Other publications by Yellow & Finch Publishers:

e’re kicking of 2024 with two innovative ship reports this issue, both of which show courage and adaptability — two qualities that are indispensable in the shipbuilding industry. Den Breejen’s river cruise ship, Thurgau Gold, is a speculative gamble that more than paid of for the Dutch shipyard (page 26) while the world’s frst hybrid industrial cargo ship, Canopée, blows winds of change into the new year on page 12. The open-top Ro-Ro vessel has four 363m2 sails that bring a lighter environmental footprint to the ofshore industry.

It’s a similar story on page 36, where we learn more about Finnish marine engineering company Deltamarin’s appointment to design three low-emission Ro-Ro vessels supported by windassisted propulsion for Airbus. It forms part of the company’s aircraft subassembly transportation feet, which is projected to lower average annual transatlantic CO2 emissions from 68,000 to 33,000 tonnes by 2030.

The power of wind brings new vessels and large revenue for geodata specialist, Fugro, too on page 30. The Dutch company’s acquisition of two platform supply vessels, Sea Goldcrest and Sea Gull, is expected to strengthen its position as a market leader, as well as its ability to address the market shortage in geotechnical capable vessels.

Within the cruise industry, Meyer Turku is turning heads. Within the space of just two months, the company commenced the hull assembly of its third LNG-fuelled ship, Star of the Seas, and saw the world’s largest and most advanced cruise ship to date, Icon of the Seas, debut in Miami (page 32).

Premier mooring rope manufacturer, DSR, provides a solution for precise compliance on page 20, while electrotechnical specialist, MSA-Service, explains why supporting vessels with systems that deliver real-time onboard data processing is a non-negotiable for crew (page 23). And on page 39, underwater maintenance company, Hydrex, shows how to keep vessels out of drydock wherever they are in the world using a raft of skilled in-water repairs.

Afterall, continued improvement in the shipbuilding business is what it’s all about. Michiel de Vliegher, Director of Damen Shiprepair Vlissingen, shows us how to successfully navigate maritime in the digital age on page 16, while on page 42, Subsea Industries refects on a year of changing the yachting game with its range of long-lasting coating systems for all vessels.

You’re sure to fnd anything we haven’t covered this issue at the 18th instalment of Asia Pacifc Maritime (APM), the largest event for the global maritime value chain, which returns for 2024 with a plan for the next decade.

All that’s left is to wish you a very happy New Year!

Julia Zaltzman – Editor INFO@YNFPUBLISHERS.COM

Engineering supply company MacGregor, part of Cargotec, has received a signifcant order from SM Solutions/Philly Shipyard for cargo handling solutions for three 1,822FEU sized container carriers. The order is booked into Cargotec’s Q4 2023 order intake, with deliveries planned to commence during the fourth quarter of 2024 and completed within 2026. ”We are excited about this order, which is a nice continuity for the Aloha Class series and for the good collaboration with SM Solutions and Philly Shipyard,” said Magnus Sjöberg, Senior Vice President, Merchant Solutions Division, MacGregor. “Philly Shipyard is a forwardthinking shipbuilding facility, and we are committed to providing cutting-edge solutions and look forward to contributing our expertise to ensure their success.”

i. macgregor.com

Kooiman Marine receives order for new pusher tug

Kooiman Marine Group has received an order from electricity supplier Verbund Hydro Power GmbH for a new pusher tug that will facilitate the transport of split hopper barges, as well as function as an icebreaker on the River Danube in Austria where Verbund operates 10 hydropower plants. The pair of split hopper barges are required for the maintenance of the gravel bed around the dams and need to provide a lot of thrust in very shallow water.

i. kooimanmarinegroup.nl

Boluda Towage, a division of ofshore towage and maritime salvage company Boluda Corporación Marítima, has acquired the towage company Resolve Salvage and Fire (Gibraltar) Ltd. Resolve Salvage and Fire, owned by Resolve Marine Group, has decades of experience in towing and marine salvage services for all types of vessels, as well as in engineering and maintenance projects for marine installations and constructions. The acquisition marks Boluda Towage’s continued expansion into the international market, and the tugs Elliot, Hercules, Rooke and Wellington to its extensive global feet. The move also strengthens its presence in strategic points for maritime transport, such as the Strait of Gibraltar.

i. boluda.eu

Leak-free methanol pumps enable safe alternative fuel solutions

DESMI’s new mag-drive centrifugal pumps pave the way for methanol fuel system by combining the high efciency and robust reliability of centrifugal pumps with a new magnetic coupling feature that eliminates the traditional shaft seal solution in the pump. As the pump chamber is thus completely sealed, there is virtually zero risk of methanol leakage. “We introduced magnetic coupling technology in the 1990s, so we’re building on three decades of solid experience here,” said Martin Bro, global sales manager gas systems. Methanol provides several key benefts as a shipping fuel, however, it is also toxic and highly fammable which prompts safety considerations when selecting and installing a fuel infrastructure for ports and ships. The DESMI mag-drive centrifugal pump is suitable for methanol fuel systems on new-built dual-fuel ships and can also be retroftted on existing vessels.

i. desmi.com

Dutch company Amer Shipping has added Adriana Maria to its feet, a multi-purpose dry-cargo vessel that operates at low water levels thanks to a new CDS 110 hull design by Concordia Damen. Based on the Parsifal tankers previously developed by the yard, the 110m vessel can carry 200 tonnes more cargo compared to similar vessels. During ofcial sea trial in February, the vessel, which has been awarded the Green Award’s Gold Label, met requirements on speed and reduced fuel consumption (20km/hr using 230 litres/hr) and exceeded expectations on noise and vibration levels.

i.amershipping.nl

Ocean insights company, Miros, has expanded its product ofering with the launch of a new application designed to give users the necessary insights to navigate and manage ofshore operations. Dubbed Forecast, the company’s latest addition to Miros Cloud Home (miros.app), seamlessly integrates real-time measured ocean data with forecasted sea conditions, enabling marine operations teams, site managers, control room operators and diving or ROV technicians to navigate the unpredictable seas with confdence.

i. miros-group.com

Ulstein Verft AS, the Norwegian yard, has ordered 2 × 3 × MAN 12V175D-MEV methanol-ready engines in connection with the building of two CSOV (Commissioning Service Operation Vessels) for Bernhard Schulte Ofshore (BS Ofshore), the ofshore unit of international shipping corporation, Schulte Group. The vessels are designed to support the ofshore wind-energy market, and are planned for delivery in 2025, with an option for four additional vessels. The 175D variable-speed gensets enable the vessels to achieve a signifcant reduction in fuel consumption and emissions. Each comes with an integrated MAN closed-loop SCR (Selective Catalytic Reduction) system, a compact and fexible solution for the vessels. The MAN 175D gensets also feature reduced structural and airborne noise, as well as the lowest lube-oil consumption.

i. man-es.com

EST-Floattech delivers Octopus Series battery system to SFK Ferry Laboe

EST-Floattech, a leading provider of maritime energy storage solutions, has announced the successful delivery of a 560kWh Octopus Series battery system to the SFK Ferry Laboe. The ferry — the sixth in a series of seven ferries with which SFK hopes to lower its CO2 emissions — was delivered to Schlepp-und Fährgesellschaft Kiel (SFK) by Holland Shipyards Group in early 2024. The battery system ensures the energy consumption remains low during the sailing, as the vessel can easily switch between generators and the battery system. The vessel can even sail fully emission-free around the city of Kiel, where it transports commuting pedestrians and cyclists from A to B.

i. est-foattech.com

WinGD adds Mitsui E&S Tamano factory to Japanese engine building

Swiss marine power company, WinGD, has concluded an agreement with Mitsui E&S Diesel United (MESDU), part of the Mitsui Engineering & Shipbuilding group, that will see WinGD engines being built at its main Tamano works for the frst time. The agreement adds considerable engine building capacity and enables WinGD to meet growing demand in a leading shipbuilding market with a reputation for delivering sophisticated, high-quality vessels.

i. wingd.com

New repair yard Strela Shiprepair Yard celebrated its frst successful year of business in February. Founded in 2022, the northern German-based yard completed 40 ship repairs in its frst year of trading — 28 more than its predicted target of 12. It also more than doubled its number of employees from an initial 20 to the current 45.

“The strong demand for repair and maintenance services in our frst year was challenging, but we coped well,” said Jan Tebbe-Simmendinger, one of three managing directors at Strela Shiprepair.

i. strela-shiprepair.com

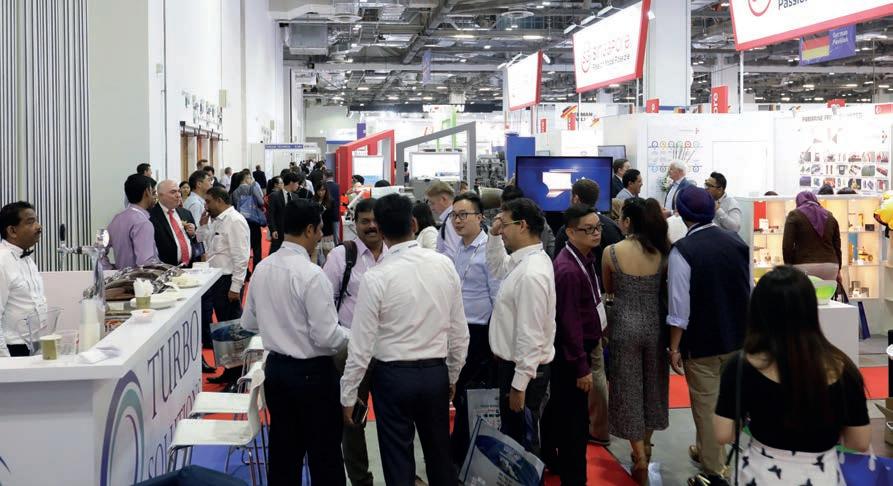

Southeast Asia’s largest maritime event focuses on sustainability, digitalisation and innovation.

The 18th instalment of Asia Pacifc Maritime (APM), the largest event for the global maritime value chain, returns for 2024 with a plan for the next decade. Taking place from 13-15th March and bringing together an estimated 14,000 shipowners, shipyards, management companies and technical procurers, this year’s conference, sponsored by DNV, will feature more than 80 speakers to deliver dialogues across six conference themes spread out across three days. These include sustainability, innovation and

digitalisation, manpower and training, maritime cyber security, port and terminals, and insurance. Held at Marina Bay Sands in Singapore, APM promises to showcase smart technologies that will shape the future of maritime.

“We have been reconnecting with global industry players to learn about their latest solutions, services and technologies that will drive the maritime sector over the next decade,” says Yeow Hui Leng, Group Project Director at RX, the show organiser. “Through APM, we

are excited to be connecting these global brands with the Asian audience and bringing their oferings here to further support collaboration and growth. We look forward to cultivating a space for conversations and discussions that will future-proof the maritime sector.”

One of the most pressing matters for the global maritime industry – which carries around 80% of the global merchandise trade today – is the need to decarbonise

Asia Pacifc Maritime (APM) 13 – 15 March 2024

Marina Bay Sands, Sands Expo and Convention Centre, Singapore

Halls A, B, C, D, E & F

Wednesday-Thursday 10am - 6pm

Friday 10am - 5pm

ocean-going vessels. With the theme “Future of Vessels, Solutions for Tomorrow”, APM is positioning itself as the platform for knowledge exchange and information sharing. Mounting pressure from the United Nations Conference on Trade and Development (UNCTAD) to be more sustainable is driving technological innovation.

The exhibition will focus on highlighting smarter solutions to achieve net-zero objectives, drive cybersecurity, improve satellite communication mobility and

embrace digitalisation. It will feature over 80 speakers and 1,400 brands –such as Wartsila, MTU, Marlink and Damen Shipyard – looking to bring innovative solutions to the fore. These include drones, batteries, electric marine engine and propulsion, sustainable paints and coatings and tech solution companies.

Examples of companies demonstrating smart innovation include Vinssen Co. Ltd., a leading provider of hydrogen fuel

Modular spreader beams up to 3,000t – Shackles up to 2,000t Grommets & roundslings – ROV hooks & shackles

Cherry pickers – Telehandlers – Waterpumps – Generators

Waterbags – Testweights – Pontoons – Fenders – Gangways

Snatchblocks – Lifting frames – Multi lugs – Hoists – Swivels

Masterlinks – Hydraulics – Container spreaders – Light towers

Safe Lifting Europe B.V. is aiming to become carbon neutral by having the largest rental feet of heavy lift equipment, which guarantees sustainability and the fastest route in your quest, with any type of demands. Many of our clients have already optimised their business and have chosen Safe Lifting Europe B.V. for their special heavy lift equipment needs. Interested in learning how renting or leasing your heavy lift equipment can lead to more sustainability? Inform about the possibilities for short- and long-term rental or lease of our heavy lift equipment via rental@safelifting.eu.

www.safelifting.eu • rental@safelifting.eu • +31 (0)10 434 63 33

cells, lithium-ion batteries and propulsion systems that has already delivered several maritime decarbonisation projects involving hydrogen fuel cell technology and full battery electric propulsion system.

“Our study of hydrogen as a maritime fuel was made possible thanks to the industry partnerships we have established in Singapore,” says Chil-Han Lee, Vinssen founder and CEO. “This is why platforms like APM 2024 are important as they allow opportunities for collaboration and mutual learning to drive the industry forward.”

Maritime drones are another area of interest. Increasingly used for inspection in environments that are tough to navigate, such as engine rooms and ports, they can help improve safety while keeping operational costs low. Swiss company Flyability has pioneered confned space inspection drones that enable professionals to improve safety, reduce downtime and cut costs for their internal inspections.

Maritime drones are another area of interest. Increasingly used for inspection in environments that are tough to navigate, such as engine rooms and ports, they can help improve safety while keeping operational costs low.

At APM 2024, Flyability will lead a session that looks to address the use of drones to enhance inspection and surveillance for port operations. Conference attendees will also be able to explore Flyability’s ELIOS 3, the world’s frst collision-tolerant drone equipped with a LiDAR sensor for indoor 3 mapping.

Among the world’s top industry experts and business leaders scheduled to shared frst-hand insights at APM 2024 are Jan-Paul de Wilde, head of decarbonisation, energy transition and innovation at RINA, Singapore; Rahul Kapoor, vice-president and global head of shipping analytics and research at S&P Global Commodity Insights; and

Jayendu Krishna, director-deputy head at maritime advisors, Drewry.

Richard Wagner, regional director for Asia at CyberOwl, who will share the latest technological innovations for marine cyber resilience, comments: “The maritime industry has transformed greatly over the last few years. We now see leading technologies reshaping the industry, but there are also challenges that these opportunities bring, including how we balance the confict between business demands for technology innovations, such as AI and the drive towards autonomous operations, with cyber risk management in the face of rising costs for cyber compromise.”

i. apmaritime.com

Canopée completes frst transatlantic sea trial with sails

Canopée is more than just a cargo ship. It is the world’s frst hybrid industrial cargo ship powered by wind. The 121m vessel uses both wind and fuel to propel itself across the oceans. It took around 100 engineers and technicians to develop and build the 22m-wide ship, and fne-tune its two 3,840kW diesel engines. The vessel was successfully delivered to French shipping company Jifmar Ofshore Services in August 2023.

The biggest challenge of all, however, were the ‘wings’ — four 363m2 sails — which were ftted this summer to literally, and fguratively, catch the winds of change. Together with its hybrid propulsion (which uses a combination of sails and traditional engines that run on either diesel or LNG), Canopée is plotting the course for more responsible cargo shipping.

The open-top Ro-Ro vessel’s build began in 2020 at the Neptune Marine shipyard in the Polish port of Sczezcin. The project is led by the maritime company Alizés, a joint venture between ofshore services specialist, Jifmar Ofshore Services and Zéphyr & Borée, a start-up specialised in low carbon shipping. The new-generation sailing cargo ship has been custom-designed by VPLP Design to ship Ariane 6 launcher components to Kourou at an estimated 50% cost reduction and with a lighter environmental footprint. A series of sea trials have been used to qualify >>

harbour infrastructure and confrm Canopée’s shipping route.

A Hoppe Marine anti-heeling system automatically activates by transferring ballast while a stabilisation system consists of anti-roll keels that operate in conjunction with the damping of the ballast water tanks. Cargo can be carried on a 94- by 17.6 space on the main deck, in a 45- by 14.4-metre space in the lower hold, and in a 21.6- by 12-metre space on a removable mezzanine deck. Ro-Ro cargo is loaded and unloaded via a stern ramp. Also ftted are a 60t gantry crane on the main deck and a smaller provision crane on the port side.

The ship is also ftted with 19 cabins for housing the 11 crewmembers and up to 11 additional personnel. The other

accommodation spaces include two mess areas, two day rooms, a gym, a bridge conference area, a hospital, and a ship’s ofce.

In November 2023, Canopée successfully completed her frst transatlantic sea trial with sails, crossing from Rotterdam to the Port of Pariacabo in French Guiana. She carried elements of the upper part of the launcher Ariane 6, including the fairing, as well as components of the boosters. These parts, destined for the inaugural fight, were unloaded and then delivered to Europe’s Spaceport in Kourou.

Canopée’s structure is tailored to be able to carry large, fragile loads and to

2 x controllable-pitch propellers 4 x Ayro sailing units

navigate the shallow Kourou river in French Guiana right up to Pariacabo harbour. Her total displacement tonnage is 10,000t, and she can travel at a speed of 17 knots. Canopée was frst launched in June 2022, traveling from Sczezcin to Rotterdam, where ftting out was completed (cabling, navigation instrumentation, system start-up, router implementation and cabin layout). Sea trials were then undertaken over several days to check that all electrical, propulsion, and safety systems were functioning correctly.

“With the sea qualifcation of Canopée, we have achieved a further milestone in the Ariane 6 adventure,” said Karl-Heinz Servos, ArianeGroup’s head of industry, following the vessel’s frst successful transatlantic crossing in 2023. “This cargo ship completely meets the programme objectives: reducing costs, shortening production cycles, and reducing our environmental footprint.”

Following the transportation of the inaugural fight Ariane 6 launcher this summer, Canopée will continue to transport further launchers, which are being integrated at ArianeGroup’s sites in France and Germany.

French company Ayro developed Canopée’s four 37m-high vertical Oceanwings. Fully automated, they can rotate 360° to follow the wind. Signifcantly more powerful than conventional sails, these wings allow Canopée to maximize the use of wind power and reduce its average annual fuel consumption by around 30%.

Capable of carrying 5,000t at a speed of 16.5 knots, Canopée will be making a dozen voyages each year between the ports of Bremen, Rotterdam, Le Havre, Bordeaux, and Pariacabo (Europe’s spaceport centre).

Since the beginning of his career, Michiel de Vliegher has been involved with data. One moment he’s working on making ships more sustainable, the next he’s focused on improving shipbuilding processes. In April 2023, he was appointed Director of Damen Shiprepair Vlissingen. Here, he explores his experience with

digitalisation and how he is making advancements in this area.

It was during his part-time jobs at logistics companies when Michiel de Vliegher frst became captivated with large ships over 200m. “My choice for

the maritime sector is intrinsic,” he says. “I began my studies at the Maritime University of Applied Sciences because I was fascinated by the beautiful ships I saw during my youth. Often, someone knows someone who works on such ship and that’s what ignites their enthusiasm. That wasn’t the case for me. I found and still fnd those sailing steel

Craftsmen at Damen Shiprepair Vlissingen.

“When it comes to software development, the maritime sector often waits until someone else takes the frst step. It’s logical, considering the substantial investments.”

giants truly magnifcent. What a feat of engineering.”

He later began work as a project engineer at Vroon in Breskens and immediately tackled an intriguing assignment. “We were challenged to make ships more sustainable,” he explains. “The fnancial situation of the shipping industry was negative between 2008 and 2009. Sailing more sustainably was a great opportunity to save money. In collaboration with MARIN, we installed additional speed logs in the hull of a ship to gather more information about the infuence of speed and other parameters on fuel consumption. This yielded a lot of information, but we lacked software to send real-time analyses to the bridge.”

Investments in software development are vital for development, but are often

costly, explains De Vliegher: “When it comes to software development, the maritime sector often waits until someone else takes the frst step. It’s logical, considering the substantial investments. Having a vision gives you the wider focus you need to achieve your goals. A clever move was forming a consortium to share costs and knowledge, making collaborative development possible. The result was a solid system that provided captains with tools to better understand the ship’s operational profle and thereby reduce fuel consumption during voyages.”

After several career steps, he took on the role of project manager at Damen in Vlissingen in 2015. At the time, the digital landscape at the shipyard was shaped by Baan’s ERP software before other ERP packages with a stronger fnancial focus were introduced.

Accurate solutions to guarantee continuity. Quick service with attention to quality.

“Tools like ChatGPT could be valuable additions to our work, however, these tools need to learn more about the complexity of the sector before we implement them.”

“The Baan’s software works well for auditability and fnancial support, however, for project managers, it was initially less smooth due to additional process steps,” he says. “For smaller tasks, we are now gradually developing a new approach where we can easily share documents with each other through a SharePoint environment, which is sufcient for small tasks. For larger, truly complex tasks, it’s a signifcant challenge and precise document control becomes a necessity. We use Shipbuilder Software as a handy tool to provide support.”

The ultimate tool for complex projects

“Shipbuilder Software ofers all functionalities to manage large projects,”

explains De Vliegher. “As a contractdriven organisation, we need digital support for precise process steps during extensive and intricate projects. This tool takes care of that for us. In fact, it reduces our workload signifcantly. With just one click, we can update our clients on the status and send detailed reports of completed tasks. Shipbuilder Software prevents us from missing the mark.”

Regarding maritime digitalisation, De Vliegher sees substantial potential in the concept of a digital twin, and he’s closely monitoring the development of AI.

“Tools like ChatGPT could be valuable additions to our work, however, these tools need to learn more about the complexity of the sector before we

implement them,” he says. “I’m also convinced that the Dutch maritime sector can stand out by providing a digital twin upon delivery. When it comes to repairs or refts, we can access and use all data in software like Shipbuilder Software. Subsequently, we can provide the digital twin.

“Currently, we often work based on estimations,” he adds. “That leads to a lot of wasted time, inefciency and compromises in sustainability. Consider, for instance, ordering too much or too little material, or having to do a lot of additional work within the same timeframe. A digital twin can, in my opinion, truly set a customer apart.”

i. damen.com

Premier mooring rope manufacturer, DSR, provides a solution for precise compliance with mooring regulations and the efcient monitoring of ship mooring lines.

DSR stands at the forefront of global synthetic fbre rope manufacturing, covering everything from fbre ropes to wires and wire ropes. Established in 1965, DSR has evolved into a top-tier global company in rope design, production and manufacturing technology, growing alongside the development of the Korean shipbuilding industry.

DSR’s fagship mooring ropes, SuperMax and OceanMax, are acknowledged as the industry’s premium ropes based on customer experience. SuperMax, designed for LNG ship mooring, maximises safety and efciency through DSR’s unique design and Dyneema fbre with special coatings. OceanMax, certifed by DNV and ABS, is optimised for deep-sea mooring and has garnered signifcant attention. Additionally,

products like New Dfex, New Superfex, and POWER ROPE cater to various ship types, reducing your time and efort in decision-making.

DSR holds diverse class certifcations for all its products, with the Mooring Line product line meeting MEG4 standards. ASB (Anti Snap Back) options, along with various jacket choices, ofer users alternatives for rope management and lifespan extension. Furthermore, the Eco Fibre option contributes to environmentally friendly practices.

Beyond product excellence, DSR endeavours to minimise risks in diverse and complex mooring environments, epitomised by the slogan ‘No Moor Problem’, symbolizing confdence in DSR’s products and dedication to customer satisfaction.

DSR’s innovation, WINZ: optimal

In response to the 2024 SOLAS MSC.1/ Circ.1619 amendments, DSR has unveiled the Mooring Line management solution ‘WINZ’, developed over four years with practical feld testing. WINZ is an innovative programme gaining attention for providing safety and efciency to users.

WINZ comprises three core solutions for quick regulation adaptation, monitoring the status of all ship lines anytime, anywhere, and receiving advice on lines. Tested with major LNG and BULK ship operators, WINZ shows a 33% average increase in operational efciency. Survey results highlight user mentions of convenience, efciency, and accuracy, proving the excellence of WINZ. >>

DSR invites readers to embark on WINZ to unlock the future of Mooring Line management, sharing current and future mooring concerns.

WINZ adopts an interface with easy understanding and a GUI using one-click actions to maximise user convenience. Designed to be applicable to most ships operating under international standards, WINZ includes customization features for refecting specifc company regulations.

Plans for WINZ include launching the WINZ mobile app in the frst half of 2024. The mobile app allows recording actions on lines even during movement, enhances communication, and integrates with DSR Rope for more convenient line management. Additionally, ongoing research aims to develop smart options for real-time tension measurement and alert systems for rope-related risks.

In January 2024, a successful customer seminar on SOLAS amendments and WINZ introduction took place in Japan. In June 2024 at Athens Posidonia and in September 2024 at Hamburg SMM, visitors will be able to directly experience WINZ through live demonstrations and explore the future of Mooring Line management at seminars held in major cities worldwide.

DSR invites readers to embark on WINZ to unlock the future of Mooring Line management, sharing current and future mooring concerns. Join WINZ for heightened safety and efciency.

i. dsr.com

Supporting vessels with systems that deliver real-time onboard data processing is a calling card for MSA-Service and non-negotiable for crew.

When electrotechnical specialist, MSA-Service, received a technical support request from Dutch equipment supplier HollandMT during the construction of its hopper dredger vessel, Hegemann V, the team responded without hesitation. Flying out to Germany to the Kooiman Marine Group’s facilities where the dredger was in build, the team assisted with instrumentation, the installation of MSAService’s VisuDREDGE and Multiped systems, and vessel communications.

“This was a wonderful assignment that gave us the opportunity to show what

our products and systems are capable of,” says Machiel ‘t Hoen, founder of MSA-Service, who visited the yard together with Jan Willem de Wit, owner and director of HollandMT. “They use VisuDREDGE both for the control and monitoring of the dredging system and for the dredging work, while our Multiped system collects information from the dredging systems. This data can then be used to generate daily reports semi-automatically.”

“Furthermore, the crew provided valuable information that will allow us to refne the software even further,” he

adds, “and we continue to develop innovations in close collaboration with them.”

A total of fve large screens were installed aboard Hegemann V, two of which display VisuDREDGE. The remaining two screens display QINSy, a survey planning, acquisition, and realtime hydrographic data processing program that provides the crew with a visualization of the seabed and accurately shows the work performed under water based on GPS positioning.

A 24-inch touchscreen was also installed allowing all dredging systems to be operated using VisuDREDGE. It also permits all on-screen data from the ship and the dredging system to be accessed simultaneously with Multiped. “We are talking about both real-time and historical data,” says ‘T Hoen. “This provides the crew with immediate insight into where improvements are possible.”

During the visit, MSA-Service discussed build requirements with many of the

crew, including surveyors Thomas Scheidl and Martin Loescher, and frst ofcer, Jean Schüssler after which, and implemented their requests in the system. “We have real-time information, and the layout of the dredging software really suits our way of working,” says Scheidl. “‘With VisuDREDGE, work can continue when we want to extract information from the system in the background or implement improvements on board. That is impossible with the other systems that we use where the entire operation must

be stopped. As a team, we can improve our dredging activities with this dredging software.”

“The programs show me all the results in a clear overview, the advantage of which is I receive the information projected in real time, allowing me to act immediately,” adds Schüssler. “The systems we used before only provided data much later, meaning I was unable to respond to certain situations in time. That real-time information and data analysis is worth its weight in gold.”

VisuDREDGE shows me all the results in a clear overview, the advantage of which is I receive the information projected in real time, allowing me to act immediately,

MSA-Service’s passion for maritime technology is leading to systems that help crew by optimising their work and efciency on board vessels, as well as onshore. “We enjoy thinking about our customers’ specifc needs in terms of both software and measurements, and fnetuning our products accordingly,” says ‘T Hoen. “We use A-class products for this. We focus on thinking along and delivering a total solution, from advice, to instrumentation, to additional programs like QINSy.”

“Our VisuDREDGE and Multiped systems truly support the maritime sector in its activities,” he adds. “In a simple and accessible way, the report on the performance of the assets can be discussed, based on both real-time and historical data. And the data and analyses from the systems ofer great potential.”

i. hollandmt.com i. msa-service.nl

Den Breejen’s pandemic gamble pays of

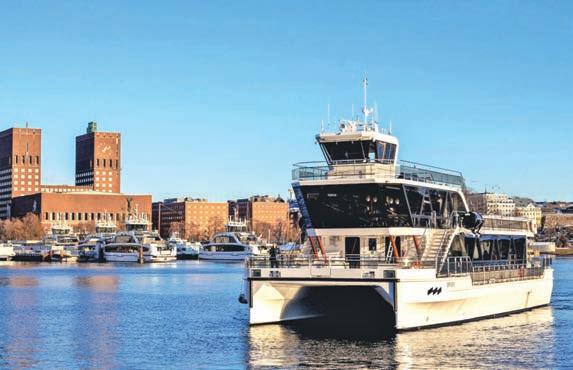

River cruise ship Thurgau Gold entered service in December 2023.

Building on speculation is a fnancial risk for any shipyard. Choosing to do it during a global pandemic adds another level of complexity. And yet that is exactly what Dutch builder Den Breejen Shipyard elected to do, commissioning the construction of a hull for a sustainable and innovative passenger ship “as an investment in the future of cruise shipping.”

Fortunately for Den Breejen the gamble paid of. A buyer was found for the river cruiser during the initial stages of construction, allowing the fnal build to commence in November 2022. Thurgau Gold entered service in December 2023.

“During the pandemic, many river cruise customers had to shut down their ships,” says Johan Kaasjager, commercial director at Den Breejen. “As a result, order intake also came to a standstill. People were looking at new construction, but investment plans were put on hold. As a yard, we decided to have a hull built ourselves with a uniform basis, which would prove to be a good platform in the market.”

The risks associated with speculative building are plentiful. Aside from the risk of fnancial exposure with no guarantee of a buyer stepping in, there are important decisions that need to be made in the early stages that may not be compatible with a future owner’s requirements. On the fip side, it gave Den Breejen the advantage of guaranteeing a delivery before summer 2023 and appealed to customers who are less committed to one style and need a ship in the short term.

“Potential buyers wanted to invest as late as possible but get in early enough to add their own touch to the ship,” says Kaasjager. “It was an exciting challenge to fnd the right moment between the yard and the market.”

With the parameters set, the yard developed a design layout that would appeal to the widest possible audience. For the interior, Den Breejen collaborated with superyacht design studio Omega Architects, to give the ship its own identity.

>>

Builder Den Breejen Shipyard

Year of build 2022

Flag state Switzerland

Class River cruise ship

Speed 12.5 knots

Length 135m

Beam 12m

Draft 1.7m

Capacity 182 passengers / 40 crew

“[The design] left sufcient room for individual, customer-oriented development. Most shipping companies were enthusiastic,” says Kaasjager. “They weren’t focused on new construction, but they did want to be able to put a new ship on the market immediately after the pandemic.”

A buyer was found with PCE from Hamburg, a German investor in the river cruise market who could put the ship into service through Thurgau Travel Cruises. Once the commissioned hull arrived at the shipyard, Den Breejen engaged its team of long-term suppliers to commence the fnishing works.

Typically, decisions around interior, fabrics and materials are made during the early design phase. However, in the case of Thurgau Gold, the yard had to make changes during the later stages of the build. Thurgau requested a ship with a golden touch, which is why golden elements and details appear in the interior. Cabins and suites have movable foor-to-ceiling windows that further emphasise the spatial layout, while the lounge has panoramic windows spanning almost the entire width.

“[The design emphasises] contact with the water and the environment,” says Kaasjager. “The end result was something to be proud of.”

Thurgau requested a ship with a golden touch, which is why golden elements and details appear in the interior.

In addition to being stylish, Thurgau Gold needed to be as sustainable as possible. The PACCAR Euro VI engines (sourced from the automotive industry and made suitable for the maritime industry) and generators meet the Stage V standard, and are economical, quiet, compact and clean.

Solar panels are incorporated in the top deck railing and onboard batteries are used for peak shaving, omitting the need to rely on a second diesel generator during peak times. “We are very happy with the system. Despite the complexity of the technology, it’s very user-friendly,”

says Kaasjager. Some heat sources, such as the main engine and the air handling unit, also have heat recovery used for the ship’s hot water, allowing for further energy savings.

“Technology is evolving quickly, and we always try to innovate further together with clients,” says Kaasjager. “Cruise shipping is an interesting market with customers who love luxury and innovation, but who are certainly also price conscious. Fortunately, that market is in full swing again and therefore remains our core business.”

i. breejen-shipyard.nl

The power of wind brings new vessels and large revenue for geodata specialist, Fugro.

The ofshore wind market continues to grow rapidly. It’s supported by the UN Climate Summit COP28’s recent decision to triple the world’s renewable energy capacity by 2030, a large portion of which is expected to come from ofshore wind. For leading geodata specialist Fugro, its strategy to capture this market growth opportunity is exemplifed by the Dutch company’s recent addition of two geotechnical vessels to its feet.

The acquisition of two platform supply vessels, Sea Goldcrest and Sea Gull (built in 2019 and 2020 respectively), will, according to Fugro, be used as key geotechnical strategic assets to strengthen its position as a market leader, as well as its ability to address the market demands and shortage in geotechnical capable vessels. Fugro now operates a balanced feet of owned and chartered vessels, maintaining fexibility towards the future. It also continues to invest in remote and digital solutions for its feet of uncrewed surface vessels.

As communicated during the Capital Markets Day in November last year, part of Fugro’s strategy for the coming four years is to secure long-term vessel capacity, especially for the global ofshore wind market, which has a particularly large need for mapping of soil composition and its associated properties via the extraction and testing of soil samples. For the foreseeable future, these activities cannot be executed with smaller platforms, either crewed or uncrewed.

Upon delivery of Sea Goldcrest in the course of 2024, Fugro will begin converting the ship to a geotechnical vessel, which is expected to be operational early 2025. Sea Gull, which is

already under charter with Fugro and fully operational, will be delivered in late 2024 or early 2025. Furthermore, the purchase of these vessels supports Fugro’s net zero 2035 roadmap as both vessels are fuel efcient and suitable for the conversion to low-carbon fuels.

In 2023, Fugro published a 24.1% revenue growth for Q2 due to continued high client demand in energy markets, particularly for ofshore wind site characterisation solutions and related nearshore activities. Employing around 10,000 people in 57 countries, it serves clients around the globe, predominantly in the energy and infrastructure industries, both ofshore and onshore. In 2022, revenue amounted to EUR 1.8 billion.

“I am very pleased to report a strong set of results [for 2023 Q2],” said CEO, Mark Heine. “All regions contributed to signifcant higher margins and cash generation, in particular the Americas and Europe-Africa. Overall, better contracting conditions, increasing asset utilisation and better operational performance led to a signifcant improvement, particularly in the marine site characterisation business.”

“Across the globe, we are beneftting from high client demand for climate change adaptation and energy transition solutions, in particular for ofshore wind developments, and we are continuing on our trajectory of further diversifcation into future proof markets,” he adds. “To remain successful in capturing the market opportunities and secure controlled growth, we continue to invest in our people and asset base.”

i. fugro.com

In 2023, Fugro published a 24.1% revenue growth for Q2 due to continued high client demand in energy markets, particularly for ofshore wind site characterisation solutions and related nearshore activities.

Meyer Turku launches largest and most sustainable cruise liners. ALL IMAGES COURTESY OF ROYAL CARIBBEAN.

Finnish shipbuilder Meyer Turku, one of the largest shipyards in the world, fnished 2023 on a high and carried its success into 2024. Within the space of just two months, the US-based cruise company commenced the hull assembly of its third LNG-fuelled ship, Star of the Seas, and saw the world’s largest and most advanced cruise ship to date, Icon of the Seas, debut in Miami. The company’s third new vessel, Utopia of the Seas, will enter the short cruise market out of Port Canaveral in summer 2024.

With a planned delivery for August 2025, Star of the Seas is billed as Royal Caribbean’s most sustainable ship to date, with a range of applications, including waste heat recovery systems. It brings parent Company Royal Caribbean Group one step closer in its aim to have a net-zero cruise ship by 2035.

In contrast, Icon of the Seas, the frst in the company’s Icon Class line-up, boasts the largest waterpark at sea with six record-breaking slides that include the Frightening Bolt, the tallest waterslide to sail, and the Pressure Drop, the frst open freefall waterslide on a cruise. Counting down to the start of a new era of vacations, residents and Royal Caribbean fans, executives and employees were on hand as the frst to see Icon of the Seas arrive at Port Miami in style ahead of its naming celebration and frst cruise.

Celebratory freboat salutes, banner planes in fight and a community celebration at Pérez Art Museum marked the arrival.

“Star of the Seas is very important for both the shipyard and the partner network: the 13,000 man-years spent on building the ship create employment and business in Varsinais-Suomi and, with the supply chains, signifcantly wider as well,” says Tim Meyer, CEO of Meyer Turku. “Once the ship is complete, it will strengthen a completely new kind of cruise experience with the standards set by its sister ship Icon.” >>

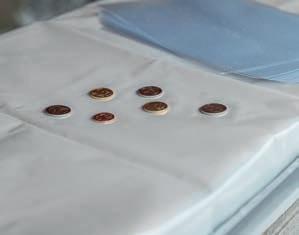

December 2023 – Only weeks ahead of the highly anticipated introduction of Icon of the Seas, Royal Caribbean International reached a milestone in the construction of the next Icon Class ship – Star of the Seas. A keel-laying ceremony for the upcoming revolutionary combination of every vacation took place at the Meyer Turku shipyard in Turku, Finland, where a massive steel block was placed in the building dock and on top of freshly minted coins that are meant to bring good luck during construction. Star is set to mark the next bold moment in a new era of vacations in Port Canaveral (Orlando), Florida, in August 2025.

“Star of the Seas is very important for both the shipyard and the partner network: the 13,000 man-years spent on building the ship create employment and business in Varsinais-Suomi...

Star of the Seas is Royal Caribbean’s second Icon Class vessel and promises something for every type of family and adventurer. The Icon Class highlights coming to Star include Category 6 waterpark’s and Crown’s Edge – part skywalk, part ropes course and part thrill ride – as well as seven diferent pools. This includes an infnity pool suspended 41m above the ocean, plus ten separate whirlpools.

Starting from August 2025, vacationers can travel from Port Canaveral (Orlando), Florida, on a 7-night cruise to the Caribbean, culminating in a beach day at the cruise liner’s private island in The Bahamas. The CocoCay destination island features 13 waterslides, the largest freshwater pool in the Caribbean and Bahamas, and the island’s frst adultsonly private beach (opening January 2024) with pools, cabanas, live music and eateries.

With Icon in Miami and Star in the greater Orlando area, it marks the next era of vacations and for Royal Caribbean.

Meanwhile, Meyer Turku’s parent company Meyer Group is diversifying its portfolio. Together with Belgian

company Smulders, it announced its entry into the construction of ofshore converter platforms at the Warnemünde site. Initially, both companies intend to establish Neptun Smulders Engineering, which will be responsible for the development and construction of converter platforms with a capacity of two gigawatts. The frst stage will create 100 jobs.

This news followed the announcement in 2023 that Meyer Re received its frst reft orders from the cruise industry, while Meyer Floating Solutions presented the world’s frst foating cruise terminals. What’s more, Meyer Group’s IT start-up, Alfred Maritime, used artifcial intelligence to efciently control energy generation and utilisation on board the Silver Nova for the frst time this year.

“We now employ 1,700 people in the Group’s engineering division – almost twice as many as before the crisis. This shows impressively how consistently we are working on our future viability and continuing to drive forward the topics of sustainability and innovation,” says Managing Director Jan Meyer.

i. meyerturku.f i. meyerwerft.de

The three transatlantic RoRos are set to carry aircraft subassemblies between manufacturing facilities located in Europe and the United States.

parties involved, which is notably evident in the projects carried out for LDA, a client with whom we have maintained a longstanding and strong partnership over the years.”

LDA will build, own and operate the new vessels, which are scheduled to enter into service in 2026. The three transatlantic RoRos are set to carry aircraft subassemblies between manufacturing facilities located in Europe and the United States, will be propelled by six Flettner rotors paired with two dual-fuel engines operating on maritime diesel oil and e-methanol. All three will have the capacity to transport around seventy 40-foot containers and six single-aisle aircraft subassembly sets, a substantial increase from current cargo ships.

In addition, routing software will help boost the efciency of the vessels’ transatlantic journeys. This technology aims to optimise the route by leveraging wind propulsion and avoiding drag caused by adverse ocean conditions.

The contract follows on the heels of LDC’s deal in December with the Spanish developer of wind-assisted bound4blue to retroft wind sail technology on chartered juice vessel MV Atlantic Orchard. Installation of the four 26m-high eSAILs is planned for later this year, and depending on vessel routing, is expected to reduce annual fuel consumption and CO2 emissions by at least 10%.

The eSAIL system is based on windassisted propulsion technology known as a suction sail. By harnessing wind power to propel vessels, this technology achieves a substantial reduction in fuel

consumption and pollutant emissions. The system leverages a thick aerodynamic profle and intelligent suction mechanisms to enhance propulsive efciency, yielding seven times more lift than an airplane wing. LDC’s decision to implement the technology was based on a third-party assessment study carried out by Lloyd’s Register, which found bound4blue’s suction sails to be the most promising.

In December 2023, Deltamarin signed a design and engineering contract with China Merchants Jinling Shipyard (Jiangsu) Co., Ltd for the design and engineering of Wallenius Wilhelmsen’s

next-generation Pure Car & Truck Carriers (PCTCs). The contract includes the complete basic and detailed design work for four confrmed, and up to eight optional, units of 9,350CEU class methanol dual-fuel PCTCs ordered by Wallenius Wilhemsen.

The vessels will be built by China Merchants Jinling Shipyard (Jiangsu) Co., Ltd. and the frst vessel will be delivered in the second half of 2026. The ships will be ammonia-ready allowing for their conversion to ammonia at a later stage.

i. lda.fr i. deltamarin.com i. wuchuan.com.cn

ShipBuilding Industry will bring readers an in-depth event preview.

This is a unique opportunity to put your brand in the right place at the right time. You can target your advertising to make the most of the show, before you even get there. Contact our sales team to make this happen.

In addition, if you have news related to Posidonia, or any other information you’d like to share, please send it to our editorial team.

A raft of skilled in-water repairs keep vessels out of drydock wherever they are in the world.

Hydrex, a provider of underwater maintenance and repair services to the shipping and ofshore industry, had quite the year in 2023. From tankers, bulkers and cruise ships to RoRo vessels, yachts and drill ships, the diversity of its skillset and projects is as far reaching as the ocean itself.

Its qualifed teams travelled across continents to carry out seal repairs, perform routine insert repairs and undertake tailor-made complex shell plating operations as far as Oman and Papua New Guinea, exemplifying the specialist techniques provided by the Belgian underwater repairs expert.

Being able to keep vessels out of drydock saves time and money, making Hydrex – one of the few companies to perform such services – a name that is in demand. Some examples highlight intuitive underwater methods, while others take advantage of the Hydrex fexible mobdock technique, which enables operations to be completed with the ship afoat and carrying out normal activities.

When a fully laden bulk carrier sufered heavy damages from a grounding in Suez, Hydrex came to the rescue. Based on initial inspections, the frm carried out precise measurements of the hull where the large damage occurred so that a 45-ton coferdam could be designed and built locally, to then be installed to make the hull watertight so that the water ballast tanks could be pumped out.

However, the pressure of the water proved too much for the structurally weak hull, which began to cave in after sufering too much internal damage. A new plan was proposed to reinforce and to build cement boxes and pour concrete to provide enough strength for the bulkheads in between the ballast tanks. Yet more challenges presented themselves when the WBT 2 port couldn’t be emptied, which meant lightening the ship until the classrequired draft could be achieved.

With the cement boxes in place, the coferdam was fully secured, and

successful sea trials were conducted. The coferdam remained frmly in place until it could be removed when the ship was in drydock and permanent hull repairs could be carried out.

Keeping the ship operational and out of drydock was the owner of a 200m roro ship’s main objective when they discovered the bow thruster needed >>

replacing. Keeping to form, Hydrex divers removed and reinstalled the unit once it had been overhauled, while the vessel stayed at anchorage in Naples, Italy.

They achieved this by setting up a monitoring station next to the vessel, while the divers carried out a detailed inspection of the bow thruster and tunnel. Working as a team, initial preparations for the removal were also made in the bow thruster engine room to prevent any water breaches the unit was removed.

The external thruster tunnel grids were removed to provide access. Next pad eyes were welded inside the tunnel to hoist the thruster unit up and down. To secure the gearbox with hoisting equipment, the team disconnected the unit from the engine room and removed it from the thruster tunnel. It was then brought to the surface where it was overhauled by the OEM’s technician, with assistance of Hydrex diver/ technicians.

As the thruster was fully assembled and prepared, it could be installed in its entirety without the need to create a dry environment in the tunnel as is required when the blades are installed separately. The diver/technicians lowered it into the water and brought it into the thruster tunnel. The team secured the unit and connected it to the engine room. The operation ended with the removal of the pad eyes and the reinstallation of the thruster tunnel grids.

A team was quickly mobilised to Singapore for a repair on a 360m bulker, last year, after a crack measuring 232mm behind the start of the landing plate on the vessel’s bilge keel was discovered.

A high current where the vessel was anchored severely restricted the divers to only work during slack tide before the current became too much to allow diving operations. At the client’s approval, the decision was made to grind out the crack and reweld it instead of installing a new insert.

The bilge keel and landing plate were then partially cropped to allow for the

installation of a coferdam on the outside of the hull over the damage. The team could then work on the crack inside the ballast tank without water ingress. The crack was ground out over its entire length and flled with the class approved full penetration welding. The coferdam was removed, and the bilge keel was further adapted to the correct shape. The project was completed when the cropped landing plate was fully welded and closed again.

Another example of quick recovery occurred in in Klaipeda, Lithuania, when a successful propeller blade cropping was carried out on a 175m bulker. The vessel’s propeller blades were damaged from impact with ice, and a fast on-site solution was required to avoid an extended of-hire period in drydock. Due

to the severity of the damage, cropping was the only option.

When the team arrived at the vessel’s location they began with a detailed survey of the afected propeller blades. As the ship could be trimmed by the bow, the entire operation could be performed above water. The team used the information acquired during the inspection to calculate and determine the ideal cutting lines. They then cropped the damaged blades and ground the edges to give them the correct shape.

When the cropping was complete, the blades were polished to make sure that any remaining loss of efciency was kept to a minimum.

i. hydrex.be

Subsea Industries refects on a prosperous year.

Sustainable underwater coating and cleaning company, Subsea Industries, is changing the yachting game with its range of coating systems and new applications that help reduce the amount of time that vessels need to spend in drydock. Its abrasion-resistant ice coating product, Ecospeed Ice, is one such example. Based on extended observation of the coating in use, Lloyd’s Register – which has just renewed and upgraded the product’s annual certifcate – has changed the classifcation to include Polar Codes 1 to 7, refecting its durability and strength and making it suitable for all ice classed vessels.

“The number one consideration in a hull coating for ice-going vessels and icebreakers is the ability of the coating to protect the hull in the harshest marine environment there is,” says a Subsea spokesperson in a statement. “Only a few types of coatings can provide this protection. Typically, they are certifed for their ice-abrasion resistance qualities by the classifcation societies.”

The abrasion resistant coating certifcate allows owners of ice-class vessels to reduce the thickness of the plating on the ice belt – the area on the bow above the waterline most prone to mechanical damage from sailing through ice – on all areas coated with Ecospeed. With less steel required to build the hull, it is most a cost and weight saving solution.

Canadian-based Group Ocean has been applying Ecospeed Ice on all their ice going tugs since January 2012. “What

we were looking for was a 25-year corrosion protection system for our icegoing tugs, as we don’t want to do any corrosion or erosion steel work,” says Patrick Chabot, director of feet planning and renewal at Group Ocean. “I believe we have now found that 25-year solution.”

The Ocean tugboats are built for service in harsh, icy conditions, and the Ecospeed Ice applied in 2012 is still in excellent condition, says Olivier Garon, director of feet maintenance. “When they’re in drydock, I can see immediately which vessels were painted with Ecospeed and which were not. The

“The number one consideration in a hull coating for ice-going vessels and icebreakers is the ability of the coating to protect the hull in the harshest marine environment there is.”

diference is very noticeable. There are a few touch-ups required, probably resulting from mechanical damage rather than ice, [but the] application has been done per instructions, so it lasts. I’m very impressed with the condition of the hulls.”

It’s not just ice-class vessels that vouch for Ecospeed’s efcacy. The 100% nontoxic nature of Ecospeed is an important additional beneft. Pols-Bom, a certifed organic oyster cultivation company operating in Zeeland in The Netherlands has been using Ecospeed for long-

lasting, non-toxic protection on the cargo hold of its cutter, YE 48 Op Hoop van Zegen. The boat has been in constant use since 2013 when the frst two coats were applied. In the 15 years since then – without any repainting in between – only minor touch-ups have been required.

It’s a similar story for the energy-efcient sight-seeing ferry MS Brisen. The ship’s hull is protected with Ecospeed’s nontoxic, hard coating system, which is expected to last the ferry’s lifetime. The sister vessel MS Berg has received the same protection. Going forward, shipbuilder Brim Explorer has chosen Ecospeed as the antifouling system of choice for its entire feet.

“With Ecospeed we eliminate all chemical emissions to the sea, preventing harmful chemicals from disturbing the fragile ecosystems in the areas in which we operate,” says Espen Larsen-Hakkebo, CEO and co-founder of Brim Explorer. “Our business is creating unforgettable experiences: it only makes sense to do this causing as little impact to the environment as possible.”

“With Ecospeed we eliminate all chemical emissions to the sea, preventing harmful chemicals from disturbing the fragile ecosystems in the areas in which we operate.”

In 2023, the Ecospeed coating system was also applied on the scrubber pipes, outlets and difusers of multiple ships, demonstrating the product’s usage outside of underwater hulls. Due to tight regulations on emissions in the shipping industry, the installation of an exhaust scrubber system has become increasingly widespread, yet the corrosive nature of the efuents from scrubbers has led to an increase in corrosive damage on scrubber pipes and outlets. This can result in water ingress into the engine room, ballast tanks and cargo holds.

As a highly chemically resistant product, Ecospeed provides a lasting, non-toxic protection against corrosion, cavitation and mechanical damage, enabling it to be used to protect exterior outlets, as well as the interiors of scrubbers. Likewise, shipping companies around the world rely on sister product, Ecoshield, to protect the rudders, thruster tunnels and other parts of the underwater ship prone to cavitation erosion and chemical corrosion. This includes hopper dredgers, which generally experience high wear as a result of their normal activities.

To date, there have been at least 700 separate Ecoshield applications to rudders, thruster tunnels, Kort nozzles, energy saving devices, stabilizer fns, sea chests, Hull Vanes and bulbous bows, as well as other parts of the underwater hull and running gear that require special protection from the efects of cavitation.

Alongside its lifetime longevity, when properly applied, Ecoshield makes the use of sacrifcial anodes unnecessary.

i. subind.net

Yavuz

Willy van Niekerk General Manager

Energy company Chevron has appointed Ayten Yavuz as the new General Manager of its Global Marine Products business. With an extensive background spanning numerous years in the industry and the company, she will lead eforts aimed at bolstering Chevron’s commitment to participate in the marine industry’s lower carbon future, as well as drive the company’s proftable growth, innovation and development within the marine business sector.

TSS, the oldest ship repair yard on Mauritius, has promoted former Assistant General Manager, Willy van Niekerk, to the role of General Manager. Under Van Niekerk’s management, TSS has already expanded into civil construction services, carrying out steel works for land projects in addition to its marine portfolio. In his new role, he will be responsible for modernising the yard, expanding its regional scope and portfolio, and tapping into new markets.

Derk te Bokkel will be appointed CEO of Royal IHC. He will thereby take over from Jan-Pieter Klaver who held this role since 1 January 2022. Te Bokkel will combine his role as CEO with his current role as CFO. Klaver will remain a member of the Board of Directors until 1 March 2024 and be responsible for custom vessels, engineering and project management, including managing the Boskalis project team. A new member of the Board of Directors is being sought who, as COO, will focus on developing the company’s shipbuilding qualities, managing the yards and, in parallel, realising build strategies.

International maritime law frm CJC has announced that Helen McCormick and Andrew Shannon have both made Partner at the company. The promotions see McCormick, an experienced disputes lawyer specialising in ‘dry’ claims, and solicitor and Master Mariner Shannon who specialises in Admiralty Law, expand the number of partners in CJC to 20. With ofces in London Newcastle, Singapore

Martin Bloem has been appointed in the new position of Group Director of Corporate Afairs at Damen Shipyards Group, with immediate efect. Bloem’s previous roles in the shipbuilding sector include working for the Ministry of Economic Afairs before he became the general director of the industry association Netherlands Maritime Technology. After that, he was made a partner at strategic maritime consultancy Marstrat alongside public-private positions in the Rotterdam region. “I consider it an honour to be part of a dynamic and innovative organisation like Damen,” he says.

Dennis White has been elevated to Vice President of brokerage at Crowley. White’s appointment is another important step in the company’s expanding land transportation strategy and will play a key role in transforming the company into a leading solutions provider for land transportation services in North America. White was previously director of digital solutions at Crowley and will be responsible for carrying out the development of an enhanced carrier support team.

From September, Kathrin Schiemann will take on the role of Sales and Marketing Manager for the DACH market (Germany, Austria and Switzerland) and Western Europe at Viking Line. In her new role, Schiemann will be responsible for the development and implementation of sales and marketing strategies. Her focus will be on enhancing cooperation with European travel agencies and operators and expanding new partnerships.

and Miami, CJC advises on all aspects of the shipping sector, from ship fnance to dry shipping, marine insurance and comprehensive casualty handling. “CJC continues to attract the best talent in maritime law, and promoting partners from within the frm remains a vital part of our continuing growth,” said Ian Short, Director at CJC.

ADS van STIGT

Avelingen-West 30

4202 MS Gorinchem

The Netherlands

T +31 (0)183 650 000

E info@vanstigt.com

I www.vanstigt.com

Contact: Sander Snoek

ADS van STIGT was founded in 1970 with the main activity in transmissions and gearboxes for maritime and industrial applications. This is still an importent activity of ADS van STIGT, but a signifcant number of other products have been added to the range, such as planetary gearboxes, pump drives, control systems, monitoring systems, controllable pitch propellers, thruster systems, carbon fbre shafts, dampers, elastic couplings and sensors. ADS van STIGT’s expertise ranges from pleasure to mega yachts, and from fshery to commercial shipping, offshore, and dredging. A well-equipped service team is supporting the sales activities worldwide.

ADS van STIGT is competence centre for: Masson, Bonfglioli, O&K, Plöger, Horn, Schaller, Katsa, Geislinger, Durst and ZF.

ANCOFERWALDRAM STEELPLATES BV

P.O. Box 190

4900 AD Oosterhout

The Netherlands

T +31 (0)162 491500

F +31 (0)162 429806

E sales@aws.dillinger.biz

I www.ancoferwaldram.com

Over 100,000 tons of quality heavy steel plates in stock

AncoferWaldram Steelplates B.V (AWS) is a stockholding wholesaler and steel service center, specializing in the supply of hot-rolled heavy carbon steel (quarto) plates, and profled parts for more than 40 years now. Over the years, AWS has developed into a business that sets the standard for its industry.

Plates from stock or profled parts

The choice is yours! It is the combination of comprehensive stocks of over 100,000 tons of heavy carbon steel plates plus the sophisticated

profling plant that gives AWS a decisive lead in experience, product range and customer service.

ART4 TECHNICAL SYSTEMS BV

Nieuwegracht 9-11

3763 LP Soest

The Netherlands

T +31 (0)35 582 2468

F +31 (0)35 642 4860

E Info@art4.nl

I www.art4.nl

Contact: Mr Paul Schraven

Art4 Technical Systems BV is an independent Dutch company. We design, build and deliver fully turnkey solutions for hydraulic and electrical systems for customers worldwide. Our clients use the hydraulic and electrical systems for various end products such as:Mobile drives, transport conveyers, winch drivers, jack up platforms, cranes, both onshore and off shore, a-frames, special equipment, fairground attractions.The systems can be custom built to ft the specifcations of the product they are used for.

BACHMANN ELECTRONIC GMBH

Offce Veenendaal:

Vendelier 65-69

3905 PD Veenendaal

The Netherlands

T +31 (0)85 210 0550

E r.epskamp@bachmann.info

I www.bachmann.info

Contact: R. Epskamp

Bachmann hardware matches the harsh conditions in the maritime and offshore industry. We take pride of extremely high availability using stateof-the-art technologies. Integration of AMS, PMS, CMS, etc. in a Redundant solution is realized with our modular and marine certifed PLCbased product range.

The group of companies includes the CMS specialist Bachmann Monitoring and Certec EDV, the developers of the 1st fully web enabled SCADA software atvise®

BREMAN MACHINERY B.V.

Sasdijk 20

8281 BM Genemuiden

The Netherlands

P.O. Box 135

8280 AC Genemuiden

The Netherlands

T +31 (0)88-27 36 200

E info@breman-machinery.nl

I www.breman-machiner y.nl

Great challenges need sophisticated solutions, the work of a specialist.

Breman Machinery fabricates critical steel components with exceptional dimensions and extreme accuracy. This is the daily job of our craftsmen. Through our unique capabilities regarding machining, welding, conservation and assembling we serve our customers to make their ambitions reality.

The welders of high-quality steel are qualifed by Lloyd’s Register or DNV for all welding positions. With 30 milling, boring and turning machines we have the possibility to offer unique services. Our preservation department can protect your projects. Our location is beside open water, we have a direct connection to the international ports. High quality is one of our most important standards!

EMIGREEN B.V.

Noordeinde 19

3341 LW Hendrik-Ido-Ambacht

The Netherlands

T +31 (0)184 415 317

F +31 (0)184 415 582

E info@emigreen.eu

I www.emigreen.eu

Contact: Niko J. Dalpis

Emission Control Technology

Emigreen produces customised, integrated emission control solutions, for, among others, the maritime sector. Emigreen also provides services including design, specifcation, production, installation instruction, training and aftersales. Emigreen has expertise in emission control technologies, fow dynamics, thermodynamics and noise and vibration control. Emigreen develops

and tests components including catalytic converters, particulate flters, selective catalytic reduction systems and related instrumentation.

The Emigreen Alfa Alfa burner assisted soot flter system has set the standard for others to beat. All Emigreen solutions are highly effcient, highly reliable and highly controllable, whether designed for an inland barge, shortsea carrier or luxury yacht.

Emigreen links science and the market

HEINEN & HOPMAN

Produktieweg 12

3751 LN Spakenburg

The Netherlands

T +31 (0)33 299 25 00

F +31 (0)33 299 25 99

E pr@heinenhopman.com

I www.heinenhopman.com

Contact: J.W.E. Hopman

Heinen & Hopman Engineering is a world leader in air conditioning, mechanical ventilation,central heating, refrigeration, sanitary systems, fre protection, environmental systems and air duct cleaning. Founded in 1965, the company is renowned for being an innovator in the design, engineering and installation of customised solutions.

We work in four specialist areas:

– Superyachts.

– Commercial shipping.

– Offshore industry.

– Navy vessels.

Our mission is to ensure that the climate ‘indoors’ will perfectly meet the needs of people and products alike, whatever the weather outside. Heinen & Hopman offers a worldwide, 24/7 service via a network of subsidiaries and sales centres.

KLAY INSTRUMENTS B.V.

P.O. Box 13

7990 AA Dwingeloo

The Netherlands

T +31 (0)521 591 550

E info@klay.nl

I www.klay.nl

Klay Instruments is a Dutch manufacturer of ‘All Stainless Steel’ Pressure- and Level transmitters for the Marine & shipbuilding. All our transmitters are ATEX and IECEx Ex ia certifed and have fve different

Marine Type Approvals.

Our Pressure transmitters are available in threaded and Flanged process connections with fush diaphragm for all pressure applications. The available accuracies are 0.2% (series 8000) or 0.1% (series 2000). For Level measurement we manufacture Compact transmitters (series 8000 and 2000) and submersible level transmitters (series Hydrobar).

Typical applications:

– Ballast Level – Oil / HFO and (waste) water level – Manifold pressure

More than 30 years experience in the Marine and shipbuilding industry!

MEN TECHNIEK BV

Caïrostraat 55

3047 BB Rotterdam, The Netherlands

T +31 (0)10 820 8717

E info@mentechniek.nl

I www.mentechniek.nl

Contact: Lucien Tuinfort

Safety, quality and innovative entrepreneurship. Men Techniek BV is a company with a very broad feld of activities. We are specialised in general repair on and offsite and have a lot of experience in welding, fre work and mechanical and electrical work. We can also offer a full NDT examination.

NICOVERKEN MARINE SERVICES BV

Algerastraat 20

3125 BS Schiedam, The Netherlands

T +31 (0)10 238 0999

F +31 (0)10 238 0988

E info@nicoverken.nl

I www.nicoverken.nl

Contact: Jacco Vermunt

Distributor, 24/7 service & spare parts agent of marine equipment. In our programme there are stainless steel marine pipes and drains, fltration, anti-fouling & cathodic protection, reverse osmosis desalinators (water makers), wastewater treatment, vacuum sanitary systems for yachts, deck equipment (doors & hatches) and watertight sliding door systems.

Our Ship Repair department is specialised in the overhaul of all types of main and auxiliary engines, including attachments i.e. governors, turbochargers, fuel equipment and the sales of spare parts and engines. We

are capable of crankshaft grinding. Our service is 24/7 worldwide!

Am Altendeich 83

D-25348 Glueckstadt, Germany

T +49 4124 9168-0

F +49 4124 3716

E pein@piening-propeller.de

I piening-propeller.de

Contact: Mathias Pein

Noise reduction relies upon the quiet operation of a yacht´s propulsion system. Piening Propeller fulfls its briefs in:

Consideration of all hydrodynamic aspects during the design and an accurate manufacturing of propellers and shafts according to highest ISO classes.The company is approved by all common classifcation societies. Repairs and adjustments of propellers are done with the same care as new buildings. Piening Propellers scope of supply includes:

Propellers FPP > 800mm Ø CPP > 1.100mm Ø

Shafts up to a several length of 16,000mm

Sterntubes with sealings and bearings

Shaft brackets complete Gearboxes Brand ZF

De Ruyterstraat 62

4335 GN Middelburg

The Netherlands

T +31 (0)6 190 358 20

E info@rbimarineconsultancy.com

I www.rbimarineconsultancy.com

Contact: Ruud Bimmel

RBi Marine Consultancy provides full-service 24/7 worldwide. This is the core of our business. We advise, manage and carry out projects with expertise and experience; a result of years in supporting the Marine industry both locally and internationally. Our business conduct inspection, surveying, new-build, repairs, refurbishment, regular maintenance, feet management, site management, owner representative, and of course project management.

Our network contains more than just that. Together with established partners we provide delivery of genuine marine parts, blasting and painting, welders,

ftters and sorts of craftsmen. For more details please call us or view our website.

SSC STEEL SHAPE CUTTERS BV

‘s-Gravendeelsedijk 200

3316 AZ Dordrecht

The Netherlands

T +31 (0)85 760 3226

E staat@ssc.nl

I www.steelshapecutters.nl

Contact: Peter Staat

SSC Steel Shape Cutters BV is a new, competent provider of 3D-profling: computer-controlled machine cutting of tubes, beams, hollow sections and plate. Subcontracting does not have to cost a lot, and it will bring substantial savings! With two state-of-the-art machines, we offer a huge range, superb accuracy, and great effciency. Round tubes up to Ø 2,500mm OD, with thicknesses of up to 150mm (oxyfuel and plasma), and robot cutting of beams and sections up to 1,200mm wide, plate up to 1,200mm wide and 3,000mm long. Fast, accurate, and cost effective.

SUHBO INDUSTRIAL CO., LTD.

6, Mipyeong-ro, 106 beon-gil, Wonsam-Myeon, Cheoin-gu, Yongin-si, Kyunggi-do, Korea

T +82 31 334 6979

F +82 31 334 1789

M +82 10 4999 6979 (Korea), +61 434 509 501 (Australia)

E joeykim@suhbo.co.kr

I www.suhbo.co.kr

Contact: Joey Kim, Export Sales Manager

Established in 1985, Suhbo Industrial Co., Ltd is the major leading Korean manufacturer and supplier of high performance roundsling for heavy & shipping building industries. We have been supplying high performance roundslings to major heavy industries companies and projects in Korea and Asia.

Our Suprime roundsling with Ultrapowerful Poly Arylate fber is highly recognized from many customers due to its excellent performance, the maximum lightening, the optimum handing effciency (slim in size) and optional functions such as anti-cutting, anti-fame and multi-checking.

WINEL B.V.

P.O. Box 70, 9400 AB Assen

The Netherlands

T +31 (0)592 366 060

F +31 (0)592 312 392

E sales@winel.nl

I www.winel.nl

Contact: Bert Knijp

Since its foundation in 1956, Winel has grown into a leading global supplier of high quality products and services tot the world’s maritime industry. An experienced team of specialists offer a wide range of doors, hatches, platforms, tank venting systems and special engineered products. Winel’s strength is offering a complete in-house service package which includes 3D design, engineering, testing, manufacturing, assembly, project management, support & logistic services.

G.J.WORTELBOER JR. B.V.

Quarantaineweg 5

3089 KP Rotterdam

P.O. Box 5003

3008 AA Rotterdam

Harbournr: 2637 – The Netherlands

T +31 (0)10 429 2222

F +31 (0)10 429 6459

E info@wortelboer.nl

I www.wortelboer.nl

Every now and then anchors and chains must be replaced, so we understand your need for quality and speedy delivery. Wortelboer has what you are looking for. Our enormous stock of anchors and chain cables of all sizes and diameters in both our Rotterdam and China ports gives you the certainty that we can deliver the required materials very quickly and to any port in the world! All our materials are approved by any of the well-known class societies such as LRS, BV, RINA, DNV/GL, ABS and RMRS.

Do you have problems with fnding the right anchors? Could you use a hand while ftting anchors and chain cables aboard your vessel? We are more than happy to help you with it. Wortelboer has been a reliable partner in the shipping industry for more than 50 years. And that is why our customers keep coming back for more.

Do you need anchors and chain cables? Come to WORTELBOER.

We have already started preparing our upcoming issues of ShipBuilding Industry. Below, you will fnd some of the main topics we are planning to cover. Please feel free to provide our editorial staf with any relevant information, so they can take your input into consideration for publication. Our commercial department will be happy to assist you with your marketing needs.

COLOPHON

COMMERCIAL DEPARTMENT

MARCO GEELS | Director marco@ynfpublishers.com

EDITORS

ARNO DIRKZWAGER arno@ynfpublishers.com

JULIA ZALTZMAN info@ynfpublishers.com

DESIGN

NATHALIE PUTMAN | Art Director nathaliep@ynfpublishers.com

Posidonia 2024

Ship design & naval architecture

Focus on Southern Europe

Workboats & tugs

Deck equipment & machinery

Copy deadline | 06 March 2024

Advertisement deadline | 01 April 2024

Release date | 30 April 2024

Electric & Hybrid Marine World Expo 2024

Focus on Northern Europe

Green ship technology

NAVCOM & marine electronics

Copy deadline | 17 April 2024

Advertisement deadline | 13 May 2024