STEP BY STEP

Once again, I am thrilled to bring you practical, entertaining, and informative articles.

Since the beginning, I had the idea that there was a lot of talent out there, which all of us working to make amazing pieces needed to hear from. I am never disappointed by our fantastic fellow laser folks who graciously take the time to share their expertise by writing a column. They share what they know freely, and I am grateful. If you have the knowledge to share, please contact me, and let’s talk!

Whether you are building a full-on business, working a side hustle, or simply having a ball ‘messing around’ with your laser, there is something here for everyone. If you want to take your side hustle bigger, check out the marketing column and the Business 101 article. If you’d rather get in there and learn new techniques, check out the acrylic column and learn what wood to choose from the wood article.

Our ‘Step By Step Projects’ section debuts this issue. It is fantastic, and I can’t thank the fabulous Kris Mayberry of Craft Closet and sensational John Kuiphoff of Glowforge for Beginners enough. In fact, as I put this issue to bed, I am excited to try both of these projects myself! Send pictures of your efforts in so we can showcase your creations in future issues!

As always, please support our advertisers. There is a directory of advertisers in this issue, so please go check them out, and take them up on their offers and discounts. They support the industry by supporting Laser Focused, which is genuinely appreciated.

Congratulations and thanks to those who have become members of our Patreon program. Read more HERE about the benefits that a small but mighty $5 membership brings you, with more business-related benefits offered at higher levels.

There is much to discover – read through it all and let me know what you think! Send me an email to share your thoughts, comments, and questions.

May you have amazing Mother’s Day, Graduation, and Father’s Day seasons! See you in July!

Laser On!

Thisissue we are catching up with That Mom With A Laser, Emily Caroline! And she has been busy!

Emily put a challenge out there to show people that paying off your laser in 90 days can be done. We have all been nervous as we invested in our lasers, whether it was our first or subsequent, so what a great idea.

To avoid leaning on her existing footprint, she started a new brand, developed products, created an Etsy shop, and went from there. In other words, it wasn’t successful because of her existing fan base; she started it all from scratch. And she proved it could be done. Understand this is not a thorough report on it: to find out more for yourself, go to her Facebook Group, That Mom With A Laser, and get in on the details yourself - there’s a pinned post!

BTW, spoiler – she did pay off her Mira 5, not in 90 days but in 52!

Right now she is in the middle of this session of her Laser Launch Academy. The next enrollment will open mid to late June and begin in August. You can go here and check it out. You can also put yourself on a waiting list to be the first to know when it opens up!

Over the summer, Emily will be in Mom Mode – one of the privileges of having your own business – as she has fun family adventures with her husband and the three kids. As a former teacher she knows the importance of keeping the kids on track over the break so she also has planned some activities to keep them sharp, ready to hit the ground running when they return to school in the fall.

Finally, Emily will speak at the Lightburn Experience – LBX - conference October 27-29 in Peoria, Illinois. This is the first in-person event for the Lightburn folks and promises to be engaging, informative and well worth the trip! Plus, if you haven’t heard Emily speak (I saw her in Dallas at The Next Level Laser Conference), you must! She is inspiring and fun!

And there’s always more! You can keep up with Emily Caroline here.

Does it drive you crazy trying to find the spot on the back of a project to attach a hanger?

Simple solutionscore the center on the back while creating it and now you know exactly where to place your hanger.

Jodi Robinson

Recommended: Box resizer and cardboard cutter.

Both I use all the time when shrinking down box sizes. The canary cutter is the bomb. These can be found on Amazon.

Alisha Pate &Tracey Carrell Bobo

Alisha Pate &Tracey Carrell Bobo

After a while the aluminum rails get a ton of build up. I recently had to file some damaged areas down on a rail that was jumping track. If you get some 0000 steel wool it will remove all the build up and polish the rail smooth again.

Jonathan Cendi StevensNeed to fill in a hole in your some sawdust and fill the drops of super glue Hole filled, Problem Quinn

Osburn

Spray paint nozzle

Take off the nozzle spirits to clean and you’re back makes sense, buy so you can Robin

Wanting to clean up those silicone sleeves? Here are several recommendations:

Several options: 1. equal amounts baking soda and water. Scrub with toothbrush. 2. White vinegar and water

1:2, scrub with toothbrush.3. Denatured alcohol (Home Depot) and scrub with toothbrush.

Eva VinczeI scrub mine with hot water, dish soap, and believe it or not with a dentures brush

Polya Hristovayour wood project? Take the hole. Then drip a few glue in it. Voila!

Problem Solved. Osburn

nozzle get gummed up? nozzle and soak it in mineral it out. Put it back on back in business! Also, if it buy 2 of the same cans swap the nozzles.

Robin RobertsAfter putting the silicone back on the glasses, I used isopropyl alcohol on a magic eraser sheet and was able to get the rest of the char/marks off.

Jenn RussellI rinse it in hot water initially. Then I take original dawn dish soap and let it sit for a bit. Then I use a toothbrush and scrub the heck out of it. I put my hand inside and try to stretch it out. Or for real difficult ones- I put it back on the tumbler and use the toothbrush and dawn. And then I use alcohol on a cotton circle and finish any leftover spots.

Brittany Siepmann

I could have made that for way less!”

These words were uttered to Sumita by Anuj when she came home with an expensive bundle of 3 books that had been repurposed into home décor. Without hesitation, she took him up on his challenge.

Now Anuj has always been a DIY kind of guy, so he went to work using books they already had and produced a beautiful set – not just rivaling but surpassing the ones Sumita had bought.

Sumita was impressed. And being the social media maven she was, Sumita knew these were a very hot retail item and thought, “Let’s put them on Facebook, in the marketplace, and see if anyone would like a set.” Two to three days and 50 orders later, it appeared they had discovered a need and started filling it. And that is how Home Bound Custom Decor launched!

That was July 2019. Within six months, that business had increased so much that they could no longer use the simple Google solutions they had been using to keep the operation organized. They went from meeting people in parking lots to having porch pickups to starting to ship. They needed to up their game so orders could be placed and paid for online, streamlining their processes. After some research, they chose Shopify and have been running the online business end of things that way ever since.

Even though their customers loved the books, came back, and ordered more for friends and relatives, baby showers, and weddings, they knew they needed to expand their offerings to take advantage of the following they had built. So, after some research, they found the Glowforge, and from July 2020, they began offering cutting boards to their product line, which was

the Glowforge’s only job. Little did they this was going to actually lead them!

It was 2020, and online shopping was holiday sales. By November, they were Glowforge Pro so that they had a backup a week, so even though the first machine missed a beat and had tremendous sales Then, again in January, with the momentum added a third Glowforge Pro into their

By this time, they had moved kitchen to the spare bedroom, the basement and garage Finally, stepping back to grasp production sense, Anuj came and said it was time to get laser. Now one of the things strength in their business their own wheelhouse: Sumita marketing and new product while Anuj tackles and turns her ideas products. So initially caught she trusted him to in hand and fully supported this expansion.

Anuj researched all kinds of lasers and FB groups for information. That was Emily, That Mom With a Laser, and the lasers. While they consider the Facebook of their mentoring team, they certainly champion for success in Emily. After talking meeting her in person, and thoroughly researching options, they added a Mira 9 to their machines 2021.

They loved their Aeon experience and became 2022. They added a Mira 7 solely for products in their lineup when they finally in March of 2022. And since then, they an employee into their business!

they know at the time where

was where the action was for were ordering their second backup plan. It arrived within machine went down, they never sales for the holiday season. momentum continuing, they production capacity.

moved operations from the bedroom, then to garage to keep up. grasp what made came to Sumita get a commercial things that creates is that each has Sumita handles the product side of things, the operations ideas into viable while she was caught a bit off guard, to have the issue expansion.

and searched the when he found the Aeon line of Facebook groups part certainly found a strong talking with her, researching their machines in May became affiliates in January for the production of rotary finally moved into a warehouse they have added a Nova 14 and

They moved operations into the warehouse not only for space and capacity but also because Sumita and Anuj were about to become parents. Their first child was due and their goal was to have the business outside of their home before he arrived. They met the deadline. Milan made his appearance in May 2022, and there was now a clear delineation between work

time and family time. Where it had been easy to slip off into the basement and work all hours, now it was about organizing and structuring their time so as not to be consumed by the business.

And while all this was going on, they both still had (and have) their corporate careers. Sumita is an attorney for a large corporation on the real estate side of things, and Anuj is in sales. Moreover, both have the good fortune to work from home, which has allowed them to take advantage of the momentum of Home Bound Custom Decor.

And why else did they need the capacity they were investing in? They had strategized and begun to build a wholesale element into their business. They started growing this branch of the business because a retailer reached out through Instagram. They were a photographer and had retail space within their studio. They wanted to offer the books they had seen in Home Bound Custom Decor’s feed. This gave the couple the nudge to find other storefronts that might also want

to carry their pieces. Sumita and Anuj began making it a habit to visit stores, drop off their card, show pictures if there was interest, and answer questions the owners had about pricing. They would point out the excellent profit margin that could be realized by outright purchasing the pieces – much better for the store owners than, for example, consigning goods (which was never a model they considered). Owners were interested, and the two followed up within 24 hours with pictures and pricing, often making the sale. The key, they made clear to me, was being prepared and following up immediately, ‘striking while the iron was hot’ is what has driven their sales.

They also became vendors on Faire, a marketplace for retailers.

Faire’s goal is to expose the smaller all over the world. This platform allows cost-effectively reach buyers they Considering what to offer on the within pieces had to the enough on it this to I would the it. If on didn’t they not digging a hole for themselves become wholesalers. (If wholesaling you, watch this whole conversation ‘play video link’ earlier in the paragraph.)

They continue to do the bulk of their with direct customers. However, the side is growing and will continue to business mix in the future.

When asked what they might want as a future project, both Sumita said they were intrigued by moving offering signs. While it isn’t on the custom item, it may be where they And while they both still have their of the question that, at some point, dedicated to Home Bound Customs life behind.

Perhaps the primary thing Sumita and laser makers world is their collaboration their business. As noted earlier, Sumita media, and at some point, she began

smaller entrepreneur to buyers from allows the smaller business to they couldn’t find on their own. site was a project within itself. The pieces chosen had to be efficient produce and the margins high enough to bear a 25% fee to Faire on their sales. Sumita explained this way, “When choosing what offer, I considered whether would give a 25% discount on the piece if I would still sell the answer was yes, it went on the product listing. If not, it didn’t “make the cut.” In this way, they were in order to wholesaling interests conversation using the paragraph.)

their business the wholesale to shift their want to tackle and Anuj moving into the table now as it is an entirely they will expand into one day. their corporate jobs, it isn’t out point, one of them may become Customs and leave the corporate and Anuj are known for in the collaboration with influencers to build Sumita is very in tune with social began noticing how influencers

were showcasing products. What she saw as an advantage was that, unlike most of the products shown, theirs was customizable, which gave them an edge. After careful research, she chose a few she felt were particularly aligned with their business, reached out, and then followed through. Fairly quickly, they had some takers, and things began to pop. Often after an influencer would post about a product, they would receive lots of orders. In fact, one Father’s Day, the extended families were called in to lend their helping hands in order to complete the overwhelming number of orders they had received!

Sumita is rock solid on how essential a social media plan is. She shares, “It’s very intimidating but very necessary.” It had, and still has, a significant impact on their business. Thank goodness they have chosen to create a class and share their expertise! Sumita and Anuj have been so successful with this tactic that they teach their strategy for working with influencers. It is a terrific class (yes, I took it) and a heck of a deal! Make sure you check it out!

As always, I wanted to know what inspires them and what advice they have received and implemented. Sumita shared that she is inspired by bringing people together and has experienced that on this laser journey. She loves being part of this community, meeting and partnering with other makers, and creating treasured pieces for her clients.

For Anuj, he loves the innovation – taking an idea and figuring out how to make it work. Watching an idea manifest keeps him motivated to bring on the next project.

In the business advice world, Sumita has been quite taken with the saying, “You don’t build a business; you build people. Good people equals good business.” For her, this applies not only to employees but also to those they serve and partner with. For Anuj, he stresses the ability to step away when needed. “Take time to reset, breathe.” Together they are a dynamic team with a strong sense of who they are and where they’re going.

... is that social media long before Home thing. In fact, they was looking for tickets selling them. She and then the two found of time chatting back One thing led to another, When Anuj proposed, Twitter-themed, and, Indian wedding celebration with the iconic blue decor, unique more. They what you

media was important to this couple Bound Custom Decor became a they met over Twitter when Sumita tickets to an event, and Anuj was contacted him, got the tickets, found themselves spending a lot back and forth via social media. another, and they became a couple. proposed, the proposal itself was and, to top it off, their traditional celebration had a twist of Twitterblue Twitter Bird featured in the Twitter-blue cocktails, and take the saying ‘practice preach’ to a new level!

As for personal advice, both of them were inspired by their dads. For Anuj, his dad often told him, “Impossible is nothing.” He has utilized that advice by never giving up easily or too soon. Instead, he takes action with the overarching thought that it isn’t ‘can it be done?’ but that it can and will be done, and he will find a way to make it happen. And Sumita’s dad’s timeless advice – “This too shall pass.” keeps her going in any situation.

Ultimately, they are a great couple, lovers of the business and the people it brings to them. Always ready for the next thing. Truly a delight!

By the way, the prophetic words that were on that first purchased bundle of books?

You can follow them here:

Time is money, honey — and it’s time to take back your precious time with a faster, more streamlined process that works better for you AND your business.

Most small business owners that I work with didn’t start their businesses because they dreamed of spending their days going live on social media, setting up ads, and pouring over spreadsheets. Like myself, most makers love delivering their beautiful products to their customers. We like making people happy. We love the freedom that comes with being a business owner. It’s the best. Being a business owner feels excellent when you can finally pay yourself well and even hire a little help.

You can’t keep working for free. You’ve been scrambling each month to meet your goals, and you must fight for each sale. If you dream of taking a vacation, hiring help, or writing yourself a monthly paycheck, all you need is a system. Once your system is up and running, you’ll gain the confidence that you can afford to take the following steps in your business.

Now is the PERFECT time to invest in your business! If you spend time setting up a plan

1. Make a plan

Who is your target audience

Build a marketing plan

Plan your budget

Build your Product Line

2. Set Clear Goals

What do you want to achieve this year:

More customers

More sales

Consolidate customer relationships

New products

Build new products lines.

3. Have a clean financial plan

You should have a system in place to help you calculate your product pricing.

Establish a business relationship with material wholesalers as early as possible.

This will help you drastically reduce your production costs. Pick between 10 to 20 core products and focus on them.

now, you’ll be set up to get the maximum results all year. Be thorough. Leave no stone unturned when determining the next steps for the rest of 2023.

Decide now who is going to be your target audience for this year. Lock yourself on a target audience to focus your marketing, budget, and products.

Consistency is the key to success for all small businesses. Yes, that file is pretty, and that new design is adorable, but you need to stay focused on continuing your path.

If your target audience is schools, you need to get in

touch with them and get a calendar overview of their events. Start marketing your services and products to the schools in your area and grow your local business. Make sure you know when you will be included and needed so you can plan your marketing and source your products. Look at what the competitors in your area are doing, and either you can set yourself apart from them, or you need to make changes.

One of the mistakes I made and saw other laser businesses are making is lowering our price to beat the competitors and hope this way for more business. This concept works for big box companies rather than for small businesses. Start reevaluating your marketing approach, products, and customer service if you want a client to buy from you. 99% of the time, the small business owners I worked with had loose ends on product marketing and customer service. You need to clearly understand your price strategy for your products and services and how this will affect your business and your customers. Pricing decisions and strategies do not include just the sling price. A price strategy includes discounts, payment arrangements, and refunds. When determining a pricing strategy, it is essential to consider the business’s position in the current marketplace. For example, if your company advertises to realtors as high-quality or premier closing gifts, the product pricing should reflect that. That means that your lowest-priced products must be set considering the market in your area or the national rate.

When you focus on max 20 products you can

sell and market all year round, you have a higher chance to establish brand recognition among your targeted audience. You created a pool of followers who can identify with your brand and products. Don’t worry. You will still have time to add one or two seasonal items to complement your core product line. The fact that you have a marketing strategy will allow you to create additional products that will complement your main line.

Focus on your product line and make your customers understand the features, advantages, and benefits of buying goods or services from you. When considering a product, consider customers’ key essential benefits, needs, and wants. Plus, you will have the benefits of working with other small businesses in the wholesale, who will for sure either bring to your attention other great products that you may like or you can request with them some products you would like to add shortly.

What drives today’s customers are emotions and feelings, some of which can’t be expressed in words and are triggered unconsciously. The most critical element in customers choosing who they buy from is how a brand makes them feel. Companies like Apple don’t sell a product; they sell a brand that embodies a delicate mix of dreams and aspirations. Apple’s ads don’t show product features like memory, speed, or device weight. The commercials are designed to provide sensory stimulation.

There are many different types of acrylic out there for both rotary and laser engraving. These acrylic types include extruded, cast, mirror, and multi-ply. Multi-ply acrylic is typically an extruded acrylic consisting of two or three different colors layered on each other. It may also be called multi-layer or two-tone acrylic depending on whom you talk to. With that in mind, let’s get into my five tips for working with multi-ply acrylic.

Tip 1 – Take off the plastic coating. Every piece of acrylic, no matter what type, comes with either a paper or plastic film on it. With the multi-ply materials, there will be a plastic film on the engravable side of the material. When you go to machine the material, I recommend taking this plastic film off. By removing this film, you will directly engrave the top thin layer of material instead of machining the plastic film first. There are two main reasons why you should remove this film:

and result in inconsistent engraving. Not only will it turn to a paste-like consistency but it will also have inconsistent engraving results.

I highly recommend experimenting with a couple of different colors for yourself and seeing first-hand what happens when you take it off or leave it on.

Tip 2 – Turn off the air assist.

CO2 lasers have an air assist system that is usually driven by a compressor. The compressor itself is sometimes built into the laser but more often, it is an additional piece of machinery that is connected to the laser via an air hose. This air assist system helps keep materials from flaring up or catching on first. CAUTION: If you turn off the air assist, you need to monitor the machining process to ensure and shut it down if you start to see larger-than-normal flare-ups. Be careful any time you shut this off.

1. If you leave it on during the engraving process, the laser will engrave through the plastic film and melt it. As it melts it will travel into the path of the laser and will continue to get engraved more which will make it adhere to the acrylic itself. This results in a paste-like consistency that will be incredibly difficult to clean and you will never get a great result this way.

2. The second reason you should remove it is for consistency. As you machine, this film will tend to lift in areas as it heats up causing it to move

In the image below you’ll see two engravings. The engraving on the left was done with the air assist turned on while the one on the right was done with the air assist turned off. Let’s start with the engraving on the left. As the engraving is occurring, fine dust is created by the machining process. As the laser engraves through the red layer, that red layer is becoming dust that is then sucked up by the exhaust system. Here in lies the problem with the air assist. As that dust is being created, the air assist is blowing the dust around and it is landing back on the ma-

terial. When it lands on the material, the laser is then re-engraving the dust at the same time it is engraving through that red acrylic. This leads to the engraving having that color in the second layer in addition to dust surrounding it. While you are able to wipe the loose dust off, the dust that was hit by the laser will embed itself into the second layer causing it to be permanently embedded into the acrylic.

In the image on the right, I shut the air assist off, meaning that the dust is sucked up by the exhaust without being blown around the material, and by laser engraving it from the bottom to the top, the dust is leaving the material before it has a chance to land back on top of it. This will produce the cleanest engraving result and ensure that you aren’t engraving the dust back into the second layer. If you have a machine where the air compressor is built into the laser, such as the Glowforge, it may not be possible to shut this feature off and it’s not recommended to modify the machinery to do this. While this is a nice lever to have, it’s not always an option.

– Try using a clean-up pass. I’m just as guilty as anyone else of trying to make it through materials in a single pass because I want to machine as quickly as possible to improve throughput and therefore profit. However, this is one material where I would advise against that strategy. Due to the material being extruded, as you engrave it you will start to see very small lines at higher powers meaning that instead of a nice white look in this example, it will be visible lines throughout the engraving. Your customer won’t like this look and it takes away from the quality.

In the following image, I used 100% power and got through the entire red layer in one pass. When I did this, it did make it through the red layer but I could clearly see individual machine lines which aren’t easy to see in this image. Think of an inkjet printer nozzle check where you see each individual print line instead of a solid black image. This is essentially what is happening in the engraving. You will see a ‘nozzle’ style result using high power and trying to get through this layer in one pass.

In the image on the right, I used a lower power for a first pass to get rid of the majority of the layer and then followed it up with a clean-up pass at a slightly higher speed to get rid of the rest of that layer. The downside to this method is that it increases how long it takes to machine your product, but it typically results in a much better quality engraving. While we all want to make products as quickly as possible to get them shipped out, I encourage you to take the time to test different methods with this material to find the best results for your needs.

Tip 4

Machine it out of focus. This tip may be something you haven’t heard of as a lever that you can utilize. When we talk

The Master Oscillator Power Amplifier, or MOPA, for short—is a technological leap above the traditional Q-switch technology in Fibre Lasers. Where the traditional Q-switch used a fixed length frequency pulse, MOPA is able to utilise a variable length of pulse which brings with it many new opportunities and improved processes. Among these is a greater control over the effects on the materials under which the laser is being operated, as well as a more gentle execution in procedures; moreover, the most impressive feat is the imbuing of colour onto materials such as steel, titanium, and aluminium, the latter of which can now see deeper, darker greyscales. It should also not go unsaid that the internals of a MOPA laser are far more sustainable than traditional lasers, able to accrue countless more hours of use before requiring replacement.

In steel and titanium, true colour is capable of being produced through a process popularly referred to as laser annealing; wherein, the potency of the laser is reduced to simply heat the surface of the material without vaporising it, the localised heating forms a layer of oxide below the surface of the metal—in essence, a more efficient and precise form of anodisation. To better provide the information on how colour is made, the thin film interference phenomenon comes into play. When an observer views the material’s surface, light is reflected between a medium—in this case, the oxide layer into the substrate—and back as a colour relative to the relationship between the constructive and destructive interference of the two layers; the heat of the laser, therefore, chemically alters the refractive index of the medium respective to the temperature applied. For example, 220° C is recognised to produce a yellow hue, while 290° C will produce a blue hue.

On the topic of rust resistance in stainless steel, the presence of a thin layer of chromium oxide is assured as the process of passivation is present; the process creates a layer that is meant to weather the abuse of well… the weather, without getting worn or removed—it’s a layer that has a natural reproducibility much like the aluminium oxide layer that naturally protects aluminium, which makes it a prime candidate for objects like road signs. In laser engraving, however, one must be careful and understand the importance of properly tuned settings

The heat of the laser, therefore, chemically alters the refractive index of the medium respective to the temperature applied.

Victor Wolansky, Laser-Mate

Victor Wolansky, Laser-Mate

in order to not heat the steel as to cause a chemical separation of the alloy and reverse the process of passivation.

Lastly, I should mention the two major softwares used in the operation of all laser systems mentioned; EZcad and Lightburn, which each have pros and cons. While my software of choice is EZcad 3—mostly due to the longer time it’s spent in the market operating with Galvos, allowing it to maintain more advanced options for the use of lasers—Lightburn is still an excellent choice, holding with it a much better set of basic design tools; however, I will always recommend a vector design software like Adobe Illustrator to create graphics that are properly transferable, while allowing for greater design potential.

To properly bookend—I use a BWM TECH 80W MOPA 2.5D, this is a laser with a JPT 7M source, my main lenses are 100, 200, and 300mm with the latter being the one I use most. You can see examples of my work at https://www.facebook.com/lasermate.us

A logo is often one of the first things a business owner creates. A logo’s purpose is to communicate your brand’s personality at first glance. Think of it as the mascot of your business. It’s the first impression your customers see and visually molds how your clients view your business.

Whether you are a hobby business or a fulltime engraving shop, your logo branding can elevate your career, depending on how you cultivate it. If you are unsure where to start, here are three simple steps to use as a guide.

1. Know Your Brand And Vision - What do you want to communicate to your audience? What personality do you want to portray in your logo? Take the old adage don’t judge a book by its cover. You may not judge a book by its cover, but your potential clients certainly will. Reflect on what your strengths and weaknesses are both professionally and as an industry leader. Your personality and authenticity will set your brand apart and grab attention. As you think about what you want your brand to convey, here are a few categories you may relate to:

a. Quirky and fun-loving

b. Minimalist

c. Corporate or Professional

d. Artistic

e. Authoritative

2. Decide On A Color Scheme - Analogous, Complimentary, or Monochromatic – Your color pallet can be the deciding factor for being noticed or overlooked. There is a science to combing colors with art when creating lo-

gos. Most color theories or color studies are based on the color wheel. The color wheel was invented in 1666 by Isaac Newton, who mapped the color spectrum, which is still used today to showcase the relationship between color combinations. If you are unsure how to choose the right colors to reflect your brand, opting for an analogous, complementary, or monochromatic color scheme will help you stay on target.

a. Analogous combines two or three colors next to each other on the color wheel. For these options, choose one bold color for the main theme and focus.

b. Complimentary is a combination of two colors that are across from each other on the color wheel. This palate provides high contrast with a bright prominence.

c. Monochromatic takes one base color and provides three tones or tints from the same base. This is a conservative approach for a harmonious look.

3. Choose Readable Typography – The older I get, the more important this is. If you have the most esthetically pleasing logo in the world, but your viewer can’t read it, it’s unlikely they will become your client. Choosing the right combination of readable fonts is crucial for your logo. The right font will help convey your message and give you a polished and professional look. If your favorite font isn’t legible, resist using it. If unsure, ask your friends and family members if your font is readable at business card size font. Here are some examples of typography options when we were rebranding. Notice some fonts are very thin and hard to read.

Incorporating an icon can ensure your brand sticks in the viewers’ memory making your logo unforgettable. Some ways to incorporate an icon into a logo can be as simple as:

a. Use an icon as an intragluteal part of your typography. An example is using an icon derived from text shown in my logo. Notice the “HY.”

4. Use An Unforgettable Icon – The right color palate and typography aren’t the only critical factors in creating a memorable logo. What most of us remember is the icon. Some of my most memorable icons are Apple’s “apple” icon, McDonald’s’s golden arches, or Nike’s swoosh.

b. Not all icons need to be symbolic. Intriguing icons can be memorable.

c. As a crafter and owner of a laser engraving business, I like to take this a step further.

c.i. How will the icon engrave?

c.ii. Will it look good as a standalone icon on your products?

As a case study, here is a picture of a logo we seriously considered when rebranding. This was my first choice, but the icon wasn’t suitable for engraving. Look at the extension of the “y” outside the circle. How will that engrave? Where you see blue will be where the laser removes the material. The white areas will remain intact. While it’s an attractive logo, I chose something else because it wasn’t engravable.

Landing big clients like schools is a tremendous opportunity for your business. But there are a lot of rules when working with publicly funded entities. Here are the steps that you should take to be an A+ partner in your local school district. So, let’s cut the line and help you get the opportunity to work with school fundraising!

As a disclaimer, these are the lessons that I have learned working with my local district, the 8th largest in the nation; however, your ‘mileage may vary’ as each state, county, and school district have their own rules that you should investigate before actively engaging any contracts. We’ll start with the county itself, work our way to a school site, and then we’ll talk about booster clubs and teams and why they are the sweet spot.

Step one to landing county jobs is to be an official business with an EIN which allows you to apply for insurance that you must carry to even apply/bid for jobs. Our local school district will not do business with any company that doesn’t have the following minimums in insurance:

· one million in liability

· one million in property, or

· a combined single limit of five million.

· workers’ compensation for any employee tied to the work being done

· Evidence of the coverage with the submission of your bid

· You must also have automobile liability insurance one million dollars for any company vehicle.

“Yeah, but I’m not going to be taking my

vehicle to the school, so I don’t have to have it!”, but that’s where you’d be wrong! Without these things you can’t even step up to the plate to work for the district or other state entities because they are governed by their own set of rules and bylaws set forth by the county. Now for some of you reading this that’s not a big deal because you’ve checked off all the boxes and you’re ready to go after the whale. In that case, try the websites of your state and local municipalities to see what they need through their vendor portals. However, for many people that opportunity may be out of your grasp initially, but there are still plenty of opportunities at individual school sites.

School sites are the best bet for most small businesses to make inroads and establish fruitful relationships that benefit both parties. You’ll still need the insurance for property and liability but that’s more accessible for fundraisers! For about $100 a month you can get the required insurance to get your foot in the door and talk to principals and other school site leaders. On-site people who have spending power are the Principal, Assistant Principal of Athletics (or APA), and the club sponsors. These three positions each have access to spending of certain monies with some limitations. Here is what you should consider with each prospective person:

· Principals in general have the largest amount of leeway to spend a prescribed amount of discretionary funds as they see fit. They can quickly approve PO’s and make decisions

Principal. But luckily you already know to have spoken with them and it should be a smooth process when they know the vendor and the reputation you have fostered at the school.

Finally, saving the best for

· APAs are great people to know because they are the contact for each coach who has teams and if they know your name and recommend you. It’s money in the bank. Beyond that, they also have specific needs throughout the year and work directly with the principal to have quick authorization of funds. While they do not have their own discretionary monies, they do have a direct line to the booster club which are 501(c)(3)’s that have autonomy to spend money as they see fit; but more on that later. They also lead clubs at school sites, so they can help you connect to sponsors who need items.

last, are the coaches and the booster club; I told you we would get back to them! You’re probably thinking they’re great because of all of the opportunities they provide to make money, and you would be right; however, their best quality is the fact that the booster club and all of the coaches’ monies come from a 501(c)(3) who can quickly cut checks and

make decisions regarding their own funding since they are a corporate entity. That means that they can place orders all year, at any time, and provide you with a check as quickly as they meet to approve funding and handle new business, which is usually weekly. It also means they don’t have the accounting rules of the government entity they work with and can

continued

here...

Imagine you’ve just purchased a toy and your child is happily playing while you enjoy watching them.

Now imagine that the toy broke and before you could hop up the child put the broken piece in their mouth and began choking.

A happy moment can spin on a dime and become a caregiver’s worst nightmare. What makes this situation worse is that this toy was from a handmade maker and now that they are aware of it, they are overrun with guilt (as an understatement I’m sure).

If you are the maker in this scenario, you are probably thinking now, “Oh! I hadn’t even considered…” and you would not be alone in this.

The Consumer Product Safety Commission (CPSC) in the US has the job of making sure that there are base requirements for many products that we see all around us to help reduce these risks, but these laws aren’t always the easiest to find.

That’s what I’m here to help you with. Today, we’ll walk through what to consider so that you don’t have this situation ever become a reality. Five steps. That’s all it’s going to take!

The first thing that you’ll do is register with the CPSC at SaferProducts.gov. This registration is FREE (I love that word!) and allows you, as a small batch maker, to save a little bit of your moolah when it comes to testing. This step is a quick 2-part process.

1. The first step is to get an account (where you’ll make reports about safety issues if ever needed).

2. The second step is getting your Small Batch Manufacturer (SBM) number (allowing you some testing relief).

These two parts are streamlined in the registration process, so it feels like you are only doing one thing. After getting your SBM number, you’ll basically ignore this registration until January when you need to renew.

Step 2 - Age-Grading

The second thing to do is take an honest look at your product. This is probably the most in-depth part of the process as we have to really consider who is using our product and how they are using it. Let’s take a wooden name puzzle.

Who is going to be using it? Well, it’s likely to be used as nursery decoration, but then be given to the child to play with once they take an interest in it. So, you’ll treat it as a toy.

What age will the child be when they begin to play with it? This is important as it tells you how much and what kind of testing to consider. A child that is under 3y is more likely to put things in their mouths so you need to keep small parts in mind (and Small Parts lab testing). A child that is over 3y likely won’t stick things in their mouths, but if you have small parts, you’ll need to make it clear that they exist (small parts warning labeling). The CPSC determines that children around 12m will begin to take an interest in puzzles in general.

The next question is, what age will the child be able to play with it? Puzzles require three major skills: fine motor skills, visual discrimination, and cognitive planning. Name puzzles aren’t particularly difficult when it comes to visual discrimination or cognitive planning. Two year olds are able, and excited, to look and learn their letters and place them into well defined wells and an ‘A’ can only go into one place that is easily discernible after all.

However, I’m sure you’ve noticed that puzzles can be made in all sorts of ways with some having large knobs, some having tiny knobs, and some having no knobs at all. This is where you’ll have more room for age grading differences. For example, in the CPSC’s standards for age-grading, 3-year olds can start playing with puzzles without knobs, but may need something like a magnetic tool to pick up the pieces. Four year olds are able to easily play with puzzles that have no knobs without the need for magnetic tools.

We’ll say you’ve chosen to make a name puzzle with no knobs, so you can go with a 3y-4y+ age grading. Additionally, you may market specifically towards caregivers with preschoolers, so this 3y-4y+ age grading works with that too.

Now you’ll get into the testing. You are making a child’s wood toy with paint for children 3y+, so you’ll need to comply with the following:

• Total Lead Content (CPSIA Sec 101)

• Lead in Surface Coatings (16 CFR Part 1303)

• Heavy Elements (CPSIA Sec 106 / ASTM F963)

• General Toy Standard (ASTM F963)

Wood is generally exempt from all of the chemical/elemental tests (untreated). Paint & sealants need to comply with Lead in Surface Coatings and Heavy Elements. The finished toy needs to comply with ASTM F963. That is going to cost a LOT. Yikes!

You registered with the CPSC so you can save a little moolah on this, remember? Instead of testing on your own right-away, you can contact your paint supplier and ask if they’ve already had their paints tested for Lead in Surface Coatings and Heavy Elements. Request a copy of their lab report.

Obtaining supplier statements of testing should be done every year to assure that nothing in the process of making the finished products or its components has changed.

If they cannot offer that information, then you’ll have to choose a different supplier or test on your own at a CPSC-accepted lab (CPSC.gov/labsearch).

Looking at your finished product, there may be some tests from the General Toy Standard that you can do at home. Huzzah!

Once you’ve got either the information from your supplier, and/or have tested on your own, it’s time to document all the work you’ve done and certify your product. That’s right, you will be certifying your product on your own! You don’t turn this information in anywhere and instead will keep it in your records collecting digital dust until specifically requested from a CPSC agent.

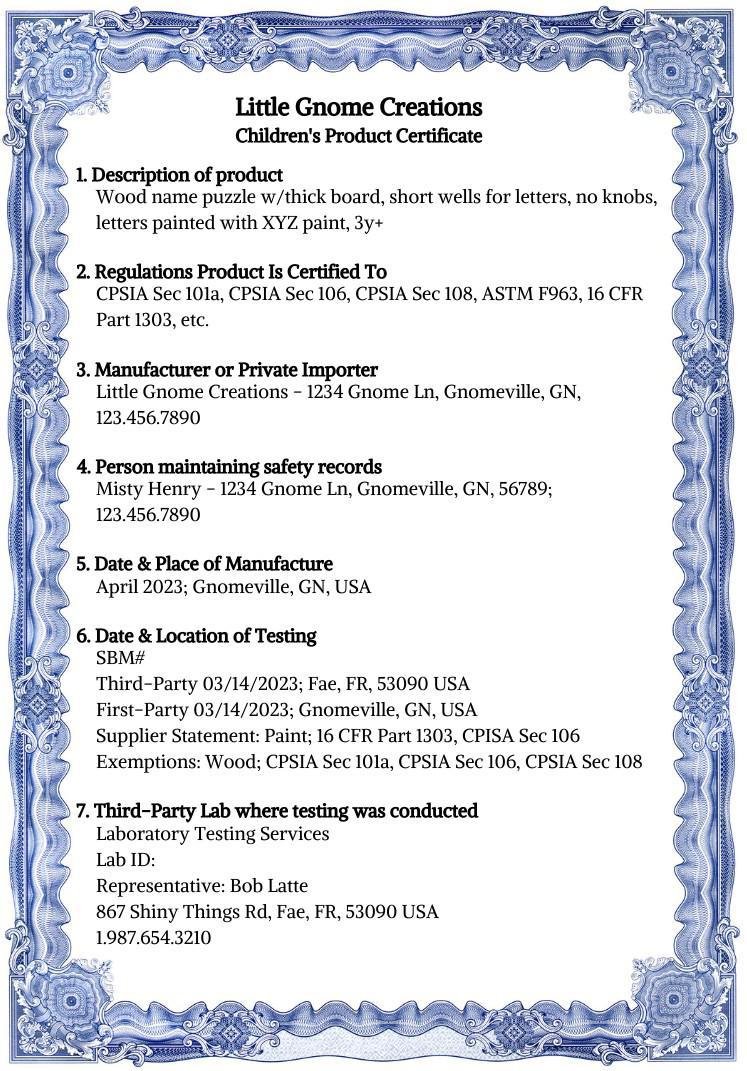

The document is called the Children’s Product Certificate. This is a seven-part, single-page paper that you can create in digital format and keep in digital format. (It does not need to be fancy, I’m just a little extra.)

Because the date in #5 is done by month, you will create a new document every month that you create your product. Many makers will make a copy, then replace the date in #5, taking just a couple minutes on the 1st of the month to keep their documentation up-to-date.

Finally, we are to the last step: Labeling! Some people dislike this part, but if I’m being frank, this is at bare minimum your branding and many small batch makers forget this step! This information needs to be permanent so that it lasts the useful life of the product through proper care and use.

For a wood puzzle, you can utilize the back of the board and include the information as an engraving, a printing, a stamp, or a very firm sticker (that can’t be removed except with Goo-B-Gone® or similar).

The purpose of this labeling is for the current consumer to know:

1. who you are (business name & website),

2. where the product came from (where it was made),

3. when it was made (month & year), and

4. be able to know if they are involved in a recall should one occur (batch/date).

This means that your labeling may look like this:

In the event of a recall, you can provide the consumer with your business name, the product image, the location it was made, the date it was made, and any other information you think would be helpful to them to know if they need to contact you about a remedy. You can look at how recalls are listed at CPSC.gov/recalls.

On your online listing, make sure you include your age grading, clear and conspicuous, so that shoppers can see who the toy is best for. Make sure your images match your age grading too!

You can also include other literature in your packaging to provide proper use and care instructions as well as reiterating the age grading. This information helps continue to remind consumers how to stay safe while using your products.

Celebrate!

WOW! That’s it!

You’ve completed:

• Registration with the CPSC

• Age Grading your product

• Testing your product

• Documenting your process to certify your product

• Labeled your product

With all of this work that you will do, you’ll be able to better avoid situations catching you off guard. Simply consider your end user, how old they are, and how they would likely use your product, and design around that.

You’ve got this, but if you’re a little apprehensive, I’m here for you! I encourage you to meet me at The Makers Resource Shop or on Facebook in the US Product Safety Compliance group.

I cannot wait to see your products out there!

Misty Henry helps makers build their passions through compassionate guidance of the product safety laws in the US and Canada so they can build a life they dream of without worry. She owns The Makers Resource Shop and you can contact her at hello@ themakersresourceshop.com.

about laser engraving or cutting, we always talk about how the material needs to be in focus with regard to the lens to get the best results. However, that isn’t always the case. Each lens size has a specific distance that the material should be away from the lens to have the correct focal point. You can think of this like a flashlight. As a flashlight shines, it spreads out the further it gets away from the flashlight itself. As a laser beam goes through the lens, it starts to spread out at an angle little by little. The closer you are to the lens, the narrower that beam spot will be. The further away you are, the wider that beam spot will be.

When it comes to engraving multi-ply acrylic if you lower the table a few clicks, it will move further away from the lens causing the beam spot to be wider and machining a slightly wider path each time it passes. This can be very useful with this material. These wider paths that are engraved will overlap each other giving the final engraving a smoother look. The downside to putting the machine out of focus is the lines and details will get slightly larger in the engraving, meaning that line thicknesses will be slightly thicker. If you look at the image below, you will see that some of the lines in the engraving on the right are slightly bolder and thicker than on the right. This can provide a great aesthetic in some cases. Try it out for yourself on a more drastic level to see the effect in action.

Tip 5 – Use acrylic cleaner post engraving. After engraving, it is a good idea in general to clean the engraving. You can do this with just a cloth, water, or even acrylic-specific cleaners. There are a lot of options when it comes to doing this. If you figure out the settings well enough, you often don’t need a cleaner, but if you notice dust or anything else in the engraving, cleaning it post-engraving will help achieve a better result.

There are two cleaners that I have found to be pretty good. The first is Enduramark Green and the second is NOVUS. These cleaners are specifically designed to clean the surface of the acrylic without harming the acrylic itself. Make sure that if you are using a cleaner, it is not going to melt or damage the surface. When cleaning, use a shop cloth like a microfiber cloth or blue shop towels that won’t leave fibers. Don’t use things like normal paper towels as they will leave lint and fibers behind on the acrylic.

There are a ton of ways to get good engraving results on multi-ply acrylic. The most important thing is to make sure you take the time to test the material with your machine to figure out what works best for your setup. What works for me and my machine, won’t be the exact same for you. It will take time to figure it out and you will have some costs when it comes to using materials to do that, but I guarantee you that it will reduce a lot of frustration when you start to make products for your customers.

If you’re using a machine where you cannot manually adjust the height, such as the Glowforge, you can make the material thickness setting thicker than the actual material to artificially throw the machine out of focus. For example, if the material is 0.125” thick, you can put 0.15” or similar to force the laser head out of focus.

Trevor

Guest Contributor: Alex Fuentes,

Starting a new project in wood can be daunting. There’s just so many wood options out there. Hardwood Vs Plywood, 1/8 thick Vs 1/4 thick. And the choices don’t stop there. There’s also the question of wood species. Do we go with MDF? Baltic Birch? Maybe something more upscale like some Walnut, Sapele, or even some Zebrawood for those lux products. Well, strap in and read on and I will do my best to help shed some light on this dilemma.

In the laser community, Hardwood normally refers to a wood sheet that’s a solid piece of wood, where plywood is a thin veneer with a core filler (either MDF or wood core).

Hardwood: Larger selection of exotic woods, like Zebrawood, Purpleheart, Ambrosia Maple. Cuts well.

Zero staining or painting required, just clear coat to showcase natural beauty.

Most expensive option.

Large pieces can be hard to source. Brittle at 1/8 thickness. It can easily snap along the grain line.

Plywood (mdf core or veneer core): More cost effective than hardwood. Large variety available in large sizes. Can

be found in Maple, Walnut, Cherry, Mahogany, and more.

Consistent cuts, especially with an MDF core.

No need to stain, just clear coat.

Lightweight.

Can work well for living hinge projects as its not brittle like hardwood.

Can be expensive.

Burns dirty because of the MDF core. Will require cleaning laser more often.

Now that we know the pros and cons of the two, when do we use what? Well, that’s really up to the artist, but this is my recommendation.

Hardwood is great for jewelry with simple designs (allows the wood to be the highlight) and for high cost art pieces.

MDF core plywood is great for high margin items where using a nicer material will help you stand out from the crowd. Think ornaments, layered designs where weight is a concern. It is also great for projects where you will have a living hinge since its not as brittle as hardwood.

1/8

This is probably the easiest decision you will make.

1/8 thickness is great for any project where space and/or weight is a concern. Earrings, layered wall pieces, layered ornaments, purses, etc.

1/4 is best when sturdiness/stability is the main concern. Usually its used as the bottom layer (backer) for wall pieces. But it can also be great for ornaments, candle boxes/desk boxes, etc.

Natural wood tones: Double sided woods or Hardwood. These products gorgeous as is and display the wood as nature intended. Just seal it with your favorite clear product to make the colors come alive (bottom half is clear-coated).

Do we use MDF, Baltic Birch, some nice double-sided wood with MDF core, or some hardwood? This decision is primarily driven by the artist and the desired end state. But there are a few questions we can ask to help narrow it down.

Is the project to be painted, stained, or left as is?

Painted: MDF or Baltic Birch. Both of these can take paint well and are low cost materials. Double sided wood or hardwood is too expensive and honestly too pretty to cover up with paint.

Stained: Baltic Birch. Baltic Birch is cost effective and takes stain well as it has wood grain to it. MDF does not stain well at all as it has zero wood grain. Nicer materials should not require any sort of stain since they are already pretty as is. They just require a clear coat to protect them and get the colors to pop.

If trying to keep cost down, then using a material like Baltic Birch or MDF will reduce cost. Keep in mind though that usually what you save in money will cost you time and effort. $3.50 for a piece of Baltic Birch plus the effort to stain it Cherry or $8 for a piece of Cherry that just needs clear coat?

If the project is going to be a layered wall piece with 7 layers, using 1/4 is probably not the best idea. It will make the piece too heavy and almost 2 inches thick. The project will usually dictate the thickness, not the other way around.

MATERIALS: WOOD... continued

Is the project going to be handled a lot? Does it have a living hinge?

If the project is going to be handled a lot, hardwood is usually not recommended as it is brittle. Earrings can be the exception but they should be kept to simple designs. If there is a living hinge involved, hardwood is not recommend at all as it will crack along the grain line.

Soooo….WHAT WOOD WOULD A WOODCHUCK USE IF A WOODCHUCK COULD USE WOOD?

As you can see, it really depends on the woodchuck and what that woodchuck is making. But, if I can leave you with one final piece of advice it would be this.

Don’t be afraid to experiment with new wood types. You’ve always used Mahogany, why not give Sapele a try? Love Zebrawood but don’t like the high sticker price? Check out some Black Limba. There’s a huge variety of wood types, colors, wood grains, etc out there. So go out, have fun, and let your inner Woodchuck go wild.

Alex and Antoinette Fuentes are

approve fundraisers and purchases. Make sure to have the APA introduce you to the president and the treasurer as they are the keys to opportunity and prompt payouts and then make your move and ask for an opportunity to sales pitch to the coaches. Make sure to:

1. Create a PowerPoint with your services, photos of your work, and all your contact info.

2. Bring samples of items you’ve already made for visual representation.

3. Discuss opportunities for fundraising and have a price sheet and a plan for those items

4. Be willing to deliver the items to the school; it’s a reason for you to be on campus and connect.

5. Offer teams that fundraise with you a discount when they buy their trophies/items from you.

So go online or make some calls to find out the names of these people and then take the chance and go meet with your local schools ASAP. End of the year opportunities are here: prom is happening now, teacher appreciation is next month, and end of the year awards are right around the corner. So put this info to the test and go speak with administrators and coaches who are already planning for next year with fundraisers, new teacher gifts, and signage that needs replacement over the summer.

Matt Boddiford is the owner of ELC Creations. You will also find him on Laser Everything as an integral part of that team. You can reach out to him here: Matt@ELCcreations.com, Instagram: @ elc_creations, Laser Master Academy: LE Matt

Having a logo is an excellent place to start your business. Don’t worry if it’s not perfect. You can change your logo, rebrand, and change things as you grow. In the last 20 years, we have rebranded three times. The important thing is to start the process of making your brand visible with a good logo today!

When creating a logo, another helpful hint is to have a horizontal, and a vertical or stacked version. In addition to the colored variations, you may want a solid black and white version for watermarking photos or videos.

An engravable logo can be a stepping stone in building brand awareness for products that might attract future clients.

Hi, I’m Hope, the entrepreneur behind Designs By Hope Yoder. I started my journey in the embroidery and fabric industry by creating products, courses, designs, and fabric for the home market. I have had the privilege of inspiring many along the way with our magazine articles, workshop, and corporate projects. Most days, you can find me dancing to Cupid Shuffle, in front of my computer designing, or behind my laser creating handmade happiness. Find all my social links here, including our laser courses and retreats.

The results show that in addition to people that purchase files (i.e., do not design their own), almost half of the 44.15% that do design files also buy files!

I will always recommend building and implementing a Customer Service System, it’s quick to implement when you get a new customer, and you have it every step of the way a guided system with excellent results.

When I started, I remember needing to be more diligent about my customers’ journey experience with my business. I often wondered why they never ordered with me again, even though they were so happy with my work. Now I know it was my nonexistent Customer Service System; I didn’t have the tools to ensure that satisfied customers were retained and transformed into repeating customers, ambassadors, followers, or fans.

A customer service journey in my business is a visual representation of the end-to-end experience that my customers have when they interact with my service or try to accomplish a goal through something I offer (an order, for example).

The customer service journey has to be tailored to your products and services, but here are a couple of points that will help you tailor your own:

The number one rule in putting a plan together is to do it! Start planning and building your next steps now! Guess what is going to be challenging! My first plan could have been better, it was not even close to perfect, but I had something to work with. To build momentum, you need to start moving. You can always go back and revise, make changes, and adjustments, but you have to start somewhere.

Anca Wetegrove is the owner of Hp Designs by Anca, based in McKinney, Texas. Anca has been in the laser business since since 2020. As a maker she is active on all social media, you can find her everywhere using @hpdesignbyanca. Feel free to contact her with any questions.

Step 1

Cut the bottom piece out of your acrylic of choice.

This piece will be the one that shows the most so pick your favorite.

Materials Needed: Acrylic sheet of choice

Clear Acrylic sheet

Acrylic scraps

Confetti pieces

Weld-on glue or other clear acrylic glue

Shaker boxes are easy fun decoration

To get started all you have acrylic to use and follow

(You can get this file for Use code

Step 2

Cut the side pieces out of your acrylic of choice. These pieces create the width of the shaker box. Add as many as you would like but at least 2. You can cut an extra piece to use as the trim in step 5 if you want to.

easy to make and a decoration or gift! have to do is decide which follow these easy steps! for free at craftcloset.com. code LFFILE)

You can watch the video by clicking here

Step 4

Cut the top piece out of clear acrylic. If you want to engrave the front, reverse the image and engrave from the back. Engraving it from the back will give you a sharper engrave. Glue the top layer to the flower piece using clear acrylic adhesive such as Weld-on acrylic adhesive.

Step 3

Add desired confetti before you glue on the top! You can make confetti out of acrylic scraps!

Step 5

Add trim to the top if desired. It isn’t needed but does cover glue spots if they show

Project Contributor: John Kuiphoff, Glowforge For Beginners

The most frequently encountered types of laserable plywood available for purchase are maple, walnut, and cherry, which I like to refer to as vanilla, chocolate, and strawberry. While these classic options are great, sometimes you need more variety for your projects.

In this tutorial, we will demonstrate how to create unique laserable plywood using veneer, glue, and MDF. I chose MDF as our core material because it offers excellent stability and consistently dark engraving results.

There are two popular methods for attaching veneer to MDF: using clamps or a vacuum bag. During my live demonstration on Glowforge’s channel, I used clamps since that approach is more accessible. In that demo, I created a series of woodland creatures using multiple types of veneer. However, a vacuum bag provides more consistent results and simplifies the process, so we’ll use that method in this tutorial.

First, I will guide you through the simplest way to create your custom laserable plywood. Then, I’ll show you how to expand upon this technique to produce even more inventive examples with various materials and processes.

Thin sheets of veneer Exotic sample packs work well when getting started.

Sheets of 1/8th MDF Baltic birch plywood can be used as a substitute; MDF is more stable than plywood.

Titebond Coldpress for Veneer Glue

Standard Titebond III wood glue can be used as a substitute. Although, veneer glue is less likely to peek through small pores in your veneer.

https://amzn.to/40w3LjQ

https://amzn.to/3TX3rZ0

https://amzn.to/3ZLTNd7

Roarockit Thin Air Press Vacuum Bag Kit

The kit comes with everything you need. You might decide to purchase an electric vacuum pump, hose, and adapter later.

Silicone Glue Brush You can use a foam brush or a roller as a substitute.

Wax paper

This will prevent glue from sticking to the vacuum bag .

https://amzn.to/3zlJ6TB

Greenstar TransferRite Ultra 582U Medium

Optional

Optional

Finish

https://amzn.to/42ZiC7V

https://amzn.to/40uUj07

https://amzn.to/3nG4Si8

Step 1: Cut three MDF sheets to the same size as your two wood veneer sheets using a table saw or laser cutter. One sheet will serve as the plywood core, while the other two will be used for stabilizing your piece and can be reused.

Step 2: Apply glue evenly to both sides of the core MDF sheet using a silicone or foam brush. Avoid applying glue directly to the veneer sheets to prevent curling.

Step 3: Attach the veneer sheets to each side of the glued MDF core.

Step 4: Place a wax paper sheet on both the top and bottom of your MDF-veneer assembly.

Step 5: Position an unglued MDF sheet on the top and bottom of the wax paper-covered MDF-veneer assembly.

Step 6: Place the entire assembly into the Roarockit vacuum bag, positioning it directly beneath the nozzle. Insert the provided red ribbon between the nozzle and your assembly.

Step 7: Seal the vacuum bag by pressing the tape firmly.

Step 8: Remove all air from the bag using the supplied hand pump or a vacuum pump. When using the hand pump, you'll know the air has been removed once pumping becomes difficult.

Step 9: Allow the piece to set for at least two hours. Ensure the bond is secure.

Step 10: Removing the piece from the vacuum bag.

Step 11: If necessary, sand away any glue residue from both sides of the veneer sheets.

Step 12: Apply 2-3 coats of spray shellac to each side of your finished piece.

Step 13: Before cutting and/or engraving, apply laser-safe transfer paper to your piece.

Step 14: Laser cut and engrave your custom plywood.

With a grasp on creating laserable plywood, you can now explore different materials and techniques to expand upon the process. For instance, you can simply glue paper to MDF as an alternative to veneer. I've experimented with other materials as well, like using contact cement to attach veneer to a colored-acrylic core. Feel free to get creative with your material choices.

You can also try laser cutting two or more veneer sheets to create inlay-style patterns. In these examples, I used transfer paper to position the smaller pieces into their designated spaces before adhering the entire sheet to the MDF.

Currently, my favorite method involves constructing thick cutting boards from various hardwood strips. I then use

a bandsaw equipped with a high-quality resawing blade to create unique ⅛-inch veneer sheets from the cutting board, similar to slicing cold cuts at a deli. Next, I glue the ⅛-inch veneer directly onto one side of the MDF and place it in the vacuum bag. Once finished, I pass the piece through a drum sander to make the veneer paper-thin. I perform this step after gluing the veneer to the MDF; otherwise, the drum sander could potentially damage the glue joints in the pattern. I then repeat this process on the other side.

I hope you find this technique helpful! Over the next few months, I'll be uploading a series of YouTube videos to further explain this process. If you have any questions or would like to share your experiments, please feel free to contact me on Instagram. While this method works with any laser cutter, I currently teach an online course called Glowforge for Beginners,