www.bakingbiscuit.com 04 23 iba ’23 special Exhibitor highlights, Organizer’s guide Bread lines Bread is best! In the spotlight Women in leadership roles: Cindy Yao

Verhoeven Bakery Equipment Family has a long and successful history of tailor-made development, engineering and production for the food industry. In the bakery market the family labels have established a strong position due our innovation and creative turnkey solutions. We sell high end production lines and state-of-the-art machines. Developed and made by a wonderful team of dedicated people. They make us proud. We would love to show you why.

HANDLING Conveying Robotizing Depanning END OF LINE Packaging solutions System integration CONDITIONING Cooling / Freezing Vacuum Cooling The Neth erlands - T +31(0)412 630 545 - info@verhoevenfamily.com MAKE UP Laminating Sheeting lines Universal lines Donut lines Pie lines

IT’S

IN

FAMILY we make to bake PRE-CONDITIONING Product conditioning Proofing VERHOEVEN BAKERY EQUIPMENT FAMILY WWW.VERHOEVENFAMILY.COM

ALL

THE

Innovation starts here

The Gulf Stream system is collapsing because of climate change. It’s on the verge of shutting down around 2050, but it could even happen as soon as two years from now, according to a new study. The warm ocean currents last ‘rebooted’ approximately 12,000 years ago, during the ice ages. This is the point of no return on the path to catastrophic climate change – for us. Admittedly, the scientific community does not entirely agree with Prof. Peter Ditlevsen’s timeline, the study’s author. Its publication might also have fallen into the background of developments in the recent hard news cycle, too. Several parts of Europe are engulfed in horrendous wildfires, to name just one example. In other news, governments are discussing proof of alien life, a loud narrative in the media recently.

Catalina Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

Arson aside, the wildfires in Greece, Italy, and Canada are – to no small degree – another symptom of climate change; moreover, planted fires are so devastatingly effective because of climate changes. We’ve had the hottest June in history and several temperature records were broken in July (the hottest month ever recorded, according to Copernicus Climate Change Service. And, even if the timeline predicted by Prof. Ditlevsen is questioned by the scientific community, the scenario remains unchanged, and we do not gain any meaningful ‘extra time’ with the generally agreed-on timeline, either.

Against this backdrop, the industry has internalized the urgency of putting a hard stop to current practices, disruptive as that may be, and is making strides to run the business in a sustainable way. The interest in more efficient production, with palpable energy savings and emission reductions, is translated into action. Changes are happening now and they are happening fast. It’s no wonder that the underlying theme for the exhibitors at iba this year is ‘sustainability’. The show will host all the new and improved solutions and ideas that will help in the ‘sustainability’ race. You can read about various companies’ latest innovations to be exhibited at iba in our preview, in the pages of this magazine.

The key to lasting change is to entirely rethink and ‘change the recipe’, as someone put it in a recent interview: from the actual product recipe, for more sustainable products (a sustainability score will be the new nutri-score), to the ‘recipe’ of how we’ve been doing things. With this mindset, innovation starts here and now. And it’s inspiring to see it unfold, every day.

We at baking+biscuit internationa l and brot+backwaren are proud to be a part of a resilient industry and witness it power through a plethora of challenges, as it has recently been doing. It is exciting to uncover new, innovative ways to address sustainability concerns. You can expect to always find them in our magazines in the hope that they can help inspire you, too.

Catalina Mihu

03 EDITORIAL

“YOU WIN THE HEARTS, YOU WIN THE WORLD”

Cindy Yao holds not one, but two leadership roles at one of the industry’s leading companies. She talks about combining her responsibilities as Chief Financial Officer and Executive Vice President at the Markel Food Group in an interview. ©

AUTHENTIC, AFFORDABLE LUXURY SELLS

David Wagstaff, the managing director of St Pierre Groupe, discusses how the cost-of-living crisis is impacting the industry. He also talks about emerging trends, new products and advice to stay one step ahead in FMCG.

IT’S NOT A SPRINT, IT’S A MARATHON!

Last time iba was staged in person, it provided a platform for EUR 2.1 billion in trade fair contracts. Five years later, anticipations run high for the industry’s first ‘official’ get-together in Europe since the pandemic.

A VERY SPECIAL ORDER

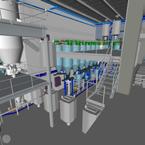

In the spring of 2023, Ölz der Meisterbäcker put its expanded production into operation. When it came to raw material handling, the Austrian plant baker relied on Zeppelin Systems for solutions.

BREAD IS BEST!

Bread consumption is once again on the rise, with the market expected to grow annually by 6.80% and reach a worldwide volume of 216.70 bn kg by 2028. The technology to support efficient, automated production of high-end, quality bread is here.

LES TARTES SONT MAGNIFIQUES

Some of the oldest patisserie creations are also an undisputed dessert staple: pies and tarts. As they are continuously evolving, various techniques can perfect product processing in industrial bakeries, preserving the artistry of the skilled patissier.

www.bakingbiscuit.com 04/2023 CONTENTS 04

HIGHLIGHTS 06

COVER STORIES

38

Markel Food Group

22

© GHM

32

©Koenig

16

© Zeppelin

© St Pierre Groupe

52

© Adobe Stock (#615666202)

IN THE SPOTLIGHT

06 Women in leadership roles: Interview with Cindy Yao, Markel Group CFO and Executive VP

BAKERIES

16 St Pierre Groupe: “Authentic, affordable luxury sells”

PRODUCTION

22 Bread lines: Bread is best!

50 VMI: How to scale up artisan bread production

52 Mecatherm: Les tartes sont magnifiques

54 Siemens: Digitization and financing - Fit for the crisis, well equipped for the future

PORTIONING, FORMING, DOSING

28 VEMAG: The product is the measure of things

32 Zeppelin: A very special order

IBA ’23 SPECIAL

38 Exhibitor highlights: It’s not a sprint, it’s a marathon!

46 Oganizer’s guide to iba: Preparations, logistics, recommendations

MARKETS

56 Prof. Dr. James Bruton: How German craft bakers survived the pandemic

REG ULARS

03 Editorial: “Innovation starts here”

62 Advertiser directory

■ With the right belt types for every processing step

■ With HACCP types that sustainably support your hygiene concept

■ With reliable service in uncompromising quality

Siegling – total belting solutions

RELIABLE AND HYGIENIC CONVEYING

Siegling GmbH www.forbo-siegling.com Welcome to our Hall/Booth B2/400 October 22 –26, 2023

Forbo

FOLLOW US ON LINKEDIN

CONTENTS Cover photo: © ADOBE STOCK (#594483076)

“You win the hearts, you win the world”

Cindy Yao holds not one, but two leadership roles at one of the industry’s leading companies. She talks about combining her responsibilities as Chief Financial Officer and Executive Vice President at the Markel Food Group, the importance of leading a team while being a team player, and creating a Leadership University to support next-generation trailblazers.

+ Catalina Mihu: You were recently recognized as the 2023 Large Company Virginia CFO Of The Year by Virginia Business magazine. Congratulations on the award! How would you outline the priorities in your responsibilities today, in your double role as Markel’s CFO and Executive VP?

Cindy Yao: First of all, people/team have always been my priority regardless of what role I have. You need to always be present for your team. I regularly am in contact with them. I work with our China team when it's my night and their morning. The time zone difference helps me juggle all priorities better. At the same time, financial reporting, and compliance especially as part of a public company, is always most important with a clear deadline. I meet with my finance team regularly to understand what is going on. For the first few years after joining the company, we put comprehensive policies and governance in place, and now all the teams can work on their day-to-day tasks together to make sure all the bases are covered.

Regarding my double role, they complement each other: the business role helps me to understand our business deeper and broader. It helps me to see what is important for our customers and our teammates. It provides me the ability to be a better strategic partner for the CEO, presidents, and other business leaders: What KPIs are more effective to drive what behavior and results? What are the customer voices? What reporting is meaningful for business users and for operations? Having a finance ‘hat’ also means that I can be more vigilant to make sure we comply with regulations and tax requirements. If we start doing business in a new country, or a new region, for example, I can collaborate with the team quickly and understand what risks and regulatory requirements we need to consider. So, my two roles help each other: the finance role helps me be a better businessperson and the business role helps me be a better operational CFO. It is more effective and efficient.

“The heart of Markel”

Mihu: What should leadership at this level entail, and what is the unique perspective that women bring to this role?

IN THE SPOTLIGHT – WOMEN IN LEADERSHIP 06

”Once you reach a certain level, you need to internalize this: you work for your team.”

Cindy Yao , Chief Financial Officer and Executive Vice President at the Markel Group © Markel Food Group

Yao: As a CFO and an EVP, it is about personal growth and the growth of the people I serve. It is about having empathy and being in their shoes. My teams do not work for me. I work for them. That is the essence of Markel Business System – Inverted organization structure. Once you reach a certain level, you need to internalize this: you work for your team. It is not a saying. It is your doing. What do women bring to the table in leadership roles? In my own experience of working full time, having two children, and going back to school for my Executive MBA, I would say time management skill is critical, as is empathy – the ability to observe and relate to other people’s feelings and emotions. You may be in your business suit, look all put together, while at the back of your mind, you might be juggling daycare or ailing parents. My experience has made me better able to be more observant, to be able to listen to other people’s problems and challenges and create an environment and culture where my teams care about each other’s wellbeing and work together more effectively.

Mihu: This is a question that is exclusively addressed to women: how do they juggle their personal life and their careers?

Yao: You have to be comfortable with the choices you make. Work/life balance is such an out-of-this-world goal. It’s very difficult to truly achieve a balance, but there are often tradeoffs. I remember the times when I missed my children’s milestones and school activities because I was either traveling or busy with meetings. But, at the same time, this has helped me be more mindful of my teammates’ time commitment for work and life. For example, if I know that there are people with children in their care, whether it is a father or a mother, I do my best to avoid scheduling meetings for early mornings. That is precious family time, when they feed the children and take them to school.

Mihu: How does the team perceive this perspective, of you working for them?

Yao: They respond well to it. With this mindset, we work together cohesively, and I have people reaching out and wanting to share their life stories and struggles. They use me as a sounding board. A heartfelt comment from a recent 360° survey stayed with me: it said I am the heart of Markel. While I was working at Bausch+Lomb, in the engagement survey of my department, teammates said my boss works for me. It’s great to see people recognize it when you put them first and work to help them. They want to work with you, enabling certain changes together or advancing in one direction. In Chinese, we say, “You win the hearts, you win the world” and this is how I operate. Care for your people first!

Mihu: What is at the heart of Markel?

Yao: The heart of Markel is a way of our doing and being. It is the peace coming from the fact that we care about each other, we respect one another, and we challenge each other for the better of our own growth and company

growth. Of course, we care about our results; but people come first. We ‘build’ our people before we build machines. That is our heart. Most recently I saw a quote: “Sight is a function of the eyes. Vision is a function of your heart.” It seemed to agree with me that it is all about the heart!

The Markel Business System

Mihu: Speaking of working with and for people, you also celebrate a significant milestone this year: 10 years with the Markel Food Group. What are some of the most significant moments for you throughout the past decade?

Yao: Several moments come to mind; for the first three years, we transformed our company from a more entrepreneur type of organization to a more professionally run organization. We set up the fundamentals and the control framework and governance process. Then, in 2017, we embarked on the journey to create and implement the Markel Business System, which combined tactical tools with a holistic continuous improvement mindset. The past three years, I took on more commercial/business responsibilities. Working with the business directly gave me more appreciation of our front-line managers and teammates. I would say the creation and success of Markel Business System Leadership University is the biggest milestone and recognition for me, my team and the company.

Markel Business System, Leadership University

+ Monthly requirements:

One 90-minute session per month

– Two separate 45-minute coaching sessions

Continuous skill application

+ The final session is held in person for one week, including graduation

+ Each student must successfully complete three Problem-Solving Projects (PSPs). They receive MBS PSP Champion certifications by December 2023

Mihu: You led the creation of the Markel Business System Leadership University. The first attendees of the MBS Leadership University graduated last year. How was it developed and how does support Markel Food Group teams and customers?

Yao: The concept of the university is to bring leaders and high potentials together, to share knowledge and support each other in understanding our customers, ourselves, and our industry. It aims to amplify the customer’s voice and teach a unified set of values and skills throughout the Markel Food Group. Those joining the Leadership University are selected and prepared to be able to lead themselves and others, as well as the business. It is designed to identify and train the successors for presidents, directors and other succession needs.

07 IN THE SPOTLIGHT – WOMEN IN LEADERSHIP www.bakingbiscuit.com 04/2023

–

–

Mihu: What does the syllabus look like?

Yao: We split the program into two categories. One hones on leadership skills and teaches how to be a genuine leader and work in a team setting. It includes team and selfassessments. The other module focuses on tactical tools that can be used to solve problems, including KAIZENs, risk assessments and VAVE. We work with the students to create a five-year personal development plan, to see how the company can provide opportunities for them achieving their career growth.

Mihu: What resources are available to students during the program and who are their trainers?

Yao: We had a certified trainer from our HR department run our first class. We also acquired specialty training materials. The MBS Director and I teach lean tools and concepts. This year, I became a certified trainer for leadership courses to coach and teach with help from an external HR consultant. Our graduates have also become coaches. The students have full access to all of us. It has been a privilege to teach and learn from my students. They call me the Dean, best title ever.

Mihu: What are your other responsibilities regarding the University?

Yao: I work with the MBS director and HR consultant in designing the curriculum. We seek frequent feedback from the students, presidents, regional leaders, and managers on how to improve our materials and course structure. We have individual coaching sessions with the students, where they share with me their career aspirations and their challenges. I also have scheduled sessions with students and their coaches (who are the graduates from last year), to make sure we maintain a cadence and that we move forward with all the problem solving. This is my way of engaging both the existing students and the graduates in implementing MBS. One example of a PSP the students must solve are along the lines of: ‘Why is my newly-built equipment module X% lower than we expected?’ The student and his coach work together to find root causes and counter measures to eliminate this gap. These case studies can be used by other sites within MFG to improve our financial results and motivate our people.

All in all, the role of the MBS Leadership University is not to issue a diploma but to create an army of problem solvers! It is about changing the culture, changing the mindset, and changing the way we do things. To put things into perspective, 31 students have enrolled in the program so far. They will be the leaders that will make a difference in the future.

Mihu: How is a problem-solving session structured?

Yao: The MBS definition of a problem takes away all the guesswork and subjectivity: ‘Do I have a standard/goal and where am I in relation to it?’ If there is a gap between the two and has a trend, then the gap is the problem! We need to close the gap and solve the problem. Once we have a problem statement, we will ask the five why’s to identify root causes and preto the data to focus on the 80%. Problem-solving is a continuously changing process, because, while we might find some causes for it at first, we might later refine the scope to make sure the potential solutions are possible. We call this process PDCA: you plan, you do, you check, you act. This is how we move forward.

PDCA

PDCA or plan–do–check–act is an iterative design and management method used in business for the control and continual improvement of processes and products.

Mihu: Who can join this program and how are the students selected?

Yao: Presidents, and regional leaders and leadership teams recommend candidates. We do have a class size limitation because we want to have extensive one-on-one time. We ask for candidates from all our companies – AMF, Reading Bakery Systems and Solbern. The only branch that hasn't been able to have students join the program yet is our China operation because of pandemic traveling restrictions. I expect that we will have someone take part next year.

Mihu: What is the role of the KAIZEN principles in the organization of the MBS Leadership University and in the day-to-day work at Markel Food Group?

Yao: KAIZEN stands for incremental improvement. It is a way of solving a problem or improving a process. A KAIZEN mindset means seeking continuous improvement, big and small. The most important thing about having a KAIZEN mindset is that you see the need for improvement.

At the MBSLU, we teach how to organize and facilitate a KAIZEN. It can be related to self-improvement or that of the team and the company.

Mihu: And why did you decide to embark on this project?

As I get feedback on our program throughout the year, we keep improving our material and planning for the next class.

Yao: I have always been extremely fortunate regarding learning and training. I believe knowledge does not simply appear. You must actively seek it and you also need

www.bakingbiscuit.com 04/2023 IN THE SPOTLIGHT – WOMEN IN LEADERSHIP 08

”KAIZEN stands for improvement. It’s a way of solving a problem or improving a process. A KAIZEN mindset means seeking continuous improvement, big and small.”

Cindy Yao , Chief Financial Officer and Executive Vice President at the Markel Group

3 reasons you should visit us. Kempf GmbH | Carl-Benz-Str. 3 | 85296 Rohrbach | Germany | +49 8442 9669 0 | www.kempfgmbh.de Visit us: A1.365 new products waiting for you low energy trays for saving money PFAS free coatings new developments & solutions bakeware and coating bakeware and coating

coaches and mentors to help you on this journey of learning and acquiring knowledge. Education is one of the best ways to obtain knowledge and change our mindset. MFG grew partially through several acquisitions. What are our shared values and ways of leading our teammates and serving our customers? Do we speak the same business language and apply the same operating principles? What binds us together is our business system. I knew we needed an institution to educate and train our people to adopt, implement and experiment our MBS. Therefore, we embarked on this education program.

We borrowed the idea of having a MBSLU through the experience I had at Bausch + Lomb, which had a university, although with a different focus. In the long run, our goal for the University is for it to run with alumni to build a network of problem solvers and KAIZEN practitioners. MBS is becoming the language of our business, a skill we keep perfecting. Personally, I also insist that more women students join the program and the company and receive training that will prepare them for future growth.

10 years with Markel

Mihu: How have values and strategies at Markel adapted and evolved over the past decade?

Yao: At the root, the values and strategies remain the same: customer satisfaction and teammates engagement are our pursuit. Through acquisition and innovation, we are able to provide broader offerings and serve more customers in different segments and different regions. The execution of the strategy evolved as we expand and with our implementation of MBS. Individually, each of our companies still needs to advance in its market segment; but collectively,

we are a much bigger and stronger company: we have presences and reach in many countries. We have groups of experts in baking and food processing technologies. We benchmark internally and externally. We leverage our innovation centers, manufacturing sites, currency advantages, geographically disbursed service techs. Our global footprint, wealth of knowledge and our multinational team enable us to win.

”As a company, we do have a high-level strategic deployment plan regarding automation and digital transformation. We will gradually introduce new solutions in the market that go beyond simply automating processes and use machine learning to continuously adjust these processes.”

Mihu: How did the pandemic bring everyone closer?

Yao: During the pandemic, we made an effort to stay connected and combat the ‘pandemic enemy’ together. I definitely increased my frequency of speaking with the leadership team at Reading Bakery Systems, Solbern and Markel TJ. It made me realize even more that we can’t take every interaction with our teammates for granted and make the best use of our time together. Through the Markel Business System Leadership University we also stay connected via MS teams solving problems. The University offers us a forum and a very collaborative and organized way to assess what lies ahead for us, as a group.

www.bakingbiscuit.com 04/2023 IN THE SPOTLIGHT – WOMEN IN LEADERSHIP 10

Cindy Yao , Chief Financial Officer and Executive Vice President at the Markel Group

© Markel Food Group

THE ONLY BAG CLOSURE THAT’S HOME COMPOSTABLE.

Mihu: How do the R&D teams from all the companies work together?

Yao: The speed of innovation is getting faster. To be the leader in the industry, we must invest in R&D. Being a CFO, I understand the short-term and long-term impact on our results. Our short-term profit needs to enable us to invest for the future. Overlooking the group companies R&D spending and direction enables me to find synergy and collaboration between the companies to make our R&D more effective.

president said to his team that “Cindy is part of us.” I totally enjoy working with Reading Bakery Systems, Solbern and MFG TJ in my EVP role. To feel part of the team and knowing you are a helper making things go right is the best feeling. The next one would be seeing the graduates getting promoted and taking more responsibilities with confidence.

Mihu: It’s inspiring to see that the focus is on people and their milestones – the people behind the innovation, rather than the innovation itself.

Yao: It’s always about the people! The right people with the right leadership make companies do great things.

Mihu: Speaking of KPIs , how would you summarize KPI priorities at Markel?

Mihu: What lean organization principles can a company with a global reach benefit from?

Yao: We are on the journey to become a lean organization. We have a lot of work to do. The pandemic exposed many of us to supply chain challenges. It helped us to focus more on our supply chain management. At the same time, to become a lean organization, our leadership must have a KAIZEN mindset. We must continuously seek ways to do better and share the knowledge of improvement across Markel Food Group.

Mihu: Speaking of success milestones, what are some of your favorite moments of the past 10 years?

Yao: In terms of favorite moments, I would single out earning trust. I remember at one of the business reviews, the

Yao: In my mind, the two biggest KPIs are safety and retention of good people. Safety shows, ‘We care about you’. No one should go to work and get hurt. Regarding people retention, we often say that people don’t leave their companies, but their managers. As managers, we need to ask ourselves ‘Do we have the right culture? Are we serving our customers well? Are we developing our people?’ Good scores in safety and retention indicates that we have done well in these three areas.

A global reach

Mihu: Looking at the global reach of the Group, How are the financial strategies of Markel Food Group’s main markets defined?

Yao: Our global reach enables us to shorten our lead time, reduce logistic costs and serve our customers faster in local languages. Our business and financial strategy of Markel Food Group has always been: 1. What’s best for the

www.bakingbiscuit.com 04/2023 IN THE SPOTLIGHT – WOMEN IN LEADERSHIP 12

”The future of the industry is ‘lights out’, highly-automated bakeries with minimum or no emissions. ”

©

Cindy Yao , Chief Financial Officer and Executive Vice President at the Markel Group

REDPIXEL –stock.adobe.com

Proven to Lower Energy Costs

ePAN® designs from American Pan have been proven to save bakeries money on every bake. In fact, one customer reduced gas usage by almost 8% year over year by switching to an ePAN.

Energy solutions like wind turbines and solar panels are a major investment and require a large amount of dedicated space. ePANs can fit on your existing bakery line and save you money from the very first bake. Here’s how:

DECREASED OVEN TEMPERATURE

Oven temperatures have decreased by up to 30°C when using ePANs.*

REDUCED BAKING TIME

Baking times have been reduced by up to 45 seconds.*

REDUCED WEIGHT OF BAKING TRAYS & TINS

Trays and tins are up to 30% lighter, requiring less energy from bakery systems and employees for handling.*

*Results from real bakery experience. Results may vary based on specific bakery conditions.

Jesper Albertsen | VICE PRESIDENT OF SALES +45 23 68 51 85 | jalbertsen@americanpan.com FIND US IN: Germany | Romania | Spain | Sweden | Turkey | UK | USA Visit us in Hall B1 - Stand 110!

customer? 2. What’s best for Markel Food Group? 3. What’s best for me (the company or region)? They are in this exact order.

Mihu: You led the restructuring and repositioning of several regional offices, including China and the Middle East. How were the group’s earnings in China doubled within 18 months?

Yao: The restructuring and repositioning of some of our regional offices are driven by tax and legal reasons. For China, I saw the day coming where TJ is not just a legal entity under AMF but a platform for AMF, the then Tromp Group, Reading Bakery Systems and Solbern for more customer reach and for more product offerings at more base models. In the past two years, we redefined our China strategy – win China and win the world. We saw the rise of Chinese competitors both in China and in emerging markets. However, our group technology, global reach, brand recognition and investment in our China operation give us an advantage. In addition, our TJ team is one of the best teams with most dedication. For example, during the pandemic, we had 26 people who slept in the factory to ensure on time delivery.

Mihu: How have recent disruptions affected Markel and what strategies emerged?

Yao: More recently, the chips supply has been an issue. As a result, we have a significant backlog. On the plus side, we could see where we can do better in response to situations such as this one.

Mihu: How would this problem be processed in the MBS Leadership program?

Yao: We must look at this problem objectively. We need to ask ourselves what are the things we can control, and what are the things out of our control? To be a lean company, we must emphasize more on what we can control, rather than just blaming the pandemic or the chip shortage. Seeing the need to improve is the KAIZEN mindset.

Imagining innovation

Mihu: One of the recent innovations developed by AMF Den Boer is the hydrogen oven. Was this solution developed in response to sustainability concerns from the industry, or does it reflect how Markel envisions the future of the industry?

Yao: The award-winning hydrogen oven is our response to sustainability concerns with our forward thinking. It is how we execute on our pledge of better food and better lives. We are making investments to lead the industry for sustainable oven technologies. When we first revealed the hydrogen oven, the market was interested but skeptical about the timing. In two years, we have seen the acceleration for adoption of green energy. When we first revealed the oven, the market thought we were 10 years too early. But now, in just two years, the market is saying that we arrived on time.

Mihu: Please highlight the group’s strategy toward investing in innovation – and the people developing it.

Yao: We redefined our innovation process within our organization. We have cross-company product development processed to share and leverage knowledge with dedicated R&D innovation centers. As we lead the effort in these breakthrough innovations such as Hydrogen/electric ovens and digital transformation, we are acquiring different talents and competence. This transformation is also for our leadership to change the mindset from a traditional mechanical engineering capability to AI embodied competence.

Mihu: We looked into the past 10 years at Markel Food Group. What would be key to continuous improvement for the next 10 years?

Yao: People are still the key. In the next 10 years, people/ talents will be retiring, including some of the presidents and other senior-level people. The University will be a good training ground for the next generation of leaders. At the same time, as technology changes, we need more talent in areas of AI transformation.

Mihu: Could more companies be joining the group?

Yao: Yes, depending on our strategy at the time, or on new segments we might want to focus on. But, that should be at the right time and with the right company so that we maintain the Markel Food Group culture and the Markel Style.

Mihu: And how should women’s representation be supported to grow in leading roles in the baking industry?

Yao: There are fewer women in the machinery industry, in general. As leaders, we need to promote people based on merit. You need to have the ability, the talent and the competence to do the job. With that said, we also need to make an effort to grow the presence of women teammates in leadership roles. Looking back at my life, I know that simply working hard is no guarantee for success. I have met managers who were willing to invest in me. Bausch + Lomb sponsored my E-MBA and put me through CXO training. Senior managers need to make a deliberate effort to grow the ranks of our women leaders and offer certain flexibility for their other roles such as motherhood. Creating an environment in which people can work better is the key. +++

www.bakingbiscuit.com 04/2023 IN THE SPOTLIGHT – WOMEN IN LEADERSHIP 14

”Senior managers need to make a deliberate effort to grow the ranks of our women leaders and offer certain flexibility for their other roles such as motherhood. Creating an environment in which people can work better is key.”

Cindy Yao , Chief Financial Officer and Executive Vice President at the Markel Group

F2M BOOK COLLECTION: the series

MULTI-LANGUAGE SPECIALTY BOOKS

AUTOMATION SCIENCE AND TECHNOLOGY

AUTOMATISIERUNG FORSCHUNG UND TECHNOLOGIE

Language: English (2021)

Hard copy: 180 pages

Price: EUR49,00*

Language: German (2022)

Hard copy: 204 pages

Price: EUR49,00*

*Including VAT, for the hard copy or e-copy. Shipping costs are not included.

Food2Multimedia GmbH Contact: Viktoria Usanova, usanova@foodmultimedia.de

YOURS NOW

ORDER

Authentic, affordable luxury sells

David Wagstaff, the managing director of St Pierre Groupe, discusses how the cost-of-living crisis is impacting the industry. He also talks about emerging trends, new products and advice to stay one step ahead in FMCG.

+Catalina Mihu: St Pierre entered a distribution agreement with ASDA in 2022, for three brioche ranges. Why were the Brioche Burger Buns, Seeded Brioche Burger Buns and Brioche Hot Dog Rolls selected to be sold at ASDA supermarkets?

David Wagstaff: The past few years have driven real shifts in consumer behavior and increased desire for premium, restaurant-quality products that can elevate at-home dishes. As such, ASDA and other major multiple grocers increasingly recognize the need to engage shoppers – and drive revenue – by ensuring their bakery department offers something ‘magnifique’. These are currently three of our biggest ranges and are enjoying growing distribution and sales in both grocery and convenience, with sales up by more than 100% compared with last year’s values and a 48% share of the brioche market, outpacing the growth of the category, which is up by 34% 1

In the last six months, the brand has secured increased distribution on its core and morning goods ranges with Tesco, Sainsbury’s, ASDA and Morrisons.

The first half of this year has proven busy for the brand in UK retail, as we steadily introduced innovative merchandising solutions, successful in the US, where St Pierre is the leading brioche brand, to UK supermarkets.

In January 2023, ASDA installed branded bays into 100 of its superstore formats, adding listings for St Pierre’s Mini Brioche Buns, Brioche Bagels, Brioche Baguettes, Brioche Loaf and Vanilla Brioche Tear & Share.

Then, in Q2 this year Morrisons followed suit, adopting new display solutions with our Eiffel Tower racks. St Pierre’s striking

Eiffel Tower displays are now driving footfall to the bakery aisle of 300 stores across the UK, with plans for further stores to introduce them in the coming weeks. After six weeks of testing, early results demonstrate that stores with the Eiffel Tower racks have seen a volume uplift of 31% 2

The branded bays and Eiffel Towers have already created significant uplift in sales for the brand but are also helping drive footfall to the category – assisting retailers in increasing basket spend. Shopper data from Tesco and ASDA shows that we are over-indexing with higher-value shoppers and we know that we are delivering category growth for our retail customers.

St Pierre is all about the experience – we prioritize the quality of our authentic products in order to deliver a brilliant experience with the brand. That experience starts in store and, through the consistent quality of our products, continues at home.

Mihu: Which consumers are you targeting with each of the three brioche ranges?

Wagstaff: St Pierre is all about affordable luxury. Our target consumer base is broad thanks to a diverse product range

www.bakingbiscuit.com 04/2023 BAKERIES 16

”St Pierre is all about the experience – we prioritize the quality of our authentic products in order to deliver a brilliant experience with the brand.”

David Wagstaff, Managing Director, St Pierre Groupe

© St Pierre Groupe

1Source: Nielsen Grocery Mults L52 Weeks to March 11, 2023; 2Morrisons Retailer Platform, April 2023

David Wagstaff is the managing director of St Pierre Groupe. He previously held high-profile commercial and management roles with some of the world’s biggest food brands. He had been running the US operation of St Pierre Groupe for two years before taking on the role of managing director in December 2022. The St Pierre Groupe portfolio includes the St Pierre, Baker Street and Paul Hollywood ready-to-bake brands and is headquartered in Manchester. The company also has offices in Ohio, US. The business joined the Grupo Bimbo family in October 2022.

that caters to all meal occasions. This versatility attracts everyone, from family shoppers to young professionals and empty nesters. We have seen, though, that we are bringing higher-value shoppers to the fixture for UK retailers.

St Pierre’s Brioche Bun and Hot Dog Roll sales continue to increase – and that growth isn’t just driven by people eating burgers. We know that consumers are enjoying our products for breakfast, lunch and dinner, because we are offering an affordable luxury. Despite recent challenges, consumers are still opting for quality products from trusted brands like St Pierre, to treat themselves at home. What happens when consumers ‘feel the pinch’, is not that they spend less money necessarily, but that they become more discerning with where and how they spend that money. That means that brands and suppliers offering quality goods have an opportunity.

The financial difference for consumers between buying ‘good’ or ‘best’ is marginal – therefore, shoppers are more likely to opt for the better quality, or premium offering in a low-value category. It’s different if you’re talking about cars or high-value purchases, but everyday grocery brands are subject to a different purchase journey – and knowledgeable brands – and retailers – should be ready to highlight quality goods to shoppers.

This also creates an opportunity for St Pierre specifically. Because we win out in independent hall tests on taste, texture and flavor, along with the versatility of our core items, we understand that driving trial is key. Whilst inflation might create a more risk averse consumer, perceived quality and multi usage is so important. Inflation is being felt across the board, in every sector. There will be two camps of shoppers, those who spend a little extra knowing they’re getting a better-quality product and become brand loyal; and those who don’t spend the extra, but consequently don’t have an experience that keeps them coming back. With St Pierre, retailers – and their customers – can make sure they have that positive experience every time.

Mihu: St Pierre products are now present in all of the UK’s top supermarkets. What is the distribution strategy for each of the chains (Tesco, Sainsbury’s, Morrisons and ASDA)?

Wagstaff: We are experiencing phenomenal growth in the top UK supermarkets, and that has stemmed from our core range of grilling season products – they were the first to be listed in the big four multiples. Our focus now is on driving the depth of distribution, making sure we are present across the full estate of the big four, and on broadening the range available through each of the major multiples. Our breakfast goods and recent listings there are a great example of how we are doing that. And as we’ve done that, we’re able to drive brand presence too, with the major UK supermarkets now trialing branded bays and our innovative Eiffel Tower displays.

Just in: St Pierre Brioche Bagels

Mihu: What are some of the most requested ranges and what new offerings have been introduced?

Wagstaff: One major new offering we recently introduced was St Pierre Brioche Bagels. These were launched in America first and were a product of many years of development. Bagels are an American staple and elevating and bringing some French flair to an American classic is a formula that has worked well for us so far, to make St Pierre the leading brioche brand in America. Equally, in the UK, breakfast is a booming market, with Brits eating an extra half a billion breakfasts in recent years 3 and consumption of breakfast staples like eggs and bacon on the up. 4 The appeal of a bagel is two-fold though; increasingly part of the UK bakery repertoire, bagels are on the rise and used more and more for lunchtime occasions too. We can help to further drive that growth through innovation and by offering a different experience, again tapping into multiple meal occasions. We have a unique proposition with our soft brioche bagel, that offers something different while combining two growing markets.

At St Pierre Groupe, any new product development is born of research and insight that demonstrates our products will

17 BAKERIES www.bakingbiscuit.com 04/2023

3Kantar, 52 w/e 17 May 2021; 4Waitrose

Drink

2021 – 22

© St Pierre Groupe

Food &

Report

(October 2021)

meet consumer demand. In the US, we have a pipeline of new products to introduce over the next few months. Often, we see US trends cross the pond to the UK. If that happens, we’ll be in a strong position to meet consumer demand here with a product range that is ahead of the curve. That was certainly the case with our Brioche Bagels. We have launched a number of other new products in the UK over the past 12 months, including a new vegan range of morning goods under the St Pierre brand, and so now, rather than focusing on new products, we are looking at pack sizes and how best to cater to changing consumer habits.

Mihu: The burger bun and hot dog category reached GBP 38 million (180% growth) in the last two years. How was this growth achieved?

Wagstaff: St Pierre is driving category growth by 39% by bringing higher-value shoppers into the store and encouraging premiumization in the bakery category. Our growth is down to our stellar team who continue to listen to consumer feedback, share insight with our partners and then deliver products to meet needs.

Grupo Bimbo acquisition

Mihu: What are the biggest changes since Grupo Bimbo acquired St Pierre Groupe? And what remains unchanged?

Wagstaff: Grupo Bimbo’s acquisition of St Pierre Groupe presents us with a fantastic opportunity to further our brands, globally. As part of the world’s biggest bakery business, we now have access to incredible resources and insight. The opportunity, particularly in America, is still phenomenal. We are steadily increasing distribution, but the market is huge, and so the potential for growth is unmatched. Our entrepreneurial spirit and our drive remains unchanged, and we continue to operate as an independent business, but with the impressive backing of Grupo Bimbo. It’s a very exciting time for St Pierre and our business.

Mihu: In light of the recent takeover, what are some of St Pierre’s priorities for 2023 and beyond? How do they vary on your main markets?

Wagstaff: We continue to operate as St Pierre Groupe, so our strategy and approach remain as they were. Our focus is on both grasping the opportunity in America and developing our business with our customers in the UK. As part of Grupo Bimbo, our exploration of new markets may accelerate, but the focus remains the same. We continue to push in the markets in which we already lead and maximize brand presence.

Mihu: What was the impact of the disruptions caused by the COVID-19 pandemic and by Brexit?

Wagstaff: The past few years have been challenging for the industry across the board. Rising costs of ingredients, production and freight, matched by labor shortages have meant bakery businesses have faced strong headwinds.

However, St Pierre has continued to face these challenges head-on, grow and assign resources to prepare for future trials. Throughout the last 12 months, we have invested heavily in our US and UK supply chain to ensure we continue to serve our customers at the impeccable level for which we are known.

The other challenge the industry needs to address is the cost-of-living crisis. We are seeing the impact of inflation in both the UK and the US – and while it means that for many, purse strings will be tightened as costs continue to rise, there is an opportunity for brands like ours.

Now is a great time for retailers to lean into premium brands like St Pierre – with the understanding of what ‘premium’ means for shoppers – beyond price point. For consumers, the trend for premiumization is here to stay. During the pandemic, shoppers were elevating their meals at home because they couldn’t travel or dine out. Now that the cost of living is on the up, consumers are still looking to treat themselves at home. Preparing and consuming better-quality foods along with entertaining guests at home is once again becoming more convenient and cost-effective than dining out. Elevated meals and quality products like St Pierre brioche, which save shoppers time and provide an easy solution for quality entertaining at home, are doing well throughout the store.

Mihu: How is sustainability addressed and communicated at St Pierre?

Wagstaff: We face two sustainability challenges at St Pierre Groupe: food waste and plastic-based packaging. Food waste is a huge challenge, and it’s increasingly being addressed both by the industry and by consumers at home,

www.bakingbiscuit.com 04/2023 BAKERIES 18

© St Pierre Groupe

who are more aware than ever before of the impact food waste has on climate change. Bakery goods are more likely than any other household food item to be thrown away.

St Pierre Groupe believes in making bakery magnifique –and as part of that mission, we are ensuring that our products do not go to waste.

That’s why all of our products benefit from extended life, helping to reduce waste from the moment they are produced. Beyond that, the business is committed to donating products regularly to food banks via charity partners, to ensure that our products are never wasted. We work with a number of charities, both in the UK and the US, and our partnerships are mostly organic, driven either by our team, or because they have a direct link to our business. We review our charity partnerships regularly, to ensure their objectives align with our own, either on an international, national, or regional basis. Any product not suitable not suitable for charitable donations is donated for animal feed wherever possible.

The other challenge we face is plastic-based packaging. Part of what allows St Pierre Groupe products to maintain shelf life and reduce food waste is the plastic packaging in which they are sold. Of course, as a business, we recognize that there is work to be done in reducing reliance on plastic packaging. Moreover, we are committed to exploring greener alternatives where such solutions do not compromise product quality.

As a result, we are committed to an annual review of all our packaging, in order to reduce our impact. In 2021, we removed unnecessary plastic from two of our core ranges saving almost 4 tonnes of plastic. The annual review from 2022 has been carried out and, as part of our commitment to action and transparency, the results are published on our corporate site. We know that our shoppers care that we are taking steps to counteract our impact on the planet and what’s important to consumers is of primary importance to our business.

New product development: trend spotting and social listening

Mihu: How are the special occasion recipes developed?

Wagstaff: At St Pierre Groupe, our recipe development starts with a mixture of trend spotting and social listening, allowing us the opportunity to put our products into multiple meal occasions. We look at the ‘demand moments’ rather than the product – what are people looking for, and then how do our products satisfy the need? We invest a huge amount in research and insight so that we can be helpful to our customers, and we take notes on what the competition is doing. The sector is dynamic and we are leading the way, trying new things, and working in partnership with our customers to get the best results.

”St Pierre’s Brioche Bun and Hot Dog Roll sales continue to increase – and that growth isn’t just driven by people eating burgers. We know that consumers are enjoying our products for breakfast, lunch and dinner, because we are offering an affordable luxury.”

David

Director,

David

Director,

Mihu: What new territories could hold potential for further market expansion?

Wagstaff: As I previously mentioned, the opportunity for St Pierre in America is still phenomenal – we are increasing our depth of distribution, but the market is huge, and so the potential for growth is unmatched. Our focus remains on maximizing opportunity in our existing markets for the time being. As part of Grupo Bimbo, our exploration of new markets may accelerate and with Grupo Bimbo’s backing, we’re in a strong position to fulfill new market demands. We have ambitious growth targets and an entrepreneurial approach to meeting them, so it’s an exciting time for the business.

Mihu: What are the main differences between doing business in European markets vs. the US, from St Pierre’s perspective?

Wagstaff: American consumers are used to a sweeter flavor profile in baked goods, but European consumers have greater knowledge of what brioche is. Delivering bakery staples like burger buns and hot dog rolls has helped with the US education piece around brioche, how it differs and how to use it. It’s a little easier in the European market, because shoppers are more likely to understand brioche, but it is perhaps a ‘bigger leap’ to switch to a sweeter flavour profile than it is for American shoppers. So long as our commitment to quality is consistent, we will continue to make bakery ‘magnifique’, wherever we supply our products. +++

www.bakingbiscuit.com 04/2023 BAKERIES 20

Wagstaff, Managing

Sr Pierre Groupe

© St Pierre Groupe

PROGRESSA bread

Highest precision on the smallest footprint.

Our brand-new expert for tasteable quality.

Ben Baker

Ben Baker

Bread is best!

Bread consumption is once again on the rise, with the market expected to grow annually by 6.80% 1 and reach a worldwide volume of 216.70 bn kg by 2028 2 . The technology to support efficient, automated production of high-end, quality bread is here. The key is gentle dough handling.

+Per capita, bread consumption should be over 24 kg this year, and it is poised for steady growth. Among the categories that entice consumers, artisan-style breads, premium ranges and perennial favorites such as baguettes are popular choices.

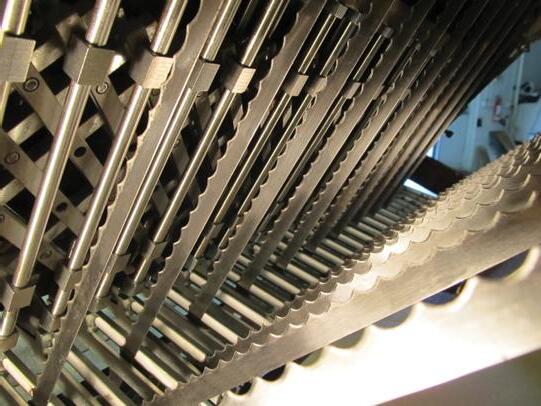

Royal KAAK: Baking freestanding bread

The Dutch ‘silo to truck’ solutions manufacturer develops production lines for all kinds of freestanding bread, with a capacity of around 7,500 kg/h, depending on the production process, type of end products and available space. Recently, lines with production volumes ranging from 2,500 to 5,000 kg/h have been frequently requested.

Rolls and boules can be made, from 80 g to 1,000 g, as well as crystal buns with an open structure. Molded products such as (demi-) baguettes and loaves can also be produced with this line, as well as pointed baguettes. When a sheeting line is utilized, ‘die-cut’ products are also an option, with several shapes (e.g.: triangle cut, angled cut, omega cut, hexagonal cut, or octagon cut). The line is not just limited to bread: it can also be used to manufacture pinsa, which, in some cases, should be proofed on peelboards.

The line replicates all the traditional process steps of when the dough was kneaded by hand, proofed in baskets and

baked in a stone oven. Delicate operations when forming and handling the dough are key.

KAAK offers bulk fermentation solutions for this line, which support the quality of the end products and help reduce the additives needed.

”A focus point while using peelboards is the correct use of the release agents and flour on peelboards in combination with the type of dough processed. We always carry out internal project tests to optimize it.”

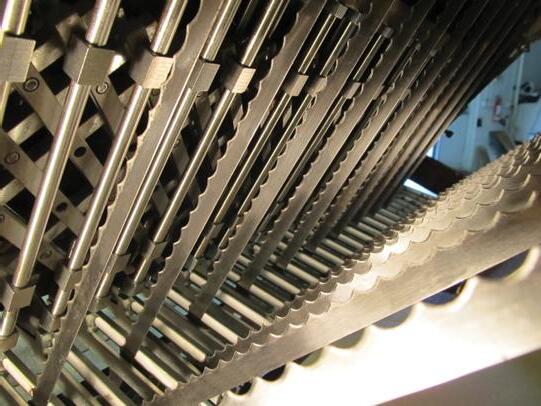

Dough processing and the end products are the central points of a freestanding bread production line designed by KAAK, explains Rens van Heesch, Product Sales Manager, DrieM sheeting lines. This means that the utmost care is given to the gentle handling of the dough, during the volumetric dividing process, or as it goes through dough sheet reduction. Either dough makeup systems can be used (lining up a divider, rounder, proofer and molder), or a sheeting line that is designed especially for bread processing. The standard line configuration features a sheeting line that is suitable to handle highly-hydrated doughs with long fermentation times. The operating principle is that the dough is gently reduced with the help of two multi-rollers.

Bread on peelboards and directly on belts

Highly hydrated doughs are placed on peelboards for processing. Once the dough is deposited on the peelboards, the dough pieces are placed in the KAAK final proofer. After decoration, they are ready for the oven, where a machine ‘peels’ the products from the peelboards and places them on the oven belt. The line cleans the

www.bakingbiscuit.com 04/2023 BREAD LINES 22

Royal KAAK specialists

© Koenig

1CAGR 2023-2028. Source: Statista; 2Source: Statista

© Royal Kaak

peelboard again and transports it to the start where new dough pieces are prepared for production.

“A focus point while using peelboards is the correct use of the release agents and flour on peelboards in combination with the type of dough processed. We always carry out internal project tests to optimize it,” KAAK highlights.

Even after the dough make-up phase, gentle handling is the main priority for the next process steps; for example, the pieces are carefully removed from peelboards and placed on the oven belt.

For dough dividing, the Dough Master was the equipment selected to be a part of this line. Nigel Morris, global head of technology at KAAK explains why: “This divider guarantees better control of the dough because it is completely servo-driven.” The company recently delivered two freestanding bread lines for rounded and oval molded loaves equipped with this divider.

Many other options are possible to meet the individual needs of the customer, for example top and bottom decoration of the dough piece as well as decoration by guillotine stamping.

New features

KAAK has recently brought new features to the freestanding bread line, making it more flexible and hygienic. “We introduced several new innovations: the robot scoring system is vision-based, which ensures a high degree of accuracy and flexibility in scoring patterns. It is perfectly suitable for multi-product, freestanding bread lines,” KAAK highlights. Different types of cutting tools can be used, depending on the type of dough being processed and the desired cutting pattern.

The rounding unit of the DrieM sheeting line has also been recently upgraded and can now handle 5,350 pieces of dough of up to 850 g. In addition, the soft dough sheeting section has been revised and now provides better access for cleaning, to meet increasing hygiene requirements from the industry and based on the specialists’ field experience.

Process consistency

The line closely controls the process to maintain it under the optimum parameters. For example, standard solutions integrate check weighing into the dough make-up lines. The mixing process is monitored, with temperature sensors that can be placed in several hoppers. This ensures mixing consistency at all times. All temperature and, in some cases, humidity settings for proofing, baking, cooling and freezing are checked and automatically adjusted. The PLC data can be connected with existing MES systems, to share information related to production to the overall data management

system. “On request, we also offer the possibility of integrating constant monitoring of the motor amperages,” KAAK specialists explain.

In addition, detection points have been integrated into the sheeting line to automatically control the process. As a result, fewer interventions will be needed from the single operator, required to run the line.

Flexibility: FRITSCH IMPRESSA bread line

FRITSCH will showcase a completely new design of its IMPRESSA bread line at iba this year. The new improvements focused on its hygienic design, as well as making it more compact and more flexible. The IMPRESSA bread can run as much as 9 tons of dough per hour, depending on the product, with various resting times – as long as 24 hours.

”The

centerpieces of our SoftProcessing

technology are the dough sheeter SDS and the satellite head.”

FRITSCH specialists

“With a special sheeting technology (which also includes an improved dough sheeter for soft doughs), not only do we save a lot of space, but we also produce a uniform dough sheet and reduce scrap dough,” FRITSCH highlights. All the components of the line are designed with the new hygienic design; they offer improved accessibility, are easy to clean and are washdown capable. There are different options available to ensure high flexibility when manufacturing a wide range of products. The line’s modular design means it is always configured according to the needs of the individual operation. Various features can be integrated into existing lines, such as decoration units, for example.

23 BREAD LINES www.bakingbiscuit.com 04/2023

© Royal Kaak

For process consistency, FRITSCH equipped the IMPRESSA bread (and all its industrial lines) with a new, output-based line control. How does it work? The operator simply has to enter the number of products he wants to produce per hour and the line calculates all the necessary parameters to achieve this result. “The software even checks whether the desired performance change is feasible quality and reproducible results,” the specialists explain.

Soft processing technology

The modular design of the IMPRESSA bread supports the manufacturing of a wide range of products, either cut, roundmolded, or long-molded shapes. Rye dough or special doughs, for example for Pinsa, can easily be processed. Moreover, strewn products or special decorations are also possible, utilizing the product decoration unit.

The Dough Sheeter SDS on the IMPRESSA bread can process soft doughs with a long pre-proofing time, and it does so very gently and with a minimum amount of oil. FRITSCH explains the principle of the SoftProcessing Technology supporting the process: “The centerpieces of our SoftProcessing technology are the dough sheeter SDS and the satellite head. In the SDS, a sensor monitors the filling level above the two-star rollers. This ensures that there is always a constant level of dough above the star rollers and that no compression of the dough occurs. If dough is needed, it is automatically fed through the conveyor belt. The big advantage of the SDS is that it flours the dough sheet on all sides. For the outer sides of the dough sheet, we use a fold-up belt (FRITSCH patent) which is previously dusted with flour. Flouring the dough sheet on all sides means that there is no need for oil during further processing.”

The SDR then sheets the dough very gently. The satellite head technology produces a consistently uniform dough sheet. Even its edges are homogenous, as no shearing forces and separating agents are used. Stretching and compressing are avoided at transfer points with the use of knife edges.

In addition, drop heights are also either avoided entirely or reduced to a minimum. “This allows even soft and rye dough to be processed reliably,” FRITSCH explains. The use of non-contact dough loop control helps with stress-free dough processing, with the added benefit of high accuracy in shape and weight, over the entire width of the dough sheet. In this way, scrap dough is reduced to a minimum.

And process-control software

Process efficiency can be optimized by integrating the FRITSCH Smart Services. With the ‘Smart Production Insights’ (SPI) service, operators have access to live production updates and ensure complete process transparency. “Production managers or shift supervisors want to have an overview of the most important performance data of the equipment in as close to real-time as possible, even more so in the case of downtimes caused by minor malfunctions, or the maintenance status of the equipment.” FRITSCH explains.

The latest Smart Service FRITSCH developed is the so-called ‘Watchdog’ for the line drives, which constantly measures and analyzes their operating parameters. As soon as the deviation from the empirical value exceeds a certain limit, the production manager receives a warning to check the motor at the next maintenance and, if necessary, to replace it before it breaks down.

A flexible product portfolio

The IMPRESSA bread is most frequently used to manufacture round-molded products with long pre-fermentation times. Many lines are also equipped with a baguette unit for long-molded products. FRITSCH can offer several features that can be integrated into existing lines to further increase the product variety that can be made with them. “Our latest product innovation is for twisted bread rolls, which can now be produced fully automatically, in high volumes, with the new Dough Twisting Unit (DTU) on our IMPRESSA bread,” FRITSCH reveals.

www.bakingbiscuit.com 04/2023 BREAD LINES 24

© FRITSCH

With the Product Decoration Unit (PDU), decoration patterns can be printed or cut into the surface of products, for unique-looking products. The machine can make decorations by pressing or cutting shapes into the dough, not only on round-molded products but also on rectangular and longmolded ones. In addition to molded bread rolls, dough pieces can also be stamped/punched or cut out, then decorated with a pattern. Products of virtually any weight can be processed: a vision system ensures that the desired pattern is always applied exactly in the center of the product.

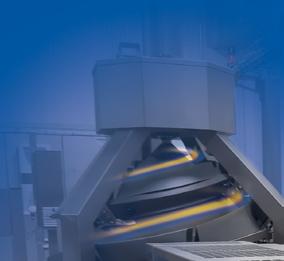

Automated premium bread lines: Koenig

‘Artisan’ and ‘premium’ are often used interchangeably when referring to bread. To Koenig, ‘premium’ products are crusty breads, with complex flavor and a chewy crumb. They are the result of long and slow fermentation and processes that cherish the tradition of handcrafted bread, made from scratch without preservatives or enhancers, but with high-quality ingredients, the specialist shares.

make-up as technology has advanced to allow the retention of dough cell structure and made it easy to process different kinds of dough and perform changeovers. Products were traditionally made by hand can now be automated, while still retaining their artisan character. “When using an elaborate processing line, bakeries can achieve higher weight accuracy, more gentle dough processing and absolutely even density of the dough sheet, when producing artisan bread doughs,” the company’s specialists stress. For example, a dough sheet forming system for various dough types can be incorporated into the line, or the TwinSat double satellite head for the gentle processing of the dough sheet.

Koenig can accommodate any product forming requirements: “We integrate guillotines for cutting breads in different sizes and shapes, including decorative patterns.” Forming stations can also be incorporated in these lines that flatten dough pieces, convoluting them. With subsequent seeding, breads can also be decorated. “We built a large bread line with a long intermediate belt. Along this belt, production staff twisted the bread dough pieces into the company’s typical shape. The customer wanted to have this ‘hand -crafted’ style, so we integrated it. After manual forming, it became a fully automated line again,” Koenig shares an example of a recent setup.

”In transferring artisan knowledge to industrial production, we always look for solutions that make the equipment easier to clean, easier to operate and minimize downtimes.”

For final proofing, the company recommends solutions such as step proofers, rack proofing chambers or tray proofers, ideally fully enclosed by thermo-insulated panels.

The Austrian technology specialist designed its automated bread lines with premium bread ranges in mind – which mostly encompass doughs with long fermentation times and very high water ratio, such as Mediterranean white bread with more than 80% water content, or rye breads containing up to 90% water. These premium bread lines cover all processes from mixing up, to dough processing, product handling, proofing, baking and through to cooling and freezing. Dough processing mostly determines production capacity, which can go as high as 5,000 kg of dough throughput per hour, on setups that use the Menes-H dough sheeting line. Small-pore and large-pore dough can run on this line. For processing and forming of bread doughs, Koenig recommends dough sheeting lines, such as its Menes, designed for this purpose.

Sheeting lines have become a popular solution for dough

For baking, the multi-deck tunnel oven MDI STRATOS with indirect heating is Koenig’s choice for this line, due to its ability to combine modularity, power and control in a compact design. The heat transfer to the product takes place mainly by radiation, but also by contact and natural convection, Koenig explains. The decks are completely independent, which allows the management of different production rates and/or different products to be baked simultaneously. “Each adjustment zone has a dedicated combustion, ventilation and heat exchange system, as well as a set of probes, allowing the independent control of temperature,” Koenig’s specialists explain.

When dealing with long fermentation times, which is often the case for premium breads, a final proofer can help to achieve consistent quality by ensuring constant conditions.

www.bakingbiscuit.com 04/2023 BREAD LINES 26

Koenig specialists

© Koenig

For cooling and freezing, custom spiral solutions from the newly-acquired Finish manufacturer Vulganus are added to the equipment lineup.

Custom-designed, automated processing

When working with bakers to customize a premium bread line, Koenig first aims to learn the artisan handcraft process and then transfer this knowledge to industrial production volumes, without any loss in quality. “This means creating dough processing principles for the most gentle dough handling with regards to the latest trends in bread consumption, e.g. processing bread doughs with long fermentation time, seeds, sprouted grains, etc.,” details the specialist, adding that, “In transferring artisan knowledge to industrial production, we always look for solutions that make the equipment easier to clean, easier to operate and minimize downtimes.”

Automating sensitive bread doughs does not mean the exact same procedure will be used every day. The competence to make small changes, also in automated production, is still a very necessary skill to have, in order to be able to react to a number of variations that may occur. Factors such as temperature, humidity, flour quality, etc. can have an impact on artisan bread production. “In our experience, we find that bakeries sometimes underestimate the effect of these surroundings or have problems with finding the right staff to react to these parameters in the operational business,” Koenig illustrates.

Consistent bread quality

The biggest challenge in processing artisan, premium breads is consistency – regarding dough quality and texture, dough processing, and bread quality, respectively. “Bakeries wanting to scale up their bread production with consistently high quality need to have one thing: a perfect process organization,” Koenig underlines. All the solutions lined up in the premium bread production contribute to increasing the quality of artisan products. By establishing a full process, it is easier to control the production, even if it is scaled up, Koenig points out.

The company shares advice on how to mix and process artisan bread doughs, for consistent results: “Doughs with extensive fermentation time need steady conditions, e.g. by placing the mixing bowls in evenly air-conditioned rooms or chambers. When mixing several batches for use on one processing line, the mixing times need to be coordinated with the floor resting times and the processing times. The floor resting time must be exactly the same for each bowl of dough. We recommend making the batches in a size that can be each processed in approximately 15 minutes on the dough processing line – preferably on a dough sheeting line for bread doughs. This has turned out to be a good referential number.”

Improving equipment features

For new technology developments, Koenig focuses on producing artisan and premium breads and buns with high weight accuracy. For this, scaling systems that are built into the dough sheeting lines play a key role, as they continuously coordinate cutting the dough sheet in the right place, to achieve the right weight.

“We are also working on processing long-fermented doughs in large batches. Scaling up artisan doughs to an industrial level without quality loss was not possible until recent years but today’s technology enables it,” Koenig highlights.

Flexibility remains in high demand, too: “Customers ask for ‘all-in-one’ solutions - one line for all sorts of doughs. The key is to form a homogeneous dough sheet on one line for both soft and large pore doughs. Koenig overcomes this challenge both for the Menes-H line and Artisan SFM EC line with a sophisticated dough sheet forming system, which can be adjusted with rollers and sensors for individual doughs,” the specialists explain.

Koenig has been closely focusing on hygienic design for several years now, to ensure machines stay clear of flour, dust and waste dough, which can all cause machine wear and can even bring bread production to a stop. Allergens and staff safety are also addressed by new equipment features. To meet such industry demands, Koenig developed the wash-down ‘H’ hygienic design series and the ‘Easy clean’ series for easy cleaning and accessibility, which cut cleaning time at least in half, according to their customers, the specialists point out.

Solutions to support the growing preference for high-end, nutritious breads are here, for any production requirements. +++

27 BREAD LINES www.bakingbiscuit.com 04/2023

© Koenig

The product is the measure of things

Every gram counts. This is especially true when raw materials become more expensive or even scarce. VEMAG takes weight accuracy very seriously with its portioning technology. The machine manufacturer also sets the bar high in terms of product quality and flexibility.

By Helga Baumfalk

+With systems and machines that perform tasks such as portioning, forming and dosing, VEMAG Maschinenbau GmbH is represented in many sectors of food production. The spectrum ranges from butcheries and dairies, the production of snacks/protein bars, confectionery, or plant-based products to pet food and, of course, bakeries. “Passion for products – that describes us pretty aptly,” explains Managing Director Christoph Thelen. “By that, we don’t mean our products, but those of our customers. Orientation to the end product has always been important to us. In recent years, we’ve further expanded our focus on the respective industries and aligned our development accordingly with our own teams of specialists.”

Around 20 employees work at VEMAG for the bakery sector alone, including master bakers, bakery technicians and food technologists who are active in the BIC, the new Bakery Innovation Center (see box). Separate testing and competence centers have also been set up for other food and non-food sectors at the company’s headquarters in Verden, Germany. “Different industries have different requirements,” observes Alexander Bressler, Product Manager, Sales, Bakery. With test centers appropriately equipped to meet the respective requirements, it is possible to respond individually to customers’ needs, he adds. “Our goal is to communicate with all our customers at eye level,” says Thelen. This is why it isn’t unusual for many people in the company to have a ‘food background‘.

Since 2001, VEMAG has been a part of the US-based Robert Reiser & Co of Canton, MA. Reiser itself does not build any machines and gives its German subsidiary free rein in the management of the company. Both are in a kind

© VEMAG

“Despite the challenges posed by the war in Ukraine and the pandemic, we have managed to continue our overall growth. Here we benefit from our broad-based structure and proximity to international markets through our agencies.”

www.bakingbiscuit.com 04/2023 PORTIONING,

28

Christoph Thelen, Managing Director, VEMAG

FORMING, DOSING

of supplier-customer relationship with each other. VEMAG manufactures, Reiser sells the equipment – and that of other manufacturers – in the USA, Canada and the UK. Similarly, VEMAG works with other independent agencies and its own subsidiaries, e.g. in China, the Netherlands, or Poland, through which the machine builder is represented in more than 120 countries worldwide.

A functioning after-sales system is important, says Christoph

Thelen. No one can afford downtime, he adds. “When it comes to service, we don’t differentiate by industry, because the technology is similar.” In export markets, agency technicians are responsible for maintenance and service. All service personnel are trained at the VEMAG Academy in Verden.

More than 80% export share

At over 80%, the company’s export share is high. North America, the UK and European countries such as the Netherlands, France and Poland are among the main sales markets. The

The bakery all-rounder

It is one of the latest developments from VEMAG: the HP1 or better said, the bakery all-rounder. The dough portioner is designed for medium-sized artisan bakeries. It can convey thin or stiff masses even with pieces (according to the company, without losing volume or destroying pieces) and divide or dose doughs with a dough yield of 155 to 220 just as well. The machine operates in a weight range from 5 g to 50 kg. “One customer where it is already in use is using it to produce 25-gram cookies for food retailers,” Alexander Bressler tells us. “He could just as easily run his bread doughs over it.” The dough portioner can be combined with various attachments. One attachment can be used, for example, to fill sponge cake and stirring masses into molds or cake rings with weight accuracy. “The attachments give the baker product flexibility with one system,” Bressler said. The hand-filling head could be used to dress macarons, meringues and macaroons, or to fill masses into jars. As for the variety of shapes, that is almost infinite, he says.

company is also successful in the South American markets, as well as in South Africa, China and Australia. Thelen: “Despite the challenges posed by the war in Ukraine and the pandemic, we have managed to continue our overall growth. Here we benefit from our broad-based structure and proximity to international markets through our agencies.” From approximately 840 employees, around 400 work in production and assembly. In line production, they build up to 1,800 systems and machines per year with a five-day week. Added to this are the respective accessories. Controls, motors, or various auxiliary parts are outsourced. Everything else – from sheet metal and surface processing to welding and assembly work – takes place at the plant in Verden. The high level of vertical integration creates independence and allows the company to respond more quickly to inquiries. In addition to the series production business, there is also the ‘customised construction department‘, which develops customized solutions.

© VEMAG © VEMAG 29 PORTIONING, FORMING, DOSING www.bakingbiscuit.com 04/2023

© VEMAG

Procurement is a topic that can currently become a challenge for all companies worldwide. Christoph Thelen: “We are not completely spared either. Nevertheless, with our vertical integration and because we work in partnership with our suppliers, who we hold in high esteem, we manage to maintain the supply chains, even if this ties up a lot of resources at the moment.”

Part of VEMAG’s philosophy is to keep spare parts available for customers via a spare parts warehouse. Thelen: “If a part is defective, it is needed immediately. In the foreign markets, the agencies stock up. It is also part of our philosophy that we do not discontinue spare parts.”

Tower clocks and honey extractors