As I write this column, summer has been underway for a few weeks. In terms of news, this period is often called the ‘silly season’, during which there is usually little to report. But for our sector, this is certainly not the case.

Of course, there may be a lack of major news, but that doesn’t mean the industry has nothing interesting to share. With this issue, we’ve once again managed to showcase the diversity of our industry. Whether it’s the oil & gas industr y, CO2 storage, shipbuilding, green energy, or ocean mining, there’s always plenty to talk about in every part of the industry.

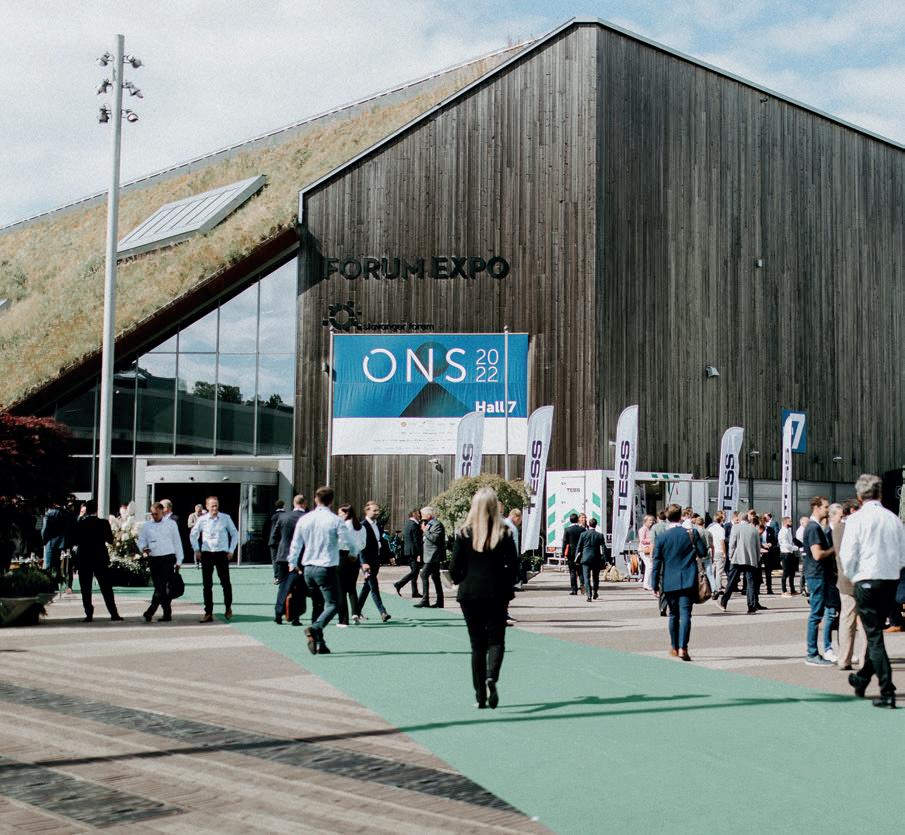

When this issue reaches your desk, the trade show season will gradually be starting up again. ONS Stavanger, traditionally a trade fair for the oil & gas industry, exemplifies the development our sector has undergone over the past decades. This fair demonstrates that the oil & gas industr y is working hard on sustainability and there is also ample focus on companies active in the energy transition. Wind Energy Hamburg was organised for the first time in 2014 and has since grown in terms of space, exhibitors, and visitors. The development of this exhibition highlights the increasing importance of wind energy, both onshore and offshore, over the past decade.

I hope you have had a wonderful summer. Who knows, maybe you have gained plenty of new ideas and insights. We certainly look forward to your news, so please do not hesitate to share this with us. We are always eager to write about it.

industry

Other publications by Yellow & Finch Publishers:

Kind regards,

Arno Dirkzwager Editor

ARNO@YNFPUBLISHERS.COM

NAVILUS product. Expect the best project support for your propulsion train.

Profit also from our Marine Services for global lifecycle support. We specialize in the supply of spare parts and field service engineers for the complete mechanical drive portfolio. With both the Lohmann & Stolterfoht and current Flender NAVILUS brand, we serve ship owners and a wide range of vessels across the globe from our Rotterdam office.

Contact us at any time:

Marine Spare Parts: bruinhof.nl@flender.com

Marine Field Services: marine.services@flender.com

flender.com flender.com/en/bruinhofmarine

CRANES & WINCHES

09 New contracts for Huisman

DECOMMISSIONING

18 A historic lift

HEAVY LIFTING

34 Setting new standards

O & M

14 Fully charged turbine maintenance

OCEAN MINING

26 World-first cobalt sulphate from deep-seafloor polymetallic nodules

OFFSHORE CONSTRUCTION

30 New contracts awarded for the Princess Elisabeth Energy Island

OFFSHORE CREW TRANSFER

20 Damen set to build sixth CSOV for Windcat

OFFSHORE SOLAR ENERGY

38 SolarDuck and RWE successfully install offshore floating solar pilot Merganser off Dutch coast

OFFSHORE WIND

28 First contract for Van Oord’s Boreas

42 Optimising offshore wind monopile installation

OIL & GAS

40 Production from Kristin South has started

ONS STAVANGER

10 Bigger and better 50-year-old

SUBSEA SERVICES

33 N-Sea Group closes acquisition of Geo Plus

WINDENERGY HAMBURG

22 The world’s energy hub

REGULARS

01 Editor’s note

04 News in brief

45 People

46 Yellow & Finch pages

48 Next issues & Colophon

On the cover

Just six months after United Heavy Lift launched the UHL Fresh, the Hamburgbased heavy lift shipping company is now strengthening its environmentally-friendly F900 Eco-Lifter fleet with another newbuild. Read more on page 34. Photo courtesy of United Heavy Lift.

William Thomson will be the name of Jan De Nul’s new cable-laying vessel ordered earlier this year. The vessel will be an identical copy of the previously ordered Fleeming Jenkin. With their three carousels and cablecarrying capacity of 28,000t, the sister vessels will be the largest cable-laying vessels in the world. William Thomson (1824 - 1907), later also known as Lord Kelvin, was born in 1824 in Belfast, Ireland. He had a strong interest in thermodynamics, and his theories were fundamental to the concept of absolute temperature, better known as the Kelvin scale. However, his primary focus was on the study of electricity and his most famous achievement is the success of the transatlantic telegraph cable successfully installed in 1866. Through this connection, Europe and America could communicate via Morse code within minutes.

i. jandenul.com

Altera Infrastructure celebrated the naming recently of its Floating Production Storage and Offloading vessel FPSO Petrojarl Kong and its Floating Storage and Offloading vessel, FSO Yamoussoukro. The vessels are now in their final stages of upgrading and conversion prior to their mobilisation to Côte d’Ivoire for Eni’s Baleine Phase 2 project. Together with Eni, Petroci, and Drydocks World, Altera Infrastructure held a naming ceremony to mark this key milestone in Dubai. The FPSO Petrojarl Kong previously operated under the name Voyageur. The FSO Yamoussoukro, converted from the Altera shuttle tanker Nordic Brasilia, will provide additional storage capacity and oil export facilities at the field. Altera owns and will operate both vessels, which are set for deployment on the Baleine field with a fifteen-year firm contract, and operations are scheduled to commence in December 2024.

i. alterainfra.com

SLPE opened a new office in Bristol in July. Joseph Hilton, managing director of SLPE, comments on the expansion: “Opening our new office in Bristol is a testament to the incredible progress we have made as a company. Our wider geographical footprint not only enhances our recruitment capabilities, enabling us to attract the best offshore wind professionals, but also allows us to manage our growing pipeline of work sustainably. This move is a clear indicator of our increasing profile in the market and reinforces our commitment to delivering excellence for our clients.” The new Bristol office is strategically located to support SLPE’s growth plans. Being within relatively easy travelling distance of its London office ensures SLPE can maintain its culture and ‘one team’ ethos across both locations. The Bristol office is set to accommodate a growing number of SLPE engineers, with plans for further recruitment and provisions for visitors from SLPE’s London office, as well as hosting clients and industry partners.

i. slpe.com

>> | Read more on offshore-industry.eu

KENC has been awarded a design and engineering contract for the seafastening of two large jackets. These large jackets are integral components of an offshore high voltage station. Upon completion, the offshore wind farm will stand as the largest and most powerful offshore windfarm in the Baltic sea boasting an impressive total capacity of 927MW. The steel jackets each weigh 3,700t and stand approximately 33m tall. During transport, these jackets will be positioned vertically on a barge. The lower and upper grillage system, designed and engineered by KENC, will provide crucial support for the jackets during the transition. Eric Buining, managing director of KENC Engineering, expressed enthusiasm, “We are excited to be part of the this offshore wind farm project. We are proud to contribute in large-scale initiatives like this and we look forward to work on this project.” The engineering work is scheduled for delivery in November 2024.

i. kenc.nl

WIND Group has announced that equipment engineering and manufacturing company Draftec will join the WIND family. Together they will enhance the support and services provided to their shared clients in international offshore and renewable projects.

Draftec was founded in 2009 by Martijn Boone who, together with fellow director Martijn Holtkamp, will continue to manage the company, bringing with them extensive experience in mechanical design, hydraulic and electrical systems, and control system software and automation. Over the years, Draftec has grown into a specialist system integrator and manufacturer of custom-designed, multidisciplinary systems and mission equipment for sectors including offshore wind, marine & dredging, and heavy lift. The company offers a comprehensive service covering everything from engineering to realisation and maintenance.

i. wind.nl

Ramco Norway has secured a long-term contract with Equinor. This provides the company with stable employment and strategic growth opportunities, says CEO Arild Moe, from the headquarters in Florø, Norway. This is the third time Ramco has entered a long-term contract with the energy giant Equinor, having had good cooperation since signing the first contract in 2008. The renewed trust is testament to the high quality of work Ramco delivers. The long-term contract with Equinor ensures stability, enabling the company to invest in its employees and facilities. Constantly building on its expertise in preparing pipes for the oil & gas industry, Ramco is committed to developing the technology further with a goal of ensuring costeffectiveness, safety, and sustainability.

i. ramco.no

GEV Wind Power has marked an industry first after further investing in its network of training facilities to help bridge the global skills gap for technicians. The group has established the North American Wind Academy at its US headquarters in Texas. One of the first of its kind, the facility sees GEV become the first independent service provider of in-house accredited Global Wind Organisation (GWO) blade repair courses and trade testing programmes to assess technician competence. GEV has also built on the success of its UK training academy in Hull by introducing a new turbine training initiative which will allow technicians to conduct rope access procedures and technology applications at the Port of Blyth’s pioneering Wind Turbine Training Facility. The company, which also has a training academy in Australia, has more than 1,000 technicians worldwide, believed to be the world’s largest blade maintenance-focused talent pool, and has trained over 300 people globally.

i. gevwindpower.com

| Read more on offshore-industry.eu

Be sure to take part in the world’s biggest and most important business platform for the onshore and offshore wind industry!

• Meet up with 1,500 exhibiting companies from 40 countries across 10 halls

• Get in touch with the key decision makers of the international wind energy sector

• Visit the firstrate conference programme on 4 stages in the halls free of charge

• Two days dedicated to recruiting –for career starters, specialists and career changers

Aker BP has been awarded a new CO2 storage licence in the Norwegian North Sea, in partnership with PGNiG Upstream Norway. The storage licence is named Atlas and is located in Norwegian North Sea, near the Yggdrasil area, where the Aker BPoperated Yggdrasil field development project is currently underway. Aker BP has been awarded the operatorship with an 80%. PGNiG Upstream Norway, also partner in Yggdrasil, has been offered a 20% interest. The licence comes with a work programme that includes reprocessing 3D seismic data, conducting geological studies, and a drill-or-drop decision after two years. Aker BP is evaluating CO2 storage opportunities on the NCS as a potential new business venture and a potential decarbonisation lever for Aker BP in the longer term. In March 2023, Aker BP was awarded its first licence for CO2 storage in the Norwegian North Sea, named Poseidon (Aker BP 50%, operator), with OMV (Norge) as a 50% partner.

i. akerbp.com

Pulse Structural Monitoring has been awarded a contract by Ørsted Taiwan for the design, engineering, procurement, installation, and commissioning of measurement and associated data acquisition systems for the Greater Changhua 2b and 4 offshore wind farms. Pulse is part of Acteon’s Geo-services business line. The project-based systems integration and software development will be executed at the modern Pulse Technology Centre in Wokingham, UK, with installation to be carried out in construction yards in South Korea and Taiwan.

i. action.com

Wells and subsurface specialist, Elemental Energies has acquired Norway-based well management and consultancy company, Well Expertise. The acquisition forms one of the world’s largest specialist wells, subsurface and project management companies, boasting more than 230 experts worldwide. For Elemental Energies, the acquisition adds significant growth to its North Sea expansion ambitions in Norway. For Well Expertise, its team and clients will benefit from access to an extensive track record of delivering complex global energy projects. The companies are closely aligned in their ambitions of growth in well management services across oil and gas, decommissioning, geothermal, and carbon capture and storage projects.

i. elementalenergies.com

Huisman has announced two contracts to deliver cranes and installation tools for Cadeler.

COSCO has awarded Huisman the contract for a +3,000mt leg encircling crane (LEC) and a 40mt pedestal mounted crane for Cadeler’s latest A-Class vessel, Wind Apex. This vessel will be capable of installing the largest foundation dimensions anticipated in the offshore wind industry. Huisman’s LECs meet these evolving requirements by being lightweight yet robust, highly energy-efficient, and offering high positioning accuracy, thus helping to reduce the emissions footprint during the installation of increasingly large turbines.

For Cadeler’s A-Class jack-up vessel Wind Ally, Huisman has been awarded a contract by Cadeler to deliver a monopile storage and upending system.

Huisman will also deliver the monopile gripper and main crane and auxiliary crane for this vessel. Delivering this complete installation spread allows for smooth integration and interface alignment, providing additional value and reducing risk for the overall project. The monopile storage system is designed to maximise monopile storage on the vessel, allowing Cadeler to transport up to five monopiles, each up to 12.5m in diameter, in one trip. It features adjustable storage cradles that accommodate various monopile diameters and can be height-adjusted to keep them level with the vessel. The upending frame supports monopiles ranging from 80 to 120m in length, with enhancements for safer and more efficient upending. Key features include a crane automation mode that aids in

maintaining the monopile’s position and retainers that secure the monopile during upending.

David Roodenburg, CEO of Huisman, states, “We are honoured to expand our partnerships with COSCO and Cadeler. Our track record in designing and building cranes for the F-, M-, and P-Class vessels has now culminated in these exciting projects for the A-Class. These vessels will be designed to reduce project transits and enhance operational efficiency. By providing them with our lightweight and compact equipment, we aim to contribute to their advanced design and effectiveness.” Both orders will be built at Huisman’s production facility in Zhangzhou, China. i. huismanequipment.com

From 26 to 29 August, the city of Stavanger’s population will once again increase by tens of thousands. Tjensvoll will become more than just a roundabout. And Stavanger will again be the place where important discussions in one of the world’s most crucial industries take place.

Best ONS ever. Pure magic,” as summarised by Leif Johan Sevland, CEO of ONS, two years ago.

“ONS 2024 will be even better,” he now promises. ONS 2024 – the 25th in the series – will undoubtedly be larger and more geographically diverse. This year there are no travel restrictions due to the pandemic, as was the case for Asia, Latin America, and Africa in 2022. However, the event will also elevate in other areas. The exhibition, the programme, and the content are good this year, with even more utility value this time. Those who visit will get something out of it – and quickly too.

“This year’s theme is ‘Imagine’,” Mr Sevland continues, “and many examples of new ways of working will be presented. At ONS, we aim to make the journey from imagination to action as short as possible. Everything from the use of artificial intelligence to new methods and technologies. It is important to make people aware of these in a practical way, which they can use in their own work lives. Changes have also occurred regarding renewable energy and ONS Young.”

“The renewable programme is even more extensive with a brand-new arena for the Net Zero Market, with its own exhibition

hall. Additionally, we have further improved the Young arena, ensuring even better content aimed at young people than in 2022. The ONS+ programme is bigger, and we will transform downtown Stavanger into Northern Europe’s largest dance floor. We will continue the discussions from ONS to the city centre. There will be relaxed gatherings, political debates, concerts, good food, and social settings in pavilions, nightclubs, and on ship decks,” Mr Sevland says. “And like other 50 year olds, we are not only inviting people to celebrate, but also to reflect historically. We want to honour our

ONS venue: Exhibition and Conference Stavanger Forum

Gunnar Warebergsgate 13 4021 Stavanger

Opening hours ONS Venue:

Monday 26 August: 09.30 AM – 5 PM

Tuesday 27 August: 09.30 AM – 5 PM

Wednesday 28 August: 09.30 AM – 5 PM

Thursday 29 August: 09.30 AM – 3 PM

Opening hours ONS+:

Monday 26 August: 5 PM – midnight

Tuesday 27 August: 5 PM – midnight

Wednesday 28 August: 5 PM – midnight

pioneers this year. Many sacrificed life and health to build the industry that has provided the prosperity we have today.

On Thursday 29 August, we will invite the pioneers to a very special event.”

The status of the oil & gas industry has undoubtedly changed over the past 50 years and Mr Sevland takes the opportunity to remind us of two things.

“We will still depend on oil and gas for many decades to come, but we must produce cleaner. It is therefore important that the industry attracts the brightest minds and continues the green trend.

Just think about all the expertise that has been created on the shoulders of the oil industry! In low-emission technology, offshore wind, solar energy, carbon capture, and storage… we are world leaders in these areas. While many still call ONS the ‘oil exhibition’, this is actually rather misleading.

Yes, those who sell bolts for oil platforms are still at ONS. But the same bolt is also used for offshore wind constructions.

The path to the renewable future is best found together.”

“The Norwegian energy adventure continues on a steady, green course

• It is believed that Torolf Smedvig, Conservative Party member, shipowner’s son, and one of the city’s wealthiest individuals, launched the idea of an oil exhibition in Stavanger. “This new oil industry might be useful for something,” he reportedly said.

• The first ONS in histor y took place in 1974, but it was originally supposed to happen the year before. When ONS discovered they had a Scottish competitor, they chose collaboration over rivalry. The two competitors agreed to hold the event every other year.

• ONS turns 50 this year. Since its inception, the event profile has shifted from being solely an oil exhibition to becoming an energy meeting place. Renewable energy, green transition, and innovation have become increasingly important parts of the programme.

• ONS+ as a debate venue was introduced at ONS 2022. ONS took over Vågen in Stavanger city centre, with debates, podcast recordings, and concerts –open and free for all.

• Students and apprentices get free entry to ONS. ONS also has a dedicated committee that works on a programme for young participants, and there is a separate ONS Young Arena at the exhibition area with a daily programme aimed at young people.

towards the future. And we will not be afraid to show the way,” Mr Sevland voices. “Our history is a story of change. In the beginning, ONS was just an exhibition. We still have this part, but ONS is now also a place where energy political trends are set and decisions are made. Whether you are a platform worker or a politician, a top executive in a large international company or a green

entrepreneur, a fresh student or an oil pioneer: ONS is for all of you.”

This is also the main reason why Mr Sevland avoids terms like ‘oil exhibition’ or ‘energy exhibition’. “I prefer to call ONS an energy meeting place,” he concludes.

i. ons.no

Over time turbine maintenance has become an increasingly complex and multi-tiered process. Experience of offshore maintenance and component service life cycles combined with the need to optimise generating performance has broadened the scope and depth of turbine maintenance.

WORDS BY ERIK

Driven in part by the advent of artificial intelligence (AI) and use of sophisticated sensors, turbine maintenance is now a multifaceted activity embracing scheduled maintenance, component repair/ replacement, and turbine optimisation. The question now arises, have the tools used to maintain turbines kept up?

Enerpac believes they have and what’s more, new developments in battery-

operated tools are set to deliver higher levels of safety and turbine maintenance efficiency.

Turbine maintenance involves an array of special tools depending on the type of wind turbine and the maintenance/ repair requirements. Wind turbine technicians will rely on torque wrenches, bolt tensioners, cylinders, and hydraulic pumps. Structurally a wind turbine may contain as many as 25,000 bolts – the more powerful and larger the turbine, the more bolts needed. Only a proportion of the thousands of bolts require regular maintenance, of course. Typically, these include those in the nacelle housing the gearbox and generator, the hub where the blades are bolted in, pitched and attached to the rotor, and the turbine blade bolted connection to the rotor.

Precise bolting lies at the heart of the successful maintenance of wind energy structures. The need for accurate torquing and tensioning are a given. Now let’s add height and accessibility issues, exposure to extreme weather conditions, and complexity of turbine structures and components. Add limited weather windows and the high cost of vessels, and the efficiency of maintenance procedures begins to have significant financial implications. The maintenance tools industry has not been slow in responding to the environmental and practical challenges of turbine maintenance. Overcoming height and accessibility issues has led to

the introduction of a new class of torque wrenches that set a higher standard in safety, versatility, simplicity, and performance. For example, lightweight aluminium torque wrenches reduce the risk of serious injury to workers from a dropped wrench. Using a fully enclosed square drive keeps technicians’ hands protected from moving parts, and its optimised weight-to-output ratio and slim design help prevent operator fatigue.

Maintenance schedules for wind turbines are dictated by the turbine’s original equipment manufacturer. For bolting, maintenance contractors generally operate to a pre-defined maintenance schedule or as required when remote monitoring indicates a bolt or nut is off torque. If there is zero variation in the bolted joints from the last maintenance check, the wind tower operator can ask for an exemption on the next service, saving time and money. Tightening requirements, torque specifications, and the complexity of turbine structures and components means there are significant variations in bolt types, sizes, and torque and tensioning requirements. Confidence in the precision of the torque wrench is fundamental to record keeping across a full range of maintenance cycles. In recognition of the growing reliance on data keeping, today’s torque wrenches can achieve pinpoint torquing precision with a +/- 5% accuracy across their entire torque range. >>

Turbine maintenance involves an array of special tools depending on the type of wind turbine and the maintenance/ repair requirements.

Torque wrenches and pumps can be pre-programmed ahead of deployment offshore, giving an operator instant access to job-specific usage data for traceability and improved precision.

Time is of the essence when maintaining offshore wind turbines. Equipping the engineer with the tools they need to perform jobs more quickly while maintaining accuracy is where battery-powered tools are coming into their own. For batterypowered also read portable. If the amount of equipment needed to be transported offshore can be reduced, then not only is it safer but also quicker. Until now, use of battery powered tools had been hampered by the lack of power and battery life. The benefits of cordless tools can’t be overstated. By removing the need for extension cords, cable trip risks are eliminated. Moreover, heavy, noisy and emission producing generators are no longer needed thereby reducing environmental health and safety concerns. Instead, maintenance pods now contain more fully charged battery packs – a lighter alternative. According to one maintenance company, the switch to batterypowered tools is a game changer, “Using battery torque wrenches, we’re looking to double the productivity of our bolting teams. The handheld and portable wrench can be operated by a single operator rather than the two operators needed previously. Moreover, we can more easily reach places where space is limited without the need for awkward tool set-up”, they explain.

Pumps too, are benefitting from the development of high-capacity battery technology in combination with the switch from brushed to brushless motors. As a result, pumps can now offer higher speeds and longer battery run-times, which together with greater oil capacity allow larger tool and multiple cylinder applications to be undertaken on a single charge. It’s an important development for maintenance teams performing a gearbox changeout where multiple hydraulic cylinders are needed. It’s not all about the battery, of course. Some pumps now offer a wider range of pressures enabling greater control of the speed of tool or cylinder operation. In addition, modification to pump bladder reservoir design can allow pump use

in any position; ideal for projects where access and working space are limited.

Developments in battery technology have increased the utilisation of tools, and the efficiency of turbine maintenance offshore. Although the focus has been on enabling maintenance engineers to do their job more quickly and safely, the role of tools within a wider, data driven turbine maintenance context has not been overlooked.

Torque wrenches and pumps can be pre-programmed ahead of deployment offshore, giving an operator instant access to job-specific usage data for traceability and improved precision.

Access to job-specific torque setting will reduce set up times and provide valuable data collection for each bolt torqued for subsequent analysis using AI tools, for example. In this way a complete maintenance history for each bolted joint can be developed, providing planning data for future turbine maintenance scheduled shutdowns. Maintenance tools have come a long way since the first offshore wind turbines were deployed. Making tools more portable, battery-powered and self-contained, as well as easier and safer to use, has increased turbine maintenance efficiency. By adding a data collection capability, maintenance tools are set to play an increasing role in the wider context of turbine optimisation and maintenance planning. This is

especially true given the growing importance of the global availability of tools. As installation and maintenance contractors expand their global footprint, tool availability, consistent servicing and calibration provide a common framework for managing maintenance operations and data collection.

i. enerpac.com

Allseas recently safely removed Shell UK’s 31,000t Brent Charlie platform topsides from the UK sector of the North Sea.

Executed on 9 July, the single-lift removal of Brent Charlie by Allseas’ heavy lift vessel Pioneering Spirit represents the heaviest offshore lift ever performed, and concludes years of engineering and planning. The former production facility will be delivered to Able UK’s Seaton Port facility in Hartlepool, northeast England for disposal, where more than 97% of the materials will be recycled.

Removal of the fourth and final Brent platform is a significant milestone in a

remarkable project spanning more than a decade. On all four occasions, Shell UK has opted for Allseas industry-defining single lift, motion-compensated technology.

Allseas chairman Edward Heerema states, “It started in 2013 with Shell’s decision to award Allseas the contract for the engineering, preparation, and removal of its four Brent platforms. The trust shown then in Allseas’ technical expertise served as a milestone in the 20-year development of Pioneering Spirit. At the time, the vessel was still under construction, but Shell’s belief in

Allseas gave us the opportunity to showcase our single-lift technology.”

The Brent decommissioning project is unique in its scale and complexity, comprising four platforms: three concrete-based and one steel jacket. Allseas has played a key role, performing the engineering, preparation, and removal of all four platforms. In executing Allseas’ scope, Pioneering Spirit has removed and transported close to 100,000t of topsides weight to Hartlepool for disposal at Able UK

Seaton Port facility. To date, 98% of all materials from Delta (2017), Bravo (2019), and Alpha (2020) topsides have been recycled.

Built to install and remove offshore platforms in a single lift using an advanced motion compensation system, Pioneering Spirit has revolutionised the offshore energy industry. Capable of lifting entire topsides up to 48,000t (upgrade to 60,000t capacity is ongoing) and jackets up to 20,000t, the vessel

drastically reduces the amount of offshore work associated with platform installation and decommissioning, shifting the activities onshore where it’s safer and more cost effective. The single-lift technology reduces the time spent on offshore preparation such as cleaning, separating into smaller pieces, and installing lift points, thereby significantly reducing health, safety, and environmental risks in a harsh offshore environment.

i. allseas.com

Built to install and remove offshore platforms in a single lift using an advanced motion compensation system, Pioneering Spirit has revolutionised the offshore energy industry.

Damen Shipyards has secured the contract to build a sixth commissioning service operation vessel (CSOV) for offshore personnel transfer provider Windcat, thus completing the six-ship ‘Elevation Series’ of future-proof CSOVs.

The contract marks the further strengthening of the working relationship between Damen, Windcat, and CMB.TECH. Windcat will deploy the ‘Elevation Series’ to provide in-field technical and maintenance support to offshore wind farms for up to 30 days at a time.

Damen will build the sixth CSOV at Ha Long Shipyard in Vietnam, where construction of the first five vessels is currently proceeding at various stages. The first CSOV will be delivered early

next year. “Working together with Windcat and CMB.TECH over the last few years shows the power of collaboration,” says Damen’s sales manager Benelux Joost van der Weiden. “Working closely with CMB.TECH to develop the hydrogen component of this vessel – turning a new technology

into a proven technology – is a ground breaker for the industry. And, of course, we appreciate working with Windcat in making the entire series of six vessels effective – the fact that Windcat has ordered this sixth vessel demonstrates their clear vision.”

“Working together with Windcat and CMB.TECH over the last few years shows the power of collaboration.”

Joost van der Weiden – sales manager Benelux of Damen.

The ‘Elevation Series’ of CSOV is a result of the close cooperation between the three disciplines of offshore crew transfer services, future-proof fleet owner, and shipbuilding with the three parties of Windcat, CMB.TECH, and Damen bringing their respective expertise to the drawing board. Specific attention has been paid to the internal design of all six vessels of the ‘Elevation Series’. “We are really excited to confirm the sixth vessel in this series of innovative, efficient and high performing vessels. Together with Damen, we have also spent a lot of time thinking about the onboard workflow of the offshore wind farm technicians. How they can move from point A to point B as efficiently as possible, both for operational efficiency and for safety,” says managing director of Windcat, Willem van der Wel.

The focus on internal design included creating a premium ‘look and feel’ of Windcat’s CSOV. Mr Van der Wel continues, “The interior design is quite similar to a premium hotel as we really

wanted to give the technicians a comfortable place to live while at work.” The final design is for an 87m long vessel that can accommodate 120 people on board. Drawing on input from CMB.TECH, as well as lessons learned from Windcat’s hydrogen-powered crew transfer vessel, the CSOV will be equipped with dual fuel hydrogen technology. This will not only substantially reduce CO2 emissions, but will also give Windcat a leading position in terms of using sustainable fuels.

Windcat is a leading provider of safe and efficient specialist crew transfer services

to the offshore wind industry and has been at the forefront for more than 20 years. The company is part of CMB. TECH, a diversified maritime group. The group focuses on large marine and industrial applications on hydrogen or ammonia. CMB.TECH’s hydrogen technology is integrated into all Windcat’s newbuild vessels to reduce their clients’ CO2 emissions. Several hydrogen-powered CTVs are already in operation.

i. damen.com i. cmb.tech

From 24 to 27 September 2024, it is once again time for the famous port city of Hamburg to become the world’s energy hub. For four days, it will be all about wind energy generation and distribution at WindEnergy Hamburg, held on the campus of Hamburg Messe und Congress (HMC).

Every two years one of the most fascinating industries meets for the leading global networking event for wind energy. At WindEnergy Hamburg, which takes place right in the heart of the vibrant northern German port city, around 1,500 companies from 40 countries present their innovations and solutions in ten exhibition halls to up to 40,000 visitors from 100 different

nations. Covering 73,500m² across the exhibition campus, equipment manufacturers and suppliers representing all stages of the onshore and offshore wind energy value chain provide a comprehensive overview of the market. The trade fair will be accompanied by conference sessions where top-ranking experts address the industry’s current key topics.

WindEnergy Hamburg is much more than just a trade fair. It covers the whole value chain of wind energy, and provides a special focus for expertise in its section on storage technologies. It also has an extensive supporting programme and lots of added value, such as synergy with SMM, the leading international maritime industry fair, which is held at the

Hamburg Messe site shortly before WindEnergy Hamburg. This and many other benefits make WindEnergy Hamburg the key wind industry event.

Enormous interest

The industry is already showing enormous interest in the largest international onshore and offshore wind energy expo. After Hall A3 had been

added earlier in response to the strong demand, HMC has since expanded the exhibition floor once again by including the upper level of Hall B2, which will be dedicated to the offshore segment.

“More than 1,500 exhibitors from 40 countries will showcase the entire value chain of the wind industry,” Andres Arnheim, director of WindEnergy Hamburg, says. “An event of this breadth

Date

Tuesday 24 September until Friday 27 September 2024

Opening hours

Tuesday – Thursday: 10.00 AM - 6.00 PM

Friday: 10.00 AM - 4.00 PM

Venue

Hamburg Messe und Congress, Messeplatz 1, 20357 Hamburg, Germany

Entrances

–

Central entrance (Messeplatz)

– East Entrance (Bei den Kirchhöfen/ St. Petersburger Straße)

– South Entrance (Karolinenstr., Hall B6)

– West Entrance (Lagerstr. / Hall A3)

and depth is only conceivable in Hamburg. Featured topics this year will include Digitalisation, Artificial Intelligence, and Recruiting.”

Industry visitors will meet with companies specialising in key stages of the value chain, from turbines and rotor

We will help you to clear things up! Meet our portable ballast water treatment containers. High flow rate, low power consumption. A 20ft container with a filterless active substance, USCG/IMO approved BWTS, reducing carbon footprint and cost per cubic meter. Ideal for barges, FPSOs, jack-ups, drill rigs and semi-subs. Contact us on info@uniballast.nl www.uniballast.nl

blades to mechanical and electrical components, and from logistics, safety, and finance to insurance, innovative materials, and Smart Energy. The special requirements of the offshore segment will be addressed in several exhibition halls where exhibitors will include providers of specialised ships or other maritime components and services.

As an additional highlight, many exhibitors offering employment opportunities will also be represented in the Recruiting Area. On Thursday 26 and Friday 27 September 2024, skilled professionals and young talents will be able to make contact with personnel managers from exhibiting companies. Start-up companies are welcome to be part of the joint exhibition stand for young, innovative enterprises.

Furthermore, Hamburg Messe und Congress will for the first time present its AI CENTER, located in Hall A3. It will be entirely dedicated to advanced AI technologies and their potential application in the wind industry, providing investors, entrepreneurs, and technology experts with a great opportunity to learn about the latest developments and join the highly dynamic AI community. A supporting programme featuring leading experts will enable knowledge exchange at the highest level.

Visitors and exhibitors will be able to take part in the accompanying conference programme on five open stages located within the exhibition halls, engage in subject-specific dialogue, and build their networks. “How can I tap new markets?” “How can I be competitive with my product?” “How can we utilise wind power to meet all the energy needs of the future?” These are just some of the questions that will be discussed and explored in depth by national and international experts from politics, industry associations, and the business world in around 150 conference sessions. Following the speeches and presentations, the networking format ‘Wine o’clock’ will turn the stages in Halls A3, B1, B5, and B6 into meeting places for fair participants to exchange views and ideas

in a relaxed atmosphere.

The WindEnergy Hamburg team jointly developed this year’s programme with their partners, including the Global Wind Energy Council (GWEC), the European organisation WindEurope, and the national industry associations VDMA and BWE.

i. windenergyhamburg.com

TMC the metals company has successfully produced the world’s first cobalt sulphate derived exclusively from seafloor polymetallic nodules.

The cobalt sulphate was generated during bench-scale testing of TMC’s hydrometallurgical flowsheet design with SGS Canada. The test work was carried out at SGS’ Metallurgical Centre of Excellence testing facility in Lakefield, Ontario.

Milestone

Based on samples of nickel-cobaltcopper matte first produced by TMC

in 2021, the Extractive Metallurgy team at SGS tested TMC’s efficient flowsheet to process high-grade nickel-coppercobalt matte directly to high-purity cobalt sulphate without making cobalt metal, while producing fertiliser byproducts instead of solid waste or tailings. This milestone follows the recent successful production of nickel sulphate, a key raw material input used in the production of energy-dense electric vehicle batteries.

“This achievement further demonstrates the potential for seafloor polymetallic nodules as a valuable resource,” says Dr Jeffrey Donald, TMC head of onshore development. “Following the success of our first nickel sulphate production in April, production of the world’s first cobalt sulphate from deepseafloor nodules is another important milestone for TMC and for creating a responsible supply of metals required for human flourishing. SGS continues to execute at a high level and this milestone demonstrates the viability of our process and our dedication to near-zero solid waste nodule processing.”

Carlos Cordoba, vice president of natural resources at SGS North America, comments, “SGS is pleased to support TMC in achieving another milestone towards commercialisation of polymetallic nodules suitable for the battery chemicals market. Our technical expertise in extractive metallurgy is driving innovation in the mining industry and we look forward to continuing to set the benchmark as a trusted service provider at every stage of the mining project lifecycle.” TMC and SGS’ success in deriving cobalt sulphate from seafloor polymetallic nodules is a key milestone in advancing TMC’s mission to supply metals for the global energy transition with the least possible negative impacts on planet and people.

“In April, TMC and SGS produced the world’s first nickel sulphate derived exclusively from seafloor polymetallic nodules. TMC’s NORI and TOML projects are ranked as the world’s #1 and #2 largest undeveloped nickel projects according to mining.com, containing in situ quantities of nickel, cobalt, copper, and manganese sufficient to meet the needs of 280 million electric vehicles –

SGS is pleased to support TMC in achieving another milestone towards commercialisation of polymetallic nodules suitable for the battery chemicals market. The cobalt sulphate was produced in a testing programme applying TMC’s efficient flowsheet design that processes high-grade nickel-copper-cobalt matte directly to high-purity cobalt sulphate and produces fertilizer products instead of solid waste or tailings.

roughly the size of the entire US light vehicle fleet. With analysts warning that the quantities of critical battery metals like nickel and cobalt available from domestic or allied partners will be insufficient to meet US demand from the energy transition, there is increased interest in and prioritisation of marine minerals to support energy and national security. In May, the US Congress allocated USD 2 million to the Defense Department’s Industrial Base Policy Office to study the feasibility of domestic nodule refining capacity. In March, members of the House of Representatives introduced draft legislation calling for the US to ‘provide financial, diplomatic, or other forms of support for seafloor nodule collection, processing, and refining.’ In November 2023, TMC signed a Memorandum of Understanding with Pacific Metals Corporation (PAMCO) to complete a feasibility study to process 1.3 million tonnes of wet polymetallic nodules (PMN) per year into high-grade nickelcopper-cobalt alloy / matte and manganese silicate, which are feedstock

for the production of lithium-ion batteries, electrical infrastructure, and steel.

i. metals.co

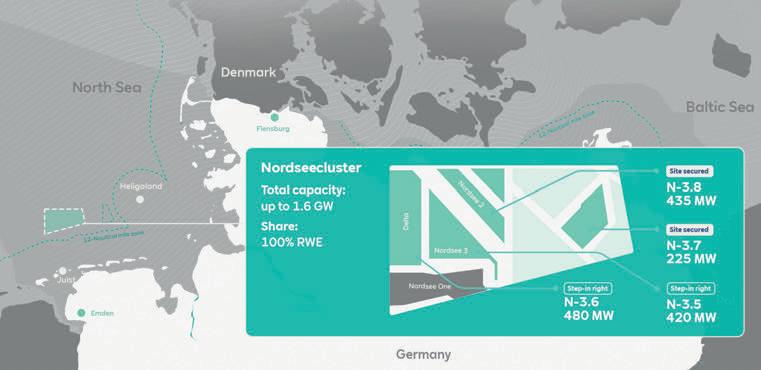

Van Oord has been awarded the contract for the transport and installation of the monopile foundations for the Nordseecluster offshore wind project in Germany by RWE. This project award is a major milestone for Van O ord because it will be the first project for the brand-new offshore installation vessel Boreas, which is currently under construction.

The 1.6GW wind farm cluster is expected to generate enough renewable energy to supply the equivalent of 1,600,000 German households.

Van Oord’s scope includes the installation of 104 extended monopiles as well as the installation of the scour protection. In 2025, 44 monopiles are planned for installation in 2025 and the remaining 60 monopiles in 2027. The Boreas will be the largest offshore installation vessel of its kind, purposebuilt for the transport and installation of the next generation foundations and turbines for offshore wind farms. The jack-up vessel, with a crane capacity of more than 3,000t, can install up to 20MW wind turbines at sea.

Boreas has the capability to fully operate on methanol, drastically reducing its carbon footprint by more than 78%. This is in line with Van Oord’s ambition to reduce emissions and to achieving netzero emissions by 2050.

Boreas was successfully launched earlier this year, at the Yantai CIMC Raffles Offshore shipyard in China. Because of its size, the launch was a challenging job. First, it had to be moved from the construction site to the quay, using the so-called ‘skidding method’. Skidding is a safe and efficient load-out method for the horizontal transport of heavy and oversized objects along a linear track.

The vessel was then skidded from the quay onto two pontoons. These pontoons were later submerged in a controlled operation after which the Boreas became afloat.

After safely moored alongside, the works on the Boreas continued with the installation of the main crane and the extension of the legs of the jack-up vessel. Meanwhile the vessel’s technical installation will be further commissioned, after which sea trails will take place to test performance. Subsequently, the Boreas will be handed over by the shipyard to Van Oord. Johan de Graaf, project manager shipbuilding at Van Oord, states, “The launch of the Boreas is a major

The Boreas will be the largest offshore installation vessel of its kind, purpose-built for the transport and installation of the next generation foundations and turbines for offshore wind farms.

milestone for Van Oord. With the Boreas now afloat, we’re entering the final stages of the newbuilding, and we are excited to continue our journey towards successful delivery!”

Future-proof Boreas is preparing Van Oord for the increase in scale in the offshore wind industry. The vessel measures 175m in length and has a crane with a 155m high boom, able to lift over 3,000t. Four giant legs, each measuring 126m, allow the vessel to be jacked up and work in waters up to 70m deep. It will therefore be able to install the next generation of 20MW offshore wind turbines at sea.

Being an example of the energy transition within Van Oord, the Boreas is the first of its kind to be able to run on the future fuel methanol. Green methanol is one of the most promising future fuels, as it is produced using only renewable energy sources. In addition, the vessel will be equipped with a cutting-edge active emissions control technology (Selective Catalytic Reduction) to reduce the NOx emission to an absolute minimum. A battery pack of about 6,000kWh can take peak loads and regenerate energy to reduce the fuel consumption and corresponding emissions even further.

i. vanoord.com

A number of contracts were recently awarded by transmission system operator Elia Transmission Belgium for the construction of the world’s first artificial energy island, Princess Elisabeth Island.

Princess Elisabeth Island will be the first artificial energy island in the world that combines both direct current (HVDC) and alternating current (HVAC).

The HSI Joint Venture, consisting of HSM Offshore Energy, Smulders, and Iv has been awarded the contract for the Modular Offshore Grid 2 (MOG2). Jan De Nul, together with LS Cable & System, will take care of the export cables.

The EPCIC contract (engineering, procurement, construction & installation, and commissioning) of the MOG2 includes the further design and construction of four high voltage AC substations (2 x 1.050MW, 2 x 700MW), a facility module, and a garage. Engineering, which also includes development of the layout and 3D model of all the MOG2 transmission assets located on the energy island, will be done from the Iv office in Papendrecht. For prefabrication works, Smulders will use its Belgian branches and HSM will use its Schiedam facilities. Final assembly of the modules will take place at the HSM Offshore Energy yard in Schiedam and at the Smulders yard in Vlissingen.

Two HVAC cable contracts have been awarded to two consortia: one comprising of Belgian group DEME and Greek company Hellenic Cables (165km), and a second made up of Belgian firm Jan De Nul and Korean corporation LS Cable & System (165km). The cables will transmit the renewable energy from the energy island to the Belgian highvoltage onshore grid. “With this new project, we have confirmed our leading position in the subsea power cable market,” explains CEO of DEME Luc Vandenbulcke. “Our expertise in cable installation, dredging, rock dumping, and marine infrastructure works combined with our modern and versatile fleet offers our customers an efficient, integrated solution. This is how we are supporting the energy transition and helping countries achieve their climate goals.”

Wim Dhont, manager offshore cables at Jan De Nul Group, states, “We are delighted to be awarded this landmark project further enhancing Jan De Nul Group’s position as the reference for

“We are delighted to be awarded this landmark project further enhancing Jan De Nul Group’s position as the reference for constructing the offshore energy transition.”

Wim Dhont – manager offshore cables at Jan De Nul Group.

constructing the offshore energy transition. Thanks to our versatile fleet, we are able to offer a one-stop-shop solution which involves offshore cable laying, dredging, rock protection, civil and environmental works, all with inhouse equipment and expertise.”

Princess Elisabeth Island will be the first artificial energy island in the world that combines both direct current (HVDC) and alternating current (HVAC). The high-voltage infrastructure on the island will bundle the export cables of the wind farms of the Princess Elisabeth zone, and at the same time become a hub for future interconnectors with

neighbouring countries such as Denmark and the UK. The energy island will also be built nature-inclusive to promote biodiversity around the energy island. The energy island will be located approximately 45km off the coast and will measure approximately 12ha above the waterline. The area provided for the installation of the electrical infrastructure is approximately 6ha. The artificial island will be located within the Princess Elisabeth wind zone and built on concrete caissons filled with sand that are currently constructed by the joint venture TM Edison in Vlissingen. Elia aims to have the installations ready to welcome the first offshore parks in 2030.

i. elia.be

N-Sea has concluded the full acquisition of Geo Plus based in Groningen, the Netherlands. Geo Plus, established in 1994, is a worldwide operating service provider in the survey industry.

Geo Plus offers, among others, sophisticated survey platforms and a highly qualified, experienced, and pro-active marine crew; survey vessels which are equipped with a highly graded hull and moonpool mounted survey equipment and technical, survey, and operational support. Geo Plus operates a fleet of five highly specialised survey vessels (the Geo Ranger, Focus, Explorer, Motion, and Connection), which are currently operating on long-term projects in Europe and the Middle East. The fuelefficient vessels are well equipped for all

types of geophysical surveys and inspection activities.

The acquisition will play a key role in realising N-Sea’s ambition to become the subsea services contractor of choice. By acquiring Geo Plus, N-Sea increases its capacity and capabilities in the field of shallow water hydrographic surveys, both geophysical and geotechnical. Geo Plus has now become a member of the N-Sea Group, but will continue to operate as an independent company out of the same office in Groningen and with the same team. Patrick Defilet,

managing director of Geo Plus states, “I’m extremely happy that Geo Plus has become part of N-Sea, safeguarding our growth ambitions with a partner that is very successful in the current markets and allowing us to take full advantage of their organisational capabilities and resources, an excellent starting point for an integrated market approach.”

i. n-sea.com

i. geoplus.nl

Just six months after United Heavy Lift launched the UHL Fresh, the Hamburg-based heavy lift shipping company is now strengthening its environmentallyfriendly F900 Eco-Lifter fleet with another newbuild.

The UHL Fable is the nineteenth vessel to complete this series, which was further developed and is operated by United Heavy Lift. With the F900 EcoLifters, the globally active shipping company is setting new standards for environmentally-friendly breakbulk and heavy lift shipping, making a significant contribution to the energy transition.

On 15 July, the UHL Fable was named at the Baakenhöft Terminal near the Elbphilharmonie concert hall in the Port of Hamburg in a festive ceremony attended by 400 invited guests. “We are very happy to be naming yet another vessel in our home port of Hamburg,” says Andreas Rolner, managing director of United Heavy Lift, at the ceremony.

“The UHL Fable completes our F900 Eco-Lifter fleet, which stands for United Heavy Lift’s commitment to promoting sustainable shipping. It is the most modern and homogeneous heavy lift fleet in the world. There is a strong global demand for alternative energy sources, and we are proud to be part of the supply chain for green energy.”

The maiden voyage of the UHL Fable clearly reaffirmed this commitment: On her way from Tianjin and Dongzhao to Cuxhaven (Germany), the multi-purpose (MPP) heavy lift vessel transported a project cargo of rotor blades for onshore wind turbines for the UHL customer, Danish manufacturer Vestas Wind Systems. Like her sister vessel UHL Fresh, which entered service in January 2024, the UHL Fable was built at the CSSC Hudong shipyard in Shanghai, which is known for its outstanding quality. The construction time from keel laying in July 2023 to delivery to the German bridge crew led by captain Karsten Strotmann and his first officer Pit Awe in April 2024 was just nine months.

The F900 Eco-Lifter class is designed and built according to the latest technological standards. It is equipped with state-of-the-art systems and the most economical

propulsion technology. About 150m long, the ultra-modern UHL Fable also features an IMO Tier III certified main engine. In accordance with the international standard, up to 95% of the vessel’s NOx emissions are washed out while diesel particles are burnt off in the catalytic converters. With bunker consumption of 7t/9 knots, 10t/12 knots, and 21t/15 knots, the Eco-Lifter is characterised by low bunker consumption compared to similar heavy lift vessels. As the newest addition to the now nineteen vessels strong UHL F900 fleet, the UHL Fable (like her sister vessel UHL Fresh) can also be fuelled with biodiesel, which makes the operation of the main engine climate-neutral. Overall, the carbon footprint of United Heavy Lift’s F900 Eco-Lifter fleet, which has an average age of three years, is 30 to 50% lower compared to other fleets in the heavy lift sector. This makes it the most modern and environmentally-friendly MPP heavy lift fleet in the world.

“We are supporting the energy transition with our vessels, and the transport of onshore wind turbines is part of our core business.”

Andreas Rolner – managing director of United Heavy Lift.

The global shipping company United Heavy Lift has attuned its fleet to the requirements of the growing market for eco-friendly breakbulk and heavy lift ocean transport. “We are supporting the energy transition with our vessels, and the transport of onshore wind turbines is part of our core business,” says Mr Rolner. “The market for this is developing well with demand driven by the desired expansion of renewable energies. Our customers have already reserved extensive capacities for wind power: we are already 30% booked in this segment until 2028.” The shipowner believes that the reason why market players are currently securing tonnage so early is that while there is high demand for heavy lifter services, hardly any new vessels are expected for this segment in the foreseeable future.

“Shipbuilding sites are expensive and also scarce because they are occupied by newbuilds such as tankers or bulkers.

What’s more, heavy lift vessels are also complicated to build,” he adds.

The tonnage and crane capacity of the UHL-F900 vessels also make the fleet suitable for cross-sectoral use like container transport. UHL Fable is the shipping company’s second new addition this year. United Heavy Lift is one of the leading providers of maritime transport services for heavy lift, breakbulk and project cargo. The shipping company operates a versatile fleet of 24 modern heavy lift vessels with lifting capacities of 160 to 900t, the core of which are the F900 Eco-Lifter sister vessels. Founded in 2015, United Heavy Lift is part of the UNITED Group based in Hamburg’s HafenCity, and has a global team of 120 employees. The engineering with stowage plans, manuals, et cetera as well as commercial chartering also lie within the Group’s responsibility: both are carried out by United Engineering Solutions, also situated in Hamburg.

After completing her maiden voyage, the UHL Fable has now been named at United Heavy Lift’s home port with Nora-Katrin Rolner, wife of shipowner Andreas Rolner, performing the ceremonial act. The festive and cheerful event was hosted by Northern German entertainer Annie Heger while the 30-strong shanty choir ‘Stader Hafensänger’ provided the musical accompaniment.

Following the naming ceremony, captain Karsten Strotmann and his bridge crew took over the vessel. Also on board are three cadets (two nautical officer’s assistants and a ship’s mechanic in training), as United Heavy Lift will be training its own crew on the UHL Fable in future, as indeed on all ships in the F900 fleet.

i. unitedheavylift.de

With the support of RWE, the Dutch-Norwegian company SolarDuck has installed its offshore floating solar (OFPV) project Merganser. The pilot project aims to test and demonstrate the structural, mooring and electrical designs, and acquire knowledge about manufacturing, assembly, offshore installation, and maintenance methodologies required for large-scale commercial deployment of OFPV.

Merganser has a capacity of 0.5MWp and is located in the Dutch North Sea, approximately 12km off the coast of Scheveningen. The scalable concept consists of six interconnected platforms that can withstand extreme offshore conditions. The floating platforms were successfully connected to the mooring system in a water depth of 20m. RWE will continue to provide its offshore know-how and technical support to the pilot project. Sven Utermöhlen, CEO of RWE Offshore Wind, says, “Standalone or also in combination with offshore wind farms, offshore floating solar could open up further offshore renewable energy opportunities – especially for countries with lower average wind speeds but lots of sunlight. With Merganser, we are gaining unique insights and first-hand experience in one of the most challenging offshore environments in the world.”

Taking solar farms offshore requires technology that is able to withstand rough offshore conditions. SolarDuck´s triangular-shaped platform is designed to float several meters above the water, following the waves like a carpet. In this way, the design keeps critical components dry, clean, and stable, as well as securing the structural integrity of the semi-submersible floating structure. The design recently received the world’s first certification for OFPV by Bureau Veritas. Koen Burgers, CEO of SolarDuck, states, “The successful installation of Merganser is proof of the dedication of SolarDuck’s team to electrify the world with offshore floating solar. However, we are not doing this alone. Our project partner RWE is a supporter of our technology and vision, in addition to other partners such as TNO, TU Delft, MARIN, and Deltares. Together with numerous supply chain partners, including Damen Shipyards, TMA, and Norsk Hydro, we have turned hard work into a positive change for the energy space.”

The combination of RWE’s leading global market position in offshore wind and SolarDuck´s technological ingenuity sets the perfect base for accelerating the deployment of OFPV. Over the coming two years, Merganser will be monitored remotely with its more than 180 sensors fitted to monitor structural loads, connector and mooring loads and electrical performance, among other important performance criteria. Further to the above, Deltares, a Dutch independent institute for applied research, will support an extensive monitoring campaign on the ecological impact of OFPV.

SolarDuck is a Dutch-Norwegian offshore floating solar company with strong roots in the maritime industry. The company was established following a Damen spin-off. Since then, SolarDuck has worked towards the vision to ‘Electrify the world with offshore floating solar’. SolarDuck’s technology is fully scalable to match specific local requirements worldwide. It offers an attractive value proposition in a wide array of user cases, ranging from islands in the sunbelt to hybrid offshore energy parks in the North Sea, including the Netherlands.

i. solarduck.tech

Taking solar farms offshore requires technology that is able to withstand rough offshore conditions. SolarDuck´s triangularshaped platform is designed to float several meters above the water, following the waves like a carpet.

Equinor and its partners Petoro, Vår Energi, and TotalEnergies EP Norge started production from the first Lavrans well in the Kristin South area on 7 July.

The partnership submitted the plan for development and operation (PDO) of the Lavrans and Kristin Q discoveries as satellites to the Kristin field in 2021. This is the first phase of the Kristin South project. The PDO was approved by the authorities in 2022.

“The Kristin South project demonstrates our strategy to create value by developing existing infrastructure on the Norwegian Continental Shelf. Together with our partners and suppliers, we have developed the project and started the

production from Lavrans in a safe and good way,” says Trond Bokn, senior vice president for project development at Equinor.

A new subsea template has been installed and tied into the Kristin platform, now processing oil and gas from the first well at the Lavrans field. The gas will be exported through the pipeline system to the European market, while the oil will be transported to the

market by ship via the Åsgard C storage vessel. Four additional wells are planned as part of the first phase of the Kristin South project, three at the Lavrans field and one in the Q-segment at the Kristin field. The latter will be drilled from an existing subsea template that has been tied back to the Kristin SEMI.

The expected production in phase one of the Kristin South project is in the PDO estimated at 6.2GSm3 of gas and

• Aker Solutions/OneSubsea and subcontractors: subsea production facilities.

• TechnipFMC and subcontractors: pipeline fabrication, pipelaying, and subsea installation.

• Aibel and subcontractors: engineering, procurement, construction, and installation for Kristin platform modification.

• Transocean Spitsbergen: rig contractor.

The CO2 intensity for extraction and production of Kristin South phase 1 is very low, less than 1kg of CO2 per barrel of oil equivalent.

1.9MSm3 of oil (a total of 58.2 million barrels of oil equivalent). “This is a key milestone in our plan to continue to develop new resources in a mature area in the Norwegian Sea. Tying in additional resources to our producing hubs is a cost-efficient way to add production and extend the lifespan of our fields in operation. This approach contributes to energy security and job creation in Norway,” says Grete B. Haaland, senior vice president for exploration & production North.

The CO2 intensity for extraction and production of Kristin South phase 1 is very low, less than 1kg of CO2 per barrel

of oil equivalent. The emissions will mainly be generated from the project’s drilling activities. Norwegian suppliers have been awarded over 60% of the contract values in the development phase, creating ripple effects along the coast. The project is estimated to have created 4,000 person-years across Norway, with 800 in the Mid-Norway region, over the 2020-2025 period. Lavrans was discovered in 1995, while the Kristin field was put on stream in 2005. The technical lifetime of the Kristin platform is currently estimated to be 2043 with potential for further extensions.

i. equinor

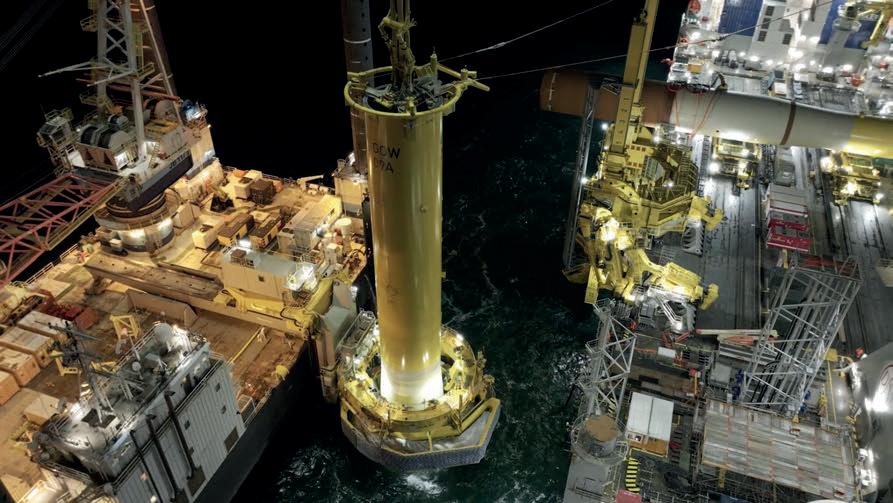

Ørsted has developed a new, lower-noise installation method that could potentially revolutionise the way offshore wind foundations are installed.

Building on existing marine life protections, Ørsted has developed a new, lower-noise installation method that could potentially revolutionise the way offshore wind foundations are installed.

ALL PHOTOS COURTESY OF ØRSTED, UNLESS STATED OTHERWISE.

The groundbreaking new technology has been successfully tested in Germany, proving that this innovative approach can dramatically reduce noise levels during foundation installations, strengthening existing protections to marine life, and potentially paving the way for the next generation of monopile foundations.

This leading-edge technology represents one of the greatest advancements yet in offshore wind foundation installation methodology. It is also the latest

example of how Ørsted continues to harness innovation that supports biodiversity, protects the environment, and creates the green energy systems of tomorrow. Ørsted is already implementing a range of effective protective measures during offshore wind farm construction, including limiting the duration, intensity, or extent of certain offshore construction activities. Examples of these mitigating measures include the deployment of bubble curtains or other noise barriers during traditional installation. The new installation method allows Ørsted to

further reduce the potential impact from construction activities on the marine environment and build in a more costeffective way.

At the new German offshore wind farm Gode Wind 3, Ørsted has successfully tested an innovative installation method on three monopile foundations. The noise mitigation method involves a patented jetting technology attached to the monopile, which lowers the resistance of the surrounding sandy soil, effectively allowing the foundation to

sink into the seabed – completely replacing conventional installation methods such as pile driving. The implementation of the new installation technology has resulted in a substantial decrease in underwater noise levels: with a reduction of 34db relative to the most commonly used installation method, and without additional mitigation, noise levels were reduced by over 99% to a level just marginally above the ambient noise found in the German Bight in the North Sea.

Beyond the noise reduction, this new technology is a step change in offshore wind monopile installation that, once adopted at scale, can provide for more efficient and cost-effective installations of offshore wind foundations. 11MW wind turbines have already been installed on top of the foundations, and Gode Wind 3 is expected to start commercial operation later this year.

Patrick Harnett, executive vice president and chief operating officer at Ørsted, says, “Ørsted has been at the forefront of offshore wind innovation and marine protections for 30 years, and we continue to push the envelope on new innovative solutions. This new technology is a potential game changer for how we build offshore wind. Once industrialised, it could not only be cheaper, faster, and far quieter – without additional mitigation – than any other monopile installation technology, it also has the potential to make nextgeneration foundations lighter as they won’t need to be designed for conventional installation process.”

This is the first time a jetting technology has been used to install full-size

Beyond the noise reduction, this new technology is a step change in offshore wind monopile installation that, once adopted at scale, can provide for more efficient and cost-effective installations of offshore wind foundations. >>

The new technology is a testimony to Ørsted’s approach to innovation, which has been core to Ørsted’s business from the very beginning, helping to take offshore wind power from a demonstration concept to a large-scale energy technology.

monopile foundations, making the tests a milestone for the entire industry. Ørsted carried out the installation together with Jan De Nul Group and their installation vessel Les Alizés as well as contractor Aarsleff. Ørsted has been developing the technology over the past years and is now looking into how to introduce the technology into the future pipeline, which includes assessing the feasibility of the method on more complex ground conditions than the pure sand conditions found at the Gode Wind 3 site. Further regulatory approvals will also be needed before the technology can be implemented in other markets globally.

The new technology is a testimony to Ørsted’s approach to innovation, which has been core to Ørsted’s business from the very beginning, helping to take offshore wind power from a demonstration concept to a large-scale energy technology. Advances in technology have already brought down the costs of renewable energy, making it cost-competitive with fossil fuels, and Ørsted believes it can continue to harness cutting-edge technology to make green energy more affordable, reliable, efficient, and sustainable across the value chain. Recently, Ørsted has

deployed an autonomous vessel for offshore surveying, and the company is testing the use of large drones to transport cargo to offshore wind turbines.

For successful implementation at Gode Wind 3, Ørsted will receive subsidies from the German Federal Network Agency (BNetzA) under the Offshore Wind Energy Act, intended to drive innovation in the offshore wind buildout.

i. orsted.com

Peter Zorge

Teus Visser has been succeeded as director of Reikon by Peter Zorge, a well-known figure in the national and international maritime sector. Mr Zorge has worked for more than 30 years at Royal Econosto, which later became Eriks, the last 23 years as director of the maritime business unit. He has worked with the Reikon team since June to ensure a seamless transfer. Mr Visser will remain active until the end of the year to complete and transfer his duties, before commencing a new role as CEO of Reikon Beheer.

Barriau

Hempel A/S has appointed Emilie Barriau as chief technology officer, a new position in the Executive Group Management, bringing a dedicated focus on innovation. The new technology executive vice president area comprises R&D, Procurement and Sustainability to serve as mutually reinforcing powerhouses of innovation. This appointment ensures that innovation is more prominently featured at the highest level of the organisation. Ms Barriau is an internationally experienced senior innovation executive who spent fifteen years with Henkel Adhesives Technologies, serving transport, metals and electronics industries in various global roles.

Sachs

Sebastian Sachs has been appointed as managing director of SCHOTTEL Nederland, taking over from his predecessor René Lange. Sachs joined SCHOTTEL in 2016 as controller and has held various management positions, most recently as director finance and administration. His previous activities have equipped him with a particularly comprehensive knowledge of SCHOTTEL’s worldwide subsidiaries, which he will bring to his new position.

Pier Solutions has appointed Gary Gallon as managing director of its recently acquired electrical engineering businesses, V-TES and V-TES Renewables, as it strengthens its service offering across the energy sector. Mr Gallon boasts extensive experience in various commercial roles, including twelve years at Dron & Dickson. Working alongside Pier Solution’s leadership team, Mr Gallon’s appointment will support the business in achieving its strategic growth objectives in the energy sector and strengthen its services for both onshore and offshore customers.

OrbitMI, has announced the appointment of Youn Lee as its new chief financial officer. Mr Lee, who officially joined OrbitMI in 2023, brings a wealth of experience in finance and operations, with a distinguished career that includes leadership roles in digital transformation across various industries.

Sebastian Sachs will be supported by sales specialist Ewoud Hooymans, who will assume a larger area of responsibility in the operational business in his new role as sales director.

Following many years as sales manager at SCHOTTEL Nederland, Ewoud Hooymans is now responsible for the entire new sales and after service sales in the BeNeLux region as well as for new sales in the UK.

Camm-Pro has appointed five key individuals to its board. The appointments come as Camm-Pro continues to increase its portfolio of contracts across upstream, midstream, decarbonisation, and energy transition projects.

Jim Craig will assume the position of projects director. Mr Craig has a strong track record in project delivery roles.

John Duncan brings CFO and investment experience to the board, which will be significant in supporting the company’s growth plans.

Joanna McLaughlin With over 20 years of experience as an executive PA, as well as roles in business and facilities management, Ms McLaughlin will assume the role of facilities director.

John Verling joins the board as a non-executive director. He has a breadth of experience in business development, with over 40 years as a senior advisor and business development leader across the international energy sector.

Steve Martin brings a breadth of technical engineering knowledge and rejoins the board as technical director.

ADS VAN STIGT

Avelingen-West 30

4202 MS Gorinchem

The Netherlands

T +31 (0)183 650 000

E info@vanstigt.com

I www.vanstigt.com

Contact: Sander Snoek

ADS van STIGT was founded in 1970 with the main activity in transmissions and gearboxes for maritime and industrial applications. This is still an importent activity of ADS van STIGT, but a significant number of other products have been added to the range, such as planetary gearboxes, pump drives, control systems, monitoring systems, controllable pitch propellers, thruster systems, carbon fibre shafts, dampers, elastic couplings and sensors. ADS van STIGT’s expertise ranges from pleasure to mega yachts, and from fishery to commercial shipping, offshore, and dredging. A well-equipped service team is supporting the sales activities worldwide.

ADS van STIGT is competence centre for: Masson, Bonfiglioli, O&K, Plöger, Horn, Schaller, Katsa, Geislinger, Durst and ZF.

ANCOFERWALDRAM STEELPLATES B.V.

P.O. Box 190

4900 AD Oosterhout

The Netherlands

T +31 (0)162 491 500

F +31 (0)162 429 806

E sales@aws.dillinger.biz

I www.ancoferwaldram.com

Over 100,000 tons of quality heavy steel plates in stock

AncoferWaldram Steelplates B.V. (AWS) is a stockholding wholesaler and steel service center, specializing in the supply of hot-rolled heavy carbon steel (quarto) plates, and profiled parts for more than 40 years now. Over the years, AWS has developed into a business that sets the standard for its industry.

Plates from stock or profiled parts

The choice is yours! It is the combination of comprehensive stocks of over 100,000 tons of heavy carbon steel plates plus the sophisticated profiling plant that gives AWS a

decisive lead in experience, product range and customer service.

BREMAN MACHINERY B.V.

Sasdijk 20, 8281 BM Genemuiden, The Netherlands

P.O.Box 135, 8280 AC Genemuiden,

The Netherlands

T +31 (0)88-27 36 200

E info@breman-machiner y.nl

I www.breman-machinery.nl

Great challenges need sophisticated solutions, the work of a specialist.

Breman Machinery fabricates critical steel components with exceptional dimensions and extreme accuracy. This is the daily job of our craftsmen. Through our unique capabilities regarding machining, welding, conservation and assembling we serve our customers to make their ambitions reality.

The welders of high-quality steel are qualified by Lloyd’s Register or DNV for all welding positions. With 30 milling, boring and turning machines we have the possibility to offer unique services. Our preservation department can protect your projects. Our location is beside open water, we have a direct connection to the international ports. High quality is one of our most portant standards!

EMIGREEN B.V.

Noordeinde 19 3341 LW Hendrik-Ido-Ambacht

The Netherlands

T +31 (0)184 415 317

F +31 (0)184 415 582

E info@emigreen.eu

I www.emigreen.eu

Contact: Niko J. Dalpis

Emission Control Technology

Emigreen produces customised, integrated emission control solutions, for, among others, the maritime sector. Emigreen also provides services including design, specification, production, installation instruction, training and aftersales. Emigreen has expertise in emission control technologies, flow dynamics, thermodynamics and noise and vibration control. Emigreen develops and tests components including

catalytic converters, particulate filters, selective catalytic reduction systems and related instrumentation.

The Emigreen Alfa Alfa burner assisted soot filter system has set the standard for others to beat. All Emigreen solutions are highly efficient, highly reliable and highly controllable, whether designed for an inland barge, shortsea carrier or luxury yacht.

Emigreen links science and the market

DELTA SUBSEA

550 Club Dr, Suite 345 Montgomery, Texas 77316, USA

T +1936-582-7237

I www.deltasubsea-rov.com

Delta SubSea (DSS) is a leading integrated independent provider of ROV Services and Solutions. Delta SubSea’s ROV fleet is focused on solutions for customers in the inspection, repair and maintenance, construction, drilling and decommissioning market segments.