It will soon be one year since the invasion of Ukraine began. Since then, we have been experiencing an unprecedented energy crisis, with Europe scrambling to mitigate staggering hikes in prices and secure new sources. The baking industry has been bearing the brunt of this instability, the worst Europe has witnessed, arguably, since WW2, with the war swiftly adding to the disruptions brought on by two years of various degrees of global lockdowns.

We’ve witnessed businesses shutter, with smaller bakeries being particularly vulnerable to energy bills that have grown by up to 400% overnight, in some parts of Europe. We supported national associations to amplify their message as they were lobbying for state aid. And we were delighted to witness solidarity in action, as the EU energy ministers reached an agreement during the Energy Council in December to have market correction mechanisms established to protect people and economies against excessively high gas prices. The new measures will make it possible for member states and energy companies to purchase gas together on global markets, rather than competing over it. The new regulation aims to limit “episodes of excessive gas prices that do not reflect world market prices”, and also contributes to energy supply security and financial market stability. ‘Stability’ is the key word here, with countries being able to ensure uninterrupted energy throughout the (eventful, albeit mild) winter. What’s more, not only has Europe been able to secure energy without the Nord Stream, but natural gas prices have also returned to pre-war prices. And falling energy prices have also helped with inflation: across the European countries using the Euro currency, consumer price inflation dropped to 9.2% in December from 10.1% in November.

What’s more, the conversation is now clearly geared toward sustainability, which has quickly escalated from a ‘nice to have’ long-term, loosely-defined goal to a must-have priority for immediate, measurable results. The same Council meeting also put on paper the agreement “to accelerate deployment of renewable energy”, in this regard. The ‘green transition’ is meant to lower the dependency on fossil fuels and reduce energy dependencies altogether, while turning the page to an urgently needed cleaner environment.

These are steps for which the baking industry has been preparing. Its resilience has been relying on it. With a vast majority of new developments geared toward improving sustainability in operations, we’ve started a year of promising new solutions that will propel bigger strides in this direction. Overdue trade events are returning and are already preparing to host new innovations. Exciting changes are ahead!

Catalina Mihu

Catalina Mihu

Widely different concepts, approaches and methods lead to advancing sustainability throughout a company’s operations. For Kwik Lok, sustainable materials used in packaging closures are immediately visible as a result of this mindset.

MIXING

Managing energy consumption is a growing concern for bakers, in Europe and beyond, now and for the long term. How can equipment help industrial bakery, pastry, and snack manufacturers reduce their energy consumption?

The ‘simply unique’ interpack returns after six years of forced absence during the pandemic, with a clear business idea – a renewed hall concept based on clear points of interest for each industry, targeted exhibition areas, new specialty shows and forums.

To maximize the benefits of automating bread slicing and bagging, industrial bakeries need to keep their customization options open.

The beginnings of pinsa making go all the way back to the Roman Empire. A fresh new take on the Roman pinsa is now rising to the top among consumer favorites all over the world.

Research by Future Market Insights puts the vegan cookies market at USD 359.23 million in 2023 and anticipates it to reach USD 773.31 million by 2033.

PACKAGING

06 Kwik Lok: The science of sustainability

INTERPACK

20 Trade shows: An anticipated return – interpack ‘23

25 Exhibitor news: Stand previews

MIXING

10 VMI: Energy savings improve sustainability

14 Exact Mixing: Continuous mixing for higher volumes

CUTTING AND PACKAGING

16 BAKON: Cutting straight to the chase – cakes

18 AMF Bakery Systems: Sliced, bagged and delivered

LAMINATING AND SHEETING

22 Rademaker: Pinsa production, from past perfect to future simple

SCIENCE

26 ttz: Margarine versus oil performance in bakery applications

34 Campden BRI: Egg replacement challenges and solutions

MARKETS

32 AIBI: From Europe, with grain

COOKIES

37 Vegan cookies: New ingredients drive product segment

REG ULARS

03 Editorial: “A bold and sustainable new step”

36 News

38 Advertiser directory

Food2Multimedia is a publishing house operating at an international level and specializing in researching and editing technical information for the baking sector.

Our specialist journal concentrating on production professionals in large companies in the industrial and chain-store sectors. Published six times a year in the English language.

Our Review series provides in-depth analysis of clearly defined issues. This involves market analyses and is a comprehensive, informative presentation of the state of the art in process engineering.

The f2m dictionary translates bakery terms into a mulitude of different languages.

www.foodmultimedia.de

Widely different concepts, approaches and methods lead to advancing sustainability throughout a company’s operations. For Kwik Lok, sustainable materials used in packaging closures are the immediately visible result of this mindset. And, this priority also influences the process.

Viktoria Pakhnyuk, PhD, Sustainable Product Development Manager, Kwik Lok, contributed to this article

+Just before the end of 2022, Kwik Lok launched Fibre-Lok in the US, following a successful reception from the Australian market of a recyclable lok made of 100% post-consumer recycled fibers. Kwik Lok also released a certified home-compostable version of the locks (branded as ‘loks’) in the European market, made of responsibly sourced natural cellulose wood and cotton fibers. Each product provides the same functionality and durability that the plastic version brings. The Fibre-Lok joins a sustainable family of products including the Eco-Lok, a closure launched in 2019, formulated with a plant-based biopolymer –NuPlastiQ. Producing this material lowers the use of traditional plastics; it is reusable and metal detector-compatible.

It is a growing family of products, with Kwik Lok focusing its efforts on “transitioning the industry toward a sustainable future through innovation,” as Don Carrell, Kwik Lok’s CEO, emphasized at the launch of the Fibre-Lok. To support the R&D in this direction, Viktoria Pakhnyuk joined Kwik Lok in 2020 and is the Sustainable Product Development Manager, bringing on board her expertise in material science. She leads multiple projects in the research and development of environmentally-conscious, bio-based bag closures. The young scientist earned her PhD in Chemistry from the University of Washington, where she served as an Innovation Development Fellow and a Chair of the University’s chapter

of the Materials Research Society. In her role, Pakhnyuk coordinates the way different efforts contribute to the company’s sustainability vision.

With various kinds of input coming in from all departments – including sales, engineering and marketing, she oversees projects from the concept stage through developments into new products. With Kwik Lok’s growing material options, she leads in establishing a process with specific milestones by involving the right people in each phase. Her scientific background is especially important in the testing and development stages.

The goal seems straightforward: making (more) sustainable loks; but, variables leading to their development need to be carefully balanced. The answers to preliminary questions refine the concept by defining a target market’s demands while understanding available material options. Preferences and regulations are part of the equation. For example, France is familiar with and has readily available composting options, which would make a compostable product suitable. Alternatively, other markets will prefer certain types of plastics for which they have recycling capabilities. The UK, for example, has defined different types of plastics using a color-coded system. Product costs will also be influenced by the availability of the materials and their composition.

Technical aspects must also be reviewed: How can other materials be formulated to behave like the original plastic? How well are new materials processed on existing specialized equipment? The company follows steps deriving from these questions.

Forming partnerships is key to developing options with suitable material properties by combining scientific and industrial expertise. Material grades and blends are designed and analyzed for the bag closing application. Testing includes assessing the materials’ mechanical and melt properties, for example. The right balance needs to be found so that the loks can be easily separated from each other on the strip without breaking individual loks. Specific utilization requirements are taken into consideration in the development process, such as the temperature and humidity of application and storage conditions.

Kwik Lok also needs to address the challenge of making the new materials work with the company’s own established manufacturing processes. Supply volumes are evaluated to ensure availability for customer projections. Once lab tests have been carried out successfully, a larger sample goes through production trials replicating the manufacturing process normally employed, followed by further optimization.

Since the company provides not only the bag closures, but also the machines that attach them to their packaging, it aims to release new products that will not require replacing bag closing machines already in the field. “Being sustainable does not have to mean taking big leaps,” Pakhnyuk highlights.

Working to improve the sustainability of packaging solutions and all related processes for day-to-day operations started at Kwik Lok by clearly categorizing the concept into three separate ‘boxes’:

1. Feedstock – the material source and composition (e.g. petroleum-based, bio-based, recycled content)

2. Processing – the inputs and outputs of raw material

production and product manufacturing (energy usage, water needs, carbon footprint, etc.)

3. End-of-life – the product’s fate after serving its intended purpose (landfill/incineration, recycling, or compost)

Bio-based materials are an interesting option for new product development in the future, since their costs are also likely to decrease as they become more widely available and regulations support their use. “The challenge is how to make a bio-based material act like it isn’t bio-based,” Pakhnyuk explains. There are different approaches to incorporating bio-based materials to offset the use of fossil-based materials. One approach is to introduce a bio-based additive to form a plastic composite, as Kwik Lok has done with NuPlastiq in the Eco-Lok. Another approach is to use plastic created by alternative chemical process while replicating the same final chemical structure – instead of coming from crude oil, it may be made from a renewable bio source such as agricultural by-products. The third option is to replace traditional plastics with a compostable plastic, which are often bio-based.

“You can prioritize one box over another or try to target all three. This is why it is difficult to rank what materials are ‘better’ than others – the answers will vary according to the selected priorities,” she explains. Lifecycle analyses are instrumental in providing more insights that can give direction for the specific sustainability path chosen. By inputting factors such as material type, processing steps and geography, a lifecycle analysis will quantitatively compare the environmental impacts of different packaging options. A lifecycle analysis is an iterative process, which is improved as updated information becomes available. Like many companies, Kwik Lok goes by carbon emission as their top sustainability metric. Other impact factors can include fossil fuel usage, water usage and water pollution. It should be noted that sustainability does not necessarily mean removing plastic, as it can still be the better option depending on whether it meets functional requirements and which environmental metrics are compared.

Making sure the appropriate waste infrastructure is in place is one determining factor to ensure that a circular economy is supported at a lok’s end-of-life. The type of bag for which the closure is used also plays a role – if it’s plastic, it makes sense for to lok to be made of a similar material for recycling, for instance, while a paper bag would better match a fiber-based lok.

Recycling has always been a part of the norm for the scientist herself, growing up in Seattle. Not being wasteful is also a part of Viktoria Pakhnyuk’s personal journey, deeply rooted in the culture of the immigrant family that relocated from Ukraine. Combining these values with her background in chemistry and focus on working with polymeric materials,

There is a lot of information out there. Ask for supporting evidence and if the claim has been verified by a 3rd party. If you have any questions about sustainability claims, we’re happy to help.

Composting is very earth-friendly, but its effectiveness depends on a municipality’s capability to actually compost material. Without that capability, materials are likely to end up in a landfill.

It depends. There are trade-offs, and you should compare the impacts of different materials, including their carbon and water footprints.

Pakhnyuk helped define Kwik Lok’s own sustainability process that would also support companies to improve on theirs. “Research is very much curiosity-driven, and it becomes especially interesting when following specific targets with applicable ideas,” she explains, which is what drew her to the industry as a natural progression of her academic work.

Once a product is developed, it is important to communicate a products qualities by using data to back up claims to prevent greenwashing. The gold standard is having it reviewed by a third party, Kwik Lok adds, which can earn the product useful certifications. Therefore, product claims gain more weight and harder to challenge. The home compostability of the FibreLok, for example, has been tested and certified according to rigorous lab standards. Kwik Lok also makes sure to pay attention to terminology in the sustainability space as it is changing and being refined to provide the most clear messaging.

R&D remains Pakhnyuk’s priority in this field, from a manufacturing company’s perspective. This means establishing various partnerships to develop and test different product samples that fit the concept. Another priority is ensuring that the research direction stays within the defined technical and environmental framework. R&D also means making adjustments so that new solutions work with minimum impact on the process, she prioritizes.

In addition to R&D, sustainability education has also been an evolving resource that Kwik Lok offers, both internally and within the community of peers sharing this focus. To this end, Kwik Lok has also joined up with Plastics Pacts, to

Not quite true. Everything breaks down in one way or another, but only biodegradable items can be turned into natural components by bacteria and other organisms.

For some applications, plastics are the best solution. Plastics can help reduce overall packaging or keep foods fresher longer, which reduces food waste.

actively participate in an ongoing knowledge exchange. Kwik Lok also supports companies in their effort to define what sustainability should encompass for them, and to establish how to improve it. In this case, the function of the desired solution is a good place to start, the scientist recommends, so that it meets expectations in production, utilization, storage, and end-of-life. Selecting between different trade-offs that come with each type of bag lok need to be considered, whether it is function, cost, or sustainability. These aspects are usually combined with changing regulations and other environmental goals, such minimizing carbon.

On top of everything, consumer pressure for certain solutions should not be overlooked – usually, this takes the form of the demand to remove plastic, even when doing so may actually add to the company’s carbon footprint or not be the optimum choice for the product’s end-of-life fate, for instance. Process transparency to help educate consumers will go a long way, but, it requires dedicated efforts. Accessible labeling practices can easily help provide consumers with more meaningful information.

Increasing sustainability is more of a winding road than a traveled avenue: “Plastics are going to be around for a while as a solution that makes sense for its qualities. Many times, there isn’t a good substitute, either. There is definitely an opportunity for innovation here; the challenge will be making it work with existing systems,” Kwik Lok’s research specialist anticipates. Standardized transparency is bound to play an instrumental role in sustainability advances, re -

If someone makes a sustainability claim, it must be true.

COMPOSTABILITY IS THE END-ALL BE-ALL. PAPER AND FIBRE ARE 100% GOOD FOR THE EARTH.

Managing energy consumption is a growing concern for bakers, in Europe and beyond, now and for the long term. How can equipment help industrial bakery, pastry, and snack manufacturers reduce their energy consumption?

+Controlling energy expenses is becoming more critical to manage than ever, as manufacturers are facing several hard knocks, such as the increase in the price of raw materials, supply difficulties, and now the rise in the cost of energy. It is also bound to drive competitiveness for companies looking to improve their environmental performance and their transition to more sustainable development.

VMI targets sustainability when designing equipment. The French mixing specialist strives to support its customers in this transformation process, taking into account sustainability and environmental impact measurements when developing equipment and services. As part of its design strategy, VMI has three specific goals in this regard:

+ Optimizing energy consumption, especially during the machine design phase

+ Improving the way equipment monitors water and electricity consumption

+ Identifying areas for improvement and implementing corrective actions together with its customers

Working on custom solutions for mixing equipment, VMI’s engineers consider specific plant issues for the design of the machine, starting with the project study. In addition to

safety, standardization, or modularity, they also consider energy efficiency when developing or upgrading equipment. “A well-thought-out design can result in significant energy savings. VMI complies with European regulations as our heavy-duty equipment is fitted with IE3 motors. While the latter may have higher purchase prices, they have reduced operating costs due to lower electricity consumption. For a motor that operates intensively throughout the year, this opens up the prospect of a quicker return on investment,” VMI’s specialists explain. Installing a more efficient motor can be a sustainable investment for continuously running equipment with high maintenance costs, since it can increase both the reliability and the lifespan of the equipment.

Several VMI machines are equipped with a variable speed drive, which ensures the equipment starts smoothly with an acceleration ramp for a gradual increase in speed. “It is especially useful in reducing the stress on mechanical

“For a motor that operates intensively throughout the year, this opens up the prospect of a quicker return on investment.”

VMI specialists

parts and can consequently limit their wear and tear while avoiding consumption peaks during start-up,” VMI details.

Some types of equipment incorporate technologies for more sustainable production. For example, the Kneadster vertical batch mixer has a drive on the tool and on the bowl that enables the mixer to store and re-inject energy into the tool drive circuit and vice versa, reducing its consumption.

Moreover, another main design feature that can have a significant impact on energy consumption is the shape of the tool and the tool/bowl ratio. “Our R&D team works to ensure efficient pairings, which may allow quick and efficient dough mixing, with minimal machine heating and stress, which, in turn, makes it more durable and more reliable,” VMI highlights.

Choosing the right equipment directly influences energy consumption. As far as the process is concerned, the first step in reducing consumption is being able to measure it. VMI is convinced that information is the key to making improvements in this area. Accessing and analyzing data is a challenge for many bakery and food manufacturers.

How can it help reduce energy consumption?

Different applications have been designed to provide a high level of analysis. Operators can not only view the overall consumption levels of their facility but also that of each connected machine. In addition, energy consumption can also be related to the amount of dough to compare different production flows. Recipes can be sorted to help identify the most energy-intensive and the most eco-efficient options. Manufacturers can then choose to change their recipe management according to this new criterion. Resulting areas of improvement could range from adjusting speeds, improving dough hydration, or checking ingredient dosing, among others.

To help manufacturers access and analyze this data, VMI has developed Octopus Solutions®, an IoT platform designed to monitor industrial performance. This tool gives centralized access to all machines and connected processes and allows bakeries to visualize their operations and optimize them.

“The smart Octopus Solutions ® can collect, store, analyze and use data to monitor key equipment indicators for more intelligent, integrated and efficient production.,” adds VMI. Applications cover:

+ Production monitoring

+ Consumptions – electricity, water for washing, overall water consumption

+ Preventative maintenance, as well as stops and defaults that can impact production and efficiency

IoT also helps to follow water consumption, especially during cleaning, to identify differences between production operations. In addition, the consumption of water that is used for cleaning should not be overlooked, VMI notes. “On an automated mixing system, and for a standard bakery recipe with 60% hydration, a bowl can be cleaned, on average, every five minutes. This requires several liters of water. With accurate measuring, inconsistencies or overconsumptions will be identified. They can be related to production (e.g., using more water to clean after a certain production cycle or specific recipes), or to maintenance, such as leaks (a leaking seal, for example) due to wear and tear and poor maintenance. By comparing the consumptions between similar production runs, unjustified deviations can be corrected,” VMI explains. One of its customers managed to

reduce its water consumption used for cleaning on one of their lines, by 50%. They were able to identify that one washing ramp was clogged and they were wasting time and energy cleaning their bowls, in this instance. This type of optimization may also represent substantial financial savings, the mixing specialist points out.

Since a global dashboard gives access to all the installed lineup of machines, data can easily be correlated to each other, and KPIs to some observed events during the production process. Implementing such a web platform, connected to equipment and processes, can be a powerful analysis and decision-making tool.

Once overconsumptions, inconsistencies, or abnormal use have been identified, corrective actions become more obvious. VMI aims to support bakeries in the optimization of their processes and equipment in the following ways:

+ If improvements must be made to the process such as recipe management or cleaning cycles, technical coaching is a good solution. VMI technicians will coach operators and supervisors on best practices to limit any production interruptions to help get optimal operation of production processes.

+ If human errors occur, proper training can avoid stoppages or unwanted changes in settings. With visual and easy-to-interpret data, it also becomes easier to highlight inconsistencies or regular issues on the line, to

raise team awareness. Follow-up and training are essential to limit downtime or slowdowns. VMI is working on developing flexible training methods aimed at all levels and professions to meet the needs of bakery manufacturers.

+ Overconsumption linked to the machine such as leaks can signal that more regular and thorough maintenance may be recommended. Consistent maintenance visits are recommended for prevention before troubleshooting arises. Retrofitting operations can also help optimize the machine’s process or prevent equipment obsolescence.

VMI believes that IoT systems like Octopus Solutions ® will play a major role in the future, in meeting changing manufacturing challenges. By developing and growing this technology, VMI also gets to know its customers and better understand their challenges: “In the long run, we hope that our customers will be able to build their own benchmark in terms of production performance or energy efficiency, compared to reference values.”

Compiling KPI data thanks to IoT tools will support decisionmaking. It can work throughout the facility to compare performance between production sites, to ensure consistency. Finally, it can also help guide the choices in terms of production, renewal of the machine base, or the choice in ingredients suppliers. VMI will work on further developing this tool, in partnership with key market players. +++

ePAN® designs from American Pan have been proven to save bakeries money on every bake. In fact, one customer reduced gas usage by almost 8% year over year by switching to an ePAN.

Energy solutions like wind turbines and solar panels are a major investment and require a large amount of dedicated space. ePANs can fit on your existing bakery line and save you money from the very first bake. Here’s how:

DECREASED OVEN TEMPERATURE

Oven temperatures have decreased by up to 30°C when using ePANs.*

REDUCED BAKING TIME

Baking times have been reduced by up to 45 seconds.*

REDUCED WEIGHT OF BAKING TRAYS & TINS

Trays and tins are up to 30% lighter, requiring less energy from bakery systems and employees for handling.*

*Results from real bakery experience. Results may vary based on specific bakery conditions.

Over the years, advances in continuous mixing have been developed to improve ingredient metering, process controls and include specialized mixer designs and ultra-high capacity mixers. Compared to batch mixing, such technological developments make continuous mixing a better option than batch mixing, especially so for high-volume production.

+High throughput continuous mixers are becoming the best sellers in this equipment category, as the benefits that continuous mixing systems bring are amplified at higher production rates, compared with batch mixing.

Jim Warren, Vice President of Exact Mixing (Reading Bakery Systems), highlights the main reasons why the advantages of continuous mixing will amplify exponentially, with larger production volumes.

Beyond the initial investment considerations, for largecapacity production lines, continuous mixing is a more cost-effective process than batch mixing.

The key concept to understand is that when the throughput of a continuous mixing system increases, the cost of the system changes at a much lower ratio than with batch mixing. This is because the ingredient metering portion of the cost is nearly constant, no matter what the new throughput is. For example, at four times the throughput (from 500 kg/hr to 2,000 kg/hr), the continuous mixing system cost only increases by 50%. At 7.5 times the throughput (from 2,000 kg/hr to 15,000 kg/hr), the system cost would only double. When considering batch mixing, the cost of the model is quite different: doubling the throughput of a batch mixing system increases the equipment cost by 80-100%. Both the mixer and the downstream metering system must double in capacity. In short, when comparing the cost per pound of dough produced, continuous mixing is the more costeffective option.

Being a fully-automated process, continuous mixing requires significantly less labor in comparison with batch mixing. With batch mixing, the higher the volume, the more people are needed for every stage of the mixing process. A larger staff also implies more training is required, as the quality of the final products directly relies on the actions of the operators.

Alternatively, continuous systems provide controls over the entire system including bulk delivery, ingredient infeed and mixing via automated recipe control systems. With continuous mixing, no matter what the rate, only one operator is required and for only a small portion of the day.

Continuous mixing requires less dough-handling equipment than batch mixing. In the case of continuous mixing, the resulting dough generally takes the form of a rope or log, which can be cut into chunks of the desired sizes. The dough pieces then fall onto a conveyor belt or directly into a hopper of the forming equipment. The process remains the same no matter the production capacity of the line. Batch mixers, on the other hand, produce a large mass of dough, which is discharged and must be resized for further processing – meaning, additional costs need to be considered for this dough handling equipment. Bigger volumes add to the batch-mixing challenges, as more equipment and operators will be needed.

“Anytime training becomes critical, retention is also critical. As the dough requirement increases with a batch system, the demands on the staff are multiplied. In the case of continuous mixing, no matter what the rate, only one operator is required and for only a small portion of the day.”

Warren,

Warren,

Continuous mixing is a more efficient process compared to batch mixing. There are no variations in the characteristics of the dough, which can occur between batches, which means less product waste. Additionally, if the manufacturing line needs to be stopped for an extended period, there is much more dough at risk when using the batch mixing method

– typically, around three mixer volumes. With continuous mixing, the only dough at risk is the small amount of dough inside the mixer.

When using fully automated continuous mixing systems, consistency is guaranteed. The minor ingredients are blended with the use of loss-in-weight technology and a blender on load cells. All measurements are weighed automatically, and the data is saved in the system. Dry and liquid ingredients are carefully metered into the mixer, and automatically weighed and recorded. Metering rates are graphed in real time and saved for future reference. With batch mixing, as the mixer throughput increases, hand measuring creates a greater opportunity for errors, more employees are required to batch ingredients and the pressure to create blends quickly increases. Often in a batch system, the plan for correction is at the operator’s discretion. Forget to add something? The dough is too warm or too stiff? Not enough development? Wrong consistency? Downstream shutdown? When presented with these problems, if there is no plan to act quickly, product will often be inconsistent and out of spec, creating waste. With continuous mixing, the system anticipates potential concerns, determines proper corrective steps in advance and is programmed to take those steps automatically.

While continuous mixing technology has been around for over 30 years, only the last 10 years have brought the development of mixers with production rates in excess of 8,000 kilograms per hour. The benefit is that this increase has been made with no change to the process itself – the mixer’s operations remain unchanged, with no new requirements. Continuous mixers will cost less to operate over time than comparable batch mixing systems, which offsets the higher initial costs. Exact Mixing has developed a Continuous Mixing Calculator (exactmixing.com/calculator) that can show what savings can be achieved when using continuous mixing compared to batch mixing. +++

Perfecting the recipe and baking are prerequisites for successful products. Next, it is the cutting that adds the final touch to ensure a successful delivery and customer experience, for bakeries of all sizes.

For smaller and medium-sized operations and their footprint challenges, BAKON recently added a new solution to its portfolio of cutting equipment: the Pico ultrasonic cutting machine. The Dutch specialist introduced this solution in 2022 to bring an additional choice to its range of cutters. An entry-level machine, the Pico was designed to provide the balance between costs and benefits for smaller operations, since it is more cost-effective for smaller production volumes, BAKON details the development thought process. “Within the Slicer range, the investment bar is way lower for customers with the Pico,” explains Halilcan Durgun, Order Manager, BAKON.

All the necessary features for a clean-cut, accurate process, are featured: in a standard configuration, the Pico is equipped with a cutting board, a knife washing installation and a Full Wave Titanium cutting blade (180 mm), which can cut products of up to 100 mm in height. The blade is programmed to be able to move over the product following both x- and y- axis movements. It can also rotate to cut triangles and round cakes, without having to reposition the product. In addition to automating the cutting process, it can cut cakes of up to 300 mm in diameter into same-size portions, according to how they are defined in the set recipe. Ultrasonic technology makes the process highly accurate, as it performs cuts fiber by fiber, which results in perfectly clean cuts – particularly beneficial for delicate and premium products such as cakes. For rectangular products, it can work with trays sized 600x400 mm and 660x440 mm (i.e., American sheet pan size).

The Pico is standardly delivered with one cutting board, but it has a dedicated storage space in its undercarriage, where different cutting boards can be placed, for ease of access. The PICO is fixed into its dedicated place in the bakery during the installation but the machine remains mobile if movement is required., thanks to its heavy-duty wheels.

The PICO is a semi-industrial, manually operated solution with a wide range of functions designed for ease of operation. Recipes can be created, adjusted and saved in the menus, via the touchscreen. They are set up into the system with preset parameters, which can be adjusted to optimize results. The cutting process itself is automated, following these recipes. “Every product behaves differently when being cut. Some products go really well with fast settings, whereas other products need to be cut more slowly to get the best end result. This is why we always say that the capacity of a

machine is entirely customer-specific,” Durgun points out. BAKON can program any requested languages for the touchscreen menus, which are also set up with different levels of access, to further ease operating the Pico. For example, production managers can access more settings than the operating staff. This also ensures the machine is correctly used, which safeguards it, the products and the employees working with it.

A fixed production process is required to achieve maximum benefits during the cutting process. This means that all products must be produced on the same baking plate and will have to undergo the same production process.

To determine how to best match the options with the product, BAKON evaluated how different products behave. The cutting speed for deep-frozen products should be lower, for example, to prevent them from breaking, BAKON illustrates. Alternatively, when cutting products such as round red velvet cakes, the speed can be increased, as this product is relatively soft, the specialist recommends.

Depending on the products and individual preferences, the blade can be cleaned automatically during production. Cutting residues are removed from the blade with air before entering the washing unit with fresh water nozzles and air nozzles for drying. For more thorough blade cleaning, “We do advise cleaning the knife by hand during breaks, for best results,” Durgun suggests.

The Pico ultrasonic cutting machine joins BAKON’s Nano, Compact XL and Inline Ultrasonic slicers. +++

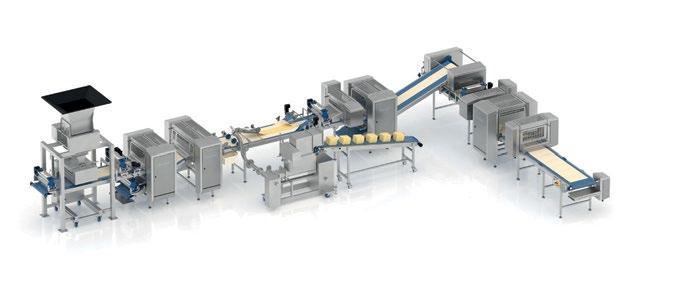

To maximize the benefits of automating bread slicing and bagging, industrial bakeries need to keep their customization options open. Aside from processing speed and reliability, flexible and easy adjustable equipment is a must.

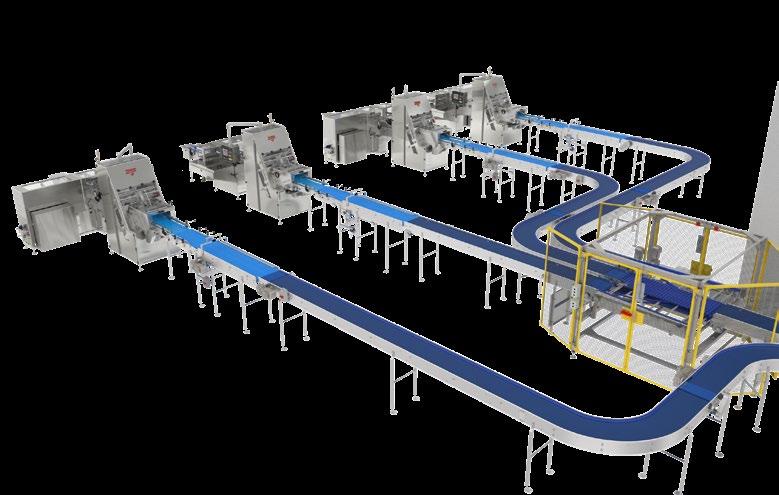

+AMF Bakery Systems looked into slicing, bagging and streamlining both processes with the Combo Bread Slicer and Bagger, which was designed to process a variety of pan breads. This machine can cut slices ranging from 92 mm to 140 mm in width, with a height of 76-152 mm and 203 mm to 432 mm long. The lattice allows slicing from 9.5 mm to 15.9 mm. It features a Hansaloy lattice, mounted on a mechanism that slides out partially or can fully extend, to allow the lattice to open evenly across the entire width of the machine. Chromed blade backing rollers maintain blade stability through the slicing process.

To switch between different products for slicing, recipes can be accessed through the product menu, with preset guides and slicing parameters. In addition, “Out-of-box equipment can be also adjusted using manual handles, or electrical knobs. The HMI will maintain the initial setting until the recipe is adjusted with a new value,” AMF Bakery Systems explains.

The system is equipped with a pendulum-style scoop drive, to minimize vibration during operation. Different pan or bag sizes may require changing scoops. An operator will be able to swap them out in about a minute, AMF explains. They are equipped with handles so they can be easily manipulated.

The 75S Slicer and Bagger units can process pan breads ranging from varieties with wheat, wholegrain and fruit dough. Supporting such variety also means special attention needs to be paid to the system’s sanitation. Depending on the intended usage, an optional blade and drum cleaning

system can also be equipped – it can be used for fruit or gluten-free breads, for example. Certain product recipes can automatically activate the steam or water features, as well as blade oiling.

A straight in-line product flow design was preferred for this system instead of a 90° transfer, to allow easy handling and access around the equipment. Products are fed into the slicer and bagger via a continuous, high-speed conveyor.

For bagging, a scoop system that brings the bag over the bread is used, to protect the package from damage that might occur if it touched the sharp edges of crusty loaves. The bagger uses the pendulum technique to bring the bag over the bread. “Our pop-up patented flight moves the bread from the slicer and electronically times the operation with the pendulum and scoop to capture the loaf and slide the bag over the bread, while top and bottom scoops are holding the bag. The pusher keeps the loaf stationary

during this operation. As the scoops move back with the pendulum, the bag lands safely on the flusher belt,” AMF explains the bagging process. Two removable crumb collection slides can be included under the conveyor to collect the crumbs and reduce sanitation time.

Access to the machine and operator safety were both considered in the design of the bagger. With the new concept, the infeed and discharge conveyors do not have a protective guarding around them, to allow visibility of the process and products. This open design allows for the removal of non-conforming products or placing loaves on the conveyor without having to open a hatch and interrupt the equipment. “AMF's concern for the safety of the operators required the design of a conveyor with popflights, to remove the cages from the conveyors. These patented pop-flights removes the pinch points. They have the property of bending and disengage from the chain if the operator's hand encounters it,“ the specialist explains.

The slicer and bagger system can be further automated with additional features, including:

+ Automatic pressurized oiler system –designed for low-fat or gluten-free loaves, it automates the daily lubrication procedure of the felt pad. This kit includes the pressurized manifold, oil bottle and HMI screens. The bottle should be filled with oil (mineral or vegetable) and delays should be set up for each recipe. Alternatively, a manual cycle can be run. The oil will be sprayed evenly on the blades and lower/ upper drums.

+ Automatic water spray system – designed for a raisin/weight ratio of under 20% and short batch production runs of raisin bread loaves (less than 2 hours). This kit includes the water spray nozzles, catch pans and HMI screens. A drinkable water

line must be supplied to the slicer. Delays can be set per recipe for it, or a manual cycle can be run. “This system will avoid any stoppages for cleaning during the production run. Deep cleaning will be required at the end of the production run to avoid fruit gum hardening on the blades and drums,” the specialist recommends.

+ Automatic steam cleaning system –designed for a high ratio of raisin/ weight, from 20% to 50%, or the continuous production of raisin bread. This kit includes the steam manifold with spray nozzles, the steam valve, a piping heat protective shield, catch pans and HMI screens. The slicer will require a connection to dry steam. This system also requires deep cleaning at the end of the production run to prevent fruit gum from hardening on the blades and drums.

+ Automatic blade tensioning – it uses a proportional–integral–derivative (PID) controller to secure the blade tension and optimize its lifespan. It also detects broken blades.

Just like the slicer, the bagger also has an automatic product changeover feature, which can independently adjust the infeed, lattice height and discharge guides. Optionally, the bagger can be equipped with a pendant arm to allow the staff to operate the machine from different positions. The slicing and bagging processes can be monitored via the single-swivel operator control panel.

between the slicer and bagger menus via the swivel option. A ‘skip loaf’ option is available and can be activated to manually insert a loaf on the bagger infeed. Preventive maintenance can also be scheduled here. Data about most active components can be accessed on the screen, to support maintenance planning. With the design of the system, AMF aimed to ensure the balanced flow of the overall process. +++

Every process parameter can be controlled via its new interface, which also provides data on the machine’s performance. The operator can switch the screen

The ‘simply unique’ interpack returns after six years of forced absence during the pandemic, with a clear business idea – a renewed hall concept based on clear points of interest for each industry, targeted exhibition areas, new specialty shows and forums.

Around 2,700 companies from around the world will meet in Düsseldorf from 4 -10 May, 2023. The 18 halls in Düsseldorf will feature a custom concept based on the core target groups. Professional visitors looking for processes and machinery for the packaging of confectionery and bakery can find these solutions in halls 1, 3, and 4. Exhibitors here will include AMF Baking Systems, Sollich, Aasted, FRITSCH, Reading Bakery Systems, Bühler, Hebenstreit, Rheon Automatic Machinery, Colussi Ermes, Tonelli, Mecatherm, TT Italy, VMI, Middleby Corporation, Baker Perkins, Diosna, Cepi, Minipan, Spiromatic, GEA, AZO, and Vemag, among others.

Sustainable solutions will constitute an important theme this year, Messe Düsseldorf anticipates, including innovation in packaging materials – such as mono or novel materials. Digital technology will also be among the highlights at the exhibitor stands. The food sector is expected to be among the most popular with the visitors to interpack

Starting in hall 5, the focus is on the food sector, with market players such as Handtmann, Multivac Sepp Haggenmüller, Ulma Packaging, Weber Maschinenbau and Fuji Machinery. In hall 6, companies including Syntegon Technology, Fanuc, Siemens and Duravant will showcase their innovations in many areas of application for processing and packaging.

Halls 7 and 7a, 8a, 9 and 10 will host more than a third of all exhibitors, focusing on materials and finished packaging products. All packaging materials will be represented in these halls, with sustainability and resource preservation in

the spotlight – solutions ranging from new materials, sustainable raw materials, and packaging using recycled materials should be excepted here. interpack will highlight, through the exhibited solutions, the influence that trends such as connectivity, security and sustainability have on the future of the packaging industry.

Themed days will be organized to provide focused information and answers to current challenges within the packaging industry. Topics that visitors can expect include circular economy, resource management, digital technology and product safety.

“Conditions such as scarcity of resources and disrupted supply chains pose great challenges to the industry, while simultaneously factors such as increasing demand, new technology and a growing awareness of sustainability offer us big chances to take huge strides forward,” said Thomas Dohse, interpack Project Director. “interpack is the place where the industry creates the future at a global level.”

interpack debuts a new slogan that defines its image this year – ‘Simply Unique’. The show’s uniqueness primarily stems from “the unparalleled diversity of the products and services that our exhibitors offer, but it is rounded out by our special themes that pick up on the trends for the coming years. In 2023, sustainability and all of its facets will be even more significant than it has been in years past, which means that we will be tackling this set of themes in cooperation with our partners,” added Dohse. +++

For more information, call (01) 610-693-5816 or visit readingbakery.com.

For over 130 years, the Thomas L. Green brand has been supplying biscuit and cracker manufacturers with the industry’s most efficient, reliable, and sanitary production systems. As the world’s most trusted brand, we offer a full line of modern, high-volume systems for laminated and sheeted products. The unmatched baking experience and advanced technology that goes into every Thomas L. Green system ensures that you consistently bake your best product, day in and day out. Contact us to learn about our latest energy efficient baking solutions. LEARN

The beginnings of pinsa making go all the way back to the Roman Empire. A fresh new take on the Roman pinsa is now rising to the top among consumer favorites all over the world. Modern techniques and new ingredients are here to help meet production needs.

+Pinsa’s unique taste and flavor were the result of the baker’s artistry in preparing the dough by grinding cereals and adding the right combination of herbs into the mix. Its very name honors the process, coming from the Latin ‘pinsere’ which means to stamp, to pound. The result defines the ideal characteristics pinsa should have, starting with its oval shape; it has a crunchy exterior while remaining soft on the inside, it is easier to digest compared to regular pizza, thanks to the leavening process; and it has a strong flavor which it owes to its special flour blend, including wheat flour, rice flour, soy flour, and dried mother yeast. Its very own supporting organization, Associazione Originale Pinsa Romana, officially recognizes restaurants as Original and Certified Pinseria, following expert examination and quality control of the entire production process.

To transfer the traditional manufacturing process to high-end industrial output, Rademaker transformed the production process of this originally handcrafted specialty into an industrial production solution that maintains the crispy crust and airy structure of the pinsa.

Pinsa is made with a unique type of pizza dough, the result of a non-GMO flour mix comprising flours made of wheat, soy and rice. Each plays its own functional role: soy flour makes the dough crunchy, and rice flour helps retain water

and makes it easy to bake. Sourdough or biga is also added, for a delicate flavor, in addition to the hallmark of the pinsa – a little yeast. Moreover, this special dough is more hydrated than traditional pizza dough and it can contain as much as 75-80% water, whereas pizza dough normally ranges between 53 to 65% water.

A key step in making pinsa dough is extended proofing, of about 72 hours. Baking is also adjusted to the requirements of the highly-hydrated dough, and is done in two stages: at first, the base is baked during par-baking, and then the dough is topped and goes for the final baking. For the industrial process, the par-baked pinsa is first cooled

+ By combining wheat, soya and rice flour, a high percentage of water and a long proofing time, pinsa is a healthier alternative to pizza and easier to absorb.

+ Because of the high-water content, a correspondingly lower amount of flour is added to the dough and, as a result, it contains fewer carbohydrates, respectively fewer calories.

+ Pinsa is a GMO-free product with no added sugars, no added saturated fats, 100% less cholesterol and two-thirds less gluten.

down, packed and frozen. In this form, it travels to the shop or restaurant, where it is defrosted, topped and goes in for the final baking.

Over the centuries, the original pinsa recipe has been refined with new ingredients and the support of modern technology. Rademaker translated the traditional process intending to have a similar quality, consistently, through an industrial, dough-friendly production process. To achieve this, when forming the dough, the structure created during mixing is kept intact throughout the consequent processing steps.

Prepared before the mixing process, the sourdough is added together with the other ingredients into the mixer. The dough is then put in dough bins and undergoes fermentation over several hours. When fermentation is complete, the batches of dough are placed into the Rademaker pre-sheeter. Depending on the desired capacity, a Double-chunking Sheeting System (DSS) or Dynamic Pre-Sheeter (DPS) will be used. Both systems are specially designed for producing artisan, highly hydrated doughs. This module creates a consistent sheet of dough. It features a system that ensures the structure of the dough remains intact while sheeting.

Dough sheets of different sizes can be produced with the pre-sheeter. The production line can be used for the production of virtually any type of bread. The sheeting and make-up sections are the product-specific process steps. “That is why we have designed different sheeting and make-up units that are suitable for specific doughs. For instance, toast bread requires a very small and evenly divided cell structure, which is the complete opposite of the pinsa dough. When desired, we simply add this unit

to the line configuration. In this way, the baker can make different products on one production line,” Rademaker illustrates.

To achieve doughs of various sizes in both width and thickness, for any type of dough, the pre-sheeter’s output has a dynamic dough outfeed gap function that adjusts the thickness of the dough sheet as required. Besides dough sheet thickness, the dough sheet width is also an important parameter to watch for when changing production to different types of dough. “This is centrally controlled and embedded in our operating system. Here, the operator can set the required dough sheet requirements, after which the system recalculates the settings of the modules and automatically changes them to the correct setting,” says Rademaker.

After pre-sheeting, the dough sheet is gently reduced as it goes through a combination of reduction stations. When the dough reaches the required dough thickness, it can either proceed to the inline proofing stage before product cutting or it can be directly cut into products. The newly-created dough sheet is cut into separate dough lanes, which go through a guillotine, resulting in the desired dough pieces. The make-up units transfer these dough pieces to the applicable unit to form the products. “These units are also individually able to adjust the product dimensions to the demands of the baker,” Rademaker adds.

Any excess dough can be brought back into the production process, so none of the special pinsa dough goes to waste. “With our in-line dough recycling system, 100% of the return dough can be re-used directly onto our production line. Side trimmings and omega trimmings can be transported back to the start of the DSS as small cuts of rework and

efficiently re-introduced in the process,” adds Rademaker. Custom rework dough options can be designed for specific requirements. For example, side trimmings can be set to be transported back to the DSS, while the omega trimmings are sent further upstream, to the mixer. The dough recycling process is stable, with reliable results, by controlling the distribution of this leftover dough.

In case an in-line rework system is not used, the excess dough is collected in bins that are placed next to the line. When full, they can be manually replaced, while the collected dough can manually be placed back into the mixing process.

Next, the products are shortly baked in a high-temperature stone floor oven. After baking, the pinsa is frozen and packaged, to be delivered to the final baking destination in this form. In restaurants or shops, the pinsa pieces are topped and then baking is finished. Finally, they are ready to be served.

The Rademaker production line can produce from 500 kg of dough per hour up to 6,000 kg/h, depending on the demands of the bakery.

With the DPS, capacities ranging between 500 to 1,000 kg of dough per hour can be reached. The DPS is 800 mm smaller in footprint compared to the DSS, and has an adjustable gap setting to create a dough sheet with thickness between 16 mm and 35 mm. The DPS has a working width of 600 mm for the sheeting sections and 800 mm wide make-up sections. The DPS has one set of chunker blades. Furthermore, it has an integrated reduction station, meaning that lower-capacity lines can be built with a smaller footprint.

By comparison, the DSS has a capacity of up to 6,000 kg of dough per hour and can process a dough sheet of up to 1,000 mm wide. Its production width is 1,000 mm for the sheeting section and 1,600 mm width for the make-up section.

The DSS features two sets of chunker blades. Rademaker explains the operating principle of the DSS: “It has a dynamic hopper that transports the dough in a controlled manner,

keeping the shape of the dough chunks linear and constant. Landscape sensors and separate belts carefully guide the chunks in the sheeter, ensuring size and weight accuracy. The weight and length of each chunk are exceptionally accurate, which leads to a more stable and consistent dough sheet and eventually high-quality baked products.”

Several types of dough are made with a high water ratio, which makes them liquid and sticky. Pinsa is one of them and, a ‘family’ it shares with ciabatta and focaccia doughs, too. The previous version of the DSS required oil to prevent the dough from sticking to the hopper, which made cleaning the line a time-consuming process. For the new version, Rademaker replaced the oil with wax, while also reducing the required amount to a fourth compared to the oil it previously needed. “Cost-savings are considerable and the wax distribution system has a ROI of only 1 – 1.5 years. Equally important, the DSS using wax is more accurate on dough chunk weights due to the dynamic belt principle and therefore creates a better overall performance compared to the oil DSS,” Rademaker explains. Both oil and wax operating versions are available for the DSS, while the DPS is only available in the setup using wax.

The DSS is designed to transport dough with minimal height differences, to preserve its homogeneity and structure. It also features easy access for cleaning. Moreover, it has a hygienic design and, with its wider belts, combined with advanced flour strewing and optimized waste bins, it supports clean working.

Both models manufacture products of similar quality, the differences between them only stem from the operating principles they utilize, Rademaker highlights.

Having started from a recipe invented during the prosperity of the Roman Empire, pinsa has an enduring place in the past and sees a strong present-day comeback. With production scaled up for industrial processing, it is also ready for the future needs of bakeries that can flexibly use the equipment for their production needs, for pinsa and beyond. +++

Aasted ApS will showcase solutions for the chocolate, baking and confectionery industry, in hall 1. The StellaNova tempering machine will be among the highlights at the stand. “We will launch new exciting enrobing and molding solutions, so visitors will be the first to see them“, said Piet H. Tæstensen, CEO. “We are pleased to participate again in

FRITSCH, a company in the MULTIVAC Group, will introduce a new booth concept in hall 3 at interpack, reflecting its motto – ‘FRITSCH –your first choice for tasteable quality’. The company will focus on end products and freshly baked goods at the exhibition. Several live baking shows will be held at the booth using the company’s machines and lines, showcasing formulations with alternative and healthy raw materials. +++

SOLLICH will showcase process-optimization solutions in hall 3, together with its sister company Chocotech. R&D at SOLLICH focuses on equipment hygiene – updates for easy and efficient cleaning will be introduced at the show, for machines across the company’s portfolio. Novelties unveiled at interpack will include a wheel-out heat exchanger for the Thermo-Flow ® cooling tunnel, designed for easy cleaning. In addition, the mobile belt washing unit features an integrated hygiene washing drum. For the Turbotemper ® , a machine for chocolate pre-crystallization, Sollich KG offers a complementary cleaning device that supports quick mass changeovers. The segment of the Enromat ® enrobing machines now comes with CIP capabilities. A further solution to improve the quality of chocolate during the handling process is represented by the Sollich Tempergraph®. This device allows automatic measuring of the degree of temper in the chocolate. For the production of bar products Sollich KG will present the new Miniconbar ® system. +++

Interpack after six long years. We have been improving our equipment and making it more sustainable. We will exhibit some energy-saving products, a complete bakery line, and our entire portfolio of tempering machines. Also, our After Sales & Service team will share the best-fitted plans for businesses to prevent production downtime.” +++

MULTIVAC is presenting its solutions in four exhibition areas at the trade fair (halls 4, 5, 16 and at North Entrance 1), in line with the fair’s updated theme structure, including technologies for the food industry. “We are very happy that the industry is coming together again after the C OVID -induced hiatus. The focus is on innovative, sustainable process and packaging solutions as well as digital services which help to create efficient production processes while avoiding unnecessary waste of resources”, said Christian Traumann, CEO and spokesman for the board of directors at MULTIVAC and vice president of interpack. +++

Syntegon will highlight its solutions in an exhibition space spanning almost 2,000 sqm at interpack (hall 6). ”We present intelligent and sustainable solutions for tomorrow – automated, digital and efficient,” said Dr. Michael Grosse, CEO of Syntegon Technology. +++

At the Linxis Group joint booth in hall 4, VMI will highlight the Kneadster ®, its vertical batch mixer fitted with an intuitive HMI, a removable bowl and a double mixing tool of exclusive design. It is designed for bakers who want to make quality artisan bread on an industrial scale. It is also suitable for a wide range of products such as sandwich bread, pastries, brioche, cookies and snack products. The Phebus will also be presented –a planetary mixer designed for bakery, pastry and snacking products. It features VMI’s Digy touch interface. It is designed for easy use, with its asymmetrical feet, a bowl height adjustable to the user, and raising/lowering of the head and the bowl. +++

Margarine has been a key ingredient in fine pastries for decades, with dedicated products being offered for nearly every single application. A potential contender is investigated for its properties in baking: liquid oil.

By Frida Köning, ttz Bremerhaven

By Frida Köning, ttz Bremerhaven

Over the last few years, manufacturers have been increasingly questioning the status quo and testing liquid oil as a substitute for baking margarine in their recipes, according to CSM Ingredients’ observations. This motivated a joint team, with specialists from CSM Ingredients and ttz Bremerhaven, to have a fresh look at the topic and perform its own comparative investigations into the functionality of baking margarine vs. liquid oil in selected applications.

From the theoretical point of view, vegetable oil – after refining – is a liquid product with a fat content of almost 100%.

Margarine, on the other hand, is a water-in-oil emulsion with a fat content of at least 80%, which is solid at room temperature. Usually, both phases contain further components. In addition to oil, the fat phase consists of solid fat (e.g. palm or coconut), emulsifiers (e.g. mono- and diglycerides), colorants (e.g. β -carotene), flavorings, antioxidants (e.g. α-Tocopherol) and sometimes other fat-soluble vitamins (e.g. vitamins A, D). In addition to water, the water phase usually contains table salt and acids (e.g. citric acid).

On the basis of these different compositions, hypotheses can be formulated for the expected effects of margarine on baked goods compared to liquid oil: the use of solid fats, which are partially crystalline at room temperature, may result in a firmer consistency of the doughs/batters and the pastries. Crystalline fat is more tightly enclosed in the structure of the pastry, which may release less fat to fingers or packaging. Due to the crystalline fat structures with different light refraction

than liquid oil, the pastry may appear brighter. The use of colorants such as β -carotene counteracts this phenomenon. When pastries with margarine are eaten, the fat crystals melt in the mouth. This endothermic melting process may cause a ‘freshness’ sensation. The use of flavors may create a more complex flavor profile that may be further enhanced by the salt in the margarine. The use of emulsifiers may stabilize the structures in the dough and may ensure greater pastry volume, more homogeneous structures and a finer pore appearance.

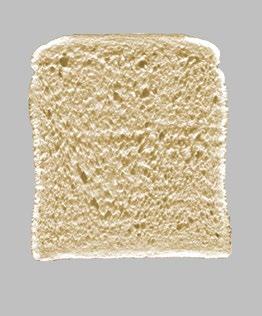

To investigate the original question and the above hypotheses empirically, a series of tests were carried out at the ttz Bremerhaven in which three different products were baked with both margarine and a refined oil (fat equivalent +80% water) and compared with each other. The selected baked goods were sandwich bread (∼ 5% fat), brioche (∼ 10% fat) and pound cake (∼ 20% fat). The solid fat used for the sandwich and brioche was Meister Goldback margarine (CSM Deutschland GmbH) and for the pound cake Meister Goldcreme margarine (CSM Deutschland GmbH). The refined oil was rapeseed oil (Power Oil Rostock GmbH). The evaluation was made with respect to the sensorial and physical differences in the final products.

Characterization of the final products was performed by Volscan (Stable Micro Systems Ltd) for the determination of the specific volume, C-Cell (Calibre Control International Ltd) in order to analyze the crumb structure and Texture Analyzer (Stable Micro Systems Ltd, TA-HD plus) for the measurement of the crumb texture concerning hardness

and springiness. In terms of sensory evaluation, a simple descriptive assessment was completed for all products.

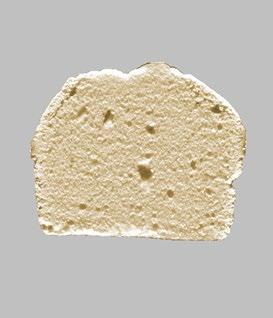

Both the sandwich breads with baking margarine and the sandwich breads with refined rapeseed oil had a good appearance after proofing and baking and filled the baking tins properly. They were described with a typical wheat bread flavor and taste. The mouthfeel was perceived as pleasantly soft, not chewy and succulent. The crust was golden brown and the crumb was even and fine-pored. Concerning the samples with rapeseed oil, the tendency pointed towards a slightly thinner and softer crust, especially towards the bottom of the bread. Furthermore, one test person noted a slight inherent odor also reflected in the taste. (Figure 1)

With the C-Cell, the sensorial impressions were confirmed by a comparable number of cells per area and on average less than one hole per slice for both recipes. Furthermore, a significantly higher slice brightness for the sandwich bread with baking margarine was measured. The cause for this phenomenon may lie in a difference of the refraction of the actual dough possibly due to the crystalline structure of the margarine or less deep cells of the crumb. Checking the cell volume confirms a tendency (not significant) of smaller cells. (Figure 2)

The analysis of the crumb texture measured with the Texture Analyzer revealed a significantly firmer crumb with baking margarine. The springiness was similar for both sandwich breads. Both crumbs reached more than 80% of their original height after the application of force.

All in all, in the evaluation of the sandwich breads with a fat content of approximately 5 %, hardly any differences were found between the products with baking margarine and with refined rapeseed oil.

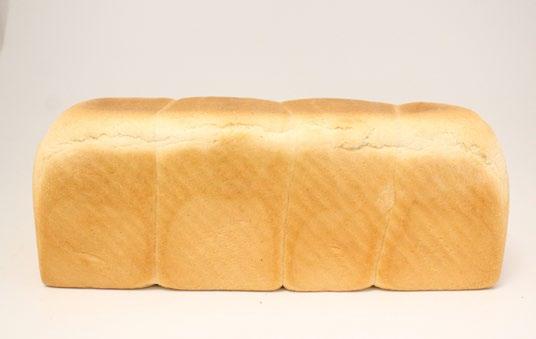

The comparison of the brioche produced with baking margarine and with refined rapeseed oil revealed obvious differences in the outer appearance. While the crust of the brioche with baking margarine was characterized by a golden-brown, smooth and even surface, the crust of the brioche with refined rapeseed oil was darker and softer with blistering of the surface. In accordance with the blistered crust, the volume measurement revealed a consistently greater specific volume for the brioche recipe with refined rapeseed oil compared to baking margarine. (Figure 3)

The overall impression of both crumbs also differed. While the crumb with baking margarine appeared fine and uniform, the poring of the samples with refined rapeseed oil was perceived to be more irregular and coarser with a tendency towards detachment of crust and crumb. With the C-Cell, a

slightly higher number of cells per area (significant) could also be measured in the samples with baking margarine, indicating a finer poring. In addition, a significantly smaller cell volume was determined. Both are also reflected in an overall higher slice brightness. A detachment of the crumb was only detected in individual samples with refined rapeseed oil. Overall, a comparable number of crumb defects in the form of larger-than-average pores/ holes was detected. (Figure 4)

Furthermore, the texture analysis of the brioche revealed that the application of the different types of fat influenced the hardness and the springiness of the crumb significantly. The brioche crumb containing the baking margarine was firmer and less elastic than the crumb with refined rapeseed oil. The latter matches with the impression of a tougher behavior when tearing the roll apart during the sensorial analysis. Nevertheless, a more elastic crumb is associated with better performance when it is buttered with a knife. If crumbs are too elastic, this may lead to the issue of a spongy mouthfeel. In the sensory evaluation, both brioches were described as sweet and typical yeast-based pastry

products with a pleasant mouthfeel. In direct comparison, the brioche with refined rapeseed oil smelled a little less fresh, but the mouthfeel was a little more succulent/slightly less dry.

All in all, the comparison of brioche with a fat content of 10% produced with baking margarine and with refined rapeseed oil revealed differences, especially in the outer appearance, and also in the texture of the crumb.

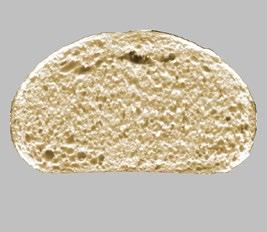

During the manufacturing process of the pound cake, two completely different batters resulted. While the batter with baking margarine was very airy and creamy, the batter with refined rapeseed oil had a more liquid appearance. (Figure 5)

After the baking process, on one side, the cake with baking margarine had an even appearance, a smooth, shiny surface and an optimum crust crack. On the other side, with refined rapeseed oil, the cake surface appears significantly less shiny, rougher and more porous. (Figure 6)

Nevertheless, analysis of the crumb structure by C-Cell showed that there was no significant difference in the number of cells per area or holes. However, a significantly larger cell volume and a significantly lighter crumb were measured for the cake with baking margarine. At this point, a small effect of the margarine, which was added to the cake at 20%, on the color of the dough is inferred. (Figure 7)

Sensorially, both cakes were described as sweet, typical lemon cakes. The pound cake with baking margarine was perceived as more aromatic/flavored and buttery. In terms of mouthfeel, the pound cake with baking margarine was soft and fluffy, but also crumbly, while the pound cake with refined rapeseed oil was firmer, more elastic and oilier, which was also reflected by an oily film on the fingers. Although a comparable firmness of both crumbs was measured with the Texture Analyzer, it could also be determined that the crumb of the cake with refined rapeseed oil was almost twice as elastic as the crumb of the cake with baking margarine. This result aligns perfectly with the sensory impression of the pound cake with baking margarine being crumbly and the pound cake with refined rapeseed oil behaving spongy. This behavior is also captured by a picture of a sample of each product right after the texture analysis.

(Figure 8)

“In terms of mouthfeel, the pound cake with baking margarine was soft and fluffy, but also crumbly, while the sand cake with refined rapeseed oil was firmer, more elastic and oilier, which was also reflected by an oily film on the fingers.”

pound cake with a fat content of almost 20%. In summary, the results show that in the production of pound cake, the choice of fat used is clearly reflected in the properties of the baked product.

The most striking differences were seen in the baking tests with baking margarine and refined rapeseed oil in the

Reflecting on all results generated in the scope of this research project leads to the conclusion that the kind of fat (baking margarine vs. refined rapeseed oil) used for bakery applications does make a difference in the performance of the product. It seems that the intensity of the effect is product-dependent. While little to no impact was identified for the sandwich bread, a more noticeable effect was measured for the brioche and the most intense consequence appeared for the pound cake. It can be assumed that these observations are related to the fat content of the products. The sandwich bread only had a fat content of approximately 5%, while the fat content of the brioche was set to 10% and the pound cake reached a fat content of almost 20%. Most significant was the effect of a higher springiness of the crumb by the use of refined rapeseed oil. On the contrary, this means the application of baking margarine is accompanied by a reduced springiness. The possible explanation lies in the physical state of the fat. While the refined rapeseed oil is liquid at room temperature, the margarine is partially solid due to the crystalline state of some fat components. Even though the margarine melts during the baking process, it recrystallizes in the final product at room temperature, resulting in a less elastic crumb

one hand, but also a less spongy mouthfeel on the other (especially so for pound cakes). Furthermore, the use of baking margarine in the conducted tests has a positive effect with regard to the common expectations on the external appearance of the product. The brioche as well as the pound cake made with refined rapeseed oil was characterized by an irregular and rough product surface, while the brioche and pound cake with baking margarine showed a smooth and shiny surface. Partially, effects on the pore structure of the crumb were identified. Here, the actual number of cells was influenced to a lesser extent, but rather the slice brightness reflected a combined impact in the number of cells, the average volume of the cells and the actual color of the product.

All in all, the research project successfully characterized the differences in bakery performance concerning the use of baking margarine compared to refined rapeseed oil. The existence of margarine for bakery applications finds justification, especially regarding the outer appearance of the products. Margarine and oil can be used for different structural adjustments. A joint application for the optimization of the target parameters is conceivable.

More baking trials based on additional products and the detailed characterization of the doughs and their properties are planned.

A two-year Science Cooperation Contract was signed in December 2021 between CSM Ingredients and the Technology Transfer Zentrum (ttz Bremerhaven). CSM Ingredients is a manufacturer of ingredients with a broad portfolio of specialty fats, products for the manufacture of fine baked goods, bread and rolls, and food solutions for a wide range of industrial applications.

ttz Bremerhaven is an independent provider of research services and operates in the application-oriented field of research and development. The common aim is to explore new technologies in the areas of bakery, plant-based food, nutrition and metabolism, clean label and new functional ingredients. Therefore, joint innovation workshops are held and scientific experiments are conducted at the ttz Bremerhaven.

+++

Bread has been seeing a return among consumers’ favorites lately. The main obstacles in the way of further market growth still come from the way it is perceived. To educate consumers, a multi-national, targeted campaign addressed the source of the problem. And it works.

+Bread’s staple role among foodstuffs in Europe remains undeterred. Its image with consumers has received considerable help from communication campaigns, such as those organized by the Dutch and the Belgian bakery sector. The purpose: raising awareness among consumers regarding bread’s nutritional and health benefits, its authenticity value and unique characteristics in terms of sustainability, quality, taste, diversity and traditions. This follows the first bread campaign, which saw good results in tackling the issue of decades-long declining bread sales. “Secondly, we learned that, besides quantitative goals, we need to work more on qualitative goals such as awareness,” says Linda van Zonsbeek, Specialist in Nutrition & Health at the Dutch Bakery Center (NBC).

The associations in both countries recently worked together on a new campaign, called ‘Bread good story. With grain from Europe’ is the second round of a two-year-long campaign promoting the qualities of bread. It officially started in January 2022, with the first messages being sent out to consumer from September. It is presented as an integral part of a health-conscious lifestyle – nutritious, contributing to the daily protein intake, plant-based, locally produced and suitable throughout the day – through PR, special events, communication for food professionals that would help them promote bread, educational materials for schools, messages displayed in shops and online, as well as via TV announcements, social media messages and YouTube videos. The campaign’s dedicated websites,

www.brood.net, www.broodgoedverhaal.nl (the Netherlands) and www.broodgoedverhaal.be and www.lepainunebelle histoire.be (Belgium), highlight the main focus points surrounding bread and its benefits: wholegrain, carbohydrates and fibers, protein, sports and weight management, gluten sensitivity and recipe ideas. Wholegrain bread is the hero of the campaign, starting with a necessary introduction to different types of flour and pointing out scientific-backed data that explains its lifelong benefits to health. The ‘Success story – what makes it whole grain’ message was promoted on TV and online. In November, two other videos were aired: ‘Nonsense story, the facts on the table’ and the ‘Tall story, the superpowers of bread’. NBC and the Belgian Institute Bread & Health want to reach as many consumers as possible. In addition to consumer campaigns, the project also aims to get nutrition professionals involved. For the National School Breakfast, an event held in the second week of November, NBC also distributed educational material to primary school children – through schools in the Netherlands and through school magazines and special events in Belgium.

Even though wholegrain bread is the campaign’s star, other varieties are also promoted. The information shared by the organizations covers bread in general, to get the full benefit of a deliciously diverse product segment.

To ensure the messages are effective for their intended audience, the campaign clearly distinguished its target groups to address each segment specifically. For instance, the story about protein in bread is focusing on active, sport-inclined consumers, whereas the health-conscious