“Artificial General Intelligence (AGI) has the potential to bring about numerous benefits and advancements in various fields. However, it is also important to consider the potential risks and dangers associated with AGI development. Here are some of the key concerns: superintelligence, value misalignment, unintended consequences, rapid self-improvement, strategic advantage, job displacement and security risks.” This was ChatGPT’s answer to my question about AI dangers – you can read the full text it generated by following the QR code on this page. I finally made a ChatGPT account just for this one question.

OpenAI released ChatGPT in November last year. Over the past six months, Generative AI has been the trending topic related to Artificial Intelligence, an exploding buzzword in conversations among interpack exhibitors and visitors as well. It has unequivocally entered every aspect of our lives, from the education system, to sciences and a widening range of fields in the workforce. The ominous warning of having a superintelligence system that is allowed to develop unregulated came in May in the form of an open letter signed by AI pioneers and released by the Center for AI Safety. In just 22 words, it spoke of scenarios we have only seen in sci-fi literature before: “Mitigating the risk of extinction from AI should be a global priority alongside other societal-scale risks, such as pandemics and nuclear war.” The New York Times speaks of “societal-scale disruptions within a few years if nothing is done to slow it down”, fears shared by the very industry leaders competing in developing AI.

With potentially overwhelming power comes great responsibility and Europe has been leading the way in setting up the first rules on AI through the AI Act, to ensure its human-centric and ethical development. The goal is to ensure that “AI systems are overseen by people, are safe, transparent, traceable, non-discriminatory, and environmentally friendly”.

Rather than attempting to slow down this AI tsunami, the goal is to harness its power – for good. The systems AI disrupts are also starting to quickly adapt: universities can already identify ChatGPT-generated work when testing papers for original content value – and grade it accordingly. In manufacturing, we’ve begun to see the invaluable benefits AI can bring for some years, even before the age of ChatGPT and the exacerbated enthusiasm over its (weaponized) potential. It can entirely revolutionize logistics, streamline supply chain management, control machines, IT operations and entire automated factories. It can also support R&D work. The possibilities are endless, as long as it plays by the emerging rules. In Europe, regulations are being formulated now. Exciting developments will follow.

Jeff Greenall, the director of Cavan Bakery, shared with baking+biscuit international the story of the recent GBP 1.5 m investment and the company’s take on innovation.

Koenig closed FY 2022 with sales amounting to EUR 114 million, a new record in the company’s history. Wolfgang Staufer, the company’s CEO, gives us a glimpse into the work behind these results and shares his views on the state of the industry, its future and Koenig’s role.

To optimize in-store baking efficiency, the UDO baking technology is one to watch. It stands for Univac Double-bake Oven and is powered by Cetravac AG’s patented innovation. Developed under the bakeXperts brand, the UDO opens the door to a new world of baking in-store.

Family-owned Via Oliveto Bakery set out to quadruple production and boost its capabilities to manufacture its staple products and new innovations at its facility in Barrie, Canada.

36

How to better meet today’s customer expectations with modified dough processes for baked goods containing rye.

Cost-sensitive and inflation-wary consumers in Germany are bound to increasingly head to the supermarket and discounters for their bread for baked goods in 2023, as they search for a cheaper weekly shopping basket overall.

BAKERIES

06 Cavan Bakery, UK: “Quality tells”

IN-STORE OVENS

12 BakeXperts: A vacuum baking revolution

17 MIWE: In-store baking efficiency – check

INTERVIEW

20 Wolfgang Staufer, Koenig CEO: “The demand for bigger, centralized bakeries has been instrumental”

PRODUCTION

26 Tray handling: Handle with automated care

28 Case study: Via Oliveto Bakery, from rack baking to tunnel ovens

40 FRITSCH, JRS: Competence for gluten-free dough

RAW MATERIALS

32 DIOSNA: How to lower sugar using thermic predough processes

SOURDOUGH

36 IREKS: The stages of perfecting sourdough

MARKETS

44 Euromonitor International: Germany – Supermarket bread is making strides

REG ULARS

03 Editorial: “The line between extinction-level events and revolutionary opportunities” 16 News

Throughout its century in the business, Cavan Bakery has kept a keen eye on the future. The company has recently started a new chapter by moving into a new home, a facility three times the size of its old one. Jeff Greenall, Cavan Bakery Director, gave baking+biscuit international a glimpse into the work behind the recent GBP 1.5 m investment and the company’s take on innovation.

+Family-owned Cavan Bakery recently moved into a new, 15,000-sq ft baking facility on Lyon Road in Walton-on-Thames in December 2022, an expansion supported with GBP 1.5 m funding it secured from Lloyds Bank. It is three times the size of its previous bakery. The expansion means that Cavan can now increase production, with better streamlined operations. “The design and flow of the new bakery and segregation of different stages of production allow us to maintain more stability and control over our products and overall production,” says Jeff Greenall, director at Cavan Bakery.

Cavan currently sends around 80,000 products each week to its shops and local businesses. Among them are 40 different types of bread and 30 ranges of pastries, buns and cakes, as well as snacks such as the popular sausage rolls and sandwiches. The business also runs 13 bakery shops across Surrey and South London and a café at Molesey Boat Club. In a typical week, it sells over 12,000 loaves, 7,000 morning goods and pastries, 3,000 savory pastries, 8,000 sandwiches, 4,000 cakes and 3,000 coffees in its shops and other wholesales businesses. With the expansion complete, it has boosted its storage and production capabilities.

The business opened its first shop in Twickenham, South-West London, in 1929. “Right from the start, David Cavan – my wife’s grandfather – used the phrase, “Quality tells”, when placing local adverts. He valued producing and selling

quality products and that has stayed with us to this day. We pride ourselves in producing premium bakery goods at reasonable prices,” says Greenall.

The business has been forward-thinking since the start and its values remain the same today. In 1944, it became one of the first bakeries in the country to change from hand-drawn bread barrows to electric-powered carts to carry out its home deliveries. And 70 years later, Cavan became one of the first bakeries to invest in a modern electric delivery van, Greenall recalls. That was in 2018. Since starting on this sustainable road, Cavan Bakery is now looking into turning their entire fleet electric.

”Success for me personally is still being in business after 23 years and having the honor of keeping the family business going, now in its 94th year. Over the years, we have developed – and, I hope, improved – our product range and offering to our existing customers to ensure that they keep coming back, while at the same time appealing to new customers as we grow and expand.”

The moment when Jeff Greenall and his wife, Sarah, bought the business from her parents, in 2000, was a major milestone for the business. The bakery grew and has moved twice since, in 2010 and more recently, in November 2022, when it relocated to Lyon Road. “When we took on the business, we started with three shops and now have 13, plus a café on the Thames (Eight on the River), with plans for more shops,” he says.

Greenall finds validation in having happy customers talk about how great the products are. “Success for me personally is still being in business after 23 years and having the honor of keeping the family business going, now in its 94th year. Over the years, we have developed – and, I hope, improved – our product range and offering to our existing customers to ensure that they keep coming back, while at the same time appealing to new customers as we grow and expand,” Greenall explains. He also prides himself on not resting on their laurels as the company enjoys success. Instead, the company worked on innovating and staying competitive. “We have been mindful to keep our brand up to date while maintaining an artisan, craft feel that reflects our values,” he highlights.

There has been, of course, no smooth sailing for the entire industry recently, successful businesses such as Cavan Bakery included. Starting with pandemic restrictions, more waves came, from supply issues to energy costs and inflation worries, to build up a storm. By and large, the company kept baking through COVID issues, even if the wholesale business disappeared with the lockdowns. “Fortunately, our shops were busy and we gained lots of new customers, most of whom are still with us,” Greenall adds.

Cavan’s anchor throughout the recent and ongoing industrywide storms has been staying true to its affordable quality

concept, which has been rewarded with loyalty from its community. After all, bakeries and consumers weather the same storm: “We want our customers to have a great experience when shopping with us and enjoy our products over and over again. The cost of living crisis is a real problem for so many people and customers will be increasingly discerning about what they buy. It’s vital that whatever we sell is memorable and of great value,” Greenall underlines. With this mindset, Cavan will never compromise on using quality ingredients and the best flours. In the past few years, that meant keeping their suppliers very close in working together to ensure supply continuity. This is not to say the bakery has not also seen material prices soar in recent years. Much of the cost increase is absorbed, but some had to be passed on to the customers.

To manage skyrocketing energy costs, Cavan Bakery has been working on striking long-term deals with suppliers and being able to negotiate sensible tariffs. One of the biggest challenges post-COVID was one severely felt in the industry: staff shortage, which “is causing huge wage inflation, much bigger than rising ingredient prices. This I cannot see changing,” he estimates.

The business now works with a staff of 150 people. In line with the facility expansion, the head office team was also recently increased with the addition of financial and HR departments. Together, they work on developing new products, opening new shops, growing the wholesale network and establishing the company’s online shop. Doing business locally is a priority at Cavan Bakery, starting from their products to sourcing ingredients and supporting the local community. The daily production surplus is donated to local charities and social programs, a twice-beneficial initiative since it also means that food waste is minimized. Cavan

Bakery established partnerships with charities such as Glassdoor, The Real Junk Food Project and Surplus to Supper, who collect the food surplus at its shops and ensure it is redistributed responsibly.

Sustainability is inherent to every aspect of the company’s work. “We are very conscious that we use a lot of energy within our production and delivery. We are always looking ahead at new technology and at reducing our carbon footprint by replacing or upgrading machinery and ovens,” Cavan’s co-owner emphasizes. The transition to electric vans is underway and solar panels will be installed on the roof of the bakery, for green, self-produced energy.

Packaging sustainability is also important. “We moved away from using plastic bags for our baked goods some time ago and now only use paper bags and cardboard packaging. All our branded packaging is made from 100% recycled materials and is, in turn, fully recyclable,” Greenall says. One area still in need of a solution is sliced bread packaging. This is a work in progress, with several trials attempting to package this product in a variety of compostable and biodegradable bags. However, they were found to promote moisture loss. Until the best green solution for shelf life is found, plastic bags make sense, in this case, and are still used for sliced bread to keep it fresh for longer and prevent staling. For other baked treats, the company sells cotton drawstring bread bags as well as reusable bamboo coffee cups in all of its shops as a sustainable alternative, and they encourage customers to reuse and recycle wherever possible.

The bakery opened its three newest shops in the last two years, in Shepperton, Wimbledon Park and Sunbury. The goal is to reach 20 shops by the end of 2024 – seven more to go, out of which, at least three should be opened sometime this year. The business is currently looking to expand into Surrey, Hampshire, and Berkshire. It is also slowly making its way towards central London, but it may have some way to go yet. “We look out for areas that already have independent shops, post offices and parking. I always know when we find the right spot and will wait until a site becomes available rather than compromising on any of our considerations,” Greenall explains regarding the location hunting process.

The latest expansion, which effectively tripled Cavan Bakery’s production real estate, was a huge undertaking for the business, one that was the cause of many sleepless nights for Jeff Greenall: “I had known for some years that our old bakery was too small and, therefore, inefficient. I had many criteria that the new site needed to fulfill, so I viewed many, many buildings until I found the right one,” he recalls.

The size of the new bakery was also crucial in the choice. It had to be a site that the business could grow into and not one that it would quickly outgrow. Having generous offices was also on the checklist, keeping in mind accommodating and attracting more people into the business. “Recruiting more staff and upskilling them to our standards is our biggest factor in optimizing our production flow,” explains Greenall. The location also played a role. “We had to

move to a place where our staff would still be able to get to work easily, so good transport links were really important.” What’s more, the working environment is much more pleasant at the new address, which the staff can enjoy, he appreciates.

Once the site was chosen, then the real work started. Greenall had to plan the bakery, considering workflow, access, cleanliness, power and water requirements, as well as areas that could be temperature regulated. “I tendered the project as a whole turnkey solution, as well as in parts, with the idea that I would manage the project. Eventually, I went with a specialist company to do the whole project,” he shares. The planning started in March 2022 and the facility was operational in November 2022. The project grew organically: the original plan saw numerous tweaks along the

way, and there are more things to be added even now to improve efficiency and workflow, Greenall reveals.

The expansion brought improvements to the production process. The bakery incorporates updated technology overall, including motion sensor lights throughout the facility, so that lights are not left on unnecessarily, and electric ovens replacing gas-fired technology, or temperature-controlled environments in the different production areas so that they are not affected by outside changes in temperature.

Some processes, however, are meant to attest to the artisan bakers’ craft skills, on which the company relies. This is why shaping and finishing are still done by hand, for example. “Production capacity has scaled up, but our traditional methods, values and means of production were preserved.

Good baking takes skill, time and passion and we are not prepared to compromise on any of these,” Greenall points out.

As he puts it, the bakery’s “single most important technology” is its workforce, as it relies on the hand and the craft of its bakers. Because of ongoing recruitment challenges, Cavan Bakery is looking into automating some of the more routine parts of the production process, such as dough dividing, pastry cutting and piping.

The majority of the specialty breads Cavan Bakery makes are sourdoughs. Interestingly, sourdough is a weekend favorite among the bakery’s customers: “Sourdoughs account for about 30% of our overall bread sales, although this rises considerably at weekends. We are currently working on Spelt varieties, Sweet Potato and Rosemary, and a Chocolate Sourdough.”

In addition, there are still more traditional breads, morning goods, cakes, savories, sandwiches and coffee on the menu, as always, but, within these categories, the selection has changed, Greenall observes. In the bread segment, Cavan Bakery now sells a large range of sourdough varieties every day, which has overtaken the old classics such as sandwich bread. These still have their customer base, but are becoming less popular with changing tastes. Cavan favorites such as jam doughnuts and brownies also perform well, but they have been developed and improved.

More delicious specialties will be introduced soon: “We are currently developing some amazing pastries – savory and sweet – and flatbreads. And, of course, some interesting new sourdoughs,” Greenall anticipates.

For seasonal offerings, the busiest holidays for Cavan Bakery are Christmas, Valentine’s Day and Easter. Other special dates in the bakery’s calendar include Hampton Court, the Chelsea Flower Show, and European finals (football). “Though we say it ourselves, we believe our Mince Pies and Hot Cross Buns –following traditional family recipes – really are the best out there and our customer feedback and sales reflect that,” he says.

The bakery’s relationship with its customers is key; there would simply be no business without them. In this regard, “Our three guiding values are all about our Passion, our Product and People. It is heartwarming to see that our customers are loyal, and loyal throughout the generations; having been part of our local community for nearly 100 years; we have children and grandchildren of our first customers still shopping with us,” says the business owner. Social media helps them connect, and the bakery is happy to invite them behind the scenes with photos and videos, in which they highlight their values: the people, their passion for the craft and the process behind the products.

Wholesale customers are equally important: “We try our best to accommodate any unusual requests. We want companies that are driven by quality so we avoid companies whose only motivation is price.” The bakery supplies over 100 wholesale customers in the area, including local cafés, restaurants and farm shops, which account for around 15% of its total business.

“We’re really privileged to have been able to grow at a strong and steady rate, particularly over the last decade as people have discovered the craft of skilled artisan bakers who provide quality and diverse goods,” Greenall acknowledges. “We are proud to provide our customers with local, sustainably-sourced products.” +++

Change the tools of our lines within the blink of an eye and vary your portfolio.

Ben Baker

Ben Baker

Tasteable quality ready to go within 5 minutes – even on our industrial croissant line.

To optimize in-store baking efficiency, the UDO baking technology is one to watch. It stands for Univac Double-bake Oven and is powered by Cetravac AG’s patented innovation. Developed under the bakeXperts brand, the UDO opens the door to a new world of baking in-store.

+The UDO can bake frozen, ambient-stored raw dough, or parbaked products such as rolls, baguettes and even larger loaves and cool them to perfect-to-eat level in less than 5-10 minutes. It does so while achieving perfectly even heating and retaining all product characteristics, consistently. How is such a process, which is nothing short of revolutionary, even possible? The answers are in vacuum conditioning. The process steps are straightforward: the frozen product goes into the preheated oven. In a matter of seconds, a vacuum is created, removing all air from the product’s pores and clearing the way for steam. The steam is then used to heat the product, a highly-effective process that only takes seconds and boosts crumb and crust qualities. Simultaneously, infrared radiation heating is deployed. With starch gelatinization comes heightened freshness, as this process delivers moisture to the crumb. The final step is vacuum cooling, again a seconds-long phase, which further stabilizes the structure of the baked product. The speed of the baking-off process makes it possible to react to fluctuations in demand at very short notice, thus minimizing unsold residual stocks at the end of the day.

The control system is designed so that the operators only need to place the goods on a tray, assign them to a product image and press the start button. The control system can also be integrated into other management systems such as Semco One or Shop IQ. In this way, new products can be added centrally into the interface, while also enabling comprehensive control of the oven.

There is an entire array of adjustments that can be combined to improve baking quality and efficiency. To embark on an optimization process, the goals should clearly be defined

“When developing the UDO vacuum baking oven, we focused on a holistic approach because it is important to us that economy and product quality are not seen as conflicting opposites.”

Adolf Cermak, founder and President, Cetravac AG and bakeXperts

at first, before building a path to them: “What is meant by optimization, process organization, the time and effort required, the energy costs, the availability of products, or their quality? Which sub-goals are in the foreground at the same time, which can definitely vary from one company to another? When developing the UDO vacuum baking oven, we focused on a holistic approach because it is important to us that economy and product quality are not seen as conflicting opposites,” explains Adolf Cermak, founder and President of Cetravac AG and bakeXperts.

Looking at the entire process, from start of production to sales, the UDO can shorten the processing time by 40-70% compared to conventional in-store baking, depending on the product, and save considerable energy and labor force requirements, respectively. In addition, it also supports raw materials savings, because baking losses are reduced to a minimum, thanks to the accurate control of the water balance in the baked goods. With this method, there is no volume or weight loss even if, initially, up to 10% less dough was used. Moreover, the stability of the process means that larger batches can be produced efficiently and quickly, with lower manufacturing costs, whereas certain products are only made in small quantities with traditional ovens to ensure their quality.

Yet another advantage of this process is that products do not usually require cold storage between initial baking,

in the production facility, and final baking, in the store (depending on the duration of storage before the final preparation). “This saves refrigeration and/or freezing and the corresponding transport costs and contributes to saving energy overall,” the specialist highlights.

It is a sustainable process not only from a savings standpoint: “Since the ‘refrigerant’ in vacuum cooling is water and nothing else, it is the most ecological cooling process available today,” Cermak points out. Moreover, only products containing water can be vacuum cooled, meaning the baked goods themselves. Carrier materials (baking trays, rack trolleys, pans, etc.), which are unavoidably cooled in the conventional cooling process, are left out with vacuum cooling, which lowers the total weight of the mass that is to be cooled by approximately two-thirds. Along with this reduction, the corresponding cooling capacity or energy consumption also goes down.

Controlling water balance greatly contributes to product quality. “A 1-kg parbaked bread, for example, can be baked to completion (with a core temperature higher than 75°C) and cooled to slicing temperature within 6 to 10 minutes. It is clear that this promotes moistness and freshness for hours. Even products, in which starch retrogradation has already begun, can thereby be restored to their former freshness. The stabilization of moistness, shape and crispness immediately after baking opens up new opportunities in

Product group

Advantages

Small pastries, e.g. rolls, baguettes and ciabatta Shorter process time, less baking loss, volume stability, longer crispness than with a conventional baking method, process reliability and certainty

Fine pastries such as croissants and Danish Shorter process time, halved baking loss, more aroma and significantly improved and longer-lasting volume

Large bread loaves including double-bake

Filled products such as tarts, strudels, etc.

Snacks such as pizzas, muffins/crumpets, pretzels

Packaged goods

Fresh large loaves from an in-store vacuum oven in a cycle lasting a matter of minutes, no loss of moisture and therefore of weight, long-lasting freshness

Volume without E-numbers, filling remains airy, fills the product even after baking and does not become greasy

Very short process time, juicy, crisp bottoms and attractive-looking outer surface, at eating temperature immediately

Baking-off pre-packaged breads/toast breads in-store according to demand

the highly topical market of delivery services that rely on quick availability,” Cermak adds.

Another relevant case is that of filled products such as snacks or sweet Danish pastries. When baked in conventional in-store ovens, the end product features a compacted filling, lying in a cavity. With vacuum baking, the product’s structure is preserved, hardly any cavities occur, and the product comes out of the oven with a stable volume and warm to the touch. “The visual appearance of such a pastry is completely new,” adds the company’s founder, a result that also applies to pizzas.

When using vacuum conditioning, savings already start with the pre-baking stage, which is usually 20-25% faster than with traditional technology, for any type of product –be it a baguette, a ciabatta, or a pan bread. Vacuum technology also makes the second baking phase, which is done in-store, significantly shorter. Cermak explains: “In the UDO vacuum oven, the applied vacuum is only enough to just exceed the gelatinization temperature of the starch. Steam is then added to the baking chamber. Because the heat in the hot oven goes to the coldest point, which is inside the bread, the steam releases its heat to the crumb by condensing into water. The crumb is heated over the gelatinization temperature by absorbing the hot water. This

process freshens up the crumb. In the next step, the bread is cooled by applying vacuum again and by evaporating water from the crumb down to a temperature at which it can be sliced.”

The adjoining table highlights the characteristics of different types of processes. The products pictured clearly show the positive influence that baking in a UDO has on the shape and stability of the products. With frozen dough pieces, which usually have to go into a proofer or at least be partially or fully thawed out before conventional baking, the total processing time is reduced by up to 70%. Just as importantly, the demand for the expertise of responsible employees is also minimized. The products can go from the freezer directly into the oven, without having to worry whether the proofing is perfect or not.

Prof. Dr. Friedrich Meuser is an internationally renowned authority in the field of cereal and bakery technology. He commented about the process and technology developed by BakeXperts: “The oven is sensational. Cermak has approached the whole thing with an engineer’s eye, and you may ask yourself why no one has done that before him.” Meuser explains the theory and the core of the patented innovation behind the UDO: “Harry Levine and

ePAN® designs from American Pan have been proven to save bakeries money on every bake. In fact, one customer reduced gas usage by almost 8% year over year by switching to an ePAN.

Energy solutions like wind turbines and solar panels are a major investment and require a large amount of dedicated space. ePANs can fit on your existing bakery line and save you money from the very first bake. Here’s how:

Oven temperatures have decreased by up to 30°C when using ePANs.*

Baking times have been reduced by up to 45 seconds.*

Trays and tins are up to 30% lighter, requiring less energy from bakery systems and employees for handling.*

*Results from real bakery experience. Results may vary based on specific bakery conditions.

Louise Slade established the glass transition temperature theory more than 30 years ago. It states that a mixture of starch and water can change into a glass-like state at a very specific temperature. The process corresponds to a melting process in which the crystalline structure of the starch changes into a glassy state. If the glass is left to stand for a while, the starch gradually recrystallizes again. This temperature-dependent process is reversible several times, i.e. it can be repeated over and over again. The principle of the vacuum baking oven is based on the reversibility of the starch’s glass transition.”

The UDO can be used in a very wide range of applications:

+ It can bake off deep-frozen small and fine pastries, as well as bread rolls weighing less than 250 g each, considerably faster than conventional technology

+ It carries out the baking process in the shortest possible time for part-baked whole loaves with a higher unit weight (up to 1,000 g), stored at a cool or ambient temperature

+ The UDO can quickly prepare baked snacks that are also cooled down to a temperature suitable for immediate consumption

+ The UDO can be used to double-bake unsold goods from the previous day. These products can simply be baked again the next morning, and the original freshness and

desired degree of crispness are restored. “For the baker, however, this also means that the range of products available for sale may well go up again the next morning, since everything can be re-baked, thanks to the UDO,” he observes.

+ It can have baked goods ready for dispatch in a matter of minutes, for delivery services or click & collect

The patented UDO technology has been tested in well-known European bakeries over the past year, with positive reviews. “We have just delivered the first 25 ovens to our first customers, which are prestigious bakeries in Germany, Austria and Switzerland; and 15 more will follow in the upcoming weeks. After a testing phase of around three months, the official sales will start,” Cermak reveals.

The UDO configurations start with models for 6 to 8 baking trays, depending on tray spacing and product height. At the request of the first customers, the next model series will be a rack oven for a trolley with 10 to 18 trays, measuring 40 x 60 cm each, and a combi version with two separate baking chambers. A snack oven for pizzas and baked snacks will also go into production soon, which will be baking and vacuum cooling in under two minutes. The new oven will be the first in a series of its own. +++

Baker & Baker launched a new cookie range in the UK. The Brooklyn Coffee Bar cookies come in two flavors (double chocolate and rich chocolate) and each cookie is individually wrapped, to suit food-to-go convenience needs. Each thaw and serve 75g cookie is Rainforest Alliance certified, Palm Oil SG, and suitable for vegetarians. The cookies have a post-defrost shelf life of 10 days.

“The American-style cookies offer the eating quality of a freshly baked cookie with the convenience of a wrapped cookie,” the bakery highlights. The soft baked rich chocolate cookie is made from a dark short dough with white and dark Belgian chocolate chunks and a hint of vanilla, while the double chocolate cookie is made from the same short dough, with dark Belgian chocolate chunks. +++

Harry-Brot broke ground for the expansion of its production site in Troisdorf, which will also create 100 new jobs. The goal is to bake fresh bread and toast here from Q1 of 2024, in addition to frozen rolls, baguettes and lye products. The company seeks specialists as well as trainees in fields ranging from machine and plant management to food technology, technicians and more.

“Our commitment to the region goes far beyond job creation. We are planning partnerships with schools to offer internships for young people and make it easier for them to enter the workforce. In addition, we regularly participate in events such as the ‘Night of Technology’ to share our knowledge and experience with the community,” Harry-Brot wrote in a LinkedIn post. +++

There are numerous approaches to in-store baking optimization, depending on the concept of each bakery, its product needs and the baseline of its operations. The big expectations come from oven innovation.

The very concept of in-store baking is to efficiently provide customers with oven-fresh baked goods, with the ability to flexibly react to changing demands and even using the oven as a sales assistant. To optimize sales and minimize product waste, baking can be done – as needed – in an area accessible to customers and passers-by, for the all-enticing ‘sight-and-scent’ baking, in the words of Prof. Edgar Wenz.

Energy usage can be optimized by only baking full decks, in shorter time frames to benefit from residual heat instead of reheating the ovens entirely every time. Monitoring makes perfect control, and energy management tools such as the MIWE sbs:energymonitor does just that: it can help analyze baking times, monitor the status of the oven and be used to create practical baking calendars.

They are more, in terms of useful tools that help increase baking efficiency: smart refrigeration systems. “Product freshness can be optimized with procedures such as the MIWE smartproof, for products like rolls, or even baking bread via the MIWE smartfresh system, which also helps take the toll off tiring night shifts because raw or parbaked products can be stored overnight easily and in the positive temperature range, saving energy,” MIWE’s experts point out.

There are several ways to shorten baking times and save energy by using the MIWE optitherm temperature control (which is now available for the MIWE condo), by accurately adjusting the heating power to the baking

process, respectively to the specific needs of various types of products. The MIWE optitherm system consists of a special lining in the baking chamber, a new controller for heating elements, a modified temperature sensor, and updated software.

In addition to a shorter baking time, it helps achieve evenly baked products as the energy is evenly distributed inside the baking chamber, and can even be used for more demanding specialties such as soft doughs. “This is possible because MIWE optitherm allows for more precise regulation of the heating power output of the heating elements. By using this feature, the temperature curve in the baking chamber can be guided more precisely along the ideal curve, which leads to more efficient and faster baking results,” the specialist explains.

“MIWE optitherm was developed on our international customers’ requests to make systems even more flexible in the bandwidth of products they could bake and regarding baking times.” Baking faster means less energy is needed for the same amount of baking goods. Shorter baking times also support increased productivity, since more products can be baked in a given timeframe.

To further optimize energy use, an essential variable needs to be addressed, inherent to in-store baking: demand fluctuations and balancing baking for and in between peak hours. MIWE’s answer to this variable is called the MIWE flexbake®, an automatic system that compensates for process and volume fluctuations.

With the flexbake, the temperature in the baking chamber of a convection oven is controlled via the output of the heating element and air circulation. When placing cold goods in the oven, a ‘counter-cooling’ effect is enabled in the baking chamber: if fewer dough pieces than usual are brought in, or if they are warmer than usual, the countercooling effect is less intense. This causes the temperature curve inside the oven to rise significantly. Conversely, leaving a door open for a long time cools down the baking chamber considerably. “Process fluctuations of this kind occur time and again; but, they result in a baking process that is optimized for the right operating scenario,” the specialist explains. The MIWE flexbake ® system ensures that the baking station compensates for any process fluctuations of this kind automatically, intelligently and flexibly. As such, it is ‘taught’ – in one ‘learning session’ per product/baking program – set up under ideal conditions for baking efficiency (full load,

correct loading temperature of the goods). It saves the temperature curve recorded and then always controls the baking chamber temperature along this ideal curve, while operating in flexbake® mode. “This is how the same perfect baking results are always achieved in the process, even with fluctuations,” MIWE’s specialist underlines.

The MIWE eco-Mode provides additional tools to adjust to demand fluctuations: it maintains the oven in a low-energyconsuming standby mode that keeps it ready to quickly begin baking. The ‘eco mode’ automatically identifies the optimum balance between the lowest-possible level of energy consumed to keep the oven bake-ready at any given moment. To achieve this, the temperature of the baking chamber is automatically decreased to a freely-configurable value, either after a baking cycle finishes or after a preset idle period. The eco mode can also be activated manually, defining the time when it should start baking.

How (and when) to work with it? On paper, “Using the MIWE eco-Mode is always a good idea,” the expert observes. However, switching the oven off entirely makes for the biggest savings. This will be the most advantageous course of action when it is very likely that the oven will not be needed for a predictable/extended amount of time. “The same goes for deck ovens: one deck can stay in eco-Mode, while others can be fully switched off,” MIWE illustrates. When (un)predictable demand fluctuations are expected, the MIWE eco-Mode helps to have the oven ready to bake faster than a ‘cold start’. In addition to saving energy, this also means that the

Recent updates and previous (energy) efficiency helpers:

a. MIWE optitherm

MIWE optitherm is an optional feature that enables a more precise temperature control of the MIWE condo. With a new controller, modified temperature sensors, and special chamber lining, MIWE optitherm provides more accurate and uniform heat distribution for high-quality baking results. It also helps save energy by allowing for shorter baking times and/or lower temperatures.

b. MIWE sbs:energymonitor

MIWE sbs:energymonitor is an energy monitoring system that tracks and analyses energy usage in in-store baking. It helps identify energy-saving potentials, reduce energy consumption and costs, and provides valuable insights into the bakery’s energy usage patterns.

c. MIWE condo handmode

The handmode in the MIWE condo is a feature that allows manual control of the MIWE condo oven through simple, user-friendly controls. It provides quick and easy access to temperature and time settings for baking without pre-programmed settings. This is of advantage to professional bakers, for an artisan-style of baking, as well as to untrained staff for easy operation.

The general Touch Control MIWE TC and its intuitive user interface make baking very simple even for untrained or frequently changing staff, which contributes to increasing efficiency in bakeries.

d. MIWE eco-Mode

The MIWE eco-Mode is an energy-saving feature that allows bakers to reduce their energy consumption while still remaining ready for almost immediate baking. It can be set to automatic functioning or manual activation.

oven can bake faster, or more products, in a certain interval. This feature can be used on almost all MIWE ovens.

Choosing from an array of useful tools and combining them for the best results is the answer to optimizing in-store baking. For example, the central management system, the MIWE smart baking suite, and especially the sbs:energymonitor, display a baking efficiency indicator. To calculate it, the system analyzes the different oven states (ready-to-bake, baking, heating, eco-Mode) and the amount of time they are active. Ideally, baking times should be high compared to ready-for-baking intervals, for optimum energy use. “This can be optimized by implementing ‘blocking times’, when an oven or deck is not allowed to bake, so that other decks can be used more efficiently, instead,” MIWE explains.

The MIWE sbs provides a number of benefits through its intelligent networked systems: “The software package allows

for full-scale mapping of the organizational structure, central administration, monitoring, and synchronization of systems. Bakers can create, manage and centrally store baking programs and related information, assign uniform sets of baking programs to specific groups of stores, and analyze metrics-based reports about baking processes, capacity utilization, consumption, and adherence to process quality standards, in real-time,” explains the specialist.

Introduced at the end of 2022, the sbs:energymonitor feature was specially designed for networked baking stations, recording the energy consumption of the oven, while also compiling information about each mode of operation. This feature can even break down the energy consumed for different types of products and calculate an itemized energy bill. The system runs comparisons between days of the week, or over several weeks, with details about different products or baking programs, highlighting good and inefficient energy use.

It breaks down baking efficiency as a key operating parameter given by the ratio between the actual baking time and the total switch-on time. Depending on the value, this baking efficiency coefficient is displayed using a traffic light system, with red indicating very low efficiency, amber representing an average efficiency level, and green symbolizing high efficiency.

While each operation defines its own path to sustainability improvements, many roads lead to ovens. There are plenty of technologies, functionalities and features to choose from. The innovation going into baking ovens is a direct route to sustainability improvements, from features such as the MIWE flexbake, or the energy-saving MIWE eco-Mode. The company’s e+ products are designed to prioritize it: “MIWE products, especially e+ products are very energyefficient with effective insulation, efficient steam condensers and LED-lighting,” highlight the specialists. In addition, cleaning has simplified, to optimize the energy the oven needs to bake and to expand its availability. +++

Koenig closed FY 2022 with sales amounting to EUR 114 million, a new record in the company’s history. Wolfgang Staufer, the company’s CEO, gives us a glimpse into the work behind these results and shares his views on the state of the industry, its future and Koenig’s role.

+Catalina Mihu: In light of record-breaking financial results last year, what types of solutions were among the most requested? What innovations drove sales momentum throughout a challenging year for the industry?

Wolfgang Staufer: Requests received last year were increasingly shifting towards the big industrial lines we offer. We are seeing high demand in this segment as the industry is investing considerably in order to achieve more cost-efficient production. Although a high proportion of our turnover comes from the artisan market – small and mid-sized bakeries, we have been seeing a shift over recent years to bigger, industrial lines.

Mihu: What have been some of the popular requests in each category?

Staufer: For the industrial sector, it’s big bread roll lines, for which we are offering complete solutions that typically start from make-up or even from mixing through to baking and cooling products. For small and mid-sized bakeries, mid-size sheeting lines have been in high demand in recent years. In addition, we have developed a new line in this range, the Artisan SFM sheeting line with Easy Clean design; it brings a very innovative approach to line cleaning as it was designed to ensure complete access to the line for cleaning, as well as maximum flexibility to allow bakers

“TheWolfgang Staufer, Koenig CEO © Koenig

to maximize the ranges of products that they can manufacture using it, with minimum changeover times. These features have received a positive response on the market.

Mihu: Speaking of the Easy Clean design and flexibility, what are the main innovations that have helped drive sales, especially so in a particularly challenging year?

Staufer: Looking at the main demands in artisan baking, hygiene has become a predominant topic in recent years. This is why line cleanability has become a main focus for Koenig, which has been met with positive feedback on the market. Production efficiency is another aspect, leading to the demand for increased production capacities; we are now producing lines that we could not imagine would ever have been requested 10 years ago. A bakery that doubles its production of bread rolls per hour does not need to double its investment costs, or double the operating personnel, cleaning costs, or energy needed, in order to achieve this volume. The energy factor, especially, is in very high demand at the moment, because of the dramatic rise in energy costs and the cost of raw materials. To do this, entire production chains need to be optimized so that operations can ultimately provide affordable products to the final customer. This has been a peak motivation for investments in the industry, particularly over the past year.

Mihu: And what changes can be observed, when compared to the year before, which was also a year not without challenges?

Staufer: The main change we have observed over the last year has been in energy-efficiency improvements and the overall efficiency in production capacities – including waste reduction. Looking at changes on our side, from the perspective of plant and machinery builders, in turn, one of the biggest challenges has been the supply chain factor. It is a problem we encountered over the past years, which has been exponentially increasing recently. Material costs have seen a steep increase over the past few years. The same is true regarding the cost of components, especially electronic parts. Sourcing components such as CPUs, or display panels, for example, is one of the biggest challenges at the moment. Steel, in particular has become more easily available this year. Electronics and plastics markets are still very volatile. These challenges bring a decisive factor for our customers: the delivery time that we can currently offer. If I compare the time currently required to complete a project to that of a similar installation from three to five years ago, the time from the finalization of the engineering up to the delivery of the machine ex-works has increased by at least two-three months. In some cases, this means double the time, a delay mainly caused by the availability and delivery time of specific components. There are also seemingly almost absurd situations that occur, when certain components had delivery times of 200 working days. This means that if you want to supply something next year, you need to already know from this year what you want to supply;

otherwise, you will not be able to supply it to the market. The management of the logistics chain has been one of the stringent challenges in the market. A reliable delivery time has also become one of the biggest demands from customers.

Mihu: What are the strategies that contributed to such a positive outcome to FY 2022?

Staufer: We have made significant investments in the design of our lines over the recent years. When we were considering the marketing strategy for Koenig’s 50-year anniversary in 2016, we thought about drawing a comparison between bakery lines, ‘now and then’. But we saw that when we compared the lines with those that were delivered 40 years ago, there were few design changes. Materials had changed with painted materials being replaced by stainless steel; but, the overall designs of the two models, 40 years apart, were virtually identical. However, this is no longer valid today: there have been significant design changes recently, due to the focus on hygiene and ease of cleaning. We kept the proven Koenig process and technology concept, but have completely reworked all the machinery we supply. The equipment now allows easy access for cleaning, a feature that was very well received in the market. We have clients telling us that they save up to three hours when cleaning one of our new lines, compared to one of our older designs. This is a decisive factor for cost-efficient production. Alternatively, the capacity and the capability of the line have improved considerably over recent years. When we were opening our final assembly facility in Hungary, five years ago, we could compare old peak lines to the maxed-out new ones: they were miniatures. We have been very successful in the market because we are able to provide these very large capacity lines, in line with market requests. They allow our customers to be more cost-efficient in production to give them a decisive edge in their field. Higher production capacity has been an ongoing request.

If you look at the design of our lines, the Koenig standard design is that, when standing directly in front of the machine, the operating direction is from right to left. This has remained unchanged for the better part of 50 years. In recent years, we have had to produce mirrored lines to answer capacity requests. These often included capacity increases that could not fit onto one line, and therefore mirrored, side-by-side configurations were built so that the operator could manage the parallel lines simultaneously while being in the middle, in between the two. The desired output was achieved in this way, while only having one operator running both lines. This meant a design change to our lines. The demand for bigger, centralized bakeries running with high-end efficiency levels has been one of the determining factors in the industry recently, in response to in-store bakery growth. Small bakeries inside supermarkets is a trend that goes back 15-20 years and is one that is growing, with the demand for making fresh products from

scratch. Koenig has been able to accommodate this by selling smaller machines. Larger supermarket chains would order 100 pieces of equipment, to install in all of their stores, for example. The lack of skilled personnel for these operations and the demand for consistent product quality across all sales outlets, however, shifted the focus to centralized baking configurations, which allow products to simply be baked off in the market, instead of being prepared from scratch.

Mihu: What other market changes have brought growing opportunities for Koenig in 2022?

Staufer: For the artisan market, it is the demand for higher product quality and more efficient machinery. Efficiency, in this respect, is not only related to producing more pieces per hour but having a higher level of flexibility and lower cleaning requirements. Hygiene has become more and more important, especially in European bakeries. Looking at the German market, authorities have been enforcing hygiene regulations much more strictly in recent years. It is therefore much more important for the baker to have a machine that is easy to clean, since an unannounced inspection can happen at anytime. In combination with the flexibility and reliability of our machinery, providing hygiene-supporting features has given us an upper hand on the market.

Mihu: How was hygiene brought to the designing table when Koenig redesigned its machinery? How was accessibility balanced with maintaining equipment safety and production efficiency?

Staufer: Safety features contribute more and more to the overall cost of a line. The challenge that required a tremendous engineering effort was to keep the machine compact while making it easy to clean. On the one hand, lots of metal coverings fixed into place with bolts had to be replaced with metal coverings that could be easily removed; then, we had to design bigger – and removable – doors for easier access. Another aspect, applied to many of the lines, was to separate the drive unit from the portion of the machinery that was exposed to contact with flour. Machines with older designs would have the motor covered in flour dust; chains running inside this area, which were consequently much more difficult to clean. Nowadays, much of the machinery has its drive and electronics separated from the dough-processing sections. In this way, we could minimize the cleaning efforts required for these machines, by isolating the hard-to-clean parts away from direct contact with raw materials.

Mihu: 2022 was also a year of acquisitions for Koenig –with the takeover of cooling spiral specialist Vulganus Oy. What made the Finnish manufacturer an interesting acquisition for Koenig?

Staufer: Our strategy over the past few years was to transition from being a company that supplied make-up lines (for product dividing and forming) to a full turnkey solution supplier for bakery lines. This required us to have competence in every process stage, starting from mixing, dividing and rounding, to forming, proofing, baking and cooling. In this way, we could control the parameters of the entire process and ensure its efficiency. We had started on this path by supplying spiral coolers and freezers in Italy, although that operation was rather small. However, we saw that the potential of spirals – proofers, coolers, or freezers – would continue to grow in importance in the future. By acquiring Vulganus Oy, we wanted to expand our technological capability and capacity, to better establish ourselves in this field, because our Italian operation specializes in sidedrive spirals, while the Finnish operation is manufacturing drum-drive spirals, a different technology suitable for different applications.

Mihu: Should investments such as this be made even in challenging years?

Staufer: Definitely! It may be more risky, but if you want to have a certain footprint in the industry, then you need to take opportunities when they come along. The results already look promising, and we hope they will further improve in the future.

Mihu: What has the acquisition entailed from an operational standpoint, for both companies?

Staufer: It’s an ongoing process; the first step was the integration of our engineering environment, to have compatible engineering solutions and to be able to source parts within the group of companies. We have manufacturing sites in Austria, Germany, Hungary, Italy and in Finland. We

integrated Vulganus Oy to become a part of our manufacturing network. We are also utilizing the resources of the Finnish company for some work for our Austrian operations. In addition, we are now in the process of establishing centers of competence for certain products. The Finnish operation will become our center of competence for spiral products, from proofers to coolers and freezers. Some of the proofers will be assigned to the Italian center of competence.

Mihu: And what were the changes at Vulganus Oy? Has it expanded the volume of its operations?

Staufer: We made the acquisition in the summer of 2022, so the expansion is still underway. In the meantime, Vulganus has already gained better market access, because it is now connected to our network. While before it was predominantly focused on the CIS and European markets, it now has a global reach. Moreover, we are in the process of expanding its reach into certain markets, and we will be bringing Vulganus to the North American market in the coming years. Koenig is well-established on this market, as it has been present in the US market for over 20 years with our own subsidiary, and via dealers before that. We are supplying bread roll lines on this market, for medium and large sized bakeries. Over the past few years, Koenig has also entered the turnkey market, supplying complete bigger, lines. In this segment, we are planning to include Vulganus equipment. Vulganus will be supported to also expand its markets in the years to come. We are pursuing a two-brand approach, in which Vulganus is selling standalone units under its own name as well as under the Koenig brand, with solutions being integrated into some Koenig turnkey solutions.

Mihu: How has the acquisition repositioned the development and delivery of engineering solutions? How are complete, turnkey solutions developed now, compared to the steps carried out before Vulganus Oy joined?

Staufer: The turnover of Vulganus is about EUR 10 million; the turnkey portion of our operations is about EUR 20 million, so, from this perspective, the business has increased, in terms of turnkey parts that include final proofers, ovens and cooling solutions. The make-up line part, Koenig’s core processing field, is not influenced by the acquisition. We are planning to expand the turnkey segment of our business over the following years, a market where we see the opportunity for growth.

Mihu: Following an impressive business year, what are the anticipations for FY 2023? How is the year shaping up?

Staufer: We have a very high order backlog this year and we expect the business to match last year’s performance. We hope it will be even better.

In addition, we are entering new fields such as tin bread lines in the next few years. Of course, the race is on and,

looking at the solutions we were supplying 10 years ago, in comparison with our current portfolio, we have made a big step in terms of closing the gap between high-capacity, extrusion-based bun lines and the capabilities of the lines based on dividing and molding, which we are currently developing.

Mihu: How have current and ongoing challenges changed the way in which Koenig works?

Staufer: We have taken the step forward from a machinery company to a project-oriented company that manages the implementation of complete lines. This has changed the way we work, from project management to resource planning and time scheduling in our operations as we expand. We used to synchronize between Austria and Hungary production facilities at first, while now we coordinate projects with components coming from Austria, Hungary, Italy, or Finland, into one project. We are shifting from a more centralized company operating from our Graz headquarters to a more distributed, international way of working within the group.

Mihu: At a time when sustainability is among the biggest priorities in the industry, what does sustainability mean at Koenig? How is it reflected in the way solutions are designed and in the way equipment is manufactured, revised, updated and customized?

Staufer: From the standpoint of our in-house operations, we have greatly emphasized our focus on energy efficiency in the production area. We’ve invested in new, more efficient machinery and higher electrical power supply capability in our facility. We will be able to optimize processes such as electric heating, which was previously using gas. We are also switching to electric cars, in our efforts to reduce Koenig’s CO 2 footprint.

The biggest change that we are generating is through our products. We are designing them for more energy efficiency. Looking at our rack ovens, for example, improvements made over time are rather easy to quantify. Talking with a client who has been using our ovens for decades, we learned that, with the latest-generation technology, the bakery could achieve around 30% energy savings compared to using the old oven. It’s quite an impressive improvement! With the developments we made over the past decade, we have achieved energy savings in the range of 10-20%. Another important aspect is the sustainability improvement achieved via our new production and logistics strategy. Looking at mid-sized bakeries, vacuum conditioning is increasingly a standard for products. This means the cooling process, performed by placing the product into a vacuum chamber and evacuating the air, is very fast, while also stabilizing the product. This gives us three main advantages for our customers in terms of sustainability: the energy efficiency of the vacuum process is better than actively cooling and freezing the products; vacuum-conditioned

products allow energy savings because baking times can be considerably reduced; by vacuum conditioning parbaked products, they can be brought to the point of sale for bake-off. In this way, bakeries can work around a limited shelf-life of only three-four days, which, again, means saving energy. Moreover, the new vacuum process called the ‘ready-to-eat’ process entails that the fully-baked product is vacuum conditioned and frozen. When thawed, this product is crispy and retains the properties of a freshly-baked product, while skipping the bake-off process entirely – meaning, more energy is saved (typically, point-of-sale ovens are not as energy efficient as centralized baking solutions available in bakeries). In this way, flexibility is higher and product waste is also minimized. All these steps contribute to increasing production sustainability.

Mihu: Do times of crisis hinder sustainability efforts, or can they also act as a catalyst for improvements?

Staufer: From what we are seeing now, it is dramatically acting as a catalyst, because the CO 2 reduction achieved by lowering the energy bill is at the moment a very high priority for bakeries. We have been speaking with bakeries that currently have energy bills 10 times higher than before the crisis. In such cases, energy-efficient solutions are a first priority, to lower costs. Improving production efficiency is the driving factor for investments in the industry at the moment, which, in turn, also drives innovation for better machinery solutions.

Mihu: Since 2015, Koenig has been increasingly focusing on large-scale roll lines. What changes in industrial baking have you experienced since the first crisis in the series began, the pandemic restrictions?

Staufer: There are no significant changes in demand. The increasing request for bigger lines was a trend even before the pandemic. As we have become more experienced in developing this type of lines, we are also in a better position to fulfill these market demands now. From our perspective, we observe that the demand is shifting to bigger lines because they can be more easily financed. A small, artisan bakery is currently struggling so much with energy bills, that it cannot easily invest in efficiency-upgrading technology, even if they wanted to. Alternatively, it is easier for larger bakeries to finance such projects, which also explains the market shift to bigger lines. The request is clear for us: more economic, more affordable solutions are needed, especially in the industrial sector.

For the mid-sized range, we also see customers who are still investing in improving their market position by upgrading to more hygienic and energy-efficient solutions, such as vacuum conditioning technology or new-generation baking ovens.

Mihu: What strategic priorities are outlined for the upcoming two-three years for Koenig, as the company approaches its 60th anniversary?

Staufer: We are working on consolidating our market position. We re-entered the turnkey market about six years ago and we want to strengthen our foothold as a sustainable supplier of turnkey solutions. In the future, our solutions could also be aimed at other products, in addition to bread rolls, a segment in which we are established. We are also planning to expand our operations internationally and improve cooperation within the Koenig network, between our various centers of competence. We are planning on expanding our position in key markets, by being close to our customers for their service needs.

In addition, there is the ongoing challenge of developing new products. We see a growing demand for automated solutions, a demand which has heightened since the pandemic. To meet this demand, we are also developing our robotics expertise and our automation offerings, in order to develop more intelligent lines in the future.

Mihu: How would a decentralized network structure be managed to ensure that Koenig consistently provides the same values anywhere in the world?

Staufer: Establishing the centers of competence is key to that. We are also working very closely together, utilizing digital tools. This is a lesson we learned early on in the pandemic crisis, expanding our digital capabilities worked well when we were unable to travel. To some extent, such tools can be used to install production lines remotely, in cooperation with our service partners. This was the case in South America, where we were able to install lines with local partners and supervision from our headquarters here, in Graz, via digital channels.

Mihu: To summarize our conversation, what are the biggest trends at Koenig now?

Staufer: Continuous optimization of the machinery designs is among the biggest trends – for improved flexibility, efficiency and hygiene. The next step is developing more intelligent machines. In this regard, we are installing new sensors, new controls and planning features into the machinery for a higher automation level. This is why we started delving into robotics in our Italian subsidiary. Developing fully-integrated solutions is key in the market, for industrial bakeries as well as for artisan operations, which can benefit from linking production optimization features incorporated in the machines. +++

Read the full interview on www.bakingbiscuit.com.

”Improving production efficiency is the driving factor for investments in the industry at the moment, which, in turn, also drives innovation for better machinery solutions.”

Wolfgang Staufer, Koenig CEO

Transform your production with AGV-supported automation concepts

You are in search of innovative automation technology for your production? Our AGV solutions are the answer!

The term AGV (Automated Guided Vehicle) describes a driverless, floor-bound transport vehicle. Equipped with state-of-the-art navigation systems, AGVs transport raw materials and products with precision and efficiency within defined workflows. Become part of the logistics revolution!

→ Efficient: AGVs operate continuous and autonomous

→ Flexible: Solutions with low and high lift function

→ Innovative: Cost-efficient, optimised room concepts

→ Functional: Seamless integration into existing systems

→ Adaptive: Retrofit and capacity upgrades optional

→ Safe: Equipped with cutting-edge security features

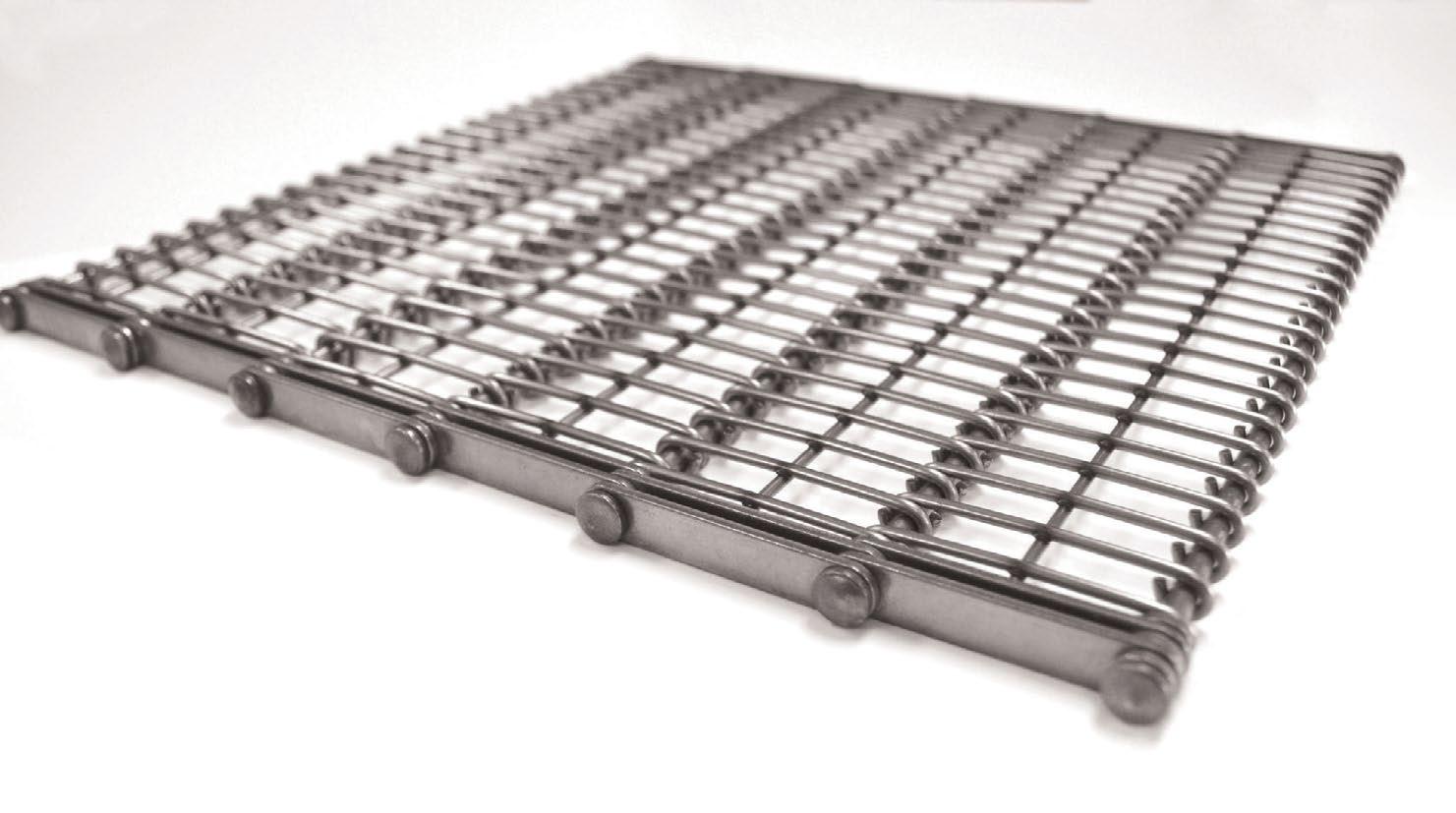

Innovative dough production with automated transport systems from DIOSNAAutomating bakeware handling saves time and precious human resources. It also ensures that trays, pans and tins are handled exactly as instructed by the tray and coating manufacturers, time and again.

+Streamlining bakeware handling alleviates manual labor requirements and increases productivity for several operations, from loading and unloading racks, to stacking, transporting, cleaning, depositing and retrieving trays. Such tasks are performed with reliable consistency and virtually eliminate damage from accidental mishandling. Handling automation can take many forms: to load and unload racks, solutions such as Minipan’s automatic system can be customized to fit specific bakery requirements, and can be used by artisan and industrial operations. The equipment developed by the Italian specialist receives the trays via a conveyor and transfers them to an elevator that fills empty racks continuously. The system can work with trays and racks of any size.

Some of the latest alternatives to choose from were presented at interpack 2023. The IQ-Move Spider, recently developed by Döinghaus, for instance, enables automated tray handling for ultrasonic cutting with a vertically movable working unit for cake sheet handling: entire rack trolleys with baking trays go into the system from the docking station, saving operating time and straining manual work requirements. The baking trays are automatically pulled out of the rack, and the sliced cake sheets are returned after cutting.

For automatic or even semi-automated production lines, several bakeware handling methods can be incorporated to minimize manual intervention required and production downtimes. Their features address the type of tray, pan, or tin, while keeping in mind preserving the integrity of the products.

Cakes are especially unforgiving when it comes to handling; from the moment they are deposited, through to filling, decorating, depanning, cutting, packaging, and conveying throughout, and therefore accuracy ensures efficient processing, for the product and its support. Several depanning options can be employed for best results. SAM Machinery, a cake machinery manufacturer from Türkiye, illustrates four types of depanning technology that can be incorporated into its cake production plants – which were also highlighted at interpack. Its axial depanners, controlled by servo motors, flip the pans on the axis of the conveyor, then hammer the pans with a pneumatic system for product release. With the

rainbow unloading system, the products are transferred from the pan to the conveyor on a side. The same hammering method is applied to release the products. With needle depanning, the needles used vary according to the types of cakes, while vacuum depanners use vacuum pads, which makes them suitable for all types of pans (the pads themselves are customized according to the products). Moreover, pans can also be automatically lubricated before depositing for cake lines such as these, to precisely spray the required amount of lubricant in the product enclosures of each tray, while monitoring the temperature of the oil. Any excess oil is drained and collected for reuse. SAM’s lubrication spray system uses custom-made spray guns with air-splitting nozzles that can be automatically adjusted according to the size of the pan.

Magnetic handling systems can be used to automate tray storage in bakeries. They can work with various bread tins, straps, bun trays and lids and can lift single items or several in a single lifting motion. The system developed by Eclipse Magnetics, for instance, can handle up to 16 straps simultaneously, off-loading and stacking them into storage areas, or placing them onto conveyors to enter production. These systems provide several benefits, which include avoiding direct contact with the tins and eliminating damage risks. Moreover, the magnets can be used for several types of bakeware, with no need for adjustments or damage to the coatings.

Tray cleaning can also be automated, ensuring process efficiency and maximizing the lifespan of the bakeware. The system JEROS highlighted at interpack, for example, is developed for industrial bakeries and can clean up to 10,000 trays in 24 hours. It can be used for large two-sided trays as well as perforated trays (max. 60° edge), which go through a brush system with the soiled side down, so that they can immediately be ready to use once cleaning is finished, without having to turn them.

The correct handling of the products and their trays not only ensures the optimum results with consistency, but will also preserve the hygiene, safety and integrity of the trays and that of the lines. +++

+The story of Via Oliveto started in Toronto in 1988, when Italian-born Pasquale Zappia and his wife Mayra started a business that worked both as a restaurant and a bakery supplying nearby hotels, restaurants and caterers. A baker by trade, Pasquale handled the bakery. His wife ran the restaurant, joined by their sons Patrick and Adriano, when they were old enough. Pasquale had always put his own spin on Italian breadmaking, but when he began baking crispy artisanal flatbread crackers — essentially a European-style flatbread cracker — he truly found his niche.

As demand for the triangular flatbread spiked among their foodservice customers, it became Pasquale’s sole focus. In 2006, the family sold the restaurant, and the sons joined their father in the bakery as it relocated to a 2,000-squarefoot facility in Toronto. In 2007, they started packaging the product for retail sales in a few local food shops and ‘Pasquale’s Glorious Flatbread’ was born. Soon, it was also selling in local supermarkets, and, by 2009, Via Oliveto moved into an 8,000-square-foot location in Vaughan, just north of Toronto.

To produce the flatbread, the family evolved a unique, laborintensive process involving convection baking in rack ovens. Their 24” wide system included a bowl mixer, a three-roll sheeter, three gauge rolls and 18” by 26” pans. Semi-automatic equipment sprayed the cut triangular pieces of dough with water, salt, seeds and herbs before the trays were manually placed into the rack ovens to bake, then manually removed to cool. This process included four double-rack ovens with 32 aluminum racks and 2,500 baking pans, which were handled by four people.

Production on this system peaked at about 100 kg per hour, and it made growing the bakery a challenge. In 2015, Patrick’s wife, Rachel, began managing the business and

relieved much of the administrative pressure; but, the production obstacles remained. The Zappias needed to upgrade to a more automated, labor-saving solution.

”We don’t have to worry about opening oven doors, checking on the product, adding baking time, or closing oven doors – the oven part of our production is now 100% hands-off, so we can really focus on other parts of the process.”

The family began reaching out to tunnel oven manufacturers in 2019 to explore their options. It was on their wishlist for their trip to the IBIE in Las Vegas that year, where they met more oven manufacturers and got system quotes. The selection process seemed overwhelming, in the search for an oven system that would fit their needs and wouldn’t be too big or too expensive. One of their visits there was to the RBS booth. The Zappias saw how RBS could help Via Oliveto move from rack ovens to a tunnel oven system. “We thought it was going to be such a challenge – but, RBS made it sound like the opposite,” recalls Patrick Zappia. The family was impressed by the company’s willingness to work with such a small bakery. They also liked that RBS was able to propose a convincing one-stop-shop solution that featured an integrated sheeting line and oven, and the flexibility to produce new ranges in the future.

The owners invited RBS to Via Oliveto to observe their production process and further assess their requirements. After seeing the family’s flatbread line in action, RBS technical sales reps proposed a configuration of the modular, fully automated Multi-Crisp Baked Snack System. Interesting as the

Original Sea Salt

Herbs and Onion

Sesame Seed

Everything

Cranberry and Pumpkin Seeds

family remained wary of making such a big move. To help allay their concerns, they visited the RBS Science & Innovation Center for a flatbread trial run.

In January 2020, Pasquale, Patrick and Adriano made the eight-hour drive to the RBS Science & Innovation Center to see how the Multi-Crisp System would handle their five flatbread varieties. The pieces of the system were all available for demonstration in smaller, pilot-sized equipment. The Zappias wanted to be sure that the final products would be similar enough to what they were already producing that their customers would not notice any difference.

Their concerns were addressed quickly, they said. They had booked the Innovation Center for a two-day trial; but, they were able to successfully recreate all their flatbread recipes on the first day. In fact, the Multi-Crisp System actually improved product quality. By eliminating the hot and cold spots the family faced with their rack ovens, the RBS system delivered a more even baking process that gave the flatbread a better mouthfeel. After seeing the Multi-Crisp System up close, working with it and tasting the results, the bakers were convinced that investing in it was the right decision. Within a few months, Via Oliveto and RBS sealed the deal, even as COVID-19 quarantines were in full swing.

Despite the pandemic, Via Oliveto’s orders remained steady as RBS manufactured their production line. Meanwhile, Rachel searched for both a larger facility to fit the new line and funding sources to pay for it all. She found an 18,000-squarefoot facility in Barrie, Ontario that was still under construction when the family committed to it in February 2021. In the following month, she learned that Via Oliveto had secured a CAD 500,000 repayable contribution from the Canadian government for which she had applied months earlier.

Just as things appeared to be falling into place, construction delays at the new facility in Barrie forced the Zappias to stay in their old location longer than they had planned. The delays also meant the new facility would not be ready for the scheduled delivery date of the RBS Multi-Crisp System. RBS was able to hold on to the system components for several more weeks, a critical delay that gave the Zappias the extra time they needed to find a storage solution.

RBS installed Via Oliveto’s new Multi-Crisp System in September 2021 as the family kept baking in their old facility. The roughly three-week overlap was made easier by the RBS project team responsible for installing the new system and instructing the Zappias on its operation. “We needed

a lot of handholding,” Patrick recalls. “But the RBS project managers were supportive and always available.”