4 minute read

Trial and error

standard, so mass customization of these suitcases would be of little interest, as it is its standardization that facilitates its use.42

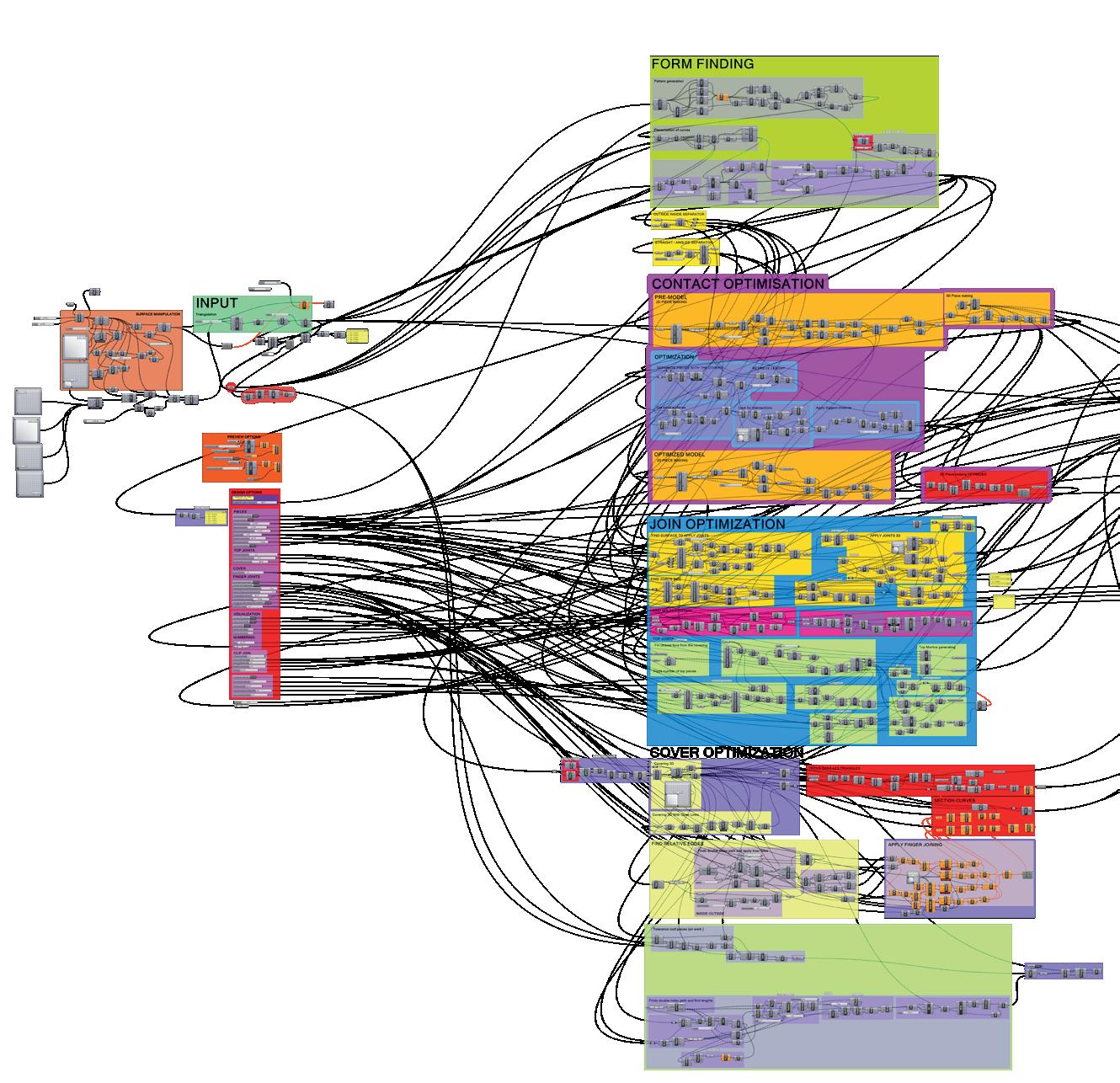

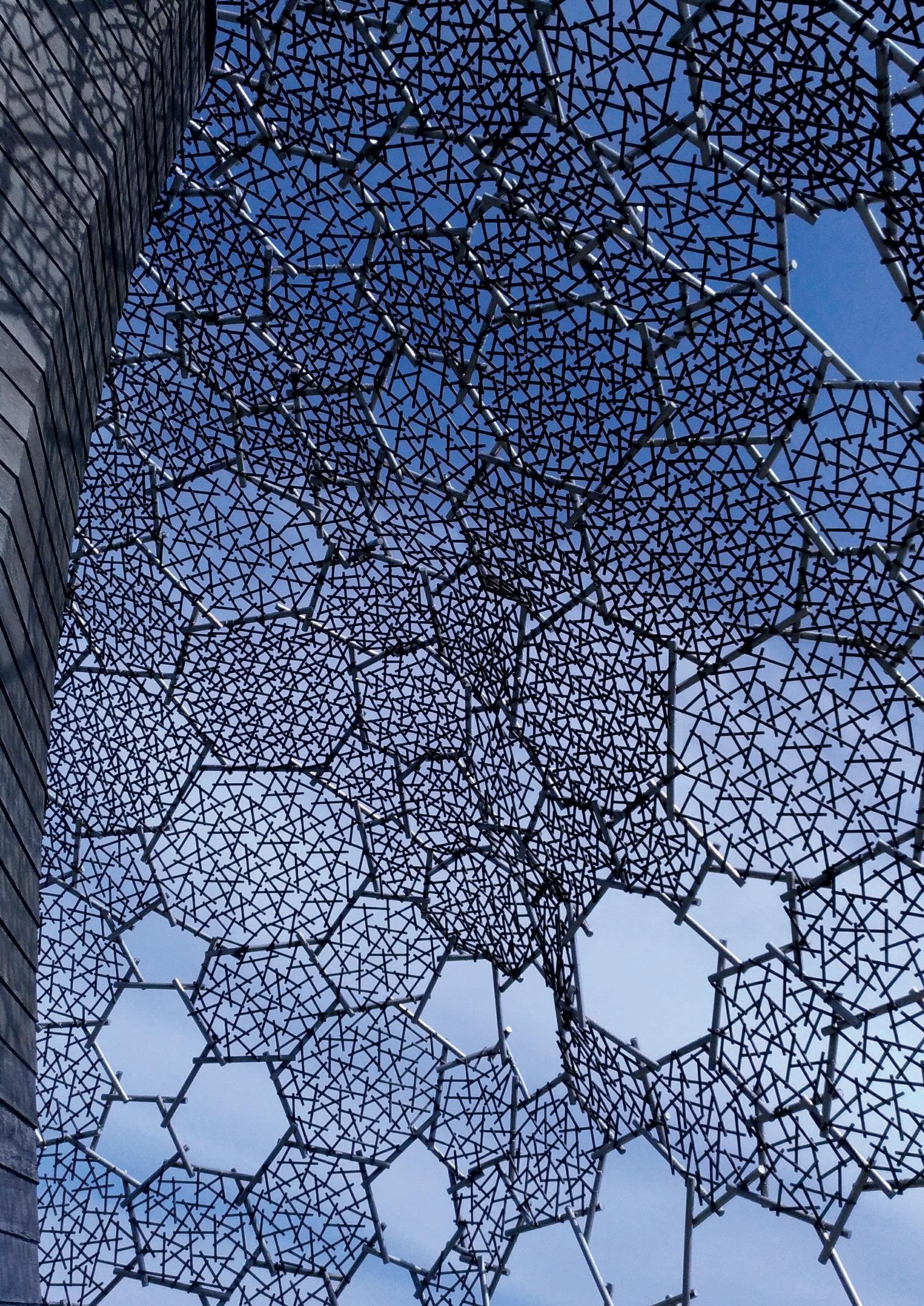

c. Trial and error Traditional craftsmen, not necessarily engineers, develop objects through a succession of trials and errors. They make a chair, if it breaks, they rebuild it until it doesn’t give up anymore. Today, computational design is used in the same way to simulate as many possible solutions as possible and then to randomly examine as many as possible, until two or three are found that meet expectations. It’s like making an infinite number of chairs and then testing them all to see if they break. Selecting the lighter of all those that have resisted will probably give the best version. This method is limited, but works quite well given the speed with which computers are able to accomplish it. The structural calculations developed by the engineers are more economical and clever, they try to define in advance if the chair will break or not. Over time, we have thus begun to trust engineers more than craftsmen. But today, these new approaches to algorithmic design recreate an enthusiasm for this process of empirical research, however Carpo is concerned to see it as a mechanism where this ‘groping’ research generates a generalized lack of knowledge of the reason for successes or failures. There is therefore a widening gap between theory and accomplished work. This lack of theoretical knowledge is aggravated, in my opinion, by the popularized complexity of algorithmic languages. The author concludes by emphasizing that the non-standard strategy will get the most out of its capabilities if the right methods are used in the right places. Everyone has their place, the standard for a common vocabulary, the customizable for individuality, the computer must do what it is good for, it is the same for the designer.43

Advertisement

2.11. Conclusion

In view of all the reflections that feed the subject, we can conclude that the algorithm, and by extension the robot, are first and foremost tools, which therefore come with their techniques and results. Every new instrument brings its share of knowledge without necessarily distorting the importance of another. Robotic manufacturing does not have to turn crafts into a nostalgic hobby. It is also unlikely that the popularization of digital manufacturing will return control and knowhow of products to consumers. It is not knowledge of the object to master the launch of a machine using a plan. As Carpo pointed out, it is likely to be more of an empirical approach to manufacturing, trial and error without a deep understanding. However, if I do not think that the democratization of technology gives the consumer real manual skills, it is possible that this will make him more responsible. The feeling of having participated in the development of the object or building may commit the buyer to take better care of it and find ways to repair it instead of replacing it, a more sustainable economy, therefore. With regard to the architect, the algorithm and its manufacture seem to have two tendencies, on the one hand it simplifies life and work through pre-written tools, as in BIM, on the other hand it allows the exploration of new production processes. The algorithm is now present in almost all architectural drawing modes, but its application is highly variable. However, its use must be adapted to the size of the offices and projects that employ it. Everyone has their place, and that’s important. For example, the project Wikihouse should not be intended to produce housing developments, it is rather part of a self-built, personal architecture. Although it seeks to democratize construction, I have a feeling that the project is more related to the particular desire of a DIY resident than to a real need. Nevertheless, the project approach is very interesting, because it unifies the design process with the constructive system, it may be necessary to imagine the project nevertheless carried out by architects, capable of going even further in the detail of the project, which, once completed, can be delivered in a rather similar way. Some architects are now more familiar with digital tools than with manual work. A form of conflict can take place when both parties misunderstand each other. Thus, perhaps it would be fruitful to see the emergence of a category of architect in symbiosis with his mode of construction, who controls and knows the entire process of manufacturing his work. However, I think this would only work on a particular scale of project. Indeed, if the project is too large, the architect cannot manage all its facets. The constructive aspect is then in the hands of experts, an architect trained in the concepts of integrated computational design no longer has any reason to be. This architecture, of moderate size, would allow a well-prepared architect to rediscover a kind of total architecture through digital technology. The diversity offered by digital manufacturing offers a solution to take small architecture out of the standard production mode through