INDUSTRY NEWS

Phenom ParticleX AM Addresses the Challenges of Additive Manufacturing Source: ATA Scientific

Additive manufacturing (AM) is on track to revolutionise manufacturing processes by not only reducing costs but by creating complex parts that are not possible with traditional methods. The adoption of AM by many industries relies heavily on its ability to solve current manufacturing challenges. The Phenom ParticleX AM is a specialised high-resolution desktop scanning electron microscope (SEM) dedicated to aiding additive manufacturers improve to product quality. The ParticleX AM rapidly profiles feed powders for size and morphological distribution, as well as elemental

composition. Operators can then complete high-resolution imaging of the finished part to assess quality and look for defects in the print. This fully integrated system is simple to operate and eliminates the need for outsourcing for quality checks, speeding up time-to-market. Challenge #1: Feed quality analysis Obtaining regular-shaped and ideal size distribution of feed powder is crucial to creating high-quality parts. Smooth, regular-shaped particles flow more easily due to reduced friction and a lack of interlocking provides a more continuous powder bed. Additionally, achieving the optimal mix

of small and large particles is critical to densely packed beds. Therefore, understanding the morphology and size distribution of particles is the key to produce high-quality parts with a smooth finish and high strength. The ParticleX AM can be used to quickly identify the morphological and the elemental composition of thousands of feed particles. From the resultant size distribution, morphological and elemental profiles, a given batch of powder can be assigned for specific use as per internal criteria. ParticleX AM allows ready access to extensive information on the starting material to deliver a powerful method for improving the quality of the final product.

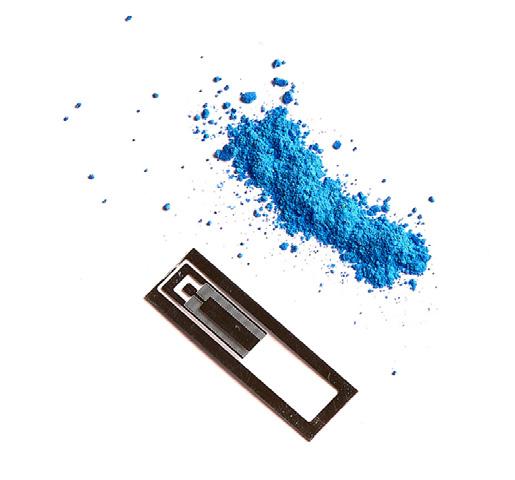

Figure 1. ParticleX AM quantitatively analyses the morphology of feed powder. The intuitive software enables the user to revisit standout particles instantly, and produce plots and reports.

Figure 2. Criteria for qualifying feed may be formed based on the content of fines amongst the feed.

26 | APRIL 2021

BACK TO CONTENTS

WWW.MATERIALSAUSTRALIA.COM.AU