9 minute read

Integrity software: a helping hand

Alfred Kuhn, PMP, Switzerland, and Cornelis Bal, PIPECARE, UAE, talk through a new integrity management software solution designed to assist operators transitioning into the digital pipeline era.

Very often, pipeline integrityrelated data are dispersed across organisations, large or small. This creates challenges to manage a holistic approach due to multiple data locations.

Some information may still be paper based and massive amounts of digital information are also available in different departments. The worst case happens when information is stored in people’s heads only.

In such an environment, fact-based decision making will be difficult and time consuming, with one question often looming over the decision maker – do I have all the relevant information, and is it accurate and up-to-date?

PIPECARE is proud to announce its latest software development, the Predicta® software suite, for efficient pipeline network integrity management with its main objective to ‘maintain the pipeline condition to operate safely, reliably and economically within its design parameters until the end of its design life.’

More often than not, it is the case that operators concentrate on and action the short list of features in pipeline inspection reports, usually to to three pages, that form an instant threat to the pipeline integrity only. The rest of the report, which forms the major part and could be up to hundreds of pages, is rarely analysed in detail.

This is understandable, as the decision making for justifying the optimisation of maintenance cost can be too complex to comprehend, with many factors playing a role in the deterioration process of pipeline materials.

International standards, such as API, ASME, DNV, the Predicta software utilises the results of inline inspection and other datasets, as a base to evaluate the pipeline integrity by: ) Consolidating all available data.

) Presenting all available information in a comprehensive way.

) Recommending maintenance and repair optimisation.

) Visualising information in easy-to-understand graphs and dashboards.

) Supporting quick decision making.

Predicta integrates data quickly and accurately, and enables access to existing databases and formats like PODS, APDM, GIS, SCADA helps to use various standards for integrity assessments and extend the pipeline network life cycle efficiently.

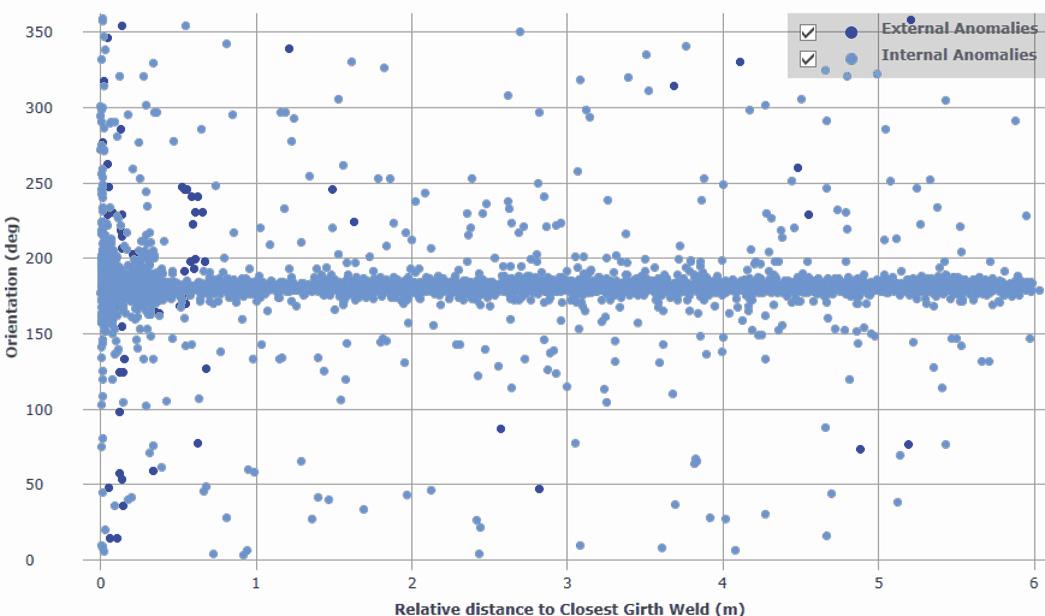

The alignment – or rather, the lack of it – in pipeline inspection reports makes it even more difficult to assess progress development of the deterioration process. This is also caused by the limited accuracy of distance measurement of pipeline inspection intelligent tools. They measure distance by so-called odometer wheels, but these wheels are subject to proportional slippage over the entire distance or localised slippage at areas in which the inspection has accelerated. Alignment of inspection reports has always been extremely difficult and that has also resulted mostly in aligning only the most severe features for urgent repairs, as the opportunity to maintain had passed long time ago. The inspection per pipeline caused the integrity managers also to concentrate on single pipelines only, rather than on the maintenance of the entire pipeline system. Even the information on single pipelines is massive; it is not uncommon for some pipelines to have hundreds of thousands of pipe wall deteriorating features. This information is digitally reported but it is not comprehensible as it not aligned with previous reports, and figuring out the impact of each feature is as good as impossible.

Predicta modularity Predicta’s modular design and built-in integration capabilities supports effective and efficient pipeline network integrity management. The Predicta software suite has been designed modular with the following structure: • Predicta Basic Entry-level – Desktop module.

Figure 1. Anomalies distribution.

Figure 2. Circumferential as distance function of relative distance to closest girth weld plot.

• Predicta Risk Assessment – Server based module. • Predicta Integrity Management – Server based module.

Predicta Basic Entry-level is the base module with main focus: • Alignment (weld, feature and anomaly). • Leak prediction (whole pipeline and for each anomaly). • Corrosion growth rate (CGR) calculation. • Segmentation. • Report generation.

This module uses mostly information obtained from the inline inspection of pipelines. Various data set formats can be imported and used for alignment and further assessments.

Predicta Risk Assessment is the second module incorporating: ) Visualisation of the pipeline network in 2D and 3D maps, graphical views, and tabular format.

) Advanced dashboarding facilities displaying integrity parameters, risk-based assessments, and repairs optimisation.

) Pipeline integrity assessment based on a wide range of assessment standards and generation of all available digital information of your pipeline, with recommendations for optimising your maintenance expenditure.

Predicta Integrity is the third module integrating the following functionalities: ) The prediction of the pipeline’s asset lifetime and integrity for future optimisations. The self-learning abilities of Predicta increase the accuracy over time.

) Pipeline joint severity classification that guides to the areas requiring attention.

) Repair recommendation for each joint based on feature growth, risk-based assessment, end of design pipeline life and optimisation of rehabilitation works.

) Corrosion growth model compatibility for future prediction calculations to show the deterioration of the pipeline integrity by active corrosion growth including fatigue cracking, HIC, SCC, and weld cracks.

) Based on available data, PIPECARE research of international standards, and statistics, the leak and rupture prediction model helps to optimise expenditure and avoid product spills.

The three modules build on each other and may be implemented all at once or step by step, thus giving the users flexibility in time and expenditure. Predicta project phases The typical Predicta project consists of the following eight phases:

1. Data gap analysis The targets of this project phase are to understand: • The project team. • The customer’s project organisation, especially the point(s) of contact in the departments. • The needs and challenges the customer has so that the project outcome meets these requirements. • The data infrastructure and which data are available in the organisation. • Which data need to be migrated from paper into electronic format. • Identify all stakeholders. • Agree the implementation path and possible schedule.

2. Risk model definition Together with the customer the risk model will be defined, based on the specific customer situation. The results of the data gap analysis will be considered and additional data historical information and operational data, will determine which shall be implemented in the model. The risk model may either be based on available basic risk model or on the customer’s model if it already exists.

After the initial meeting with the customer’s subject matter experts (SME) the model will be described in the so-called risk manual which will be reviewed, discussed and approved in a follow-up session before the implementation starts.

3. Data conversion In this phase the output of phases 1 and 2 will be used to establish the exact location(s) where data are stored and how they will be accessed by the software. Data which are available on paper only, will be digitised. Additional required data, identified in phases 1 and 2 will be provided. This phase might be supported by having a data specialist on site.

4. Predicta configuration The software is configured based on the results of the previous phases. This includes but is not limited to the Risk model, agreed upon reports, dashboards and the interface(s) to the customer’s data sources.

A meeting or conference call, where the results of phases 1 - 3 are reviewed and explained, will make sure that the scope of work and the functionality is clearly understood by all involved departments. During this phase the training documentation and schedule will be prepared.

5. Testing Test procedures are performed to check the quality of the Predicta configuration. These tests cover the functionality of the software as well as the replication of the customer environment. Test procedures ensure that all customer requirements are covered and meet expectations. The testing

will be performed at a PIPECARE premises with customer participation.

6. Onsite implementation After the test phase is successfully completed and Predicta functionality is confirmed as specified, the software will be implemented in the customer’s IT environment. If required an ‘isolated’ IT system environment may be provided by the customer to perform tests prior to implementation in the ‘hot’ customer IT system. Another series of tests will be performed to check that Predicta is compatible with all requirements of the IT department before the software Is handed over to the customer’s experts.

7. Training and handover During the implementation phase customer user training may already start. Predicta product SMEs provide formal training specific to the customer’s implementation and data. Training documents and manuals are provided for future reference. The successful conclusion of the training and handover will be documented in the handover protocol.

8. After implementation support Predicta SMEs will be available to support on customer request with further training, data migration, and configuration changes. After project handover it is recommended to have monthly follow up meetings to discuss any questions which are beyond the daily routine works. On customer request a PIPECARE SME may stay on a customer’s premises for a defined time period for direct support.

Predicta holistic approach The Predicta software suite provides a holistic approach to future maintenance guidance services allowing: ) Comprehensive and straightforward guidance for integrity decision-makers.

) A unique tool for considering asset life extension management which adapts to future changes with its self-learning ability.

) Self-learning ability to adapt to future conditions.

) Reducing cost of ownership by optimising pipeline maintenance and preventing failures.

Conclusion Predicta is an innovative pipeline integrity management software system designed to assist pipeline operators to transit into the digital pipeline era. Easy data access and import from various sources ensures that Predicta is the tool to use to support and improve integrity management decision making. Machine learning and artificial intelligence help Predicta to adapt to operational changes in the future. The advanced new features, future vision and co-operation with oil and gas industry leaders differentiates Predicta from other pipeline maintenance software.