colour trends. Dark organic timber tones, on-trend around the world, are reflected in our new Woodgrain decors. Look out for our new Melteca catalogue and updated folder artwork. Merchandising started in November for areas of New Zealand at Alert L2. Check out our website at www.laminex.co.nz for more information and for samples!

Thanks to everyone who participated in our recent customer survey. It helps us to prioritise and focus on the key areas we need to improve. We appreciate the opportunity to listen to feedback on how we can better serve our customers.

We know collectively this is the busiest time of year and it’s been great to have so many customers ordering online after registering at Laminex.co.nz/e-commerceregistration. We also appreciate so many customers consolidating, rather than making several small orders, as it’s more efficient and productive.

As we head into the festive break, I’m reminded of the Wellbeing session with Mike King at the Master Joiners Conference in March. He urged us to take care of our own mental wellbeing and that of our family, friends and workmates. One of the most powerful things we can do is check in with our team - take time to listen to each other and know it’s ok to ask for help.

Enjoy your festive break and we look forward to working with you all in 2022!

Mike Arthur General Manager Laminex New Zealand

Laminex ranges expanded

Laminex™Acrylic Panel & Laminex™ Woodgrain increase choice

To ensure you have the best possible selection of product and decors Laminex New Zealand™ has recently expanded its popular Laminex Acrylic Panel range to include a 26mm panel. They are also launching 31x1mm ABS and 31x1.2mm laser, to edge these sheets.

The Laminex Woodgrain Collection range will also be available in 25mm panels with matching 31x1.2mm laser edgetape for all decors and 31x1mm ABS edgetape.

Laminex is building stock of both ranges now, with all decors available by the end of January.

The expansion to offer a thicker version of the current 18mm offer is being welcomed by customers who share positive feedback on why they prefer working with Laminex Acrylic Panels and Laminex Woodgrain Collection.

“Laminex Acrylic Panel is our favourite product to use, it's what runs through our factory consistently. The luxury point of difference it provides for our clients from a standard colour board range, coupled with the durability is a win-win. It's also great to finally have an option to revert to for dark kitchens without fear of complaints in the future. Durable, aesthetically pleasing, giving our kitchens that next level finish.”

Ahmad Zammit, Creative Kitchens & Stone, Taupo.

“I have been in the kitchen manufacturing industry for 18 years and when it came to choosing a product for my own kitchen in our new house it was an easy choice to go with the Laminex Acrylic White Linen.

With 1mm laser edging, it is a superior and robust product that wears, cleans and looks better than any other product on the market!”

Ben Page, The Kitchen Centre, Auckland.

“Reilly Joinery has been using the Laminex Acrylic and Woodgrain range of panels ever since they were introduced to the market. We've never had an issue with these products and get regular feedback from customers that they are always happy with the finish on the board. We have no problems regularly recommending them to our clients.”

Andrew Reilly, Reilly Joinery, Feilding

“The large sized acrylic panels made it easy to work with for a large reception area. We also find the laser edging creates almost an invisible and clean join. A high-quality product.”

Frank Tong, Frankco & Simon Furniture, Auckland.

For more information about Laminex Acrylic Panels and Laminex Woodgrains or to order samples, visit laminex.co.nz.

“it is a superior and robust product that wears, cleans and looks better than any other product on the market”

Handles form & finish

The sheer range of styles and finishes available means handle selection causes as much comment and uncertainty as any component within the kitchen. We aim to make that selection a little easier for you and your client with a look at some of the current best sellers and recent innovations from our leading handle suppliers.

H21 Handle Collection from

A carefully curated collection of top quality decorative hardware in a range of modern forms and finishes. View the latest catalogue at www.hafele.co.nz or scan the QR code below with your phone camera to view the full range.

Pulls & extrusions from Halliday & Baillie

(top left)

HB675 flush pulls

Made in NZ. Suitable for drawers, cupboards, hinged and sliding doors. Available in 12 different finishes.

Project: Hahei House

Architect: Paul Clarke Studio 2

(Bottom left)

HB2240 aged brass pull handle H&B brass pull handles made in NZ. Available in 4 different finishes and various lengths and profiles.

Interior Designer: Rose Schwarz

Photographer: Samuel Hartnett

hallidaybaillie.com

™

Halliday & Baillie offer an extensive range of continuous drawer extrusion, brass pull handles and cabinet handles made in New Zealand, Germany and England. Please contact us on 09 358 1172 or louise@hallidaybaillie.com

(top right)

HB385 anodised bronze

Continuous drawer extrusion made in NZ and sold in 2m and 3m lengths. Available in 6 different profiles.

Project: Waimauku House

Architect: LTD Architectural

Interior Designer: Renelle Gronert

Photographer: Tiffiny Hodgson

(Bottom right)

HB1470 flush pull

Manufactured in NZ from solid brass the HB1470 is ideal for large sliding doors. Available in 12 finishes.

handle pedigree

from Katalog

Premium wall lining TGV

Engineered by Juken New Zealand, Triboard TGV is a three-layered panel, with a wood strand core, sandwiched between MDF outer “skins”. The result is a clean-lined panel that has great resistance to impact. The dimensionally stable core provides superior screw holding ability, and the tongue and groove system allows for fast and easy installation. For more information go to jnl.co.nz scan

Peter Hay Kitchens makes next move new edgebanding technology from HOMAG Group

In forty eight years of operation Peter Hay Kitchens have always been at the forefront of the New Zealand kitchen manufacturing industry in the development of new processes and the use of technology. The recent purchase of three edgebanding lines from German machinery supplier HOMAG Group including the latest airTec technology has continued that tradition, keeping the company in touch with the marketplace and more importantly, expanding on their journey of creating the most advanced Batch One processing line for cabinet production, a process that started back in 2015. Bob Nordgren from JOINERS Magazine spoke with founder and owner Peter Hay and his Sales and Marketing Manager Karl O’Hanlon about this next step in the journey and what these edgebanding lines mean for Peter Hay Kitchens.

“The nature of the kitchen business has changed. We saw that back five years ago when we went through a major change in production theory: the move to Batch One production which enables us to effect large volume manufacturing of a one off product thereby meeting the emerging demand for customisation but at an economic cost.” says Peter.

“The move to HOMAG Group with the three new edgebanding processing lines is a significant next step: it allows us to keep pace, but more importantly expand on our 4.0 project which we see as market leading.” explains Peter. “We have invested a lot over the last few years but we have achieved a lot as well. We believe what we are doing is the right thing for this business, that’s why we bought not one, not two but three of the latest in edgebanding production line machines.”

The attitude and approach to this business is impressive as Peter comments “At Peter Hay Kitchens we have a great group of people developing and deploying this pathway forward. We all understand kitchens, where they are heading and how we fit into that. Technology, automation and software play an important role in that while the move to HOMAG Group brought synergy through not only factory processing but a strong connection through the integration of the Imos software that runs the design and production planning as well.”

One of that team is Karl O’Hanlon, Sales and Marketing Manager. Peter Hay Kitchens is the biggest business of its kind here in New Zealand. Operating from their 10,000 square metre site in the Auckland suburb of Manukau it produces up to a thousand kitchens a month. Karl comments “We have always struggled

for benchmarking ideas and theories here in New Zealand as the scale of the business sets it apart a little. Because of this we have often looked overseas however I believe where we are now is truly world class.” Peter adds “It’s amazing how far we have come, but also where we are heading. It really is exciting and its that excitement that pushes the team and provides them unique opportunities to work on pathways forward which are not always possible in a lot of businesses. The funny thing was, when we sat down and finally made the purchase decision, it was those things that stood out with HOMAG Group as well.”

The objective has been to network the entire production process from board to finished product, to make it a more efficient, successful business. “HOMAG Group, in addressing the production issues we faced were genuinely interested in getting the process right: they bought new ideas to the table. This is these days an ‘intelligent” business where the efficiencies and gains made from automation for example are balanced against the realities of running a business of real size.” comments Karl.

This next step for Peter Hay Kitchens begins with the arrival and installation of the three edgebanding lines in the coming months. We will check on progress in a later issue.

Less material more sales

New features for cutting and nesting

Where do joinery and carpentry businesses lose the most time? Where is the most potential to save material and thus money? HOMAG has looked at these questions intensely. The result is practical solutions that make manual cutting and nesting processing more comfortable and that save more material

Reusing offcuts

In the intelliDivide cutting optimization, the employee defines an individual dimension that specifies the size from which an offcut should be reused. This offcut can be registered as available material with a simple click in the app. It is then included in the next optimization of the cutting patterns. Practical: the cutting assistant prints a special offcut label with all relevant information directly. This ensures that the offcut is clearly labeled and easy to find again.

Overview of the panel stock

The ‘Cutting Production Set’ now allows the user to manage both the stock location and the panel stock, including offcuts. As soon as a cutting pattern has been transferred to the tablet at the saw, the material required is reserved. Once a job has been processed, the assistant automatically deletes the panels used. An individual minimum stock level for each panel type informs the operator in good time when material needs to be reordered.

More flexibility with strip cutting

The assistant also supports those who cut their panels into strips first. The operator sees a graphical display of how wide the strips should be cut. Each strip can also be given a separate label, thus preventing them from being mixed up. The operator can therefore cut a large number of strips first and then process them later. Longer interruptions or continuing work the next day are no longer an issue.

Nesting assistant: Reduce costs and increase efficiency

The new ‘Nesting Production Set’ brings the advantages of the cutting assistant to your nesting machine. The assistant supports you in the automatic calculation of your nesting patterns. The optimization software places the individual components in the nest as close to each other as possible. This allows you to reduce material consumption and save costs. At the same time, you print an individual label for each nested part. This ensures that each workpiece has all the information required for the subsequent processing. The set is the ideal entry level solution for labeling your components and is perfect for retrofitting label printing on HOMAG nesting machines. You can thus create the basis for integrated processing data in your joinery during the nesting process.

What’s in a name?

The name Toitū was the result of a brainstorm at the company’s sales conference and was enthusiastically supported by the company’s manufacturing manager and a key account manager who represent different iwi – and ensured there was consultation with iwi around its usage in this context. Toitū has several interpretations, including 'enduring', 'untouched', 'kept pure', 'protected' – and also 'sustainable'.

New veneer offer emulates the look of solid timber

Prime Panels has introduced a new veneer range which meets the growing demand for the solid timber look but at the same time satisfies architects’ requirements for more sustainable timber options.

The new Prime Toitū Veneer range uses mis-matched leaves to create a stunning planked effect. It makes it easy and more affordable to use veneer panels, especially in larger scale commercial projects. The Prime Toitū Veneer range includes six NZ native veneer options along with American White Oak, American Walnut and Macrocarpa.

Veneer Category Manager for NZ Panels Group, Johnny Dobbyn says that with no need

for matching leaves or panels, the irregularities, knots and beauty of natural timber are brought to the forefront.

“Due to the mis-matching of leaves considerable variation between panels will occur and is what architects are increasingly seeking.”

For best effect, he suggests they are used on large-scale cabinetry and for wall and ceiling panels.

“With the introduction of Toitū, it adds a whole new level of efficiency by using even more of the tree, and at the same time celebrating the look of the whole tree, with all its complex colours and textures.”

“While veneer has always been a far more sustainable option than

solid timber, with a .6mm layon going more than 20 times further, Prime Toitū Veneer uses more of the tree, showing greater respect or mana to the whole tree, which is fantastic,” says Johnny.

As you'd expect, all Prime Toitū Veneer panels are from certifiably sustainable sources. But the added advantage of using any of the NZ Native Toitū veneer panels is the ability to track back to the trees they came from with the company’s world-leading Track my Tree initiative – a finalist in the Sustainable Business Awards.

All Prime Toitū Veneer panels carry Environmental Choice NZ accreditation and come in panels sizes up to 2750mm x 1220mm depending on the MDF or plywood substrate chosen. American White Oak in both

Crown and Quarter Cut is also available at 3050mm long.

"This new range of veneer panels offers a different look for our local architects, designers, joiners and end-users,” says Johnny. “Each plank of Toitū is different and should be celebrated as such.”

www.primepanels.co.nz

Keep it real ...and interesting.

Emulating the look of solid timber, Prime Toitū Veneer is an exclusive range of timber veneer panels that have been individually hand-crafted to create a stunning planked effect.

Prime Toitū Veneer will add huge impact to any interior project, especially wall and ceiling panels and floor to ceiling cabinetry.

Prime Toitū Veneer represents the sustainability of these unique timber veneer panels where 900 square metres of veneer can be made from one cubic metre of solid timber.

All our NZ Native veneer species have Track my Tree codes and our American White Oak, Walnut and Macrocarpa panels are sustainably sourced. All have Environmental Choice NZ accreditation.

0800 477 463 / primepanels.co.nz

Saws

panel saws, beam saws, hybrid saws

Drill bits have taken over many of the functions of the saw blade in processing panel and solid timber, but sometimes the saw remains the best option. We look at a couple of different examples of recent saws purchases and find they can provide both a general purpose cutting tool around the factory as well as the best solution to specific cutting requirements.

Considering the many advantages of beamsaws such as

it

surprising

saws for all reasons

When it comes to cutting panel or solid timber SCM have a saw to fit most requirements and production levels. We spoke to three recent buyers of different SCM saws, a beamsaw, a panel saw, and a hybrid of the two, and found that while they were purchased for different reasons the results were the same, efficient cutting of panel and happy owners.

Savory Group

Auckland based building company Savory is a large construction firm whose work covers both build and fit-out, a lot of it in the commercial sector, a lot of it requiring a beam saw. Recently they decide it was time to replace their existing one.

“Our old saw had done its timeit was actually run on a windows 98 operating system,” says Production Manager, Greg Burkett. “It had performed well but was becoming too outdated, prone to break downs and replacement parts were getting difficult to obtain. Our saw doesn’t get used solidly all day but we need it there when we have the right job.”

“When looking for a replacement we needed something that pretty much did the same thing, which was to efficiently cut large runs of components. Our selection was narrowed to a couple of companies whose range of saws and service

suited our requirements and in the end we purchased the SCM Gabbiani from Machines R Us, for several reasons.

“We had had good experience with John Fleet and Machines R Us in the past, and they had a beamsaw in the SCM Gabbiani P which was ideal for our use and volume requirements, finally it was also in our price range.

“It is a very cost effective and time efficient saw when doing the same thing to a lot of panel. We generally use it for squaring up large quantities of sheet material such as ceiling tiles or cutting sheets of ply for wall linings. Depending on panel size we will cut up to 4 sheets at a time

“It is the ideal saw for us. Easy to set up, easy to change blades, easy to adjust the scribers, it’s a nice machine.”

Masterwood Joinery

Masterwood Joinery in Cromwell are known for their award winning kitchens and know the importance of having the right machinery options for each part of the manufacturing process to achieve the optimum result.

Their machinery include various CNC and edgebanders and also a recently purchased SCM sliding table saw. Operations Manager, Dave Wilson comments on the reasons behind the purchase and what they use it for.

It is a very cost effective and time efficient saw when doing the same thing to a lot of panel.

Minimum space Maximum performance

SCM further re-confirms its presence in the beam saws sector with an even wider range of technological solutions suited to all market ranges and every panel processing requirement. The latest new entry is the result of a collaboration between SCM and an industry leader and comes in the range of “gabbiani vsi” vertical panel saws. It is a complete range of models, 100% "made in Italy", developed to meet the different configuration needs and deal with every kind of production requirement.

The range offers numerous advantages.

• Reduction in space taken up on the factory floor: SCM's new vertical panel saws are functional and compact and can be easily placed into any work space, even the narrowest ones, while still providing maximum cutting performance.

• Greater power and resistance over time: the new "gabbiani" range is powerful and sturdy, and has a stress-resistance capability far superior and longer than that of standard machines in its category. This is thanks to the special frame that is assembled with electro-welding.

• Several models in the range for a better price/ performance ratio: you can pick the vertical panel saw that best suits your production needs. There are numerous options: without scoring unit or with paired scoring unit with 2 saw blades or, moreover, with the addition of an independent motor with mechanical insertion. The advantage is identical: constant topquality performance at a highly competitive price.

• Great versality: The “gabbiani” vertical panel saws can be used to cut different types of wood materials.

• Speed and precision, a feasible duo: the "gabbiani" vertical panel saws allow for one or more panels to be cut simultaneously, but always with maximum precision. Some of the different models are able to make particularly precise cuts, others are more suitable for making pre-cuts that will be completed by sizing edge banders or cnc machining centers.

“We choose SCM because we believe they are the best saws on the market. We bought this particular one, a Class SiX mainly because it is able to do very precise panel length 45 degree angles for our cut-back fronts. We also use it day to day to cut panel to size and it is easy to change the blade to rip timber when we need to, but its ability to cut on the angle was our main requirement. It actually does 45 degrees both ways, which is useful.

“It’s easy to use and very precise, with the automatic fence setting you simply key in the measurement and it does it - bang on.

“Dealings with Daniel and the team at Machines R Us was very pleasant, great technicians and training was exactly what was required. Great saw, very happy with the purchase.”

Mr Shelf

Mr Shelf in Tauranga specialise in storage cabinets and shelving systems for the residential, commercial and retail sector and as such cut a lot of sheets of panel, until recently on a beamsaw.

When it came time for a replacement they opted for a SCM Class PX 350i, a type of hybrid panel saw with features found on both a beamsaw and a sliding table saw. The material stays still, the

saw carriage moves when cutting and the operator can work from both sides. But the main benefit for Mr Shelf was the blade tilts to 45 degrees.

“With our business getting more mechanised we were not using the beamsaw to cut such volume anymore and this machine provided the ability to cut angles as well,” says manager Russell Reardon. “This way we have the beamsaw capability when we want it but are able to do angle cuts as well and the changeover and set up from one to the other is very quick and easy.

“From ordering to installation and subsequent use everything has gone very smoothly, no issues. It was a good buy and a very good machine to use.”

DRY Dust Filtration

WET Dust Filtration

Introducing Format-4’s kappa automatic automatic classic series of beamsaws beamsaws

Considering the many advantages of beamsaws such as productivity, easy material handling, accuracy and safety to name just a few, it’s surprising beamsaws aren’t more common in New Zealand workshops. Perhaps the face-lift range of Format-4 kappa automatic classic f beamsaws will change that.

At just over $100K for the base model, kappa automatic classic beamsaws are very affordable for smaller and medium sized businesses.

The classic model has a generous basic specification: cutting lengths of 3200 or 4300mm, two moveable support tables with air cushion function and a solid steel fence for an exact right angle cut when cross-cutting.

For perfect, chip-free results, the main saw blade is equipped with a 7.5kW motor, and a 68mm saw blade projection (with a 320mm sawblade) offers great bookcutting ability. An intuitive 15” touchscreen ensures quick and simple control of the machine.

Plenty of options are available across the range including the new innovative front lifting table system where the standard

tables are replaced by solid fully automatically controlled scissor lifting tables. This assists with increased efficiency and greatly reduce the operator’s effort.

For more information call Jacks on 0800 522 577 or Email sales@ jacks.co.nz

Chat to a Registered Master Joiner near you and find out why our members - stay members!

Like us!

Follow us!

Join us!

...being Master Joiner connected is a nationwide connection of networks.

....membership is intuitive branding alignment. It just makes sense!

...membership grows your personal brand. Recognition by industry peers is the greatest compliment.

High quality clean cuts with guaranteed repeatable accuracy • Large ergonomic support area for easy handling of large sheets • Extremely safe with blade completely enclosed during the cutting process

High productivity - cut multiple sheets simultaneously • Quiet operation and excellent extraction channels

K940 - innovation and accuracy

Set up by Gary Firman 30 years ago, Firman Joinery is the largest joiner in Oamaru, with 15 staff and large, new premises on the city’s Northern boundary. Hamish Kane joined the Firman team in 2000, eventually joining Gary as Co-owner 12 years later.

Today Firman Joinery have a history and reputation for craftsmanship that extends well beyond Oamaru and deep into the Central Otago region. Working almost exclusively with a regular group of building companies in the area, Firman’s are well known for their quality work in high-end residential joinery, with plenty of Master Joiner awards in their showroom to prove it.

It’s easy to see how the stack of awards came about, because Firman Joinery’s staff are all trade qualified or in the apprentice

programme – even the project managers/detailers in the office have a trade (builder, joinery). With such a high level of skill available then it’s no surprise that quality comes as standard from the Firman Joinery team. But good skills need to be paired with good tools, and Firman’s Felder panel saw is certainly a good match.

Felder’s K940 X-Motion, supplied by Jacks, offers all the renowned features and innovations of the Austrian woodworking group’s panel saw range. The K940 has a 3.2 metre sliding table with Felder’s “X-Roll” system - a precision guiding system that handles maximum loads without compromising the smooth and accurate movement of the table. Named after the ‘X’ shaped configuration of the roller bearings, the X-Roll system prevents wear, eliminates maintenance and provides playfree accuracy over the lifetime of the saw.

Also maintenance free, the ‘EasyGlide’ saw unit tilt mechanism features a highly durable synthetic material that sits between the cast iron guides. This eliminates the need for grease to lubricate the guides and is therefore completely unaffected by dust (not that you see any in Firman’s near spotless factory!). Easy-Glide provides smooth and precise tilting of the saw unit over the long term.

“Accuracy was a key reason for buying the Felder,” says Hamish. “We were looking for a quality cut - something that enabled us to take material straight from the saw and assemble it, every time.” With a powered rip-fence controlled from an overhead touchscreen panel, the K940 X-Motion provides powerful, fast and programmable cutting. “For the right job, the overhead controller and powered fence certainly saves us time” says Hamish. “And we’re getting repeatable results and consistent quality.”

A 7.35kW (10hp) motor means the K940 X-motion is equally at home working with panel or solid timber – an important factor given Firman Joinery’s wide variety of work, from high-gloss panel kitchens through to recently completing a complete house-lot of solid timber joinery for a 900 square metre build.

With Oamaru and the wider Central Otago’s residential market booming, and an order book just about to stretch into 2023, Gary and Hamish are confident about Firman Joinery’s future. “I’ve never seen Oamaru so busy in my lifetime” says Hamish. “We’ve been lucky in the South Island - even at Level 3 we were able to work nearly as normal.We’ve needed to because business is booming.”

“We were looking for a quality cut –something that enabled us to take material straight from the saw and assemble it, every time.”

Cut at Full Speed with RazorCut Circular Sawblades

In furniture production, high feed rates and perfect machining results are required for sizing individual panels. Especially when support materials and coatings are constantly changing.

RazorCut and RazorCut PLUS circular sawblades make it easy to cut panels in finish cut quality at high feed rates. A wide variety of panel materials and surfaces can be processed perfectly - regardless of whether the saw cut is edged later or remains unprocessed.

Your benefits due to...

Perfect edges, finishes free of marks, high feed rates

Finish cut quality and perfect cutting edges

Consistently high machining quality

RazorCut PLUS: Best cutting quality due to special edge geometry, smooth running and suitable for production lines with high part outputs due to long tool life

A tool for a wide variety of materials

Suitable for sizing panels in batch size 1 production Best results even with matte, glossy and structured surfaces

Advantages for people and the environment

Can be resharpened several times due to large resharpening zone

High tool life thanks to wear-resistant cutting material and vibration dampening

Less noise and vibrations using irregular tooth pitch and adapted gullet areas

Welcome to our Team

We would like to take this opportunity to introduce you to our new Leitz ANZ team member, Kane Mayo. Kane is joining us as our Service Representative for the greater Auckland region. Kane previously worked as a joiner in the timber industry for the last 18 years and has a huge passion for woodworking and all the tools that go along with it.

Freephone: 0800 578 665

+50 % BETTER PRODUCTIVITY*

Irregular tooth pitch

Use in combination with DP scorer recommended

Can be resharpened several times

For processing individual panels or flat panel stacks up to 60mm thick Available from stock Cutting material HW

-4 Db(A) LESS NOISE*

-100 % FINISH-PROCESSING IS NOT REQUIRED*

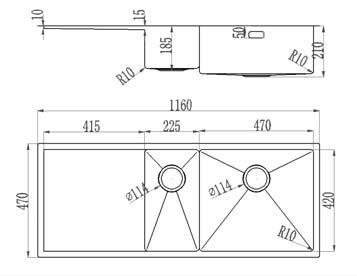

a new range of sinks

the DST range

Introducing the latest addition to the Burns & Ferrall range, the DST contemporary sink and drainer. The DST has been designed to offer complete functionality, and a stunning minimalistic design that will complement the busiest kitchen. The range has arrived into stock and offer many amazing features and benefits to enhance thew way you use your kitchen.

The flat draining tray is on a gentle gradient, which drains water directly into the sink. The large capacity bowl is due to the unique 420mm deep sink (front to back), and the tight 10mm radius corner to give maximum bowl capacity, allowing for larger dishes and backing trays to be cleaned and soaked in the sink. The 3mm knife edge divider is a unique feature on the DST double bowl. The 3mm divider also helps maximize space, and avoids the annoying splash when pivoting the tap from one sink to the next.

The DST is fabricated, hand made sink, which can be installed as an Under Mount into any solid surface material, or installed Top Mount. The 254mm flat flange also allows for FLUSH mounting and is ideal for welding into stainless steel benchtops.

An impressive designer, negative detail overflow complies with all regulation, and archives the 15L per min flow rate required by the building code.

A special concertina roller mat is included with every DST model, and a full range of accessories are available for both models.

The DST range is in stock now – contact you local Burns and Ferrall sales representative or contact our Customer service team on 0800 697 465 or sales@ burnsferrall.co.nz

These fabricated double bowls are available in topmount, undermount or weld in options.

At a total width of 685mm and 15mm radius, these bowls come complete with 2 x 90mm waste and 1 x designer overflow - with left and right hand main bowl options, and with the same over all width, all you need to do is choose the size of the sink to suit!

There is a full range of accessories available - get in touch today to find out more!

Projumbo delights retail sector

Since March 2021 Hutchco has been on a mission to grow the Projumbo colour match offerings

“We started out with a handful of colours to meet committed orders, and now 8 months down the track we have approximately 70% of our range covered” says Mark Leith Managing Director, he adds, “The demand for extra wide edging is growing, and to be able to produce this with minimal waste both economical for us and cost effective to the end user.”

As the demand grows, Technical & Marketing Advisor at Hutchco Tux Hika reached out to a couple of end users to see how Projumbo has delighted their clients.

Hutchco has had a long history supplying edging to Auckland based Retail Dimension (RD). RD covers every dimension of retail and draws on 20 years’ experience to deliver custom retail solutions,

from design, manufacturing to fitout, signage and technology. Tux caught up with purchasing and production coordinator, Francesca Crowther at RD to talk about their experience to date with Projumbo edging. “I have taken it upon myself to order this where I have found it applicable. This

Hutchco offers 5 design inspired edging finishes across a range of over 250 colour matches. Order samples today!

saves us significant costs in not only material but also in Labour”

Francesca continues on to note the direct financial benefits she has seen for RD “ We don’t need to purchase additional sheets of laminate which can be very costly and the team don’t have to spend labour working the laminate”.

When asked who does she see as benefiting from Projumbo,“easy application for manufacturing and clean sleek lines [for the client]” adding “This product creates a seamless edge and consistent grain/pattern when clashing the length of the laminate limits this.”

Since 2007, the team at BBC Commercial in Tauranga have been providing commercial fitouts, shop fittings and a range of tailored and versatile joinery solutions to businesses throughout NZ. Hutcho has serviced their joinery needs steadily for the past few years now, and the

introduction of Projumbo has eliminated some productivity and processing pain points notes Mark Crowhurst, Manger at BBC.

Mark often specifies 55mm & 65mm Projumbo where he can and credits this by saying “The jumbo edging gives us clean lines

The Ultimate Hands Free Waste Solution.

With Concelo, the smart Active Lid system opens automatically as the bin is opened. When combined with an electronic Push to Open system the user can simply drop waste into their Concelo bin without having to use their hands at all.

For technical or sale enquiries, contact Hideaway Bins hideawaybins.co.nz / 09 426 7456

and a hard wearing edge” and adds “[Projumbo gives a] seamless edge as the alternative (laminate) leaves a dark line”.

Check out some of BBC’s recent work at Farmers Sylvia Park.

Contact our Sales Manager James@hutchco.co.nz or customer services on cs@hutchco.co.nz to find out if Projumbo is available for your next project.

The jumbo edging gives us clean lines and a hardwearing seamless edge without the dark lines of some alternatives.Mark Crowhurst BBC PUSH TO OPEN compatible with electronic push to open systems ACTIVE LID automatically opens and closes with bin motion

hinges

While looks are important, function is critical and durability is necessary, a big plus for cabinetmakers when it come to hinges is that they are simple to fit and easy to adjust. We look at options from leading suppliers that cover all these criteria and more.

Salice Silentia+Perfect and constant closing

Silentia+ is also equipped with an innovative switch to delay the decelerating action. The activation of this switch allows the ideal decelerating strength to be achieved for all door sizes.

Silentia+ allows a perfect and constant closing of the door in any condition, use and application. The innovative soft close technology guarantees excellent performance to the complete range of hinges. Silentia+ includes numerous technological elements and maintains the aesthetics of the hinges of the first generation.

The next generation.

Integrated soft close technology with two silicone oil dampers. The two integrated dampers guarantee an exceptional regularity of the decelerating strength providing a perfect closing to any kind of door under any conditions.

It's not just design; it's style.

Dark furniture radiates sleek elegance, inside and out. The global trend requires hardware that creates a visual impact without compromising on quality. At Blum, we stay in motion to move ideas. We have produced the onyx black hinge range to discreetly complement furniture and give your ideas and creations a greater scope for designing fine furniture.

An extensive range of our hinges, such as the top-selling 110° hinge, profile hinge for thick doors, blind corner hinge or even our EXPANDO T hinge for thin doors, are available in onyx black. With built-in BLUMOTION, the product becomes even more attractive, with no extra protruding parts; simply flick the switch on the hinge boss to deactivate the BLUMOTION.

To create seamless integration or visual impact in your cabinetry, order onyx black online at e-services.blum.com or find more at www.blum.com

One hinge - endless applications

With a 155° opening angle, the 0-protrusion hinge is ideal for use on doors with inner drawers and pull-outs, mitred fronts or double overlay carcase applications. The technology in the hinge arm pushes the door outwards upon opening, stopping binding where the door meets the carcase or allowing drawers to open freely without using a packer.

The 0-protrusion hinge is available with built-in soft closing BLUMOTION or unsprung to use with TIP-ON for handleless fronts and available in two finishes, including onyx black for dark interior design and visual impact without compromising quality.

Find the full scope of use for Blum's 0-protrusion hinge within Cabinet Configurator or place an order within Order Management, both online at e-services.blum.com

Slim, sleek and streamlined

Zero protrusion

AVENTOS HF, HS and HL cover caps have been given a new look and offer a fresh design to the lift system ranges. Tailored to match the existing AVENTOS HK top cover cap, the new, linear appearance allows a harmonious design to be achieved in furniture.

Along with a sleek new form, the entire AVENTOS range now offers a dark grey cover cap option to compliment the movement of dark fittings and interiors trending worldwide. Make a statement; pair light wood-look cabinetry with a dark cover cap for a bold design that stands out.

Personalisation? Say no more! The removable plate on the cover cap can be embossed or printed with your company name or logo and can also be used on LEGRABOX drawers for exceptional hardware unity!

Place your order for the new-look cover caps for AVENTOS online at e-services.blum.com for your upcoming projects, or contact your Blum Account Manager to learn about personalised branding.

Sensys by Hettich the perfect connection for manufacture and design

The award-winning Sensys hinge by Hettich is perfectly suited for creative interior cabinetry solutions of the highest quality.

Proven performance in temperatures from 5 – 40 degrees, the proprietary design offers a broad range of applications. Day to day, that means that you have the biggest choice in what you create and how you create it when using Sensys.

Sensys has among the widest soft-close on the market with the Silent System catching and pulling itself closed at 35 degrees. This wide soft closing angle sustains performance across non-standard applications such as thick doors and is discretely tucked within the hinge itself.

To see all the possible applications, check out the ‘Hinges by Hettich – Sensys’ poster inserted with this issue.

Installation

Different installation methods available

• Fast assembly hinges for maximum efficiency, requiring no tools

• Push-in installation, otherwise known as knock-in

• Screw installation

• Expanding dowel installation. Choose the installation most compatible with your manufacturing processes.

Design Finish

Choose from the classic nickel plated or obsidian black finishes for hardware that complements the wider design.

Wide material choice for door fronts

Sensys hinge applications include

• Thick doors from 15-32mm

• Thin doors from 10-16mm

• Glass doors.

This opens up the choice of possible door front materials, allowing experimentation and outside the box design. For example, tiny home or campervan applications may benefit from lighter cupboard doors and Sensys for thin door fronts.

Wide angle and zero protrusion

With applications for zero protrusion doors to accommodate pantry stackers and blind angles for corner storage, Sensys is applicable to all common – and some less common – interior cabinetry requirements.

For all catalogue and purchase information visit shop.hettich.com. For supporting installation information visit HettichEnglish on YouTube, or the media library on our website.op

We work behind the scenes to bring your living space together, creating the top quality hinges, drawer systems and sliding and folding doors you need for a truly luxurious interior.

Every day, all over the globe, our furniture fittings are creating extraordinary kitchens, bathrooms, and custom furniture with remarkable and durable results.

www.hettich.com

www.designwithhettich.co.nz

Hettich Sensys Hinge

Hettich AvanTech YOU Glass Inlay Drawer

Hettich Sensys Hinge

Hettich AvanTech YOU Glass Inlay Drawer

Salice & Fit enhancing living spaces together

Pocket doors? Overhead lifts? Falling flap stays? Bifold gear? Soft close hinges?

You know you can count on Salice’s Italian designed and made quality and on Fit’s service.

Multipurpose spaces are where it’s at! This is a trend that began well before the pandemic that has literally plagued us for the last two years, but Covid-19 has fast-tracked the need of many households to maximise use of space and make existing spaces like kitchens, dining rooms, living rooms and bedrooms suitable for work and study. Good hardware, like that from Salice, can really assist in creating multipurpose cabinets and spaces.

Pocket doors – currently the rock star of multifunctional spaces! Pocket doors pivot 90° to slide back inside a double walled cabinet, so walkways and light are not blocked when the area is in use. Salice’s Exedra pocket door is perfect for creating laundry spaces, work from home spaces, study spaces or appliance spaces within larger rooms or hallways. Suits doors 18030mm thick, 2200-2500mm high, 500-700mm wide. Vertical, horizontal and front adjustment all without removing door from cabinet.

Overhead lifts – EvoLift is the latest from Salice with options for single flap and folding flap doors in wood or with aluminium frames.Right or left kits, plus options for super heavy projects. And for a contemporary, compact look; the Wind range in white or satin metal black includes paired kits for 5 door weight levels plus a supplement for very wide doors.

Creating horizontal surfaces like fold down desks tables? Salice’s Pacta is the falling flap door solution that is both robust and stylish – with no stays or cables needed! Everything you need in a paired kit, plus an extra support hinge is available for wider surfaces. Pacta is compatible with Salice’s magnetic push to open system too!

And, of course, Fit carries a wide range of Salice soft close hinges.

Contact your Fit rep, phone 0800 852 258 or email sales@fit-nz.co.nz to discuss your Salice hinge and hardware requirements.

show your vision

3D presentation software VORTEK Spaces has been creating a bit of talk in the New Zealand design community lately. Easy to use and compatible with a wide range of popular CAD design software, Vortek Spaces enables designers to present their designs to clients in stunningly realistic videos and walk-throughs. We spoke to several early users who are finding the software particularly useful in allowing them to share their vision with clients and personalise their presentation.

For kitchen designer Sydney Young from Matamata Glass & Joinery, Vortek Spaces is a great selling tool. “It allows me to present a new design and make it look like the clients home. It gives me the ability to easily show what I am trying to do and really helps with colour and material selection which can speed up the process considerably”.

Sydney purchased Vortek in June last year and uses it alongside Cabinet Vision. “I found it very easy to pick up, some initial assistance from Joinery It and then an hour or so link up to Vortek in Canada gave me the basic operation and it was easy from there.”

“It is a very effective program, I simply import my design from Cabinet Vision and from there can change lighting or materials

as I or the client wish. I would probably spend a couple of hours on finishing my kitchen design but it is definitely worth it. In fact once you start you really get hooked it gets into your blood.”

Cherie van der Poel, designer and director at Got It Made Kitchens in Te Awamutu has been using Vortek for the last 18 months and has found it a game changer for selling designs and concepts. She uses it with CabMaster software to produce 3D walk-throughs which are recorded and shown to clients.

“Customers love its visual nature and it gives them the confidence to go with a design, they can see it and imagine themselves in that space. Not everybody is good at reading plans and Vortek saves time in getting ideas across. It makes a big difference to us in closing sales quicker.

“It is not as difficult to learn as you might expect you can be up and running within a couple of days on basic designs and pretty specialised within a couple of months. The online assistance is very good although we haven’t needed to use it much as it’s pretty easy to work things out yourself.

“It’s great to have access to such technology in our industry - the future is the visual product it is huge for our industry and great that it is available to the joinery and kitchen industry without it being cost prohibitive for smaller users.

Michael Murray a designer with Kitchen Inspirations in Auckland has been using Vortek Spaces for four years in kitchen and cabinet design and appreciates its realism and its ability to easily makes changes on the fly.

“Colours and lightning are really good and it produces excellent high quality renders. I post renders on social media and get a lot of request from other designers as to what I am using. It works very well with Cabinet Vision, the transfer of files is very simple and any changes upload automatically, just like resaving a file.

“The software has undergone a lot of development recently with an expansive 3D warehouse/ store where you can not only find but also upload and develop components to achieve that personalised look for your client.

“The 3D walk-through video is very good. It really helps people to read the space, not everybody is necessarily very good at understanding floor plans and elevations whereas they instantly identify with the 3D visual.

(continued over page)

Show

“I didn’t really have any tuition, a workmate showed me how to use it and off I went. It is pretty self explanatory but you do need an eye for lighting and angles.”

Alexandra Riddell from Niche Design Co Ltd in Tauranga has used the software for several years with both Cabinet Vision and 2020 Design software and finds it builds on the existing software.

“You really are able to bring your designs to life through the use of colour and realistic rendering. The walk-through is very impressive, it provides a real wow factor and instantly shows clients your vision. As a consequence we need

to do less concept work, clients are sold quicker because they can see how it is.

“Very user friendly, a great asset for designers.

For Daniel Billings from Maple & Stone in Hamilton, who began using Vortek Spaces alongside Microvellum in the middle of this year, the software works well with the bespoke nature of their business providing ‘visualisation’ for clients.

“The realism is great and it is the easiest rendering software I have used. The direct communication channels with Canada are very useful when starting out and I like the way they are constantly updating their library to include NZ based products such as Laminex and Bestwood colours.

Craig Hooper from Cooper Webley in Nelson has used Vortek Spaces for three years and loves the programme. He works in Cabinet Vision then exports to Vortek for the final rendering and then client presentation. He enjoys the ability to make changes on the fly while talking and discussing options with clients.

“It is very useful tool for selling directly and efficiently. Clients very quickly get a good feel for what we are doing in an environment they recognise. It is very easy to use, largely click and point based with a very easy to follow drop down menu. I can do a full blown render in 15-20 minutes and the beauty is, it is a live render, any changes are automatically updated to the original file - superb.

You really are able to bring your design to life through the use of colour and realistic rendering. The walk-through is very impressive, it provides a real wow factor and instantly shows clients your vision.

“Vortek are very client interactive constantly updating and supporting with more facilities and functions and lighting and design features. It is a very dynamic and powerful tool - I think of it as a portable showroom.”

Joinery It are New Zealand re-sellers and service providers for Vortek Spaces for more contact Phil Smith on 021 201 4450

More doors from Sage Doors

Originally known for roller doors, and then Laseredge doors, Sage Doors is now branching out into more door options: presanded-paintable-profile doors. Paintable profile doors have been a much-requested addition to the Sage Doors’ range for a while; here’s a few reasons why you’ll want to use them:

Short Lead Times

Like all of our doors, we’re committed to keeping our lead time as short as possible. Our lead time for standard orders is 4 days.

Pre-Sanded

It’s important that your doors are ready to roll (err, spray!) when you receive them, so we do the sanding for you. They should be ready to send to your painter.

Online Quoting & Ordering

Our profile doors can be ordered and quoted online. Contact us for the tech specs so you know which profile you’re after.

Pre-Drilled

Like all our laseredge doors, our profile doors can be pre-drilled, either by sending through a Cabinet Vision/Microvellum file, or by entering in the drilling on our website when you place your order.

Make it Your Own

Because we like to be flexible with options, we do our profiles a little differently! You can order any face profile (USA State name in our range) with any edge profile option. For example, you could have the Arizona face profile with edge options of arised edge, 1.5/3/5mm radius or a Roman Ogee edge. It’s up to you! You can also choose to have raw HDF on both sides, or white melamine on the back.

Custom Profiles

Do you need something slightly different? Bigger frame? Smaller frame? Deeper rebate? Featured end panel? Let us know and we’ll do our best to help!

Bowing Reduction

We offer a pocket-routed-back option to reduce bowing on framestyle doors. The pocket on the back removes some of the tension from the back of the board, to reduce the bowing. While this is not necessary for all doors, it is helpful for tall or bi-fold doors, where it’s more important to have them straighter. (note – they may still bow a bit, but we’re just doing what we can to reduce it).

We look forward to working with you on your next profile door project!

Real shows are back for Homag

Our trade show Live. HOMAG has shown us how much we have missed being together: live demonstrations, personal conversations and wellattended webinars.

Even though it was ‘only’ a digital conference, a lot of us experienced the real feeling of being at a trade fair: talking shop with like-minded people, impressing those who love wood with the latest technology or answering practical questions on machinery. Our experts were in their element, just like the 1700 carpenters and joiners who also took part. We would like to express our heartfelt thanks to everyone for this and we have built on it, with digital content and real events on site, at the HOMAG Treff. Because for the first time since 2018, there was a classic HOMAG Treff in October and November in Holzbronn and Herzebrock.

Among other things, HOMAG presented solutions about intelligent automation, process optimization and further development of mobile operation. Visitors also could see how they can use digital assistants from

HOMAG to increase performance and efficiency while ensuring sustainability at the same time.

(continued over page)

Live.HOMAG

The face-to-face events and demonstrations in Holzbronn, Herzebrock and St. Johann were accompanied by the well-known online format Live.HOMAG.

Live.HOMAG offers the opportunity to experience HOMAG products and solutions digitally: in live webinars, individual machine demonstrations and presentations of technology highlights.

So far, more than 500 live online events have been held, allowing participants to gather information about the latest HOMAG technologies and to put their questions to product experts.

“We are really pleased that Live.HOMAG has been so well received, particularly by woodworking shops.”

Achim Homeier, Director for Product Management

Automation sets new standards

Fully automated installations, such as the SAWTEQ B-320 flexTec panel dividing cell for batch-size 1 production or WEINMANN's autonomously operating cells for the fully automated production of building components with industrial robots, set new standards in terms of performance and flexibility. Intelligent automation creates an interlinked material flow with high performance. This is the case, for example, with the LOOPTEQ O-600 gantry return system as a supplement to the edge banding machines of the EDGETEQ S-500 series.

Equipment thought through New equipment variants and clever software assistants increase efficiency and create more transparency in production, as with the latest version of the storage management system, woodStore8.

Another new addition to HOMAG's equipment portfolio is a specially designed interchangeable container for fast and unmixed switching between EVA and PUR hotmelt adhesives in edge banding machines.