1 minute read

Mafoombey — Martti Kalliala, Esa Ruskeepää, 2005

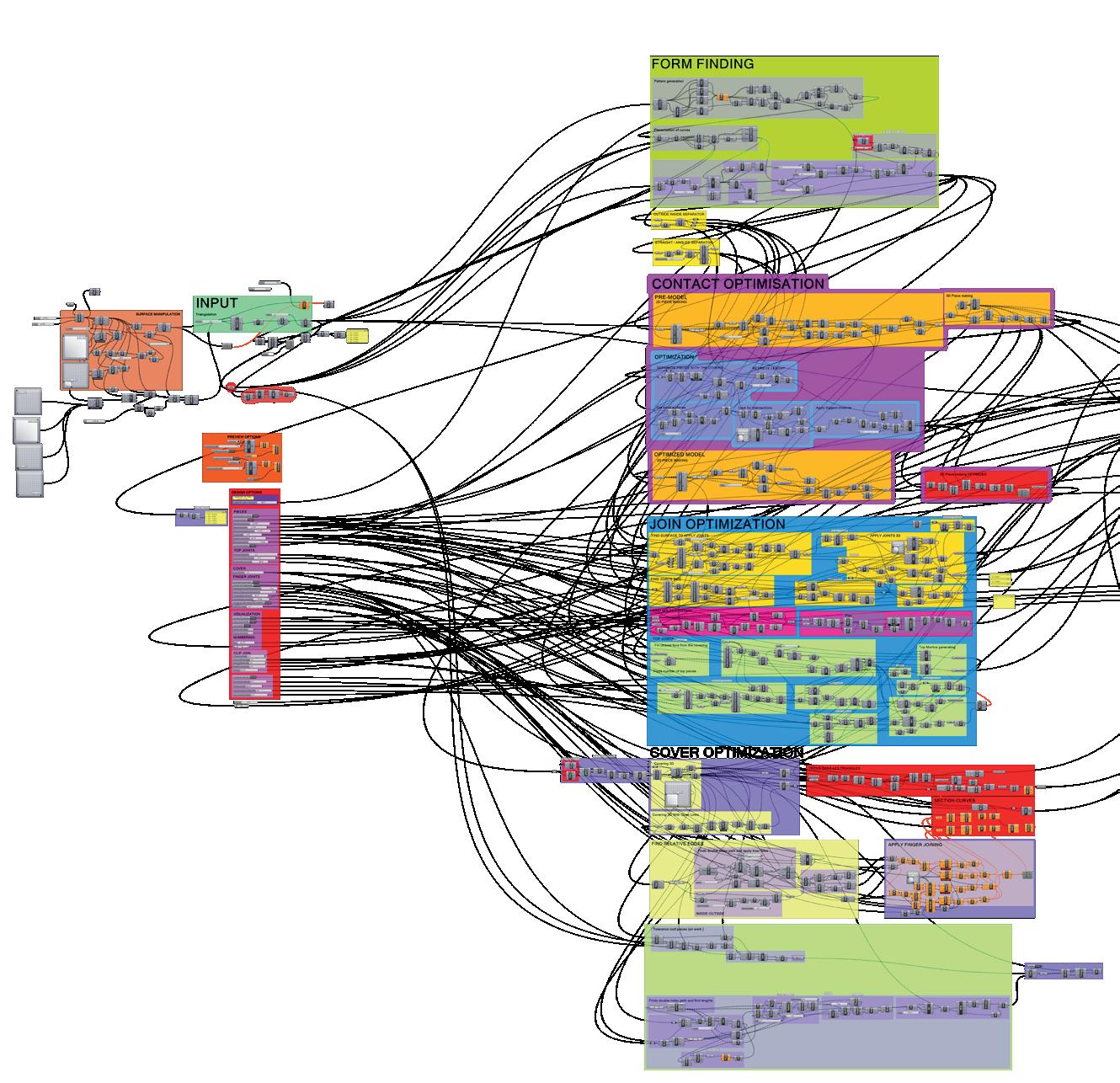

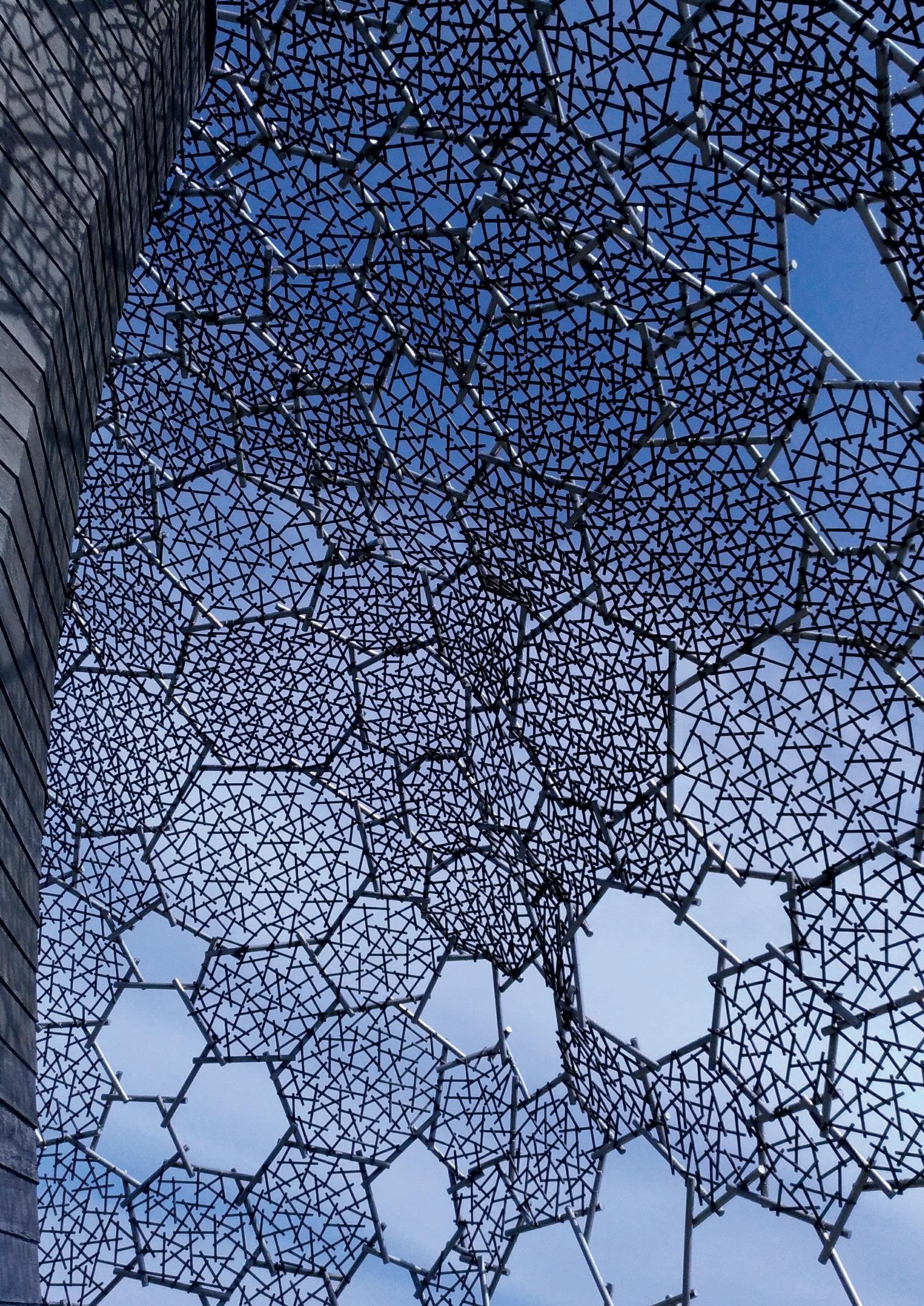

Mafoombey — Martti Kalliala, Esa Ruskeepää, 20057

Advertisement

In order to understand the rest of this research, it is interesting to define some methods that represent the transformation of matter in digital manufacturing. Beyond the use of digital tools (3D printer, digital milling machine, water cutting machine...). There is a world of possibilities related to the way they are applied. According to Lisa Iwamoto, there are at least five of them : Sectioning, tessellating, folding, contouring, forming.

«Digital fabrication : A way of making that uses digital data to control a fabrication process»23

She argues that if the CAD has replaced lattice and pencil drawing well, but building design has not really taken on different forms. It was not until the arrival of 3D modelling software and the democratization of digital manufacturing that different architectural forms were developed. The few examples she offers demonstrate the ingenuity that can emerge from the use of these techniques. These experiments are based on the premise that buildings are made up of a series of elements and that the challenge for architects is to learn how to manipulate their assembly. They are intended to serve as « Wills» a small-scale experiment that will provide opportunities for future buildings.24 This list is not exhaustive, it is simply used to visualize a variety of solutions associated with a technique.

2.7.1. Sectionning

This is a manufacturing work directly derived from the use of the cut in architecture. It is a set of planes of sections of the object superimposed in order to reproduce a model. This method is very similar to the operation of 3D printers, which form their objects by successive layers of material. It is therefore possible to use other materials in a similar technique, create more spaced slices and connect them by connectors in the perpendicular axis then requires less material.

a. Mafoombey — Martti Kalliala, Esa Ruskeepää, 2005 Project realized for a musical experience, a cave with organic shapes represented by 360 layers of cardboard. The accumulation gives a form of heaviness to the project and the cardboard confers the desired acoustic properties. This example shows a rather literal way of approaching slice decomposition.