9 minute read

Celebrating the future of the pipeline industry

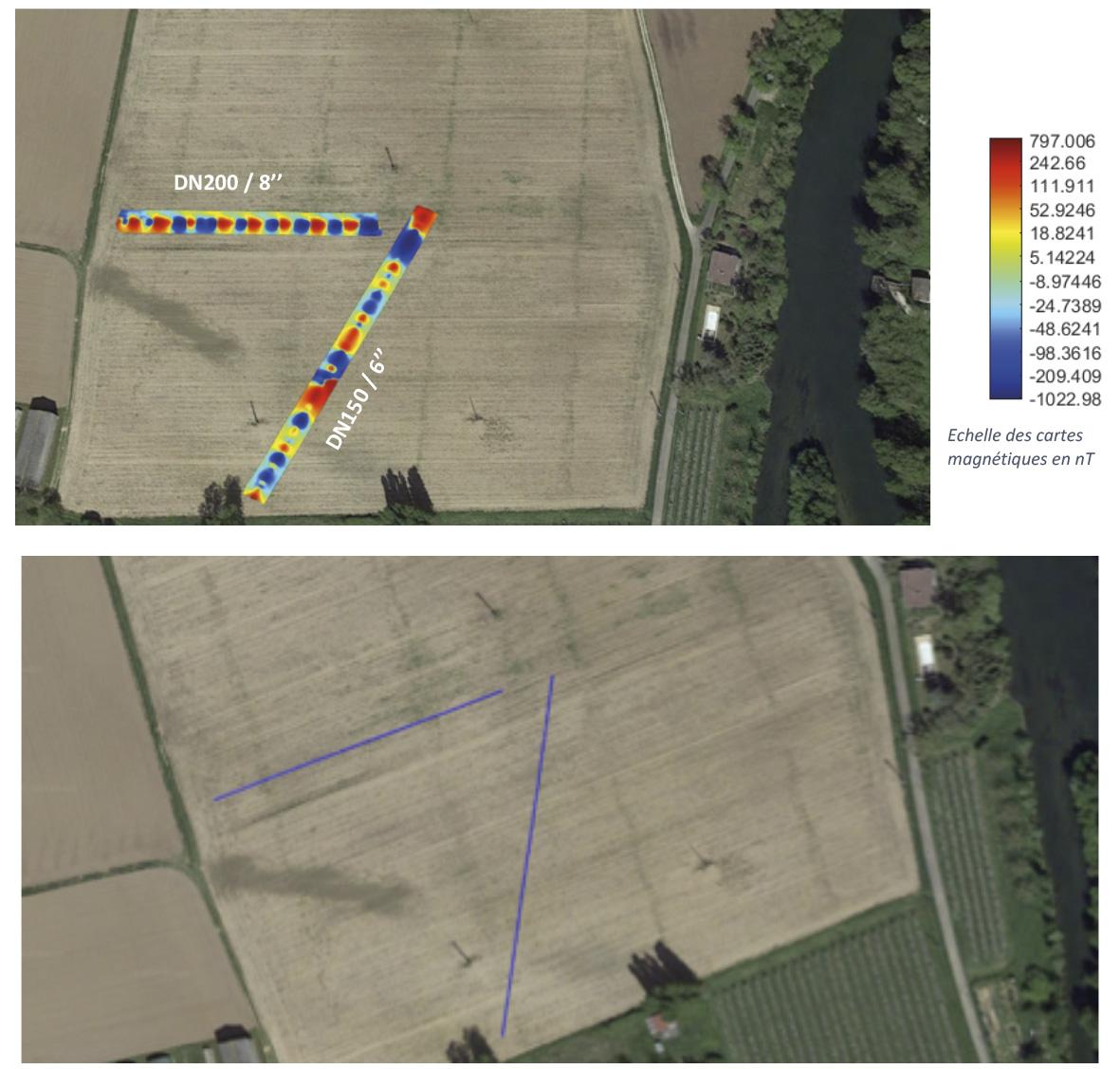

Figure 4. Magnetic maps of each inspected areas with its corresponding colorbar (in nanotesla) on the left. Estimated XY position of the corresponding pipeline in blue line. options will ensure an optimal result regardless of terrain conditions.

Case study: comparison between traditional tools and SKIPPER NDT’s technology In collaboration with Teréga, France’s second largest gas network operator, a field trial under real conditions was conducted. Surveyors contracted by Teréga geolocated two pipelines of 6 in. and 8 in. diameter respectively, in an open ditch. The ditches were then backfilled, and SKIPPER NDT was requested to geolocate the pipelines in a blind test. SKIPPER NDT conducted two tests using two different vectors, ground-based mobile equipment as well as a UAV described in the Material and Methods section.

Inspection parameters The two distinct pipelines were inspected with our protocol and the parameters of each inspection are outlined in Table 1.

Magnetic maps and pipeline positioning Through data acquired during each inspection using our tools, a high-resolution

Accurate • Tough • reliable

THE LEADING BRAND OF HOLIDAY DETECTION EQUIPMENT SINCE 1953

georeferenced magnetic map of the inspected area is generated. The automatic SKIPPER NDT data analysis process allows us to infer the absolute position of each inspected pipeline (Figure 4).

SKIPPER NDT performances: comparison to the reference line Results of each of the two detections are compared to the reference position taken by the land surveyor in open ditch.

Figure 5 illustrates SKIPPER NDT’s positioning performances compared to the reference line for each tool on each inspected pipeline. ) Field machine results: 5 in. accuracy for 90%, compared to the reference, for both inspections.

) UAV results: 13 in. accuracy for 90%, compared to the reference, for both inspections. The acquisition time is 6 minutes.

Additional detections: pipeline’s magnetic environment SKIPPER NDT’s does a continuous measurement along the pipeline. As a result, it can precisely map bends and elbows. Furthermore, it can detect metallic objects and structures around the pipeline. Hence, during this pilot test, SKIPPER NDT was able to identify a crossing point with another pipeline which presence was not previously reported (Figure 6).

Conclusion SKIPPER NDT’s localisation solutions are precise and cost-efficient for protecting pipelines from third party damage and for identifying pipeline movement on unstable slopes. The main features include access to the entire pipeline while ensuring high safety standards, precision of measurements, continuity of detection, and quick response to clients.

Table 1: Summary of the inspection parameters for each of the two inspections

First Inspection Second Inspection

Pipe’s Nominal Diameter (DN) DN 200/8 in. DN 150/6 in.

Dimensions of the inspected area Duration of the inspection using the Field Machine Duration of the inspection using the UAV

Field machine 6 in./482 ft

Acquisition time 14 min. Average precision 2.4 in. 387*33 ft 482*33 ft

13 min. 14 min.

6 min. 7 min.

Drone 6 in./482 ft

Acquisition time 6 min.

Average precision 6.1 in.

Standard deviation 1.7 in.

90th percentile 4.7 in. Standard deviation 3.8 in.

90th percentile 12.9 in.

Field machine 8 in./387 ft

Acquisition time 13 min.

Average precision 1.5 in.

Standard deviation 0.7 in.

90th percentile 2.5 in.

Drone 8 in./387 ft

Acquisition time 5 min.

Average precision 5.2 in.

Standard deviation 4 in.

90th percentile 10.3 in.

Figure 5. Tables of distance discrepancy between SKIPPER NDT’s predicted position of the pipeline and land surveyor’s reference. Each table displays the duration of the acquisition (in minutes), the mean error along the line, the standard deviation, and the error for 90% of the given results (in inches).

References

1. Common ground alliance, 2019 report, https://commongroundalliance.com/ Resource-Redirects/excavation-relateddamages-to-utilities-cost-the-usapproximately-30-billion-in-2019 2. French Standard: NF S70-003-3 Figure 6. On the left side, high frequency and low frequency magnetic maps showing an anomaly tagged with (1). These anomalies illustrate the presence of a pipeline crossing the inspection area horizontally. On the right side, the position of the anomaly is correlated to the true position of the crossing pipeline.

World Pipelines’ Senior Editor Elizabeth Corner interviews the winners of the John Tiratsoo Award for Young Achievement, awarded by Young Pipeliners International, in partnership with PPIM.

Jess Tufts, Superintendant, Gray Oak Elizabeth Corner: Congratulations Jess! What are your thoughts upon winning the award? Jess Tufts: I am flattered to have been nominated by a co-worker for this award, and very grateful to receive the recognition of this industry panel for my achievements. I have a strong work ethic which has led me to succeed thus far in my career.

EC: What’s been your career highlight so far? JT: That would have to be my promotion to the current role of Operations Superintendent for the Gray Oak Pipeline back in September of 2020. This is the large crude oil pipeline asset that Phillips 66 operates, and I am responsible for a team of 20 employees.

EC: Do you have any mentors or role models in the pipeline industry? JT: Stephanie Wilson at Phillips 66 has been a great role model for me. She is currently the Manager for the Midstream Engineering and Projects organisation, and she was previously the Region Manager over operation of several of the Gulf Coast assets that I’ve worked on.

EC: What is your message to other young pipeline professionals? What makes this industry rewarding and attractive for young professionals? JT: This industry offers an abundance of opportunities, and there’s something for everyone. You are in the business of providing

energy, which the world desperately needs. This includes fuel to heat homes and enable vehicle and air transportation. I get satisfaction out of knowing that what I do every day makes a positive impact.

EC: Can you talk about your hopes for the future? JT: Professionally, I want to continue to learn and grow to be the best leader that I can be. I enjoy managing and developing people to their full potential. In general, I hope the world goes back to normal soon.

EC: What does a typical day look like in your current role? JT: I am responsible for the pipeline operations of the crude oil system that goes from west Texas all the way to the coast at Corpus Christi. So I have a lot of meetings, like everybody, but day-to-day I’m responsible for ensuring that the field operations are maintained adequately. I’ve got a team of 20: there’s a team that sits in west Texas, and one that sits in south Texas. They do all of the equipment inspections; they’ll go and turn valves, take samples for quality management of the crude oil that ships on the system. I’m based in Houston and I’m probably in the field 25 - 50% of the time. My job has been a little bit challenging with COVID-19 – I haven’t been able to be in the field nearly as much as I would like to be.

EC: How did you get into the pipeline field? JT: I am a chemical engineer, with a minor in economics, graduated from Ohio State. My first job out of school was with a manufacturing company, not in the oil industry, and then I was looking for a new opportunity and I had family that lived in Houston and worked in oil and gas, including both of my sisters, so I applied to a variety of roles and the pipeline role was the one that was the right fit for me. I joined the midstream operations team seven years ago and haven’t looked back.

Jess Tufts. Kaella-Marie Earle, Engineer in Training at Enbridge Gas Inc. Elizabeth Corner: Congratulations Kaella! What are your thoughts upon winning the award? Kaella-Marie Earle: I was surprised and honoured, but my first thought was that I hope the visibility inspires other young Indigenous people to be more involved in the oil and gas pipeline industry. Its such a great place to work, and a place that has so much room for innovation.

EC: What’s been your career highlight so far? KE: I would say one of my biggest career highlights was just joining the industry a few years ago. Right before I was an engineering intern at Enbridge Gas (from May 2018 to August 2019) – I was an antipipeline and environmental activist for years.

The last thing I expected was to work in oil and gas. I thought the industry was dying, and an unethical place to work because of climate change and other social issues.

When I got the job offer, I was actually afraid that I was drinking the proverbial Kool-Aid, but I chose to accept the internship because I saw that the company was working on a number of carbonemission reduction projects like hydrogen blending and renewable natural gas (RNG).

During my first few weeks at Enbridge Gas, I expected to be surrounded by people who didn’t care about Indigenous people and didn’t care about the environment. And boy was I proven wrong. I was surrounded by people who poured all of their energy into delivering high quality work – putting the safety of communities and the environment first. I remember making friends with a welder there who used to sit with me over engineering drawings and we would have amazing discussions about Indigenous culture right there in the weld shop. Those first few months at Enbridge changed my world. I realised oil and gas is full of