committed to delivering the best possible customised turnkey dewatering solutions to solve challenges that mining companies face on-site as they are increasing output. Carl Hamm’s involvement helps mining operations focus on their core business and rest assured about high quality and backup service.

Media

Editor’s Note

A stitch in time saves nine

As you may well be aware, mining companies are ramping up production, eyeing the pot of gold that is high revenue from record-high commodity prices. And in the course of this hot pursuit, the biggest worry is that mining managers could lose sight of the requisite safety measures, putting their employees at risk of accidents - resulting in injuries at best, and fatalities at worst. Sadly, if left unmitigated, this situation can negate any envisaged gains.

There are situations where mining companies have suffered from reputational damage as a result of bad press, costly litigation from fatalities or injuries, and suspension of operating licence by regulators, only to single out a few. Simply put, the consequences of lapses are too ghastly to contemplate.

That is why commentators in this edition emphasise the importance of utilising ‘tried and tested’ measures to mitigate the identified safety risks that mining companies may be exposed to. Sometimes the acquisition of proven methods necessitates paying an arm and a leg. This is something that penny-pinching management in companies loath. However, as far as the safety of mining companies goes, any envisaged gains from cutting expenditure are outweighed by the increased accident risks.

In fact, when it comes to safety measures in mining operations from pit to port, a stitch in time of proactively using effective measures minimises the risks that mining companies face from exposure to accidents. Investment in technologies that, when used as per manufacturers’ specifications enhance, is always worthwhile, as the saying goes: A stitch in time saves nine.

editor@miningbusinessafrica.com

16 24 02 CONTENTS November - December 2022

Icon (Pty) Ltd makes every effort to ensure the accuracy of the contents of its publications, but no warranty is made as to such accuracy and no responsibility will be borne by the publisher for the consequences of actions based on information so published. Further, opinions expressed are not necessarily shared by Media Icon (Pty) Ltd. www.miningbusinessafrica.co.za

Nick Barnes

Editor Nick Barnes editor@miningbusinessafrica.co.za +27 10 055 3356 Web/Sub-Editors Jimmy Swira Jimmy@miningbusinessafrica.co.za + 27 10 055 3356 Anita Anyango anyangoanita18@gmail.com Contributing Writers Chantelle C. chantellec@miningbusinessafrica.co.za + 27 10 055 3356 Susan M. susanm@miningbusinessafrica.co.za Sales and Marketing Winnie Sentabire winnie@miningbusinessafrica.co.za +27 83 530 6832 | +27 10 055 3356 Angeline Ntobeng angien@miningbusinessafrica.co.za + 27 078 322 5938 + 27 010 055 3356 Accounts Precious Chirunga accounts@miningbusinessafrica.co.za + 27 10 055 3356 Art Director/Layout Augustine Ombwa Arobia Creative Consultancy austin@arobia.co.ke +254 772 187 334 Circulation/Sales info@miningbusinessafrica.co.za + 27 10 055 3356 Published By Media Icon (Pty) Ltd TEAM Effective Dewatering, Compliant and Productive Mining COVER STORY: PG02 Cover Image: Carl Hamm’s Turnkey Dewatering Solutions for African Mining Projects Carl Hamm Pipes Pumps

10

Solutions is

Carl Hamm’s Turnkey Dewatering Solutions for African Mining Projects

Effective Dewatering, Compliant and Productive Mining

Carl Hamm Pipes Pumps Solutions is committed to delivering the best possible customised turnkey dewatering solutions to solve challenges that mining companies face on-site as they are increasing output. Carl Hamm’s involvement helps mining operations focus on their core business and rest assured about high quality and backup service. It offers businesses in the mining industry specialised pipes, pumps and solutions to industry-related problems.

The implementation of sound dewatering practices in a mining project is one of the most critical obligations that are stipulated under the conditions of an operating licence. Among others, this is regarded as one of the ways of mitigating the impact of various activities on the environment through the Life Of Mine (LOM).

However, as various reports have indicated, dewatering can be a big challenge in mines affecting production and causing environmental pollution. In extreme cases, where there is evidence of pollution, regulators - in the South African context, the Department of Mineral Resources (DMR) - can suspend a licence for violation.

Increasingly complex burden

Presently, mining companies are increasing output to get more revenue from a spell of high commodity prices. And with this situation, Carl Hamm Pipes Pumps Solutions is concerned that dealing with excess water produced from various processes will become an increasingly complex burden on mine sites. This is taking into account that already most of the dewatering methods that mining companies use are not as effective as desired.

Adoption of novel techniques

Considering what is at stake, Carl Hamm Pipes Pumps Solutions urges mining companies to adopt novel techniques of mine dewatering. The company is sufficiently qualified to share pertinent know-how based on broad experience gathered from consulting for mining projects for clientele. Through a project house approach, Carl Hamm South Africa offers businesses in the mining industry specialised pipes, pumps and solutions to industry-related problems.

Customised turnkey dewatering solutions

Concerning excess water, Carl Hamm recommends its turnkey dewatering solutions to

2 Mining Business Africa | November - December 2022 FEATURE

mining companies. Its customised solutions have proved very effective in handling excess water conditions where traditional tried and tested techniques fail.

The solutions are structured in the form of a ‘one-stop under-one roof’ solution, which has been widely lauded for the convenience it offers. The Chief Executive Officer of Carl Hamm Pipes Pumps Solutions, Chris Munnick, highlights two benefits of the approach of consolidating all supplier costs and having a shared infrastructure. “The turnkey approach assists us in having a good overview of which products can be put together to have the most effective result. It’s also effective in maintaining timelines for expeditious completion of projects – when there is a deadline to be met, we work together to make that happen.”

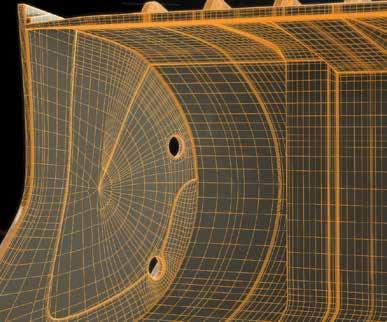

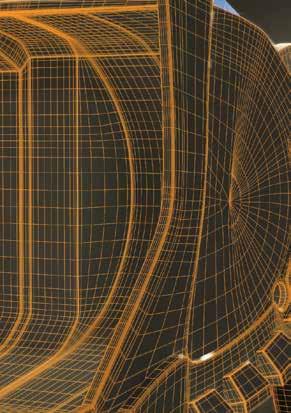

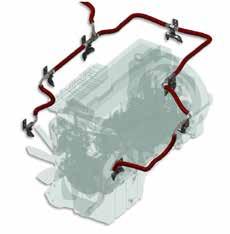

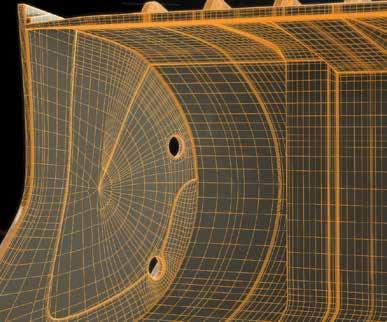

Carl Hamm’s solution encompasses the pumps, motor and shrouds. If needed at the start of the system, the ZSM piping, header works and electrical instrumentation to protect and monitor the system and the electrical equipment to best operate the system are included.

Shedding more light on why the company decided to introduce customised turnkey solutions, Munnick states that every mine has distinct conditions. Thus, accordingly, Carl Hamm customises a solution to suit a customer’s specific needs. “

Quality assurance and backup service, increased output

By and large, through engaging Carl Hamm PPS to solve complex water dewatering problems they encounter, clientele should rest assured about quality assurance and backup service. “While we cannot control what the pipes are used for, we can assure a Quality product that will not fail and cause environmental spillage and damage. More importantly, our turnkey solution removes the burden of dewatering from mining companies, which ensures that they

devote focus to their core business and increase output, over and above achieving compliance,” Munnick wraps up.

Besides specialised pumps and solutions to industry-related problems, Carl Hamm PPS together with its industry partners, has solutions for drilling, well construction, borehole sinking and geotechnic divisions as well. Another vital accessory used in dewatering is the Carl Hamm ZSM Connection. ZSM, the tight sleeve connection, is an axial non-positive and detachable pipe connection. It is used as a vertical riser pipe in open-pit and underground mines as well as in deep wells. The ZSM system is highly regarded for its versatility. Besides mine dewatering, the ZSM system can be used in the batching of Concrete, Shotcrete, and emulsion into mines from the surface.

Small service centre in the pipeline

While Carl Hamm generally exceeds customer expectations, it is cognisant the needs of mining companies are constantly changing. And so, as a forward-thinking entity, Carl Hamm constantly adds new products or services to its range to address.

Mines normally service in-house. Unfortunately, this proves to be very costly, a liability, as it is not their core business. To help mining companies free up their resources for better use elsewhere, Carl Hamm is building a small service centre at its new premises to service its HPX pumps range when required by the client. The centre will be fully equipped with all the correct tools and personnel with specialised know-how to ensure that services are done in full and to the highest standard.

Failsafe and robust pumping

Carl Hamm recognises the significance of failsafe and robust pump performance that guarantees process uptime with minimal downtime in mining projects. This is what Düchting HPX offers.

Munnick describes Düchting HPX as a high-quality pump brand that has excelled and prevailed in harsh conditions in mining and other industrial applications globally. “The conventional Multistage pump can take water contamination of 300 PPM (Parts per million). In contrast, most remarkably, Düchting HPX does 50 000 PPM and can cope with 5% silt per volume. It also has a mean time between services of 24 000 hours versus conventional pumps offering 8 000 hours.”

Manufactured by Düchting Pumpen, a fourth-generation German company, Düchting HPX is a proven product with a global footprint developed with German technology. It is available in single-stage and multistage centrifugal pumps for several applications.

Each Düchting Pumpen is custom-made to the application criteria, for example, shut-off pressure, and water quality. Then it undergoes a stringent quality assurance process i.e., each weld is checked by x-ray and every coupling is tracked through a serial number.

Learn more at carl-hamm.co.za/

Mining Business Africa | November - December 2022 3

Hydrogen production for mining vehicles

Generating Hydrogen –Alkaline vs. PEM Electrolysis

Discerning the Optimal Choice for Your Mining Operation

By Nick Barnes

There has been much interest, and deservedly so, surrounding the world’s largest hydrogen-fueled vehicle – the 300ton mining truck delivered to Anglo American’s platinum mine in South Africa last spring. More information about the day-to-day experience and decarbonization results will be announced in the coming months as all involved gather quantifiable information to share. Meanwhile, since hydrogen is at the center of South Africa’s energy roadmap towards zero carbon emissions by 2050, it makes sense to have a better understanding of the two most dominant

means of generating hydrogen today – alkaline electrolysis and proton exchange membrane (PEM) electrolysis.

Both types are suitable for hydrogen fuel making on-site and on-demand at mining companies. They make the appropriate hydrogen purity and dryness for operating fuel cells and provide sufficient pressure so that the vehicles’ tanks can be quickly filled. However, there are some differences that are worthwhile knowing to better discern what is best for differing circumstances.

As a basic electro-chemical refresher, electrolysers use an electrochemical reaction to split water into its components of hydrogen

and oxygen which yields hydrogen without a carbon byproduct. The process only emits clean, carbon-free oxygen. Like a standard fuel cell, an electrolyser has an anode and a cathode divided by an electrolyte. Electrolysers can vary in size, from the size of a household appliance to large-scale systems that might take up an acre of land. Alkaline electrolysers use a liquid electrolyte – a potassium hydroxide solution –with a porous separator between the anode and the cathode. Hydroxide ions cross the separator by the liquid solution to form oxygen and water. At the other electrode, hydrogen is generated with the hydroxide ions. Alkaline electrolysers operate at 100-degrees C to 150-degrees C.

4 Mining Business Africa | November - December 2022 FEATURE

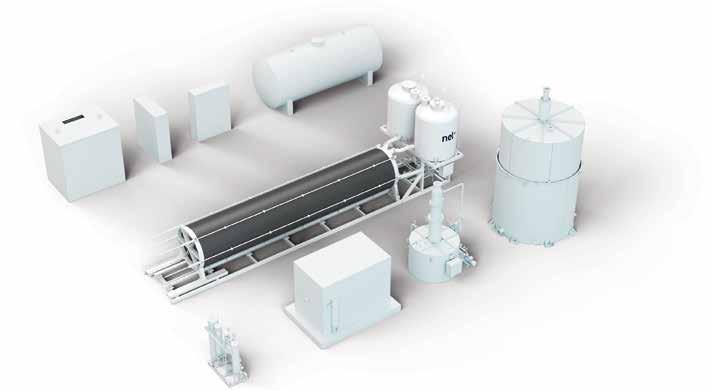

Hydrogen Mining Truck: Nel Hydrogen provided the alkaline electrolyser that is generating renewable hydrogen for the world’s largest hydrogen fuel cell electric vehicle project with ENGIE – the electrical utility providing the renewable hydrogen solution – and Anglo American. The 300-ton truck is a retrofitted Komatsu haul truck and developed at Anglo American’s Mogalakwena platinum metals mine, in Limpopo. Ballard Power is the provider of the fuel cell.

Alternatively, PEM electrolysers use a solid polymer electrolyte membrane and an applied current to separate, with protons, hydrogen and oxygen from water. The electrons are then transported from the anode electrode to the cathode electrode by an applied electrical circuit. PEM electrolysers require temperatures ranging from 70-degrees C to 90-degrees C. The temperature ranges for both types are considered low-temperature electrolysis, or LTE.

The choice for Alkaline vs. PEM electrolyser technologies comes down to the application and other parameters. Scale, input power characteristics, electricity cost, and rate of technology development are likely factors that may play into the decision. In reviewing the differences, alkaline electrolysis is the more mature technology track record. Around 1890 Charles Renard constructed a water electrolysis unit to generate hydrogen for French military airships. It is estimated that around 1900 more than 400 industrial alkaline water electrolysers were in operation worldwide and large-scale deployment of the process started. Its long history comes with a sense of comfort. Hence, alkaline electrolysers may be familiar to maintenance personnel, and the alkaline types are inherently more simply engineered than PEM types. This characteristic also makes alkaline electrolysers less expensive than PEM electrolysers. The PEM types feature a more novel membrane technology and catalyst compositions. However, it’s those attributes – the membrane and the catalysts – that can

provide the compelling reasons to choose PEM electrolysers for certain projects. For instance, they are more compact. If an alkaline electrolyser and a PEM electrolyser are side by side, and both are producing the same amount of hydrogen, the alkaline system will be substantially larger in footprint than the PEM. Choosing a smaller “box” could be reason enough to go with PEM if land is at a premium, or the mine encroaches on a residential area. PEM types use pure water rather than the liquid caustic solution that alkaline electrolysers do. Further, since the PEM technology is comparably newer, there is potential for further development lower cost and improve power efficiency.

According to Nel Hydrogen, the world’s largest hydrogen electrolyser manufacturer with more than 3,800 units delivered in 80+ countries since 1927, both types are far from reaching the end point for improvement. The company’s vision for the future comprises a balance of continually improving and further developing both technologies. In fact, the latest research on electrolysers focuses on overcoming various challenges, including the capital cost of electrolysers, improving energy efficiency, and adding compression to increase pressure for optimal hydrogen storage.

Nel provided the alkaline electrolyser that is generating renewable hydrogen for the world’s largest hydrogen fuel cell electric vehicle project with ENGIE – the electrical utility providing the renewable hydrogen solution – and Anglo

American. The 300-ton truck is a retrofitted Komatsu haul truck and developed at Anglo American’s Mogalakwena platinum metals mine, in Limpopo. Ballard Power is the provider of the fuel cell. The adjustments to the truck consisted of swapping the diesel tank for hydrogen tanks and exchanging the diesel engine for a battery and hydrogen fuel cells. The electricity for the electrolysis process is supplied by a solar power system at the mining location.

In operation at Anglo American, the Nel 3.5 MW alkaline electrolyser splits water into hydrogen and oxygen, and the excess hydrogen is stored for use at night or when solar radiation is poor. Anglo American’s long-term target is to convert the entire fleet of haul trucks at Mogalakwena to hydrogen and to also introduce decarbonized hydrogen mobility at other Anglo American mining locations. This is a key initiative of the company’s larger sustainable mining efforts. According to the company’s official website, a sustainable mining plan promotes innovation and produces benefits across the entire value chain.

It is well established that the mining industry alone accounts for up to 7% of all global emissions, so decarbonizing mining equipment can yield dramatic results since diesel trucks can make up to 30% to 50% of their mines’ total energy use. Just one of these standard diesel engine trucks consumes over 900,000 liters of diesel fuel and coughs out enormous carbon emissions. For example, there is an estimated 28,000 of these types of open-pit mining trucks

Mining Business Africa | November - December 2022 5

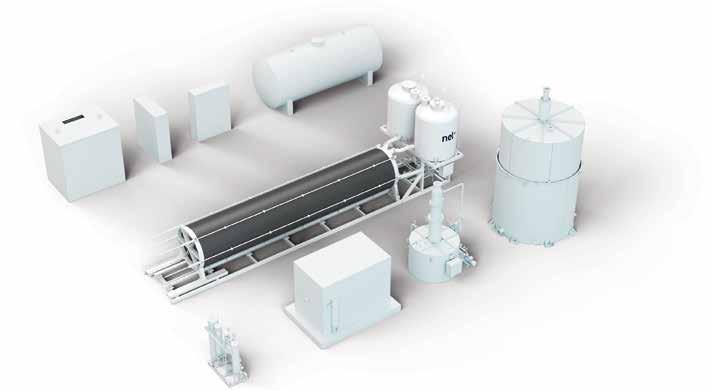

Alkaline Electrolyser: Alkaline electrolysers comprise a more mature technology – the first one was developed in the late 1800s. As such, alkaline electrolysers may be familiar to maintenance personnel, and the alkaline types are inherently more simply engineered than PEM types. This characteristic also makes alkaline electrolysers less expensive than PEM electrolysers.

working around the globe. In a recent published blog by Ballard, that number of trucks emits 68 million tons of CO2 (MtCO2) each year, the same as certain countries such as New Zealand or Finland. Decarbonizing all those trucks would be like removing the impact of 150-million gasoline-powered cars off the roads.

If you are considering fuel cell vehicles, there are considerable benefits for mining’s off-road vehicles, according to Ballard. There are fewer regulatory requirements and certifications compared to on-road vehicles. Larger mining and construction companies may be able to reduce costs by ordering in quantity and leveraging economies of scale. Centralized hydrogen refueling can be built on site, and potentially renewable hydrogen can be leveraged on site to generate green hydrogen to be used as fuel for vehicles.

Certainly, those of us who are stakeholders in Africa’s mining industry can appreciate such efforts surrounding Africa’s hydrogen roadmap, and we look forward to hearing more about the hydrogen fueled haul truck as Anglo American’s experience with it can be relayed. In the meantime, as you may be contemplating just how hydrogen can play a role at your operation, it’s clear that the electrolyser choice is an important place to begin.

PEM Electrolyser: The PEM electrolysers are more compact than alkaline types. Choosing a smaller “box” could be a wise choice if land is at a premium, or the mine encroaches on a residential area. PEM types use pure water rather than the liquid chemical solution that alkaline electrolysers do. This technology is newer than the alkaline process; it was developed in the 1960s. Both electrolyser types are far from their end point for further development and improvements, according to Nel Hydrogen, which invests heavily in ongoing electrolysis research and development.

6 Mining Business Africa | November - December 2022

MBA Half Page Horizontal Ad - Water Footprint.indd 1 2/11/22 5:06 PM

FEATURE

3D HDPE Seamless Bends for Mining Applications

Superior quality 3D Seamless HDPE pipe bends

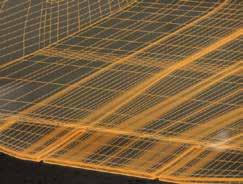

The reputation of Pipestar International in the delivery of 3D seamless HDPE pipe bends to diverse industries globally is unquestionable. Pipestar Africa is eager to replicate this success to clientele in metric sized markets worldwide. The company now offers HDPE Seamless Arc Bends™ as a locally African-manufactured product.

Recently, this publication engaged member organisations of the South African Plastic Pipe Manufacturers Association (SAPMA) to establish whether or not the current increase in the rollout of mining projects has impacted the value of their order books. Generally, the pipe producers confirmed the increase in demand or enquiries for their products from clients in the mining, petrochemicals and other sectors for the conveyance of liquids. Simultaneously, this translates into an increase in the demand for various accessories that are critical to the use of the pipes, among them are pipe bends. Traditionally, segmented pipe bends enjoy common usage. However, increasingly, 3D HDPE seamless pipe bends are now regarded as a viable alternative.

3D HDPE seamless pipe bends are used to change the direction of a pipeline. Typically, a seamless pipe bend is a pipe bend where the bend radius is three times the outside diameter of the pipe. While the significance of 3D HDPE seamless pipe bends is without question. However, it is the product’s robustness in harsh conditions and relevance to an application that matters most. Consequently, the Technical

Team at Pipestar, who are responsible for HDPE seamless pipe bends, advise mining companies to be well-versed in fundamental elements in the procurement of pipe bends. Mainly, they highlight the following: bends that are certified by reputable international accreditation bodies in accordance with internationally accepted standards such as ISO4427-3 and EN12201-3, that offer improved flow and durability.

i. Qualities of suitable products “HDPE seamless pipe bends need to be robust, hardwearing and easy to install, they should also be accredited to international standards. When you have the option to install a certified product, that should always take preference over an uncertified product.” states Renier Viljoen, a director of Pipestar Africa, explains, referencing Pipestar Africa’s seamless Arc Bends™ as products that have demonstrated these features.

Pipestar’s seamless Arc Bends™ are designed to have a radius that is three times that of the outside diameter of the pipe. This, combined with the roundness of its bends throughout the curvature, ensures improved flow rates and less friction. This results in saving

electricity costs due to improved flow rates when pumping materials. “Due to the lower friction and consistent wall thicknesses throughout our Arc Bends™ our bends offer a much longer operating life compared to the alternatives available in the market,” Viljoen says.

The nature of the materials of construction augments the robustness of the pipe bends. The Arc Bends™ are manufactured from virgin grade HDPE PE100 raw materials which are extremely robust and have a very low coefficient of friction. It also has good wear-resistant properties which are especially important in mining applications where abrasive slurries are transported.

ii. Price or cost?

Due to the escalation of operating costs, mining companies find the selection of cheaper options tempting. But inevitably, wrong products can cause downtime to processes, leading to a huge loss of income.

Pipestar stresses the need for end-users to distinguish between price and cost in the procurement process of 3D HDPE seamless pipe bends. “Price is what you pay for a product up front whereas cost is what it costs you when

Mining Business Africa | November - December 2022 7 FEATURE

you suffer downtimes due to premature failures of seamless bends over the lifetime of the product. Procurement departments often focus just on price. Nonetheless, what they overlook is that the long-term cost of choosing the cheapest alternative may be exponentially higher once a cheaper alternative of inferior quality is installed,” Viljoen states.

iii. The convenience of a one-stop solution

Pipestar International offers the convenience of one-stop solutions under one roof. Its product range includes a range of 3D Seamless HDPE Arc Bends™, Moulded HDPE fittings, HDG Backing flanges and fasteners and HDPE stub ends that are machined from the solid hollow bar. Noteworthy, Viljoen highlights, quality assurance is of prime importance at Pipestar.“Both the seamless Arc Bends™ and stub ends are certified to ISO 4427-3 and European EN12201-3 standards. They are the only locally manufactured products of this nature that are certified to these international standards.”

Comparative benefits

Overall, the benefits of 3D seamless HDPE pipe bends, when compared to welded-pipe bends, have been extensively documented. Particularly, even more, there are numerous benefits of adopting Pipestar’s arc bends, points out Viljoen.

Reducing energy costs

Energy constitutes a big percentage of operating costs at a mine. Companies will save electricity costs in terms of their pumping costs and have an extended product lifetime which will result in lower downtime on site.

•

Bends retain manufactured dimensions

The bends do not revert. Therefore, maintaining their angle will make it easier for mines to keep stock of our bends in their maintenance stores as they can rest assured that the bends will retain their manufactured dimensions.

• Reduced installation times

The improved roundness of the pipe ends will also reduce installation times on site as the Arc Bends™ can be both butt-welded and welded with electrofusion couplings without the requirement for the bends’ legs to be cut back on site.

Supplier of choice

All things considered; the technical staff recommends that mining companies choose Pipestar Africa as a supplier of choice for their 3D HDPE seamless bends based on the company’s track record. “Pipestar International has for years been the leading manufacturer of HDPE Seamless Arc Bends™ in North America. It is a proven product and comes with years of

development behind it.”

Interestingly, for African mining companies, Pipestar Africa now offers HDPE Seamless Arc Bends™ as a locally African-manufactured product. “All mining clients should choose Pipestar Africa as their supplier of choice when it comes to seamless 3D bends. In my opinion, there simply is no other manufacturer that can compete with the quality of the product that we manufacture.”

More information on 3D Seamless Arc Bends™

• Arc Bends™ are reputed for excellent hydraulic properties.

• They are easy to transport

• Arc Bends™ have very high dimensional accuracy. There is no need for additional brackets or similar stabilisers for transport and storage.

• Arc Bends™ are fully pressure rated and derating as with segmented bends is not applicable.

It is a small wonder that they have become a product of choice where these features are preferred in mining, petrochemicals, oil and gas, just to cite a few amongst numerous others.

8 Mining Business Africa | November - December 2022

FEATURE

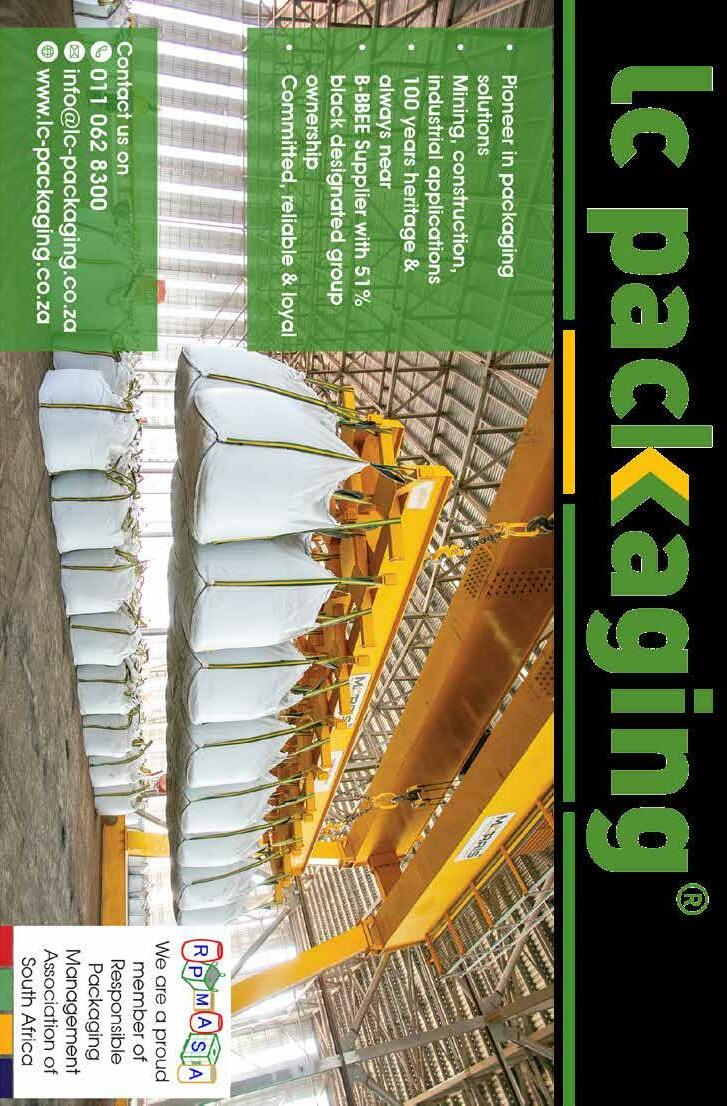

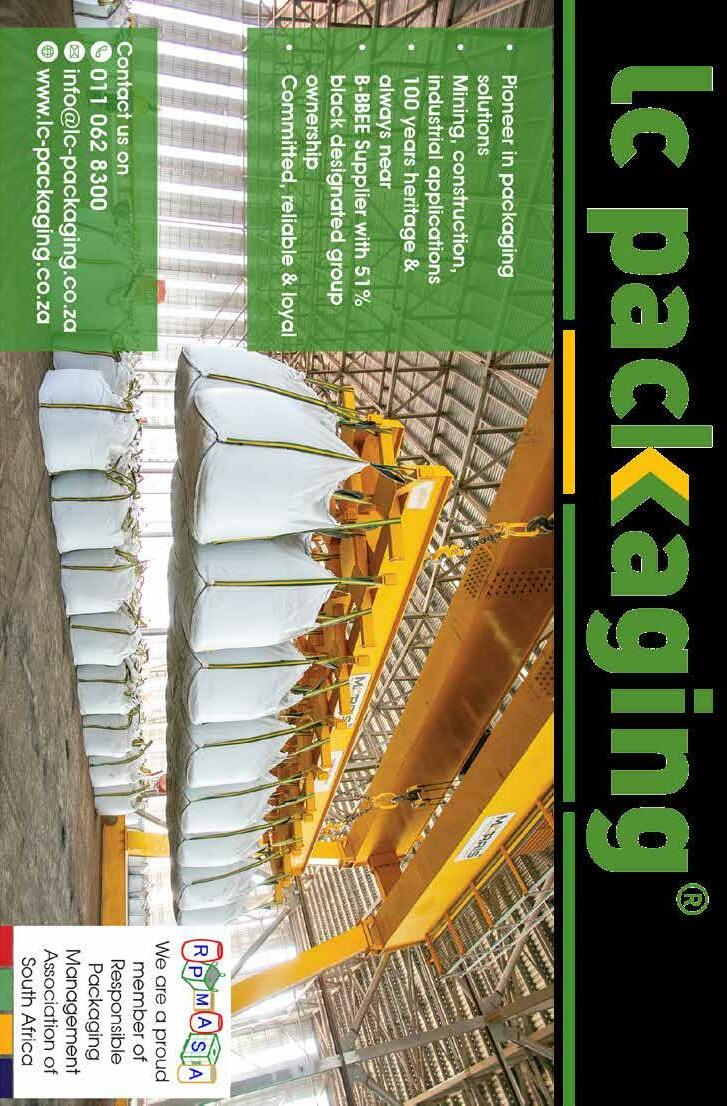

Flexible intermediate bulk containers (FIBCs) for mining projects

Committed, reliable and loyal

LC Packaging advises mining companies to be prudent when sourcing flexible intermediate bulk containers (FIBCs) for the transportation of ore and related products. As a provider of packaging and logistical solutions to blue chip companies, the company is eager to share its know-how to help mining houses make informed choices in the selection of FIBCs.

Mining companies are spoilt for choice with a vast array of innovative ‘fit for purpose’ packaging options for the transportation of ore and other products readily available on the market. Noticeably, Flexible Intermediate Bulk Containers, also known as FIBCs or big bags have emerged as one of the popular options.

Given the harsh environments in which they operate and the nature of their products, mining companies need robust and reliable FIBCs. Unfortunately, sometimes, having the luxury of a wide choice of products can become a big predicament when making informed procurement decisions. What renders decision-making in the procurement of FIBCs for contemporary needs complex is that it is not only informed by durability and affordability, but also by compliance with the Environment, Social and Governance (ESG).

Considering this, LC Packaging is keen to provide its expertise to prospective clientele in the mining sector. LC Packaging is a family business that has been active in the packaging industry for four generations. What started as a jute bag repairer and trader in 1923 has evolved into a full-service manufacturer and distributor and one of the world’s largest packaging experts in the field of Flexible Intermediate Bulk Containers, also known as FIBCs, and big bags.

Packaging and logistical solutions

LC Packaging provides packaging and logistical solutions that enable blue chip

mining companies across the continent to move processed materials to final end-users around the world safely and cost-effectively. It can support an operation from numerous factories, ensuring peace of mind that sufficient bulk bags will always be available on sight to keep the export target on track. Alexander Rohlf, LC Packaging’s Business Development Manager, guarantees to mining companies that LC Packaging has the requisite wherewithal to address particular needs for their respective applications. He says that the company’s products tick all vital boxes for mining-specific FIBCs, unsurprisingly, they have earned industry-wide respect for distinctive properties. Furthermore, the company ensures that its designs are customised to the clientele’s particular needs.

Distinctive

While different FIBC brands are in the market, LC Packaging’s products are distinctive due to the following properties:

• Customised and cost-effective

LC Packaging offers customised packaging solutions, following a detailed analysis of the client’s requirements.

• Easy storage and handling FIBCs are easily stored in warehouses or open areas as they can be lined, ultraviolet protected and water-resistant. They are easily handled by

forklifts or overhead cranes and can be readily transported by truck, or on rail. LC Packaging also offers stock holding agreements, which show their commitment to providing a continuous supply of FIBCs.

• Environmentally friendly

The lined and water-resistant nature of this packaging ensures a low risk of external environmental impact when compared with other forms of packaging (i.e. bulk storage). It is in the quality of materials used and the state-of-the-art production process, the quality of transport and storage and the service provided, the working conditions in which the FIBCs are produced, and sustainable practices when it comes to reducing their environmental footprint.

•

Multiple handling cycles

Whilst the majority are for single trips, they do undergo multiple handling cycles. External test certificates are available per FIBC design.

• Certification

When a particular commodity is classified as hazardous, LC Packaging ensures that UN Certification is available for the client and related transport entities. Certified bag designs ensure quality handling, filling & storage attributes of the bulk bag.

Customised FIBCs

Thanks to over a century of experience, LC Packaging can provide customised FIBC

10 Mining Business Africa | November - December 2022

FEATURE

solutions to clientele scrupulously through in-depth technology and research. This is besides conducting client operations where possible to be fully aware of the challenges and opportunities presented by the client operation. Afterwards, sample testing is done onsite before the mass production of bulk bags. Over and above, LC Packaging renders onsite technical advice, where the client’s wishes, packaging demands, and product requirements are addressed.

Prudence in selection

All in all, LC Packaging advises potential clientele to be very prudent as they are in pursuit of reliable suppliers. In particular, Rohlf highlights the following attributes that made LC Packaging to be ahead of the pack:

• Long-standing central values, committed, reliable and loyal.

• Always near with 21 offices, 5 production facilities, and multiple warehouses in 15 countries.

• A company that upholds the highest standards in quality and sustainability.

LC Packaging has been awarded many leading certifications, such as SA8000, ISO14001, ISO45001 &.

• Supplier of certified bag designs (ISO Certification).

• Own manufacturing and R&D facilities

• The company offers tailor-made stockholding agreements.

• Engage with suppliers with shared values on topics such as health and safety, a living wage, no child labour, ESG and ongoing improvements for the betterment of its people and the environment.

“We pride ourselves on the quality of our bags and the high service delivery of our supply chain team. With our bags you are guaranteed

of FIBCs that meet contemporary requirements, which are predominantly robust and reliable,“ pronounces Rohlf.

On the whole, LC Packaging is committed to being a long-term partner in sustainable packaging solutions, for every product and

Eco-friendly production and usage

LC Packaging employs eco-friendly practices in the production and usage of its products to reduce emissions.

This is steeped in its philosophy: Growing environmental efforts – Ambition 2030 goals... A World Without Waste. To realise this objective, LC Packaging is driving company-wide change, revolving around people, environmental betterment and production efficiency to limit its impact on people and planet. The company has established its 2030 Ambition which has been mapped against the United Nations 2030 Agenda For Sustainable Development

To this end, in its daily operations, it directly contributes to four of the seventeen global sustainable development goals (SDGs), being Decent Work and Economic Growth,

Innovation in mining-specific FIBCs

LC Packaging always upgrades its products, as and when necessary. Its multi-trip bags (6-1 certified) for non-hazardous minerals typifies constant innovation. Mainly, the bags are renowned due to the following attributes:

• Reduces the carbon footprint by using fewer bags to move products.

• Reduces warehouse storage and bag stock levels.

every industry. From bags suited for mining, and construction, from stable and ventilated bags to food-safe, pharma-clean, UN and electrostatic FIBCs: its motto is: “To keep your industry going.”

Responsible Consumption and Production, Climate Action and ultimately partnership for the goals.

Deservedly, LC Packaging’ sustainability efforts have been acknowledged by EcoVadis with the highest CSR ratings over the past three years, with special acknowledgement for its structured and proactive CSR approach, because of policies and tangible actions on major issues. Ecovadis provides a system to allow organisations to evaluate their own and their supply chain’s corporate social responsibility levels. It covers 21 CSR indicators across four main themes: Environment; Labour & Human Rights; Ethics; Sustainable Procurement. It is expecting its new EcoVadis CSR rating to be available by February 2023.

• Ultimately, this reduces the cost of movement per ton of a product.

Over and above this, LC Packaging is widely reputed for innovative designs in UNcertified big bags, Q-bags and electro-static bags, which offer safety during the filling & discharging of flammable gas, vapour or dust atmosphere.

12 Mining Business Africa | November - December 2022

FEATURE

Do you know if your employees wear their hearing protectors?

The effectiveness and success of a hearing conservation programme depends on how often and well it is monitored and controlled.

Says Pieta van Deventer, Director of H.A.S.S Industrial, “Annual monitoring of hearing protection devices is part of the overall hearing conservation programme of a company. It is an

monitored for effectiveness. This is where Noise-Ban plays an important role and could close the loop in ensuring an effective hearing conservation programme.

“Since 1992, H.A.S.S. Industrial has been partnering with various industries to provide custom-made hearing protection devices to their employees and assist in their hearing

peace of mind.

Our annual monitoring service includes:

• Ensuring a continuous leak tight seal;

• Accessing the use and condition of the Noise-Ban

• Confirming the attenuation requirements;

• Retraining the employee on the use and maintenance of his hearing protection device; and

• Record-keeping and feedback to management.

Please visit www.noiseban.com or scan the QR code below for more information.

ADVERTORIAL

Big on noise protection. Small on size. Get the optimum custom-made hearing protection ideal for Tel: +27 (12) 403 - 8740 www.noiseban.com Since 1992

Mining Business Africa | November - December 2022

Steel wire ropes for mining projects

Correct selection, perfect performance

Conveyances are moving people and materials up and down in underground mining operations. Steel wire ropes are used for hoisting this critical equipment. Given their vital role, suitable products must be used for applications. Over and beyond, after installation and commission, the steel wire rope must be tested regularly to ensure that it is in perfect working condition. This is because steel rope failure can result in an accident.

wire rope is in perfect working condition.

Opportunities and challenges for supplies

Currently, mining companies need a predictable supply chain that can meet their need for robust steel wire ropes and accessories at any time. For manufacturers/suppliers, the increasing demand presents both a challenge and an opportunity. It is a challenge, for it pushes them to pull out all the stops to produce innovative products. Of course, this can be an intricate task as every mine has unique needs. Ultimately, it requires mining companies to work closely with the client to develop the best possible solutions for various applications in the harsh mining environment.

Selecting wire ropes for duty

For end-users, there is little margin for error in the selection process. This calls for prudence in the procurement process. However, understandably, in a market awash with many steel wire rope brands, selecting a suitable product can be a convoluted process.

At first, it is paramount to evaluate particular characteristics required for the application, and later, to choose the rope possessing these qualities in the best combination.

Currently, the underground mining environment is a beehive of activity.

Conveyances, draglines and scrapers are among numerous pieces of equipment that are being overexerted as mining companies increase production. Concurrently, there is an increase in demand for steel wire ropes used with this equipment.

Steel wire ropes are considered an alternative to chain ropes. Among others steel wire ropes are desired for several factors, commonly higher strength-to-weight ratio, rendering them easier to install and lighter. The steel wire configuration commonly used is six strands.

It is not surprising that, due to their unique features, steel wire ropes remain the tried and tested technique of suspending and moving a conveyance between operating levels in the shaft and surface.

Thus, it is critical to have robust steel wire ropes for this application and others as safety is paramount.

This presents both challenges and opportunities for suppliers. And as for end-users, they need to be adequately informed in the specific products they need for their applications. Most importantly, after installation and commissioning, as a standard practice, there is a need for regular testing to ensure that the steel

Wire rope testing

After the most suitable steel wire rope has been procured, installed and commissioned, it is important to ensure that it is in perfect working condition. In South Africa, the Department of Minerals and Energy (DME) recommends that statutory testing be carried out every six months. The rope has to conform to the code of practice (SABS 0293, 1996).

Typically, in rope testing the following

Manufacturers produce information to help their end-users when selecting steel wire ropes. In general, the information calls for mining companies to consider the following factors when shopping around for suitable products. Chiefly, these are: strength, fatigue and abrasion resistance, crushing resistance, resistance to rotation and the operating conditions and physical environment, over and above, and the kind of machinery used. At all times, mining companies must consult rope manufacturers to choose the most suitable rope. The rule of the thump is: Correct Selection, Perfect Output.

Coping with contemporary requirements

Changes in legislation have increased the obligation of mining companies to enhance safety. Thankfully, advances in technology are enabling mining companies to cope with contemporary requirements in steel wire ropes. One of the groundbreaking innovations is larger diameter ropes with higher breaking forces catering for increasing mining depths and heavier payloads.

elements on the rope are evaluated: absolute breaking force, mechanical properties, modes of wire and strand failure, the extent of corrosive and abrasive damage, and the state of lubrication.

Once the rope is tested, the information is captured in the rope-test database. Then, a certificate is issued to the mine indicating the rope’s general fitness for purpose.

14 Mining Business Africa | November - December 2022

Advances in technology are enabling mining companies to cope with contemporary requirements in steel wire ropes

FEATURE

The South African mines ha ve to operate at increasing depths to access their ore r eserves The most cost e ffec�ve method of doing this has been to use a single li� sha �, as opposed to the tradi�onal, more expensive mul� sha� system (sub ver�cal sha�s underground). Thi s approach has however required innova�ve, l eading edge tech nological advances not found outside of South Africa.

WITH THE ABOVE AS A CRITICAL REQUIR EMENT

Haggie® St eel Wire Ropes (SWR), in collabora�on with the Mining industry, carried out extensive research in the development of ropes, which are stable enough to operate at depths of around 3200m This was 27% deeper than the pre June 2002 deepest single li� sha� in the country. It should be noted that a 27% deeper sha� does not equate to 27% increa se in technical difficulty of a�aining those depths , but rather an exponen�al increase in design, engineering and manufact ure

As a leader in the steel wire r ope manufacturing industry Haggie® SWR was approached to d esign and manufacture a new triangular strand rope for Ultra Deep Hois� ng (UDH Triangular Strand Rope). This was for use at Anglo Gold Asha n�’s Moab Khotsong M an Winder and Goldfield s flagship mine South Deep Rock Win der. Pa r�cular a�en�on had to be paid to the rope design and manufacture A condi�on of supply that is s�ll evident in every order received to this day, in con�nuous a�empts to ever more improve the cycle lives of these ropes and apply this knowledge and experience to shallo wer mine sha�s Addi�onally, special improved quality steels were employed in manufacture and stringent quality plans were put in place for theses ropes t o ensure con�nu ity of quality from Rod Yard to Dispatch.

Robin

/ Manager Mining Haggie Steel Wire Rope (Pty) Ltd, Registra�on Number: 2021/845504/07 Lower Germiston Road, Heriotdale, Johannesburg, South Africa T: +27 11 620 0256 | M: +27 79 887 2747 | F: +27 11 620 0256 |

Wilson | Consul�ng Engineer

robin.wilson@haggie.co.za | www.scaw.co.za

Cloud-based Inventory Management for Mining Projects

Cloud-based inventory management optimisation

The COVID-19 pandemic and the War in Ukraine have exposed gaps that have persisted in both material and labour visibility in mining operations. Unfortunately, paper-based techniques, with inherent limitations, cannot address this challenge. Fortunately, Linkederp’s Cloud Inventory® platform has proved effective when deployed in complex conditions in mines globally. By increasing efficiency and adaptability across a customer-focused supply chain, Linkederp’s Cloud Inventory® platform can optimise inventory management, enabling a mine to maintain operational excellence and safety.

No matter the circumstance, inevitably, mining companies are always faced with pricing volatility for commodities. Making operations leaner and pulling commodities out of the ground at a lower cost is the sure-fire way they employ of managing this challenge.

Gaps

Currently, mining companies are operating in an atmosphere where both the COVID-19 pandemic and the War in Ukraine have made this task all the more complicated. Particularly, these two critical events have highlighted gaps

in both labour and material visibility (inventory management) respectively.

•

The pandemic

The pandemic has underscored the need for improved visibility in the following areas: knowing who is where at any given point in time, prescribed maximum capacities at a given job site/mine, and over and above tracking selfassessment health screenings.

•

The Ukraine war

The Ukraine War has impacted the global mining

business prominently in several ways, in the main:

• No matter the industry, many companies ceased business engagements with Russia. For mining, this has meant a mass exodus of companies with operations in Russia. Many of them made decisions to spinoff Russian investments as a way to mitigate risk and still attract investors in non-Russian assets;

• Sanctions and bans have forced mining companies to exit partnerships, Joint Ventures that go against sanctions;

16 Mining Business Africa | November - December 2022

FEATURE

• Rising energy prices and production disruptions are hitting the mining sector hard; and

• Stockpiling of fast-moving inventory.

Importance of operational efficiency and safety

Linkederp provides customised cloud-based inventory management solutions to clientele in diverse sectors. Carel Bouwer, the company’s Managing Director, has been observing how these two events are impacting the operations of mining companies in the contemporary environment. She predicts that operational efficiency and safety at operations and projects will be even more important to global mining companies during the atmosphere of industry uncertainty. He singles out improved inventory management as one of the ways that can help them achieve this.

Regarding inventory management, Bouwer urges mining companies to adopt and utilise the best possible innovations, as paperbased processes are limited in the scope of capabilities.

The drawbacks of paper-based processes

One of the common reservations that industries have with paper-based processes is the lack of mobility and data granularity needed in their ERP systems. Inescapably, this results in two challenges that are significant obstacles to creating an optimally efficient mining operation. Usually, in the disconnected environment in which they operate, for mining personnel, using an inventory management approach that involves constantly updating spreadsheets or using paper-based card systems to monitor inventory use and location is not effective. This is because materials go dark at several points along the supply chain, due to a lack of visibility across facilities, once an asset has left a facility, is in use, or is in a disconnected environment. “Costly gaps in field inventory data can have a negative downstream effect on other aspects of the business and lead to counter-productive business decisions at other points of the supply chain. However, in inventory management, it is critical to know what you have and where to avoid decreasing inventory adjustments,” Bouwer elaborates.

The second challenge is that paperbased processes often don’t have granular enough understanding of the state, location and authenticity of assets (including operating equipment) to keep on regular maintenance cycles. Yet effective processes are central to a safe environment and avoiding incidents.

An alternative solution

Given the two aforementioned challenges and their impact on operational efficiency and safety, Bouwer states that the need for an alternative

solution to optimise inventory management does not need to be overstressed. “Many mining firms operate in environments where connectivity is limited or non-existent. For this reason, having a collaboration platform to see what inventory is where – even in a disconnected environment – is critical for mining operations. Data is integral to improving operations and safety and maintaining SOPs.”

Cloud Inventory® platform

Clearly, for efficient inventory management, mining companies need a solution that works in both connected and disconnected environments, removes manual processes, and ensures accurate real-time information is fed back to the systems that require that information. Thanks to advancements in cloud-based inventory management technology, this is possible. Cloud Inventory® management technology can enable mines to drastically improve their capability to access inventory data with speed and accuracy.

Bouwer strongly recommends the Cloud Inventory® platform to mining companies as a suitable cloud-inventory management technology for the present environment. “Cloud Inventory® is a mobile-first inventory management solution that utilises the power of the cloud to offer unprecedented real-time inventory visibility and control throughout the supply chain It is ideally suited for mining firms that depend on operating in the wild, where a lack of reliable connectivity can stall operations and reduce productivity.”

By empowering mining firms to control inventory in real-time despite the disconnected nature of the mining environment, Cloud Inventory® increases efficiency and adaptability across a customer-focused supply chain.

Typically, mining firms are fundamentally reliant on field operations. Hence, equipped with Cloud Inventory®, mining firms can be assured that data from the field is real-time and accurate and that it can be quickly and efficiently communicated across the supply chain. In addition, Cloud Inventory® is built on an infinitely configurable low-code platform. This means that mining firms can easily build apps to meet the unique needs of their operations and can adapt to unforeseen challenges on the fly without costly delays in production or reconfiguration of existing systems.

Ultimately, by increasing efficiency and adaptability across a customer-focused supply chain, Cloud Inventory® can optimise inventory management, which enables a mine to maintain operational excellence and safety.

Insourced or sourced?

The onus is on mining companies to decide on the cloud-based inventory solution option that would best suit them – outsourced and insourced. Usually, Bouwer explains a company’s unique situation informs a decision.

“It is hard to make a complete generalisation without an individual understanding of each operation. However, if you have easy-to-use / easy-to-implement (and support) solutions that allow you to manage inventory for instantaneous connection with your investments, then insourced inventory management might make the most sense.”

Linkederp is a business partner of the company now called “Cloud Inventory”, previously known as DSI (Data Systems International).

Cloud Inventory transforms Kinross Gold Corporation

With 9,322 employees, headquartered in Toronto, Canada, Kinross Gold Corporation is a senior gold mining company with operations in the United States, Brazil, Chile, Mauritania, and Canada. Kinross is focused on delivering value through operational excellence, balance sheet strength, disciplined growth and responsible mining. It has a revenue of US$3.7billion.

Cloud Inventory® has helped Kinross Gold Corporation to solve complex challenges it encountered with inventory management. Now, the company has an efficient inventory management system.

Linkderp automated Kinross’ once paper-based processes in the field (maintenance checklists and work orders, environmental data for the lab) with Cloud Inventory® mobile applications. So far, with Cloud Inventory®, Kinross has been able to eliminate hundreds of hours of manual work and support this data capture even in disconnected environments. The solution is easy to use and deploy.

Interestingly, Kinross has also been able to develop its applications through the Cloud Inventory® no-code Platform to ensure its solution meets their needs as requirements evolve.

Linkederp is a business partner of the company now called “Cloud Inventory”, previously known as DSI (Data Systems International).

‘By empowering mining firms to control inventory in real-time despite the disconnected nature of the mining environment, Cloud Inventory ® increases efficiency and adaptability across a customer-focused supply chain.”

Mining Business Africa | November - December 2022 17

Onsite-PPE vendor-managed services for mining projects

Partner with the Proven Onsite PPE-vendors

Sheq Safety is the manufacturer of Sahara Workwear, a SABS-accredited brand, and is informing mining companies to only engage companies that have a proven track record in the provision of PPE-vendor services to the industry. The company services the industry with PPE VMI on-site stores, over and above supplying gifts and fatalityfree shift packages and other relevant products

Partnering with established service providers of PPE vendor-managed services is one of the ways that can enable mining companies – with respect to South Africa - to comply with the Mine Health and Safety Act (MHSA) and Occupational Health and Safety Act (OHSA). This is the timely advice of the management of Sheq Safety as they observe increased mining activity which necessitates procurement of relevant personal protective equipment (PPE) in order to mitigate the escalating risk of accidents.

Sheq Safety’s advice is based on tons of experience accumulated from years of servicing the industry diligently with PPE VMI on-site stores, over and above supplying gifts and fatality-free shift packages and other relevant products. Sheq Safety strives to meet customers’ full needs in relevant PPE.

Need for prudent decisions

Management of Sheq Safety advises mining companies to make prudent decisions when looking for partners to provide onsite vendor-based PPE stores. This is bearing in mind that, with the complex demands of the current mining environment, traditional approaches to PPE procurement fall short in helping mining companies achieve compliance. In particular, over and above striving to achieve cost containment and increasing revenue, mining companies have to contend with changes in regulations, mainly safety and environmental compliance.

The limitations of traditional PPE procurement

Rapid changes in the operating environment throughout the world are exposing the limitations of traditional approaches to the procurement of commodities in different sectors. This is underscoring the need for the industry to adopt innovative means.

Duly, in response to shifting customer needs, some players in the FMCG sector in South Africa have adopted online Apps. For instance, FMCG companies like Pick-n-Pay, Checkers, Spar, among others, now all have online Apps where a customer can procure and they deliver without a customer even having to leave their homes. Similarly, this is happening to procurement platforms like Takealot where the buyer or the customer sits in the comfort of their home and places their order.

Generally, traditional approaches are turning out to be old-fashioned, cumbersome, and inefficient. In particular, employing the traditional approach in the procurement of tier-one products becomes a drag and drain on limited resources.

Consequently, Sheq Safety management tell mining companies that the most practical approach for them is to farm out resources tied up in the procurement of very important tier-one products (viz PPE) to capable contractors. “Let the people that are paid by the mining companies focus on the core business of the mining companies and for no extra cost agree with a professional, efficient supply partner by way of a PPE VMI on-site store.”

Vendor-managed PPE on-site stores

Sheq Safety has gathered from mine sites it services that vendormanaged PPE on-site stores can help mining companies address inventory challenges and productivity. By freeing up the staff, capital and time of the mining companies, mining companies can focus on their core business.

No doubt, having vendor-managed PPE on-site stores is critical as PPE is a tier-1 product at mining companies. Without PPE, the mine cannot operate

in terms of Department of Mineral Resources (DMR) safety standards and expectations. However, the challenge is finding a suitable supply partner, a task complicated by the presence of many ‘specialists’ out there on the market, management lament. “The challenge facing the mining company – like everything in life – is finding a supply partner who has standards, capabilities and is likeminded to your company’s standards and values.”

Sheq Safety’s VMI onsite PPE

stores

Sheq Safety asserts that potential clientele in the mining sector customers that its approach is rooted in excellent customer satisfaction. Particularly, it is tailored to the delivery of stock of the expected quality and quantity at competitive prices unfailingly/devotedly. Their approach in the delivery of PPE VMI on-site stores involves the following:

•

Product brand, quality and price

The brand and quality of the product are discussed and agreed upon prior to the inception of the contract. Once the quality of the product is agreed upon, so is the price. The contract price is fixed for twelve months from inception. However, the big challenge is how the vendor-managed company operates the DIFOT (Delivery in full on time). Fortunately, the secret lies in relationships ….. relationships with suppliers, relationships with staff and relationships with customers.

•

An area manager for

contract

Sheq Safety has an area manager associated with each one of its contracts. Generally, the company clubs those contracts together so that one area manager looks after several

18 Mining Business Africa | November - December 2022

FEATURE

individual contracts within the same area. This allows a representative from Sheq Safety to communicate to people like the HR department to ensure that we are informed when new staff are coming into service and make sure that we are fully equipped. In addition, it always insists that its procurement department has very close relationships with its OEMs and as a result has regular meetings to ensure that forecasts are updated and governed.

Sheq Safety recognises that the communication between the store and the area manager and the area manager and the group planning department is fundamental for the successful implementation of a PPE VMI on-site store.

•

Daily involvement of senior staff

The other ingredient of success in this model is the involvement of senior management on a day-to-day basis. The CEO of Sheq Safety is involved in inventory planning as well as inventory management on a day-to-day basis. Sheq Safety is fortunate enough to have a clothing manufacturing factory, which is SABS accredited, under its management and control.

Founded on integrity

Cases of clientele being left to their own devices by unscrupulous providers are worrying. Sheq Safety’s advice is that clients should exercise due diligence when looking for reliable suppliers.

Sheq Safety’s business conduct is founded on integrity in every process. In general, when dealing with the company, customers are assured of the following:

• Sheq Safety is an entrepreneurial company where the shareholders of the company work in the company on a day-to-day basis. As such there are no demands from “money” hungry shareholders for super large dividends. Any gained profits are

ploughed back into the company in the way of increased stocks or absorption of overheads.

• Sheq Safety is a black women-owned company in a country that is trying to transform its economy to an all-inclusive economy.

• Sheq Safety is currently a level 1 BBBEE contributor where we focus a lot of time and effort in staff training and skills transfer

• Sheq Safety manages and controls its own clothing factory which is SABS accredited

• The senior management of the company has more than 100 years of experience in the PPE industry and the staff are young and energetic backed by the experienced directorate.

• Sheq Safety is a member of SAPEMA

• Sheq Safety is a member of a number of technical committees at SABS where we play an important role in maintaining quality standards for the South African PPE industry

• The senior management/directorate in this company has a hands-on day-to-day approach concerning the PPE VMI on-site stores

Small wonder, due to its attributes, since its first PPE VMI On Site store contract was signed on 1

April 2006, it has built a rich portfolio of clientele contracts. The fact that Sheq Safety still services the first client underlines its firm commitment to strong customer relations.

‘The vendor of first resort’

Presently, clients are very particular about their requirements in PPE, especially as they are increasing production. However, as it is adequately resourced, Sheq Safety regards the challenge of meeting client expectations as an opportunity to seek practical solutions specific to the client. With an impressive track record to match, Sheq Safety advises clientele to entrust the company as ‘the vendor of first resort’ for their PPE requirements.

Astute leadership steer Sheq Safety

Sheq Safety has been able to forestall the current disruptions to the global supply chain, which has affected delivery of orders to industries like mining and others. This is thanks to the astute management under two hands-on shareholders, Lindiwe Kubheka and Elma Wallis, who are consistently committed to excellent customer delivery. Lindiwe is responsible for the production while Elma is responsible for the marketing. The benefit of the company having working owners is that they appreciate the importance of adding value to the company. Hence, any financial benefits that are earned by the company are immediately reinvested into the companyeither by the way of an increase in stock or by absorption of overhead costs for customers. This allows Sheq Safety, in times like these very disruptive supply chain periods, to increase its stock holding in “supply restrained” products.

PPE ON-SITESTORESVENDOR MANAGEDSPECIALISTS

Mining Business Africa | November - December 2022 19

Fast-track buildings for mining projects

Light steel convenience

‘LSF building method is growing in popularity. This growth is evidenced by the membership of SAFSA, which now stands at more than 60 member companies. Member organisations are involved in projects for clients in the mining, oil and gas, and petrochemicals, just to cite a few.’

• Accuracy

A LSF building is dimensionally far more accurate than masonry building or concrete construction. This saves time and cost when installing pre-made components such as kitchen cupboards and wardrobes. With light steel framing, one can work to a tolerance of less than +5 mm.

Evidence of growth

A major advantage of LSF building is that a structure takes much less time to complete than a similar brick-and-mortar building.

Mining companies need fast-track building solutions for their projects. Thankfully, the construction industry is pulling out all the stops to meet this need with innovative designs that serve the purpose. The growth in the niche of light steel frame buildings is a case in point.

Huge potential

Light steel frame buildings (LSFB) present an option worth exploring for mining companies due to the comparative advantages they offer. In a review on the method, the Southern African Institute of Steel Construction (SAISC) sees huge potential through the reduction of building costs, less time to finish, energy efficiency, and accuracy.

• Reduced building costs

The growth in the popularity of LSF construction locally is because it reduces building costs, in several ways.

• Less time

A major advantage of LSF building is that a structure takes much less time to complete than a similar brick-and-mortar building. As the construction team can finish the outer shell of the building in a much shorter period, work on the inside of the building (completing internal lining, ceilings, tiling and painting) can get underway much earlier – as can the installation of services (water and electricity. In addition, having the outer shell completed earlier means that the building can be secured against unauthorised access much sooner.

• Energy efficiency

With its installed insulation, LSF buildings are more energy-efficient than heavy masonry buildings. A research project carried out by the Council for Scientific and Industrial Research (CSIR) for SASFA, indicates that an LSF building will require less than half the energy needed to heat and cools an uninsulated masonry residential building.

The use of LSF allows for energy conservation on two levels. The energy used in the manufacture of the actual building materials – the embodied energy – is considerably less than the amount consumed by traditional building materials. Secondly, the operational energy used in heating and cooling the building over its lifespan is also considerably less.

LSF building method is growing in popularity. This growth is evidenced by the membership of SAFSA, which now stands at more than 60 member companies, that are involved in projects for clients in the mining, oil and gas, and petrochemicals, just to cite a few.

LSFB should not be confused with prefabricated buildings. In LSF buildings, the supporting frame is made from a thin gauge, high-strength galvanized steel sheet, which has been cold-formed into lip-channel sections. These sections are joined using rivets or self-tapping screws to form strong wall frames, roof trusses and floor joists. The wall panels are then clad using fibre-cement and gypsum boards, and fixed using battery-powered screw guns to install the self-drilling screws. Insulation (glass wool) is installed in the wall cavities to provide thermal efficiency and enhance the acoustic properties of the walls.

20 Mining Business Africa | November - December 2022

‘LSFB is not prefabricated building’

FEATURE

Expand your network with attendees from 120+ countries 1,100+ exhibitors showcasing the best in the industry Hundreds of hours of programming presented by industry experts Engage with private, retail and institutional investors and senior executives REGISTER AT pdac.ca/convention | #PDAC2023 Metro

Centre, Toronto, Canada MARCH 5 - 8

Toronto Convention

Fire detection and suppression for mining operations

Fully monitored automatic fire detection and suppression

A fire suppression system is up there with mining’s most important safety systems. Fires can take hold in seconds, and the source of many fires is often concealed, meaning there is little time for operators to react. This is where the JSG Industrial Muster fire suppression system comes into its own offering 24/7 integral monitoring of the system to ensure immediate response when called upon. The Muster Fire Suppression System offers both LHD (linear heat detection) and LOP (loss of pressure) capabilities in the detection of fires on mining equipment, all certified to AS5062-2016. The company’s team of fire engineers are eager to render their know-how to address the complex challenges mining companies in Africa face in fire protection.

they have noted the prevalence of lapses in the traditional approach to fire mitigation. Particularly, the biggest concern is that these expose mines to the high risk of fire incidents. Mining companies do not always get away with utilising techniques that have shortcomings for a very long time. The fire engineers urge mining companies to regard the likelihood of an accident occurring as a matter of ‘When, not if’, particularly in very hot areas such as turbos & exhaust manifolds.

Mining companies are more focused on increasing output to realise more revenue from high commodity prices. Inevitably, in pursuit of this goal, they must contend with escalating safety risks that could result in loss of the high-cost asset or worse, fatalities. To ensure the best management of their assets & personnel, part of the Muster support has a detailed Risk Assessment program that can be designed to meet all use of equipment. The Muster 360 system design program also ensures the fire system is designed to high standards under AS5062-2016. Understanding the fire risks helps reduce the impact of fires on vehicles.

The risk of fire incidents

The area that concerns JSG Industrial the most is the risk of fire incidents to mobile and static equipment. This should be not surprising as the company is very passionate about helping mines mitigate potential sources of fire incidents identified on mine sites. “Mining companies should ask themselves whether or not they would be able to cope should all of a sudden they encounter a fire incident during a shift,” Niel

Terblanche, JSG’s International Sales Manager for Africa and Madagascar, states, advising mining companies to treat the risk of fire incident as real at all times.

Prevalence of lapses

The company’s team of fire engineers have been studying trends together with mining companies. Judging from the information gathered,

The inherent limitations of what can be considered as ‘traditional’ fire suppression techniques in protecting mining equipment and its operators are the very risks themselves. Mainly, traditional fire suppression systems for mining equipment use Dry Chemical Powder as the extinguishing agent. Terblanche points out that the technology in Aqueous foams has advanced a long way since the early 1990s, such that these foams are as capable as Dry Chemical powder in use on mobile equipment with added benefits; great cooling effect, no cleanup, environmentally friendly, very low cost to recharge for further use.

JSG Industrial’s Solution for the environment as well as the equipment

JSG Industrial has devised a solution that specifically addresses all aspects of fire suppression & the environment. The company uses a 1% Fluorine Free foam solution with fast knockdown capabilities as an extinguishing agent. On the choice of the 1% Fluorine Free foam solution as an extinguishing agent, Terblanche demonstrates: “It is vital to cool down the risk area as quickly as possible and that is why we use a 1% Fluorine Free foam solution with fast knockdown capabilities, as an extinguishing agent with a minimum discharge time of 50 sec to ensure the fire is rapidly suppressed and entire risk area cooled down. Being Fluorine Free, the solution does not impact any environment where the solution was discharged.

22 Mining Business Africa | November - December 2022

FEATURE

Muster Fire Suppression System

JSG Industrial is committed to improving the quality of technologies to significantly minimise the risks and at the same time protect the operator and the machine. JSG Industrial works in association with Muster, a company that has built a reputation for manufacturing robust easy-to-install systems with 21st-century technology & stainless-steel components which demonstrate accuracy in performance.

Terblanche recommends the Muster Fire Suppression System to mining companies based on features and capabilities enabled by meticulous engineering.

Linear Heat Detection (LHD) and Loss of Pressure Solutions (LOP) Solutions

The Muster Fire Suppression System offers both LHD (linear heat detection) and LOP (loss of pressure) solutions for the detection of fires in mining equipment. It is installed to cover the entire fire risk area for effective and early detection of fires, coupled with instant activation of the fire system.

The detection and suppression cover any part of the equipment identified for protection in the risk assessment which is done as part of the initial design. The system is backed up by a fully interactive and fully monitored cloud-based design program.

The Muster alarm panel monitors pressure through transducer technology thereby providing the capability of monitoring the pressure in the cylinder & the integrity of the fire sensor, be it LHD or LOP, every minute of every day. Should the alarm panel not receive the signal from both locations every minute it will go into alarm to highlight the integrity of the fire system has been compromised & requires immediate attention. This ensures that the system is always in a state of readiness for its intended function as a first-line safety system to protect the machine & operator. As the alarm panel has diagnostic capabilities, it provides ease of finding the fault & thereby reducing downtime to fix.

Compliance with international fire suppression standards

Terblanche affirms to mining managers that the system meets international fire suppression equipment quality standards for mobile equipment. “Our system is AS5062-2016 (Australian Standard for Fire Suppression Systems on Mobile Machinery) certified and all designs, installations & maintenance are done following this high standard. Additionally, distributors and installers are fully trained and certified to ensure the standard is always met. We focus on reducing risks to the minimum, increasing safety, and placing responsibilities on authorised people to make sure this is achieved.”

The edge

Overall, the Muster fire suppression system has the edge over comparable products on the market. It is particularly respected for the following: a fully monitored system, diagnostic capabilities, it is fast acting, a strong cooling effect, extensive discharge time, flows with gravity to follow pooling fuel fires, and easy to service in the field. What is more, JSG ensures that the client benefits from the risk reduction the Muster Fire Suppression System provides. For instance,

with instant monitoring and the latest technologies, the system has an extended warranty period when the installation & commissioning document is registered. Most importantly, going the extra mile JSG Industrial & their trained technicians conduct an annual audit on the fire to ensure the fire system meets the AS5062-2016 performance standards.

Advanced fault diagnosis, improved uptime

If ever there is equipment in mining that must always work optimally it is the one used for fire protection applications, considering the risks and impact on operations. Terblanche assures the clientele in mining that they can be operating its equipment with a piece of mind.

The alarm panel logs all events and this data can be downloaded via the Muster Diagnostics Module for full reporting through the Diagnostic Utility Program. Telemetry and auxiliary options are also available such as external alarms and external flashing lights. In the case of any fault on the system, the alarm panel will indicate this to the operator and by using the Diagnostic Module we can quickly find the fault and rectify it so that the machine can get back into production.

Risk analysis before installation

Risk is the potential of adverse damage, injury or loss to a person or equipment, asset and/or operation. Before commencing a design, JSG Industrial considers the unique risk that clients face. This is done per AS 5062-2016, which states: “A risk analysis must be carried out with consideration to the health and safety of the operator and passengers, the health and safety of others in the vicinity, property losses, production losses and environmental effects.”

Your Fire Suppression Partner

24/7 Fully Monitored Solutions

Muster is a frontline safety system designed to provide automatic protection by detecting and suppressing a fire, allowing a window of opportunity for safe operator egress. Your personnel & equipment are protected by one of the world’s most sophisticated fire suppression systems, which utilises the latest engineering technology to provide 24/7 fully monitored solutions.

Our strength comes from high-quality distribution partners who manage installation, service, technical support & training nationwide.

Instrumentation & Flow Management | Fire Suppression

Quality Engineered Systems | jsgindustrial.co.za

JSG Industrial South Africa Pty Ltd E: onlineenquiry@jsgindustrial.co.za

Mining Business Africa | November - December 2022 23

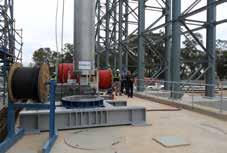

New high-tech African facility for Sew-Eurodrive

SEW-EURODRIVE South Africa, a specialist in drive and control technologies, moved into its new stateof-the-art 26 000-m2 headquarters complex in Aeroton, Johannesburg, earlier this year. The new complex more than triples the floor and factory space that was available at its previous premises.

SEW-EURODRIVE South Africa, a specialist in drive and control technologies, moved into its new stateof-the-art 26 000-m2 headquarters complex in Aeroton, Johannesburg, earlier this year. The new complex more than triples the floor and factory space that was available at its previous premises.

Built and equipped at a cost of R200 million and modelled on SEW-EURODRIVE’s showcase factory in Graben-Neudorf in Germany, the facility – which accommodates approximately 150 employees– makes extensive use of the latest technologies to effectively network people, processes, services and data.