The art of circular thinking

New name

International advancement

Theme

Circular economy

Qualifications and projects

An insight into the market

New name

International advancement

Theme

Circular economy

Qualifications and projects

An insight into the market

PAGES 20-25

About 4 / Welcome to Artelia

8 / International expertise

10 / A new pharma division

12 / Artelia in numbers

14 / Our community

16 / Career : Working abroad in Paris

18 / Career : From double internship to a regular job

Theme : The art of circular thinking

21 / Circularity and timber in 20 floors

24 / A recycling station in recycled materials

Projects and services

26 / Utilisation of excess heat

28 / Modernisation of Copenhagen Central Station

30 / Lighting in Copenhagen Central Station

32 / Bicycle planning in Le Mans

34 / Storage facility for nuclear waste

36 / Healing gardens at Bispebjerg Hospital

38 / Award-winning BIM design for UN17 Village

40 / Reduction of process energy

42 / Construction with a much lower CO₂ footprint

46 / Power plants on land for cruise and cargo ships

47 / Organisation

In 2023, MOE changed name to Artelia. We have done so to demonstrate our affiliation with Artelia Group and to further strengthen our international cooperation.

By changing our name to Artelia, we will strengthen our profile as a multidisciplinary engineering company and consultant driven by the employees’ entrepreneurial spirit, strong professional qualifications and a solid social environment.

Christian Listov-Saabye CEO, Artelia Denmark

Christian Listov-Saabye CEO, Artelia Denmark

The name change is a natural development after three years of cooperation and positive synergy. This will give us the opportunity to strengthen the connection across Artelia Group, increase awareness of Artelia’s brand in the European market, and it will be an advantage when we bid on large international projects.

Clocheret CEO, Artelia Group Chairman of the Board, Artelia Denmark

Benoît

Benoît

In 2019, MOE became part of Artelia Group because we wanted to become part of an international consultancy group where we would be responsible for the Nordic countries and be able to export our key services and offer new services to our clients. When we chose Artelia, it was decisive that we would become part of a consultancy group owned by leading employees in Denmark as well as internationally and a group with a high level of autonomy for each unit.

We chose not to change the name right away but to let our cooperation develop and let the affiliation with Artelia become clearer over time. In March 2023, the time was right for taking the next step and change our name to Artelia. We did this to demonstrate the affiliation, to stand stronger in the competition for employees and clients and in order to strengthen the international cooperation.

Our business is growing and developing, and we are now more than 1,100 employees. We see the sustainable agenda as a significant focal point for the ongoing growth and development. Therefore, our focus is on how we can contribute to more sustainable solutions for buildings, energy and infrastructure – our three business units. Thanks to our employees’ strong professional qualifications and ability to think outside the box, we take active part in the development of new solutions that push the green transition forward. The use of data and digital tools have had key roles in the transition for a long time, and we are well prepared for meeting the large demand for more sustainable solutions.

In the construction industry, focus on climate impact has increased significantly in 2023. From the turn of the year, LCA calculations are required for all new constructions over 1,000 m2 with a limit value of 12 kg CO₂ eq/m2/year. Artelia is well prepared since we have a large and strong team of sustainability experts and already have participated in several building projects with a CO₂ footprint even lower than the new requirements. Through several development projects, we help demonstrate how the impact on the climate may be reduced further, and we have many years of experience with the LCA calculations that will now become a mandatory element in practically all new constructions.

The energy sector is in the middle of a historical change process where Artelia contributes on many levels due to our position as one of the leading consultants within the area. Our specialists take part in implementing district heating, modernising the electricity network, establishing more climate-friendly production units and introducing new technologies such as Power-to-X and Carbon Capture.

A similar agenda applies to the ongoing expansion of infrastructure where we take part in promoting green transport modes such as bicycling, optimising public transport and creating mobility solutions that will reduce the CO₂ footprint.

Continues on the next page

Nyhavna Owner / Nyhavna Utvikling Architect / Cobe, Topic Architecture Rain water park in Nimgårdsparken Owner / KLAR Forsyning Contractor / Tscherning Pit thermal energy storage Owner / Dronninglund District HeatingIn 2022, LBP Engineering became part of Artelia. For some time, we have experienced strong growth in projects within the pharma industry, and we wanted to become a full-service consultant within this area. With LBP as the foundation, we have now created an independent pharma division.

With the establishment of a strong pharma division, our other industry units have been able to increase their focus on other segments such as the food industry and electronics companies where we now take on even more projects.

We are part of an international consultancy group with more than 7,000 employees worldwide and a long tradition for solving large and complex projects where technical synergies are used across country borders.

In Scandinavia, Artelia Group is represented in Denmark and Norway with ambitions to be present in more countries. Artelia Business Unit Nordics consists of Artelia in Denmark and Dr.techn. Olav Olsen in Norway.

We are experiencing an increasing demand for our expertise in other countries where we are able to use Artelia’s connections and geographical presence in more than 40 countries. Sustainability, district heating and bicycle traffic are examples of the qualifications that are now easier for us to export. We generally expect increased growth on the international scene as being part of a global group opens many new doors.

The opportunity for combining Artelia’s qualifications across international units has resulted in many international projects, e.g. the new Bus Rapid Transit system in the capital of Iceland, Reykjavík. At the same time, the cooperation with Dr.techn. Olav Olsen has strengthened our position in the Norwegian market and led to exciting projects for our employees in Denmark ; for instance assistance with the digital design of bridges in Norway.

Furthermore, we experience that the international support base provides significant advantages when bidding on projects in Denmark, particularly heavyweight projects. We can draw on global expertise when it comes to climate adaption, coastal protection and the entire maritime area which will become more and more relevant in the future.

Our employees are our most important resource, and it is crucial to ensure a highly professional environment where expertise is shared and developed. With many different professional qualifications at various levels and a project organisation with various roles, clear career paths and development opportunities are important. We offer career paths as e.g. expert, project manager or personnel manager. We have our own academy where employees can take various courses that are adjusted to their development needs and levels.

We are among the leading consultants regarding sustainable solutions, and as a workplace, we want to be even more responsible and contribute to the sustainable development. Together, we must ensure that we make sustainable choices when it comes to Artelia as a workplace. We have set ambitious goals as to how we can deliver significant and measurable contributions to the green transition via purchase and behaviour, and we focus on increasing our employees’ attention and contribution to sustainable behaviour.

An even better workplace

We have talented, qualified and flexible employees who everyday contribute to the development of our business – we have the best employees in the industry. We aim at creating a workplace where we grow and have fun, and the project An even better workplace is an important strategic focus area. We attach great importance to having an open and involving culture with

short decision paths where the employees have a great deal of influence on the planning of their own work as well as many social activities which form the basis for strong ties across departments, geography and technical qualifications.

A teaching organisation

Each year, we welcome several students, either as interns or student assistants or when they write their school projects or theses. Each year, we also have several trainees who are employed by us during their period of training. We see it as a win-win situation as we get new energy and knowledge while getting the opportunity to see the young people grow. We support them in their development and give them exciting challenges via their work on some of our many projects.

As part of a global group with more than 7,000 employees, we can exchange qualifications and experiences that will be relevant for the development of the Danish society in the coming years.

Artelia Group has offices in more than 40 countries and projects in more than 100. In addition to the global geographic presence, the group is in the global major league of engineering consultancy within several areas. For us in Denmark and the rest of the Nordic countries, it means access to expertise that is highly relevant for the development of society.

Large-scale marine engineering

In a flat country like Denmark, an extensive effort to prevent floodings is crucial. Coasts must be protected against rising sea levels and an increased surge risk while the many lowlands must be able to resist extreme rain. Artelia Group constitutes a valuable knowledge bank. In several continents, our foreign colleagues have assisted in climate adaptation of large areas and long stretches of coastal protection. As one of the more spectacular examples, they have analysed the effect of revitalising a historical breakwater system to protect Fort Boyard which is known as the location of a popular TV game show.

The qualifications are manifested physically in an 11,000 m2 hydraulic laboratory in Grenoble. The facilities are used for studying and validating design of complex marine engineering projects such as dams, pumping stations, harbour structures, coastal protection and marine structures. Physical models were used at a reconstruction of Europe’s biggest wastewater treatment plant Sein Laval near Paris. When it comes to size, these projects are in a different category than what we normally see in Denmark.

Our Corporate Technical Director for Water and Drainage Hydraulics Martin Werlin Munk got the same impression when he, out of curiosity, decided to visit Artelia in Hanoi during a vacation in Vietnam :

I was really well received. It was interesting to learn how they handle for instance water supply for a city with twice as many inhabitants as all of Denmark. That tells us something about the scale of Artelia’s projects and the group’s expertise in hydraulics – useful knowledge to have access to in many situations. In Denmark, we are fairly advanced when it comes to climate adaptation, and I believe we can contribute with our experience in return.

Martin Werlin Munk Corporate Technical Director Water and Drainage Hydraulics Copenhagen

Marine structures and wind energy

Dr.techn. Olav Olsen, who is part of Business Unit Nordics, also has hydraulic qualifications. Among other things, the Norwegian engineering company specialises in CFD calculations used in hydraulic computer simulations in 3D of different types of marine engineering. Dr.techn. Olav Olsen has solid experience with offshore projects and other marine engineering assignments. This has enabled them to develop several concepts for fixed and floating wind turbines.

Public transport experts

Infrastructure is another important area where Artelia’s global qualifications are relevant in a Danish context, especially when it comes to public transport which is essential in achieving a more sustainable development. Artelia has experience with everything on tracks – subways

and metros, high-speed trains, light rails and traditional trains. Currently, the group is involved in the expansion of Grand Paris Metro.

Bus Rapid Transit (BRT) is another one of our niche areas. Our qualifications in this field played a decisive role in winning the project of designing a new BRT system in Iceland’s capital Reykjavik with our French colleagues.

Gita Monshizadeh, Corporate Technical Director for BIM – Infrastructure, agrees with Martin that combining the foreign expertise with our own creates a value-adding interplay :

Artelia’s strengths when it comes to large infrastructure projects and public transport enable us to bid on projects in an entirely different league. In return, we can contribute with BIM and ICT knowledge. Denmark has a digital edge, and we have made great efforts to develop this area in our own business. For instance, we have chosen to specialise in the international BIM standard ISO 19650 which is gaining importance in many countries outside of Denmark. This helps us export our digital know-how and cooperation across borders.

The BRT system in Reykjavik is a good example of that.

Gita Monshizadeh Corporate Technical Director BIM – Infrastructure Copenhagen

Tripod OO Star Wind Floater Concept developed by Dr.techn. Olav Olsen.

Artelia's hydraulic laboratory in Grenoble.

Grand Paris Express Metro Client / Société du Grand Paris © Société du Grand Paris, Atelier Novembre and Benthem Crouwel Architects

Grand Paris Express Metro Client / Société du Grand Paris © Société du Grand Paris –Olivier Brunet

High-speed railroad from Le Mans to Rennes Client / SNCF Réseau © Dire L’Entreprise

Tripod OO Star Wind Floater Concept developed by Dr.techn. Olav Olsen.

Artelia's hydraulic laboratory in Grenoble.

Grand Paris Express Metro Client / Société du Grand Paris © Société du Grand Paris, Atelier Novembre and Benthem Crouwel Architects

Grand Paris Express Metro Client / Société du Grand Paris © Société du Grand Paris –Olivier Brunet

High-speed railroad from Le Mans to Rennes Client / SNCF Réseau © Dire L’Entreprise

In May 2022, LBP Engineering joined Artelia. The merger was a win-win match. With LBP’s strong skills within process engineering, tests and qualification and Artelia’s wide range of multidisciplinary qualifications, we have created a pharma division that is among the greatest in the Danish market.

Today, Pharma is an independent division in Artelia that provides full-service consultancy and is able to manage all project phases within concept and development in the pharma industry. The division consists of strong resources from LBP and a number of skilled employees from Artelia who will take the discipline to a new level and will have a strong foothold in an exciting growing market.

When we joined forces with Artelia, our focus was on continuing to deliver services in the market we were used to. At the same time, we saw a synergy in working with Artelia’s specialists within ventilation, fire safety and building installations as well as structures. LBP previously had to buy these services from other consultants. Earlier, we also had to turn clients down, as we did not have the resources to take on the projects. Fire safety consultancy in particular was a challenge, but after the merger with Artelia, we have gained access to that specialised knowledge, and that is a huge advantage, Lars Bjarne Pedersen, Business Manager in the Pharma division, explains.

The ambitions go further than the merger, even though our pharma division is among the largest in the market to cover the entire spectrum of consultancy to the medical and biotech industry. The dream is to be able to bid on more and larger projects that cover the entire range of consultancy from concept to execution – and the drive is there. Since LBP was founded in 2004, the company has experienced strong and solid growth of 10-15% per year and has been awarded the Gazelle Prize for being among the fastest growing companies several times.

Our strength is that we have a lot of knowhow regarding pharma and a close relation to our clients. We aim at providing focused consultancy adjusted to each client’s needs. After the merger with Artelia, we have

been able to develop and strengthen these relations further. We have gained more than 1,000 new Danish colleagues with qualifications within a wide range of disciplines which will also benefit our clients, says Lars.

The pharma industry's specific demands LBP has specialised in the specific requirements within the pharma industry – that is, everything from cleanrooms and supply facilities to production equipment. In the pharma industry, a room is not just a room. Everything must be taken into consideration, from entrance gates to supply roads and connections such as pure steam, sterile gases and water for injection (WFI), which are just some of the requirements that must be met in connection with firstclass production of medicinal products.

A typical example of a pharma project could be a new production machine that must be connected at the client’s facilities. It often requires very special sterile conditions which presupposes that production flow and design are thought out and live up to the specific requirements. Usually, pharma productions consist of closed processes with no human

contact to the product. All in all, the facilities require a layout that is prepared in detail, and the division therefore also has process architects who are specialised in designing optimal production flows and accommodating complex needs.

We are in a very good place with Artelia. We share the same values, and team spirit and a sense of community are central in our company culture. We have good synergies between our qualifications that we must utilise. We must therefore focus on getting to know each other better to be able to strengthen our cooperation and reap the benefits from the merger.

Lars Bjarne Pedersen Business Manager Process Engineering Vipperød

Lars Bjarne Pedersen Business Manager Process Engineering Vipperød

Numbers are an important part of our everyday life in Artelia. Here, we present some of the numbers that say something about who we are on a national and an international level.

10 years of fundraising for the fight against cancer.

2035 we want to be CO₂ neutral.

25+ different social clubs and organisations. In Artelia, you can join clubs for running, knitting, doing yoga, e-sports, cultural activities, art, football and much more.

8 offices across Denmark.

3 business areas : Building Energy & Industry Infrastructure

we changed our name to MOE & Brødsgaard.

42.4 years is the average age. 2019 we became part of Artelia Group.

50+ interns annually.

66% men.

34% women.

5.8 years is the average duration of employment.

29% women in Management.

10 divisions. 2023 we changed our name to Artelia.

We fully believe that going to work should be fun, and that job satisfaction is based on strong communities.

That is why Artelia actively supports the many social activities that take place both during and after work – initiated and planned by our employees – from sports and cultural events to parties, family excursions, study trips and our annual skiing trip.

It is a perfect way to get to know each other across departments and offices. It forms a solid basis for a strong professional cooperation in Artelia.

Even though we work with the same expertise and use the same standards, we think differently and use different methods and interpretations. One is not more correct than the other, but the differences affect the output. That is why it is important to collaborate and learn from each other.

Alberte Munk Hansen Specialist Sustainability CopenhagenWhen we became part of Artelia Group in 2019, it was with a clear ambition of creating new opportunities for our employees as regards secondment and cooperation across country borders. But as was the case with so many other things, the pandemic put an end to all travel plans.

However, the idea of working abroad stayed with Alberte. She is an LCA specialist and works with sustainability, energy and indoor climate. The foundation was laid with some international assignments where she tested the cooperation with the French colleagues digitally. Both in Denmark and in France, there was an interest in expanding the cooperation and seeing how we could learn from each other and use each other’s qualifications across country borders. An agreement with Artelia’s headquarters in Paris was made via Alberte’s manager and his counterpart in Paris, and in autumn 2022, Alberte could say au revoir to the office in Copenhagen and head towards Paris.

I was received very well by the colleagues at the headquarters in Paris. I could really sense that they were excited to welcome a colleague from Denmark. I was introduced to colleagues at every floor in the office, and I also went to meet Artelia’s Management and CEO Benoît Clocheret, says Alberte.

Alberte’s team leader even helped her find an apartment close to the office in an otherwise overheated Parisian housing market.

During her secondment, Alberte worked 50% on projects from her own Danish department and 50% on projects in the French department. Even though we in Denmark are very advanced within sustainability, it was still an eye-opener to experience how they work with sustainability, energy and indoor climate in France, where the department is approx. twice the size the Danish counterpart

Even though we work with the same expertise and use the same standards, we think differently and use different methods and interpretations. One is not more correct than the other, but the differences affect the output, says Alberte.

Alberte got the chance to try working with the new perspectives on her field, e.g. on an English project on development of a CO₂ benchmark across six Central European countries. Since the countries’ methods for LCA calculations vary, it is difficult to create a common benchmark. It is therefore necessary to scrutinise each

country’s methods and assess what to emphasise. She continues to benefit from the experience she gained, as she is still working on the project and since it is very likely relevant to use some of the foreign methods on Danish projects.

Fewer cultural differences than expected Alberte experienced that the work environment and the tone in France reminded her very much of what she was used to, although the workday began and ended later than in Denmark. As in Denmark, there was high potential for socialising with colleagues during and after work, but where we often gather for cake or a beer at the end of the working week, in Paris people generally meet for a croissant for breakfast – or a glass of champagne after hours. When in France …

All in all, Alberte benefited a lot from her stay, both professionally and personally, and she did of course also find time to enjoy the charm and pulsating city life of Paris. She hopes that her experience can help provide the setting for other colleagues who want a similar experience, just as well as she imagines trying secondment again some other time.

Alberte and her collagues visiting the construction site for the Arboretum project – a huge campus with offices built of timber and a nine hectare park on the banks of the Seine.For three months, Alberte Munk Hansen was seconded to Artelia’s headquarters in Paris, where she worked with sustainability, energy and indoor climate as part of the French team.

Some people have known since childhood which way to go in life. Others need to try many different things before they are certain. Veronica Velling Sveistrup let her curiosity show the way which among other things led her to a double internship.

Nurse, structural engineer or a journey with the school ship Skoleskibet Danmark? Veronica wanted to try it all when choosing her educational path. She ended up applying for admission to BEng in buildings and civil works – partly because she knew the construction industry via her father, who is a carpenter, and partly because it is a profession with a higher level of freedom compared to the other options :

As an engineer, you can be yourself and express who you are without being limited by a uniform or other requirements to your appearance, which I found appealing, Veronica explains.

Even though she initially aimed at a future as a structural engineer, Veronica ended up choosing Roads & Traffic as her specialty after she had gained a broad introduction to the different engineering disciplines during the first two years of her education.

When working with roads and traffic, you help tie things together. You get in contact with the entire infrastructure area as well as with other fields, e.g. environment, water, supply and structures. You get an understanding of the other disciplines and see the connection between everything. I get to use most of what I have learnt during my education, Veronica explains.

The fact that Veronica can let her creativity unfold during the drawing and modelling processes was also part of her consideration.

Curiosity also played a decisive part when Veronica had to plan her internship. It was important for her to try a broad range of tasks to make out which way to go. On recommendation of the university’s intern coordinator, she ended up applying for a job at Artelia in Aalborg – an office that had just the right size for taking a broad approach. It turned out that the internship offered several opportunities for Veronica.

Veronica’s careers advisor in Artelia, Stine Vistrup, contacted her former employer in the contractor company Arkil and suggested a double internship so Veronica could get even more out of her internship. As both Arkil and Veronica liked the idea, Veronica spent two out of her 24 weeks as an intern with Arkil and their excavators. It was a very useful introduction to how the engineers' material is transformed into actual roads, Veronica explains :

It was a bit of an eye-opener. When working on the computer, most scenarios are possible, but that is not always the case in real life. I realised how important it is to be precise in my drawings, because when the machines are fed with our data, they dig 100% according to them.

In addition to valuable insight, the double internship also gave Veronica an even larger network which might turn out to be a huge advantage in the future.

After her internship, Veronica was hired as a student assistant in the department for Roads and Traffic, where she has continued working with some of the projects from her intern period and still gets to put her qualifications to the test. The projects include one for the Danish Road Directorate where she has designed a two-way cycle track.

As part of the project, Veronica also got the responsibility for creating an overview of the Road Directorate’s specific requirements and standards for layout of drawings and models which were also new to her colleagues as this was the office’s first project for the Road Directorate. Veronica was therefore also responsible for training her colleagues, and it has boosted her faith in herself that the colleagues completely trusted her to have everything under control.

In the beginning of 2023, Veronica finished her graduation project with well-deserved top marks and can now call herself BEng in buildings and civil works specialising in roads and traffic engineering. Her next career step is also determined, as Veronica is now employed on a permanent basis by Artelia, where she has really settled in.

It is awesome that I get to try everything and show my skills. I am thrown into new challenges and get to try things on my own while always being helped along.

Veronica Velling Sveistrup Design Engineer Roads & Traffic AalborgClimate changes and scarce resources call for far better utilisation of the buildings we normally demolish and the materials we discard, even though they have a potential for a new life. However, this is not an easy task. Issues like environmentally dangerous substances and the lack of proper documentation pose a challenge – but it should not stop us from trying.

We must become better at preserving instead of demolishing, and we must recycle materials on a larger scale, which requires an effort from all links in the value chain.

As bio-based materials such as timber make an entrance in the construction business, the next important step will be to examine the construction parts consisting of materials that do not necessarily have a low carbon footprint by nature. They will be the most challenging item in future buildings’ climate report.

The extensive transformation that our energy supply is facing and the ongoing expansion of infrastructure require similar attention to maximum utilisation of the resources available.

That is why circular thinking is an important beacon in Artelia.

The pioneer project TRÆ is a laboratory both for high-rise timber buildings and for the use of recycled materials. LCA calculations and fire safety consultancy are two disciplines that are at play and go hand in hand when assessing the solutions.

At Sydhavnen in Aarhus, preparations have been made for the establishment of the office building TRÆ, which will be the tallest timber house in Denmark with its 78 metres and 20 floors. This combination in itself will make the building an engineering landmark which will require technical skills. The building has another technically interesting dimension since reuse and recycling are applied in all possible parts of the building.

New life to wind turbine wings

One initiative that has already made headline news in the Danish media is the pieces of worn-out wind turbine wings which will be used in the façade for solar screening.

The development of wind energy is a central part of the green transition in Denmark which will make turbine wings a more common waste product in the future. Since they are commonly made of epoxy and glass fibre, the wings often end up in waste repository which means that there is a double advantage of using them in buildings, says Astrid Nørgaard who is responsible for LCA calculations on the project :

We have compared with aluminium, which is often used as solar screening, and the estimated CO₂ footprint of the wings is 27 times lower. Even if we compared with a material that was less CO₂ heavy than aluminium, we would still see a noticeable difference. It is therefore a good idea as it also contributes to the solution to a waste challenge.

Continues on the next page

Even though we in many instances are able to demonstrate that reuse and recycling are good for the carbon reports, this does not count in the formal LCA. The building regulations state that materials must be considered new products if an EPD (Environmental Product Declaration) has not been made for the recycled material. This is rarely the case, and Astrid believes that the project will help illustrate the problem :

You might say that TRÆ is ahead of its time. We hope that our experience will have an impact on the development so that the building regulations will take circular economy better into account in the future.

Astrid Nørgaard Consultant Energy Design, Sustainability & Indoor Climate Aarhus

Astrid Nørgaard Consultant Energy Design, Sustainability & Indoor Climate Aarhus

In the office construction, reused timber is among the materials that will get a dominant role. This addresses another green advantage which unfortunately is invisible when following the specifications in the building regulations.

As a building material, timber has the huge advantage that trees absorb CO₂ from the atmosphere as they grow. It is therefore expected that the production phase will lead to a huge CO₂ decrease. On the other hand, in the regulations, it is assumed that the timber will just be burned and thus release CO₂ when the building’s days are numbered. The indisputable CO₂ savings connected to reuse of timber are therefore conspicuous by their absence and may be problematised in several ways, says Astrid :

The reused timber has CO₂ embedded which we now store even longer – something we will not be rewarded for. There is even a large amount of new timber in the building, and due to the contents of the building regulations, we must assume that everything will be engulfed in flames after the expected lifetime of the building. But with this building, we want to show just how large the potential is for reuse of timber. This illustrates very well the double-edged problem that may arise if the circular aspect is not included in the LCA calculations. There should be good incentives to use both new and reused timber.

The fact that the purpose with TRÆ is to explore ways to incorporate sustainability in buildings is also seen in that the building will have three floors that will each represent a specific type of material. The three categories are bio-based materials,

pure recycling materials and upcycling where the recycled materials are processed for a new purpose. This is one of the reasons why the creative phase in the design process rests on a valuable interaction between sustainability specialists, fire safety consultants and the architects from Lendager.

In 2022, Technical Director for Fire Safety Helle Bugge gave a presentation about the building at the conference Build In Wood, where timber was the focal point. She vouches for the safety check of the reused materials :

I find it inspiring to work closely with people who are so dedicated to sustainability because as fire consultants, we change our perspectives when we are being challenged. When assessing so many different types of materials, we can also set a precedent for which materials to use in the future, says Helle and points out another aspect :

Safety is crucial in our field, but sometimes it is expressed a bit rigidly where CO₂ savings would have been possible. When projects like these are so focused on sustainability, we also spot various places where the material load is unnecessarily high. We trim where we can, but at the same time, we are inspired to enter into a dialogue with the government agency to be able to legally slim down future buildings in cases where it is completely safe.

Helle Bugge Technical Director Fire Safety – Certified for fire class 3 and 4 and third party AarhusAt the new recycling station in Lisbjerg, waste is turned into resources. This core assignment is physically manifested in the facility structure itself, as most of the building blocks are made from recycled materials.

We must improve our abilities to recycle. Not just due to environmental concerns or for the benefit of our common CO₂ accounts, but also because resource scarcity will be a significant challenge in the years to come. In Lisbjerg near Aarhus, the new recycling station is one of the many parts in a big system built to strengthen the circular economy through more recycling. It makes sense that recycled materials are strongly represented everywhere in the station’s building components and construction works.

The substructures for the open spaces and roads of the facility are made of crushed concrete and bricks, while pavements are made of recycled concrete and asphalt. The perimeter wall, retaining walls, pillars and the load-bearing walls in the staff building are made of a concrete mix containing 60% recycled crushed concrete. The remaining part of the staff building is made of recycled timber. This is also the case with the two halls functioning as an exchange centre for recycled materials.

All façades and fascia boards are made of undressed wood, and the interior surfaces are made partly of recycled materials, partly of surplus materials from suppliers.

The building industry is a major supplier of waste and generates approx. 35% of the total amount in Denmark. It is also clear that far more could be done to ensure a good flow of materials from worn-out buildings to new ones.

We have worked with recycled materials in several contexts, but in the grand perspective, it is still unknown territory. Hence, projects like these contribute to gradually educating the industry when it comes to the circular proces.

As engineers on this project, we were responsible for detailed project design of all structures and construction work, which included special calculations for the use of the recycled materials. Another significant assignment was obtaining the permission to use the unorthodox materials, Morten explains:

Generally speaking, we are missing clear guidelines, and that can easily be a challenge for streamlining the process. We could have risked having to seek exemptions for all materials, which would have been a staggering amount of work. Luckily, we had a constructive dialogue with the construction authorities, which allowed us to reach our goal more easily. It takes flexibility and an open mind from all parties if we are to increase the use of recycled materials.

Lisbjerg Recycling Station Owner / Kredsløb Architects / LOOP Architects, Schønherr and Krilov Arkitekter © Ib Sørensen

Morten Hansen Project Manager Energy & Industry Aarhus

Lisbjerg Recycling Station Owner / Kredsløb Architects / LOOP Architects, Schønherr and Krilov Arkitekter © Ib Sørensen

Morten Hansen Project Manager Energy & Industry Aarhus

The cooling processes at Danpo’s factory in the town Farre emit enough excess heat to cover half of the consumption at the heating cooperative Give Fjernvarme and make the production of chicken products greener.

If you like sinking your teeth into crispy nuggets or hot wings from Danish chickens, you will probably come across products from Danpo’s factory in Farre. For instance, the nuggets from McDonald’s restaurants in Denmark are produced here. Each week, the factory produces 1,000 tons of chicken products of which the majority are frozen down immediately after being processed. This represents an untapped resource as the strong cooling processes related to the refrigeration emit large amounts of heat.

Danpo and Give Fjernvarme spotted an opportunity for a valuable sector coupling where excess heat can be used the best way possible by being channelled to the district heating customers. Artelia was full-service consultant on the project and started by producing a project proposal to account for the socio-economic gain and

the green potential. The analysis clearly showed that the economy is very good, not to mention the sustainable aspect, says Kenneth Graa :

We can reduce Give Fjernvarme’s wood chip consumption by more thank 50% and remove the need for natural gas completely. Additionally, the town of Farre can be connected to the district heating network instead of being heated with natural gas and oil.

Kenneth Graa Business Manager Energy & Industry Aarhus

Give Fjernvarme supplies heat to 1,600 customers who can look forward to competitive and even greener heat supply. The new solution will also benefit Danpo :

The heat that the cooling process emits must be channelled away to keep the temperature at minus 20 degrees, and that requires a great deal of energy. There is therefore a lot of synergy in the project since Danpo is able to save significant amounts of electricity for the cooling

towers by emitting the excess heat to Give Fjernvarme. It is a win-win situation for all parties, says Kenneth.

The technical solution consists of a 5 MW power-operated heat pump which receives hot water from the cooling towers and via a heat exchanger sends the water to the district heating system at the right temperature. In that connection, a 3.6 km long heat transmission line to Give Fjernvarme will be established.

Artelia will be responsible for the heat pump procurement based on operational needs as well as project design and tender procedure for the district heating main. During the preliminary phases, we have screened for the amount of excess heat by analysing operational data for Danpo’s cooling equipment. Based on that, energy system calculations have been made for Give Fjernvarme’s future heat production system by using the modelling tool energyPRO.

A large modernisation of Copenhagen Central Station will create a more open and safe experience of the station. With this, one of Denmark’s most important transport hubs will be ready for the renewed attention given to trains and railways as more sustainable national and international transport modes.

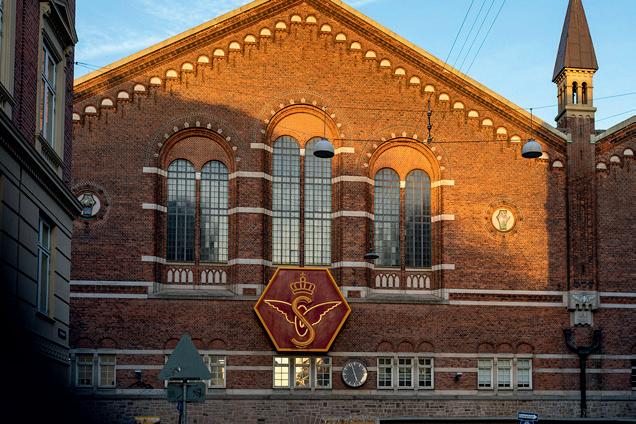

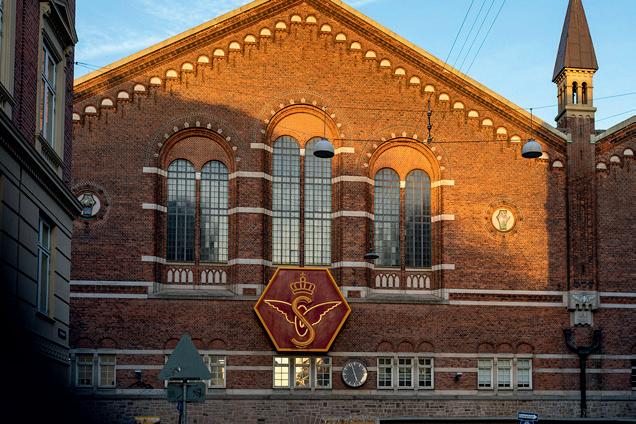

For several years, Artelia has contributed to preserving the classic beauty of the capital’s Grand Old Lady, Copenhagen Central Station, and to ensuring that the station appears functional and attractive via ongoing renovation and modernisation projects. Now, the time has come for a significant change of the more than 100 years old and listed building.

On the inside, the shop pavilions will be transformed and modernised so travellers can stock up for their trips without

going off course in the large hall. On the outside, the façade towards the street Reventlowsgade will be opened for shops, cafes and service functions to create flow and urban life in the otherwise overlooked street that connects the central station with the new metro station.

I consider this the crown jewel of our projects for DSB (Danish state railways). The transformation will take place in the presence of history as Copenhagen Central Station is the heart of DSB and a historic building. We will put great emphasis on conducting the work with full respect for the existing surroundings, says Division Director, Klaus Jørgensen.

Since the building is listed, the façade opening must be planned in close contact with the Agency for Culture and Palaces. Even though significant changes will be made, it is important that they are fused together with the existing surroundings in a frictionless process to maintain the special spirit and appearance of the central station. Among other things, this requires special knowledge of traditions and peculiarities regarding brickwork, which is one of the characteristics of the building.

In connection with the modification of the shop pavilion, there are many considerations to balance. The pavilions must be flexible enough for varying use and an expected increase in number of passengers with the opening of the new metro lines. Practical needs such as cooling and ventilation installations must be taken into account, and it must be easy to carry on existing procedures for waste separation, delivery of goods, etc.

In that way, it is a typical assignment for Copenhagen Central Station with the constant balance between requirements related to listed buildings and to functionality, passengers’ expectations and needs, the wish to create a beautiful and image-bearing look, aligning with many difference stakeholders, special railway conditions, etc.

It is a very experienced team with a broad range of qualifications that is full-service consultant on the project which was put out to tender under a framework agreement with DSB. While Artelia is responsible for all engineering services, Gottlieb Paludan Architects is responsible for architecture, flow

and interior design with Ole Drachmann from Drachmann Architects as an expert regarding matters related to listed and culture-historical conditions. Malus and AFRY are responsible for consultancy regarding railway safety in connection with the reconstructions. All team members have long-term experience with assignments for DSB and the central station – both at company level and as a team – and they are well aware of the special conditions to consider.

It is a really interesting project that fits well into Artelia’s portfolio of DSB projects. We have worked with Copenhagen Central Station for a long period, and we look forward to continuing the cooperation.

Jørgensen Division Director Zealand

Jørgensen Division Director Zealand

A sustainability vision was prepared, which the project rests on throughout the process. The vision includes that the project – where it makes sense – complies with the requirements from the optional sustainability class (the Danish Civil Aviation and Railway Authority, May 2020).

Among other things, it will be relevant to consider choice of material and robustness to changes and wear and tear, well-functioning indoor climate with minimal energy consumption, low costs for operation and maintenance, etc.

KlausSome projects take place in the shadows. Together with Gottlieb Paludan Architects, Artelia shines a light on all the corners of Copenhagen Central Station.

The current lighting in Copenhagen Central Station was designed by architect and lighting designer Gunver Hansen more than 25 years ago. Since then, a lot has happened within light sources and requirements to energy consumption, and DSB has therefore begun changing to LED lights. However, it has turned out to be quite difficult to reach the required level of light. Anni Høy is a lighting designer and has for many years worked closely together with Jesper Ravn from Gottlieb Paludan Architects, DI-Teknik and DSB to shed the right light on the central station.

Where the original lighting was designed to 200 lux, the level was measured to merely 12 lux some places at the beginning of the project. This was not satisfactory, neither for visitors nor employees. The original light level has to be re-established, but the assignment contains much more than just creating light, Anni explains :

There are many things to consider in order to find the right solutions. We have to comply with listing requirements, so everything must be examined and approved. The ceiling lights are placed up to 19 metres above ground, and it requires a lifting platform when changing them. It is therefore important to find long-lasting light sources.

warm and neutral light. This will ensure sufficient lighting of the surroundings as well as an interesting play of light that will also highlight the characteristic dark red colour of the bricks of the walls of the hall. In the archways towards the street Bernstorffsgade and the open space Banegårdspladsen, several different models of the selected lighting were tested to obtain exactly the right representation of colours.

Sometimes you are not supposed to see the actual light source – just the effect of it. This is the case in the lobby where a discreet solution will ensure that the actual lighting does not attract attention but instead enhances the beautiful arch.

A lot of energy is put into obtaining the right representation of colours and a good play of light. The many lamp pendants that light up the hall have been provided with different light sources with both

The same is the case when you leave the lobby and move to Banegårdspladsen. This is where the future façade lighting – which will consist of mast floodlight and is one of the last tasks to be completed – will create light and play along the varying façade – from the entrance to the spire and the weathervane at the top.

Anni Høy Specialist Lighting Design Copenhagen

Le Mans is world-famous for its annual 24-hours motor race where former Danish racing driver Tom Kristensen has won no less than nine times. In Artelia, we are taking part in making yet another Danish mark in Le Mans – this time with our bicycle traffic expertise.

Along with the client Le Mans Métropole, Danish and French colleagues discovered the area on bikes to register current bicycle conditions.

Along with the client Le Mans Métropole, Danish and French colleagues discovered the area on bikes to register current bicycle conditions.

As part of the green transition, many large French cities have started focusing on moving people from cars to greener and more sustainable transport modes. In that connection, the bicycle has rolled into the spotlight. This has been noticed in Denmark where our experience with planning safe and efficient bicycle routes is a requested qualification. It is therefore one of the areas in which we have established a close cooperation with our French colleagues which has led to several interesting projects.

One of them is Chronovélo – an extensive project with a development pool of EUR 74 million with the purpose of establishing a 315 km network of bicycle routes that connect the entire Le Mans Métropole area which covers the city Le Mans and its surroundings.

From Artelia in Denmark, we have helped our French colleagues make an infrastructure plan that defines and prioritises the bicycle routes that together will form a network. Project Manager Elena PerezRebollo explains about the cooperation :

The process and cooperation with the client were primarily managed by Artelia in France while we have contributed with our expertise in bicycle planning in design meetings and workshops. It was important for the client that we, as part of the team, were present physically and participated actively during the process.

Elena Pérez-Rebollo Head of Department Client Consultancy –Infrastructure Copenhagen

During the project, the FrenchDanish team also spent a day in the saddle with the client to register and analyse the current conditions in Le Mans and its surroundings.

The city had clearly made an effort to introduce bicycles and create attractive, green solutions, but there was a need for creating an interconnected network where bike riders can move around in a safe and secure manner, Elena explains.

It therefore became the focal point in the preparation of the plan that was founded on four primary routes : three transverse routes that connect the city's surroundings and cross each other in the centre of Le Mans as well as a circular route around the city. A number of secondary routes connect and support the primary routes. During the process of prioritising primary and secondary routes, it is important to determine which centres attract many visitors in connection with e.g. work, education, shopping, leisure and culture – so-called pôles d’attraction – and which types of road users that should be able to move around simultaneously in the different areas.

The Chronovélo project draws many parallels to the network of cycle superhighways that, in a larger scale, provide bicycle commuters with express routes to and through Copenhagen. The Danish team has used experience from Copenhagen to create clear signs and markings that separate bike riders from other road users and not least to minimise disruptions and obstacles that could affect the bicycle experience negatively.

In France, it is not common for people to ride a bike every day to the extent that it is in Denmark. It requires extra effort to gain

support for a bicycle network of this size. The project is therefore characterised by a high level of public involvement, e.g. via public meetings, info stands at strategic places, workshops, bicycle rides and a web platform. A French sub-consultant facilitates this process which has the purpose of both informing people about the project and receiving feedback and suggestions from the citizens in order to match expectations.

Our Danish team has contributed with good examples of what makes a good cycling experience and how we in Denmark work thoroughly with infrastructure to support this. However, we have also had to find alternative solutions and make compromises, Elena explains :

In France, there are other conditions which means that we off course must have an eye for creating practical and financially realisable solutions in the scale they work in. I think we have achieved a very good result that meets the client’s ambitions.

This is due not least to our strong cooperation with Artelia in France who has shown a great interest in working with the bicycle area and benefit from our Danish experience.

The bicycle plan for Le Mans is completed and approved. During 2023 and 2024, the project design will be carried out, and the execution of the project will begin in 2024. The first routes are expected to open at the end of 2024.

Allonnes Arnage Yvré-l’Evêque Saint-Saturnin Trangé Chaufour-Notre-Dame Coulaines Le Mans Champagné La Chapelle-Saint-Aubin La Milesse Aigné Fay Saint-Georges-du-Bois Pruillé-le-Chétif Rouillon Ruaudin Mulsanne Sargé-lès-le-Mans

Security is the keynote in everything we do at Risø.

We have looked at a total of 27 scenarios and calculated the probability related to each of them.

New Upgraded Warehouse (NOL) Owner / Danish Decommissioning Architect / Christensen & Co. © Christensen & Co.

Willy Paulsen Technical Director Airports & Counter-Terrorism Copenhagen

Karlotta Thórhallsdóttir Consultant Soil & Groundwater Copenhagen

New Upgraded Warehouse (NOL) Owner / Danish Decommissioning Architect / Christensen & Co. © Christensen & Co.

Willy Paulsen Technical Director Airports & Counter-Terrorism Copenhagen

Karlotta Thórhallsdóttir Consultant Soil & Groundwater Copenhagen

Together with the architects from Christensen & Co Architects and Langebæk, we help Danish Decommissioning realise a project that reaches far into the future and had its starting point all the way back in the 1950s. The project is a new storage facility where all of Denmark's radioactive waste must be stored until 2073 at the latest, and a large part of the waste has an interesting history.

We must go back to 1955, when the commission for nuclear energy, headed by Danish physicist Niels Bohr, was responsible for establishing a public research centre with focus on promoting the use of nuclear energy for peaceful purposes. In the years that followed, three test reactors were built, but as is it turned out, Danish nuclear power never progressed beyond the test stage. Popular opposition to nuclear power grew throughout the 1970s, and in 1985, it was completely taken out of Danish energy planning. However, under the name Forskningscenter Risø, two reactors were used for teaching and research right up until the year 2000.

In 2003, Danish Decommissioning was established as a state enterprise which since then has been responsible for

dismantling the nuclear facilities and handling all radioactive waste in Denmark. The remains from the test reactors constitute the largest part, but radioactive materials from hospitals, enterprises, etc., are also handled. In addition, certain fire alarms are good examples of radioactive waste.

It is still uncertain where a final repository for the waste will be placed, and it has therefore been decided instead to establish a warehouse on the peninsula Risø, which will require the special storage facility that we are now helping to establish.

A secure facility

The project consists of three buildings : The main storage building of 8,736 m2, a gatekeeper building and an unheated storage facility for the so-called NORM waste which is already in Danish Decommissioning’s possession. Project Manager and Head of Risk & Security Willy Paulsen explains that there is one dominating factor that characterises the project in every detail :

Security is the keynote in everything we do at Risø, and it has resulted in a number of very unique engineering tasks and technical challenges. We work with a risk and security assessment which will end up providing

Danish Decommissioning with a license to operate the new upgraded storage facility. The risk and security assessment takes various scenarios into account, and many of the considerations will have an effect on the design. On one hand, we want to protect the buildings from illegal trespassing with advanced access control and several confidential initiatives and on the other hand, we have an eye on accidental incidents such as flood or in worst case plane crash.

One of the people who have participated in the assessment of the many scenarios and their probabilities is Karlotta Thórhallsdóttir who has experienced the project as exciting and out of the ordinary :

It is actually an academic excise where we have researched our way to historical data in very different areas. I have dived into a great many subjects, and we have, of course, had to look at empirical data on a global scale to have reasonable grounds for our presumptions. A large part of the risk evaluation also consists of technical analyses that our own specialists have been responsible for. We have looked at a total of 27 scenarios and calculated the probability related to each of them.

Bispebjerg Hospital’s healing gardens Helende Haver have given patients a green haven. They were also named best urban space in Copenhagen by the Danish newspaper Berlingske with the award Byens Bedste Byrum.

The Danish architect Martin Nyrop is part of Danish architectonic history. He is the architect behind the famous Copenhagen City Hall, and Bispebjerg Hospital is another one of the treasures he has left behind. The respect for the cultural inheritance was therefore a general theme when we were to revitalise the hospital’s listed gardens together with Erik Brandt Dam Architects, Charlotte Skibsted Landscape Architects and Malmros. The original gardens were established in 1913 by landscape architect Edvard Glæsel, and many of the original qualities are either recreated or reconsidered in combination with new initiatives.

The best urban space in the city Healing gardens says it all. Supported by the foundation A.P. Møller Fonden, the Capital Region of Denmark wanted to revitalise the green outdoor areas since research suggests that it makes a notable difference for patients. The hospital is also an integrated part of the Copenhagen neighbourhood Nordvest, and every day, many people cross the area by foot or bicycle even though they do not have an errand at the hospital. It therefore made sense for Berlingske to nominate the project for Byens Bedste Byrum in 2022, and after a public vote, the gardens won the award.

An important aspect has been to make the gardens accessible to wheelchair users, the walking-impaired and bedbound patients. We have therefore designed upgraded path systems, new pavement and level access to the gardens. Due to the many changes to the surface, we have made reinforcement proposals for the hospital's underground tunnels where necessary.

The areas' new tiles are seen clearly when moving up through the central axis of the hospital, which rises in floors from south to north. On the northern top of the axis, Christian Lemmerz's statue of the biblical figure Lazarus, whom Jesus raised from the dead, gazes out over a fountain that was rebuilt in connection with the project.

The fountain is built in romantic style with a small cave system with new water treatment equipment, which is now located in one of the basements of the hospital buildings. Lazarus' fountain is one of our interesting subtasks, which also include static calculation of pavilions and pergolas. Last but not least, drainage and climate adaptation are ongoing themes in the project. We have assessed the capacity of the hospital's existing drainage system, made changes to the drainage and added fascines.

Helende Haver opened on 10 May 2022.

When designing a number of different façade cassettes for the 35,000 m2 large UN17 Village, we automatically mass-produced 3D models and working drawings that could be put directly into production. An efficient method that automatically combines various programmes made it possible and helped us win a Tekla BIM Award.

The housing construction UN17 Village is in many ways an enquiring project that examines different ways to comply with the UN’s Sustainable Development Goals. The residents' health is paramount, and as one of the sustainability aspects, the project contains the so far tallest timber construction in Denmark. In that spirit, it was also relevant to work innovatively with digital design, and it made sense to put the efforts in the many timber cassettes that constitute the substance of the buildings’ façades. A varied architectonic expression and the static details mean that there is a great deal of different cassettes which makes it very time-consuming to model manually. Automation was therefore in high demand, and that is exactly what we introduced.

The combination of Tekla, parametric design and openBIM made it possible to autogenerate 3D models of the many different timber cassettes with working drawings that could be handed over directly to the cassette manufacturer. The underlying technique was based on a good method to extract and combine large amounts of data from our own Tekla model, the architect’s Revit model and from the window manufacturer.

The efficient work procedures and the good cooperation between the parties were the reasons why we in 2022 won a regional Tekla BIM Award that covers constructions in Denmark and Norway. Every

year, the award is granted to a project that transforms the way we build and helps develop the construction industry.

The first step in the process was to develop a general structural concept for the cassettes which was achieved through an iterative process with the contractor CG Jensen. To reduce the amount of waste, the elements were designed to match the lengths of timber available from the supplier to the extent possible. Furthermore, the design team found a way to avoid the use of laminated timber which resulted in a considerable CO₂ reduction and a cost reduction.

The cassette concept itself is designed in close cooperation between Artelia and the building contractor CG Jensen. The façade cassettes are produced by JBS and the windows by VELFAC.When the general design concept was in place, a small number of Tekla components were developed to prepare for parametric modelling and control of all the cassettes via Grasshopper-Tekla Live Link.

The next challenge was that the cassettes have many variations and different attributes which means a host of data distributed between several sources. The engineering work was made in Tekla, but the architect used Revit for their design which contains information on placement and size of windows and doors. In addition, the window manufacturer held a lot of data, while the contractor had to deliver information on production flow and installation plans.

We wanted to combine all this data in the tool Rhino Grasshopper for parametric design of the cassettes. We therefore started by developing a data structure for what information to integrate and how. The link in the data structure and the relation between the models were created by comparing the three-dimensional locations of all elements.

Thanks to Grasshopper-Tekla Live Link and Revit plugins, data were easily integrated in Rhino Grasshopper along with the other information from the window manufacturer and the contractor. Afterwards, Rhino Grasshopper could automatically feed data to the Tekla component which was customised as a kind

of template for the numerous types of cassettes. From the Tekla component, the many different cassettes were distributed to the actual Tekla model that could generate working drawings to the manufacturer. The drawings could be used directly due to a very high Level Of Detail of 450 LOD.

The combination of Tekla Structures, parametric design and openBIM really proved its worth in this project. Even though the trinity was already known for solving challenges in advanced structures, this project illustrates that the value of the efficient

automation process can be as significant as for less challenging building structures. Especially when the end product is drawings that are ready for production.

When innovation does not seem to be decisive to finish the project, the construction industry sometimes has a tendency to stick to traditional procedures, but the results of this project show great potential for automated work procedures even though it requires a bit more preparatory work. We are therefore pleased that our BIM specialists and other experts made an extra effort and even were honoured with an award.

Client / NREP Architects / Lendager and Sweco Architects Denmark Contractor / CG Jensen

Client / NREP Architects / Lendager and Sweco Architects Denmark Contractor / CG Jensen

consumption in research facilities, at hospitals and in other buildings with many installations. It is therefore important to bring focus to the often overlooked process energy which requires a crucial effort in the early design phase.

Technically advanced buildings comprise an essential part of our knowledge society and health system. Unfortunately, these buildings are also in an exposed position when energy prices explode, as was the case in 2022. A significant part of the explanation is found in the energy intensive processes that are fundamental for the functions of the buildings. For example, neither laboratories nor operating theatres can function safely without efficient ventilation solutions, and much of the technical equipment will also increase the need for cooling – often significantly. Here, the concept process energy is used –also known from industrial production.

According to a report from the Danish Building and Property Agency, process energy is responsible for approx. half of the total energy consumption in laboratory buildings. Even though the fee for this specific electricity consumption is lower and not subject to the same requirements in the building regulations as building energy, it still constitutes a considerable cost and a consumption that ought to be addressed seen from a climate point of view.

From the beginning, the process energy was therefore given special attention when designing the Climate Challenge Laboratory at the Technical University of Denmark.

Senior Project Director Erik Krøll has worked with laboratory buildings for more than 20 years, and he also has experience from the pharmaceutical industry. Process energy is one of his professional passions, and he stresses that size is paramount :

To put it very simply, you can compare air to water. It is easy to understand that the smaller the pipe you press water through, the more energy you need to use. The same principle applies for air. When laboratories require a large change of air, the smaller the pipes and shafts the air must be pressed through, the larger the pressure loss will be. It is of course more complicated than that, but to put it bluntly, it requires a large ventilation system to reduce the process energy.

Erik Krøll Senior Project Director Laboratories & Health CopenhagenAs Erik emphasises, it requires an early effort to create the best possible conditions to reduce this part of the electricity bill. The same considerations were at play in the design of Building 310 – the neighbour of the Climate Challenge Laboratory. For both projects, Artelia was responsible for design management and was able to influence the design from the beginning.

Sizes like these do, of course, have a decisive influence on the entire design of the building. The project therefore also contains an aesthetic dimension to be solved in collaboration with the architects – something which is impossible to adjust late in the process and which must as a minimum be considered in the conceptual design, says Erik.

When the volume is increased, is has a corresponding effect on the technical rooms that are twice the normal height in both the Climate Challenge Laboratory and in Building 310. This illustrates in itself what kind of influence minimising the process energy has on the building design.

The pressure loss that causes the electricity consumption to skyrocket will increase further if air is pressed through a 90-degree angle where turbulence will occur – one of many reasons why the building’s energy consumption will become unnecessarily high if the challenge is not addressed.

These corners may cost a lot on the energy budget. We will therefore make sure to establish bends instead of angles while creating an intelligent pipe design to lead the air around the corner, Erik explains and mentions a last important aspect of the ventilation design :

To stay in the water metaphor, there are many rocks in the river such as heating and cooling surfaces. In some laboratories, there might also be a need for a HEPA filter that increases the pressure loss in the entire system, and we will have to place a ventilator locally to increase air velocity again. Overall, this means that we need to create good solutions in relation to a number of components in the system.

Finally, Erik mentions that cooling is another important aspect in advanced buildings as well as generally :

In general, cooling has become an even more important focus area as insulation in modern buildings are better than before. This also applies to less advanced buildings such as office and housing buildings. In laboratories and similar buildings, it is an additional challenge that technology emits a lot of heat which must be reduced. This can be solved partially with the right design of the ventilation system. For that, we use several other solutions that will ensure energy efficient cooling.

With the construction of several beacon projects and with an award-winning CO₂ roadmap, we help set the course for how the construction industry can live up to the climate goals in the Paris Agreement.

Building Green is Denmark’s leading event for green solutions in the construction industry and hosts the prize-giving for the Sustainable Element award. On 3 November 2022, Artelia was on stage in the event arena Forum with the architectural offices EFFEKT and CEBRA to receive the cooperation award for Reduction Roadmap, a brand new tool that maps how the climate goals in the Paris Agreement can be translated into specific annual CO₂ goals for new Danish housing constructions. The tool, which is supported by the foundation VILLUM FONDEN and the association Realdania, is based on the latest knowledge on climate change and indicates that we must reduce emission by 96% within 7 to 14 years in order to reach Earth’s safe operating space.

This means specifically that emission from buildings must be reduced from a current average of 9.6 kg CO₂eq/m2 per year to an average of 0.4 kg CO₂eq/m2 per year. In this connection, the tool shows the speed with which the necessary reduction must take place year by year in order to reduce the construction industry’s contribution to climate changes.

This is of course a challenge that no industry player can take on alone, but something that requires joint actions.

The transformation from ambition to action is often difficult. Artelia is involved in several projects which give physical form to the idea of reducing climate footprint of buildings significantly.

One of them is the housing concept Living Places developed in cooperation with VELUX, EFFEKT and the contractor Enemærke & Petersen. The first prototype, Boligværkstedet, is being established in Jernbanebyen in Copenhagen in connection with the city's role as World Capital of Architecture in 2023. The whole idea with the concept is to show the road to a new generation of housing that takes both the planet and people’s health and well-being into consideration. Boligværkstedet has a record low CO₂ footprint which has already received much attention. Living Places was even presented at COP27.

We work towards the same goal with the project Housing from 4 to 1 planet, where Realdania and VILLUM FONDEN have allocated DKK 60 million to a joint effort to promote residential projects with a climate footprint 75% below average. In this project, Artelia is facilitator for knowledge sharing and client consultant on the demonstrational projects that leading players on the market are asked to build. Part of the partnership’s funds will be invested in the innovation process in the individual projects, e.g. time used for creating ideas, for tests and documentation of different methods and materials, or for building damage insurance related to untested solutions.

The purpose is to create an ecosystem of knowledge where we provide our own expertise to the construction work while reaping new experiences that can be shared across the projects and create inspiration to the entire industry. We have taken part in several demonstrational projects previously and have experienced how new knowledge has been created –knowledge that other projects have benefited from.

Steffen Maagaard Market Director Energy Design, Sustainability & Indoor Climate Aarhus

Bio-based floor structures of the future is the name of a project that illustrates how we go the extra mile to find even greener solutions that should be expanded across the industry. Realdania initiated the project that is based on the association’s test construction Mini CO₂ Houses Timber, where Artelia is engineer. In this project, it was obvious that floor structures were worth examining further with special focus on acoustics.

Floor structures are easily responsible for extensive CO₂ impact in constructions. They comprise a significant part of the building stock and are rarely made with bio-based materials with a low CO₂

footprint. This is due both to fire safety and not least to acoustics. To ensure efficient noise protection towards upstairs and downstairs neighbours, concrete is preferred in order to create weight, and mineral wool is used for suspension.

When focusing only on tower blocks in general, the floor structures often comprise approx. 15-20% of the total CO₂ footprint. The goal in the project is to examine the extent to which it is possible to minimise the climate footprint in floor structures if they also have to comply with the requirements in the building regulations regarding acoustics. In addition, constructability, economy and fire safety are also examined in the project.

For this purpose, Artelia, JaJa Architects and the contractor CG Jensen have designed 23 floor structures that are primarily bio-based : 14 joist floor solutions and 9 CLT solutions. During autumn 2022, the many variants were tested at the acoustics laboratory of the Technical University of Denmark. Artelia conducted acoustics measurements of the two sound parameters listed in the building regulations’ requirements regarding floor structures : airborne sound insulation, which

covers airborne sound such as speech, and impact sound pressure level, which covers structure-borne noise such as footsteps, chair legs, etc.

The results were very promising : for most of the CLT and the joist floor solutions, it is possible to comply with the sound requirements in building regulations 2018 and at the same time reduce the CO₂ footprint by 50-70% compared to a typical box girder solution in concrete.

As an acoustician, I am immensely satisfied with the result. I would dare to call it groundbreaking that we have tested materials and structures that are not normally part of the toolbox when we are creating satisfactory sound isolation. Therefore, these tests might very well open up for a greener approach to acoustics.

Jan Christensen Head of Department Acoustics Copenhagen At the Building Green event in 2022 we received the cooperation award for Reduction Roadmap along with architects EFFEKT og CEBRA.

At the Building Green event in 2022 we received the cooperation award for Reduction Roadmap along with architects EFFEKT og CEBRA.

As Jan emphasises, the project sheds light on a number of completely new combination solutions with both untraditional components and constellations. For instance, materials such as sand and paper wool are used to obtain the acoustic qualities.

Specific EPDs give the greenest solutions

Another significant discovery in the project is the importance of using productspecific EPDs (Environmental Product Declarations) rather than generic and industry-specific environmental data. This is necessary when determining the actual CO₂ footprint for bio-based floors. This is because the generic data used for biobased materials are both very limited and at the same time show a higher average CO₂ footprint to be on the safe side. Product-specific EPDs, on the other hand, can show the road to products with an actual documented low footprint.

Our own comparison shows that the use of product-specific EPDs for bio-based materials showed a CO₂ footprint 25-70% lower than with the use of generic data. That is quite a difference when looking for the most sustainable solution, and the risk of deselecting the greenest alternative on that basis is high, says Steffen.

As Steffen points out, the difference is only 15% compared to box girders with EPS concrete. This illustrates that the generic data for concrete show a somewhat more accurate picture of the average and probably use better data as the material is more widespread.

But bio-based materials should definitely not be deprioritised just because generic data give an artificially high CO₂ level which can easily sway the decision in the wrong direction. On the contrary, they are crucial if we really want to do something about construction climate footprint. It is therefore important to use the product-specific EPDs, concludes Steffen.

One of the many floor structure combinations that were tested at DTU. Floor structure seen from below in the acoustics laboratory.When large ships are supplied with renewable energy from the landward side, it reduces both CO₂ emission and air pollution. Artelia helps establish the popular power plants on land in Hamburg and Aarhus.

Many large cruise ships and cargo ships use fossil fuels. This is a major item in the CO₂ balance and contributes to the particle pollution in the cities where the ships dock like Aarhus which is a popular destination for cruise tourists.