2 minute read

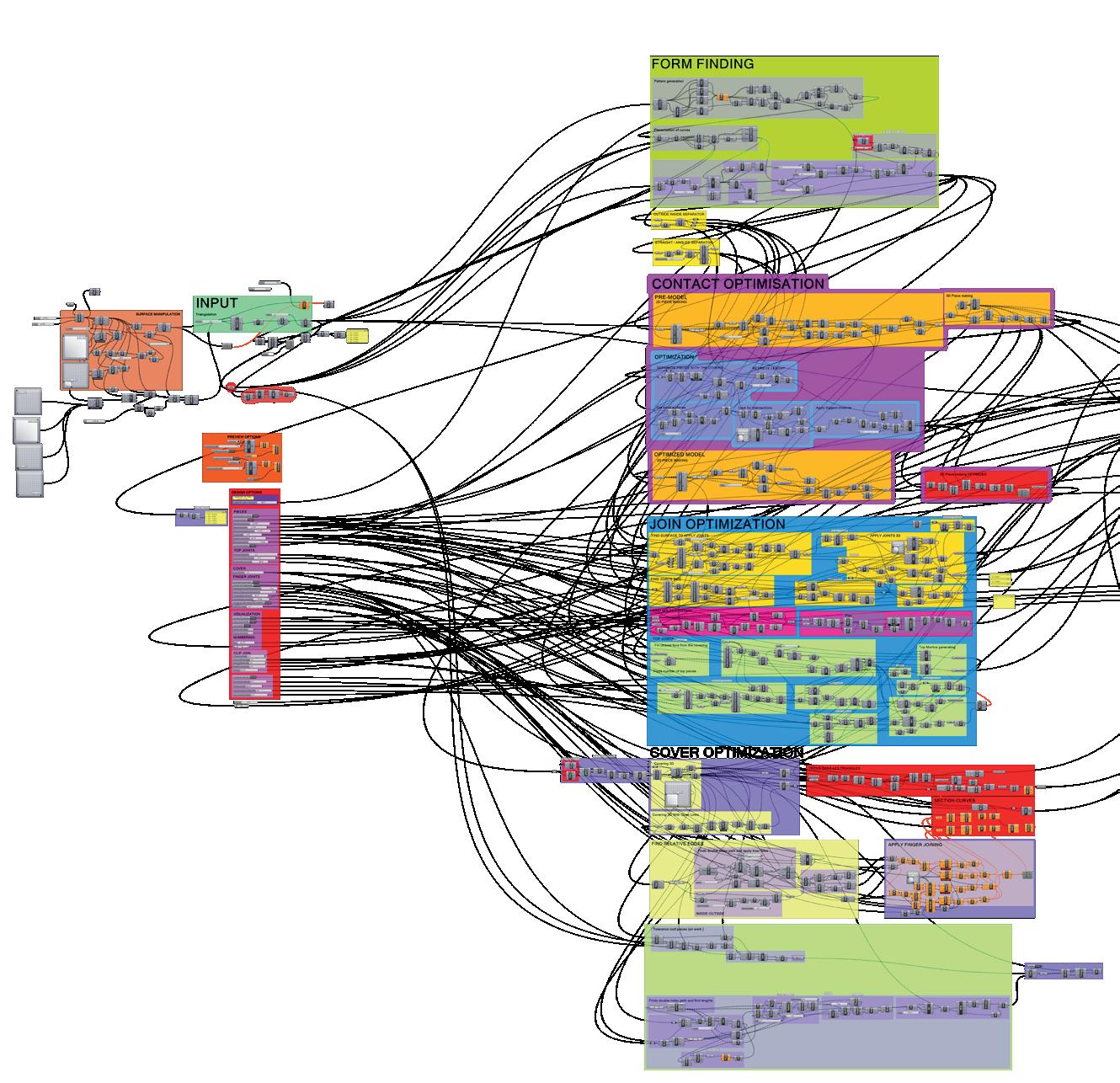

A micro-factory on site

c. A micro-factory on site Although the complexity of a house is not so much higher than that of a car, the building cannot be manufactured according to identical criteria. There are many construction methods and socio-cultural frameworks that make building design highly contextual. Conditions can change quickly, even during the realization. Faced with such a need for flexibility, digital construction often requires expensive factory prefabrication, as it operates on a case-by-case basis. Moreover, the slightest mistake is costly, since it requires a complex system to correct it. Bringing a plant directly to the site with the help of small businesses allows you to initiate and explore a digital vision of the architecture without having to use a complete plant. The worksites would thus become temporary micro-factories, which would not favour large projects of small ones from a financial point of view because of their ability to deploy a prefabrication system in series.36 Scale is no longer an economic factor and this encourages individuality and proximity. In the Wikihouse project, which attempts to revisit selfconstruction through this micro-factory, it becomes an essential tool for construction. A robot could in the future have the same presence on the site as a excavator could today. Moreover, although not yet fully exploited, there is another potential for the construction robot that is of great interest, namely the hybrid, robot-human digital construction. To illustrate this, in the project The endless wall by Gramazio & Kohler, a robot is programmed to erect walls with algorithmically generated patterns while following a line drawn on the floor by an intervener. The robot then establishes itself as an interactive tool, capable of bringing the digital universe into the real world.37

The Endless WAll - Gramazio & Kohler37

Advertisement

Project Icon38, relating to the FutureFactories project, it is a series of necklaces, all different but nevertheless recognizable by their similar morphologies

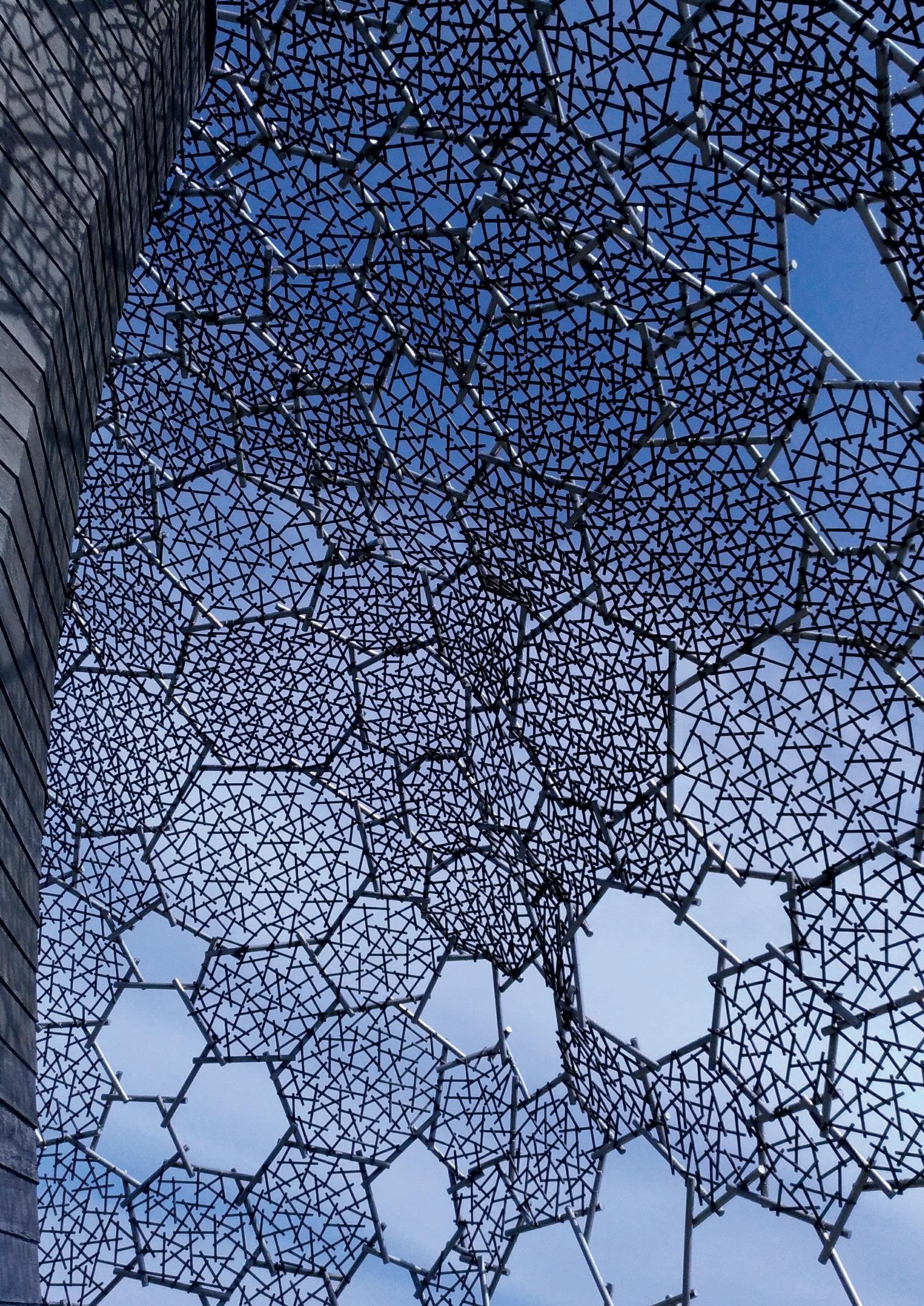

2.10. The non-standard manufacturing method

FutureFactories38 is a project or rather a program concept where an object changes shape by following a series of algorithmic rules. An innovative element is in the hands of the customer who has the ability to ‘freeze’ the subject, to stop his constant metamorphosis and to be able to buy it. The object is in this case unique, impossible to reproduce, because there are an infinite number of variations. It is a so-called generative system, i.e. the relationship between the designer’s intentions and the object is indirect. In traditional design, the relationship to matter is direct, the designer explores a spatial solution. Michael Hansmeyer proposes a similar architectural concept with four columns printed in 3D, the final aspect of which is the result of the fractal decomposition of a cube. Presenting a baroque spirit, these architectural elements have similar proportions while presenting a unique morphology. He questions the texture in architecture and how the evolution of digital manufacturing could influence the production of reliefs, a smooth surface requiring no more work than a complex surface39. In this generative approach to drawing, the result is the result of a method of modifying, creating and empowering rules and devices. The draftsman no longer acts directly on the subject. There are an infinite number of variants at that moment, called generations.