Targeting Africa’s Mining Decision Makers

Celebrating Women in Mining

Gold Processing: Turning Challenges into Golden Opportunities

miningbusinessafrica.co.za

Carl Hamm PPS in Namibia

THE INANDA CLUB, FORREST ROAD, INANDA, JOHANNESBURG

The Joburg Indaba is a highly influential mining industry platform, renowned for its straight talk, refreshing insights and collaborative atmosphere. Since its inception, the Joburg Indaba has developed a reputation as a highly regarded and influential industry platform which unpacks a wide range of critical issues affecting all stakeholders in the mining industry.

This 11th edition of the Joburg Indaba will bring together CEOs and senior representatives from all major mining houses, investment firms, Government, parastatals, communities, organised labour and legal and advisory experts.

Plus, the Gala Dinner will be held on 3rd October, when we will be inducting new members into the SA Mining Hall of Fame!

Joburg Indaba 2023 is proudly sponsored by: Lead Sponsor Premium Sponsors

sponsorship@resources4africa.com +27 (0) 11 463 7799 // +27 (0) 61 421 9492 // registrations@resources4africa.com // www.joburgindaba.com REGISTER TODAY!

- 5 October 2023 LEAD SPONSOR Follow us on our website for the latest speakers and programme developments www.joburgindaba.com

For sponsorship opportunities please contact us on:

4

Industry Par tners

Mining

Networking Sponsors

M&D

Cover Image: Carl Hamm PPS

COVER STORY: PG 02

Carl Hamm PPS - The Turnkey Pipe and Pump Partner Delivers Again!

It was more of the same for the team at Carl Hamm PPS as they delivered comprehensive pipe and pump solutions to B2Gold Nambia’s project. The project’s success is attributed to partnerships with industry-leading manufacturers; involving the client in customising suitable solutions; and exceptional support through the project lifecycle.

Editor

Nick Barnes

editor@miningbusinessafrica.co.za

+27 10 055 3356

Web/Sub-Editors

Jimmy Swira

Jimmy@miningbusinessafrica.co.za

+ 27 10 055 3356

Anita Anyango

anyangoanita18@gmail.com

Contributing Writers

Chantelle C.

chantellec@miningbusinessafrica.co.za

+ 27 10 055 3356

Editor’s Note

A Healthy Dose of Reality Vital

Beneficiation is a complex venture whose success is not always cast in gold.

Resource nationalism is the buzzword in some gold-producing African countries. Conspicuously, it has dawned on the countries that they can extract more value from their resources through various avenues of ‘Incountry beneficiation’.

Truth be told, this is within their right. So, the zealousness of some politicians (sometimes overzealousness) to achieve their countries’ realigned goals is understandable to some extent.

However, the downside from what we have observed is a romanticized notion of the success of their planned ventures at the expense of reality. For instance, this is emerging in West Africa, where leaders of new military juntas are issuing decrees banning the export of raw gold. This move is in a bid to ensure that gold is refined locally.

To call this naïve would be mild.

It is as though the decrees can magically develop a country’s capacity for full-fledged local beneficiation.

While the drive to increase a bigger slice of the cake from a revenue perspective is commendable, a healthy dose of reality is vital

In a nutshell, the reality is that beneficiation is a complex venture whose success is not always cast in gold.

Nick Barnes editor@miningbusinessafrica.com

Susan M. susanm@miningbusinessafrica.co.za

Sales and Marketing

Winnie Sentabire winnie@miningbusinessafrica.co.za

+27 83 530 6832 | +27 10 055 3356

Angeline Ntobeng angien@miningbusinessafrica.co.za

+ 27 078 322 5938

+ 27 010 055 3356

Accounts Precious Chirunga accounts@miningbusinessafrica.co.za

+ 27 10 055 3356

Art Director/Layout Augustine Ombwa

Arobia Creative Consultancy austin@arobia.co.ke

+254 772 187 334

Circulation/Sales info@miningbusinessafrica.co.za

+ 27 10 055 3356

Published By Media Icon (Pty) Ltd

34 52 04 CONTENTS July - August 2023 Media Icon (Pty) Ltd makes every effort to ensure the accuracy of the contents of its publications, but no warranty is made as to such accuracy and no responsibility will be borne by the publisher for the consequences of actions based on information so published. Further, opinions expressed are not necessarily shared by Media Icon (Pty) Ltd. Location: Max Offices Sandton, 145 Second St., Parkmore Gauteng 2196, South Africa www.miningbusinessafrica.co.za

min ngbus nessa r ca co za Target ng A r ca s M n ng Dec s on Make s Carl Hamm PPS n Namibia Celebrating Women n M n ng Gold Process ng: Turning Challenges nto Golden Opportun t es

TEAM

20

Carl Hamm PPS - The Turnkey Pipe and Pump Partner Delivers Again!

It was more of the same for the team at Carl Hamm PPS as they delivered comprehensive pipe and pump solutions to B2Gold Nambia’s project. The project’s success is attributed to partnerships with industry-leading manufacturers; involving the client in customising suitable solutions; and exceptional support through the project lifecycle.

In the dynamic world of mining, success hinges on efficient and reliable infrastructure that can withstand the rigorous demands of projects. Carl Hamm PPS, a leading provider of specialised pipes and pumps, has consistently proved its expertise in helping mines meet this unique challenge through the delivery of turnkey solutions.

Another remarkable success story Recently, Carl Hamm concluded another remarkable success story in Namibia. The dynamic engineering firm provided a comprehensive pipe and pump solution to an ambitious mining project undertaken by B2Gold

Namibia, a prominent mining company. However, accomplishing this feat required meticulous planning and prudent implementation, as the project had unique pipe and pump requirements.

Extensive expertise and impeccable track record

B2Gold Namibia’s project necessitated robust and efficient infrastructure to support its operations. Recognising the critical role of pipe and pump systems, the company turned to Carl Hamm PPS based on its extensive expertise and impeccable track record in the field.

With a rich history spanning almost a century, Carl Hamm PPS has earned a reputation for

2 Mining Business Africa | July - August 2023

Turnkey Pipe and Pump Solution for B2Gold Namibia Project

excellence, offering innovative and high-quality products to the mining industry. Hence, B2Gold Namibia did not hesitate to engage Carl Hamm PPS for its unique pipe and pump requirements.

Customised Pipe and Pump Systems

Understanding the unique requirements of B2Gold’s project, Carl Hamm PPS worked closely with the client to design and implement customised pipe and pump systems. The team involved conducted thorough assessments of the site, leveraging extensive experience in the mining sector to consider factors such as water management, dewatering, and material

transportation. Carl Hamm PPS provided suitable comprehensive solutions to optimise efficiency, reduce operational costs, and ensure the smooth flow of operations.

Partnerships with industry-leading manufacturers

Carl Hamm PPS was able to provide these comprehensive solutions thanks to its partnerships with industry-leading manufacturers, one of its key strengths. Through these collaborations, the company can offer a comprehensive range of top-quality products and services.

Regarding the B2Gold project, Carl Hamm PPS collaborated with renowned partners such as Prinsloo Drilling and Woodrow Engineering.

Collaborative Approach and Exceptional Support

Another key element pivotal to the project’s success was the company’s collaborative approach and unwavering dedication to customer satisfaction. From the initial consultation to project completion, the company’s team of experienced professionals worked closely with B2Gold, providing exceptional support and guidance at every stage. In the end, by fostering strong relationships with clients and maintaining open lines of communication, Carl Hamm PPS ensured that the solutions provided aligned perfectly with the project’s requirements and exceeded expectations.

Concrete Testament

Without a doubt, the collaboration between Carl Hamm PPS and B2Gold stands as a concrete testament to the company’s expertise in delivering turnkey pipe and pump solutions. Moreover, it highlights how tailored solutions can drive success in the mining industry. Ultimately, by leveraging its expertise, cuttingedge technologies, and strong partnerships, Carl Hamm PPS provided B2Gold Namibia with reliable, efficient, and durable infrastructure that contributed to the project’s triumph.

Mining Business Africa | July - August 2023 3

Progressing towards the Promised Land

At 12%, the mining sector has one of the lowest representations of women compared with other sectors. However, Women in Mining South Africa (WiMSA) considers this as a springboard to progress from.

August is Women’s Month in South Africa. And as you would have thought, in celebration, traditionally, there is a lot of pomp and ceremony. But the lingering question is: After the dust settles, in fairness, are women progressing, regressing, or stagnating? Specifically, how can we objectively assess performance in a critical sector like mining?

It all depends on the criteria employed; progress is relative.

This is the position two executives - Raksha Naidoo, Chairperson of WiMSA, and Noleen Pauls, the Chairperson of the WiMSA Board of Directors, hold. Briefing Mining Business Africa, they shed light on the following areas of the participation of women in mining: status of progress, implications of enabling policy, and WiMSA’s role and the obstacles and how to tackle them.

Measuring the progress of women

Granted, the criteria for measuring women’s progress in mining can be a grey area. However, Pauls suggests that analysing the number of women in core positions and management could be more rational.

Based on the statistics furnished, there is an indication of measured progress, though not at the level WiMSA or other stakeholders in the mining sector would have wished. The number of women working in the mining sector has increased significantly over the years – from 4% before 2002 to the current 12%.

Ostensibly, compared with other sectors, this modest statistic makes the mining sector the least gender-diverse industry. Markedly, the sector has its work cut out.

However, the mitigating circumstances could be that the challenges that mining - as a skills and capital-intensive sector - faces are quite intricate. That is without mentioning the complexity of policy-related issues.

Additionally, gathering current data is a challenge. Hence, statistics for core workers, support staff, and contract workers are not well documented. Possibly, this implies that the data could be underestimated.

Enabling Policy

Asked if there may need for further policy changes to create a more enabling environment. Pauls clarifies that, in fact, the changes registered thus far can be credited to policy. She hails the 2002 Mining Charter (BroadBased Black Socio-Economic Empowerment Charter for the South African Mining and Minerals Industry) as the most groundbreaking development. The Charter set a baseline of 10% female participation within five years.

“Having legislation in place highlighted the need for change and drove gender equality in the workplace. And this focus has led to necessary adjustments e.g. change facilities, PPE and equipment, recruitment strategies, BEE policies, women-only core-business teams, mentoring and support structures.

These changes have made the mining industry a more inclusive and safer workplace that has attracted women in all areas, more especially underground,” Pauls illustrates.

Having witnessed the relative gains of the Mining Charter, WiMSA is cautiously optimistic that the updated Charter of 2017 will result in further advances, precisely in management positions and business.

• Management positions

Pauls firmly believes higher thresholds for management positions underlined in the Charter of 2017 will facilitate more participation of women in decision-making roles. “I think the updated Charter will lead to higher retention of women within the industry. Many women leave when they hit the ‘glass ceiling’ in the industry

• Business

Another area where WiMSA sees the updated Mining Charter of 2017 bringing forth tangible changes is increasing the participation of women-owned businesses in the supply chain, specifically black-women owned. According to the updated Charter, a minimum of 5% of total mining goods procurement spend and 10% of the total spend on services must be sourced from Black-Owned Companies. Specific to women, a minimum of 50%+1 vote female Black Person which is a start for increasing female entrepreneurs in the mining industry.

Nonetheless, the reality is that it is one thing to have a comprehensive policy, and totally another to ensure it produces desired outcomes.

Taking the bull by the horns

For this reason, cognisant of this, Naidoo pronounces that WiMSA is taking the proverbial bull by the horns. She enthuses that the organisation is playing a part in facilitating the increase in participation of women in the mining sector within the ambit of its mandate, highlighting the Career Booklet, and Mentorship and Support.

• Career booklet

Naidoo defines the core focus of the Career

4 Mining Business Africa | July - August 2023 Women in mining

Noleen Pauls, the Chairperson of the WiMSA Board of Directors

Booklet: “At WiMSA we focus our efforts on attracting women to the industry from the time they are in high school. We developed a Career Booklet in 2022 aimed at piquing the interest of young girls in the world of STEM and showing them the opportunities for the career development of women in mining.”

• ·Mentorship and support

In addition, WiMSA focuses on personally and professionally helping women become the best versions of themselves. This is through mentorship and by creating a world and support system that is a safe place for women to share their truths and seek guidance and help.

More ground to be covered

While there have been strides, there is still more ground to be covered, Naidoo points out. “Amongst a host of aspirations, we would love to see more bursaries being offered to young girls to study STEM subjects. We want to see a more inclusive workforce focused on the development of women’s careers. We want to see women’s voices heard and their ideas implemented, and see their leadership bring about positive growth in our industry.”

Another challenge that the mining industry faces is attracting women and retaining them. So, WiMSA’s position is that, at the outset, practices that perpetuate gender biases should be removed. “It should be about finding the best people, by the best people in the recruiting process, including both men and women who know a company’s technical and emotional values. But it’s human nature to be drawn to similar people. And so, people recruit others like themselves, meaning that the male domination of mining companies leads to a self-perpetuating problem,” Pauls notes.

Another possible cause for the high turnover of skilled women from the mining sector is huge wage disparities. Sadly, even with South Africa’s legislation aimed at preventing gender discrimination in the workplace, the country has a median gender pay gap of about 20%.

Equitable approach

Given this, WIMSA calls for an equitable approach to achieving retention, mainly entailing the following:

• Removing male-biased management strategies and bringing in visible and effective policies geared towards meeting both men’s and women’s needs and practices to create femaleintegrated cultures.

• Providing appropriate emotional support and mentorship.

Besides, Naidoo believes mechanisation could be just the right tool from the perspective of achieving wage disparity.

There have been a lot of reservations about the adoption of mechanisation in mining, with

unions fearing it could render some careers obsolete. On the flip side, Naidoo is hopeful that, indirectly, mechanisation will help narrow the gender pay gap. “As mining becomes more mechanised, physical strength and stamina will become less important than fine motor skills, dexterity, and problem-solving creating significant opportunities for women in the industry.”

Continuous pursuit

Playing its part, WiMSA is not resting on its laurels in its continuous pursuit of increasing the representation of women in South Africa’s mining sector.

One of the low-hanging fruits within reach that the organisation has earmarked aimed at the foundation stage is the continuous development of its Career Booklet. Additionally, it will expand its work by hosting more Career Days and getting involved.

A critical part of the initiative at the foundation stage is keeping more girls in school and allowing them to further studies uninterrupted. One of the ways of realising this is through the drive to end period poverty, which is a big challenge resulting in absenteeism.

Ultimately, WiMSA hopes that, through its initiatives and those of other stakeholders, more women will be encouraged to explore career opportunities in mining.

Advice to young women

Nevertheless, WiMSA and other stakeholders can only do so much. Ultimately, the onus is on the girls to seize available opportunities. One of the challenges young girls face is that young women are discouraged by societal stereotypes attached to careers traditionally associated with men. ‘Manly’ careers as one analyst called them.

So, imparting a nugget of wisdom to young women, Pauls says, “My advice to young women interested in joining the mining industry would be not to be put off by its reputation as a male-dominated world. There are so many opportunities within the sector where you can find your niche and have a fulfilling and exciting career. But retaining confidence and selfesteem can be a challenge because many male colleagues will try to undermine your capabilities by painting you as incompetent. And don’t put yourselves in the stereotypical boxes either. Find mentors and networks to support you and to remind you that you are awesome.”

Wish for Women’s Month 2024

On her part, Naidoo’s Women’s Month 2024 wish is to see more women in leadership positions in the mining sector. “We want to see more female graduates at university, and we want to see more young girls given the freedom to study, learn and grow. We want to hear more men advocating for change and working alongside WIM organisations to create a safer working environment for women. Above all, we want to see sustainable plans in place that allow for a better world for women in mining.”

By and large, WiMSA views the steps as progress towards reaching the Promised Land of gender parity in mining.

COVID-19 – a silver lining behind the dark cloud

The COVID-19 pandemic, most especially the prevention measures, unwittingly had a telling economic impact, with record losses for businesses, some employees were retrenched. Women were the most affected, bearing a huge burden.

It is too early to understand the full impact of COVID-19 on the impact of women in mining. But there is a silver lining behind the dark cloud, observes Pauls.

She says one positive result is that employers have had to become more flexible and innovative. “Women have been advocating for years to be able to work from home, and COVID restrictions proved that it is possible to do this effectively while taking care of their families.”

Mining Business Africa | July - August 2023 5

Raksha Naidoo, Chairperson of WiMSA

Determining the safety of wastewater

WearCheck Water operates two ISO/IEC 17025:2017-accredited laboratories – one in Cape Town, the other in Johannesburg, and conducts water analysis for clients from all over Southern Africa.

The mining industry is strictly regulated by national laws that govern the disposal of environmentally safe wastewater, and in many countries, is one of the prerequisites for the renewal of a mining licence.

Additionally, increasingly stringent regulations compel mining companies to comply with acid mine drainage in line with the global trend towards earth-friendly business practices.

WearCheck Water, a division of condition monitoring specialist company, WearCheck, assists many mines in the Southern African region to comply with wastewater regulations. The company conducts scientific analysis of water samples, which reveals the chemical composition of the water to a precise degree.

Moses Lelaka, WearCheck Water’s technical water lab manager in Johannesburg, explains that the company tests water from any source. ‘We conduct analysis on water from many sources – ranging from drinking water to factory/ industrial/mining effluent, and everything in between – to determine the presence and levels of potentially harmful substances, whether the water is used for drinking, agriculture or to be

disposed of after an industrial process,’ he said.

Lelaka outlines some of the mine licence regulations. ‘For example, in South Africa, wastewater regulations are regulated and monitored by the Department of Mineral Resources (DMR), which is mandated to ensure the transparent and efficient regulation of the South African mineral resources and minerals industry.

‘The DMR works hand in hand with the Department of Environmental Affairs and the Department of Water and Sanitation to ensure that the process of mineral regulation does not have any impact on the environment. In some cases, if the mineral is next to a river or stream, water samples are taken from upstream and downstream of the mine to ensure that the mining activities do not affect the water quality of the stream or the river.’

WearCheck Water operates two ISO/IEC 17025:2017-accredited laboratories – one in Cape Town, the other in Johannesburg, and conducts water analysis for clients from all over Southern Africa.

Lelaka outlines the analysis process, ‘Water

samples of around one litre are sent to our laboratories. Our technicians select the relevant tests for the water sample, depending on the needs of the customer. They identify what is wrong with the water and advise customers on possible consequences of using / discarding such water.

‘Water analysis is conducted using various accredited techniques, such as: photometric, electrometric, colorimetric, gravimetric, ICPOES, ICP MS and enzyme substrates. These techniques obtain the best possible results in chemical and microbial analysis of effluent/ wastewater, drinking water, processed water, surface water and groundwater.

‘In the case of the mining sector and other industrial operations needing to dispose of wastewater into a river system, the sea or even simply down the drain, there are strict by-laws that must be adhered to, outlining the “acceptable” levels of contaminants before disposal, to prevent possible fines or even prosecution. WearCheck Water’s technicians determine the exact levels of contaminants and advise on acceptable levels for safe discarding.

8 Mining Business Africa | July - August 2023 Waste water safety analysis

Moses Lelaka, WearCheck Water’s technical water laboratory manager, helps mining projects to comply with strict wastewater disposal regulations through regular monitoring of water samples.

WearCheck Water laboratory technician, Katlego Mokoroane, conducts scientific metal-content analysis of water samples using an Inductively Coupled Plasma (ICP) in the company’s Johannesburg laboratory.

‘Many of our mining customers operate boreholes, using the water in the mining process. We regularly monitor the water quality from the boreholes to test whether contaminants from the mining process have leached into the water supply.

‘As an example - cyanide is commonly used in gold mining, the presence of this toxin must be constantly monitored. Furthermore, uranium is commonly found in the ore with gold, and as uranium is radioactive, it is important to monitor the levels and check whether it has leached into the water supply. This is even an issue on disused mines and mine dumps – many of our customers living near these come to us to test the quality of their drinking water. Chromium-6, a carcinogenic element, is a by-product from chrome mines, so it is important to know if humans will be ingesting water with high levels of this.

Wastewater quality testing solutions for mining projects:

‘In South Africa,’ says Lelaka, ‘the DMR provides the mines with the guidelines depending on what is being mined, and these are very specific – in other words, coal mining has different specifications from gold mines and diamond mines, and so on.

‘WearCheck Water is cognisant of the government wastewater regulations and

requirements, and advises all mines to comply with their national laws and follow all stipulations regarding the quality of wastewater.

‘In South Africa, the National Water Act of 1998 ensures that nation’s water resources are protected, used, developed, managed and controlled in a way which takes into account promoting equitable access to clean water.’

The South African National Water Act of 1998, Government Gazette 4 June 1999 can be viewed via this link: https://cer.org.za/wpcontent/uploads/2010/11/GN-704-Regulationson-Mining-Water.pd.

Outlining the additional benefits of scientific water analysis, Lelaka, indicates that health is a primary reason for many customers testing for drinking water safety, both private and in the restaurant trade. Additionally, water quality is critical in the medical sector, for example in dialysis machines, as well as in the agricultural field - irrigation water quality is a critical aspect of greenhouse crop production. Water with high alkalinity can affect nutrient uptake by the plants and cause nutrient deficiency, which compromises crop health.

WearCheck’s extensive range of condition monitoring services also includes the scientific analysis of used oil and other fluids, asset reliability care (ARC), transformer oil testing, lubricant-enabled reliability (LER) services and advanced field services (AFS), (rope testing,

technical compliance and non-destructive testing), amongst others.

‘Ongoing water condition monitoring is an invaluable tool that signals environmental changes in the water table that can quickly occur due to seasonal changes, rainfall, drought, heavy industry, agriculture, natural disasters, and so much more. Responsible monitoring gives an indication of any changes in water quality that may cause harm to life or the environment.’

WearCheck Water offers water analysis services in every region in Africa where the company has a presence (RSA, Zambia, Zimbabwe, Ghana, Namibia, Mozambique, and the DRC). These locations are predominantly based near areas where mining is the primary economic activity.

For more information, please visit www. wearcheck.co.za, email marketing@ wearcheck.co.za or call WearCheck Water in Johannesburg on +27 11 392 6322 and Cape Town on +27 021 001 2100.

WearCheck, Africa's leading condi�on monitoring company, is commi�ed to serving the mining industry with its range of sophis�cated analy�cal techniques.

Our specialist oil, coolant and fuel tes�ng programmes allow customers to reduce maintenance costs, avoid unexpected mechanical failures and ul�mately reduce unscheduled down�me.

Unlock Machine Reliability!

Mining Business Africa | July - August 2023 9

Branches Botswana DRC Ghana Mozambique Namibia Uganda Zambia Zimbabwe +267 311 6829 +260 977 622 287 +233 54 431 6512 +258 85 792 7933 +264 81 141 7205 +256 78 529 6994 +260 212 210 161 +263 24 244 6369 + 27 31 700 5460 marke�ng@wearcheck.co.za www.wearcheck.co.za South Africa (Head Office)

Tes�ng and Analysis | Lubricant-Enabled Reliability | Asset Reliability Care C M Y CM MY CY CMY K WCK Mining Business Africa 180x130 copy.pdf 1 2023/05/17 10:40:14

Condi�on monitoring is KEY to mining produc�on

Certification of hauliers for transportation of high-value cargo

Certifying Hauliers, Safeguarding Assets

DPS March is dedicated to providing effective certification services for hauliers before they are contracted to transport High-Value Cargo (HVC) for mining companies, or their contracted Logistics Service Provider (LSP), to transhipment ports within Southern Africa for export abroad. In this way, the risk of theft of HVC is mitigated.

DPS

DPS March (Africa) has 30 years of extensive experience in the investigation of HVC thefts and risk management assessments on behalf of Lloyds of London and, international Insurers of mining companies, as well as LSPs and HVC owners in the region. The company has set the benchmark in security standards for HVC in transit in the SADC region through its Haulier Certification Service.

Haulier Certification

Introduced in 2010, DPS March’s Haulier Certification Service meets the need for cargo owners, freight forwarders and cargo insurers to identify responsible hauliers who can better safeguard their HVC in transit. The DPS Marchcertified contracted hauliers strictly operate to a

prescribed code of security standards to mitigate theft, hijacking and / or driver ‘handovers‘ of HVC.

Mining companies and commodity trading companies, together with their appointed LSPs, are among the biggest clients of DPS March. Through engaging DPS March-certified hauliers, mining companies and traders considerably enhance the prospects of their high-value nonferrous metals and other products reaching their destination securely.

Because of prevailing conditions in the present economic environment, DPS March is advising mining companies and other clients that contracting certified hauliers is more imperative than ever.

Economic hardships, high risks

Currently, there are economic hardships in the SADC region, due to international geopolitical events, as well as poor governance in some countries. Usually, under these conditions, facing hardships, people seek the easy way out of making ends meet and turn to crime.

Even employees of big transport companies, such as drivers, can fall into the temptation of colluding with criminal syndicates to steal the goods they carry. The common modus operandi is driver ‘handovers’, whereby the driver of a loaded truck and trailer combination is corrupted through a financial inducement into handing over his load to thieves.

Evidently, in the current economic climate, there is an elevated level of safety and security

10 Mining Business Africa | July - August 2023

March spares no effort in carrying out rigorous steps in the certification of hauliers

Risk

The Leopard Lock

The Leopard Lock from PUMA is the ul�mate container lock, significantly mi�ga�ng the risk of transpor�ng goods.

Since 2010, more than 500 000 containers and trailers have been secured by the Leopard Lock, with an average of aver 2 000 containers and trailers secured a month in Southern Africa.

Lock Specifica�ons

The Leopard Lock’s unique, patented design includes the following characteris�cs:

• Strong and robust

• Unique locking mechanism

• Disables the handle mechanism of the container at the most vulnerable spot

• Easy and quick to fit and remove by professional in-house teams at all strategic ports and major ci�es

• Withstands conven�onal cu�ng equipment such as hacksaws, crowbars and bolt cuters

Satellite Tracking

A Global System for Mobile communica�on (GSM)-tracking unit is fited within the lock and is protected by a unique housing system. The lock can be fited to a closed-body truck, trailer, rail wagon or sealed cargo container, enabling real-�me GSM tracking of cargo from loading point to des�na�on.

Control Centres

Leopard Locks are con�nuously monitored by dedicated tracking teams situated in secure control centres in South Africa, Tanzania and Zambia, with specialist armed reac�on teams on standby to respond to cargo the� or hijacking alerts.

Rapid Reac�on Team

A network of teams is strategically situated at key ports and loca�ons across South Africa, supported by 24/7 standby helicopter emergency services.

Peace of Mind

Leopard Lock is recommended by insurers and underwriters, with preferen�al rates available for Goods in Transit and 3rd Party Liability insurance premiums.

Cargo can be pinpointed in transit at any �me of day or night and tailored daily progress reports are available, giving clients the reassurance that cargo is being securely transported across Africa.

LEOPARD LOCK Stealth – Strength - Security

pumariskmanagement.com info@pumariskmanagement.com

PUMA

Management

IF IT’S NOT A LEOPARD LOCK, IT’S A CHEETAH!

Certification of hauliers for transportation of high-value cargo

risk in the transportation of HVC. A case in point is the N3 Highway to the Port of Durban, where arson attacks and looting of trucks carrying HVC have been reported.

Thus, cargo owners, in this context mining companies and / or LSPs, must be very circumspect by enhancing measures to safeguard their invaluable assets, and engaging certified hauliers should be a fundamental practice.

Sparing no effort

Given the challenges mining companies are facing, in a brief to Mining Business Africa, the team at DPS March pronounce their commitment to meeting the need for reliable and responsible hauliers, as they have been consistently doing in the past years.

Typically, DPS March spares no effort in carrying out rigorous steps to certify the competence and integrity of hauliers as well as the inspection and Risk Management of Transhipment Depots. All parties who bear the risk of handling the HVCs are engaged - hauliers, mining companies (owners of HVC), owners or administrators of freight forwarding companies, and insurance companies. Ultimately, they all benefit from the know-how of the seasoned DPS March team enormously.

• Competence and integrity of Hauliers

DPS March undertakes a certification process, as well as ensuring that the haulier stays compliant for the duration of the certification. The certification process covers a broad scope. Some of the areas include driver vetting and recruitment, driving in convoys, levels of experience of directors/senior managers, references from reputable clients of hauliers, and history and claims records of cargo losses arising from accidents or thefts within the last three years.

Furthermore, annually, regular verification of responsible hauliers is carried out. This is aimed at maintaining current data on a haulier’s

continued adherence and compliance to the prescribed code of security, hence, suitability to continue transporting High Value and ‘thief attractive’ Cargo.

•

Inspection and risk management of transhipment depots

Another critical step is the inspection and risk management of transhipment depots of HVC and commodities to minimise the risk of thefts or robberies. This is aimed at, amongst other things, preventing the malpractice of the surreptitious substitution and theft of containerised HVC and commodities after their loading and sealing for onward shipment, whilst leaving the shipping line seal seemingly intact. Particularly, some of the areas of focus during an inspection and risk assessment include the following:

• Inspection of physical security of depot, including perimeter walls, access/exit control points, deployment of security guards/dogs, warehouse intruder alarm systems and CCTV surveillance cameras ; and

• Daily inventories on high-value cargo; and

• Procedures to verify loaded cargo specs and quantum, as well as correct loading and security procedures; and

• Examination of access and exit control procedures for pedestrians and vehicular traffic.

Enormous benefits

Ultimately, DPS March Certification benefits all stakeholders – hauliers, cargo owners (mining companies or commodity brokers), freight forwarders and insurance companies (underwriters).

• Hauliers

Amongst others, hauliers benefit from the enhancement of reputation, potential for increased volumes of jobs/assignments, and better vetting of drivers, and adherence to tried and tested security protocols whilst in transit .

• Cargo owners

Mainly, cargo owners benefit from the easier selection of DPS March Certified Hauliers, as well as the means of verifying arriving trucks and drivers to load cargo and elimination of risk from loading bogus trucks and drivers.

• Freight forwarders/clearing agents

For Freight forwarders/clearing agents, it serves as a means of easier selection of DPS March Certified Hauliers and identifying potentially undesirable hauliers, above and beyond, ensuring greater transparency on drivers, trucks and trailers assigned by contracted hauliers, just to cite a few.

• Insurance companies/ underwriters

The value for insurance companies/underwriters is in the following areas: Easier confirmation of DPS March Certified hauliers; Means of scrutinising claims/loss record of new or existing Insured Parties; Means of verifying fleet size and registered truck and trailers of Insured Parties against those declared; and determining a benchmark for Insured Party’s qualification for premium discounts / preferential rates.

Committed to rendering effective services

In general, the team at DPS March recognise the scale of challenges that mining companies are confronted with to ensure the safety and security of their HVC in the current economic climate. And so, adequately resourced, they reiterate their commitment to rendering effective certification solutions to mitigate the risk of theft and enhancing the prospect of their HVC reaching their intended destination.

12 Mining Business Africa | July - August 2023

Shifting approaches to wire rope lubrication in South Africa

Newer lubricants include penetrating oil, used instead of grease for wire rope lubrication, as it decreases the risk of product flinging off because the oil gets deep into the core of the rope.

increasing labour costs and a greater imperative to minimise downtime has led to wire rope operators seeking long-lasting products that require less frequent applications and which contribute to safer operating conditions.

“We have seen this particularly in the mining industry, where ropes have to be well lubricated for safety purposes, but having a wire rope on a lift out of action for lubrication means people can’t get up or down into the mine. Being able to lubricate these components less frequently with a product that lasts up to three times as long is very important. Nowadays, in some instances, you can even effectively spray or lubricate a rope while it is in use,” says Ford.

Industries embracing change

Some of the key applications where there has been a shift in the lubrication used for wire ropes include platinum mines and crane operations. LE South Africa was also approached by an original wire rope equipment manufacturer to supply its Wirelife™ wire rope lubricants as the recommended solution for the OEM’s equipment.

Engineers in various industries are also beginning to rely on the technical specs that are published by companies like LE to help them select lubricants with a proven track record and the right corrosion and wear protection to increase the performance and lifespan of equipment. This is an important shift in attitudes and speaks to the increasing focus on sustainability, in terms of costs, time and more broadly, in high-intensity applications and environments.

There has been a move towards safer and more efficient application of lubrication.

The approaches to wire rope lubrication have shifted in recent years, largely due to important technological advances to improve the application and performance of lubrication products for wire ropes. Locally, Lubrication Engineers (LE) South Africa has been at the forefront of these advancements.

Issues with “old-school” lubricants

LE South Africa’s Managing Director, Colin Ford, explains that one of the bigger problems that older types of lubricants have is that they “fling off” as a result of the force that is applied when a rope goes back onto a winder or over a sheave. More durable, modern products no longer have this issue as they dry quickly and

are designed to be more adhesive, sticking to the rope better.

Ford says these newer lubricants include penetrating oil, used instead of grease for wire rope lubrication, as it decreases the risk of product flinging off because the oil gets deep into the core of the rope. “Penetrating oil is recommended to infiltrate into the core of the rope and protect it from corrosion from the inside out,” he says.

Ford explains that another of the key shifts for wire rope lubrication has been a move towards safer and more efficient application of lubrication. In the past, lubrication of wire ropes required equipment downtime as a general type of grease was applied to the ropes. However,

Improving lubrication at a prominent gold mine

In an important example of the value of using long-lasting wire rope lubricant products like Wirelife™, Wirelife™ rope lubricants were applied by LE at a renowned gold mine in early 2020.

With the subsequent arrival of the COVID-19 pandemic, maintenance access and general supply constraints because of lockdowns meant that frequent lubrication of the ropes would have been challenging. However, the initial application of the Wirelife™ rope lubricant product kept the wire ropes running smoothly for over two years and helped the mine’s operations during that difficult period for everyone around the world.

Mining Business Africa | July - August 2023 13 Wire

lubrication

rope

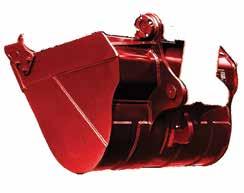

Turning challenges into golden opportunities

Certain gold-producing African countries are considering establishing local refineries. However, there is a risk that some may harbour a romanticised notion of the business. While the business is ‘worth its weight in gold,’ it is only through proper planning and thorough implementation that challenges could be turned into opportunities.

By Jimmy Swira

In recent years, there has been an upswing in resource nationalism in certain gold and other mineral-producing countries on the African continent, resulting in steps being taken to effect drastic changes to mining rights. The politicians driving the move posit that mining rights have been overtaken by events, and so changes are long overdue.

‘In-Country Beneficiation’

Consequently, countries are amending mining rights to ensure that they extract more value from their minerals than they currently do. One of the areas they have identified niche opportunities in is the “in-country beneficiation” of minerals, particularly in the gold refining and manufacturing of jewellery and other products. However, the main challenge is that currently, most resource-rich countries do not have local capacity in the area of gold refining, let alone conducive conditions for refining industries to flourish, with the exception of South Africa. As a result, the bulk of the gold is exported to refineries overseas, which, in effect, is “offshoring” the refinery industry.

For this reason, the countries are aiming for the gold to be refined locally. Some of the options they are exploring are the establishment of state-owned entities or outfits in which the state has a controlling stake.

While the fervour in countries is admirable, one would ask: What would it take to establish a sustainable gold refinery in Africa?

Project Viability

Two specialists are eager to share their views with Mining Business Africa on the viability of a refinery in Africa. Their views are gathered from a combined experience of over fifty years in the gold refinery business.

Chris Horsley is a consultant to high-profile organisations in the gold sector, who previously served as Executive Head: Technical and Advisory, amongst other positions, at Rand Refinery for more than two decades. On the other hand, Vic Hills is the Principal Consultant at V W Hills Mineral Processing Consulting CC, Cape Town.

Not a new discussion

First of all, before delving into the matter, Hills draws attention to the fact that the discussion on “in-country” beneficiation is not new in Africa’s gold mining and refining industries. “In-country

beneficiation has been talked about for about the last twenty-five years, particularly in West Africa, which is now the most prominent gold-producing region in Africa,” he says, adding that he hopes to see new ventures succeeding through meticulous planning and sound implementation.

Scrupulous Planning and Implementation

Relating to meticulous planning and sound implementation, Horsley mentions the following important areas: a Comprehensive feasibility study; Plant design, and the optimising of operations for specified inputs and outputs and for a robust metal accounting methodology; and the need for responsible upstream and downstream supply chains.

1. Feasibility Study

The primary step in a feasibility study is to be thoroughly versed in the regulations governing the global gold refining business and how the planned refinery will navigate as a new entity. “Mining companies have to understand the most important aspects of this notion of upgrading newly mined gold or secondary gold to a beneficiated product. Mainly, the product must be able to be sold into the international gold market to realise the inherent value of the gold

Gold processing -in-country beneficiation

Al Etihad Gold Refinery in Dubai

May - June 2023

for investment and monetary trade. And for this to happen, the gold must be accredited by the recognised exchanges and certifying bodies in the market. Typically, these are centred in London, Shanghai, Singapore, Tokyo, Dubai and New York, to name some of them,” Horsley points out.

So, even gold that is refined “in-country” to a purity of at least 99.50% will need to be re-refined by a refinery that has accreditation to a body like the LBMA (London Bullion Market Association) or the DMCC (Dubai Multi Commodities Centre). Without this accreditation, the gold cannot be traded on the international market and thereby realise its full value in monetary terms.

Unfortunately, this is often a step that governments overlook in their drive to establish a gold refinery in their respective countries. Besides basic regulations, Horsley tells mines to be aware of the following information before embarking on a project:

• The location, size, and shape of the desired market for refined gold, for example is the gold to be used for local jewellery manufacture or exported into the international market

• On a global basis, gold refining capacity far exceeds the supply of newly mined and secondary gold input.

• The size and capacity of the refinery that is to be established.

• The type of gold that is to be refined, e.g., newly mined gold, artisanal gold, secondary material, or gold scrap.

• The volume of gold of each type that is to be treated.

• The characteristics and nature of the gold supply chain to the refinery and after the gold has been refined.

• The weighing, sampling, and assaying of the incoming gold, in-process materials, and final products. The methodology used is very important.

2. Design

After a thorough feasibility study has been carried out, a crucial step is designing a refinery that operates efficiently, cost-effectively, and is environmentally friendly. The adage: “Look before you leap may” sound like a cliché, but it is as relevant as ever. Particularly, Horsley brings attention to the following realities:

• Financially, the actual refining step is financially very marginal. Revenue incentives are found in the degree of “value-add” to the refined gold.

• The disposal methodology of the final effluent streams (gaseous, liquid) from the refining process is vital. Residual gold can be entrained in these streams.

• One of the most critical steps in the design of the plant is the control of the metal balance across the process, efficiencies of >99.98% are necessary.

• It is necessary to minimise the work-inprogress gold inventory and the time it takes to refine the incoming gold. Control of the inventory is a necessary part of managing the metal balance.

3.

Optimising Output

Last but not least, the bottom line in any refinery is to efficiently maximise the output. The convoluted part is how to put a handle on this task. While there may be numerous approaches to optimising operations to meet the desired

output levels, Horsley suggests the following steps: Minimising the gold inventory pipeline; Keeping process efficiencies close to 100%; and processing incoming gold as fast as possible so that it can be dispatched to the customer quickly. Furthermore, the use of suitable technologies is central to the successful operation of refineries. Thanks to advances in research and development, there are several innovations at the disposal of refinery asset owners. Among the available technologies that can be adopted, Horsley suggests Miller Chlorination for larger volumes, as well as wet chemical processes for smaller volumes and easier process control.

4. 4. Responsible upstream and downstream supply chains

Last but not least, refiners are strongly advised to understand and take steps to comply with the appropriate standards and guidelines issued by amongst others, the LBMA, OECD, DMCC and the World Gold Council.

Encouraging success

By and large, Hills hopes plans by certain countries to establish sustainable refineries bear fruit. He is encouraged by African countries that have implemented the above-mentioned steps thoroughly. The established refineries can produce gold bars and other products of 9950 fineness and above. This gold is used by jewellery manufacturers to produce their wares, coin, medallion manufacturers and others who use the gold for various decorative and industrial purposes. “Hopefully, the models of those successful ventures are being replicated in other countries. However, enhanced proper prior due diligence is critical, and then challenges can be turned into golden opportunities.”

Mining Business Africa | May - June 2023 15

Drone-based photogrammetry for underground mining environments

Efficient Inspection, Enhanced Safety

By eliminating the involvement of humans (employees), the deployment of drones in underground inspection enhances safety and improves efficiency. Using reliable tools such as LiDAR and SLAM, drones can obtain high-quality images that help mine managers make informed decisions.

obtained are relevant and reliable, as dronebased surveying solutions providers recently told this publication.

A necessity

The significance of drones becomes better comprehended when the myriad of challenges that businesses face in the contemporary operating environment. The challenges can be narrowed down to the twin objectives of onerous compliance requirements (ESG, Occupational Health and Safety in the main), above and beyond ensuring the long-term sustainability of a business.

The surefire way they can meet the abovementioned objectives and prevail is through digitising workflow and operations to enhance efficiency and reduce environmental footprint (emissions), removing or minimising as many as possible humans from hazardous situations. Concerning inspection, the ready availability of advanced drone technology has become a lowhanging fruit right within their grasp.

By Nick Barnes

In mining jurisdictions throughout the continent, recent changes in legislation governing health and safety indicate that authorities (regulators) have assumed a zero-tolerance stance toward safety breaches in mining. Ideally, this obligates mining companies to comply at all costs. However, in reality, unavoidably, there are some areas where mining companies might lack capacity, rendering them vulnerable to high levels of safety risks and potential breaches.

Interestingly, the passing of stringent legislation has coincided with the exponential advancement of a wide spectrum of technologies. The use of some of the technologies has significantly lightened the burden on mining companies of meeting compliance requirements.

Removing human involvement

Mainly, technology has enabled mining companies to remove human involvement in some critical functions, minimising safety risks.

On the whole, the exploration of drone technology can help meet the objective of enhancing safety and improving efficiency in underground mining operations. This task would be difficult to accomplish by assigning employees. Conventionally, these tasks have involved the physical presence of employees.

Drones in underground surveying One of the innovations that is having a groundbreaking impact is drone technology. Among a host of other fields, the versatility of drone technology has revolutionalised how surveys of underground mining environments are performed. These are areas such as stopes and voids, mine shafts and abandoned declines, as well as potentially harmful environments that arise from post-blast situations.

Typically, when conducting surveys in underground environments, inherent risks, deploying employees poses a big dilemma. As an alternative, handily, when deployed properly, drones perform the duty capably in rugged duties. They eliminate the concern of the risk of harm or injuries to workers while acquiring vital data in high-wall precision scanning. And the results, in terms of the volumes of images

LiDAR and SLAM enhance dronebased inspection

Global positioning systems have limited scope in some areas of the underground environment. Handily, as alternatives, simultaneous localisation and mapping (SLAM) and light detection and ranging (LiDAR) technologies have opened up new opportunities. Based on results from recent surveys conducted in African mining, LiDAR and SLAM drones can produce high-resolution images of their high-value, mission-critical assets. Vitally, clients can visualise and map inaccessible areas. The data computed from the images help mining houses make informed decisions on their assets.

16 Mining Business Africa | July - August 2023

A drone on duty in an underground mine (Image: Sandvic Group)

Customised Mining-Specific Turnkey Laboratory Development

Lablink Africa is a South African-based, African-focused provider of Customised Turnkey Laboratory Development Solutions to organisations in mining and other sectors. Previous experience in Africa gives the company the edge to meet the needs of existing and prospective clients involved in Africa.

Currently, several exploration and mining projects are being launched in Africa. Reliable assaying and analysis are one of the services being core to their successful implementation. Continuous monitoring of both the performance and environmental effects of mines requires well designed laboratory services.

Opportunities

The projects have created opportunities for providers of laboratory solutions to render their services. And as expected, the service providers are appreciating the involvement for development.

Additionally, Dr Wesley Feldmann, Managing Director of Lablink Africa, is urging providers to be well-equipped to effectively serve the needs of their existing and prospective clients. “Effective laboratories that are fit for purpose, require a combination of the correct equipment and a team of well-trained staff trained to be both confident and competent to make the laboratory a continued success”.

Prudence in partner selection

Thus, service providers have to be prudent when choosing companies, they partner with in

the planning and implementation of laboratory development projects. The importance of engaging a company with a proven track record does not have to be overstressed.

Well-resourced and functional Feldmann ensures mining-specific laboratory service providers are well-resourced and functional. Lablink Africa goes the extra mile to deliver customised turnkey solutions for their respective laboratory development projects. Particularly, he attributes the company’s success in recent projects to its approach to meeting client-specific needs through the customisation and flexibility of solutions, and dedication to high-quality standards in results.

Turnkey laboratory development solutions

Lablink Africa provides turnkey solutions for laboratory development projects within Africa. It works to provide and support all aspects of a laboratory, including:

• Floorplan and workflow design

• Utility considerations

• Equipment and instrumentation supply

• Installation and training

• Method validation and accreditation

consultancy

• Continuous supply of reagents and consumables

All the above are important considerations and steps that result in a fully functional laboratory. In the end, the completed laboratory will be able to produce high-quality results for decision-making in the mining and environmental sectors.

Regarding the fine details that a typical turnkey solution requires, Feldmann explains: “Lablink Africa works on such projects in partnership with the organisation (public and private) implementing clear communication, education and understanding, ensuring the resultant laboratories are fit for purpose. A welldesigned and effective laboratory, producing high-quality results, ensures integration into the industry value chain to meet both import and export requirements, as well as environmental regulations. Once a laboratory is set up, Lablink Africa offers continued supply and support for effective operation, with shortened lead times for consumables and frequently used items.”

Customising a client-specific solution

It is worth noting that every client has unique needs. So, Lablink tailors a turnkey solution to

Mining Business Africa | July - August 2023 17 Laboratory development for african mining projects

Equipment and instrumentation supply

Laboratory Development For African Mining Projects

of African countries and have gained knowledge and experience with operational challenges that are frequently faced. These have been overcome with effective local partnerships leading to solutions, ensuring laboratories operate uninterrupted and efficiently.”

Meeting expected quality standards

Tapping into the depth of experience of its employees at the management and operational level, Lablink Africa is devoted to meeting optimal quality standards at every level of laboratory management. Feldmann regards this as pivotal for laboratory development projects in Africa. He underscores the company’s commitment: “As standard practice, laboratories are required to produce high-quality results, and these are important for effective and reliable decision-making within the mining and environmental sectors. A variety of prerequisites need to be met for a laboratory to produce highquality results and Lablink Africa provides the best solutions to fulfil these prerequisites.”

suit these needs. Specifically, the development and subsequent operation of a laboratory is a partnership between the organisation requiring a laboratory and Lablink Africa.

Lablink works together with the client from the planning of the project to ensure clear communication and understanding of all aspects required to make the project and laboratory a success. Accordingly, regular updates are central to keeping all aspects on track and implemented effectively. The communication process involved is extensive, which includes management personnel, the laboratory staff and everyone in between.

Feldmann cites the depth and extensive know-how of Lablink’s personnel as the most invaluable asset in efficient project delivery. He highlights that project success comes from Lablink Africa’s staff’s experience and expertise to handle complex projects for the client.

The education of Lablink’s core members is at a PhD level, along with experience in the industry, giving extra confidence and ensuring the correct solution is offered and discussed with the customer. Additionally, it has developed a network of experts, both from industry and academia that offer support to any unforeseen and unique issues that may be encountered. This high level of support and troubleshooting expertise for all aspects of laboratory work, ensures laboratories are never left in the dark or without a solution.

In addition, Feldmann mentions an immense plus for the client in engaging Lablink is the confidence of working with a company experienced in laboratory projects specific to Africa. “We have the experience working both in and with laboratories, for successful development, operation and accreditation. We have travelled and worked within a wide scope

Lablink Africa follows a thorough process to ensure that laboratories achieve the expected quality of results. This includes the choice and selection of equipment and instrumentation, the implementation of quality control measures, staff training and ongoing support and aftersales services.

Fundamentally, the choice and selection of equipment and instrumentation that is fit for purpose is critical to the laboratory’s success, as well as an important financial consideration. Ultimately, the correct instrumentation ensures the results meet the expected quality standards and can be used by the industry at large.

Important considerations in selection include limits of detection and quantification, accuracy and precision, turnaround time and cost of analysis. A growing trend is investment into automated equipment for increased accuracy and precision with reduced error, over and above the cost-effectiveness.

Lablink Africa recognises the importance of informed product selection in laboratory development. This is because the results inform the clients decision making. Lablink Africa advises on the equipment and instrumentation selection and works closely with high-quality and reputable manufacturer brands. In this way, they ensure laboratories are outfitted with the best options to produce high-quality and reliable results.

Apart from the laboratory hardware, quality control procedures and the quality management system need to be set up correctly. Additionally, the staff must be well-trained to work effectively to produce high-quality results. Concerning staff training, Lablink has the experience and expertise to offer both in-person and remote training, above and beyond support services. The support services ensure that the laboratory has access to assistance and guidance.

18 Mining Business Africa | July - August 2023

Equipment installation and training are part of the package

Floorplan and workflow design is part of turnkey solutions provided

Succinctly, Lablink has worked in a variety of African countries and has built up a broad wealth of experience to ensure all the aspects of work are covered, including:

• Instrumental operation and troubleshooting

• Implementation of quality control procedures

• Implementation of a quality management system

• Results evaluation and reporting

Notable milestones

So far, Lablink Africa is scaling notable milestones in African countries in both turnkey laboratory development and the provision of laboratory services. The company has successfully delivered turnkey laboratory development solutions to clients and is committed to continuously building its portfolio. Recently, the company has successfully developed and accredited a laboratory in Malawi, as a complete project. This work has led to further laboratory development projects in Nigeria and Rwanda, which are currently underway and will be completed before yearend.

Besides the provision of turnkey laboratory development project solutions, as a growing

company, Lablink Africa is actively building a customer base across the Sub-Saharan region. Feldmann explains that this is aimed at meeting the needs for quality laboratory services in industries such as mining and environmental services. “Access to laboratory services leads to improvement, development, and growth over time in industries. We are committed to providing the best laboratory services and solutions to organisations.”

Lablink Africa is working throughout subSaharan Africa, particularly in the DRC and Tanzania, to supply and service laboratories in the mining and environmental sectors.Feldmann recaps the company’s commitment to meeting the need for relevant solutions in turnkey laboratory development: “We are well-resourced and ever ready to handle projects within Africa. We thrive in tailoring unique solutions for our clientele needs.”

For more information, contact us at: Email: info@lablinkafrica.co.za Tel: +27 73 999 7605 Website: www. lablinkafrica.co.za

Keeping Abreast

Lablink Africa spares no effort to ensure that its services meet contemporary industry expectations and standards. Mainly, this is through the adoption of technologies that allow for automation and staying abreast of contemporary quality standards.

• Automation

Laboratory technology is constantly developing, with a focus on automation within all laboratory processes. This includes processes such as sample preparation, extraction and analysis, which can often be linked into a continuous process with minimal input from an operator.

Lablink Africa recognises the central role of automation in enhancing the efficiency of laboratories. And so, it has embraced it as pivotal to its operations. “Automation has the advantages of reduced error, leading to higher quality results, decreased turnaround times, and lower cost of analysis. Lablink Africa works with a variety of manufacturers that offer automation options and makes effective use of this advantage to offer laboratories the best solutions for their specific requirements.”

• Quality Assurance

Lablink Africa is committed to adopting new standards that can improve quality assurance. “Laboratory work is standardised in a variety of different ways to ensure results are standardised at a global level. ISO 17025 covers the operational considerations for a laboratory in terms of technical, quality, business, and management systems. This is important to give confidence to the mining and environmental industries for the quality, accuracy, and reliability of the results produced by the laboratory.”

Lablink Africa offers consultancy services to guide laboratory management and staff through the ISO 17025 requirements and ensures readiness for the mandatory audit. With the continuous improvement and development of instrumentation, methods are updated to take advantage of these improvements. So, Lablink Africa keeps up to date with all published methods and literature from international standard organisations, such as ISO (International Organization for Standardization), AMIS (African Mineral Standards), and CEN (European Committee for Standardization).

Mining Business Africa | July - August 2023 19

A partnership set to transform mining with AIoT

“The Smart Conveyor is the future of idler roller monitoring, utilising cloud-based temperature sensors to identify problem areas along the conveyor belts. The alarm system eliminates the need for manual problem identification and provides instant location detection. Furthermore, it can reduce unplanned maintenance, thus increasing the asset availability in the mining operation.”

Smart

Bosch Rexroth Smart Mine (Smart Mine) has joined the Bosch Rexroth Africa Group to revolutionise the mining industry with innovative Artificial Intelligence of Things (AIoT) solutions. These include Smart Conveyor, Stop-Start Retrofit, Smart Inspection, and Smart Lockout, all of which aim to optimise mining operations and promote sustainable business practices.

Jonas Corali, General Manager of Smart Mine, will be responsible for driving the mission and vision of the company. Other key personnel

include Eddie Kleingeld, Regional Sales and Business Development Engineer, and Rodrigo Conte, Project Manager. The team also includes field engineers: Sifiso Shange, Themba Nyathi and Tshanduko Matshusa. The latter two were graduates of the Yes4Youth Programme, a government-business collaboration that seeks to reduce youth unemployment in South Africa.

Corali discusses how Smart Mine is committed to delivering cutting-edge solutions to the mining industry, driving growth across the African continent:

Smart Mine’s history in South Africa

Smart Mine previously operated primarily in Brazil and Chile in South America until it landed its first South African deal in 2019. The company later joined the Robert Bosch brand and is now a fully fledged South African company that falls under Tectra Automation in the Bosch Rexroth Africa Group.

“Our mission is to provide AIoT mining solutions that promote sustainability, future readiness, and business growth through digital transformation,” Corali said. “Our solutions have

20 Mining Business Africa | July - August 2023

Conveyor is highly scalable, allowing up to 5 000 sensors per kilometre on a conveyor.

Conveyor Digitisation For Mining Projects

Smart Mine strategically bolsters the Group’s services to the mining industry by offering cutting-edge, AIoT-based solutions, driving growth across the African continent.

Smart Mine’s Solutions, Smart Lockout, Smart Conveyor, Stop-Start Retrofit, and Smart Inspection, aim to optimise mining operations and promote sustainable business practices.

Smart Conveyor

Maximise conveyor system efficiency with Smart Conveyor by Bosch Rexroth Smart Mine. Prevent downtime and reduce maintenance costs.

Smart Lockout System

Smart Lockout from Bosch Rexroth Smart Mine ensures personnel safety during machine and equipment repairs and maintenance.

Smart Inspection Application

Smart Inspection from Bosch Rexroth Smart Mine is a customisable web-based application that streamlines inspection processes.

Stop-Start Retrofit

Boost your mining efficiency with Bosch Rexroth Smart Mine's Stop-Start Retrofit. Cut fuel use and emissions while enhancing productivity.

BOSCH REXROTH SMART MINE

BOSCH REXROTH SMART MINE

+27 11 971 9400

Conveyor Digitisation For Mining Projects

already shown a significant return on investment for both Smart Mine and our clients.”

Mining industry solutions

“Safety and efficiency are top priorities in mining, and our innovative solutions can help businesses achieve streamlined processes. Our Smart Conveyor is the future of idler roller monitoring, utilising cloud-based temperature sensors to identify problem areas along the conveyor belts. The alarm system eliminates the need for manual problem identification and provides instant location detection. Furthermore, it can reduce unplanned maintenance, thus increasing the asset availability in the mining operation,” said Corali.

Smart Conveyor is the most scalable conveyor belt monitoring system available, allowing up to 5 000 sensors per kilometre. It is currently used in three locations in South Africa and is also suitable for various industries such

as cement, logistics, sugar, and paper.

Installed on heavy-duty mine equipment, the Stop-Start Retrofit solution detects lack of motion, and stops the engine. It plays an imperative role in reducing CO2 emissions and supports a mine’s decarbonisation goals.

Smart Inspection and Smart Lockout are two other solutions offered by the company. Smart Inspection is a locally developed, web app-based system that streamlines inspection processes, eliminates paper-based forms, and reduces errors. It is customisable to meet each business’ specific needs.

Smart Lockout supports on the isolation energy process in specific areas for any asset maintenance, which is often located at a distance from the energy source. The solution ensures the safety of workers by preventing the accidental startup of machinery during maintenance or repair work, reducing the risk of accidents and injuries.

Smart Mine highlights

Smart Mine has experienced some remarkable milestones since inception, but one achievement stands out. Despite facing the challenges posed by the COVID-19 pandemic, its first Smart Conveyor solution was installed in Africa when the virus was at its most rampant. “It was a challenging time,” says Corali, “but we pushed forward with our mission to revolutionise the mining industry with our cutting-edge technology and great results have been achieved to date.”

“The installation of this ground-breaking technology was a true highlight and it presented an opportunity to showcase the incredible capabilities of our innovation,” Corali points out. “Smart Conveyor’s remote monitoring capabilities proved invaluable when site access was difficult, ensuring successful mining and minimised risks.”

“Subsequently, there has been an influx of enquiries and interest from potential clients. The success of Smart Conveyor has proven to be a game-changer for the mining industry,” Corali added.

Smart Mine benefits

AIoT enables secure and transparent data sharing, enhances efficiency, reduces costs, and improves safety in the mining process. It also enables the tracking and tracing of materials, promoting responsible sourcing and sustainability. Smart Mine’s innovative solutions benefit the wider community and environment, reinforcing Bosch Rexroth Africa’s commitment to sustainable economic growth.

Bosch Rexroth Africa is committed to the digital transformation of the mining industry by supplying it with the best cutting-edge solutions on the market.

22 Mining Business Africa | July - August 2023

Bosch Rexroth Smart Mine also offers Smart Inspection and Smart Lockout. Smart Inspection is a customisable web app that simplifies inspections, reduces errors, and eliminates paper forms. Smart Lockout guarantees worker safety during maintenance by preventing accidental machine startup.

Installed on heavy-duty mine equipment, Stop-Start Retrofit detects a lack of motion and stops the engine.

Low Emission Valves, Compliant and Safe Piping Systems

As low-fugitive emission valves are used in critical applications, it is important to select products with correct specifications. And so, AZ-Armaturen South Africa (Pty) Ltd advises mining companies to be discreet in the product selection of Low-fugitive emission valves.

Mining companies are obligated to comply with legislation to reduce emissions in their operations from pit to port. To achieve this, they should explore every available avenue. Relating to piping systems, one of the common problem areas is uncontrolled leaks of gas or vapours.

This is an area where special low fugitive emissions valves are utilised to eliminate fugitive emissions. Nonetheless, things do not always go according to plan as mining pipes handle corrosive and abrasive substances. Unfortunately, failure can occur when least expected, usually at a huge cost. This is in the form of potential breaches of regulation in case of over-the-limit emissions, accidents due to exposure to fumes or explosions, above and beyond downtime and expenses on fixing the problem.

Discreet production selection

Concerned about how poor choice of lowfugitive emissions impacts operations, Application Engineers at AZ-Armaturen South Africa (Pty) Ltd tells mining companies to be prudent in product selection. “Low-fugitive emission valves are used in critical applications and it is important that products with correct specifications are selected,” they say in response to Mining Business Africa

Engineered for rugged requirements

Low emissions fugitive valves should be engineered to handle rugged requirements of mining-specific piping systems, the application engineers say, demonstrating AZ-Armaturen’s approach to designs, customising products to operational conditions, materials of construction, and adherence to quality standards.

1. The design

Regarding the design of plug valves and related equipment, the emphasis is on the following characteristics:

• Free of cavities

• Maintenance free

• Self-lubricating

• Mounting-flange for actuators acc. to DIN ISO 5211

• Easily accessible adjustment of the plug, even with a mounted actuator

• Vacuum tight

• Fugitive emission certified, resp. German Clean Air Act (TA-Luft 2002 approval)

• Certified according to Directive 2014/68/EU

• Firesafe design API 607 / ISO 10497

Mining Business Africa | July - August 2023 23 Low Fugitive Emissions Valves For

Projects

Mining

The popularity of AZ-Armaturen’s low-emission valves pivots around quality

Low Fugitive Emissions Valves for Mining Projects

2. The operational conditions

The operational conditions can be in the following parameters for a plug valve for fluctuating temperatures:

Firesafe DIN-EN:

• DN 15 – 600

• PN 10 – 40

ASME:

• NPS ½“– 24“

• Class 150 – 300

PT range:

• -30 < T < 230/280°C

• Vacuum 10-8 mbar.

3. The material of construction used

The nature of some liquids or solids can accelerate the wear of valves. Thanks to tons of experience gathered from and investment in continuous product research and development, AZ-Armaturen South Africa (Pty) Ltd has built a reputation as an expert in “3D media”: Dirty, Difficult, and Dangerous.

“Depending on the media, the pressure and the temperature combination of the application, the right combination of standards materials for the body and the plug, as well as the sealing materials are chosen by the client´s process expert,” explain the Application Engineers.

Typical standard body materials include:

Carbon Steel 1.0619, ASTM A216 WCB

Stainless Steel 1.4408, ASTM A351 CF8M

Stainless Steel 1.4308, ASTM A351 CF8

Unalloyed stainless-steel casting (low Temp.)

1.1138