www.oimconsulting.com More productive tonnes safely Our coaching equips supervisors for sustained growth Measurable Operational Results

Cover Image: Carl Hamm’s Flangeless Hi-Pressure Pipe Coupling enables effective dewatering

COVER STORY: PG 02

Flangeless Hi-Pressure Pipe Coupling, Effective Dewatering

High-pressure and high-tensile, Carl Hamm’s ZSM duplex stainless-steel coupling system enables rapid coupling and uncoupling of pipes, which in turn allows reduced installation and abstraction of pumps. In this way, it contributes to the reduction of downtime and maintenance costs, facilitating the efficient and effective dewatering of mines.

TEAM

Editor

Nick Barnes

editor@miningbusinessafrica.co.za

+27 10 055 3356

Web/Sub-Editors

Jimmy Swira

Jimmy@miningbusinessafrica.co.za

+ 27 10 055 3356

Anita Anyango

anyangoanita18@gmail.com

Contributing Writers

Chantelle C.

chantellec@miningbusinessafrica.co.za

+ 27 10 055 3356

Editor’s Note

Increased Trade with China May Not Transform Africa

In many resource-rich African countries, the main problem has been leaders who misappropriate billions in revenue meant for development.

Judging from the current trends, we are witnessing a seminal epoch in world geopolitics. The War in Ukraine, the catalyst, has widened the schism between the West and BRICS countries (China, South Africa, Brazil, India and Russia).

Fascinatingly, envisaging more economic benefits, most developing countries are cementing ties with the BRICS block and its associates, seeking ‘fair’ trade terms.

Observing the recent developments, some commentators are going overboard, gushing about immense opportunities for resource-rich countries. This renaissance of confidence is admirable.

Unfortunately, in many African countries, the abundance of resources is more of a curse than a blessing. Corrupt leaders misappropriate revenue, and little, if at all, trickles down to the ordinary people.

The often-cited root cause of the problem is poor governance, particularly the dearth of accountability and transparency.

Needless to say, unless there is a mindset shift in managing revenue from resources, African countries will be stuck in economic stagnation, irrespective of whether they trade with China or the West.

Hold your horses!

Nick Barnes editor@miningbusinessafrica.com

Susan M. susanm@miningbusinessafrica.co.za

Sales and Marketing

Winnie Sentabire winnie@miningbusinessafrica.co.za

+27 83 530 6832 | +27 10 055 3356

Angeline Ntobeng

angien@miningbusinessafrica.co.za

+ 27 078 322 5938

+ 27 010 055 3356

Accounts

Precious Chirunga

accounts@miningbusinessafrica.co.za

+ 27 10 055 3356

Art Director/Layout

Augustine Ombwa

Arobia Creative Consultancy

austin@arobia.co.ke

+254 772 187 334

Circulation/Sales info@miningbusinessafrica.co.za

+ 27 10 055 3356

Published By Media Icon (Pty) Ltd

34 40 04 CONTENTS March - April 2023 Media Icon (Pty) Ltd makes every effort to ensure the accuracy of the contents of its publications, but no warranty is made as to such accuracy and no responsibility will be borne by the publisher for the consequences of actions based on information so published. Further, opinions expressed are not necessarily shared by Media Icon (Pty) Ltd. www.miningbusinessafrica.co.za

18

Cost-effective Solution for Acid Mine Drainage

Flangeless Hi-Pressure Pipe Coupling, Effective Dewatering

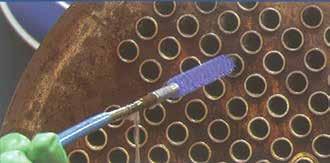

High-pressure and high-tensile, Carl Hamm’s ZSM duplex stainless-steel coupling system enables rapid coupling and uncoupling of pipes, which in turn allows reduced installation and abstraction of pumps. In this way, it contributes to the reduction of downtime and maintenance costs, facilitating the efficient and effective dewatering of mines.

Acid Mine Drainage (AMD) has been a challenge for many years. However, it wasn’t until last two Decades, with the large-scale mining of the past century, that people realised the negative impact of abandoning mines and leaving the effects of AMD to impact the environment for generations. This is especially evident in the Witwatersrand Goldfields of South Africa, where the Western, Central, and Eastern basins stretch for over 70 km and are interconnected so that flooding in one mine affects adjacent mines. The last operating mine in each basin was responsible for the costly pumping and neutralization of AMD, which often led to mine

closure and liquidation. However, treatment plants in each basin have made significant progress in stopping decant and preventing breaches of Environmental Critical Levels (ECL).

Carl Hamm’s ZSM system has played a crucial role in contributing to the safe and environmentally friendly abstracting of AMD. The ZSM coupling system is employed in the Shafts to facilitate the efficient and effective dewatering of the mines. By using high-pressure, hightensile, duplex stainless-steel couplings, the ZSM system enables coupling and uncoupling of pipes, which in turn allows rapid change of Submersible pumps. Ultimately, this reduces downtime and maintenance costs.

2 Mining Business Africa | March - April 2023 FEATURE

The ZSM system enables coupling and uncoupling of pipes, which in turn allows rapid change of Submersible pumps.

Advantages of ZSM coupling system ZSM coupling system enables cost-effective, safe, environmentally friendly, and efficient management of AMD Abstraction thanks to the following features:

• The ZSM system is designed to withstand high pressures and is made of duplex stainless steel, which offers superior strength and durability compared to other materials. Thus, it can withstand harsh environments, making it a reliable and efficient solution for pumping AMD.

• The ZSM coupling system is designed to be leak-free, which enhances safety and reduces the risk of environmental contamination.

• With the ZSM coupling system, pumps can be lowered from the surface, and no one needs to enter the mine. In this way, the risk of exposure to Gas and Toxic Acid mine Water is eliminated.

• The ZSM system’s quick and easy 15-second assembly and disassembly allows for faster and more efficient installation and maintenance and replacement of submersible components. This is especially important in mining operations where downtime can be very costly.

• The ZSM system’s high-pressure capabilities allow for the effective dewatering of mines with rising water levels. The system can handle high volumes of water and pump it out quickly, which can help prevent flooding and maintain safe working conditions in the mine.

Overall, the ZSM system’s durability, ease of maintenance, and high-pressure capabilities make it an effective solution for managing rising water levels in mines and ensuring compliance with safety and environmental regulations.

Challenges of using conventional pipe connection systems

ZSM coupling system is a critical solution in water treatment plants for AMD. Typically, managing rising acid mine water levels in mines using conventional pipe connection systems can pose several challenges, such as:

• Cost: Acid mine drainage treatment can be expensive due to the complex and intensive abstraction, including high capital costs for installation and maintenance of equipment, and high operating costs to ensure effective treatment.

• Time and labour: raditional pumping systems require continuous maintenance and monitoring to ensure that the system is functioning properly. The need for regular maintenance can be timeconsuming and requires significant labour resources. It requires Staff to be lowered into the mine and as such the mine remains an active mine with all

associated costs.

• Environmental impact: Acid mine water can have a detrimental effect on the environment, as it can cause pollution in nearby water sources and harm wildlife. Therefore, it is important to effectively manage and treat acid mine drainage to minimize its impact on the environment.

• Regulatory compliance: Mines are required to comply with environmental regulations regarding acid mine drainage, and non-compliance can result in fines and penalties.

• Safety concerns: Rising water levels in mines can pose safety risks to workers, as it can lead to flooding and damage to equipment.

Generally, the challenges associated with managing rising acid mine water levels using conventional pumping systems can have a significant impact on mine operations, compliance, and safety.

Partnership delivers reliability and efficiency

Carl Hamm’s recent partnership with Esser Pipe Solutions offers an innovative solution to the challenges of acid mine drainage dewatering. By combining Carl Hamm’s ZSM coupling system with Esser’s twin-walled pipe components, mining companies can benefit from a reliable and efficient system that is resistant to wear and can withstand high pressures.

The ZSM coupling system’s quick and easy assembly and disassembly allows for flexible and efficient deployment of the twin-walled pipe components in acid mine drainage dewatering systems. The combination of the ZSM coupling system’s high-pressure capabilities and Esser’s wear-resistant twin-walled pipe components

results in a solution that is cost-effective and environmentally friendly, while also meeting international safety standards.

On the whole, the partnership between Carl Hamm and Esser offers mining companies a cutting-edge solution for their acid mine drainage dewatering needs, with the potential to significantly improve operational efficiency and compliance.

For more information on the products and services that Carl Hamm PPS provides, contact Desmond Enslin at +27 83 556 4642 or send an e-mail to desmond@ carl-hamm.co.za. Visit our website at www.carl-hamm.co.za.

Mining Business Africa | March - April 2023 3

Mine Dewatering

IPR’s dewatering plan saves the day at Iron Mine

Groundwater ingress combined with seasonal rainfall was creating such a challenge for a South African iron ore mine that the bottom of one of its pits had become completely inaccessible. When dewatering specialist IPR was called it, it developed a plan that would combine on-mine pumps and a rental fleet as required. The results have put the mine back to work in top gear.

“In this case, we identified that the primary issue was the application of incorrect dewatering pumps, which were not performing the duty required,” he says. “IPR implemented a programme to assess and then repair the existing pumps on site – bringing them up to OEM specification so that they would perform reliably and deliver the expected results.”

In line with the dewatering plan, the mine’s own fleet of pumps was supplemented by a custom offering from IPR. This involved some units being purchased outright from IPR, and other pumps taken on a long term rental agreement. Venter notes that dewatering has seasonal variations, and this could mean that some pumps stand idle for several months during dry periods.

“Our rental programme is offered in recognition of this to relieve customers of the cost of owning equipment that is not optimally utilised,” he says. “Instead, we supply pumps sets that are fully kitted out according to the customer’s requirements – and they are ready for operation.”

When flooding at an iron ore mine in South Africa’s Northern Cape province meant it could no longer access the floor of one of its pits, it called in IPR for a sustainable solution.

Rental Development Manager at IPR, previously known as Integrated Pump Rental, Ruaan Venter says the solution began with a dewatering plan. This was vital, as the mine had experienced challenges with groundwater ingress for many years – and these were not being resolved.

“A common open pit dewatering method is to use pumps to extract water from the lowest levels of the mine,” explains Venter. “However, it is often not enough to perform only this step. Rather, the whole groundwater table around the mine has to be lowered, so that the pit is not continually filled with incoming water.”

He says IPR’s eight years of experience in designing and manufacturing dewatering systems has given it a depth of insight into efficient and reliable groundwater control. The company’s approach is to apply best practice

in dewatering applications, and not just send a pump set to site without a good understanding of the operating conditions and the specific challenges being faced.

He points out that the plan for this mining customer also included an appreciation of water quality and characteristics.

“Groundwater and process water contain abrasive and corrosive elements in varying quantities,” says Venter. “These have an adverse effect on pump performance and life – and need to be built into the pump specifications.”

A key aspect of the plan was therefore to ensure that all pumps performed optimally, to eliminate the risk of repeated flooding. IPR is therefore maintaining all pumps on site, including its own fleet and those belonging to the mine.

“Well-matched solutions help to maximise the longevity and efficiency of the system and also optimise cost-performance ratios,” he says. “IPR ensures we deliver these results, by supplying a complete dewatering package made up of the pump, engine or motor and couplings – as well as auxiliary equipment such as vacuum pumps, control panels and monitors. This service delivers high head pumping where the water levels must remain low for continuous production reliability.”

4 Mining Business Africa | March - April 2023 FEATURE

IPR supplied a large diesel driven pump set to an iron ore mine in the Northern Cape.

IPR is the Atlas Copco master distributor for its range of dewatering pumps.

Chute design for coal mines

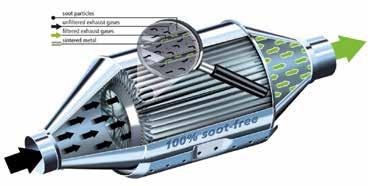

Careful chute design can cut coal dust generation

Coal dust impacts on the efficiency of coal handling systems, hence productivity and profits. Alwin Nienaber, Technical Director of South Africa’s Weba Chute Systems, a globally recognised leader in chute technology, says a more effective approach is to focus on the engineering and positioning of the transfer chutes that form an integral part of most conveyor systems.

which invariably creates much more dust than is necessary.

Tintinger says Weba Chute Systems can provide custom-engineered chute designs which deliberately create a flow path for the material based on its inherent qualities, speed and volume and the throughput requirements of the installation.

“Using sound engineering principles, chutes can be designed to minimise the physical impacts that create dust,” he says. “We base designs on the ‘supertube’ effect, allowing controlled transfer of material onto the conveyor belt. This also reduces wear and tear on the belt.”

The generation of coal dust around conveyer systems and transfer points is a problem for operators of coal mines, coal plants and similar facilities. Coal dust is a contributor to lung disease and it therefore poses a threat to not only workers in these facilities but even to residents of neighbouring communities. It also poses a safety hazard, as it can spontaneously ignite causing potentially life-threatening fires.

Coal dust also impacts on the efficiency of coal handling systems – and hence productivity and profits. Equipment and machinery can become thickly coated with dust, which increases the need for regular cleaning, while dust ingress into moving machinery reduces its lifespan.To control the problem, reliance is generally placed on dust suppression and dust extraction systems. While this all well and good, there is a tendency to over-rely on these systems, which results in them doing more ‘heavy lifting’ than they need to and often more than they can manage.

According to Alwin Nienaber, Technical Director of South Africa’s Weba Chute Systems, a globally recognised leader in chute technology, a more effective approach is to focus on the engineering and positioning of the transfer chutes that form an integral part of most conveyor systems.

“This can relieve 50 to 80 % of the problem,” he says. “Suppression and extraction of the remaining dust then becomes a much more

efficient component in a broader and more holistic solution.”

He adds that at the heart of any effort to control dust is an understanding of material flow and of the effects of uncontrolled velocity and impact. As he says, “Dust is really just one of a number of unwanted consequences of a lack of control over material flow, including degradation of the material being moved.”

Reinforcing this point, Nienaber’s colleague, Dewald Tintinger, Technical Manager at Weba Chute Systems, notes that most chutes simply provide an open channel for material to fall through, before being discharged onto the next conveyor or outlet. The result is that material can spread in an uncontrolled manner as it travels,

To allow it to model the behaviour of material being transported via conveyors and chutes, Weba deploys specialised technology including three-dimensional software. It also verifies its designs prior to manufacture using discrete element method (DEM) simulation.

As a final point, Nienaber says that strategies to control coal dust are best formulated at the design stage and that the earlier Weba Chute Systems is involved, the better the outcome.

“The configuration or general arrangement of equipment within a plant or between structures is important,” he maintains. “In our experience, we have seen the benefit of being able to advise plant designers on the optimal positioning of chutes and related equipment at the planning stage. The result is invariably a sharp reduction in dust creation and a more efficient flow of material.”

Mining Business Africa | March - April 2023 5

Visual inspection of a transfer chute underway.

FEATURE

Showing a moving head chute installed at a coal mine in Limpopo.

Package Cooling Towers: The solution to minor heating processes

By Patience Chimbetete

By Patience Chimbetete

The machines and processes used at mining sites generate tremendous amounts of heat, which require continuous cooling so they can operate efficiently. The most effective and least expensive solution to removing this heat is the installation of cooling towers.

Though the majority of processes at mining sites require field-erected cooling towers, minor applications such as small boilers, machinery etc, call for the use of package cooling towers. Also known as factory-assembled towers, package cooling towers are pre-fabricated off-site and brought as a single component that will take little time to erect as it is basically “plug and play”. This means that there will be minimal

interruption at the mining operation.

“As a global specialist in designing package cooling towers as well as field-erected towers for the mining sector, we are uniquely positioned to provide bespoke solutions for a mining company’s cooling needs,” says Danie Krüger, Operations Director at Lekwa Cooling Tower Services (LCTS) – a Sasolburg-based cooling tower company in South Africa.

Specialising in cooling towers for South Africa and sub-Saharan Africa, LCTS offers package cooling towers to suit a mining site’s specific needs and thermal requirements. As an accredited company based on the ISO 9001:2015 standard, with an in-house team experienced in developing ventilation and cooling technology, the company supplies high-quality, durable units that are designed

for long life and low maintenance. Due to the unpredictable weather patterns, all structural components and mechanical support are made from 304 stainless steel, rugged fiberglass, stainless steel fasteners and UV-resistant gel coating, which work to resist the corrosion and deterioration that would result from the conditions and environment. Additionally, PVC piping distribution system means the chance of rust developing is eliminated, resulting in less maintenance costs. “These features give our clients the confidence that the equipment we supply is protected and running at maximum efficiency,” Krüger explains.

“We always look at the best option to help our customers to ensure that they can keep their processes cool. We supply package cooling towers ranging from 3m3 /hour to 140m3 /hour,

6 Mining Business Africa | March - April 2023 FEATURE

Process cooling is an important aspect in mining, making it crucial to find a functional cooling system that ensures that production continues with minimal interruption.

LCTS offers package cooling towers to suit a mining site’s specific needs and thermal requirements

COOLING TOWER SERVICES

Empowering, Localizing and Transforming

PRODUCT OFFERING:

Lekwa Cooling Tower Services (LCTS) is a South Africa based cooling tower services / maintenance and spares provider. LCTS have a wide range of package cooling towers available and are designed to suit our clients’ speci c needs.

As a B-BBEE majority black-owned Level 2 company, we are an equal opportunity company which strives to provide our workers with learning opportunities to grow to their fullest potential.

Lekwa Cooling Tower Services o ers very competitive pricing, quick turnaround times and availability on new built cooling towers as well as

Contact details

Tel: +27 16 931 2061

Email: info@lcts-sa.com

39 Saturn Street, Naledi, Sasolburg, Free State, 1947, South Africa

www.lcts-sa.com

all related spares and services for all types of cooling towers such as:

Package cooling towers ( ll blocks, sprayers, drift eliminators, air inlet louvre frames, air inlet louvre insert etc.

Cooling tower impeller blade refurbishments as well as new impellers (blades and hub).

Deliveries to neighbouring and regional countries are undertaken on a regular basis as well as site visits to ascertain and understand the client’s speci c cooling tower needs.

- MAINTENANCE - ASBESTOS

SPARES

FEATURE

which gives customers the highest assurance of attention to detail,” he adds. Additionally, LCTS has a technical team that will visit the customer site or send them customer some technical questions to determine the thermal specs, site needs and all, to propose the most effective option.

New units not the only option

Not only does LCTS offer new units for its customers, the company also provides complete cooling tower refurbishment and services, from a basic flush and clean to a complete refurbishment of any type or size cooling tower. This includes all mechanical and structural work, concrete repairs, among other things.

LCTS

is also a registered Asbestos contractor –

With many of the older cooling towers still fitted with asbestos piping, drift eliminators and fill

material, LCTS also offers a full turnkey project on such towers. “It is not always possible for some clients to buy a new package cooling tower due to budget constraints. We therefore have the cheaper option of a completely refurbished unit,” Krüger advises. He explains that the refurbished units come with a 12-month guarantee, which is proof of how confident LCTS is in the workmanship and quality rendered during the refurbishment process. Additionally, the company also offers customers the option to trade in an old tower for a new one.

“We understand just how money saving is important to our customers and look for ways to ensure they can do this while continuing with their business operations. This is another way we warrant that saving,” Krüger says. The company has highly trained mechanical engineers, project managers and site managers who can attend to your unit timeously.

To top it all, the majority black-owned company’s package cooling towers are competitively priced, with quick turnaround times.

Cooling tower service and maintenance

As a value-add for its customers, LCTS is well-positioned to offer complete assistance to customers with breakdown teams available 24 hours. Additionally, the company has ex-stock on most of the common cooling tower spare parts, which means it will be able to assist in the event of a breakdown with minimum downtime. With all types of spare parts available, ranging from fill blocks, drift eliminators and nozzles to fibreglass blades and hubs, LCTS would be a great partner for any business seeking cooling tower solutions.

Advantages of packaged cooling towers

Due to advancements in the manufacturing and design of the cooling towers that LCTS supplies their use have evolved from a valuable support tool to that of productivity and savings. Factoryassembled, package cooling towers have become more popular in the industry as they save time and are cost-effective. With this in mind, it is a wise move to consider these cooling towers to better meet your process needs. Below are more reasons:

• Life expectancy - The 304 stainless steel, rugged fiberglass, stainless steel fasteners and UV-resistant gel coating that the cooling towers are made of mean that the units will have a longer lifespan with minimal maintenance.

• Easy set up - The basic design advantages of the latest packaged cooling towers include easier installation. Because the cooling towers come already assembled, the only thing that would be required is to set them up onsite. This results in minimal interruption to production.

Lekwa Cooling Tower Services (Pty) Ltd. 39 Saturn Street, Naledi, Sasolburg, Free State, 1947, South Africa Contact number: +27 16 931 2061 Email: info@lcts-sa.com Website: www.Lcts-sa.com

Factory-assembled, package cooling towers save time and are cost-effective

Electrical Power Transmission Apparatus

Explosion-Protected Electrical Apparatus a Necessity

flammable medium-to-air ratio determines the scale of the reaction – whether igniting and burning or an explosion. Nonetheless, these are risks that mining companies would not want to encounter at any cost.

Factors in selection

No question, informed decisions should be made in electrical-protected apparatus for deep-level mining.

By Nick Barnes

The observation that, increasingly, hard rock mining is going deep-level or ultra-deep has been mentioned in this publication several times. Operating in these environments comes with its unique challenges - one of them is increased safety risks or exposure to hazards. Hence, the success of mining operations in this environment hinges on the effectiveness of measures to mitigate these risks. One of them involves choosing equipment or products used in those environments, especially when it comes to the risk of explosion.

Explosion protection

To improve safety, productivity and environmental sustainability at a deep level, electrifying mining operations has become a necessity. That’s why in the selection of electrical apparatus products used, explosion protection should be the main criterion. This is due to the risks that persist in those environments.

In this context, reference to electrical apparatus used for mining applications includes but is not isolated to the following: motors, starters, lamps, switches, junction boxes, fuses, cut-outs or any other appliance, equipment or fitting.

Concerning Explosion Protected Apparatus, South Africa’s Department of Mineral Resources and Energy defines it as the following: “Any apparatus used in a hazardous location

and selected in accordance with the guidelines as defined in the South African National Standard SANS 1 01 08-2005.”

Explosive atmospheres

The risk of explosion in underground mines should not be taken lightly.

Underground mines are explosive atmospheres with the presence of a flammable medium of gas, mist or vapour or dust. Most prevalent in underground mines is methane and air (based on Mining Business Africa’s engagement with mines).

Usually, when mixed with air, a flammable medium forms an explosive mixture. The

For this reason, several factors have to be thoroughly analysed before selecting electrical transmission products. Mainly, these are external mechanical damage, environmental conditions, handling operations, explosive gases combined with dust, etc. Most importantly, ATEX Certification and IECEx Certification are highly recommended.

No compromises

The significance of using explosion-protected electrical transmission products should not be underestimated at any given time. The hazards that lurk in underground mines are high, even when, ostensibly, there is proof that they are not. This is given the unpredictability of conditionscircumstances can change in a split second. And so, no compromises should be made in product selection, even though there has never been a history of an explosion in a mine.

In general, it goes without saying that: It is better safe than sorry, err on the side of caution.

Mining Business Africa | March - April 2023 9 FEATURE

When selecting an explosion-protected electrical apparatus for deployment in underground mines, the adage, “Better safe than sorry” should always apply. It is better to err on the side of caution by investing in a high-quality product that meets all considerations regarding explosion products.

An explosion-protected electrical apparatus engineered for deployment in underground mines

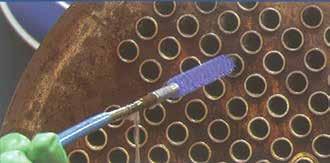

Mechanical Seals for Slurry Pumps

AESSEAL Modular Mechanical Seals Earn Industry Recognition

AESSEAL’s modular mechanical seals have gained the trust and approval of customers in the African mining industry over the years. These seals have been particularly successful in improving the availability and enhancing the durability of slurry pumps. In a recent project, AESSEAL provided a solution to a copper mining company that resulted in increased efficiency of its slurry pump.

Mining companies must maintain optimal working conditions of their critical equipment at all times to meet their production targets. For slurry pumps, mechanical seals are the most essential component for ensuring high availability and efficient performance in harsh conditions. By selecting high-quality mechanical seals specifically designed for mining applications, companies can guarantee uninterrupted operation and extend the service life of their pumps.

As one of the top suppliers of mechanical seals for slurry pump applications, AESSEAL has earned the highest regard from its customers across diverse industries. Anticipating an increase in demand from mining operations throughout Africa in 2023 and beyond, the company is reaffirming its commitment to delivering dependable and customised solutions. AESSEAL’s unwavering focus on innovation and customer satisfaction ensures that it will continue to be a trusted provider of mechanical seals to the mining industry.

Poised for Success

Managing Director, Shane Chester, at AESSEAL is determined to replicate the success achieved in complex projects. He is confident that the company is poised for success and will deliver

to the customer’s expectations. Chester highlights several strengths of the company, including its comprehensive solutions, ability to manufacture a wide range of products for diverse applications, and meticulous approach to application engineering.

Complete Mechanical Seal Solutions

At AESSEAL, the team understands the unique needs of their customers in the mining industry, as well as across all other industries. That’s why they offer a full turnkey solution for mechanical seals and their support systems. Their key solutions include:

• Design and Engineering: AESSEAL offers a wide range of design options and custom engineering solutions to meet the specific needs of our customers

• Manufacturing: AESSEAL has a state-of-the-art manufacturing facility that produces high-quality mechanical seals and related products

• Testing and quality assurance: AESSEAL conducts thorough testing and quality assurance procedures to ensure that our products meet the highest standards for performance and reliability

• Technical support and aftersales services: AESSEAL provides ongoing technical support and after-sales

service to help customers maintain their mechanical seals and systems – which ultimately extend their equipment life.

Robust Mechanical Seals for Different Industrial Applications

In slurry applications within the mining industry, AESSEAL offers a range of high-performance seals, including the CURC™, CDSA™ or FIDC™, CDPH™, and UHDDS™.

These seals are designed with self-aligning technology, modular construction, large ports, increased radial clearances, and solid tungsten carbide gland inserts for ultimate abrasion resistance. AESSEAL’s slurry seal range is engineered to withstand even the most arduous duties, delivering significant cost savings to customers. “Our seals can be provided with exotic wetted components if required,” explains Chester, adding that the modular design of the mechanical seals offers several benefits.

Top Choice for Mechanical Seals

It comes as no surprise that AESSEAL is the preferred supplier of mechanical seal solutions for various industrial sectors, thanks to the outstanding attributes suggested above. The relevance of AESSEAL’s solutions is clearly demonstrated by the prestigious customer portfolio, which includes top manufacturers

10 Mining Business Africa | March - April 2023 FEATURE

such as Warman, Denver Orion, Goulds, and KSB. The company has successfully sealed nearly all major slurry equipment types and models, proving its expertise and reliability in the industry.

Pursuit of Perfection

Maintaining the production of high-quality mechanical seals and related products is a top priority for AESSEAL. The company continuously strives for improvement in its product development approach, and this mindset has led to significant investments in various areas.

These include state-of-the-art manufacturing facilities, quality control systems, research and development activities, and employee training and development. Chester emphasizes the criticality of these investments. “Our commitment to providing our customers with reliable, highperforming products that meet their specific needs and requirements is demonstrated through these initiatives. It’s no surprise that we have gained industry recognition and approval for our efforts“

New approach for slurry pumps reduces water usage by 95%

Acopper mining company in the central Africa was encountering problems of excessive water usage combined with leakage into the process as a result of the use of unsuitable gland packing.

The process involved the pumping of a combination of sulphuric acid and slurry. In order to keep the packing in serviceable condition, the company was using 42 litres of water per minute, or 22 million litres a year for each of its 24 pumps.

In addition to the costly use of huge volumes of water, leakage from the gland

packing was also leading to bearing failures, resulting in periods of downtime.

The company turned to AESSEAL® for a solution. The problem was rectified by the installation in January 2022 of two AESSEAL® 180mm FGDSS-N™ single seals. These are using water at a rate of just two litres a minute (as opposed to the previous rate of 42 litres a minute), with no leakage, no bearing failures, and saving over 21 million litres of water each year.

The company was impressed by the speed with which AESSEAL® responded

to their request for assistance, and by how effectively the new mechanical seal has been operating. “It’s a huge improvement,” said the plant’s maintenance manager. “We have not had to touch the pumps since the seals were installed.”

The company is now in talks with AESSEAL® about the installation of similar seals on all its 24 pumps which could potentially save more than 500 million litres of water each year!

Sealing applications in the mining industry are some of the most arduous and often require a custom engineered design. AESSEAL® has many years of experience in designing solutions for the industry that deliver improvements in reliability for our customers.

To see why customers are switching to AESSEAL® visit our website or contact your regional Manager for Sales & Operations:

TEL: 011-466 6500 Email: info@aesseal.co.za www.aesseal.co.za

Mining Business Africa | March - April 2023 11

AESSEAL® offers a range of mechanical seals suitable for the challenges of most mining applications.

Mechanical Seals for Slurry Pumps

Premier Prestressed-steel Prestanks

Prestank, Structa’s flagship pressed-steel sectional tank, is hot-dip galvanised for corrosion control in accordance with SANS 121 (or ISO 1461) galvanizing standards. The robust tank offers extended maintenance-free life when water with aggressively corrosive properties needs to be stored. It meets all properties for mining-specific water storage tanks.

for rugged demands in the mining sector. It is fabricated in accordance with SANS guidelines and meets South Africa’s hot-dipped galvanising requirements.

Typically, all Structa’s pressed-steel sectional tanks are hot-dip galvanised for corrosion control in accordance with SANS 121 (or ISO 1461) galvanizing standards. Uniquely, the thickness of the hot-dip galvanising coat on the Prestank is applied within a range of 80 to 100 µm. This is more than five times what is regarded as the standard thickness of zinc on pregalvanized corrugated steel cylindrical tanks. This treatment ensures that extended maintenance-free life when water with aggressively corrosive properties needs to be stored.

Why the Prestank sectional tank design

A mining company rests assured of the following main benefits by choosing Prestank:

There has been an increased need for water storage solutions for mining projects in remote areas in Africa in the past two years. Naturally, the preference is for water storage tanks that are robust enough for extreme environments. This is not least in the persisting drought conditions.

Press-stressed sectional storage tanks

Thanks to innovations in engineering, there are numerous liquid storage tanks on the market for mining houses to explore for their respective projects. One of the storage tanks types that have proved their worth – and continue to do so – in tough conditions are pressed-steel sectional tanks, earning the trust across industries.

Structa Technology’s Prestanks

Pressed-steel sectional storage tanks are a niche area where Structa Technology has excelled, emerging as one of the highly regarded providers. Based in Gauteng Province in South Africa, steel tank manufacturer, Structa Technology, a member of the Structa Group, provides robust temporary or permanent water storage installations for mining projects. The company is renowned for the fabrication of the premier Prestank. For over 40 years,

consistently, the Prestank brand has been widely esteemed for being a hygienically safe, costeffective and reliable water-storage solution.

Meticulous engineering

Meticulous engineering has made Structa Technology’s high-quality Prestank suitable

• It features a variety of construction elements and an infinite range of sizes and configurations to meet clients’ specifications. These include walkway options and staircases, as well as roof options.

• The profile panel sections provide excellent strength properties and are structurally sound for storing water. The stand is designed strictly in accordance with SANS 10160 for structural loading and SANS 10162 for structural steel design. Tanks mounted on steel towers above ground level have an aesthetically pleasing appearance.

• Another significant advantage of the sectional tank design is that it facilitates easier handling and transportation over long distances to remote areas, regardless of the final dimensions of the assembled unit.

• On-site assembly is quickly achieved without the need for sophisticated tooling methods.

• Minimum maintenance is required as the galvanised steel panels resist weathering from the elements while maintaining the integrity of the water it holds and protecting it from most forms of contamination.

• Access to the water tank can be restricted

12 Mining Business Africa | March - April 2023

FEATURE

Structa’s Pressed-steel sectional tanks for water storage

using a lockable, ventilated access cover, providing safety and peace of mind for clients.

A customised turnkey solution

Structa Technology offers a customised turnkey water storage tank solution spanning the design, manufacturing, material selection, corrosion protection, supply, delivery and erection of the tank over and above commissioning.

The engineering team always guarantees to the clientele that Structa Technology goes all out to deliver a project on time, within budget and to the expected (quality) specifications.

“We are always pleased to assist mining companies and organisations in other industries

The Circotank Range

Besides Prestank, Structa offers a quickerecting range of circular tanks which can be applied in a variety of roles in mining applications. The range, branded as Circotank, is manufactured from galvanized steel sheet cold rolled with a stiffening profile.

Circotank is offered in two size ranges - a Maxi-range covering tank sizes of 100,000 litres up to 1,5 million litres and a Midi range covering a very user-friendly range of 5,000 – 20,000 litres.

The Maxi-range is aimed at large-scale water storage projects, with typical applications in industrial water storage such as fire tanks

with products and services that contribute to water storage solutions in South Africa and Africa.

“We are looking forward to supplying our storage tank solutions to clients involved in both Greenfield and Brownfield mining projects,” they

Successful delivery to projects

Some of the notable projects to which Structa Technology has supplied Prestanks include:

• Styldrift Marengski mine Rustenburg

• Northam Platinum Booysendsdal UG2 mine

• De Beers Venetia mine in Limpopo

and process tanks. The tanks are transported in pre-rolled segments, thus allowing for compact transport and easy off-loading. They are erected on concrete ring beam foundations and require reasonably simple earthworks before erection. Erection is done with a strake lifting system that requires no craneage.

This all adds up to a very economical total cost per cubic metre water storage. Structa has well-trained teams available to install the Maxi range. The Midi-range fills a gap not covered by typical moulded plastic tanks and would find good application where users need storage between 5,000 and 20,000 litres, often on

sustainable & long term WATER STORAGE SOLUTIONS

Pressed Steel Sectional Water Tanks

Prestank tank capacities range from 1 500 litres to 4.2 million litres designed to SANS 10329:2004 guidelines and SANS structural codes. Our Hot Dipped Galvanising units are easily transported and assembled on even the most remote sites.

explain in a brief to Mining Business Africa.

The Structa Group of companies are active in the manufacturing and supply of structural steel products for the water, electrification and telecommunications infrastructure, mining, petrochemicals and industrial sectors.

• Coal of Africa mine, Vele coal mine in Mussina

• Amplats Bafokeng Rasimoe mine

Rustenburg

Furthermore, Structa has supplied Prestanks to mines in Zimbabwe and Angola, in addition to Sasol (Timane gas pipeline project) in Mozambique.

stands to provide distribution pressure These tanks are transported in segments and can be assembled on top of stands if required.

This eliminates the usage of cranes in difficult rural applications. Structa supplies package systems of tanks and stands, ready for assembly, even by the user.

A Zincal version of the Circotank is currently being tested for application in corrosive areas. The tanks utilise a PVC liner which hugely improves the speed and quality of the build, resulting in a reliable product. Liner replacement is possible thus resulting in ease of maintenance and longevity.

Mining Business Africa | March - April 2023 13

Structa Technology is a Level 1 BBBEE Contributor, and is part of the STRUCTA GROUP of Companies Specialists in the manufacturing of domestic and industrial water storage. Manufactured in SOUTH AFRICA MEYERTON | watertanks1@structatech.co.za Director: Rodney Cory rodney@structatech.co.za | 082 575 2275 +27 (0)16 362 9100 www.prestank.co.za Halfpage Hor Feb22.indd 1 2022/02/17 16:21:51

Drone Technology: Making Mining Inspections Safer

Drone Utilisation in Mines

Below are the most impactful ways that drones are used in mines:

VOLUMETRIC MONITORING

The integration of a mine drone allows for quick deployment of volumetric measurement with inexpensive and reliable volume data. Tracking variations in stockpiles is cost-effective and helps reduce unnecessary waste. Mining drones can also track how much material has been excavated from a particular area and approximate how much backfill would be needed to fill a stope. As more 3D models are obtained, it’s easier to analyse data and see changes over time. Moreover, by providing high-quality visual data inside a stope, drones can help mining personnel identify remaining ore as well as other geotechnical areas of interest that might otherwise be missed.

IDENTIFYING HAZARDS

By Patience Chimbetete

Developing mining operations is expensive and dangerous due to traditional methods that require teams of miners to traverse unknown areas with uncertain conditions to conduct stability analyses, surface mapping, ventilation modelling and to detect hazardous gasses.

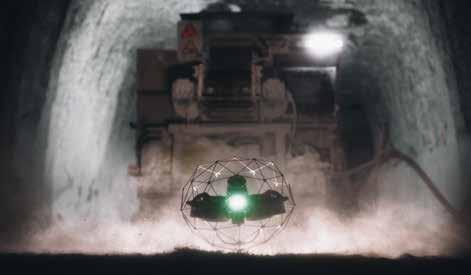

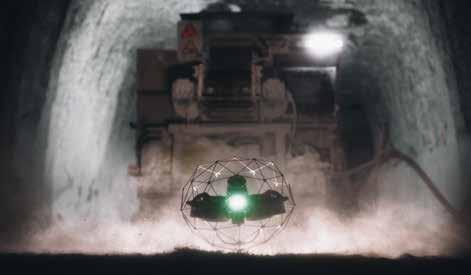

Instead of sending people into inaccessible areas, a mine drone can easily gather the required data at minimal cost. While drones will not eradicate every danger associated with traditional mining practices, they can be deployed to collect data in areas that are unsafe for humans. This is where Flyability comes in. “Our mission is to provide high-quality drones that can be used to collect data in dangerous places,” says Junio Palomba, Flyability’s EMEA Regional Manager.

A dynamic robotics company based in Switzerland, Flyability focuses on making drones for confined and inaccessible places. These indoor drones are used to collect high-quality visual data inside stopes and other unstable areas within mines. This data is then used to create 3D models and sparse point clouds of mines, which help operators to better understand the conditions inside their mines and ultimately improve their ability to make determinations

about safety, stability and remaining materials. These improvements represent a potential step change for the mining industry, allowing operations to become safer, more efficient and more cost-effective.

“A key aspect of a mine drone as compared to a typical consumer one is that it is made to fly without GPS, which is unavailable in most mining environments,” Palomba explains.

Crumbling rocks, gas leaks, dust explosions, chemical by-products, and the general instability of underground environments challenge even the best equipment and miners. By using Unmanned Aerial Vehicles (UAVs) in mining, surveyors reduce these risks by removing humans from the inspection process. Remote monitoring improves on-site safety, which saves time and reduces operational expenses.

In surface mining, stockpiles create sloped terrain that requires continuous stability monitoring. This data allows mine teams to

14 Mining Business Africa | March - April 2023 FEATURE

Mines can present hostile environments for humans. As a result, mining companies are turning to inspection technology that prevents humans from being exposed to risky situations – enter drones!

Flyability focuses on making drones for confined and inaccessible places

A mine drone can easily gather the required data at minimal cost.

FEATURE

detect warning signs of instability early and mitigate the issue to keep everyone safe while maintaining maximum efficiency with operations.

DRILLING AND BLASTING ASSESSMENT

3D models generated by mine drones have multiple use cases, making them a cost-effective tool. Before drilling and blasting begins, a model can be created as a historical record check to analyse the after-effects of the work. An updated version of the model allows miners to make data-driven decisions about potential hazards from drilling and blasting in the future.

MINE MONITORING AND PLANNING

A mine consists of numerous moving components requiring systematic analysis and adjustments to achieve maximum efficiency and safety. Mining drones are highly effective for determining haulage road designs, equipment inspections, work site security and environmental monitoring.

MINE DEVELOPMENT AND EXPLORATION

Instead of sending people into inaccessible areas, a mine drone can navigate tight spaces safely and more efficiently than any human could. “In underground mining, Elios 3 is one of the few drones on the market at the moment that can handle confined spaces with reduced visibility, poor air quality and signal interruptions,” Palomba boasts.

PROCESSING PLANT INSPECTIONS

Drones are used in on-site mining processing plants to inspect machinery. The benefit here is that drones can collect this data without stopping processing operations, keeping the mining business profitable.

The New Elios 3

“Our newest offering, Elios 3, can navigate dusty, wet and rocky ore passes to locate blockages. In addition, it can also fly through and around the stockpile feeder, mills, flotation cell, and even the crusher, collecting high-quality visual data, which is usually better than the data that could be collected manually,” he continues.

Why Elios 3?

“There are many capable drones on the market, but very few match the functionality, durability, and beyond-line-of-sight transmission of Elios 3,” Palomba says.

He adds that Flyability’s drones are built to keep humans safe while collecting data in areas that have been inaccessible in the past. With a unique, spherical cage that is collision tolerant, Elios 3 helps pilots to navigate mine shafts with ease. It also boasts dual thermal and 4K camera sensors, and a 10K lumen dust-proof lighting system that highlights different textures and defects in the mine.

Additionally, Elios 3 carries a laser imaging, detection and ranging (LiDAR) sensor, making

it more than just an inspection drone - it can also be used to map out inaccessible areas and block caving. This is an important factor as mine operators will immediately be able to see the full dimensions of these spaces. Compared to photogrammetry, LiDAR has the advantage of not needing lighting and can penetrate dust and smog, which is a big challenge in mines.

The all-new SLAM-based stabilisation algorithm catches the tiniest unpredictable movements of the drone and instructs the flight controller to compensate for it. This allows for the drone to float in the air, still as a stone, even in the toughest conditions. With Elios 3, pilots of all skill levels will succeed at performing complex missions with close to no training. However, with included training, easy maintenance and a dedicated support team, Elios 3 is one of the best mine drones on the market.

Drone Operation

Flyability is committed to ensuring its customers have sufficient product knowledge and knowhow to avoid interruptions. The company offers customers a test drive of an Elios drone in the form of a proof of concept mission. This trial mission is the best way to experience the efficiency of indoor drone solutions. With distributors and representatives around the world, Flyability is able to ensure customer needs are met.

“Our experts can organise a proof of concept on the user’s site, which helps to test the potential impact of Flyability’s drone technologies for the specific mining operation,” Palomba explains. Flyability also proposes training as flying a drone indoors has its own particularities, which are different from operating outside. As such, the company has defined a complete set of certifications and thorough training courses to ensure that its drones are operated in the safest conditions and in the most efficient way to maximise the return on investment.

16 Mining Business Africa | March - April 2023

SA communication@flyability.com www.flyability.com

FLYABILITY

A key aspect of a mine drone is that it is made to fly without GPS

Underground mining utility vehicles

A Promising Alternative

One of the challenges of sustaining operations in deep-level and ultra-deep mining environments is the high cost of providing reliable ventilation. Interestingly, the adoption of Battery Electric Vehicles (BEVs) as an alternative to diesel-powered mobile vehicles has been demonstrated to be effective in reducing requirements for providing ventilation. This indicates that the use of BEVs does not only reduce greenhouse gas emissions to enable compliance with relevant legislation.

The results

Results indicated that the adoption of BEV for primary haulage and loading equipment could result in a potential reduction of the ventilation system airflow demand by 50% of the original airflow and fan power by 80%. It has to be pointed out that this can be achieved without making any modifications to the original mine infrastructure, besides redistributing the required airflow in the mine to meet various mining demands.

In deep level - ultradeep levels - in which hard rock mining is migrating in search of valuable ore, it is becoming increasingly expensive to provide vital services like ventilation. This is prompting mining companies to explore costeffective, alternative ways - with relative success in some instances.

Study

Findings of a 2019 study conducted at a gold mine in South America suggest that there could be untapped opportunities in replacing dieselpowered vehicles with battery electric vehicles (BEV) in underground mines. According to ventilation specialists (in ventilation engineering, mine ventilation and emission analysis) from SRK Consulting USA, a mine could cut ventilation requirements (costs), above and beyond reducing greenhouse gas emissions from diesel emissions. Considering the current challenges in the mining environment, these two have far greater significance.

Perhaps the impact of BEVs on ventilation requirements is more comprehensible when emissions from vehicles are considered.

Emissions from diesel-powered trucks

Typically, diesel-powered large mine-hauling trucks are the main source of emissions on mine sites. The Mckinsey report (Decarbonisation–What every CEO should know) estimates that mining vehicles account for 30% to 50% of total direct greenhouse emissions at a mine site. Besides, it observes that, in some regions, it is not uncommon for a figure of up to 80% to be recorded.

Hence, the team from SRK Consulting sought to establish the impact on ventilation of using BEVs as an alternative to the equivalent ‘traditional“ diesel-powered haul trucks (Primary haulage) and load haul dump loaders (LHD) (loading). Typically, to get the correct statistics, the local regulatory agency’s values specified for diesel engines and for pollutants generated from the combustion of the entire mining fleet are applied. The following aspects are consideredtotal minimum mine airflows and localised, zonespecific, airflows are generally straightforward using this method. And the South America BEV impact project was no exception.

Ultimately, less airflow demand as a result of BEVs would result in a reduction in the size and number of raises (development savings). And so, there would be significant reductions in ventilation system infrastructure requirements. Not only would the use of BEVs save high costs on ventilation and cooling but also improve worker health. Besides, BEVs produce a fraction of noise as diesel-powered engines.

More cases to be documented

Doubtless, there are potential opportunities for using BEVs as an alternative to diesel in hard rock underground mines. Certainly, with the uptake of BEV set to increase, more cases of reduction of ventilation costs will be documented.

However, at this juncture, it is rational to avoid overstating the potential of BEVs in underground mining environments. The SRK report acknowledges that there are challenges yet to be addressed relating to the reliability of batteries. These are namely, battery degradation, potential production losses due to charging and/or battery swap outs, and power grid requirements for charging of batteries. SRK report fittingly concludes: “Despite these potential issues, a more significant use of BEVs provides a promising alternative.”

Mining Business Africa | March - April 2023 17 FEATURE

There are potential opportunities for using BEVs as an alternative to diesel in hard rock underground mines (Pic: McLean Engineering)

OEM-Approved Lubricants for Uninterrupted Production

Mining equipment is expensive and expected to work continuously, making it critical to ensure that it is properly taken care of. With only a 0.4% increase to a mine’s overall maintenance budget towards lubricants spend, follows a likely reduction of up to 20% of the overall maintenance spend in the long run. Opting to use OEM-approved lubricants is therefore a smart move given the ongoing tight economic conditions.

In the business of mining, many variables are to be considered. Unfortunately, many operators resort to allocating a very small percentage of their monthly operational budget to lubricants,

in a bid to save anywhere they can. However, saving on lubricants tends to be costly along the way.

The South African mining industry is already under a lot of pressure due to failing infrastructure, making any other interruption to production unbearable, especially if it’s something that could have been circumvented. It is with this backdrop that Oily SA CEO and Co-owner, Viesturs Zalaiskalns, says: “Our company’s mission is to provide OEM-approved products for clients to ensure continued operations. This enables mining companies to focus on mineral production rather than spending time addressing downtime caused by mechanical faults.”

“With an exclusive mandate to import MOL lubricants in South Africa and other SADC countries, we remain true to our promise to clients to supply them with high performing

lubricants” Viesturs adds.

MOL Lubricants is a Hungary-based, international oil company with a record of more than 100 years in the industry. The company is active in over 50 countries and employs expert workforce with highly experienced scientists and practitioners that provide the necessary knowhow to customers all around the world.

With a continuous supply of full-range lubricants, Oily SA’s imported products are approved by major, original equipment manufacturers (OEMs) such as Mercedes Benz, Volvo, Cummins, Parker, Voith, MAN, Bosch Rexroth and Scania, among others.

“This makes our lubricants a lot safer and more reliable to use as we are able to provide the certifications issued by these OEMs,” Oily SA Technical Sales Manager, Henco Booysen, explains.

Why OEM-Approved Lubes?

It is imperative for customers to ensure that the lubricants they use are OEM-approved rather than just a product that meets their specifications. The difference between the two is that the former goes through rigorous bench tests carried out by the OEM to warrant suitability for specific machine components, while the latter is merely a claim by the oil producer, which is not verified or backed up by the equipment manufacturer.

FEATURE

18 Mining Business Africa | March - April 2023

OEM-approved lubricants that Oily SA supplies ensure equipment is operational for longer

High cost of equipment – Using an OEM-approved oil is particularly important for the mining industry due to the nature of the business and the fact that the equipment is operated in extreme conditions. For this reason, mine owners should consider that the price difference between a cheaper lubricant and an OEM-approved one has narrowed to as little as 10 to 15%, but the cost can be a whole engine, which can go as high as R600 000. “Our driving force is reduction of total cost of ownership, which means equipment is operational for longer without having to replace the parts or components,” Henco elaborates.

Reduction of maintenance costs

– The mineral-based, as well as synthetic OEM-approved lubricants that Oily SA supplies ensure equipment is operational for longer without needing to take the machines for servicing frequently. “The maintenance cost can potentially be reduced by 20% over the lifespan of the equipment,” he promises.

Quality assurance – Working with worldclass oil producers enables Oily SA to present their customers with an insurance guarantee to the value of €1 million that “would cover loss of equipment due to the unlikely failures caused by

our lubricants”. Henco explains that Oily would send its specialists to investigate and have used oil tested at an independent laboratory, ultimately arriving at a conclusion of what caused the failure. All this is followed with recommendations from Society of Tribologists and Lubrication Engineers’ certified professionals, whose advice would assist to avoid repeat failures.

Dedicated to quality products and service

In the past six years that Oily SA has been operating in South Africa and the SADC region, the company has established itself as a dependable importer of OEM-approved, fullrange lubricants; from engine oils, gear oils and hydraulic fluids to greases and coolants.

The company’s commitment to quality is demonstrated by the fact that it only works with fully vertically integrated oil producers that mine crude oil, refine it, then blend and package the finished lubricants all under one roof. Oily SA also provides after-sales service for customers to ensure the equipment is running smoothly. “We are dedicated to taking care of lubrication for our customers’ equipment so they can focus on mineral extraction and have one less factor to worry about,” Viesturs summarises.

Mining Business Africa | March - April 2023 19

Sustainable Organisational Performance, People Management and Operational Optimisation for Mining Supervisors

Competent Supervisors, Profitable Mines

OIM Consulting’s ‘Coaching to Performance” is a Supervisory & Operational Leadership Development programme designed to develop leadership skills in employees holding supervisory positions in mining companies. The consultancy has established that effective and efficient supervisors enable organisations to improve productivity which translates into increased profits.

according to findings of a survey OIM Consulting conducted across industries. “At a baseline, only about 19% of supervisors have the required competencies for their job, and 78% of them have an “unstructured approach” to their work,” de Bruin narrates.

OIM found that planning and organising are among the least developed competencies of supervisors, besides the ability to lead and develop their teams, and the inability to analyse and problem-solve.

The root of the problem is that employees who have technical competencies are thrown into the deep end by being entrusted with supervisory roles. The main flaw with this approach is the assumption that their technical competencies automatically make them capable leaders.

By Jimmy Swira

There is a need for a mindset shift in the mining sector in 2023: Only effective and efficient supervisors have to be assigned leadership roles. This is one of the readily available ‘low-hanging fruits’ that mining companies can utilise to achieve long-term sustainability and increase profitability.

Cape Town-based business management consultancy, OIM Consulting, reiterates this advice to mining companies in the second interview with Mining Business Africa (the first one was in the second half of 2021). This is in the wake of developments unfolding in the mining sector that have even more underlined the need for proactive supervisors at the coal face of operations.

Currently, mining companies are grappling with high operating costs which are impacting the bottom line. One of the sure-fire approaches to offsetting this challenge within their grasp is through increased productivity, which effective leadership at the supervisory level is

fundamental to its realisation.

OIM Consulting is committed to playing a part in making supervisors more capable by imparting critical leadership skills. Consequently, it devised an on-the-floor coaching framework called ‘Coaching to Performance”, a Supervisory & Operational Leadership Development programme.

In an update to the industry, OIM Managing Director, Arjen de Bruin, recommends ‘Coaching to Performance’ as a more relevant intervention that can enable mining companies to fill the gap for effective and efficient supervisors.

Without a doubt, the relevance of the solution can be appreciated better when the scale of leadership challenges it addresses is analysed thoroughly.

The scale of leadership challenges Ideally, a supervisor should make everything happen in an organisation. However, unfortunately, that is not always the case,

Unfortunately, most supervisors would assume their positions while not fully understanding their roles. Typically, in the context of mines, they would come to a shift without planning. As a result, inevitably, more often than not, they tend to be more reactive to issues. “Instead of leading as expected, supervisors play a ‘fire fighting role’ – perpetually solving problems that could have been avoided with proper planning in the first place.

Eventually, it becomes a vicious circle, as the problem never gets solved. As fire fighting is an erratic task, there is no progress in pertinent issues,” laments de Bruin, adding that nine times out of ten, the manager has to keep intervening and help the supervisor, which distracts the manager from carrying out their duty.

The impact of unqualified supervisors in mining operations should not be underestimated, as it has a significant bearing on the bottom line. A case in point is the spell of the commodities boom, during which some mining companies may have got a huge turnover. Nonetheless, due to ineffective supervisors, they may have incurred huge costs per tonne, narrowing profitability.

22 Mining Business Africa | March - April 2023 FEATURE

OIM Consulting’s groundbreaking success was its involvement at Gold Fields’ South Deep mine

‘An empowered supervisor, a driven team’

Thus, to tackle these enormous challenges, a mining company has to ensure that the people appointed in supervisory roles are assertive –adept in planning, leading and implementing, de Bruin suggests. “The supervisor is the ‘culturecarrier‘ so he has to break down strategy so that individual teams understand and are willing and focused to be part of it. A supervisor needs to sell an organisation’s value, vision and mission to their team. Every member has to know what it’s in for them and the benefits of working towards one goal.”

The supervisor’s role hinges on the Three I’s – ‘Insight, Influence and Impact’. “The more insight, the more influence on the individual, the more impact you have,” de Bruin defines.

Ultimately, for supervisors to execute their roles effectively, the following four pillars are critical:

• Efficient and effective processes

• Managed processes

• Right structures in place

• Leadership must be capacitated to deliver processes

‘There is no silver bullet. Make sure the four pillars happen. Without the supervisory role, this would be farfetched. An empowered supervisor creates a driven team,” stresses de Bruin.

What ‘Coaching to Performance’ entails

OIM Consulting recognises that supervisors are an essential component in meeting daily targets. Accordingly, its ‘Coaching to Performance’ solution is aimed at showing supervisors that if they plan their day better, and if they had a more effective team meeting, and used visual and shift management books correctly, they would then be able to manage their teams much more effectively.

‘Coaching to Performance” involves coaching the supervisors on-site and showing them how to do their work in a more effective

and organised way for a more consistent benefit. Results-oriented, ‘Coaching to Performance’ entails implementing a few development aspects and measuring them. “We implement the framework, and then we measure to see if success happens because, without measurement, you don’t know if things have improved,” de Bruin elaborates.

The individual’s performance is baselined through a three-pronged approach: a development needs assessment, role assessment and team targets. “We look at the key performance indicators to get a picture of the individual’s targets. Once the baselining has been completed, we know how competent the individual is, how they execute tasks and what their targets are and whether these are achieved consistently,” Debruin explains what this involves.

Potent long-hanging fruit

On the whole, in the current environment mining companies have to seek avenues that can help them realise more value from their assets in the long term. Developing effective and efficient leadership skills in supervisors through initiatives like “Coaching to Performance’ is one of the potent low-hanging fruits they can use to increase profitability in the face of escalating operating costs.

On a different note, OIM informs mining companies that, it recently unveiled a Target Attainment Programme (TAP), a short-term programme, to help them to reach targets within 90 days. As part of the programme, OIM first performs root-cause analysis and implements what is termed an ‘Instructive coaching programme’. “We push and help where we can. By the end of the 90 days, the programme would have achieved the desired results,”

However, while the TAP‘s objective may be reached, the programme may not be sustainable in the long term. And so, this may necessitate the implementation of “Behavioural Coaching” under the Coaching to performance” programme.

Leaving no stone unturned

Coaching for Performance is comprehensive and leaves no stone unturned in improving the effectiveness and efficiency of the supervisor. It covers focused training of between three and five days through either a classroom or line-as-coach training.

For the classroom, the bulk of the training centres on management and safety training. On the other hand, line-as-coach training is often directed at direct managers of supervisors to continue the operational coaching conducted by OIM. This includes training direct managers on how to be successful coaches, what to look for and how to measure individuals.

Following the coaching, OIM compiles an individual coaching plan and conducts on-thefloor coaching for 16 weeks.

During this coaching framework, the consultancy measures if the operational key performance indicators, role execution and the effectiveness of operational tools improve. Benefits at a site level are also measured through a Benefits Realisation Model, following which a post-assessment of competencies takes place at the end of the training period.

Clearly, the coaching framework leaves no stone unturned in inculcating the supervisor with fundamental leadership skills.

Notable milestones registered

The consultancy’s groundbreaking success was its involvement at Gold Fields’ South Deep mine, where it managed to assist in turning the mine around and making it more effective (an increase of 41% in gold production).

De Bruin proudly states that, since Gold Fields’ success, OIM has registered more milestones. The consultancy has since added several blue chips to its project portfolio – among them Anglo American Platinum, Venetia, Kumba Iron Ore (supervisors of the future), Letseng Diamond Mine, and Northam Group.

OIM aims to increase its footprint beyond Southern Africa. it views Africa as a promising growth frontier where opportunities abound in organisations. “We are increasing our footprint into Africa. Currently, we are exploring Congo, Ethiopia and other areas.”

He hastens to mention that OIM is also servicing organisations overseas, where the competence of supervisors in mining companies is also a big problem. “Contrary to the general perception, the problem of competence (or incompetence) of supervisors is not unique to mining companies in Africa and other emerging markets. It is prevalent even in developed countries as we have noticed in North America and Australia.”

Mining Business Africa | March - April 2023 23

KSB and sustainability of energy

As the mining industry in Southern Africa continues to grow, there is an increasing need for pumps and valves that are bigger, more energy-efficient and sustainable.

KSB Pumps and Valves, a leading manufacturer of pumps and valves, has been at the forefront of this movement, designing and manufacturing pumps that are specifically built to meet the needs of the mining industry. With a focus on sustainability, KSB is leading the charge when it comes to providing equipment that can handle a variety of mining conditions, is easy to maintain, and can provide a long wear life.

“In addition to our focus on sustainability, KSB also dedicates time and energy to minimising downtime on our mining pumps which is achieved through a range of measures, including the use of high-quality materials and manufacturing processes, as well as extensive testing and quality control procedures,” says Rob Bond, KSB Pumps and Valves, area manager for mining in Southern Africa. This in turn ensures that KSB pumps are built to last, with minimal need for maintenance or repairs.

Global expertise

But when issues do arise, KSB’s after-sales service is there to provide support and assistance. With a global network of service centers and technicians, “KSB can provide rapid response times and quick repairs, minimising downtime and ensuring equipment is up and running as quickly as possible,” says Rob. This commitment to after-sales service is a key part of KSB’s approach to sustainability, as it helps to extend the life of their pumps and reduce the need for replacement or disposal.

“One of the biggest challenges facing the mining industry is the need to operate in a sustainable and environmentally friendly manner. To meet this challenge, we have focused on developing pumps and valves that are designed to reduce energy consumption and minimise the environmental impact,” says Rob.

By using the latest technology and materials, KSB has been able to produce pumps that are more energy-efficient, while still delivering the high performance that the mining industry

demands. KSB’s after-sales service is also focused on preventative maintenance, with a range of services available to help customers keep their pumps and valves in top condition.

From regular inspections and maintenance schedules to training and technical support, KSB’s after-sales service is designed to help customers get the most out of their equipment, while also reducing the environmental impact of their operations.

Customer centric

“We have 37 production sites in 18 countries and nine foundries on three continents. Plus, we have over 3500 worldwide service staff ready to assist you wherever you may be. KSB Mining has proven it is well-equipped to offer our partners a complete package of products and services. We use our expertise to make our customers’ experience easy and successful. We provide exceptional and unparalleled customer service.”

24 Mining Business Africa | March - April 2023

LCC MDX LSA LCV Wear Resistant, High Performance –Locally manufactured. Global Quality Mining Pumps. WE PROVIDE GIW ® SLURRY PUMP SOLUTIONS KSB Pumps and Valves (Pty) Ltd • Tel: +27-11-876-5600 www.ksb.com/en-za • Level 1 B-BBEE Supplier FEATURE

High-Intensity stirred milling for Energy-Efficient Fine & UltraFine Grinding Energy Cost Savings, Improved Recovery and Liberation

There have been groundbreaking findings from case studies of mining projects where stirred milling techniques have been used as an alternative to tumbling ball mills in fine and ultra-fine grinding applications. Thus far, the results gathered substantiate that there are huge opportunities for energy savings as well as improved liberation and recovery in concentrators of metalliferous ores.

Energy constitutes the biggest component of a mine’s operating costs, which significantly impacts the bottom line. That’s why mining companies are in continuous pursuit of energyefficient techniques to be used in concentrator circuits.

This is no exception with fine and ultrafine grinding requirements for effective liberation and recovery of metalliferous ore in concentrators circuits. It is emerging that what is considered the traditional technique of using tumbling ball mills falls short, necessitating the exploration of viable alternatives.

Interestingly, there has been a growing preference for high-intensity stirred milling technologies, as an energy-efficient and effective grinding option. Stirred milling uses very inert high-intensity attrition and small media size. Typically, cheap natural products (local sand, slag and ore) can be used as grinding media.

It has to be pointed out that reference to energy efficiency in high-intensity stirred milling

in this context is the optimal use of energy in various concentrators.

Doubtless, one would appreciate the relevance and business case of stirred mill technology better by first analysing the shortcomings of tumbling ball mills.

Shortcomings of traditional techniques

There has been extensive literature highlighting the inherent limitations of tumbling ball mills in fine grinding. Two papers expound on this subject vividly from energy consumption and efficiency perspectives. The two papers are Technology Selection of Stirred Mills for Energy Efficiency in Primary and Regrinding Applications for the Platinum Industry and Fine Grinding as Enabling Technology – The IsaMill.

• Energy consumption