www.bakingbiscuit.com 06 22 Trays, pans, molds Trays with a mission: cake production Cookies, crackers Next-generation equipment priorities Vacuum cooling The VACTORR vector

As consumers have become more demanding than ever and the industry has become increasingly more complex, you need more than great products to inspire new levels of success. You need a true partner: one who’s walked the walk and acutely understands the various challenges of running your day-to-day operation. A complete partner, with the tools, solutions and support to help you stand out in today’s highly competitive marketplace. An innovative partner, one that’s always looking ahead for the ideas and inspiration to create new excitement. We are creators. Collaborators. Experts and inspirers. For growing your business, we’re the total package. We are Dawn, your partner for bakery success. Discover

Baking is a labour of love.

at

true partnership by contacting us

dawnfoods.com/eu

What’s in it for you?

The world’s population reached eight billion people this month. It has only taken us about a decade to be one billion more, with much of this growth (about 70%) coming from poorer parts of the world. According to UN data, most of the further growth will be concentrated in just eight countries: Congo, Egypt, Ethiopia, India, Nigeria, Pakistan, the Philippines and Tanzania –interesting markets to watch. “Countries of sub-Saharan Africa are expected to contribute more than half of the increase anticipated through 2050,” when the population should reach 9.7 billion, the UN projects. There’s more: at the other extreme, countries with slowing growth rates, which leads to an ageing population, should take steps to adapt their public programs to support these demographic shifts, the organization recommends.

Catalina Mihu, Editor-in-chief

Your commments or suggestions are always appreciated: e-mail: mihu@foodmultimedia.de

“The relationship between population growth and sustainable development is complex and multi-dimensional,” said Liu Zhenmin, UN Under-SecretaryGeneral for Economic and Social Affairs. ‘Sustainability’ is the key – and multifaceted – concept here, and one reshaping the baking industry as well. The painfully acute issue of labor shortage is a common denominator throughout the bakery world. An interesting idea I heard in a recent conver sation at IBIE was that shows could support companies looking to hire with a section working as a job fair within the trade fair.

Need always inspires innovation, so there are several approaches the industry is taking to tackling people scarcity. A great place to start – always – is to value existing staff, individually and as a team, from ensuring working conditions to training and advancement opportunities. When bakeries have to lower production volumes because there are simply not enough people to fill all shifts, more measures need to be taken, and quickly. In this instance, sustainability is increased by automation, to take over the burden of the heavy load and to better streamline the work of the employees. Smarter, more self-reliant technology is literally the ‘next best thing since sliced bread’ for its contributions to sustainability on every level, from the people needed to work with it, to optimizing each production step, and providing the highest process accuracy level that has been possible to date. Resource-saving and reallocating are high on the list of benefits, too.

Sustainability is also at the top of our list, for new trends to watch, new solutions and ways to do business. You can expect to find as many different approaches as the concept entails, covered in our articles. This is why we would like to learn about your experiences, what is sustainability for you, which are the right-now priorities and your long-term vision. Our inbox is always open!

In the meantime, we want to wish you a joyful year-end, and a successful New Year! With warm wishes on behalf of our wonderful team to yours,

03 EDITORIAL

Catalina Mihu

TRAYS, PANS, MOLDS

One product, infinite possibilities: cakes come in all shapes and sizes, with unique concepts to mark memorable events or casual experiences. To create the cake that will stand out, the tray is the limit.

BRAMMIBAL’S

COVER STORIES HIGHLIGHTS 20

What started as a farmers’ market stall for vegan donuts in 2015 is now a company with its own bakery and six stores in the German capital Berlin and a location in Hamburg - so far, because Brammibal’s has plans to grow further.

INTERVIEW

COOKIES, CRACKERS

Low moisture, long shelf-life, diverse sizes and shapes – crackers and cookies are a segment filled with opportunity. Their characteristics also dictate process improvements and how equipment can support optimization.

VACUUM COOLING

Vacuum cooling specialist Verhoeven Bakery Equip ment Family recently developed three new systems to handle the process.

Dawn Foods launched a patent-pending glaze that strictly sticks with donuts, and never with the packag ing or fingers.

Sourdoughs are much more than just an ingredient. “They are an entire system of biotechnology,” ex plains Dr. Georg Böcker, Managing Director of Ernst BÖCKER GmbH & Co. KG, in an interview with baking+biscuit international.

www.bakingbiscuit.com 06/2022 CONTENTS 04

© Reading Bakery Systems 16 © American Pan

06 © Brammibal’s

28

© Anton –stock.adobe.com

© BÖCKER

34

Verhoeven Bakery Equipment Family 26

©

– this is more essential than ever. IT will be the key to meeting your challenges. ERP, MES, subsidiary management, or intelligent planning software: the CSB-System is the comprehensive solution for bakeries. It enables you to optimize your production processes immediately, laying the foundation for the future digitization of your entire plant.

BAKERIES 06 Brammibal’s: The vegan donut concept PRODUCTION 10 AMF Bakery Systems: Proofing systems to get dough rising to full potential 26 Verhoeven Bakery Equipment Family: The VACTORR vector in vacuum cooling HYGIENE 12 Antimicrobial lighting: The lightbulb moment 24 Forbo Movement Systems: New homogeneous belts TRAYS, PANS, MOLDS 16 Trays with a mission: Cake production COOKIES, CRACKERS 20 Reading Bakery Systems: Next-generation equipment priorities INTERVIEW 28 Dr. Georg Böcker, Managing Director of Ernst BÖCKER GmbH & Co. KG: “Sourdoughs are an entire system of biotechnology” MARKETS 32 Euromonitor International: Have the cake! NEW INGREDIENTS 34 Dawn Foods: Do not get sticky with it! 36 Palsgaard: How to make egg reduction a ‘piece of cake’ 44 Wanted: Added fibers SUSTAINABILITY 38 Van de Weijer Drogerij: Terms of separation SCIENCE 40 ttz Bremerhaven, BIBA: Artificial intelligence for the fermentation chamber 48 DIOSNA: The ever-trendy clean label evolves REG ULARS 03 Editorial: “What’s in it for you?” 18 News 31 News 50 Advertiser directory CONTENTS Titelfoto: © Michael –stock.adobe.com FOLLOW US ON INSTAGRAM www.instagram.com/food2multimedia

business

transparency, flexibility

out more about our solutions for bakeries:

My ERP. Covers what my

needs. Efficiency,

Find

www.csb.com

BRAMMIBAL’S DONUT CONCEPT

"Oh, that's vegan"

What started as a farmers’ market stall for vegan donuts in 2015 is now a company with its own bakery and six stores in the German capital Berlin and a location in Hamburg – so far, because Brammibal’s has plans to grow further.

By Helga Baumfalk

By Helga Baumfalk

+

“We are Europe's first purely vegan doughnut chain,” says Jessica Jeworutzki, who founded the company together with her business and life partner Bram von Monfort, whose nickname was pivotal in naming the busi ness. Since then, they have boasted growth rates of 20% annually and recorded a turnover of EUR 5.9 million for 2021.

It’s yeast donuts...

It is yeast donuts that Brammibal’s makes – not cake donuts – and they are delivered fresh (not frozen) two to three times a day to their six Berlin stores. “I hate it when they freeze them,” Jeworutzki points out. “A donut has to be fresh.” That, she says, is her understanding of a good product.

In the bakery in Berlin’s Neukölln district, which has just been expanded to 1,000 square meters, as many as 10,000 donuts are produced daily. During the holiday season, this number is even higher. In 2021, the record was 23,000 pieces on New Year’s Eve. Up to 15 people work in production, including two master bakers, a master confec tioner, seven bakers and confectioners, production assistants and drivers. Repetitive tasks are automated. The company just invested in a larger continuous deep fryer that can pro duce outputs of up to 2,900 ring donuts/hour, or about 3,400 filled donuts/hour. “We try to strike a balance

between craftsmanship and automation,” says the company director. “Where handwork has its value, it stays there –and that’s in decorating the donuts.”

The challenges

Instead of animal products, Brammibal’s relies on plantbased alternatives such as vegetable cream, oat milk, fruit purees instead of flavorings, vegetable binders, or margarine. Vegan donuts that lack the convenience of conventional ingredients pose production challenges. “Achieving a dough that was stable enough so the donuts would not collapse when cooked and would bake well was a problem we had to solve, as well as making sure they stayed fresh throughout the day.” The entrepreneurs have been tinkering with their recipes for a long time and continue to do so because, as they say, they are perfectionists. Finding suppliers who could provide the plant-based raw materials they needed in bulk was also difficult at first. They are now well positioned.

“Sustainability and charity are part of the concept. Many consumers today expect companies – especially vegan companies – to position themselves in this way.”

all pics by © Brammibal’s www.bakingbiscuit.com 06/2022 BAKERIES 06

Jessica Jeworutzki, Founder and Managing Director, Brammibal’s Donuts

“Let’s do it!”

It all started in 2014 with an idea for a friend’s birthday. Jessica Jeworutzki: “I’ve always been interested in baking and, since going vegan, I have tried a lot of different products. Since many of our friends are also vegan, I have always brought something for special occasions. On one occasion, it was donuts. It then dawned on us that there was no vegan donut concept in Europe at all. Handmade donuts are also in short supply, vegan or otherwise. ‘Let's do it,’ we thought, and started selling through farmers’ markets.

The founders consolidated their new business alongside their full-time jobs after work. Jeworutzki is a health and nursing professional. “But, I actually always wanted to be a pastry chef. I just could not imagine working with animal products. I have now finally arrived in the baking industry, with a few detours along the way.” Today, Brammibal’s rarely supplies farmers’ mar kets. The time commitment, Jeworutzki says, is too great. The focus has now shifted to their own shops.

Gut feeling decision

Some of the compa ny’s six standalone stores are in promi nent locations in Berlin, such as Potsdamer Platz, Prenzlauer Berg, Alexan derplatz and KaDeWe. Yet, as Jessica Jeworutzki says, Bram mibal’s doesn't have particularly high

standards for locations at all. “We make our decisions according to our gut feeling. At Potsdamer Platz, we took over a Starbucks location, which I personally think is pretty good. When a landlord takes on a vegan concept in such a central location, it also shows that 'vegan' is becoming more mainstream.” Other locations are in quieter neigh borhood locations. The company does not depend on walk-in customers, and has online ordering and a delivery service.

Putting aside prejudices

More women than men buy vegan donuts, observes the company manager; “But, I can’t otherwise identify a typical donut buyer.” The clientele is mixed, including construction workers, police officers, young people and families. Jeworutzki: “Some don't even know that our donuts are ve gan. We do not advertise it as a primary selling point. People should try them first and maybe notice afterwards 'oh, that’s vegan!'. At this point, they will have already had a positive experience, prejudice aside.”

Everything offered in their shops is vegan. The throughand-through vegan concept is not just related to the founders’ personal prefer ence; they see it as a mis sion. “We want to change the perception of plant-based food.” Jeworutzki adds, “Why use animal products when you can go purely plant-based?”

07 BAKERIES www.bakingbiscuit.com 06/2022

Brammibal’s Vegan Donuts

+ Founded: 2015

+ Founder and Managing Director: Bram van Montfort and Jessica Jeworutzki

+ Around 100 employees

+ Six stores in Berlin and one location in Hamburg

+ Online ordering with in-store pickup or Wolt delivery service

+ Catering and custom donuts

+ The assortment includes 14 different varieties. The range extends from the classic donut to unusual creations such as the Strawberry NY Cheesecake Donut or the Maple Coconut-Bacon Donut. There are also seasonal donuts that change monthly.

+ Prices: EUR 2,90 to 3,50 per donut

+ Website: www.brammibalsdonuts.com

Sustainability and charity

Sustainability is also part of the business model, from using green energy to the choice in packaging materials, and donating leftover donuts to local non-profit organizations. Every month, Bramibal’s also sells a different ‘charity donut’, through which it has raised more than EUR 250,000 to date. Is that attitude or marketing? “We don’t just do it because it looks good, it also represents our personal stance,” explains the boss. “Of course, it is also a positive marketing tactic,” she adds. “Many consumers today expect companies – espe cially vegan companies – to position themselves in this way.”

Next step: Hamburg

Brammibal’s has recently rolled out its concept in Hamburg. In the new Altona-Mitte district, the company has set up a 400-square-meter bakery and café. “It might not be the best space for walk-in customers,” Jessica Jeworutzki ex plains, “But that has not deterred us from selling our donuts elsewhere.” The plan is to add more retail locations in the future. Jeworutzki adds, “We want to master Hamburg first and gain experience on how to work in two cities at once. Then, we will see if further expansion is feasible.”

www.bakingbiscuit.com 06/2022 BAKERIES 08

+++

Rising to full potential

Ensuring the correct proofing conditions and timings is a key step in dough development. For heavy-duty processing with consistent results, various technologies of industrial proofers accommodate the needs of the dough and the plant itself.

+There are different technologies available for setting up automated industrial proofing, from rack, tray and step proofers, to continuous equipment – all of which provide control over the key process parameters: tem perature and relative humidity.

Rack proofers, for example, provide a compact solution suitable for limited floor space. AMF’s Vesta Automatic Rack Proofer is designed around the required specifica tions of the racks and shelves, with interlocked, hinged access doors on both sides for rack maneuvering. Its latest design improvements started with its structural materials, for a more sturdy construction. It uses heavy-duty aluminum racks, also with durability in mind, as well as (removable) stainless steel grids, which also stand in for center support. Its PLC-control proofing system helps provide the optimal combination of temperature and humidity over time. A cooling damper can be used to mitigate over-proofing and offer flexibility in timings for the next production steps.

Alternatively, spiral technology is at the heart of continuous processes, including proofing. The Vesta Spiral Proofer, also manufactured by AMF Bakery Systems, was designed for easy cleaning and maintenance operations. Sanitary design elements include a patented monopiece cage bar, which provides access for installation, cleaning and main tenance, the use of modular plastic belts incorporating the Intralox DirectDrive™ System, and its full wash-down con struction. Its enclosure is easily assembled, AMF says, and helps control airflow. The optional conditioning humidity

unit ensures uniform conditions for consistent proofing results as the dough pieces are traveling through the belt proofer. It incorporates the AMFConnect suite, for automated data tracking and management.

When proofing is done directly on the belt, the peel-off synthetic belt conveyor gently transfers proofed products between the spiral and conveyor and a scraper removes any remaining dough before new pieces come in. When products are going into the spiral proofer in pans, guides position them correctly, and inserts on the belt ensure any type of pan securely stays in place until it is ready to be discharged.

Optional features can further simplify working with the Vesta: an internal drum access platform can be added for main tenance, in addition to the conditioning unit. Remote VPN access can be incorporated for machine troubleshooting and data monitoring.

www.bakingbiscuit.com 06/2022 PRODUCTION 10

© AMF Bakery Systems

© AMF Bakery Systems

Weighing all options

To select the best technology from the available options, several factors should be considered, AMF lists, from the required capacity, product variety, the desired level of automation. “These are factors with a great deal of variety,” the specialist points out, which is why the optimum solution is always a tailor-made one. Costs are also a determining aspect, especially for medium-sized production lines, so the initial budget and the ROI are taken into consideration in the design. “AMF’s proofing system is very flexible and modular, so we can adapt to any bakery situation and challenge. These can range from entry-level production bakeries that are entering the automation arena for the first steps in scaling up their process, to large-scale opera tions with long continuous runs, where stability, quality control and throughput are key performance indicators,” the company says. In all of these cases and their respective proofing technologies, the environment inside the enclosure is maintained at constant temperature and humidity until a change is made, so every product within the proofer is exposed to uniform process conditions.

Certain features were built into AMF’s proofers to facilitate their operation: automatic washers are used for sanitation within the proofers, and dual conditioning systems are also available as a backup, in case one system is not working or is in service mode.

For best results

Since only one set point of temperature and humidity can be maintained for uniform proofing, recipe control and preparation are key to identifying the optimal proofing conditions. If different types of dough can be proofed with the same parameter settings, they can be proofed together seamlessly. Alternatively, If products require significantly different proofing conditions, then the settings need to be adjusted for the new product’s profile before the next batch enters the proofer, AMF recommends. AMF’s proofers provide product tracking so the operator always knows which products are in each stage of proofing.

To adjust the capacity of the proofers, AMF suggests changing the dwell times. Process optimization, on the other hand, requires balancing several process parameters, including a consistent climate and the speed of the belt –for belt-proofers. AMF explains the process behind optimizing proofing efficiency: “Compressed air and filtered cold water are mixed and atomized to produce fine cool droplets that travel through the heating coils to reheat the air and filter any droplets that have not turned to humidity.” Calcu lation models at AMF also include pan sizes, their travel direction, the number of pans per minute, required times, pan and weight, and the weight of the belt itself. The result of the equation must be identical dough development throughout the proofing system. +++

11 PRODUCTION

© AMF Bakery Systems

The lightbulb moment

Middleby Corporation partnered with Vyv to provide baking equipment that comes equipped with antimicrobial LED technology, a continuous hygiene solution based on UV-free, visible light that safely offers protection against bacteria, viruses, mold, fungi, yeasts and other microorganisms.

+Middleby announced the investment and license agreement with Vyv in 2021, with the goal of creating cleaner food processing environments by combining their technologies. Vyv started with the goal of making health care environments cleaner, but has broadened its portfolio of antimicrobial lighting solutions that lower microbial counts on surfaces in a wide range of commercial and industrial environments and applications. These are LED-based lights and do not contain bulbs or other consumable parts and are warranted for five years. The technology brings notable added benefits, too: it is energy-efficient and environmen tally sustainable as it continuously works to prevent microbial growth indoors. In addition to cleaner surfaces, Vyv's clients have reported significant reductions in air contamination. All of these are highly sought-after in bakery production facilities, where they can now be incorporated into Middleby equipment.

Antimicrobial lighting works so efficiently and precisely because it never stops, unlike traditional disinfection methods, which allow germs to reenter the space as soon as the cleaning has finished. Vyv’s technology works non-stop and in between routine cleaning times and addresses all challenges commonly associated with food production environments, from mold, to listeria, salmonella and other food-borne organisms, while preventing the formation of biofilms. Several bakeries are convinced by the technology and are now already running it, both in the overhead light ing of production facilities and in areas prone to microbial development such as proofing and conveying. They were able to validate the microbial reductions they achieved, with measurable results. Potential uses that can benefit baking production facilities do not stop here; the company

is exploring implementation into automated guided vehicles, which are increasingly present in industrial baking.

Scott McCally, Auto-Bake Serpentine President, underlines the value of this solution: “The key message is in the imme diate impact this solution will have, starting with uptime. If you lower the time spent sanitizing, you gain production time, which is especially valuable in bakery. Mold is inherent to what we do; if we can reduce mold, we can extend shelf life, which is another immediate benefit. And, with cleaning better managed, less water is needed, which brings down operating costs while production rates goes up.”

Each light, regardless of the mechanical housing specifica tion, is designed to deliver the needed dosage for the space. Kristin May, Vyv’s Chief Commercial Operations Officer, states the company will support individual installation needs: “Vyv’s antimicrobial lights look, feel and act just like a standard light. Vyv’s specialists will work with the client’s facilities team to review existing lighting and requirements to recommend the type of replacement light.” This antimi crobial lighting includes a vast range of specifications, starting with general-use luminaires to specification grade IP69 (the highest Ingress Protection tier), and NSF-rated luminaires (suitable for use in food-preparation facilities). These lights include both modes of operation, Antimicrobial+ Light and Enhanced Antimicrobial, the company explains: + Antimicrobial+Light mode delivers high-quality white light for illumination and antimicrobial action at the same time. As this type of light can be used around the clock, it can entirely replace conventional overhead lighting. While working continuously against germs, it can be installed in any type of facility, from production spaces to

www.bakingbiscuit.com 06/2022 HYGIENE 12

Benefits of using antimicrobial lighting in bakery production areas

Sustainability

+ It is a non-chemical solution that cleans continuously, which means that the use of harsh chemicals in the facility can be reduced or entirely eliminated.

+ Antimicrobial light works constantly against the microbes in a space, so less aggressive mitigation is needed overall.

+ It contributes to improving yields, reducing waste and to the shelf-life of products.

+ Vyv’s technology contains no damaging UV light, so it can be used around people and it will not degrade equipment and machinery.

Productivity

+ The improved hygiene helps with labor challenges inherent in spaces that are required to be continuously clean.

+ Vyv’s patented antimicrobial light technology works continuously in the background, to clean surfaces and supplement existing sanitation procedures.

+ Regular cleaning can be done faster and is easier.

Protection

+ This antimicrobial solution helps prevent product recalls and the consequent damage to the brand image.

+ Organizations using this technology can promote their commitment to health and wellness.

+ Vyv meets international standards for unrestricted and continuous use around people.

commercial areas and offices. No specialist technicians are required to install the overhead lighting systems and fixtures.

+ Enhanced Antimicrobial mode delivers a violet hue with an even higher dosage of antimicrobial light, used when illumination is not needed. For example, in between shifts, this mode can be switched on for even faster germ-killing action with a visible violet hue (non-UV). It was developed specifically to address hard-to-reach spaces, such as under equipment or within conveyor belts. Vyv’s Antimi crobial Light Bar can be designed onto new equipment or installed on existing machines. A working AutoBake oven featuring this deep-cleaning, violet light made its debut at IBIE this year, where it received top honors in the sanitation category.

Tried and tested technology

The company explains how this technology is designed for continuous and unrestricted use around people: “Vyv’s antimicrobial technology harnesses specific wavelengths of visible light that target molecules exclusively found within microbes and problematic spoilage organisms. This ultimately creates an inhospitable environment for viruses, bacteria, mold, yeast, and fungi. Vyv lights have been tested to IEC photobiological safety standards, and fall into the exempt category, which states that there are no exposure limits and can be used unrestrictedly and continuously around people.” In environments such as a bakery or food produc tion facility, Vyv recommends 24x7 usage for optimal results.

Vyv’s technology has been tested by several independent research and commercial organizations to prove its effec tiveness in killing viruses, bacteria and mold. “Our antimicro bial technology has been proven to eliminate 90-99.99% of

the surface contamination that occurs within spaces such as a production floor or within/around equipment, without harming the people occupying the space, or the equipment,” Vyv says. The results are dosage-dependent, where dosage comprises an irradiance (power of light hitting the surface) and a time element. The higher the irradiance and the longer the exposure time, the higher percent kill achieved.

Vyv’s clinical efficacy claims are based on ASTM testing. For example, “Laboratory-controlled testing on SARS-CoV-2 (enveloped virus) showed a 98.45% reduction in four hours on hard surfaces. Testing on a non-enveloped virus (MS2 bacteriophage) showed a 97.12% reduction in controlled laboratory testing on hard surfaces in eight hours. Testing on MRSA and E. coli showed 90%+ reduction in controlled laboratory testing on hard surfaces in 24 hours,” Vyv tells us.

Bluezone

Middleby also provides Bluezone, a patented technology for indoor air purification, which it provides via an exclusive licensing agreement with an investment in Bluezone Products Inc. This no-filter air purification system destroys 99.9995% of viruses and other indoor contaminants such as bacteria, mold and gases that impact indoor air quality. This means airborne pathogens such as the flu, colds and COVID-19 are eliminated with UV-C germicidal lamps. “Ultraviolet lamps have a long history of sanitizing surfaces in labora tories and food-processing industries and also for disinfecting water supplies. Since the UV-C lamps are locked inside the Bluezone chamber, it is safe to operate 24/7 in occupied spaces to keep your guests and employees safe,” Middleby explains. The Bluezone system works by pulling air into a chamber, where it is scrubbed with an ultraviolet germicidal

13 HYGIENE www.bakingbiscuit.com 06/2022

© Middleby

light process that destroys a virus’ RNA. This eliminates its ability to replicate.

Bluzone’s UV-C bulbs kill up to 99.9995% of viruses in the air, including colds, flu and COVID, model sizes treating from 4,000 ft3 (113 m3) up to 15,000 ft3 (425 m3) per chamber with 30-150 CFM flow rate (cubic feet per minute) circulating the air quickly and continuously killing airborne viruses in dining and working spaces. Furthermore, oxidation catalysts destroy volatile organic compounds (VOCs) and unpleasant odors, adds Middleby. How does it do all this? “The Bluezone by Middleby Viral Kill models utilize enhanced UV irradiation around 254nm, optimized for destroying viruses in occupied spaces,” the company explains. The UV radiation over time, coupled with the flow rate through Bluezone’s reaction chamber, results in a log five kill rate for the MS2 (SARSCoV-2 Surrogate) virus, Middleby points out. The Viral Kill unit also features a room-temperature oxidation catalyst to convert VOCs into CO 2 and H 2O.

After the initial investment in this unit, the only requirement is to change the bulbs roughly once a year, Middleby points out. “No more switching out filters every few weeks. Plus, the unit lets you know when a new bulb is needed, eliminating the guesswork.” Bluzone is also safe to use in spaces with people coming within its reach, as it received clearance as a Class II medical device from the Food and Drug Administration (FDA) based on clinical data that demonstrated efficacy, safety and reliability.

Bluezone comes in model three sizes, with three mounting options: drop-in ceiling, enclosed floor cabinet, and wall shelf mount.

+ Model 300 is a hybrid model for killing viruses in small spaces or keeping refrigeration environments free of

damaging contaminants to extend product shelf life and eliminate flavor transfer. This model uses UV-C bulbs to inactivate airborne viruses and disinfect the air. Up to 4,000 ft3 (113 m 3) can be treated, at a 30 CFM flow rate. It utilizes a combination of self-contained ultraviolet light and room-temperature oxidation to destroy viruses and VOCs.

+ Model 450 is an air purifier, which also uses UV-C bulbs. It can treat up to 9,000 ft3 (255 m 3), with a 150 CFM flow rate circulating the air continuously. Oxidation catalysts destroy VOCs, odors and airborne viruses (including COVID), which makes it beneficial for dining in and working spaces.

+ Model 2400 is designed to keep refrigeration environ ments contamination-free. For this equipment, UV-en hanced oxidation is used to destroy contaminants such as ethylene, mold, bacteria and odors. It eliminates 99.9% of mold and bacteria, as well as ethylene gas in walk-in refrigerators to extend shelf life and reduce waste, Middleby explains. Ozone-generating UV bulbs use a combination of high levels of ozone and UV to oxidize and irradiate airborne contaminants. Up to 15,000 ft3 (430 m 3) can be treated, at a 30 CFM flow rate.

The collaboration

James K. Pool III, Middleby Chief Technology and Operations Officer, shared insights into the collaboration between the companies to provide this solution together: “Partnering with Vyv ensures we will offer the most advanced products in the market to promote the health and wellness of our operators and their customers. [We] are well positioned to deliver cleaner food preparation environments, with an extensive assortment of overhead antimicrobial lighting fixtures for processing plants, commercial kitchens and any foodservice facility.” +++

www.bakingbiscuit.com 06/2022 HYGIENE 14

Vyv Enhanced AntimicrobialTM Maximum enhanced antimicrobial impact

Vyv Enhanced Antimicrobial+LightTM The same protection + high quality light © Middleby

THAT’S HOME COMPOSTABLE.

THE ONLY BAG CLOSURE

PART II

Trays with a mission: cakes

One product, infinite possibilities: cakes come in all shapes and sizes, with unique concepts to mark memorable events or casual experiences. To create the cake that will stand out, the tray is the limit.

+Having a clear idea of the cake ranges on the to-bake list, there are several considerations to help determine the choice of cake pans. American Pan uses its proprietary ePAN aluminized steel together with aluminum to combine the benefits of both materials: it is up to 2.5 times stronger than standard material while weighing less. To optimize their structure design, ePAN cake pans are manufactured with aluminum cups and aluminized steel frames, as alumi num heats and cools faster than aluminized steel, but is not as strong and resistant to damage. However, the ePAN ma terial does also heat and cool faster than standard alu minized steel due to the fact that it has less mass. This characteristic of ePANs, and a very timely one at that, contributes to energy savings at bakeries. Some American Pan customers that use ePANs have reported decreasing baking times up to 45 seconds and decreasing oven temperature by up to 21°C. In one case, a bakery saw nearly 8% energy savings from one year to the next using ePANs.

Depanning methods also factor in choosing a new pan, as they may require different construction features depending on the type of depanning used (the best depanning method for various cakes can include anything from gentle depanning to needle depanning and slam depanning). “Depending on the stress that is put on the pans during this process,

“One customer using an ePAN design saved nearly 8% on energy from one year to the next.”

Jason Bowman, President – American Pan Europe & MENA

they might require additional strengthening features such as the type of panel used for the cups. They can be built with a standard panel, or a ‘channel frame’, for added strength,” Jason Bowman, President – American Pan Europe & MENA, explains.

www.bakingbiscuit.com 06/2022 TRAYS, PANS, MOLDS 16

© American Pan

© American Pan

The shape of the product will, of course, dictate that of the pans. For example, products such as large muffins, which need deeper cups during processing, benefit from having these cups brought together and attached to a frame, for process efficiency. American Pan has addressed the issue of metal fragments breaking loose from these frames when welded and is using a seaming method to put them together instead of welding, which results in a stronger bond and eliminates this concern. In addition, American Pan also developed methods to place the cups closer together and increase the number of molds per pan, for higher production volumes. To strengthen the structure of these pans, cross supports can be built into them, which will also protect the cups against impact damage.

Product consistency is always a priority, especially for indus trial operations. To ensure consistent results, the American specialist uses a shielding for the inner molds on pans, which supports similar product browning. This shows its role particularly well when used in the production of blonde or light cakes: “Using metal strips to shield cups in the center of the pan will prevent them from browning faster than the products in the cups on the outside of the pan, which are shielded by the outer rim of the pan,” Bowman explains.

Coating and cleaning considerations go hand in hand with cake production, too. American Pan recommends the DuraShield coating for its crumb-release properties. A silicone glaze requires using release agents, if selected as a coating solution. As many cake pans are washed after every pro duction cycle, American Pan provides design and material options to minimize the risk of corrosion. The design of the pans also includes holes in the top panel to allow water to drain properly.

Special cakes go in special trays

The creativity put into making cakes puts forth a wide variety of (delicious) products. The same goes for the pans in which they are made: they have to suit the product and the production line in every aspect: “The shape, design and size have to lead to the best baking results, and the coating has to create enough no-sticking effect so that the cake is easily depanned, with no damage to its integrity,” Guido Kempf, CEO, Kempf, explains. The German company develops a custom solution for nearly every project, including designing unique shapes, such as those required by the famous Austrian Gugelhup cake or special designs for tartlets, for example.

The company takes into consideration the usual suspects in threatening the lifespan of trays used for cakes: unsuitable cleaning with aggressive chemicals or overheating the pans and/or the coating, and designs them with high-qual ity materials, to extend their lifetime. Ingredients can pose challenges to the integrity of the pans, too: “The most

Guido Kempf, CEO, KEMPF

challenging ingredients/toppings are egg wash and dough with high sugar content. If the sugar content goes up to 15% or even higher, it becomes difficult to find a coating solu tion to provide a sufficient non-stick effect. Of course, we have several options available for such cases, in our high-quality coating portfolio of KG-Flon coatings,” Kempf explains. They were developed to provide an excellent nonstick effect and to be resistant against routinely occurring abrasion. Alternatively, when the sugar ratio is even higher, only a combination of high-grade non-stick coating dou bled with greasing is successful, according to Kempf.

When using these trays to bake cakes, vacuum depanning should be considered as a method that will protect both the cake and the pan coatings, Kempf recommends. Using this process where applicable will improve the lifespan of the non-stick coating.

For cake trays of any shape and size, the right cleaning processes are key to a balance between optimum hygiene and ensuring the pans’ protection. Ease of cleaning is included in the design of the pan, Kempf highlights: “The right design will eliminate any gaps that are very difficult to clean.” To optimize cleaning, the company always recom mends using a continuous inline cleaning solution, because only hot water is used in most cases (no detergents).

The ongoing question remains: what original and unex pected creation will be popular with the consumer? Solutions to support production are therefore available – or can be perfected. +++

“The shape, design and size have to lead to the best baking results, and the coating has to create enough no-sticking effect so that the cake is easily depanned, with no damage to its integrity.”

©KEMPF 17 TRAYS, PANS, MOLDS www.bakingbiscuit.com 06/2022

Reading Bakery Systems introduces new rotating die

Reading Bakery Systems (RBS) designed a new 18-nozzle rotating die for increased throughput capacity. Depending on the size of the finished snack product, it increases throughput capacity by up to 33% on the same size production line when compared to the 12-nozzle die that has been available to the industry for 40 years, RBS details.

The rotating nozzle die creates wound shapes spirally while continuously extruding a rope of dough, which is then cut into twisted pretzel and stick products. The number of rotations made and the speed of the extrusion can be controlled independently – to increase the range of product that can be made in terms of shapes and textures.

The new design has incorporated gear-driven nozzles constructed of stainless steel with internal nozzle inserts made of FDA-approved sanitary plastics. These new components utilize a food-grade semi-solid lubricant, instead of gear oil. The rotating nozzle die mounts directly onto all standard RBS low-pressure extruders, expanding these systems’ flexibility. +++

Groundbreaking ceremony for new KEMPF plant

KEMPF held the groundbreaking ceremony to announce the official start of the construction of its new plant. Spanning around 21,000 sqm, the facility will house an upgraded production area, logistics and administration offices. The expansion will also include new staff member hires, with the total number of employees estimated to reach 200. There are plans for the production area to be set up with highly-automated, new technologies. The project is designed to source its electricity from a 2,100 kWp photovoltaic system that will be installed.The plant is scheduled to be ready by the end of 2023, and the relocation to be complete in the first quarter of 2024.

Guido Kempf, the company’s CEO, commented on the start of the expansion project: “The construction of our new plant is an important milestone in our company’s history. The step is well-considered. In the current political and eco nomic situation, the plans have certainly been called into question once again. But, in the family, we agreed to stay true to the motto ‘Standing still is a step back’ and we would like to take the courageous step.” +++

DSM highlights new solutions at FiE 2022

Royal DSM introduces its latest developments at this year’s Food ingredients Europe (FiE), held December 6-8, 2022, in Paris. Among the new launches, DSM showcases Panamore® Xtense, a label-friendly lipase and a more sustainable alternative to the common emulsifier, DATEM. The new solution helps bread producers maintain dough stability and improve volume and shape in more challenging appli cations like wholewheat, frozen dough and while using flours or varying quality, DSM explains. A breakfast cookie is among the highlights, formulated to aid digestion while providing an energy boost and containing reduced acryla mide levels, DSM says. New additions to its plant-based portfolio are also presented in Paris. +++

MECATHERM launches patisserie know-how sharing series

Loïc Le Denmat, a patisserie expert at MECATHERM, is preparing a series of knowledge-sharing videos, called ‘Ask Loïc’. Each episode will be focusing on a unique product, including muffins to madeleines. The first video will become available soon, MECATHERM said. “He will share his passion, knowledge, and expertise with you. Through each unique episode, you will discover the secrets of baking pâtisseries on an industrial scale and the keys to achieving product quality and industrial performance,” the company detailed. +++

www.bakingbiscuit.com 06/2022 NEWS 18

© KEMPF © Mecatherm

©ReadingBakerySystems

When Intralox invented the original low-tension spiral conveyor solution in 2012, it raised the bar for spiral technology beyond the reach of other belting manufacturers.

1000+ INSTALLATIONS WORLDWIDE DIRECTDRIVE™ SYSTEM Scan QR code to see it in action. The One and Only DirectDrive System delivers: Improved production Reduced maintenance Simplified sanitation

Next in line

Low moisture, long shelf-life, diverse sizes and shapes – crackers and cookies are a segment filled with opportunity. Their characteristics also dictate process improvements and how equipment can support optimization.

+Every step of the manufacturing process contributes to perfecting production. For crackers, techniques can range from working with straight, dual-sheeted or laminated dough. Baking is then key to finding the perfect balance between reaching adequate moisture content, the right color and a stable product that will reach the consumer intact. The automated cracker line developed by Reading Bakery Systems (RBS) can process fermented and unfer mented cracker dough, biscuit dough and other products. The company recently completed a redesign of their sheeting system, focusing on a modular design, so it can be built starting from a base machine model, onto which functional upgrades can be implemented, according to specific plant operational needs. In this way, the system can receive add-on features and upgrades after installation, to adapt to pro duction changes.

The redesigned sheeting line incorporates several new features aimed at making it easier to operate and more flexible. Among the notable new developments, RBS highlights ‘high-visibility’ guarding that helps get a clear view of the process areas, endless belt replacements for conveyors, and removable roll scrapers, for sanitation and maintenance operations. The remote input/output system has also been improved to simplify the electrical require ments of on-site installations, while also lowering the amount of wiring required to connect individual machines to the main control panel.

Endless belts help minimize downtime, as replacing them is performed in a matter of minutes, while also simplifying the machine. “This design also includes an easier way to release scraper blades to simplify cleaning procedures,” RBS points out.

The unique characteristics also include roll skewing, which is available on the final gauge roll. This was added for increased control of the dough sheet toward the edges,

without the need for product-specific roll tapering, the company details. The new system also includes RBSConnect, the company’s latest custom control systems. Energy effi ciency is also continuously monitored, from motor loads to electrical system loads. The system provides graphical trends and sends notifications about potential/upcoming maintenance tasks.

For further process optimization, load cells can be utilized on the gauging and rotary cutting processes to monitor machine loading levels. “Machine loads can vary depending on the consistency of the dough being processed, but any irregular forces measured will alert operators. Those flagged values will display on a trend screen to pinpoint undesirable pro cess deviations or incorrect manual adjustments,” explains the line’s manufacturer. Product trends are also available, to generate notifications of changes such as dough quality and gaps in production.

“The new features allow an even greater variety of doughs to be processed, such as glu ten-free or products with more

www.bakingbiscuit.com 06/2022 COOKIES, CRACKERS 20

Reading Bakery Systems

Systems

©

© Reading Bakery

‘exotic’ ingredients that were previously very difficult to produce. These rotary-type forming systems are somewhat limitless in their outputs, so the only limits in production speeds are set by the oven size,” explains RBS.

Focus on hygiene

At the same time, the upgraded line addresses heightened market concerns over hygiene optimization throughout production plants. To this end, quick-access panels were added, for easier sanitation and maintenance. Moreover, including unobstructed views into the new design of the machine allows operators to better visually inspect, assess and plan downtime for line sanitation or maintenance.

Reading Bakery Systems specialists

This new sheeting line was also designed to prioritize hygiene by including fewer components, to minimize the parts that need to be removed to clean and maintain. In this way, both the cost and the workload required to clean the machine are reduced. “Designing more toolless access and decreasing the total width of the line for better access were important goals that were set for our design team to improve the user experience,” RBS details.

The blueprint

The cracker line from RBS comprises all process steps, from mixing, dough handling and forming to baking and drying, as well as additional steps that may be required. Continuous mixing is the preferred technology for this line, covered by the Exact EX Continuous Mixer, an auto mated system that can work with doughs with various hydration levels, with production rates ranging from 100 to 10,000 kg per hour.

Next, the Thomas L. Green 3-Roll Sheeter or 4-Roll Sheeter generates a consistent dough, which is instrumental to packaging efficiency, after baking the crackers. The thick ness of the dough is controlled by adjusting the distance between the rolls. The sheeter can range from 600 mm to 1.6 m in width, with production volumes starting from 200 to 5,500 kg/hr. The dimensions are determined by the oven’s length and width as well as by the characteristics of the product. The resulting dough sheets are ready for lamination if required. The laminator ensures product consistency by accurately placing each sheet so that the sheet has the same dough density throughout its surface.

www.bakingbiscuit.com 06/2022 ADVERTISEMENT Kempf GmbH | Carl-Benz-Straße 3 | 85296 Rohrbach ++49 8442/9669-0 | www.kempfgmbh.de bakeware and coating

“These new features allow an even greater variety of doughs to be processed, such as gluten-free or products with more ‘exotic’ ingredients that were previously very difficult to produce.”

line, in charge of baking and delivering consistent product characteristics. Cracker oven zones available include direct gas fired and convection. For maximum efficiency, hybrid and electric ovens are available. Each of the zones can be controlled to precisely combine heating modes for specific baking effects and timings. Optionally, fans, topping units, or thickness sensors can also be added, depending on the product and process requirements.

materials. Less viscous materials such as jelly fillings can be pumped into the wirecut head with an optional external pump.

To ensure safety, the WCX machine uses a light curtain system that surrounds the machine. When the curtain is ‘broken’, the machine immediately shuts down. In addition to enhanced safety, the light guard system maximizes access to machine components for easier maintenance or wash-down.

Process consistency

The WCX can produce throughput yields of up to 300 cuts per minute (cpm). It cuts individual shapes uniformly using a removable wirecut harp assembly. “Combined with recipedriven linear servo motors, it can be programmed with a virtually unlimited number of cutting profiles,” RBS says. The profiles include cutting position, stroke length and cutting speed, which can be adjusted without having to stop the machine. Custom-designed die and wirecut assemblies are created for specific product characteristics.

Wirecut cookie technology

For wirecut cookies, the Thomas L. Green WCX wirecut machine from RBS also includes newly-developed upgrades, focusing on flexibility, control, safety and sanitation. The R&D team looked at challenges traditionally met with this type of technology, from difficulties in handling different dough viscosities and compositions to difficult changeovers, complex maintenance and cleaning operations.

RBS’ solutions for these issues are bundled in the WCX Wirecut Machine that was introduced at IBIE 2022. Its product range was expanded to include standard and filled bars, multi-color products, filled and encapsulated cookies, pet treats and frozen dough applications. The system’s modular design supports this, as well as a wide range of optional equipment that can be integrated. This flexible setup allows multiple configurations, according to the desired product ranges. The WCX Wirecut Machine was also designed with fewer parts – it has 50% fewer moving parts than standard wirecut machines, RBS says, which simplifies maintenance. The head is removed from the side of the machine and manually rolled onto a sanitation cart, for cleaning, without the need for a crane.

The WCX offers several ways to co-extrude cookies and bars. With optional attachments, two doughs can be combined

An optional ultrasonic cutting attachment can be used for materials that are more difficult to cut or separate. Applica tions that commonly cause wires to break, sticky products, or those that contain raisins, oats, nuts and jams are best cut using an ultrasonic cutting blade, RBS recommends. On the WCX, ultrasonic units are mounted below the die cups, replacing the wireframe assembly.

For additional product flexibility, an internal pump and iris cutter are also available. The internal pump ensures consistent flow, while the iris cutting system separates and encapsulates the cookie. The iris cutter is recommended for use on premium cookies as well as cutting or crimping filled cookies. With a maximum rate of 40 cpm, this integrated cutting system is mounted beyond the wirecut machine on the transfer conveyor frame. With these upgrades, the door is open to future developments: “For manufacturers who operate with traditional wirecut technology, the material difference between soft biscuits, cookies, ingredient-dense snack bars and gooey filled products has always meant changeovers, undesired downtime and slowed production. Today, the technology present in the WCX Wirecut Machine has the potential to create a whole new kind of changeover — a one-time switch to the ideal dough-forming platform,” the company anticipates. +++

www.bakingbiscuit.com 06/2022

© Reading Bakery Systems

© Reading

Bakery Systems

ASSEMBLY SOLLCOCAP ® www.sollich.com UNIQUE FOR YOUR NEEDS

PERFECT

CONVEYOR BELTS

When the stakes are high

With the ‘Siegling Fullsan’ product range, Forbo Movement Systems has launched new homogeneous conveyor and processing belts made of TPU (thermoplastic polyurethane) particularly for hygiene-sensitive applications.

+ Everyone in charge of the processes in food produc tion is directly interested in avoiding any hygiene risks. Product contamination, whether with bacteria, foreign bodies, or other impurities, could ultimately have incalculable consequences.

Hygiene for conveyor belts

According to Forbo Movement Systems, homogeneous belts have become indispensable primarily because they withstand all thermal and mechanical challenges, and are also easy to clean and resistant to the chemicals used in cleaning. In addition, homogeneous belts are completely sealed, the company says, and therefore allow no access for contamination with oil, grease, moisture and bacteria. Moreover, they are also UVC-resistant, making them suitable for regular sterilization with UVC irradiation.

The newly introduced Siegling Fullsan products are the reinforced ‘Pro’ version (FLT+) of the ‘Flat’ series, with embedded aramid cords running lengthways. The cords increase the tensile force and minimize belt elongation, which makes these belts particularly suitable for longer conveying distances and larger loads. They are designed for use in the baking industry, dough processing and snack production, among others, and comply with the current FDA and EU regulations.

The new additions bring the company’s portfolio to four variants:

+ A FLT+ with a matt surface for accumulation operations or the transport of dry and packaged products,

+ A version with a smooth, glossy surface with good cleanability for applications with moist products, and

+ Two versions with a negative pyramid structure (NP structure) on either the top or the bottom side of the belt. The NP structure on the top (on the carrying side) improves the release properties. This is particularly interesting for conveying fatty or sticky types of dough and can reduce the need for flour as a release agent, according to the manufacturer. The NP structure at the bottom (on the running side) reduces the friction value of the belt to the table. This saves energy and the belt hand handles ad ditional loads.

If frequent cleaning cycles are necessary for a process, Forbo recommends the reinforced FLT series as it brings additional benefits for the user due to the hydrolysis

resistance of the belts and the resulting increased service life. Another advantage is said to be the high k1% value with low elongation at fitting. The high k1% value enables a significantly higher loading of the belt compared to commonly-used, non-reinforced versions and guarantees high dimensional stability. +++

www.bakingbiscuit.com 06/2022 HYGIENE 24

The negative pyramid structure on the support side facilitates the detachment of products or doughs

Wafer biscuits conveyed to the packaging station

© Forbo Movement Systems

© Forbo Movement Systems

Proven Quality & Durability to keep your bakery moving forward

Invest in bakeware that has proven its value in bakeries around the world for over 40 years. Achieve maximum product quality and consistency while minimizing your cost per bake by partnering with us to select the right design, coating, and pan refurbishment schedule for your tins and trays.

STOCK & CUSTOM BAKEWARE

Select from our stock bakeware or create a custom pan designed for your bakery’s exact needs and specifications to maximize throughput and increase efficiency.

PAN COATINGS

Work with our experienced team to select the optimal silicone or long-life coating to reduce the use of oil and provide clean release from your bakeware.

BAKEWARE REFURBISHMENT

Jesper Albertsen | EUROPEAN SALES DIRECTOR

WE ARE HERE MANUFACTURING & SERVICE LOCATIONS: ROMANIA | SPAIN | SWEDEN | UK

Maximize pan life and product consistency with a refurbishment program personalized for your bakery’s product, pan usage, and production requirements.

Tel: +45 23 68 51 85 | jalbertsen@americanpan.com

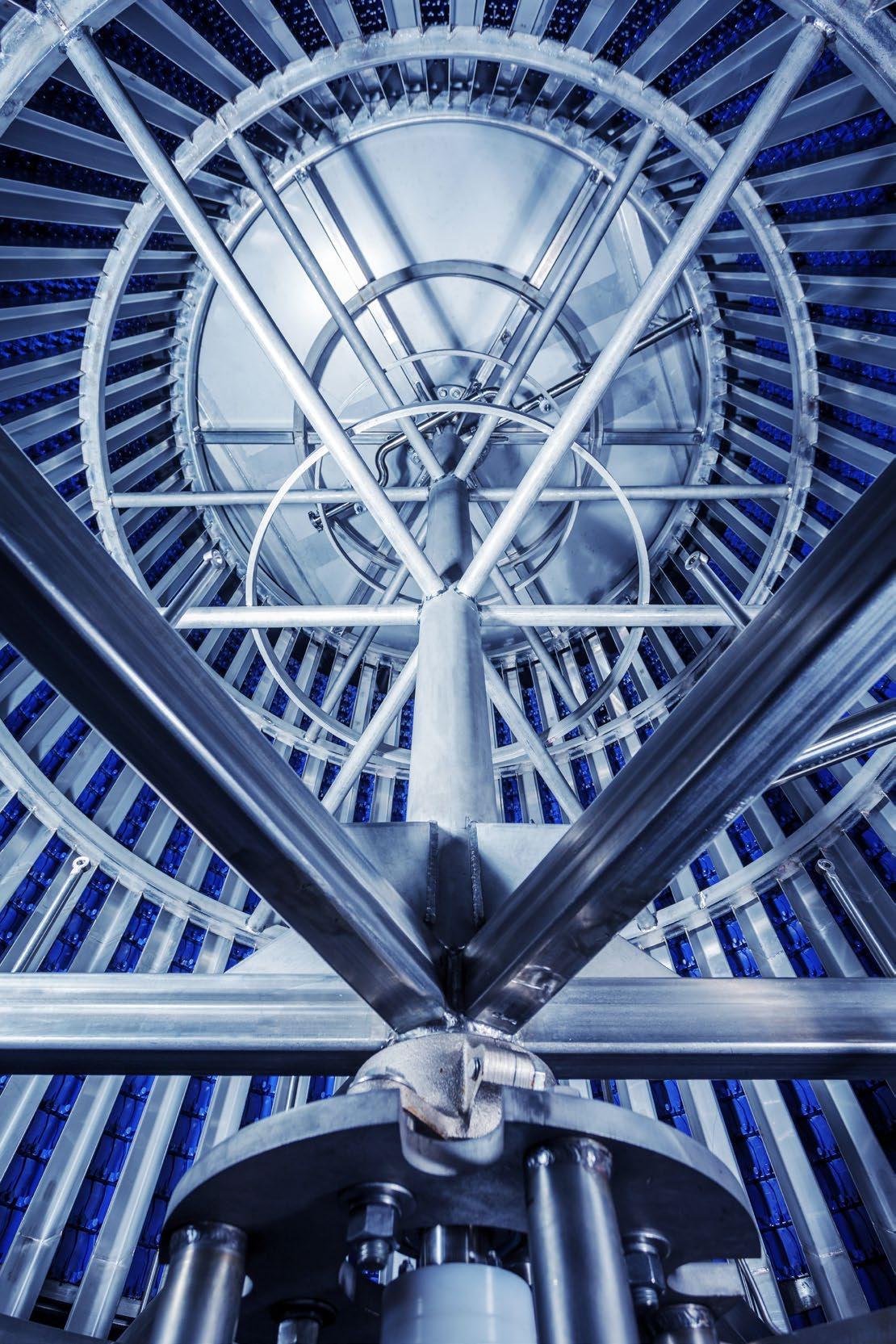

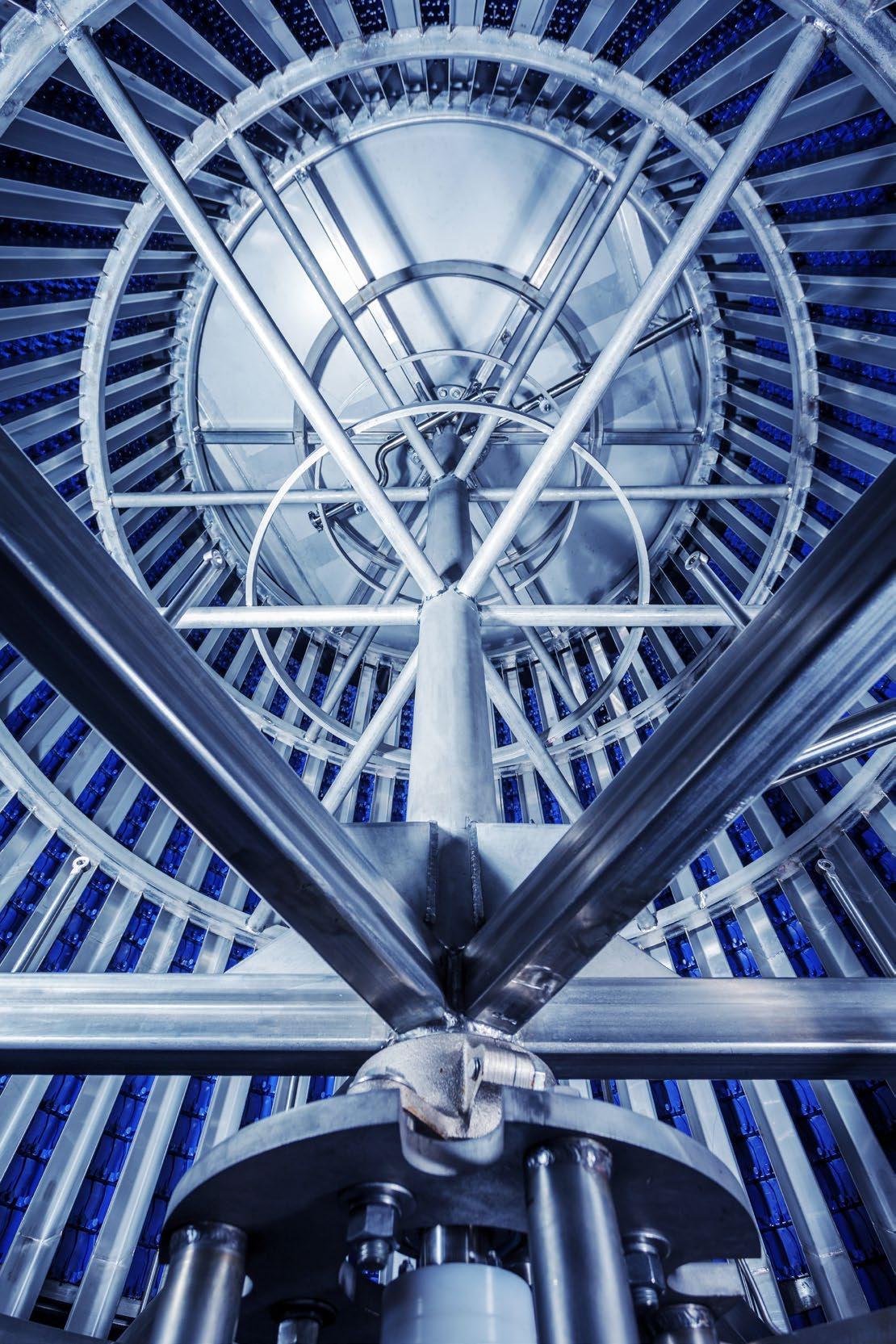

The VACTORR vector

A game-changer in the baking process. Vacuum cooling and baking is recognized for its benefits, not just in processing speed, but also in stable results for delicate products. Vacuum cooling specialist Verhoeven Bakery Equipment Family recently developed three new systems to handle the process.

+The principle behind the effectiveness of vacuum cooling and baking is the combination of the final part of baking with the cooling stage in the overall process. This process step is significantly shortened by changing the conditions in the environment: baking-off and cooling are done in just a few minutes instead of hours. To achieve this, the necessary environmental conditions are created in a separate chamber where the products have been moved from the oven, after 60-70% of the total baking time (the exact timing is determined according to each type of product). By lowering the pressure in this chamber with a pump, the boiling point is brought down to just a fraction of the normal boiling point, as low as 7°C, resembling an outer-space-like environment. “By changing the pressure in the chamber, we can manipulate the temperature and the moisturization of the products,” explained Rogier Vos, Commercial Product Group Manager, Vacuum Cooling & Baking Solutions, Verhoeven Bakery Equipment Family, at the launching event where the VACTORR was introduced. Very fine steam is immediately created in the product which also contributes to rapid cooling.

The R&D process and the result

By comparison, conventional cooling and baking processes have a boiling point of 100°C at sea level, wherein the

sub-optimal temperature for the gelatinization process, while the same process under a vacuum creates a higher starch gelatinization grade,” René van Ass, Business Development, points out. “For over eight years, the Verhoeven Bakery Equipment Family has studied in-depth various process es and recipes to create the ideal circumstances and the technology to precisely master the processes of baking-off and cooling, in order to manage the moisture distribution and structure of the final product,” he shares. To perfect the technology, the company appointed a specialized Vac uum Cooling and Baking Team, consisting of bakery and technical specialists who joined forces with specialized technologists such as Swiss Patrick Duss (a name synonymous with vacuum cooling). The specialist addresses the safety of this technology: “A vacuum is created and, while this takes place, enormous pressure variations are created in the machines. Safety first is our standard. This is why we were happy to learn and to develop our solutions meas ured to the standards and production testing software that NASA is using.”

The result was the VACTORR range, a pandemic-time launch, which was held virtually, with a Dutch Deputy Member of the Provincial Government unveiling the first machine remotely. The equipment made its in-person debut at IBIE in Las Vegas. “In the meantime, the solutions have been installed at various bakeries throughout the globe,” René van Ass says. The name VACTORR comes from a combination of the definition ‘Vacuum’ with the name of physicist and mathematician Evangelista Torricelli, the student of Galileo and the inventor of the barometer (the ‘Torr’ pressure unit was also named after him).

www.bakingbiscuit.com 06/2022 PRODUCTION 26

© Verhoeven Bakery Equipment Family

© Verhoeven Bakery Equipment Family

VACTORR A

VACTORR B

“Energy saving was regarded as ‘nice to have’; but recently, the enormous increase in energy prices gave the interest in vacuum cooling and baking a substantial boost.”

René van Ass, Business Development, Verhoeven Bakery Equipment Family

The VACTORR range comprises three solutions, plus a com plete production line to cover all bakery segments:

+ VACTORR A – the test laboratory version of the technology, which can work with small product volumes, for R&D purposes

+ VACTORR B – suitable for a range of batch-production operations, with 1 to 4 decks

+ VACTORR C – designed for a range of continuous pro duction solutions, with 2 to 6 decks

+ VACTORR D – a complete production line with integrated vacuum cooling and baking, which is developed in coop eration with the Dijko ovens

Verhoeven Bakery Equipment has developed this as a ‘standard’ portfolio, but it can accommodate individual requirements for unique, custom-made solutions.

Enjoy vacuum cooling

Vacuum cooling brings numerous advantages, derived from being able to closely control the process, and respectively the outcome. This is reflected in product characteristics such as crispness, moisture distribution, volume and structure. In addition, the fast process leaves no time for bacteria to multiply during cooling. The ‘contamination’ phase is con tracted to a few minutes, which spells gains in increasing the product’s shelf life.

Also, the production capacity can be increased dramatically due to the substantial time savings it helps achieve. For example, if products need around 20 minutes to reach the desired temperature with ambient cooling, the same temper ature can be reached in 3-4 minutes with vacuum cooling.

René van Ass observes a renewed interest in the technol ogy’s sustainability, too: “During the past years, we have learned that the market was mainly focusing on rationalizing the process and improving the product quality, when consid ering the implementation of this technology. Energy saving was regarded as ‘nice to have’; but recently, the enormous increase in energy prices gave the interest in vacuum cooling and baking a substantial boost.” With the process, the raw materials used are also fewer, leading to a lower cost-perunit. And the resulting product can claim a greener label.

For best results, all conditions should be taken into consid eration, given by the match between the individual and personalized product recipe and the chosen vacuum process (the duration and chosen baking and vacuum curves). Once this has been analyzed and established, the settings can be saved with the software supporting ‘semi-automatic’ oper ation. The software is regularly upgraded with new versions, based on the information the system collects. +++

27 PRODUCTION www.bakingbiscuit.com 06/2022

© Verhoeven Bakery Equipment Family

© Verhoeven Bakery Equipment Family

VACTORR C

VACTORR D detail

The taste developers

Sourdoughs are much more than just an ingredient. “They

By Helga Baumfalk

By Helga Baumfalk

+bbi: At BÖCKER, everything has revolved around the topic of sourdough since the company was founded in 1910. What does this expertise cover today?

Dr. Böcker: We see sourdough as an entire system of bio technology and have been working on covering it world wide for more than 20 years. Whereby, it is not only about rye, but in most regions of the world about wheat sourdoughs. Sourdough is a process, a comprehensive way of thinking. In this respect, the expertise we have built up, which is represented by our employees such as Dr. Markus Brandt or Dr. Peter Stolz and also by me, is broad.

bbi: What does this ‘system’ entail?

Dr. Böcker: Sourdough encompasses many aspects. In bakeries, it starts with the cultivation of the starter cultures, through which bakers accomplish something that is basically unusual in biotechnology: they do not grow a single strain, but a mixed culture, which has to remain stable with organisms of very different needs. This is actually a technical impossi bility. Nevertheless, it is supposed to work. This is where we come in. Our ‘sourdough system’ – our concept – starts with the cultures, continues with propagation and extends to processing, encompassing all processes and related parameters. In other words, it covers the entire bread-making process, including times, temperatures and mixing ratios. Since bakers do not sell sourdough, but bread, we, too, have to look at the whole chain and provide advice. We see ourselves as a supplier of knowledge. We turn bakers into biotechnologists without them even noticing.

bbi: How far do your consulting services go?

Dr. Böcker: Because we produce our starter cultures our selves, we can advise exactly which sourdough cultures are optimal for which bread or pastry, which management and which production facilities. We can also tell which aromas can be achieved and which properties can be enhanced. Only then does the plant manufacturer come in. The sale of starter cultures makes up only a small part of our turnover. Our expertise consists of starters, concepts and know-how. In doing so, we strive to take the inquiring companies on this journey along with us and to work out exactly what they want during the consultation. After all, we not only offer a wide range of ready-made sourdough products, but we also develop individual special solutions.

bbi: What questions do bakers ask you?

Dr. Böcker: Apart from new starter concepts, bakers often reach out to us to find out the cause of pastry defects. In this case, one of our master bakers usually goes to the company and identifies the root cause of the specific problem. Alter natively, the bakeries send us breads and sourdoughs, which we then analyze. Once or twice a year, we also conduct basic training sessions in companies. Due to COVID, we have expanded our baking technical center in recent years to include a system of digital, video-supported lectures. Those who book such a package bake live, in parallel with us. Afterwards, we compare results and dis cuss online.

bbi: Are there any problems that come up again and again?

www.bakingbiscuit.com 06/2022 INTERVIEW 28

are an entire system of biotechnology,” explains Dr. Georg Böcker, Managing Director of Ernst BÖCKER GmbH & Co. KG, in an interview with baking+biscuit international.

© BÖCKER

Dr. Böcker: Recently, avoiding the need for night shifts has become a regular topic. For example, a chain bakery has asked how a concept can be developed with long-time fermentation and delayed proofing, in which baking first takes place in the morning and then continues throughout the day. With breads that require longer processing times, it can be done. Other issues that are often brought up include new types of baked goods or production defects, such as the ‘ropy bread’ effect caused by Bacillus mesen tericus. Due to climate change, this could possibly become an issue more often. Sourdough can counteract the ‘ropy bread’ texture, because it forms acetic acid in wheat pastries and creates a certain pH value.

bbi: What kind of companies request your services?

Dr Böcker: It is predominantly large bakeries. However, we also provide consultancy to smaller companies, but less frequently. Most of them are companies with large baking lines and worldwide networks, from countries such as Greece, Brazil, or Mexico.

bbi: Speaking of worldwide, you mentioned that interna tionally, wheat sourdough dominates. Can you explain that?

Dr. Böcker: Sourdough has been extensively dealt with in the wheat world, as it discovered its influence on bread quality and taste. On international markets, there is added value to be gained with the claim ‘Sourdough Bread’, which is well understood. This is as true in Spain as it is in Latin America, the UK and many other countries. The San Francisco sourdough has actually run its course in the spotlight. Today, milder wheat sourdoughs are preferred for breads with long-time dough processing. This is the big trend worldwide, even in traditionally rye-heavy markets such as Poland or Estonia.

bbi: And what is the situation in Germany?

Dr. Böcker: In Germany, some bakers are still of the opinion that sourdough cannot be used in wheat breads because the gluten would be destroyed. This is not true, of course, but it is a complicated game of different processes. It depends on making the right sourdough in the right time frame. Then you can achieve doughs that can also offer protection against mold in the wheat sector, among other things.

bbi: What is your stance on educational work?

Dr. Böcker: That is what we are working on. We want to ensure that sourdough is not viewed one-dimensionally, but we rather want to highlight its many dimensions. There is a positive effect on taste, texture and freshness, and there is the market's perception of fermented foods with their nutritional effect, which is increasingly catching on with consumers. Sourdough can produce completely different product groups and brings advantages in terms of produc tion technology. In many countries, it is used in croissant

doughs, for example. Then, they do not stick together when rolled out. And in France, there is a trend towards using sourdough in sweet doughs as well.

bbi: Ever since it became possible for bakers to train as bread sommeliers, people in DACH have been talking about bread aromas. What is your view on this?

Dr. Böcker: We are one of the drivers of this story. Only those who can define taste can talk about tastes. We have to awaken the desire for sourdough, from its visual language to its aroma. That is why we are working on a language, a dictionary of aromas.

”‘Gluten-free’ is not a new trend, but it is a segment in which we have been specializing for years, and from which we've learned techniques for turning non-grain ingredients into bread – that is what has suddenly become a global issue.”

bbi: You have extensive experience in foreign markets. What developments are you observing in sourdough cultures and semi-finished products?

Dr. Böcker: There is a whole range of developments. Almost ready-made, pumpable ready-to-use live sourdoughs are a segment that is growing strongly abroad. They are espe cially popular when sourdough is not used on a daily basis and a dedicated plant is not worthwhile. They are widely used in England and Scandinavia, and occasionally in France. In Germany, we primarily have a culture of bakeries making their own sourdoughs.

29 INTERVIEW www.bakingbiscuit.com 06/2022

Dr. Georg Böcker

© BÖCKER

bbi: Companies around the world are struggling with increas ing prices. How is this reflected in your field?

Dr. Böcker: Thanks to the high added value of our work, the price increases for raw materials are less massive for us than for mills, for example. But, of course, we are also registering jumps, especially in energy, personnel costs, packaging and logistics. Like the entire industry, we have to follow the power of necessity when it comes to our prices.

bbi: What role do special sourdoughs play in your range and how are raw material prices shifting in this category?

Dr. Böcker: Around 10% of our production is made up of organic spelt alone, and another 10% comes from gluten-free raw materials such as rice, rice bran, buckwheat, or corn. In this field, we have to accept price increases of 50%. In some cases, we can only agree on daily prices. Other raw materials are not nearly as badly affected. There are price increases for lactic acid, but not to such an exorbitant extent.

bbi: Back to the development trends: in your experience, what concepts from outside of Germany could also be suc cessfully implemented here?

Dr. Böcker: In fact, I always come back to the topic of wheat sourdough and long-time-run breads. There is a huge difference between processing flour for bread over 6 to 8 hours, compared to only processing it for around 1.5 hours. A completely different product is developed, with an entirely different flavor, which cannot be obtained with flours with high swelling power, guar gums, or enzymes. We are not advocating a three-stage fermentation, or three days, as with panettone; but, we want to make it clear that there is no substitute for flour swelling. That is what long-term leavening is all about, whether it is done with sourdough or a long-term leavened dough. Then, even high-protein flours are no longer absolutely necessary; one can bake breads with completely different flours. Perhaps the trend can be called traditional or historic bread baking, because it is basically about going ‘back to the roots’. Incidentally, it takes three full days for a rye grain to swell completely.

bbi: What about the ‘gluten-free’ issue?

Dr. Böcker: 'Gluten-free' isn't a new trend, but it is a segment in which we have been specializing for years, and from which we've learned techniques for turning non-grain ingre dients into bread – that is what has suddenly become a global issue, in view of the scarcity of wheat resources. How can we bake bread using premixes (composite flours) made from local raw materials such as tapioca instead of wheat flour? This issue is currently affecting all manufacturers of baking ingredients without exception.

bbi: What are your plans for the near future at BÖCKER?

Dr. Böcker: We want to actively promote the trends we have discussed and make sourdough even better known. This is our specialty in the industry and we want to cultivate it. On the one hand, we stand out due to our variety in raw materials – we have up to 160 sourdough products in our range – and, on the other hand, due to our focus on R&D. This is why we have always been involved in extraordinary projects. That's why we have always looked at unusual ingredients. At the moment, we can offer various products that use legumes, for example. Ideally, we do not want to simply follow trends, we rather set them. In addition, new exciting markets are opening up for us, such as vegan food, a segment in which there is not only a lack of raw materials, but also a lack of taste. That is exactly what we can develop through fermentation. This does not only apply to bread, but also to meat substitutes and beverages. We want to position ourselves as a taste devel oper, namely a taste that is based on natural raw materials. Fermentation renders raw materials usable for the first time, especially those that are commonly rejected because of their bitter substances, such as buckwheat, lupins or linseed. Flavoring is one thing, and the bakeability of ingredients – a different aspect of the many dimensions of sourdough.

bbi: Dr. Böcker, thank you very much for our insightful con versation. +++

© BÖCKER © BÖCKER ©BÖCKER www.bakingbiscuit.com 06/2022 INTERVIEW 30

Wafer producer Kägi builds smart factory

Swiss chocolate wafer producer Kägi Söhne AG plans to have its entire machine park digitally networked and all process data visualized by 2024. The company is working with Bühler on this project, which started in 2019, when the two conducted a Performance Assessment Workshop to assess where production improvements could be made. “Our vision is to produce the perfect Kägi every day, whether it is 30°C in summer or minus 10°C in winter,” said Pascal Grin, Chief Operating Officer of Kägi Söhne AG. One of the first steps was to connect most of Kägi’s pro duction to the Bühler Insights platform, a digital tool that connects devices, operational metrics, and analytics. By linking and visualizing the data in Bühler Insights, Kägi expects to see an Overall Equipment Effectiveness (OEE) increase of 5% to 8%.

Based on the outcome of the Performance Assessment Workshop and product tests in the Bühler Wafer Innovation Center, Kägi will invest in a fully automatic BM-W 180-H batter mixing plant, a SWAKT-80 wafer baking oven, and a fully automatic WIS-EAGLE In-Line wafer sheet inspection system. +++

New executive product manager for AMF Workhorse

AMF Bakery Systems promoted its product team leader, Wes Bryant, to product group leader and exec utive product manager for AMF Workhorse, a brand that recently joined AMF Bakery Systems. In this role, Bryant will lead the AMF Workhorse team focused on developing solutions for pan and peel board handling, automated storage and retrieval systems, as well as all post-packaging automation solutions. As Product Group Leader, Bryant assumes overall business leadership and product strategy responsibilities for AMF Workhorse. The brand plans developments across appli cations for soft bread and bun, artisan breads, pizza, flatbreads, cakes, pies, pastries, and more. +++

© AMF Workhouse NEWS ADVERTISEMENT

© Kägi Söhne

Have the cake!

After putting consumer resilience and adaptability to a test in 2021, access and action are driving worldwide trends this year. Euromonitor International analyzes market sizes, with historical and forecast data, and finds consumers favor their cakes: this product segment is set to record the biggest year-on-year growth –5% between 2021 and 2022.

Category

Baked Goods

USD million 379,691.7 386,090.2 407,164.2 425,226.5

Bread USD million 210,793.6 213,315.8 225,334.8 234,779.6

Cakes

Dessert Mixes

Frozen Baked Goods

Pastries

USD million 82,272.5 84,137.6 89,453.1 93,954.3