VOLUME 55 | NO 3 SEPTEMBER 2022 ISSN 1037-7107 Official Publication of the Institute of Materials Engineering Australasia Limited Trading as Materials Australia | A Technical Society of Engineers Australia www.materialsaustralia.com.au CONFERENCES APICAM2023 PAGE 13 LMT2023 PAGE 15 UNIVERSITY SPOTLIGHT Edith Cowan University PAGE 36 Online Short Courses PAGE 55 Australia’s Aeronautical and Space Materials Market Takes Full Flight CL I C K A B LE L I N K S

From the President

Welcome to the September 2022 edition of Materials Australia magazine.

Since the last magazine was prepared, things have continued to move at full speed around us. It has been a very busy time for many Materials Australia members, with the northern hemisphere conferences in full swing. In my previous president’s message, I mentioned that I had recently attended two conferences. Since that time, I have attended another two and presented eight conference papers, all of which had been carried over from delayed events in 2020. Inflationary pressure globally is continuing to be a worry for many companies, and the difficulty in recruitment of staff is a global phenomenon. The ‘great resignation’ that has occurred over the past few years during the pandemic is impacting businesses all over the world. It has been forecast for some time that workers born in the mid to late 1950s would be retiring around 2020, but it seems the pandemic has exacerbated the issue, with those retirees suddenly unable to train new employees. At the recent World Congress on Investment Casting, for example, representatives from all over the world told the same story.

A topic that has arisen on multiple occasions recently from existing and prospective Materials Australia members is recognition of Materials Engineering as a discipline within Engineers Australia (EA). Currently, Materials Australia is a Technical Society within EA (as we do not have enough practising people for a separate college). This means that Materials Australia has, for example, aligned our CPD requirements with those of EA to reduce paperwork for people who are members of both. Part of this discussion has been spurred on by the requirement for engineers to be registered in Victoria and other states. I have personally had a lot of experience

with dealing with this topic so thought I might share some insights.

* If a person has a four year engineering undergraduate degree recognised under the Washington Accord, they are immediately able to meet the requirements of Stage 1 competency within EA upon graduation.

* If a person has a three or four year degree that is different to the above (such as a three year science degree plus postgraduate honours), and wishes to become a member of EA then the person needs to apply in writing to EA and have their qualifications recognised as meeting Stage 1 competency.

with the Mechanical College does not mean you are a Mechanical Engineer!

* Most qualified engineers should aim to gain Chartered status. This means you meet the requirements for EA Stage 2 competency, and this usually requires experience in a more developed role where supervision of complex projects may be involved. You can also be included immediately on the National Engineering Register without separate assessment. In some areas of practice, this means that you are able to certify engineering drawings, designs and compliance certificates. Gaining chartered status with EA also makes registration as a professional engineer in states such as Queensland and Victoria simpler.

* Later, people who attain more distinguished professional roles have the option of gaining Level 3 competency with EA (known as the Engineering Executive). This gives recipients chartered status in Leadership and Management together with their affiliated College, if they choose to retain it. If they haven’t already, they may also become registered as an International Professional Engineer and can be included on the APEC Engineer register if they choose.

* For people who attained their degree overseas from a non-accredited university, the person needs to have their qualifications assessed by EA to ensure they meet the competency requirements before working as a professional engineer.

* When you join EA, you choose a ‘College’ to be affiliated with. This is the most contentious issue for materials engineers, since for EA this is the Mechanical College. This affiliation includes not only Mechanical Engineers, but all other engineering disciplines who work in the field, including manufacturing, industrial engineering, and a surprisingly large number of other fields. Importantly, being affiliated

With respect to advocating for Materials Engineering within the engineering disciplines, I take part in the EA meetings on this topic with other technical societies, and currently EA’s position is to maintain the status quo, at least for now.

It’s hard to believe the year is nearly over, but when I think of where we were only 12 months ago to where we are now, it is quite extraordinary. Like many people, I have travelled a lot internationally (having flown over 72,000km this year already), and tried to keep on top of a very busy workload.

The year is quickly coming to a close, and I would like to wish you, your family and colleagues the best of health and to stay safe through the remainder of 2022. We have a lot ahead of us in 2023!

Best Regards

Roger Lumley

National President Materials Australia

Roger Lumley at the World Conference on Investment Casting, Anaheim, USA, 2023

Roger Lumley at the World Conference on Investment Casting, Anaheim, USA, 2023

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS SEPTEMBER 2022 | 3 MATERIALS AUSTRALIA

36 MANAGING EDITOR Gloss Creative Media Pty Ltd EDITORIAL COMMITTEE Prof. Ma Qian RMIT University Dr. Jonathan Tran RMIT University Tanya Smith MATERIALS AUSTRALIA ADVERTISING & DESIGN MANAGER Gloss Creative Media Pty Ltd Rod Kelloway (02) 8539 7893 PUBLISHER Materials Australia Technical articles are reviewed on the Editor’s behalf PUBLISHED BY Institute of Materials Engineering Australasia Ltd. Trading as Materials Australia ACN: 004 249 183 ABN: 40 004 249 183 Cover Image From feature article on page 44. Letters to the editor; info@ glosscreativemedia.com.au 13 CONTENTS 4 | SEPTEMBER 2022 WWW.MATERIALSAUSTRALIA.COM.AU Reports From the President 3 Contents 4 Corporate Sponsors 6 Advertisers 7 Materials Australia News WA Branch Technical Meeting - 11 July 2022 8 WA Branch Meeting Report - 8 August 2022 9 QLD Branch Report - 6 July 2022 10 SA Branch Report 12 APICAM2023 13 VIC | TAS Branch Report - 2 September 2022 14 NSW Branch Report 15 LMT 2023 15 CMatP Profile: Professor Gwénaëlle Proust 16 Our Certified Materials Professionals (CMatPs) 18 Why You Should Become a CMatP 19 MISE2023 21 28 CLI C K A B LE L I N K S

Industry News

RAYMAX:

Achieving Consistent

Topological Superconductors: Fertile Ground

Elusive Majorana

and DST Group Commission Australia’s First 2800°C Thermophysical

20

22

26

Analyser 27

The Australian Research Council Commits $5 million to Establish UOW Centre for Training and Research into the

of Mining

28

HRL Technology Group: What Makes Them Different 29

New Shape-Shifting Material can Move like a Robot 30

PPE Can Be Recycled To Make Stronger Concrete 31

AXT Appointed Australian Distributor for Exaddon’s Metal Additive Micromanufacturing Technology 32

World’s First Spectral CT – Combining Chemical Composition Analysis with Non-Destructive 3D Imaging 33

CSIRO to Create World's Best Respirator for Defence Force Personnel with Australian Business 34

Lastek: Photonics Technology Solutions 35

University Spotlight - Edith Cowan University 36

Feature - Australia’s

-

Courses

https://www.materialsaustralia.com.au/training-courses-and-

This magazine is the official journal of Materials Australia and is distributed to members and interested parties throughout Australia and internationally.

Materials Australia welcomes editorial contributions from interested parties, however it does not accept responsibility for the content of those contributions, and the views contained therein are not necessarily those of Materials Australia.

Materials Australia does not accept responsibility for any claims made by advertisers.

All communication should be directed to Materials Australia.

Materials Australia National Office PO Box 19 Parkville Victoria 3052 Australia T: +61 3 9326 7266 E: imea@materialsaustralia.com.au W: www.materialsaustralia.com.au NATIONAL PRESIDENT Roger Lumley 48 46 40 CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU SEPTEMBER 2022 | 5

Making Light Work for You

Essential Tools for

Quality in Additive Manufacturing

for

Particle

NETZSCH

Property

Future

Equipment

Breaking News 38

Aeronautical and Space Materials Market Takes Full Flight 44 MA

Short

55

workshops/online-training Join Now! 56

Corporate Premium Corporate Sponsors

6 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU MATERIALS AUSTRALIA

-

MATERIALS AUSTRALIA Corporate Advertisers

SEPTEMBER 2022 GLOBAL STEEL HEAT TREATMENT WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS SEPTEMBER 2022 | 7 APICAM2022

WA Branch Meeting Report - 11 July 2022 Joint meeting with Australian Corrosion Association

Stainless Steel – Not just a Single Alloy

Source: Stuart Folkard, Principal Materials and Corrosion Engineer, Wood

Stuart Folkard (Principal Materials and Corrosion Engineer, Wood) recently presented to the Western Australian Branch on the topic Stainless steelnot just a single alloy.

Stuart recently returned to the Wood office, having been seconded to Chevron’s Gorgon Foundation and Gorgon Stage 2 projects over the last 13 years. Prior to joining Wood, Stuart spent almost 20 years in the stainless steel industry in South Africa with Columbus Stainless.

The term ‘stainless steel’ refers to a large number of iron-based alloys, each of which has different properties and service behaviour. Stuart’s presentation summarised how the alloys are grouped and classified and provided an overview of each group’s chemical, mechanical and corrosion resistance properties. He also referred to some aspects of fabrication, as well as the typical applications in which these alloys are used.

The defining feature of a stainless steel is that the surface can form a thin transparent protective coating of chromium dioxide, referred to as a passive film. In order to form this film, the minimum chromium content must be approximately 11-12 weight percent. Stuart emphasised that thermal scales and oxides are not protective, and that when the passive film is destroyed, as in welding, the surface must cleaned by pickling, and re-passivated.

The broadest division of stainless steels is based on the predominant crystalline phases present in the alloy: ferrite (bcc), austenite (fcc), and martensite (metastable tetragonal). Stuart pointed out how the major alloying elements (chromium, nickel and manganese) stabilise different crystal phases found in the iron-carbon phase diagram, and how they affect the potential to form the brittle intermetallic sigma phase.

Phase composition in stainless steels is complex, but the Schaeffler diagram provides a convenient approximate summary. This delineates phase

regions against two axes: equivalent nickel content and equivalent chromium content. Commercial stainless steels grades fall into an area in which, depending on grade, the phases present vary from 100 percent austenite, through ferrite and martensite to 100% ferrite. This diagram is particularly useful in specifying welding of stainless steels.

Stuart provided a broad overview of grades and their uses. He described the common ferritic grades 409 and 430, the common (but more expensive) nickel-containing austenitic grades 304 and 316 (‘18-8’: 18% chromium and 8% nickel) and the martensitic grades 410, 420 and 440, which are essentially ferritic grades with high carbon content. The more complex (and generally more expensive duplex grades, such as 2507, contain both austenite and ferrite. Precipitation hardening grades, like 17-4PH are supplied in a soft annealed state and are subsequently heat treated to develop high strength.

Referring to general mechanical properties, austenitic grades are ductile and can be work hardened, ferritic grades are ductile, while martensitic grades are not so ductile, but are amenable to heat treatment.

While it is corrosion resistance that gives stainless steels their name, and they are generally resistant to corrosion on exposed surfaces with intact passive films coverage, they are not infallible. While general corrosion can occur, it is usually easily monitored. The particular issue with stainless steels is the potential for rapid localised corrosion.

One of the common failings of cheaper grades is resistance to pitting corrosion. This occurs when the passive film is damaged at localised points, particularly in the presence of high concentrations of chloride ions. Once a small area becomes anodic, with the remaining (and much larger) undamaged area being relatively cathodic, the corrosion current is increased in the anodic area

leading to rapid penetration (‘pitting’).

The stability of the passive film increases with chromium content, and also with other alloying elements present in various grades. This is summarised by the pitting resistance equivalence number, which relates the influence of other elements to that of chromium.

Another common type of corrosion failure is crevice corrosion, as can easily occurs under bolt heads. Again, the large cathodic area presented by the non-corroding external surface drives rapid corrosion under the head, where it might not be visible.

The third common form of localised corrosion of stainless steels is stress corrosion cracking, to which austenitic stainless steels are susceptible. The presence of ferrite in duplex grades means that growth of stress corrosion cracks in the austenite can be arrested when they encounter ferritic grains.

Another mode of failure is intergranular corrosion, which can occur when carbides are deposited in grain boundaries adjacent to welds.

Stuart concluded with a review of common applications of stainless steels. The bulk of production is of cheaper ferritic grades, which are widely used where the objective is aesthetic; the highalloy grades, including duplex grades, make up about 25% of production.

After the conclusion of his talk, Stuart’s expertise proved to be in high demand as he answered audience questions at this well attended meeting.

L to R: Schree Chandran, Stuart Folkard

MATERIALS AUSTRALIA

8 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

WA Branch Meeting Report - 8 August 2022

Joint meeting with Australian Foundry Institute

Weld Repair of 1960s Low Alloy Cast Turbine Casing with Microstructure Replication

Source: Louise Petrick, Senior Welding Engineer, Materials & Welding Solutions

Louise Petrick recently presented a case study for the Western Australian Branch on Weld repair of 1960s low alloy cast turbine casing with microstructure replication.

Louise is a Senior Materials and Welding Engineer with Materials and Welding Solutions. Prior to this, she provided materials and welding consulting support through Weld Australia, where she worked for six years. Her power generation experience started at Eskom in South Africa, where she spent eight years, and continued after her move to Australia with two years at Synergy, supporting Muja Power Station. Louise started her engineering career at Highveld Steel and Vanadium after completing a research masters on welding and corrosion of stainless steel (at the University of Pretoria) before moving to Mintek, working on corrosion research.

The case study concerned weld repairs to three steam turbine casings so that they could be de-mothballed and returned to service, with an expected additional service life of at least 15 years. The turbines had been in continuous use for around 20 years from the late 1960s and had been mothballed for nearly 20 years after that. They had been cast from a proprietary Cr-Mo-V low alloy steel, made at a time when there was limited capacity for control of tramp impurity elements.

They had been operating in the temper embrittlement, and creep, temperature range for around 150,000 hours (longer than their 100,000-hour design life), and had also been subjected to low cycle fatigue through around 150 cold starts over that time. Non-destructive testing revealed manufacturing defects, cracks, and a number of cosmetic carbon steel weld repairs.

Louise became involved as a specialist

welding engineer after the maintenance team attempted a weld repair with nickel, expecting that this relatively ductile metal would accommodate any stresses induced by welding. It did not. The result was nearly disastrous, with deep cracking occurring in the cast metal surrounding the filled area.

The welding specialist team was brought in see if the situation could be remedied. Initial testing showed that the cast metal had a Charpy impact energy absorption of about 5J – tougher than a cracker biscuit, but so brittle as to require exceptional care as a candidate material for weld repair.

The prescribed solution, developed jointly with the maintenance team and the OEM, was to excavate the cracked material and undertake a full weld repair with post-weld heat treatment to match microstructure. In a few areas, the excavation required machining away 90% of the 80mm casing thickness.

The process selected was manual metal arc welding with the smallest available electrode of similar composition, with minimal penetration and a prescribed pattern of overlapping beads so that each deposit normalised the underlying ones.

The practical challenge was how to achieve this. The solution was to bolt the two halves of the casing together, to avoid distortion. However, this meant that the welder had to work inside the casing, which was stood vertically, with steps to give the welder access. The additional complication was that the casing had to be heated to around 200°C (with ceramic bead heaters). This meant that the welder had to wear a full heat-reflective suit, and each member of the welding team could only lay one rod before exiting the casing.

After each layer of deposit had been completed, the casing was allowed

to cool to 100°C for magnetic particle inspection. After completion of the repair, the casing was heated to 700°C (with ceramic bead blankets), held for around four hours, cooled under control to 300°C and finally allowed to cool under the unheated blanket.

It all worked, and the passing of time has proved that desired life extension had been obtained.

Louise illustrated her presentation with photographs of casings, the welding being undertaken and photomicrographs of replicas showing the microstructures, including defects, cracks, grain boundary precipitates and creep voids.

The very engaged audience had many questions for Louise, and one in particular drew a most emphatic response. This concerned excavation of the cracks prior to welding. Working with such a brittle metal, grinding was absolutely not an option; grinding simply propagated the cracks.

Louise explained that when this work was done in 2006, Eskom had a fully integrated operational, maintenance, R&D and internal consultancy structure. Whether such an ambitious repair could (or would) be undertaken with outsourced repair capacity and outsourced consultancy remains an intriguing question.

L to R: Schree Chandran, Louise Petrick, John Wootton

MATERIALS AUSTRALIA

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS SEPTEMBER 2022 | 9

QLD Branch Report - 6 July 2022

ICEFA IX Wraps Up Six in a Row for Dr Richard Clegg

Source: Dr Richard Clegg

The 9th International Conference on Engineering Failure Analysis (ICEFA IX) was held online from 11 to 13 July 2022. Organised jointly by Elsevier and the journal, Engineering Failure Analysis, and originally scheduled to run in-person in 2020 in Shanghai, the conference was postponed a number of times due to the pandemic. Unfortunately, an in-person conference in Shanghai was also not achievable, so the joint Chairs of the conference; Queensland Materials Australia Member and CMatP Dr Richard Clegg of Queensland University of Technology (QUT) and Explicom, and Professor Zhen-Guo Yang of Fudan University in Shanghai, worked hard with the team at Elsevier to make the conference a success. While ICEFA had not been run in an online only mode before, Elsevier has had considerable experience in virtual conferences since the beginning of the pandemic.

The total number of delegates was 225, with 124 oral presentations and 118 poster presentations. The conference also had five plenary lecturers: three from China, one from Portugal and one from Brazil. The conference was well supported by the Chinese Failure Analysis Institution of the Chinese Mechanical Engineering Society, with many delegates from China in attendance. Programming the conference over many time zones presented a challenge, particularly to ensure that no-one was being asked to present at 3am.

The Chairs were grateful to the commercial sponsors who helped support the conference and contributed some very interesting presentations through the sponsors session. Although the conference committee look forward to the return of in-person events, the tools now

available to run online conferences are impressive and worked well.

This was the sixth ICEFA Conference that Dr Clegg helped organise, the first being in 2010 in Cambridge, United Kingdom. The ICEFA conference series first started in Lisbon in 2004 and was organised by Dr Dai Jones, the former Editor-in-Chief of the journal Engineering Failure Analysis.

As Dr Clegg took over the role of Editorin-Chief in 2009, this came with the responsibility of helping organise the conferences. In 2022, a new Editor-inChief of Engineering Failure Analysis was appointed, Professor Cesar Azevedo of the University of Sao Paulo. Dr Clegg will continue his affiliation with the journal as a member of the Editorial Board and Honorary Editor and is looking forward to having more time to pursue other projects back in Australia.

QLD Branch Report

Materials Selection, Choice and its Importance to Engineers – Andy Reilly

Source: Dr Richard Clegg

In conjunction with Engineers Australia, the Queensland Branch of Materials Australia hosted a presentation on 6 July by Andy Reilly of Total Materia, entitled Materials selection, choice and its importance to engineers.

Andy has over 30 years of engineering software experience, particularly with CAD, CAE, PLM and enterprise materials tools and processes.

Total Materia is a Swiss-based company that has developed an online database and software system for the

management of engineering materials data. It is now one of the largest materials databases in the world. Andy discussed the importance of managing the materials selection process and materials data for modern engineering firms, particularly from the perspective of managing IP and compliance issues. He also introduced the capabilities of the Total Materia system and how it can integrate with modern CAD and CAE systems.

As Andy is based in the United Kingdom,

so the presentation was available by webinar. It is very exciting that the technologies available at Engineers Australia can enable us to hear from speakers from around the world without needing to travel. Over 360 people registered for the presentation, with over 200 attending the talk live, with many choosing to view the recording after the event. The talk was followed by a lively discussion, moderated by Dr Richard Clegg. The Queensland Branch of Materials Australia is grateful to Andy for his time and expertise.

MATERIALS AUSTRALIA

10 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU Dr.Richard

Dr.Richard Clegg

gold nanoparticles screening chemicals uorescent microparticles 99.999% ruthenium spheres process synthesis cryo-electron microscopy transparent ceramics diamond micropowder alternative energy dysprosium pellets sputtering targets 3D graphene foam tungsten carbide refractory metals glassy carbon macromolecules isotopes epitaxial crystal growth drug discovery biosynthetics quantum dots superconductors spectroscopy metamaterials platinum ink Fe3O4 rare earth metalsspintronics thin lm osmium buckyballs zeolites Nd:YAG enantioselective catalysts dielectrics deposition slugs organometallics janus particles optical glass © 2001-2021. American Elements is a U.S.Registered Trademark mesoporous silica chalcogenides laser crystals calcium wiresindicator dyes graphene oxide shift reagents ferro uid metallocenes CVD precursors silver nanoparticles MOFs palladium catalysts nickel foam bioactive compounds III-IV semiconductors metal carbenes ITO pharmacoanalysis nano ribbons nanogels surface functionalized nanoparticles cermet anode excipients ultralight aerospace alloys rhodium sponge nanodispersions cisplatin conjugated nanostructures h-BN MOCVD BINAP InGaAs NMR ZnS AuNPs EuFOD YBCOMBE Now Invent. TM The Next Generation of Material Science Catalogs American Elements opens a world of possibilities so you can Now Invent! Over 30,000 certi ed high purity laboratory chemicals, metals, & advanced materials and a state-of-the-art Research Center. Printable GHS-compliant Safety Data Sheets. Thousands of new products. And much more. All on a secure multi-language "Mobile Responsive” platform. www.americanelements.com 1.00794 Hydrogen 1 1 H 6.941 Lithium 3 2 1 Li 9.012182 Beryllium 4 2 2 Be 22.98976928 Sodium 11 2 8 1Na 24.305 Magnesium 12 2 8 2Mg 39.0983 Potassium 19 2 8 8 1K 40.078 Calcium 20 2 8 8 2Ca 85.4678 Rubidium 37 2 8 18 8 1Rb 87.62 Strontium 38 2 8 18 8 2Sr 132.9054 Cesium 55 2 8 18 18 8 1Cs 137.327 Barium 56 2 8 18 18 8 2Ba (223) Francium 87 2 8 18 32 18 8 1 Fr (226) Radium 88 2 8 18 32 18 8 2 Ra 44.955912 Scandium 21 2 8 9 2Sc 47.867 Titanium 22 2 8 10 2Ti 50.9415 Vanadium 23 2 8 11 2V 51.9961 Chromium 24 2 8 13 1Cr 54.938045 Manganese 25 2 8 13 2Mn 55.845 Iron 26 2 8 14 2Fe 58.933195 Cobalt 27 2 8 15 2Co 58.6934 Nickel 28 16Ni 63.546 Copper 29 2 8 18 1Cu 65.38 Zinc 30 2 8 18 2Zn 88.90585 Yttrium 39 2 8 18 9 2Y 91.224 Zirconium 40 2 8 18 10 2Zr 92.90638 Niobium 41 2 8 18 12 1Nb 95.96 Molybdenum 42 2 8 18 13 1Mo (98.0) Technetium 43 2 8 18 13 2Tc 101.07 Ruthenium 44 2 8 18 15 1Ru 102.9055 Rhodium 45 2 8 18 16 1Rh 106.42 Palladium 46 18 18Pd 107.8682 Silver 47 2 8 18 18 1Ag 112.411 Cadmium 48 2 8 18 18 2Cd 138.90547 Lanthanum 57 2 8 18 18 9 2La 178.48 Hafnium 72 2 8 18 32 10 2Hf 180.9488 Tantalum 73 2 8 18 32 11 2Ta 183.84 Tungsten 74 2 8 18 32 12 2W 186.207 Rhenium 75 2 8 18 32 13 2Re 190.23 Osmium 76 2 8 18 32 14 2Os 192.217 Iridium 77 2 8 18 32 15 2Ir 195.084 Platinum 78 18 32 17Pt 196.966569 Gold 79 2 8 18 32 18 1Au 200.59 Mercury 80 2 8 18 32 18 2Hg (227) Actinium 89 2 8 18 32 18 9 2 Ac (267) Rutherfordium 104 2 8 18 32 32 10 2 Rf (268) Dubnium 105 2 8 18 32 32 11 2 Db (271) Seaborgium 106 2 8 18 32 32 12 2Sg (272) Bohrium 107 2 8 18 32 32 13 2 Bh (270) Hassium 108 2 8 18 32 32 14 2 Hs (276) Meitnerium 109 2 8 18 32 32 15 2 Mt (281) Darmstadtium 110 18 32 32 17Ds (280) Roentgenium 111 2 8 18 32 32 18 1Rg (285) Copernicium 112 2 8 18 32 32 18 2 Cn 4.002602 Helium 2 2 He 10.811 Boron 5 2 3 B 12.0107 Carbon 6 2 4 C 14.0067 Nitrogen 7 2 5 N 15.9994 Oxygen 8 2 6 O 18.9984032 Fluorine 9 2 7 F 20.1797 Neon 10 2 8 Ne 26.9815386 Aluminum 13 2 8 3Al 28.0855 Silicon 14 2 8 4Si 30.973762 Phosphorus 15 2 8 5P 32.065 Sulfur 16 2 8 6S 35.453 Chlorine 17 2 8 7Cl 39.948 Argon 18 2 8 8Ar 69.723 Gallium 31 2 8 18 3Ga 72.64 Germanium 32 2 8 18 4Ge 74.9216 Arsenic 33 2 8 18 5As 78.96 Selenium 34 2 8 18 6Se 79.904 Bromine 35 2 8 18 7Br 83.798 Krypton 36 2 8 18 8Kr 114.818 Indium 49 2 8 18 18 3In 118.71 Tin 50 2 8 18 18 4Sn 121.76 Antimony 51 2 8 18 18 5Sb 127.6 Tellurium 52 2 8 18 18 6Te 126.90447 Iodine 53 2 8 18 18 7I 131.293 Xenon 54 2 8 18 18 8Xe 204.3833 Thallium 81 2 8 18 32 18 3Tl 207.2 Lead 82 2 8 18 32 18 4Pb 208.9804 Bismuth 83 2 8 18 32 18 5Bi (209) Polonium 84 2 8 18 32 18 6Po (210) Astatine 85 2 8 18 32 18 7At (222) Radon 86 2 8 18 32 18 8Rn (284) Nihonium 113 2 8 18 32 32 18 3 (289) Flerovium 114 2 8 18 32 32 18 4 Fl (288) Moscovium 115 2 8 18 32 32 18 5 (293) Livermorium 116 2 8 18 32 32 18 6 Lv (294) Tennessine 117 2 8 18 32 32 18 7 (294) Oganesson 118 2 8 18 32 32 18 8 140.116 Cerium 58 2 8 18 19 9 2Ce 140.90765 Praseodymium 59 2 8 18 21 8 2Pr 144.242 Neodymium 60 2 8 18 22 8 2Nd (145) Promethium 61 2 8 18 23 8 2Pm 150.36 Samarium 62 2 8 18 24 8 2Sm 151.964 Europium 63 2 8 18 25 8 2Eu 157.25 Gadolinium 64 2 8 18 25 9 2Gd 158.92535 Terbium 65 18 27Tb 162.5 Dysprosium 66 2 8 18 28 8 2Dy 164.93032 Holmium 67 2 8 18 29 8 2Ho 167.259 Erbium 68 2 8 18 30 8 2Er 168.93421 Thulium 69 2 8 18 31 8 2Tm 173.054 Ytterbium 70 2 8 18 32 8 2Yb 174.9668 Lutetium 71 2 8 18 32 9 2Lu 232.03806 Thorium 90 2 8 18 32 18 10 2 Th 231.03588 Protactinium 91 2 8 18 32 20 9 2 Pa 238.02891 Uranium 92 2 8 18 32 21 9 2 U (237) Neptunium 93 2 8 18 32 22 9 2Np (244) Plutonium 94 2 8 18 32 24 8 2 Pu (243) Americium 95 2 8 18 32 25 8 2 Am (247) Curium 96 2 8 18 32 25 9 2 Cm (247) Berkelium 97 18 32 27Bk (251) Californium 98 2 8 18 32 28 8 2 Cf (252) Einsteinium 99 2 8 18 32 29 8 2 Es (257) Fermium 100 2 8 18 32 30 8 2 Fm (258) Mendelevium 101 2 8 18 32 31 8 2 Md (259) Nobelium 102 2 8 18 32 32 8 2 No (262) Lawrencium 103 2 8 18 32 32 8 3 Lr Nh Mc Ts Og

SA Branch Report South Australian Branch Visits Defence Science and Technology’s Research Engineering Division

Source: Colin Hall

Defence is becoming a major focus for South Australia. The construction of the Hunter Class Frigates, the service life extension of the Collins Class submarines and the Future submarines are three majors programs—just to name a few.

The focus of the Defence Science and Technology (DST) group on the six new STaR Shot programs has also brought greater focus on research and force structure alignment (https://www.dst. defence.gov.au/strategy/star-shots).

With this also comes the strategy of expanding DST’s collaborative effort with universities and industry partners. Underpinning this activity will be enhanced material science requirements—a perfect match with Materials Australia and its members.

The Materials Australia South Australia branch recently visited the Research Engineering department at Edinburgh. Research engineering delivers specialised engineering, design and fabrication solutions to DST, Defence and industry. Their areas of expertise are:

Electronic engineering and fabrication

• Complex electronic hardware design and fabrication

• Surface Mount Assembly Technologies

— automatic loading, assembly and inspection of printed circuit boards in prototype quantities

• Software engineering with embedded or hosted software

• Firmware and printed circuit board design

Mechanical engineering and fabrication

• Complex mechanical engineering, design and fabrication

• Design and development of complex electromechanical systems

• Additive manufacturing — metallic and polymer 3D printing capability

• 3, 4 and 5 axis simultaneous machining for complex geometries

• Sheet metal, welding, model making and carpentry Microengineering

• Microfabrication

• Micro-packaging and metrology

• Laser micromachining

We spent around an hour touring their facilities, including their cleanroom facilities for their

Advertise with Materials Australia!

Email rod@materialsaustralia.com.au for more information

Advertising with Materials Australia will give you the opportunity to:

• Maintain and build on professional relationships

• Connect with a highly targeted audience

• Showcase your new products and services

• Gain instant market feedback

• Increase and strengthen brand awareness

• Stay at the forefront of industry developments and innovations

• Show your dedication to, and support of, the industry

electronic fabrication processes and the additive manufacturing area with their extensive metal and plastic printing capability. It was a great tour that was enjoyed by all. We even left with a gift, the team had some bottle openers additively manufactured for us. Given the limitation to numbers we will look to run this visit again later next year.

Above: A gift of an additively manufactured bottle opener. Below: SA branch members after the visit to DSTG

MATERIALS AUSTRALIA 12 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

21st - 23rd June 2023 | The University of Sydney

CALL FOR ABSTRACTS

Abstracts

21st - 23rd June 2023

The University of Sydney

The 3rd Asia-Pacific International Conference on Additive Manufacturing (APICAM) is the not-to-be-missed industrial application focused conference of 2023.

The 5th Asia-Pacific International Conference on Additive Manufacturing (APICAM) is the not-to-be-missed industry conference of 2023. APICAM was created to provide an opportunity for industry professionals and thinkers to come together, share knowledge and engage in the type of networking that is vital to the furthering of the additive manufacturing industry.

APICAM was created to provide an opportunity for industry professionals and academic researchers to come together, share knowledge and engage in the type of networking that is vital to the furthering of the additive manufacturing industry.

Some of the leading minds in the industry will give presentations on pressing issues and the ways in which innovations can navigate challenges. Important areas such as 3D printing and additive manufacturing in the automotive, biomedical, defence and aerospace industries will be covered by experts from each respective field.

Some of the leading minds in the field of additive manufacturing will give presentations on pressing issues and the ways in which innovations can navigate challenges. Important areas such as applications of additive manufacturing in the, biomedical, defence and aerospace industries will be covered by experts from each respective field.

The event is being curated by Materials Australia, the peak Australian materials technology body, which has drawn on its considerable pull in the industry to create a world-class event that is a must-attend for anyone involved in the additive materials industry.

The purpose of this conference is to provide a focused forum for the presentation of advanced research and improved understanding of various aspects of additive manufacturing.

CALL FOR ABSTRACTS

You can submit an abstract in the following areas of interest:

TO

Additive Manufacturing Defence Application

Additive Manufacturing Green/Clean Energy

Abstracts are able to be submitted in the following areas:

Additive Manufacturing Space Application

Additive Manufacturing of Metals

Additive Manufacturing PostProcessing

Additive Manufacturing of Polymers

Additive Manufacturing of Concretes

Bioprinting and Biomaterials

Advanced Characterisation Techniques and Feedstocks

The main features of APICAM 2023 will include presentations by experts as well as workshops that will help attendees sharpen their skills and then be able to pass on this knowledge to other industry professionals. The event has been designed to allow for ample networking time so that important knowledge-transfer can take place and partnerships can be created that will enrich the industry.

The APICAM2023 organizing committee is seeking abstracts for either an oral or poster presentation.

Enquiries:

Tanya Smith | Materials Australia

+61 3 9326 7266 | imea@materialsaustralia.com.au

www.apicam2023.com.au

Enquiries: Tanya Smith | Materials Australia +61 3 9326 7266 | imea@materialsaustralia.com.au

Computational Modelling of Thermal Processes for Metallic Parts

Ceramic and Concrete Additive Manufacturing Design, Qualification and Certification

Part Design for Additive Manufacturing Failure Mechanisms and Analysis

Digital Manufacturing

Emerging Additive Manufacturing Technologies

Mechanical Properties of Additively Manufactured Materials

Metal Additive Manufacturing Modelling and Simulations

New Frontiers in Additive Manufacturing Process Parameter and Defect Control

Polymer Additive Manufacturing Sustainability

Process-Microstructure-Property Relationships

Testing and Qualification in Additive Manufacturing

Asia-Pacific International Conference on Additive Manufacturing

APICAM2023 - CLICK HERE TO SUBMIT

close31 January 2023

APICAM2023

www.apicam2023.com.au CLICK HERE

SUBMIT YOUR ABSTRACT

VIC | TAS Branch Report - 2 September 2022

24th Annual Technologists' Picnic

The Design Parameters of Bicycles Used For Travel, with an Historical Perspective

Guest Speaker: Noel McFarlane

The 24th Annual Technologists' Picnic was well attended, with Materials Australia members from Geelong and Melbourne joining those from Ballarat to welcome Noel McFarlane as our guest speaker. Noel very generously flew in from Tasmania for the event.

Noel gave a personal and interesting presentation on the historical development of a touring bicycle. Noel has been involved in the Australian bicycle industry for nearly 50 years and was pleased to share his knowledge with attendees.

Noel emphasised that the essential qualities of a touring bicycle are reliability, stability under heavy loads, ease of

repair in isolated locations and comfort during long hours in the saddle. Consequently the key criteria for a road racing bike—namely the need for lightness and manoeuvrability— are secondary considerations in a loaded touring bike.

Noel personally road tests all of the components that he uses in the construction of his ‘Vivente’ touring bikes. He enjoys seeking out challenging road surfaces in different countries on which to test the bicycles; an enviable and necessary requirement for continuous improvement.

There were several questions from an appreciative audience that included interested members of local cycling clubs. The questions related to the type of materials used in the construction of the frame, forks, brakes, drive assembly, tyres, lighting, handle bars and saddles.

In answering all of the questions, Noel confirmed that the guiding principle is that the material selection and types of components must primarily improve the reliability and performance of the bicycle within a reasonable cost.

Noel was loudly applauded for his excellent presentation and his generosity in travelling from Tasmania for the event. He was then thanked by representatives of the five participating groups and presented with a fluid expression of appreciation.

Above: The traditional thanks to the guest speaker from the participating groups.

(L to R): John Everton (EA), Graham Sussex (MA), Peter Darveniza (AusIMM), Noel McFarlane (Guest Speaker), Gary Bunn (Convenor), Alan Cooke (AFI), Scott Wade (ACA).

Right: The cosy Charlie Napier Hotel was filled to capacity for Noel McFarlane's presentation.

An appreciative Gary presents Noel with a bag of Ballarat gold.

Right: The cosy Charlie Napier Hotel was filled to capacity for Noel McFarlane's presentation.

An appreciative Gary presents Noel with a bag of Ballarat gold.

MATERIALS AUSTRALIA

14 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

MATERIALS AUSTRALIA

NSW Branch Report

Source: Dr Rachel White

The latter part of this year is full of events for the New South Wales (NSW) Materials Australia Branch.

On 20 September, our Certified Materials Professional miniconference was held once again. The speakers this year included:

Dr Yi-Sheng (Eason) Chen (University of Sydney) who spoke about hydrogen embrittlement in alloys

Dr David Harrison (Galvanizers Association of Australia) who spoke about atmospheric corrosion exposure testing of zinc alloy coatings in a C5 environment

Waldemar Radomski (Plastral) who spoke about welding techniques for plastic and composite materials

Dr Mark Reid (ANSTO) who spoke about neutron diffraction for the measurement of residual stress in additive manufacturing

· Dr Olga Zinovieva (UNSW Canberra) who spoke about process-structure-property modelling in laser powder bed based additive manufacturing

In October, the University of NSW (UNSW) student materials society (MATSOC) will be running a careers event. The committee will be supporting this event, along with the Australian Ceramic Society.

We are excited to announce that our popular student presentation event will be held as a hybrid event this year. This will take place in early November and we are currently confirming a venue at UNSW. Each year we have a number of undergraduate students present their work. Prizes from branch sponsors are awarded by a judging panel. We will advertise the date when it is confirmed.

Fundamentals of Metallurgy and Additive Manufacturing

17 to 19 August 2022

Materials Australia NSW branch held its annual Fundamentals of Metallurgy and Additive Manufacturing training course from 17 to 19 August 2022 in a virtual format. The course was co-sponsored by the ARC Industrial Transformation Training Centre in Surface Engineering for Advanced Materials (SEAM) at Swinburne University of Technology. Attracting industry and academic attendees from South Australia, Victoria and New South Wales, the event covered a range of different topics related to traditional metallurgy and additive manufacturing.

The course consisted of an introduction session chaired by NSW Materials Australia president, Dr Rachel White followed by three days of lectures by Professor Huijun Li and Professor Madeleine du Toit from the University of Wollongong, and Dr Nima Haghdadi from UNSW Sydney. The course was closed with a Q&A and open discussion session hosted by Professor Madeleine du Toit and Dr Nima Haghdadi.

Despite all the efforts to make this event interactive and success in attracting interstate attendees, we all miss the good old days when this course was facilitated in-person and provided an opportunity for demonstrations and lab tours. We hope this can happen next year.

The Light Metals Technology (LMT) Conference is a biennial event that focuses on recent advances in science and technologies associated with the development and manufacture of aluminium, magnesium and titanium alloys and their translation into commercial products. The conference presents an opportunity for academic researchers, students and industry to discuss cutting edge developments and to facilitate new collaborations.

CALL FOR ABSTRACTS

You are invited to submit abstracts on topics within the themes of Net Shape Manufacturing, Solid State Transformations and Mechanical Performance, and Translation to Applications.

For example, but not limited to:

> Alloy development

> Solidification and casting

> Thermomechanical processing and forming

> Machining and subtractive processes

> Mechanical behaviour of light metal alloys

> Corrosion and surface modification

> Advanced characterisation techniques

> Joining

> Applications in bio-medical, automotive, aerospace, and energy industries

> Simulation and modelling

> Integrated computational materials engineering

Opportunities for sponsorships and exhibitions are available for both APICAM2022 and LMT2023.

Enquiries: Tanya Smith Materials Australia

+61 3 9326 7266

imea@materialsaustralia.com.au

WWW.MATERIALSAUSTRALIA.COM.AU www.lmt2023.com

CMatP Profile: Professor Gwénaëlle Proust

in New Mexico, USA. Her research focuses on understanding and modelling the relationships between manufacturing, microstructure and properties of materials.

Where do you work and describe your job

Gwénaëlle Proust is a Professor of Materials Engineering at the University of Sydney. She started there in 2008 as a joint lecturer in the School of Civil Engineering and the Australian Centre for Microscopy and Microanalysis. Gwénaëlle studied in France and the USA and worked as a post-doctoral research associate at Los Alamos National Laboratory

I work at the University of Sydney where I share my time between the School of Civil Engineering, where I am a Professor, and the Sydney Manufacturing Hub for which I am the Academic Director. I have different responsibilities and duties with these two roles. I coordinate and teach a Unit of Study on Materials for the first-year students in our Bachelor of Engineering program, and I supervise honours and High Degree Research students on different research projects, some of which are in collaboration with industry.

I also oversee a Core Research Facility specialising in Additive Manufacturing, the Sydney Manufacturing Hub. This entails supervising technical and administrative staff, liaising with different offices at the university

to ensure the good running of the lab, networking with industry to promote additive manufacturing as a new solution to be included in their production lines, facilitating academic research projects, and carrying out my own research on material and technology development in this new and exciting field of additive manufacturing. What I like the most about my job is that each day is different.

What inspired you to choose a career in materials science and engineering?

When I started to look for an engineering program for my undergraduate studies, I was originally thinking of studying chemical engineering as I had enjoyed chemistry classes in high school, especially organic chemistry.

Then I saw an engineering school that was offering materials science and engineering, as well as some chemistry classes (like polymer chemistry, corrosion, adhesion and so

16 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU MATERIALS AUSTRALIA

on). The university also offered some manufacturing classes which, for me, seemed to be more applied than what was offered at the other chemical engineering programs I had looked at. I decided to apply to that materials science and engineering school and was accepted in their program. I enjoyed the variety of subjects that were offered. There were some very interesting hands-on laboratories that developed my passion for working in a laboratory.

My passion for research developed while I was studying for my Masters of Engineering in the USA. Originally, I move to the USA to gain some international experience and improve my English. I was thinking of staying there for two years maximum.

Eventually this turned into an eight-year long trip during which I obtained my PhD and worked at—in my opinion— one of the most iconic research places, Los Alamos National Laboratory.

Who or what has influenced you most professionally?

That is a difficult question to answer. I have had the chance to work with many great researchers since I started my research career. I had two fantastic supervisors for my PhD, Professor Surya Kalidindi and Professor Roger Doherty. Their ethics, dedication and innovative minds were quite an inspiration for me. They were also really supportive during my studies and provided me with great opportunities to pursue my career in research.

I was also very lucky to work along great minds in Los Alamos. I especially want to mention Professor Irene Beyerlein with whom I collaborated. At that time there were not many women in our research group so being able to see how successful and brilliant she was gave me quite a lot of hope for my career.

Which has been the most challenging job or project you’ve worked on to date and why?

I think the new role I have as the Academic Director of the Sydney Manufacturing Hub has been my biggest challenge so far. It forced me to get out of my comfort zone and to take more risks in my career.

I had to start interacting with different interlocutors than the traditional

academic crew I was used to. I had to take on new responsibilities and to become more engage with other aspects of the university life. It has been so rewarding to work in the Sydney Manufacturing Hub—I have no regrets taking on the challenge.

What does being a CMatP mean to you?

Being a CMatP means being part of a group of people with common interests and goals. It is also important as a recognition of the work I have done to reach my present role at the University of Sydney.

What gives you the most satisfaction at work?

I enjoy working with my team at the Sydney Manufacturing Hub and my colleagues in Civil Engineering. I have managed to build a very supportive and stimulating network at the university such that I can thrive in my work.

What is the best piece of advice you have ever received?

I think that would be the one I received from one of my mentors at the university who told me not to wait for opportunities to come to me, or for someone to tap on my shoulder, but to make my own opportunities and be more assertive. I think that’s advice

that everyone should follow. It has been quite rewarding for me to put it into practice.

What are you optimistic about?

There are many open research questions in the field of additive manufacturing. The Australian Government has made advanced manufacturing one of its priorities, so research support is available to progress in this field. I think materials scientists and engineers are well positioned to advance manufacturing in Australia and many opportunities exist for us to thrive.

What have been your greatest professional and personal achievements?

I would have to say that my personal and professional journeys have been quite successful thus far. I have lived on three different continents, made friends from all over the world and have a great job. Can’t complain!

What are the top three things on your “bucket list”?

Because I haven’t been able to travel as much in the last two years as I would have liked to, my bucket list at the moment is made of places I want to visit. The three firsts on my list are: Scotland, Peru and Iceland. Hopefully I can start on that next year.

MATERIALS AUSTRALIA

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS SEPTEMBER 2022 | 17

Our Certified Materials Professionals (CMatPs)

The following members of Materials Australia have been certified by the Certification Panel of Materials Australia as Certified Materials Professionals.

They can now use the post nominal ‘CMatP‘ after their name. These individuals have demonstrated the required level of qualification and experience to obtain this status. They are also required to regularly maintain their professional standing through ongoing education and commitment to the materials community.

We now have over one hundred Certified Materials Professionals, who are being called upon to lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

A/Prof Alexey Glushenkov ACT

Dr Syed Islam ACT

Prof Yun Liu ACT

Dr Karthika Prasad ACT

Dr Takuya Tsuzuki ACT

Dr Olga Zinovieva ACT

Prof Klaus-Dieter Liss CHINA

Mr Debdutta Mallik MALAYSIA

Prof Valerie Linton NEW ZEALAND

Dr Rumana Akhter NSW

Ms Maree Anast NSW

Ms Megan Blamires NSW

Dr Phillip Carter NSW

Mr Ken Chau NSW

Dr. Igor Chaves NSW

Dr Yi-Sheng (Eason) Chen NSW

Dr Zhenxiang Cheng NSW

Dr Evan Copland NSW

Mr Peter Crick NSW

Prof Madeleine Du Toit NSW

Dr Azdiar Gazder NSW

Prof Michael Ferry NSW

Dr Yixiang Gan NSW

Mr Michele Gimona NSW

Dr Bernd Gludovatz NSW

Mr Buluc Guner NSW

Dr Ali Hadigheh NSW

Dr Nima Haghdadi NSW

Dr Alan Hellier NSW

Prof Mark Hoffman NSW

Mr Simon Krismer NSW

Prof Jamie Kruzic NSW

Prof Huijun Li NSW

Dr Yanan Li NSW

Dr Hong Lu NSW

Mr Rodney Mackay-Sim NSW

Dr Matthew Mansell NSW

Dr Warren McKenzie NSW

Mr Arya Mirsepasi NSW

Dr David Mitchell NSW

Mr Sam Moricca NSW

Dr Anna Paradowska NSW

Prof Elena Pereloma NSW

A/Prof Sophie Primig NSW

Dr Gwenaelle Proust NSW

Prof. Jamie Quinton NSW

Mr Waldemar Radomski NSW

Mr Ehsan Rahafrouz NSW

Dr Mark Reid NSW

Prof Simon Ringer NSW

Dr Richard Roest NSW

Mr Sameer Sameen NSW

Dr Luming Shen NSW

Mr Sasanka Sinha NSW

Mr Frank Soto NSW

Mr Michael Stefulj NSW

Mr Carl Strautins NSW

Mr Alan Todhunter NSW

Ms Judy Turnbull NSW

Mr Jeremy Unsworth NSW

Dr Philip Walls NSW

Dr Rachel White NSW

Dr Alan Whittle NSW

Dr Richard Wuhrer NSW

Mr Deniz Yalniz NSW

Mr Michael Chan QLD

Prof Richard Clegg QLD

Mr Andrew Dark QLD

Dr Ian Dover QLD

Mr Oscar Duyvestyn QLD

Mr John Edgley QLD

Dr Jayantha Epaarachchi QLD

Dr Jeff Gates QLD

Mr Payam Ghafoori QLD

Dr David Harrison QLD

Miss Mozhgan Kermajani QLD

Dr Andrii Kostryzhev QLD

Mr Jeezreel Malacad QLD

Dr Jason Nairn QLD

Mr Sadiq Nawaz QLD

Mr Bhavin Panchal QLD

Mr Bob Samuels QLD

Dr Mathias Aakyiir SA

Mr Ashley Bell SA

Ms Ingrid Brundin SA

Mr Neville Cornish SA

A/Prof Colin Hall SA

Mr Nikolas Hildebrand SA

Mr Mikael Johansson SA

Mr Rahim Kurji SA

Mr Andrew Sales SA

Dr Thomas Schläfer SA

Dr Christiane Schulz SA

Prof Nikki Stanford SA

Prof Youhong Tang SA

Mr Kok Toong Leong SINGAPORE

Mr Madhusudhanan Jambunathan UK

Mr Devadoss Suresh Kumar UAE

Dr Shahabuddin Ahmmad VIC

Dr Qi Chao VIC

Dr Ivan Cole VIC

Dr John Cookson VIC

Miss Ana Celine Del Rosario VIC

Dr Yvonne Durandet VIC

Dr Mark Easton VIC

Dr Rajiv Edavan

VIC

Dr Peter Ford VIC

Mrs Liz Goodall VIC

Mr Bruce Ham VIC

Ms Edith Hamilton VIC

Dr Shu Huang VIC

Mr Long Huynh VIC

Mr. Daniel Lim VIC

Dr Amita Iyer VIC

Mr Robert Le Hunt VIC

Dr Michael Lo VIC

Dr Thomas Ludwig VIC

Dr Roger Lumley VIC

Mr Michael Mansfield VIC

Dr Gary Martin VIC

Dr Siao Ming (Andrew) Ang VIC

Dr Eustathios Petinakis VIC

Dr Leon Prentice VIC

Dr Dong Qiu VIC

Mr John Rea VIC

Mr Steve Rockey VIC

Miss Reyhaneh Sahraeian VIC

Dr Christine Scala VIC

Mr Khan Sharp VIC

Dr Vadim Shterner VIC

Dr Antonella Sola VIC

Mr Mark Stephens VIC

Dr Graham Sussex VIC

Dr Jenna Tong VIC

Dr Kishore Venkatesan VIC

Mr Pranay Wadyalkar VIC

Mr John Watson VIC

Dr Wei Xu VIC

Dr Ramdayal Yadav VIC

Dr Sam Yang VIC

Dr. Matthew Young VIC

Mr. Mohsen Sabbagh Alvani WA

Mr Graeme Brown WA

Mr Graham Carlisle WA

Mr John Carroll WA

Mr Sridharan Chandran WA

Mr Conrad Classen WA

Mr Chris Cobain WA

Ms Jessica Down WA

Mr Adam Dunning WA

Mr Jeff Dunning WA

Dr Olubayode Ero-Phillips WA

Mr Stuart Folkard WA

Prof Vladimir Golovanevskiy WA

Mr Chris Grant WA

Dr Cathy Hewett WA

Mr Paul Howard WA

Dr Paul Huggett WA

Mr Ehsan Karaji WA

Mr Biju Kurian Pottayil WA

Mr Mathieu Lancien WA

Mr Michael Lison-Pick WA

Mr Ben Miller WA

Dr Evelyn Ng WA

Mr Deny Nugraha WA

Mr Stephen Oswald WA

Mrs Mary Louise Petrick WA

Mr Johann Petrick WA

Mr Stephen Rennie WA

Mr James Travers WA

MATERIALS AUSTRALIA 18 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

Why You Should Become a Certified Materials Professional

Source: Materials Australia

Accreditation as a Certified Materials Professional (CMatP) gives you recognition, not only amongst your peers, but within the materials engineering industry at large. You will be recognised as a materials scientist who maintains professional integrity, keeps up to date with developments in technology, and strives for continued personal development.

The CMatP, like a Certified Practicing Accountant or CPA, is promoted globally as the recognised standard for professionals working in the field of materials science.

There are now well over one hundred CMatPs who lead activities within Materials Australia. These activities include heading special interest group networks, representation on Standards Australia Committees, and representing Materials Australia at international conferences and society meetings.

Benefits of Becoming a CMatP

• A Certificate of Membership, often presented by the State Chapter, together with a unique Materials Australia badge.

• Access to exclusive CMatP resources and website content.

• The opportunity to attend CMatP only

networking meetings.

• Promotion through Materials Australia magazine, website, social media and other public channels.

• A Certified Materials Professional can use the post nominal CMatP.

• Materials Australia will actively promote the CMatP status to the community and employers and internationally, through our partner organisations.

• A CMatP may be requested to represent Materials Australia throughout Australia and overseas, with Government, media and other important activities.

• A CMatP may be offered an opportunity as a mentor for student members.

• Networking directly with other CMatPs who have recognised levels of qualifications and experience.

• The opportunity to assume leadership roles in Special Interest Networks, to assist in the facilitation of new knowledge amongst peers and members.

What is a Certified Materials Professional?

A Certified Materials Professional is a person to whom Materials Australia has issued a certificate declaring they have attained all required professional

standards. They are recognised as demonstrating excellence, and possessing special knowledge in the practice of materials science and engineering, through their profession or workplace. A CMatP is prepared to share their knowledge and skills in the interest of others, and promote excellence and innovation in all their professional endeavours.

The Criteria

The criteria for recognition as a CMatP are structured around the applicant demonstrating substantial and sustained practice in a field of materials science and engineering. The criteria are measured by qualifications, years of employment and relevant experience, as evidenced by the applicant’s CV or submitted documentation.

Certification will be retained as long as there is evidence of continuing professional development and adherence to the Code of Ethics and Professional behaviour.

Further Information

Contact Materials Australia today: on +61 3 9326 7266 or imea@materialsaustralia.com.au or visit our website: www.materialsaustralia.com.au

GLOBAL STEEL HEAT TREATMENT

MATERIALS AUSTRALIA

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS SEPTEMBER 2022 | 19

RAYMAX: Making Light Work for You

Source: Sally Wood

Since 1992, Raymax Lasers has connected those working in science, manufacturing, and industry with precise and sophisticated lasers to achieve their goals.

How does Raymax do it? They start by first investigating the complex outcome you’re looking to achieve:

• Does a unique material need to be cut, welded or cleaned?

• Do you want to improve your production process?

• Do you have a research goal?

Raymax works across a diverse range of industries and sectors:

• Material Interaction Research: laser evaluation and laser process development

• Solutions for Scientific Research: lasers, lithography, spectrometers, and custom optics

• Manufacturing: additive and bionic manufacturing, metal cladding and part repair, heat treatment, infrared and blue lasers, welding and cutting

• Micromachining and Microstructure Engineering Applications: thin wire stripping and processing, surface profiling and modification, metal ablation, micro-

sized welding and cutting

• Hyperspectral Imaging: optical identification

• Product Marking: tracing and identification, anti-counterfeiting and security

can improve operation in ways you might not have imagined possible.

Technical excellence is balanced with commercial interests to ensure that the equipment that Raymax assists you with meets your exact requirements.

Once the most fit-for-purpose and costeffective solution has been identified, Raymax ships and installs the laser or laser equipment for you. They will even train your team on your laser system, leaving you to sit back and relax, thanks to the reliable Australian-based service and support Raymax provides.

Raymax is a secure TRAC compliant company with international ethical accreditation.

The Raymax mission: Making light work: Delivering the best laser and photonics solutions to advance Australian and New Zealand industries and R&D organisations.

When you partner with Raymax Lasers, you’ll be working with a team of physicists and factory-trained engineers – leaders in the supply of laser solutions and optronics equipment. We’re experts in material interaction research.

Wherever possible, Raymax works to introduce you to new technology that

The Raymax vision: Facilitate Australian and New Zealand industry to set the global benchmark for excellence and innovation with lasers.

Further Information www.raymax.com.au T: +61 2 9979 7646

INDUSTRY NEWS

20 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU Make Laser light work for you Raymax distributes specialised laser and photonics solutions Discover what is possible with our advanced Laser and Photonics Solutions • Advanced Manufacturing & Industrial Laser Processing • Micromachining & Microstructure Engineering Applications • Hyperspectral Imaging, Custom Optics, Lithography • Product Marking and Perforation Lasers • Laser safety products and Fume Extraction • Material Interaction Research • Solutions for Scientific Research • Laser Consulting & Engineering www.raymax.com.au

The fifth International Materials Innovations in Surface Engineering (MISE) conference will be convened in Brisbane, Australia. The conference will be located at the state-of-the-art St Lucia Campus of the University of Queensland: only seven minutes from the centre of Melbourne.

MISE2023 features eminent academic and industrial plenary, keynote and invited speakers who encompass the engineering modification of a material’s surface to improve its performance.

The conference will cover topics such as:

• Coatings and Thin Films for Extreme Industrial Environments

Surface Modification for Industrial Applications

Surface Modification for Biomedical Applications

• Modelling and Simulation related to Surface Engineering

• Vacuum Deposition Coatings and Technologies: PVD and CVD

• Thermal Spray Coatings and Technologies

Weld Overlays and Technologies

Laser Processing and Technologies

• Characterisation of Surfaces, Coatings and Films

• New Horizons in Coatings and Thin Films

• Educational and Training of Early Career Researchers in Surface Engineering Case Histories for Surface Engineering, including Failure Analysis

Abstracts

Abstracts open 1 November 2022 and can be submitted online through the MISE website - www.mise2023.com.au

• Guidelines and an abstract template can be downloaded

Sponsorship and Sponsorship and Industry Displays

A number of limited sponsorship packages will be available. There will also be opportunities for sponsors to reserve space to exhibit their products and technologies. Please see the MISE2023 website for details.

Why should you participate in MISE?

• Networking opportunities to kick-off and maintain your research profile

• Interacting with leading, global industrialists to promote future activities Contribute to your Continuing Professional Development (CPD) portfolio Learn of the emerging manufacturing technologies that are on the near-term horizon

• A post-conference intense workshop

• Plus, the weather and climate in Brisbane during spring is fantastic!

Enquiries

Tanya Smith | Materials Australia

+61 3 9326 7266 | imea@materialsaustralia.com.au

St

www.mise2023.com.au University of Queensland | Brisbane, Australia | 24 - 26 September 2023 Enquiries: +61 3 9326 7266 or imea@materialsaustralia.com.au SUPPORTING SPONSORPRESENTED BY

Lucia Campus – University of Queensland.

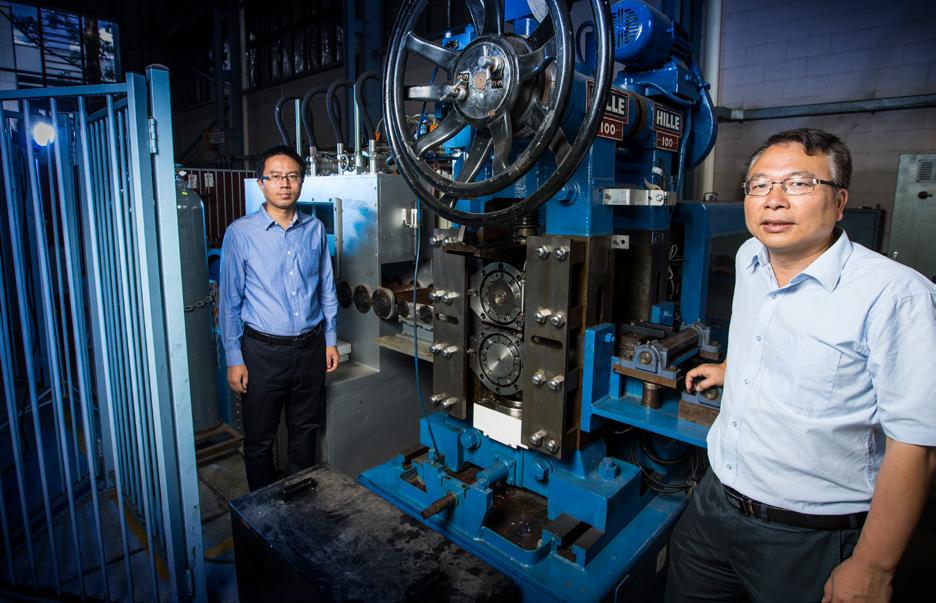

Essential Tools for Achieving Consistent Quality in Additive Manufacturing

Source: ATA Scientific Pty Ltd

Australia’s Additive manufacturing (AM) industry is off and running, transforming the way we produce and distribute goods. Also known as 3D printing, AM allows complex parts to be produced, on-demand using digital files in a one-step build process. In the heat of the COVID-19 pandemic, 3D printing stepped up to provide solutions during severe disruptions in supply chains ranging from personal protective equipment (PPE) to emergency dwellings to isolate patients. From aerospace to automotive engineering, and from the medical to the dental industry, AM is an evolving technology revolutionising industries across the country.

Why Do Your Materials Matter?

3D printed structures are usually built layer upon layer, so consistency in the final product relies on the consistency of the materials being laid down. For powder bed AM processes where a laser or electron beam fuses the raw materials together (such as selective laser melting, electron beam melting, and binder jetting), the quality of the finished component will depend on the properties and behavior of the metal, ceramic, or polymer powder being applied. Poor powder quality can produce defects in the end part including pores, cracks, inclusions, residual stresses, and sub-optimal surface roughness, as well as compromise throughput. To avoid these issues, the relationship between material properties, processing performance, and endcomponent properties need to be assessed.

What Makes An Ideal AM Powder?

High purity powders that pack consistently with high density are associated with the production of consistentquality components with fewer flaws, while good flowability enables the powder to spread evenly and smoothly across a bed to form a uniform layer with no air voids. Smooth, regularly shaped particles tend to flow more easily than those that are irregular and/or rougher, because of reduced interparticle friction and a lower risk of mechanical interlocking. Similarly, spherical particles tend to pack more efficiently than those that are irregular, giving rise to higher bulk densities. The forces of attraction between particles increase with decreasing particle size, therefore fine metal powders usually flow less freely than coarser powders. Thus, optimising particle shape and including both coarse and fine particles (finer particles fill the interstices left by larger ones) can enable maximum packing density and maintain good flowability.

How Does The Production Of Metal Am Powders Affect Their Properties?

Most metal powders used in AM are produced by gas atomisation, where a feedstock is melted and ejected through a nozzle into a high-pressure gas stream to create droplets. The size of particles produced can be controlled by varying process parameters such as gas pressure, melt properties, nozzle design, and gas-metal ratio. However,

Figure 1: Laser diffraction measurement using Malvern Mastersizer 3000.

Figure 1: Laser diffraction measurement using Malvern Mastersizer 3000.

INDUSTRY NEWS 22 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

the resulting powder is not ideal for AM processes, which require a narrower particle size distribution to produce a consistent powder layer of the correct thickness. Additional processes like ‘scalping’ can remove oversize particles but these reduce yield and therefore increase the cost of AM powders. Unwanted features such as satellite formation, where small and larger particles fuse or agglomerate during atomisation can impair flowability and packing. More spherical particles can be produced by Plasma Atomisation or the Plasma Rotating Electrode Process (PREP), but at a higher price. What’s more, when using recycled powders, the risk of mechanical damage, oversized particles, or surface oxide layer formation increases. So, to take full advantage of AM’s sustainability benefits while ensuring that their materials don’t compromise final part quality, manufacturers must ensure they can reliably characterise and optimise their materials.

How Do You Measure Particle Size and Shape Reliably?

Laser diffraction

With a measurement range from 0.01 to 3,500µm, the Malvern Mastersizer 3000 is the particle sizing technology of choice for most AM applications, particularly at smaller size ranges; from <25µm used in Metal Injection Moulding to up to 1mm used in Hot Isostatic Pressing. Particle size distribution (PSD) is determined using Mie theory from the measured angular dependence of the scattered light as a collimated laser beam passes through the sample (Figure 1). Large particles scatter with high intensity at narrow angles relative to the incident beam, while the signal generated by smaller particles is weaker but extends to wider angles.

The Mastersizer 3000 is highly automated and offers high-throughput analysis with minimal manual input. It is highly efficient at revealing the presence of any small quantities of oversized or agglomerated material that could cause a powder sample to be out of specification. Insitec

is an online system that deliver real-time particle size monitoring for automated process control. It can be used either to monitor particle size evolution during atomisation, grinding, or spray drying, or at an end-user facility for automated powder handling and recycling (Figure 2).

Figure 3 shows measurements for four fractions of metal powders, made using both wet and dry dispersion on the Mastersizer 3000. Both wet and dry dispersion are suitable for analysing metal powders to validate the primary particle size and should give equivalent results. Wet dispersion offers an alternative particularly when particles carry ignition risk or health and safety concerns. For the <150µm fraction, there is a noticeable discrepancy between the wet and dry measurements. This is likely due either to fine particles adhering to larger particles in the dry state which may impact powder flowability, or a difference in sampling.

Figure 3: Comparisons of wet and dry measurements for four stainless-steel 316L powder samples. Red trace shows dry PSD and green trace shows wet PSD. Each trace shows the average result over five measurements.

Figure 2: Schematic of a gas-atomisation process for manufacturing metal powders, showing the points where laser diffraction can be employed.

Figure 3: Comparisons of wet and dry measurements for four stainless-steel 316L powder samples. Red trace shows dry PSD and green trace shows wet PSD. Each trace shows the average result over five measurements.

Figure 2: Schematic of a gas-atomisation process for manufacturing metal powders, showing the points where laser diffraction can be employed.

INDUSTRY NEWS

WWW.MATERIALSAUSTRALIA.COM.AU BACK TO CONTENTS SEPTEMBER 2022 | 23

Dynamic Image Analysis

The Malvern Hydro Insight offers dynamic imaging which can be integrated with the Malvern Mastersizer 3000 to give particle shape information at the same time as particle size measurements. Particles suspended in a flowing stream by the laser diffraction dispersion unit flow through the Hydro Insight and are then photographed by a high-resolution digital camera. The images are stored for viewing and converted to a digital format for real-time image analysis and quantification of size and/or shape (Figure 4). Large numbers of particles are measured quickly with all three particle dimensions captured due to the random orientation of the particles. The Hydro Insight can detect small numbers of oversize particles or contaminants that laser diffraction alone may miss and help to troubleshoot or optimise laser diffraction methods. It also provides a built-in algorithm for correlating particle size data with sieve analysis which tend to correlate better than equivalent circular areas or spherical

diameters reported by laser diffraction, especially when dealing with non-spherical particles.

Static Image Analysis

The Malvern Morphologi 4-ID combines all the benefits of automated static imaging with chemical identification of individual particles by Raman spectroscopy in a single measurement. It captures individual images of tens of thousands of particles from approximately 0.5 µm to > 1mm and calculates component specific size and shape parameters, including circularity, elongation, convexity, and solidity (Figure 5). Because the position of each particle is recorded, particles of interest can be revisited with higher magnification for a more detailed study. It can also support customised classifications to examine features such as satelliting.

Conclusions

The size and shape of metal powder particles affect powder bed packing and flowability. In turn, these features impact the build quality and final properties of components manufactured using AM. As such, understanding and optimising particle size and shape is critical to the success of powder-bed AM. Laser diffraction and automated image analysis are complementary tools that can be used to characterise and optimise metal powders for a range of powder-bed AM processes.

Contact us for more information today: ATA Scientific Pty Ltd +61 2 9541 3500 enquiries@atascientific.com.au www.atascientific.com.au

Reference: Exploring the role and measurement of particle size and shape in metal additive manufacturing https://www.malvernpanalytical.com/en/learn/knowledge-center/ whitepapers/wp20210727particlesizeshapemetalam

Figure 4: Images of metal powders, captured by Hydro Insight.

Figure 5: Particle classifications for an AM metal powder using the Morphologi 4.

INDUSTRY NEWS 24 | SEPTEMBER 2022 BACK TO CONTENTS WWW.MATERIALSAUSTRALIA.COM.AU

of use is what the

come to

desktop

for.

fast,

high contrast

2. Unsurpassed user experience

2. Unsurpassed user experience

2. Unsurpassed user experience

Unsurpassed user experience

experience means the

Easy to use without extensive training or SEM experience means the Phenom is accessible to everyone.

Easy to use without extensive training or SEM experience means the Phenom is accessible to everyone.

to everyone.

Fully

Multiple

reveal

3. Multiple detectors reveal finer details

details

3. Multiple detectors reveal finer details

Multiple detectors reveal finer details

together with a low kV beam (1

Fully integrated EDS and SE detector together with a low kV beam (1 kV) allows thin contamination layers on the surface can be observed (Phenom Pharos)

Fully integrated EDS and SE detector together with a low kV beam (1 kV) allows thin contamination layers on the surface can be observed (Phenom Pharos).

allows thin contamination layers on

observed (Phenom Pharos)

Intuitive

with

4. Intuitive software with advanced automation

4. Intuitive software with advanced automation

4. Intuitive software with advanced automation

Simply click and go to work or use automated recipes with elemental mapping and line scan functionality

with elemental mapping and

functionality

Simply click and go to work or use automated recipes with elemental mapping and line scan functionality.

5. Huge time and money saver

5. Huge time and money saver

5. Huge time and money saver

Provides rapid, multi scale information in house for process monitoring and improvement.

COMPLETELY

QUE

NG 1

in house for process monitoring and improvement.

in house for process monitoring and improvement.

High performance desktop

Fully integrated EDS

GSR SEM

Steel, Technical cleanliness

reduce risk for sample damage

for high resolution FEG SEM

FEG SEM

U PSI DE DOWN DESI GN

U PSI DE DOWN DESI GN

TRI PLE FUNCTI ON ALI TY

TRI PLE FUNCTI ON ALI TY

ROBUST DESI GN, M ADE I N GERM AN Y

ROBUST DESI GN, M ADE I N GERM AN Y

your interest for a demo today!

your interest for a demo today!

9 5 41 3 5 00 egister

Phenom Pharos FEG SEM Phenom XL G2 SEM Phenom ProX G6 SEM old or Platinum coatings ideal for high resolution FEG SEM imaging

AU TOM ATED UNI

A² TECHNOLOGY COATI

to 100nm THI CKNESS

Full y automated LUXOR sputter coaters reduce risk for sample damage Field Emission Gun (FEG) SEM with 1 20 kV range For large samples (100x100 mm) High performance desktop SEM Fully integrated EDS Steel, Technical cleanliness and more Automated GSR SEM Dedicated for gunshot residue analysis 9 5 41 3 5 00 egister

Phenom Pharos FEG SEM Phenom XL G2 SEM Phenom ProX G6 SEM old or Platinum coatings ideal for high resolution

imaging COMPLETELY AU TOM ATED UNI QUE A² TECHNOLOGY COATI NG 1 to 100nm THI CKNESS U PSI DE DOWN DESI GN TRI PLE FUNCTI ON ALI TY ROBUST DESI GN, M ADE I N GERM AN Y

Provides rapid, multi scale information

Full y automated LUXOR sputter coaters

Field Emission Gun (FEG) SEM with 1 20 kV range For large samples (100x100 mm)

SEM

and more Automated

Dedicated for gunshot residue analysis 9 5 41 3 5 00 egister your interest for a demo today! Phenom Pharos FEG SEM Phenom XL G2 SEM Phenom ProX G6 SEM old or Platinum coatings ideal