In this, the fourth issue of Shipbuilding Industry in 2024, we bring you news of multiple christenings, with both Van Oord and Wagenborg celebrating the delivery of their latest new builds. Van Oord’s all-new hybrid vessels are the builder’s most sustainable water injection dredgers built to date (page 38), while Wagenborg’s second and third hull of its ice-strengthened EasyMax model are among the biggest ships ever built in the north of the Netherlands on the landward side of the dikes (page 22).

We speak to those in the know at Breman Wesco to learn about the company’s fast and efcient mobilisation for vessels specialising in the ofshore wind industry (page 12). Scott Raeside, Product Business Analyst at SSI, explains why intelligent 3D ship models can automate the shipbuilding process for the better (page 42), and mooring specialist DSR reveals its plans for even more advanced solutions to revolutionise the industry (page 18).

As the maritime industry prepares for the impending revision of MEPC 107(49) in 2025, we learn how Marinfoc, a leader in wastewater treatment solutions, stands in a league of its own with future-ready products that have been setting industry standards since 1996 (page 36). Likewise, an increased focus on use and transport of fammable gasses in the guise of ‘new fuels’ has increased demand for deck equipment that is explosion proof, and lighting manufacturer Lopolight explains how its Professional Ex Series gives the freedom to place navigation lights on vessels at the correct location without compromise (page 26).

Other publications by Yellow & Finch Publishers:

Hagland Shipping breaks new ground on page 16 with its selfdischarging bulk carriers that are currently in build, and which form part of the company’s aim to achieve greener short sea shipping. Dutch Dredging BV gives the green light to Royal IHC , a leading supplier of maritime technology, for the design and construction of its ffth custom-built trailing suction hopper dredger (page 28). And Hydrex founder Boud Van Rompay refects on fve decades of success (page 32).

With innovation at the fore, SMM Hamburg, the world’s foremost event for the latest technologies in maritime, is just around the corner in September. Read all about its plans for this year on page 8.

We look forward to seeing you there!

Julia Zaltzman – Editor INFO@YNFPUBLISHERS.COM

NAVILUS product. Expect the best project support for your propulsion train.

Profit also from our Marine Services for global lifecycle support. We specialize in the supply of spare parts and field service engineers for the complete mechanical drive portfolio. With both the Lohmann & Stolterfoht and current Flender NAVILUS brand, we serve ship owners and a wide range of vessels across the globe from our Rotterdam office. Contact us at any time:

Marine Spare Parts: bruinhof.nl@flender.com Marine Field Services: marine.services@flender.com flender.com flender.com/en/bruinhofmarine

Washington State selects ABB for fve hybrid ferries

Washington State Ferries (WSF), the United States’ largest ferry system has selected ABB to serve as the propulsion single source vendor (PSSV) for its fve new hybrid electric 160-auto ferries. The contract will see ABB playing a pivotal role in the development and delivery of the fve new builds, including its systems integration expertise deployed from the project’s shipyard bidding stage through to vessel commissioning and initial service. The 1,500-passenger, 160-vehicle hybrid electric ships are pivotal to WSF’s Ferry System Electrifcation plan and support its goal of a zeroemission feet by 2050.

i. abb.com

ITOCHU, Nihon Shipyard, ClassNK and MPA sign MoU for joint study

ITOCHU Corporation, ClassNK, Nihon Shipyard Co., Ltd., and Maritime and Port Authority of Singapore (MPA) have signed a Memorandum of Understanding (MoU) regarding a joint study for the design and safety specifcations of ammonia-fuelled bulk carriers that are under development by ITOCHU and partners. MPA, the government agency overseeing the world’s busiest bunkering hub, will review and provide its views on the designs of the ships to ensure their safe operations. The necessary clarifcations of the specifcation for the ammonia-fuelled ship to carry out ammonia bunkering in Singapore will be conducted among parties of this MoU, for the commercialization of ammonia-fuelled ships.

i. classnk.com

In July, Cobham Satcom, a market-leading provider of radio and satellite communications solutions and services for the maritime and land segments, unveiled its most advanced maritime satellite TV antenna yet. Designed primarily for use on cruise ships and yachts, the 3.7m Sea Tel 370s TV is designed to expand onboard access to the highest quality programming anywhere in the world, while signifcantly reducing lifetime technical costs. The new fagship TVRO antenna features automatic C-band switching between circular and linear polarization, ensuring uninterrupted viewing and continuous availability of live television such as ESPN, which is one of the most popular cruise ship channels especially when major sporting tournaments are playing.

cobhamsatcom.com

eCap Marine, a pioneer in sustainable maritime power generation technologies, is set to showcase its emission-free Hydrogen Power Generator - H2PowerPac, at the 2024 SMM in Hamburg. The retroft and hybridisation of one ofshore supply vessel (OSV) with eCap Marine’s innovative H2PowerPac and H2Tank Systems successfully received the DNV Case-by-Case Approval in February, highlighting the company’s comprehensive engineering expertise. The H2PowerPac, assembled in a 20ft container-shaped module, serves as an emission-free energy source for the vessel’s extended propulsion, enabling it to navigate through the delicate environment of the Wadden Sea Nature Park in the North Sea.

i. ecap-marine.com

efciency

i. arkitech.eu

Dutch technology startup Arkitech, an Amsterdambased innovative software platform company dedicated to the maritime industry, has confrmed that its smart-data and AI software solution enables up to 12% increase in chiller efciency on board MSC’s luxury cruise ship, Magnifca. The technology delivers signifcant efciency improvements to the HVAC systems onboard that equate to 1600 Megawatt yearly energy savings — the equivalent to removing 687 electrical cars from European roads or removing the yearly energy consumption of 400 European homes.

Jan De Nul to connect Princess Elisabeth Island to Belgian high-voltage

Ofshore expert Jan De Nul Group, in consortium with LS Cable & System, has won a contract to supply, install and test three 220kV alternating current cables to transmit renewable energy from Princess Elisabeth Island – the world’s frst artifcial energy island located of the Belgian coast – to the Belgian high-voltage onshore grid. The artifcial energy-island, which is being constructed by a Jan De Nul Joint Venture and due to supply 3.5GW of renewable energy to the Belgian grid, is an electricity hub that bundles the cables of the second ofshore wind zone in Belgium (the Princess Elisabeth Zone) with future cable connections to other European North Sea countries, such as the UK and Denmark. It represents an important milestone in Belgium and Europe’s transition to renewable energy and is crucial for the integration of energy systems.

i. jandenul.com

Lehmann Marine to showcase advanced LFP battery systems at SMM

Lehmann Marine, a leading provider of LFP-based battery systems for the maritime industry, has confrmed its presence at SMM in Hamburg in September, where it will showcase its safe and compact energy storage solutions CUBE and COBRA. A mock-up of the CUBE battery system at Lehmann Marine‘s booth (A4.105 in Hall A4) will be on display, along with a team of experts available to answer questions. Guided tours of the company’s production site nearby, including transportation to and from SMM, will also be possible via prior arrangements.

i. lehmann-marine.com

Global technology and engineering company, Emerson, has announced that it now ofers a free template confguration for marine applications, based on its Movicon.NExT HMI/SCADA system, and its PACSystems edge controllers, industrial panel PCs, and other control and networking products. This marine demonstration confguration provides a comprehensive user visualisation and interface experience and is available free of charge to designers and shipbuilders to accelerate their eforts to deliver a thoroughly modern and unifed “single pane of glass” shipboard monitoring and control system. Emerson edge controllers incorporate operational technology (OT) communication protocols, and are adaptable to specialised marine industry protocols, meaning all instruments, devices, and subsystems can be integrated.

i. emerson.com

CM Technologies (CMT) has announced the appointment of Singapore’s Junma Services, a leading marine engine sales, repair, and services company, to facilitate increasing demand for CMT’s machinery and fuids testing, measuring and analysis solutions. Junma Services joins an established CMT network of 10 distributors across the Asia Pacifc region. The development is part of a wider strategy to ensure that all major maritime hubs are stocked with CMT’s PREMET range of diesel engine performance optimisers to help shipowners and managers curtail their ships’ CO2 emissions in line with carbon reduction requirements. i. cmtechnologies.de

Meet us at booth A4.105

• Superior energy density

• Compact and lightweight

• Flexible and easy installation

• Innovative air-cooling technology

• Inherently safe LFP chemistry

• Cobalt- and nickel-free

• Scalable and modular design

• Integrated BMS and Pre-Charge

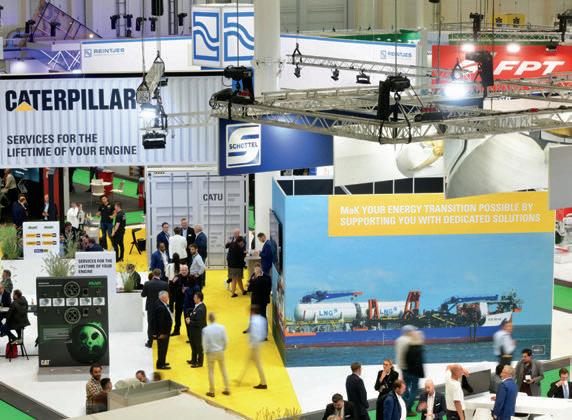

ALL PHOTO COURTESY OF SMM HAMBURG.

SMM Hamburg, the world’s foremost platform for innovation and the latest technologies in maritime, covers the entire value chain of the nautical industry on 90,000m² in 12 exhibition halls. The international maritime trade fair takes place in Hamburg from 3 to 6 September 2024. More than 2,000 exhibitors and around 40,000 visitors from over 120 countries are expected to attend this year.

Themed “SMM – driving the maritime transition”, the 31st SMM will focus on the decarbonisation of ships, Artifcial Intelligence (AI), and the recruitment of young talent. For the frst time, the conferences that supplement the exhibition will take place on open stages inside the exhibition halls – free of charge and accessible to all fair visitors.

Throughout maritime, the drive to decarbonise is a key priority. The core challenge is to provide enough alternative fuels – such as green hydrogen, methanol or ammonia –while creating the required distribution infrastructure. At SMM, companies specialising in these clean technologies and their derivatives will be assigned a dedicated exhibition zone called the Future Fuel Area. This year, there is particularly strong interest from China, Korea and Japan, the three leading shipbuilding nations, with every tenth exhibitor at SMM based in Asia.

Hauke Schlegel, managing director of VDMA Marine Equipment and Systems, stresses that SMM is an important interface between European technology >>

Hall

Hall

Hall A3/A4

Hall

Hall

Hall

Hall B5

Hall B6

Hall B7

leaders and major Asian shipyards:

“International cooperation is essential; it enables shipowners around the world to tackle huge technological challenges in feet renewal and maintenance in a manner that is tailored to their needs, timely and economically feasible,” he says.

Other nations are also represented in growing numbers, with Greece, the world’s foremost ship owning country, doubling its participation in 2024. The Greek national pavilion will cover nearly 800 sqm and host 35 organisations showcasing their products.

“As an association, our goal is to continue to ensure that leading Greek marine equipment manufacturers build lasting international and local partnerships, and that the collective strength and innovation of our suppliers is at the forefront of owner and yard thinking,” said Eleni Polychronopoulou, president of Hellenic Marine Equipment Manufacturers & Exporters.

Another key area of interest is the development and application of Artifcial Intelligence (AI) within maritime. For the frst time, SMM is providing a section specifcally dedicated to AI — the AI Centre — where start-up companies can highlight AI-based technologies and projects for the maritime industry.

In a bid to also attract younger talent, the two-day Maritime Career Market, taking place from 5 to 6 September, will combine training and job ofers with rewarding networking events. Practical insights into the maritime professional world are also available at the Career Forum on 6 September. “This SMM job initiative is an important contribution to securing the future of the maritime industry,” says Selbach.

With the industry aiming for carbon neutrality by 2050 and driving digital change, all while negotiating volatile global supply chains and a shaky geopolitical situation, these are challenging times for maritime, said Claus Ulrich Selbach, Business Unit Director at Maritime and Technology Fairs at Hamburg Messe and Congress during a press conference at Posidonia

in Athens. “The sector can only tackle these difculties by working together closely,” he said. “At SMM we ofer ship owners, suppliers and shipyards an optimal platform for their joint eforts to develop feasible technology solutions that address the pressing challenges of our time. The enormous interest from exhibitors and visitors alike tells us that there is a tremendous need for communication.”

In the wake of the current geopolitical climate, many countries are modernising

their feets, and the importance of military operational readiness has moved into focus. At SMM, navies and coast guards have the opportunity to network and connect with exhibitors, such as NVL Group, MTU and Kongsberg, whose innovations carried over from civilian shipping can supply state-of-the-art dual-use technologies for both segments.

i. smm-hamburg.com

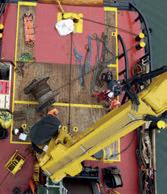

Installing pipework on the Sand Carrier 106.

The fast mobilisation of a skilled workforce necessary for the construction and maintenance of ships operating within the ofshore wind industry is not the easiest of tasks, but it’s something that Breman Wesco — a leader in engineering, manufacturing and maintaining mechanical engineering projects — has turned into a unique selling point. In the 40 years since the company was founded, its expertise within the concrete and dredging industries has grown exponentially, today delivering some of the most cost-efcient solutions on the market.

Ideally located in the Dutch coastal port of IJmuiden, Breman Wesco’s construction site in the harbour is central to providing its fast and efcient services. “We provide vessels with a team

of construction welders that can quickly be mobilised to carry out a large range of specialist jobs, therefore minimising a vessel’s downtime,” says Aaron Visscher, sales engineer at Breman Wesco.

Key to Breman’s service and engineering oferings is its ability to work with customers to fnd solutions to a wide range of specifc problems. This includes developing high quality equipment and machinery for specifc needs.

“Every job is bespoke and presents diferent challenges, from the number of workers required to the types of skill set,” says Visscher. “Our expertise within engineering extends to the fabrication of steel products and equipment for various industries, the installation within the vessel and the follow up inspection

and maintenance. So, together with our mobilisation, clients can use Breman Wesco as a one-stop-shop to get their vessel ready for any project within a tight timeline. It eliminates the need for clients to go to a third party, as we can deliver on all requirements in-house.”

Recent examples of projects that Breman Wesco has worked on include the manufacture and installation of a suction tube for Ecodelta, a trailing suction hopper dredger owned by Van Der Kamp International. “ We built a lot of specialist equipment for the ship and continue to carry out routine maintenance every six weeks to ensure the vessel is in optimum condition for its ongoing projects,” says Sander Brouwer, construction manager at Breman, whose team fies around the world carrying out necessary works. “We’ve carried out

“Our focus is on expanding how waterside construction sites to further our assembly capacity, which, in turn, will keep in line with the increasing size of clients’ vessels required to serve the ofshore wind industry.”

repairs and maintenance in Germany, Denmark, England – wherever the vessel is located.”

Seeing it through “Our expertise lies in our ‘never give up’ attitude,” adds Brouwer. “When there is a problem, we fx it. Sometimes it requires two people, other times it’s six, but we don’t stop until the job is fnished.”

Other examples of recent projects include the Sand Carrier 106, a 134m HB Hopper Barge, that Breman Wesco designed, engineered and manufactured platforms, pipelines and bridges for, which were then installed on-site. “The work, together with fabrication, took us approximately six months, followed by a rapid two-week installation,” says Visscher, again demonstrating the company’s swift response time.

A second client placed an order for an A-frame just two weeks prior to its specifed delivery date. “Thanks to our network of local partners and in-house all-round construction workers, from welders and draughtsmen to engineers and people on assembly, we built and ftted the A-frame based on the client’s sketches, before installing it on the client’s vessel,” adds Visscher. “The installation itself required deck reinforcements as the vessel was not originally designed to handle an A-frame of this size and weight. We secured reinforcements below deck to ensure the vessel was properly prepared for a safe installation.”

Another unique client saving that results from Breman Wesco’s approach is the fact it mitigates the need for vessels to

go to dry dock. “Carrying out works onwater from our harbour site is less time consuming and less costly for the client,” says Visscher. “We get jobs done, because we provide a client with solutions for all their needs, but as well as a fnancial and time saving, there is also a sustainable beneft too.”

In 2023, the company invested in bigger milling machines to enable it to manufacture even larger products, and extended its existing facilities by 5,000m2 to allow for the assembly of larger projects, along with more storage and greater lifting capacity. “Our focus is on expanding our waterside construction sites to further our assembly capacity,” says Visscher, “which, in turn, will keep in line with the increasing size of clients’ vessels required to serve the ofshore wind industry.”

i. breman-wesco.com

Four new self-discharging methanol-ready bulk carriers for Hagland Shipping.

Hagland Shipping confrmed in June that it has entered a contract with Dutch shipyard Royal Bodewes for the construction of four self-discharging bulk carriers. The ships of 5,000dwt enable zero emissions at harbour and a substantial reduction of emissions during sailing.

The commission forms part of Hagland’s aim to achieve greener short sea shipping through reduced local and global greenhouse gas emissions and reduced noise. The move will replace older vessels with traditional propulsion systems with modern, optimised vessels with plug-in battery hybrid solution and electric cargo handler.

“We are proud to be able to enter yet

another contract for new builds with a high focus on efciency and low emissions,” the company said in a statement. “Our experience with the last three ships has been very good and the new vessels will be a further improvement.”

Hagland Shipping took control of three ships from Royal Bodewes in November 2023. The new ships will be of the same design, but with several innovations that will further reduce emissions. Compared to the oldest ships in Hagland’s existing feet, the ships are expected to reduce CO2 emissions by up to 50% and NOx emissions by 95% from deliver y.

The bulk carriers are also futureproofed, equipped with an engine solution that can be converted to methanol operation once available. A system that recovers the waste heat from the engines will produce enough electricity to cover the ship’s hotel load. The frst vessel is expected to join the feet at the end of 2025 and will fy the NIS fag. The project has received support from the feet renewal programme for shortsea shipping and marks the single biggest investment in the group’s history.

Hagland Shipping was established in 1983 and operates a total of 13 self-discharging vessels in sized

3,700-5,000dwt, in addition to the four new builds. In 2021 in collaboration with NOAH, the group successfully converted its vessel, Hagland Captain, to be the world’s frst battery-hybrid ship in the shipping company’s segment. That same year, it ordered its frst three new builds, all with similar technology. The current commissions build on the experience gained from these projects and will be used for normal trade and operation. The order is expected to strengthen the company’s position in the market for self-discharging bulk carriers.

Hagland Shipping is among the leading operators of self-unloading bulk carriers in the segment from 2,500 - 7,000dwt, ofcially known as short-sea shipping. The ships mainly operate mainly in northern Europe and the Baltics. It had a turnover of around EUR 48.5 million in 2023 and forms part of the Hagland Group.

DSR to showcase revolutionary WINZ Mooring Solution at SMM 2024.

September 2024 promises to be a groundbreaking month for the maritime industry. DSR, the global leader in mooring solutions, is set to unveil its cutting-edge WINZ Mooring Line Management Programme at the SMM Hamburg exhibition. DSR, renowned for providing comprehensive solutions from A to Z in mooring ropes, will ofer attendees an immersive experience with its latest innovations.

Those in the maritime industry, particularly in mooring operations, will likely be familiar with DSR’s stellar reputation. Their heritage of excellence and unmatched customer engagement are well-recognised. Now, DSR is back with even more advanced solutions to revolutionise the industry

WINZ represents the latest in DSR’s innovations, providing real-time monitoring and maintenance capabilities that keep mooring lines in optimal condition. This programme not only cuts maintenance costs but also enhances operational efciency while ensuring compliance with the latest IMO and SOLAS regulations.

“WINZ ofers rapid adaptation to regulations, continuous monitoring of all

“WINZ ofers rapid adaptation to regulations, continuous monitoring of all ship lines anytime and anywhere, and provides expert advice on line management.”

ship lines anytime and anywhere, and provides expert advice on line management,” says David Jo, DSR project manager. “Tested by leading LNG and bulk ship operators, WINZ has shown a remarkable 33% improvement in operational efciency. Users have praised its convenience, efciency and accuracy.”

Designed with a user-friendly interface and one-click actions to maximise convenience, WINZ is customisable to meet specifc company regulations and is applicable to most internationally operating vessels. The future of WINZ includes a mobile app slated for release within 2024, enabling users to record line actions on the go, enhance communication, and integrate seamlessly with DSR Rope for more efcient line management. Additionally, smart options for real-time tension measurement and risk alert systems are under development.

At the SMM exhibition, attendees will have the unique opportunity to

experience WINZ through live demonstrations. “Visitors to our booth will see frsthand how WINZ revolutionises mooring line management,” says Jo. “We’ll showcase its full capabilities and how it can transform their operations.”

Established in 1965, DSR has grown alongside the Korean shipbuilding industry to become a world leader in synthetic fbre rope manufacturing. Its fagship mooring ropes, such as SuperMax and OceanMax, are renowned for their superior quality and performance. SuperMax, specifcally designed for LNG ships, maximises safety and efciency, while OceanMax, certifed by DNV and ABS, is optimised for deep-sea mooring and ofshore wind farm applications.

“Our slogan ‘No Moor Problem’ encapsulates DSR’s commitment to providing our customers with complete reliability,” says Martin Cho, European division director. “We are dedicated to ensuring safety and efciency in all our

Liftal Vlissingen Groenlandweg 4 Havennummer 4056 4455 SN Nieuwdorp (Vlissingen-Oost)

Tel: +31 (0) 118 - 488 450 Email: vlissingen@liftal.com

Liftal Rilland De Poort 15 4411 PB Rilland

Tel: +31 (0) 113 - 571 523 Email: rilland@liftal.com

Liftal Rotterdam p/a Admiraal de Ruyterstraat 24 3115 HB Schiedam

Tel: +31 (0)10 - 60 036 60 Email: rotterdam@liftal.com

Liftal Belgium Duitslandstraat 4 9140 Temse

Tel: +32 (0)3 710 11 82

Email: temse@liftal.com

solutions. DSR’s past success is just the beginning; our continued innovation will lead us to a brighter future.”

In May 2024, DSR successfully hosted a seminar in Japan to explain the SOLAS amendments and the WINZ programme. This was followed by signifcant interest at the Athens Posidonia exhibition. At the upcoming SMM in Hamburg, and subsequently at the IMPA in London, attendees can explore WINZ in depth through interactive sessions. These global seminars and exhibitions ofer a glimpse into the future of mooring line management, as DSR continues to address current and future challenges in the industry.

Join DSR at SMM 2024, hall A1, stand 301 to discover how WINZ can enhance safety and efciency in your operations. Experience the future of mooring line management frsthand and engage with experts to address your unique mooring concerns.

i. dsr.com

The sister vessels Maxima and Alexia signal a taste of the future.

Royal Wagenborg’s new EasyMax vessels, Maxima and Alexia – both fying the Dutch fag – were christened by Her Majesty Queen Máxima in a much anticipated ceremony in June. The ceremony took place during Delfsail in the presence of 2,000 employees and guests.

After a welcome address and speech by CEO Egbert Vuursteen, Queen Máxima performed the world’s frst droneassisted name giving and christening

ceremony. By pushing a button, the drone few to shipyard Niestern Sander, a mile ahead, where the EasyMax vessel nearing completion was christened as yard number 853, Alexia. Queen Máxima then proceeded with the christening of her namesake vessel, Máxima.

The EasyMax is the latest icestrengthened vessel built by Wagenborg with unparalleled fuel efciency. It currently boasts the lowest CO2 footprint

per tonne of cargo carried, leading the global Energy Efciency Design Index. The ship features the traditional Wagenborg red and grey colours yet fies the fag for a green future.

The open-top multi-purpose ice-classed vessel has a load capacity of 14,200 tonnes and a hold volume of 625,000 cubic feet. The combination of that large load capacity and very low fuel consumption makes it a leader in its segment in terms of sustainability. The

Multipurpose Open Top, Box shaped/ Single-decker, incl. movable bulkheads.

Ice Class 1A. Lakes/Grain/CO2 ftted.

Vessel is equipped with a ballast water treatment unit (600m3/h)

Call sign

P.D.V.Q.

IMO number 9882061

Built 2021

Shipyard Niestern Sander

Classifcation Bureau Veritas

Class notations I + HULL +MACH

General cargo shipheavycargo (tanktop 150kN/m2, Tanktop (non-uniformal)

200kN/m2) – occasional dry bulk cargo AUTUMS, +SYS-NEQ-1, MON-SHAFT, ICE CLASS 1A, INWATERWAYSURVEY

Ice class Finnish /Swedish 1A

Port of registry Delfzijl Flag Dutch

Main particulars

unique design was developed by Royal Wagenborg and Royal Niestern Sander in cooperation with a few carefully selected partners.

“Our focus with this design was to meet clients’ need for signifcantly more efcient and reliable transportation,” said Wagenborg in a statement. “The EasyMax is also relatively simple to build and operate.”

The EasyMax vessels are the biggest ships ever built in the north of the Netherlands on the landward side of the dikes.

The EasyMax vessels are the biggest ships ever built in the north of the Netherlands on the landward side of the dikes. With a length of 149.95m, a beam of 15.9m and a draught of 8.6m, the model is the largest possible vessel that

can be built at the Royal Niestern Sander shipyard. With two large rectangular holds, the EasyMax excels in its class with a high capacity for heavy or light cargo, timber and paper, and open-top loading. This allows for maximum deployment in Wagenborg’s operating

Her Majesty Queen Máxima spoke with the contractors who built both EasyMax vessels, as well as various domestic and foreign guests closely involved with Wagenborg, and descendants of shareholders.

area and makes it suitable for worldwide commercial operations, including the Baltic, the North Sea, the Mediterranean, the St Lawrence Seaway, the Panama Canal and the Suez Canal.

In honour of the memorable christening, the vessel Máxima was moored at the Royal Niestern Sander shipyard in Wagenborg’s home port of Delfzijl. Following the ceremony, 42 dancers, each carrying a fag representing diferent countries, performed a spectacular dance. Her Majesty Queen Máxima spoke with the contractors who built both EasyMax vessels, as well as various domestic and foreign guests closely involved with Wagenborg, and descendants of shareholders, discussing their visions for a sustainable future. During a boat tour through the port, Queen Máxima also met various captains of the tall ships.

The programme refected on 126 years of Wagenborg, before looking to the future of the family company. The EasyMax ships play a prominent role in the shipyard’s next chapter, which made it even more signifcant that Queen Máxima was its guest of honour during Delfsail.

“In 1995, we had the christening of Kroonborg by the Crown Prince Willem Alexander. In 2009, Queen Beatrix christened our Beatrix vessel, and now Her Majesty the Queen Máxima was our guest of honour during Delfsail,” said Egbert Vuursteen, CEO of Royal Wagenborg. “I am delighted that she wanted to christen no fewer than two vessels!”

i. wagenborg.com

The increased focus on use and transport of fammable gasses in the guise of ‘new fuels’ has increased demand for deck equipment that is explosion proof. Navigation lights with LED technology that have ATEX and IEC Ex Zone 1 certifcation — as is the case with lighting manufacturer Lopolight’s new Professional Ex Series — give the freedom to place navigation lights on vessels at the correct location without compromise. This allows for the continued use of navigation lights, even in the event of a gas leak.

“It has been a wild ride with customers essentially wanting delivery immediately as the lights came out of our production facility in Denmark,” says Lopolight CEO and owner Jan Moeller. “We knew there would be a

demand from ‘new fuel’ vessels, but we are also receiving strong demand from tug builders such as UZMAR, who are among the frst to fully integrate the Lopolight Ex lights in their newbuilds 158 and 159. We are humbled by the interest we are receiving for this product series and very grateful to our customers for their trust in us.”

Ex zones are categorised into three zones, where in zone 2 there is a risk of the presence of fammable gases. Equipment for zone 2 can be selfdeclared to be intrinsically safe by manufacturers. Zone 1 is defned as locations where there is a high probability for the presence of fammable gases. Here, the demands for equipment to have ofcial product certifcation and assembled under an

approved management systems are high. Zone 1 equipment can also be used in zone 2. The last zone, zone 0, is inside the tank.

The number of vessels with an ATEX/ IEC Ex zone is rapidly increasing. This includes the growing feet of LNG tankers and the associated infrastructure, such as tugs, pilot boats, and service vessels. There are also hundreds of vessels currently in build that will use LNG, methanol, ammonia, and others – all with ATEX/IEC Ex zones. There’s also the additional need of oil rig signal and warning lights, which also require a no-compromise, robust and all-encompassing light solution.

The expanding reach

One way to reduce onboard risk is to increase clear lines of sight and safety lighting. One example is the introduction of zone 1 Ex certifed navigation lights. The location of onboard navigation lights leaves little room for fexibility. It is important that the vessel is displaying the correct lights, at the correct positions, as described by the COLREGS to enhance safety at sea by lowering the risk for misunderstandings. Lopolight, which designs and manufactures LED navigation lights, control and monitoring systems and other functional lighting for use on vessels, is now ofering a full range of Zone 1 ATEX and IEC certifed LED navigation lights.

The frst designs Lopolight brought to market 20 years ago — where the electronics of the lights was fully encapsulated in epoxy and power consumption was a tenth of the comparable incandescent lights —

had scope to be safely used in areas where fammable gases could be present, says CTO and owner Peter Hancke. Once the company received its ISO 9001 quality management certifcation, which is a pre-requisite for any ATEX certifcation, it went to work

on getting the Lopolight Professional Series certifed for ATEX and IEC Ex.

“It was obvious to us that a zone 2 classifcation with a high temperature class was easy for us to achieve; this is where you fnd our competitors, but we

The number of vessels with an ATEX/IEC Ex zone is rapidly increasing. This includes the growing feet of LNG tankers and the associated infrastructure, such as tugs, pilot boats, and service vessels.

wanted more,” says Hancke. “We knew from our other navigation lights series that having third-party certifcation of the products and the quality management systems is promoting trust and very benefcial to continuous improved product quality, so we went for zone 1 and importantly a low temperature class – T5. This means the Lopolight Ex navigation light can be placed freely on any vessel with any cargo or fuel, except for inside the tank.”

i. lopolight.com

ZONE 1 – CATEGORY 2

Zone 1 is an area that is classifed ‘as a place in which an explosive atmosphere consisting of a mixture with air or fammable substances in the form of gas, vapours and mists is likely to occur occasionally during normal operation’.

TECHNICAL DETAILS | Design dimensions and quality as the Lopolight Professional series navigation lights: Hard coat anodised aluminium housings, PMMA optics, fully encapsulated, all upgraded to ATEX/IEC Ex APPROVED TO: COLREG’72, MED (Wheelmark), UL1104, DNV, ABS ATEX/IEC Ex equipment group II, Category 2, Zone 1. STANDARDS: ISO/IEC 80079-34:2020, IEC 60079-18:2015, IEC 60079-7:2015 Ex eb mb IIB T5 Gb Ex = Explosion protected.

ZONE 2 – CATEGORY 3

Zone 2 is a hazardous area classifed as an atmosphere where a mixture of air and fammable substances in the form of gas, vapour or mist is not likely to occur in normal operation, but if it does occur, will persist for a short period only.

THE LOPOLIGHT ATEX/EX NAVIGATION LIGHTS CAN BE USED IN THESE ZONES!

Dutch Dredging BV, based in Sliedrecht in the Netherlands, announced in June that it has awarded Royal IHC , a leading supplier of maritime technology, a contract for the design and construction of a custombuilt trailing suction hopper dredger with a hopper capacity of 2,300m3. The new trailing suction hopper dredger, which meets the latest IMO Tier III Euro Stage V environmental regulations, will be an upgrade of the LESSE, a hopper dredger that was delivered by Royal IHC to Dutch Dredging in 2019.

This marks the ffth custom-built vessel that Royal IHC has built for Dutch Dredging, underlying the constructive collaboration between Dutch Dredging and Royal IHC. The LESSE, the most recently delivered dredger, proved to be a versatile trailing suction hopper dredger and a perfect ft for Dutch Dredging’s international projects. The success of the LESSE, as well as the growing need for feet expansion and ever more stringent emission requirements in project tenders, has led Dutch Dredging to rely on Royal IHC as

a solid partner for the construction of a trailing suction hopper dredger upgrade.

Reliable collaboration

“The LESSE is an ideal vessel for maintenance dredging,” says Kees van

de Graaf jr., director of Dutch Dredging. “Thanks to its shallow draught in combination with state-of-the-art dredging technology, our professional crew can dredge optimally. This allows us to work reliably and be highly

To minimise environmental impact during dredging, the vessel is equipped with the latest innovation in the feld of overfow – the IHC Plumigator. With a dredging depth of 30m below the waterline and a hopper capacity of 2,300m³, the LESSE is extremely effcient and can be deployed worldwide.

Thanks to its shallow draught in combination with state-ofthe-art dredging technology, our professional crew can dredge optimally. This allows us to work reliably and be highly competitive.

competitive. The collaboration with Royal IHC is running smoothly and with our combined experience we are building a fne new addition to our feet,” he adds.

“It is a textbook example of the best of both worlds coming together,” says Derk te Bokkel, CEO of Royal IHC. “Dutch Dredging’s operational experience with the LESSE and Royal IHC’s technical expertise formed the basis for design improvements, resulting in a successful upgrade.”

Anchored in rich Dutch maritime history, Royal IHC continues to build on its position as a leading provider of maritime technology and craftsmanship. With the right expertise on board and driven by innovation, Royal IHC ofers a clear

competitive advantage to its global clients in the dredging, ofshore, mining and defence industries.

Through its equipment, ships and services, Royal IHC delivers reliable, integrated solutions to increase

customers’ operational efciency and enable more sustainable solutions. In an ever-changing world, its goal is to fnd the smartest and safest way forward for all.

i. royalihc.com

In the 50 years that Hydrex has been in operation, the company has grown from a small diving frm operating from a home ofce to a large underwater maintenance and repair company with a 5,000m² facility in the Port of Antwerp.

“I wanted to do something that was tangible, that I could touch with my hands, and that I could look at with my eyes,” says Hydrex founder and CEO, Boud Van Rompay, who dropped out of law school before founding the company. “Not some theory from a book. It had nothing to do with formal education. I had to fnd out for myself.”

Five decades on, Van Rompay remains very involved in the daily workings at Hydrex. “I was terribly attracted to anything to do with mountains, glaciers and underwater caves. It wasn’t the adventure, but the exploration that fascinated me. The experience of discovering things. That’s what made me

create the company,” he says. “I saw so much careless handling of water and so much pollution in it, that I said: ‘This is what I need to be involved in – I need to start exploring it further.’”

The frst goal for the company was clean rivers, seas and oceans. “That’s a static goal towards which you can work,” explains Van Rompay. “The sub-goal or purpose was action oriented: To build expertise with water, which gave us the name Hydrex.”

For Van Rompay, the purpose was clearcut. “Expertise is knowing what you are talking about. The frst thing to do is to look. I read a lot, but I assessed it against my own observations. This exercise of increasing knowledge leads to an increased responsibility. When you know what you are doing, you can control your actions. This is what an expert does. That is what we have been doing for 50 years, from day one.”

It wasn’t long after establishing the business from a home ofce that Hydrex moved to the city. “We rented a small ofce and one of the warehouses of a ship repair company in Antwerp,” recalls Van Rompay. “From day one we had a dedicated training centre.”

In 1980, the company moved to its current headquarters in Antwerp. The warehouse included a dive tank to practice underwater welding and other repair work. “I felt we needed to have direct access to the water. The Asiadok was ideal because it looked like a swimming pool, and still has very little trafc today,” says Van Rompay. “This allowed us to do all kinds of experiments. Being located there was part of the urge to discover. You don’t need much water to discover things, you just need to get wet, and that’s what we did.”

From that point onwards, Hydrex continued its expansion, active in Rotterdam and throughout the Netherlands from the beginning. The rest of Europe soon followed, and by the ‘80s, the company went global.

“The demand for our services was there,” says Van Rompay. “Back then, when you had a ship in port with a problem – with a condition or defect – it had to go to drydock. We challenged that industry norm and began repairing ships in-situ during loading and unloading. It was a simple solution. I had an underwater welding certifcate from the start, which meant we could ofer weld repairs from the early days. If there was work to do, we did it. Together with my team, I looked at any problem thoroughly until we cracked it.”

The next phase of development required new techniques, which in turn led to industry frsts, such as the development of the coferdam for fxing damage to shell plating in dry conditions. “We didn’t know we were the frst back then,” he says. “We used our frst coferdam in 1979 on the general cargo ship Lunar Venture. This was the frst major repair with no condition of class and no need to drydock the ship for follow-up repairs. Since then, we have built many coferdams.”

By the early ‘90s, Hydrex had up to fve coferdam interventions per week, enabling the company to consistently keep ships out of drydock. Following coferdams, Hydrex went on to adapt diving bells into its ‘habitats’ — or dry environment — the second of its key factors in repairing ships underwater. “They work very simply. When dry welding or other dry work is required, you create a dry environment, whether that’s a stern tube seal, a bow thruster, or a shell plate repair,” explains Van Rompay.

Next came propeller blade repairs. “We encountered bent propeller blades –propellers that were vibrating and had to go to drydock. We cut the blades to solve this.” Later, in 2002, the company developed a cold straightening machine. “It was simple for us because we had direct access to the water,” says Van

Boud Van Rompay is the founder and CEO of Hydrex and sister company Subsea Industries.

Hydrex has been a world leader in underwater repair and maintenance technology since 1974. Subsea Industries was founded in 1983 with a simple and clear goal: clean rivers, seas and oceans.

Subsea Industries began with designing and producing a line of high quality, efective underwater hull and propeller cleaning equipment designed to cover every underwater cleaning need. But it soon became obvious that cleaning the hulls of ships coated with toxic paint was simply adding to the already existing pollution of the sediment and that what was needed was a hull coating system that was completely non-toxic.

Boud has always been deeply involved in research, innovation and development. He has registered at least 65 patents in the areas of underwater repair, hull coatings, hull cleaning, contained dredging, tidal turbines and other environmental and water-related subjects.

In 2022, Boud founded Hydrex Research Center in order to coordinate and pursue further research. This research includes work with engineering students at TU Delft.

By the early ‘90s, Hydrex had up to fve coferdam interventions per week, enabling the company to consistently keep ships out of drydock.

Rompay. “We understood the hydrodynamics of what we were doing.”

This process led to a vast range of methods and methodologies, including repairs on a very large scale. “We were asked to repair a gash of 100 meters on a ship in Boston in winter and we did not see this as a problem. We just went for it,” he says. “When Hydrex started, proper repairs underwater did not exist. We created the whole gamut of services. Most of these evolved over a period of 30 years, after which, we were ready to tackle any kind of problem a ship could encounter.”

“From the beginning we were more than a diving company,” says Van Rompay.

“Our engineering department has always found new technologies to help the customer. For example, we developed a system to clean up polluted sediment for ports, rivers and estuaries. A variant of this technology can be used to remove dropped ammunition that was distributed in 700 depots worldwide.”

Problem solving on a large scale fuelled the growth of the company. By 2000, Hydrex had outgrown its warehouse. A state-of-the-art fast response centre was constructed, which increased its capacity to three dive tanks allowing the company to continue to provide its customers with the best possible service.

September 2015 saw the start of another large expansion and refurbishment of

the Antwerp headquarters, including new ofces and meeting rooms, a new workshop, and new training facilities bringing the total premises to over 5,000m². In early 2024, another large warehouse was added, and the feet of vans, trucks and workboats — still painted in Hydrex’s signature yellow for clear visibility at sea — have all been updated.

The goal remains the same

Over the years Hydrex has built up a network of support bases in over 50 countries, enabling it to provide fast ser vice at reasonable costs and to send out highly trained diving teams worldwide.

For the coming years, Van Rompay sees a lot of potential, including building and testing new ways to carry out ultra-fast

underwater cleaning without the use of divers. “Prototypes have been tested and are very promising,” he says. “This will allow us to clean any ship in less than an hour, even a 400m container ship 20m

deep in the water. I can safely say there are big things coming to the shipping and ofshore market: better protection, no more pollution, better fuel savings. Much has been achieved, but there is

more to come.”

“Our accumulated know-how, skill and experience is one of the main factors that sets us apart from anyone else in the feld,” concludes

Van Rompay. “It established our reputation, and we will never stop doing it.”

i. hydrex.be

Marinfoc helps shipping clean up its act

ALL PHOTOS COURTESY OF MARINFLOC.

In December 2022, during the MEPC 79 session, a crucial decision was made to amend the revised Guidelines and specifcations for Pollution Prevention Equipment for Machinery Space Bilges of Ships. This signifcant update might not have garnered widespread media attention, but it represents a vital improvement for the maritime sector.

As the maritime industry prepares for the impending revision of MEPC 107(49) in 2025, a regulation overdue for more than 15 years, many manufacturers of bilge water separators are facing the challenge of redesigning their concepts

to adapt to a new reality. This is particularly challenging for ships with dual fuels. However, Marinfoc, a leader in wastewater treatment solutions, stands in a league of its own with futureready products that have been setting industry standards since 1996. Since its inception, Marinfoc has put all its energy into creating the world’s best solutions for treating and controlling wastewater from vessels and ofshore platforms. It’s done this by ensuring every product is adaptable and capable of handling any changes in onboard conditions without the need for complete redesigns. This means Marinfoc separators can seamlessly

Marinfoc’s water treatment systems are designed for longevity, ensuring it serves vessels throughout their lifecycle and preventing harmful pollutants from entering the seas.

adjust to shifts in fuel types, lubricating oils, and chemicals, providing a signifcant advantage as the industry moves towards new regulations.

Innovation and solutions

This forward-thinking approach ensures that Marinfoc’s customers enjoy continuous compliance without the disruption of frequent equipment upgrades or replacements. They trust Marinfoc to deliver solutions that not only meet current regulations but are also ready for future challenges. For over a quarter of a century, Marinfoc has been at the forefront of wastewater treatment solutions for vessels and ofshore platforms. Its unwavering commitment has always been to craft the world’s fnest systems, ensuring pristine waters across the globe. This includes sustainable solutions for a clean maritime industry.

Marinfoc’s water treatment systems are designed for longevity, ensuring it serves vessels throughout their lifecycle and preventing harmful pollutants from entering the seas. Its focus on renovating equipment from scrapped vessels and preparing them for reuse emphasises a circular economy approach. At its new ofce buildings, it has installed solar panels which, combined with its location in Varekil, produce over 31,000kWh annually. Any surplus energy is exported to the grid. The company also supports renewable energy through biofuel-powered vehicles and electric car charging stations at our facilities. Marinfoc has also adopted stringent measures to ensure the responsible use of chemicals and efcient waste management, and it organises annual clean-up days, removing plastic debris from the shores of Orust, where its headquarters is located.

The Marinfoc Whitebox – a failsafe overboard discharge monitoring and control unit. Positioned between the oily water separator and the overboard valve, the Whitebox® is designed with precision to prevent non-compliant bilge water discharge, ensuring your operations remain within the regulatory bounds of MEPC 107(49).

Every innovation and solution provided by Marinfoc is driven by its vision of “a clean sea,” emphasising their commitment to a sustainable and thriving marine ecosystem for generations to come.

i. marinfoc.com

Van Oord celebrates the christening of two hybrid water injection dredgers

The sister vessels are the most sustainable water injection dredgers to date.

Dutch company Royal Van Oord celebrated the christening of two new ship builds in April 2024 following the successful completion of its all-new hybrid water injection dredgers, Rijn and Rhône. The sister vessels of the Maas and Mersey were commissioned in 2021. Rijn’s christening ceremony was performed by Bartje de

Boer-Veenstra, wife of Van Oord’s staf manager, Hidde de Boer, and Rhône was christened by Liedy Bijsterbosch-Meijer, wife of Herman Bijsterbosch, an inhouse captain at Van Oord for 50 years.

The christening ceremony also marked Pieter van Oord’s departure from the family-owned company, following a

Van Oord is the global market leader in water injection dredging, which uses an environmentally friendly natural process to remove sediment efciently by maintaining the depth of navigation channels, ports and rivers.

30-year career at Van Oord, including 15 years as CEO, as well as the inaugural ofcial act of the new CEO, Govert van Oord, the ffth-generation CEO.

The sister vessels are Van Oord’s most sustainable water injection dredgers built to date, classifed as Ultra Low

Emission Vessels (ULEV). The combination of hybrid energy management systems, heat recovery systems and exhaust gas aftertreatment devices reduce the vessels’ energy consumption and emissions of greenhouse gases, nitrogen oxides and particulate matter. In addition, innovative technologies, such as active

heave compensation and a dynamic positioning system, mean much of the dredging process can be automated.

Van Oord is the global market leader in water injection dredging, which uses an environmentally friendly natural process to remove sediment efciently by maintaining the depth of navigation >>

channels, ports and rivers. Thanks to the vessels’ manoeuvrability and limited draft, they are well suited to maintenance dredging in shallow harbours. Both new builds are equipped with a hybrid energy management system and will be able to store energy in batteries that can be used later for propulsion and other purposes. The new dredgers also comply with IMO TIER III legislation for reducing harmful NOx emissions and take account of EU STAGE V legislation.

Van Oord’s ffth USV Christened alongside the hybrid water injection dredgers was Van Oord’s ffth unmanned autonomous survey vessel (USV), the VO:X Barentsz, which is specialised for operations at sea. The christening ceremony was performed by Lucienne van Leeuwen-Koper, wife of Van Oord’s director survey, Michel Koper.

The vessel is jointly developed by Van Oord’s in-house survey department and DEMCON Unmanned Systems. Both companies have successfully operated

four USVs in recent years, and following these successful deployments, Van Oord contracted DEMCON unmanned systems for a larger USV that builds upon the same hardware and software USV platform system as used for the previous four models. The ffth model is also equipped with new technologies and more functionalities for ofshore operations.

In 2024, Van Oord’s 5,800 employees worked on 198 projects in 43 countries. The feet consists of around 60 vessels and various special-purpose and auxiliary equipment. Unmanned survey vessels enable Van Oord to obtain more measuring data for its clients at lower costs. In addition, deploying these vessels increases safety by eliminating an onboard operator and surveyor. With this advanced and specialised technology, Van Oord can help its customers to achieve refned results and raise the bar for sustainable and safe operations.

i. vanoord.com

Builder Kooiman Marine Group

Year of build 2024

Flag state The Netherlands

Class hybrid water injection dredgers

Length 44m

Beam 12m

Propulsion diesel electric

Manual intervention is still relied upon to drive machinery on the production foor, but intelligent 3D ship models can automate the process WORDS BY SCOTT RAESIDE,

The ability to free up highly skilled workers to focus on complex production tasks rather than tedious and menial ones is a major win for any shipyard. Why then, have so few shipyards been able to embrace this

innovation? Part of the reason lies within the detailing and control of the production information generated to control shop foor machines, which can be time consuming and error prone.

Automated robotic cutting, bending and welding of steel components in ship construction has been possible for years. Likewise, reducing the amount of time designers must spend interacting with mainly 2D production documentation or

The level of complexity in every phase of construction and the workfow of a shipyard will always vary, but the desire to incorporate automation where possible remains constant.

manipulating fle formats allows for both for better accuracy and more efciency in creating and revising the model and in automating the manufacturing process.

The level of complexity in every phase of construction and the workfow of a shipyard will always vary, but the desire to incorporate automation where possible remains constant. For decades there has been a dependence on manually created outputs, which in turn drive manual tasks for the production team. This can mean updating multiple drawings based on time-consuming workfows to get the output data back on to the shopfoor or manually measuring and marking up plates from a 2D drawing.

For example, opening thousands of spool and assembly drawings, annotating and validating them is slow and tedious. Such tasks represent a large time burn for designers and, as a result, a more expensive ship design process.

Often the answer proposed to some of these manual workfow issues is to incorporate third party software, in

addition to the core 3D package used for ship design, which in turn may create bigger changes to shipyard workfows to ensure compatibility. On projects where schedules are aggressive and budgets are tight, this degree of upheaval is a non-starter.

Removing the need to introduce thirdparty software or reducing the amount of user interactions needed to create an output by driving this information directly from the 3D digital model software is an exciting step in the right direction. It would be unrealistic to suggest that it is possible to create such outputs with no physical intervention at all, but at SSI, we believe a strategy of ‘80% no touch’ is achievable and in sight.

The philosophy behind this approach is simple: we enable the creation of the deliverables that are required to accurately build the ship. This includes traditional production documentation, as well as an increasing capacity to drive machines on the shop foor based on data from the Marine Information Model (MIM).

The complexities of shipbuilding, nonrepeating production tasks and the fact that humans are still better suited to complex cutting/welding/bending means we are still working towards complete and transparent automation. But we do have the knowledge and information required to reduce some of the pain points. By using a rich 3D product model, it is possible to create

more efcient production outputs and communicate directly with the machinery in place in most shipyards.

Automation will not eliminate the need for the user to interact physically with some of the outputs from the model, but the aim is to make it faster for them to access, modify or verify information accurately and efciently. The ability to drive production machinery directly

from information stored in the MIM creates the potential for tremendous efciency and accuracy improvements. This approach can reduce, or in some cases eliminate, the risk of human errors.

Taking a shipbuilding project from concept to completion is a long and complex process. Task-specifc software that supports people and tools is the path innovative shipbuilders are taking to simplify this complex process. Shipyards will always rely on the skills and expertise of people in construction but if we can make the process easier, then the result will be more efcient and higher quality builds.

Decades of experience in the industry lead us to recognise that change is a reality and that solutions must adapt to the changing needs of the yards. A strategy of enabling operators to drive machinery with as little manual intervention as possible seeks to create efciencies and keep shipyards up to date with the latest technology and approaches that are available to support their projects.

i. ssi-corporate.com

Arkitech International BV, a leading software development company specialising in maritime sustainability, has announced the appointment of Philip Woodcock as its new chief commercial ofcer. With over 30 years of experience in the maritime industry, Woodcock brings a wealth of knowledge and expertise to his new role. Prior to joining the company, he served as the founder and principal consultant for Wyndward Maritime, a consultancy frm catering to stakeholders in the maritime sector.

Emilie Barriau

Hempel A/S has appointed Emilie Barriau as chief technology ofcer, a new position in the Executive Group Management, bringing a dedicated focus on innovation. The new Technology Executive Vice President area comprises R&D, Procurement and Sustainability to serve as mutually reinforcing powerhouses of innovation. This appointment ensures that innovation is more prominently featured at the highest level of the organisation. Barriau is an internationally experienced senior innovation executive who spent 15 years with Henkel Adhesives Technologies, serving transport, metals and electronics industries in various global roles.

OrbitMI, a leading provider of maritime intelligence and analytics solutions, has announced the appointment of Youn Lee as its new chief fnancial ofcer. Lee, who ofcially joined OrbitMI in 2023, brings a wealth of experience in fnance and operations, with a distinguished career that includes leadership roles in digital transformation across various industries.

“OrbitMI’s innovative approach and commitment to sustainability and efciency were major attractions for me,” said Lee. “My goal is to optimise fnancial performance and drive strategic growth, ensuring long-term sustainability for the company.”

Sebastian Sachs has been appointed as managing director of SCHOTTEL Nederland, taking over from his predecessor René Lange. Sachs joined SCHOTTEL GmbH in 2016 as Controller and has held various management positions, most recently as director fnance and administration. His previous activities have equipped him with a particularly comprehensive knowledge of SCHOTTEL’s worldwide subsidiaries, which he will bring to his new position.

Bernhard Schulte Shipmanagement (BSM) has announced the appointment of Bjoern Sprotte as chief people and sustainability ofcer to the Management Board. Based in Limassol, Cyprus, and reporting to Ian Beveridge, CEO of BSM, Sprotte will oversee all HR activities for shore and marine operations at BSM, as well as the environmental, social and governance (ESG) strategy across the wider Schulte Group. Sprotte joins BSM from V.Group, where he served as the CEO of the ship management business. Prior to V.Group, he spent four years in senior roles at OSM Maritime.

Methanol Institute (MI) has appointed Alexander Döll as its new chief operating ofcer. Döll will take on his global position from MI’s Brussels ofce, with his onboarding commencing in Washington DC. He has extensive experience in the chemical industry and energy transition, having previously held leadership positions at OCI Global, Dow and Hill & Knowlton. Originally from the Netherlands, his broad-based experience in public and government afairs, commercial and sustainability issues spans Europe, Africa, the Middle East, Northeast Asia and the United States.

Teus Visser has been succeeded as director of Reikon by Peter Zorge, a well-known fgure in the national and international maritime sector. Zorge worked for more than 30 years at Royal Econosto, which later became Eriks, the last 23 years as director of the Maritime Business Unit. He has worked with the Reikon team since June to ensure a seamless transfer. The organisation has experienced signifcant growth in recent years and expects to continue this trend. Visser will remain active until the end of the year to complete and transfer his duties, before commencing a new role as CEO of Reikon Beheer.

Sebastian Sachs will be supported by sales specialist Ewoud Hooymans, who will assume a larger area of responsibility in the operational business in his new role as sales director.

Following many years as sales manager at SCHOTTEL Nederland, Ewoud Hooymans is now responsible for the entire new sales and after service sales in the BeNeLux region as well as for new sales in the UK.

ADS van STIGT

Avelingen-West 30

4202 MS Gorinchem

The Netherlands

T +31 (0)183 650 000

E info@vanstigt.com

I www.vanstigt.com

Contact: Sander Snoek

ADS van STIGT was founded in 1970 with the main activity in transmissions and gearboxes for maritime and industrial applications. This is still an importent activity of ADS van STIGT, but a signifcant number of other products have been added to the range, such as planetary gearboxes, pump drives, control systems, monitoring systems, controllable pitch propellers, thruster systems, carbon fbre shafts, dampers, elastic couplings and sensors. ADS van STIGT’s expertise ranges from pleasure to mega yachts, and from fshery to commercial shipping, offshore, and dredging. A well-equipped service team is supporting the sales activities worldwide.

ADS van STIGT is competence centre for: Masson, Bonfglioli, O&K, Plöger, Horn, Schaller, Katsa, Geislinger, Durst and ZF.

ANCOFERWALDRAM STEELPLATES BV

P.O. Box 190

4900 AD Oosterhout

The Netherlands

T +31 (0)162 491500

F +31 (0)162 429806

E sales@aws.dillinger.biz

I www.ancoferwaldram.com

Over 100,000 tons of quality heavy steel plates in stock

AncoferWaldram Steelplates B.V. (AWS) is a stockholding wholesaler and steel service center, specializing in the supply of hot-rolled heavy carbon steel (quarto) plates, and profled parts for more than 40 years now. Over the years, AWS has developed into a business that sets the standard for its industry.

Plates from stock or profled parts

The choice is yours! It is the combination of comprehensive stocks of over 100,000 tons of heavy carbon steel plates plus the sophisticated

profling plant that gives AWS a decisive lead in experience, product range and customer service.

ART4 TECHNICAL SYSTEMS BV

Nieuwegracht 9-11

3763 LP Soest

The Netherlands

T +31 (0)35 582 2468

F +31 (0)35 642 4860

E Info@art4.nl

I www.art4.nl

Contact: Mr Paul Schraven

Art4 Technical Systems BV is an independent Dutch company. We design, build and deliver fully turnkey solutions for hydraulic and electrical systems for customers worldwide. Our clients use the hydraulic and electrical systems for various end products such as:Mobile drives, transport conveyers, winch drivers, jack up platforms, cranes, both onshore and off shore, a-frames, special equipment, fairground attractions.The systems can be custom built to ft the specifcations of the product they are used for.

BACHMANN ELECTRONIC GMBH

Offce Veenendaal:

Vendelier 65-69

3905 PD Veenendaal

The Netherlands

T +31 (0)85 210 0550

E r.epskamp@bachmann.info

I www.bachmann.info

Contact: R. Epskamp

Bachmann hardware matches the harsh conditions in the maritime and offshore industry. We take pride of extremely high availability using stateof-the-art technologies. Integration of AMS, PMS, CMS, etc. in a Redundant solution is realized with our modular and marine certifed PLCbased product range.

The group of companies includes the CMS specialist Bachmann Monitoring and Certec EDV, the developers of the 1st fully web enabled SCADA software atvise®

BREMAN MACHINERY B.V.

Sasdijk 20

8281 BM Genemuiden

The Netherlands

P.O. Box 135

8280 AC Genemuiden

The Netherlands

T +31 (0)88-27 36 200

E info@breman-machinery.nl

I www.breman-machinery.nl

Great challenges need sophisticated solutions, the work of a specialist.

Breman Machinery fabricates critical steel components with exceptional dimensions and extreme accuracy. This is the daily job of our craftsmen. Through our unique capabilities regarding machining, welding, conservation and assembling we ser ve our customers to make their ambitions reality.

The welders of high-quality steel are qualifed by Lloyd’s Register or DNV for all welding positions. With 30 milling, boring and turning machines we have the possibility to offer unique services. Our preservation department can protect your projects. Our location is beside open water, we have a direct connection to the international ports. High quality is one of our most important standards!

EMIGREEN B.V.

Noordeinde 19

3341 LW Hendrik-Ido-Ambacht

The Netherlands

T +31 (0)184 415 317

F +31 (0)184 415 582

E info@emigreen.eu

I www.emigreen.eu

Contact: Niko J. Dalpis

Emission Control Technology

Emigreen produces customised, integrated emission control solutions, for, among others, the maritime sector. Emigreen also provides services including design, specifcation, production, installation instruction, training and aftersales. Emigreen has expertise in emission control technologies, fow dynamics, thermodynamics and noise and vibration control. Emigreen develops

and tests components including catalytic converters, particulate flters, selective catalytic reduction systems and related instrumentation.

The Emigreen Alfa Alfa burner assisted soot flter system has set the standard for others to beat. All Emigreen solutions are highly effcient, highly reliable and highly controllable, whether designed for an inland barge, shortsea carrier or luxury yacht.

Emigreen links science and the market.

HEINEN & HOPMAN

Produktieweg 12

3751 LN Spakenburg

The Netherlands

T +31 (0)33 299 25 00

F +31 (0)33 299 25 99

E pr@heinenhopman.com

I www.heinenhopman.com

Contact: J.W.E. Hopman

Heinen & Hopman Engineering is a world leader in air conditioning, mechanical ventilation,central heating, refrigeration, sanitary systems, fre protection, environmental systems and air duct cleaning. Founded in 1965, the company is renowned for being an innovator in the design, engineering and installation of customised solutions.

We work in four specialist areas:

– Superyachts.

– Commercial shipping.

– Offshore industry.

– Navy vessels.

Our mission is to ensure that the climate ‘indoors’ will perfectly meet the needs of people and products alike, whatever the weather outside. Heinen & Hopman offers a worldwide, 24/7 service via a network of subsidiaries and sales centres.

P.O. Box 13

7990 AA Dwingeloo

The Netherlands

T +31 (0)521 591 550

E info@klay.nl

I www.klay.nl

Klay Instruments is a Dutch manufacturer of ‘All Stainless Steel’ Pressure- and Level transmitters for the Marine & shipbuilding. All our transmitters are ATEX and IECEx Ex ia certifed and have fve different

Marine Type Approvals.

Our Pressure transmitters are available in threaded and Flanged process connections with fush diaphragm for all pressure applications. The available accuracies are 0.2% (series 8000) or 0.1% (series 2000). For Level measurement we manufacture Compact transmitters (series 8000 and 2000) and submersible level transmitters (series Hydrobar).

Typical applications:

– Ballast Level

– Oil / HFO and (waste) water level

– Manifold pressure

More than 30 years experience in the Marine and shipbuilding industry!

MEN TECHNIEK BV

Caïrostraat 55

3047 BB Rotterdam, The Netherlands

T +31 (0)10 820 8717

E info@mentechniek.nl

I www.mentechniek.nl

Contact: Lucien Tuinfort

Safety, quality and innovative entrepreneurship. Men Techniek BV is a company with a very broad feld of activities. We are specialised in general repair on and offsite and have a lot of experience in welding, fre work and mechanical and electrical work. We can also offer a full NDT examination.

Algerastraat 20

3125 BS Schiedam, The Netherlands

T +31 (0)10 238 0999

F +31 (0)10 238 0988

E info@nicoverken.nl

I www.nicoverken.nl

Contact: Jacco Vermunt

Distributor, 24/7 service & spare parts agent of marine equipment.

In our programme there are stainless steel marine pipes and drains, fltration, anti-fouling & cathodic protection, reverse osmosis desalinators (water makers), wastewater treatment, vacuum sanitary systems for yachts, deck equipment (doors & hatches) and watertight sliding door systems.

Our Ship Repair department is specialised in the overhaul of all types of main and auxiliary engines, including attachments i.e. governors, turbochargers, fuel equipment and the sales of spare parts and engines. We

are capable of crankshaft grinding. Our service is 24/7 worldwide!

Am Altendeich 83

D-25348 Glueckstadt, Germany

T +49 4124 9168-0

F +49 4124 3716

E pein@piening-propeller.de

I piening-propeller.de

Contact: Mathias Pein

Noise reduction relies upon the quiet operation of a yacht´s propulsion system. Piening Propeller fulfls its briefs in:

Consideration of all hydrodynamic aspects during the design and an accurate manufacturing of propellers and shafts according to highest ISO classes.The company is approved by all common classifcation societies. Repairs and adjustments of propellers are done with the same care as new buildings. Piening Propellers scope of supply includes:

Propellers FPP > 800mm Ø CPP > 1.100mm Ø

Shafts up to a several length of 16,000mm

Sterntubes with sealings and bearings

Shaft brackets complete Gearboxes Brand ZF

De Ruyterstraat 62

4335 GN Middelburg

The Netherlands

T +31 (0)6 190 358 20

E info@rbimarineconsultancy.com

I www.rbimarineconsultancy.com

Contact: Ruud Bimmel

RBi Marine Consultancy provides full-service 24/7 worldwide. This is the core of our business. We advise, manage and carry out projects with expertise and experience; a result of years in supporting the Marine industry both locally and internationally

Our business conduct inspection, surveying, new-build, repairs, refurbishment, regular maintenance, feet management, site management, owner representative, and of course project management.

Our network contains more than just that. Together with established partners we provide delivery of genuine marine parts, blasting and painting, welders,

ftters and sorts of craftsmen. For more details please call us or view our website.

SSC STEEL SHAPE CUTTERS BV

‘s-Gravendeelsedijk 200

3316 AZ Dordrecht

The Netherlands

T +31 (0)85 760 3226

E staat@ssc.nl

I www.steelshapecutters.nl

Contact: Peter Staat

SSC Steel Shape Cutters BV is a new, competent provider of 3D-profling: computer-controlled machine cutting of tubes, beams, hollow sections and plate. Subcontracting does not have to cost a lot, and it will bring substantial savings! With two state-of-the-art machines, we offer a huge range, superb accuracy, and great effciency. Round tubes up to Ø 2,500mm OD, with thicknesses of up to 150mm (oxyfuel and plasma), and robot cutting of beams and sections up to 1,200mm wide, plate up to 1,200mm wide and 3,000mm long. Fast, accurate, and cost effective.

SUHBO INDUSTRIAL CO., LTD.

6, Mipyeong-ro, 106 beon-gil, Wonsam-Myeon, Cheoin-gu, Yongin-si, Kyunggi-do, Korea

T +82 31 334 6979

F +82 31 334 1789

M +82 10 4999 6979 (Korea), +61 434 509 501 (Australia)

E joeykim@suhbo.co.kr

I www.suhbo.co.kr

Contact: Joey Kim, Export Sales Manager

Established in 1985, Suhbo Industrial Co., Ltd is the major leading Korean manufacturer and supplier of high performance roundsling for heavy & shipping building industries. We have been supplying high performance roundslings to major heavy industries companies and projects in Korea and Asia.

Our Suprime roundsling with Ultrapowerful Poly Arylate fber is highly recognized from many customers due to its excellent performance, the maximum lightening, the optimum handing effciency (slim in size) and optional functions such as anti-cutting, anti-fame and multi-checking.

WINEL B.V.

P.O. Box 70, 9400 AB Assen

The Netherlands

T +31 (0)592 366 060

F +31 (0)592 312 392

E sales@winel.nl

I www.winel.nl

Contact: Bert Knijp

Since its foundation in 1956, Winel has grown into a leading global supplier of high quality products and services tot the world’s maritime industry. An experienced team of specialists offer a wide range of doors, hatches, platforms, tank venting systems and special engineered products. Winel’s strength is offering a complete in-house service package which includes 3D design, engineering, testing, manufacturing, assembly, project management, support & logistic services.

G.J.WORTELBOER JR. B.V.

Quarantaineweg 5

3089 KP Rotterdam

P.O. Box 5003

3008 AA Rotterdam

Harbournr: 2637 – The Netherlands

T +31 (0)10 429 2222

F +31 (0)10 429 6459

E info@wortelboer.nl

I www.wortelboer.nl

Every now and then anchors and chains must be replaced, so we understand your need for quality and speedy delivery. Wortelboer has what you are looking for. Our enormous stock of anchors and chain cables of all sizes and diameters in both our Rotterdam and China ports gives you the certainty that we can deliver the required materials very quickly and to any port in the world! All our materials are approved by any of the well-known class societies such as LRS, BV, RINA, DNV/GL, ABS and RMRS.

Do you have problems with fnding the right anchors? Could you use a hand while ftting anchors and chain cables aboard your vessel? We are more than happy to help you with it. Wortelboer has been a reliable partner in the shipping industry for more than 50 years. And that is why our customers keep coming back for more.

Do you need anchors and chain cables? Come to WORTELBOER.

We have already started preparing our upcoming issues of ShipBuilding Industry. Below, you will fnd some of the main topics we are planning to cover. Please feel free to provide our editorial staf with any relevant information, so they can take your input into consideration for publication. Our commercial department will be happy to assist you with your marketing needs.

COLOPHON

COMMERCIAL DEPARTMENT

MARCO GEELS | Director marco@ynfpublishers.com

EDITORS

ARNO DIRKZWAGER arno@ynfpublishers.com

JULIA ZALTZMAN info@ynfpublishers.com

DESIGN

NATHALIE PUTMAN | Art Director nathaliep@ynfpublishers.com

ADIPEC 2024

Paint & coating systems

Focus on the Netherlands

Dredging vessels & equipment

Copy deadline | 11 September 2024

Advertisement deadline | 7 October 2024

Release date | 5 November 2024

Reft & conversions

Marine propulsion & power generation

Cruise vessels / river cruise vessels

Copy deadline | January 2025

Advertisement deadline | February 2025

Release date | March 2025