3 minute read

Phenom ParticleX AM Addresses the Challenges of Additive Manufacturing

Source: ATA Scientific

Additive manufacturing (AM) is on track to revolutionise manufacturing processes by not only reducing costs but by creating complex parts that are not possible with traditional methods. The adoption of AM by many industries relies heavily on its ability to solve current manufacturing challenges.

The Phenom ParticleX AM is a specialised high-resolution desktop scanning electron microscope (SEM) dedicated to aiding additive manufacturers improve to product quality. The ParticleX AM rapidly profiles feed powders for size and morphological distribution, as well as elemental composition. Operators can then complete high-resolution imaging of the finished part to assess quality and look for defects in the print. This fully integrated system is simple to operate and eliminates the need for outsourcing for quality checks, speeding up time-to-market.

Challenge #1: Feed quality analysis

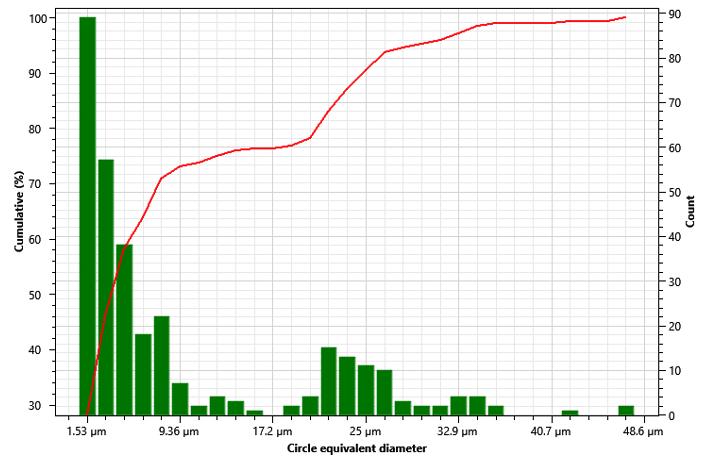

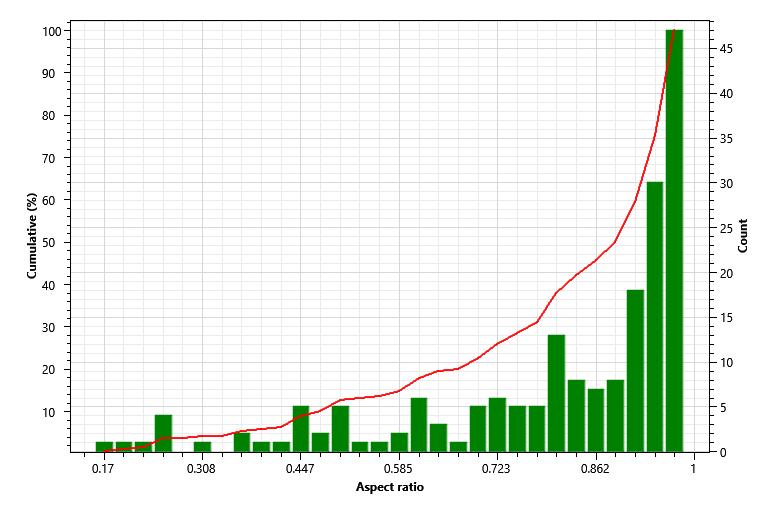

Obtaining regular-shaped and ideal size distribution of feed powder is crucial to creating high-quality parts. Smooth, regular-shaped particles flow more easily due to reduced friction and a lack of interlocking provides a more continuous powder bed. Additionally, achieving the optimal mix of small and large particles is critical to densely packed beds. Therefore, understanding the morphology and size distribution of particles is the key to produce high-quality parts with a smooth finish and high strength. The ParticleX AM can be used to quickly identify the morphological and the elemental composition of thousands of feed particles. From the resultant size distribution, morphological and elemental profiles, a given batch of powder can be assigned for specific use as per internal criteria. ParticleX AM allows ready access to extensive information on the starting material to deliver a powerful method for improving the quality of the final product.

Figure 1. ParticleX AM quantitatively analyses the morphology of feed powder. The intuitive software enables the user to revisit standout particles instantly, and produce plots and reports.

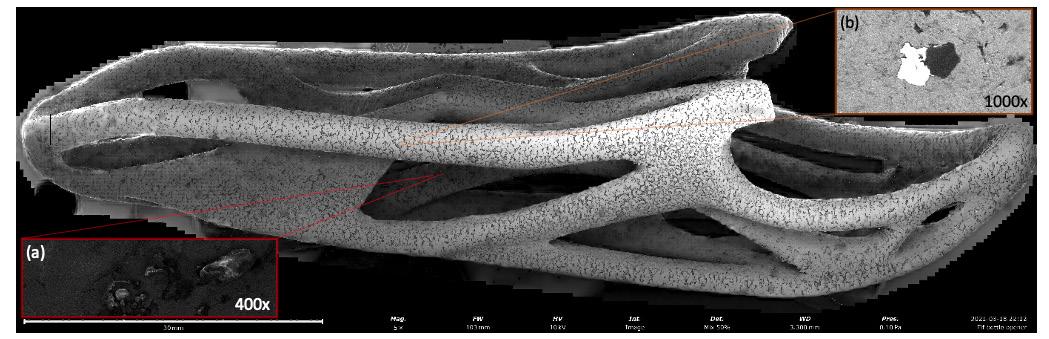

Figure 3. High-res select-area BSD-SED hybrid scan of an Aluminium (Al) bottle opener reveals (a) an irregularity on an inner support beam and (b) trace foreign element - later identified as iron using EDS mapping (c). Approximate field of view of the Aluminium (Al) bottle opener represents an area 70mm x 20mm.

Challenge #2: Product integrity assessment

The ability to scan for defects assists AM to validate a finished product. The ParticleX AM has a scanning area of 100 mm x 100 mm which grants a large degree of freedom to image and assess the size and shape of whole parts or sections of a larger component simultaneously (left). By combining an imaging resolution of <8nm and magnifications up to 200,000x, properties such as structural integrity, print resolution, surface uniformity and phases across large surfaces can be determined to contribute unique insights not possible with other systems. The secondary electron detector (SED) integrated within the ParticleX AM reveals topological features in fine detail, therefore pores, cracks and inclusions can be readily detected. The high-contrast backscatter detector (BSD) is ideal for imaging phases and the distribution of elements, complementing the energy dispersive spectroscopy (EDS) detector for elemental identification.

Challenge #3: Feed recycling optimisation

Viability of an AM process relies on the efficient utilisation of expensive powder feeds. Although recycling can save cost, it may also change the size and shape distribution and/or even composition through contamination. The Phenom ParticleX AM can be used to monitor the integrity of recycled powders by using the automatic morphological and elemental analysis capability. ATA would like to thank Dr. Haopeng Shen, researcher at Monash Centre for Additive Manufacturing, for providing the titanium powders, and Amaero for the bottle opener featured herein.

Available for demo now: The new desktop Phenom ParticleX SEM

Requiring very little lab space, Phenom ParticleX offers in-house analysis and validation of 3D printed goods against industry-approved standards. Users can obtain high-quality images in just 40 seconds—three times faster than other desktop SEM systems on the market. Contact us for a demonstration or quote today!

ATA Scientific Pty Ltd +61 2 9541 3500 enquiries@atascientific.com.au www.atascientific.com.au