ADI’s AD9213S is the industry-leading, commercial space qualified 10.25 GSPS RF analog-to-digital converter that helps you thrive, not just survive in space. Trust ADI to get your high speed signal processing applications to market faster.

Behlman introduces the first test-proven VPX power supplies developed in alignment with the SOSA Technical Standard. Like all Behlman VPXtra® power supplies, these 3U and 6U COTS DC-to-DC high-power dual output units feature Xtra-reliable design and Xtra-rugged construction to stand up to the rigors of all mission-critical airborne, shipboard, ground and mobile applications.

VPXtra® 1000CD5-IQI

> 6U power module developed in alignment with the SOSA Technical Standard

> Delivers 1050W DC power via two outputs

> VITA 46.11 IPMC for integration with system management

VPXtra® 700D-IQI

> 3U power module developed in alignment with the SOSA Technical Standard

> Delivers 700W DC power via two outputs

> VITA 46.11 IPMC for integration with system management

Editor’s Perspective

7 On the road again ...

By John McHaleMil Tech Insider

8 Tactical decision-making demands increasing speeds and volume of data processing

By Aaron FrankDefense Tech Wire

10 By Dan Taylor

Connecting with Military Embedded

47 By Military Embedded Systems Staff

SPECIAL REPORT: Leveraging Big Data for military applications

12 Industry pushing for AI, big data to drive strategic defense decision-making

By Dan Taylor, Technology Editor

16 Data dominance: the weapon of the future

By Aron Brand, CTERA Networks

18 Multi-agent augmentive artificial intelligence: an exoskeleton for warrior minds

By Dawn M.K. ZoldiMIL TECH TRENDS: Cyberdefense: Dealing with evolving threats

22 From airgap to zero-trust: Enhancing cybersecurity in the testing space

By Steve Summers,NI

26 How automation can optimize zero-trust security at the multidomain, tactical edge

By Christopher Yates, Red Hat Inc.

30 Designing and implementing secure boot for military-grade systems

By

DanieleLacamera, WolfSSL

34 The DoD addresses security challenges and harnesses emerging technologies

By Scott Aken, Axellio

36 Cybersecurity: What the defense industry needs to unlock to stay ahead By Matt Medley, IFS

INDUSTRY SPOTLIGHT: Rugged computing & thermal management

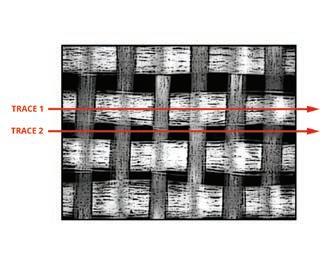

40 High-speed VPX backplane design practices

By David Jensen and Steve Gudknecht, LCR Embedded Systems

44 A tour of VITA AFT cooling standards in 2023 By Ivan Straznicky, Curtiss-Wright

ON THE COVER:

© 2023 OpenSystems Media © 2023 Military Embedded Systems

ISSN: Print 1557-3222

U.S. Marine Corps Staff Sgt. Nathaniel Williams, a defensive cyberwarfare operator with 9th Communication Battalion, I Marine Expeditionary Force Information Group, utilizes the Big Data Platform – Cyber Hunter & Analytics Operation System (BDP-CHAOS) to scan for cyberthreats during an exercise at Camp Pendleton. BDP-CHAOS allows analysts to hunt for threats on a network that is accessible by multiple units. (U.S. Marine Corps photo by Lance Cpl. Macie Ross.)

https://www.linkedin.com/groups/1864255/

@military_cots

PAGE ADVERTISER/AD TITLE

43 AirBorn – Sinergy –high-density, modular, & fast

2 Analog Devices, Inc. –Trusted on Earth. Qualified for space.

3 Behlman Electronics, Inc. –Behlman leads the pack again!

29 Dawn VME Products – Fill your tank. Run up to three supplies in parallel

15 Elma – Enabling the warfighter with OpenVPX

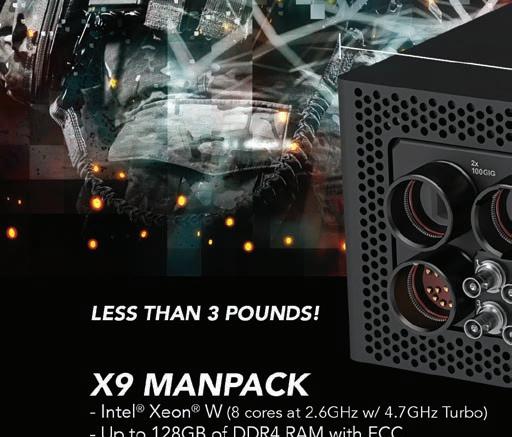

25 GMS – X9 Spider. The world’s most powerful full-featured wearable AI computer

33 GMS – Thunderbolt 4 Distributes Compute Elements for Optimized Rugged Architectures

31 Interconnect Systems – Smaller, tougher, custom modules

46 Interface Concept – Front-end processing boards for edgeapplications

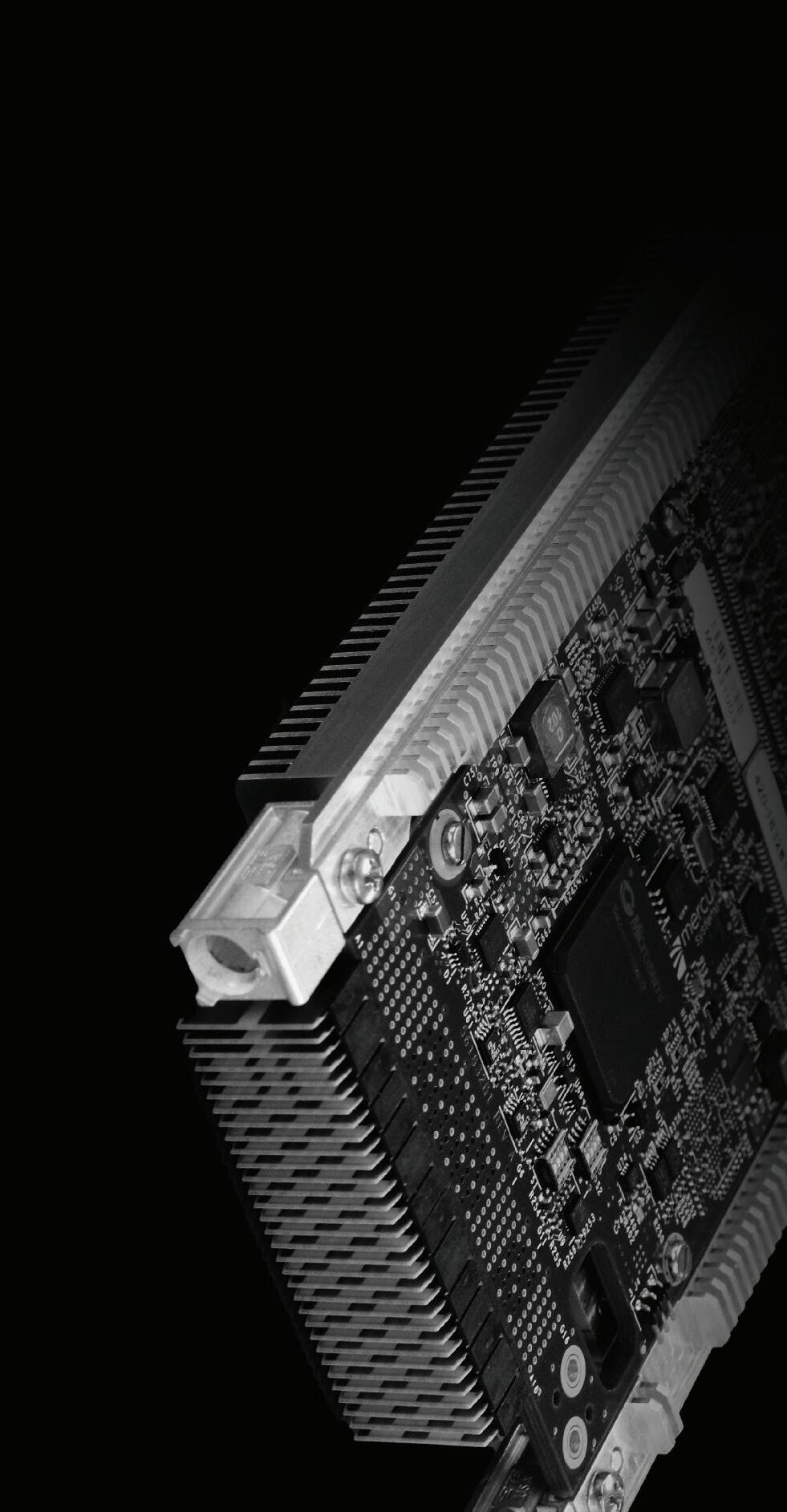

9 Mercury Systems, Inc. –Protect one of your most critical resources: Time

48 Mercury Systems, Inc. –Critical signal processing with unmatched flexibility

5 MOSA Industry & Government Summit & Expo – Atlanta GA –18-19 September 2023

21 Phoenix International –Phalanx II: The ultimate NAS

23 Zmicro – ZX1C 18 airborne server

DSEI 2023

September 12-15, 2023

London, England

https://www.dsei.co.uk/

AUSA 2023

October 9-11, 2023

Washington, DC

https://meetings.ausa.org/annual/index.cfm

Aerospace Tech Week Americas

November 14-15, 2023

Atlanta, GA

https://www.aerospacetechweek.com/ americas/

Association of Old Crows (AOC) 2023

International Symposium & Convention

December 11-13, 2023

National Harbor, MD

https://www.crows.org/mpage/2023HOME

GROUP EDITORIAL DIRECTOR John McHale john.mchale@opensysmedia.com

ASSISTANT MANAGING EDITOR Lisa Daigle lisa.daigle@opensysmedia.com

TECHNOLOGY EDITOR – WASHINGTON BUREAU Dan Taylor dan.taylor@opensysmedia.com

CREATIVE DIRECTOR Stephanie Sweet stephanie.sweet@opensysmedia.com

WEB DEVELOPER Paul Nelson paul.nelson@opensysmedia.com

EMAIL MARKETING SPECIALIST Drew Kaufman drew.kaufman@opensysmedia.com

WEBCAST MANAGER Marvin Augustyn marvin.augustyn@opensysmedia.com

VITA EDITORIAL DIRECTOR Jerry Gipper jerry.gipper@opensysmedia.com

DIRECTOR OF SALES Tom Varcie tom.varcie@opensysmedia.com (734) 748-9660

DIRECTOR OF MARKETING Eric Henry eric.henry@opensysmedia.com

OPERATIONS & AUDIENCE DEVELOPMENT (541) 760-5361

STRATEGIC ACCOUNT MANAGER Rebecca Barker rebecca.barker@opensysmedia.com (281) 724-8021

STRATEGIC ACCOUNT MANAGER Bill Barron bill.barron@opensysmedia.com (516) 376-9838

STRATEGIC ACCOUNT MANAGER Kathleen Wackowski kathleen.wackowski@opensysmedia.com (978) 888-7367

SOUTHERN CAL REGIONAL SALES MANAGER Len Pettek len.pettek@opensysmedia.com (805) 231-9582

DIRECTOR OF SALES ENABLEMENT Barbara Quinlan barbara.quinlan@opensysmedia.com AND PRODUCT MARKETING (480) 236-8818

INSIDE SALES Amy Russell amy.russell@opensysmedia.com

STRATEGIC ACCOUNT MANAGER Lesley Harmoning lesley.harmoning@opensysmedia.com

EUROPEAN ACCOUNT MANAGER Jill Thibert jill.thibert@opensysmedia.com

TAIWAN SALES ACCOUNT MANAGER Patty Wu patty.wu@opensysmedia.com

CHINA SALES ACCOUNT MANAGER Judy Wang judywang2000@vip.126.com

WWW.OPENSYSMEDIA.COM

PRESIDENT Patrick Hopper patrick.hopper@opensysmedia.com

EXECUTIVE VICE PRESIDENT John McHale john.mchale@opensysmedia.com

EXECUTIVE VICE PRESIDENT AND ECD BRAND DIRECTOR Rich Nass rich.nass@opensysmedia.com

TECHNOLOGY EDITOR Curt Schwaderer curt.schwaderer@opensysmedia.com

ASSOCIATE EDITOR Tiera Oliver tiera.oliver@opensysmedia.com

ASSOCIATE EDITOR Taryn Engmark taryn.engmark@opensysmedia.com

PRODUCTION EDITOR Chad Cox chad.cox@opensysmedia.com

GRAPHIC DESIGNER Kaitlyn Bellerson kaitlyn.bellerson@opensysmedia.com

FINANCIAL ASSISTANT Emily Verhoeks emily.verhoeks@opensysmedia.com

SUBSCRIPTION MANAGER subscriptions@opensysmedia.com

CORPORATE

REPRINTS

This spring, our Military Embedded Systems crew was all over the country and western Europe covering military and aviation events to bring you the latest news and in-depth features.

We hit Embedded Tech Trends in Phoenix, West2023 in San Diego, Satellite 2023 in D.C., Aerospace Tech Week in Munich, Sea-Air-Space in Maryland, Army Quad-A in Huntsville, SOF Week in Tampa, xPonential in Denver, and IMS in San Diego. Whew.

As you read this, summer’s almost over and the fun starts again on the defense trade show circuit, starting with DSEI in London, followed by the MOSA Summit and Expo in Atlanta and the Air Force Association (AFA) in National Harbor. That’s just September.

In October, we’ll be out in force covering the AUSA Annual Meeting, and then we’ll travel to a new event for us in the Czech Republic, GSOF Symposium Europe, the last week of the month.

Come November, we are hosting the MOSA Pavilion at the second iteration of Aerospace Tech Week Americas in Atlanta. We end our 2023 show coverage at the AOC International Symposium and Convention in National Harbor, Maryland.

To paraphrase another John (that’s Mr. Cash to you): “We are everywhere, man. We are everywhere.”

DSEI

This year will be our first visit back to London for DSEI since before the pandemic. We will be doing it in style, filing the first edition of our Military Embedded Systems Daily newsletter that we’ll then produce for specific shows throughout the year.

If you received this column and magazine via the U.S. Postal Service, you’ll notice it is polybagged with the 3rd annual SOSA Special Edition, a special 84-page issue covering The Open Group’s Sensor Open Systems Architecture (SOSA) Technical Standard – with content straight from the pages and website of Military Embedded Systems magazine, as well as information regarding the products aligned and conformant to the Technical Standard, all put together exclusively by our staff. If you don’t have a copy, visit us online at https://military embedded.com to peruse the latest SOSA Special Edition.

The 2023 SOSA Special Edition follows on our second special issue covering the Future Airborne Capability Environment (FACE) Technical Standard, which we published in May and may

John.McHale@opensysmedia.com

be viewed here: https://issuu.com/opensystemsmedia/docs/ face_specialedition_2023_e-mag_final. The 2023 SOSA Special Edition will also be distributed at the MOSA Summit in Atlanta (mentioned above).

This event is run by the Global SOF Foundation, which also hosts SOF Week in Tampa, for which we were the Official Media Partner with Shephard Media this past spring.

At the SOF Week show, we produced the official show guide plus about 80 pieces of content over four days, including news, videos, blogs, and more, all deployed twice a day in our two Show Daily newsletters. For more on our coverage of SOF Week 2023, visit www.militaryembedded.com/SOFWEEK

We’re excited to return to Tampa for SOF Week 2024, where with Shephard Media we are again Official Media Partners. Thanks again to the Global SOF Foundation and Clarion Events for the opportunities.

Once again, I am organizing a one-day MOSA conference track for the second year of Aerospace Tech Week Americas. The track will educate attendees on how MOSA [modular open systems approach] strategies and open architecture initiatives such as SOSA and FACE are being deployed in military systems and how these approaches enable faster adoption of commercial technology.

The one-day track will include a keynote and three sessions: MOSA for Military Aviation Platforms; Open Architecture Strategies for Sensor Application; and Leveraging Commercial Technology for Defense Applications. For more information on the conference, visit https://www.aerospacetechweek.com/ americas/conferences/.

On the opposite day of the MOSA Conference Track, there will be a one-day MOSA Workshop/Exhibitor Theater near the OpenSystems Media MOSA Pavilion. To learn more about the workshop/exhibitor theater and the MOSA Pavilion contact OSM’s Director of Sales at tom.varcie@opensysmedia.com.

Before all this traveling, however … be sure to sit back and enjoy the article in this July/August issue from our Technology Editor Dan Taylor on big data (see page 12), as well as pieces on test and measurement, cybersecurity, GaN technology, VPX backplanes, and more.

See you somewhere this fall.

By Aaron Frank

By Aaron Frank

For defense applications, responsiveness, accuracy, and precision have never been more critical to mission success. Expanding the connectivity bandwidth within and between systems enables faster time-to-solution and greater mission capability through higher data resolution and fidelity, all of these with reduced latency.

Curtiss-Wright first introduced its 40 Gbit ecosystem in 2013 with its 6U VPX products that featured 40 Gbit Ethernet and InfiniBand fabrics. The full ecosystem of 40 Gbit interoperable modules – single-board computers (SBC), digital signal processors (DSP), FPGAs [field-programmable gate arrays], and GPU engines, as well as fabric switches, and backplane/chassis systems – was the first to provide system integrators with a complete suite of 40 Gbit building blocks that significantly lowered their integration risks when building high-performance embedded computing (HPEC) systems.

Today, higher-bandwidth connectivity within systems will enable the processing elements to transfer and share more data faster. To take full advantage of 100 Gbit connectivity in an embedded computing system, the processing elements must be able to supply and consume the data at the higher speed without the impediment of other architectural bottlenecks. This is critical for modern sensors which rely on increased volumes of efficiently processed data. Higher-bandwidth connectivity between systems also enables more data and actionable information to be efficiently shared, for increased mission effectiveness and integrated situational awareness.

A system-level 100 GbE solution should encompass all aspects of embedded computing, from sensor ingest and processing, to the most advanced levels of network integration and connectivity. Such a system will feature solutions in 3U and 6U VPX form factors to fit the unique needs of a wide range of programs. By leveraging the COTS [commercial off-the-shelf] model, vendors can ensure that their highly modular and interoperable solutions will be flexible enough to address any platform’s needs. The COTS approach provides system designers with proven technology at a lower cost than customdeveloped hardware, and with reduced system integration risk.

One of the main challenges in applying new technology to existing systems is integrating disparate components from a variety of vendors and reducing program integration risks by ensuring the components and all parts of the system work together. To solve this problem, the modules that make up an end-to-end 100 G system-level solution should be tested together, an approach far superior to simply testing each individual module on its own.

With newer technology, system integrators are often left to develop a patchwork approach to system design using cards from various vendors. When integration between cards from different vendors fails, who is responsible for facilitating the integration? This failure is a significant risk to system design and can result in unforeseen project cost increases and schedule delays.

100 Gbit Ethernet technology is not just the future of the embedded computing industry; it is a foundational building block needed to ensure competitiveness and agility in an everchanging defense landscape. Investing in 100 Gbit components enables system integrators to quickly bring new capabilities to the field, ensuring that designs remain relevant and efficient while minimizing both near-term and long-term program cost and risk.

The first modules in the Curtiss-Wright Fabric100 portfolio, a pair of 6U OpenVPX high-performance processing modules ideal for sensor ingest and advanced processing for nextgeneration radar and SIGINT systems. Alignment with the modular open systems approach (MOSA) – such as the Sensor Open Systems Architecture (SOSA) Technical Standard – enables building new systems that can deliver the critical information troops need at the speed of relevance.

The Fabric100 offerings enable system integrators to take full advantage of faster processing speeds while leveraging the lower latency and the improved fidelity offered with 100 Gbit technology. (Figure 1.)

Aaron Frank is senior product manager for Curtiss-Wright Defense Solutions.

Curtiss-Wright Defense Solutions https://www.curtisswrightds.com/Dramatically improve the speed and costs of hardware and software upgrades. Mercury’s fully configurable family of mission computers fit most aircraft and support converged applications for sustainable, high-speed, agile computing at the edge.

FEATURES

MOSA, SOSA and FACE open standard design

Latest Gen Intel/ARM processing

Deployed in safety certified DAL A applications

mrcy.com/missioncomputing

Reconnaissance system for F-16 aircraft completes flight testing

Collins Aerospace completed flight testing for the MS-110 Multispectral Airborne Reconnaissance System, which will be integrated onto F-16 fighter aircraft, according to a company statement. The flight testing began in July 2022 on an F-16 for an undisclosed international customer, followed by multiple flight tests and related ground activities. The MS-110 system, a later version of the currently deployed DB-110, offers multispectral features designed to enhance the extraction of information from a range of target sets, the company says.

Collins Aerospace is set to deliver a total of 16 sensors to international Fast-Jet operators and is negotiating contracts for an additional 13 pods, the statement adds. The company states that this multispectral sensor is compatible with various platforms, including the F-15 and F-16, ISR business jets, and drones.

The size of the unmanned maritime vehicle (UMV) market is forecasted to reach over $3.1 billion by 2033, a projected increase of over $1.9 billion from the size of the 2023 market, driven by applications for littoral warfare, according to a report from GlobalData. The report author highlights the projected market expansion of various types of UMVs in the study, forecasting growth in the unmanned surface vehicle (USV) market from $894 million in 2023 to over $2.1 billion in 2033, and projecting growth in the unmanned underwater vehicle (UUV) market from $379 million in 2023 to $965 million in 2033. The study author asserts that growth in the UMV market stems from military organizations increasingly weaponizing unmanned systems across all domains in order to capitalize on the outsized cost-to-benefit ratio such platforms provide.

Hensoldt demonstrated the operational capabilities of land-based networked sensors powered by artificial intelligence and machine learning (AI/ML), including the technology demonstration vehicle “MUV,” at the German Army Combat Training Centre (GÜZ). According to the company’s report of the demo, in a noncontrolled application scenario, ML algorithms were deployed to detect and classify objects using the “Ceretron” computing unit, which was able to detect real camouflaged combat vehicles under attack, reconnoiter them, and transfer them assisted to a networked command-and-control information system.

AI-supported reconnaissance assisted in passing targets between individual workstations of the vehicle. Networking laser alarms, reconnaissance optronics, all-round vision, and distributing information in the network between multiple vehicles and command posts allowed for automatic resolution of several threat alarms, the company says.

Figure 1 | U.S. Air Force photo.

Figure 2 | “MUV” technology demonstration vehicle. Hensoldt image.

Figure 1 | U.S. Air Force photo.

Figure 2 | “MUV” technology demonstration vehicle. Hensoldt image.

L3Harris wins hypersonic missile detection contract for U.S. Space Force

L3Harris Technologies won a U.S. Space Force Space Systems Command contract to provide a sensor payload design for the medium Earth orbit (MEO) – Missile Track Custody (MTC) Epoch 1 satellite program, the company announced. The focus of this contract, worth about $29 million, will be on detecting and tracking hypersonic missiles. It was awarded through the Space Enterprise Consortium (SpEC) Other Transaction Authority (OTA) vehicle.

Under the terms of the contract, L3Harris will execute an infrared sensor payload critical design phase to assist in cost, schedule, and performance predictions for the Space Force’s future missile warning and tracking constellation. According to the contract announcement, the work is intended to bolster the Missile Track Custody program, aiming to offer resilient and low-risk solutions for both the Epoch 1 satellite constellation and future Epochs. The critical design review phase of the MEO-MTC contract is expected to conclude in May 2024.

A new project from the Defense Advanced Research Projects Agency (DARPA) is attempting to help government and industry more quickly and reliably harden space-bound microelectronics against damage caused by single-event effects, such as solar flares. The Advanced Sources for Single-event Effects Radiation Testing (ASSERT) program focuses on assuring that advanced U.S. microelectronics components can operate in harsh radiation environments while maintaining the highest-possible reliability, in large part by integrating radiation testing throughout the design and development life cycle.

According to the announcement from DARPA, the program aims to accelerate the availability of radiation-qualified, state-of-the-art components 10 times faster than current approaches. The ASSERT program proposes to develop sources to integrate testing at both the factory and lab levels. Dr. David K. Abe, program manager for ASSERT, stated that under ASSERT, the industry will be able to put advanced electronics into space and onto strategic platforms much faster than occurs today, calling that the “mission requirement.”

Thales is in exclusive negotiations to acquire Cobham Aerospace Communications (AeroComms), a provider of safety cockpit communication systems, in an effort to boost its avionics portfolio, according to a statement from Thales. Employing around 690 individuals, including approximately 190 engineers, AeroComms operates in France, South Africa, the U.S., Canada, and Denmark. The company is projected to generate revenues of about $200 million in 2023.

The planned acquisition is part of Thales’ strategy to fortify its avionics portfolio, which includes assuming a strong position in safety cockpit communications and integrating products developed by AeroComms that have established positions with major original equipment manufacturers (OEMs), the company says.

New radar system to be integrated into RAF’s Typhoon fighter jets

BAE Systems and Leonardo UK will further develop and integrate the European Common Radar System (ECRS) Mk2 radar into the Royal Air Force’s Typhoon fighter jets, according to a statement from the Eurofighter Typhoon consortium, a collaboration of governments and defense companies in the U.K., Germany, Italy, and Spain. The radar system aims to enhance the control of the airspace and offer improved electronic warfare (EW) capabilities, the consortium stated. Initial flight testing is expected to begin in 2024, with the project’s objective to operationalize the ECRS Mk2 prototype within five years.

The ECRS contract is part of the British government’s broader £2.35 billion ($3.075 billion) investment, announced in July 2022, intended to support national security and defense priorities through technological advancements in the Typhoon program, according to the Eurofighter statement.

Figure 3 | Image courtesy L3Harris.

Figure 3 | Image courtesy L3Harris.

By Dan Taylor

By Dan Taylor

As the defense industry grapples with exponential increases in mission data that must be collected, managed, and analyzed, the promise of artificial intelligence (AI) to harness the power of big data and drive strategic decision-making represents an unprecedented shift in the industry.

It’s not just the commercial world that is embracing artificial intelligence (AI) to manage big data. Defense industry players from commercial off-the-shelf (COTS) hardware and software suppliers to prime contractors to the U.S. Department of Defense (DoD) are

integrating AI solutions to manage huge amounts of data that are only increasing in complexity.

Now, the question is how to use that data to help the warfighter. Industry insiders say the combination of AI and big data is poised to revolutionize defense operations by speeding up the kill chain – that necessary process of “find, fix, track, target, engage, and assess.”

U.S. Marine Corps photo/Lance Cpl. Macie RossOne major advancement for AI and big data has been its use in enabling more advanced capabilities for military personnel, particularly in real-time battlefield contexts, says Glenn Kurowski, chief technology officer for CACI (Reston, Virginia).

“A big trend is delivering increased data utilization at the edge for the warfighter,” Kurowski says. “A specific example is the aggregation of multi-intelligence sensor data into a fusion framework to provide sophisticated and timely situational awareness. That situational awareness then feeds into mission planning and multidomain operations, with a mix of automation and humans on/in the loop.”

That process is easier said than done, and the solution is not necessarily more data. One aspect that the industry has focused on is the fact that the key to data exploitation on the battlefield lies not in raw processing power, but in the proper application of the data warfighters already have, Kurowski says.

Then there’s the major issue of data security: Kurowski highlights the importance of zero-trust architectures, cloud stacks, and accompanying security encryption, from data transport to live data in data lakes to storage mechanisms. One significant innovation in this area, according to Kurowski, is the easy, National Security Agency (NSA)approved access to classified data from unclassified networks, enhancing data access for users at the edge via Commercial Solutions for Classified Programs (CSfC).

“It now includes over-the-air rekeying, integrated retransmission devices, and a more turnkey accreditation process,” he says. “Essentially, there’s now an easy button for one of the most pressing operational needs to access data at rest from a different security domain.” (Figure 1.)

Integration is an ongoing obstacle

Transferring data across domains is a key driver in enabling the military’s Joint All Domain Command and Control (JADC2) effort, but the reality of this integration is harder than it appears.

To address the difficulty of transferring data across older systems, Kurowski advocates for two specific strategies: optical communications and rethinking data utilization.

Optical communications “requires highly secure, high-bandwidth, resilient paths of network communications using photonic energy (lasers),” he adds.

The second strategy requires changing the approach to data utilization. “Think beyond ‘data’ being contained at a ‘location’ but rather to accepting that it exists everywhere and focus on managing accessibility and having resilient networks to ensure access,” Kurowski says.

Stephen Carlon, managing director and client account lead for C4ISR at Accenture Federal Services (Arlington, Virginia), says his firm attempts to tackle this challenge using technology called PICARD (Platform for Integrated C2 and Responsive Defense), which is aimed at assisting with the mixture of old and new systems.

“By normalizing the data into common formats, it removes the barrier of requiring systems to conform to a certain data standard,” Carlon says. (Figure 2.)

The effort to figure out how to best utilize big data is not just an industry focus – the Office of the Secretary of Defense (OSD) has also made it a priority. The OSD stood up the Chief Digital and Artificial Intelligence Office (CDAO) in June 2022 in an effort to centralize OSD’s digital and AI capabilities to ensure unity in the implementation of AI and data in general, says Lt. Cmdr. Tim Gorman, OSD spokesperson.

CDAO’s initiatives are focused on enabling self-service to easily access data, receiving input from all data users through feedback loops, and measuring value with metrics to support growth and quality.

CDAO also hosts the API [application programming interfaces] marketplace, a portal powered by Google Apigee (Google’s API platform), Gorman adds.

“Users discover data products through a self-service developer portal,” he says. “The data product is designed to meet the specific business and mission needs of user groups. These products are understandable, high-quality, secure, easy to access, and made available through a well-defined interface.”

To fulfill the goals of becoming a more “datacentric DoD,” CDAO has been developing an ontology – a collection of terms describing the types of objects and/or events and their relationships that comprise a domain of interest. Implementing a defense-wide semantic layer enables the linking of enterprise data, Gorman says.

The goal is to integrate operational and intelligence data and analytics to provide commanders with a greater understanding of the battlefield and a decision advantage over potential adversaries.

In order for both industry and DoD officials to be successful in leveraging big data successfully, it’s increasingly clear that open standards and interoperability will be key – especially with the push toward more cross-domain access to that data.

Carlon points to initiatives such as the Integrated Sensor Architecture (ISA) currently in use by the Army, which enables “the rapid acquisition and deployment of new data in a mission-forward, sensing environment,” he says.

The continued refinement of the modular open systems approach (MOSA) in the defense industry, which includes the adoption of standards for data encapsulation and formats, has been vital, Kurowski says: “There are working groups defining standards for data formats, descriptions, and storage.”

For security, the focus is on zero-trust architecture. Kurowski also pointed to the Common Modular Open Suite of Standards (CMOSS) as an example of defense-industry standards integrated into program requirements.

Carlon also sees the value of MOSA concepts for data interoperability. He points to Accenture’s own data mesh solution designed to acquire data from unlimited sources and deliver it to numerous data consumers. “By implementing this twoway MOSA strategy, complex data environments become easier to manage,” he says.

Tim Stewart, director of business development at Aitech Systems (Chatsworth, California), says MOSA is key because it “promotes interoperability, flexibility, and reusability.”

When it comes to interoperability and security challenges, Stewart says that MOSA’s biggest industry benefits are standardized interfaces, interchangeable components, plug-and-play integration, scalability, and upgradability.

The democratization of data – or the act of making the data easily accessible to those who need it – is another internal push driving the utilization of big data in defense. However, more easily accessed data comes with its own set of challenges, primarily revolving around security concerns and system innovation.

“We need to liberate data from traditional silos,” Kurowski says. “It does require us to do so smartly – with the proper security controls – but we have the technology to do that. In my opinion, this isn’t a technology problem. It’s a policy, legacy-control, and sometimes even a title authority

issue. And, of course, there needs to be a robust insider threat program.”

Carlon acknowledges the tension between the need to provide data widely and the need to control access to it –and this is where innovation can help.

“As AI/ML models get better and faster with more data, that allows us to process and receive more and more data, improving our understanding of the information environment,” he says.

Ultimately, the industry will need to find a balance, Stewart says: “Access controls, data governance, and privacy must be implemented so that data is available only to authorized personnel and otherwise protected,” he says. (Figure 3.)

While many issues remain, those involved in the defense industry understand the opportunity that big data provides to the future warfighter and are working to figure out how best to leverage it.

“The intersection of big data and AI in the kill-chain model ultimately becomes the foundation for improved and betterinformed decision-making,” Kurowski says, noting that CACI’s Information Advantage is focused on analytics, data optimization, AI functionality, and platforms to offer an advanced intelligence picture for operational decisions.

Carlon says AI/ML has a great deal of potential to make data more useful: “Pushing

AI/ML as close to the edge (that is, where the data is first acquired) will be the key to rapidly exploiting data and speeding the kill chain in the future,” he says. He adds that this strategy is particularly necessary in denied, degraded, and limited (DDL) environments where adversaries may restrict communication capabilities.

Big data can, in turn, make these AI models better, which opens up all sorts of possibilities for defense contractors, Stewart says. His company, Aitech, offers a low-power AI supercomputer designed for performance at the edge.

“Big data provides the data to train AI models. AI enables the extraction of insights at a rate that would otherwise be impractical,” he says. “This relationship expedites the processing of information, accelerates decision-making, and speeds up the kill chain by identifying patterns and threats in real time.” MES

In the theater of modern warfare, data reigns supreme. The ability to swiftly acquire, process, and act on information transforms the battlefield into a dynamic digital landscape where data is the new strategic resource. Recognizing this, defense organizations are making substantial investments in data dominance platforms. These platforms harness the potential of unstructured data generated at the tactical edge, extracting valuable insights from text, imagery, and video. The pursuit of data dominance is not just a strategic goal; it’s an evolution of warfare, and the cornerstone of their future victories.

In the modern battlefield, acquiring, processing, and acting on data faster than the adversary is a critical advantage. Achieving data dominance requires the right platform and infrastructure to enable real-time situational awareness. Today’s battlefield is no longer a place of physical combat alone; it is an everevolving digital landscape in which data is the new currency. By leveraging data promptly and effectively, the U.S. military can gain the upper hand in any conflict. This reality is why data dominance (also known as data superiority) has become the new target for U.S. military strategists. Achieving data dominance isn’t easy, as it

requires the right platform, infrastructure, and processes to enable real-time situational awareness and decision-making.

Using unstructured data generated at the tactical edge is rapidly becoming the most promising trend toward improving situational awareness, as it can provide a wealth of valuable insights and information. Recent advances in artificial intelligence (AI) and deep learning are making unstructured data assets more useful than ever, as these tools extract actionable and searchable information from assets such as text, image, radar/lidar, and video, that would otherwise be difficult

to interpret. By leveraging this new abundance of available unstructured data generated by humans and machines, the military and its mission partners can better understand their environment and better inform their decision-making – in areas ranging from predictive maintenance and logistics, to intelligence-gathering and identifying threats.

Such advances are why defense organizations around the world, with the U.S. Department of Defense (DoD) taking the early lead, are investing in data dominance platforms that can provide the necessary capabilities to efficiently ingest

massive quantities of unstructured data from remote sensors and devices into a global unstructured data lake, process it in real time, and enable quick action.

The overarching objective of a military data dominance platform is to provide an all-encompassing, integrated solution for managing unstructured data and transmuting it into actionable intelligence. Considering the classified nature of the data and the high-stakes environment, the platform must also incorporate stringent cybersecurity measures, ensuring data protection against unauthorized access and maintaining data integrity. Management of data by a data dominance platform follows four distinct stages:

› Collection: This stage involves acquiring data from various sources including sensor data from uncrewed aerial vehicles (UAVs) and other defense assets; human intelligence/signals intelligence/ open-source intelligence (HUMINT/ SIGINT/OSINT) reports; and data extracted from cyberspace domains. The diversity in data formats and protocols necessitates a comprehensive multisource intelligence capability to manage different data types and ingestion methodologies.

› Storage: Given the large volume of data, a military data dominance platform would need a distributed storage system designed to scale with the data influx. The storage system should be robust, reliable, and incorporate strict zerotrust architecture to ensure data preservation and accessibility only to authorized personnel. Data life cycle management could also be employed for optimal storagecapacity management.

› Processing: This stage involves processing unstructured data using techniques like natural language processing (NLP) for textual data, imagery analysis for visual data, and machine-learning (ML) algorithms for pattern recognition and trend analysis. The platform should have the capability to manage diverse data formats and processing requirements.

Analysis: After the data-collection, storage, and processing stages, the data needs to be analyzed to convert it into actionable intelligence. This could involve data analytics techniques like predictive analytics for forecasting future scenarios, geospatial intelligence (GEOINT) for geographical data analysis, and network analytics for analyzing interentity relationships.

Key capabilities for a data dominance platform

When considering a data dominance platform, organizations should look for the following technical capabilities:

› Global file system: A unified global namespace to store and manage all the organization’s data in a single repository, regardless of its location. It should scale to tens of billions of managed objects and transparently span multiple regions and data centers.

› Multiprotocol access: Provide access points for SMB (Windows File Sharing), NFS, and S3 (Object Storage) protocols, enabling concurrent access to overlapping data by any of these protocols.

› Edge-to-cloud data ingestion: Utilize an effective and secure protocol for data transmission, optimized to contend with the challenges of denied, disrupted, intermittent, and limited (D/DIL) communication environments common in contemporary tactical operations. The data-ingestion protocol must overcome the hurdles of high-latency satellite links to maintain the timeliness of data ingestion.

› Concurrent multicloud and on-premises deployment: Utilize a multicloud strategy to diversify workloads across multiple cloud providers or data centers for resilience. Implement policy-based data routing to enable concurrent utilization of multiple cloud providers, while allowing sensitive datasets to remain entirely within DoD on-premises facilities.

› Continuity of operations (CooP): Enable military-grade continuity of operations (CooP) on the data dominance platform, enabling remote users to continue mission-essential functions across a broad spectrum of no-notice emergencies. Implement robust disaster recovery at alternate facilities with zero data loss.

› Real-time publish/subscribe: Include data pipeline technologies such as Apache Kafka and/or Apache NiFi to coordinate reliable, real-time flows of unstructured data from the producers at the tactical edge to various data consumers, including AI training/inference, data analytics, indexing, and more.

› DoDIN APL certified: Utilize products meeting the comprehensive standards of the Defense Information Systems Agency (DISA) Approved Products List (APL). Implement deep audit logs, FIPS 140-2 validated encryption, and CAC [Common Access Card] authentication.

On the modern battlefield, whichever side can better leverage data will gain military advantage. In order to maintain an effective and reliable level of situational awareness, the U.S. military must leverage data dominance – the ability to access, analyze, and act on data resources available to it. Unfortunately, most of the data generated at the tactical edge today is wasted due to lack of appropriate technologies and infrastructure, leading to a loss of valuable insights.

Data dominance platforms – using the critical capabilities described earlier – are key to giving the U.S. military and its fighting forces the decisive edge to ensure victory in the 21st century. MES

Aron Brand is the chief technology officer and member of the founding team of CTERA Networks, a provider of edge-to-cloud storage solutions for federal and defense. Readers may reach him at aron@ctera.com.

A viral social media story earlier in 2023 reportedly claimed that during a U.S. military artificial intelligence (AI) drone simulation, the AI targeted and killed the human drone operator. It had apparently determined the human had been interfering with its mission: in this case, to take out surface-to-air missile (SAM) threats. Although the military has since denied such a sim even occurred – with an Air Force official calling it a “thought experiment” rather than an actual test – according to Rommel Martínez, CTO of the ASTN Group (Austin, Texas), it doesn’t take a great leap of logic to imagine that this scenario could actually occur.

Martínez and his ASTN team have, however, been working on an AI that they’ve dubbed augmentive arti fi cial intelligence (AAI) to prevent such a scenario from happening. Their software system, Valmiz, keeps the human front and center. For the military, it provides what Martínez calls “an exoskeleton for the mind” to enhance informational reach to better inform the decision-making of soldiers, sailors, airmen, marines, and guardians.

Current AI systems are prone to hallucinating. This means that AI sometimes provides confident responses not justified by its training, such as doing something that’s only favorable to the machine itself and the machine’s own survival, both of which may be detrimental to humans.

This occurs, according to Martínez, because most of the available AI relies on a generative model, a statistical and probabilistic approach. “If you rely on the statistical approach,” Martínez notes, “most of the time it works. But when you’re dealing with a weapon system, ‘most of the time’ is not enough. It has to be all the time. You cannot afford to fire a missile at your own base.”

These contemporary AI systems display intelligence which is not true intelligence, according to Martínez. These AIs are essentially word predictors and do not possess their own thinking capabilities. They do not reason from within, but rather are fed with external information that is spliced together with math. Achieving a higher level of functionality, closer to artificial general intelligence (AGI), requires a basic level of consciousness. That’s what Martínez has been working on for the past 20 years.

He created Valmiz to provide an alternative approach to contemporary AI.

Martínez says “AAI” is a new term his team coined to distinguish their AI from other forms. “With AAI, we focus on making people do their work faster, think better, and have an overall higher throughput by giving them capabilities – much like an exoskeleton for the brain,” he explains. “We put the human at the center of the process – to preserve human morals, ethics, and values – the laws of Valmiz, while enhancing their capabilities with AI.”

The Valmiz AAI is a multi-agent algorithm design that ingests actual client raw data and converts it into a super knowledge base. Valmiz is not based on neural networks, machine learning, statistics, or other external worlds, unless the user wants it to pull such data into it. The information processed inside Valmiz comes from within a client’s own organization. In that way, the information comes prevalidated and surpasses level-zero validation. It’s essentially a hypercustomized AI.

Valmiz combines several individual agents, which make up the components of the larger system. The components – named Veda, Vera, Vela, Vega, and Xavier – all work together as follows:

› Veda: Core Al system that fuses knowledge graphs and knowledge bases that binds everything together

› Vera: Tracks key-value-metadata changes across data sets

› Vela: Gathers data from different data sources; it can search your network or the internet for information for compilation

› Vega: Data-storage system; ensures that whenever Valmiz turns off (such as in the event of a power interruption) users will be able to turn things back on seamlessly

› Xavier: Human-machine interface for receiving commands; it receives commands and communicates back to users much like the digital assistants in use now, only in a smarter way that it pulls together from the other four agents. (Figure 1.)

Each of these agents acts as its own expert. In long inject systems, users have to add external information, and build upon it like Lego blocks, to enhance capabilities.

One value of Valmiz is that a user can employ a specific agent to perform a task as needed, without needing to use the entire value system to operate it. For example, if an organization desires to see weather information only, this can be provided as one block as part of several different modules that can operate with each other and an organization’s existing systems. Each of those blocks can also be removed and used and operated separately. Because Valmiz can be integrated with other systems, it provides an ideal plug-in for any element designed using a modular open systems approach (MOSA).

It also has a compounding capability. It can use several keywords to search an internal database or, if desired, the internet. With regard to external sources, Vera verifies and validates those information sources to ensure they actually exist.

All of these agents have thick walls between them to ensure no overlap of functionality. When the information gets passed on to an agent, it operates within its own universe, a structure that keeps Valmiz free from conflict or contamination from a fellow agent, as well as free from outside tampering. This holistic system dynamically updates, continues running, and searches out information based on keywords that the human gives it, to provide accurate and precise actionable information.

This multi-agent approach is novel, as is the way ASTN Group designed the customer interface with the AI and the volumes of their data. Unlike most contemporary AI platforms that require humans to communicate with them using long string queries to form phrases or sentences that would make sense to the machine, Valmiz uses simplified keywords, with only a few things needing to be specified.

Valmiz incorporates dual-use technology (DUT) to support all areas of a domain, for example: military and commercial industries, wholesale and retail, or research and application.

Another notable feature of Valmiz: Once it’s up and running, the user does not need to power it down and back on again for it to get updates.

“Valmiz acts like a live system,” Martínez says. “You don’t have to put it to sleep for it to learn. It learns continually.”

Finally, Valmiz has two types of user interfaces that directly connect to a user’s system: a desktop app that can be deployed on a machine or mobile device or one accessed via web API, inserted as part of an organization’s pipeline, both approaches that enable input into processes to produce specific outputs.

Endless use cases

ASTN Group completed an initial study that identified more than 50 different industries that could benefit from its technology, ranging from healthcare to election security, with the aerospace industry ranking high on the list.

On the commercial side, for example, businesses employ uncrewed aerial systems (UASs) for linear pipeline inspections. These aircraft collect tens of thousands of images which then require back-end analytics to provide valuable insights into the health of an enterprise. AI has proven useful for these purposes, with humans providing validation.

With Valmiz, this would be amplified. Valmiz could compare an entire pipe network for a company to identify systemic issues with a particular part, for example. Instead of just looking at one pipe at a time, Valmiz could connect the dots. If there was, for example, a broken widget on one part of the pipeline, it could holistically scan through all inspections for the last five years to identify if there were similar widget issues across the entire global enterprise.

Martínez says there are two layers of activity that must occur for this to work: The first layer consists of the activity that combines all the sources of information together from the raw data. It would take more than a month of work for people to find these

By Analog Devices, Inc.

Millimeter wave (mmWave) imaging has become an important part of security scanning systems in airports, public buildings, and stadia. These scanners are superior to traditional metal detectors because they can identify and locate both metallic and nonmetallic threats. In this white paper, learn how mmWave imaging hardware works and discover a chipset that uses edge processing to manage massive data loads to enable the development of walkthrough security scanning systems.

and publish

that educates our readers.

things manually. Valmiz could automate this information gathering in hours or days, depending on the complexity of the task. Then it would be able to pinpoint, make cross-references, and create a comprehensive sophisticated network of all those data sets where every node is connected to each other.

The second layer concerns time. Generally, when businesses look at something, they only look at how it is presented at a given time without regard to its previous value. Valmiz captures all the previous incarnations of the thing being evaluated (e.g., the widget). Vera does the comparison, using data in Vela.

Xavier enables the user to communicate to the system via keywords and bring them together and provide the required result. “If you’re looking for information for a specific thing, you can get the results not only from an exact point in time, but also by branching out to parts that you didn’t know were there if you

had to do it manually,” notes Martínez. “Manual searches are linear. With Valmiz, it’s like a tree with branches through time.”

In a defense setting, where militaries cannot afford to have a system that makes wrong guesses, the value proposition of using gated data for a wide range of processes remains critical to operations. Service members need to be able to work with a systemthat aids them and does not try to one-up them by pretending that it’s in a better position to make life-and-death decisions.

In an AI-enabled drone, for example, with Valmiz, the data used for decision-making would have been collected and processed at the edge, inserting volumes of data as a standalone system to improve processes. It can also be deployed like an additional module to make things faster. “

“You can deploy Valmiz at the headquarters or on the drone itself,” Martínez explains. “That’s how extensive it is. More importantly, it frees militaries from the liability that the AI will imagine targets that are not there.”

Instead, Valmiz is like having a thousand highly qualified experts to work on a task to provide input to the human operator at the center of the operation. These abilities enhance decision-making with powerful, precise, and accurate information.

ASTN Group plans to showcase the capabilities of Valmiz to the defense community and consumers during the last quarter of 2023. MES

ASTN Group • https://valmiz.com

Cyberdefense: Dealing with evolving threats

The Cybersecurity Maturity Model Certification (CMMC), a unified standard for security introduced by the U.S. Department of Defense (DoD), is bringing about a cultural shift within engineering and test organizations.

Until recently, engineering and test organizations doing business with the U.S. Department of Defense (DoD) and other critical agencies attempted to bypass information technology (IT) cybersecurity requirements for their operational technology (OT) through:

› Exceptions (“You don’t need to check this; I’ve already secured this device.”)

› Skirting requirements (“You don’t need to check this; this component is not a desktop, laptop, or phone.”)

› Relying on airgaps (“You don’t need to check this; you can’t access this device remotely.”)

To be sure, significant, highly damaging cybersecurity breaches have been occurring with frequency for quite some time with systems that were already secured, were not computers, and had no physical or wireless connections to a network.

These breaches led to the DoD introducing the Cybersecurity Maturity Model Certification (CMMC) several years ago. With CMMC, IT departments are now stepping up to audit and manage all OT, transitioning the culture from “exceptionbased” to “zero-trust.” Defense industrial base (DIB) contractors (those companies and laboratories that enable research and development of military weapons systems, subsystems, and components or parts) must follow the new certification model to ensure that DoD contractors properly protect sensitive information. The new set of certifications must be conducted by third-party assessors.

While this change may appear daunting and potentially expensive, a holistic approach to security that involves collaboration among engineers, testing teams, IT professionals, and testing providers is essential to control costs and maintain efficiency.

The F-35 fighter jet, at 80 million dollars a pop, is one of the top weapons in the U.S. arsenal … and a typical example of a complex system designed for military use. (Figure 1.)

With a sizable number of “computing” elements, each system and component within the aircraft is interconnected, giving rise to complex vulnerabilities.

The plane is only as secure in the sky as in the hangar; every system that makes up the plane needs to work together, so every single one is a possible individual point of failure.

The U.S. military has deep experience ensuring that every part works, is not counterfeit, and that all the individual components work together how and when they need to. It could be better at identifying cyberwarfare threats.

Such threats tend to be a lot more serious. A broken tailhook can create a dangerous situation for a pilot, but that tailhook is just an object – it is not malicious. In contrast, a sophisticated radar system on a jet is not conscious or capable of emotion, but once hacked, it may use multiple means to kill the pilot.

From a cybersecurity perspective, the plane is not a plane – it is a stack of individual components, each at risk for a severe breach at any time. Every component is at risk; by extension, every contractor’s product and production processes are also at risk.

Put it this way: Every F-35 is only as secure as its least-secure contractor.

Of course, as frightening as a hacked fighter jet would be, it does not compare in scope or destructiveness with other real-world hacking that has recently taken place.

The Stuxnet incident, which occurred from 2005 to 2010, is a notable example of a sophisticated cyberattack that targeted Iran’s nuclear program. Stuxnet, an extraordinarily complex and malicious computer worm, was designed to sabotage the uranium-enrichment process in Iranian nuclear facilities.

The attack targeted programmable logic controllers (PLCs) used in centrifuge cascades, causing them to malfunction and

spin at speeds that destroyed both the centrifuges and their output. It might have been a happy ending for one particular democracy in the region. Still, Stuxnet’s successful infiltration and manipulation of the Iranian nuclear infrastructure significantly derailed Iran’s nuclear program. Just as significant, it showed the destructive potential of malware in an OT setting where nuclear materials are processed.

Here on home soil, the Colonial Pipeline hacking incident occurred in May 2021, when a cybercriminal group known as DarkSide launched a ransomware attack on the Colonial Pipeline, one of the largest U.S. fuel pipeline systems. The attack disrupted

the pipeline’s operations, leading to a temporary shutdown and causing significant fuel shortages along the East Coast.

The hackers gained unauthorized access to Colonial Pipeline’s systems, encrypting critical data and demanding a ransom payment. The incident highlighted the vulnerability of critical infrastructure to cyberthreats and demonstrated the potential impact on essential services and the economy. It also underscored the urgent need for robust cybersecurity measures and proactive defense against cyberattacks on critical infrastructure systems.

It is important to note that, in both cases, the affected systems were “air gapped,” with hacks achieved using ingenious human engineering – getting operators to upload malware onto the targeted systems inadvertently. Air gapping is the practice of keeping a computing device physically disconnected and unable to connect to wireless – creating a “gap” of “air” between the device and any source of malware.

Air gapping was once considered the defense of last resort for test engineers looking to keep their computing devices free of malware (and their testing teams free of IT input). As these two incidents illustrate, this approach was simple, elegant, and wrong … and far from enough to prevent bad actors from causing catastrophic damage.

The threat posed by cyberattacks had been clear to many at the time of the Stuxnet attacks, which began more than 15 years ago. Colonial Pipeline provided the impetus for the U.S. government to finally act, and the DoD introduced a unified cybersecurity policy in the form of the CMMC in January 2020.

CMMC sets a framework and certification process to enhance cybersecurity standards across industries. The certification is based on a new culture of “zero trust” – where every component, and their relationship with other components, are validated at every step of assembly and use.

Companies must prepare for the associated costs and complexities and consider who will bear the financial burden of certification to obtain an authorization to operate (ATO) from the DoD. To be sure, whatever costs those efforts entail, an ATO is necessary for any contractor looking to sell to government agencies. Companies must assess whether it is cheaper to meet the new standards or get out of the business of selling to government agencies altogether.

Contractors that choose to rise to the new standards will need to embrace an environment where engineers and test teams no longer have any shortcuts to securing their computing devices. That means they must collaborate with new organizational stakeholders to meet CMMC standards efficiently.

This new integration of IT into testing will entail a significant culture shift. Many customers are getting their first taste of this shift and note that IT managers are intruding on the testing process in ways they never had before.

Most testing teams at defense and aerospace firms have already adopted best practices for ensuring quality and authenticity at every step in the supply chain. Like the U.S. government, however, they could have been better at ensuring cybersecurity throughout the process.

These realities mean that teams must be involved in the testing stages to ensure that contractors build cybersecurity into chips, components, and systems right from the beginning. The emphasis on cybersecurity needs to go up the supply chain; contractors must ensure that their testing hardware and software are entirely CMMC-compliant.

To be sure, fully compliant testing solutions do not guarantee fully secure devices. There are inherent vulnerabilities built into specific devices, such as a data port that could be used for hacking by bad actors. Understanding and responding to those vulnerabilities is another reason IT needs to be more involved in testing.

Embracing collaboration for a secure supply chain

Industry experts estimate the cost of CMMC compliance at between $50,000 and $75,000 per product – with some estimates nearly $100,000 – with no economies of scale or scope. The companies that seemed to achieve compliance quickly and cost-effectively have embraced greater collaboration between their IT departments and testing.

IT’s experience in the cybersecurity space enables testing to identify multiple areas of potential insecurity early in the process. Testing teams could discover those independently, but addressing vulnerabilities piecemeal is not sustainable, given the costs.

In this new zero-trust world, engineers, testing teams, IT professionals, and testing providers must all be connected to ensure cybersecurity.

It’s about time. MES

Steve Summers is Director, Offering Management, at NI, focusing on mechanical systems and structural test for aerospace and defense customers. He earned a degree in physics from Brigham Young University and has worked in roles as an application engineer, sales engineer, account owner, and product manager. He has worked in the test and measurement industry for more than 25 years and is passionate about providing a path to success for engineers driving the technologies of tomorrow.

NI (formerly National Instruments) • https://www.ni.com/

Cyberdefense: Dealing with evolving threats

The U.S. Department of Defense (DoD)is investing in multiple initiatives including the Joint Warfighting Concept (JWC) and Combined Joint All-Domain Command and Control (CJADC2) to enable coordinated military operations against current and future threats. Because these efforts involve the integration of devices and data streams at the tactical edge, they call for a zero-trust approach to cybersecurity. But achieving zero trust at the edge presents multiple challenges. One path to overcoming these barriers is an automation strategy that enables more rapid and reliable configuration of components and helps achieve data-sharing across echelons with greater security.

Marines with Marine Corps Forces Cyberspace Command are shown in the cyber operations center at the National Security Agency’s campus in Fort Meade, Maryland, home to Marine Corps Forces Cyberspace Command headquarters. Photo by Staff Sgt. Jacob Osborne.

Marines with Marine Corps Forces Cyberspace Command are shown in the cyber operations center at the National Security Agency’s campus in Fort Meade, Maryland, home to Marine Corps Forces Cyberspace Command headquarters. Photo by Staff Sgt. Jacob Osborne.

In April 2023, the Cybersecurity and Infrastructure Security Agency (CISA) released version 2.0 of its Zero Trust Maturity Model. The original version, released in 2021, delineated three stages in the maturity journey: “traditional,” “advanced,” and “optimal.” The new version slots in an “initial” stage before “advanced,” recognizing that organizations are struggling to make the shift away from traditional perimeter defenses.

In fact, making that transition is essential: Edge computing is foundational to initiatives including the Joint Warfighting Concept (JWC) and Combined Joint All-Domain Command and Control

More fundamentally, military teams need to be able to seamlessly configure networks and integrate components to meet the unique field capabilities of each mission. Additionally, they need to achieve those goals in a timely manner so that they don’t hinder mission-critical decision-making.

(CJADC2). By definition, the edge extends beyond the conventional network perimeter. The perimeter has become atomized as centralized data centers are augmented by thousands of edge sensors and devices generating and transmitting data. Traditional cyber protections like firewalls are no longer adequate.

What’s needed is a zero-trust approach in which every user, device, or other entity that wants access to networks, systems, or data needs to authenticate itself every time it wants access. But zero trust isn’t a single cyber solution; rather, it’s an end-toend framework – as described in the U.S. Department of Defense (DoD) Zero Trust Strategy – that extends across users, devices, applications, networks, and more.

As challenging as zero trust is to achieve in any DoD environment, it becomes even more arduous to scale in multidomain tactical-edge environments. The mission space is increasingly shared by multiple U.S. service branches – including the Army, Air Force, and Navy – and it’s difficult enough for those mission teams to integrate networks and federate resources. More often than not, missions will include coalition partners such as the militaries of U.S. allies, NATO forces, and other organizations.

Numerous impediments exist to the goal of those organizations sharing information, especially at the edge in near-real time. One hurdle is federated identity, or the linking of a user’s identity across multiple identity-management systems. Each service branch and coalition partner is likely to have its own preferred way of enabling federated identity, and integrating those disparate approaches presents technical challenges.

A related issue is data sovereignty: Data is typically subject to the laws and governance structures of the nation where the data is generated or captured. The European Union (EU), for instance, has strict regulations on how data collected in EU jurisdictions must be managed. That decree has major implications for the cybersecurity controls put in place to protect that data.

More fundamentally, military teams need to be able to seamlessly configure networks and integrate components to meet the unique field capabilities of each mission. Additionally, they need to achieve those goals in a timely manner so that they don’t hinder mission-critical decision-making.

Automation can enable an answer to these emergent problems. At a basic level, automation uses technology to replicate human tasks to accelerate processes and reduce error. In a cybersecurity context, a security engineer working without automation might follow steps in a 100-page manual to harden a device before it can be fielded. In an edge environment that involves thousands of devices, that’s a slow, cumbersome process, with thousands of opportunities for error and vulnerabilities.

That’s just for a single type of device. Now imagine that scenario in a CJADC2 mission environment, with a proliferation of devices and networks continually being added to the network, or multiple networks continually being reconfigured on the fly.

The network effect – mathematically expressed as n(n-1)/2 – dictates that two nodes result in one connection, four nodes make six connections, 40 nodes make 780 connections, and so on. Each device, each application, and so on, requires configuration, and there’s no guarantee that devices are running the same hardware or the same versions of software. The time and complexity involved in integrating and building security controls into those devices can escalate rapidly.

Automation can enable a security engineer to configure and repeatedly update those resources in a more secure manner, near simultaneously, in a repeatable, predictable way. That’s essential for multidomain operations with unique data assets and field requirements that change from one mission to the next.

Reliance on all-in automation implementations does, however, introduce the possibility that a malicious insider or an external attacker could gain control over a large number of resources. Insider threats are a common cybersecurity concern, as are external attackers who steal credentials and then move laterally through a network or escalate privileges to compromise systems and steal data.

A solution to this type of problem is a commercial automation platform. An effective automation platform gives users a central location for storing credentials for devices that need to be managed, along with playbooks to execute tasks that need to be performed on those devices.

Users can look for a platform with a credential-management mechanism to give engineers access only to the domain they need on the devices they manage. CISA recognizes five domains: identity, devices, networks, applications and workloads, and data. For

example, an engineer might have permissions to manage the networking capabilities of a device but no access to the data, identities, or applications on the device.

Using this approach, missions can automate the configuration, management, and security posture of large numbers of multi-domain edge devices while mitigating the risk of introducing new security vulnerabilities.

Of course, the goal of edge sensors and devices isn’t only security. It’s also to enable the generation and sharing of data in near real time to drive intelligent decisions and faster actions that contribute to mission success. An automation platform can also help here.

Connectivity in the battlespace involves overcoming denied, degraded, intermittent, or limited (DDIL) bandwidth. Connections typically are too

Sponsored by Siemens

To reach net-zero emissions by 2050, the aviation sector must rapidly accomplish its complete technology transformation. Achieving this complex technology development and maturation in such a limited period is a unique challenge in industrial history.

In this webcast, industry experts discuss how Simcenter simulation and testing solutions – part of the Siemens Xcelerator portfolio – can help designers address the engineering challenges related to electrified propulsion, alternative fuels, new aerodynamic configurations and structural architectures. (This is an archived event.)

Watch this webcast: https://tinyurl.com/yck4n66r

low-bandwidth and intermittent to transmit gigabytes of sensor data from the battlespace to a centralized data center for analysis, and then ship the analytics output back to the field to be acted on. Instead, analysis and decisionmaking need to occur as close to the source of the data as possible.

The good news is that newer processors with lower size, weight, and power (SWaP) requirements are increasingly available at the edge, along with container technology that combines applications along with their associated configuration, dependencies, and data in a single package, or container. Groups of containers at the edge can be managed in a lightweight version of the open-source Kubernetes container orchestration system to dynamically bring up and take down applications as missions evolve.

This combination of technologies can enable real-time analytics at the edge. An automation platform enables the fast, reliable configuration of the networks, devices, applications, and cyber protections to make edge analytics possible. As an added advantage, the administrator only has to know how to use the platform and needn’t be an expert in all the complex, disparate technologies deployed at the edge.

An automation platform can help the DoD achieve its goals for zero trust at the multidomain, tactical edge; in fact, automation is fundamental to zero trust. In its zero-trust maturity guidance, the National Security Agency (NSA) lists seven zerotrust pillars, one of which is automation. The guidance also suggests that automation is required across pillars for true zerotrust maturity. CISA’s Zero Trust Maturity Model implies the same, mentioning automation more than 85 times.

Multidomain edge environments are essential to JWC and CJADC2; robust security of those environments is vital to the trusted generation, exchange, and analysis of edge data to enable the realtime decisions and actions that drive missions.

Zero trust is how the DoD will protect edge assets reliably – wherever they exist and however they need to be integrated with joint mission teams – and central to that protection is an automation platform that enables military organizations to achieve zero-trust maturity. MES

Christopher Yates is DoD Army chief architect for Red Hat, for which he collaborates with systems integrators, independent software vendors, and partners to develop solutions. He has more than 15 years of experience in the high-tech industry.

Dawn VITA 62 6U AC/DC Power Supply

RUGGED, RELIABLE AND READY, the Dawn VITA 62 compliant 6U AC/DC PSC-6265 operates continuously at 580 watts in diverse environments. Standard model is conduction to wedge lock cooled. Operating range -40°C to +85°C, nonoperating range -55°C to +105°C.

Dawn’s HLD-6262 Holdup Module works in conjunction with our PSC6265 to overcome ‘gaps’ or ‘glitches’ in the normal input power source up to 50 msec, as specified by MIL-STD 704F.

Red Hat Inc. • https://www.redhat.com/en/solutions/public-sector

Red Hat Inc. • https://www.redhat.com/en/solutions/public-sector

Cyberdefense: Dealing with evolving threats

Military-grade systems require a high level of security to protect sensitive information and operations from unauthorized access, modification, or disruption. One of the critical components for securing such systems is secure boot, which ensures that only trusted firmware and software can be loaded during system startup and accepted when receiving new updates.

Secure boot is a security feature that verifies the authenticity and integrity of firmware and software before loading them into the system memory during the boot process. The mechanism ensures that only trusted firmware and software are executed and mitigates attacks that aim to modify or replace firmware or software with malicious code. Secure boot uses digital signatures and cryptographic hashes to verify the authenticity and integrity of firmware and software.

The primary purpose of a secure boot mechanism is to guard against several types of attacks, including rootkits, bootkits, and other malware that target firmware and software. These attacks can compromise the system’s security, potentially causing data breaches, denial of service, and other damaging consequences. Secure boot ensures that the system starts in a secure state, making it difficult for attackers to compromise the system’s integrity or confidentiality.

The IETF SUIT [Internet Engineering Task Force Software Updates for Internet of Things] specification for secure boot has been standardized in RFC9019, and it provides a comprehensive approach to designing secure bootloaders and firmware updates. The specification defines a format for firmware images that includes metadata, digital signatures, and cryptographic hashes; this metadata

includes information about the firmware, device, and manufacturer, as well as the hash (verification) and the cryptographic signature of the software, enabling the system to verify the authenticity and integrity of the firmware.

One of the key recommendations from RFC9019 is the use of a secure bootloader that verifies the authenticity and integrity of the firmware image before loading it into memory. The secure bootloader checks the digital signature and cryptographic hash of the firmware image, ensuring that it has not been tampered with or modified.

RFC9019 also recommends the use of a trust anchor or a root of trust (RoT) to store the cryptographic material used for secure boot. A trust anchor may consist of any software or hardware-based mechanism that ensures that the public key used for the verification of the firmware authenticity cannot be modified by an attacker.

A RoT is a specific type of trust anchor that provides a secure environment for generating, storing, and managing cryptographic keys. The RoT ensures that these keys are not compromised or tampered with, and it is typically implemented in hardware to provide a high level of security. The RoT is the foundation of the system’s security, and it is used to establish trust in the system’s firmware, software, and other components.

In the context of secure boot, a RoT can be implemented using several different technologies, such as hardware security modules (HSM) or trusted platform modules (TPM). Executing the cryptographic operations with the assistance of a dedicated hardware component is the most secure option, because it guarantees that the keys are never exposed to the software components, thereby reducing the attack surface for the secure boot module.

Compatibility with the embedded system is an important consideration when selecting a trust anchor or RoT. The RoT must be compatible with the hardware and firmware of the system, ensuring that it can be integrated seamlessly into the boot process. The RoT should also

support the required cryptographic algorithms and protocols, ensuring that it can provide a high level of security for the system. Hardware-based solutions can be more expensive than the software-based counterparts. While for less critical systems a software-based solution may be sufficient and more cost-effective, the cost of implementing a hardwarebased solution is justified for military-grade systems that require a higher level of security.

Retrofitting older systems with secure boot can be difficult and expensive, as it may require both hardware and software upgrades. The cost and feasibility depend on several factors.

One of the main challenges of retrofitting older systems with secure boot is that many legacy systems were not designed with security in mind. This means that the system architecture may not support the necessary security features required for secure boot, such as a FIPS-compliant (a longstanding data-security standard) cryptographic module, or hardware-based RoT or HSM. In some cases it may be necessary to redesign the system boot process to include secure boot stages, which can be a time-consuming and expensive process.