Welcome to our 4th quarterly issue of the year. Besides our digital editions (English, Spanish and Chinese) we have bonus, hard copy distribution at AAPEX. Find us at Booth J3767.

Coincidentally AAPEX begins this year on Tuesday, November 5, the day of the US presidential election. Will the results if known be the talk of the show the following 2 days? Doubtful, as most people know business and politics don’t mix! And that’s a good thing

Automechanika Frankfurt is back on schedule, every other year on the “even” even years. And Laura Restrepo, our new Editor, was able to attend for the first time. It was an eye-opener for her, as it is for all who go. Yours truly has been there seven times and I never tire of it. Laura’s article is included in our 4 feature stories, listed below:

• Automotive painting and its challenges

• Automechanika Frankfurt 2024: Where innovation meets sustainability

• Refrigerant solutions for the automotive industry

• The magneto-rheological shock absorber and its remanufacturing

Here is something about vehicle electrification that I find interesting, and I think you will do. Any guesses which country is the only one where electric vehicles in operation (VIO) exceed gas-powered? It’s Norway…But leading both of them are diesel powered vehicles. This information courtesy of the Norwegian Road Federation, and was published recently in the Washington Post. Here is the breakdown

• Diesel 34.8%

• Electric 26.3%

• Gas 24.2%

• Plug-in Hybrid 7.3%

• Hybrid 5.4 %

For more information, see the full article: Electric cars now outnumber gaspowered in Norway, a global first - The Washington Post Of course Norway’s vehicle population is a sliver of the total worldwide. But it does show that progress in electrification can be made with the correct incentives and policies in place

Thank you for your support this year. Our loyal readers continue to read our digital editions, our weekly enewsletters and attend our tradeshow, AutoAmericas www.autoamericas.show/en/ This is for the South Florida and Latin American markets. We look forward to providing you timely technical information, industry news and other information.

Have a great holiday season and see you in 2025. Best Regards,

Brad Glazer, publisher Aftermarket International

It is a periodical publication owned by Latin Press, Inc.

Produced and distributed for Latin Press, Inc. by Latin Press Colombia and Latin Press USA

GENERAL MANAGEMENT

Max Jaramillo / Manuela Jaramillo

EDITOR IN-CHIEF

Duván Chaverra dchaverra@aftermarketinternational.com

EDITOR

Laura Restrepo C. lrestrepo@aftermarketinternational.com

PROJECT MANAGER

Andrés Caballero acaballero@aftermarketinternational.com

PUBLISHER

Brad Glazer bglazer@aftermarketinternational.com

ACCOUNT MANAGERS

MÉXICO

Sandra Camacho scamacho@aftermarketinternational.com

COLOMBIA Fabio Giraldo fgiraldo@aftermarketinternational.com

DATABASE MANAGER

Maria Eugenia Rave mrave@aftermarketinternational.com

PRODUCTION MANAGER

Fabio Franco ffranco@aftermarketinternational.com

LAYOUT AND DESIGN

Jhonnatan Martínez jmartinez@aftermarketinternational.com

FRONT PAGE

Latin Press

OFFICE PHONES: Latin Press USA Miami, USATel +1 [305] 285 3133

Latin Press Mexico

Ciudad de México

Tel +52 [55] 4170 8330

Latin Press Colombia

Bogotá, Colombia

Tel +57 [601] 381 9215

São Paulo, Brazil

Tel +55 [11] 3042 2103

The opinions expressed by the authors of the articles in this journal do not commit the publishing house.

Printed by Panamericana Formas e Impresos S.A. Acting only as printer

Printed in Colombia

ISSN 2834-8885

With this edition, we bring you the last issue of the year for Aftermarket International, and I can’t help but reflect on what has truly been a rollercoaster ride—one filled with highs and lows, as only the automotive and aftermarket industries can offer. It’s been an exciting year, full of experiences that have allowed us to connect with industry leaders, discover innovations that will shape the future, and witness how, despite the challenges, our sector continues to accelerate forward.

Throughout these months, we’ve shared trends, product launches, and highlights from global events, and all of this has been possible thanks to the unwavering support of our community. We want to thank you for accompanying us in each issue, for being part of this conversation, and for continuing to trust us as your go-to source for aftermarket industry news.

But this is not a farewell—it’s just a “see you soon”! We’ll see you in future issues of Aftermarket International, where we’ll continue bringing you the most relevant updates from the industry. We’re also excited to meet you at key events next year. AAPEX is just around the corner, and we know it will be an excellent opportunity to connect and explore new trends together.

Moreover, we can’t wait to share with you what’s in store for AutoAmericas 2025 in Miami. We know it’s going to be an unforgettable event, and we’re certain it will mark the beginning of great opportunities for everyone involved in the aftermarket world.

Thank you once again for your unwavering support this year. We’ll see you at upcoming events and, of course, in the pages of Aftermarket International.

See you soon!

Laura Restrepo Editor

6/The Evolution of Color Testing in the Automotive Industry

10/The Magnetorheological Damper And It Remanufacturing

13/What is an Automotive Temperature Sensor and How Does It Work?

16/Sustainable Innovations in Automotive Refrigerants

18/Innovation in Smart Vehicles and Their Hardware Requirements

Find information, contacts, links to industry associations, free literature from businesses that advertise in the publication, events, and downloadable issue archives dating to 2007 at aftermarketinternational.com

3/Out Front

21/Business

31/Trade Shows

For advertising, contact Brad Glazer at 216 233-6943 bglazer@aftermarketinternational.com

Andrés Caballero +1 [305] 285 3133 Ext. 94 acaballero@aftermarketinternational.com

By Laura Restrepo C.

The evolution of color testing in the automotive industry reflects significant technological advances.

From manual methods to sophisticated systems, the pursuit of precision has transformed vehicle manufacturing.

Color testing in the automotive industry has undergone significant evolution from its rudimentary beginnings to the advanced technological systems used today. This progression reflects broader technological advancements and highlights the increasing importance of precision in automobile manufacturing. This comprehensive overview explores the history of color testing, detailing key developments and innovations that have shaped the field.

In the early days of the automotive industry, color matching was largely an empirical and artisanal process. During the early 20th century, automakers relied on simple, manual methods to ensure color consistency. Paints were mixed according to recipes and applied using basic techniques. To match colors, technicians used physical color samples, comparing them under various

lighting conditions to achieve a close match. This method relied heavily on human perception and was subject to significant variability.

As automotive production volumes increased, the limitations of these early color matching techniques became more apparent. Variability in paint colors could lead to inconsistent finishes, affecting the overall quality and appearance of vehicles. This challenge drove the need for more precise and reproducible color testing methods.

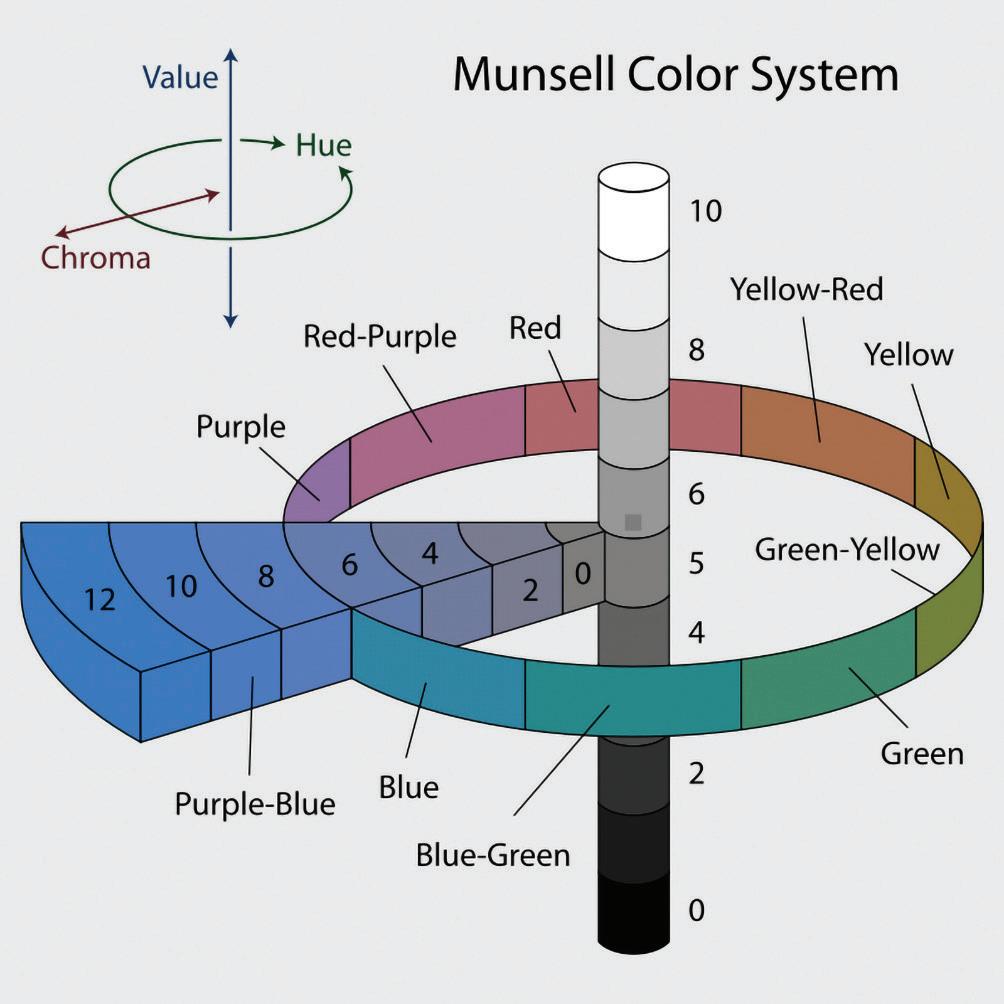

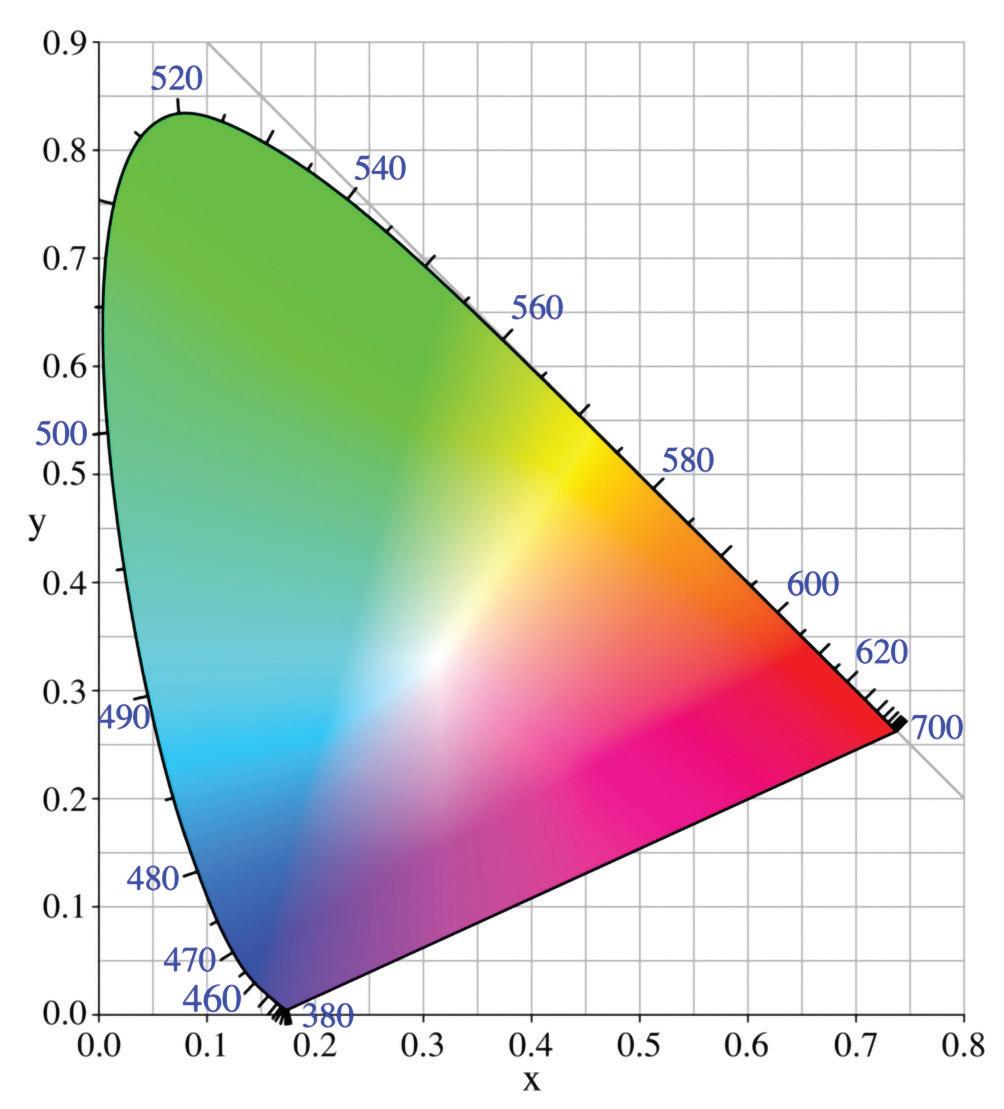

By the mid-20th century, a transformative shift occurred in color testing with the introduction of color science and standardization. During this period, the automotive industry began to adopt more scientific approaches to color matching. The development and adoption of color measurement standards, such as the Munsell color system and the CIE (International Commission on Illumination) color space, provided a structured framework for quantifying and communicating color.

Munsell Color System: Developed by Albert H. Munsell in the early 20th century, this system classifies colors based on three attributes: hue, value (brightness), and chroma (color purity). It introduced a systematic approach to color organization, allowing for more consistent communication of color specifications.

CIE Color Space: Established in the 1930s, the CIE color space offered a mathematical model for color perception. It became a cornerstone of color measurement by providing a standardized method for quantifying and comparing colors across different devices and applications.

With these systems, automakers could create more consistent and reproducible paint formulations. The use of standardized color samples and reference charts became common practice, improving accuracy in color matching and reducing variability in paint applications.

By the late 20th century, a crucial moment in color testing occurred with the advent of spectrophotometry. Spectrophotometers revolutionized color measurement by providing precise, objective data about color characteristics. Unlike earlier methods that relied on human judgment, spectrophotometers used scientific principles to analyze color.

Spectrophotometers measure the intensity of light reflected from a painted surface at various wavelengths. This data is compared to standard color samples, allowing for accurate color matching. The ability to quantify color in this way greatly enhanced the consistency and reliability of paint applications.

The introduction of spectrophotometry addressed many challenges faced by the automotive industry, including batch-tobatch variations in paint and differences in lighting conditions. By providing precise color measurements, spectrophotometers enabled manufacturers to achieve uniform finishes in highvolume production.

In the early 21st century, further advancements in color testing occurred with the integration of digital technology. Modern spectrophotometers are equipped with advanced software that enhances their capabilities. This software can handle complex color data, perform real-time color matching, and provide detailed feedback during the manufacturing process.

Digital Color Management Systems: The development of digital color management systems has been a significant advancement. These systems integrate with other aspects of automotive design and production, allowing for precise color control throughout the entire manufacturing process. From initial design to final production, digital systems ensure that color specifications are consistently met.

Real-Time Feedback and Analysis: Digital technology has also enabled real-time analysis of color data. This allows manufacturers to make immediate adjustments to paint formulations or application processes, enhancing overall quality and production efficiency.

In recent years, artificial intelligence (AI) and machine learning have begun to play a role in color testing, bringing new levels of sophistication to the field. AI-powered systems can analyze large amounts of color data, identify patterns, and predict color trends.

AI in Color Matching: AI algorithms can improve color matching by learning from historical data and making predictions about color formulations. This approach allows manufacturers

to anticipate and address potential issues before they arise, enhancing the accuracy and consistency of color applications.

Machine Learning Algorithms: Machine learning algorithms can detect subtle color variations that might be overlooked with traditional methods. By continuously learning from new data, these algorithms can refine color matching processes and provide more accurate recommendations for achieving desired color results.

As technology continues to evolve, the future of color testing in the automotive industry offers exciting possibilities. Emerging technologies, such as nanotechnology and advanced coating materials, could further influence color testing methods.

Nanotechnology: Advances in nanotechnology could lead to the development of new coating materials with unique optical properties. These materials may require new approaches to color testing and measurement, driving greater innovation in the field.

Advanced Coatings: The introduction of new types of automotive coatings, such as color-changing coatings or reflective coatings, will present new challenges and opportunities for color

testing. These coatings may require specialized testing methods to ensure they meet performance and aesthetic standards.

The history of color testing in the automotive industry reflects a journey from manual methods to highly advanced technological solutions. The evolution from rudimentary color matching techniques to today’s sophisticated spectrophotometers and digital systems illustrates the industry’s commitment to precision and quality. As technology continues to advance, color testing will remain a critical component of automotive manufacturing, ensuring that vehicles not only perform well but also meet the highest standards of visual appeal.

By Carlos Panzieri*

This article explores its fundamental characteristics, the innovation of magnetorheological fluids, and the practical implications in the design of modern dampers.

Roughly speaking, Newtonian fluids are those that flow even with minimal effort. Air, water and oil are Newtonian fluids, in fact a drop of oil, subjected to any non-zero pressure, deforms immediately. Obviously, the more viscous the oil, the less it deforms, but no matter how viscous it is, it still deforms.

Bingham fluids, on the other hand, again roughly, are those that do not deform at all below a certain pressure, behaving just like solids, while above a certain pressure they begin to flow behaving like liquids. Grease or toothpaste are Bingham fluids, in

fact, if we turn a tube of toothpaste upside down it does not flow. It still does not slide even if we apply a slight force to it, and in fact to make it slide, we must apply at least a certain force to it, and once the force is removed, it returns to behave like a solid and no longer flows.

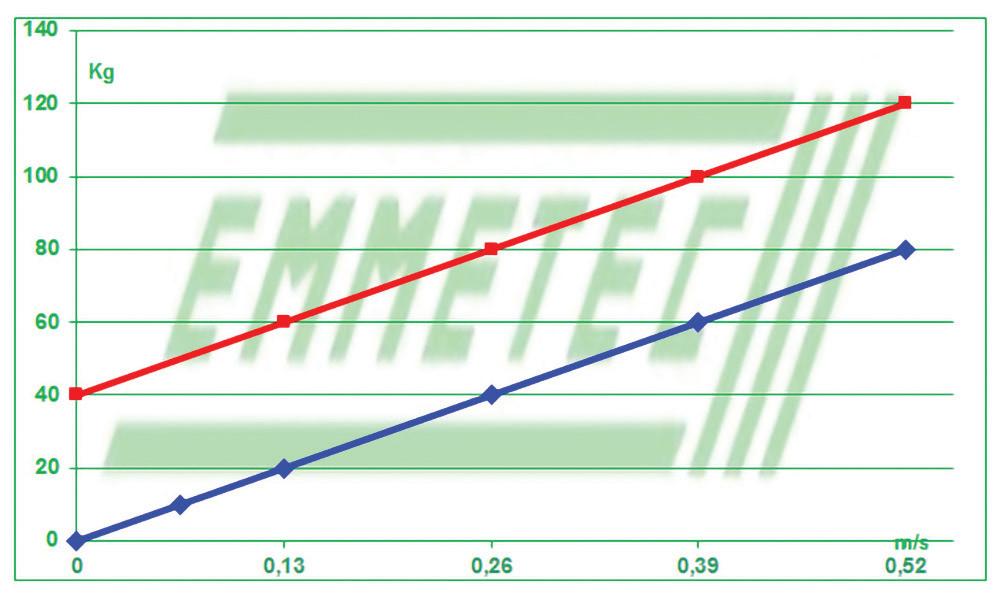

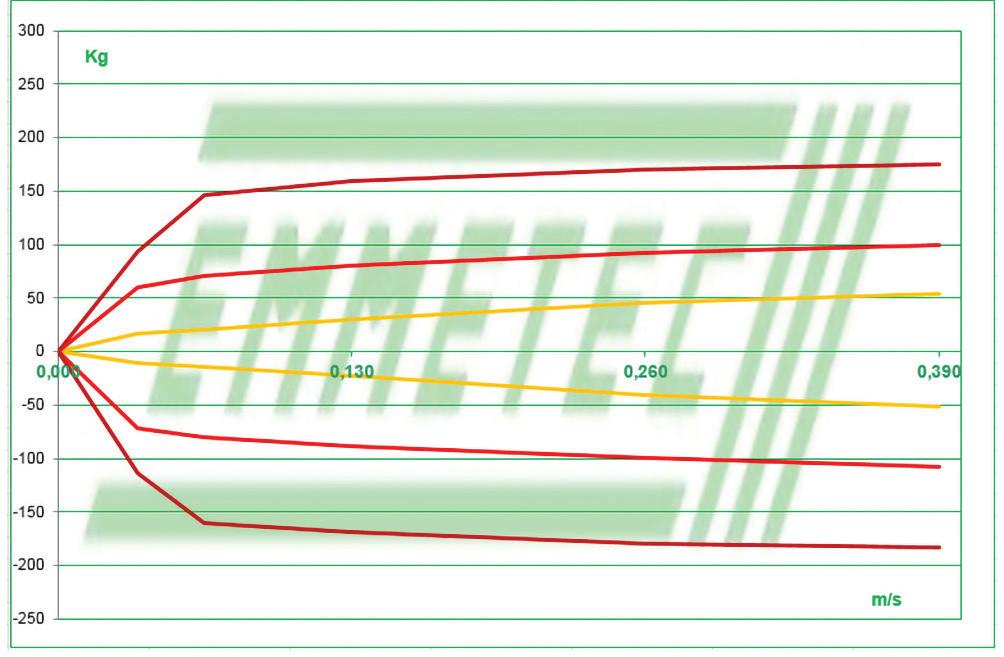

A Bingham fluid (01 red line) has many differences compared to a Newtonian fluid (blue line), and the main one is that it offers a much higher resistance to deformation at low flow speeds.

MR fluids present a behavior more or less similar to Bingham fluids depending on the intensity of the magnetic field to which they are subjected, and this is because they consist of a solution of magnetic particles in oil containing additives against sedimentation, wear and corrosion.

MR fluids have some drawbacks:

1. depending on the content of metal particles, the density exceeds 3.5kg/litre, making the shock absorber very heavy;

2. they are expensive;

3. they are extremely abrasive, which is not good for the guide and the oil seal, so the life of the shock itself is a critical issue;

4. they are highly polluting, like any other oil, but with the addition that they contain metal particles that must not be dispersed in the environment, especially in water! Therefore, since it can be recycled, it must be disposed of according to current regulations. For further information (legislation may vary in this regard), we recommend contacting your disposal service provider;

5. regarding toxicity, several conflicting rumors are circulating, so when in doubt it is always better to use gloves, glasses and work in an environment that is as ventilated as possible.

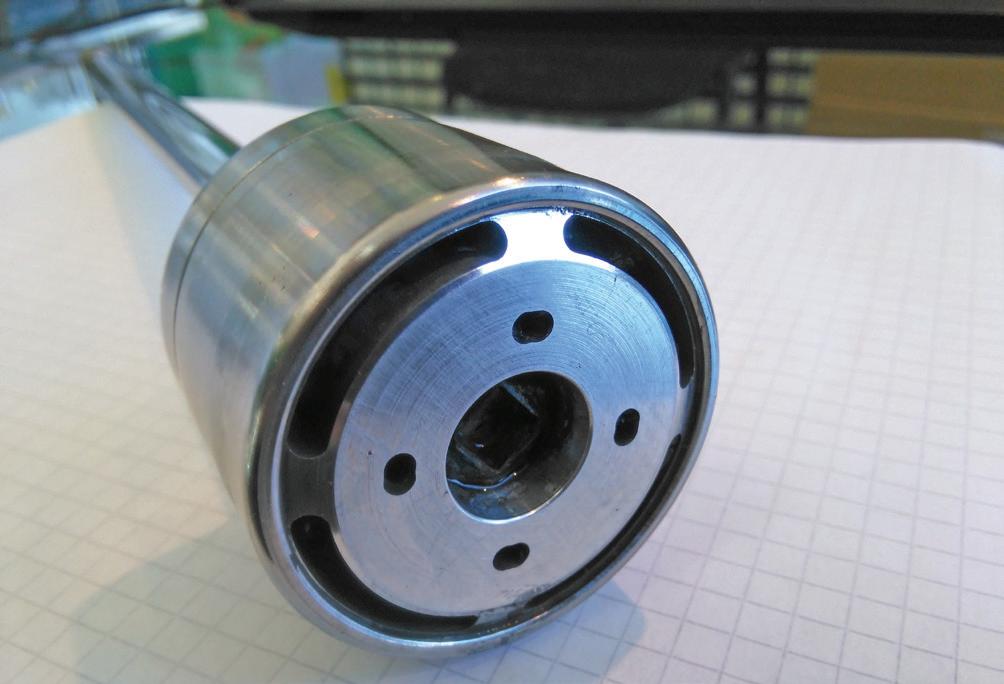

It is similar to a single-tube shock absorber except that the piston (fig.02) is equipped with large holes, is devoid of any valve, and inside contains a solenoid which, depending on the voltage, polarizes the particles of the MR fluid or not.

When the fluid is placed under tension, the metal particles tend to form clusters around the piston which offer resistance to its sliding: the greater the tension, the greater the resistance to sliding.

A good MR oil can vary its characteristics hundreds of times per second, which allows the shock absorber to instantly and continuously vary its calibration.

An MR shock absorber, at the same tension, offers the same compression and rebound damping force (fig.03), which however is not a problem because, as mentioned before, it varies continuously.

MR shock absorbers are very common on AUDI, Cadillac, Ferrari, FORD, GMC, Lamborghini, Land Rover and many other sports and luxury cars.

Due to the abrasiveness of MR oil, the original oil-seal and separator o-ring wear rapidly, lasting approximately 30,000km or less.

The first consequence is the loss of the liquid part of the oil which causes the remaining MR oil to become less and less fluid and free-flowing to the point of blocking the shock absorber. It can also happen that if the o-ring wears out, the gas ends up in the oil making the shock absorber noisy.

When this happens, the only solution is to replace the shock absorber.

The market offers the OE shock absorbers (good but very expensive) and cheap copies which often turn out to be terrible twin-tube shock absorbers. This is why the revision of the original used shocks is becoming more and more widespread, which in addition to providing an excellent product (if done in a workmanlike manner) grants a large profit margin to those who do the work!

www.emmetec.com is an Italian company specialized in components for the overhaul of shock absorbers and hydraulic and electric power steering.

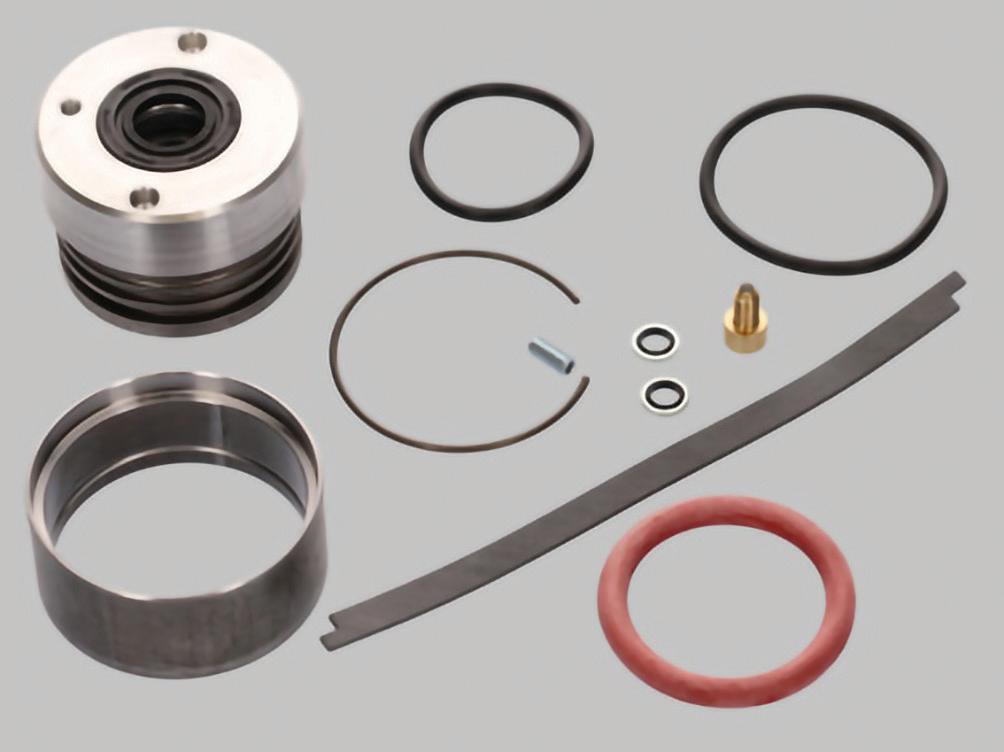

Emmetec, for the overhauling of MR shocks, has developed a wide range of kits including guides and special anti-wear oil seals (fig. 04), MR oil with the same characteristics as the original one, and MR powder (fig.05) to modify the characteristics of the original oil or make it yourself.

To understand how to repair an MR shock absorber, we invite you to see the videos in English and Italian that you find on Youtube by typing Emmetec BWI.

If you would like more information, we recommend you to contact directly www.emmetec.com or www.jadausa.com (its distributor in the USA) which will put you in contact with the Technical Department.

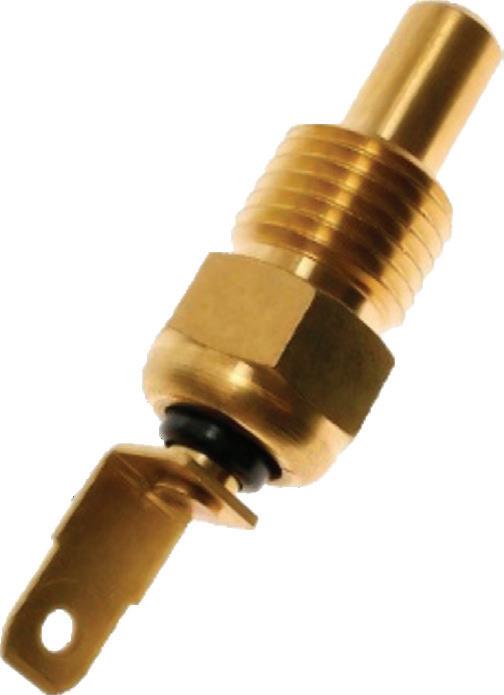

By: Ramco Automotive Technical Department

With insights from the specialists at the Ramco Automotive Technical Department, we explain temperature sensors, their operation, and some troubleshooting basics related to this component.

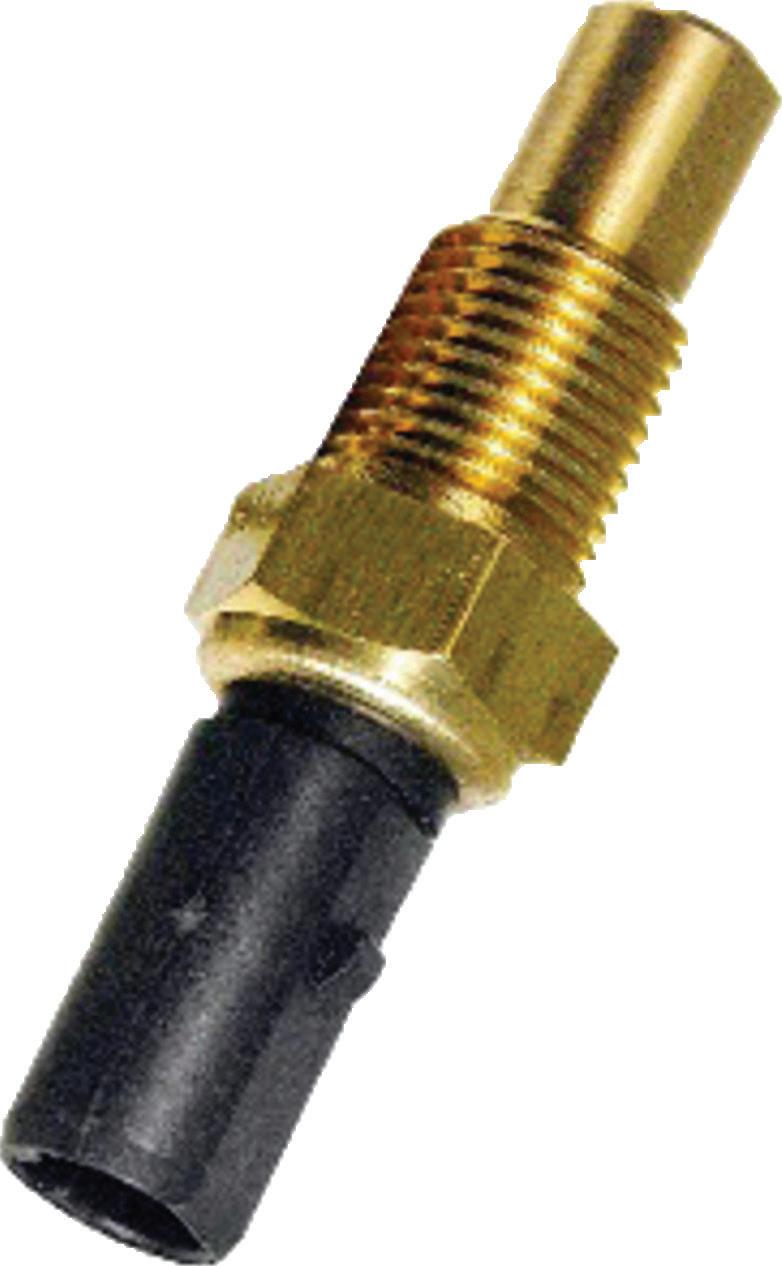

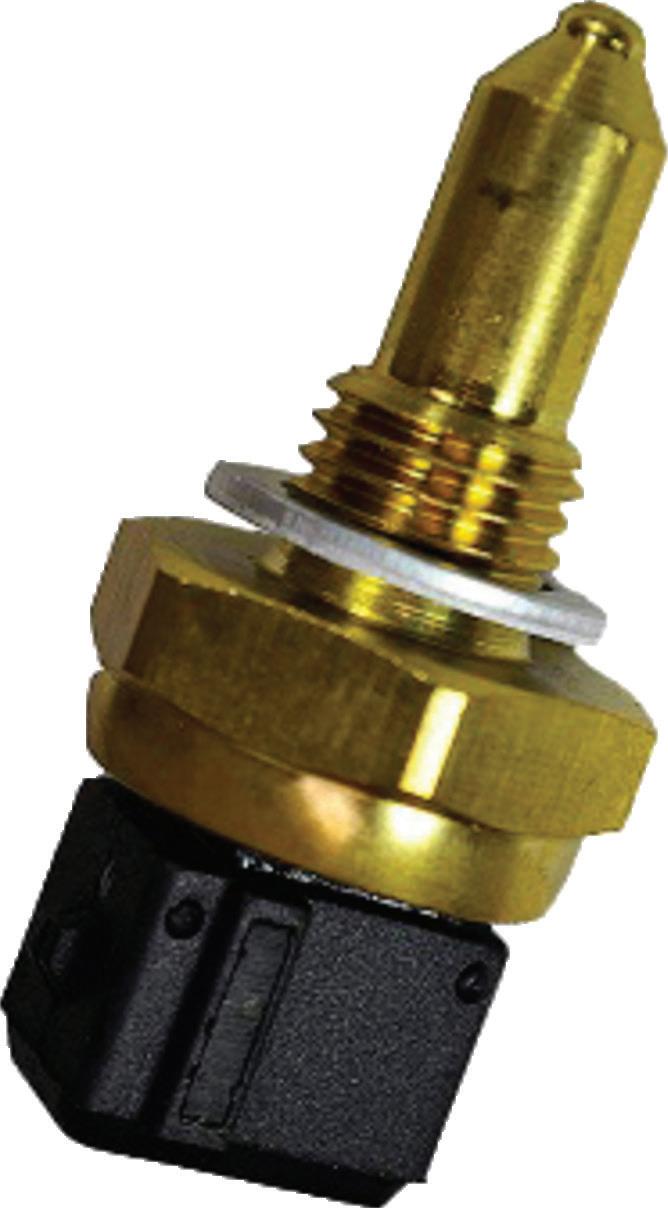

An automotive temperature sensor is a mechanical or electronic device used to measure the temperature of car engines. These sensors ensure that engines maintain a safe temperature, which is essential for engine efficiency and safety. They also help mechanics identify when an engine is overheating and diagnose related issues.

How does an automotive temperature sensor work?

The automotive temperature sensor measures engine heat using a thermistor, a variable resistor that changes its resistance with temperature. These sensors have a nominal resistance at a given temperature, and as the temperature increases, the resistance also increases.

The resistance is measured in an electrical circuit, and the change in resistance is converted into an electrical signal. This signal is sent to the engine control computer, which interprets it to determine the engine temperature. Automotive temperature sensors are designed to withstand high temperatures and extreme pressures. They are made from heat-resistant materials like stainless steel and feature a sealed construction to prevent dirt or water ingress, ensuring reliability and durability.

Automotive temperature sensors can also measure the air temperature inside the vehicle. They help air conditioning systems maintain a comfortable temperature for occupants and are used to monitor engine coolant temperature, assisting mechanics in ensuring that the engine operates at an appropriate temperature.

The temperature sensor is typically located near the engine, within the cooling system. It may be found on the engine block, cylinder head, intake manifold, or coolant duct. The exact location can vary depending on the engine design and vehicle manufacturer.

Is your car's temperature sensor malfunctioning or not working at all? The engine temperature is crucial for its operation, and a properly functioning sensor is essential. Here are some common sensor failures:

In modern cars, the temperature sensor also helps the engine computer set an appropriate air-fuel mixture, which is important for fuel efficiency and engine longevity. However, determining the cause of sensor failure or erratic behavior isn't always straightforward— it may require troubleshooting various associated issues.

1. Erratic Temperature Readings on the Dashboard One common issue occurs when the sensor has a poor connection internally, at the connector, or within the wiring harness. This disrupts the signal to the PCM (Powertrain Control Module), leading it to register a fault. In some cars, this manifests as erratic readings on the temperature gauge. The engine may switch to limp mode, the air conditioning might stop working, and radiator fans may run constantly. Damaged or shorted wires can generate multiple fault codes.

2. Check Engine Light Activation on the Dashboard Corrosion on the sensor's terminals or connectors can also cause sensor-related failures. Water contamination in the sensor connector can trigger different fault codes. Depending on the severity of the corrosion, the connector and sensor may need to be cleaned or replaced. Generally, the repair involves installing a new sensor and possibly adapting some related components. Many "Check Engine" codes related to the ECT (Engine Coolant Temperature) sensor could also stem from other issues, such as a faulty thermostat or problems with the cooling system, including a leaking head gasket. Proper diagnosis is essential. Given that the ECT sensor isn’t expensive, it’s often recommended to replace it if malfunction is suspected.

3. Overheating While overheating isn’t exclusive to this sensor, it can occur when the sensor fails to activate the radiator fans. The activation of radiator fans is controlled by the PCM based on the signal received from this sensor. In these cases, it’s important to check the sensor along with its connections and verify why the signal isn’t being transmitted. Typically, the sensor will be replaced.

4. Engine Mixture Issues Engine mixture problems can be observed in two ways: by the color of the exhaust smoke and the quality of the idle. If the idle is poor and the car doesn’t stay running, there’s a mixture failure. Dark exhaust smoke also indicates mixture problems. Both issues can be influenced by the ECT sensor. The best approach is to check with a scanner, as mixture failures may not solely be due to this sensor; many other factors could be involved.

In most vehicles, replacing the ECT or CHT (Cylinder Head Temperature) sensor is straightforward. In many cases, the sensor is secured with a clip, while others may require a special deep socket for removal. Replacing the engine temperature sensor is generally inexpensive. After replacing the ECT sensor, it's necessary to refill the cooling system and bleed out any air pockets. The cooling system is under pressure when hot, so if you decide to replace the ECT sensor as a DIY project, consult the service manual for instructions and safety precautions. When replacing the CHT sensor, it’s important to tighten the new sensor according to specifications.

Is it necessary to replace the ECT sensor every time the thermostat is replaced? No, it’s not required. However, intermittent failures related to engine temperature control may arise, making it difficult to determine whether the issue lies with the thermostat or the temperature sensor. In such cases, both components are often replaced simultaneously. In some vehicles, the engine computer may need to be reprogrammed when there’s a failure related to engine temperature control.

* Article written in collaboration with the Orbia & Koura Global team

In a context of growing concern about climate change and environmental regulations, Orbia presents innovations in automotive refrigerants aimed at transforming the market.

In the changing landscape of the automotive industry, efficiency and sustainability are more than trends: they are necessities. With increasing environmental regulations and heightened climate change awareness, automotive refrigerants are at the heart of a crucial debate. Orbia, a company focused on developing chemical solutions, is at the forefront of this transformation, offering innovations that not only meet current regulations but also provide tangible benefits for vehicle efficiency.

Among the company’s latest innovations are Klea® 456A and Klea® Edge™ 444A, two products designed as direct

replacements for traditional refrigerants like R-134a and R-1234yf. Klea® 456A extends the lifespan of vehicles using older refrigerants while reducing GWP by an astonishing 50%. Meanwhile, Klea® Edge™ 444A offers superior performance and is more cost-effective, making it an attractive option for the automotive aftermarket. These products not only represent technical advancements but also directly address sustainability demands in the industry. By providing cleaner and more efficient alternatives, they contribute to making vehicles more environmentally friendly, aligning with the mission to reduce carbon emissions and landfill waste.

The company is committed to reducing greenhouse gas emissions (GHG) and implementing more responsible practices in the production and use of refrigerants. With the launch of its Klea Edge portfolio, Orbia aims to reduce Scope 3 emissions by 30%. This involves a focus not only on manufacturing but also on the product lifecycle, from use to final disposal. This comprehensive approach is crucial at a time when regulatory pressure on carbon emissions is increasing globally. The company's ability to adapt to these regulations and its commitment to sustainability position it as a leader in the transition to greener refrigerants.

One of the major concerns in the automotive industry is energy efficiency. The company has made significant advances in this area, with data showing that R-444A offers between 5% and 12% greater efficiency in the coefficient of performance (COP) compared to R-1234yf. This increase not only enhances the cooling system's performance but also contributes to a comparable carbon lifecycle, making these new refrigerants more attractive options for manufacturers and consumers.

Despite these advances, the refrigerant industry faces considerable challenges. Developing solutions that are both sustainable and compliant with constantly evolving regulations is an ongoing challenge. Orbia is aware of these obstacles and has established close collaborations with original equipment manufacturers (OEMs) to understand their specific needs and offer appropriate solutions. Education is another critical component to ensure the transition to more sustainable refrigerants. The company is developing application guides and training documents for technicians and mechanics that detail how to properly handle and select their refrigerants. Additionally, the company has been invited to present its solutions at relevant forums, such as the Mobile Air Conditioning Society (MACS),

where the advantages of advanced refrigerants for the automotive aftermarket are discussed.

With climate change posing an increasingly present challenge, refrigerant regulations are likely to become stricter in the future. The goal of limiting global temperature rise, promoted by the Intergovernmental Panel on Climate Change (IPCC), will remain a key driver in formulating new regulations. Orbia, with its proactive approach to sustainability and innovation, is well positioned to lead this transformation. As the automotive refrigerant market evolves, the company is not only committed to complying with current regulations but is also preparing to meet future demands. With efficient and sustainable solutions, Orbia is paving the way for a future where the automotive industry can thrive without compromising the planet's well-being.

By Christoph Mutz, Product Marketing Manager, AME, Western Digital

Smart vehicles are revolutionizing the automotive industry by transforming cars into software-based devices.

Enhancing safety and personalizing user experience require high-performance, reliable storage hardware.

Today's smart vehicles, defined by their use of software, are shifting the car from a hardware-based product to a software-centered device on wheels. Premium vehicles now contain up to 150 million lines of software code, distributed among hundreds of electronic control units (ECUs), sensors, cameras, LiDAR technology, and more. This sector is rapidly growing, with global revenues expected to reach USD $4 billion by 2024.

In a world already embracing artificial intelligence (AI), smart vehicles are harnessing the benefits of this technology. They will be capable of processing and analyzing large volumes of data to optimize functions such as engine performance and safety. However, to store and process data for AI analysis, these vehicles must also be equipped with high-capacity, high-performance digital storage, representing a fundamental shift in vehicle design and functionality.

Software-defined cars and other smart vehicles will operate as components within the Internet of Things (IoT), capable of optimizing connectivity, enabling autonomous driving, enhancing safety, and adjusting settings to better meet the needs of drivers and passengers. For instance, they could adjust temperature, navigate routes, recline seats, or set up entertainment systems. Some vehicles may even automatically switch driving modes from normal to sport or eco based on the driver’s preferences. To deliver a personalized experience, these vehicles must have accessible data about users and their preferences.

Additionally, software-defined vehicles will benefit from improved maintenance features, reducing reliance on mechanics and other experts. Today's cars notify drivers of issues needing attention, but smart vehicles will proactively identify failures before they become problems, enhancing vehicle performance and longevity. In some cases, over-the-air (OTA) software updates can be used to automatically resolve issues without human intervention.

One of the greatest advantages of smart vehicles is safety. Cars equipped with sensors and integrated AI can identify real-time risks, such as traffic or obstacles in the path. The computational power of AI will allow these risks to be communicated instantly, improving vehicle safety. In some

cases, these systems may automatically steer the vehicle away from an obstacle or stop it safely.

If a connected vehicle detects that a driver may be experiencing an emergency, it can take the driver to a safe location and notify emergency services. These are steps toward fully autonomous vehicles, an innovation that eliminates the need for drivers to maintain full control at all times.

Although this technology is still in testing phases in many places, these vehicles are likely to be approved for public roads in the near future. However, before that happens, AI related to safety functions must be trained with extremely rigorous standards and high-quality data to eliminate any risk.

Despite enhanced vehicle functions, design must remain sleek and appealing to the modern driver, meaning that digital storage and computing hardware within vehicles must be powerful yet compact so as not to disrupt the car's aesthetics.

These new software-centric use cases are a significant catalyst for data storage demand in the automotive industry, primarily due to technological advancements related to increasingly intelligent vehicles. Simple smart applications, such as lanekeeping assistance, cameras, voice recognition, and Wi-Fi, will require up to 2 TB of data storage by 2025.

With cutting-edge sensors, 5G, AI, and machine learning essential for the future car, data storage requirements will continue to rise. For manufacturers, this means equipping their vehicles with systems designed to meet specific performance, reliability, and capacity demands dictated by the software-centric future of smart vehicles. As the transition to more data-intensive systems occurs, powerful networks within the vehicle must

process vast amounts of information as efficiently as possible and be future-ready.

Generally, most data memory is allocated to the operating system, application software, and log data. With new highperformance computing systems in smart vehicles, the size of the operating system and application software will continue to grow. Additionally, OTA updates will require extra storage capacity for future maintenance and use after the vehicle has been delivered. This means future storage capacity must be considered. While a 128 GB device may be sufficient today, 256 GB or more may be necessary within a few years.

As AI computing moves from the core to vehicles, these new write-intensive and read-intensive workloads will not only determine capacity needs but also introduce new performance considerations. There are various interface types, from eMMC to UFS and NVMe™ PCIe®. The choice of which to use typically depends on the selected system on chip (SoC). Some SoCs support only one or two of these interfaces, and each has its advantages and disadvantages. For example, while NVMe PCIe is fast as an interface, it is slow as a boot device, making UFS or eMMC a better option for that purpose.

In addition to performance and capacity, data reliability is also crucial. For this, the units must be extremely robust to operate under harsh conditions and withstand vibrations and potential impacts. Predictive maintenance will enable car manufacturers to analyze storage performance and condition in real time to prevent and address potential issues.

Quality is another key measure of a good storage device. Automotive SPICE® (ASPICE), an industry standard guide for assessing the development process of integrated automotive software, was developed to ensure best practices in automotive software development. Managed NAND Flash devices also incorporate software (often referred to as firmware) in their devices. Additionally, ASPICE certification assures the industry that the software will be of good quality and will reduce risks to the overall system.

The proliferation of embedded software in vehicles will bring significant advantages to the entire automotive industry. For

drivers, vehicles will have more capabilities and responsiveness and can be further personalized, with software likely taking on a larger share of the driving process as we move toward autonomous vehicles.

As cars become smarter, we may even see improved road safety through AI analysis. Roads and cities could experience fewer severe traffic jams, as real-time data analysis enables better traffic management. Undoubtedly, this will enhance the overall driving experience.

However, this rapid development requires massive volumes of data, making quality, performance, and speed in integrated vehicle digital storage essential for achieving their potential.

Mexico. The automotive and auto parts industry in Mexico and Brazil shows growth in recent years that can be strengthened, favoring the economies of both countries, representatives of the sector agreed.

Francisco González Díaz, president of the national auto parts industry, highlighted at the Mexico-Brazil Business Forum that last year, Mexico bought 1,400,000 cars, of which 120,000 came from Brazil. In turn, Brazil bought 2,300,000 vehicles, of which only 40,000 came from Mexico.

"We are going to continue moving forward and in the case of the relationship with Brazil it is extremely important (...) about 15 Mexican companies that are in Brazil and the companies that export from here, we reach 10 percent of the parts that are integrated into a Brazilian vehicle," said González Díaz.

In addition, he mentioned that the strongest amount of transactions between the two countries are auto parts, and that this industry is growing at 15 percent, positioning itself in fourth place worldwide. "And we are going for the bronze medal," he said.

For his part, Rodrigo Centeno Caballero, president of Nissan Mexico, said at the same forum that at this time there is a great opportunity for the automotive sector to improve

Nissan is integrating artificial intelligence (AI) and machine learning into its vehicle painting process, specifically at its plant in Smyrna, Tennessee.

With the implementation of AUTIS technology, the company has managed to improve paint defect detection by an impressive 7%.

AUTIS uses high-resolution cameras that capture up to 15,000 images per vehicle after the painting process, allowing technicians to identify imperfections that might go unnoticed by the naked eye. This innovation raises the quality of the final finish, and also optimizes the work of technicians, who can focus on more complex aspects of the process.

Since its implementation, more than 500,000 vehicles have undergone this rigorous evaluation process. This

value chains. "The automotive industry is the jewel in the crown because in Mexico it contributes 5 percent of the Gross Domestic Product (GDP) and has been key in the MexicoBrazil relationship." He explained that despite economic, political and social changes, trade between the two countries grew three times from 2007 to 2023. "All the changes, as well as the policies for Mexico from the United States that become very restrictive, make us rethink where our suppliers have to be located," he said.

Finally, Lula da Silva, when participating in the forum, said: "The potential of the Mexican economy is extraordinary and the same is true of the Brazilian economy; what happens is that we have not learned to use 70 percent of our potential and, therefore, we need to sign new agreements."

proactive approach reflects Nissan's commitment to continuous improvement and precision in every detail.

The introduction of AI on Nissan's production line represents a significant advancement in terms of quality and sets a new standard in the industry. This type of innovation is essential to staying competitive in a market that increasingly demands excellence in manufacturing and customer experience.

International. Continental has been recognized by U.S. magazine Time and global data and business intelligence platform Statista as one of the world's 500 most sustainable companies by 2024.

This assessment is based on a special methodology developed by Time and Statista. They assessed a total of 5,000 companies based on their sustainability strategy and reporting, as well as more than 20 key indicators, including emissions intensity, energy consumption and share of renewable energy.

Continental achieved a score of 61.39 out of 100 possible points, which places it in 265th place in the ranking. In the automotive industry category, the company is in the top 10.

International. Bavarian Econs is the company that electrifies classic BMWs for collectors located in Europe and the United States.

Bavarian Econs, co-founded by Felipe García and brothers Nicolás and Édgar Navarro, is a Colombian company located in Munich that specializes in electrifying old BMW vehicles. This year, they expect to bill more than $800,000 by offering an exclusive service that transforms iconic models such as the 2002 BMW, produced between 1966 and 1977.

The electrification process involves disassembling the vehicle, replacing the engine and suspension, and adapting the electrical system, using 400-volt technology. So far, they have completed seven vehicles, primarily for customers in the U.S., and face regulatory challenges in

"We are proud that our extensive sustainability efforts have been recognized in independent rankings," says Jorge Almeida, Head of Sustainability at Continental Tires. He adds: "We are committed to implementing sustainable solutions throughout our value chain, while maintaining the highest standards of quality and performance."

Continental Tires is characterized by innovative technologies and sustainable solutions along the entire value chain: from the procurement of sustainable materials, through design and production, to the phase of use and recycling of end-of-life tires. The Tires group sector is demonstrating outstanding performance in all areas evaluated by Time and Statista.

All Continental tire plants are working on individual and company-wide solutions to achieve carbon-neutral production by 2040 at the latest. This year, Continental took an important step towards this goal at its tire plant in Lousado, Portugal, where the company can produce tires in a carbon-neutral way, which has been made possible by the steam generated by an electric boiler.

Due to 160 energy-saving projects, Cotinental Tires reduced its annual energy consumption by a total of around 150 gigawatt hours in 2023, which is equivalent to the annual energy demand of around 12,500 single-family homes and was achieved through increased use of renewable energy and thermal insulation. In addition, CO2 emissions were reduced by 31,000 tonnes in 2023 alone.

meeting stringent safety regulations in Europe and the Americas.

The average price of electrified cars ranges from 200,000 to 400,000 euros, with a goal of selling between 10 and 15 vehicles per year. In the future, they plan to launch the BMW E30 model and a premium model called L9, aspiring to become the best manufacturers of electric BMWs worldwide.

Mexico. The Chinese automotive company BYD is negotiating with the Mexican government the extension of a tariff exemption for the import of electric vehicles (EVs) that ended on September 30, 2024.

BYD, which specializes in the manufacture of electric vehicles, has been analyzing the installation of a plant in Mexico for months and, in August, reported that it had received incentives from several states in the country to make the investment.

"We have had some conversations with the Ministry of Economy, not only about the extension of the decree, but also about investment in a manufacturing plant that would create more than 10,000 jobs in Mexico," said the firm's general director in Mexico, Jorge Vallejo.

The rapprochement with the federal government seeks to explore the possibility that, through investment in a new plant, conditions can be established to expand the decree. "We are waiting for the government's response," Vallejo added.

The growing presence of BYD and other Chinese companies in the EV market in Mexico has generated suspicion in the United States. Under U.S. pressure, Mexican authorities this year curbed incentives for U.S. cars, such as low-cost public land and lower taxes.

"The term of the decree that exempts imported electric vehicles from tariffs, enacted in September 2020, ended on Monday, September 30, one day before Mexican President Claudia Sheinbaum took office, replacing Andrés Manuel López Obrador.

"We are waiting for the new administration to pronounce on the decree on October 1, and based on that we will be able to manage more directly the conditions for an investment announcement and the benefits that would be granted," Vallejo told the newspaper.

International. SKF Automotive has launched an innovative wheel bearing technology: ultra-low friction bearing.

This new product, designed primarily for passenger vehicles, incorporates advanced features into an existing bearing design, adhering to industry standards and offering significant improvements, the company said. "It achieves a considerable increase in the efficiency of electric vehicles (EVs), with a 30% reduction in friction compared to current competitors," SKF added.

This advanced third-generation wheel bearing (GEN 3) features a unique internal geometry, a distinctive flange shape, low-friction grease, a patented lowfriction seal by SKF, an optimized preload range and a lightweight design, the company explained in a press release about the product. The noticeable reduction in friction translates into more efficient use of energy, thus increasing the battery's range in terms of miles per charge.

SKF announced that it has been selected by a leading electric vehicle manufacturer, resulting in a deal for 800,000 bearings annually. "This collaboration reflects confidence in our commitment to deliver reliable, highquality designs that exceed our customers' expectations. Our dedication to innovation is in our DNA and demonstrates our continuous efforts to improve performance and efficiency in bearing technology," the company concluded.

Germany. ZF has reached a remarkable milestone: the production of 250 million electric parking brake (EPB) units.

With this achievement, ZF is positioned as the first company in this niche to achieve this significant figure while maintaining its commitment to improving the overall performance of the braking system, safety and driver comfort.

The electronic parking brake stands out for its ability to improve fuel economy by reducing weight on the brake system. In addition, it represents a significant step in the electrification of mechanical systems, and when integrated with other vehicle systems, it enables advanced functions.

"When the transition from purely mechanical service brake functions began in the early 2000s, ZF had already established itself as a global leader in the base brake market," said Danny Milot, Senior Vice President Brake Engineering. "The continued success of the EPB underscores that position, as this technology is found in many of the world's most popular vehicles, from small cars to large pickup trucks and SUVs."

- Advertising -

ZF pioneered EPB technology almost 25 years ago, introducing engine braking on caliper. Currently, the EPB is in its sixth generation, representing an intelligent mechanical system.

ZF's EPB technology has helped to continue the trend towards electrification of brake systems, mainly the shift to all-electric braking systems.

EPB also improves driver safety by enabling two-wheel antilock emergency stops and providing convenient activation at the touch of a button.

"As we move towards advanced safety, automated driving and vehicle electrification, braking systems continue to play a critical role," Milot said. "ZF will maintain its position as a leader, continuing the relentless pursuit of innovation while setting new standards for the automotive industry."

International. The Italian companies Comau and

Prima Additive presented a robotic high-speed laser coating system for brake discs, capable of applying layers of metal powder safely and efficiently.

This innovative solution improves the durability of the discs and also reduces emission pollution by up to an impressive 80%.

The system was showcased at Stellantis Factory Booster Day in Turin and will be installed at the Stellantis plant later this year. In addition, it will allow manufacturers to comply with the Euro 7 standard, which requires a 27% reduction in brake particulate emissions by 2026.

Comau and Prima Additive, with more than 50 years of joint experience in innovation, have combined advanced laser technology with high-speed robotic arms, ensuring flexible and efficient production. Pietro Gorlier, CEO of Comau, said that this collaboration marks a milestone in the sustainability and automation of the sector. For his part, Paolo Calefati, CEO of Prima Additive, stressed that this solution not only improves the performance of the discs, but also minimizes the environmental impact of the vehicles.

This initiative represents a significant step towards sustainable automotive manufacturing in Europe and beyond.

United States. Elsa Foley, senior manager of Product Planning – Technology and Innovation at Nissan North America, has been recognized as one of the 2024 Rising Stars by Automotive News.

In his current role, Foley leads a team that manages key attributes in the automotive ecosystem, ranging from Automated Driving and Advanced Driver Assistance Systems, to Onboard Experiences and Electric Vehicle strategies. In addition, he leads the new Innovation Team, working in conjunction with Nissan's Advanced Research and Development teams to accelerate future

product innovations.

Among his achievements, Foley co-pioneered the patented Rear Door Alert (RDA) technology, which helps drivers remember items forgotten in the rear seats, and which is now present in all Nissan models.

With 14 years with the company, Foley has held a variety of roles, including a two-year assignment at the Nissan Technical Center in Atsugi, Japan. She holds a bachelor's degree in industrial engineering from Northeastern University in Boston.

United States. The Bosch company announced that Mike Mansuetti, president of Bosch in North America, will retire on October 1, 2024, after moving into an advisory role on September 1, 2024.

On September 1, Paul Thomas assumed the role of President of Bosch North America, in addition to his current position as President of Bosch Mobility in the Americas.

"In his 12 years at the helm of the North American region, Mike Mansuetti has established a dynamic culture focused on high performance and cooperation in all business areas," commented Stefan Hartung, Chairman of the Board of Management of Robert Bosch GmbH. "We are confident that Paul Thomas will continue to build on this foundation as Bosch seeks to further accelerate its profitable and sustainable growth in North America."

During Mike Mansuetti's tenure as president, Bosch's third-party sales in North America increased by more than 55%, from $10.6 billion in 2012 to $16.5 billion in 2023. It prioritized regional growth around four key success factors: innovation, customer

satisfaction, high-performance culture, and digital enablement.

He represented Bosch in numerous industry associations over the years, including the MEMA Board of Directors, the Vehicle Suppliers Association, and the Consumer Technology Association's Executive Board and Industry Leaders Board.

In his current role, Paul Thomas oversees technology, strategy and sales activities for Bosch Mobility in the Americas region, a $12.4 billion business. He has more than 25 years of experience in mobility and has held executive leadership positions in sales, production control, logistics, manufacturing and business unit management.

An Executive Committee will support Paul Thomas in his role as President of Bosch in North America. Committee members will serve in an advisory capacity and facilitate regional growth, operations, advocacy, cross-domain coordination, talent sustainability, and functional excellence:

• Mohammed Abraham, Executive Vice President, Bosch Mobility.

Automotive News' "Rising Stars" program honors executives under the age of 45 who are on track to reach senior leadership roles. Since 2014, this list has highlighted the future leaders of the automotive industry.

• Christine Zimmerman, Senior Vice President, Bosch Global Business Services.

• Alissa Cleland, Vice President, Corporate Communications and Government Affairs, Bosch.

Bosch recorded profitable growth in North America in 2023. Third-party sales in North America increased 6% year-on-year to $16.5 billion (€15.2 billion), while total net sales in the North America region increased 8% to $17.9 billion. The company continues to strengthen regional investment: since the beginning of 2022, Bosch has announced investments in North America for more than $3 billion across its portfolio.

United States. The U.S. Commerce Department has proposed new rules that would ban connected vehicle hardware and software made in China and Russia, in an effort to strengthen national security in the face of hacking threats that the department calls "very real."

These measures seek to protect vehicles that use external communication through Wi-Fi, Bluetooth, and cellular systems, which are increasingly common in the automotive industry. Officials warn that these systems are vulnerable to foreign interference, which could result in serious disruptions.

"This is not about trade. It is a national security action," said Secretary of Commerce Gina Raimondo. The proposal, which could ban virtually all Chinese vehicles in the U.S., comes against

a backdrop of accusations of unfair subsidies by the Chinese government, which distort the global market.

Connected vehicles, deeply integrated into U.S. infrastructure, pose specific risks, as National Security Adviser Jake Sullivan warned. "Today's cars have technologies that could be exploited by foreign adversaries," Raimondo said.

The Commerce Department has been in talks with industry experts about cybersecurity concerns related to so-called smart cars. The new restrictions would include both software and hardware, with a phased rollout starting in 2027 for software and 2030 for hardware.

The administration has also imposed a 100% tariff on Chinese electric vehicles, intensifying pressure on the auto industry. China, a leader in the electric vehicle sector, has seen BYD Co. overtake Tesla in sales in the final quarter of last year, raising concerns in the U.S. about its dependence on Chinese suppliers.

White House top economic adviser Lael Brainard stressed the need to protect the auto sector from unfair trade actions, noting that the Detroit area has lost more than 55,000 manufacturing jobs since 2001 due to competition from Chinese imports.

"Americans should be able to choose the car they want, but we want electric vehicles to be made in America, not China," Brainard concluded. The proposed restrictions are expected to be formalized in January, following a 30-day comment period.

International. FORVIA HELLA, an international automotive supplier, has obtained ISO/SAE 21434:2021 certification for its cybersecurity management system (CSMS).

This standard seeks to strengthen protection against external cyberattacks in an increasingly digitized and connected sector. The certification focuses on the safety of all electrical and electronic systems throughout the vehicle's lifecycle, encompassing both development processes and computer systems.

"With the continuous advancement of digitalization and connectivity of modern vehicles, protection against cyberattacks is more crucial than ever," says Fabian Käding, Product Cybersecurity Manager at FORVIA HELLA. "This certification not only demonstrates our

commitment to cybersecurity, but also allows us to meet the growing demand for advanced and safe vehicle components."

United States. DENSO, a mobility provider, has taken an important step toward sustainability by enrolling in DTE Energy's CleanVision MIGreenPower program, one of the largest voluntary renewable energy programs in the U.S.

From 2028, the Belleville Logistics Centre and a facility at DENSO's headquarters in Southfield will allocate 100% of its electricity consumption to renewable sources from DTE for 10 years.

With this initiative, DENSO will exceed the 15% renewable energy that DTE already provides to its electricity customers. 5,840 megawatt-hours per year will be enrolled, an environmental impact equivalent to the carbon absorbed by 4,763 acres of forest annually.

Denise Carlson, Vice President of DENSO, said: "We appreciate DTE's partnership as we work to be a carbon neutral company by 2035. Operating sustainably is crucial, as is innovating products that promote cleaner and safer mobility."

DENSO joins more than 1,200 businesses and nearly 100,000 residential customers who use MIGreenPower to power their sustainability efforts. This growing stake is allowing DTE to add more clean energy to the grid, with plans to add more than 2,400 megawatts of new wind and solar power in the coming years. These developments not only benefit the environment, but also boost the local economy, generating millions in tax revenue and thousands of clean energy jobs.

Sean Gouda, DTE's Director of Renewable Solutions, said, "Customers like DENSO are making a difference in their operations and sustainability goals in Michigan. DENSO is part of a growing group of automotive suppliers that are transforming the industry by reducing their environmental impact with MIGreenPower."

United States. The global market for automotive pivots, or steering wheels, is on track to grow significantly, projected to reach $7.27 billion by 2034, according to a report by Fact.MR.

This growth, driven by a CAGR of 4.4%, is driven by the increase in vehicle production and demand for replacements in heavy commercial vehicles.

The growth of the construction and mining sectors globally is increasing the need for heavy-duty commercial vehicles, which have a higher rate of pivot replacement. Growing demand for transportation and logistics will also create opportunities in the aftermarket, as operators look to extend the life of their fleets.

East Asia is estimated to be the fastest-growing region, capturing 36.2% of the market share by 2034, while in the United States automotive pivot sales are expected to grow at a rate of 3.3% annually, reaching $1.37 billion by the end of the forecast period.

Leading manufacturers such as Meritor, Diesel Technic SE and Schaeffler Technologies are implementing innovative solutions, such as the launch of ReadySet kits, to meet the growing demand in long-haul, bus and urban delivery applications.

Key points from the report:

The global market will reach $7.27 billion by 2034. The demand for automotive pivot kits will grow at a rate of 4.5% per annum.

Vehicle production and aftermarket parts replacement are projected to be the key drivers of growth.

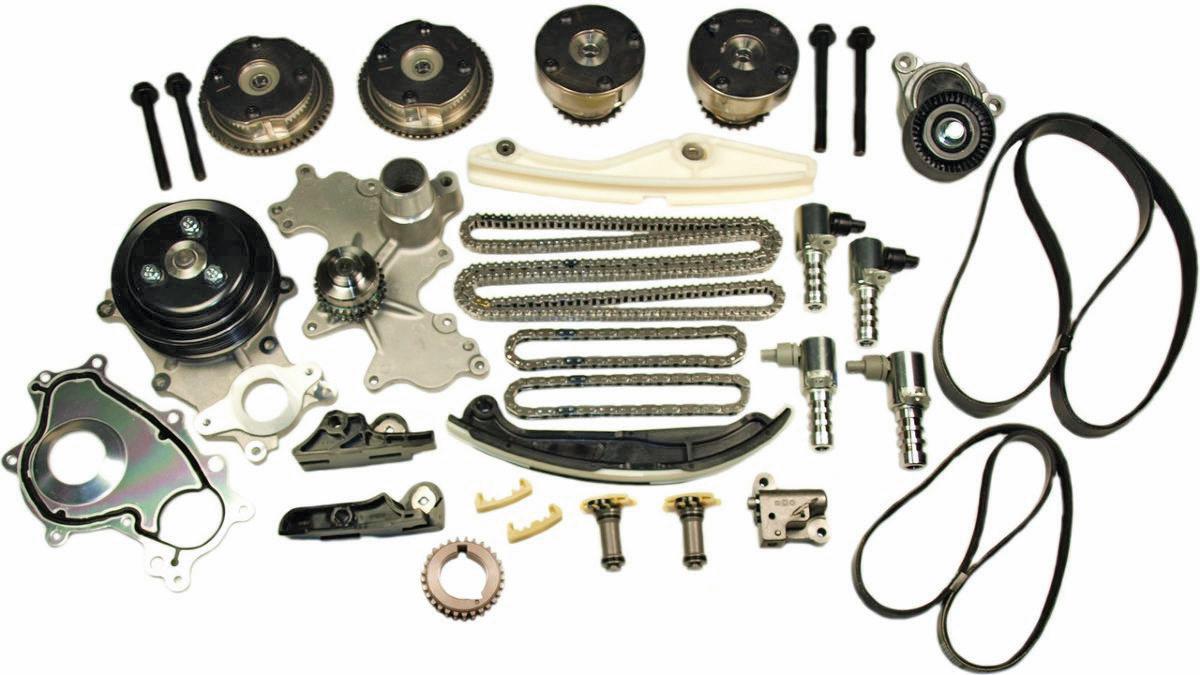

United States. Cloyes, recognized for its commitment to complete application coverage for distribution system repairs, has announced the expansion of its product line. The company now offers new kits and parts for Ford and Subaru engines, spanning models from 2011 to 2022.

New additions include:

• Ford 3.5L/3.7L (2011-2017)

• Timing chain kits for models such as the F-150, Mustang, and Transit.

• Part Numbers: 9-0738SK6C, 9-0738SAK6B, 9-0738SAK6A, 9-0738SGK6, 9-0738SK6D, 9-0738SCK6A.

• Ford 2.0L/3.0L (2015-2021)

• Timing chain and sprocket kits for vehicles such as the Continental, Edge and Fusion.

• Part Numbers: 9-0958S, S1140, S1137, S1139.

• Subaru 2.0L/2.5L (2012-2022)

International. Schaeffler Vehicle Lifetime Solutions has launched the E-Axle RepSystem-M, the first repair kit for electric motors in the first-generation Hyundai Ioniq.

This pioneering kit is designed to repair e-axle motors on Hyundai Ioniq AE-EV models, 2016-2019, with 88 kW EM09 engine, eliminating the need to replace the entire motor or the entire axle.

The E-Axle RepSystem-M allows damaged bearings to be replaced efficiently and economically. This repair process, slightly longer than a complete axle replacement, represents significant cost savings for vehicle owners, which could reach four-digit figures in euros.

Schaeffer points out that more than half of the failures in electric transmission motors are due to defective bearings, which cause unwanted vibrations and noises. The new kit includes all the components needed for a professional repair, including a seal for the rotary shaft, O-rings, flat gaskets and sealant paste. In addition, a detailed, easy-to-understand repair manual is available, with the necessary torques for safe installation.

Maik Evers, Head of Product Management Drivetrain Systems at Schaeffler, comments: "We are continuously expanding our e-mobility offering to meet the demands of the growing EV fleet. With the E-Axle RepSystem-M, we are introducing a key solution for professional e-axle repair."

• Timing chain kits, tensioners and guides for models such as the BRZ, Forester and Impreza.

• Part Numbers: 9-0975SX, 9-6114, 9-6112, 9-6115, C975, 9-6113.

For more details on these products, you can contact Cloyes technical support or visit their website.

This solution is in addition to the E-Axle RepSystem-G, launched at Automechanika 2022 for the Volkswagen e-Golf, and now also available for the Hyundai Ioniq. Schaeffler plans to introduce more e-axle kits from other manufacturers later this year. In addition, the "E-Drive Stator Lift", a specialized tool for the repair of electric motors, is in the pre-production stage.

Schaeffler continues to strengthen its role in the transition to comprehensive mobility, combining its expertise in the development and production of OE drivetrains, electric motors and power electronics to deliver innovative and market-oriented solutions.

For more information about the E-Axle RepSystem-M and other products, please visit the Schaeffler and TecDoc e-catalogues.

United States. Tricolor, the automotive retailer dedicated to the Hispanic market, celebrated the opening of its new state-of-the-art automotive reconditioning center in Surprise, Arizona.

This facility, which spans 258,000 square feet, will create more than 500 local jobs and serve up to 500 vehicles per week with comprehensive inspection, repair and quality control services.

The opening ceremony, held on September 4, was attended by Eduardo Pérez, Tricolor's director of customer service, along with local government officials and business leaders, such as Surprise Vice Mayor Nick Haney and representatives of the Greater Phoenix Economic Council.

Tricolor's founder and CEO, Daniel Chu, highlighted the importance of this expansion: "We are proud to contribute to the growth of the Surprise community and to offer mobility and financing solutions to underserved Hispanic consumers. This new facility will set a standard of excellence in the automotive retail industry."

This is the second large-scale refurbishment center that Tricolor has opened in less than two years, following the opening of a similar facility in Wilmer, Texas, in 2022. Both operations reinforce the company's commitment to quality, offering its customers refurbished vehicles under a rigorous 150-point inspection process and an 18-month or 18,000-mile limited warranty.

In addition, Tricolor uses artificial intelligence to offer affordable financing to customers with no credit history, having made nearly $4 billion in auto loans to date. The company continues its mission to provide access to reliable transportation and financial mobility to the Hispanic community.

Arizona Commerce Authority President Sandra Watson highlighted the economic impact of this new opening: "Tricolor's expansion in Surprise reinforces Arizona's position as a strategic hub for the automotive industry and underscores accelerated economic growth in our region."

With this investment, Tricolor not only boosts the local economy, but reinforces its leadership in the Hispanic automotive market nationwide.

United States. Effective September 3, 2024, Midwest Truck & Auto Parts and S&S Truck Parts will join to operate under a new name: S&S Truck Parts, LLC.

This change promises to offer customers an improved experience with more efficient service, higher quality and personalized attention.

The consolidation aims to combine the strengths of both organizations to provide exceptional service and more robust support. Customers will continue to receive communication electronically and through the sales and customer service teams, with major changes including a new website: www. sandstruck.com and updates to contact information for payments and support.

The firm will work to ensure a smooth transition, focusing on strengthening its clients' businesses for lasting success. More details will be sent throughout August to keep all customers informed and answer any questions.

International. Schaeffler's Vehicle Lifetime Solutions division has expanded its torque converter product portfolio with the new LuK TorCon 68RFE and 48RE applications.

The company claimed that the LuK TorCon torque converters are the only all-new units in the automotive aftermarket and are designed to ensure unmatched consistency in performance.

The product features a four-disc clutch system, "which offers increased torque capacity that outperforms some tripledisc converters on the market by up to 60%," according to Schaeffler.

"The LuK TorCon 68RFE is designed to perform in normal and heavy-duty conditions, with a higher torque ratio and higher holding power of the TCC to ensure reliability when it matters most," said Jason Haney, product manager.

Schaeffler stated that the LuK TorCon 68RFE is compatible with 2009-2021 RAM 2500 and 3500 trucks

with 6.7L Cummins Turbo Diesel engines, with a current VIO of more than 1 million. Schaeffler recently introduced the LuK TorCon 6F35 and 6L80, the first all-new, neverremanufactured torque converters available on the independent aftermarket. The company added that it plans to further expand its product portfolio with additional SKUs in the coming months.

Mexico. Valeo, the French manufacturer of automotive components, has announced an investment of more than 500 million dollars in Mexico over the next four years.

This decision responds to the rise of electromobility and the growth in the assisted and autonomous driving sector. The revelation was made by Marco Hernández, national director of Valeo Mexico, during the inauguration of the new Valeo Mobility Technical Center (VMTC) in Empresalia, Querétaro.

"We are opening a space where ideas and talents will converge to shape the future of software-based mobility," said Hernández. "The VMTC will not only be a center for the development of advanced technology, but also a crucial meeting point for local and national talent, making our vision possible."

This new centre, the first of its kind in the Americas and the fifth globally, represents a significant step forward in Valeo's strategy to address rapid growth in electrification and innovation in assisted and autonomous systems. The other four VMTCs are located in Egypt, India, China and France.

Located in the state of Querétaro, the VMTC will focus on the development of advanced technologies in software, embedded systems, innovation and diverse technological applications. The facility, which currently employs 102 engineers, plans to increase its workforce to 200 by 2025 and to 500 in the next two to three years. The new engineers will specialize in areas such as software development, embedded systems, electronics, mechanics, as well as protection and cybersecurity.

Jeff Shay, President of Valeo North America, underscored the potential of local talent as a determining factor in the choice of Querétaro as the site of the new center. To maximise talent attraction, Valeo has launched a dual education programme in partnership with five local universities. This program will start with two universities and expand to three more in 2025.

By Laura Restrepo C.

The Aftermarket International team visited Automechanika Frankfurt 2024. The fair had over 108,000 visitors from 172 countries and 4,200 exhibitors from 80 countries. The main reflections were focused on sustainability and the electrification of the automotive fleet.

This year, the event centered on the major trends redefining the future of cars: electrification, connectivity, driver assistance systems, and digitalization. Visitors could explore these advancements in a space of 320,000 square meters, with 26 levels of pavilions, in addition to testing new technologies in the outdoor exhibition area.

Electrification and sustainability were the prominent themes.

Over 650 companies showcased their expertise in electric vehicles, while Chinese manufacturers like BYD, GEELY, and AVATR displayed their innovative electric models in Pavilion 12.1, seeking to establish new international partnerships.

One of the major attractions of the event was the ‘Future Mobility Park,’ where attendees had the opportunity to test electric and hybrid vehicles, including a record-breaking e-van that climbed the highest volcano in the world, fully powered by solar energy. Visitors not only observed future technologies up close but also had the chance to conduct test drives.

The inclusion of this space at the fair led to significant reflections on electrification in different countries. In this regard, Rodrigo Pérez, vice president of CAREP (Chilean Chamber of Commerce for Parts and Accessories and Automotive), explained the trend in Chile regarding electrification and what could happen in the automotive fleet: “Evidently, the world is shifting toward less pollution, and that will eventually have an impact. It’s hard to estimate when, however, the electric fleet in Chile is

quite small and needs parallel infrastructure development. Major automotive companies leading in electromobility, like BYD or Tesla, have even hit a brake this year; the same has happened in Europe due to the infrastructure not keeping up with the sales of electric vehicles at the expected pace."

Pérez noted that this would delay the original plans for the transition to electromobility, stating that forecasts have all been pushed back and, obviously, we as a South American country cannot be exempt. “Electricity and electromobility will undoubtedly arrive, but I believe it will still take some time before combustion vehicles disappear.”

The support program was one of the most comprehensive in Automechanika's history, with five stages dedicated to analyzing crucial topics like artificial intelligence, cybersecurity, alternative propulsion technologies, the circular economy, and the lack of qualified personnel in the sector. Practical workshops and discussion panels attracted thousands of industry professionals.

This year, the fair also paid special attention to Generation Z,

with the ‘Ambition’ area designed to attract young people interested in automotive professions. Dynamic presentations and live acts successfully captured their attention in an effort to address the growing shortage of specialized labor in the industry.

Michael Johannes, vice president of Mobility and Logistics at Messe Frankfurt, commented: “Automechanika Frankfurt has never had a support program and range of events like this before. Our list of presentations and practical workshops covered a wide array of topics, including bodywork and painting, electric vehicles, commercial vehicles, caravan repairs, 3D printing, detailing, and much more. These were very well received by professionals, and students took advantage of the available opportunities to learn firsthand about some automotive professions. One of this year's innovations was a program and area specifically dedicated to Generation Z. We wanted to draw their attention to the career opportunities available in the fascinating world of the automotive industry, and we were very successful.”

The automotive industry demonstrated its capacity for

innovation with a record number of entries for this year's Innovation Awards, which included categories such as E-Mobility, Innovative Propulsion Technologies, Workshop Solutions, and Commercial Vehicles.

Steven Meeremans, marketing manager at Sidem, explained that sustainability is not only about products but also about processes and infrastructure: “We have two major processes in our production plant in Romania, which is also ISO certified. We have ISO 400001, which is a neutral quality certification for environmental management, covering raw materials, waste management, and pollution prevention. In addition to this, our production plant is certified by ISO 4001 and we also have 45001, which focuses on the health and safety of the people working at Sidem.”

To this, Iwan Loewen, Business Development Manager at Sidem, added that: “Environmental sustainability not only refers to products or packaging. It also includes the buildings where we have energy savings, such as solar panels and water recycling.

Overall, the automotive sector has a large footprint on the planet, especially because there are so many vehicles and parts. That huge footprint is why I believe that when every company or manufacturer allocates some of its resources to becoming more sustainable, it can have a great impact. And I think that’s why we have this great responsibility as automotive suppliers in the aftermarket and OEM market to contribute.”

Visit the full coverage on our social media @aftermarketinternational